Patents

Literature

57results about How to "Release capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

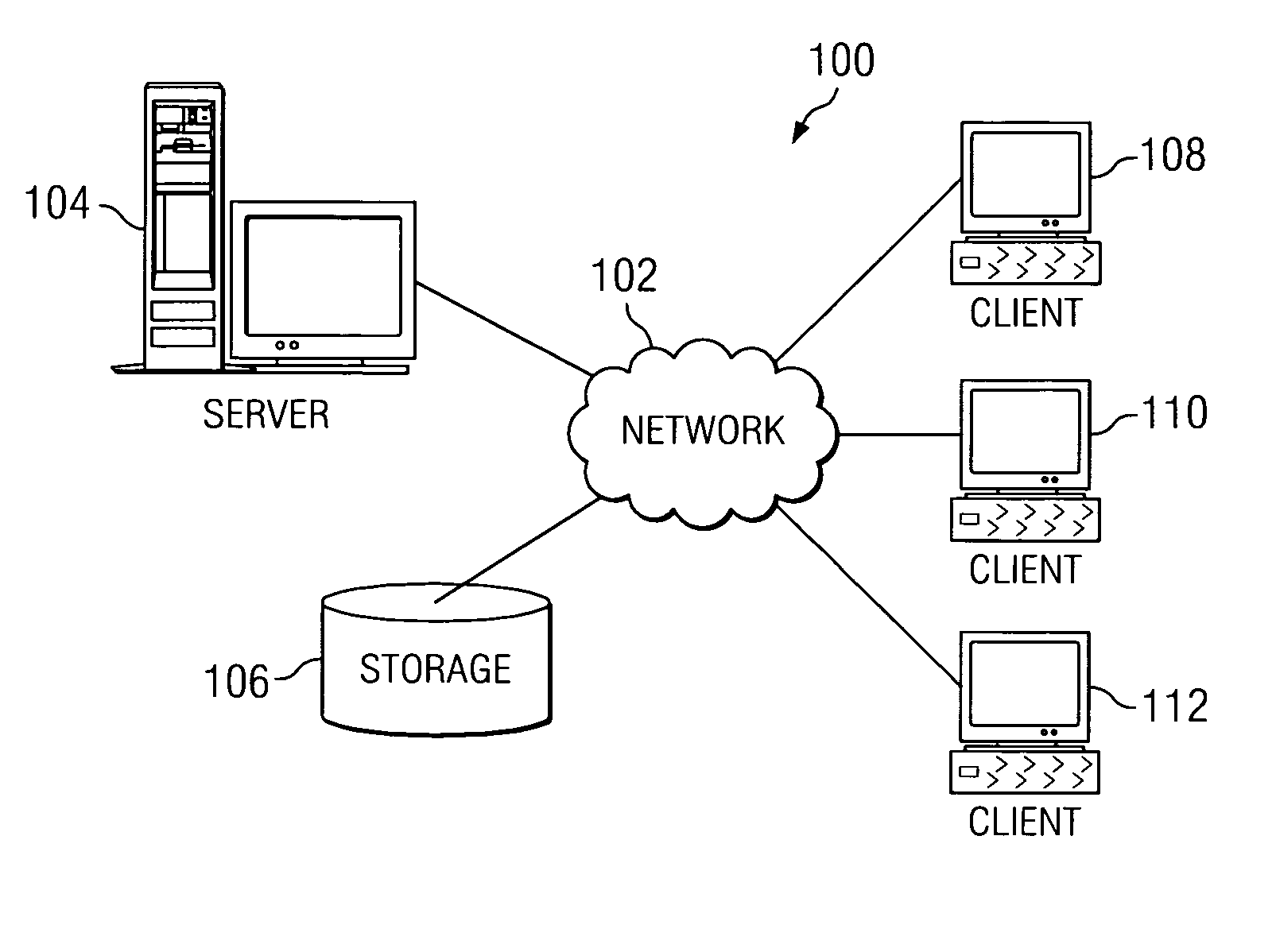

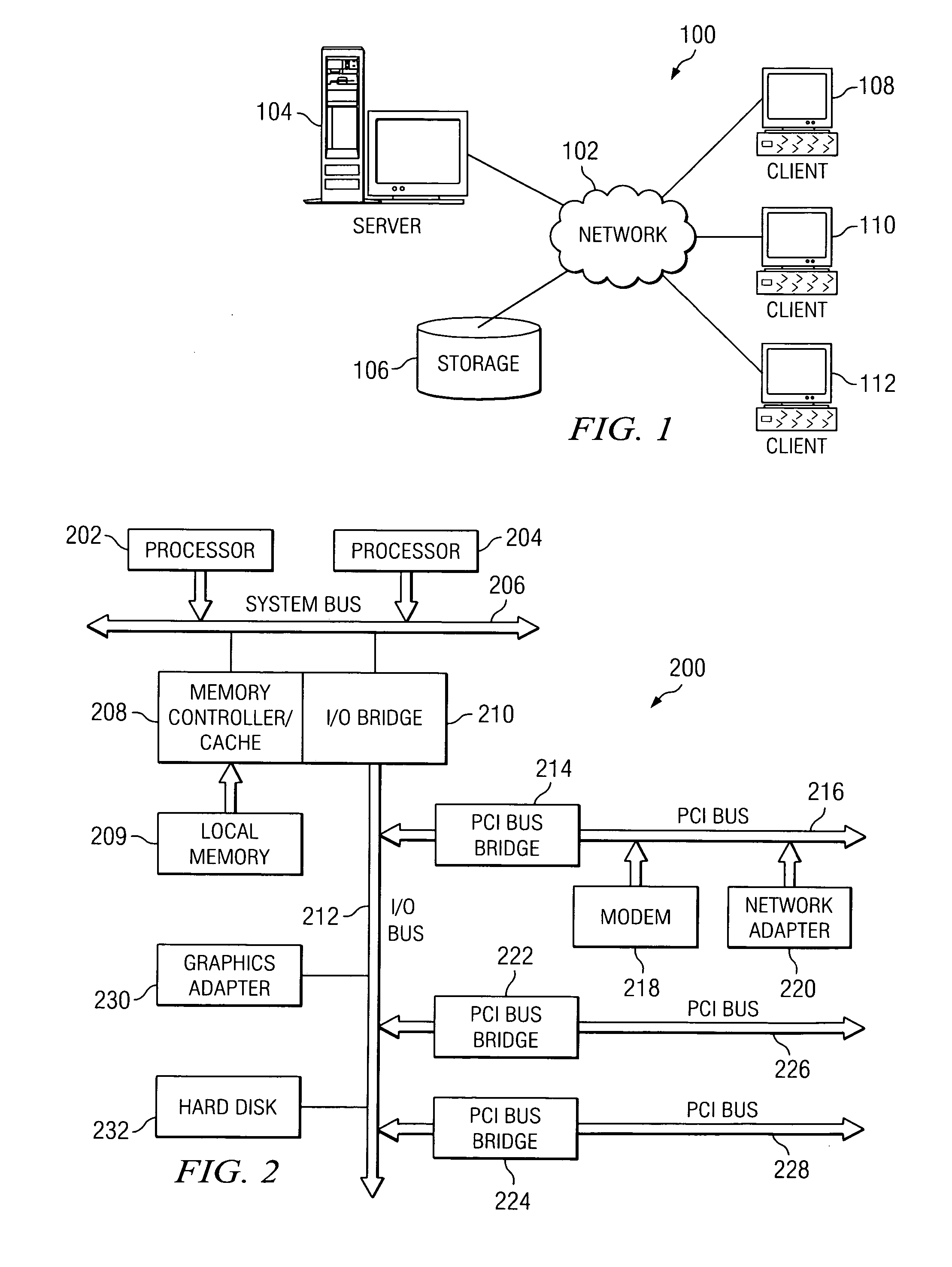

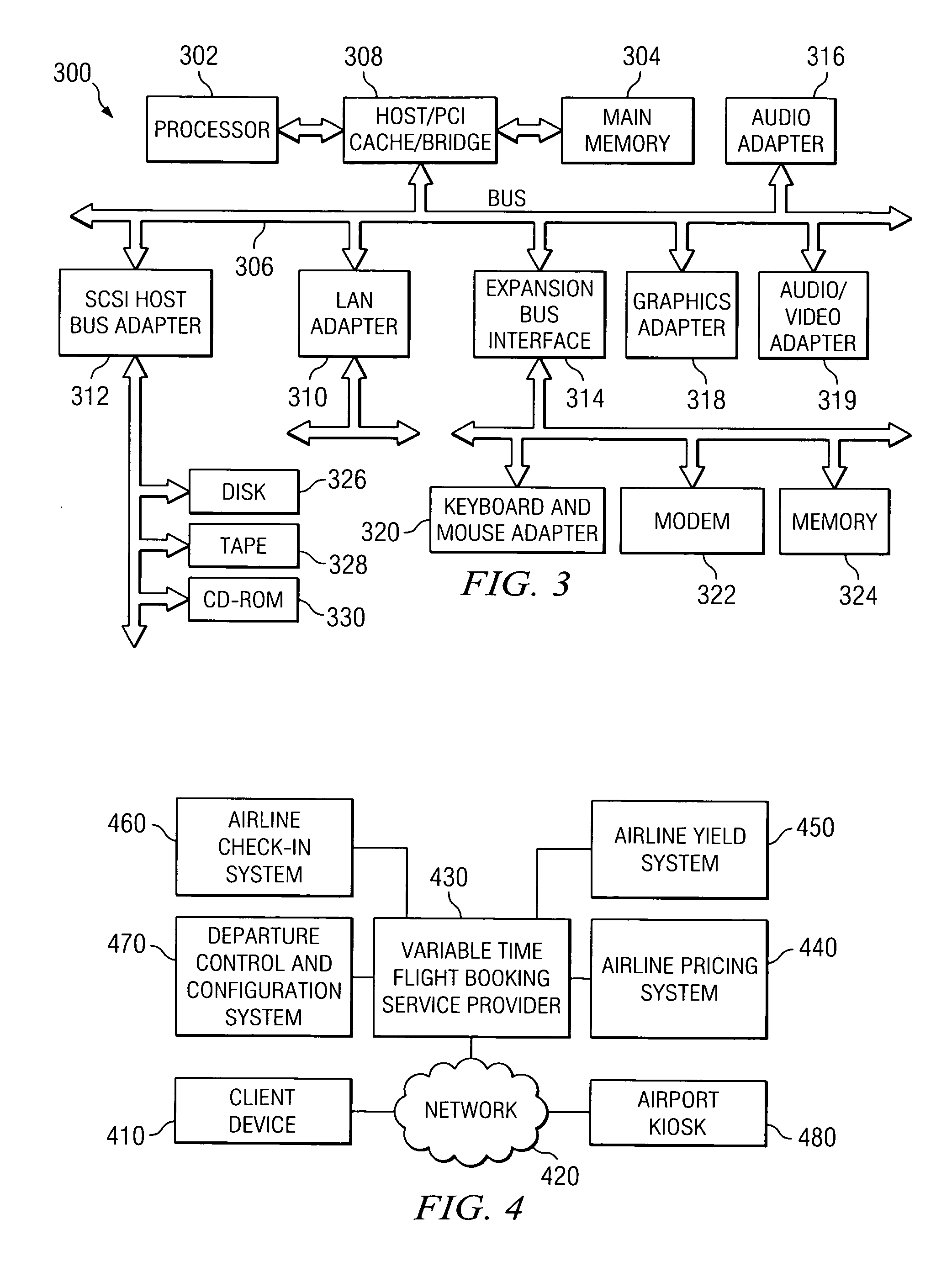

System and method for providing an airline variable routed capacity management system

InactiveUS20050216317A1Maximize returnIncrease costReservationsSpecial data processing applicationsCapacity managementManagement system

A system and method for providing an airline variable routed capacity management system. With the system and method, a user, at time of booking, identifies only the departure and arrival airports, the dates of departure and return flights, and the travel window, i.e. the amount of travel time the user is willing to endure to travel between the departure and arrival airports, or vice versa. At time of booking, there is no blocking of travel lanes since there is no reservation of seat assignments or flights but only the guarantee that the airline will provide some flight itinerary between the departure and arrival airports that meets the travel window on the departure and return dates. The particular flights or seat assignments are not identified and are not reserved. At some time prior to the departure date, the user may again access the system of the present invention to obtain a listing of flight itineraries that meet the travel window on the dates and between the cities identified by user at booking. Based on the listing of possible flight itineraries, a user may select one of the flight itineraries and then obtain their seat and flight assignments based on the flight itinerary selected.

Owner:IBM CORP

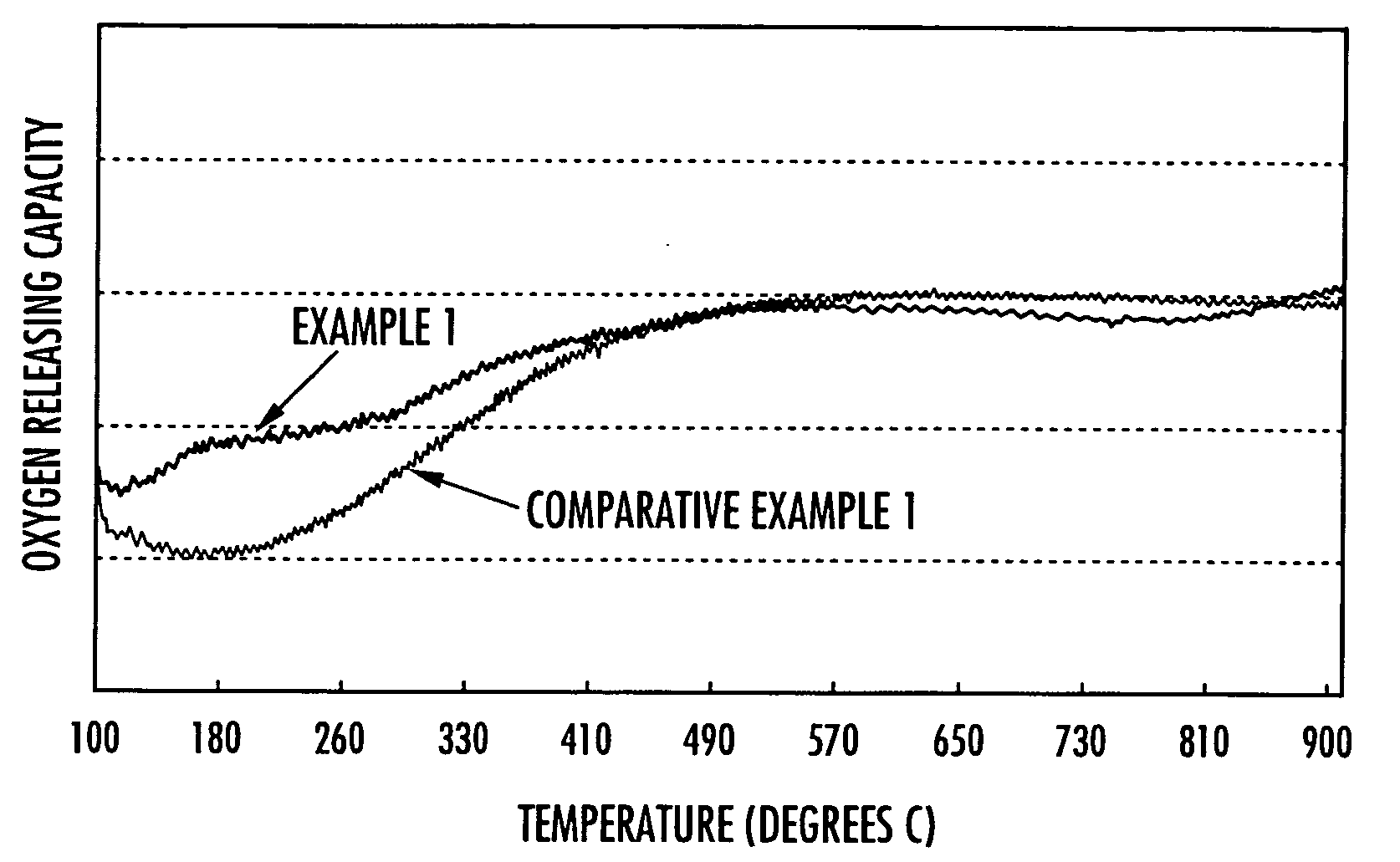

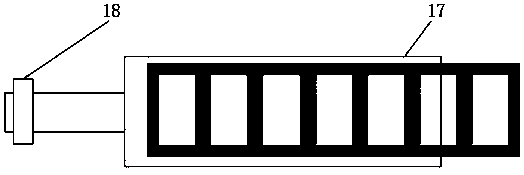

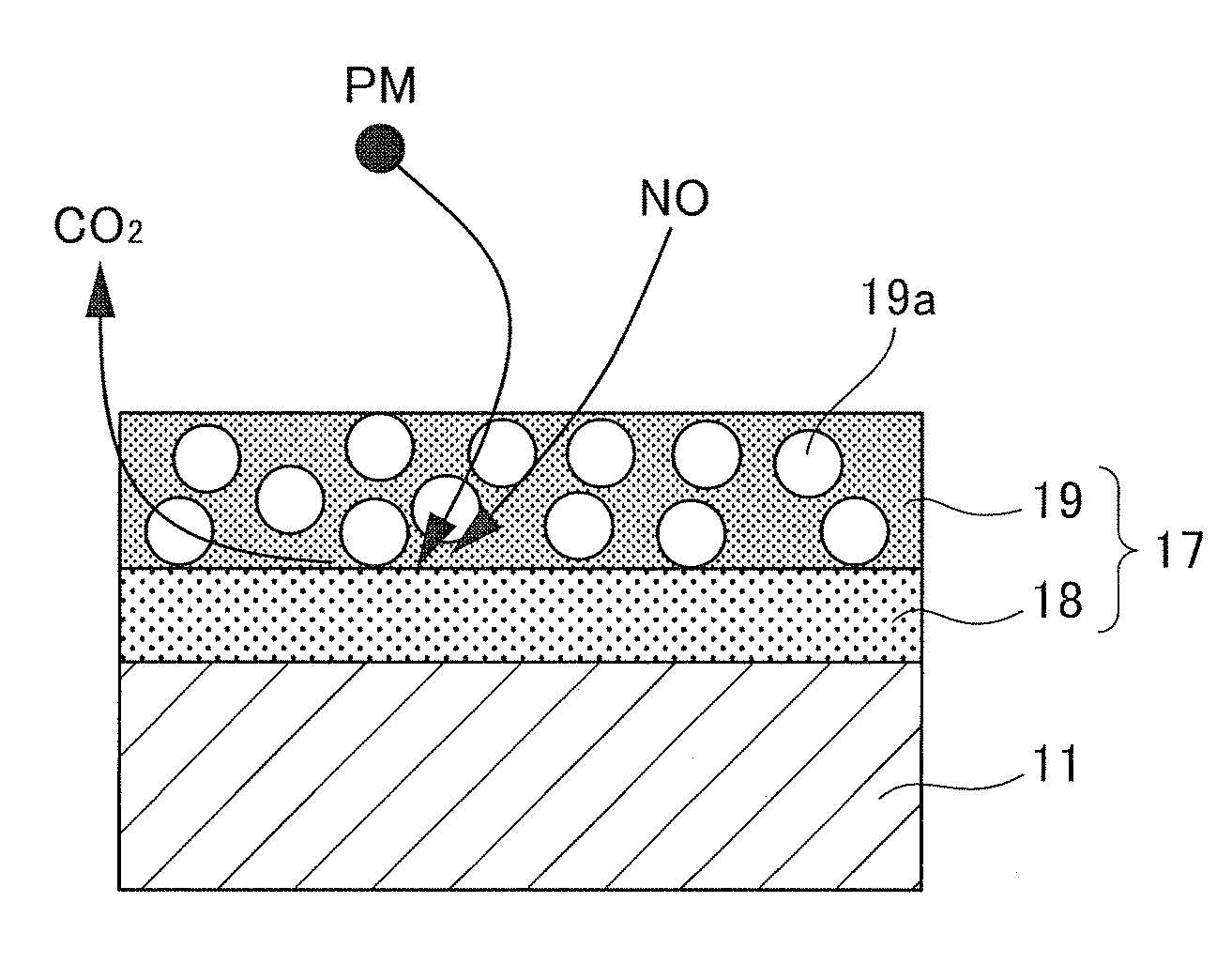

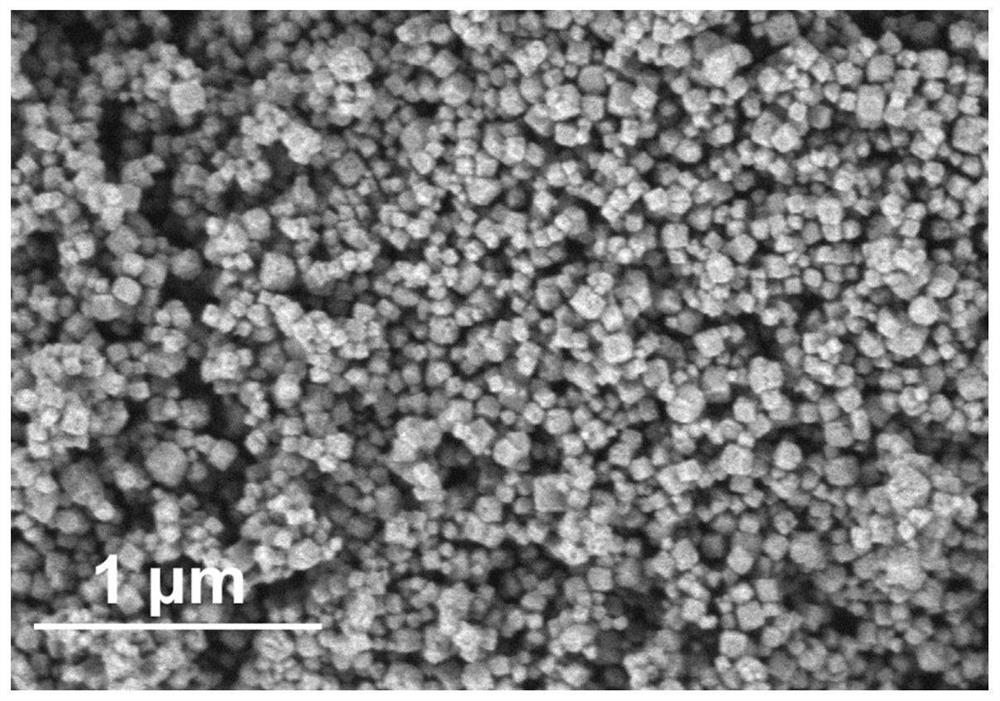

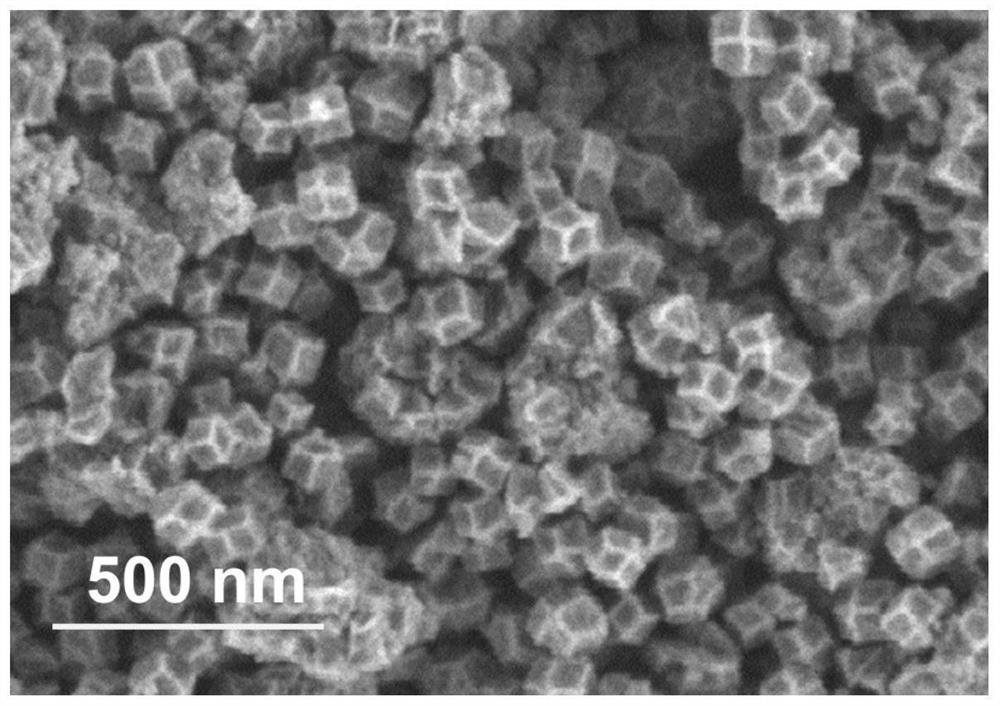

Apparatus for removing particulate matter

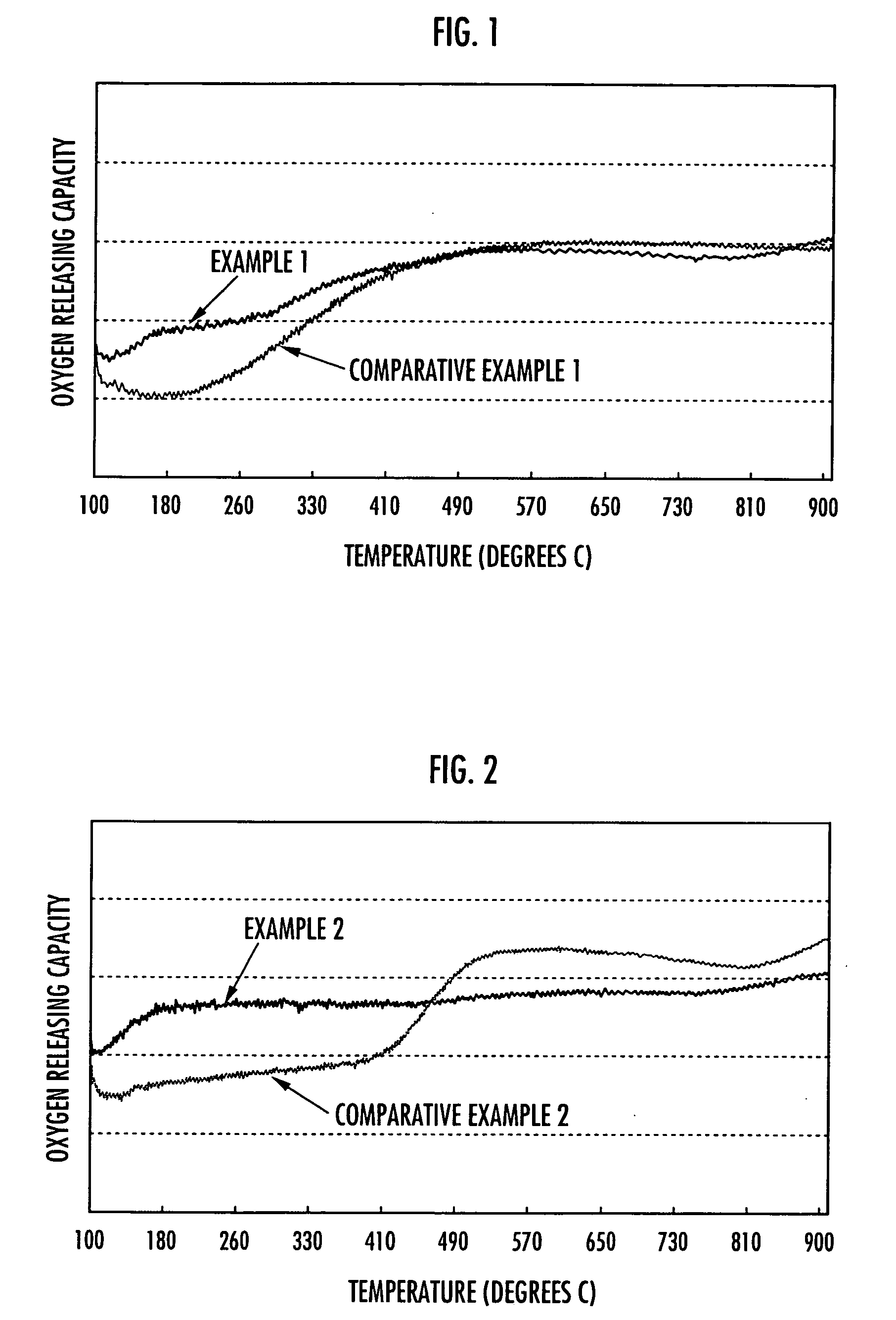

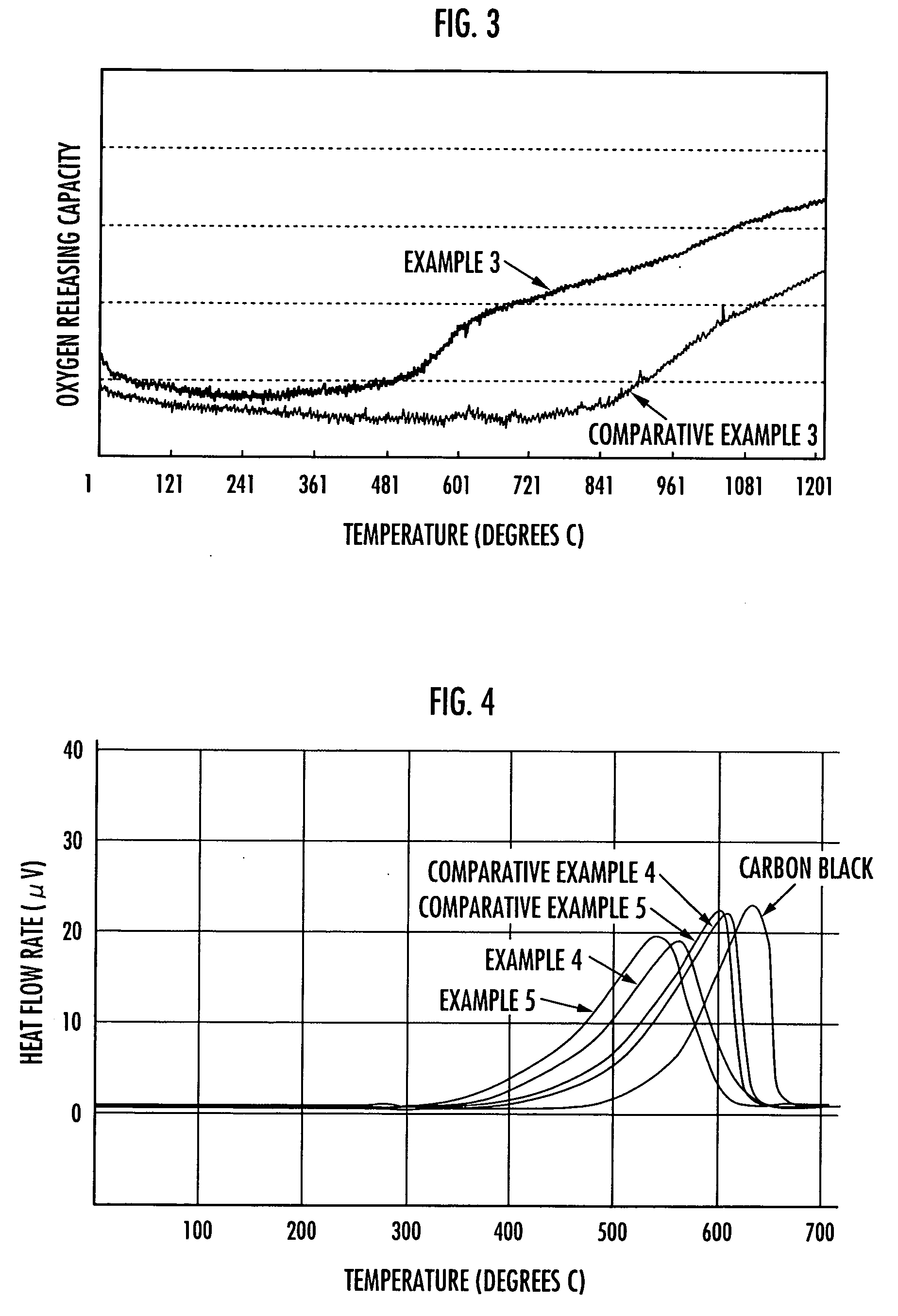

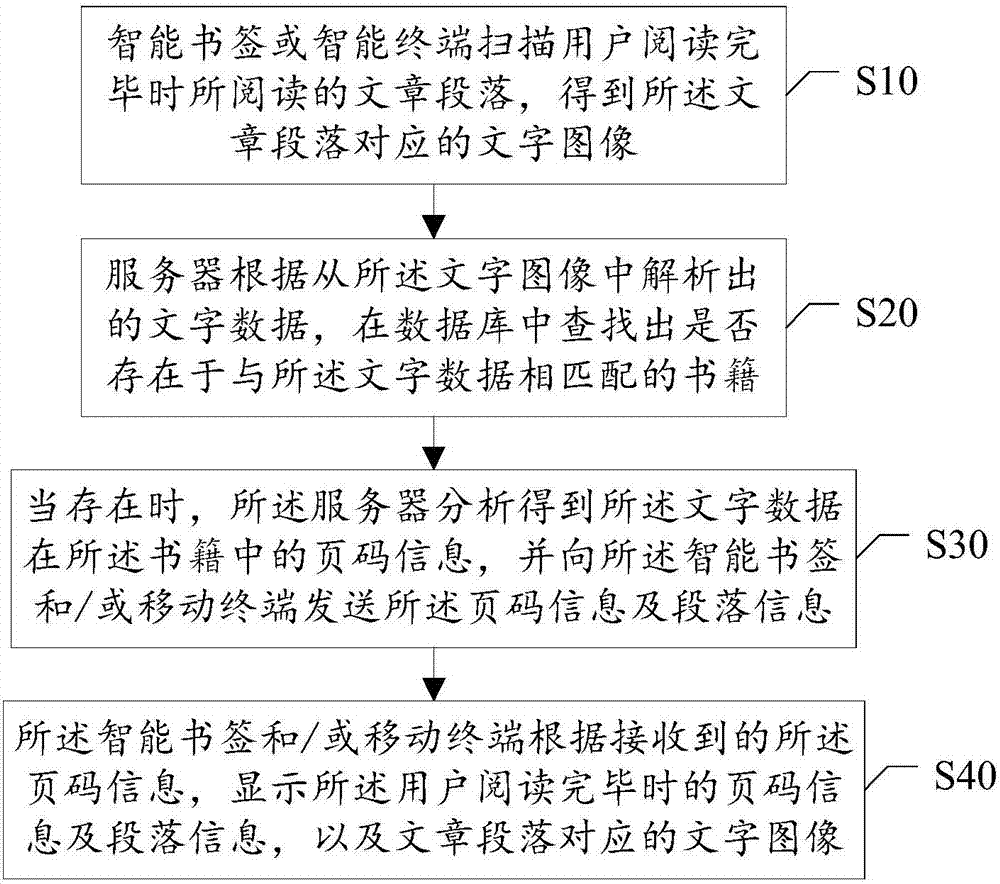

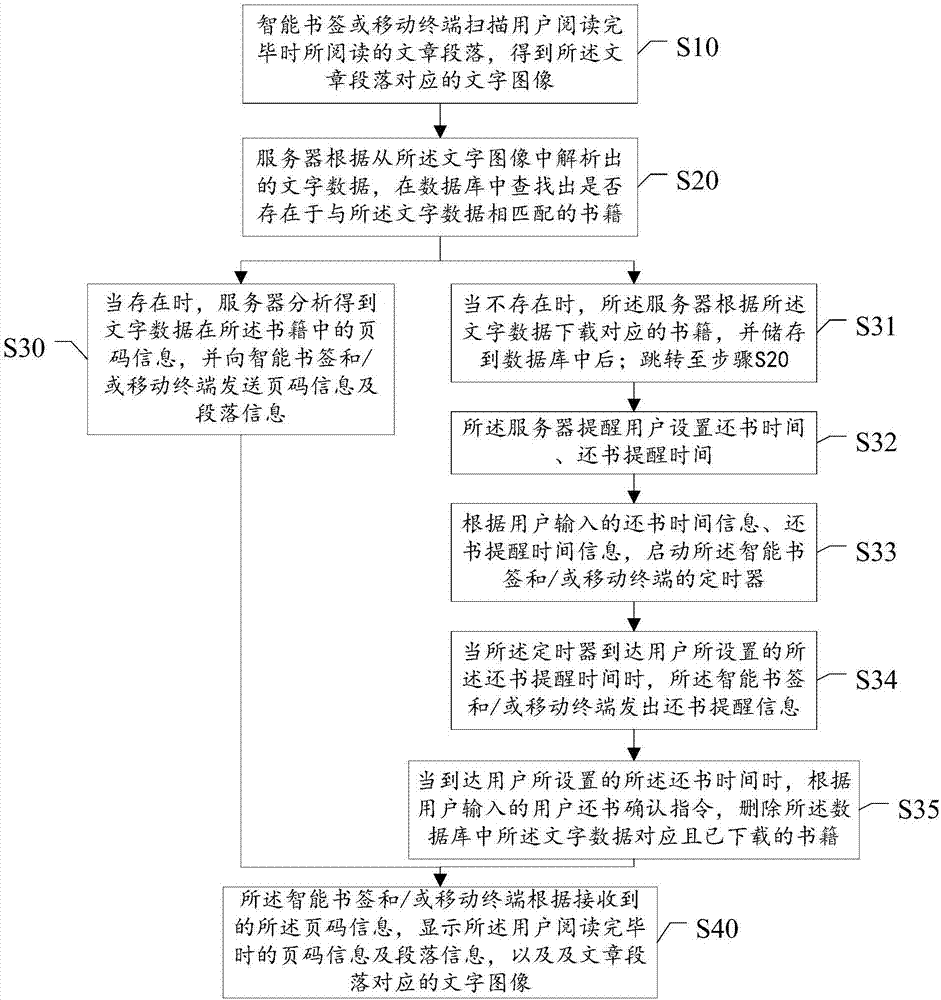

InactiveUS20070006578A1Oxygen releasing capacityExcellent oxygen releasing capacityInternal combustion piston enginesHeterogenous catalyst chemical elementsParticulatesInternal combustion engine

An apparatus for removing particulate matter is provided which is able to lower a temperature to burn particulate matter. The apparatus for removing particulate matter burns and removes the particulate matter emitted from an internal combustion engine, and comprises a perovskite-type complex oxide which is represented by the general formula ABO3 where B is a metal having a valence of +3 or more. The metal having a valence of +3 or more for B of the general formula comprises at least one metal selected from the group consisting of Ti, Zr, Hf, V, Cr, Mo, W, Mn, Fe, Ru, Co, Ni, Cu, Ag, and Au. The perovskite-type complex oxide comprises at least one complex oxide selected from the group consisting of LaMn(III)O3, LaSrMn(III)O3, and LaCo(III)O3. The perovskite-type complex oxide supports Pt or Pd.

Owner:HONDA MOTOR CO LTD

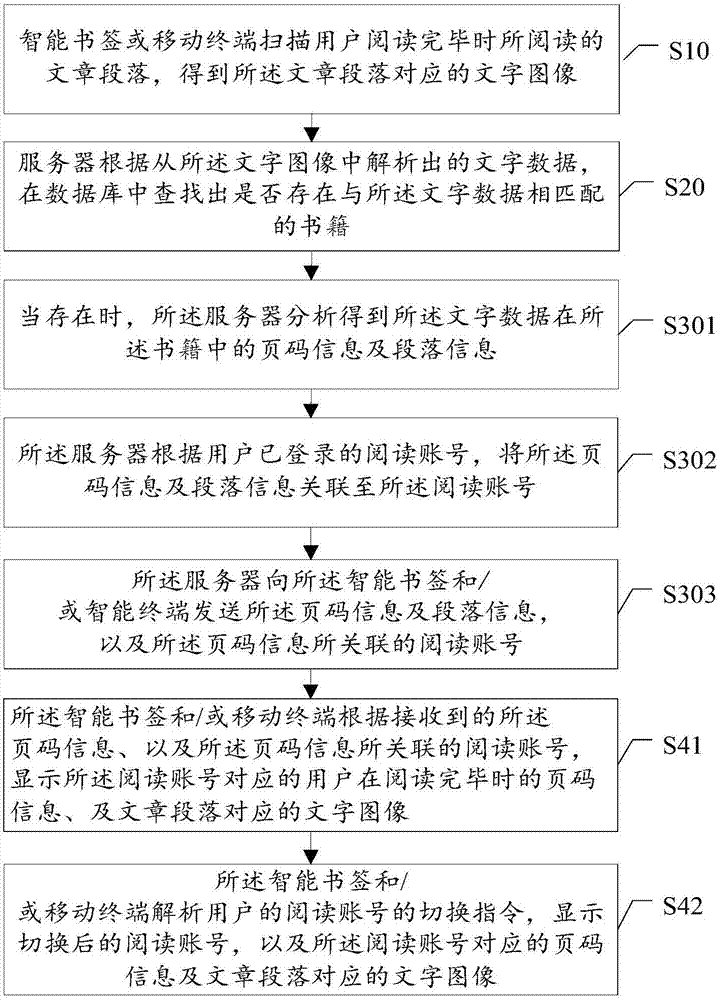

Article reading progress recording method and article reading progress recording system

InactiveCN107391742AReduce user experienceImprove user experienceCharacter and pattern recognitionOffice automationParagraphData science

The invention provides an article reading progress recording method and an article reading progress recording system. The article reading progress recording method includes: a user scans a read article paragraph by an intelligent bookmark or an intelligent terminal to obtain a character picture corresponding to the article paragraph when finishes reading; according to character data analyzed from the character picture, a server searches whether a book matched with the character data exists in a database or not; if yes, the server analyzes to obtain page information and paragraph information, of the character data, in the book and sends the page information and the paragraph information to the intelligent bookmark and / or the intelligent terminal; according to the received page information and the paragraph information, the intelligent bookmark and / or the intelligent terminal display the page information, the paragraph information and the character picture corresponding to the article paragraph when the user finishes reading. The article reading progress recording method and the article reading progress recording system are capable of recording reading progresses more precisely.

Owner:杭州吉吉知识产权运营有限公司

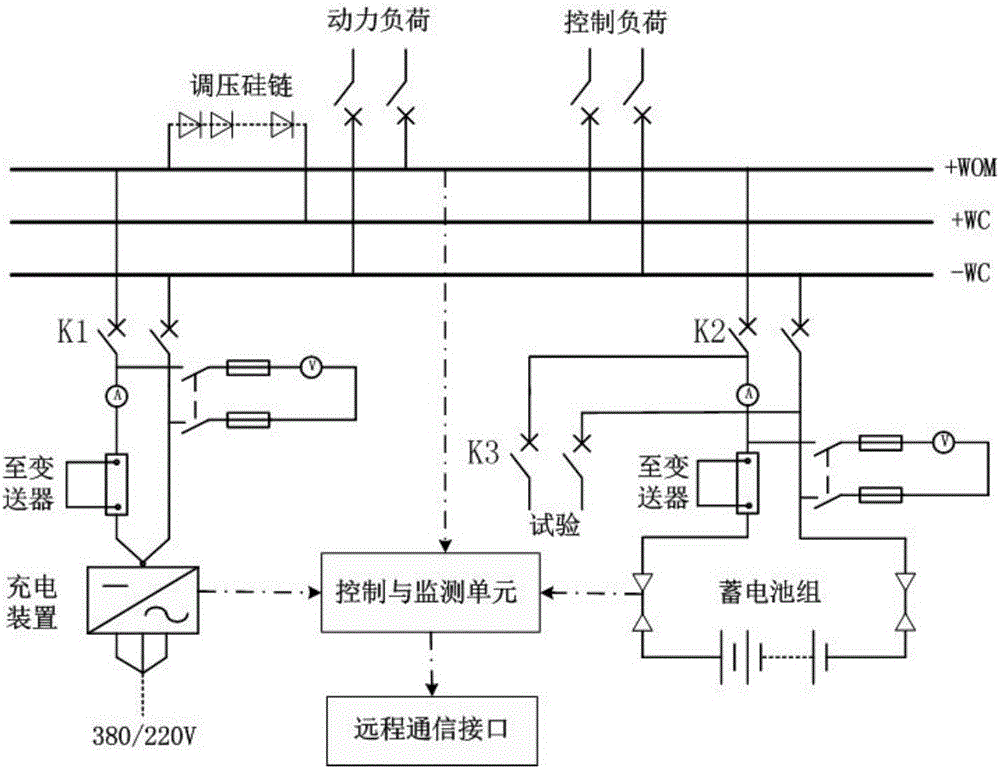

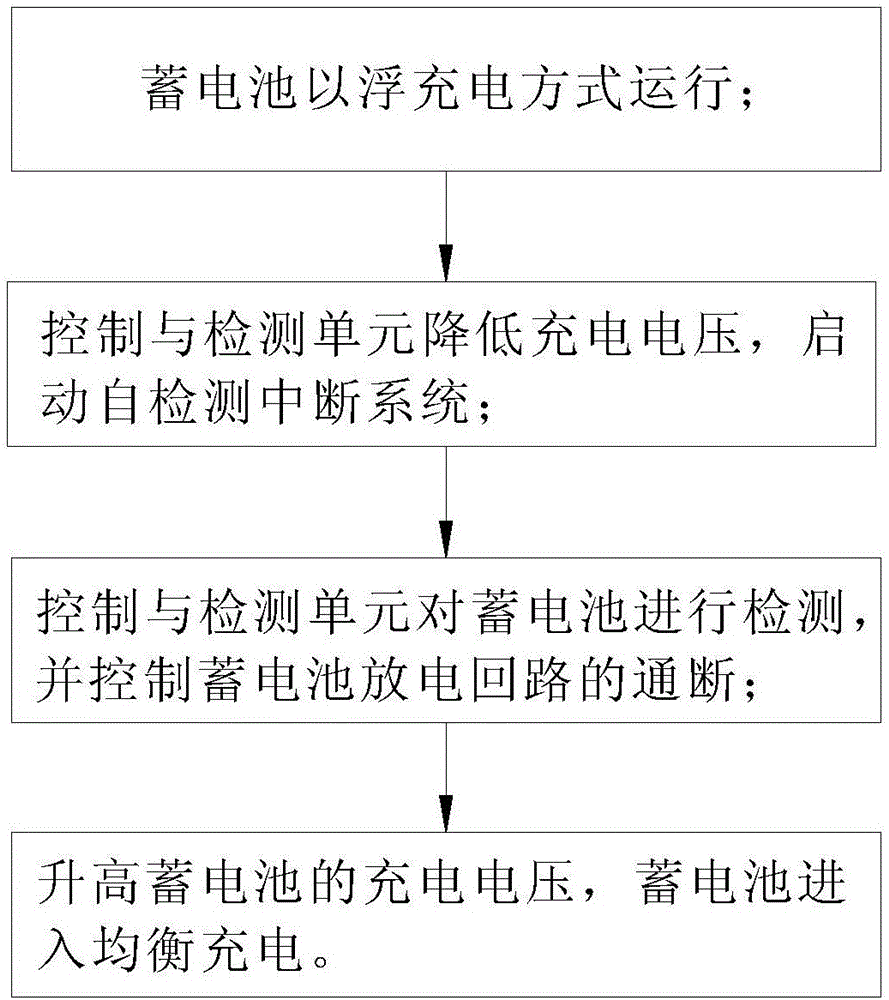

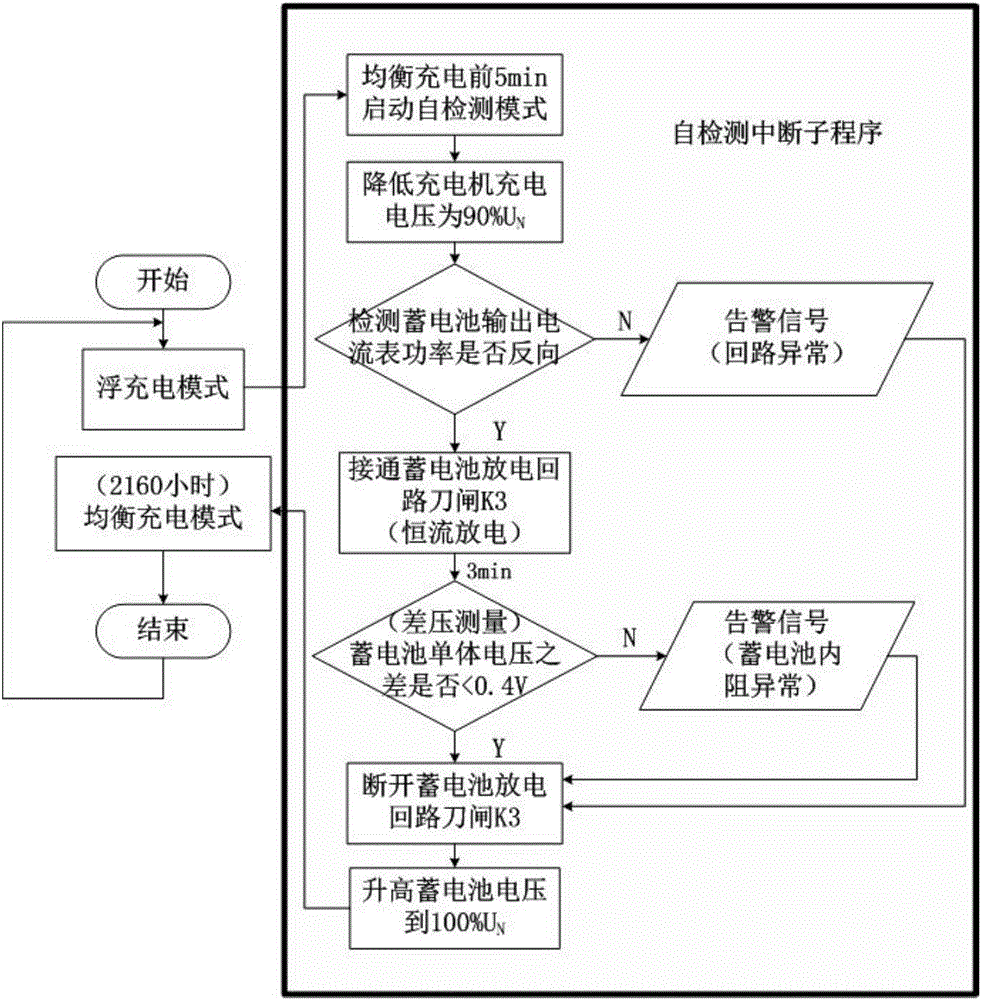

DC system real-time detection method for transformer station

ActiveCN106646037AStrengthen self-real-time detectionRelease capacityElectrical testingFloating chargeTransformer

The invention discloses a DC system real-time detection method for a transformer station. The DC system real-time detection method comprises the steps of: enabling a storage battery to operate in a floating charge mode; enabling a control and detection unit to reduce charging voltage and starting a self-detection interruption system; enabling the control and detection unit to detect the storage battery and controlling the on-off state of a storage battery discharge circuit; increasing the charging voltage of the storage battery in order that the storage battery enters an equalizing charge mode. The method strengthens the real-time self-detection of the storage battery and intensifies the connection to a DC system. The self-detection mode of the storage battery can automatically detect the advantages and disadvantages of the storage battery in real time in a normal floating charging operation mode and verify the integrity of the DC circuit through the readings of an ammeter. Compared with a conventional storage battery checking charge and discharge test, the method is safe and reliable, saves time and labor, and prolongs the service life of the storage battery.

Owner:STATE GRID CORP OF CHINA +1

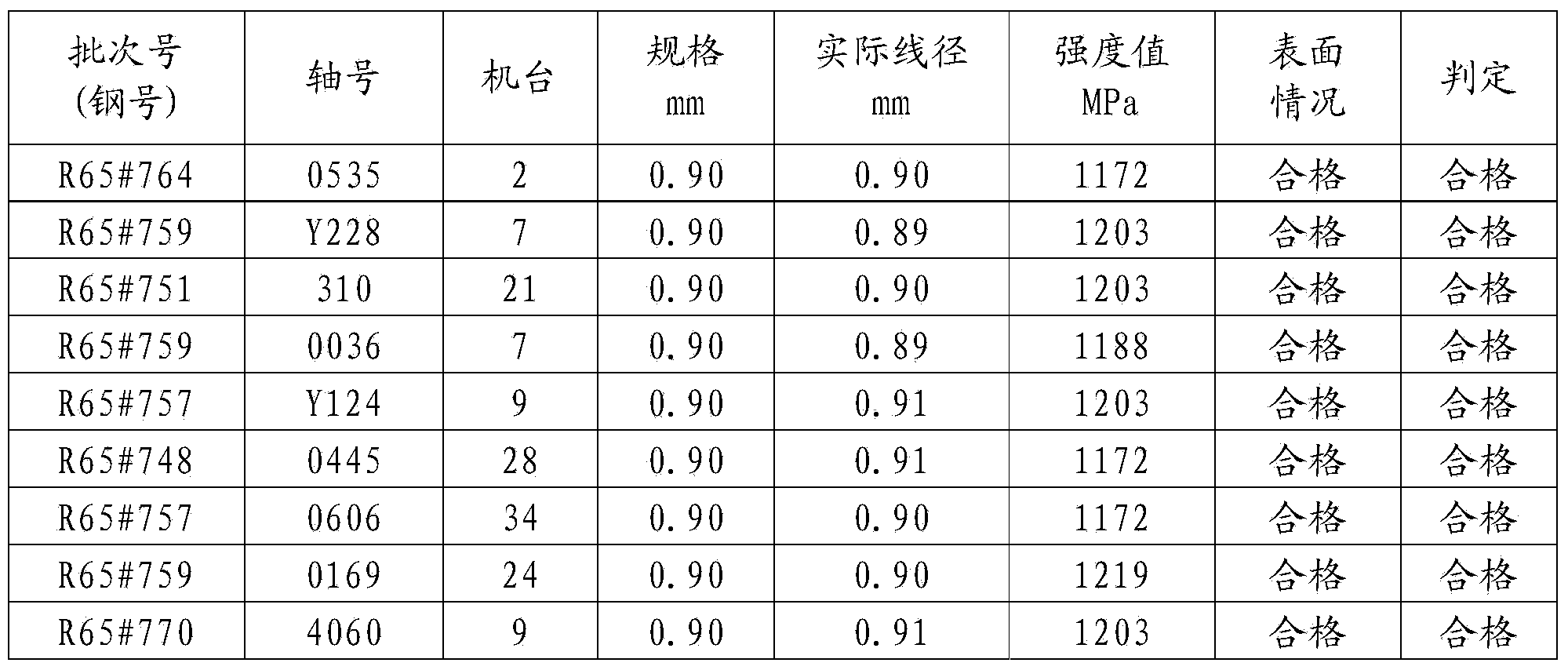

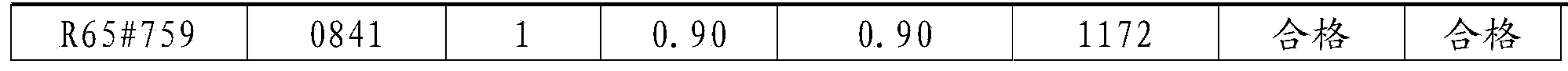

Online thermal treatment, acid pickling and phosphating process of medium and high-carbon superfine steel wire for rope making

InactiveCN104328269AImprove product qualityIncrease the DV valueFurnace typesMetallic material coating processesFurnace temperatureProduction line

The invention discloses an online thermal treatment, acid pickling and phosphating process of a medium and high-carbon superfine steel wire for rope making. The process is suitable for the production of the products which have diameters of phi 0.8-1.3mm and which are of types of high-quality carbon structural steel 45#, SWRH47A and SWRH62A and high-quality carbon structural steel 65# and SWRH72A on a same production line, and is capable of reducing the energy consumption and the consumption of the main accessories in the production process. In a steel wire heating step, a four-stage heating manner is used and the furnace temperature is respectively set to be 900 DEG C, 885 DEG C, 870 DEG C and 855 DEG C; in a lead pan isothermal cooling step, the lead temperature is set to be 565 DEG C, and the DV value is 63mm.m / min; and in the phosphating process, the phosphating temperature is 85+ / -5 DEG C, the total acidity is 80-90, the free acidity is 12-16 and the acid ratio is 5-8. Through setting the optimal acid pickling and phosphating process parameters, the obtained product steel wire for rope making is capable of obtaining favorable mechanical property after undergoing drawing, and meanwhile, the energy consumption is reduced and the production cost is reduced.

Owner:天津市新天钢中兴盛达有限公司

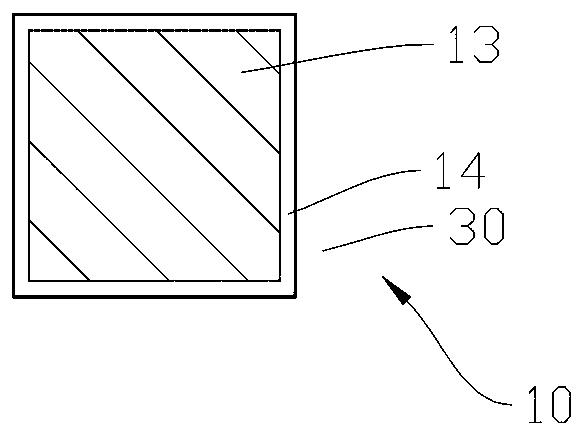

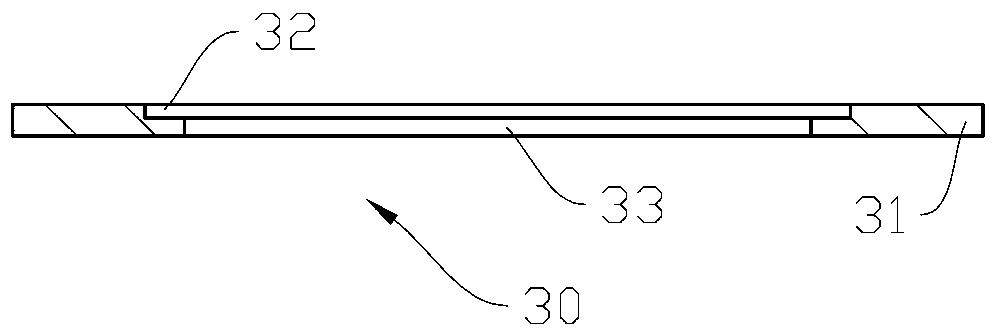

SPE membrane electrode and preparation technology thereof

PendingCN107604379AIncrease profitReduce preparation timeElectrode shape/formsPolyesterPtru catalyst

The invention discloses an SPE membrane electrode which is arranged in an SPE electrolytic cell comprising the SPE membrane electrode, a bipolar plate, an end plate and a sealing gasket. The SPE membrane electrode comprises a proton exchange membrane, a catalyst embedded into the proton exchange membrane, and a polyester frame surrounding the edge of the surface of the bipolar plate and being in charge of connecting with the bipolar plate. The invention further discloses a preparation technology of the SPE membrane electrode. The preparation technology comprises the steps of catalyst sprayingpreparation, catalyst spraying, proton exchange membrane clipping, hot pressing preparation, hot pressing and post treatment. The SPE membrane electrode is simple in structure, convenient to manufacture and low in cost; the utilization ratio of the proton exchange membrane is raised significantly; the consumption of the proton exchange membrane is reduced; the cost of the SPE membrane electrode islowered; the connecting strength between the membrane electrode and the bipolar plate is ensured and improved; the spraying efficiency of the catalyst and the manufacturing efficiency of the SPE membrane electrode are improved substantially; and the productive capacity potential of the SPE electrolytic cell is released fully.

Owner:浙江高成绿能科技有限公司

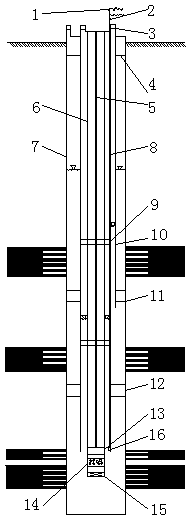

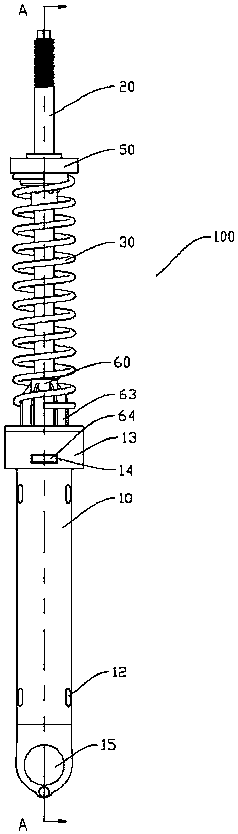

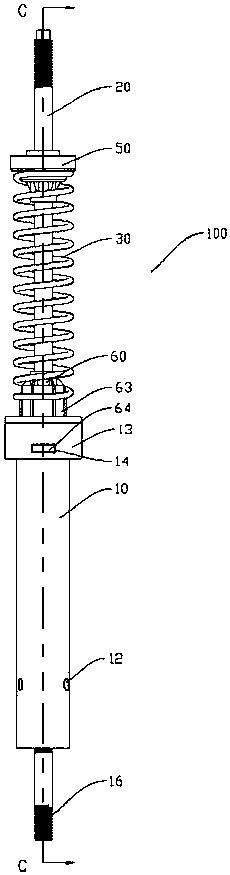

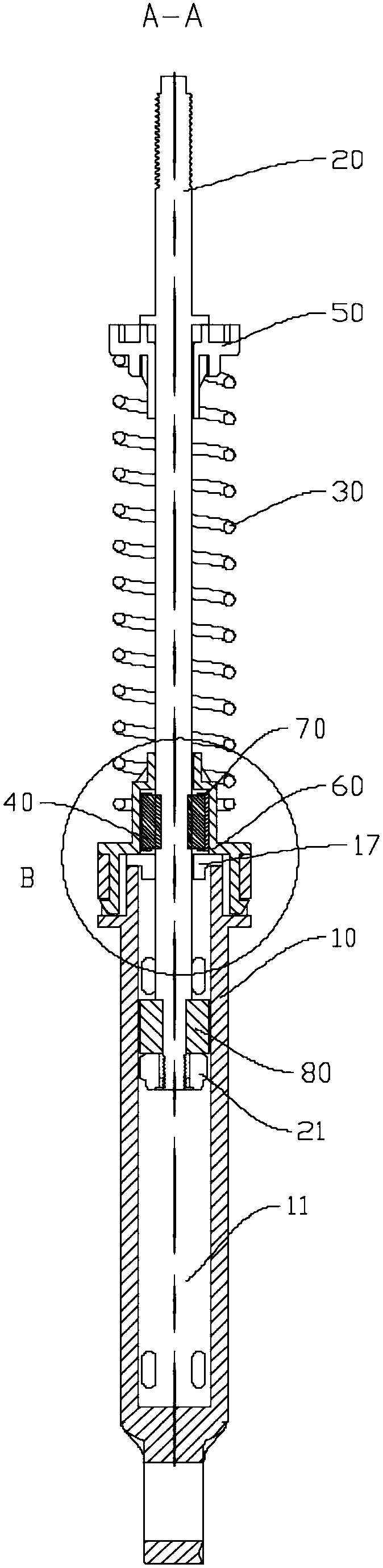

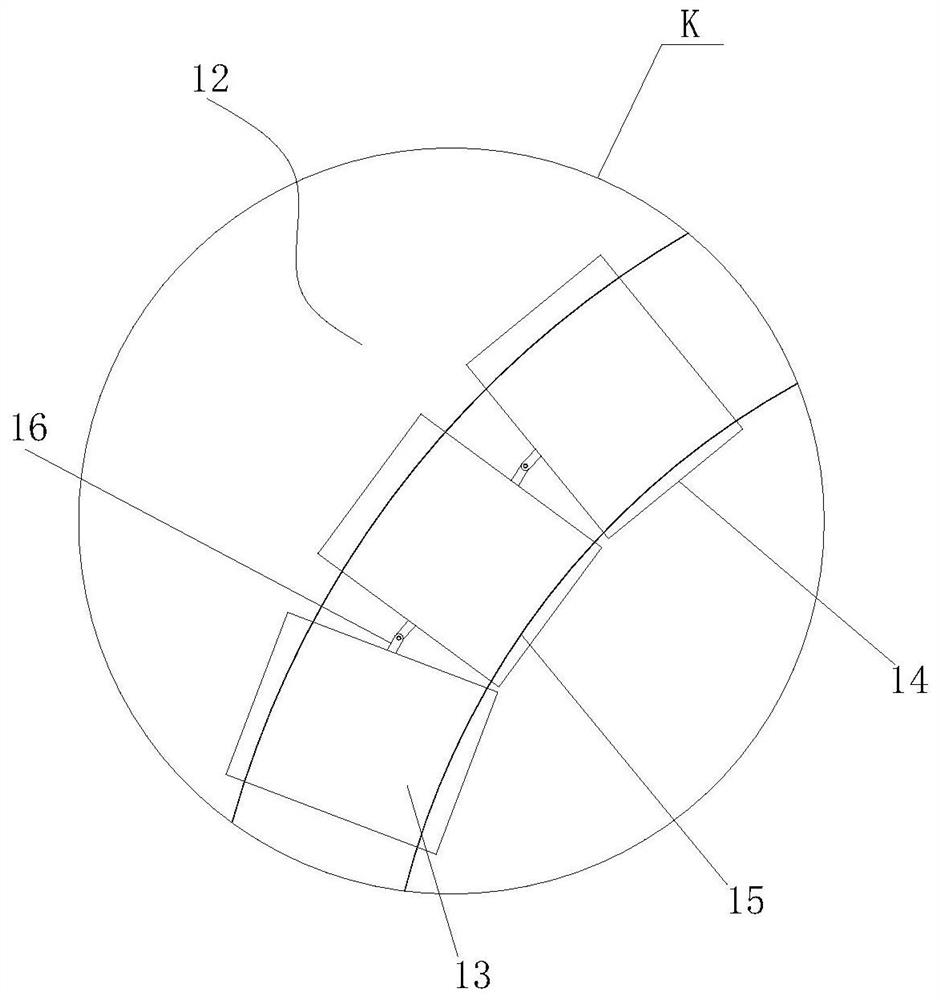

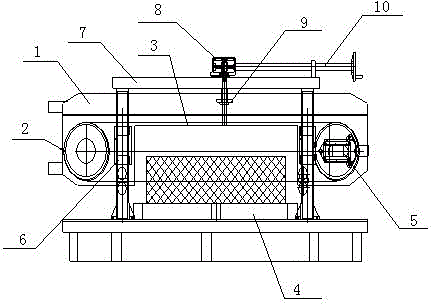

Multi-coal-seam independent gas-containing system pressure control single-pump drainage device and method

InactiveCN109458161APressure drop funnel lastsExtended stabilitySurveyFluid removalWater flowSystem pressure

The invention discloses a multi-coal-seam independent gas-containing system pressure control single-pump drainage device and method. The device comprises an inner casing pipe and an outer casing pipe,an oil pipe is arranged in the inner casing pipe, an oil pumping rod is arranged inside the oil pipe, the bottom of the oil pumping rod is connected with a tubular pump, a sand settling pipe is arranged at the bottom of the tubular pump, and a sifting pipe is further arranged above the sand settling pipe; a first packer and a second packer are arranged between the inner casing pipe and the outercasing pipe; a pressure meter cable and an annular flow limiting valve cable are fixedly arranged on the pipe wall of the inner side of the inner casing pipe, the bottom of the pressure meter cable isconnected with a pressure meter, the pressure meter is fixedly installed at the bottom of the inner wall of the inner casing pipe, and the bottom of the annular flow limiting valve cable is connectedwith annular flow limiting valves of all independent gas-containing systems. According to the multi-coal-seam independent gas-containing system pressure control single-pump drainage device and method, the annular flow limiting valves are installed to control the volume of water flowing into a pump port of the inner casing pipe; a movable liquid level assisting pipe can separate gas produced by all the independent gas-containing systems, and a gas flowmeter can be installed at the top of the movable liquid level assisting pipe to monitor the gas production yields of all the gas-containing systems.

Owner:CHINA UNIV OF MINING & TECH

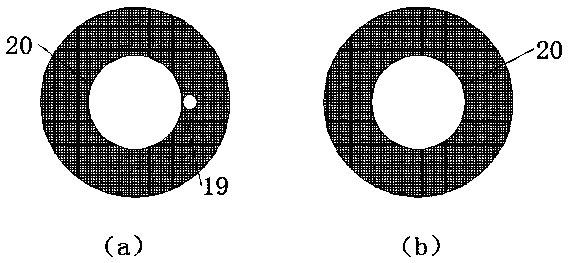

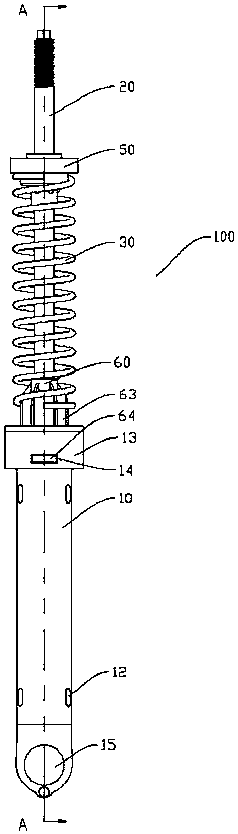

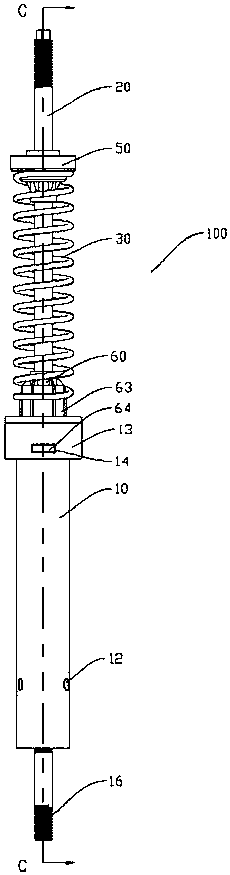

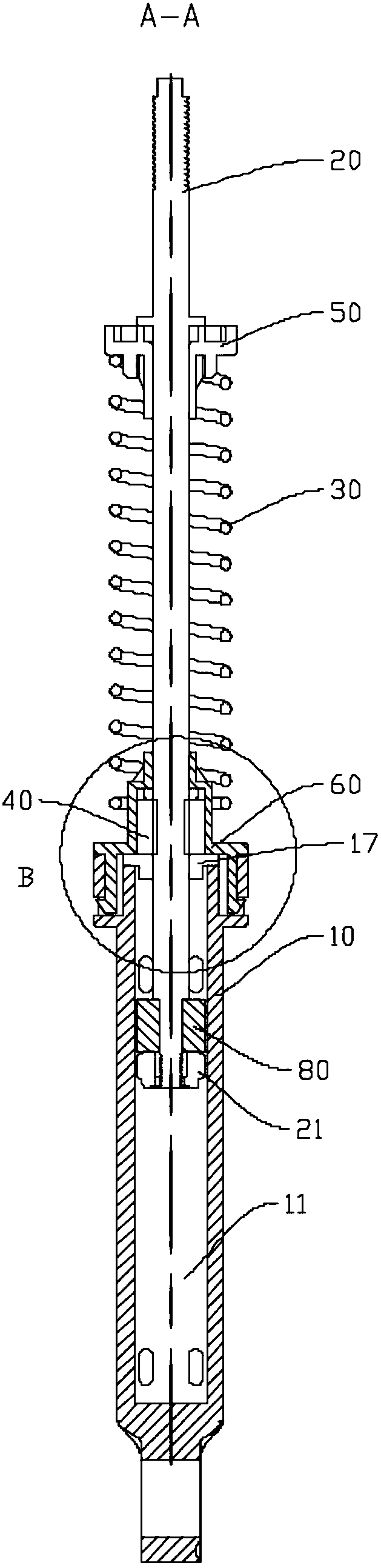

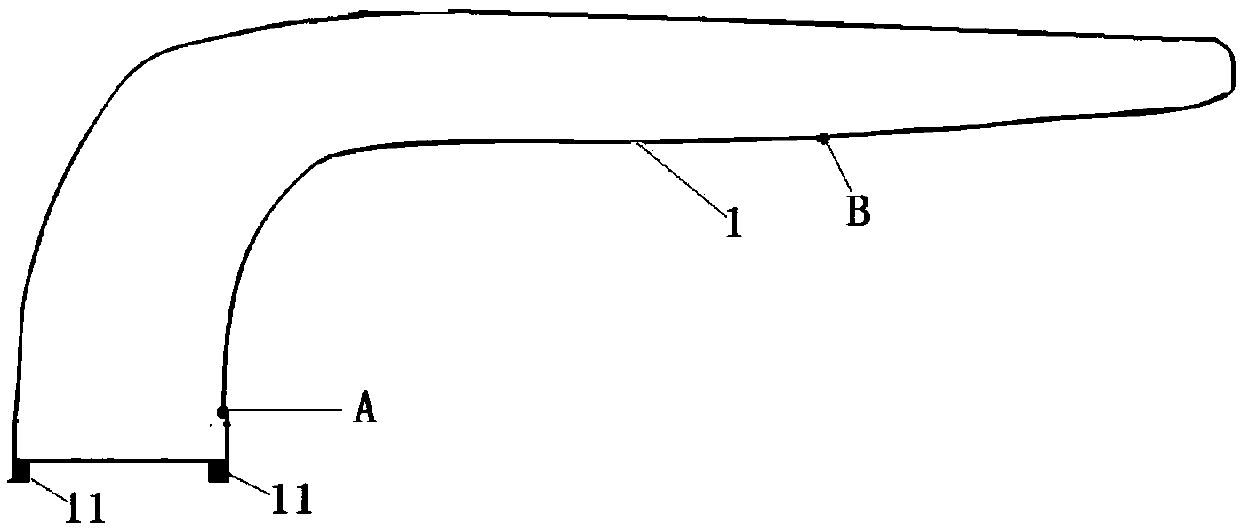

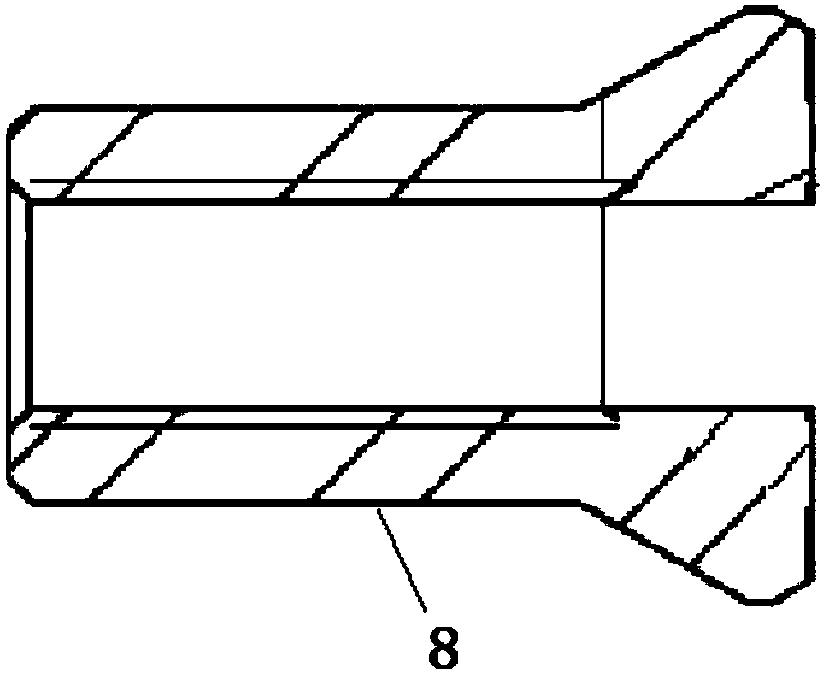

Shock absorber of washing machine and washing machine provided with same

PendingCN109594295AReduce shakingSmall footprintOther washing machinesTextiles and paperRelative motionShock absorber

The invention discloses a shock absorber of a washing machine and a washing machine provided with the same. The shock absorber comprises a shock absorber sleeve, a shock absorber rod, elastic members,a first damping member and a second damping member, wherein the shock absorber sleeve internally defines an accommodating cavity; the shock absorber rod is movably connected with the shock absorber sleeve; the elastic members are arranged on the shock absorber rod and / or the shock absorber sleeve; the first damping member is sleeved on the shock absorber rod and mounted on the shock absorber sleeve; the second damping member is mounted on the shock absorber rod and accommodated in the accommodating cavity, wherein a passage for accommodating the first damping member is formed in the shock absorber sleeve and / or the shock absorber rod; the first damping member is capable of moving a predetermined distance in the passage along a direction in which the shock absorber sleeve and the shock absorber rod move relative to each other, and when a distance between the shock absorber sleeve and the shock absorber rod in relative motion is greater than the predetermined distance, the first dampingmember and / or the second damping member produce damping. The shock absorber provided by the embodiment of the invention has good shock absorption and small volume.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

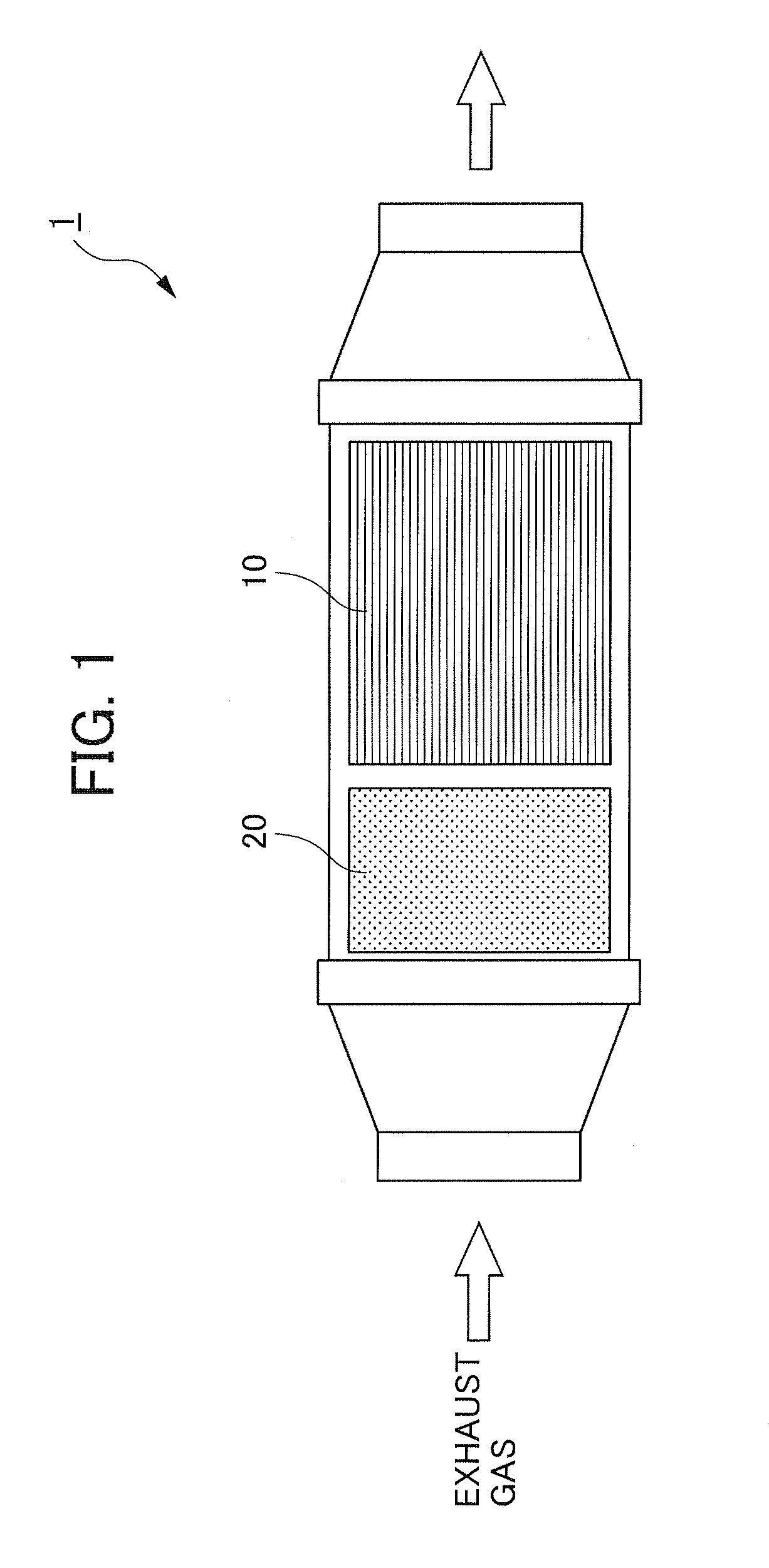

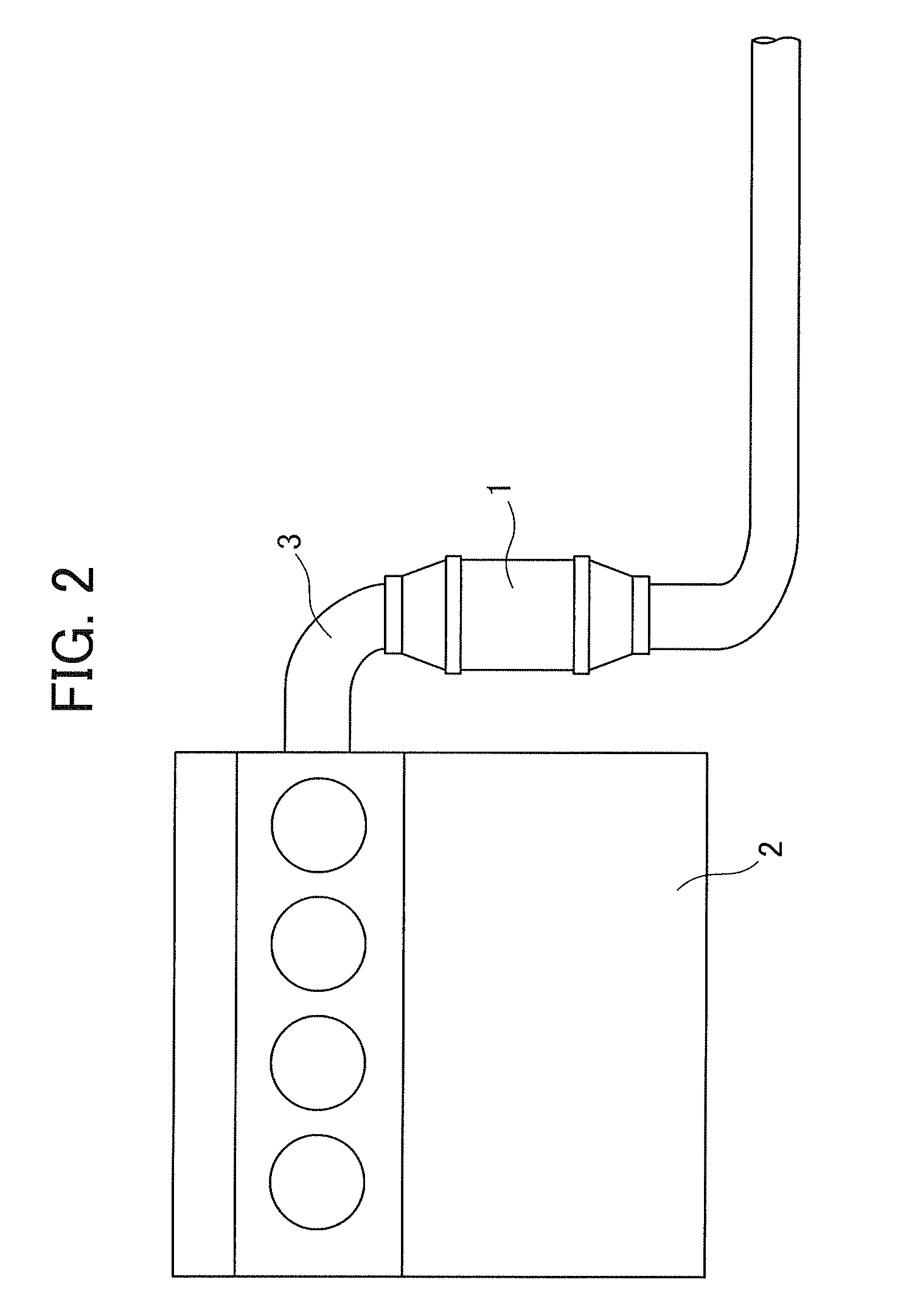

Exhaust gas purification catalyst and exhaust gas purification apparatus using the exhaust gas purification catalyst

ActiveUS8544261B2Lower the temperature of PM combustionImprove responseGas treatmentMolecular sieve catalystsCombustionExhaust fumes

This invention provides an exhaust gas purification catalyst, which can burn PM (particulate matter) at a temperature below the temperature required in the prior art technique and can realize a high PM combustion rate at elevated temperatures, and an exhaust gas purification apparatus using the exhaust gas purification catalyst. The exhaust gas purification catalyst comprises a composite oxide having oxygen release properties and Ag and a noble metal co-supported on the composite oxide. The exhaust gas purification catalyst and an exhaust gas purification apparatus (1) using the exhaust gas purification catalyst can increase the PM combustion rate at elevated temperatures and, at the same time, can burn PM at a temperature below the temperature required in the prior art technique. Further, fuel consumption loss caused by forced regeneration, EM deterioration, and catalyst deterioration can be suppressed, and, thus, the load on automobiles can be reduced.

Owner:HONDA MOTOR CO LTD

Ultraviolet (UV) base oil metal tank UV printing and coating method

ActiveCN103909754AGood flexibilityImprove impact resistancePolyurea/polyurethane coatingsOther printing apparatusUltravioletSolvent

The invention relates to an ultraviolet (UV) base oil metal tank UV printing and coating method which includes the following steps: 1) pre-printing computer direct platemaking; 2) inner coating which includes adopting inner coating to coat the inner surface; 3) conducting instantaneous high temperature processing on the surface of a base material; 4) instantaneous continuous completion of UV base oil coating, UV base oil solidification through a UV lamp and UV ink printing; 5) follow-up continuous solidification of a UV ink layer through a UV lamp group; 6) conducting polishing and coating to protect printed patterns from being scrapped and damaged. By means of the method, the UV base oil outer coating replaces the traditional solvent type base oil outer coating, the film layer is thin, natural gas energy consumed by tunnel type drying room drying and solidification and waste gas discharged to the nature are greatly reduced, the energy is saved, and the environment is protected. In addition, the new process that the UV base oil coating and UV ink printing are finished together continuously is achieved, the printing and coating production efficiency can be greatly improved, and meanwhile coating capacity of a coating line is released.

Owner:SHANGHAI BAOYIN METAL DECORATION

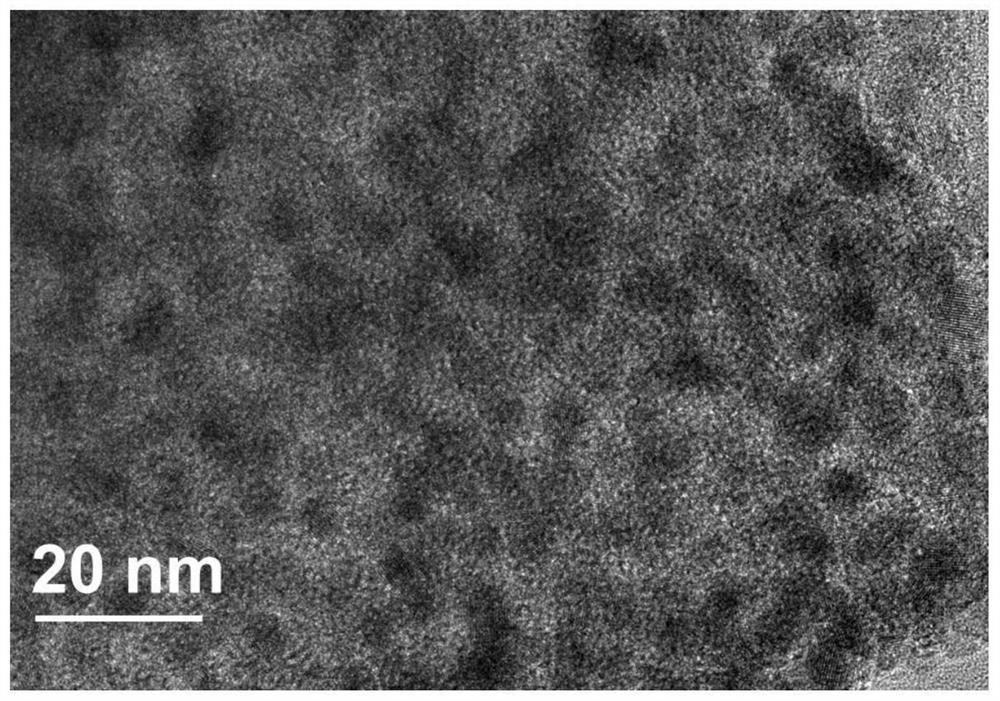

Preparation method of high-capacity nitrogen-doped carbon-coated SnOx quantum dot lithium ion battery negative electrode material

ActiveCN112271298AEvenly dispersedCoated evenlyMaterial nanotechnologySecondary cellsMeth-Zinc nitrate

The invention relates to a preparation method of a high-capacity nitrogen-doped carbon-coated SnOx quantum dot lithium ion battery negative electrode material. The method comprises the following steps: (1) preparing a zinc stannate precursor; (2) preparing a zinc stannate precursor modified by polydiene dimethyl ammonium chloride and poly (sodium p-styrenesulfonate); (3) transferring the modifiedzinc stannate precursor into a container, then adding methanol, then sequentially adding zinc nitrate and 2-methylimidazole, and stirring for reaction to obtain solid powder; and (4) carrying out heattreatment at 600-1000 DEG C for 1-5 hours to obtain the high-capacity nitrogen-doped carbon-coated SnOx quantum dot lithium ion battery negative electrode material. The reversible specific capacity of the obtained composite material reaches 1824 mAh g <-1 > after 100 cycles under the current density of 0.2 A g <-1 >, and is far higher than the theoretical specific capacity of SnO2.

Owner:HEBEI UNIV OF TECH

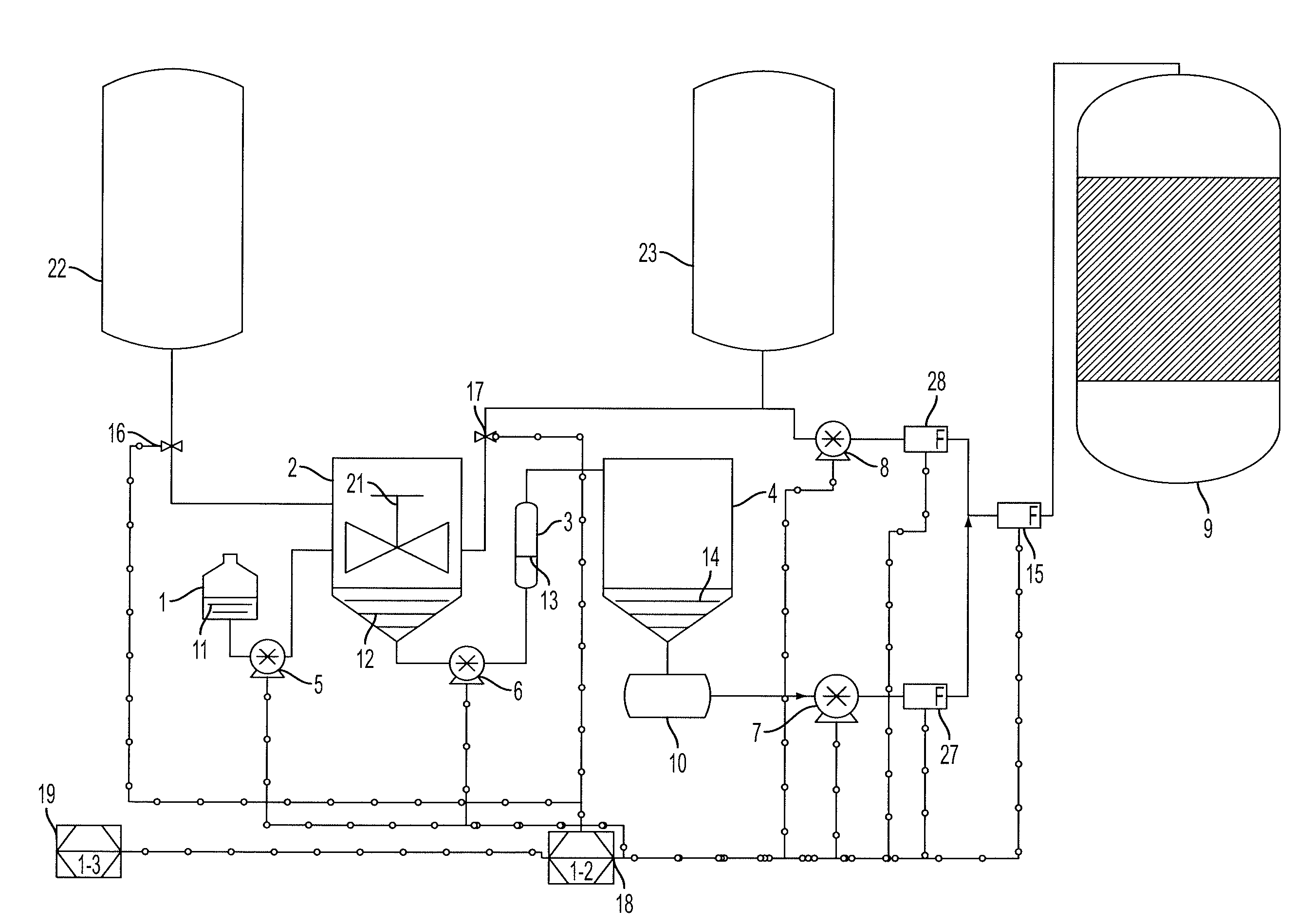

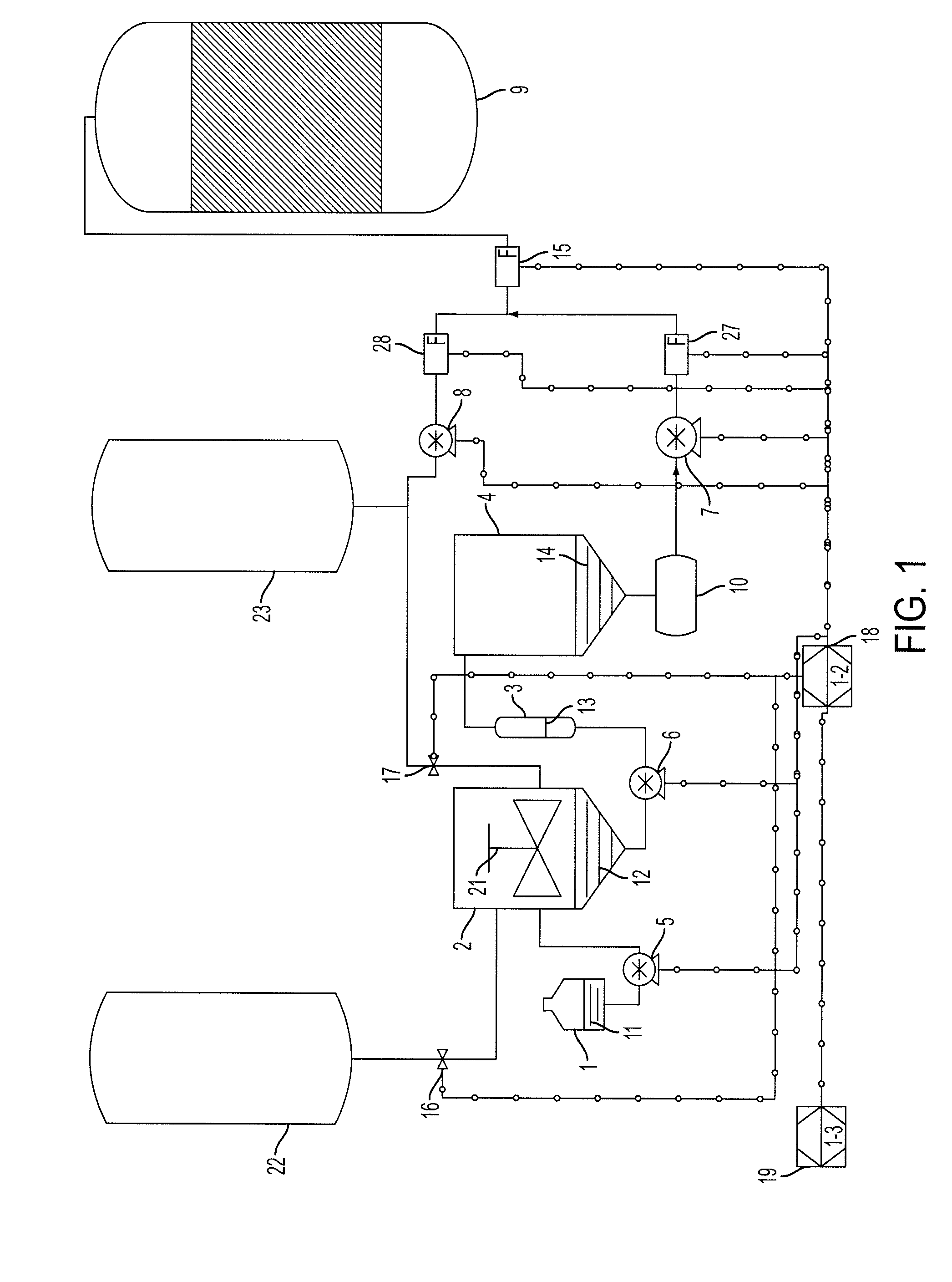

Method for reducing costs of enzymes in biorefinery

InactiveUS20130118590A1Reduce amountReducing cost for enzymeBiofuelsPipeline systemsSpecific gravityChemistry

A business methodology for optimizing enzyme use rates and enzyme supply and reducing greenhouse gas emissions for an industrial process that employs enzymes as part of the production process by changing the concentration, specific gravity and / or activity of an enzyme prior to, and just-in-time for, the addition of said enzyme to a reactor wherein an enzyme-catalyzed reaction occurs. After collecting data that describes the extent to which enzyme consumption has decreased as a result of the change in concentration, specific gravity and / or activity of said enzymes, the enzyme user can pay to the provider of technology that allows enzyme consumption to decrease, a proportion of the savings.

Owner:SCIENTEK

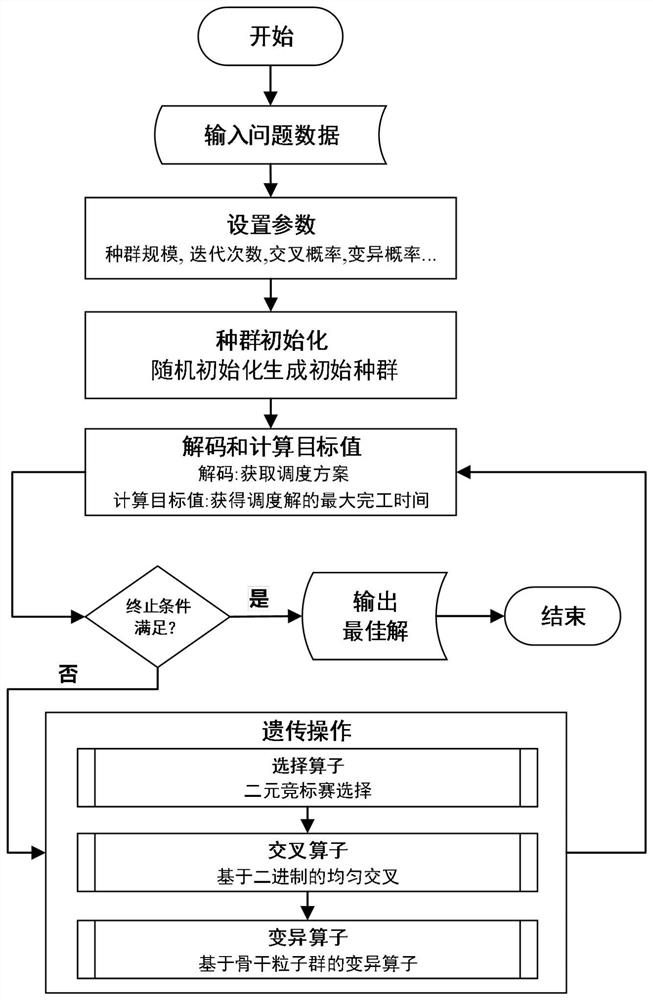

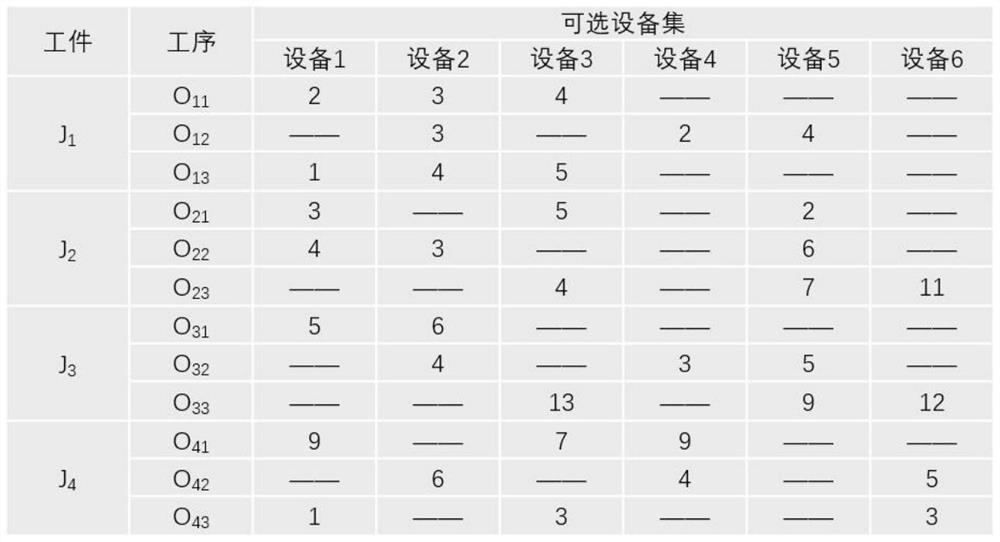

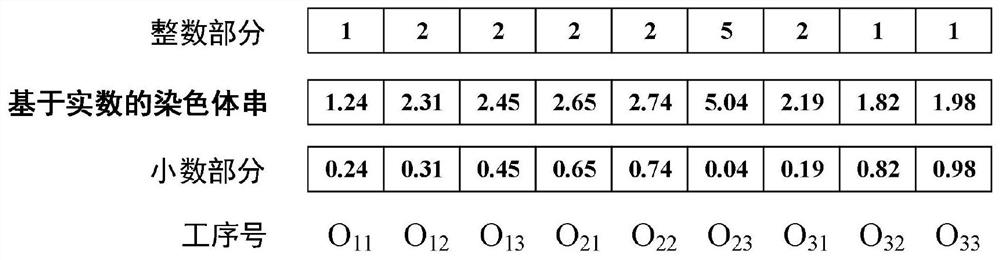

Flexible job shop scheduling method based on genetic-backbone particle swarm hybrid algorithm

PendingCN112381343AHigh solution accuracyFast convergenceArtificial lifeResourcesTheoretical computer scienceAlgorithm convergence

The invention discloses a flexible job shop scheduling method based on a genetic-backbone particle swarm hybrid algorithm, which can overcome the defects of low solving precision and low convergence rate of a general genetic algorithm for a flexible job shop scheduling problem. According to the method, the backbone particle swarm algorithm is used as a mutation operator, and the directionality ofindividual variation based on the optimal current swarm and the optimal individual history is realized through an improved particle position updating formula, so that the algorithm convergence speed and the solving precision are improved; in order to ensure that the backbone particle swarm algorithm can run in a continuous domain and avoid chromosome conversion, the invention provides a real number-based chromosome expression mode, and correspondingly provides a decoding method, an initialization method, a binary system-based chromosome crossover method and a post-mutation chromosome repair method adapting to real number chromosome expression.

Owner:BEIJING UNIV OF TECH +1

Continuous roll forming method for M-shaped steel sheet pile

The invention discloses a continuous roll forming method for an M-shaped steel sheet pile. The continuous roll forming method is characterized by specifically comprising the following steps that S1, strip steel is longitudinally sheared; S2, uncoiling and flattening are carried out; S3, shearing and butt welding are carried out; S4, continuous roller type cold roll forming is carried out; S5, a semi-finished steel sheet pile is cut; the strip steel is a steel reel with the width matched with the width of the unfolded size of the M-shaped steel sheet pile, or a steel reel with the width matchedwith the width of the unfolded size of the M-shaped steel sheet pile after being machined; and complex hooks and legs are synchronously formed through a downward hook forming process, the process ischanged into simple similar channel steel production, so that cold-bent steel sheet piles of different sizes are produced. In this way, the number of steel sheet pile product molds is greatly reduced,the mold cost is saved, the product development time period is shortened, the product can only be produced by 10 mm or below from an original unit, and 13.5 mm steel sheet pile products can be produced after the new technology is improved.

Owner:南京图信新材料科技有限公司

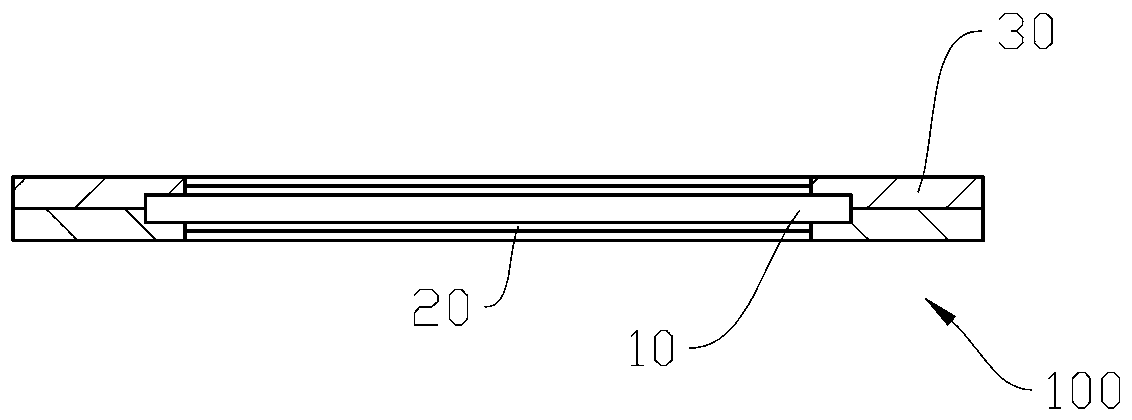

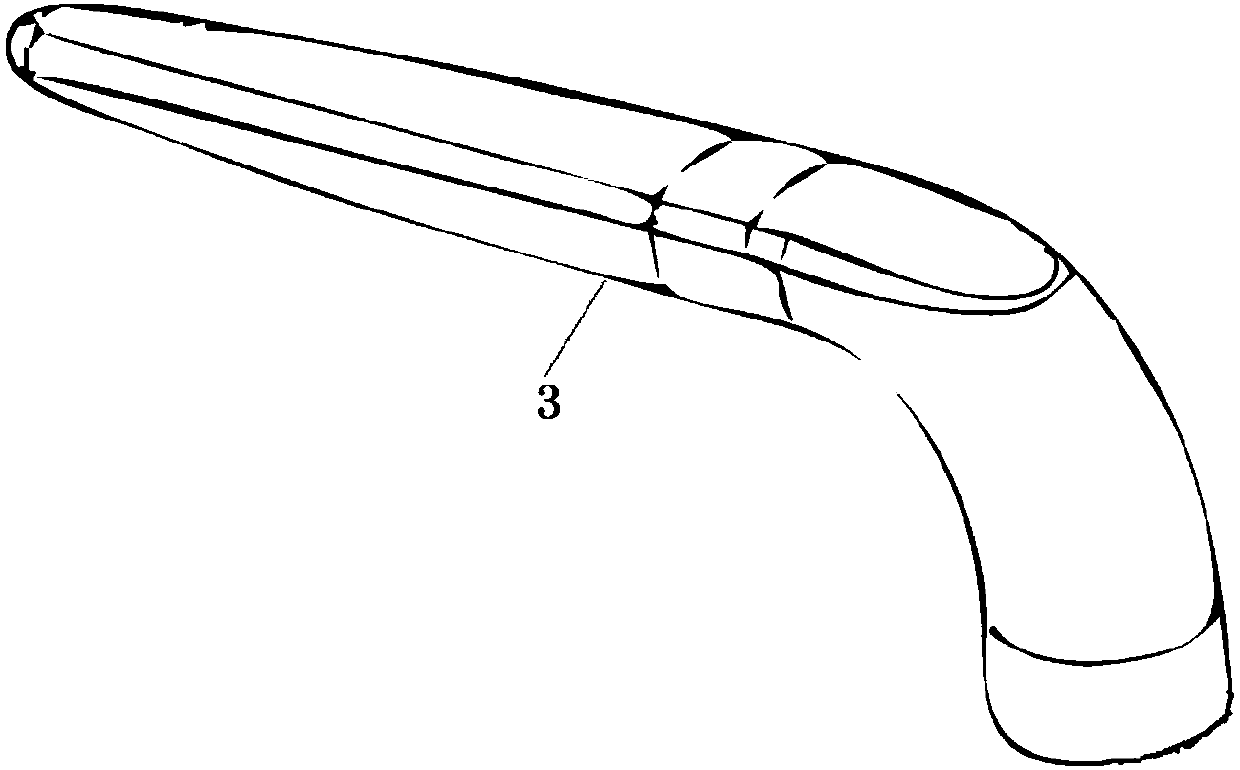

Shock absorber of washing machine and washing machine provided with same

ActiveCN109594294ASmall footprintRelease capacitySpringsOther washing machinesEngineeringRelative motion

The invention discloses a shock absorber of a washing machine and a washing machine provided with the same. The shock absorber comprises a shock absorber sleeve, a shock absorber rod, elastic members,a first damping member and a second damping member, wherein the shock absorber sleeve internally defines an accommodating cavity; the shock absorber rod is movably connected with the shock absorber sleeve; the elastic members are arranged on the shock absorber rod and / or the shock absorber sleeve; the first damping member is sleeved on the shock absorber rod and mounted on the shock absorber sleeve; the second damping member is mounted on the shock absorber rod and accommodated in the accommodating cavity, wherein the first damping member and the second damping member produce damping when theshock absorber rod and the shock absorber sleeve are in relative motion. According to the shock absorber provided by the embodiment of the invention, by providing the first damping member and the second damping member, vibration can be effectively alleviated, the sloshing of the washing machine can be reduced, and the shock absorber occupies a small space, so that the capacity of the washing machine can be released.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Manufacturing process for door handle

A manufacturing process for a door handle comprises the following steps: handle treatment: fixing two spot welding positions of an upper plate and a lower plate which are provided with lengthening ends together, and then carrying out seamless welding on the upper plate and the lower plate to form a handle finished product; and assembling a panel, a treated handle and a double-screw bolt accordingto a traditional process to form a door handle finished product. Welding defects do not exist on welding initiating and welding ending positions of the handle in the door handle, the reject ratio is reduced to be five percent from the original fifty percent, the cost is reduced by fifty percent, and the production period is shortened.

Owner:特洛伊五金(苏州)有限公司

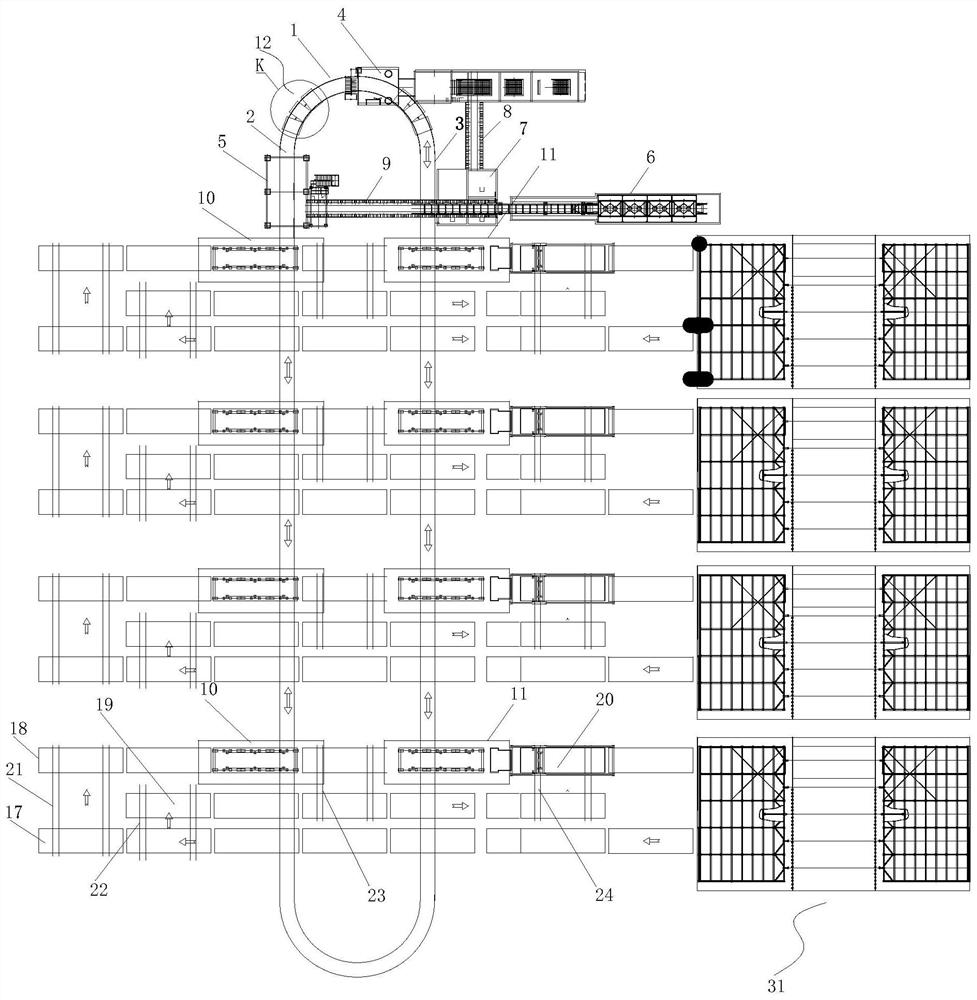

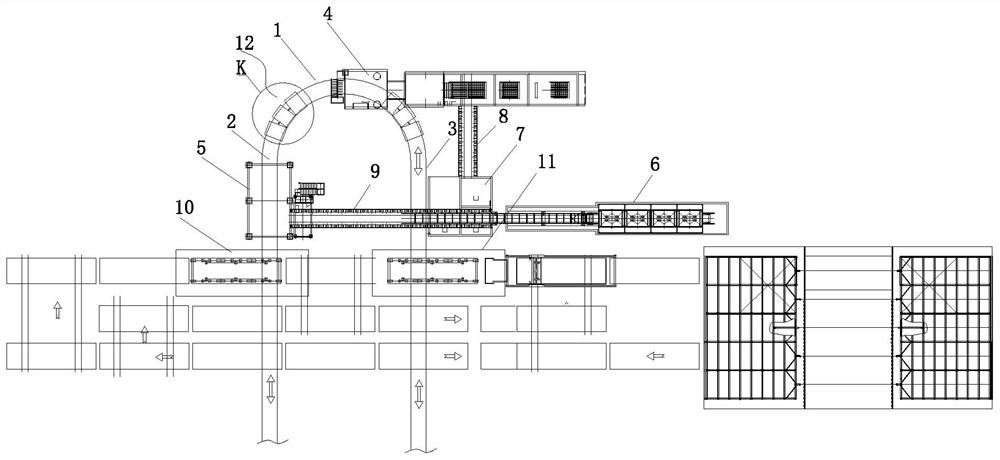

Efficient concrete prefabricated part production line

InactiveCN112917665AQuality assuranceShorten the timeCeramic shaping plantsFeeding arrangmentsMachining vibrationsProduction line

The invention discloses an efficient concrete prefabricated part production line. The efficient concrete prefabricated part production line comprises a stirring production line for concrete prefabricated part machining, a material distributing machine production line for concrete prefabricated part machining and a maintaining production line for concrete prefabricated part machining; the stirring production line for concrete prefabricated part machining comprises a bullet vehicle track which is arranged to be annular; a left track and a right track which are parallel to each other are arranged on the two sides of the bullet vehicle track correspondingly; a main stirring station is arranged at the tail end of the left track; an auxiliary stirring station is arranged at the semicircular-arc-shaped end of the side, close to the main stirring station, of the bullet vehicle track; the material distributing machine production line for concrete prefabricated part machining comprises a left material distributing machine vibration table and a right material distributing machine vibration table; and the maintaining production line for concrete prefabricated part machining comprises a maintaining kiln which comprises a left maintaining kiln body and a right maintaining kiln body. The efficient concrete prefabricated part production line is optimized in design and higher in reliability, the machining efficiency is improved, and the productivity is released.

Owner:SUZHOU JIASHENG YUANDA CONSTR IND CO LTD

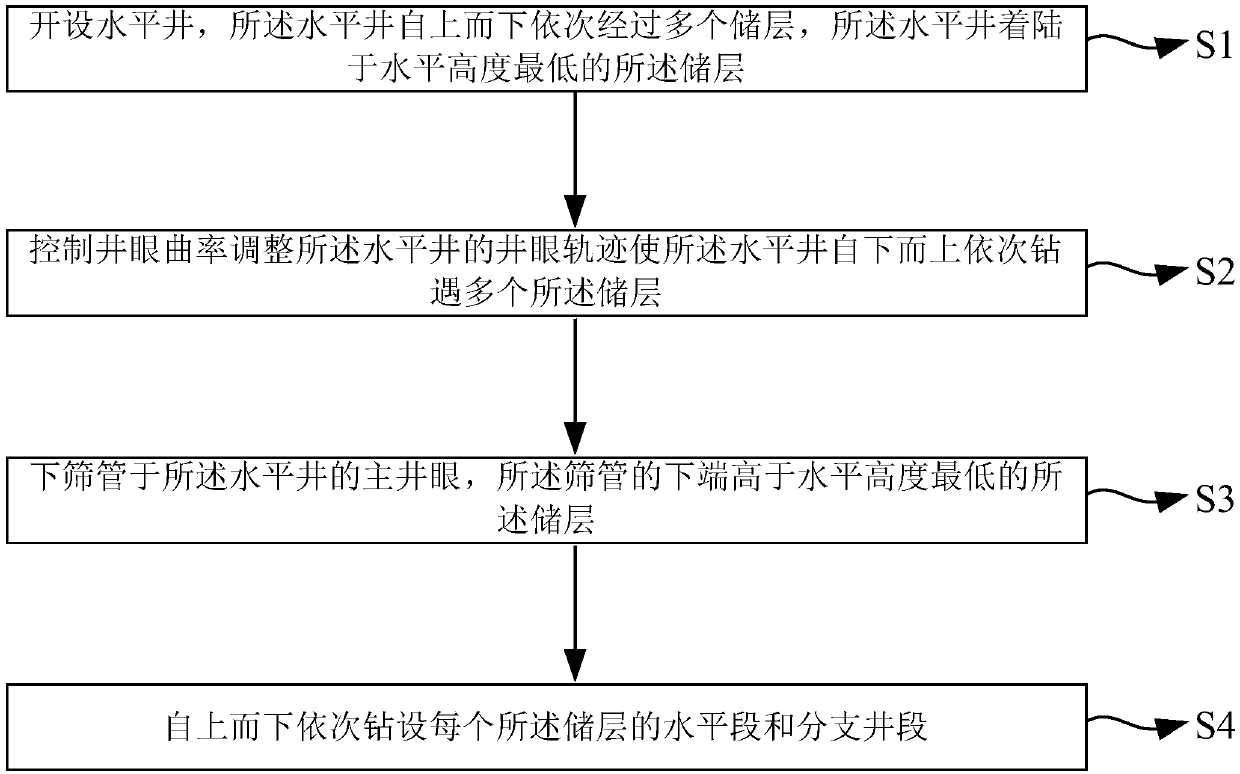

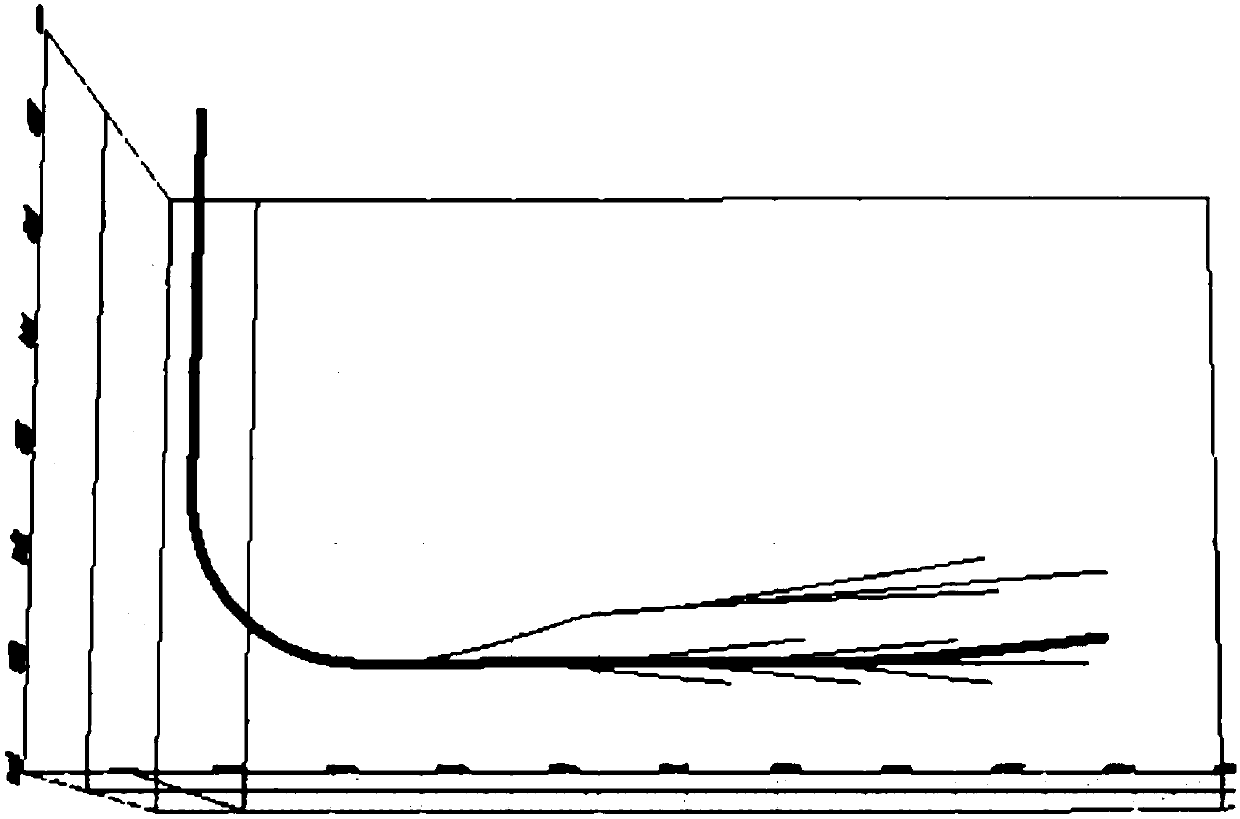

Coal-bed methane mining method

The invention discloses a coal-bed methane mining method. A plurality of adjacent reservoirs can be opened simultaneously, a main borehole communicates with horizontal sections and branch well sections of the multiple reservoirs, the multiple adjacent reservoirs play a synergistic effect, though the permeability increasing effect of the upper reservoirs, the permeability of the lower reservoirs is increased effectively, and the productivity is released to the utmost extent. According to the coal-bed methane mining method, the productivity is ensured, another borehole does not need to be additionally constructed, and thus the coal-bed methane mining cost of the multilayered-system reservoirs is lowered to a certain extent.

Owner:BEIJING ORION ENERGY TECH DEV +1

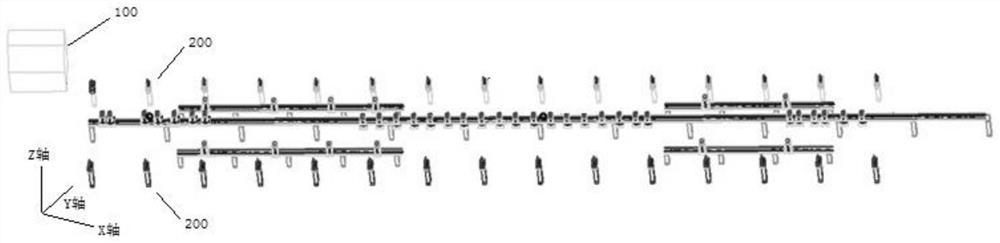

Car roof flexible assembling and welding clamp system

ActiveCN112222718AImprove and optimize welding productionReduce changeover timeWelding/cutting auxillary devicesAuxillary welding devicesProduction lineRailway passenger car

The invention relates to the technical field of railway passenger car manufacturing equipment, in particular to a car roof flexible assembling and welding clamp system. The technical problems that inthe prior art, when a stainless steel car roof welding manufacturing process is used for manufacturing and remodeling, a clamp system is complex in adjustment, and effective production time is wastedare solved. The method specifically comprises the steps that a control unit receives car roof model information of a railway passenger car based on hardware equipment, and the hardware equipment classifies the car roof model information into a plurality of execution signals based on a loaded solidification program; the preset moving distance or the preset moving height formed by execution units drives the corresponding execution units to move and act based on the instructions of the execution signals; and the execution units feed back the coordinates of the X axis, the Y axis and the Z axis ofthe execution units to the control unit, and the coordinates are received by the hardware equipment. According to the technical scheme, stainless steel car roof welding production is effectively improved and optimized, the tool remodeling time can be greatly shortened, and the capacity of a stainless steel production line is released.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

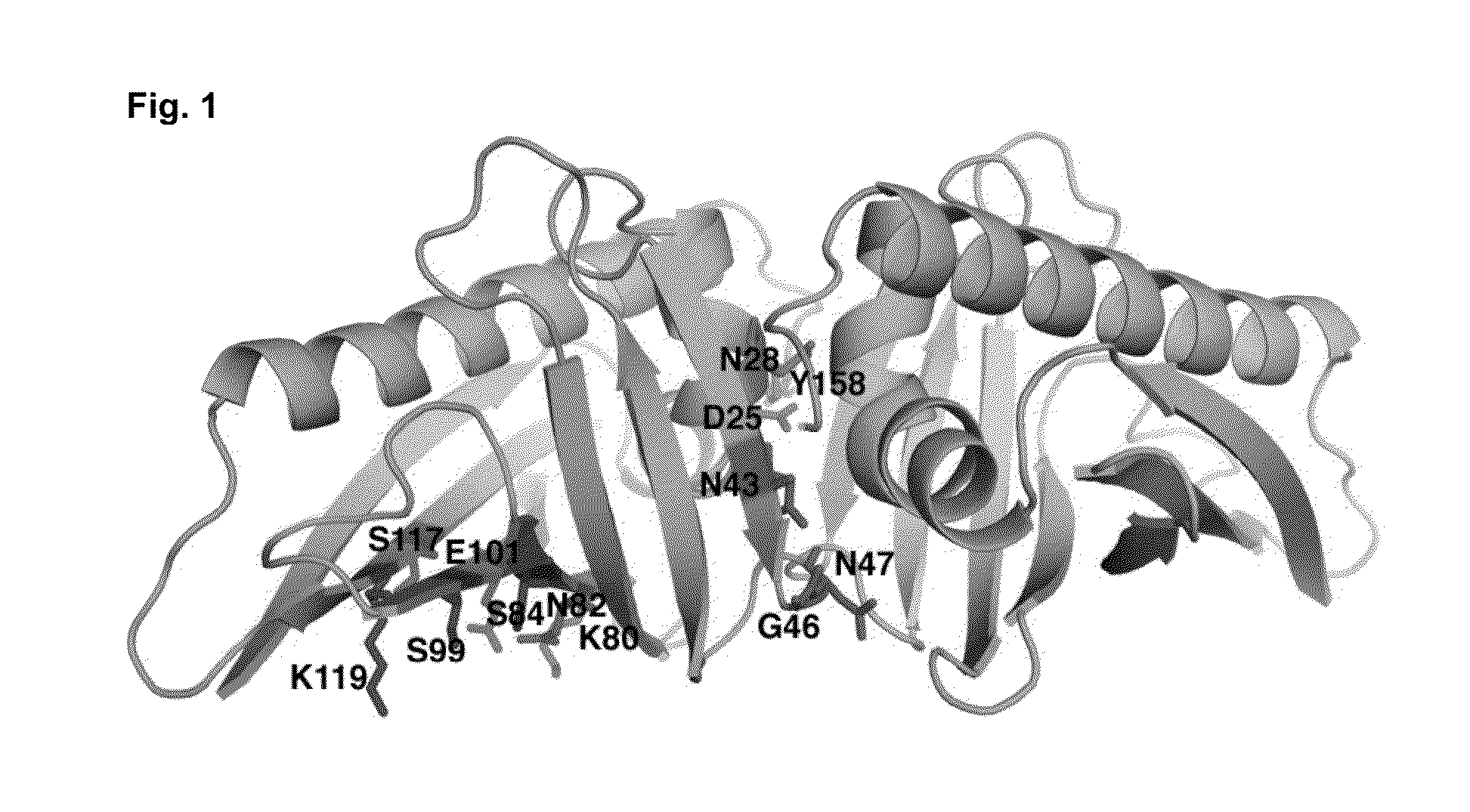

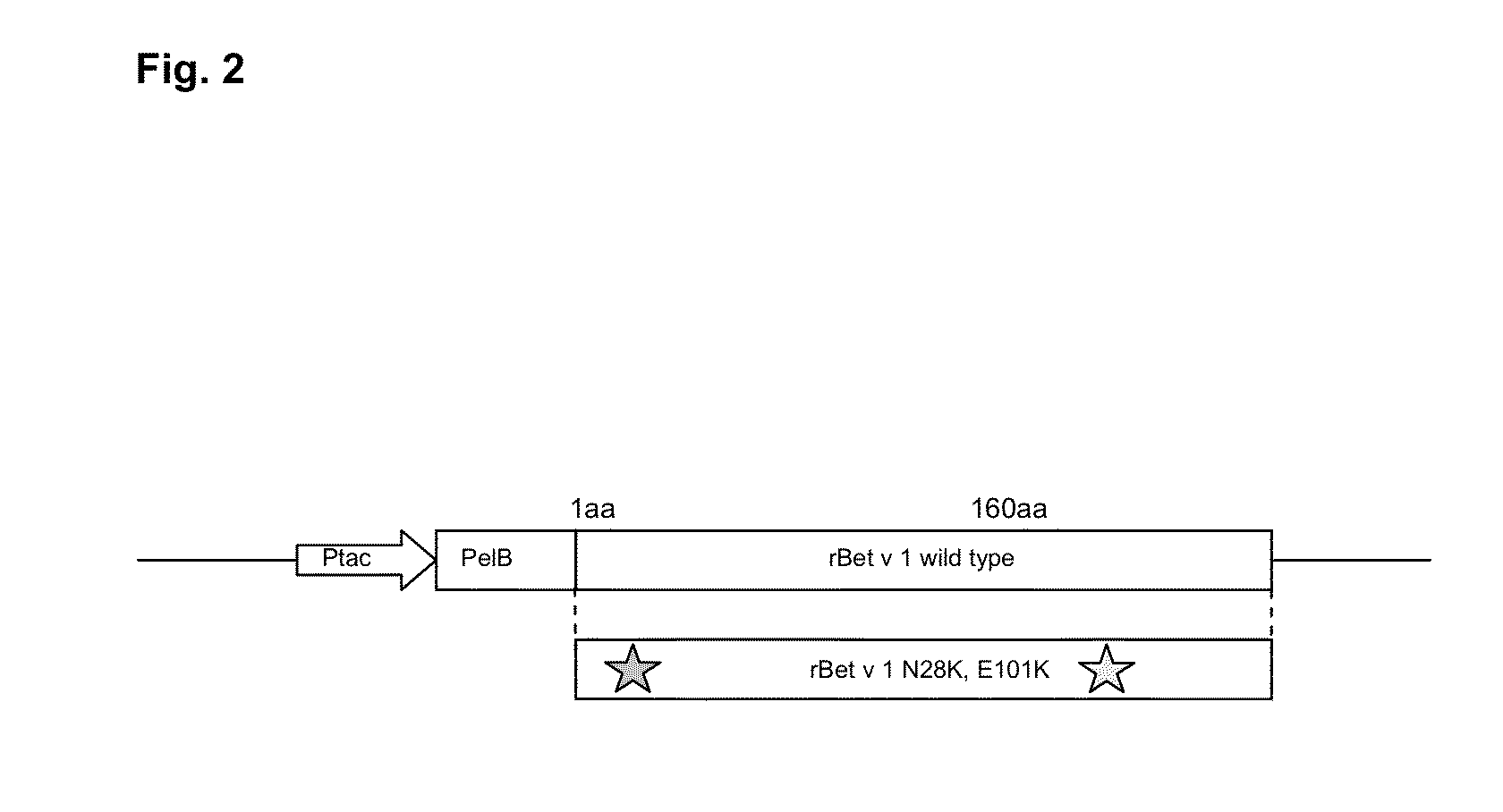

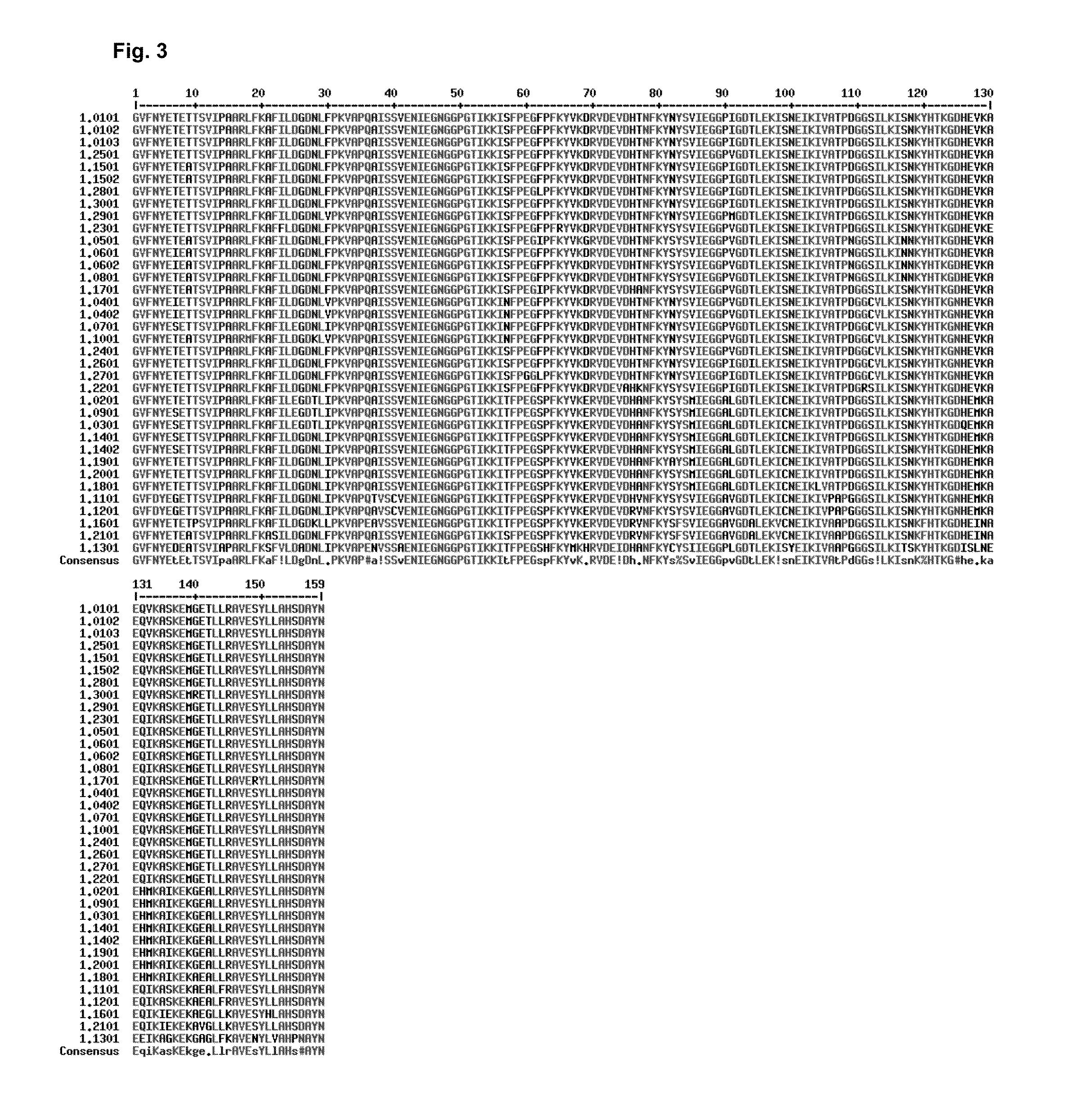

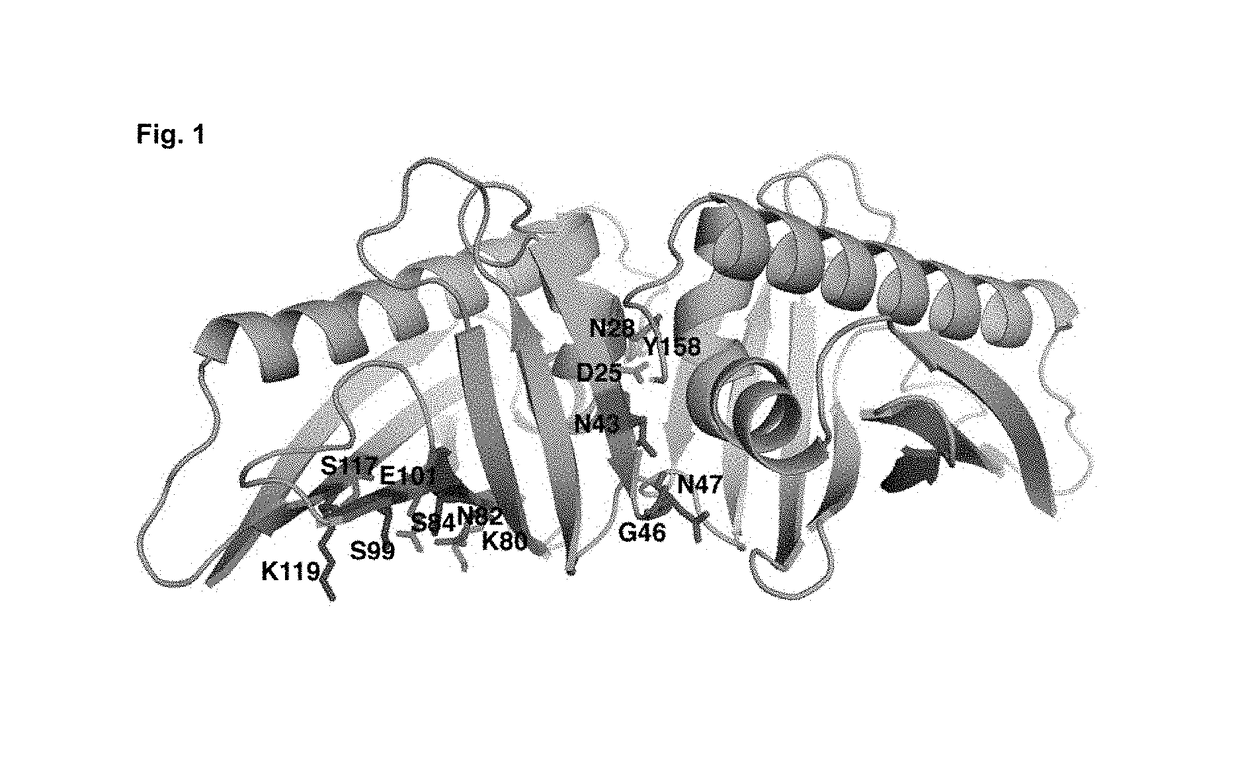

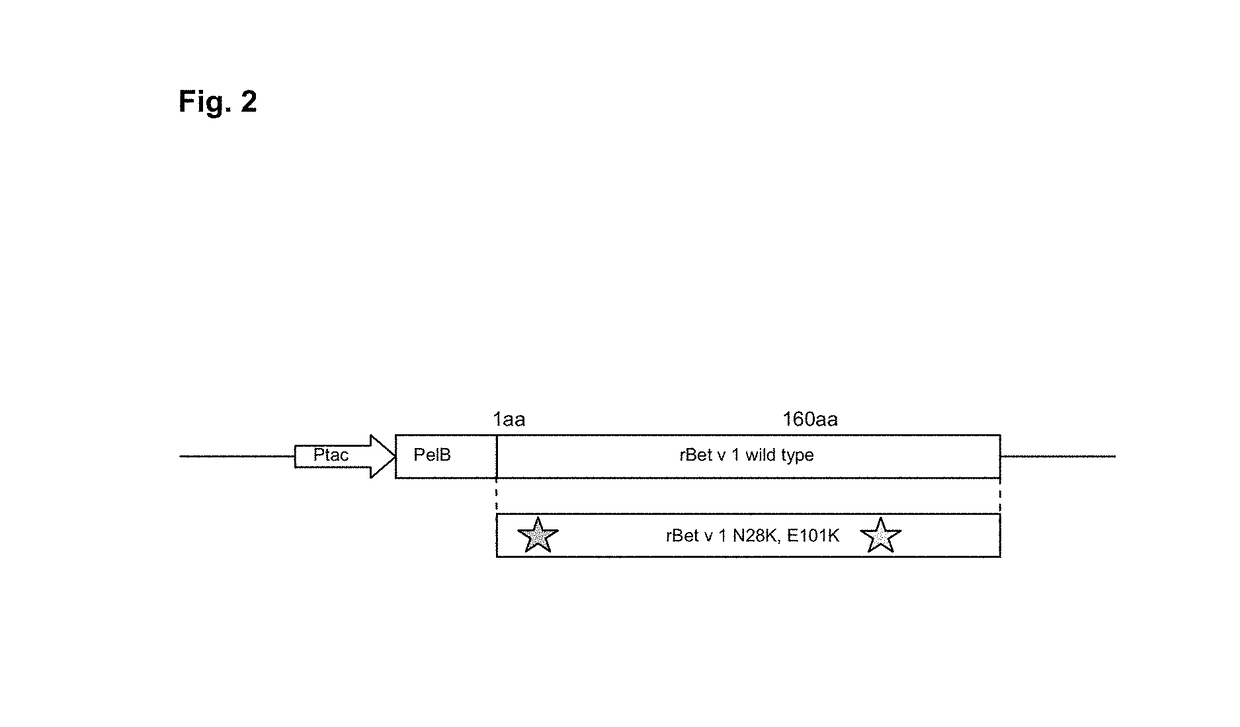

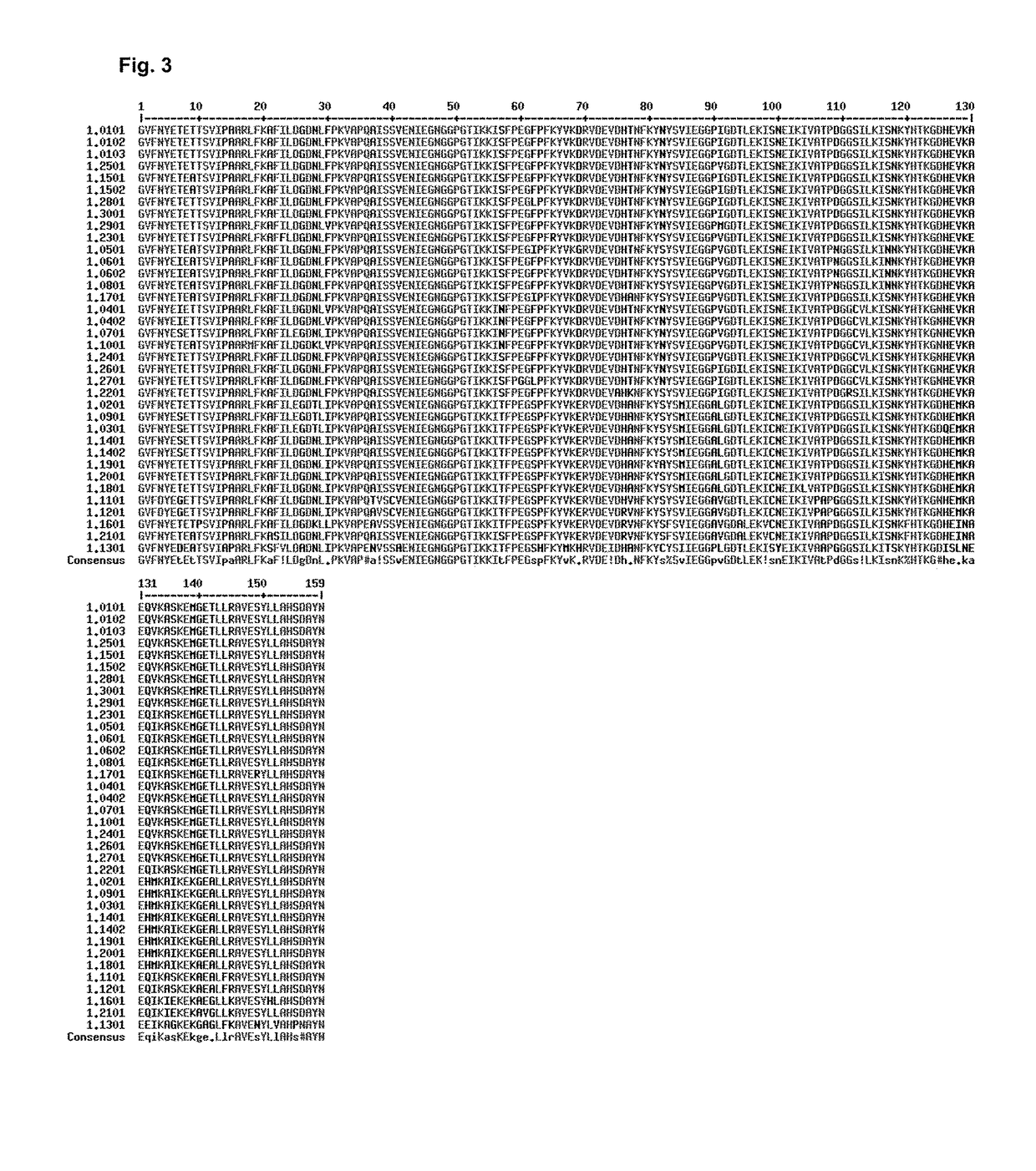

Hypoallergen

ActiveUS20140037663A1Safe and efficientRelease capacityAllergen ingredientsDepsipeptidesVaccinationBet v I allergen

The present invention provides mutant polypeptides useful as hypoallergens. More specifically the present invention provides mutant Bet v 1 proteins and the use of such polypeptides as hypoallergens for desensitizing against birch pollen allergies. Furthermore, the invention provides vaccine formulations comprising such polypeptides; the use of such formulations; and to methods of vaccination against birch pollen allergy.

Owner:DESENTUM

Novel blank-cutting machine

ActiveCN104060459AReduce line speedLine speed releaseSevering textilesProduction linePulp and paper industry

The invention provides a novel blank-cutting machine, which comprises a machine body, a blank-cutting unit, which comprises two rollers and a cutting belt, is arranged on the machine body, the two rollers are arranged on both sides of the middle part of the machine body, the cutting belt is arranged on the rollers, a conveyer belt is arranged on the lower end of the middle of the machine body, and is located under the cutting belt, a rotating motor is arranged beside the right roller, and the rollers are driven by the rotating motor to rotate, so that the cutting belt is driven to move. The ultrafine glass wool blank-cutting technique can greatly increase the benefits of factories, release all the capabilities of factories and reduce energy consumption. Meanwhile, the novel blank-cutting machine can decrease the linear velocity of a curing oven as the main equipment of a production line, thus prolonging the service lives of the main equipment and the entire production line.

Owner:安徽吉曜玻璃微纤有限公司

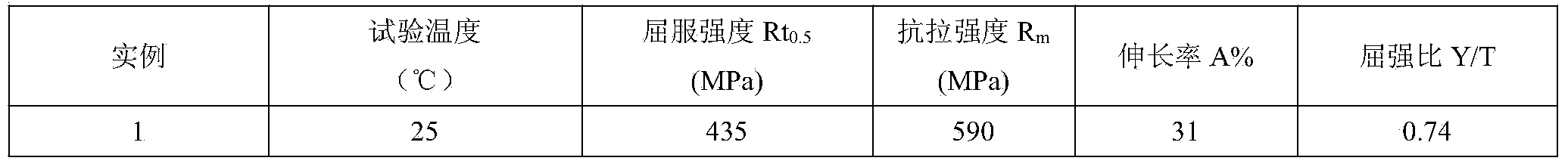

Non-quenched-tempered ocean engineering structure pipe with steel grade of more than 360MPa

The invention relates to a non-quenched-tempered ocean engineering structure pipe with steel grade of more than 360MPa. The non-quenched-tempered ocean engineering structure pipe comprises the following component elements in percentage by weight: 0.02-0.12% of C, 0.17-0.35% of Si, 1.20-2.10% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, less than or equal to 0.30% of Cu, 0.05-0.30% of Ni, less than or equal to 0.30% of Cr, less than or equal to 0.30% of Mo, 0.005-0.060% of Al, 0.03-0.12% of Nb, 0.005-0.030% of Ti, less than or equal to 0.40% of CE, 0.21% of Pcm, and the balance of Fe. The non-quenched-tempered ocean engineering structure pipe is scientific and reasonable in design, and adopts a low-carbon high-niobium steel design and a thermo-mechanically rolled non-quenching-tempering technology, and the non-quenched-tempered ocean engineering structure pipe with the steel grade of more than 360MPa is realized through transforming a rolling production line. Starting from the metallurgical design conception, offline quenching and tempering processing is not required, the production of the seamless steel pipe can be achieved only through thermo-mechanical rolling, the procedure cost of per ton can be reduced greatly, more importantly, the capacity can be greatly released, and the market competitiveness of domestic enterprises can be effectively improved.

Owner:天津市精成伟业机器制造有限公司

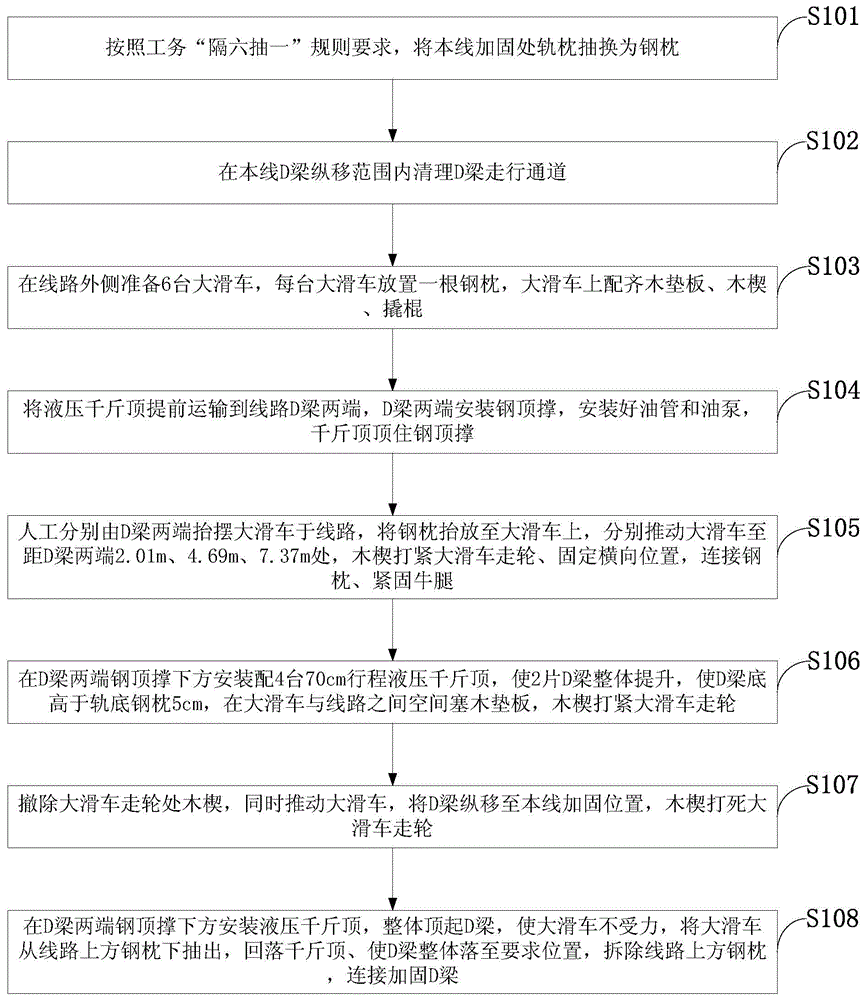

Existing line D beam overall longitudinally-moving construction method

The invention discloses an existing line D beam overall longitudinally-moving construction method. The lifting height of a D beam is calculated according to field D beam high-order arrangement, head blocks are placed on an existing line, a steel sleeper is placed on each head block, the steel sleepers are installed, upper brackets are connected, after the D beam is lifted in place, gaps between the steel sleepers above the head blocks and the head blocks are plugged through wooden footplates, wooden edges are tightly punched, the D beam is longitudinally moved to an existing line reinforced position, a jack falls back, the D beam falls to a required position, the head blocks and the steel sleepers above the line are removed, and the D beam is connected and fastened. By the adoption of the construction method, the D beam can be quickly and longitudinally moved, blocking key points and construction procedures are reduced, instability and the easy-to-topple risk in the D beam moving process are reduced, a contact net does not need to be powered off, the railway transport capacity is greatly released, station track limitation is avoided, the blocking key points are reduced, and construction time is saved.

Owner:CHINA RAILWAY SIXTH GRP CO LTD +1

Hypoallergen

ActiveUS9856296B2Release capacityAllergen ingredientsPeptide preparation methodsVaccinationBet v I allergen

The present invention provides mutant polypeptides useful as hypoallergens. More specifically the present invention provides mutant Bet v 1 proteins and the use of such polypeptides as hypoallergens for desensitizing against birch pollen allergies. Furthermore, the invention provides vaccine formulations comprising such polypeptides; the use of such formulations; and to methods of vaccination against birch pollen allergy.

Owner:DESENTUM

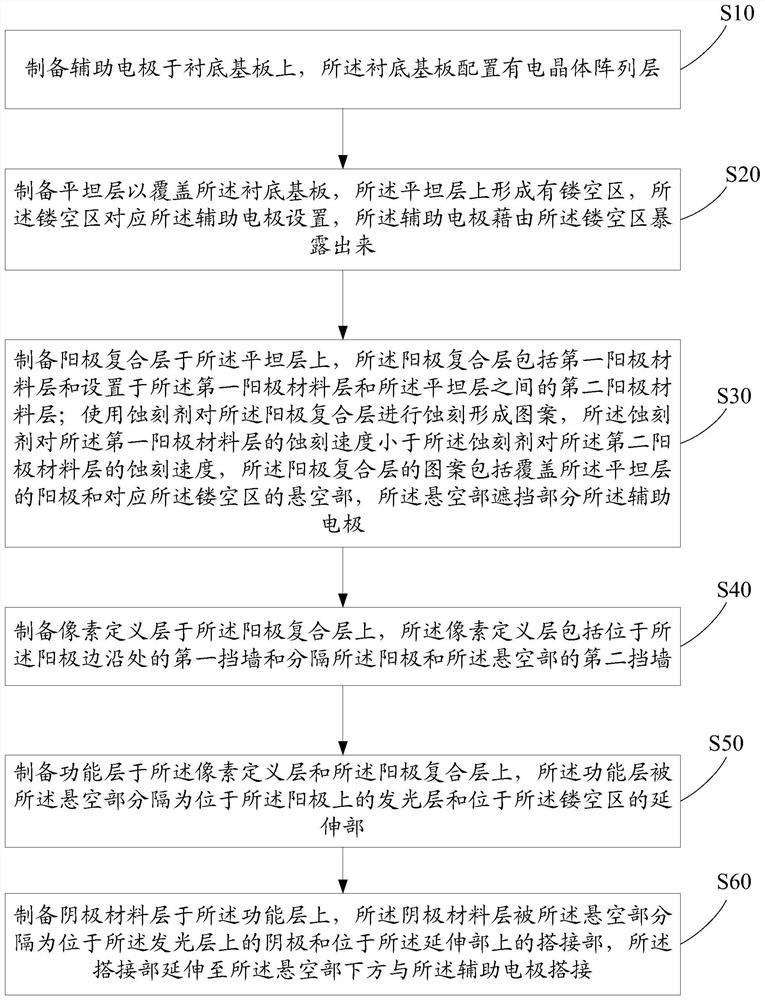

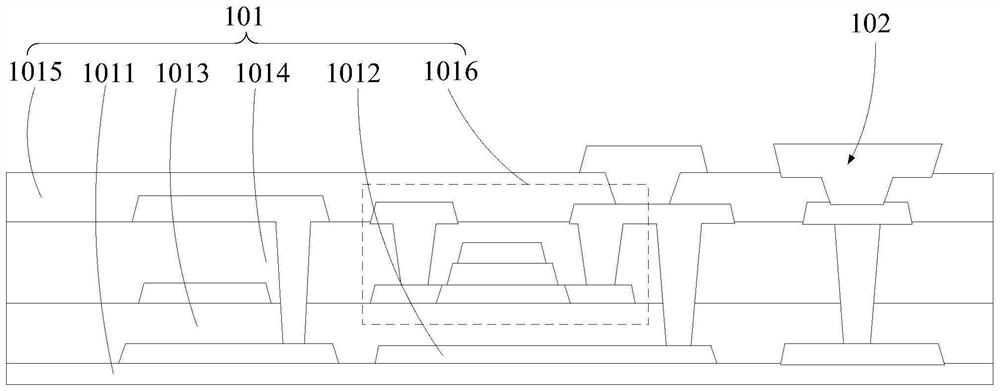

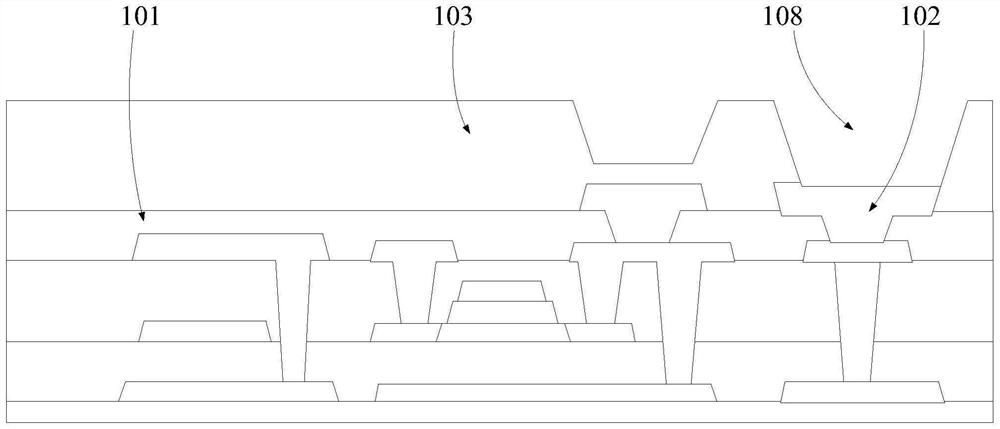

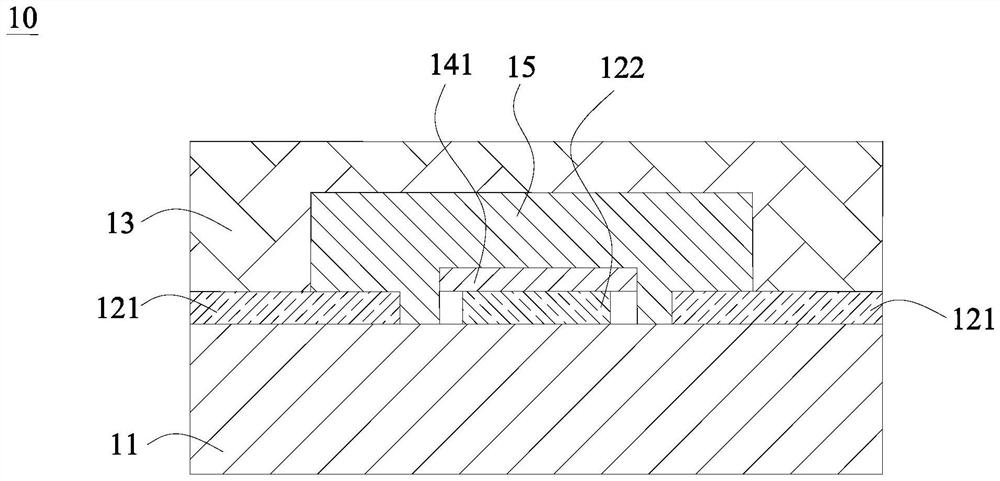

Display panel and manufacturing method thereof

ActiveCN114171566AImprove reliabilityAvoid corrosionSolid-state devicesSemiconductor devicesLap jointMechanical engineering

The invention provides a display panel and a manufacturing method thereof. In the method, an anode composite layer comprises a first anode material layer and a second anode material layer; as the etching speed of the etching agent on the first anode material layer is smaller than the etching speed of the etching agent on the second anode material layer, the edge of the formed anode pattern, the first anode material layer protrudes outwards relative to the side of the second anode material layer, and a suspended part is formed on the first anode material layer corresponding to the outwards-protruding part of the hollow-out area. And an undercut structure required by cathode lap joint is arranged below the cathode lap joint structure. According to the method, the undercut structure can be formed while the anode pattern is formed, the photomask manufacturing process is not increased, and the process is simpler.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

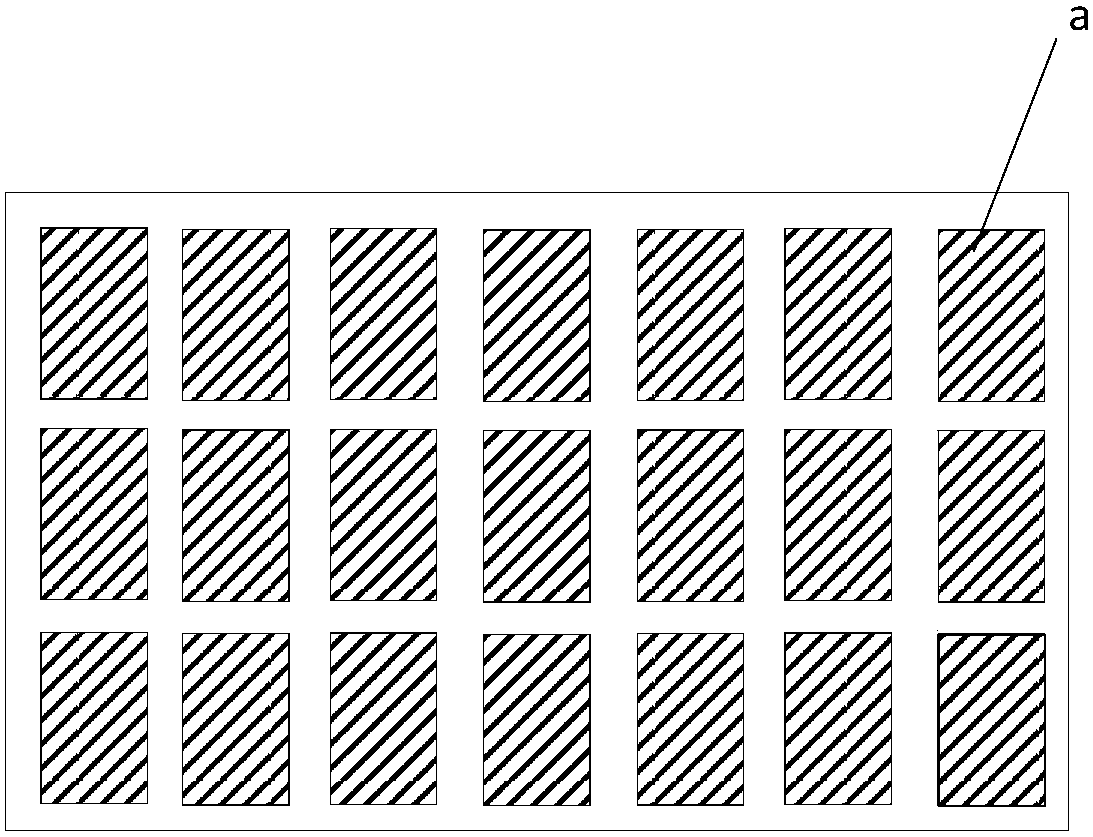

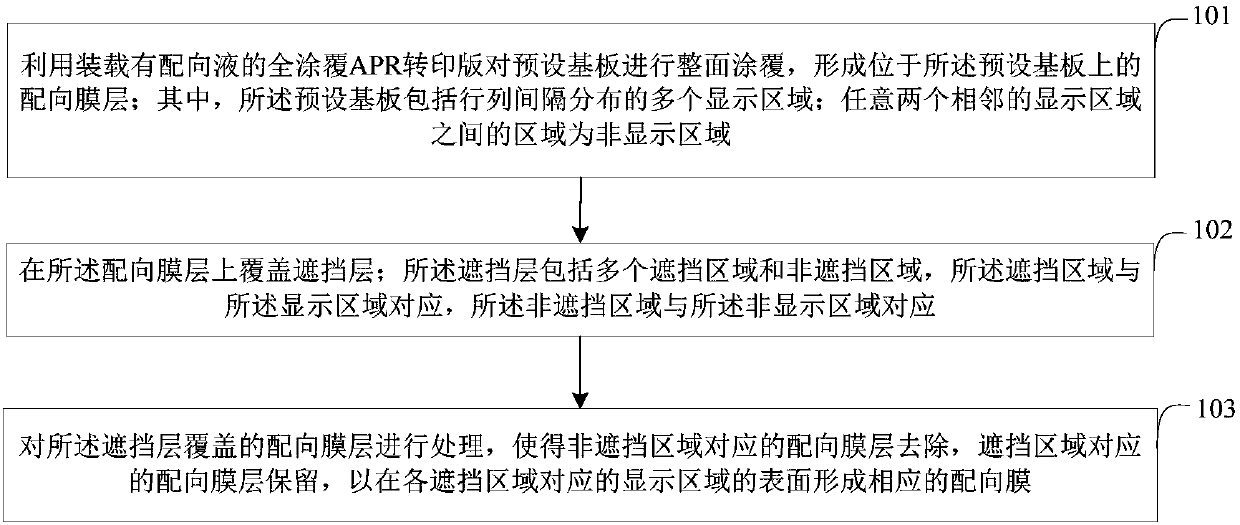

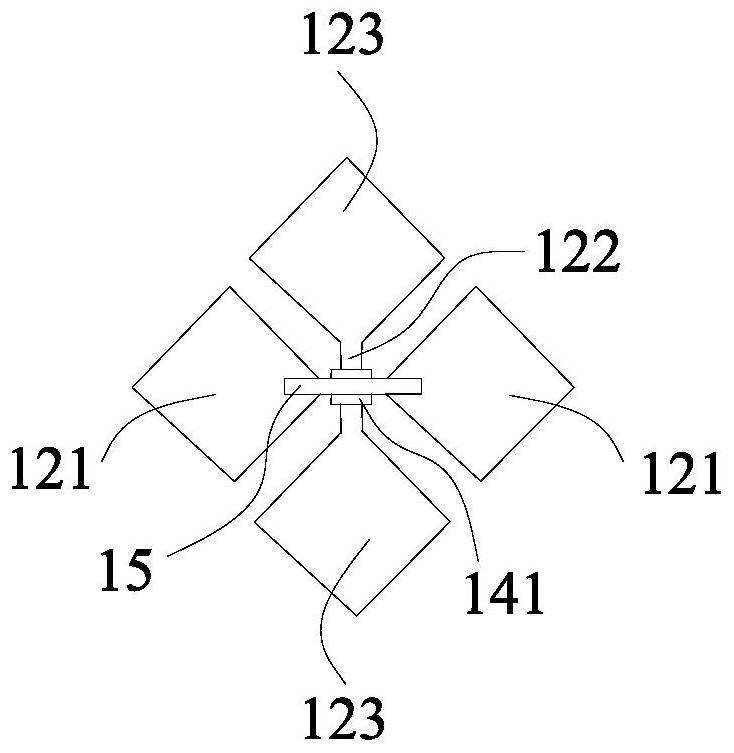

Making method and device for display substrate

The invention provides a making method and device for a display substrate. The method includes the steps that whole-surface coating is carried out on a pre-arranged substrate through a full-coating APR transfer plate loaded with alignment liquid, and an alignment film layer located on the pre-arranged substrate is formed, wherein the pre-arranged substrate comprises multiple display areas distributed in a row and list spaced mode, and the area between every two adjacent display areas is a non-display area; the alignment film layer is covered with a shielding layer, wherein the shielding layer comprises multiple shielding areas and multiple non-shielding areas, the shielding areas correspond to the display areas, and the non-shielding areas correspond to the non-display areas; the alignment film layer covered with the shielding layer is treated, so that the portions, corresponding to the non-shielding areas, of the alignment film layer are removed, the portions, corresponding to the shielding areas, of the alignment film layer are retained, and thus corresponding alignment films are formed on the surfaces of the display areas corresponding to the shielding areas. By means of the method, different products can share one full-coating APR transfer plate, so that cost is reduced, and productivity is improved.

Owner:BOE TECH GRP CO LTD +1

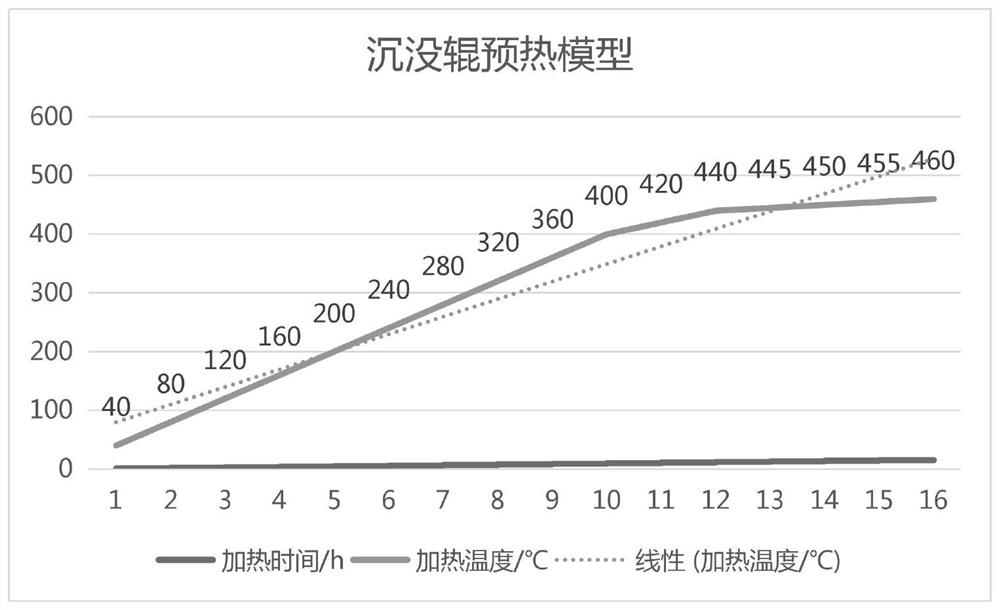

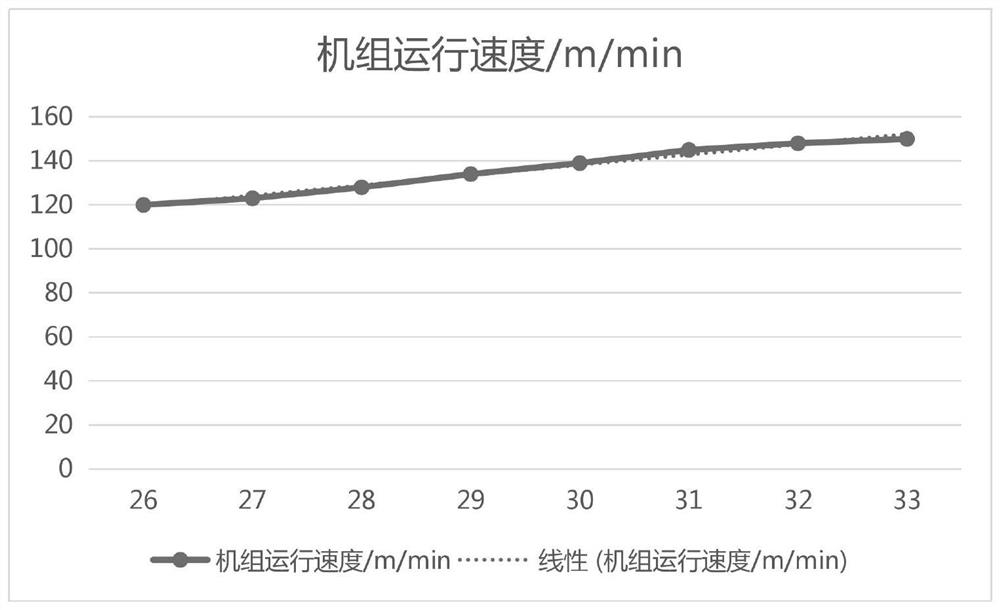

High-speed stable production method of CQ-grade thin-gauge galvanized sheet

PendingCN113088855AImprove overall running speedIncrease production capacityHot-dipping/immersion processesFurnace typesFurnace temperatureManufacturing line

The invention relates to a high-speed stable production method of a CQ-grade thin-gauge galvanized sheet. According to the method, a continuous hot galvanizing unit sink roll preheating model, the purity of zinc liquid, a plan schedule, secondary crescent shearing, the temperature of an annealing furnace, a sink roll scraper and the tension of a zinc pot are comprehensively controlled, the average running speed of a CQ-grade thin-specification galvanized sheet is improved from 90m / min to 140m / min, the capacity is fully released, and the production efficiency is improved; the in-furnace wrinkle judgment change rate is reduced from 8.11% to below 1%, the scratch and wrinkle degradation judgment change rate is greatly reduced, and the cost is reduced; and the yield is greatly improved, cost reduction and efficiency increase are obvious, order delivery is effectively guaranteed, the productivity is greatly released, and the method can be applied to a continuous hot galvanizing production line.

Owner:SD STEEL RIZHAO CO LTD

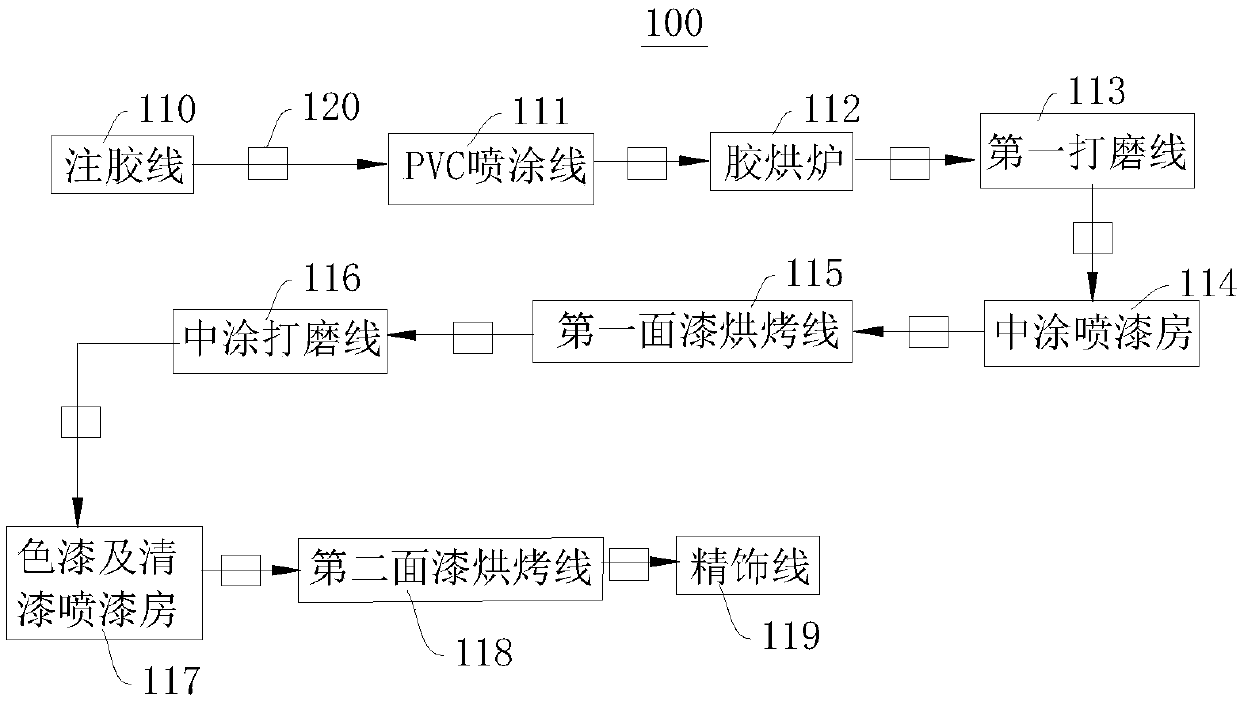

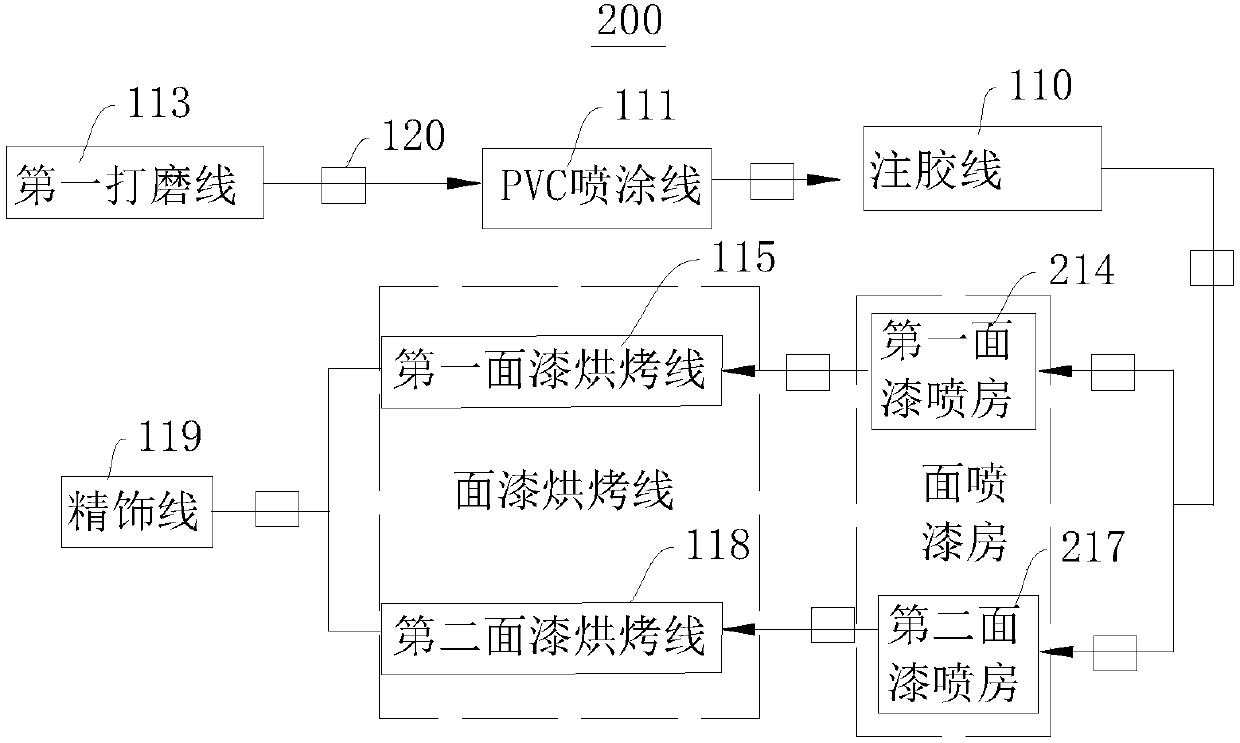

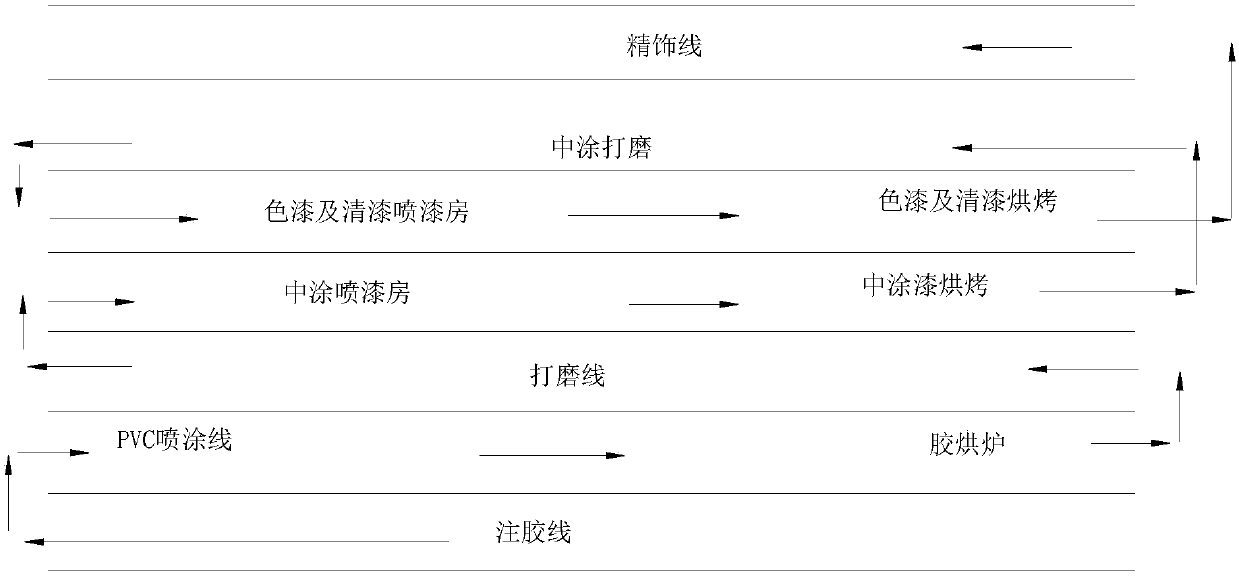

3C1B equipment and modification method of 3C1B equipment by adopting 3C2B equipment

PendingCN107552299AAdapt to needsReduce consumptionLiquid surface applicatorsCoatingsSpray coatingProcess efficiency

The invention discloses an automobile coating process and equipment, and particularly relates to 3C1B equipment and a modification method of the 3C1B equipment by adopting 3C2B equipment. The 3C1B equipment provided by the invention comprises moving devices and the following work stations: a first grinding line, a PVC spray-coating line, an adhesive injection line and final coating equipment; thefirst grinding line, the PVC spray-coating line, the adhesive injection line and the final coating equipment are arranged in sequence; and all the work stations are connected in sequence through the moving devices. With the adoption of the 3C1B equipment and the modification method of the 3C1B equipment by adopting the 3C2B equipment provided by the invention, the conventional 3C2B equipment is modified into the 3C1B equipment; besides, the capacity of the equipment is maximized, and the automobile coating process efficiency is improved.

Owner:DFSK MOTOR LTD CHONGQING BRANCH CO

Manufacturing method of touch sensing layer, display screen and display

ActiveCN107994057BRelease capacitySimple processSolid-state devicesPhotomechanical exposure apparatusComputer hardwareTouch Senses

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

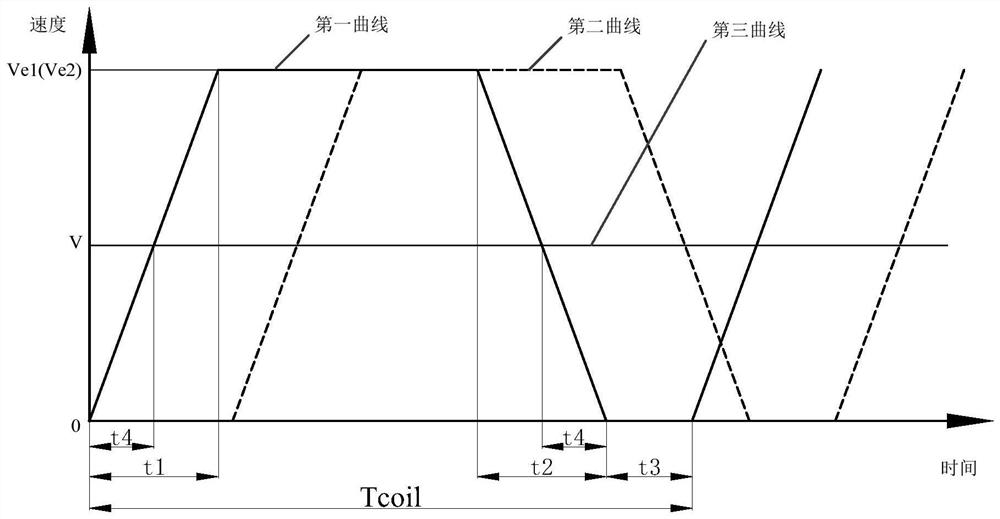

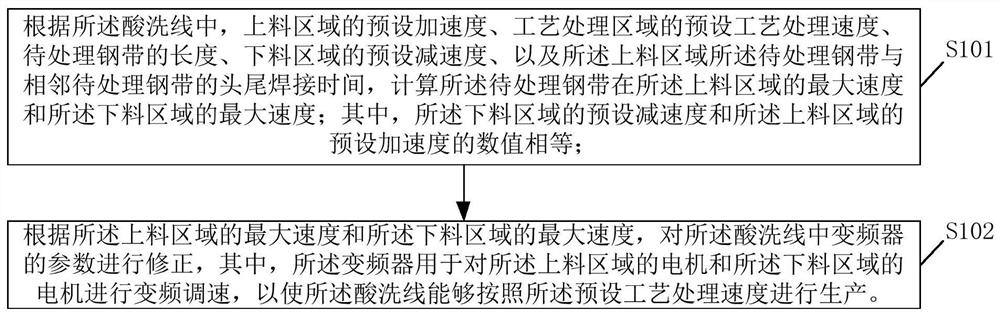

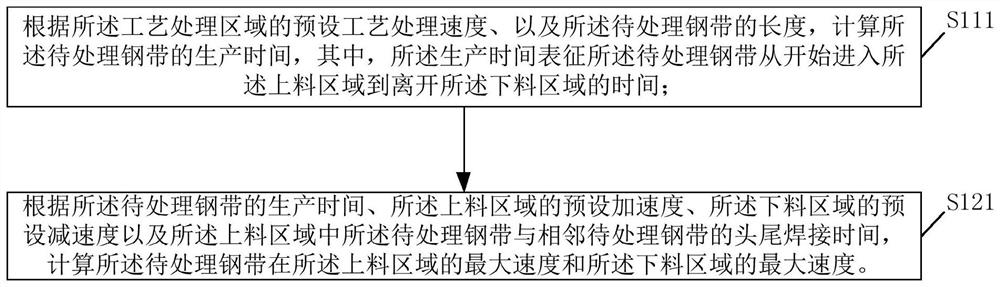

Stainless steel sheet annealing and pickling line acceleration method and system

ActiveCN112143875ARelease capacityIncrease productivityFurnace typesHeat treatment process controlFrequency changerFrequency conversion

The invention provides a stainless steel sheet annealing and pickling line acceleration method and system. The method comprises the steps that the maximum speed of a to-be-processed steel belt in thefeeding area and the maximum speed of the to-be-processed steel belt in the discharging area are calculated, specifically, the maximum speed of the to-be-processed steel belt in the feeding area and the maximum speed of the to-be-processed steel belt in the discharging area are calculated according to the preset acceleration of the feeding area, the preset technological processing speed of the technological processing area, the length of the to-be-processed steel belt, the preset deceleration of the discharging area and the head-tail welding time of the to-be-processed steel belt and an adjacent to-be-processed steel belt in the feeding area in a pickling line, and the numerical value of the preset deceleration of the discharging area is equal to that of the preset acceleration of the feeding area; and parameters of a frequency converter are corrected, specifically, the parameters of the frequency converter in the pickling line are corrected according to the maximum speed of the feeding area and the maximum speed of the discharging area, and the frequency converter is used for conducting frequency conversion speed regulation on a motor in the feeding area and a motor in the discharging area so that the pickling line can conduct production according to the preset technological processing speed.

Owner:广西北港不锈钢有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com