Tiny-crack-free curved glass hot-wire cutting method based on thermal shield membrane

A technology of curved glass and cutting method, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of instability, micro-cracks in glass section, unstable temperature field of glass surface, etc., achieve high straightness, cracks Extended stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

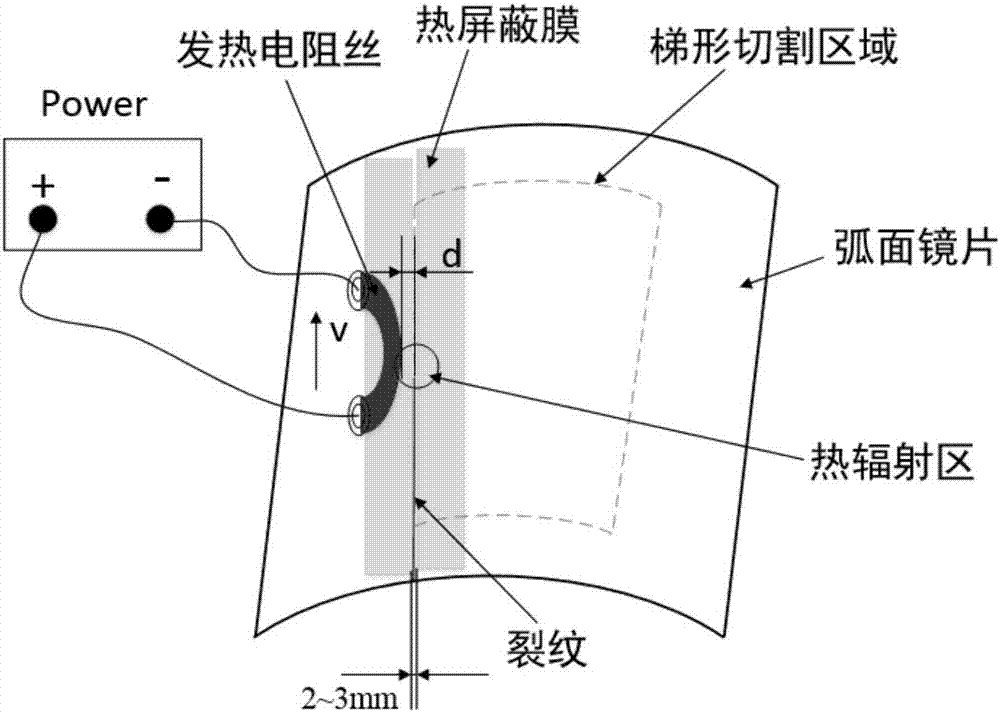

[0021] Preliminary preparations for the cutting of curved glass are made using common methods, including: glass lens prefabricated crack treatment, multi-axis processing system construction and specific processing motion parameter adjustment, followed by heat shielding film placement, hot wire cutting of curved glass lens and post-processing.

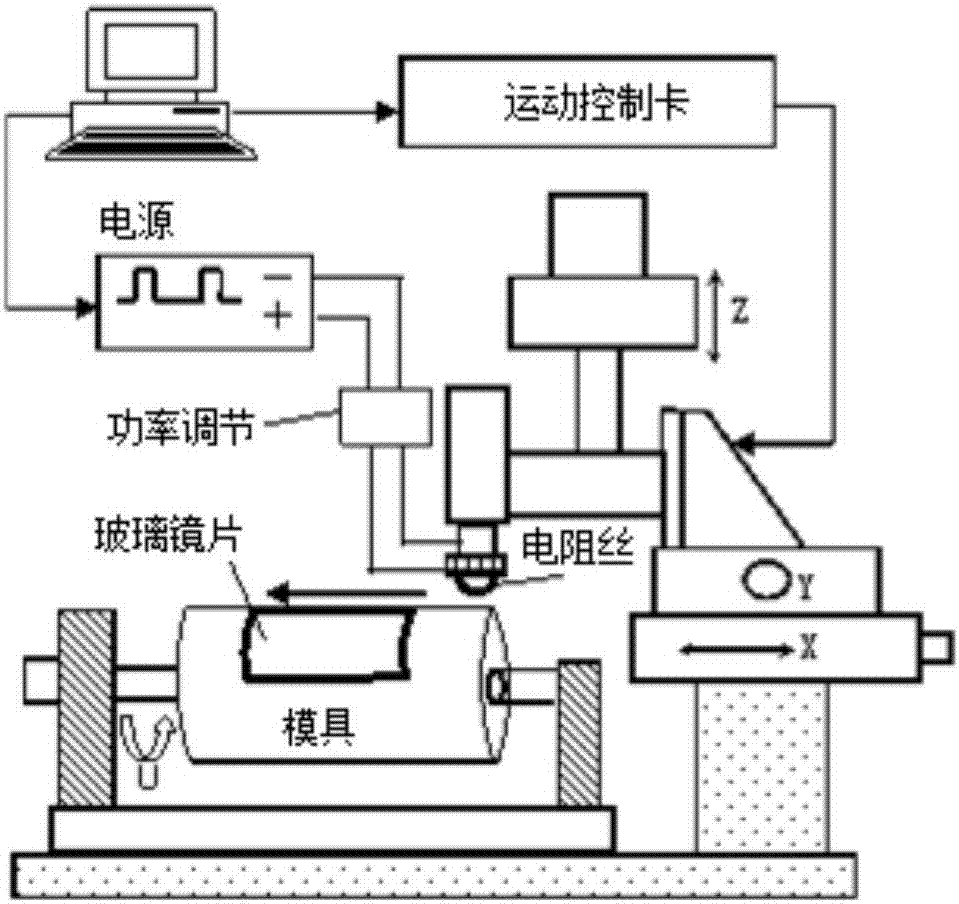

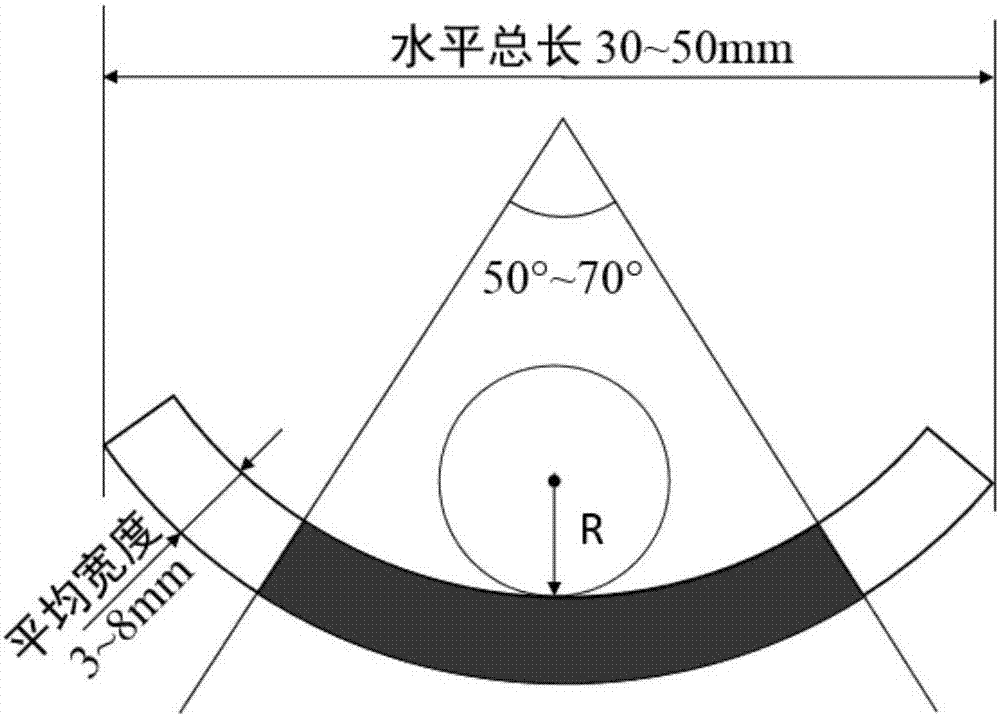

[0022] Such as figure 1 As shown, build a hot wire cutting device, connect the arc-shaped thermal resistance wire to the power supply, and connect the power supply to the controller. Z moves in three directions, and the glass lens to be processed is fixed on a polytetrafluoroethylene cylindrical substrate. Mark the expected crack on the glass surface and open the prefabricated crack at the expected position on the edge; adjust the Z axis so that there is a space of 1-2mm between the thermal resistance wire and the glass surface, and move to the top of the prefabricated crack, the size of the arc thermal resistance wire parameters such...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com