Patents

Literature

209results about How to "Meet cutting needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

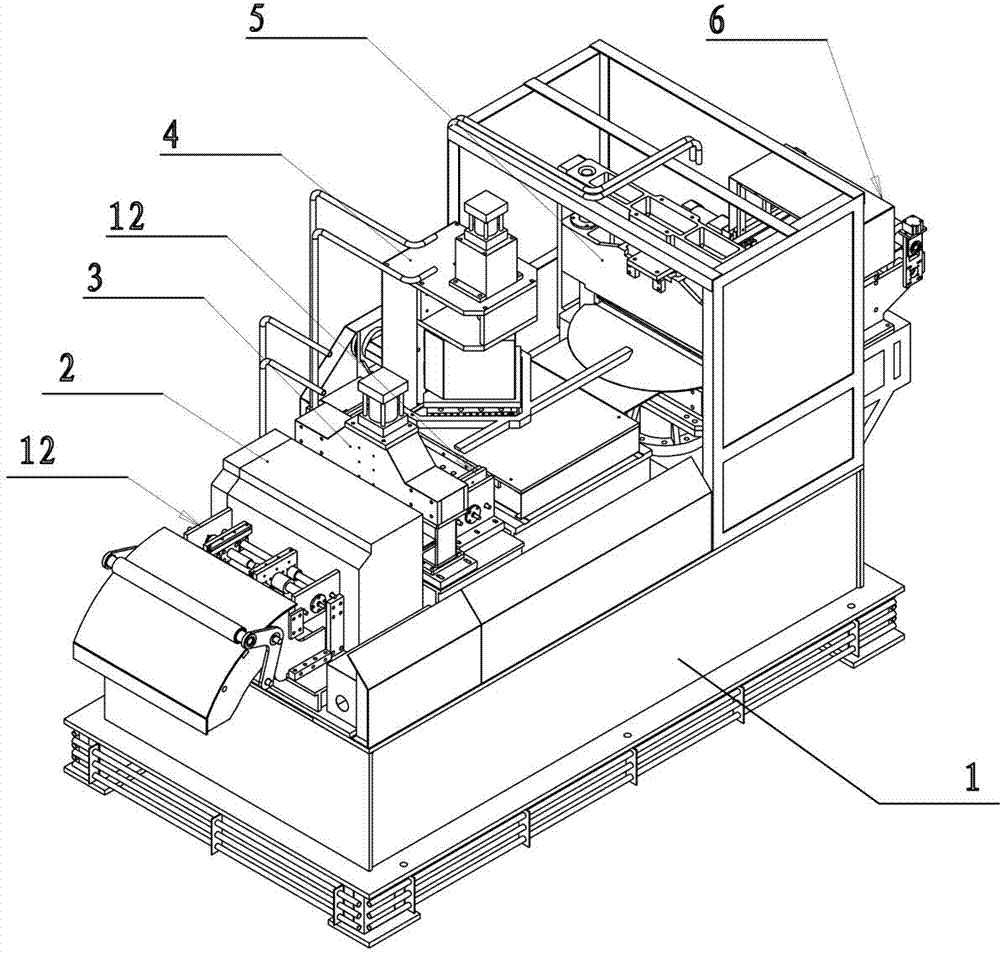

Multi-laser-head laser cutting machine

The invention provides a multi-laser-head laser cutting machine. The multi-laser-head laser cutting machine comprises a workbench, a laser cutting control system, a CO2 laser generator, a CO2 laser power supply, a CO2 laser reflector, at least one non-CO2 laser generator, for example, a fiber laser generator, a multi-laser-head cutting assembly, an X-axis movement assembly, a Y-axis movement assembly, a Z-axis movement assembly, a laser generator cooling system, an object carrying working table, a cutter console, a waste material collecting device and a dust collecting exhaust fan. Two or more than two laser sources are combined on the same laser cutting equipment by the multi-laser-head cutting assembly, so that the cutting processing of composites and the cutting processing of different single materials are realized.

Owner:GUANGZHOU GREAT YEAR LASER TECH CO LTD

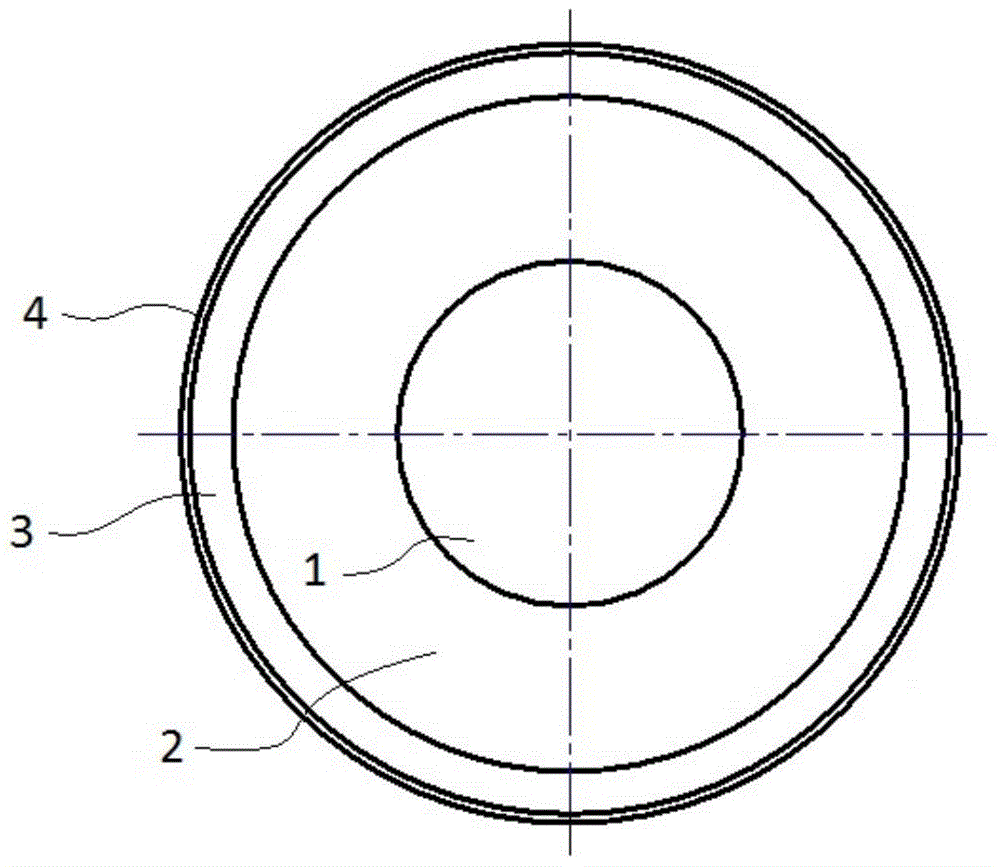

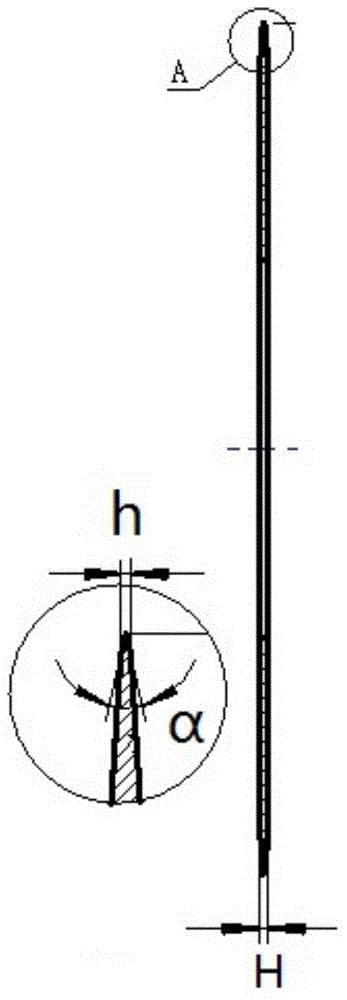

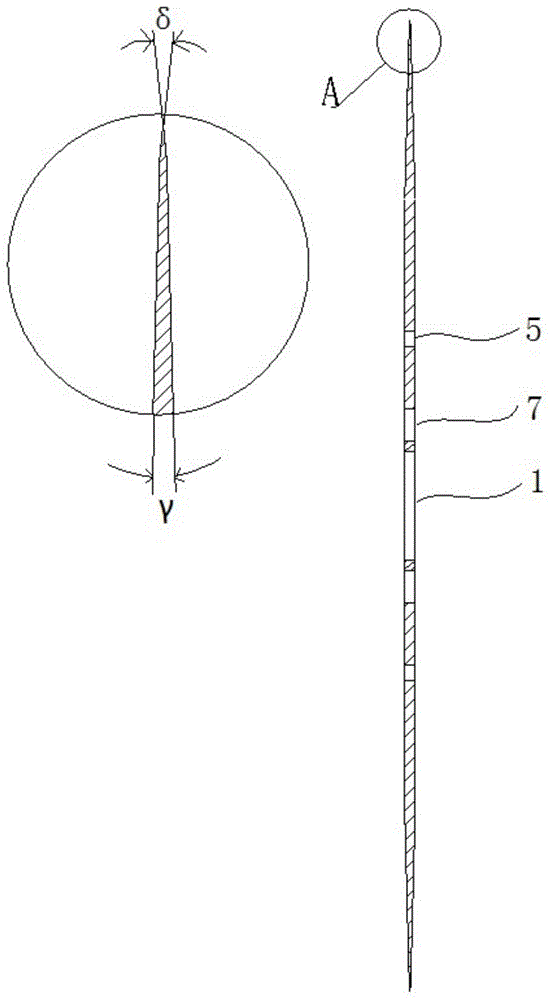

Slitting cutting disc and preparation method thereof

The invention discloses a slitting cutting disc and a preparation method thereof, which belong to the process field of cutters. The slitting cutting disc is of a circle blade, and comprises a center hole, a cutter disc and a blade, wherein the center hole is arranged in the center of the cutter disc, the blade is arranged on an outer ring of the cutter disc, a blade opening is arranged on an outer ring of the blade, and the opening angle delta ( ) of blade opening is 23-27 degrees. The opening thickness h of the blade opening is 0.24-0.26mm. The materials which are made into the slitting cutting disc comprise components with percentage by weight: carbon (C) 1.15-1.33%, nitrogen (N) 0.2-0.4%, manganese (Mn) 0.30-0.40%, silicon (Si) 0.52-1.20%, chromium (Cr) 8.50-10.50%, tungsten (W) 1.50-2.50%, vanadium (V) 0.35-0.50%, molybdenum (Mo) 0.25-0.4%, nickel (Ni) 0.30-0.40%, copper (Cu) <=0.30%, sulphur (S)<=0.020% and phosphorus (P)<=0.027%, and the allowance is ferrum (Fe). The slitting cutting disc has the advantages that the slitting cutting disc is excellent in abrasive resistance and is not easy to deform, and the blade opening resists abrasion, not easy to crack, long in service life and easy to make.

Owner:安徽华天机械股份有限公司

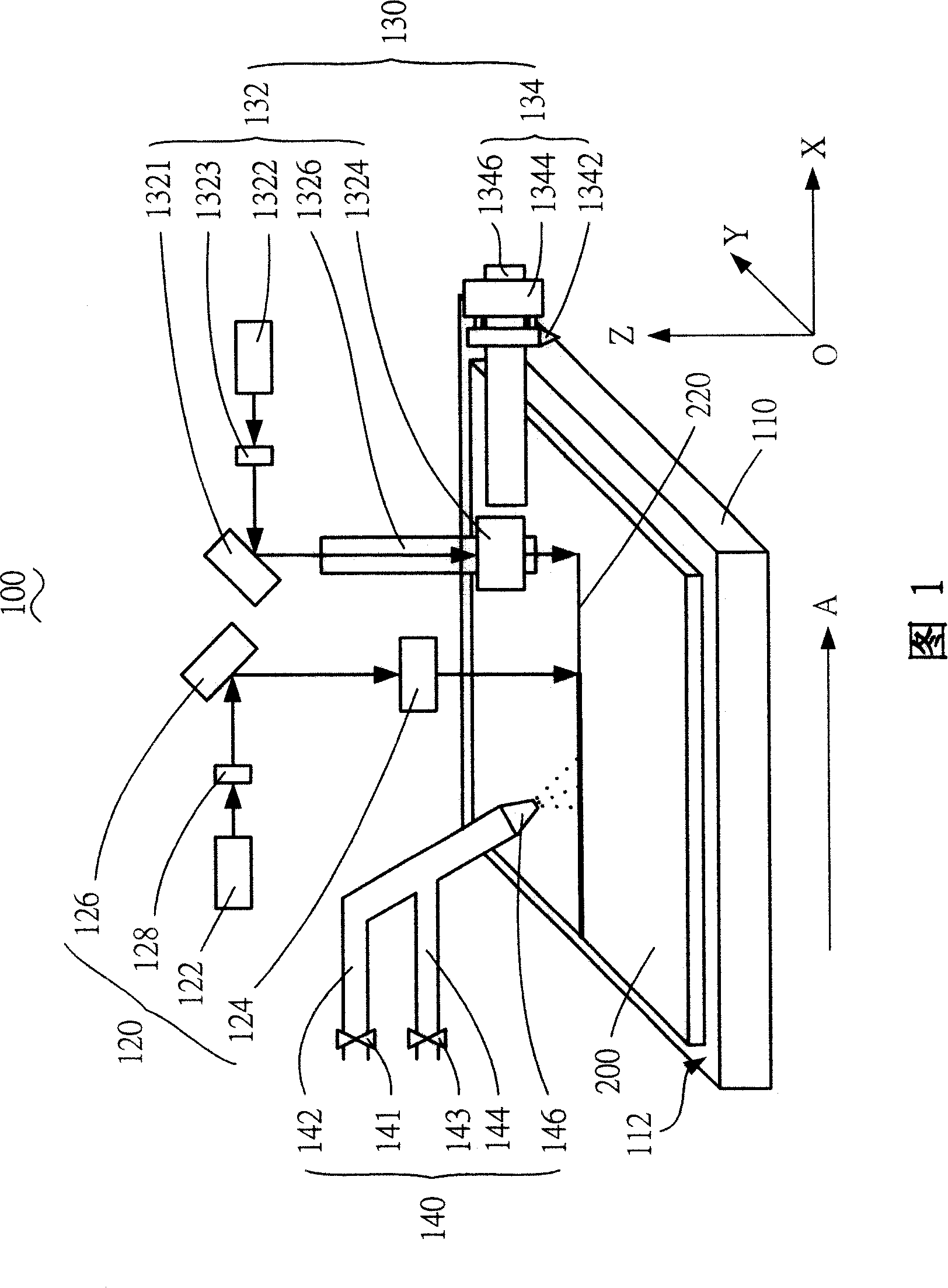

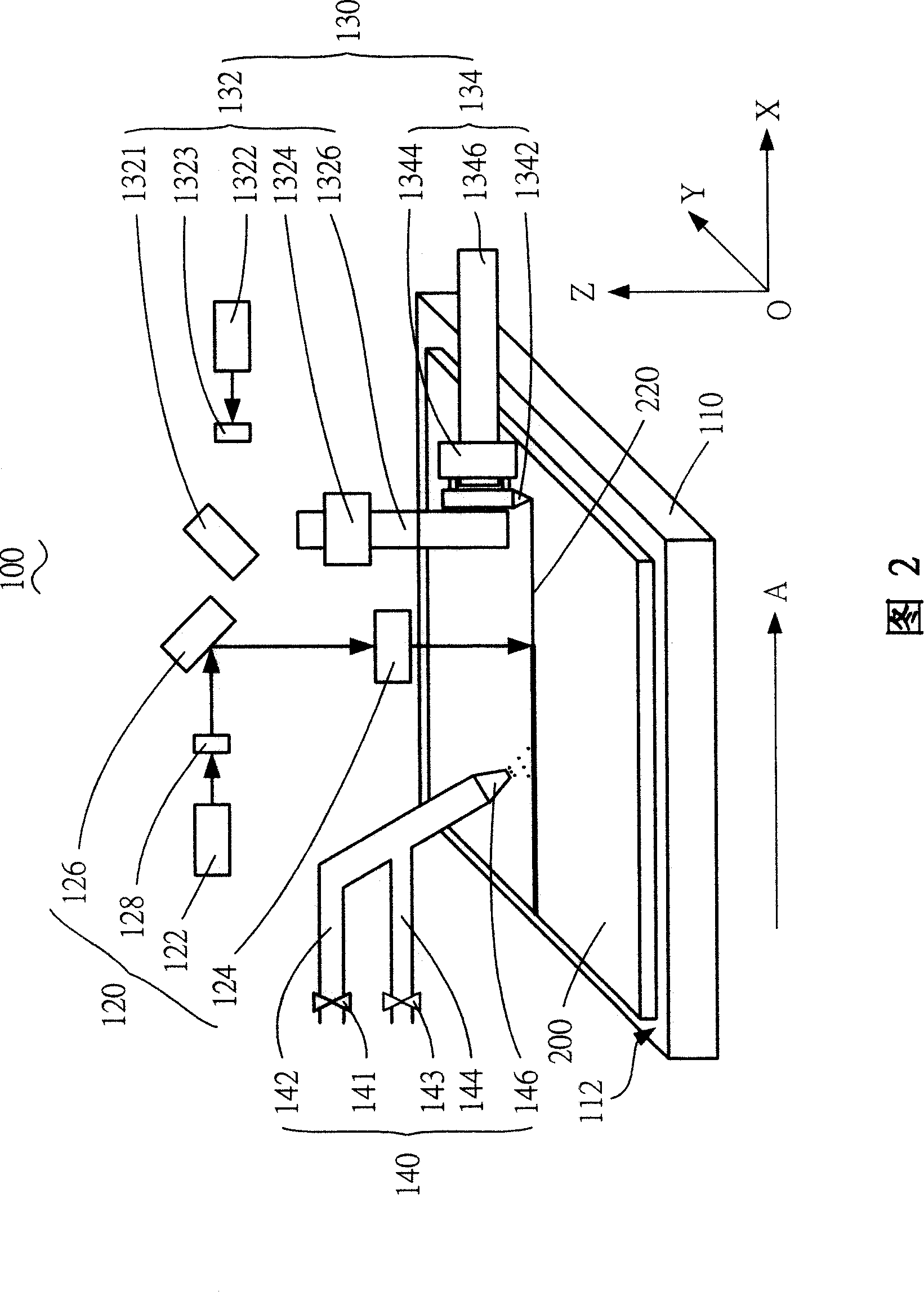

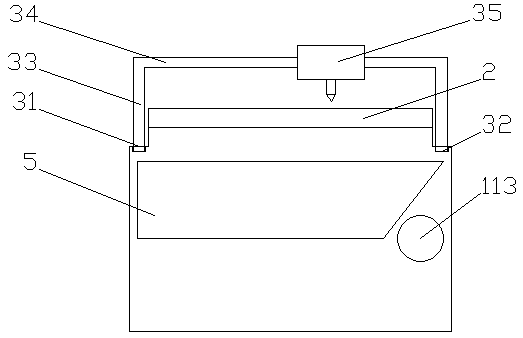

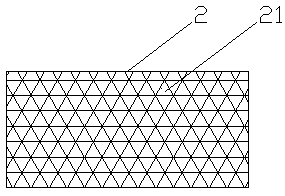

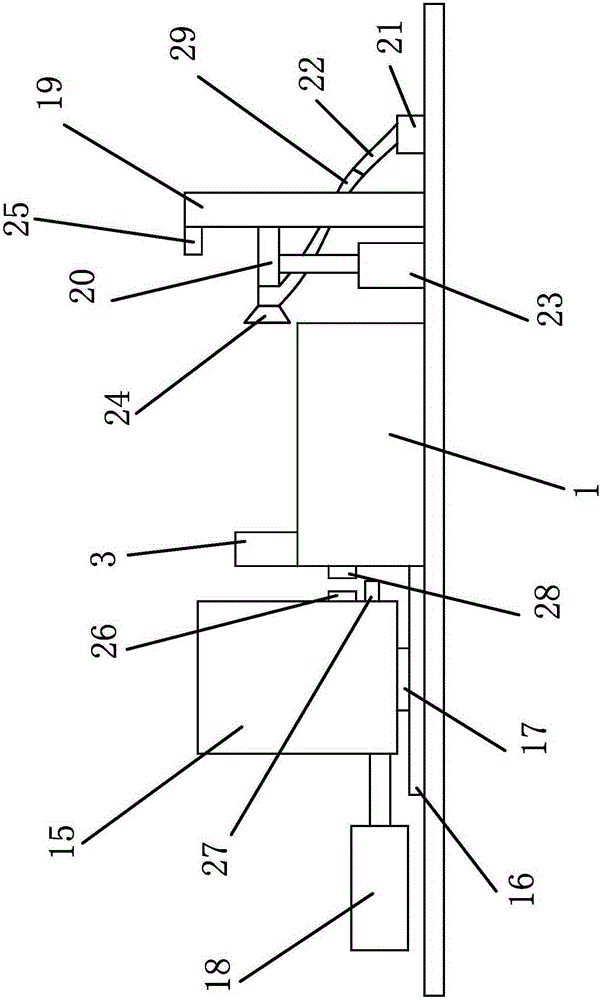

Laser cutting equipment

InactiveCN101209515AMeet cutting needsGlass severing apparatusLaser beam welding apparatusBearing surfaceLaser cutting

The invention provides a laser cutting equipment, comprising a bearing device with a bearing surface, a laser cutting device which is arranged corresponding to the bearing device and at one side of the bearing surface of the bearing device, and a pre-cutting device and a cooling device which are respectively arranged at two corresponding sides of the laser cutting device; wherein, the pre-cutting device comprises a plurality of pre-cutting units which can be switched for usage. The pre-cutting device of the laser cutting equipment can execute various laser cutting processes by shifting different pre-cutting units, thus meeting the cutting requirement of brittle baseplate with different thicknesses and materials.

Owner:FOXSEMICON INTEGRATED TECHNOLOGY (SHANGHAI) INC +1

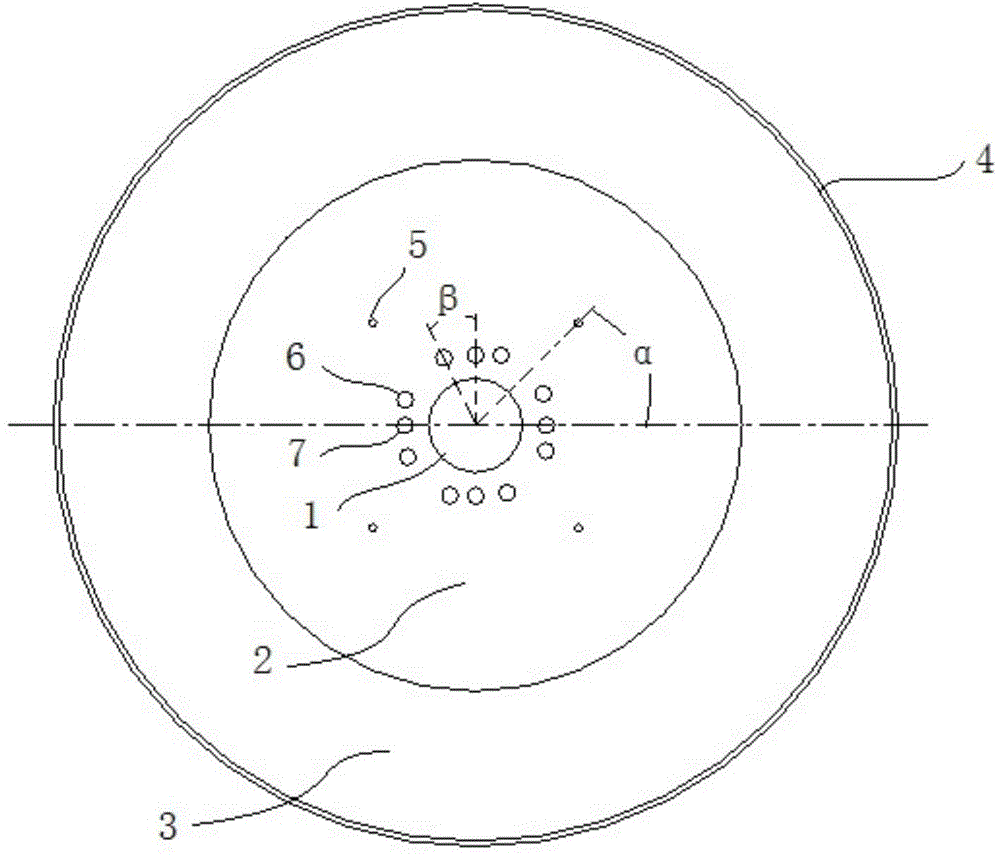

Flat and round cutter and manufacturing method thereof

ActiveCN104942879AIncrease sharpnessImprove securityFurnace typesMetal working apparatusEngineeringAlloy

The invention discloses a flat and round cutter and a manufacturing method thereof and belongs to the field of machining of cutters. The flat and round cutter comprises a center hole, a cutter head and a blade, wherein the center hole is located in the center of the cutter head, the blade is located on the outer ring of the cutter head, a cutting edge is arranged on the outer ring of the blade, the cutting edge angle delta of the cutting edge is in a range of 13-18 degrees, and threaded holes and mounting holes are formed in the cutter head. The flat and round cutter is manufactured from an alloy material comprising special elements under strictly controlled technological conditions through steps such as blank forging, isothermal spheroidizing, preliminary processing, heat treatment, rough grinding, leveling, tempering, deep processing and the like, the cutter has very high abrasion resistance while meeting the requirement for the sharpness, the service life is long, and the cutting edge is low in abrasion loss and free of cracking after long-term usage.

Owner:安徽华天机械股份有限公司

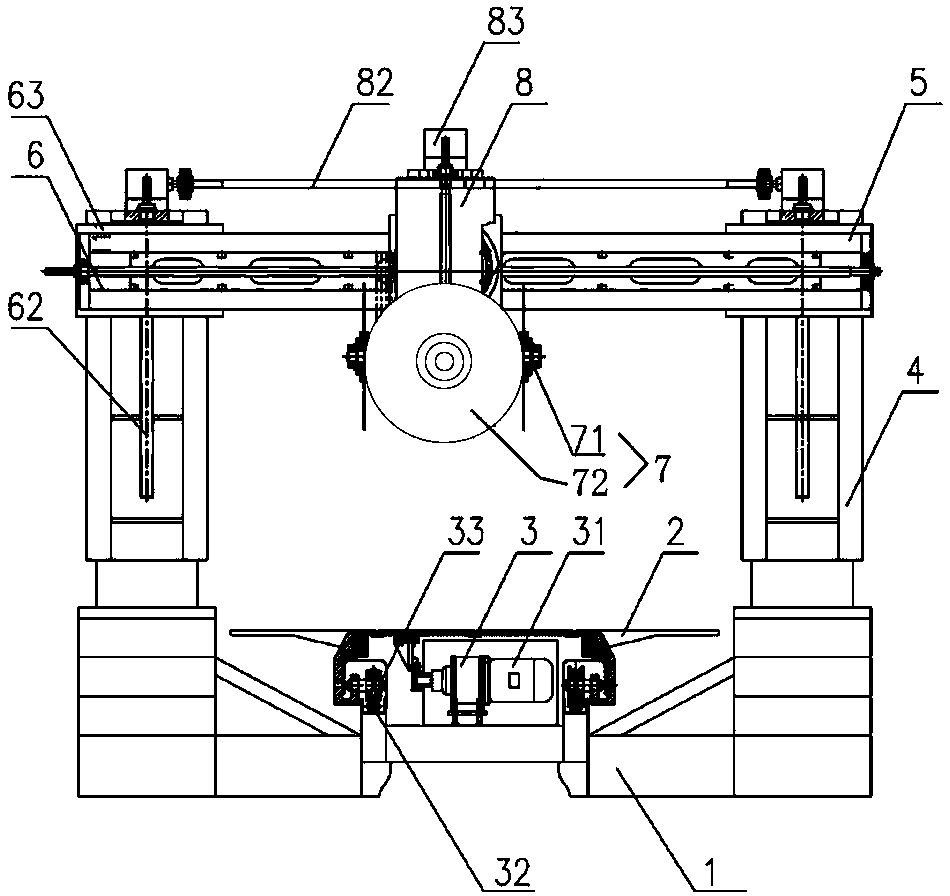

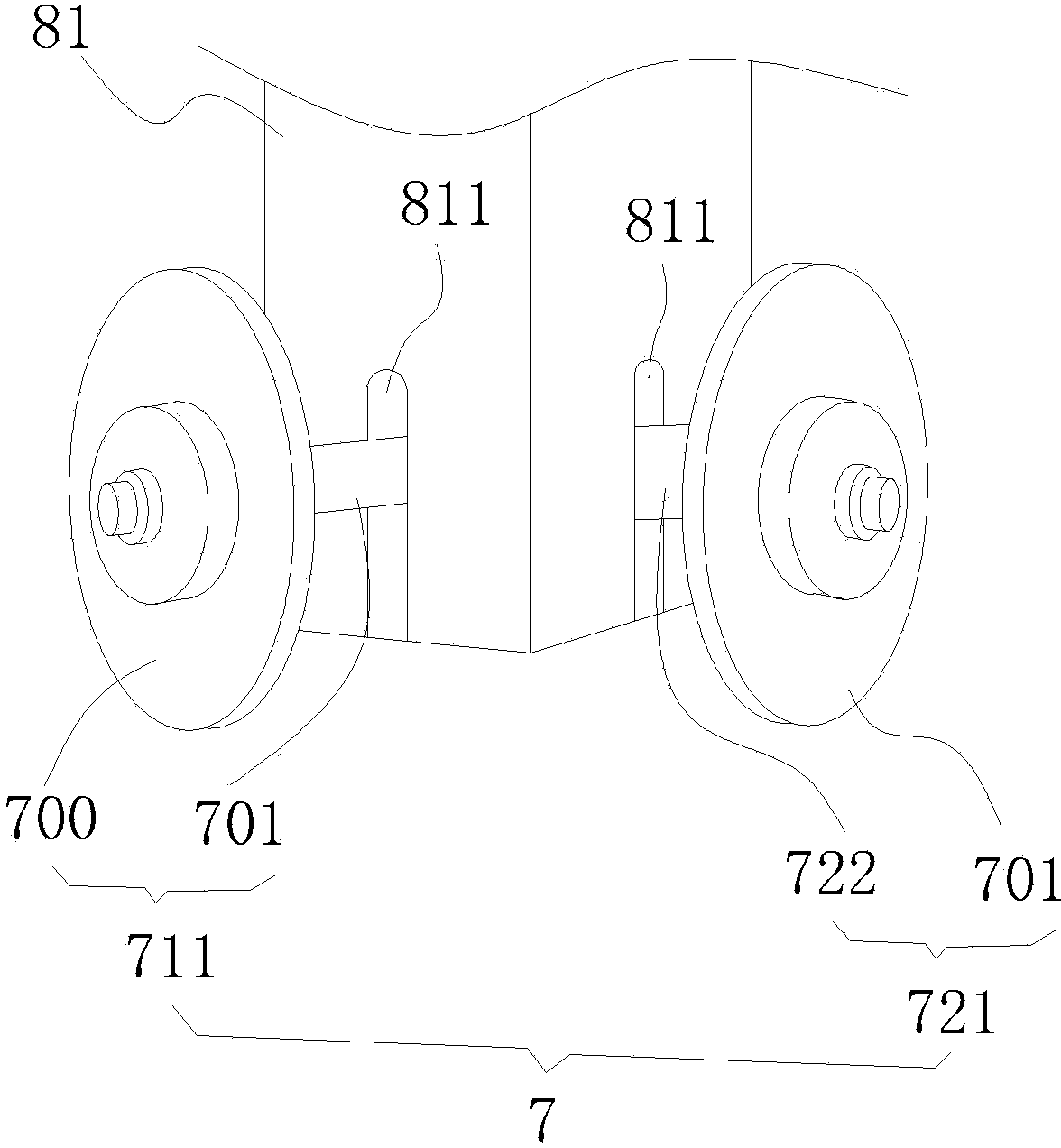

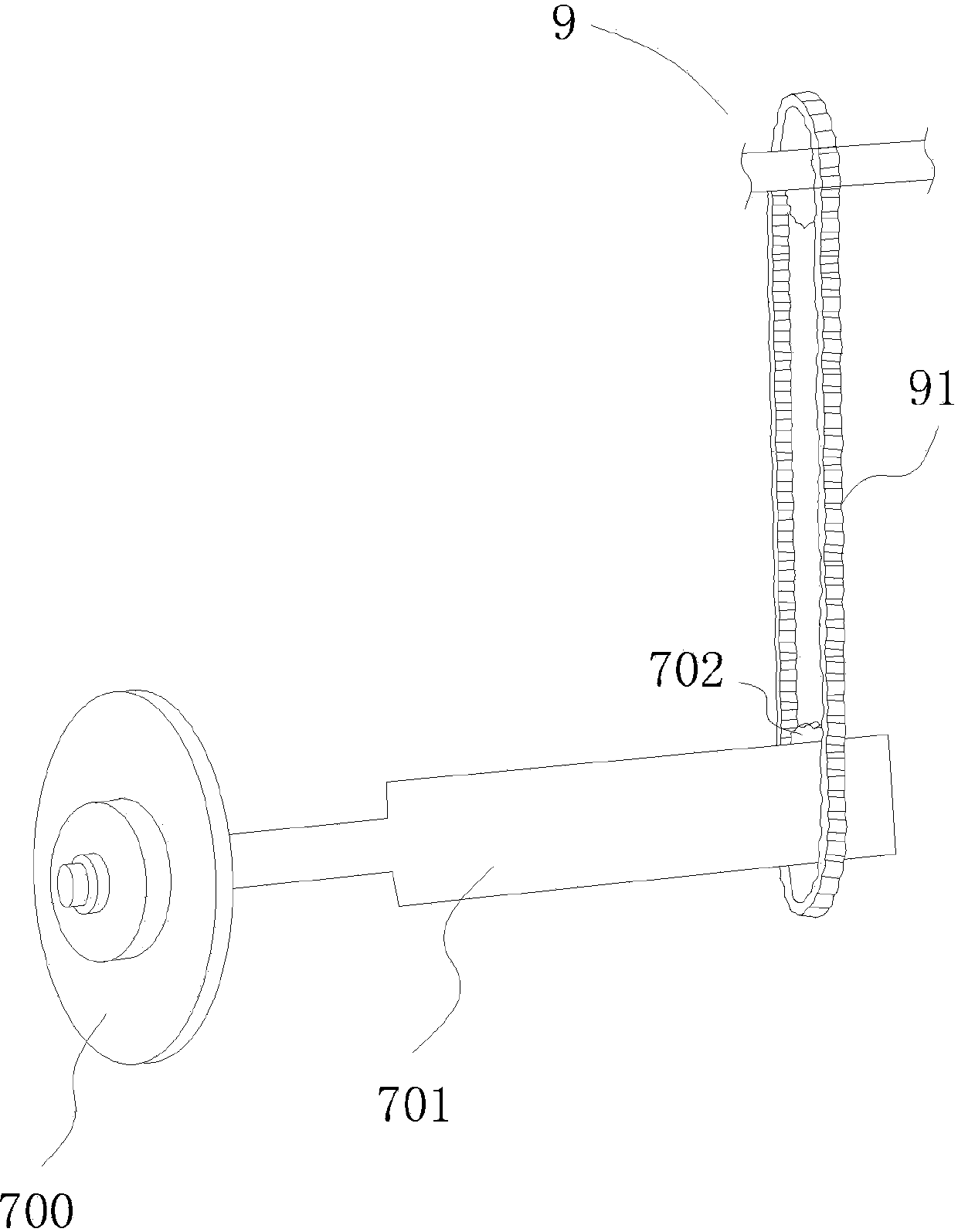

Gantry stone cutting device

InactiveCN103737729ALarge movable rangeImprove stabilityStone-like material working toolsProgrammable logic controllerStructural engineering

The invention discloses a gantry stone cutting device comprising a base, a bench disposed on the base, a bench drive mechanism, columns symmetrically arranged on left and right sides of the base, a beam arranged between the left and right columns, a beam drive mechanism, a cutting device disposed on the beam, a cutting device drive mechanism, and a PLC (programmable logic controller). The bench drive mechanism drives the bench to move back and forth on the base; the beam drive mechanism drives the beam to ascend and descend along the left and right columns; the cutting device drive mechanism drives the cutting device to shift along the beam. The cutting device comprises a transverse cutting mechanism and a longitudinal cutting mechanism. The cutting device drive mechanism drives a drive belt which meshes with shaft wheels in each of transverse and longitudinal cutting tool sets, and a linkage structure driving the single transverse and longitudinal cutting tool sets to ascend and descend is formed; accordingly, each single tool set can ascend and descend, each single tool set is applicable to cutting according to the shape of stones, and the application range of the gantry stone cutting device is effectively widened.

Owner:XIAMEN ZHONGHENG MACHINERY MFG

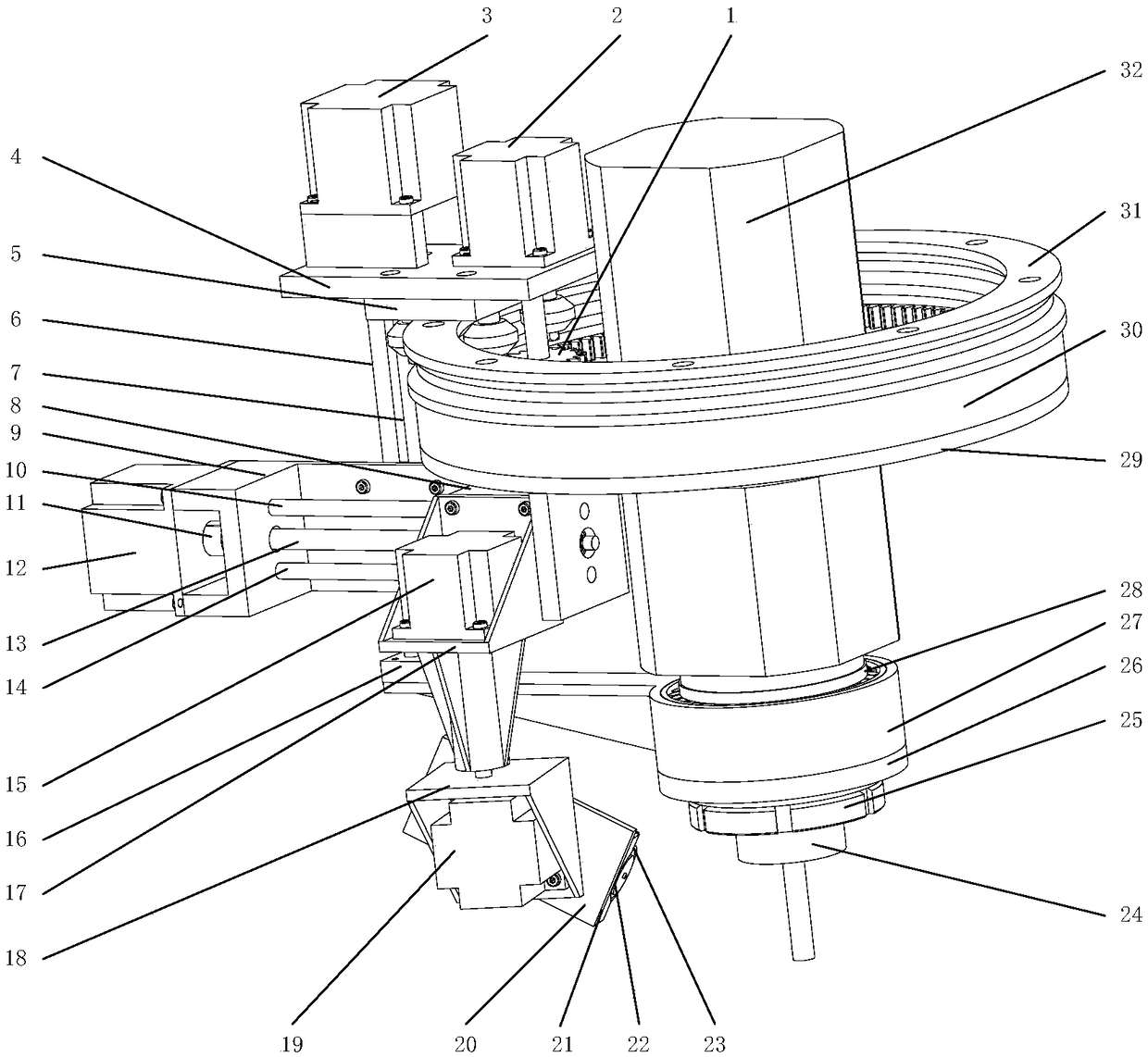

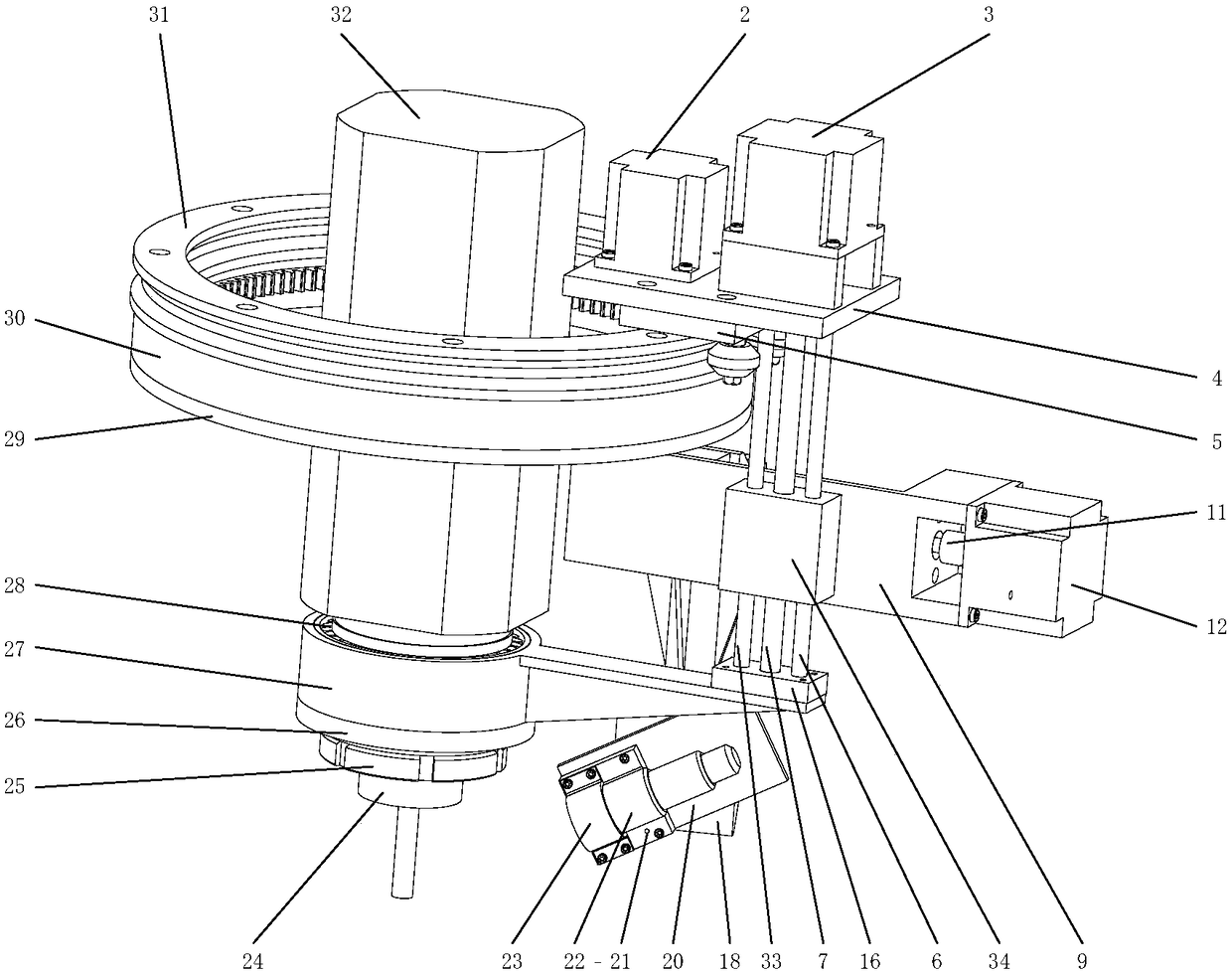

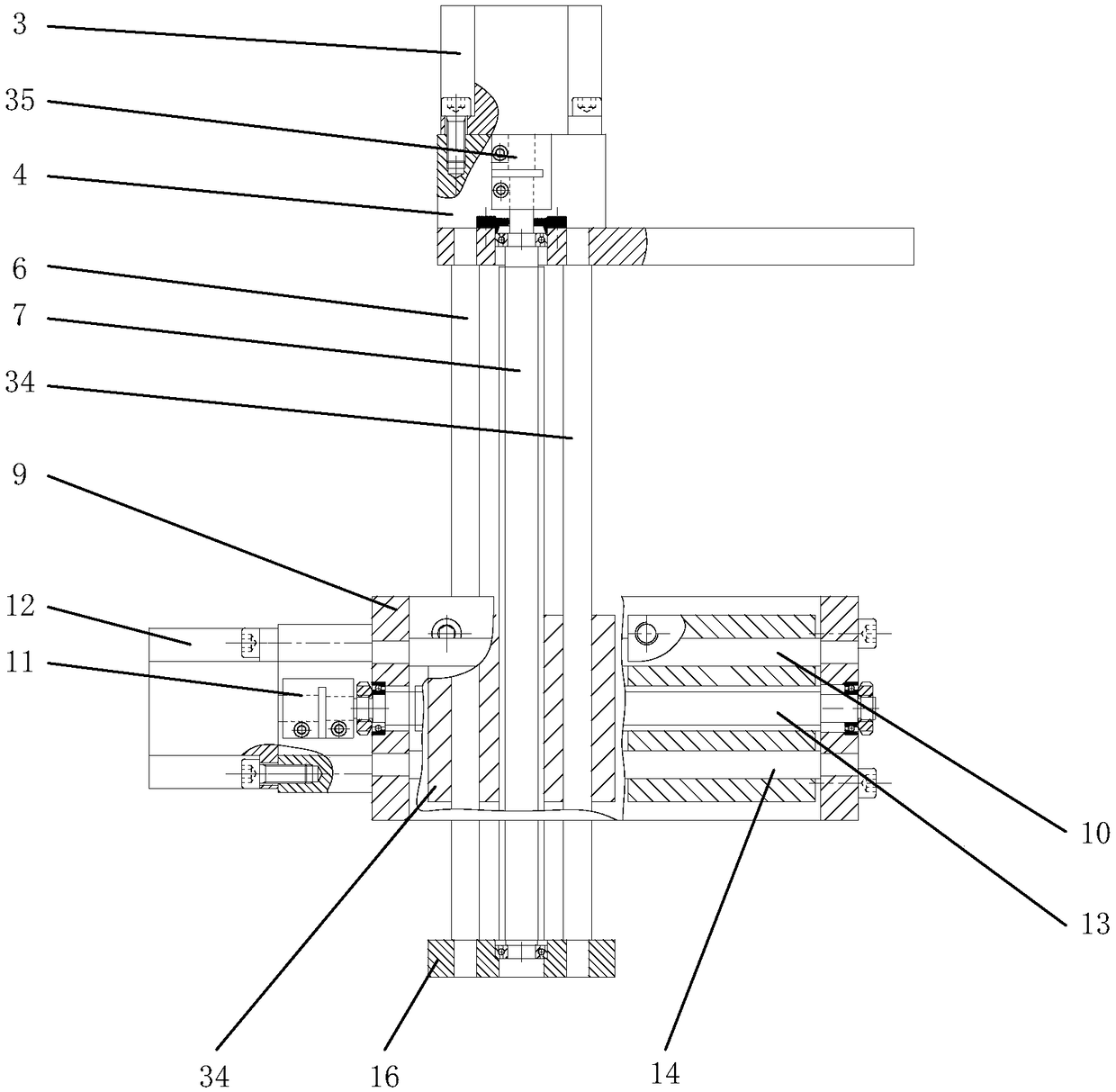

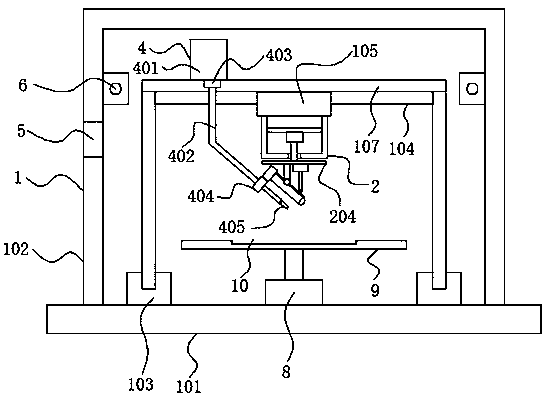

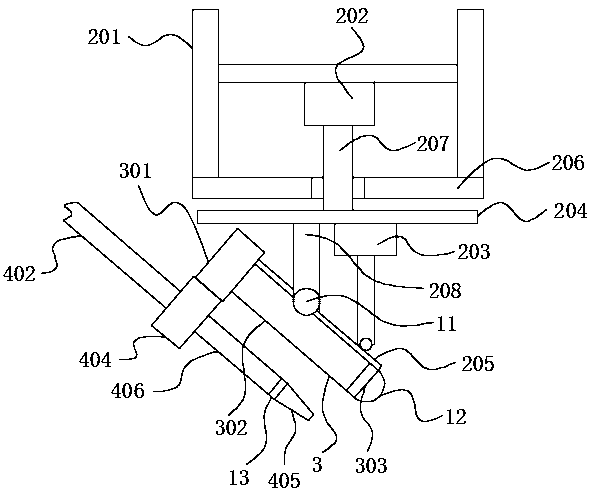

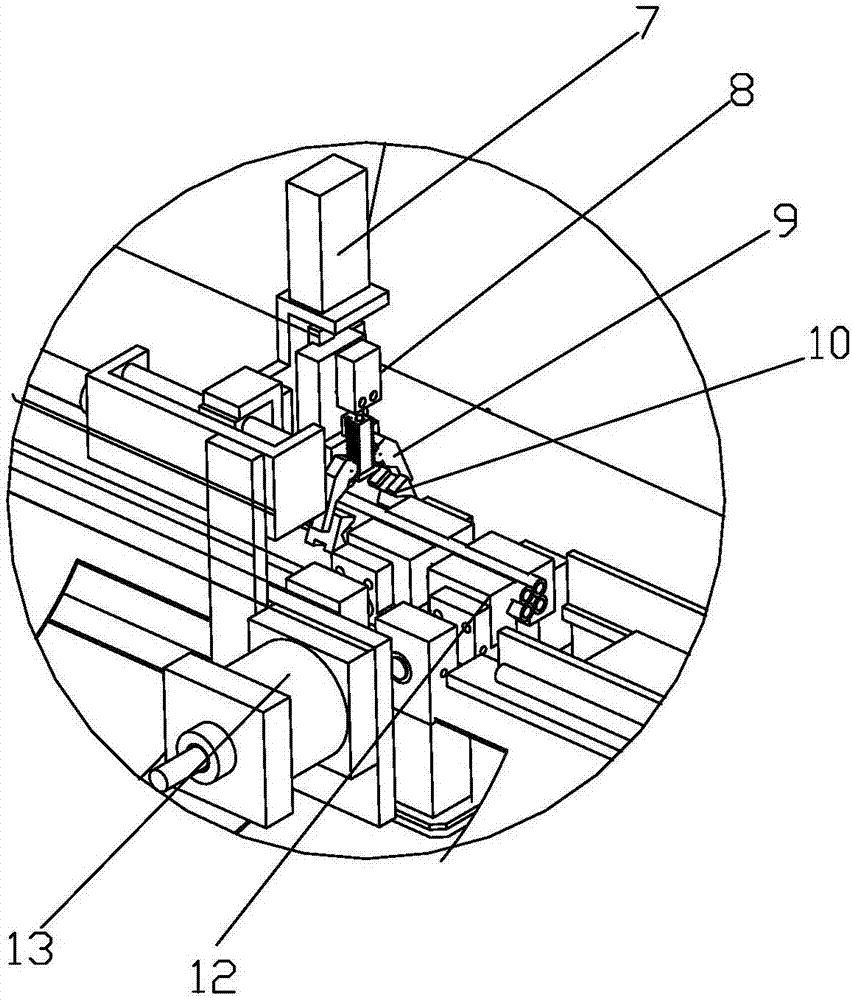

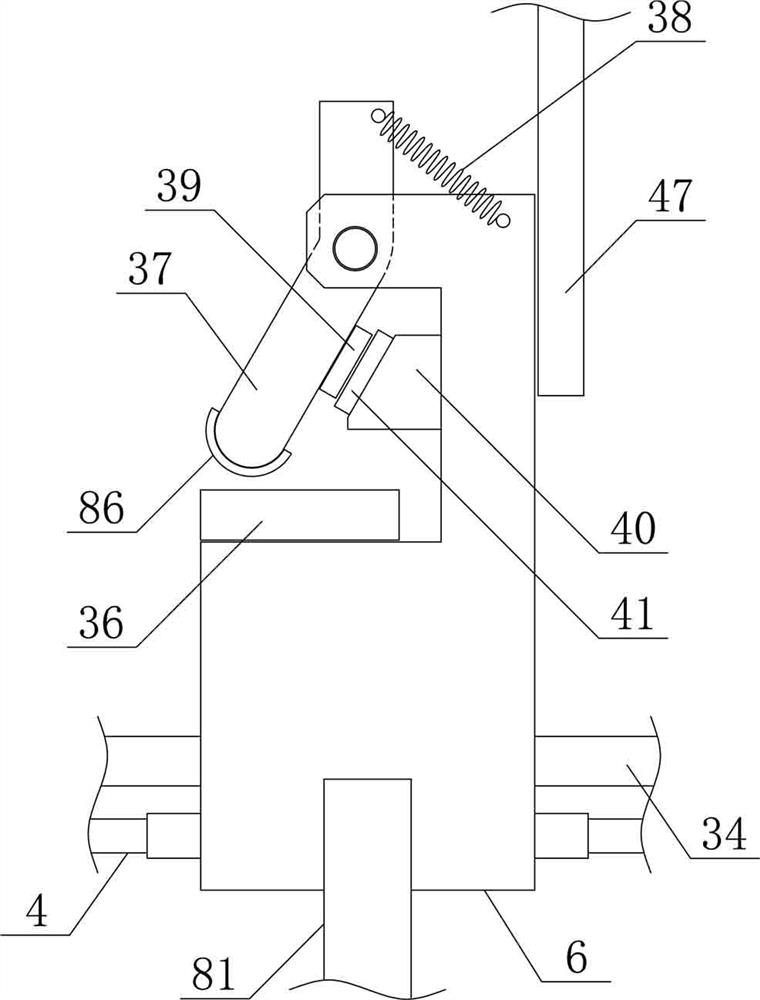

Collimator pose regulating device and method for free-form surface laser assisted milling

ActiveCN108817489AMeet cutting needsGuaranteed cutting qualityMilling equipment detailsMetal working apparatusElectric machineFree form

The invention belongs to the field of pose regulation of collimators and discloses a collimator pose regulating device and a collimator pose regulation method for free-form surface laser assisted milling. The device comprises an inside engaged gear, a circular sliding rail and a cross sliding table mechanism; the inside engaged gear comprises a main gear and a pinion, wherein the main gear is installed outside a main shaft of a machine tool in a sleeving manner; the pinion is internally engaged with the main gear; the lower portion of the main shaft of the machine tool is connected with a cutter; the main gear is fixed to the main shaft of the machine tool; the pinion is connected with a first servo motor; the circular sliding rail is installed outside the main shaft of the machine tool ina sleeving manner; the cross sliding table mechanism is positioned by the side of the main gear, is connected with the first servo motor and can do circular motion with motion of the pinion under theguidance of the circular sliding rail; a collimator is installed on the cross sliding table mechanism by virtue of a mounting and fixing mechanism; and the method is implemented by utilizing the collimator pose regulating device. The collimator pose regulating device disclosed by the invention can be used for regulating a laser spot in real time according to any cutter moving route so that the laser spot can be always positioned at a specified position of a material in front of the cutter.

Owner:HUAZHONG UNIV OF SCI & TECH

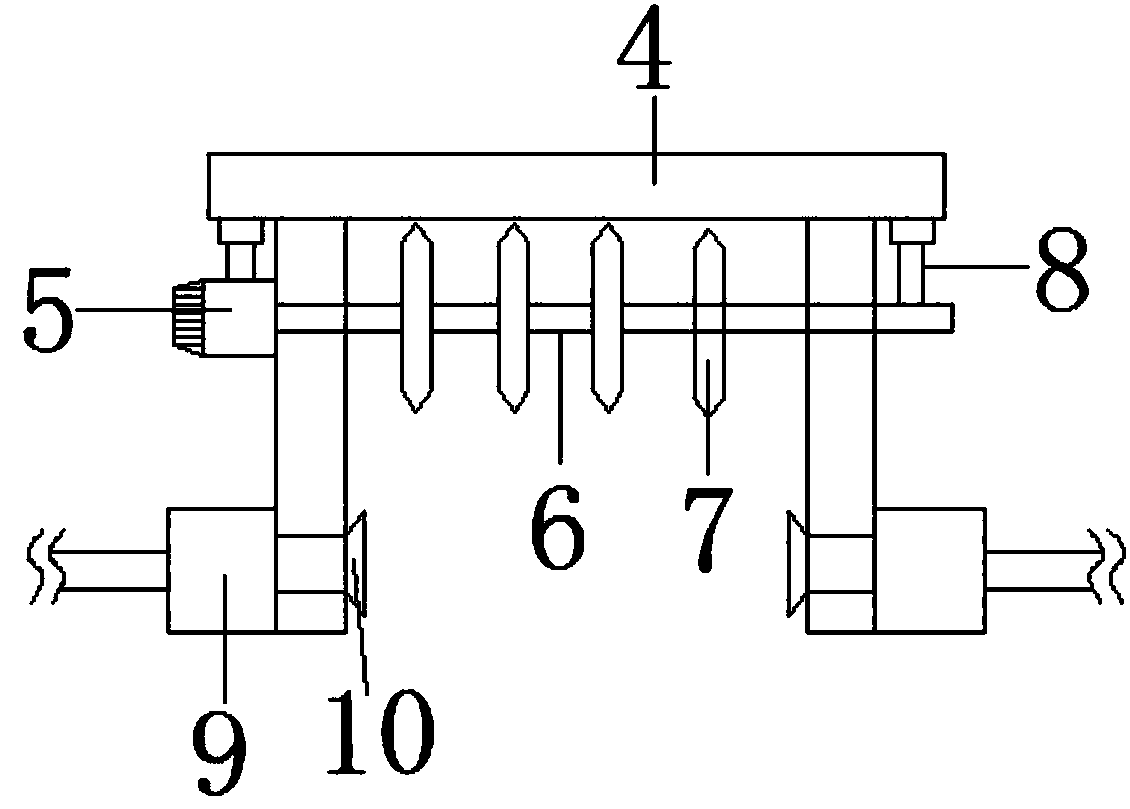

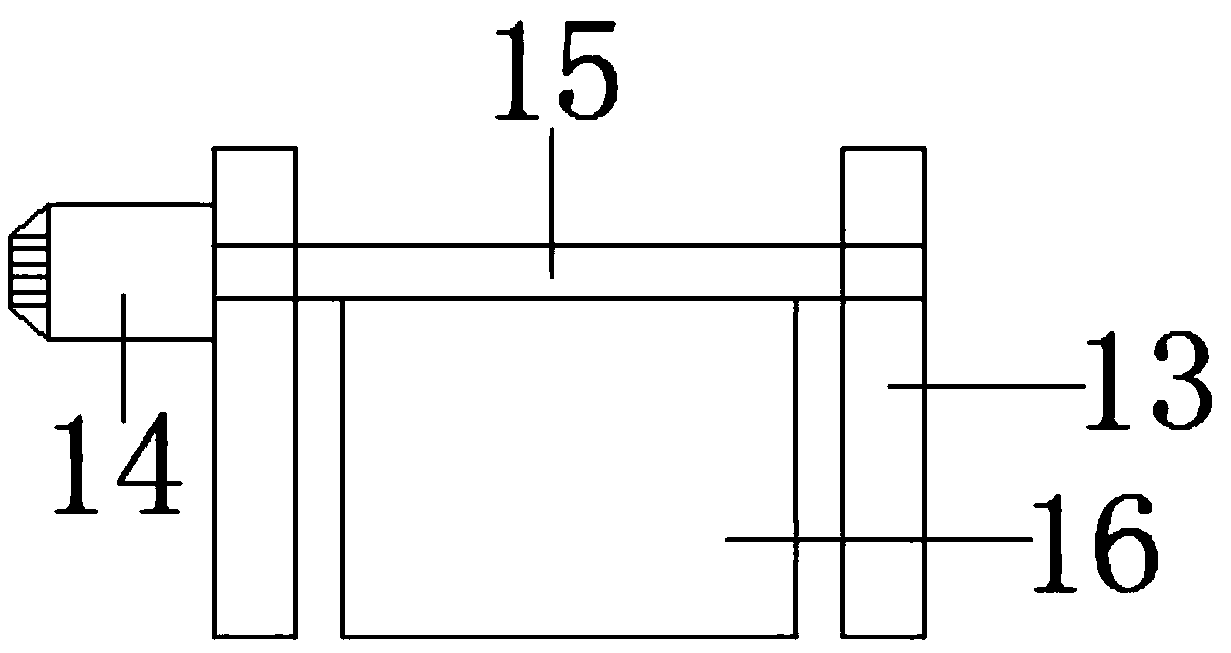

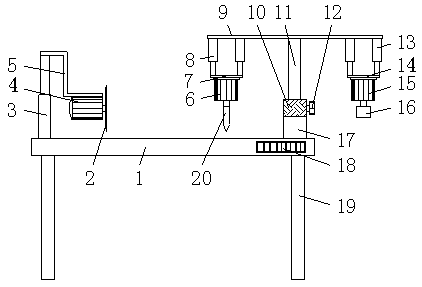

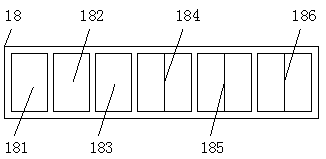

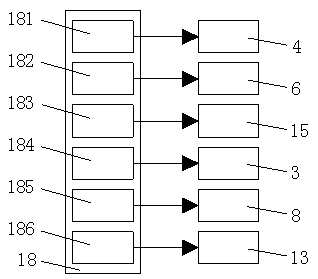

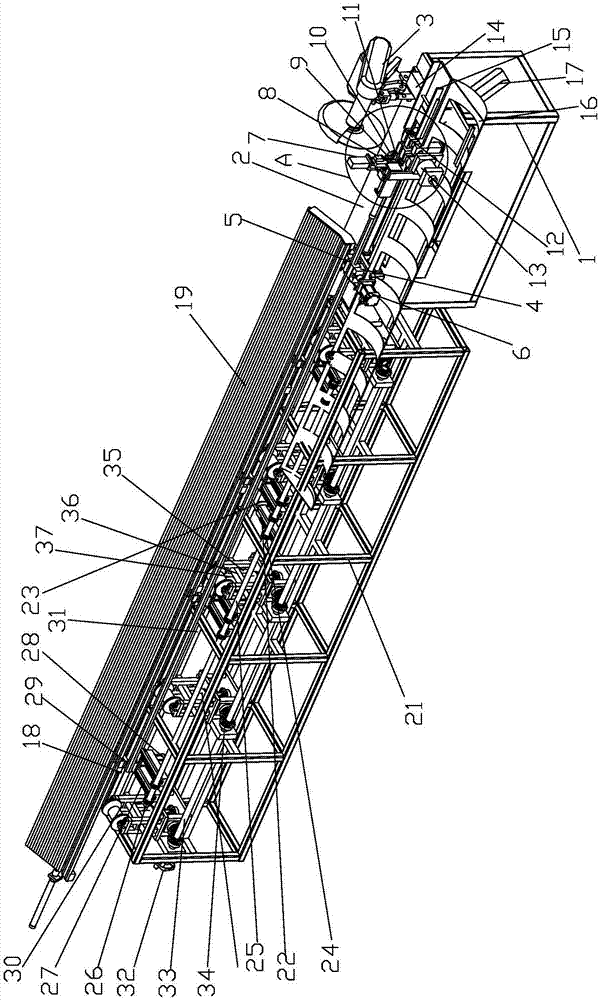

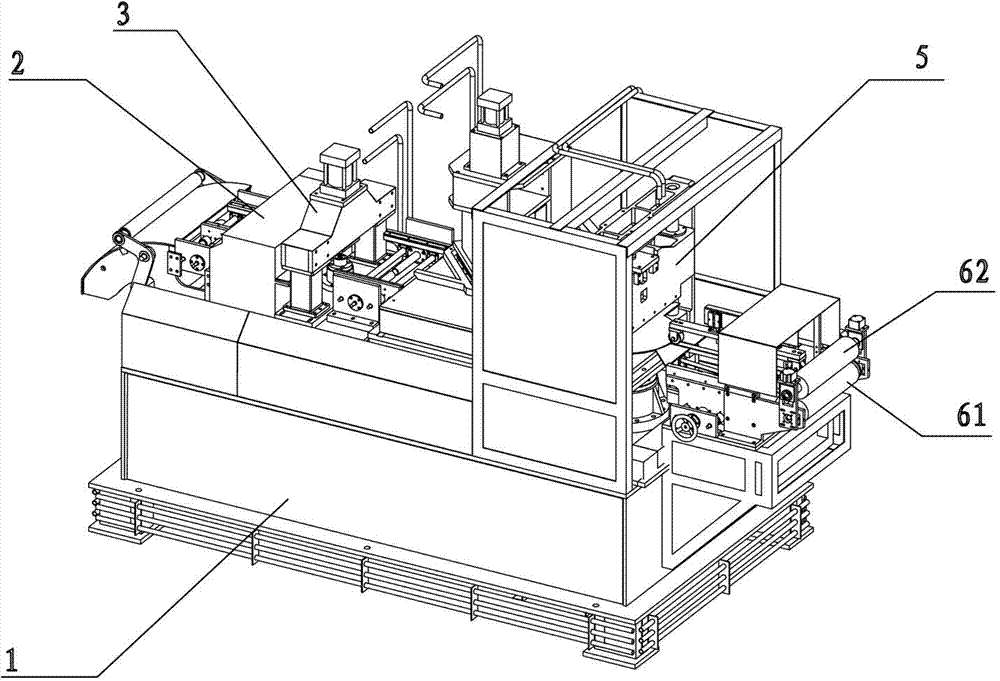

Optic-mechatronics rock wool cutting device

ActiveCN108044811AGuaranteed accuracyMeet cutting needsWorking accessoriesStone-like material working toolsElectric machineryStructural engineering

The invention belongs to the technical filed of rock wool cutting, and specifically provides an optic-mechatronics rock wool cutting device. The rock wool cutting device comprises two sets of supportsarranged up and down in parallel; a first transmission device and a second transmission device are separately arranged at the left and right sides between the two sets of supports; the left sides oftop portions of the two sets of supports are provided with first N-type supports; the top portions of the left sides of the first N-type supports are provided with servo motors; the power output endsat the right sides of the servo motors are provided with tool mounting shafts; the right sides of the tool mounting shafts penetrate through two sets of vertical rods of the first N-type supports; theleft and right sides of the bottoms of inner cavities of the two sets of first N-type supports are all provided with dust hoods; the accuracy of the size of rock wool cutting can be guaranteed, and cutting requirements of rock wool strips with different sizes are met; at the same time, when the cutting is completed, the rock wool strips can be arranged neatly to facilitate subsequent machining; and the optic-mechatronics rock wool cutting device is convenient to use and high in practicality.

Owner:WUXI CITY COLLEGE OF VOCATIONAL TECH +1

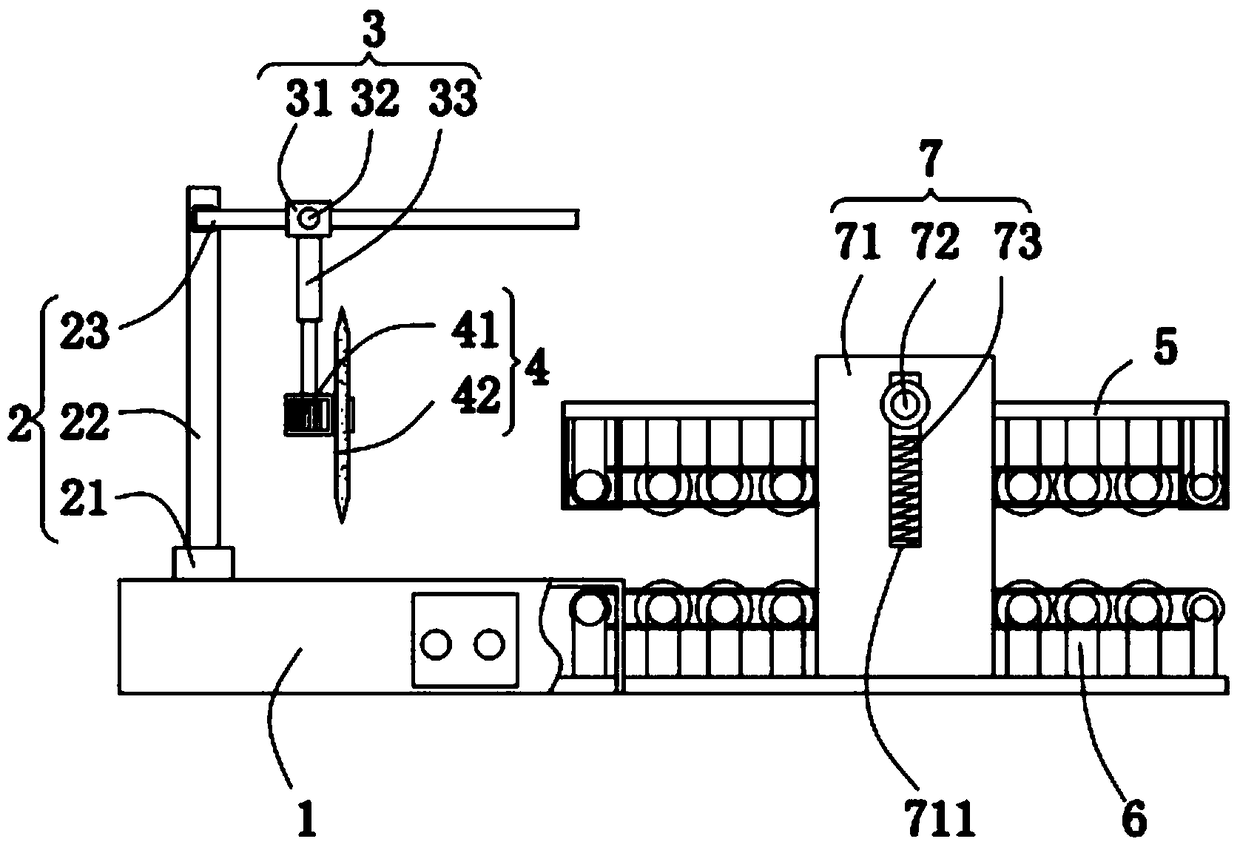

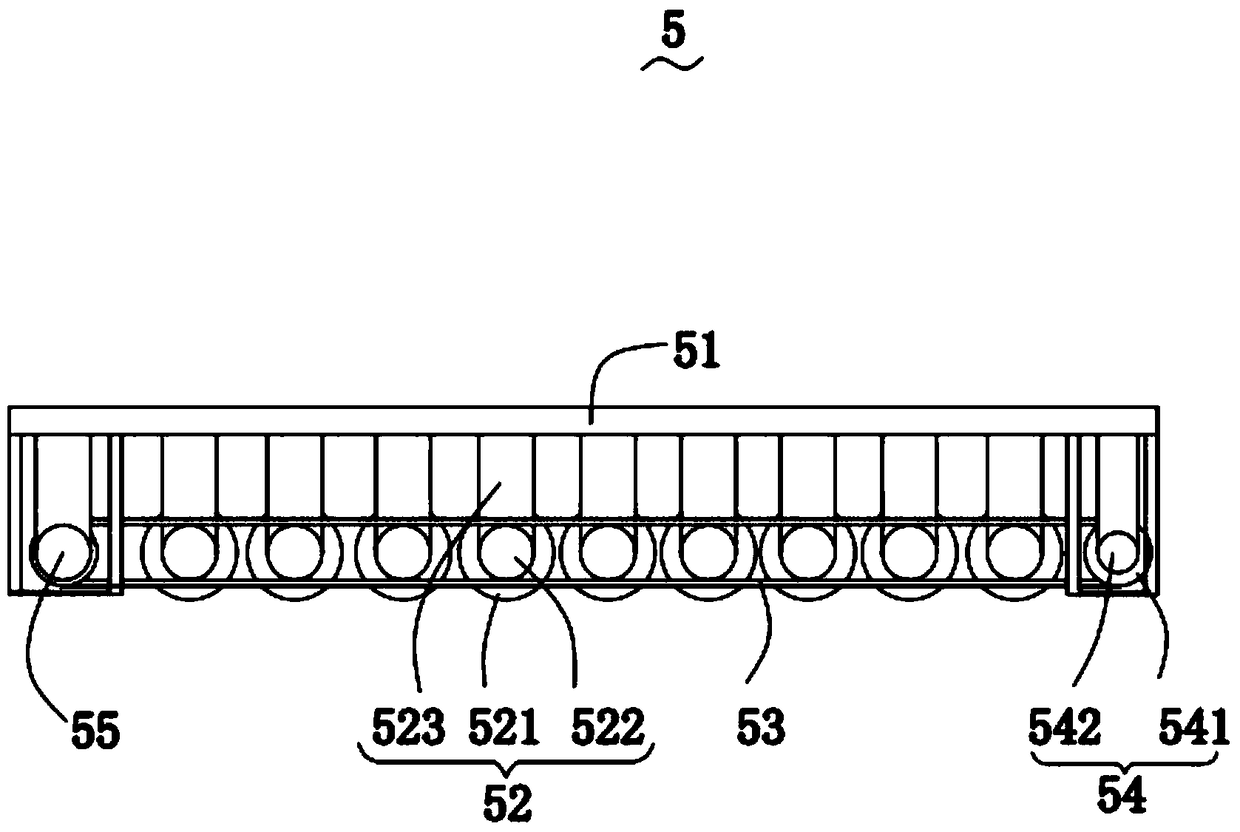

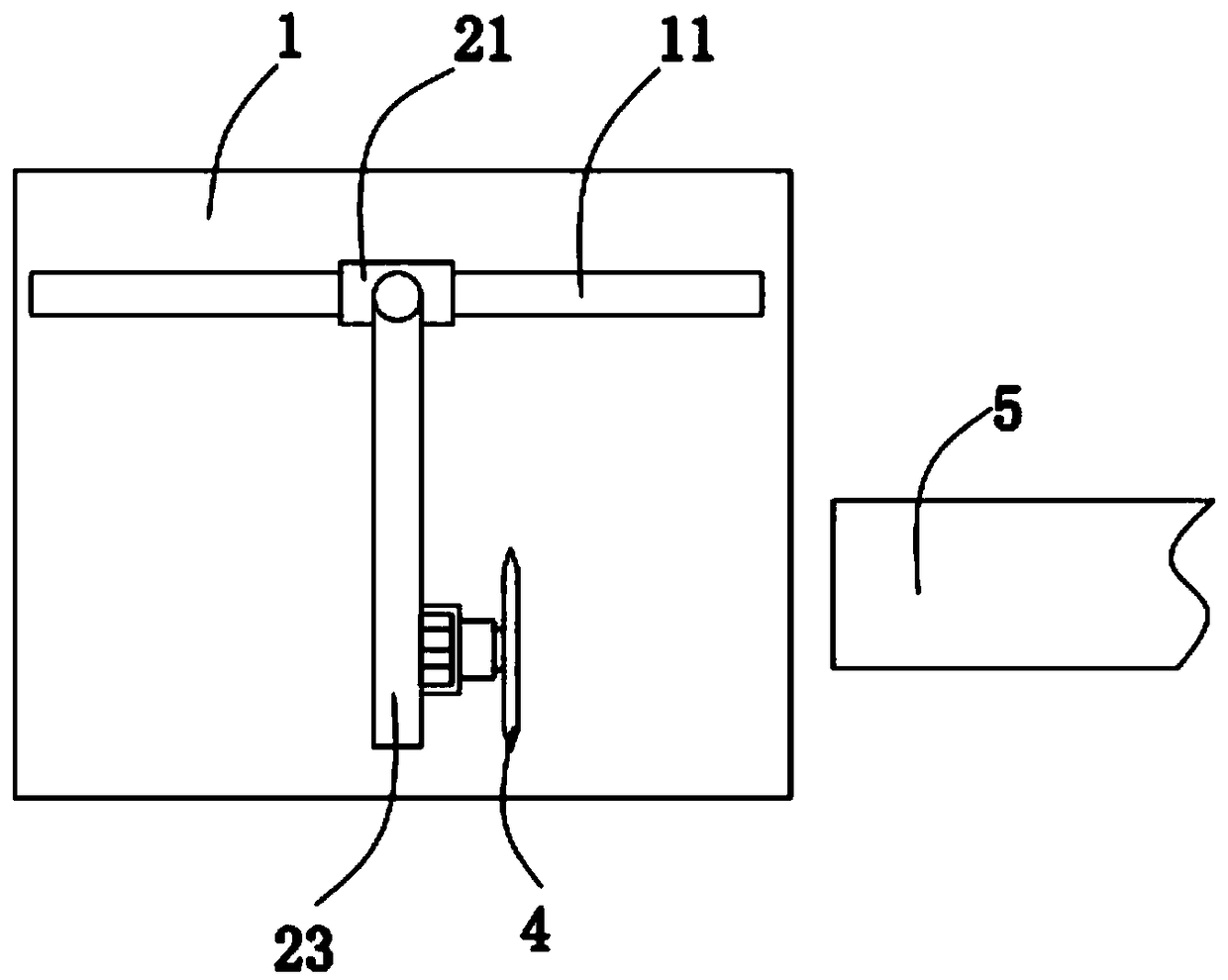

Glass cutting apparatus

InactiveCN110272195AOperational securityAvoid Situations That Cut Your FingersGlass severing apparatusSlagEngineering

The invention discloses a glass cutting apparatus. The glass cutting apparatus comprises a glass cutting apparatus body, a cutting table, a frame, a glass cutting knife and a recovery trough, the glass cutting apparatus body is provided with a workbench, the side surface of the workbench has a convex shape, the cutting table is arranged at the top end of the workbench, the cutting table is a conveying device, the frame is arranged at two sides of the cutting table, the frame is arranged on the workbench, a slide rail is arranged at the tail end of the frame, the workbench is provided with a corresponding sliding slot, a distance sensor is arranged at the tail end of the sliding slot, a guiding rod is arranged at the top end of the frame, the guiding rod is provided with a transverse sliding seat, a fixing seat is arranged on the transverse sliding seat, the fixing seat is connected with the glass cutting knife, the glass cutting knife is provided with a knife handle and a knife bit, the knife handle is fixed on the fixing sat, and the recovery trough is arranged in the glass cutting apparatus body. The glass cutting apparatus has the advantages of safety, accuracy and fastness in operation, good cutting effect, and recovery of cutting slag.

Owner:高燕珊

Trimming mechanism based on automobile injection molding part

InactiveCN109228070AMeet cutting needsMeet the punching needsEdge grinding machinesDomestic articlesPunchingEngineering

The invention discloses a trimming mechanism based on an automobile injection molding part. The trimming mechanism based on the automobile injection molding part comprises a supporting base, supporting legs, a bearing pedestal, a supporting rod, a first electric telescopic rod, a second electric telescopic rod and a third electric telescopic rod. The trimming mechanism based on the automobile injection molding part is characterized in that the left end of the top of the supporting base is fixedly connected with the first electric telescopic rod; the top end of the first electric telescopic rodis fixedly connected with a first supporting plate; a first motor is fixedly arranged at the bottom of the first supporting plate; an output shaft of the first motor is fixedly connected with a cutting knife; the right end of the top of the supporting base is fixedly connected with the bearing pedestal; and the top end of the bearing pedestal is fixedly connected with a sleeve. The trimming mechanism based on the automobile injection molding part has the following advantage: the problems in the prior art that the trimming work such as cutting, punching and polishing of the automobile injection molding part is conducted separately, the labor amount of people is increased and the processing efficiency is reduced are solved. The requirement on horizontal rotation of the supporting rod and afourth supporting plate by people can be met, so that people can use a drill rod and a grinding head conveniently.

Owner:XUZHOU YUNTAI AUTOMOBILE ELECTRICAL APPLIANCE

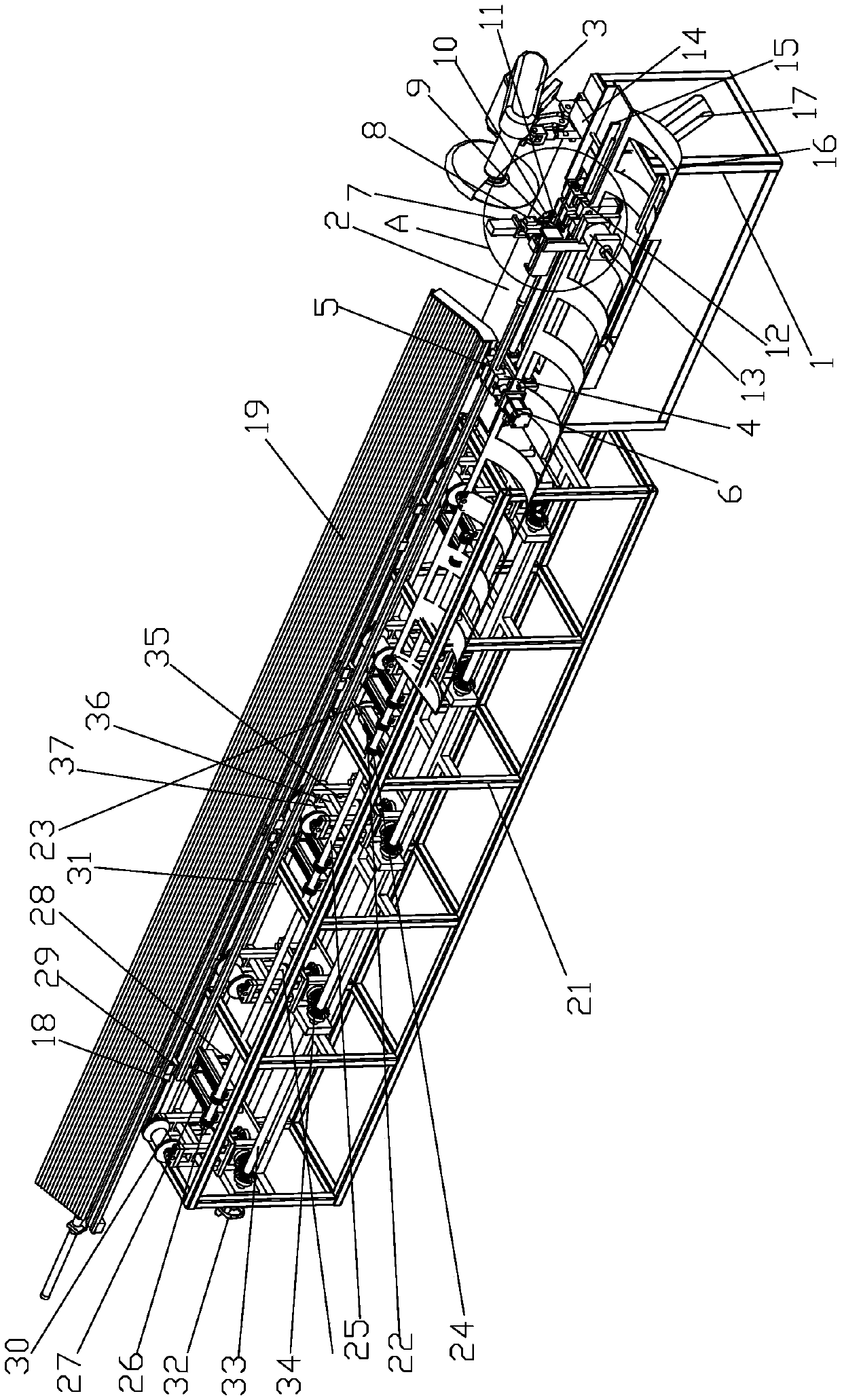

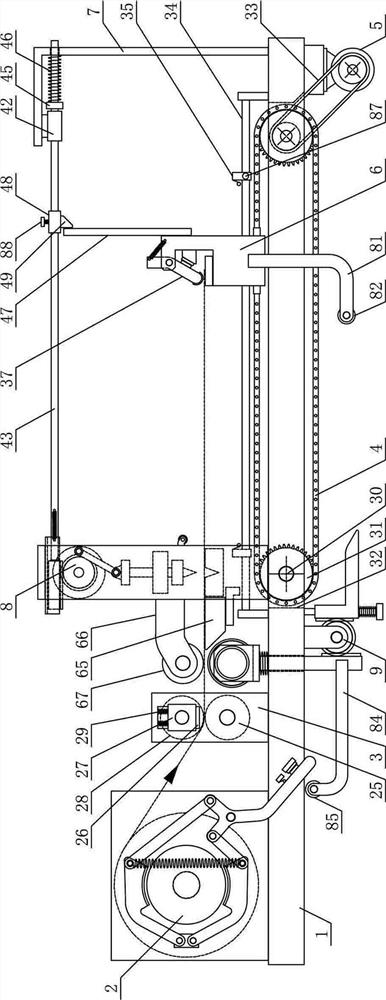

Automatic cutting equipment for aluminum profile

InactiveCN109014365AWide range of applicationsRealize longitudinal segment cuttingShearing machinesShearing machine accessoriesEngineeringMechanical engineering

The invention belongs to the technical field of aluminum product production and processing, and particularly relates to automatic cutting equipment for aluminum profile. The automatic cutting equipment comprises a base, a first sliding groove, a supporting mechanism, a first sliding seat, a supporting rod, a sliding rod, a displacement mechanism, a second sliding seat, a mounting groove, a through hole, a first limiting knob, a pneumatic rod, a connecting block, a cutting mechanism, a first rotating motor, a cutting blade, a first feeding mechanism, a conveying mechanism, a conveying wheel, afirst gear, a supporting plate, a transmission chain, a driving mechanism, a second gear, a second rotating motor, a third gear, a second feeding mechanism, a limiting mechanism, a limiting plate, asecond sliding groove, a second limiting knob and a spring. According to the automatic cutting equipment, the angle of the cutting blade can be freely adjusted, the cutting requirements of sectional materials of various shapes can be met, and the application range is wide; and the sectional materials can be automatically conveyed forwards through the first feeding mechanism and the second feedingmechanism, so that the cutting is more convenient and accurate, the sectional materials can be limited, and the phenomenon that the sectional materials shake violently and affect the cutting effect isavoided.

Owner:王桂英

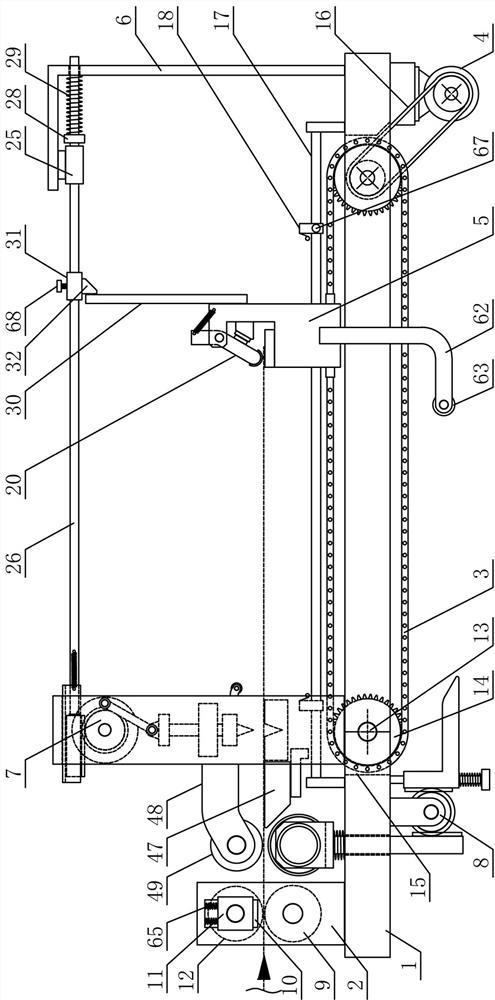

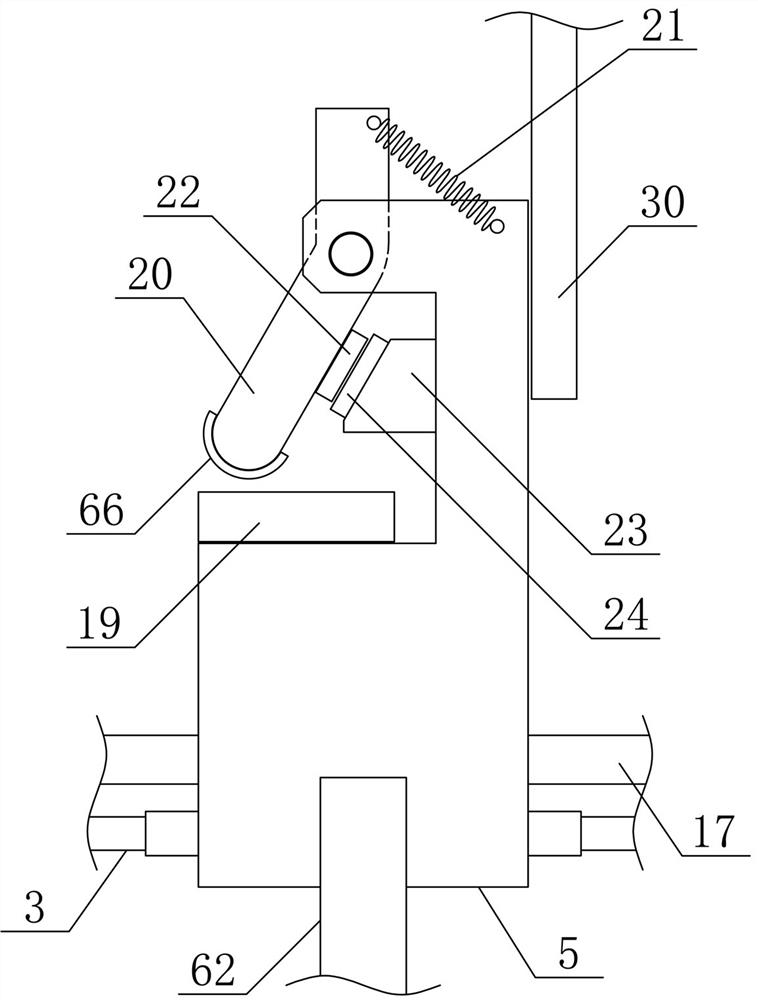

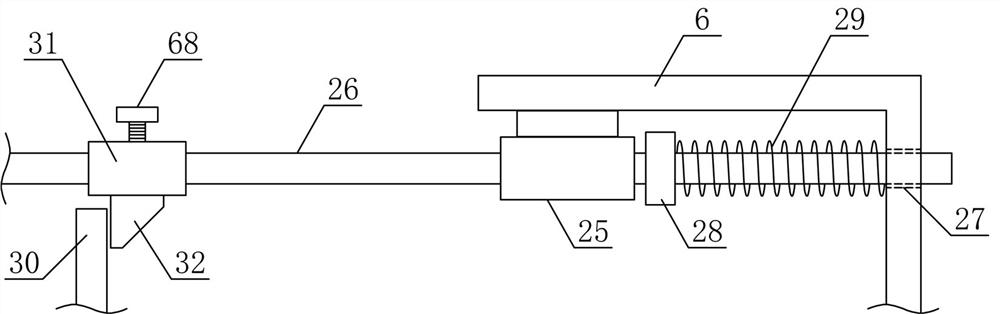

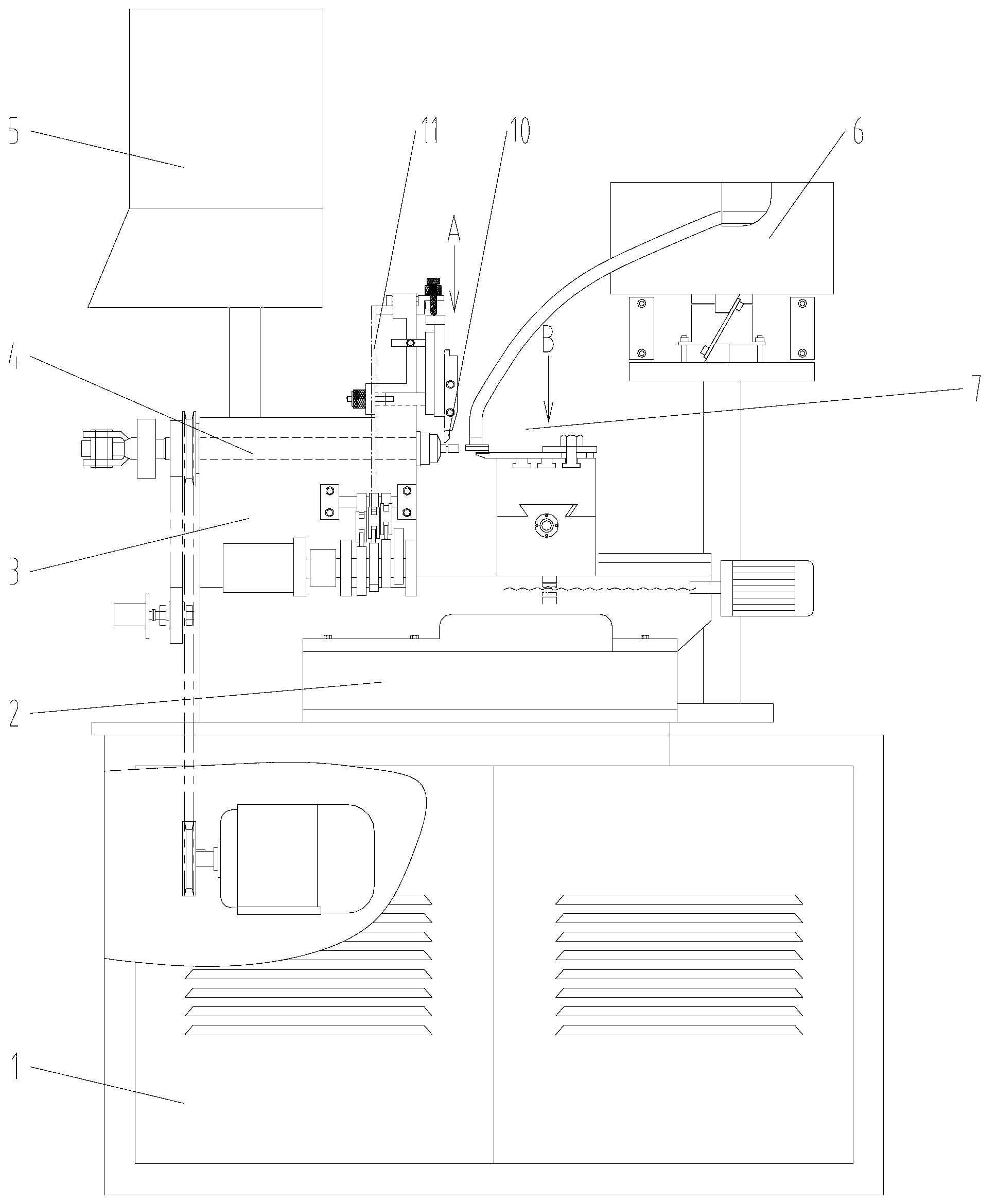

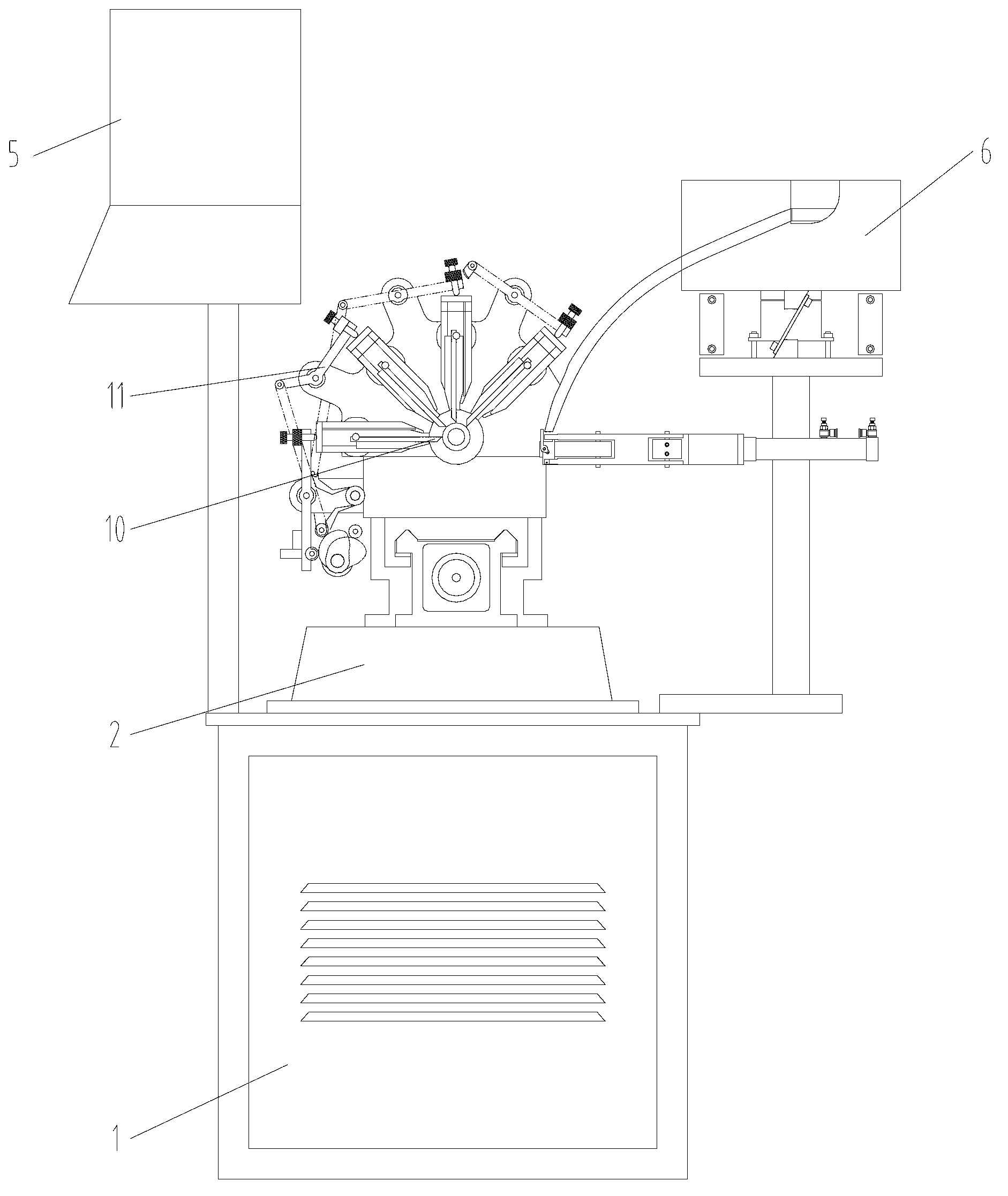

Metal bar feeding and cutting device with cutting length convenient to adjust

InactiveCN107855594AImprove processing efficiencyHigh degree of automationMetal sawing devicesMetal sawing accessoriesEngineeringMechanical engineering

The invention discloses a metal bar feeding and cutting device with the cutting length being convenient to adjust. The device comprises a rack. A fixing plate is arranged on the rack. A silo is arranged on the side portion of the rack and sequentially connected with a feeding mechanism, a cutting mechanism and a discharging mechanism. The feeding mechanism comprises a feeding assembly, and the feeding assembly is provided with a feeding chuck base and a fixing mechanism. A feeding chuck is arranged in the feeding chuck base. The feeding chuck base is connected with a chuck base air cylinder. The cutting mechanism comprises a circular cutting machine arranged on the fixing plate. A rear chuck is arranged below the circular cutting machine and connected with a clamping air cylinder. The discharging mechanism comprises a pushing air cylinder arranged on the fixing plate. The pushing air cylinder is connected with a pushing plate. A finished product hopper fixed to the rack is arranged ina position opposite to the pushing plate and connected with a chip discharging sliding groove. A scale plate is arranged below the circular cutting machine and provided with a movable limiting plate.A fixing piece is arranged between the limiting plate and the scale plate.

Owner:INST OF LASER & OPTOELECTRONICS INTELLIGENT MFG WENZHOU UNIV

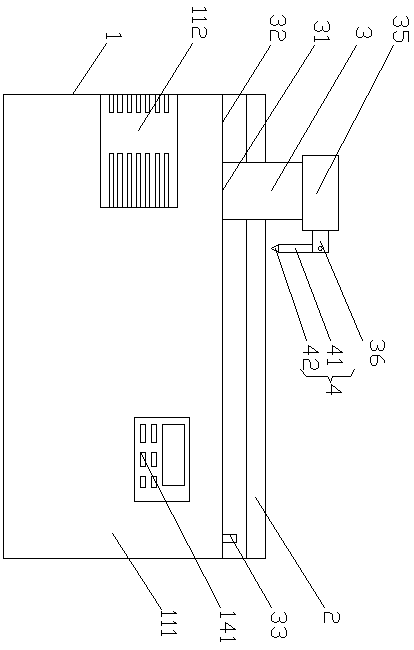

Multi-angle adjustment laser cutting machine

InactiveCN110961799AEasy to moveMeet cutting needsLaser beam welding apparatusLaser cuttingNitrogen gas

The invention discloses a multi-angle adjustment laser cutting machine. The cutting machine comprises a cutting machine main body, an angle adjusting assembly, a cutting assembly and a blowing assembly. The cutting machine main body comprises a base, a housing, a first linear sliding rail, a second linear sliding rail and a third linear sliding rail. The angle adjusting assembly comprises a connecting frame, a forward and reverse rotating motor, an electric cylinder, a rotating disc and a mounting base. The cutting assembly comprises a laser generator, a lens cone and a condensing lens. The blowing assembly comprises a nitrogen tank, a hose, a pressure reducing valve, a damping rotating shaft and a nozzle. According to the invention, through cooperation of the first linear sliding rail, the second linear sliding rail and the third linear sliding rail, the cutting assembly moves in the X-axis direction, the Y-axis direction and the Z-axis direction; angle adjustment is achieved throughthe angle adjusting assembly, so that a three-dimensional object can be cut conveniently; and blowing is conducted through the blowing assembly, the gasified part obtained after cutting is removed from the surface side of the object, and the cutting process is achieved.

Owner:芜湖镭科智能科技股份有限公司

Fabric cutting device for chemical fiber quilt production

InactiveCN112359579ASmooth and orderly transmission and processingCompact and orderly transfer processingSevering textilesFiberMechanical equipment

The invention discloses a fabric cutting device for chemical fiber quilt production, and belongs to the field of home textile processing mechanical equipment. A feeding conveying support is verticallyand fixedly arranged on one side of the upper portion of a fabric processing support, a feeding conveying pressing roller is horizontally arranged on the upper side of a feeding conveying rotating roller of the feeding conveying support, a translation reciprocating pull plate is horizontally and slidably arranged on a material pulling translation guide rod, a fabric cutting mechanism is arrangedon the fabric processing support on the side of the feeding conveying support, a connecting rod reciprocating support and the fabric cutting mechanism are vertically and fixedly arranged on two sidesof the upper portion of the fabric processing support correspondingly, a cutting translation connecting rod is horizontally arranged in a connecting rod reciprocating sleeve of the connecting rod reciprocating support in a sliding mode, and the fabric guiding and conveying mechanism is arranged on the fabric processing support between the fabric cutting mechanism and the feeding conveying support.The fabric cutting device is reasonable in structural design, capable of efficiently and stably cut chemical fiber quilt fabric in a continuous and smooth mode and high in automation degree of processing, and meets production and use requirements.

Owner:桐乡市康悦时装寝具有限公司

Strapping tape removing device

PendingCN110422417ARealize automatic cuttingReduce labor intensityBinding material removalEngineeringMechanical engineering

The invention relates to a strapping tape removing device. The device comprises a supporting part, a guide rail arranged on the supporting part, a sliding block sliding along the guide rail, a drivingmechanism driving the sliding block to move, a first cutter mechanism connected with the sliding block and a second cutter mechanism arranged on the supporting part, wherein the supporting part stretches across a conveying belt of plates, the moving direction of the sliding block is perpendicular to the conveying direction of the conveying belt, and the cutting direction of the second cutter mechanism and the cutting direction of the first cutter mechanism are perpendicular to each other. According to the strapping tape removing device, the two cutter mechanisms are arranged to be perpendicular to each other, so that strapping tapes of the plates can be transversely and longitudinally cut, and the strapping tapes of the plates can be automatically cut, so that the production efficiency isimproved, and the labor intensity of operators is reduced.

Owner:KEDA INDUSTRIAL GROUP CO LTD

Processing equipment for cut velvet fabric and operating method of processing equipment

ActiveCN105220390AHair dryer is effectiveHair dryer guaranteeTextile shapingEngineeringElectric control

The invention provides processing equipment for a cut velvet fabric and an operating method of the processing equipment, which belong to the technical field of cloth processing and are used for overcoming the defects that existing velvet cutting equipment is higher in limitation; once the equipment is selected, only materials with fixed specification can be treated, so that the utilization space of the equipment is greatly reduced. The processing equipment for the cut velvet fabric comprises a tank body, wherein a velvet cutting platform is arranged on the upper surface of the tank body; one row of elevating racks are arranged on each of two sides of the velvet cutting platform; a limiting rod is hinged to the top end of each row of elevating racks; a cutting mechanism is arranged on one side of the velvet cutting platform and comprises a supporting frame; the supporting frame comprises a vertical supporting plate and a horizontal supporting plate; one side face of the vertical supporting plate is a height adjusting surface; the horizontal supporting plate slides and acts along the height adjusting surface; the vertical supporting plate is connected with the velvet cutting platform; the horizontal supporting plate is positioned right above the velvet cutting platform; a velvet cutting hob is arranged on the horizontal supporting plate and is connected with a velvet cutting gearbox in an electric control way; a conveyor belt is arranged at the upper end face of the velvet cutting platform.

Owner:HAINING JBL TEXTILE

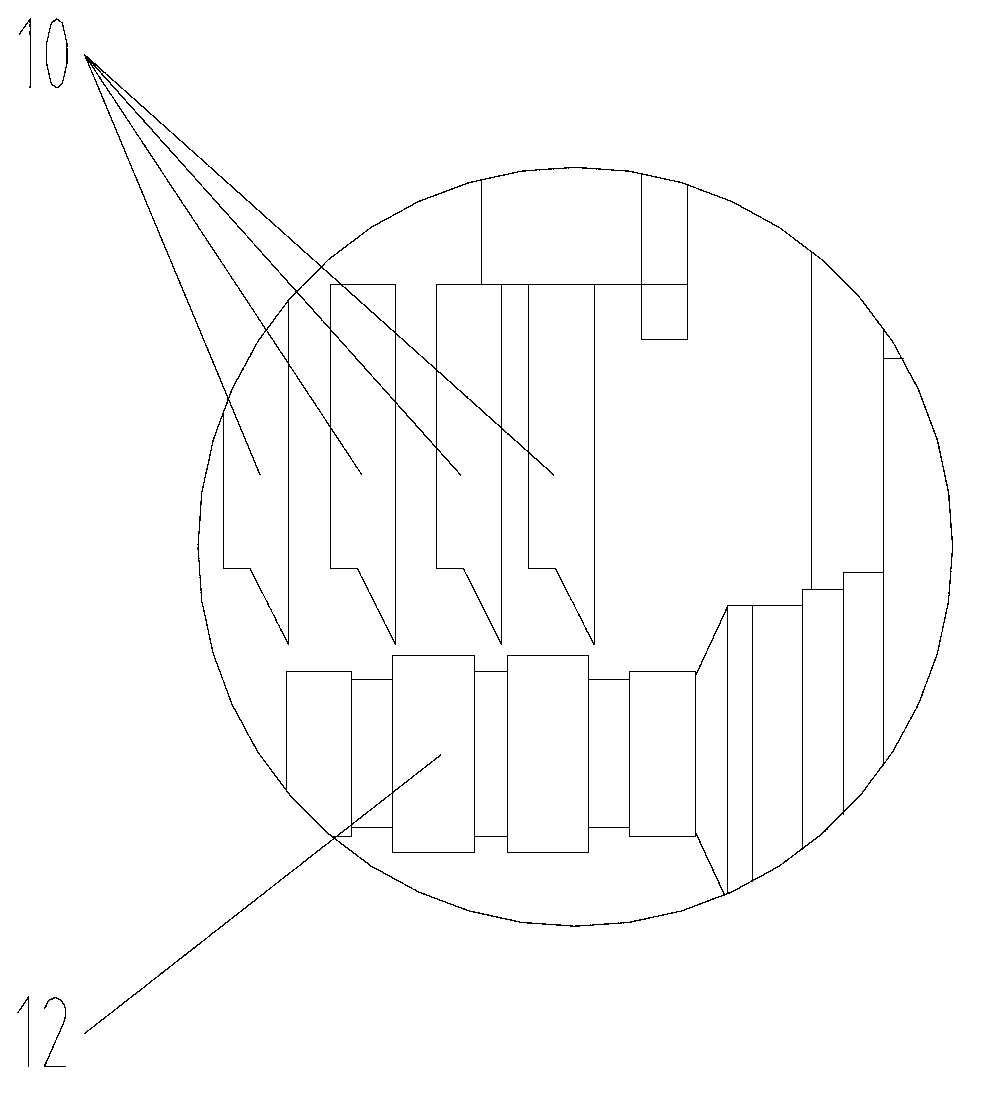

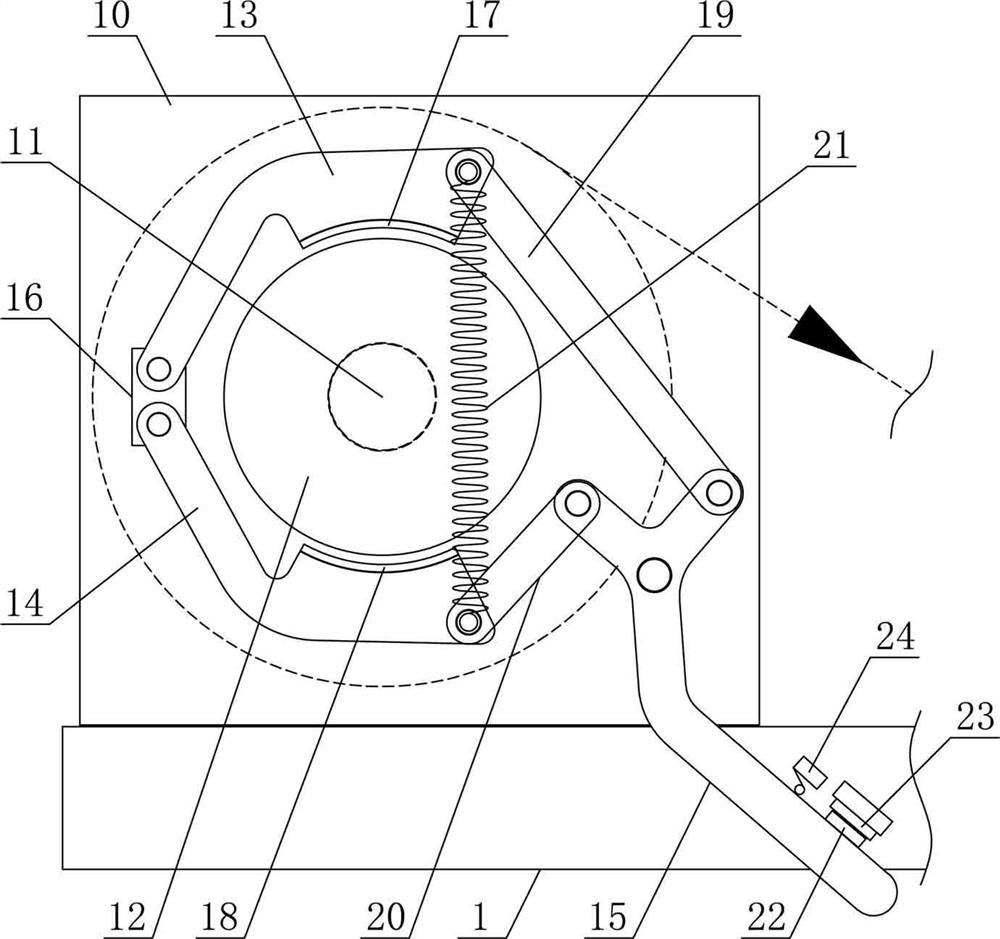

Metal bar feeding and cutting device

InactiveCN107876875AIncrease profitAvoid accumulationMetal sawing devicesMetal working apparatusEngineeringDisc cutter

The invention discloses a metal bar feeding and cutting device. The metal bar feeding and cutting device comprises a rack, wherein a fixed plate is arranged on the rack; a stock bin is arranged at theside part of the rack and sequentially connected with a feeding mechanism, a cutting mechanism and a discharging mechanism; the feeding mechanism comprises a feeding component; a feeding chuck seat and a fixing mechanism are arranged on the feeding component; a feeding chuck is arranged in the feeding chuck seat connected with a chuck seat cylinder; the cutting mechanism comprises a disc cutter arranged on the fixed plate; a rear chuck is arranged below the disc cutter and connected with a clamping cylinder; the discharging mechanism comprises a pushing cylinder arranged on the fixed plate and connected with a push plate; and an end product hopper fixed on the rack is arranged in the position opposite to the pushing plate, and connected with a cuttings removal chute. The metal bar feedingand cutting device not only can greatly improve the machining efficiency, but also is high in degree of automation, and therefore, the safety is improved.

Owner:INST OF LASER & OPTOELECTRONICS INTELLIGENT MFG WENZHOU UNIV

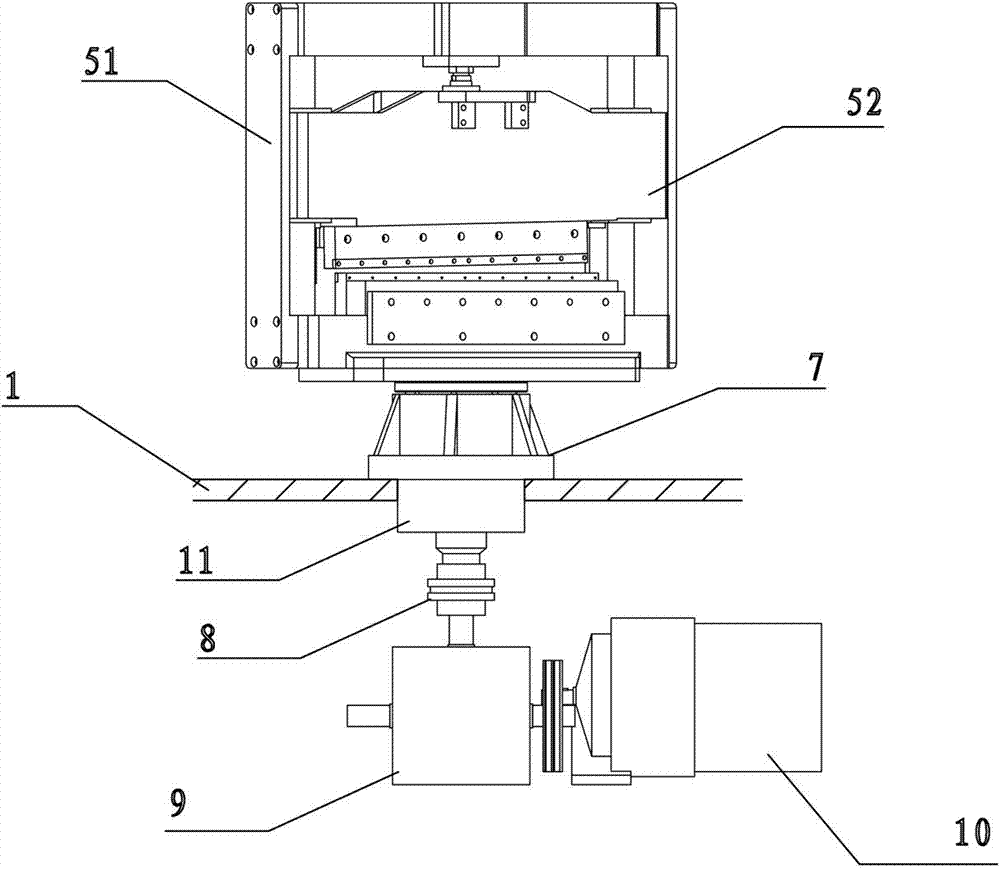

Numerically controlled shearing machine with adjustable shearing angle

ActiveCN102229005BMeet cutting needsEasy to operateShearing machinesShearing machine accessoriesCouplingDrive motor

Owner:CANWIN AUTOMATIC EQUIP CO LTD

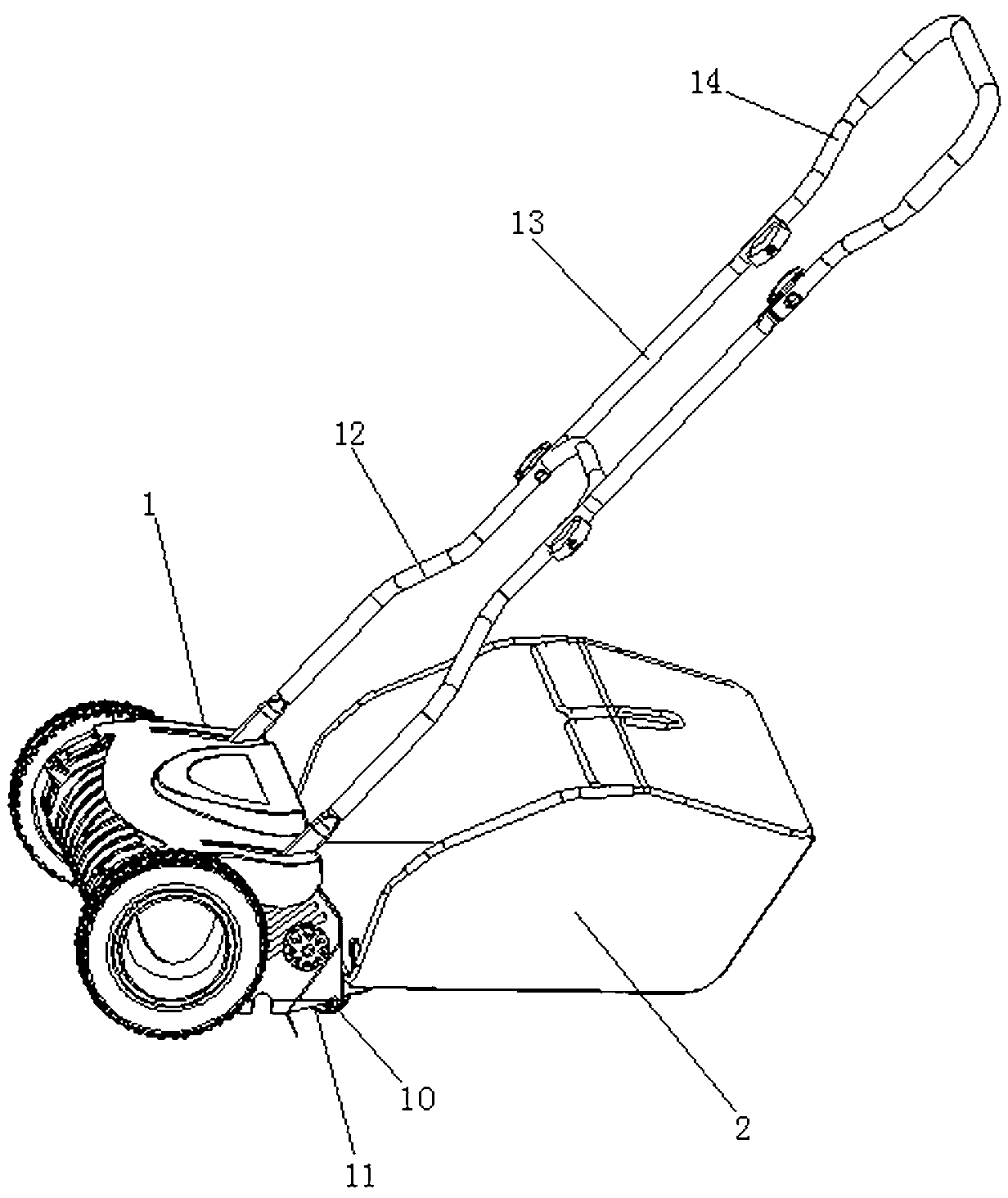

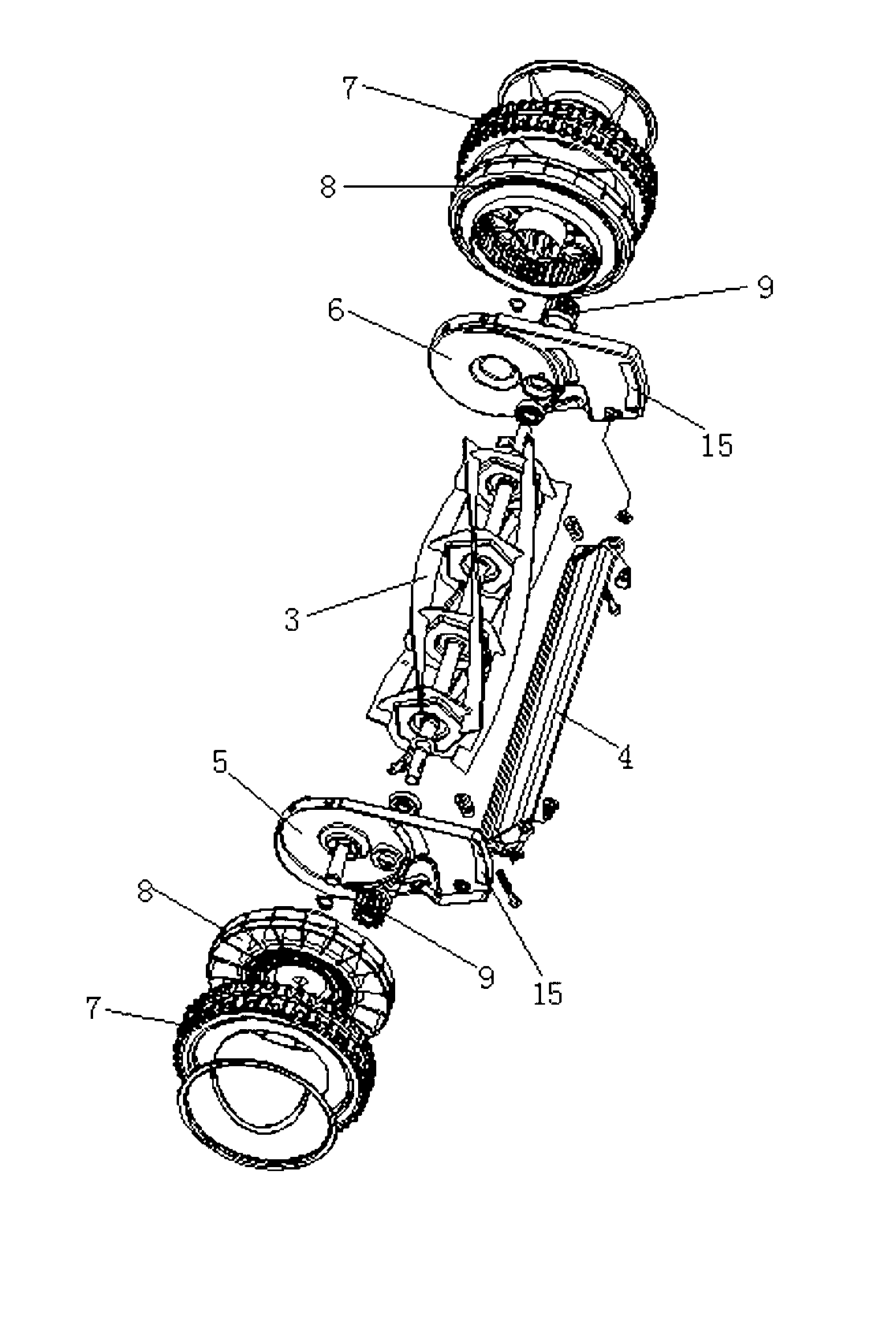

Rotary drum type mower

The invention relates to the technical field of mowers, in particular to a rotary drum type mower. The rotary drum type mower comprises a mower body and a grass collecting basket disposed at the rear of the mower body. The mower body comprises a cutting component, a drive component and a handle component. The cutting component comprises a rotary cutter assembly and a fixed cutter assembly disposed at the rear of the rotary cutter assembly. The rotary cutter assembly is fixedly connected with the fixed cutter assembly through a left support plate assembly and a right support plate assembly. Wheels of the drive component are driven to rotate by the handle component, the pinions are driven to rotate, and the rotary cutter assembly of the cutting component is driven to rotate by the pinions, and cutting is performed by the rotary cutting assembly and the fixed cutter assembly jointly. The rotary drum type mower has the advantages that the rotary drum type mower is free of motor drive, energy-saving, environment-friendly, simple in cutting, flexible to operate and convenient to control, cutting height can be adjusted to satisfy cutting requirements.

Owner:JIANGSU ALLUCK TOOLS

Fixed-width cutting device for PVC plastic floor

PendingCN108177168AMeet cutting needsImprove stabilityMetal working apparatusEngineeringMachining process

The invention discloses a fixed-width cutting device for a PVC plastic floor. The fixed-width cutting device comprises a machine frame, a conveying mechanism, fixing mechanisms, a cutting mechanism and a plate material, wherein the machine frame is provided with a guide linkage rod and a guide sliding chute, an included angle of a cutting knives can be adjusted according to requirements, so thatthe cutting precision is higher; the fixing mechanisms are arranged in the device, the plate material can be pressed and fixed through a pressing motor and a pressing roller in the fixing mechanisms;cuts of the PVC plastic floor processed is not tidy and the gap is large are pretended when the PVC plastic floor is used, due to the conveying mechanism moves on the conveying mechanism in the process of processing the plate material a double-piston-rod air cylinder is arranged in the cutting mechanism of the device, the distance between the two cutting knives can be adjusted according to different widths of the PVC plastic floors, the cutting requirements of various types of PVC plastic floors can be met, a knife rest and the pressing roller frame are connected through a connecting rod, so that the stability of the pressing roller under the pressing process is improved, and the pressing roller can better fix the plate material.

Owner:江苏正军装饰材料有限公司

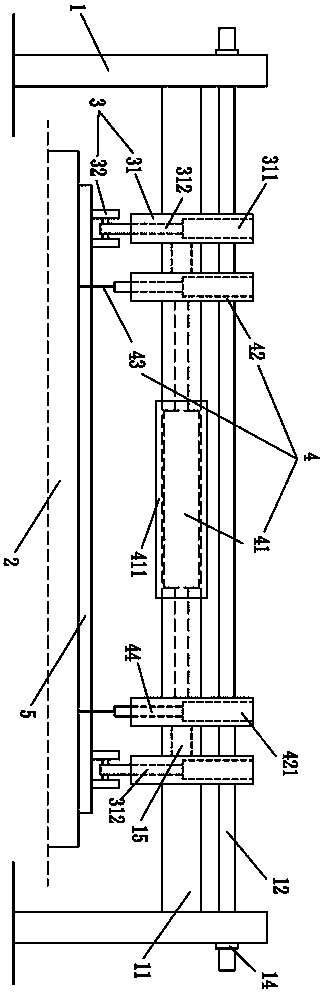

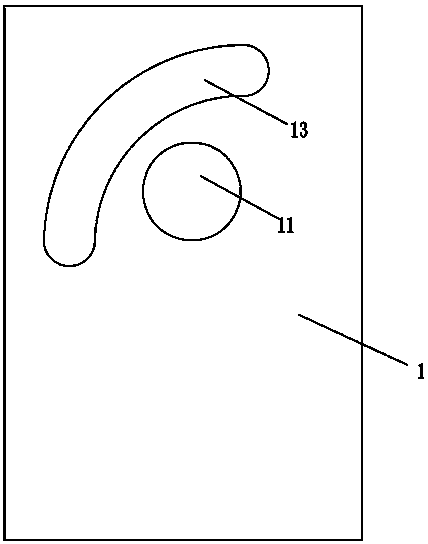

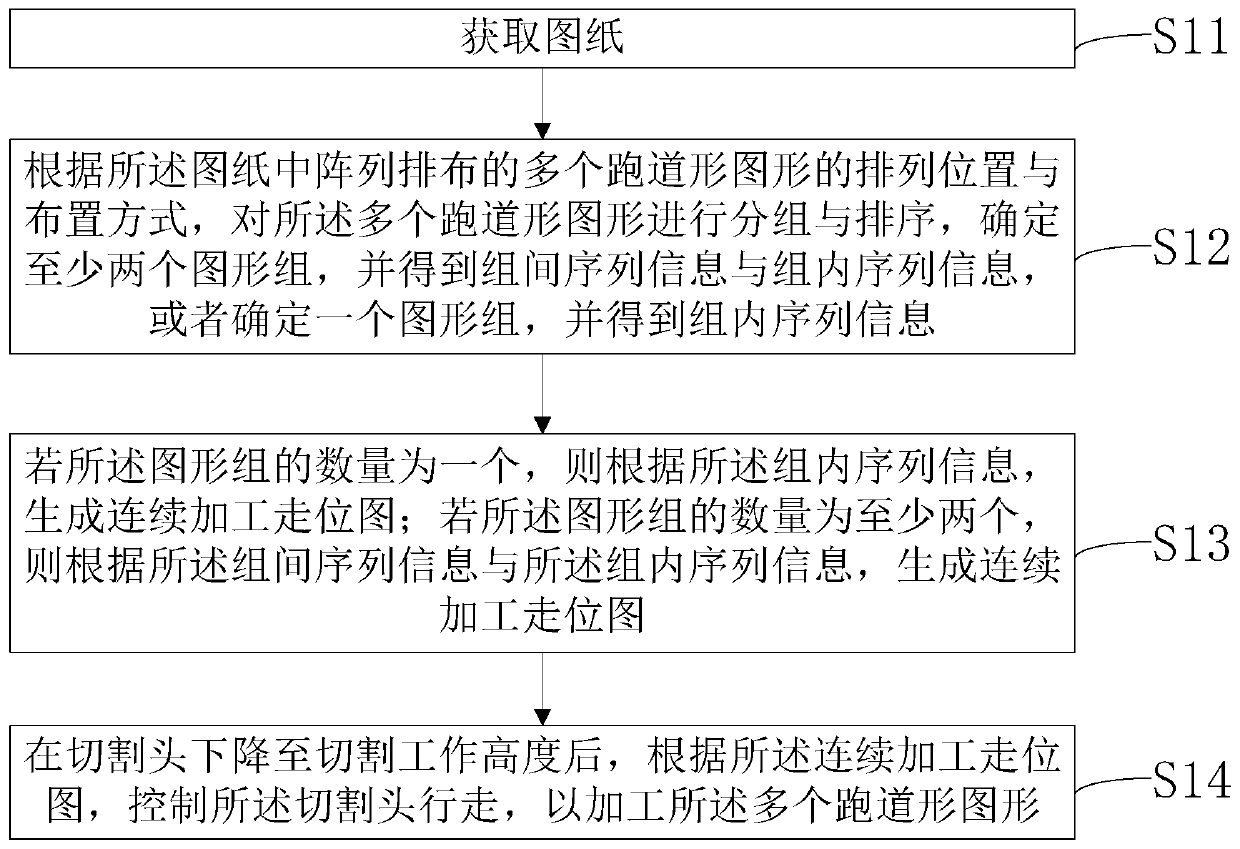

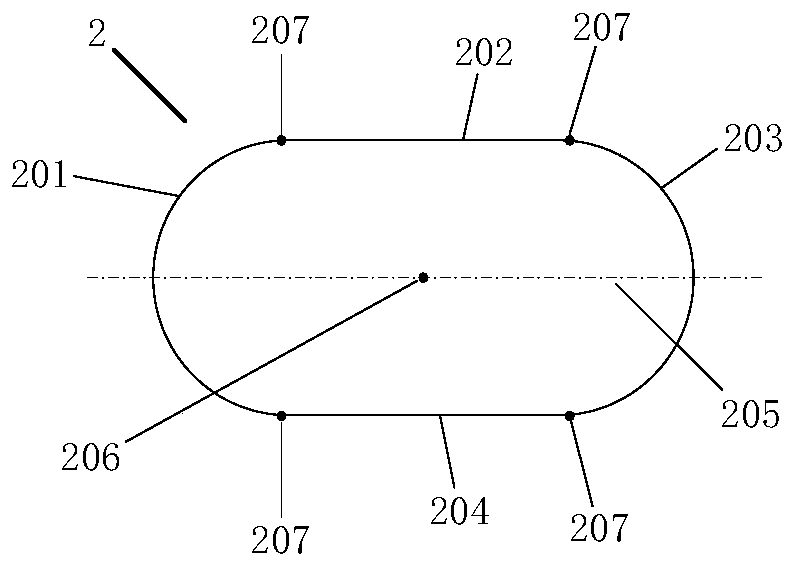

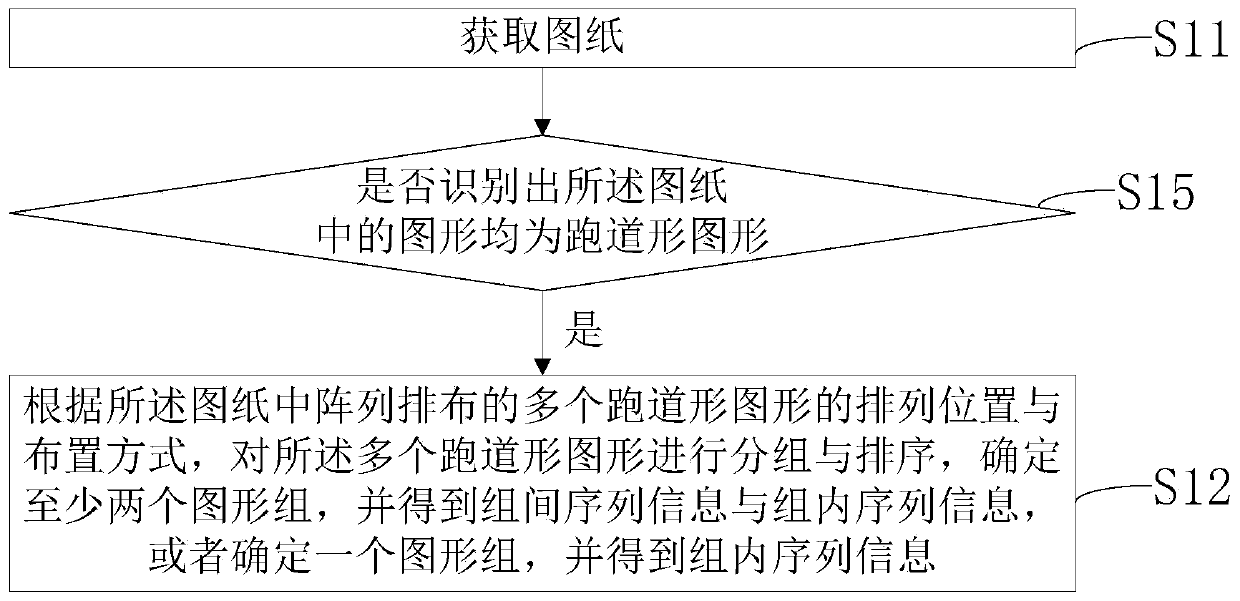

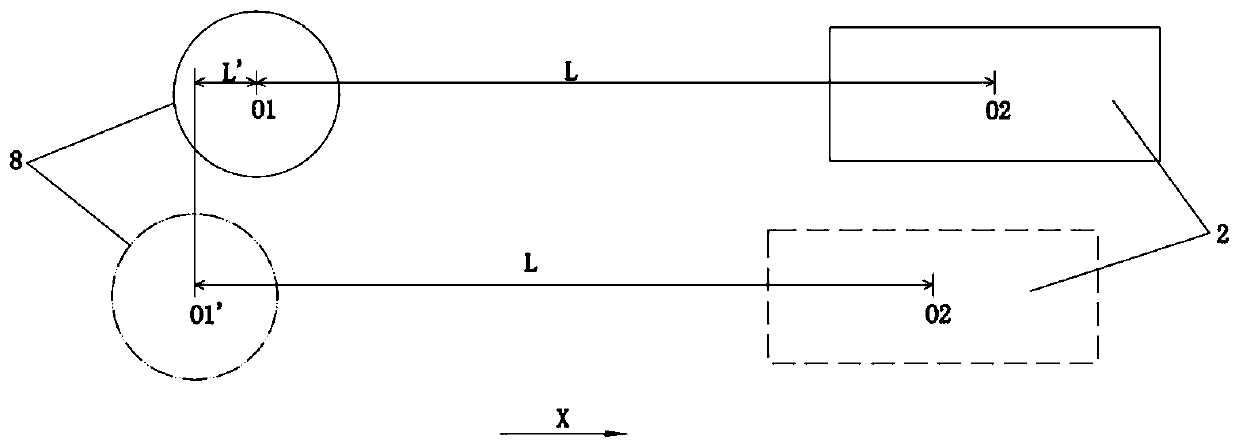

Continuous cutting control method and system for racetrack-shaped graphs, equipment and medium

The invention provides a continuous cutting control method and system for a plurality of racetrack-shaped graphs, equipment and medium. The continuous cutting control method comprises the steps that adrawing is obtained; according to the arrangement position and arrangement mode of the racetrack-shaped graphs arranged in an array mode in the drawing, the racetrack-shaped graphs are grouped and sorted, at least one graph group is determined, and sequence information in the groups is obtained; if the number of the graph groups is at least two, a continuous processing blocking diagram is generated according to the sequence information between the groups and sequence information in the groups, the continuous processing blocking diagram is used for characterizing a walking path of a cutting head when the racetrack-shaped graphs are processed; and after the cutting head descends to the cutting working height, the cutting head is controlled to walk according to the continuous processing blocking diagram to process the racetrack-shaped graphs.

Owner:上海柏楚电子科技股份有限公司

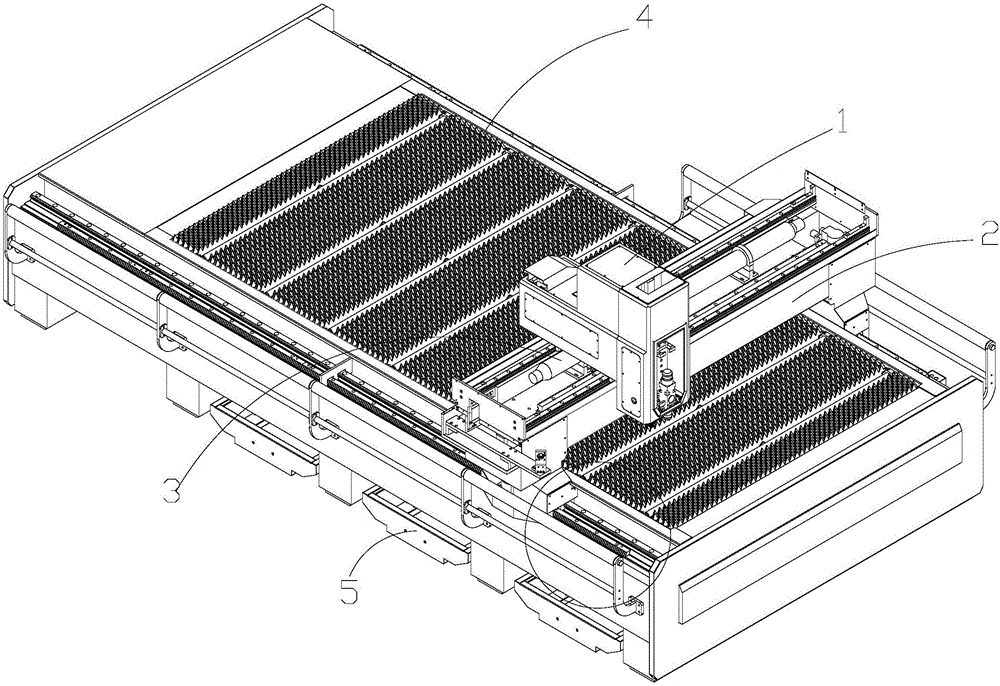

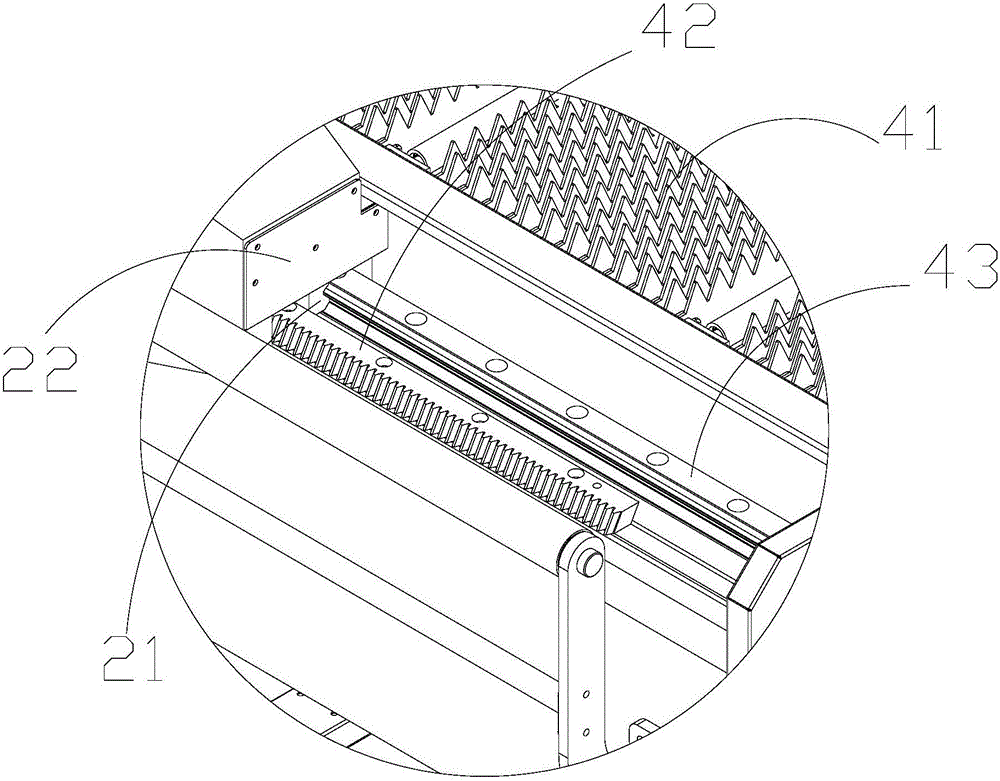

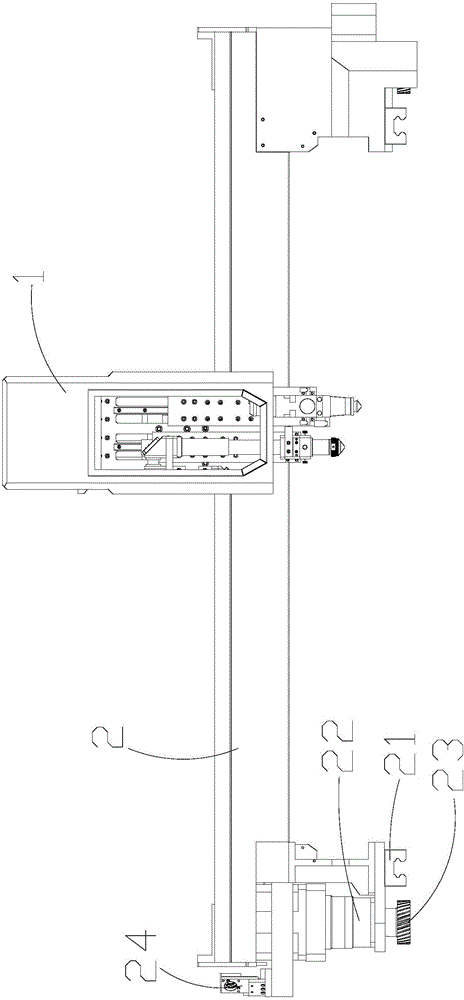

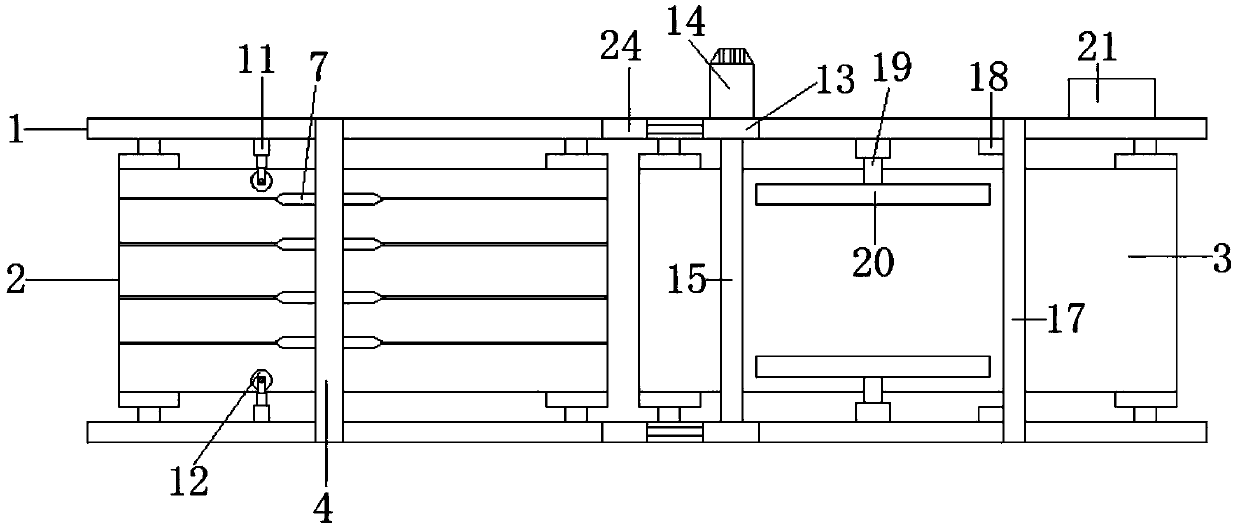

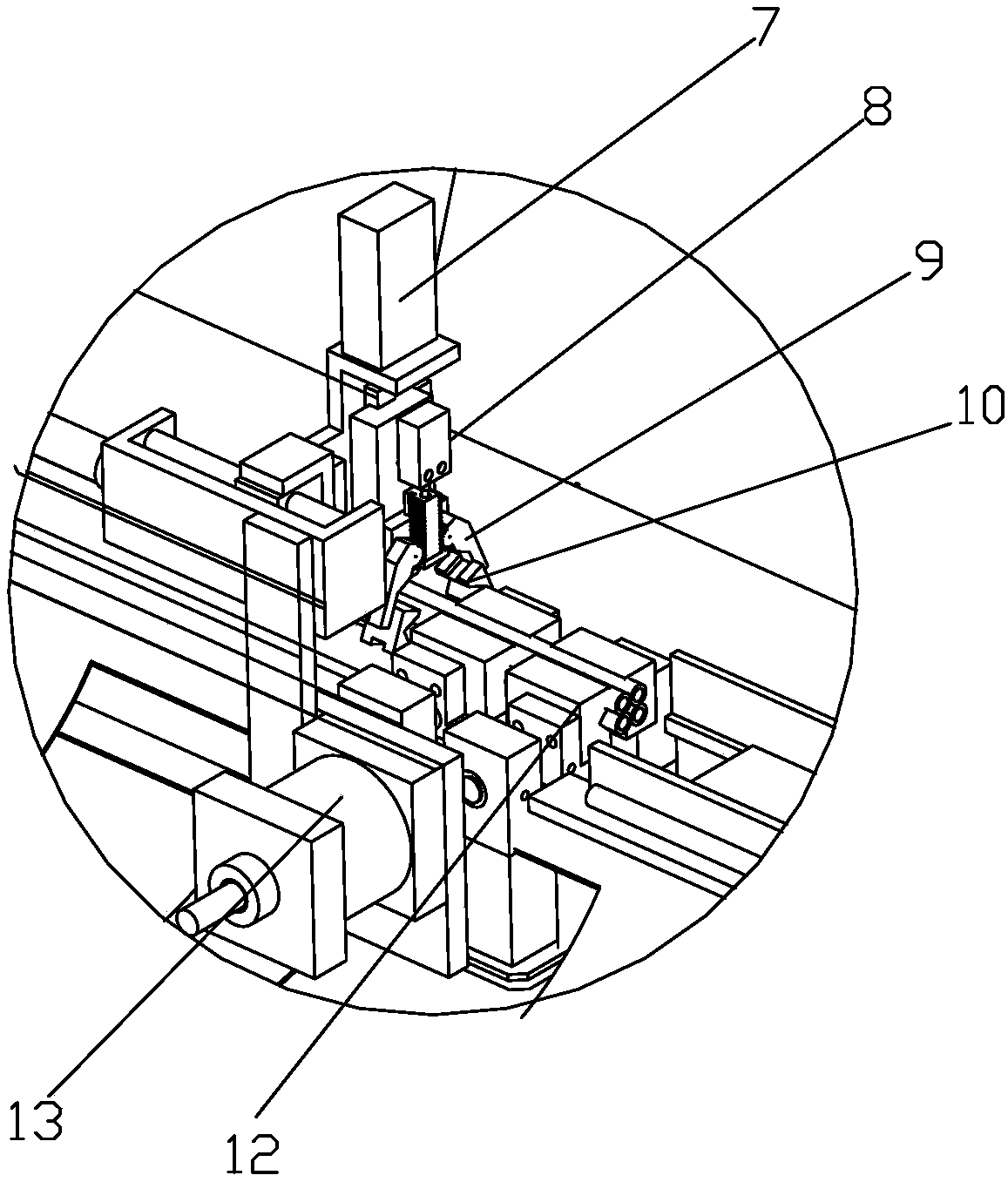

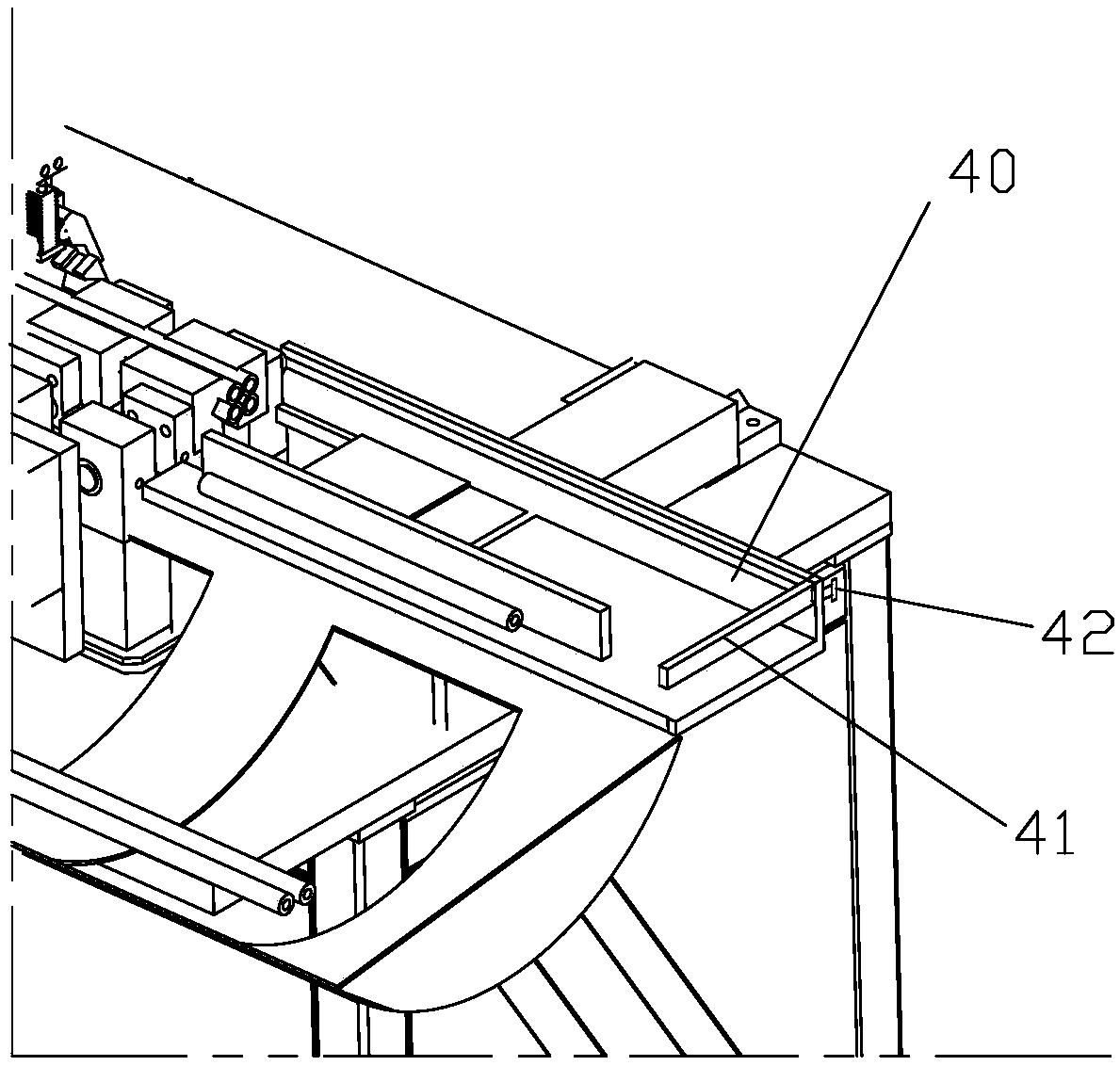

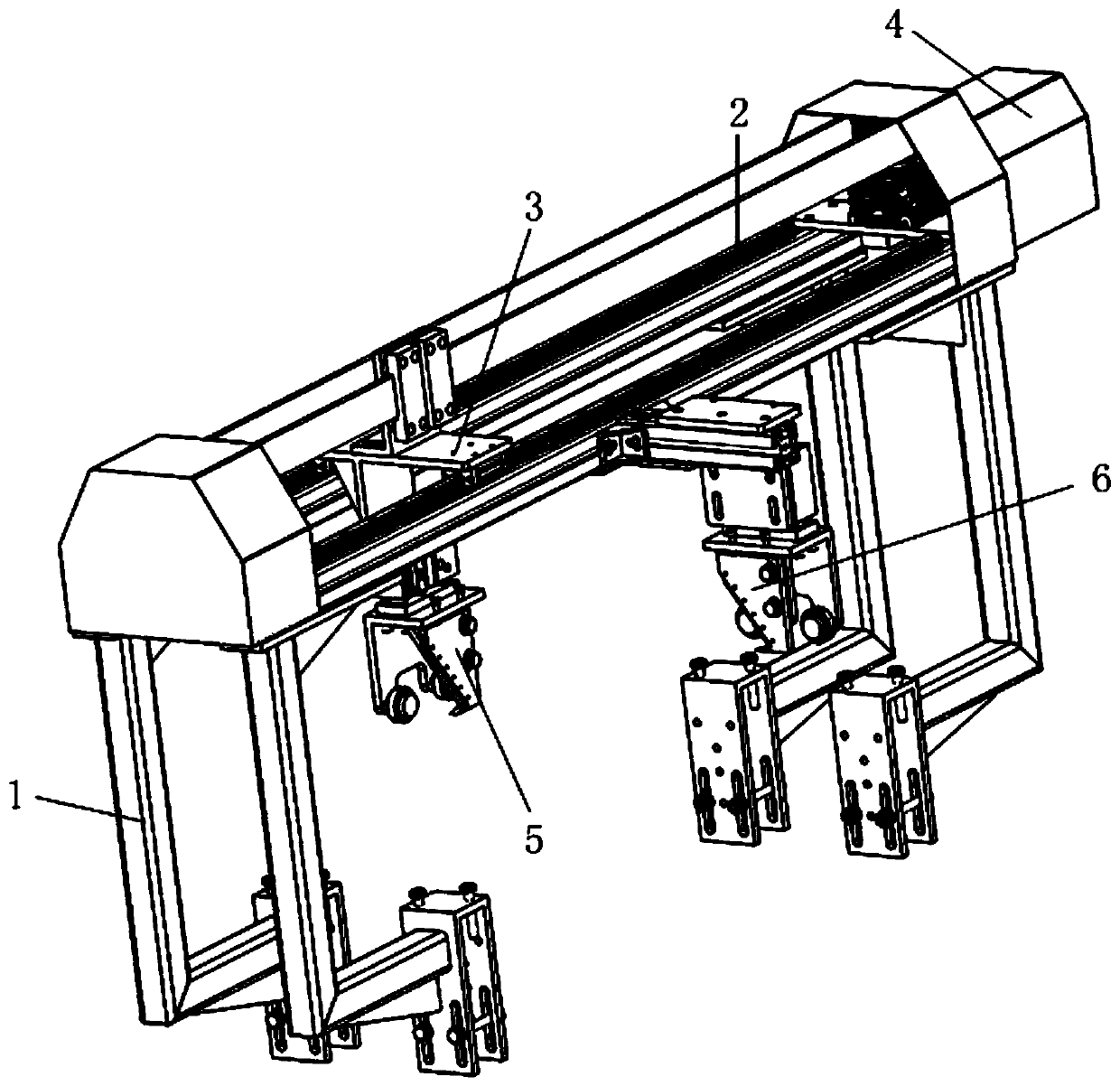

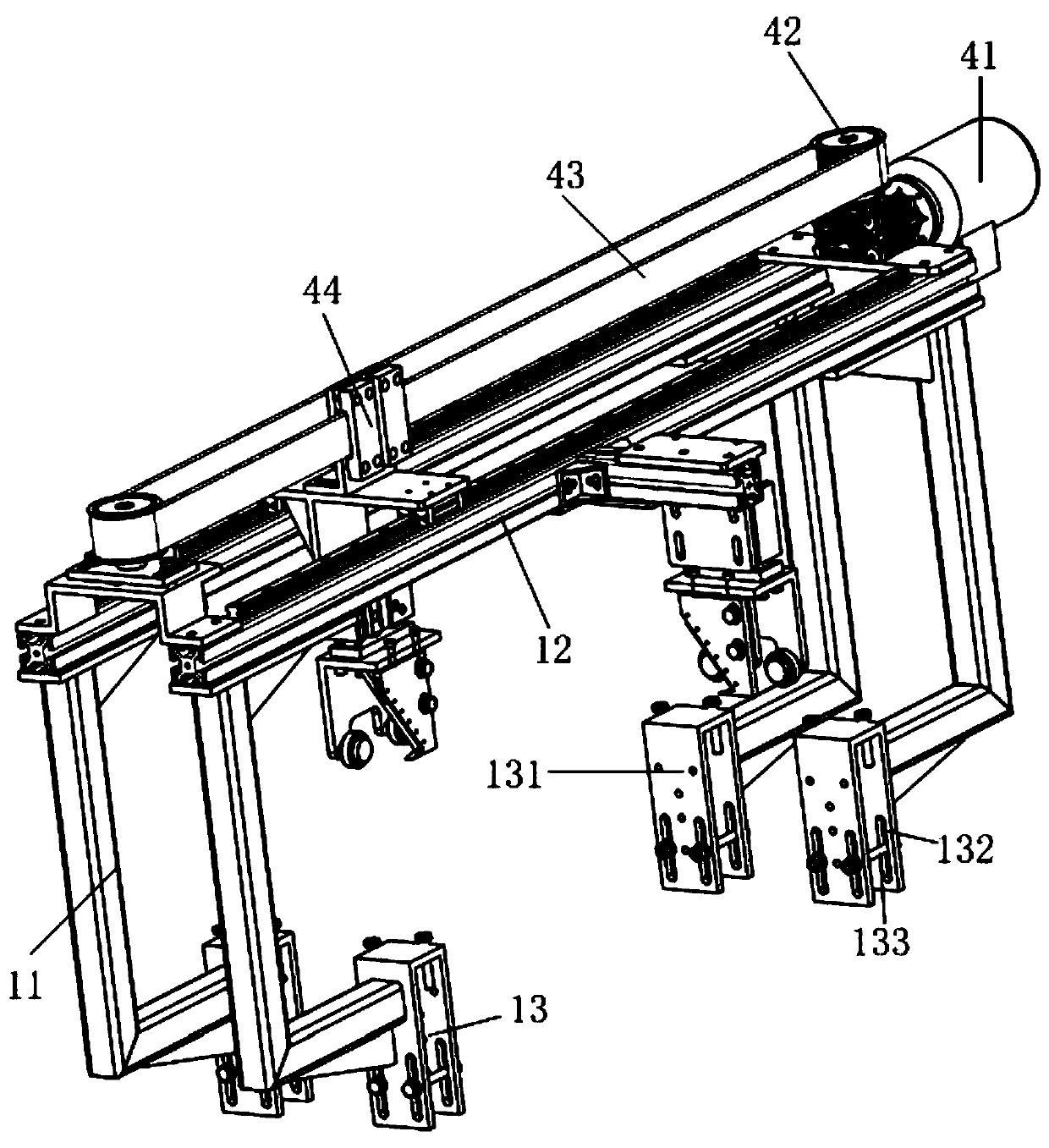

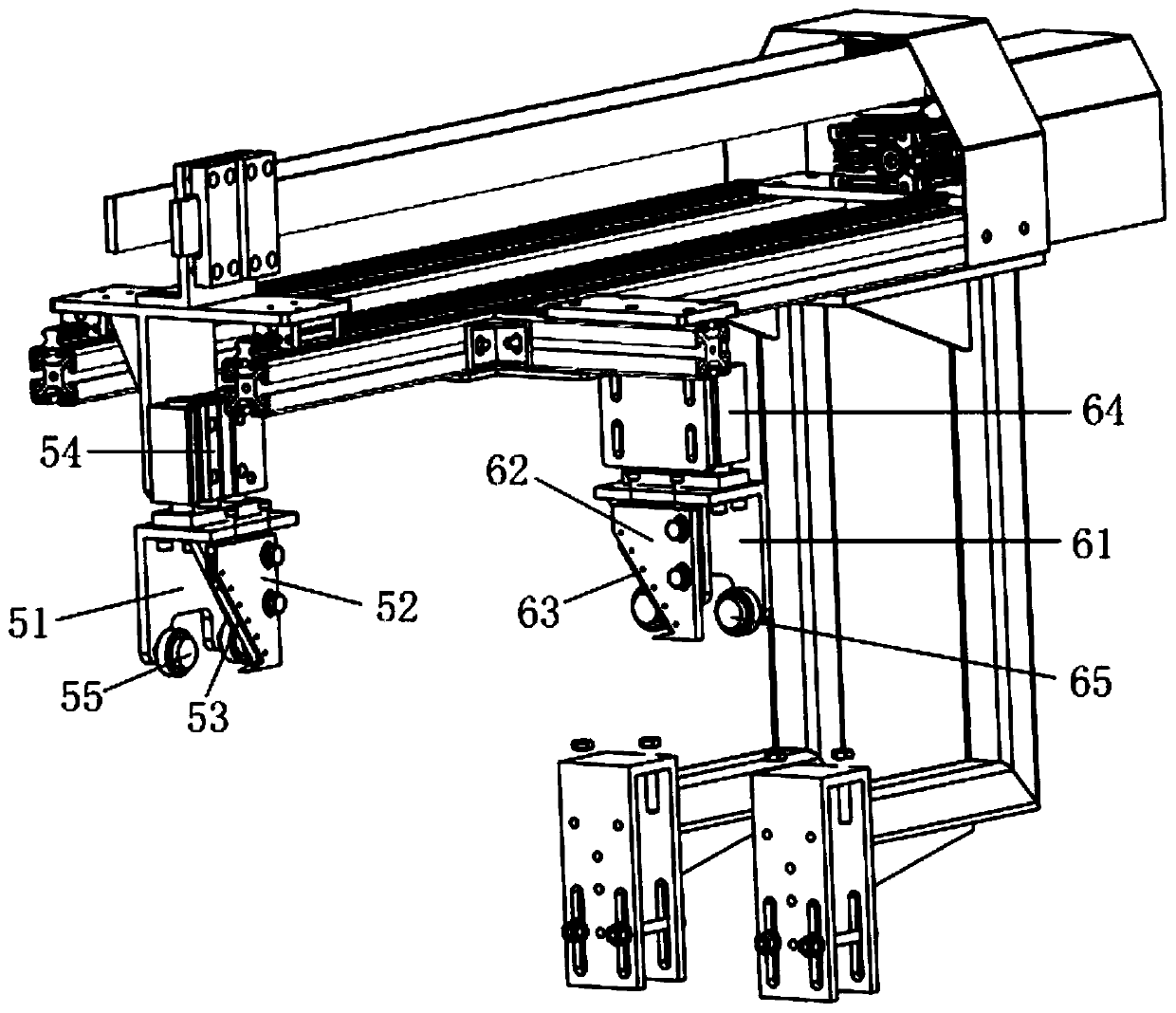

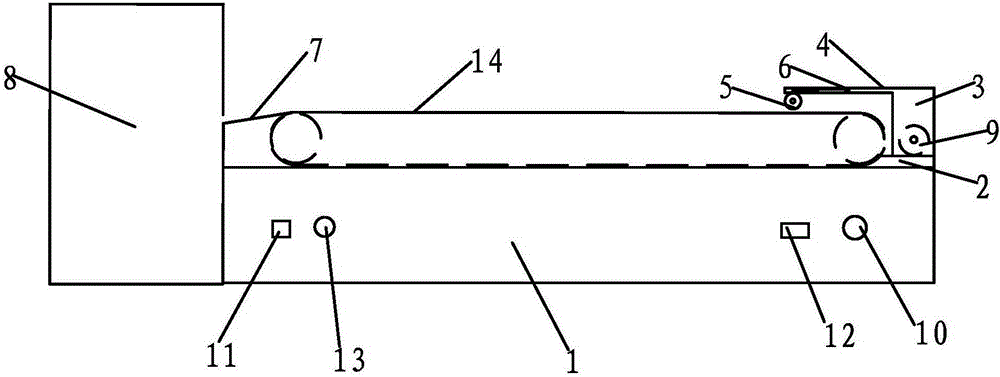

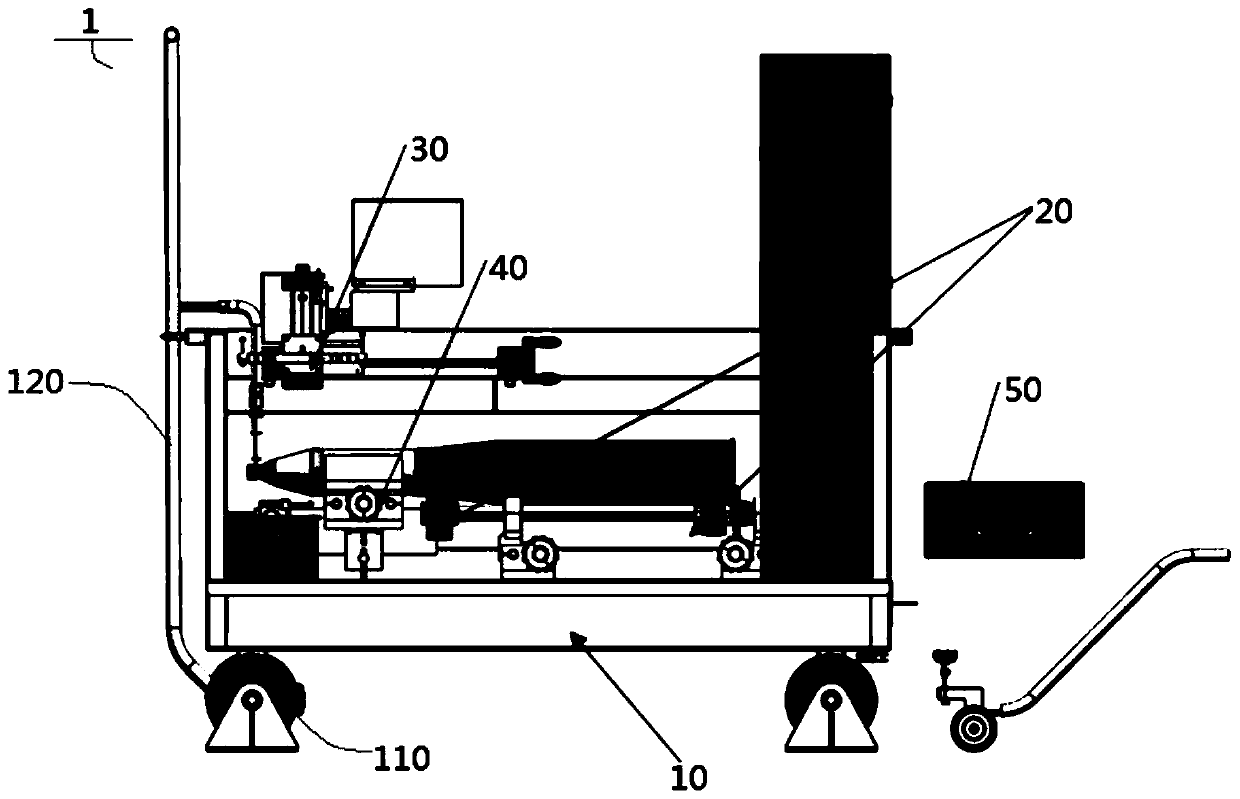

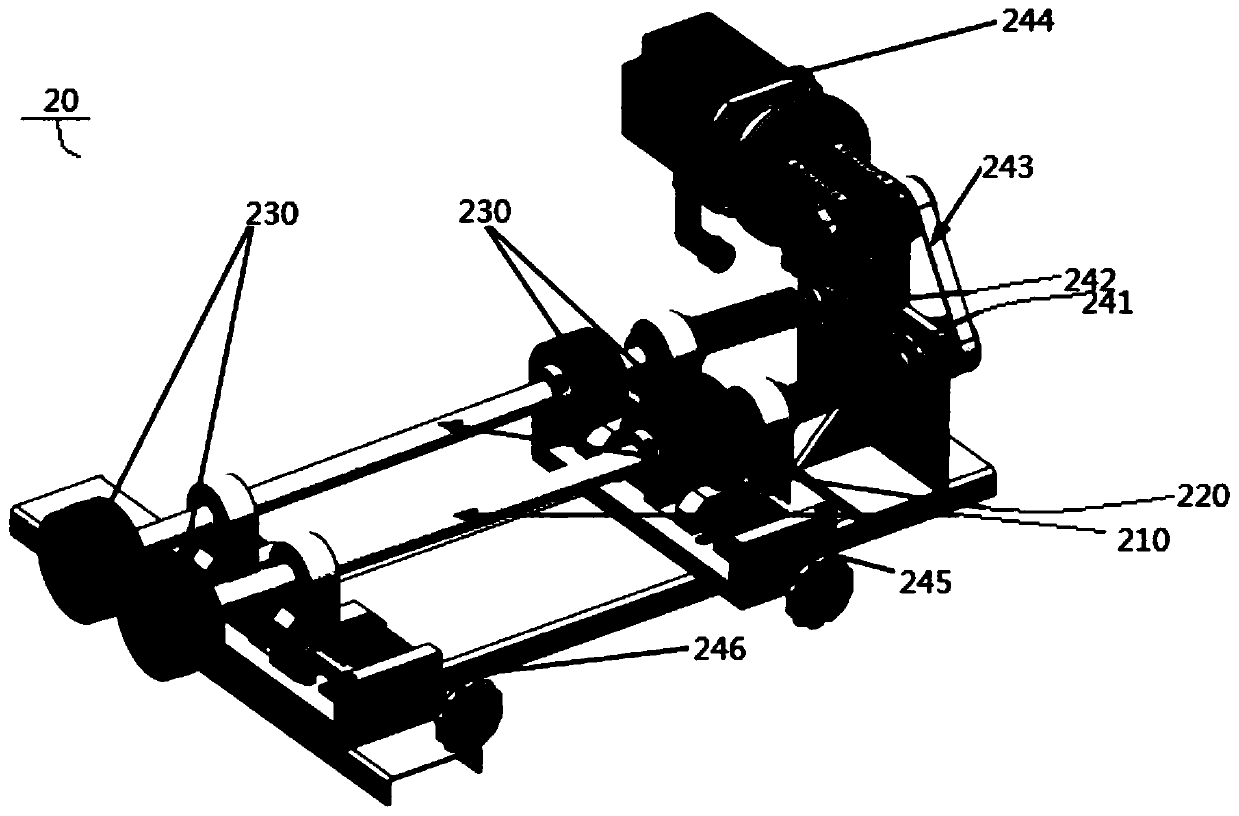

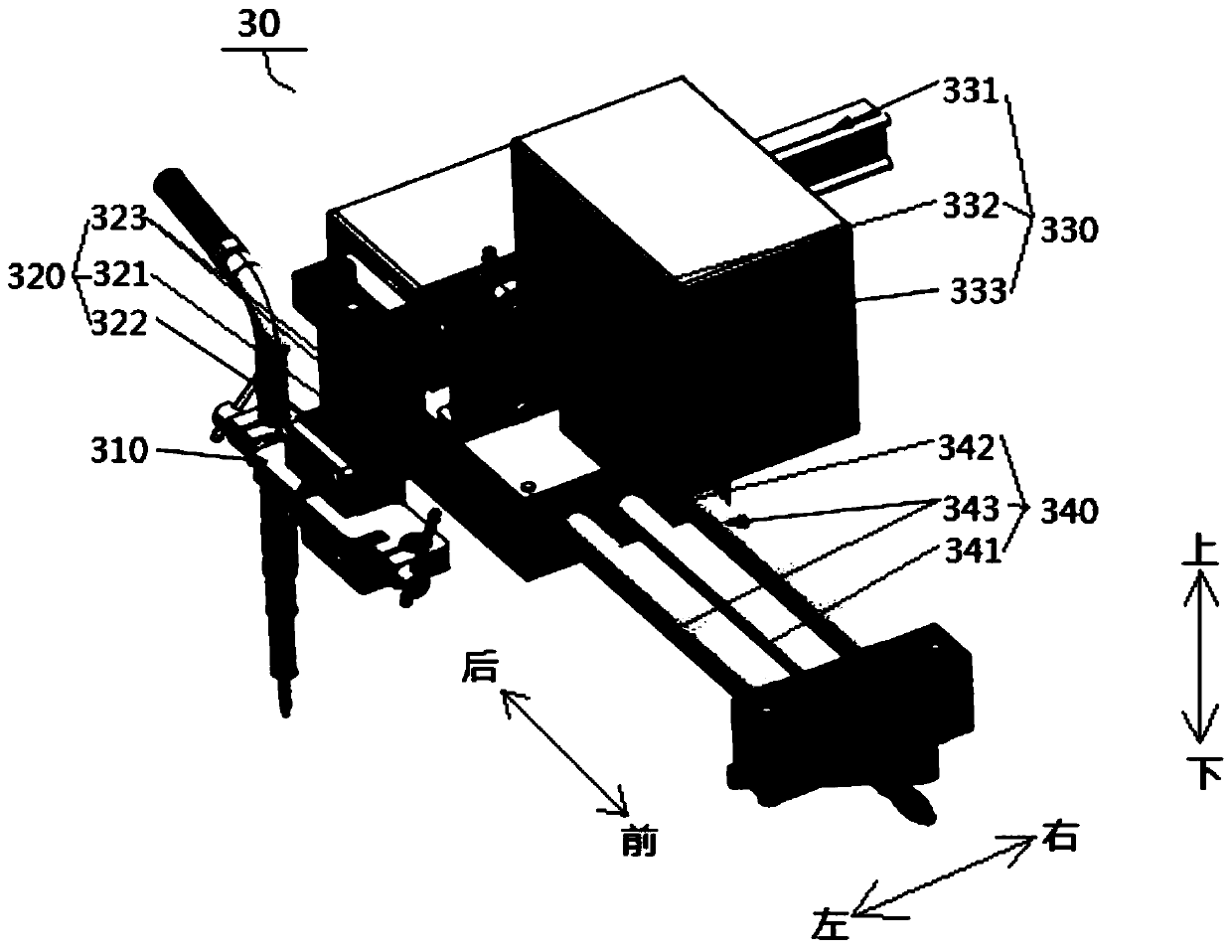

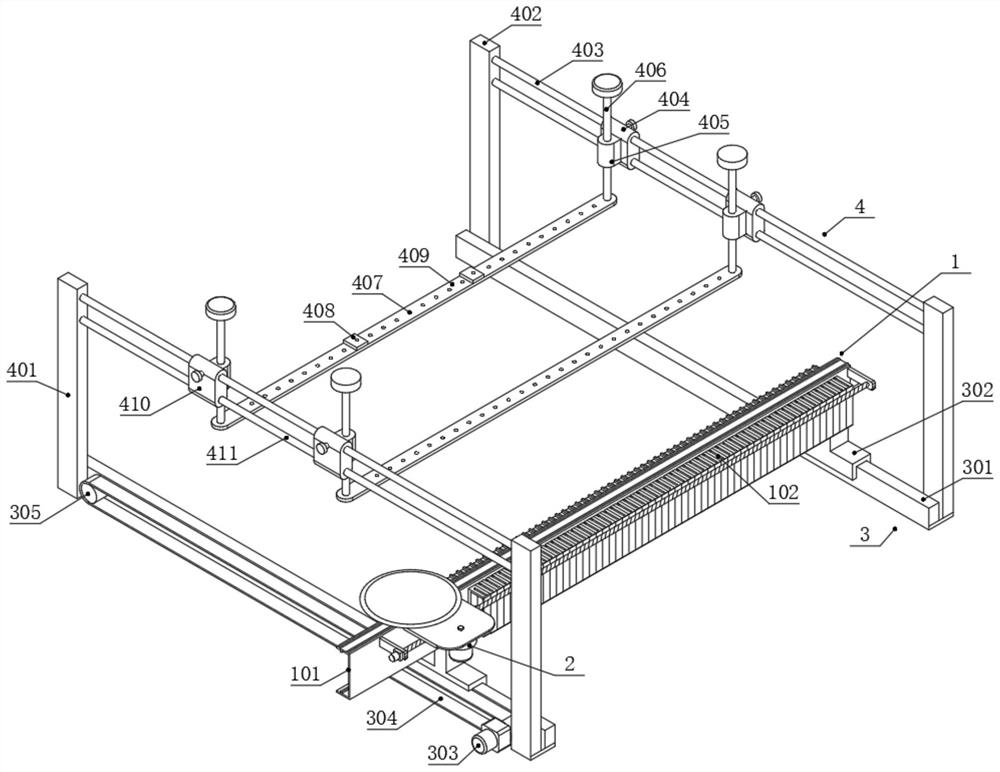

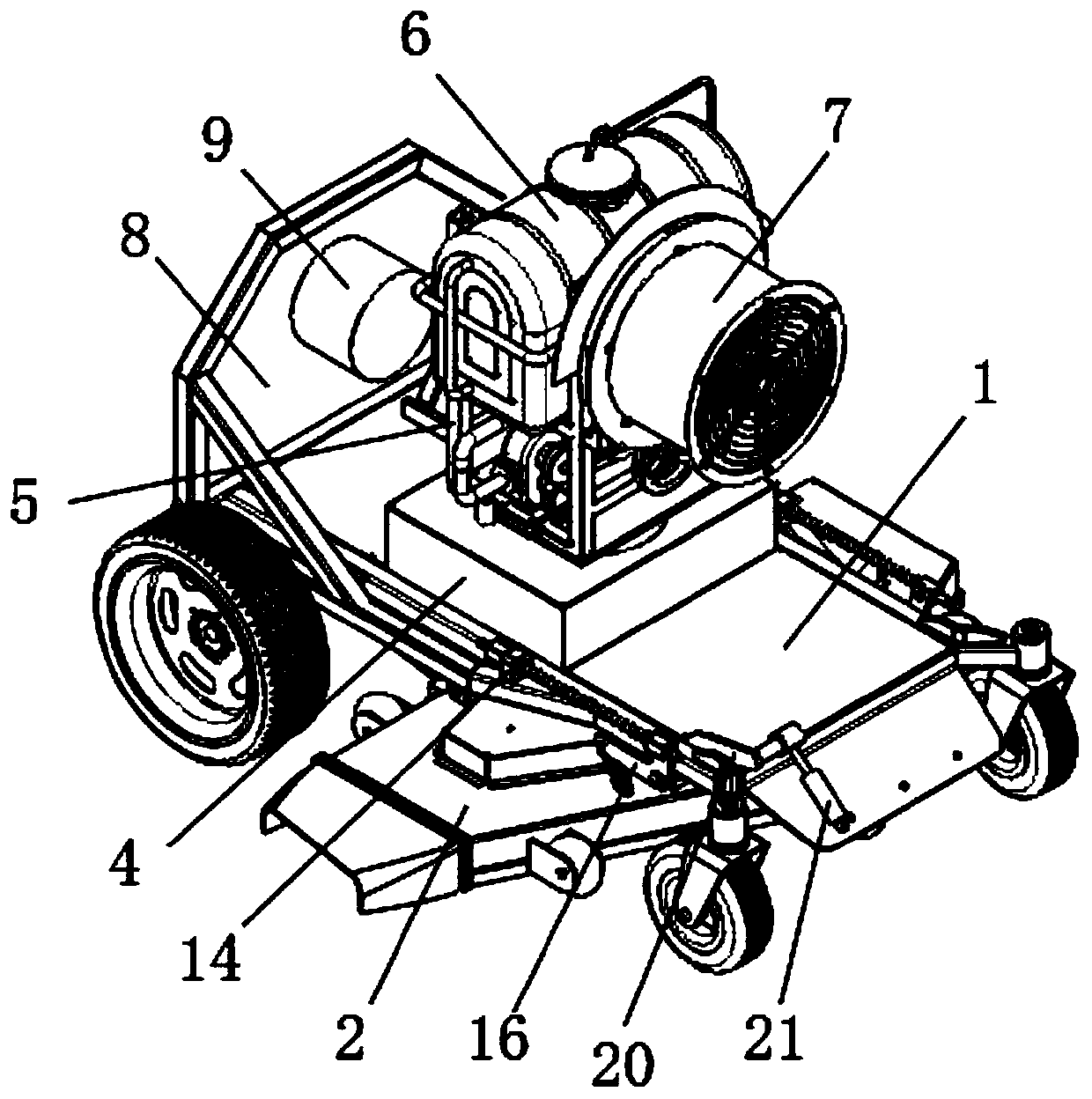

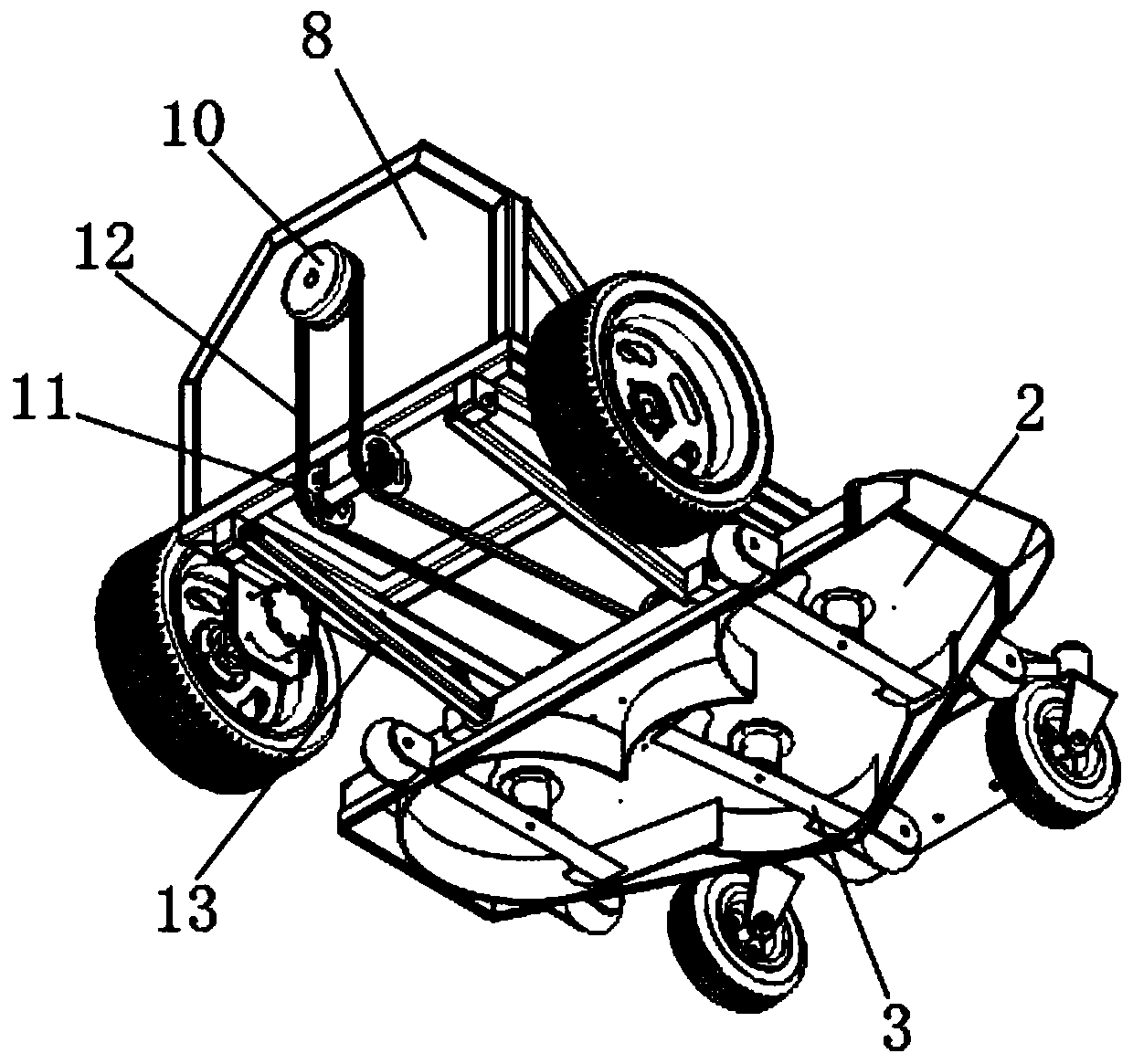

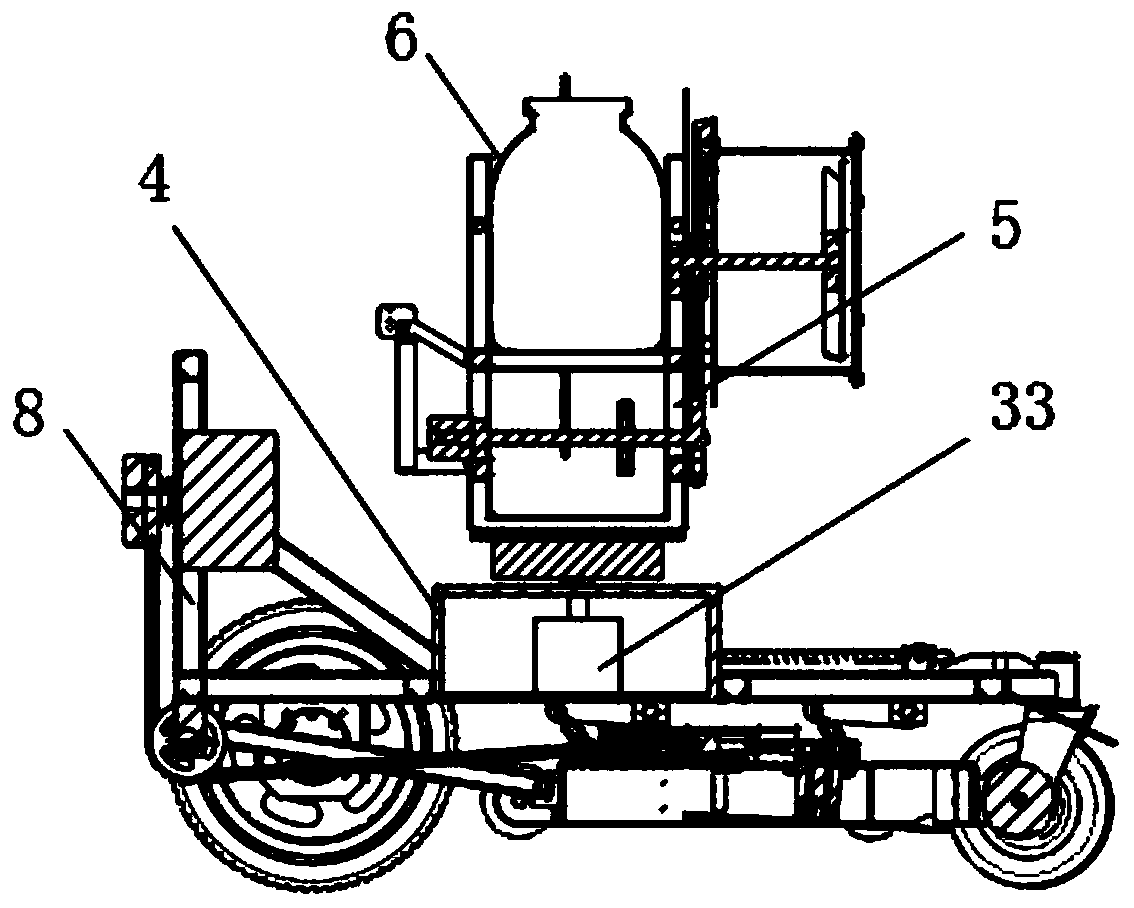

Multi-ammunition-type water cutting carrying platform

PendingCN111360940AMeet cutting needsImprove the efficiency of cutting disposal and destructionMetal working apparatusStructural engineeringIndustrial engineering

The invention discloses a multi-ammunition-type water cutting carrying platform. The multi-ammunition-type water cutting carrying platform comprises a rack, a clamping rotating driving mechanism and acutting gun clamping travelling mechanism, wherein the clamping rotating driving mechanism is arranged on the rack and comprises four supporting parts which cooperate with one another to support an ammunition in a first caliber range, each supporting part can rotate to drive the ammunition in the first caliber range to rotate, any two supporting parts can move relatively to adapt to the ammunition in the first caliber range in different shapes, and the cutting gun clamping travelling mechanism is arranged on the rack and used for clamping a cutting gun and driving the cutting gun to move. Bythe adopting the platform, the cutting requirements of the vast majority of ammunitions especially including to-be-cut ammunitions in the different shapes can be met, and the ammunition cutting, disposing and destroying efficiency is remarkably improved.

Owner:BEIJING SHENGFEIFAN ELECTRONIC SYST TECH DEV CO LTD

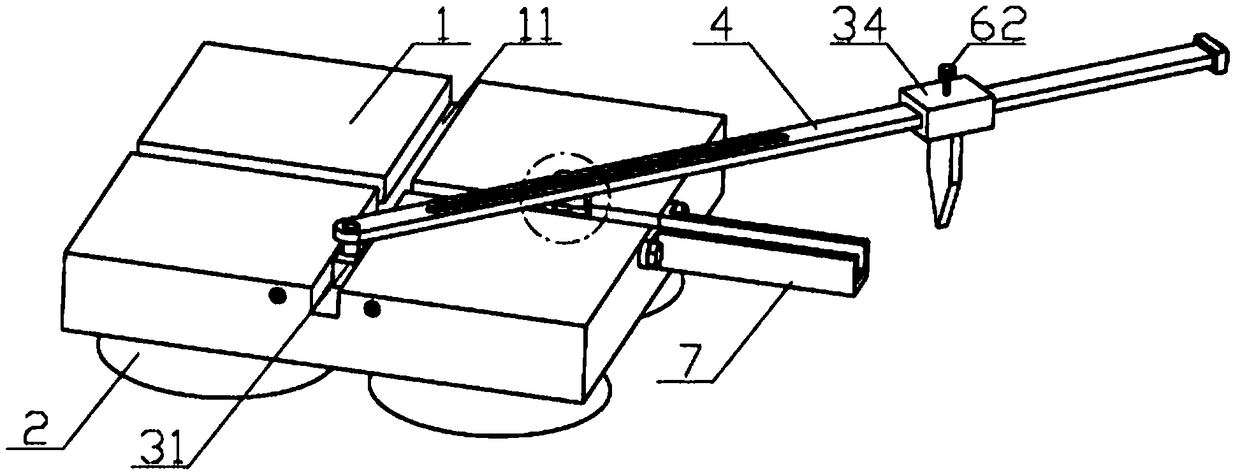

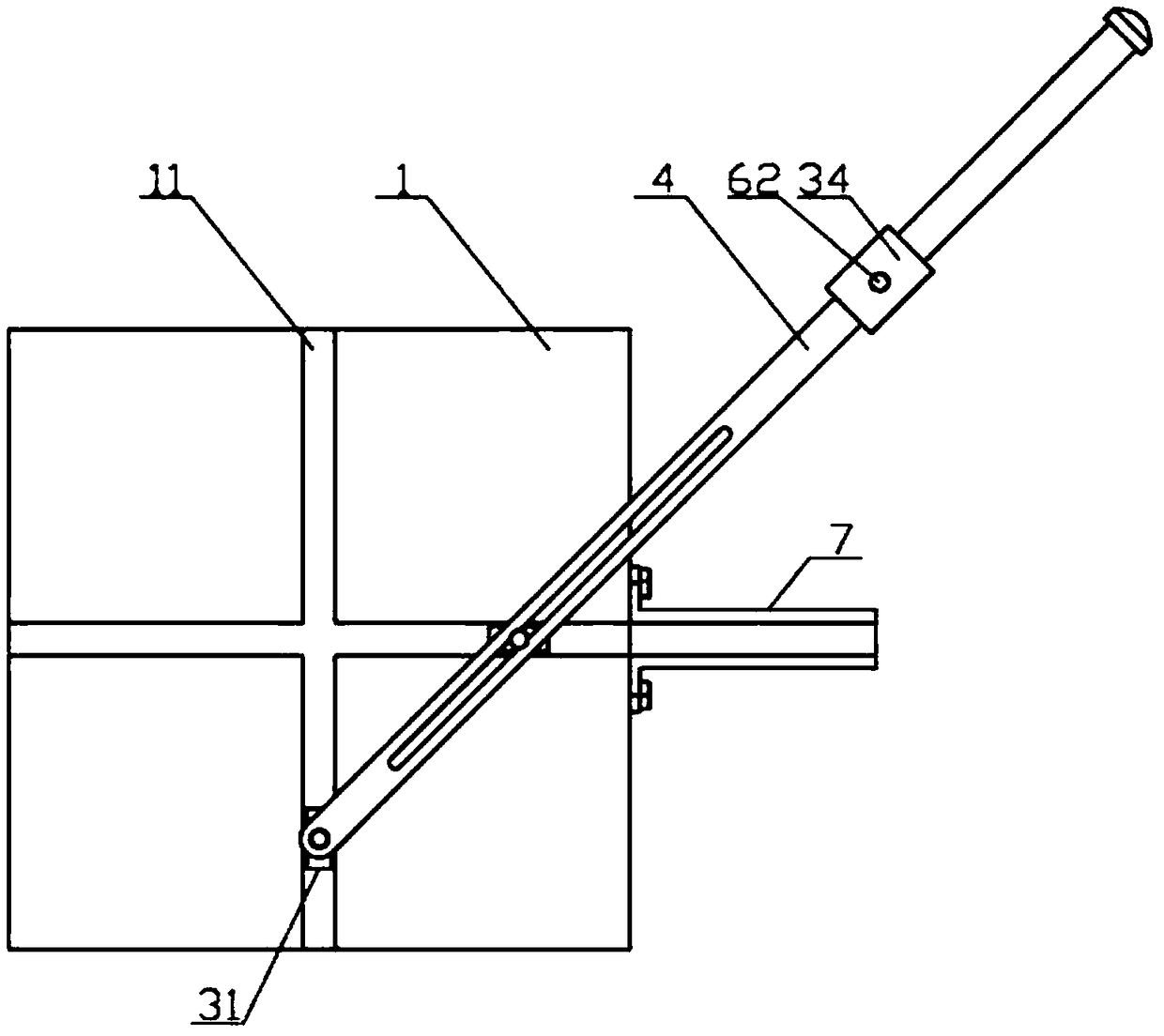

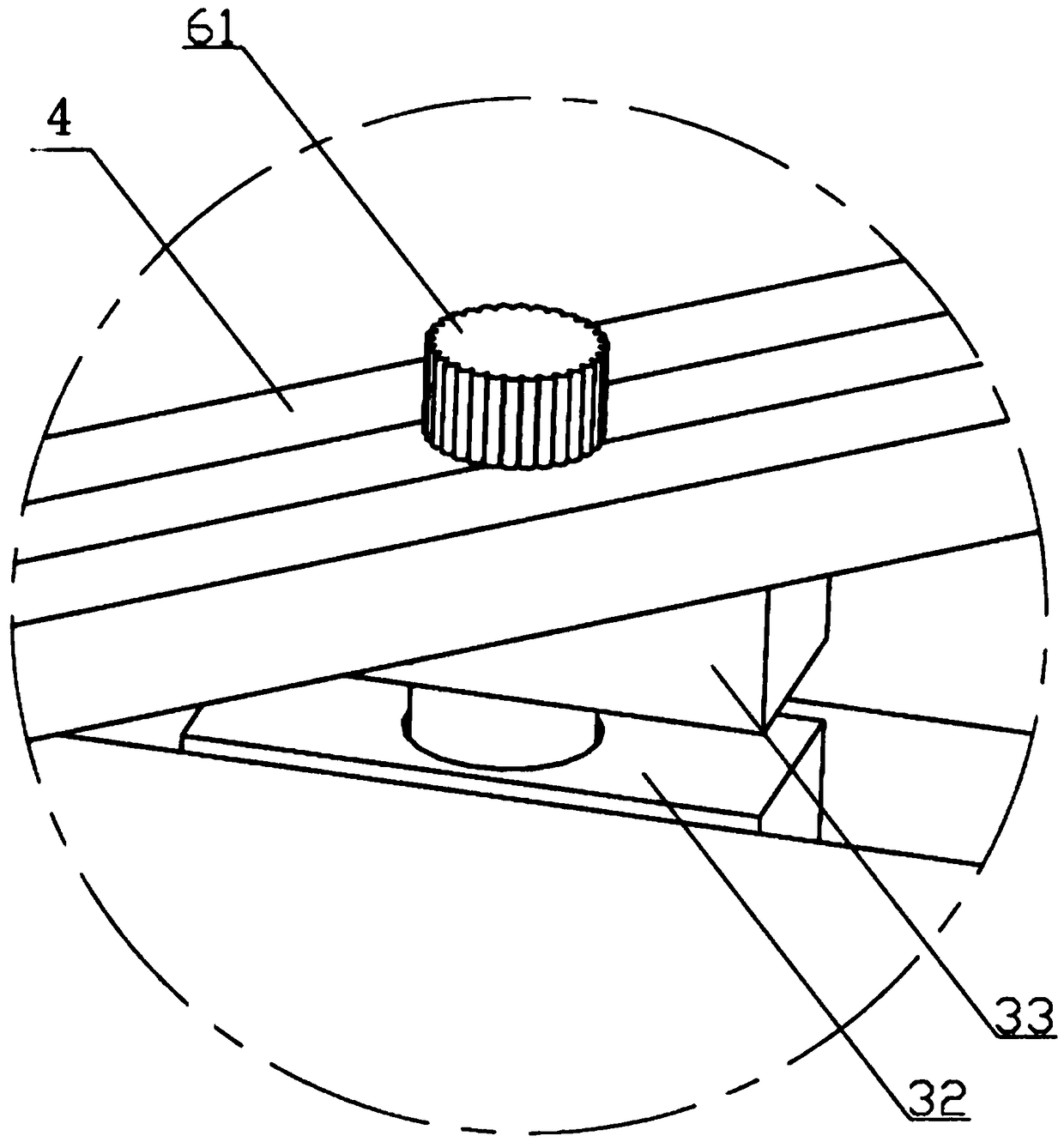

Cutting device used for cutting oval glass

InactiveCN109176915AAdjustable distanceMeet cutting needsWorking accessoriesStone-like material working toolsStub axleMechanical engineering

The invention discloses a cutting device used for cutting oval glass. A suction cup is fixed to an absorbing plate, a cross sliding groove is formed in the side, away from the suction cup, of the absorbing plate, a first sliding part and a second sliding part are arranged in the cross sliding groove in a sliding manner, the sliding directions of the first sliding part and the second sliding part are vertically arranged, one end of a rotation rod is arranged on the first sliding part, the middle of the rotation rod is rotatably arranged on the second rotation part, and a tool assembly is arranged on the rotation rod. According to the cutting device used for cutting oval glass, the rotation rod rotates by a circle, the movement locus of the tool assembly forms the oval shape, and therefore the tool assembly can cut the oval glass; the distance between the first sliding part and the second sliding part is adjustable, the distance between the first sliding part and the tool assembly is adjustable, the length of a short shaft and a long shaft of the oval movement locus can be changed, the length of the short shaft and the long shaft of the oval glass obtained through cutting can be changed, and cutting needs of the oval glass of different sizes can be met.

Owner:晋吉

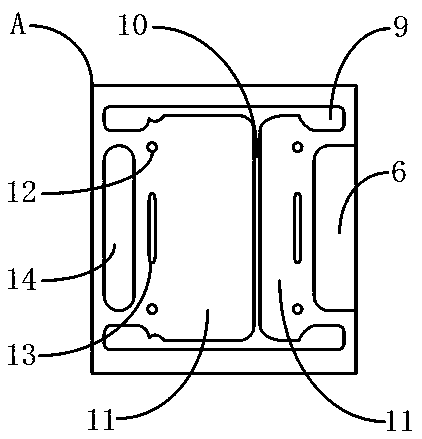

Integrated circuit board welding foot cutting device

ActiveCN113523482AAvoid bendingQuality improvementWelding/soldering/cutting articlesMetal working apparatusEngineeringMechanical engineering

The invention discloses an integrated circuit board welding foot cutting device. The integrated circuit board welding foot cutting device comprises a welding foot clamping mechanism, a movable cutting mechanism, a supporting mechanism and a fixing mechanism, wherein the welding foot clamping mechanism is connected to the top of the supporting mechanism in a sliding mode, the movable cutting mechanism is arranged at the top of the welding foot clamping mechanism in the length direction of the welding foot clamping mechanism, and the fixing mechanism is arranged above the supporting mechanism. According to the integrated circuit board welding foot cutting device, the welding foot clamping mechanism is arranged so that welding feet located in the same row can be clamped and fixed one by one, then the welding feet can be prevented from being bent during cutting, and the cutting quality and effect are improved; a clamping assembly can synchronously clamp the plurality of welding feet at different positions in the same row or an approximate row, and the cutting of circuit boards at different welding foot positions is met; and the two sides of the end part of a telescopic plate are inclined surfaces, so that the telescopic plate can be better attached to the side walls of the welding feet, and a good supporting effect is achieved.

Owner:TIANJIN UNIV

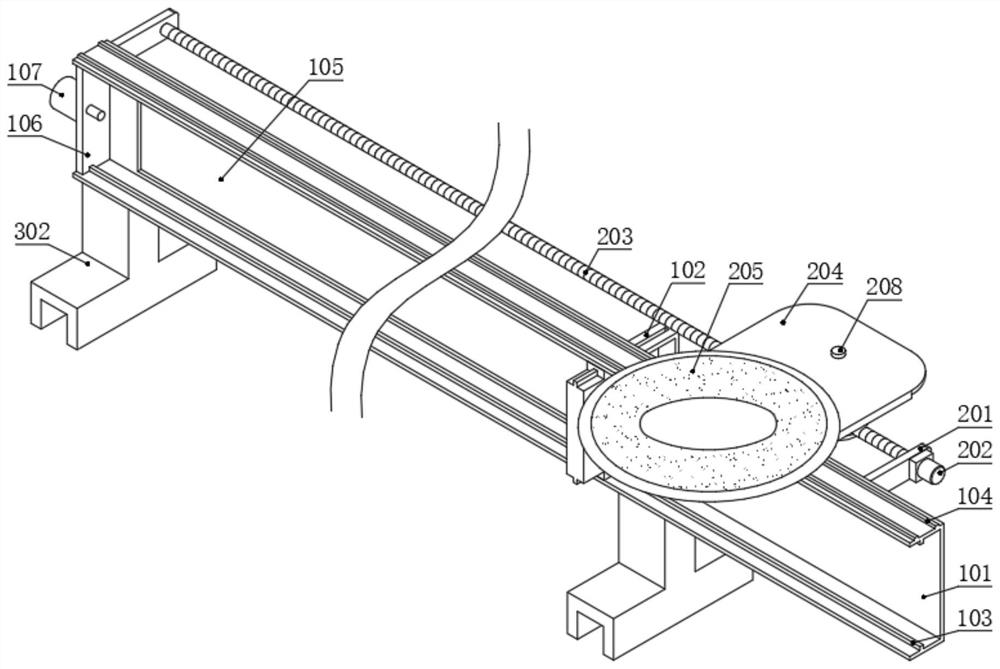

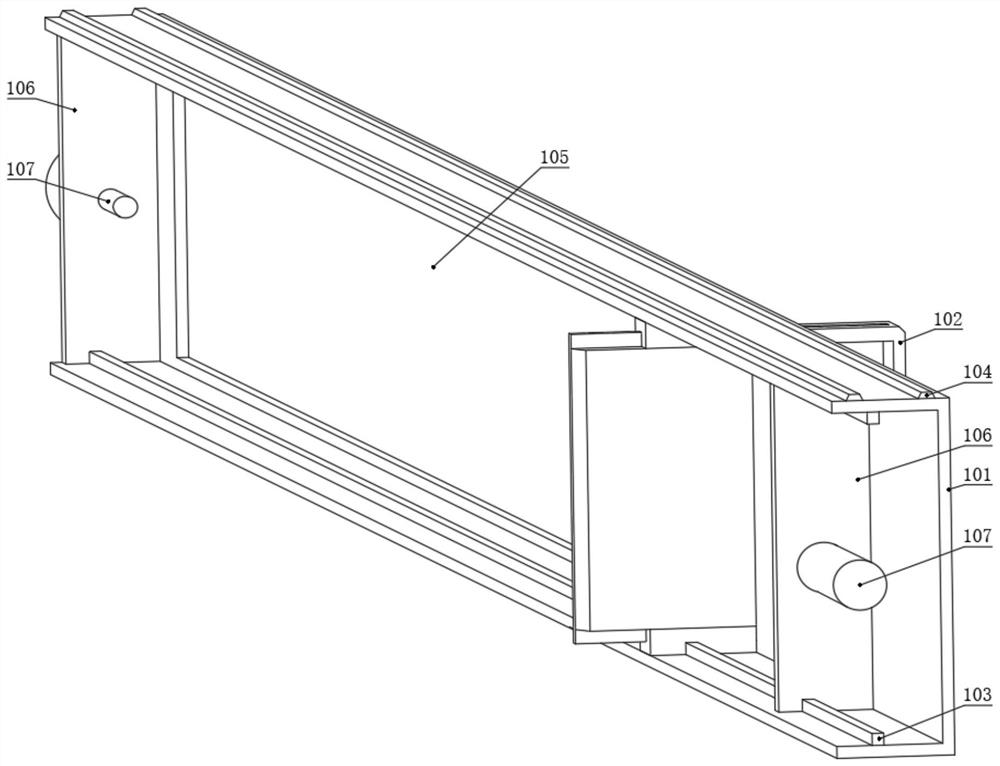

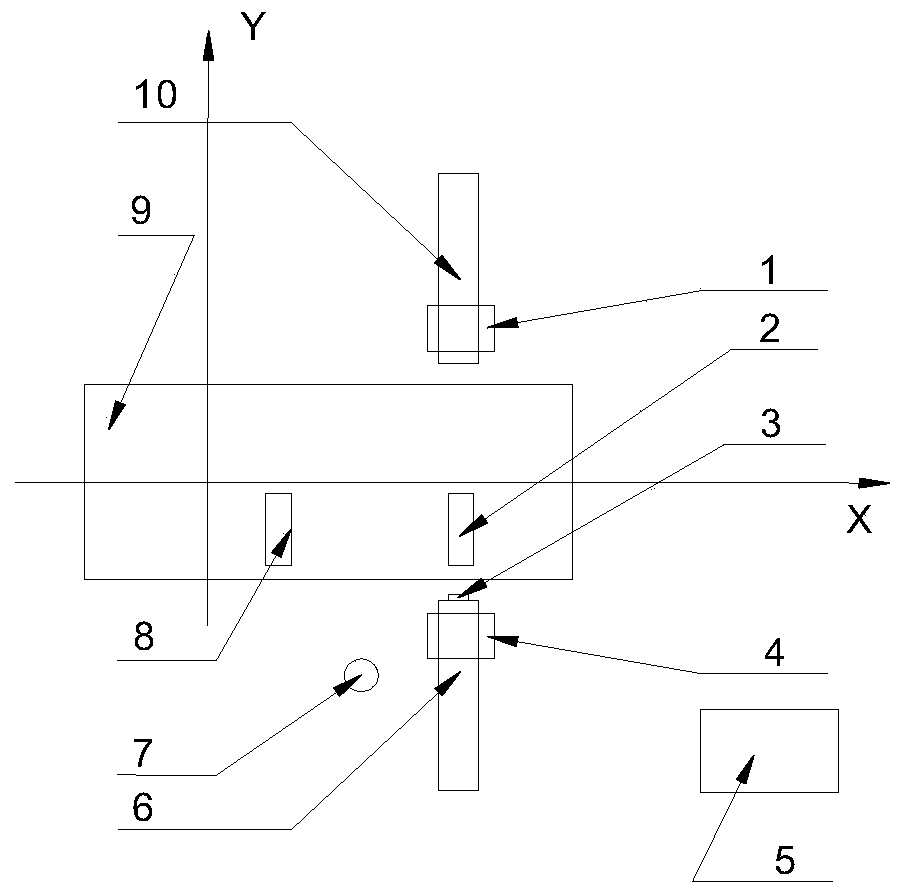

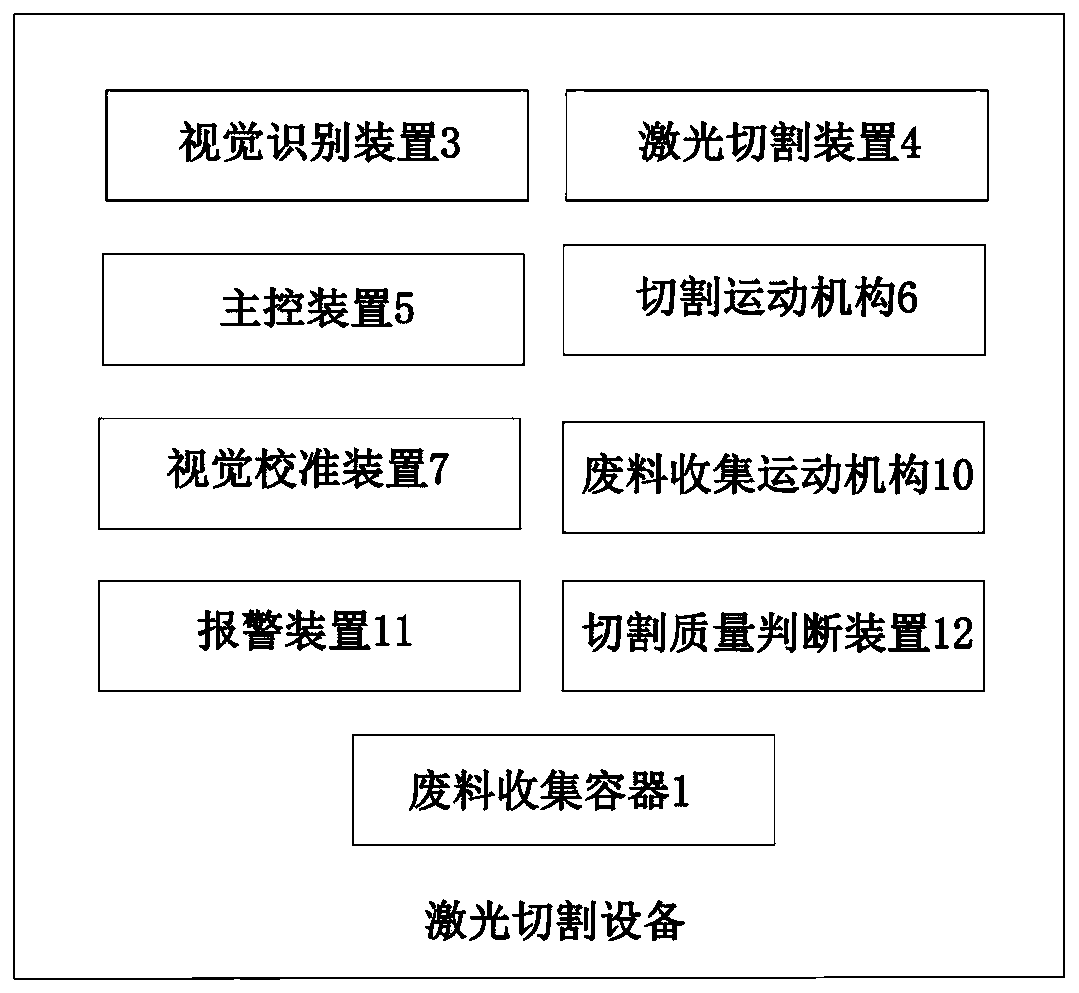

Laser cutting device and laser cutting work method

ActiveCN110711953AMeet cutting needsWon't vibrateLaser beam welding apparatusLaser cuttingVisual recognition

The invention relates to a laser cutting device and a laser cutting work method. The laser cutting device comprises a cutting movement mechanism, a laser cutting device, a visual recognition device and a master control device. The laser cutting device is connected with the cutting movement mechanism and generates lasers used for cutting. The visual recognition device is connected with the cuttingmovement mechanism and is used for obtaining image information of a specific structure on a vehicle body. The master control device is connected with the cutting movement device, the laser cutting device and the visual recognition device and is used for obtaining vehicle model information and controlling the laser cutting device to generate lasers used for cutting. The laser cutting device and thelaser cutting method are suitable for production of various vehicle models, the flexible degree is high, in addition, a cutting area can be accurately positioned, the machining precision is improved,the completion quality cutting work is detected online, and it is ensured that subsequent processes are implemented smoothly.

Owner:WUHAN FARLEYLASERLAB CUTTING SYST ENG

Multifunctional tea planting land weeding device and operation method thereof

InactiveCN110612808ASolve technical problems of growing environmentFunction increaseMowersWeed killersSurface mountingEngineering

The invention discloses a multifunctional tea planting land weeding device and an operation method thereof. The weeding device comprises a mounting bottom plate, a cutting cover plate is arranged on the lower portion of the mounting bottom plate, three cutting blades are mounted at the bottom of the cutting cover plate, a supporting seat is mounted on the upper surface of the mounting bottom plate, a supporting frame is rotatably connected at the top of the supporting seat, a liquid medicine box is fixedly mounted on the supporting frame, and an air supply cylinder is mounted on one side of the liquid medicine box and connected with the supporting frame. The cutting range of the weeding device is wide, large-area weeds can be rapidly cleaned, working efficiency is high, the height of the cutting cover plate is conveniently adjusted, and cutting requirements of different heights of weeds are met. The weeding device is simple in structure, liquid medicine is blown by fan blades, sprayingarea can be increased, spraying distance can be increased, and weeding effects are good. According to the weeding device, weed cutting and weed removal by pesticides are integrated, functions are diverse, and weeding requirements under different conditions can be met.

Owner:金寨县益农农业科技开发有限公司

Numerical-control automatic cam lathe

InactiveCN103286327AGuaranteed processing sizeEnsure shapeAutomatic/semiautomatic turning machinesFeeding apparatusPosition toleranceNumerical control

The invention discloses a numerical-control automatic cam lathe comprising a frame, an engine base, a nose, a spindle, a numerical-control operator, a feed device and a numerical-control cutter rest. The numerical-control cutter rest is provided with an X-axis cutter, a Y-axis cutter and a Z-axis cutter, and the Z-axis cutter is driven by an eccentric cam connecting rod mechanism. The numerical-control automatic cam lathe has the advantages that the eccentric cam connecting rod mechanism controls cutter feed, is combined with numerical control and the like to perform fine operation and guarantee size accuracy in product processing; workpiece clamping is completed through automatic feeding, labor is reduced and labor efficiency is improved; cut workpieces are automatically fixed, multi-directional cutting can be realized, cutting requirements of different shapes are met, the same workpiece can be processed and formed on the lathe at one step without frequent changing devices, full-automatic cutting process is realized, processing size and shape and position tolerance of the workpiece are guaranteed, and production efficiency and product processing speed are effectively improved.

Owner:JIANGSU TANGYIN PHOTOELECTRIC

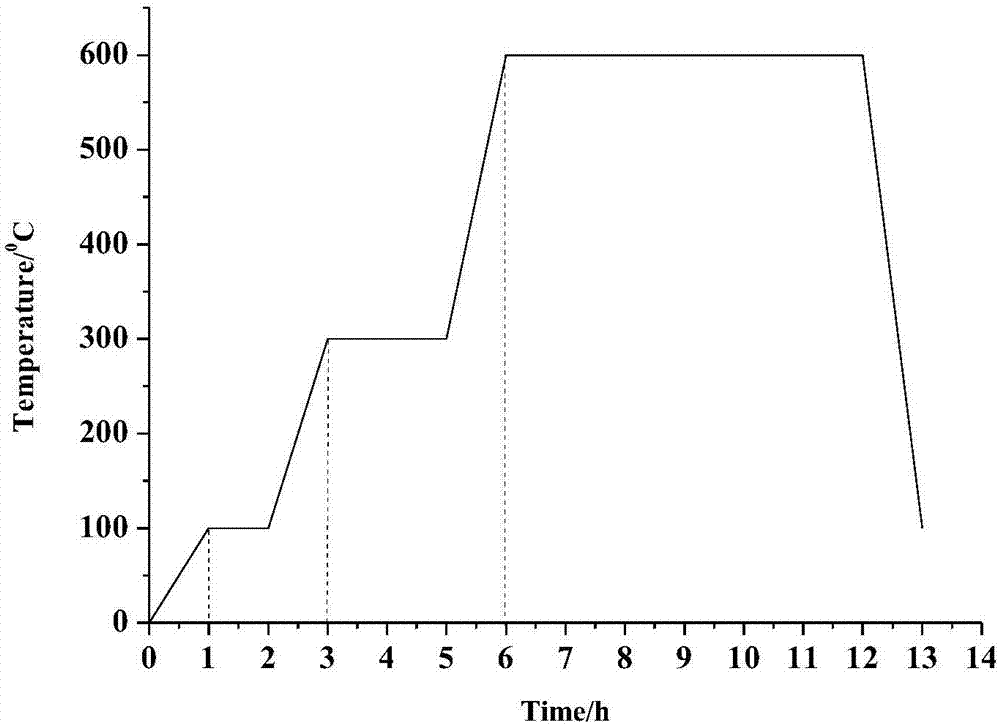

Formula of low-temperature sintering ceramics type diamond grinding head and preparation method

ActiveCN107986787AReduce wearMeet cutting needsAbrasion apparatusGrinding devicesWear resistanceMachining process

The invention discloses a formula of a low-temperature sintering ceramics type diamond grinding head and a preparation method and belongs to the field of mechanical cutting and manufacturing. The formula of the low-temperature sintering ceramics type diamond grinding head contains the following components in parts by weight: 9.5-10.5 parts of a ceramic bond, 9.5-10.5 parts of dextrin powder, 19-21parts of walnut shell powder and 95-150 parts of diamond powder. The preparation method comprises the following steps: adding water and uniformly mixing raw materials, stirring to obtain pasty materials, performing extrusion forming, and drying to obtain a ceramic type diamond grinding head blank; and sintering the ceramic type diamond grinding head blank at a temperature of 500-600 DEG C for more than or equal to 6 hours, thereby obtaining the low-temperature sintering ceramics type diamond grinding head. The low-temperature sintering ceramics type diamond grinding head prepared from the formula and by the method is high in wear resistance and small in cutting wear of the grinding head, the geometric dimension is stable in the machining process, and precision cutting requirements of SiCceramic composite materials can be met.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

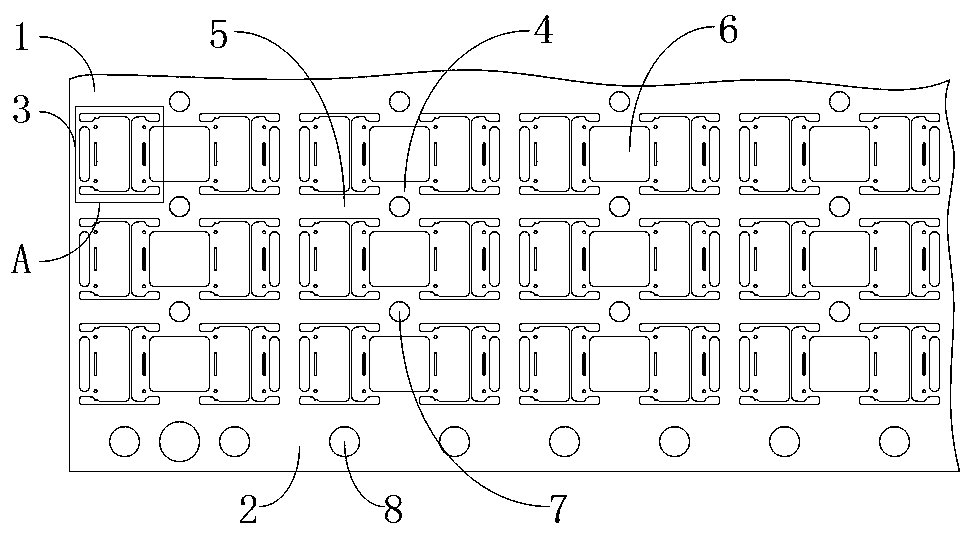

Lead frame and production process thereof

InactiveCN109742222AIngenious designMeet cutting needsSemiconductor devicesSupport matrixSurface cleaning

The invention discloses a lead frame and a production process thereof. The lead frame comprises a support matrix, wherein the support matrix comprises two side horizontal edge straps and a plurality of LED single racks, the plurality of LED single racks are transversely and longitudinally arranged between the two side horizontal edge straps in an array way, a longitudinal connection belt longitudinally arranged and a transverse connection belt transversely arranged are arranged between adjacent LED single racks, a rectangular hollow region is arranged between arbitrary adjacent LED single racks and is arranged on the longitudinal connection belt, a positioning through hole is formed in a cross part of the longitudinal connection belt and the horizontal connection belt, and a cutting positioning hole is formed in the arbitrary horizontal edge belt. In the production process, the etching step is optimized and controlled. The lead frame is ingenious in design, the cutting demand of the arbitrary LED single rack is satisfied, the deformation quantity of the LED single rack after cutting is small, and high-accuracy demand is satisfied; drying is performed after surface cleaning, the LEDsignal rack employs ingenious design of an H-shaped isolation groove, wrapping, package and base separation are easy; and the process flow is fine, etching is efficient, the formation accuracy is high, and the process is suitable for promotion and application.

Owner:昆山弗莱吉电子科技有限公司

Fabric conveying and processing device for chemical fiber quilt production

InactiveCN112299092AReasonable structural designAvoid slackSevering textilesWebs handlingFiberMechanical equipment

The invention discloses a fabric conveying and processing device for chemical fiber quilt production, and belongs to the field of home textile processing mechanical equipment. An upper damping pressing plate and a lower damping pressing plate are arranged on the upper side and the lower side of a fabric conveying rotary disc at the end of a fabric unwinding rotary roller correspondingly, a feedingand conveying pressing roller is arranged on the upper side of a feeding and conveying rotary roller, and the two ends of a horizontal moving reciprocating pull plate are arranged on material pullinghorizontal moving guide rods correspondingly in a sliding manner. The two ends of the upper side of a fabric pulling and conveying chain are fixedly connected with the two sides of the horizontal moving reciprocating pull plate correspondingly, a fabric cutting mechanism is arranged on a fabric processing support on the side of a feeding and conveying support, and a cutting horizontal moving connecting rod is horizontally arranged in a connecting rod reciprocating sleeve of a connecting rod reciprocating support in a sliding manner. A fabric guiding and conveying rotary roller is rotationallyconnected to a lifting rotary roller support on the lower side of a fabric guiding and conveying bearing roller. The fabric conveying and processing device for chemical fiber quilt production is reasonable in structural design, chemical fiber quilt fabric can be continuously and smoothly unwound, conveyed and cut efficiently and stably, the fabric processing automation degree is high, and the production and use requirements are met.

Owner:桐乡市康悦时装寝具有限公司

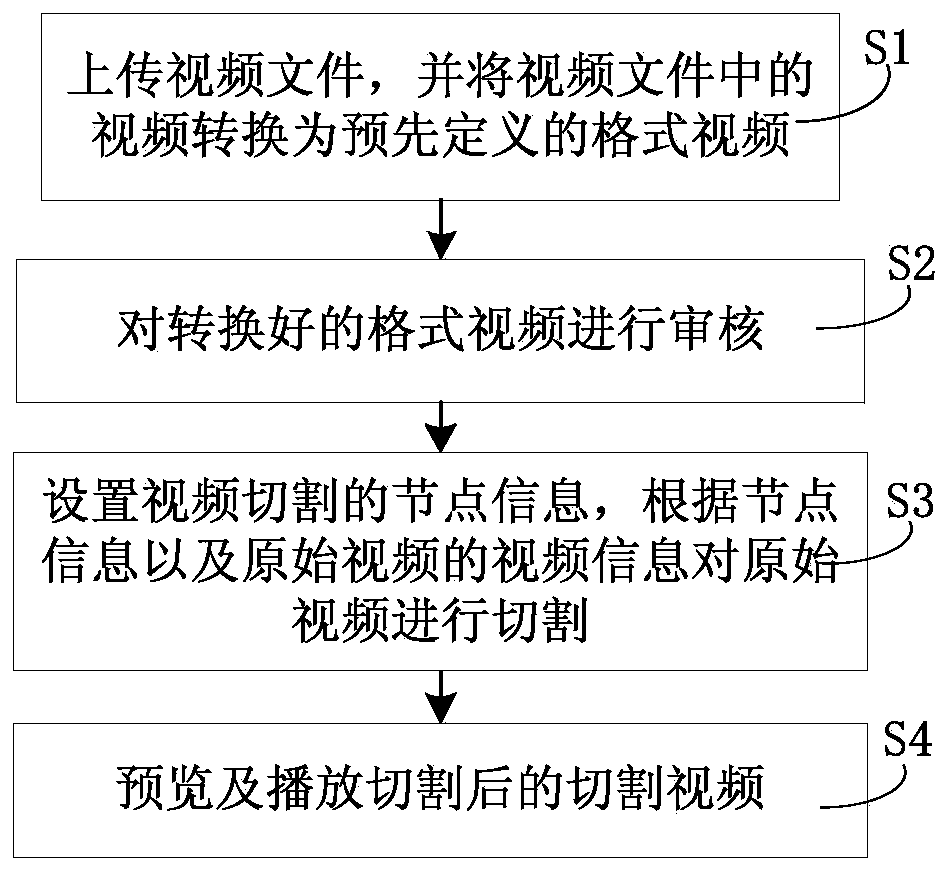

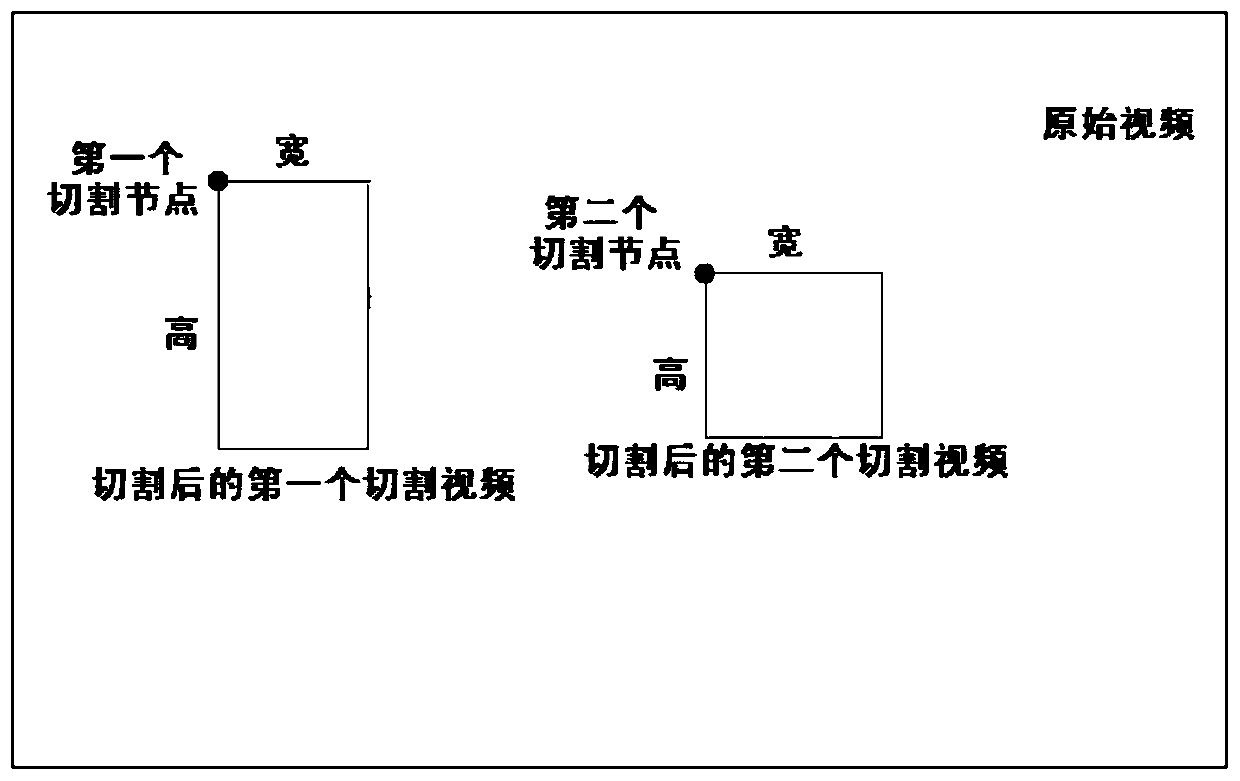

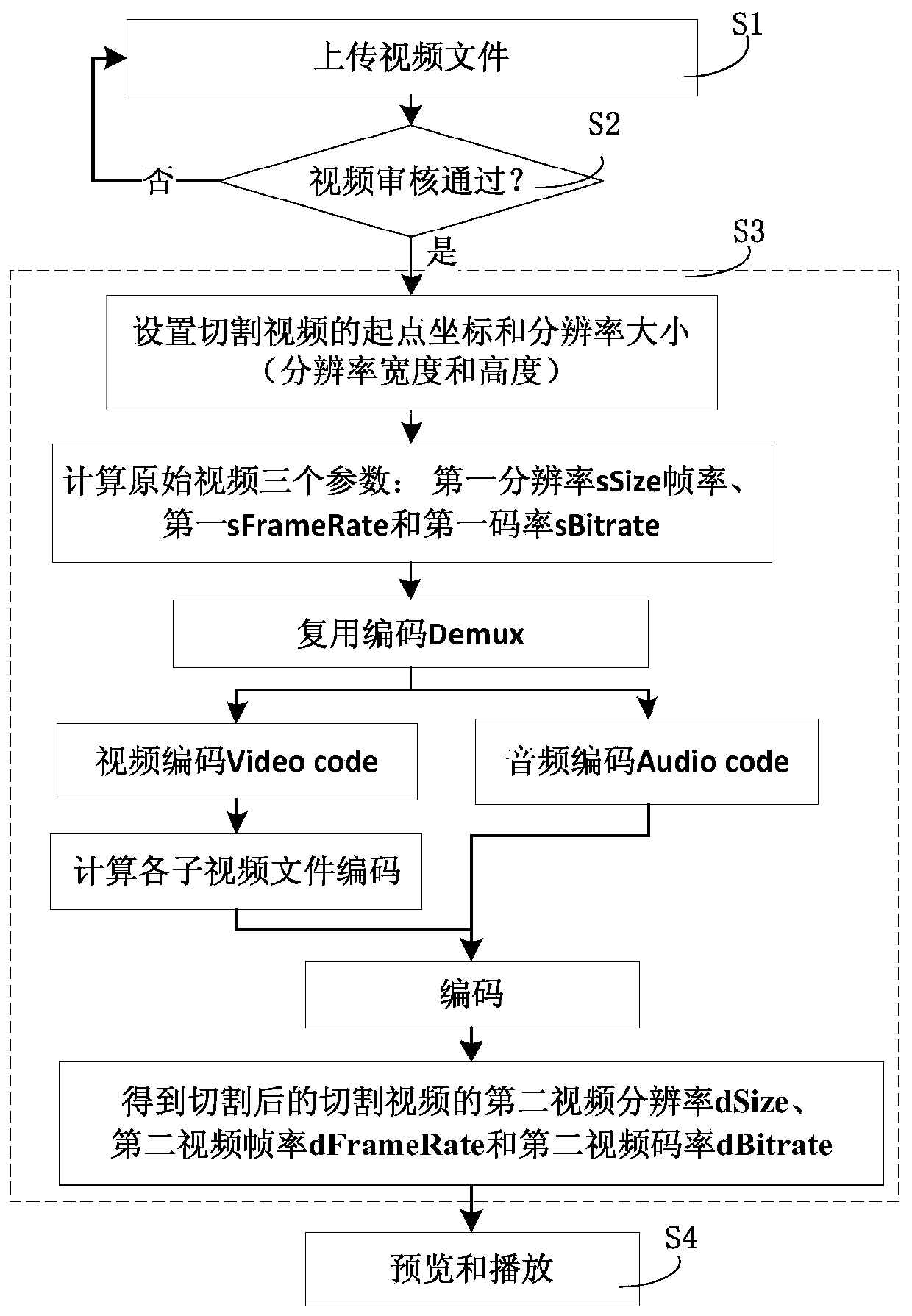

Urban media wall light show video cutting method and system

ActiveCN109769142ASmooth playbackReduce quality problemsTelevision system detailsColor television detailsComputer graphics (images)

The invention provides an urban media wall light show video cutting method and system, and the video cutting method comprises the following steps: S1, uploading a video file, and converting a video inthe video file into a pre-defined format video; S2, checking the converted video in the format, and after the video passes the checking, skipping to the step S3 to carry out video cutting; S3, setting node information of video cutting, and cutting the original video according to the node information and the video information of the original video to obtain a cut video; and S4, previewing and playing the cut video. According to the method, after the video is cut, boundaries and contours of the video cannot be blurred, definition cannot be reduced, the video can be smoothly played, pixel-levelprecision can be achieved, and therefore the requirement of urban media wall lamp light show for video cutting is met; on the basis, the video cutting efficiency is effectively improved, and the operation is simple and easy; and moreover, the cut video effect can be previewed, and the application is expanded.

Owner:深圳市睿智物联科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com