SPE membrane electrode and preparation technology thereof

A preparation process, membrane electrode technology, applied in the direction of electrodes, electrode shape/type, electrolysis process, etc., can solve the problems of low production efficiency, long spraying time, long spraying working hours, etc., to reduce the number of preparations and simplify the spraying process effect of shortening preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

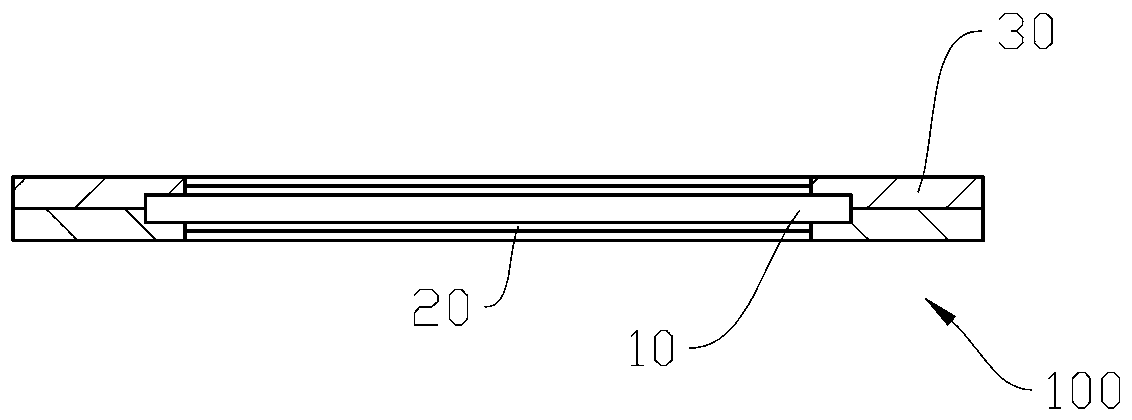

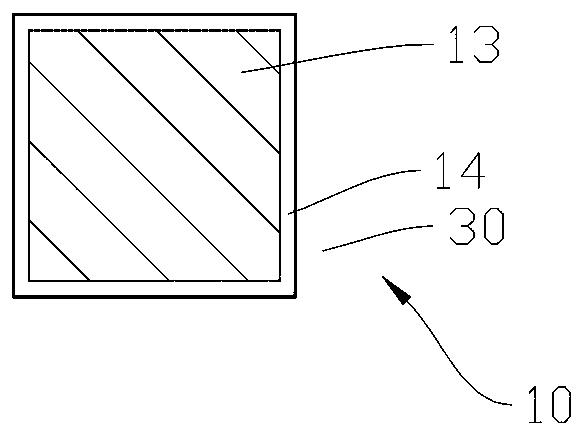

[0052] Embodiment 1: as Figure 1-3 As shown, a kind of SPE membrane electrode is installed in the SPE electrolytic cell that comprises membrane electrode 100, bipolar plate 200, end plate 300, gasket 400, and membrane electrode 100 comprises proton exchange membrane 10, and the catalyst embedded in proton exchange membrane 10 20 , a polyester frame 30 surrounding the outer edge and responsible for connecting with the bipolar plate 200 .

[0053] The proton exchange membrane 10 includes a feeding area 13 for embedding the catalyst 20 , and an unloading area 14 located on the edge of the feeding area 13 for connecting with a polyester frame 30 .

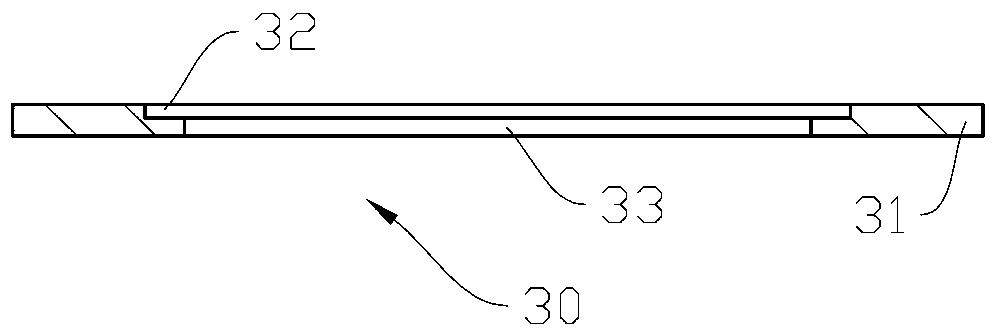

[0054] The polyester frame 30 includes a polyester frame substrate 31 whose edge is adapted to the shape and size of the bipolar plate 200, an inner frame 32 for placing the proton exchange membrane 10 in the middle of the polyester frame substrate 31, and an inner frame 32 The through cavity 33 in the middle is used to expose the ca...

Embodiment 2

[0061] Embodiment 2: as figure 1 , 4 Shown, a kind of SPE membrane electrode preparation process comprises the following steps:

[0062] A) Catalyst spraying preparation: After removing the organic and inorganic impurities on the proton exchange membrane 10, fix the entire proton exchange membrane on the spraying station, and separate the entire proton exchange membrane into integer A proton exchange membrane with a catalytically active area in a single proton exchange membrane;

[0063] B) Catalyst spraying: prepare the catalyst 20, use the spraying equipment to spray the catalyst 20 evenly on the whole proton exchange membrane, and let it dry after spraying;

[0064] C) Proton exchange membrane cutting: tear off the tape used in step A, and cut the entire proton exchange membrane treated in step B into multiple single proton exchange membranes based on the unsprayed area;

[0065] D) Hot pressing preparation: use high-temperature adhesive tape to center the single proton...

Embodiment 3

[0071] Embodiment 3: as figure 1 , 4 Shown, a kind of SPE membrane electrode preparation process comprises the following steps:

[0072] A) Catalyst spraying preparation: After removing the organic and inorganic impurities on the proton exchange membrane 10, fix the entire proton exchange membrane on the spraying station, and separate the entire proton exchange membrane into integer A proton exchange membrane with a catalytically active area in a single proton exchange membrane;

[0073] B) Catalyst spraying: prepare the catalyst 20, use the spraying equipment to spray the catalyst 20 evenly on the whole proton exchange membrane, and let it dry after spraying;

[0074] C) Proton exchange membrane cutting: tear off the tape used in step A, and cut the entire proton exchange membrane treated in step B into multiple single proton exchange membranes based on the unsprayed area;

[0075] D) Hot pressing preparation: use high-temperature adhesive tape to center the single proton...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com