Multi-coal-seam independent gas-containing system pressure control single-pump drainage device and method

A multi-coal seam, single-pump technology, used in wellbore/well valve devices, production fluids, and earth-moving drilling, etc., can solve the problems of interlayer interference, difficult drainage and production planning, and inability to monitor coal seam gas production capacity. The effect of stable expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

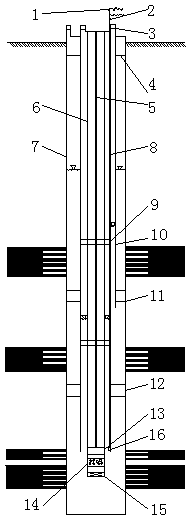

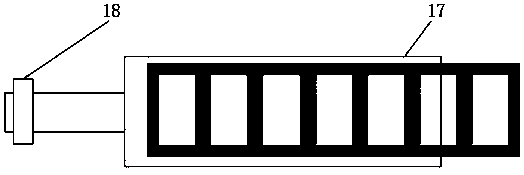

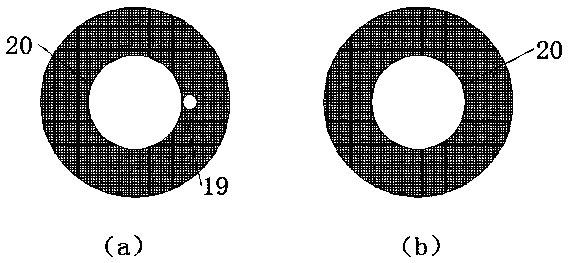

[0028] Such as figure 1 and figure 2 As shown, a multi-coal seam independent gas-bearing system pressure-controlled single-pump drainage device includes an inner casing 8 and an outer casing 7, the inner casing 8 is set inside the outer casing 7, and the outer casing 7 runs through multiple An independent air-containing system, the inner casing 8 is provided with an oil pipe 6, the oil pipe 6 is provided with a sucker rod 5, the bottom end of the sucker rod 5 is connected to a tubular pump 13, and the bottom of the tubular pump 13 is A sand settling pipe 15 is provided, and a screen pipe 14 is also provided above the sand settling pipe 15;

[0029] A packer 11 and a packer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com