Formula of low-temperature sintering ceramics type diamond grinding head and preparation method

A technology for sintering ceramics and diamonds at low temperature, applied in metal processing equipment, grinding/polishing equipment, abrasives, etc. Low wear, high grinding performance and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

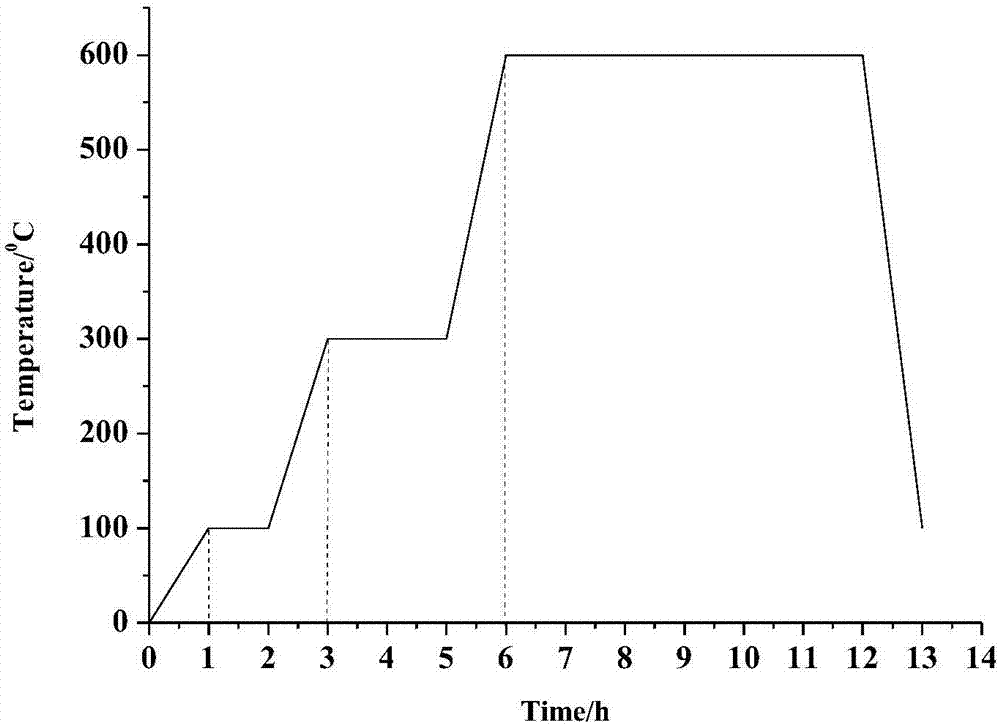

Image

Examples

Embodiment 1

[0039] A kind of prescription of low-temperature sintered ceramic type diamond grinding head, each component that comprises and the parts by weight of each component are:

[0040] Vitrified binder: 10 parts

[0041] Dextrin powder: 10 parts

[0042] Walnut shell powder: 20 parts

[0043] Diamond powder: 100 parts

[0044] Described vitrified bond, each component that comprises and the mass percent of each component are:

[0045] Silica: 55%

[0046] Aluminum oxide: 25%

[0047] Strontium carbonate: 10%

[0048] Diboron trioxide: 10%

[0049] The particle size of the dextrin powder is 400 mesh, the particle size of the walnut shell powder is 400 mesh, and the particle size of the diamond powder is selected according to the processing requirements, generally according to the roughness value of the processed surface. In this embodiment, the roughness of the machined surface is 1.6, and the particle size of the diamond powder is 120 mesh.

[0050] A preparation method of a...

Embodiment 2

[0061] A kind of prescription of low-temperature sintered ceramic type diamond grinding head, each component that comprises and the parts by weight of each component are:

[0062] Vitrified binder: 9.5 parts

[0063] Dextrin powder: 10.5 parts

[0064] Walnut shell powder: 19 servings

[0065] Diamond powder: 105 parts

[0066]Described vitrified bond, each component that comprises and the mass percent of each component are:

[0067] Silica: 45%

[0068] Aluminum oxide: 35%

[0069] Strontium carbonate: 12%

[0071] The particle size of the dextrin powder is 400 mesh, the particle size of the walnut shell powder is 400 mesh, and the particle size of the diamond powder is selected according to the processing requirements, generally according to the roughness value of the processed surface. In this embodiment, the roughness of the machined surface is 1.6, and the particle size of the diamond powder is 120 mesh.

[0072] A preparation method of...

Embodiment 3

[0081] A kind of prescription of low-temperature sintered ceramic type diamond grinding head, each component that comprises and the parts by weight of each component are:

[0082] Vitrified binder: 10.5 parts

[0083] Dextrin powder: 9.5 parts

[0084] Walnut shell powder: 21 servings

[0085] Diamond powder: 95 parts

[0086] Described vitrified bond, each component that comprises and the mass percent of each component are:

[0087] Silica: 40%

[0088] Aluminum oxide: 30%

[0089] Strontium carbonate: 10%

[0090] Diboron trioxide: 10%

[0091] The particle size of the dextrin powder is 400 mesh, the particle size of the walnut shell powder is 400 mesh, and the particle size of the diamond powder is selected according to the processing requirements, generally according to the roughness value of the processed surface. In this embodiment, the roughness of the machined surface is 1.6, and the particle size of the diamond powder is 120 mesh.

[0092] A preparation method...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com