Patents

Literature

403results about How to "Improve grinding performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

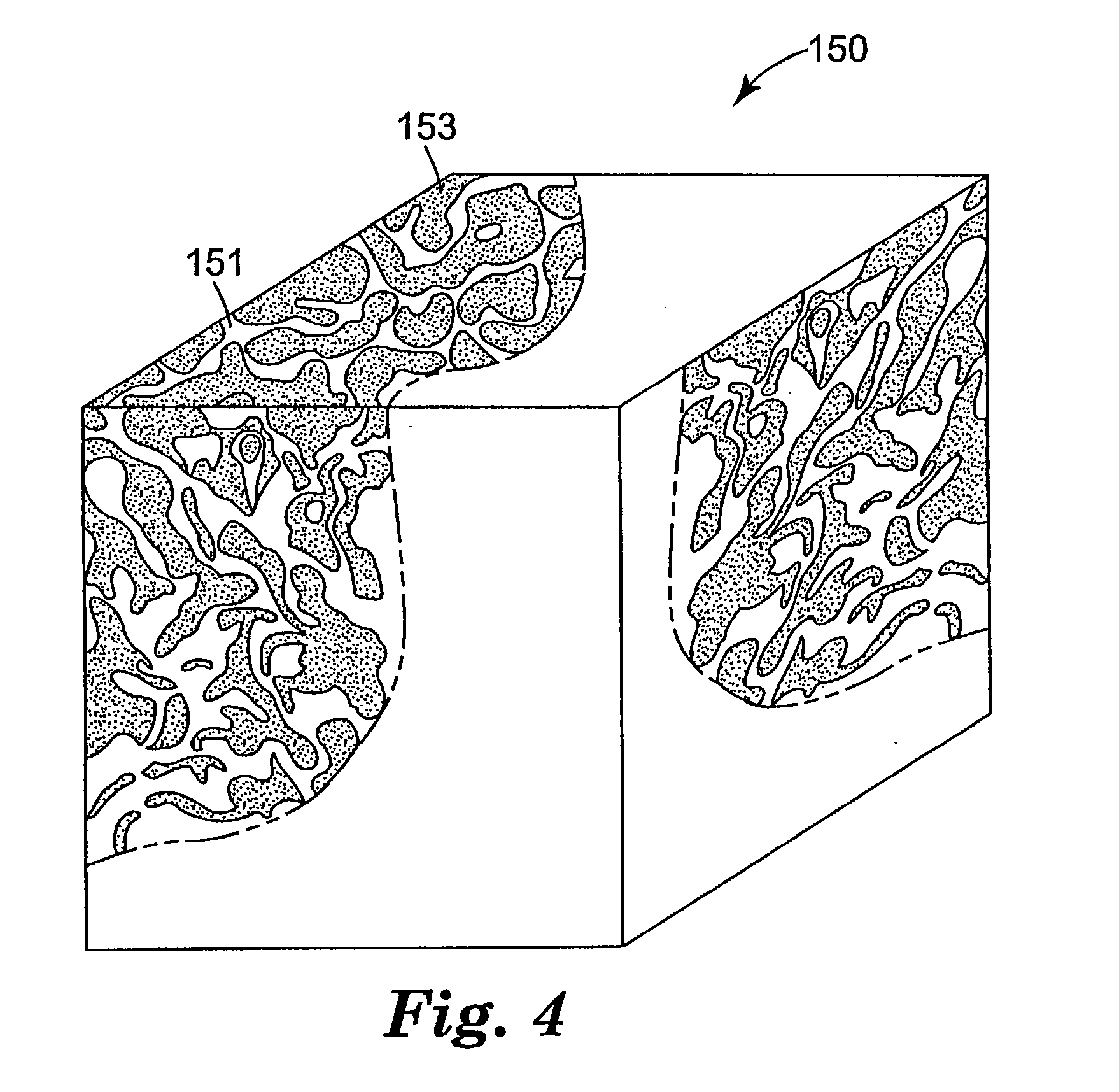

Fused Al2O3-MgO-rare earth oxide eutectic abrasive particles, abrasive articles, and methods of making and using the same

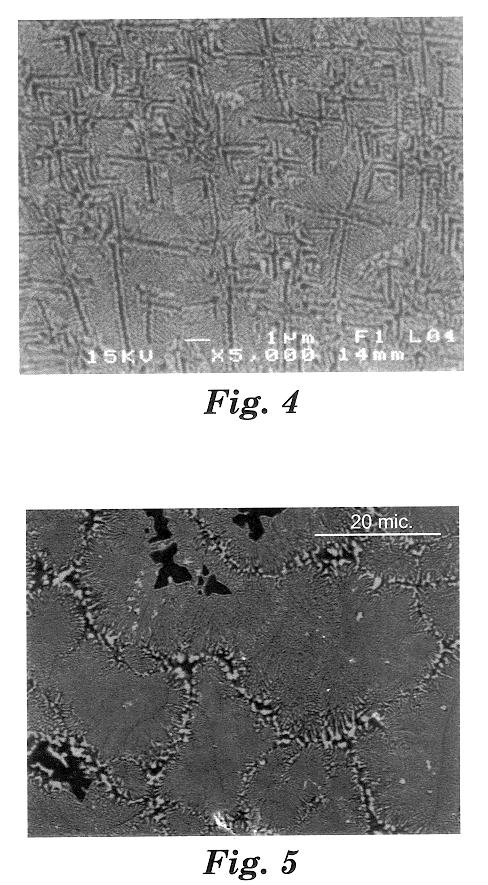

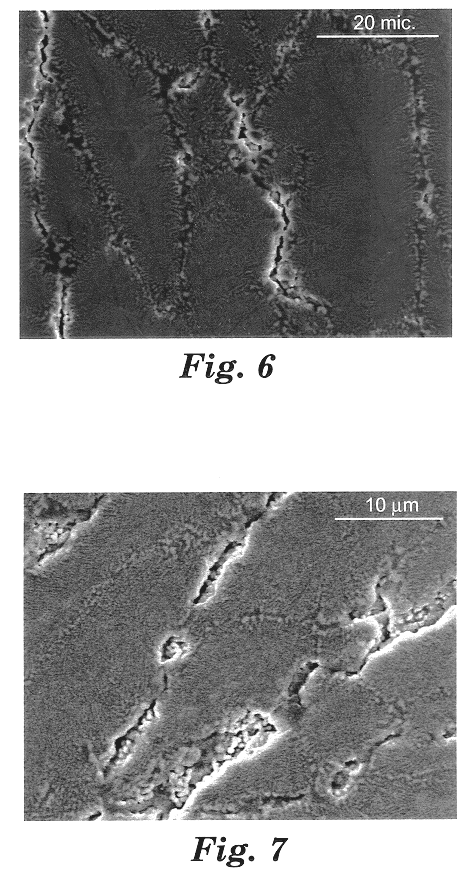

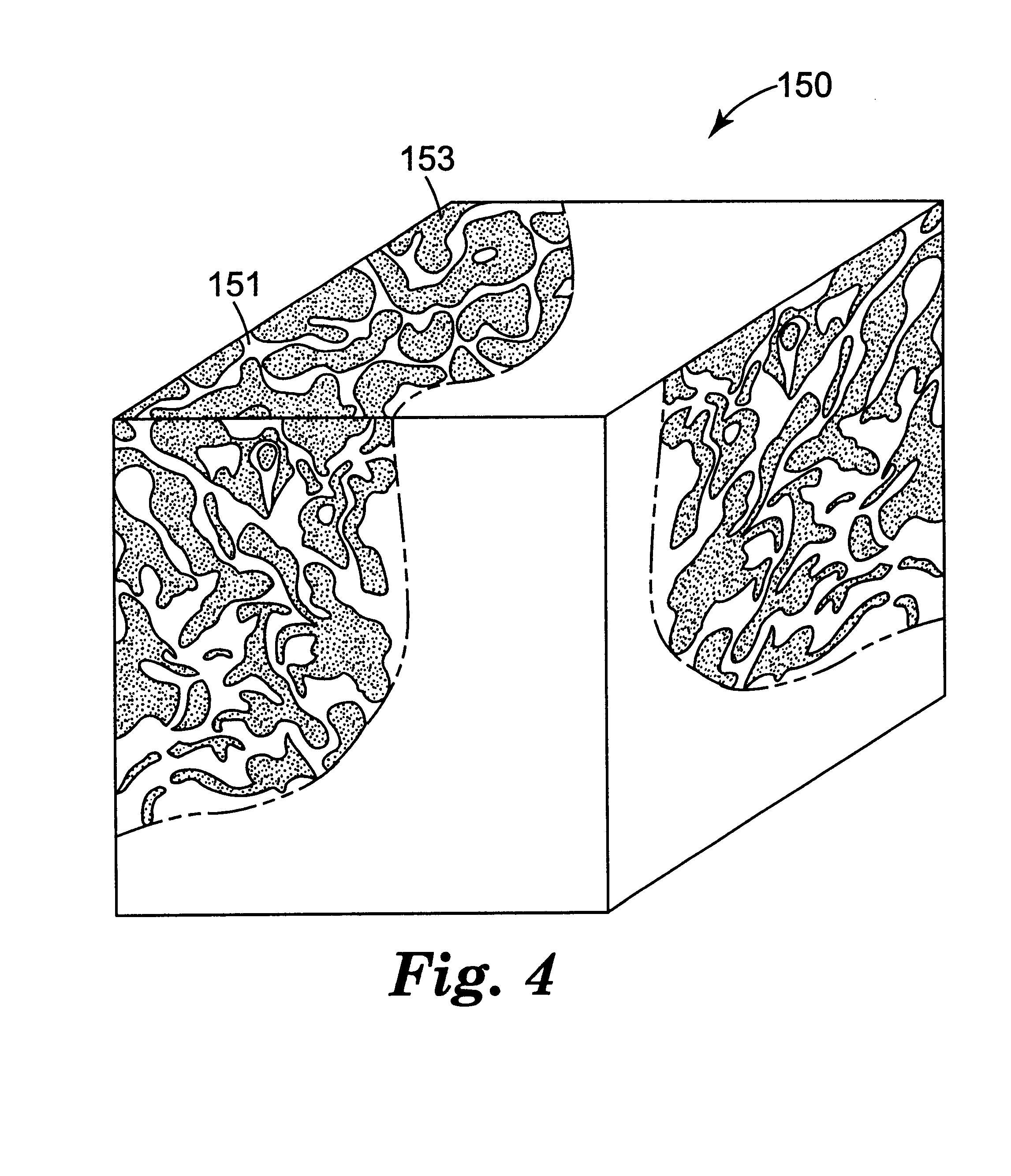

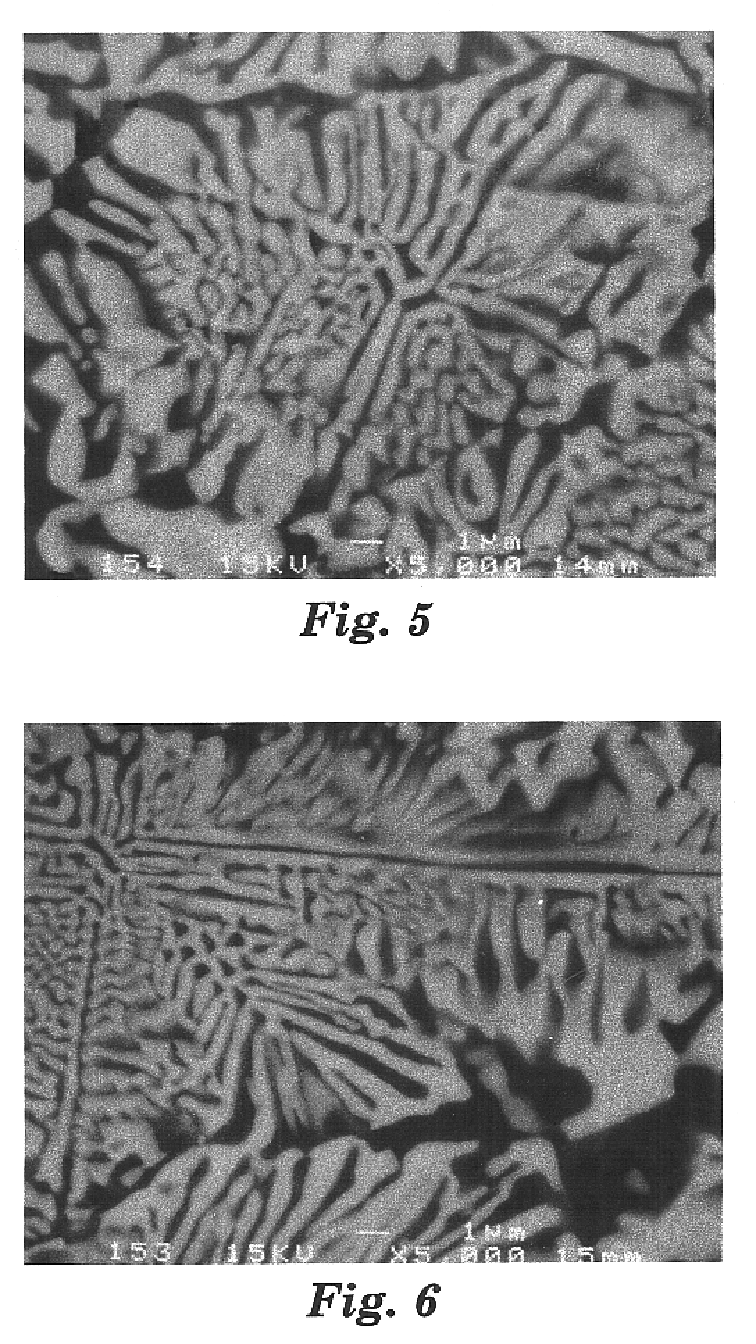

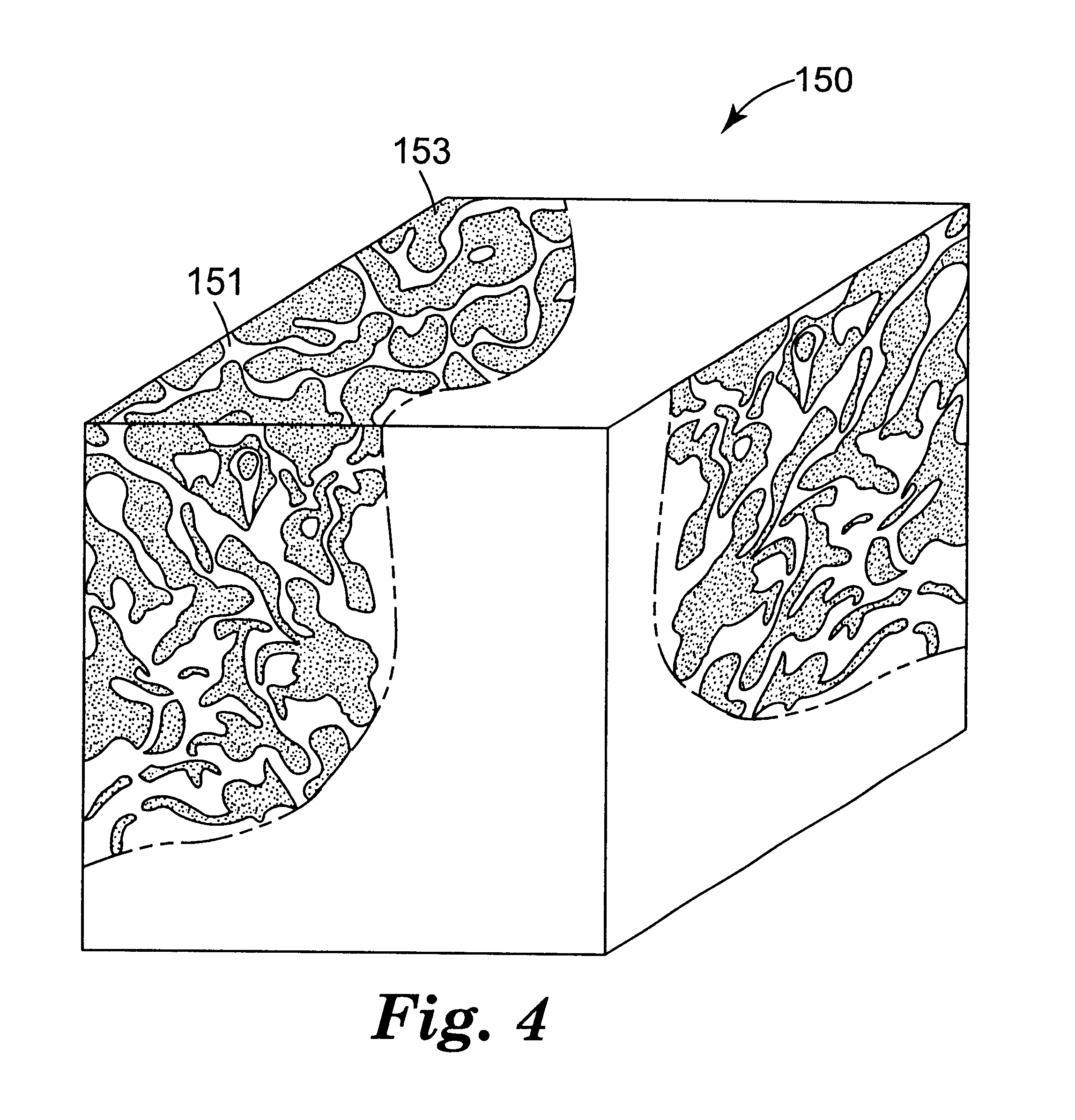

InactiveUS20010027623A1Improve grinding performanceLower performance requirementsPigmenting treatmentMangesium aluminatesRare earthAbrasive

Owner:3M INNOVATIVE PROPERTIES CO

Fused Al2O3-Y2O3 eutectic abrasive particles, abrasive articles, and methods of making and using the same

InactiveUS6592640B1Improve grinding performanceLower performance requirementsPigmenting treatmentMangesium aluminatesMaterials scienceAbrasive

Owner:3M INNOVATIVE PROPERTIES CO

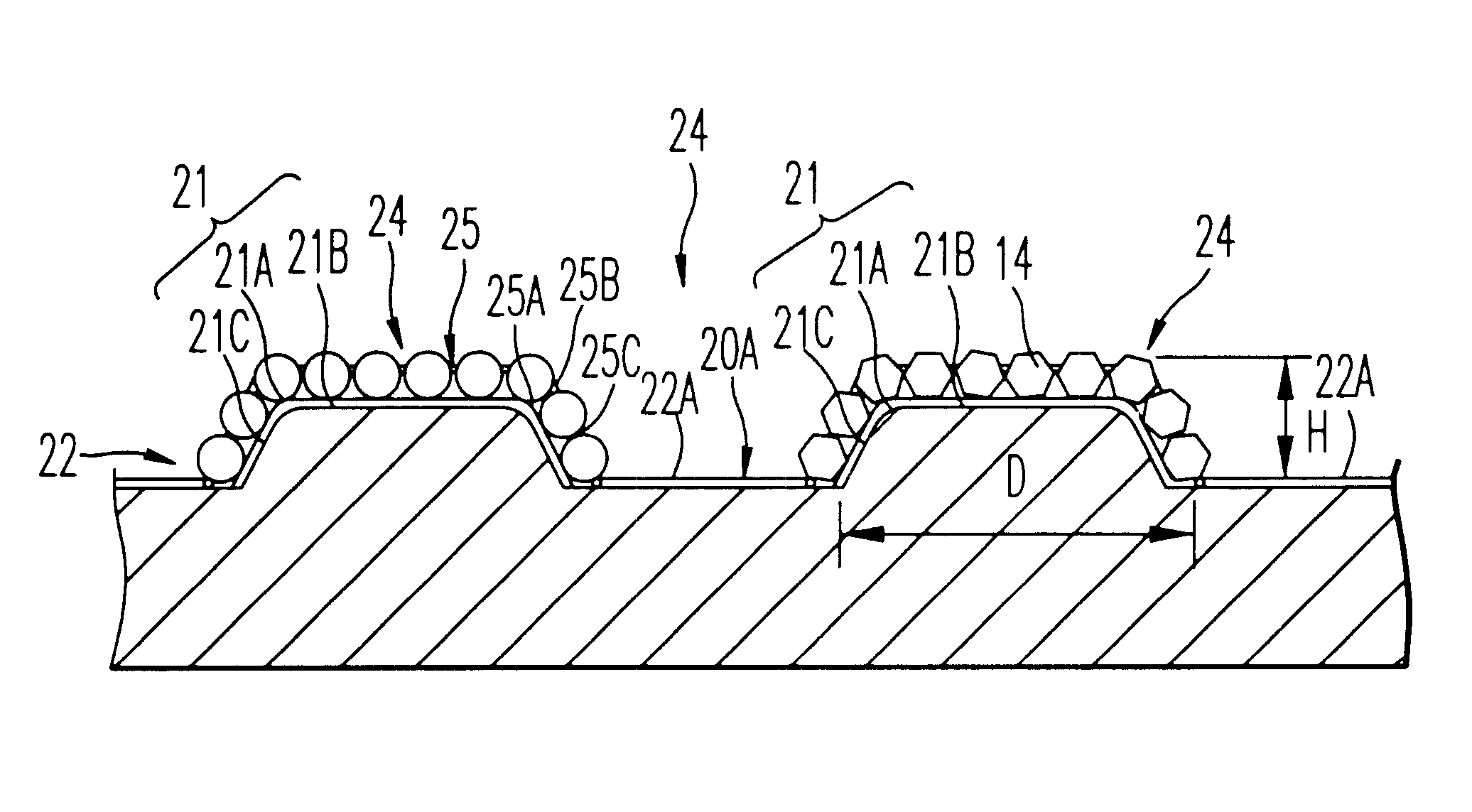

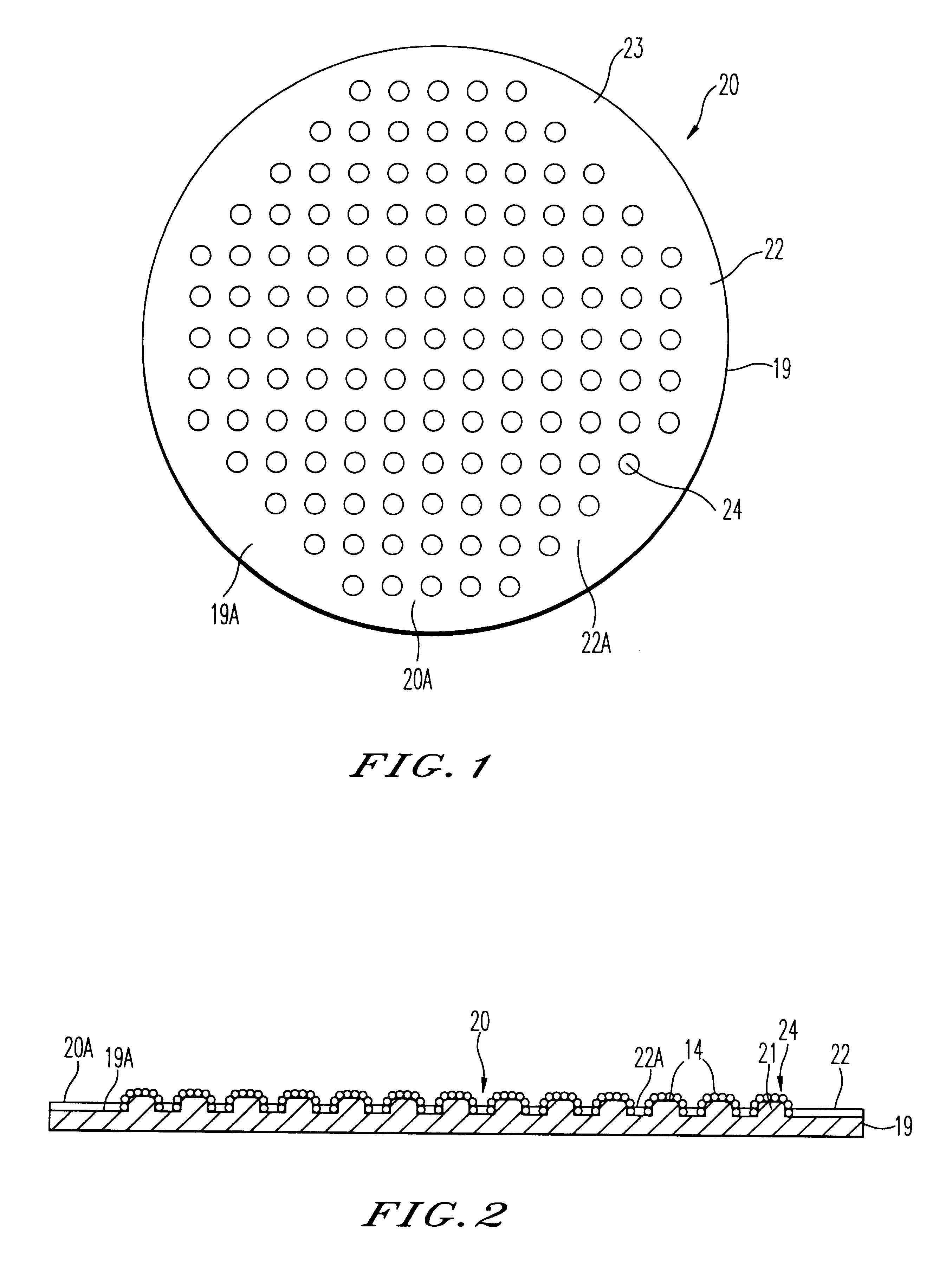

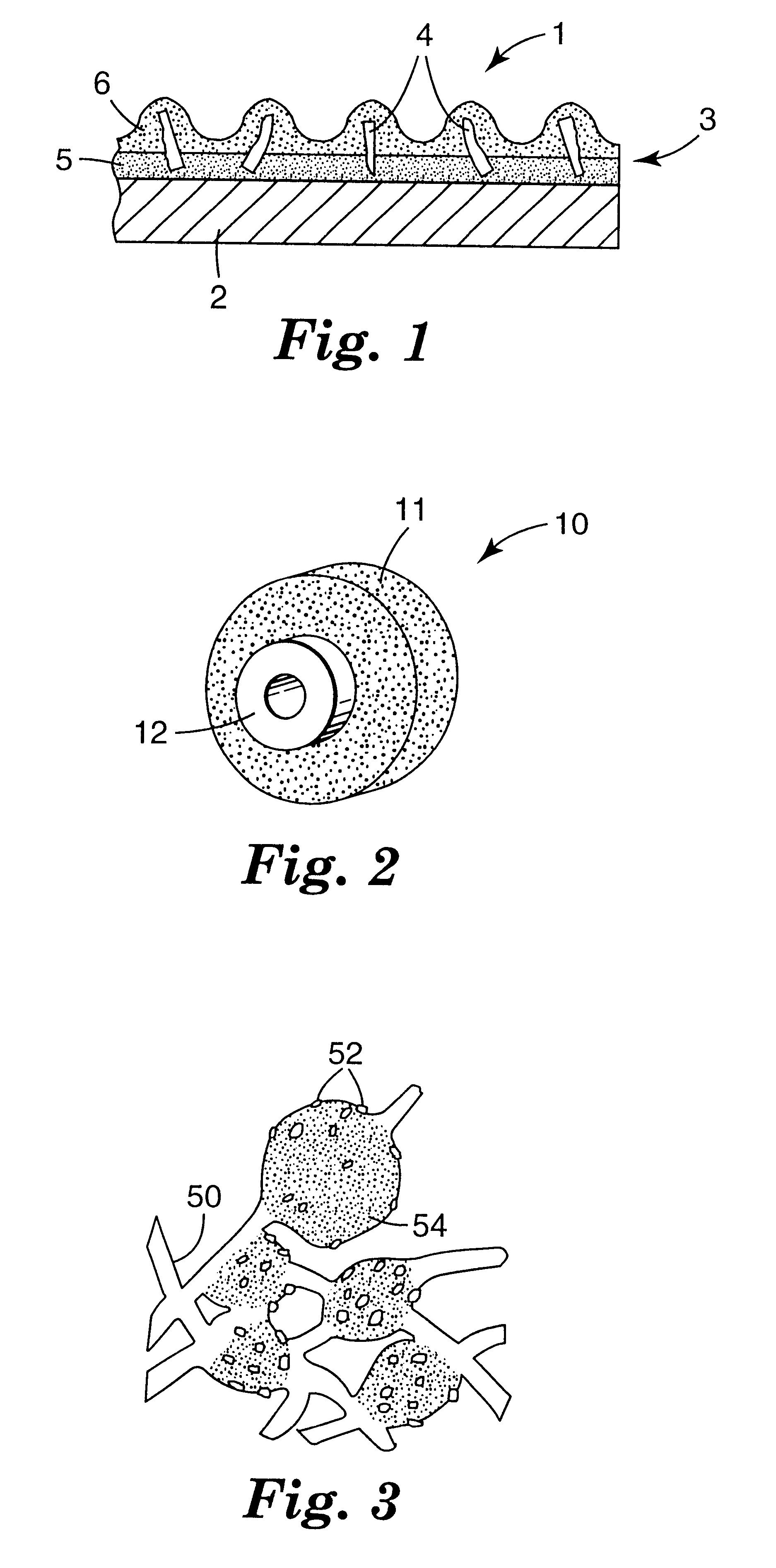

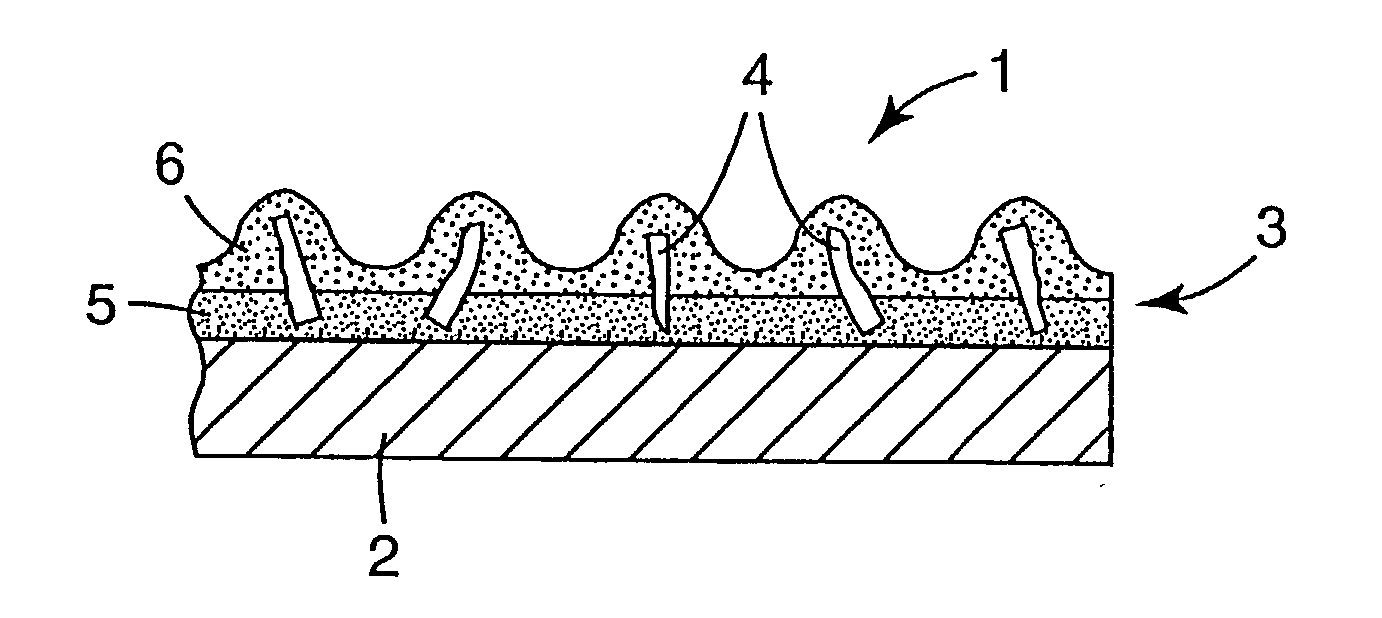

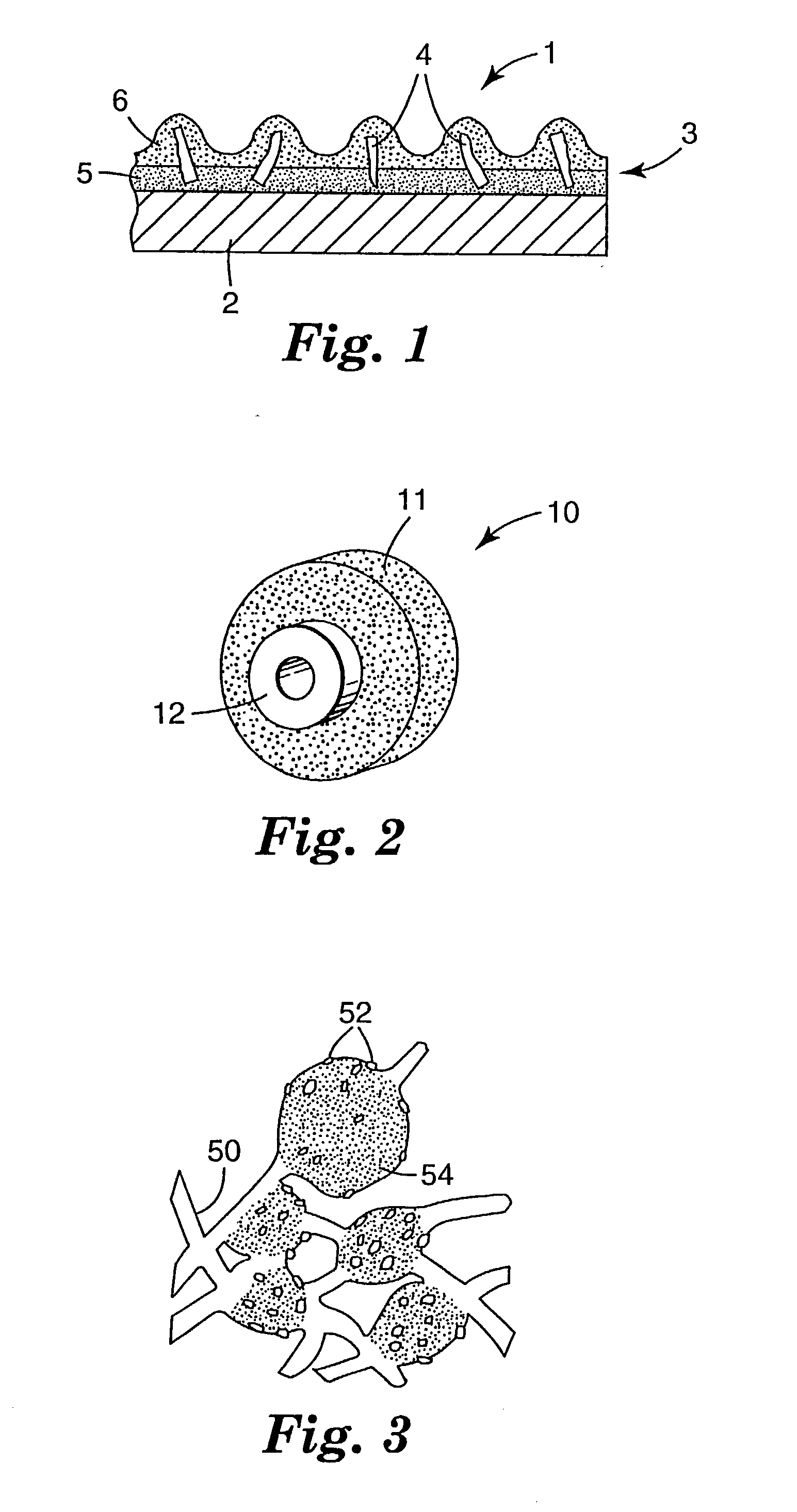

Abrasive tool with metal binder phase

InactiveUS6419574B1Sufficient sharpnessImprove discharge performanceRevolution surface grinding machinesGrinding drivesWear particleMetal

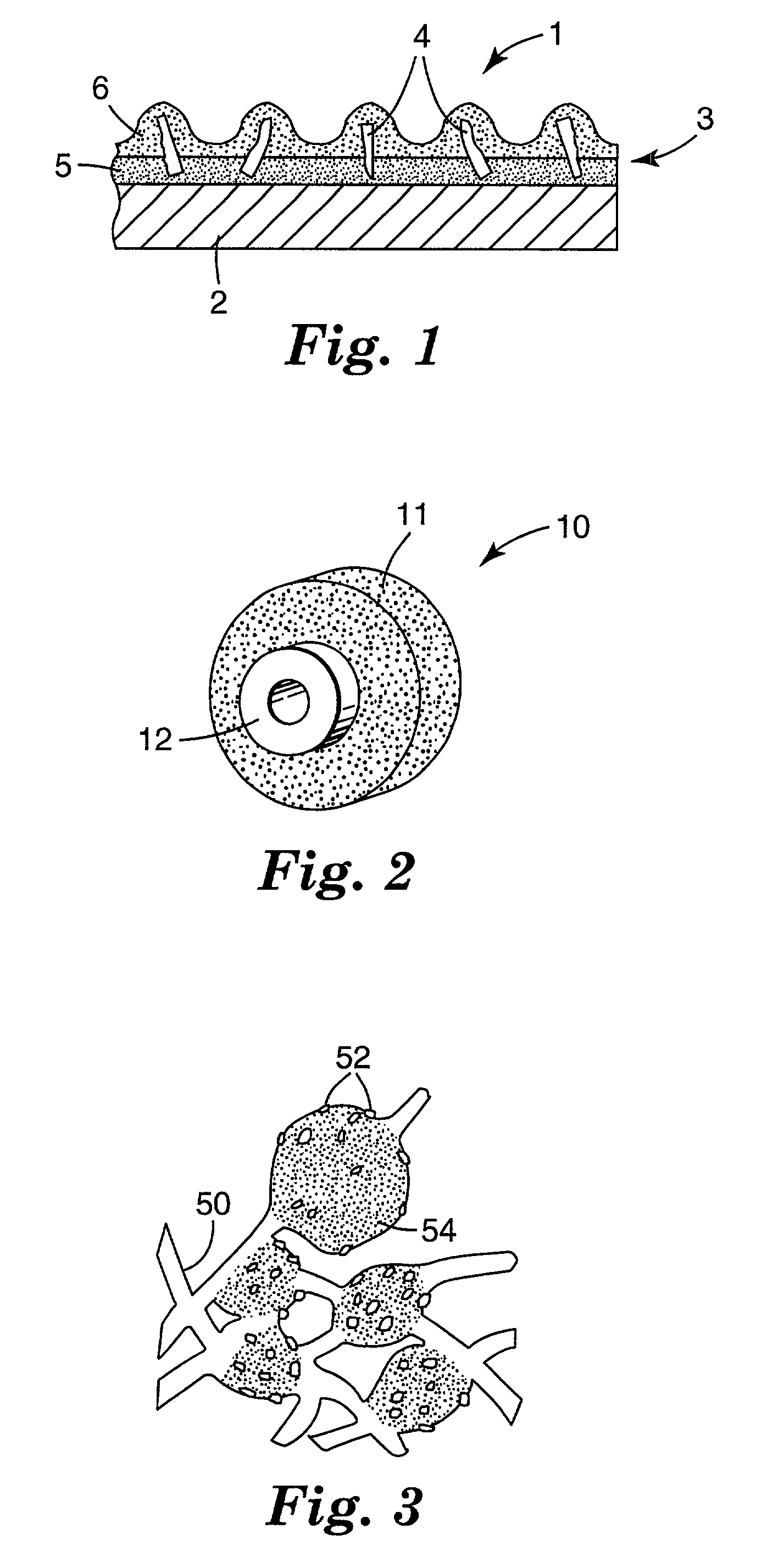

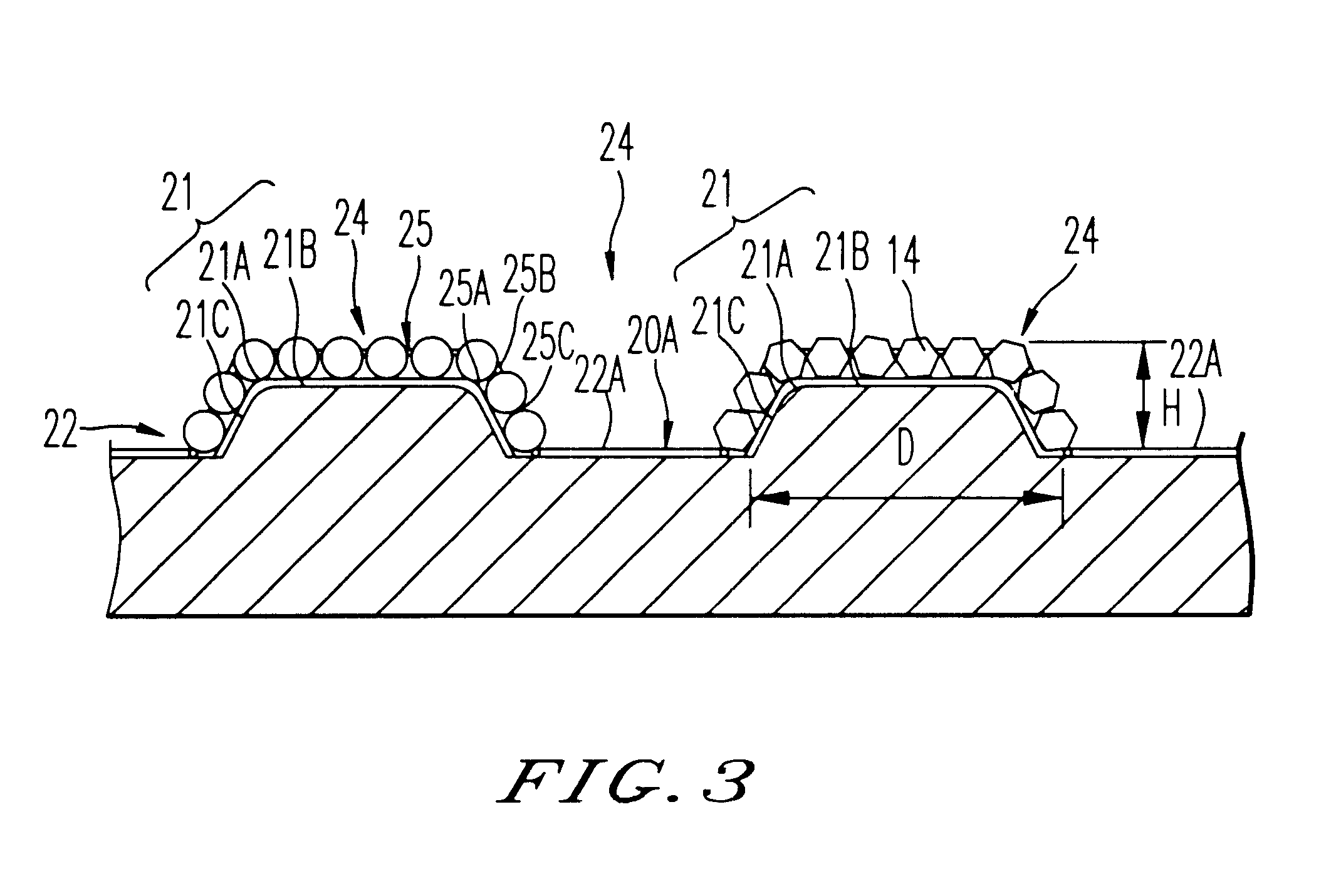

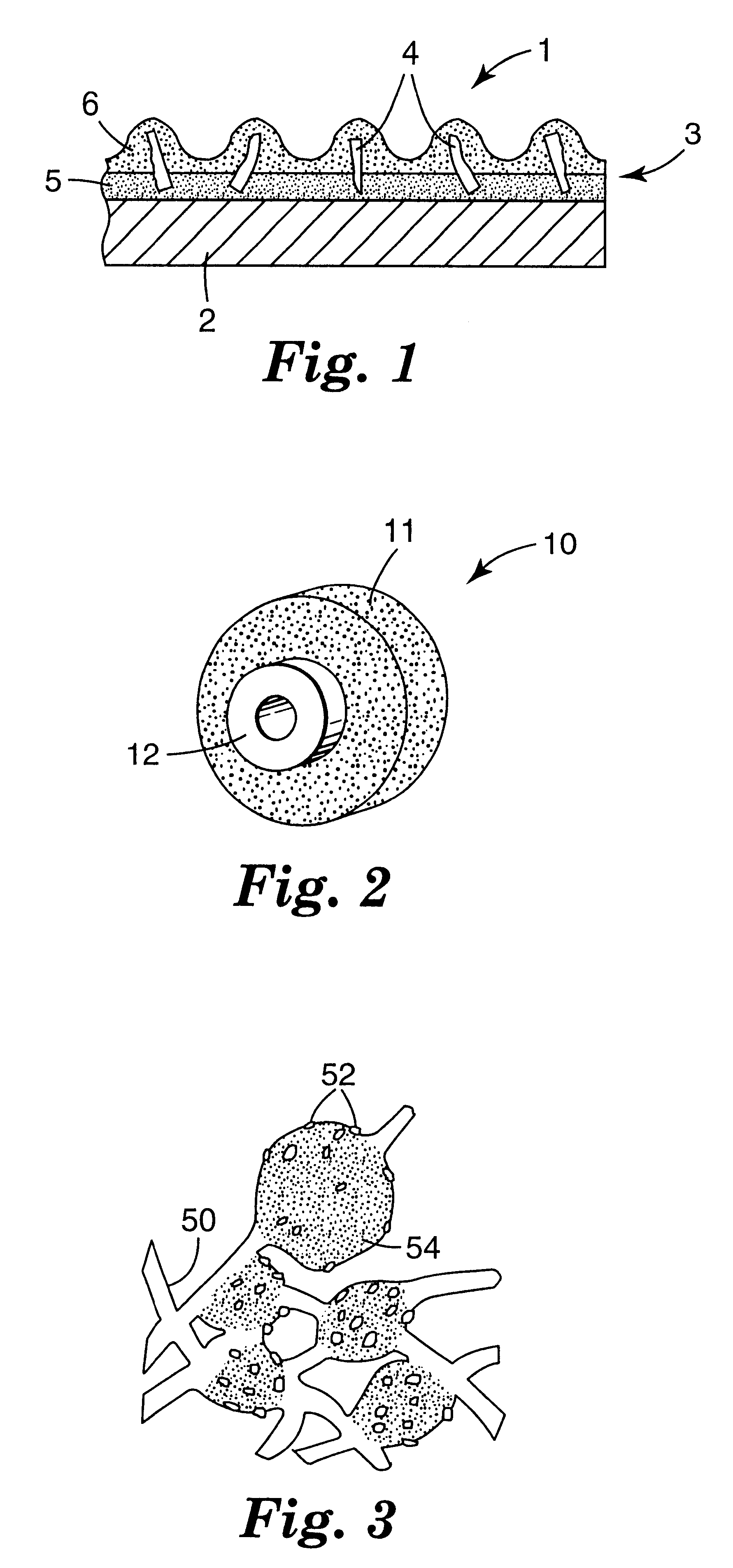

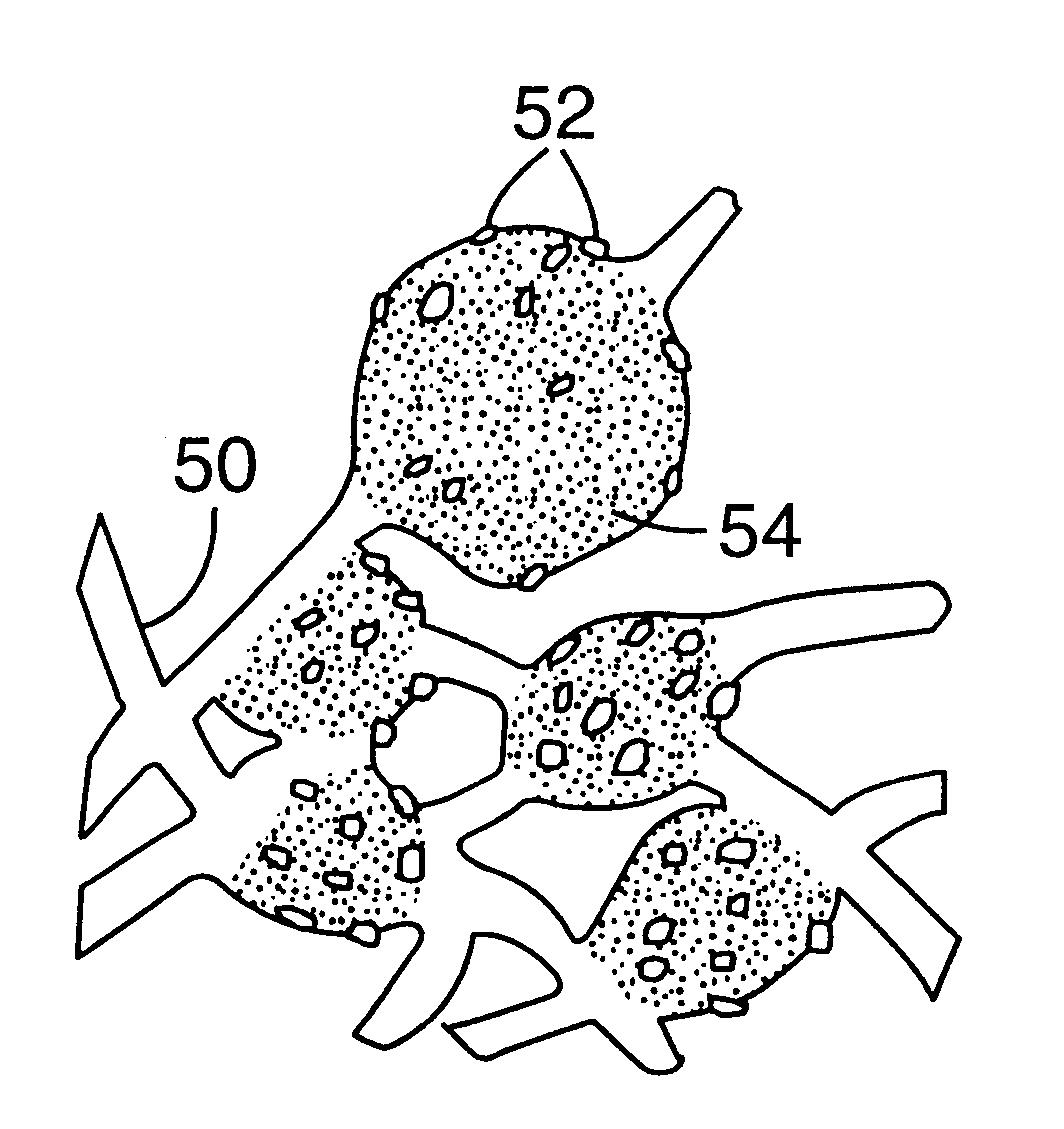

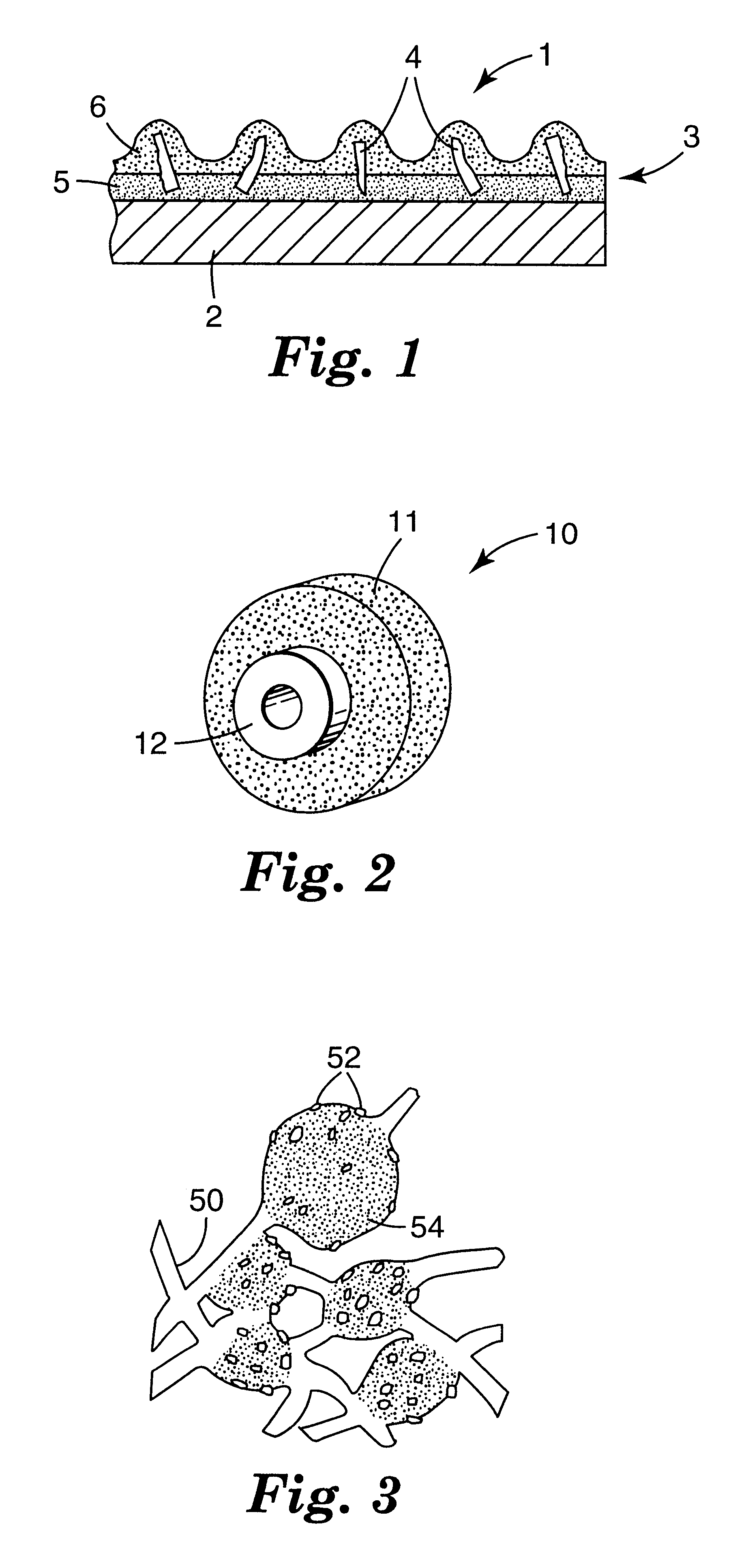

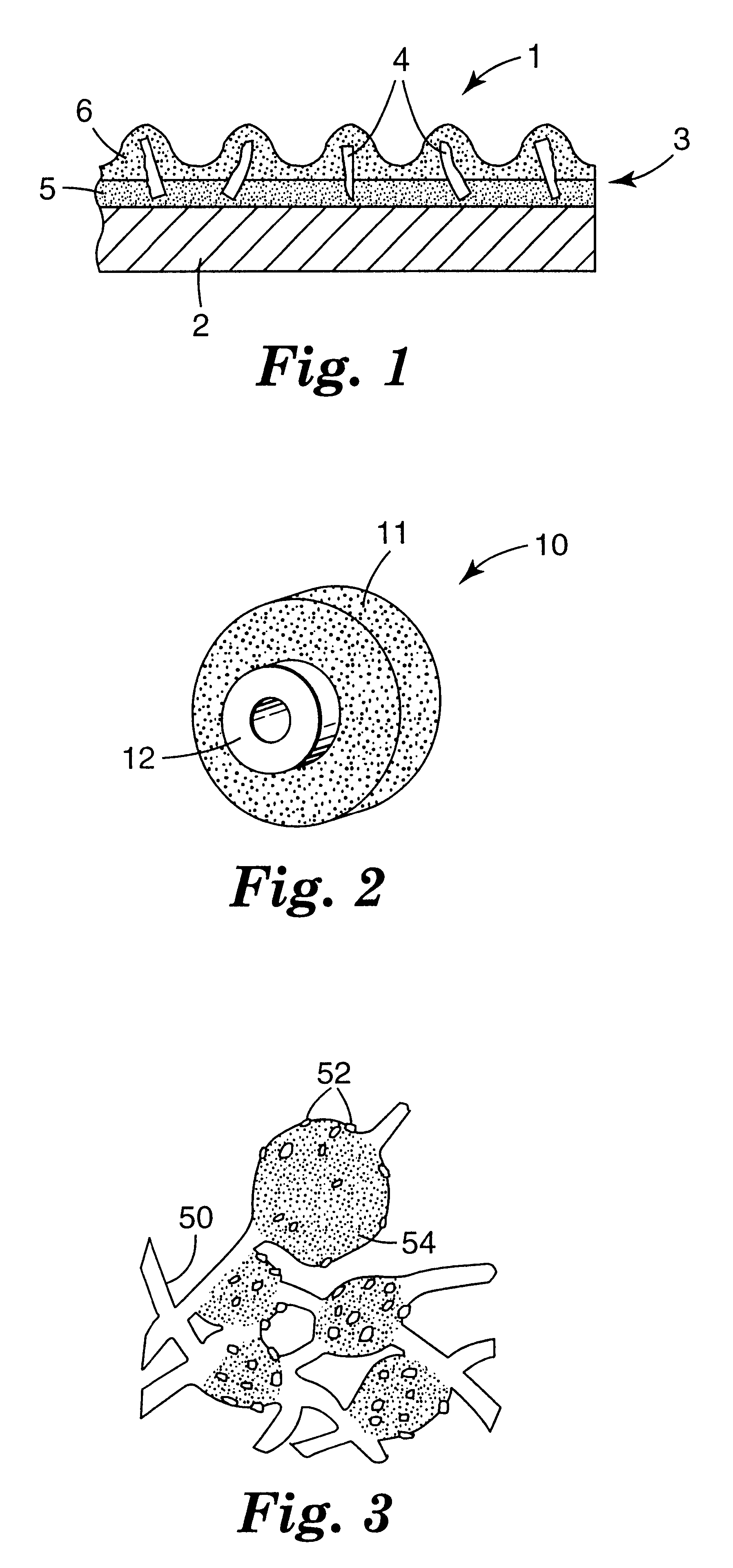

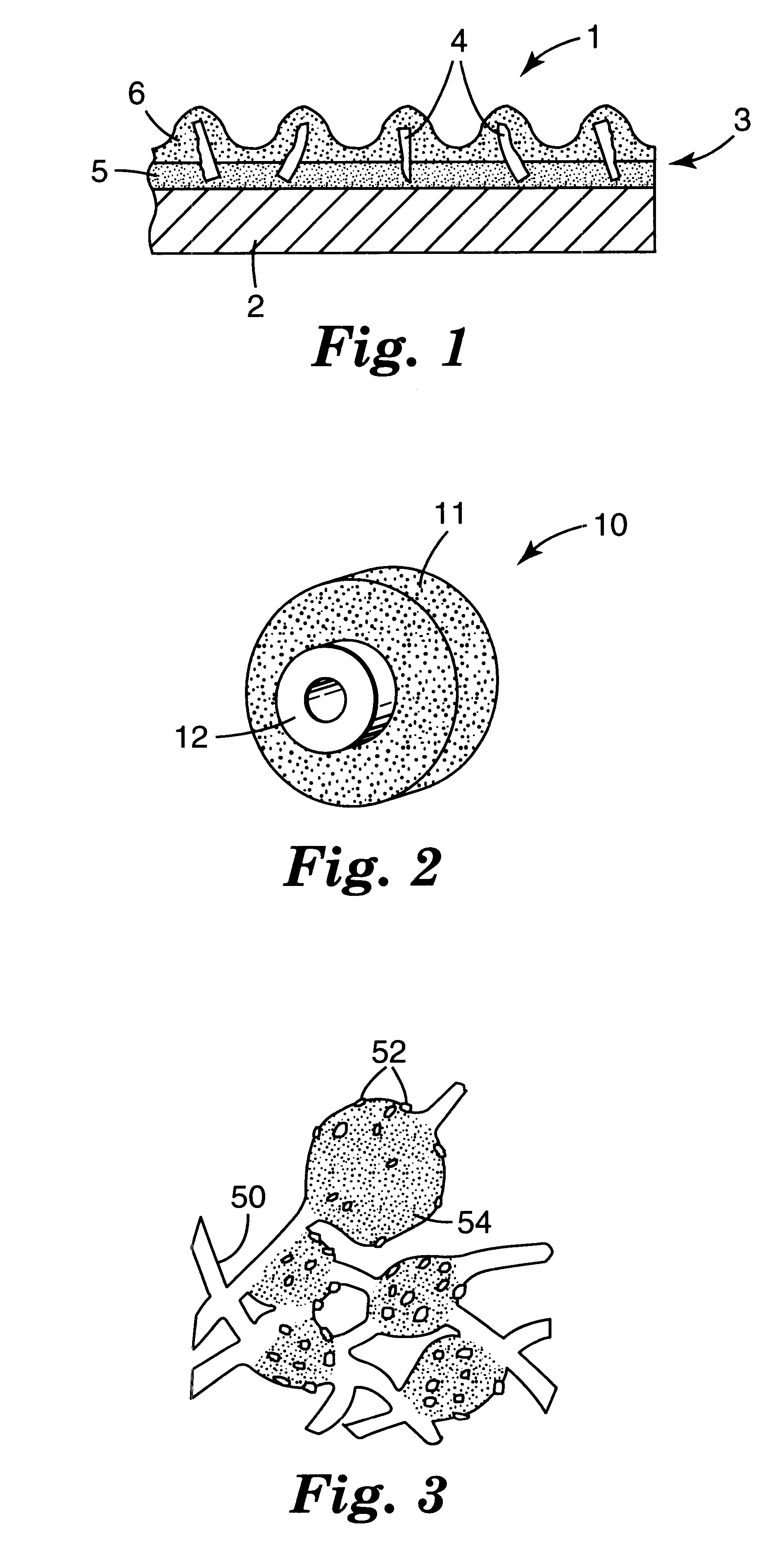

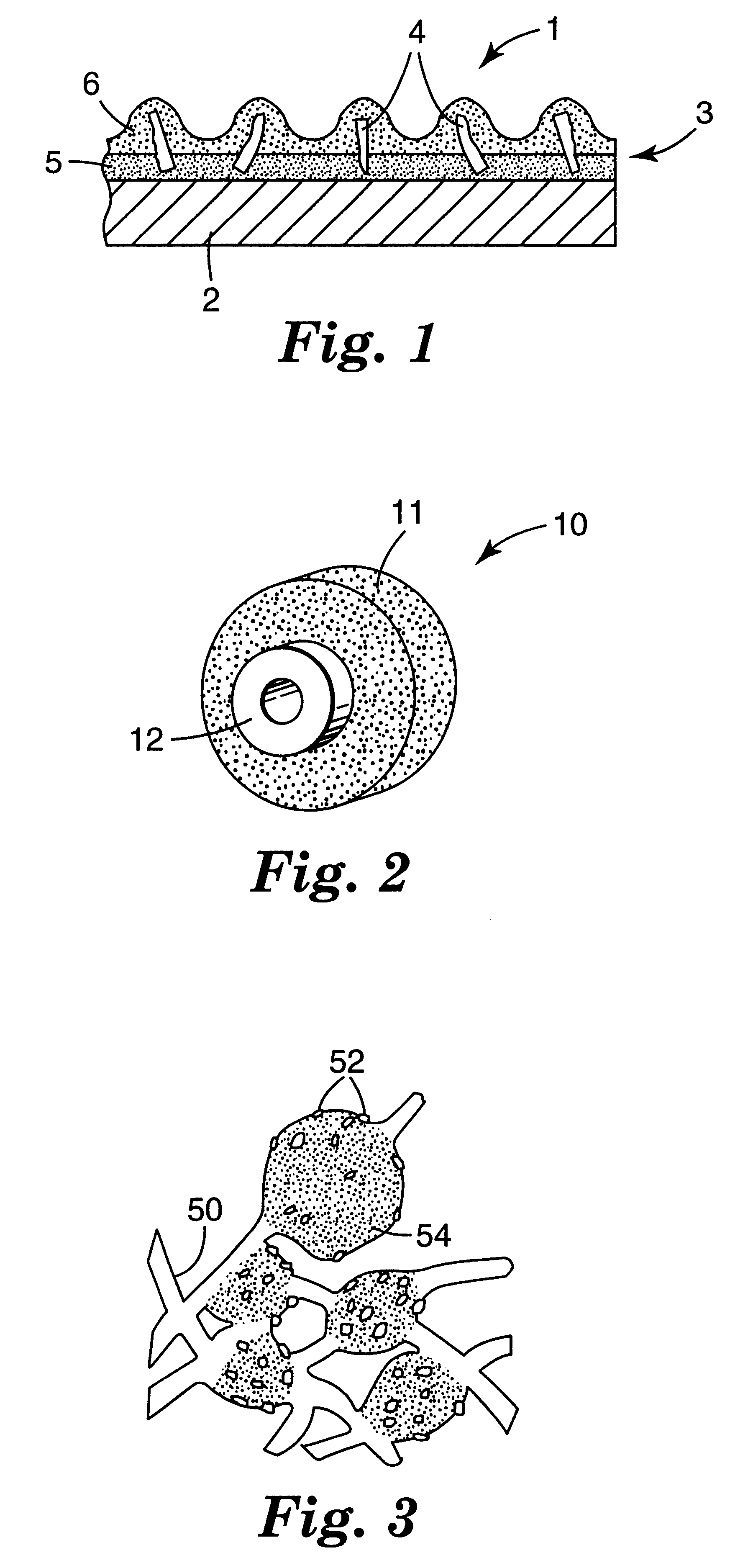

In the electrodeposited abrasive wheel 20 of the abrasive tool according to the present invention, plural mound parts 21, which are upheaved at the central domain of base metal 19 in almost columnar shape, are arranged mostly in the shape of lattice. An abrasive grain layer 22 is formed on a base metal 19, and plural ultra abrasive grains 14 are adhered only to each mound parts 21 by electrodeposited metal phase 25, and referred as the small abrasive-grain-layer parts 24, respectively. Ultra abrasive grains are laid out at corner R part 21a and top 21b of the mound parts 21 at the small abrasive-grain-layer parts 24. Ultra abrasive grains at each small abrasive-grain-layer parts are set as 11-500 pieces, and the rate which ultra abrasive grains occupy to the whole area of abrasive grain layer accounted by plane projection is set as 20%-80% of the range. At the time of grinding, only ultra abrasive grains contact to grinding work piece, then high abutment pressure is maintained, and sharpness and the discharge performance of ground wastes are good.

Owner:MITSUBISHI MATERIALS CORP

Fused aluminum oxycarbide/nitride-Al2O3.Y2O3 eutectic abrasive particles, abrasive articles, and methods of making and using the same

InactiveUS6454822B1Improve grinding performanceLower performance requirementsPigmenting treatmentOther chemical processesNitrideAbrasive

Owner:3M INNOVATIVE PROPERTIES CO

Fused abrasive particles, abrasive articles, and methods of making and using the same

InactiveUS6451077B1Improve grinding performanceLower performance requirementsPigmenting treatmentOther chemical processesAbrasiveComposite material

Owner:3M INNOVATIVE PROPERTIES CO

Fused-Al2O3-MgO-Y2O3 eutectic abrasive particles, abrasive articles, and methods of making and using the same

InactiveUS6706083B1Improve grinding performanceLower performance requirementsPigmenting treatmentMangesium aluminatesAbrasive

Owner:3M INNOVATIVE PROPERTIES CO

Fused Al2O3-rare earth oxide eutectic abrasive particles, abrasive articles, and methods of making and using the same

InactiveUS6607570B1Improve grinding performanceLower performance requirementsPigmenting treatmentMangesium aluminatesOxideAbrasive

Owner:3M INNOVATIVE PROPERTIES CO

Fused AL2O3-rare earth oxide-ZrO2 eutectic abrasive particles, abrasive articles, and methods of making and using the same

InactiveUS6666750B1Improve grinding performanceLower performance requirementsPigmenting treatmentOther chemical processesComposite materialCeramic materials

Owner:3M INNOVATIVE PROPERTIES CO

Fused abrasive particles, abrasive articles, and methods of making and using the same

InactiveUS6669749B1Improve grinding performanceLower performance requirementsPigmenting treatmentOther chemical processesAbrasive

Owner:3M INNOVATIVE PROPERTIES CO

Fused aluminum oxycarbide/nitride-Al2O3 . rare earth oxide eutectic abrasive particles, abrasive articles, and methods of making and using the same

InactiveUS6589305B1Improve grinding performanceLower performance requirementsPigmenting treatmentOther chemical processesRare earthAbrasive

Owner:3M INNOVATIVE PROPERTIES CO

Fused AL2O3-MgO-rare earth oxide eutectic abrasive particles, abrasive articles, and methods of making and using the same

InactiveUS6596041B2Improve grinding performanceLower performance requirementsPigmenting treatmentMangesium aluminatesNonwoven fabricComposite material

Owner:3M INNOVATIVE PROPERTIES CO

Sintered composites containing superabrasive particles

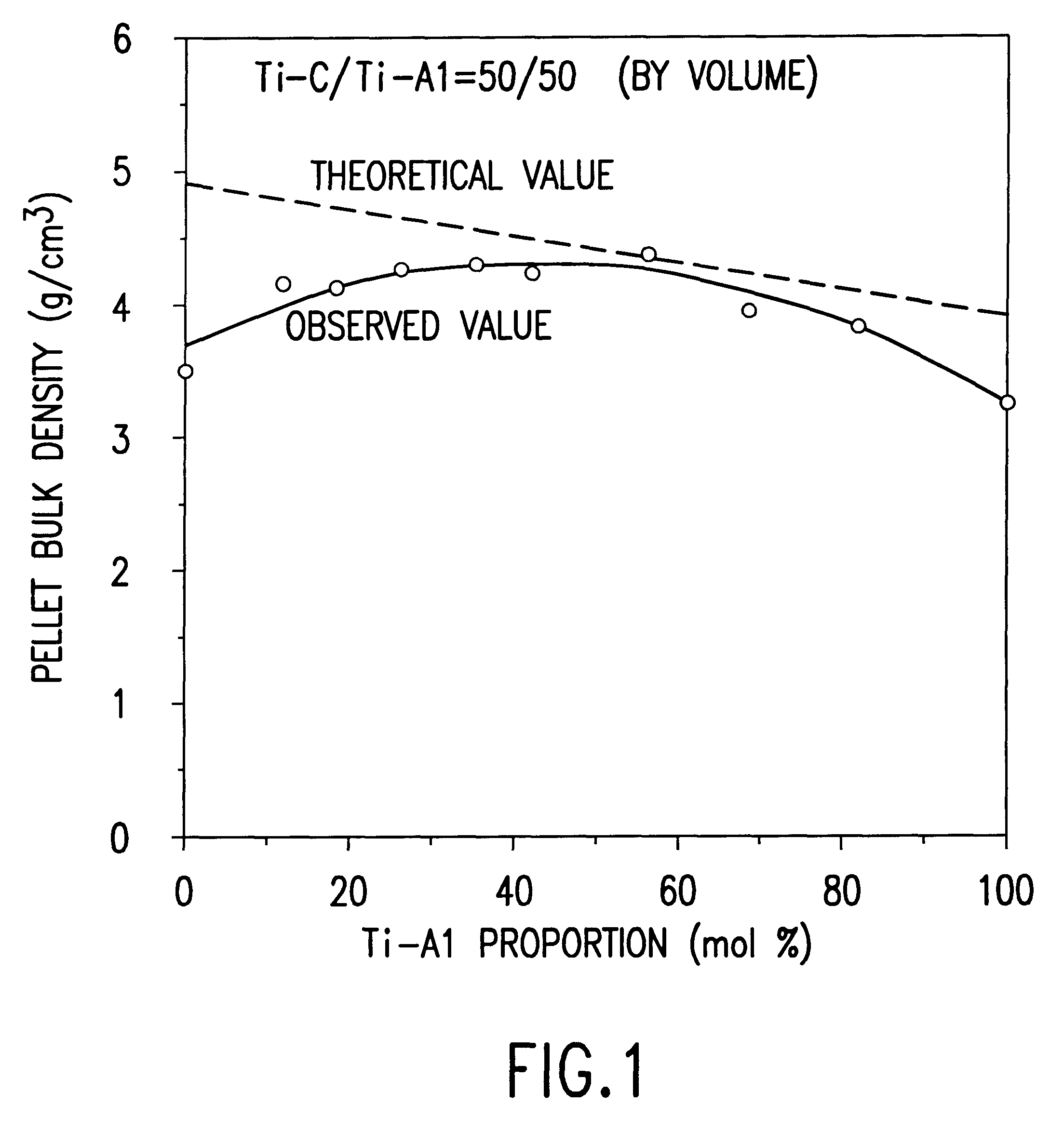

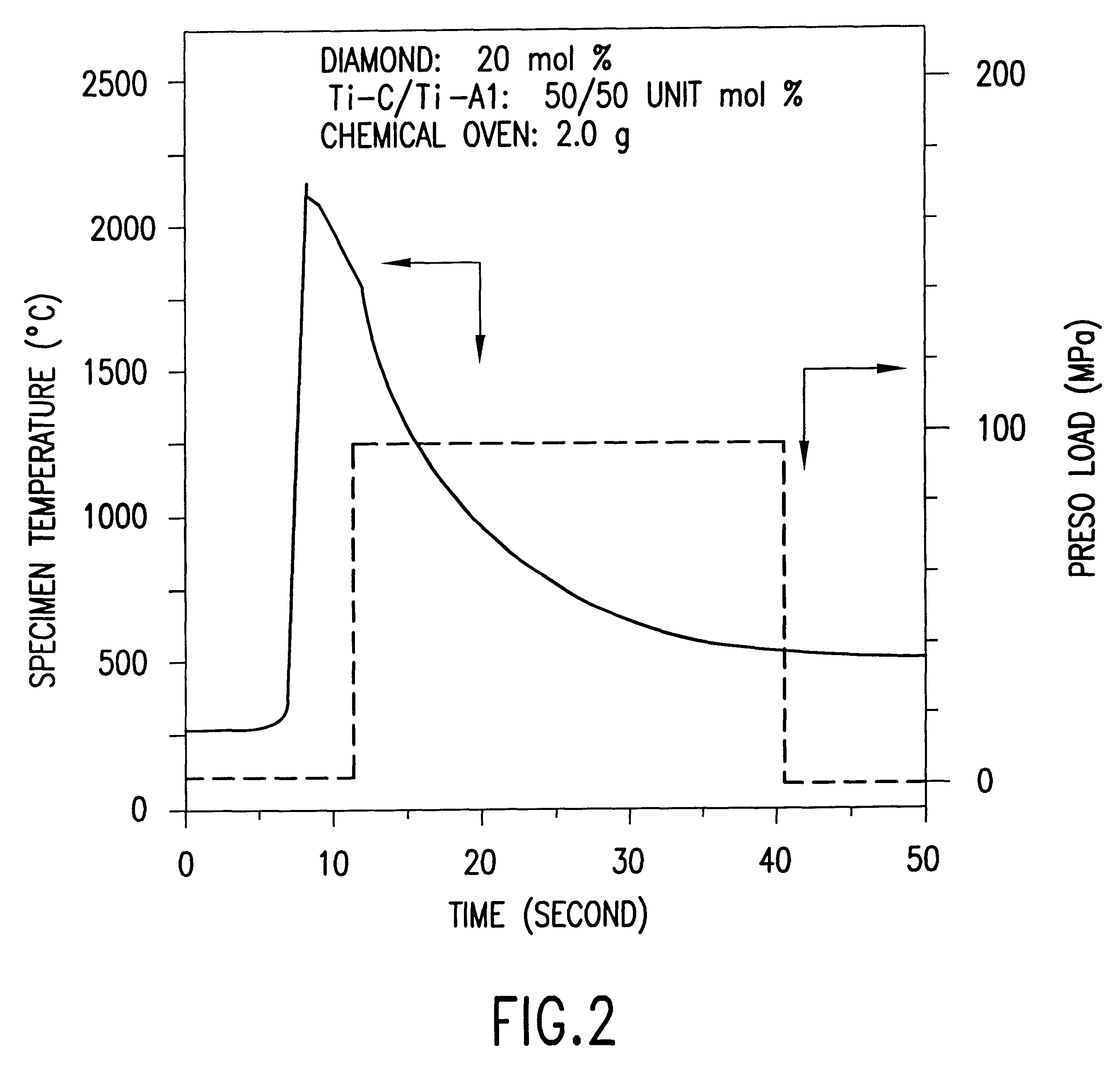

InactiveUS6203897B1Short heating timeHigh retention rateRecord information storageMagnetic recordingBorideNiobium

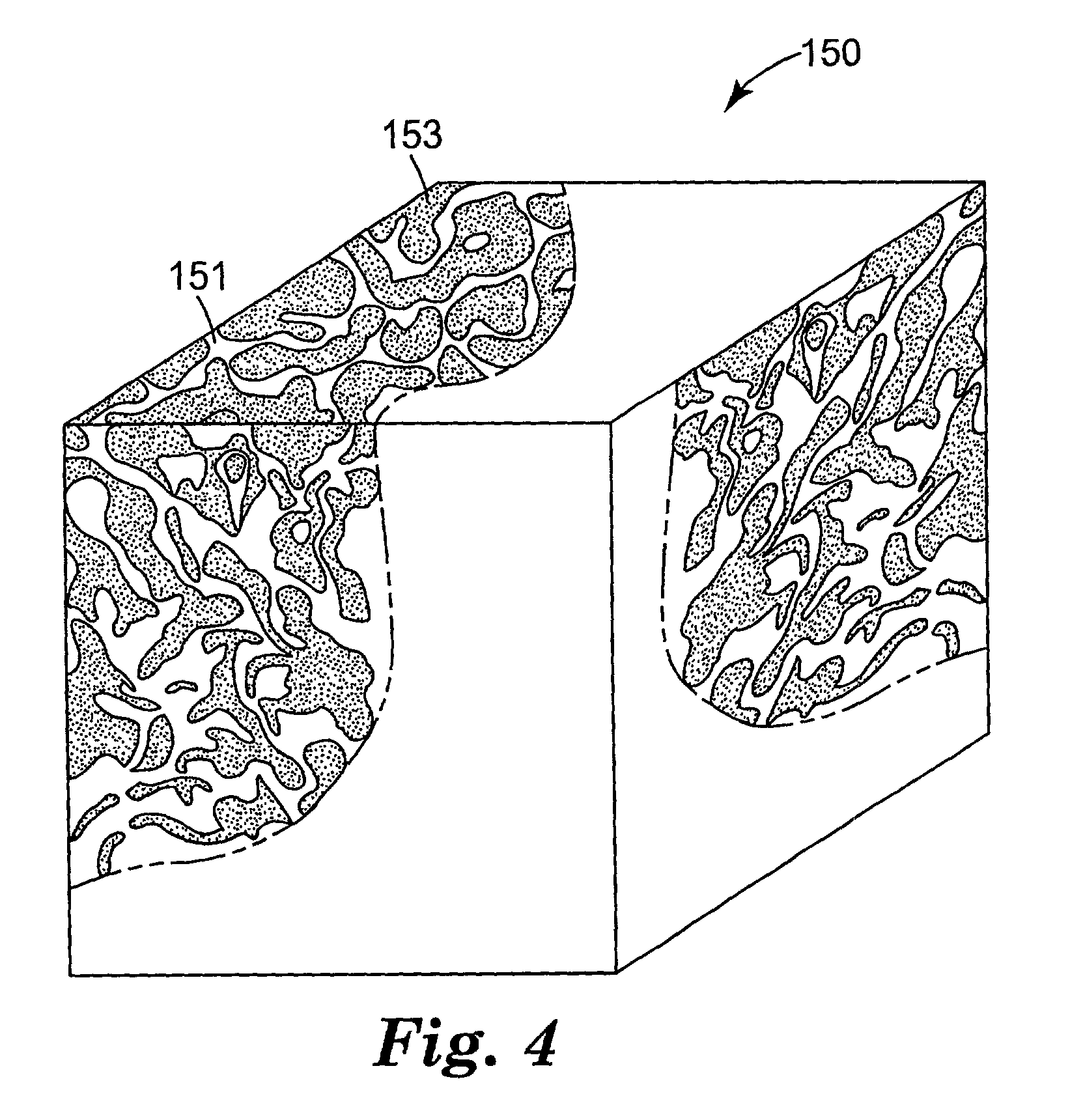

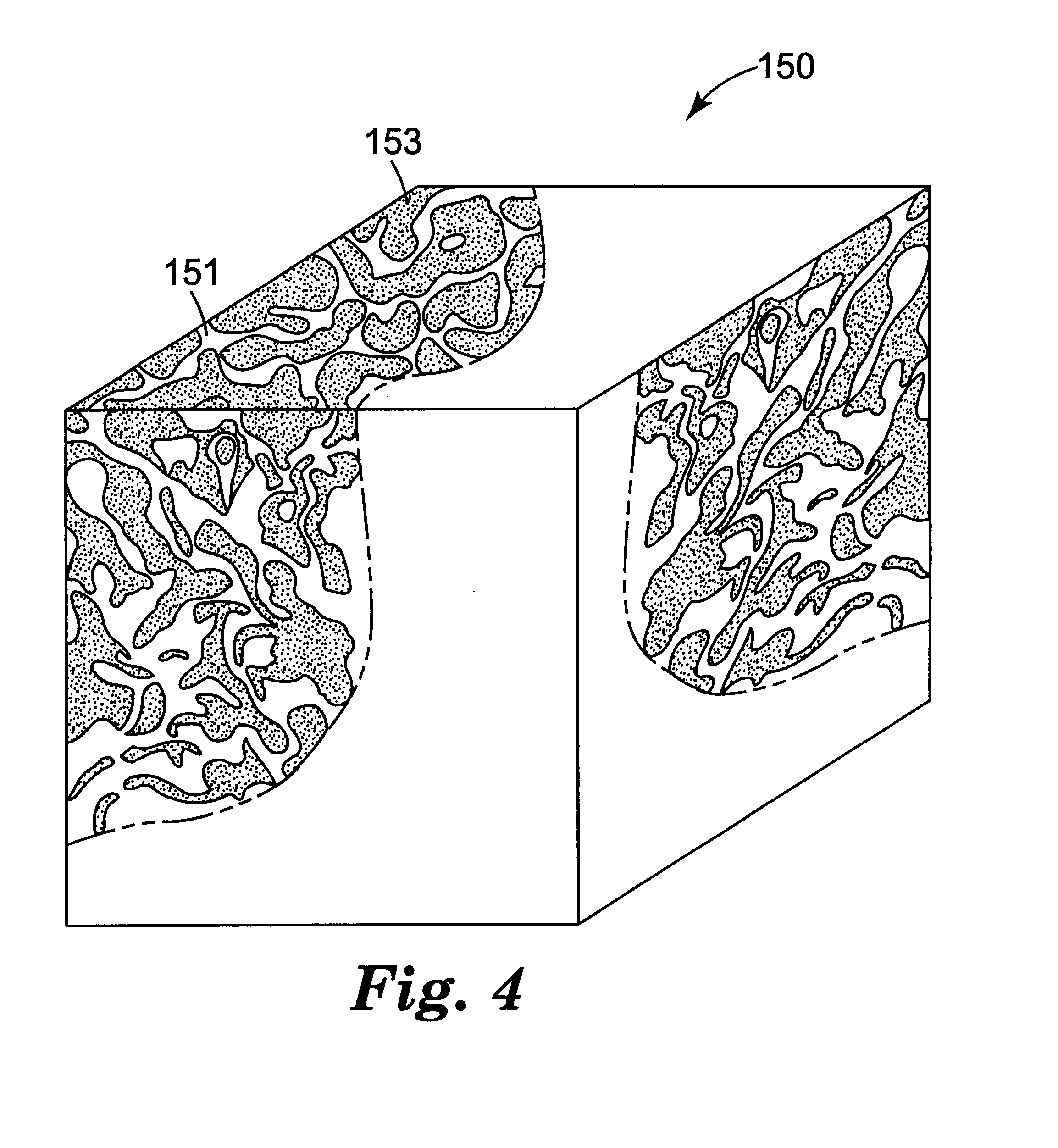

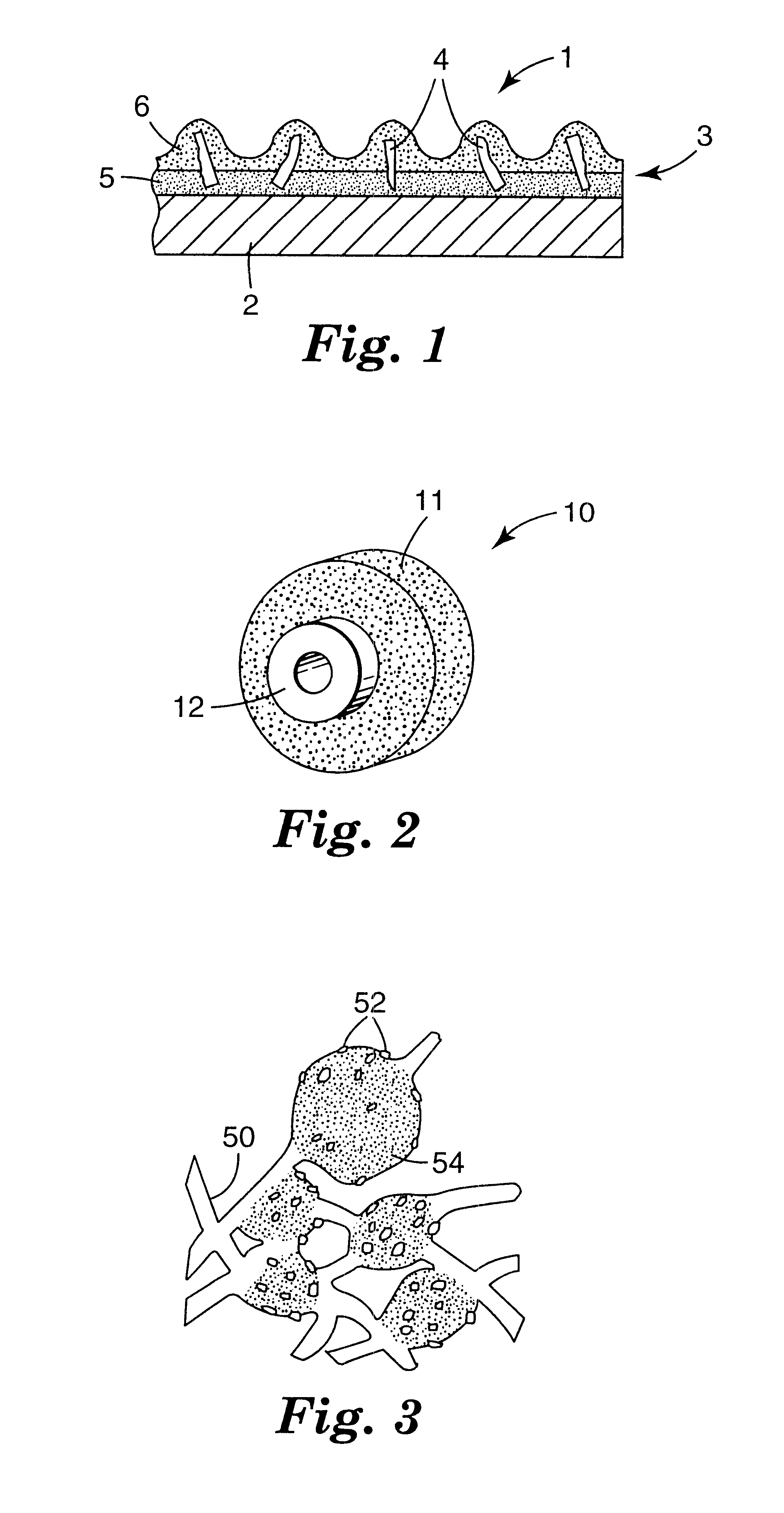

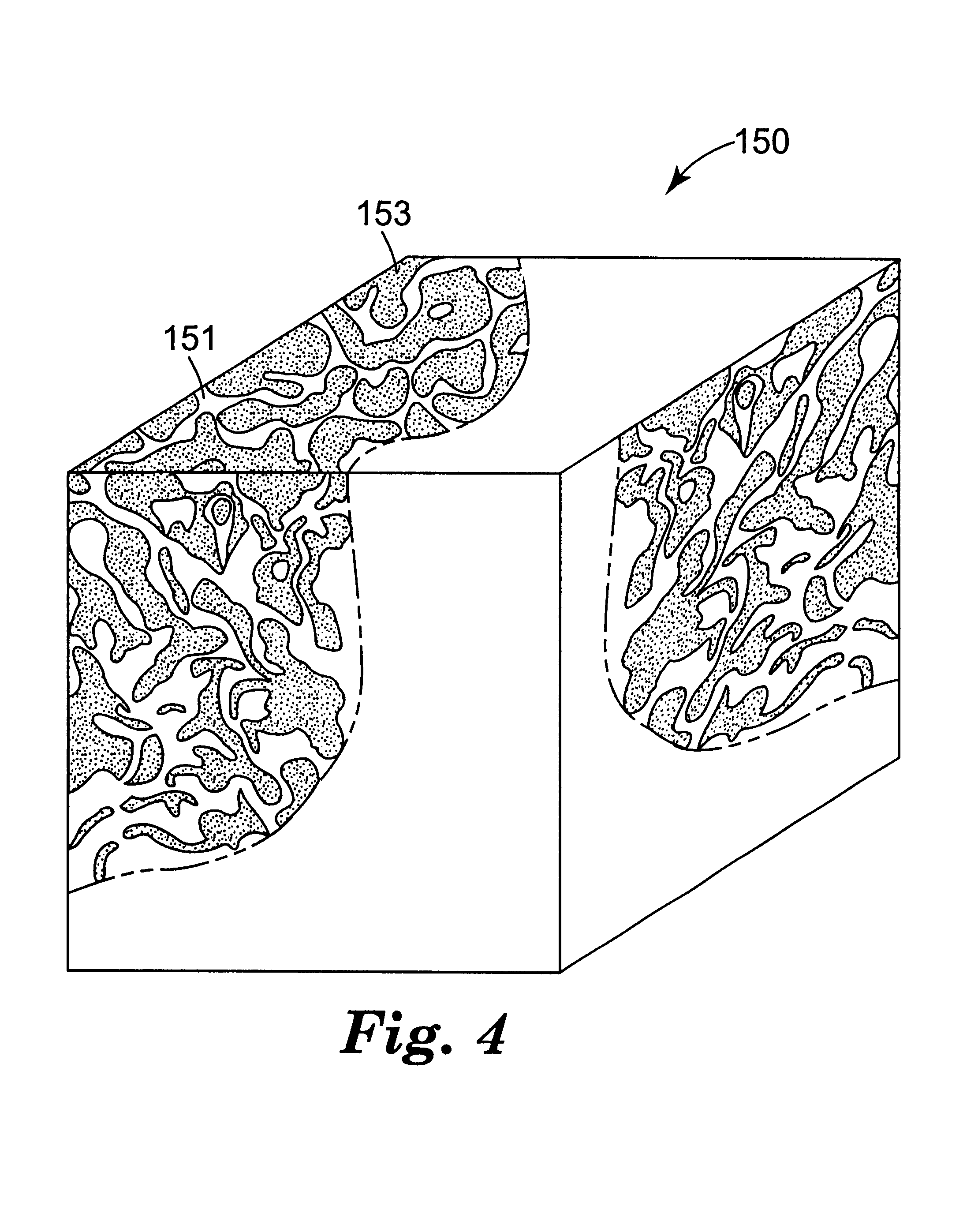

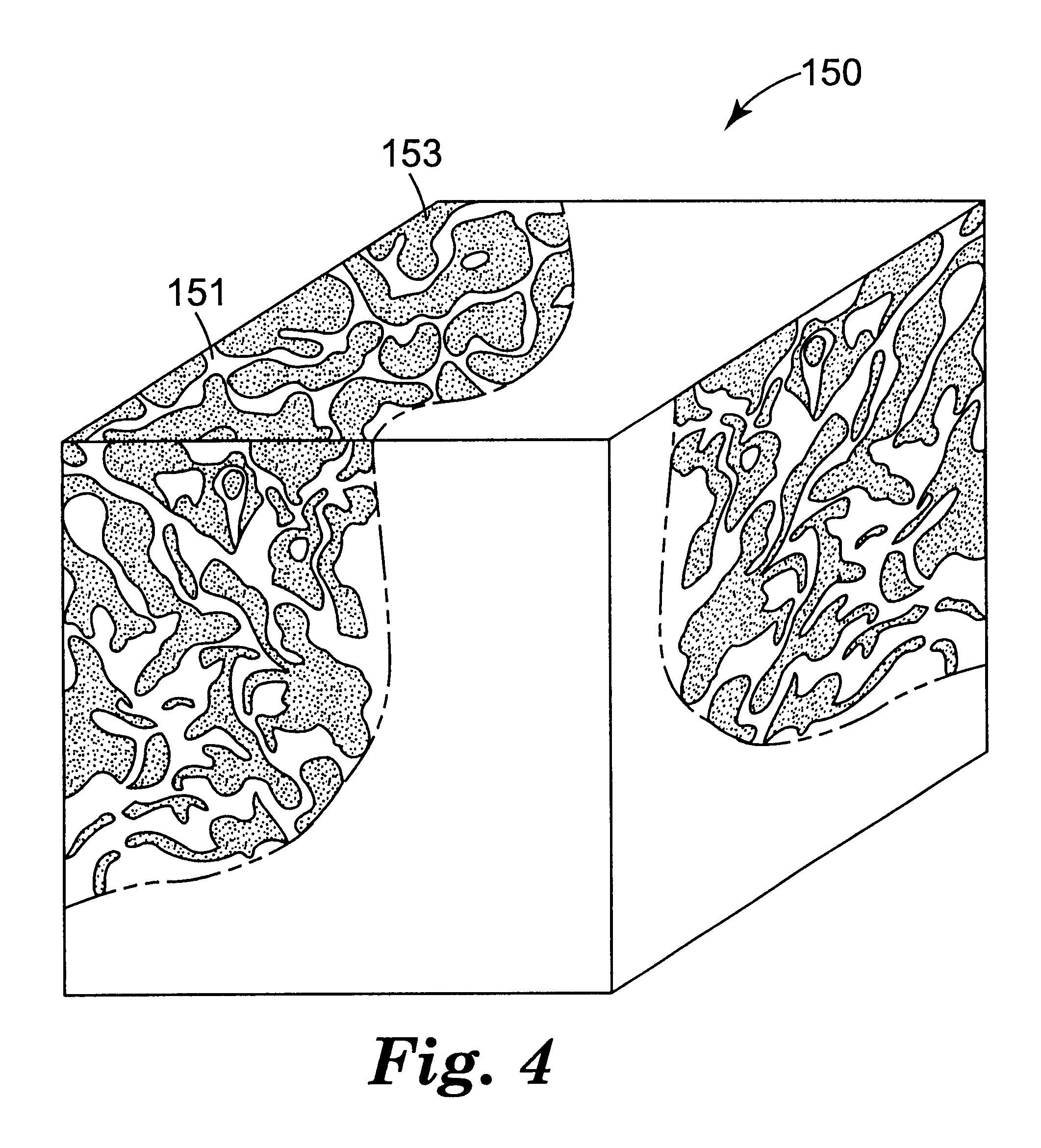

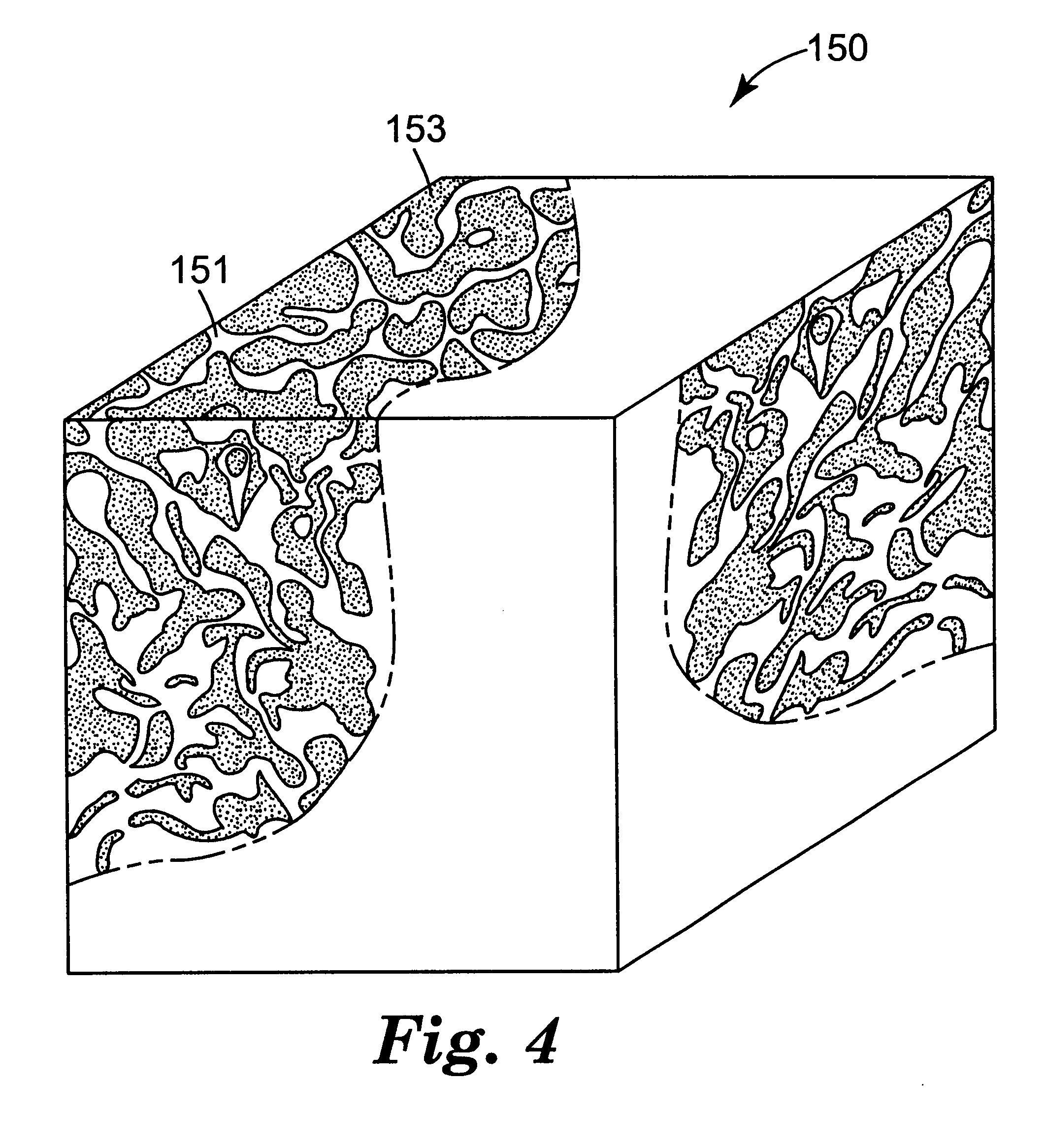

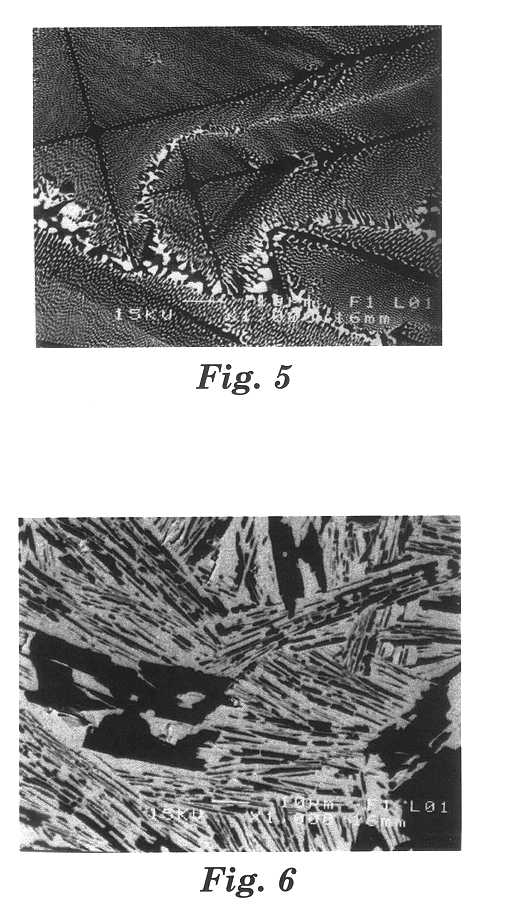

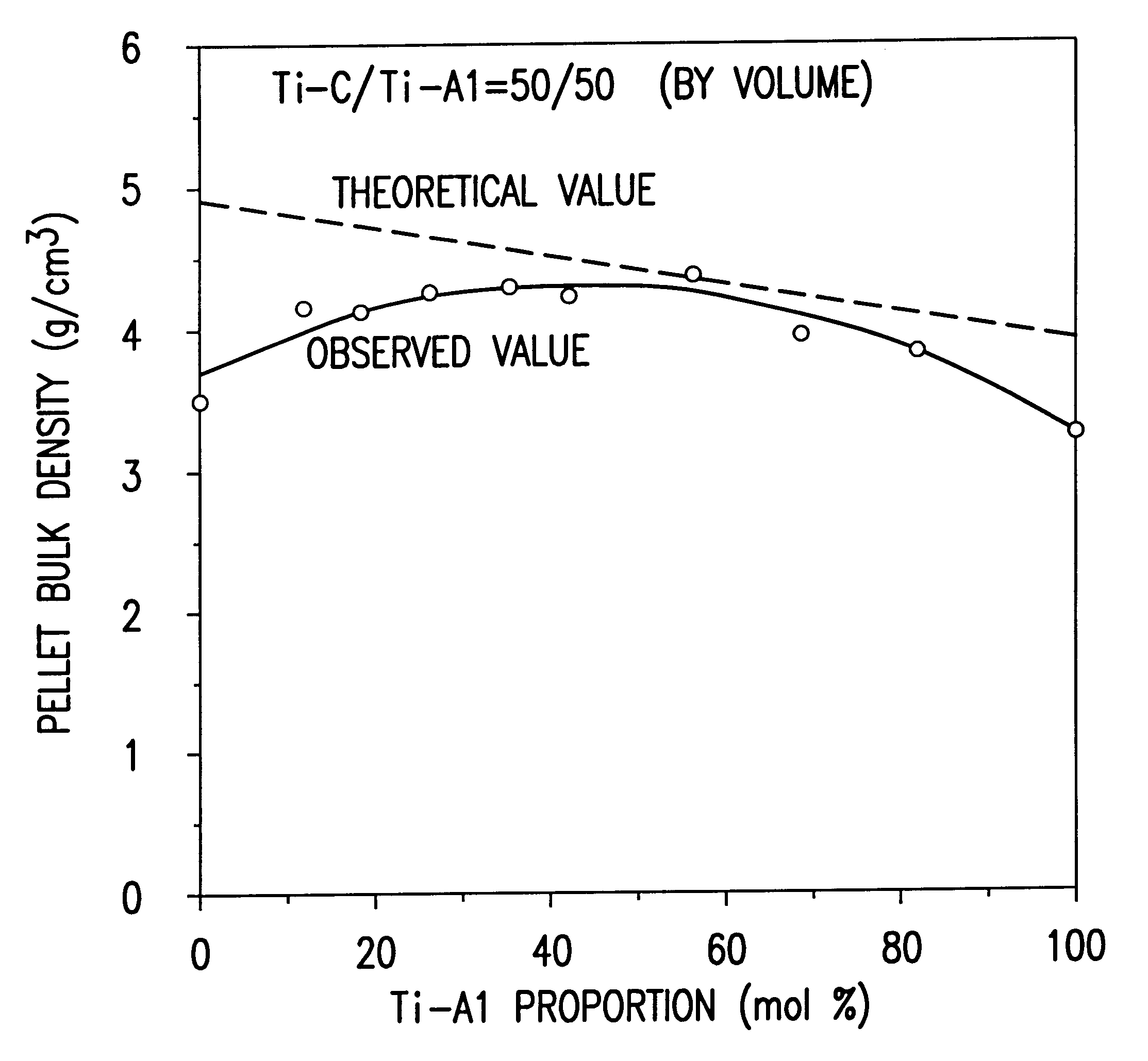

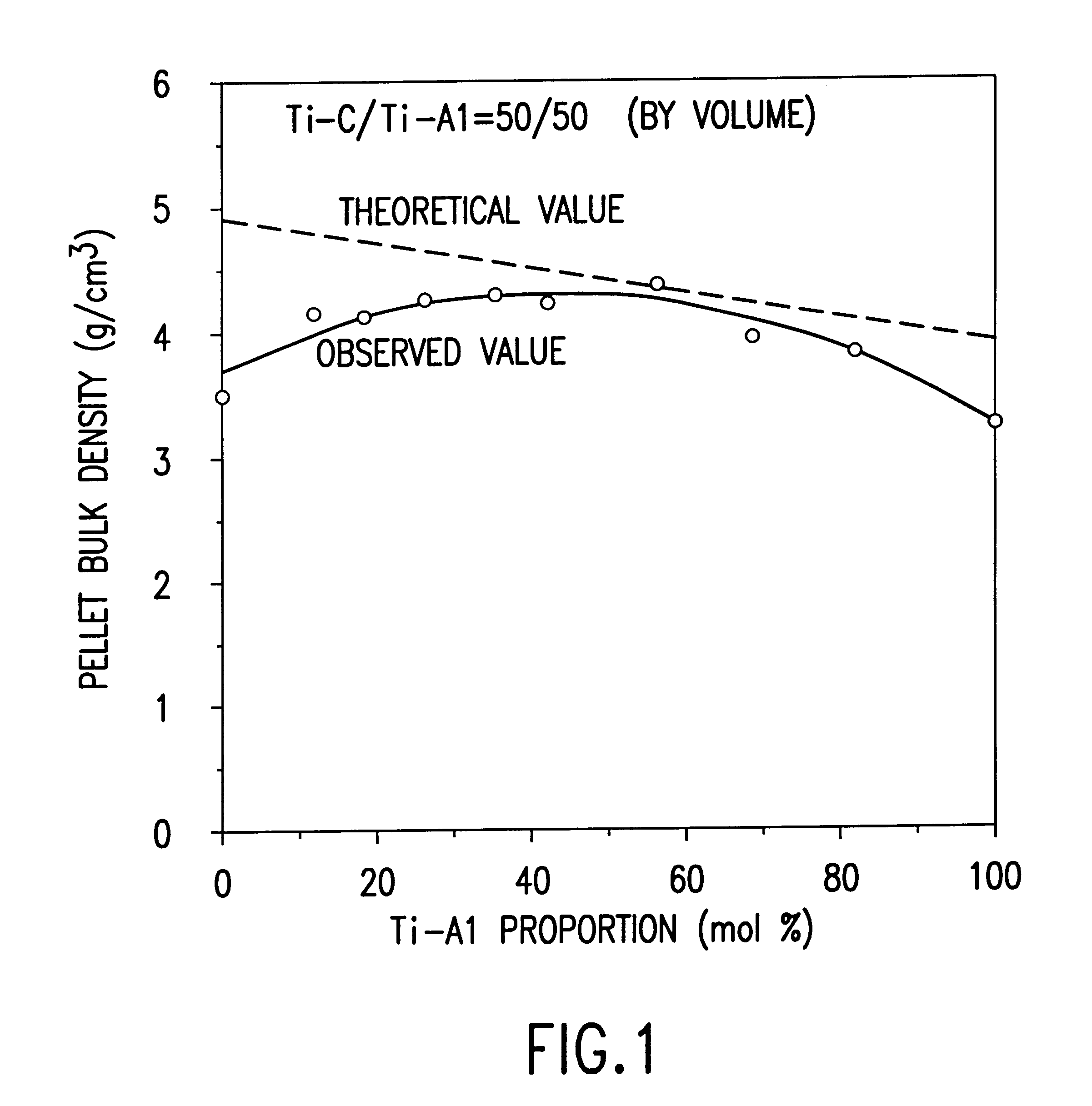

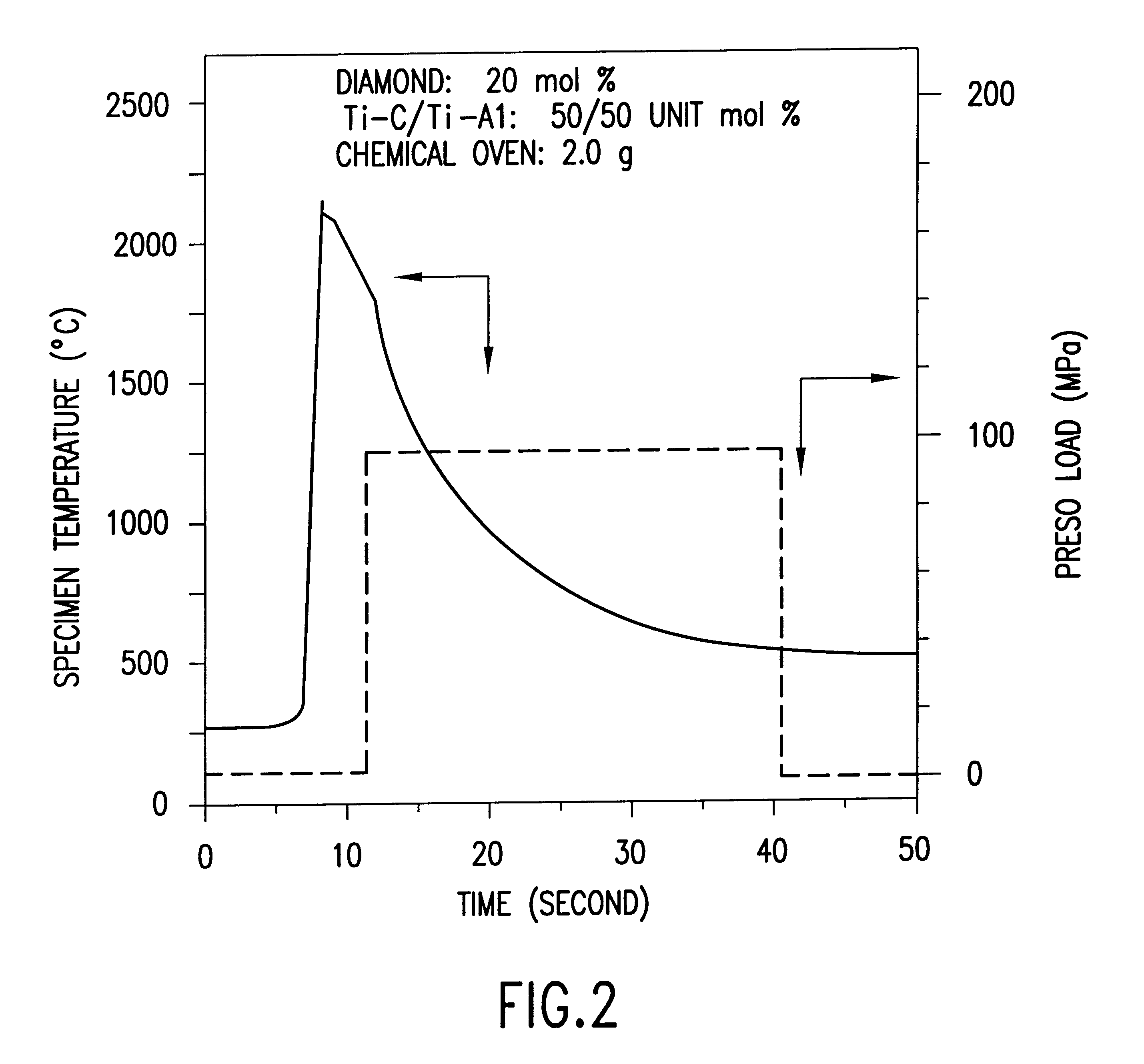

This invention provides a composite product and an effective method for producing the same, based on an SHS or intense heat producing process. Said composite essentially comprises either (1) one or more skeletal structures of three dimensionally joined pieces of at least one ceramic material selected from carbide, boride, nitride and silicide of titanium, zirconium, tantalum, niobium, silicon, chromium, tungsten, and molybdenum, and metallic material of alloy and / or intermetallic compound which fills the gaps within each and between adjacent skeletal structures, or (2) a matrix consisting of SHS products of metallic and / or ceramic substances, and particles of superabrasive selected from diamond and high pressure polymorphism of boron nitride, which are held and distributed in the matrix in the whole, in the surface or surface area comprising the portion corresponding to the end working face. Also effective is the use of superabrasive particles coated with metallic and / or non-metallic materials by some specific techniques.

Owner:2 KANAGAWA +3

Precision grinding wheel for high-efficiency aluminum oxide ceramic microcrystalline grinding materials

InactiveCN101797724AGood toughnessSmall grinding deformationAbrasion apparatusAlumina ceramicAluminium oxide

The invention relates to a precision grinding wheel for high-efficiency aluminum oxide ceramic microcrystalline grinding materials, comprising a grinding wheel basal body, grinding material particles distributed on the grinding wheel basal body and a bonding agent bonded and fixed on the grinding material particles, wherein the bonding agent comprises the following components in percentage by weight: 10-15 clay powder, 30-50 feldspar powder, 20-40 talcum powder and 10-20 high-boron glass powder. The grinding wheel has the functions of large cutting depth, high feeding strength, large load and high-efficiency grinding. According to tests, over 0.3 mm can be reached for one-way feeding and the metal removing rate is over 2 times higher than that of a common corundum grinding wheel. The grinding wheel ahs the advantages of high durability, long service life which is 5-10 times that of the common corundum grinding wheel, favorable self sharpening, no blockage and high capability of maintaining stable grinding performance.

Owner:SUZHOU FAR EAST ABRASIVES

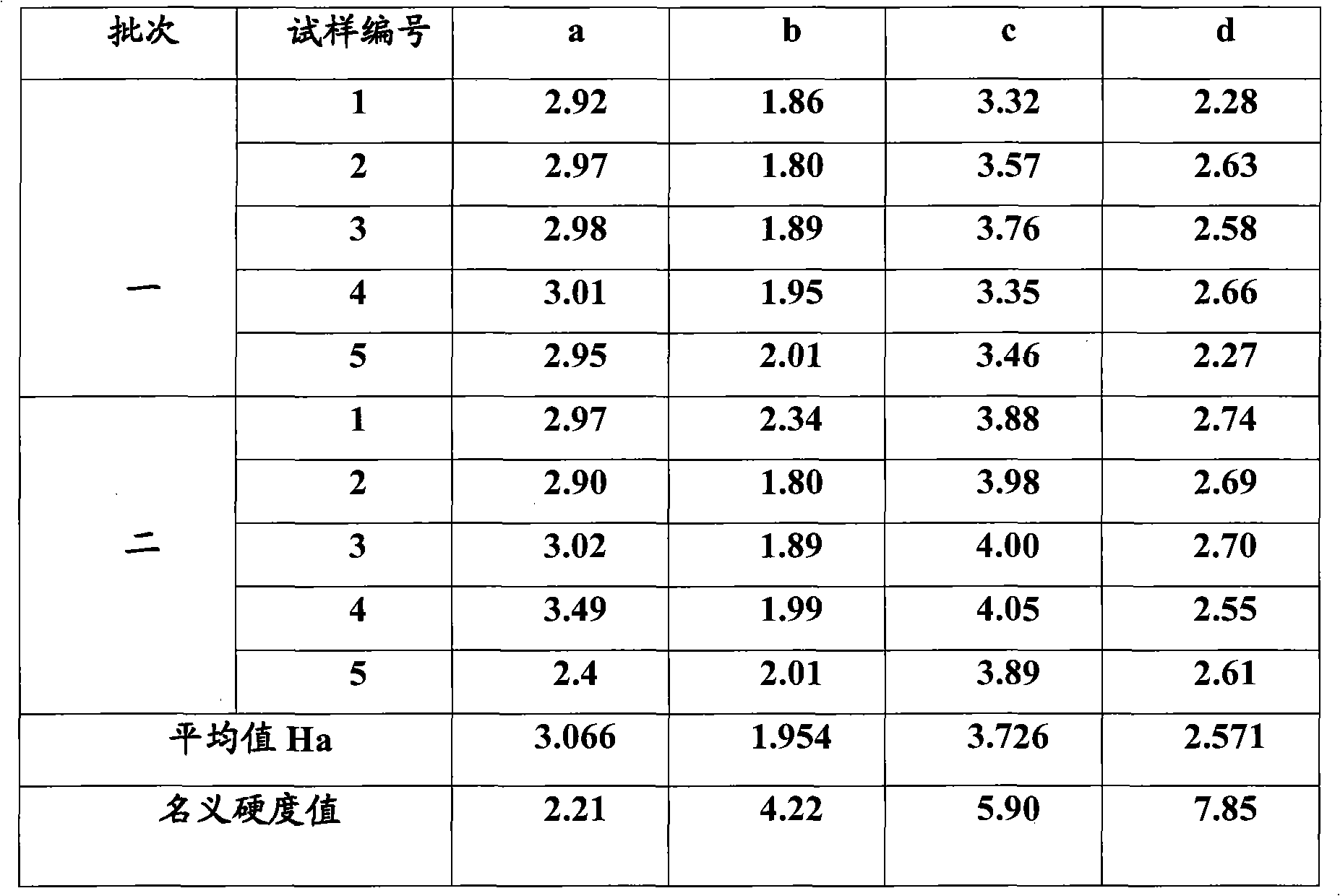

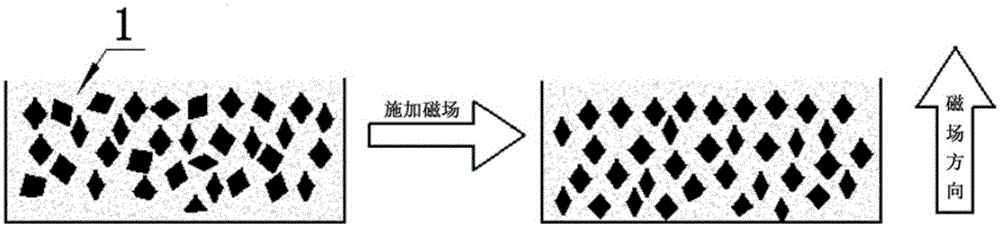

Ceramic bond grinding tool for oriented arrangement of abrasives and preparation method thereof

ActiveCN104999385AIncrease the number of effective grinding edgesImprove grinding ability of abrasive toolsAbrasion apparatusGrinding devicesSolventAbrasive

The invention discloses a ceramic bond grinding tool for oriented arrangement of abrasives and a preparation method thereof. The grinding tool is prepared by the method comprising the following steps: 1) the abrasives, a ceramic bond, a dispersing agent and a solvent are taken for mixing a slurry; 2) the obtained slurry is injected in a mold, and is put in a magnetic field with a strength of 1-50 T for magnetizing to obtain magnetized slurry; and 3) the magnetized slurry is dried and demolded to obtain a biscuit; and the biscuit is sintered and cured to obtain the ceramic bond grinding tool. In the ceramic bond grinding tool for oriented arrangement of abrasives, after the slurry is injected in the mold, the slurry is stood in the high-strength magnetic field; under the effect of electromagnetic force, the abrasives rotate to generate oriented arrangement; the ceramic bond grinding tool for oriented arrangement of abrasives is prepared through the oriented arrangement of the abrasives; an effective cutting edge in the grinding of the grinding tool is added; the grinding capacity of the grinding tool is improved; and the grinding surface quality is improved.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

High-efficiency extra strength alloy steel moderate grinding abrasive band and detection method thereof

ActiveCN101693356AImprove grinding performanceGood value for moneyAbrasion apparatusUsing mechanical meansSurface-active agentsAdhesive

The invention relates to an abrasive band, in particular to a high-efficiency extra strength alloy steel moderate grinding abrasive band and a detection method thereof. The abrasive band comprises a base material, base adhesive, grinding material and composite adhesive, wherein the base adhesive comprises the following components in percentage by weight: 60-85 percent of bonding agent, 12-32 percent of neutral or alkaline inorganic filler, 0.1-0.3 percent of surface active agent and 2.5-8 percent of thinner; and the composite adhesive comprises the following components in percentage by weight: 65-85 percent of a bonding agent, 0-30 percent of inorganic filler, 2-5 percent of dyes and 2-8 percent of thinner. In the detection method, annulus band grinding is used for detecting demetallization amount, annulus bands are abutted, and ten stainless steel bars with the diameter of 40 cm are ground under the condition that the rotation speed is 1800 rpm, the contact pressure is 200 Newton and the grinding time is 71 seconds. The high-efficiency extra strength alloy steel moderate grinding abrasive band has high grinding performance and high performance price ratio, is suitable for moderate grinding processing of various alloy steel products, and can substitute similar imported products.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

Grinding system

ActiveUS20120043405A1Improve grinding performanceSimpler and easy and less-expensiveCoffee millsSpice millsEngineeringActuator

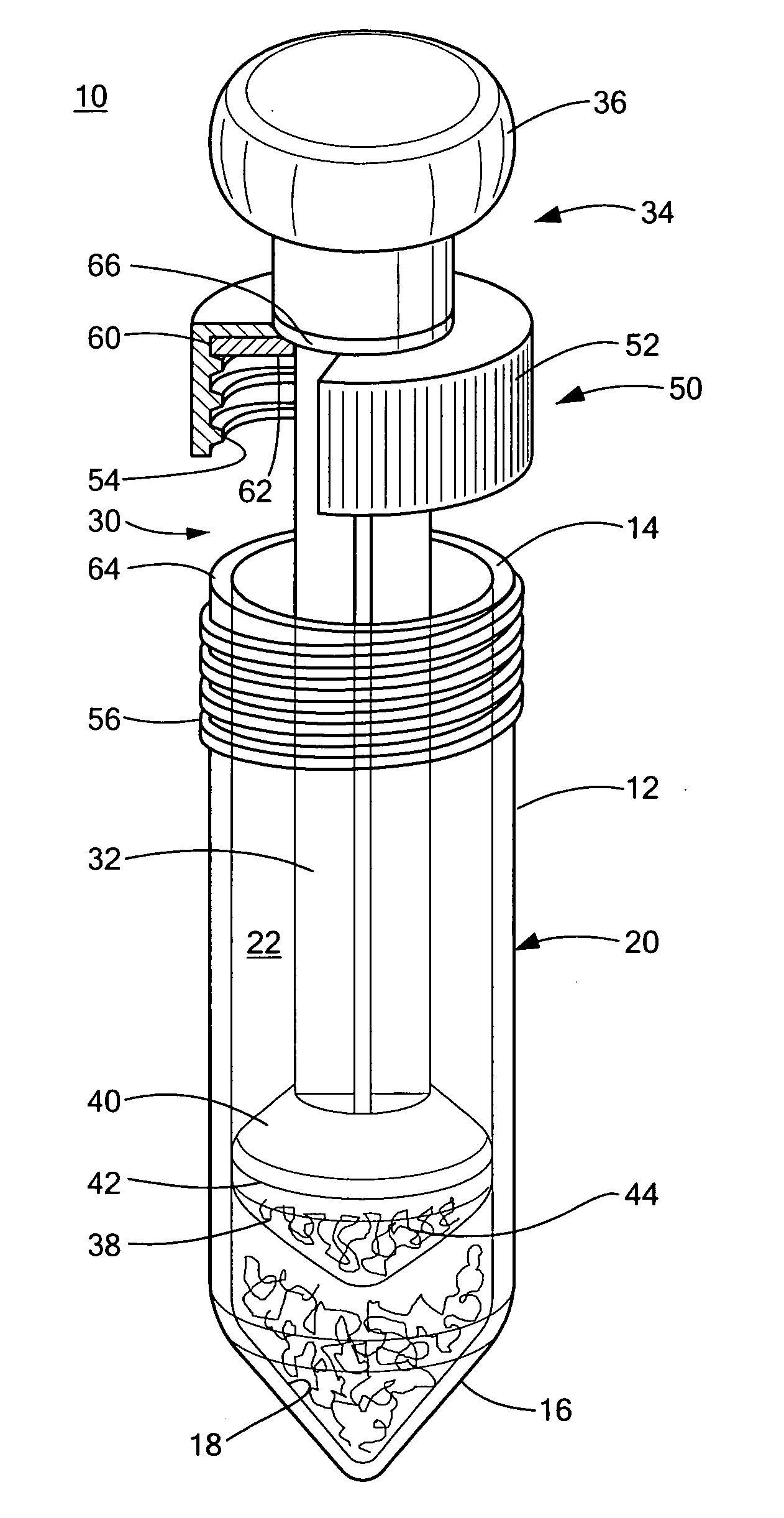

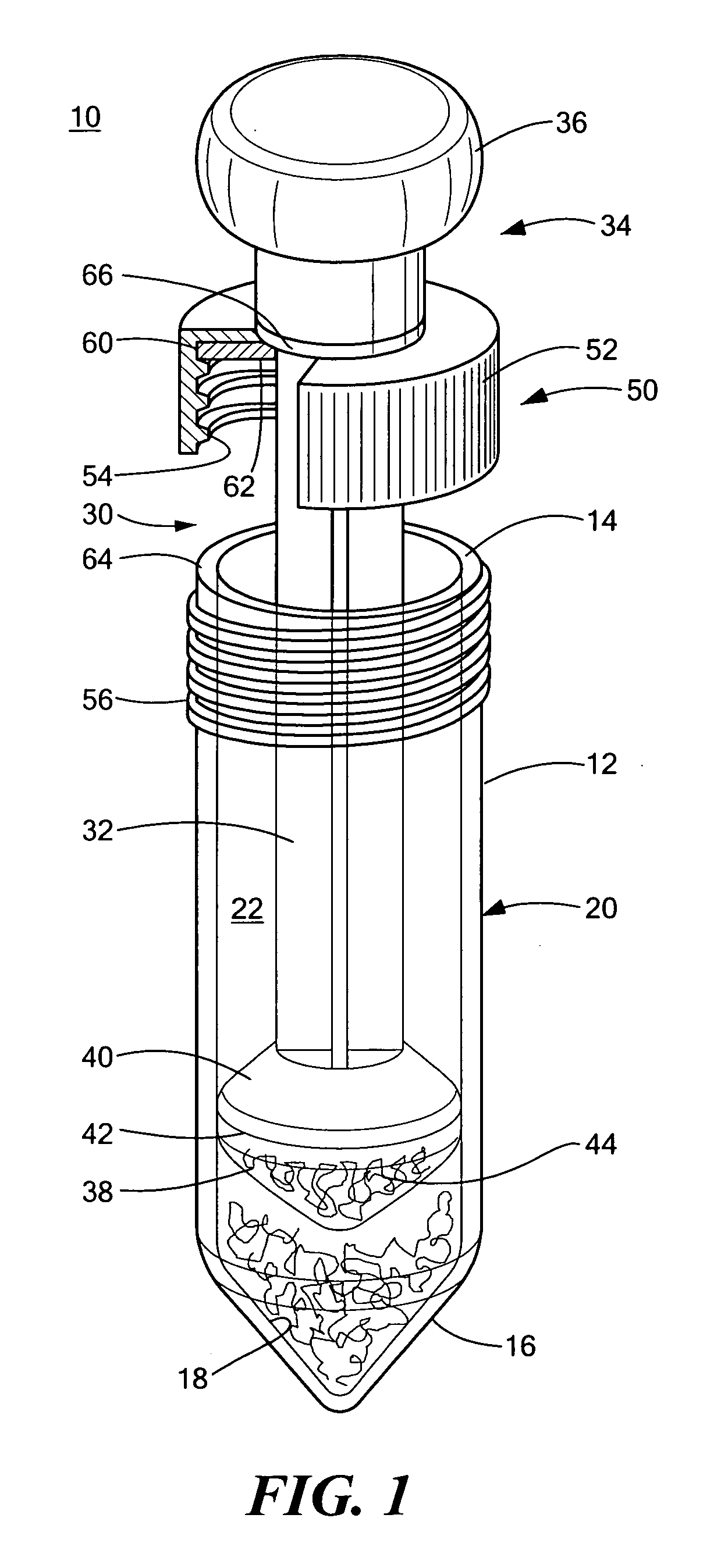

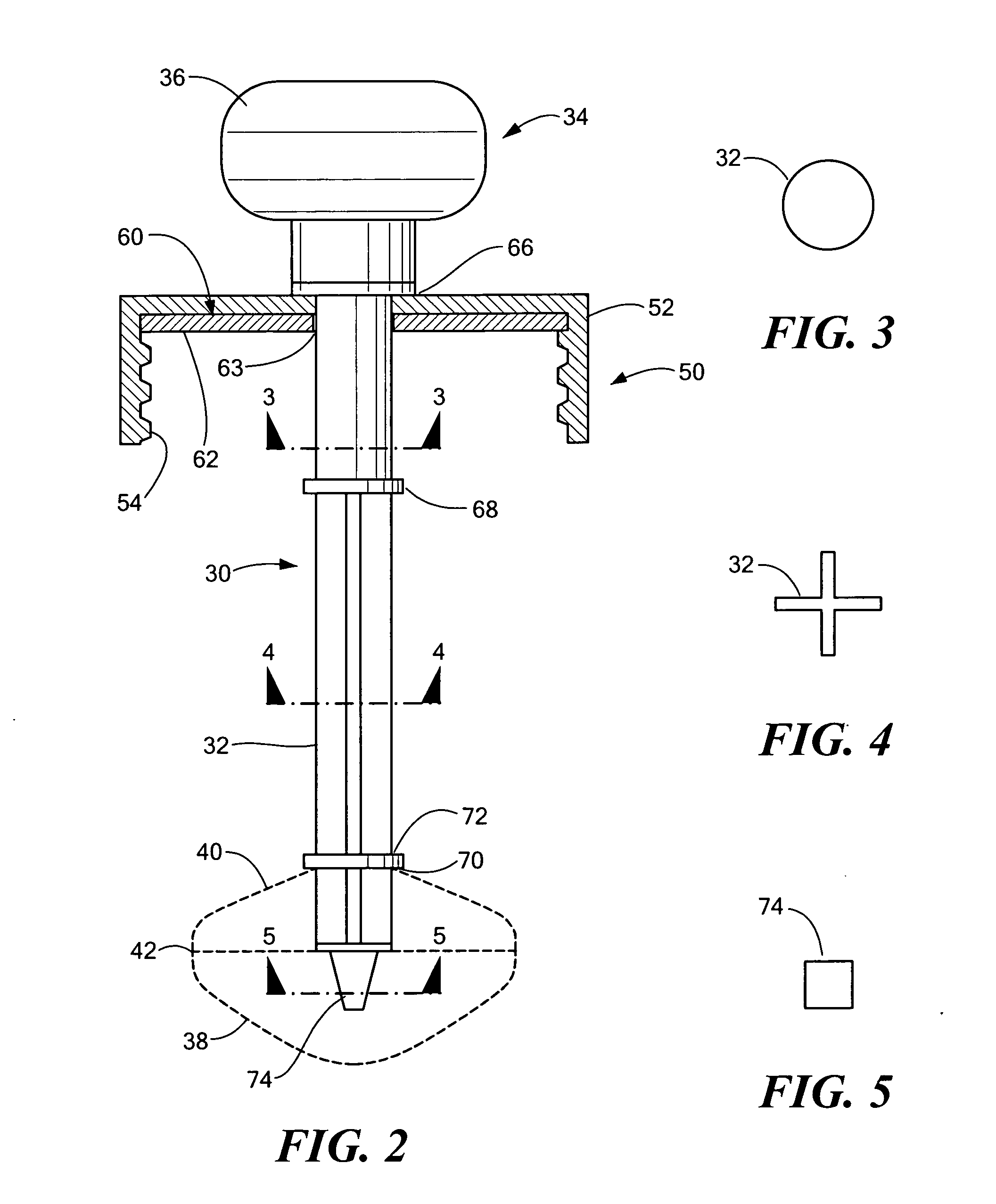

A grinding system includes a mortar container having an open top portion and a bottom portion having a first interior grinding surface and a wall portion interconnecting the top and bottom portions for defining a hollow interior collection chamber, a modular pestle assembly including a universal pestle shaft having at its proximate end an actuator portion extending above the top portion and at its distal end a mounting portion for receiving one of a set of pairs of matching tips and pestle collars, the pestle tip having a second grinding surface for engaging the first grinding surface, and a closure device sealingly engageable with the pestle assembly and the open top portion for sealing the container and the collection chamber between the grinding surfaces and the top portion of the mortar container.

Owner:BIOMEDICAL POLYMERS

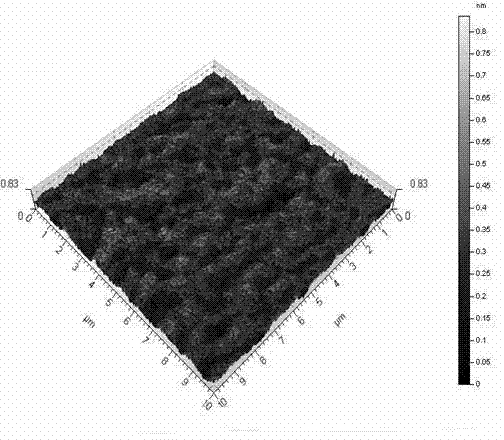

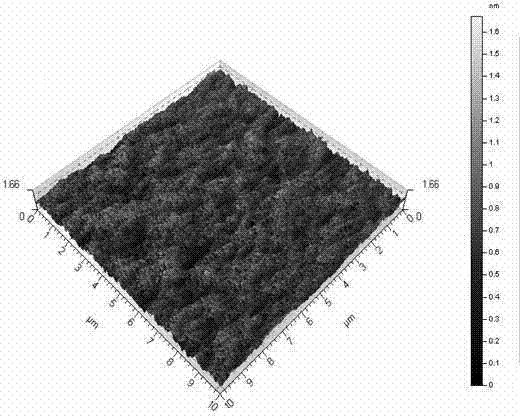

CMP (Chemical-Mechanical Polishing) polishing liquid with mixed grinding materials for alkaline sapphire substrate and preparation method thereof

ActiveCN103571333ASolve pollutionSolve many disadvantages such as easy gelPolishing compositions with abrasivesNano sio2SURFACTANT BLEND

The invention relates to a CMP (Chemical-Mechanical Polishing) polishing liquid with mixed grinding materials for an alkaline sapphire substrate and a preparation method thereof. The CMP polishing liquid consists of the following components in percentage by weight: 0.5-35% of a main grinding material, 0.015-0.09% of an auxiliary grinding material, 0.005-0.05% of a chelating agent, 0.005-0.05% of a surfactant, 0.01-0.5% of a pH adjustor, and the balance of deionized water, wherein the main grinding material is a nano SiO2 sol and the auxiliary grinding material is an Al2O3 sol. The auxiliary grinding material, the chelating agent, the surfactant and the alkaline pH adjustor are sequentially added into a nanosilicon sol suspension. In the polishing liquid, as the content of the main grinding material SiO2 sol is reduced, the phenomenon that the polishing liquid residue on the surface of the substrate after CMP is relatively severe is reduced to facilitate subsequent cleaning. A less amount of the auxiliary grinding material Al2O3 is added, so that the polishing speed is remarkably increased, and the roughness of the substrate after CMP is reduced.

Owner:江西伟嘉创展企业管理有限公司

Manufacturing method of heavy-duty grinding resin wheel

InactiveCN102513947AImprove thermal conductivityImprove toughnessAbrasion apparatusGrinding devicesFree coolingRoom temperature

The invention provides a manufacturing method of a heavy-duty grinding resin wheel. The method comprises the steps that 70 to 90 percent of abrasive, 5 to 20 percent of binder and 5 to 10 percent of filler by mass percent are mixed and uniformly stirred, so as to form mixed material; the mixed material is added into a grinding wheel die which is preheated to 120 to 185 DEG C in batches, and a wire mesh is laid between each two batches of the mixed materials, so as to form a grinding wheel initial blank; the grinding wheel initial blank is subjected to hot press molding; a grinding wheel subjected to hot press molding is put into a grinder, and the end surface of the grinding wheel is ground till the abrasive on the surface of the grinding wheel can be seen; and the grinding wheel subjected to grinding treatment is calcined and then naturally cooled to room temperature, so that the heavy-duty grinding resin wheel is obtained. The heavy-duty grinding resin wheel is unlikely to rupture, edges are unlikely to drop off, and the heavy-duty grinding resin wheel is unlikely to crack.

Owner:NINGBO DINGXIN GRINDING WHEEL MFG

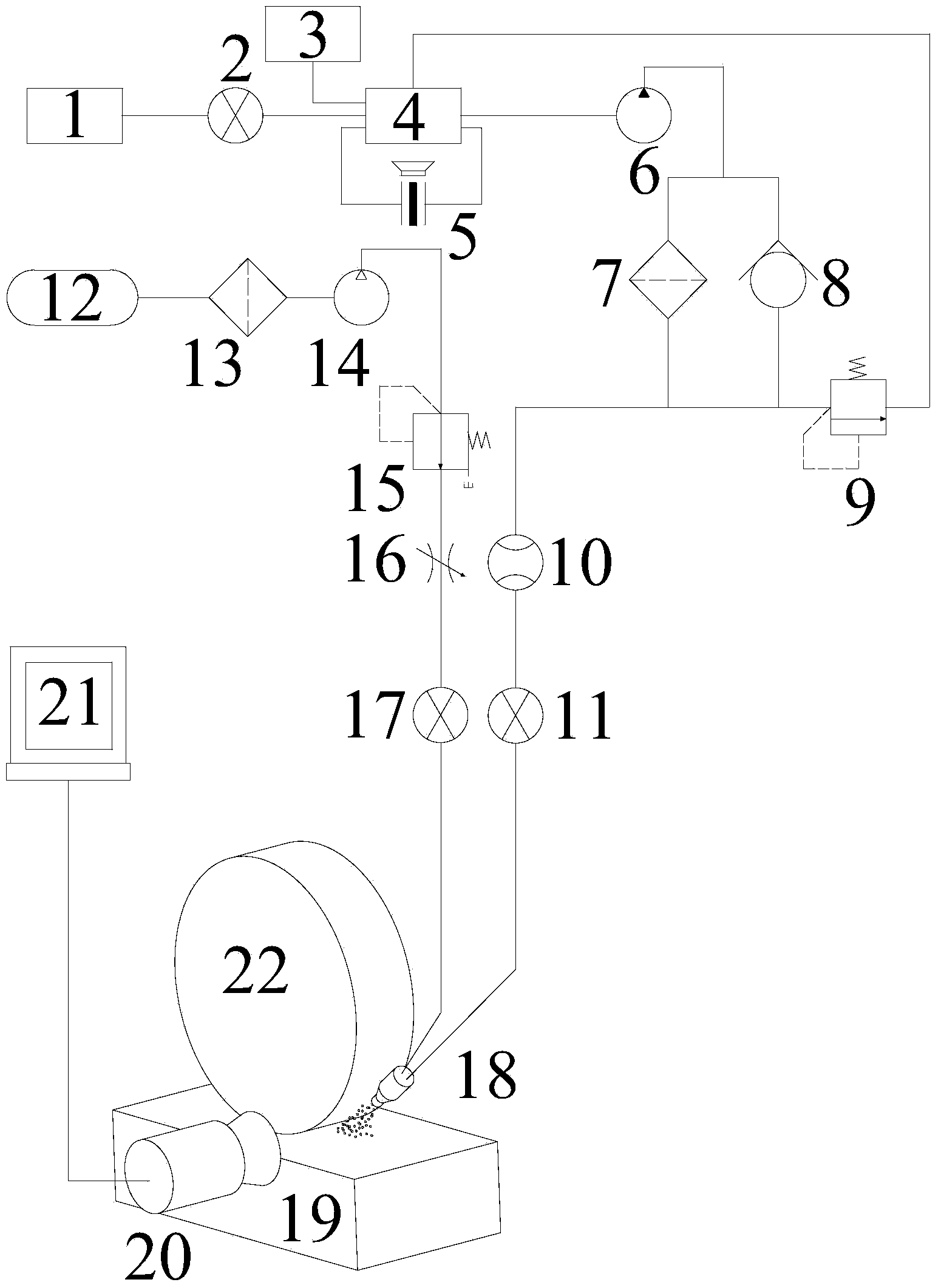

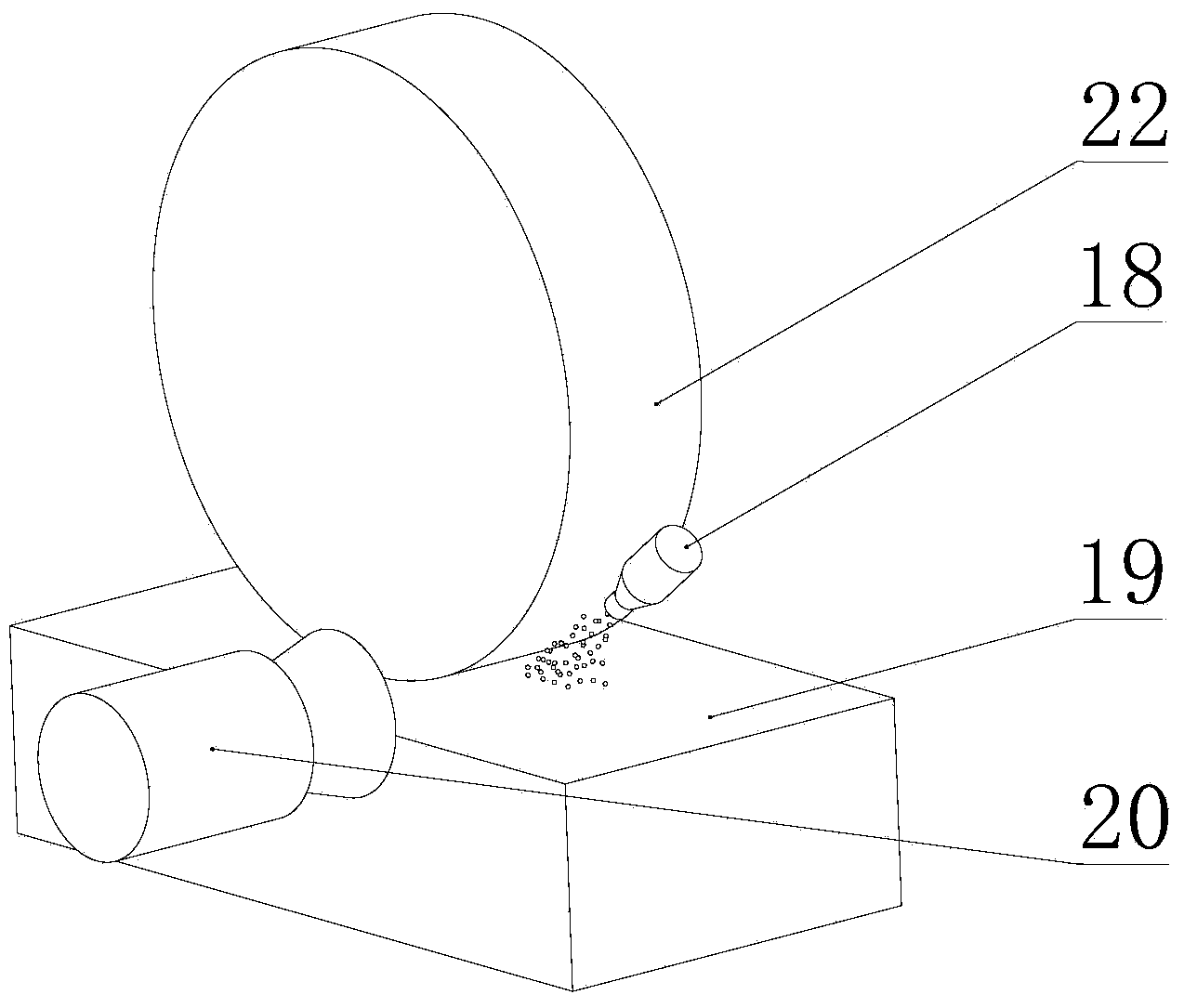

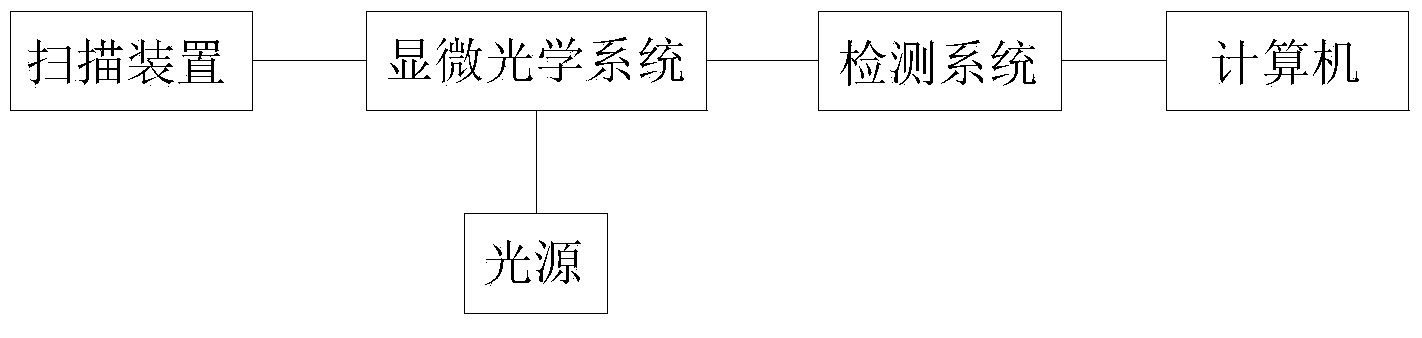

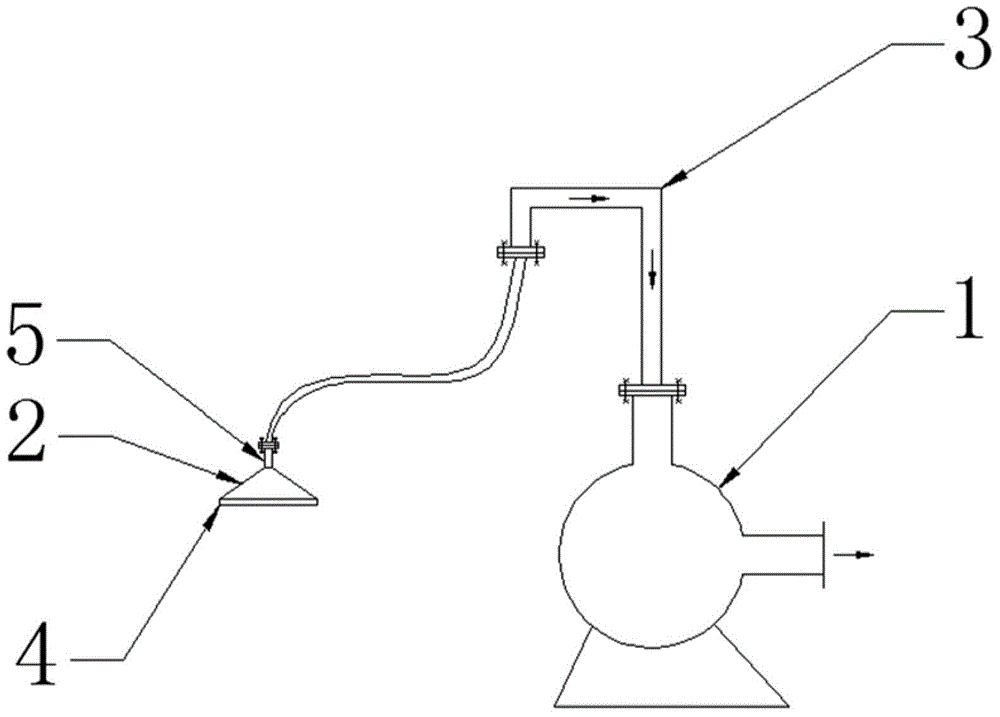

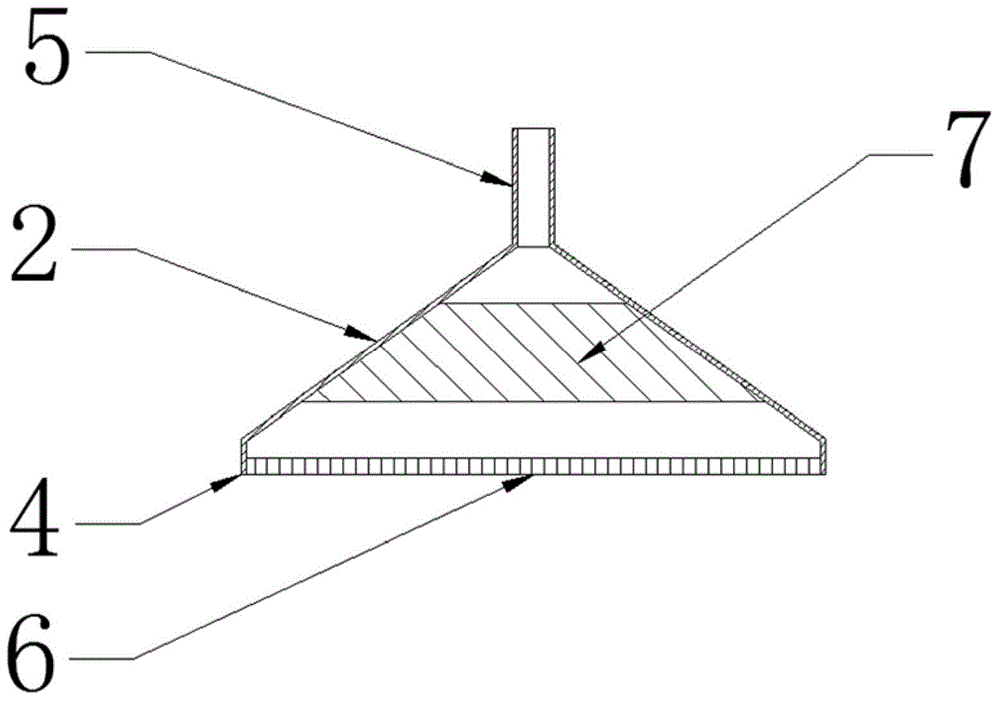

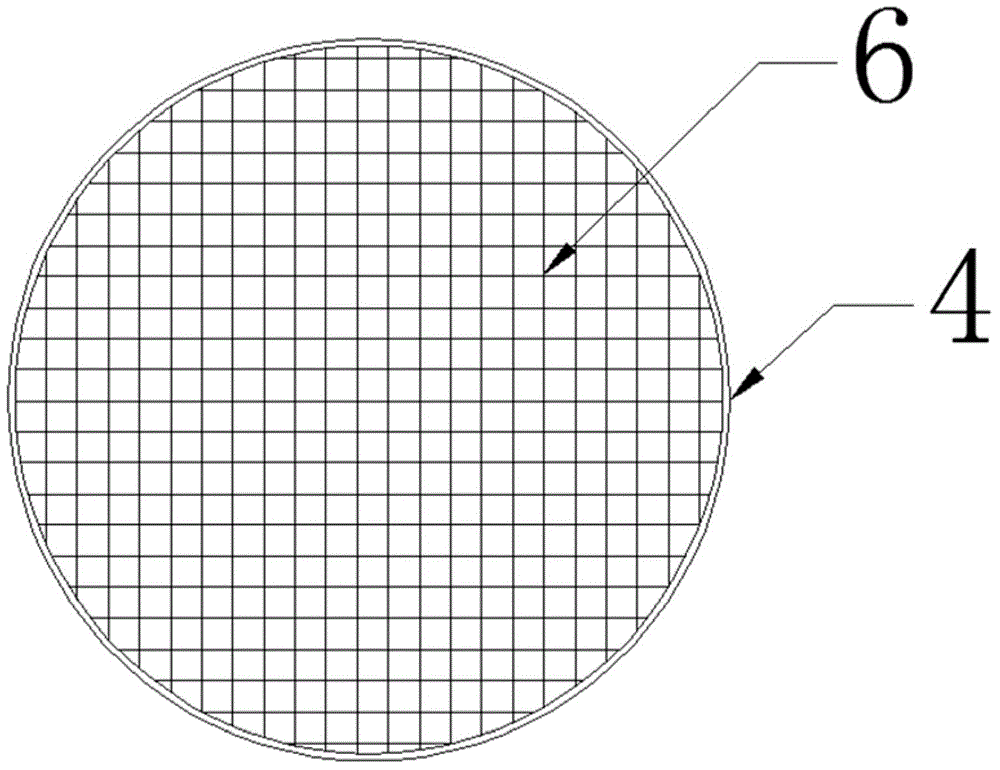

Method and device for measuring particle size of nano particle jet minimum quantity lubrication grinding droplets

ActiveCN103454190AImprove effective utilizationContribute to research coverageParticle size analysisEngineeringConfocal microscopy

The invention relates to a method and device for measuring a particle size of nano particle jet minimum quantity lubrication grinding droplets. The uniformity of a droplet spectrum, the deposition efficiency and an effective fluid utilization rate can be improved, the movement rule of the droplets is effectively controlled, and environmental pollution is reduced. The device comprises an adjustable nano fluid circuit and an adjustable gas supply circuit, wherein the two circuits are connected with a nozzle; the gas and grinding fluid are mixed in the nozzle to eject grinding fluid droplets into a grinding area on a workpiece; the grinding fluid droplets are scanned by adopting two confocal microscopes, wherein one confocal microscope is positioned in the direction perpendicular to the surface of the workpiece and moves along the xy direction, and the other confocal microscope is positioned in the direction parallel to the surface of the workpiece and moves along the xz direction; the side view and vertical view of the same single droplet which drops on the surface of the workpiece are acquired respectively, the scanned image is processed by a computer, the distribution rule of the single droplets is obtained, and the contour shape of the droplets is simulated, so that the particle size of the single grinding fluid droplet is determined.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

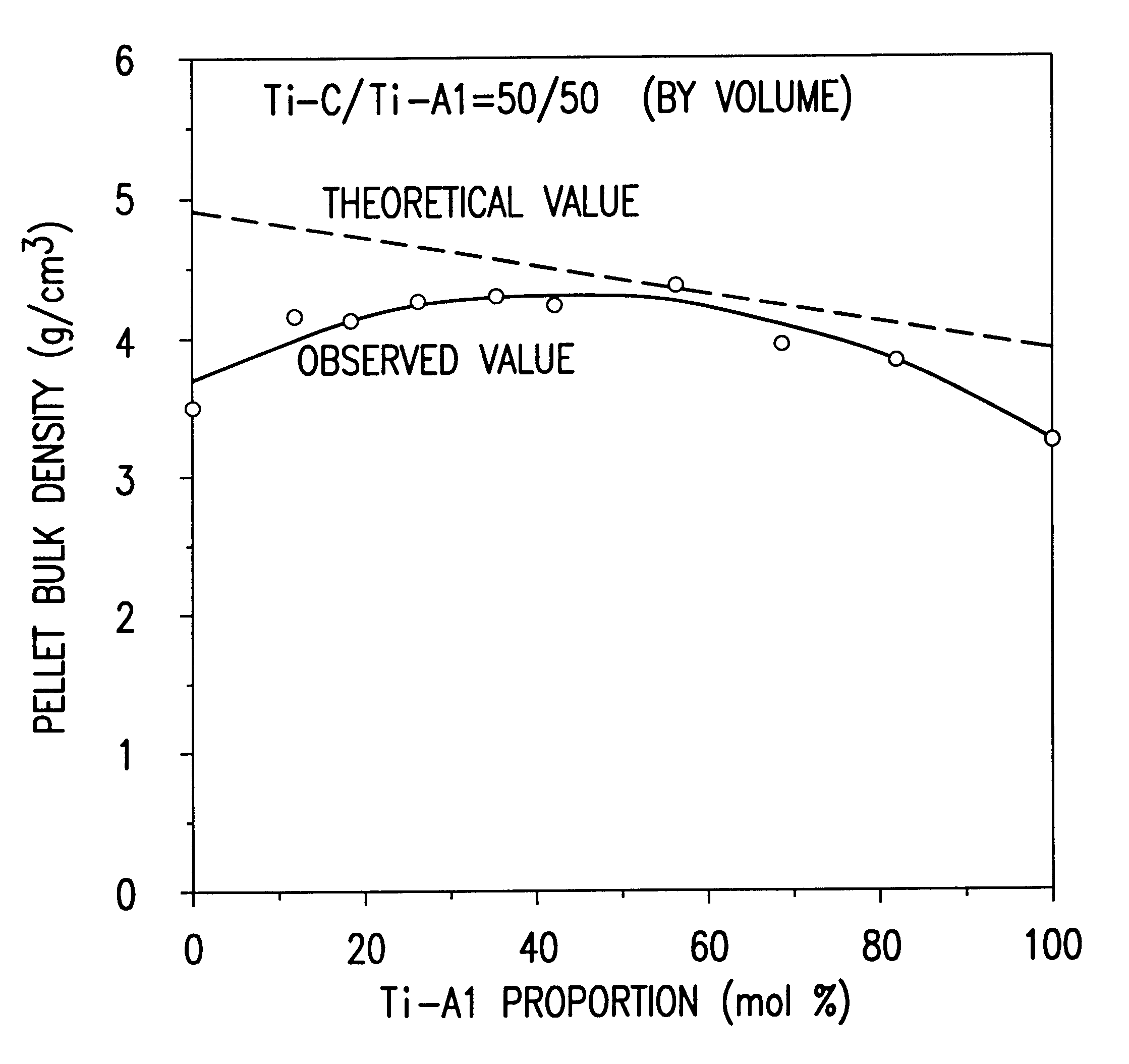

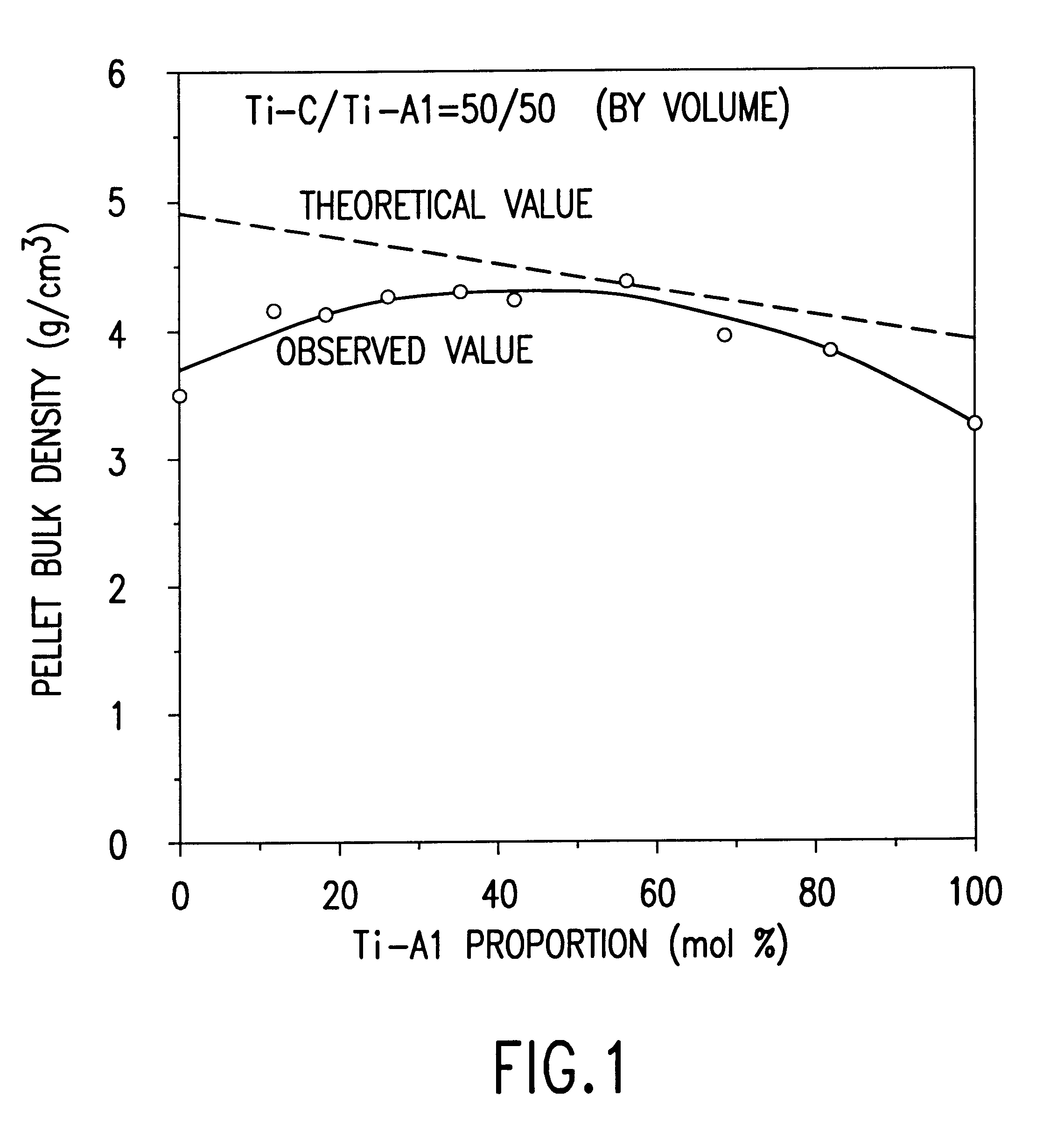

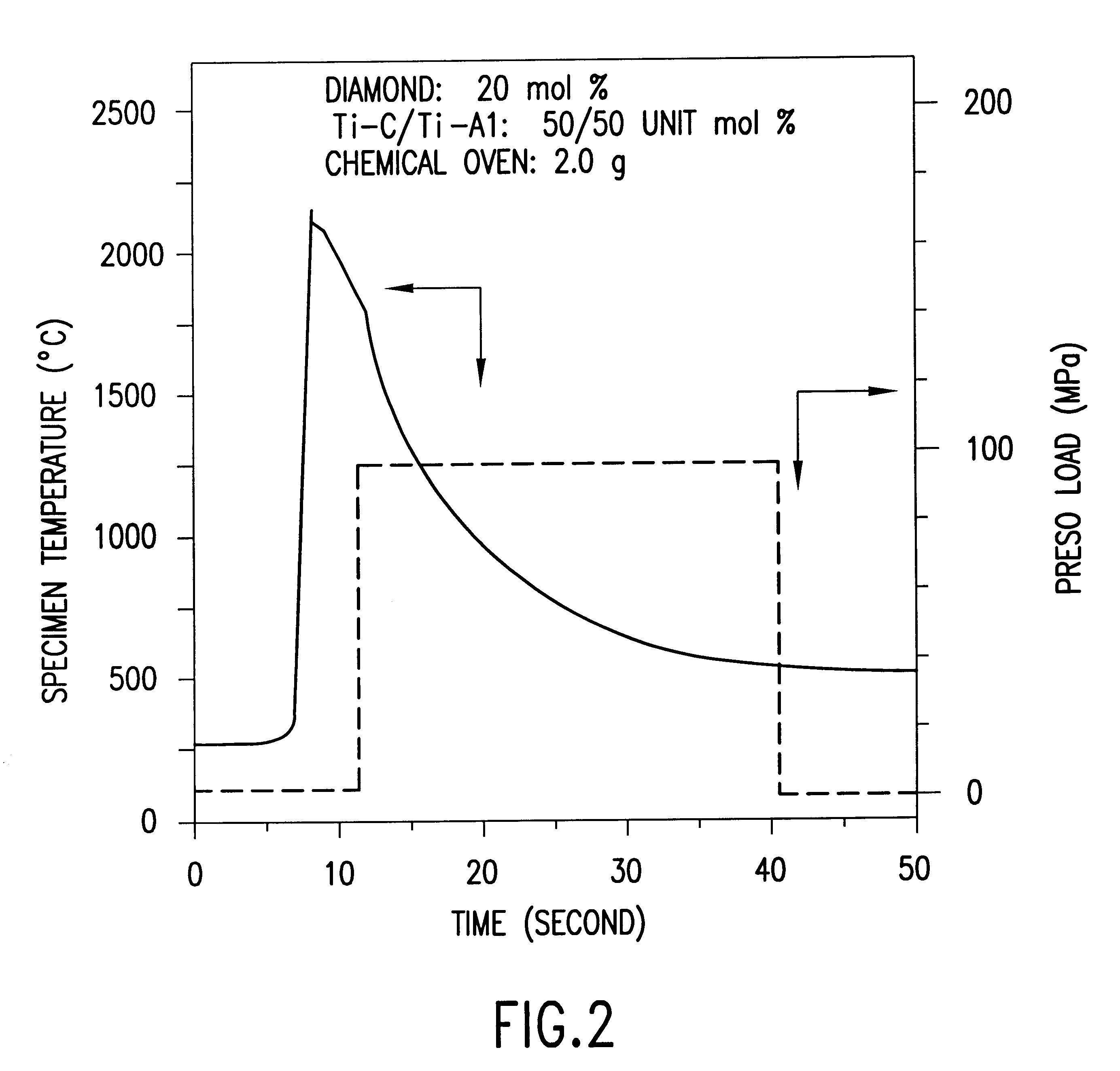

Composite and method for producing the same

InactiveUS6500557B1High retention rateImprove grinding performanceNatural mineral layered productsThin material handlingBorideNiobium

This invention provides a composite product and an effective method for producing the same, based on an SHS or intense heat producing process. Said composite essentially comprises either (1) one or more skeletal structures of three dimensionally joined pieces of at least one ceramic material selected from carbide, boride, nitride and silicide of titanium, zirconium, tantalum, niobium, silicon, chromium, tungsten, and molybdenum, and metallic material of alloy and / or intermetallic compound which fills the gaps within each and between adjacent skeletal structures, or (2) a matrix consisting of SHS products of metallic and / or ceramic substances, and particles of superabrasive selected from diamond and high pressure polymorphism of boron nitride, which are held and distributed in the matrix in the whole, in the surface or surface area comprising the portion corresponding to the end working face. Also effective is the use of superabrasive particles coated with metallic and / or non-metallic materials by some specific techniques.

Owner:2 KANAGAWA +3

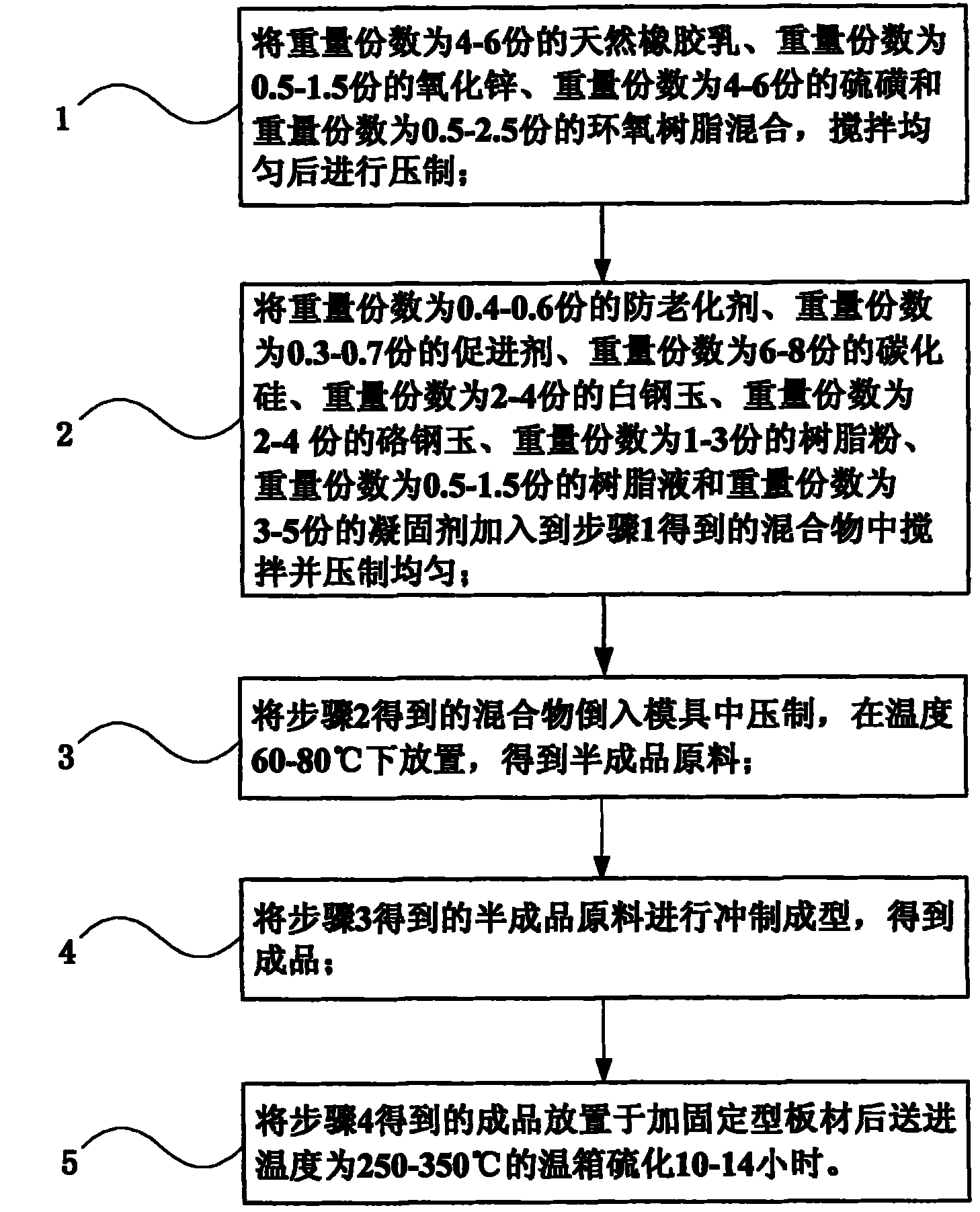

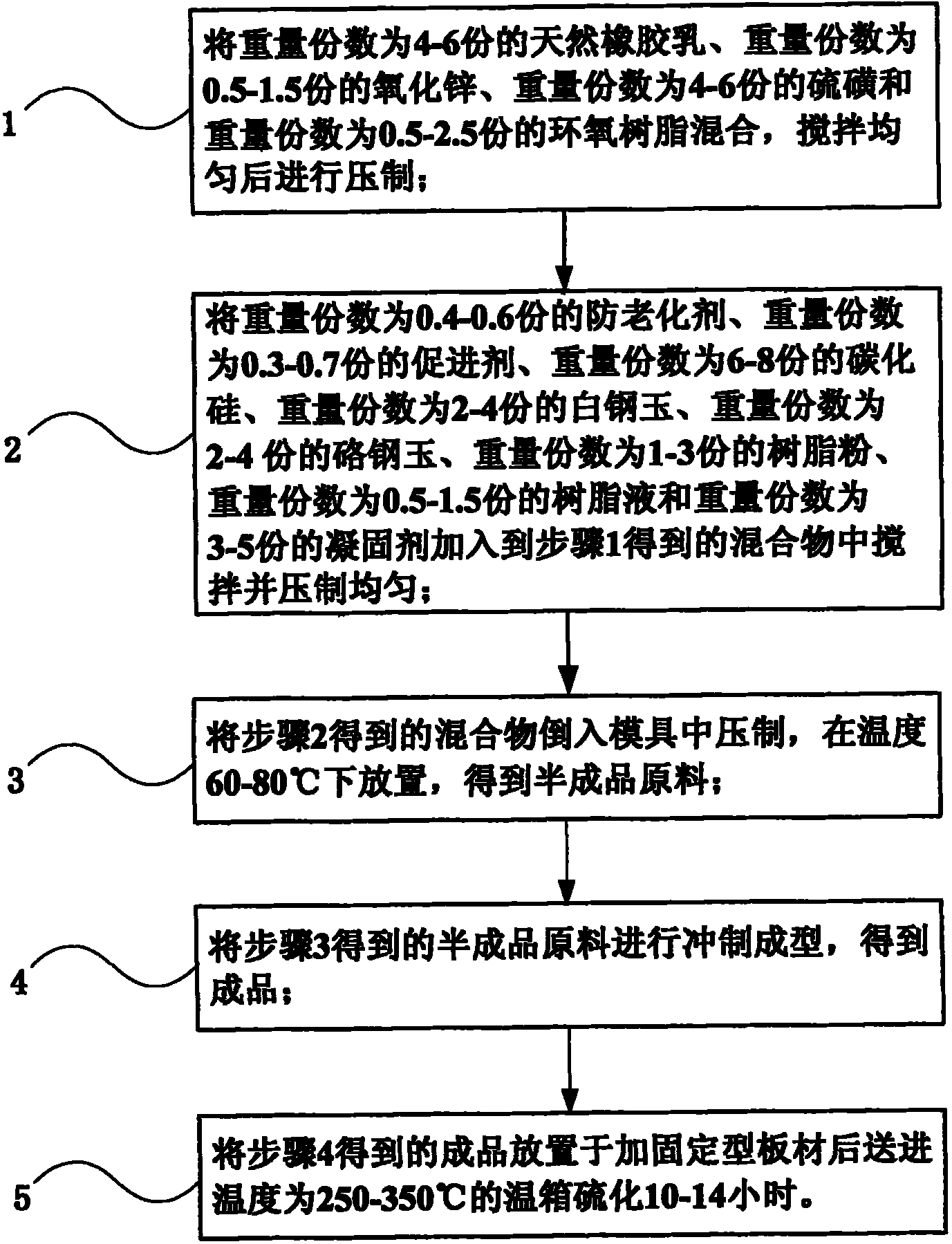

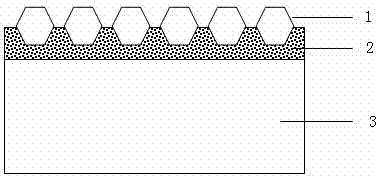

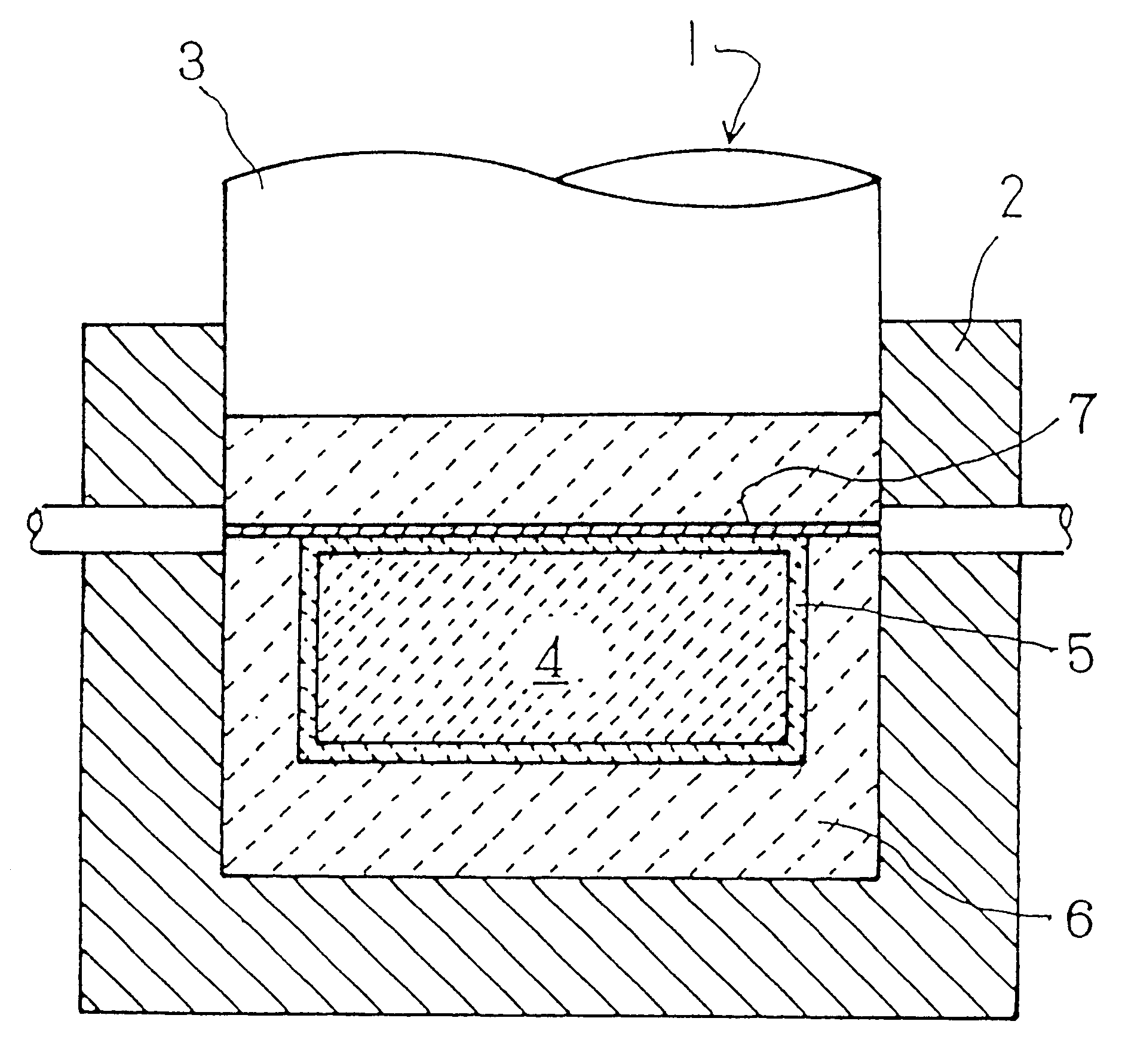

Rubber thin sheet grinding wheel and preparation method thereof

InactiveCN102001057AImprove wear resistanceHigh hardnessAbrasion apparatusGrinding devicesEpoxyPolymer science

The invention relates to a rubber thin sheet grinding wheel and a preparation method thereof. The rubber thin sheet grinding wheel comprises the following raw materials in part by weight: 4 to 6 parts of natural rubber emulsion, 0.5 to 1.5 parts of zinc oxide, 4 to 6 parts of sulfur, 0.5 to 2.5 parts of epoxy resin, 0.4 to 0.6 part of anti-ager, 0.3 to 0.7 part of accelerant, 6 to 8 parts of silicon carbide, 2 to 4 parts of diamantane, 2 to 4 parts of chromium corundum, 1 to 3 parts of resin powder, 0.5 to 1.5 parts of resin liquid and 3 to 5 parts of coagulator. The rubber thin sheet grinding wheel of the invention has the advantages of high wear resistance, heat resistance, self-sharpening property, heat conductivity, corrosion resistance, toughness, hardness and working efficiency and long service life; in addition, the rubber thin sheet grinding wheel prepared by the preparation method of the rubber thin sheet grinding wheel of the invention is very thin and has low loss and high accuracy during cutting.

Owner:施镇源

Method for manufacturing brazing monolayer diamond grinding wheel

InactiveCN103786100AReduce heat damageExtended service lifeAbrasion apparatusGrinding devicesThermal stabilityBoron

The invention belongs to the field of super-hard abrasive material tools and particularly relates to a method for manufacturing a brazing monolayer diamond grinding wheel. Diamond is boracic diamond, and the content of boron in the diamond is (50-260)*1018 at / cm<3>. According to the method for manufacturing the brazing monolayer diamond grinding wheel, due to the fact that the boracic diamond is adopted, low thermal damage of the diamond is ensured with the high thermal stability of the boracic diamond, novel solder further reduces the thermal damage after the diamond is welded, and therefore the service life of the grinding wheel is prolonged, and the good grinding capability and the good cutting capability are achieved.

Owner:禹州市和汇超硬材料有限公司 +1

Composite and method for producing the same

InactiveUS6451249B1High retention rateImprove grinding performanceThin material handlingBorideNiobium

This invention provides a composite product and an effective method for producing the same, based on an SHS or intense heat producing process. Said composite essentially comprises either (1) one or more skeletal structures of three dimensionally joined pieces of at least one ceramic material selected from carbide, boride, nitride and silicide of titanium, zirconium, tantalum, niobium, silicon, chromium, tungsten, and molybdenum, and metallic material of alloy and / or intermetallic compound which fills the gaps within each and between adjacent skeletal structures, or (2) a matrix consisting of SHS products of metallic and / or ceramic substances, and particles of superabrasive selected from diamond and high pressure polymorphism of boron nitride, which are held and distributed in the matrix in the whole, in the surface or surface area comprising the portion corresponding to the end working face. Also effective is the use of superabrasive particles coated with metallic and / or non-metallic materials by some specific techniques.

Owner:2 KANAGAWA +3

Fused abrasive particles, abrasive articles, and methods of making and using the same

InactiveUS20030000151A1Improve grinding performanceLower performance requirementsPigmenting treatmentOther chemical processesAbrasive

Owner:3M INNOVATIVE PROPERTIES CO

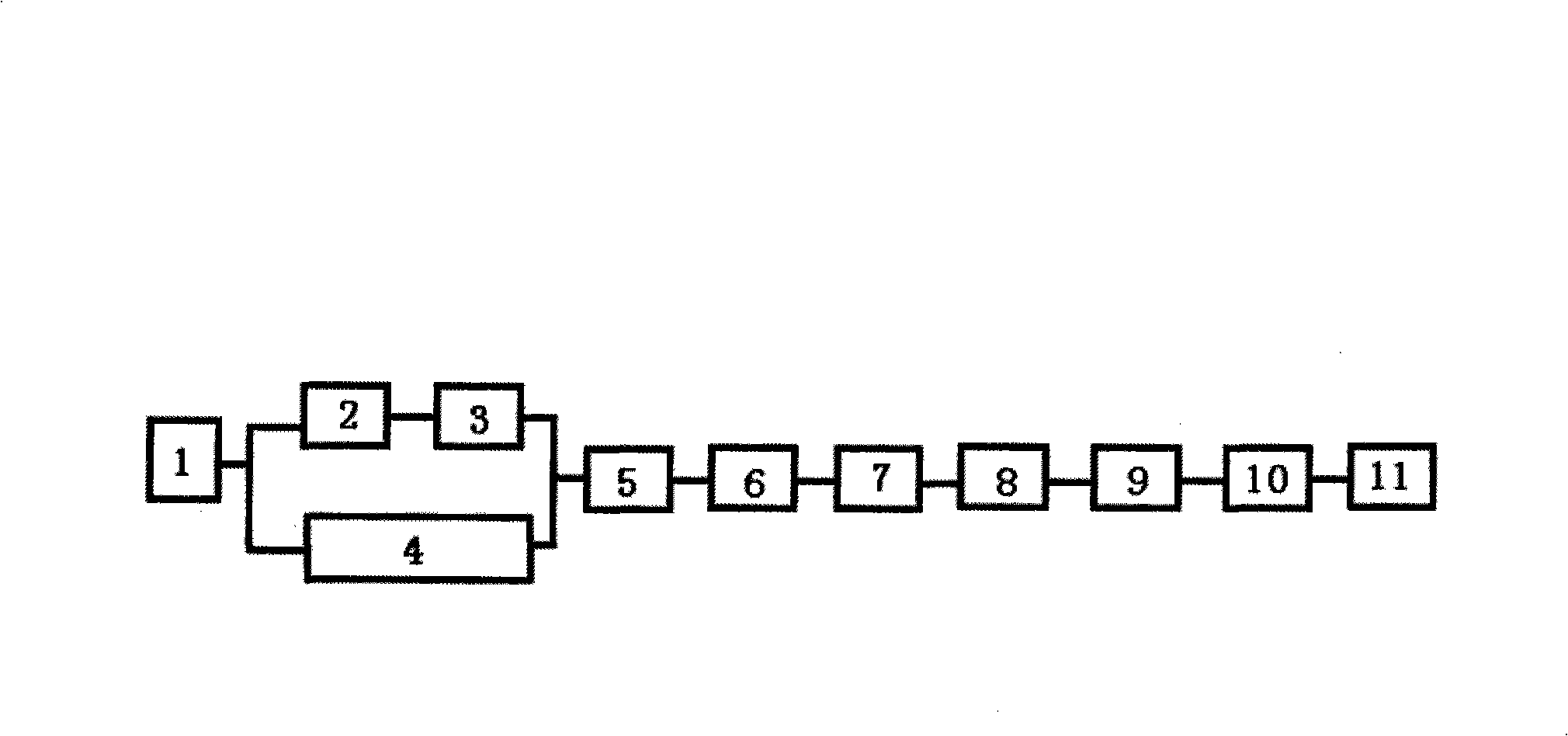

CBN grinding wheel of low temperature vitrified bond and preparation technique thereof

A CBN grinding wheel of a low-temperature ceramic bond consists of a bond, auxiliary materials, an abrasive layer and a transition layer. The components and the proportion of the bond are 48-60% of SiO2, 25-37% of Al2O3, 5-10% of Na2O and 3-7% of Li2O; the components and the proportion of the abrasive layer are 23-40% of CBN and 23-40% of SiC, 20.3-29.8% of the bond, 0.1-0.3% of dextrin powder and 0.1-0.2% of walnut powder; and the components and the proportion of the transition layer are 64-76% of the SiC, 21.9-32.9% of the bond and 0.1-0.2% of the dextrin powder. By adopting the technical processes of mixing materials, molding a blank of the abrasive layer by compression, sintering the blank of the abrasive layer, configuring, determining and processing the dimension of matrix bond, bonding the abrasive layer with the matrix, carrying out rotation test, trimming the external circle and end face of the abrasive layer, inspecting the abrasive layer of the grinding wheel, carrying out dynamic balancing, processing the appearance, and the like, and by reducing the firing temperature of the ceramic bond, the problem that burning loss happens easily due to oxidation of the abrasive is solved, and the strength of the product is improved.

Owner:沈阳中科超硬磨具磨削研究所

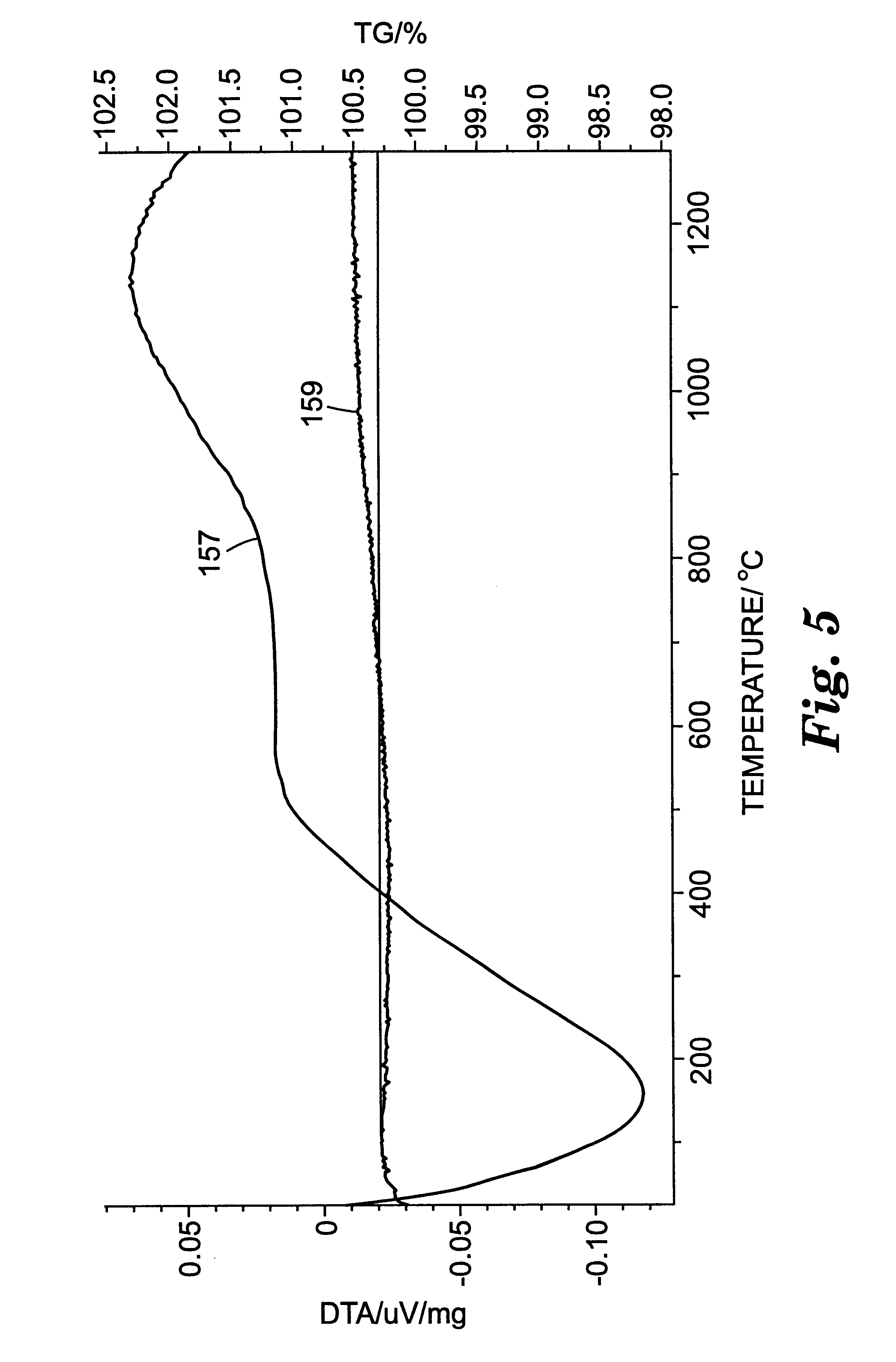

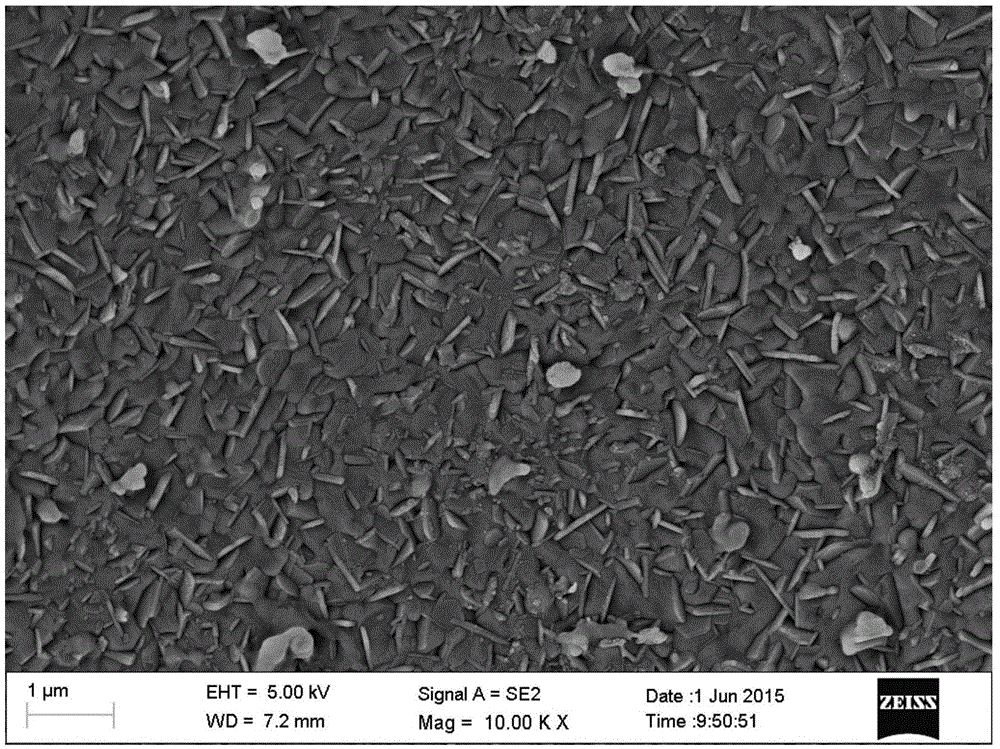

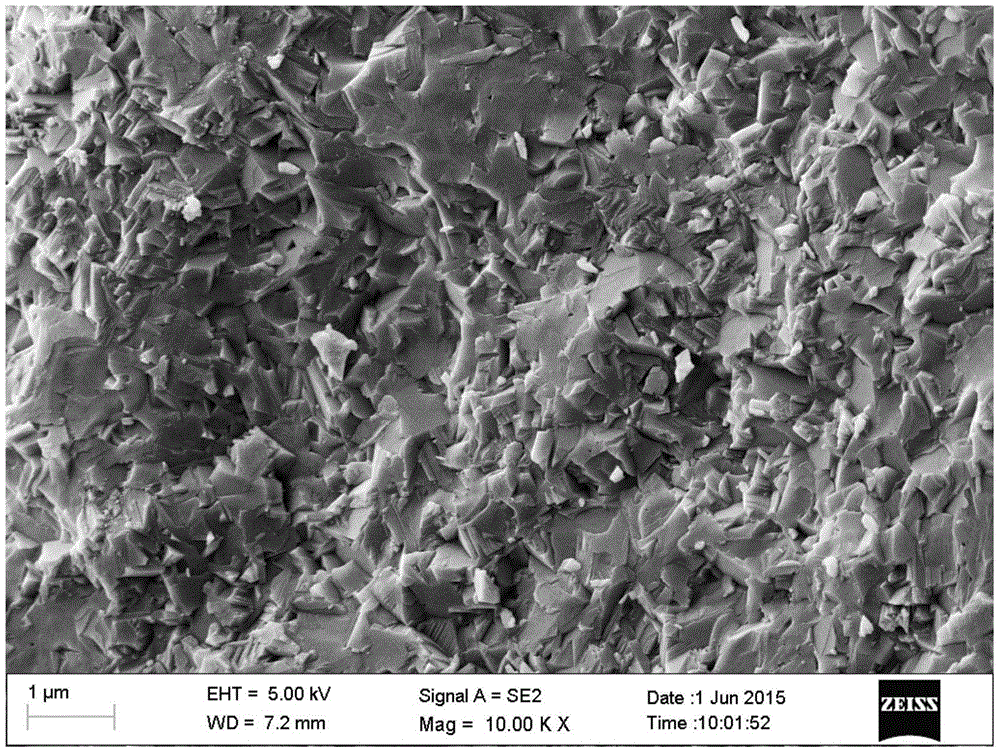

Alpha-Al2O3 ceramic particles containing lamellar microcrystals as well as preparation method for ceramic particles and application of ceramic particles

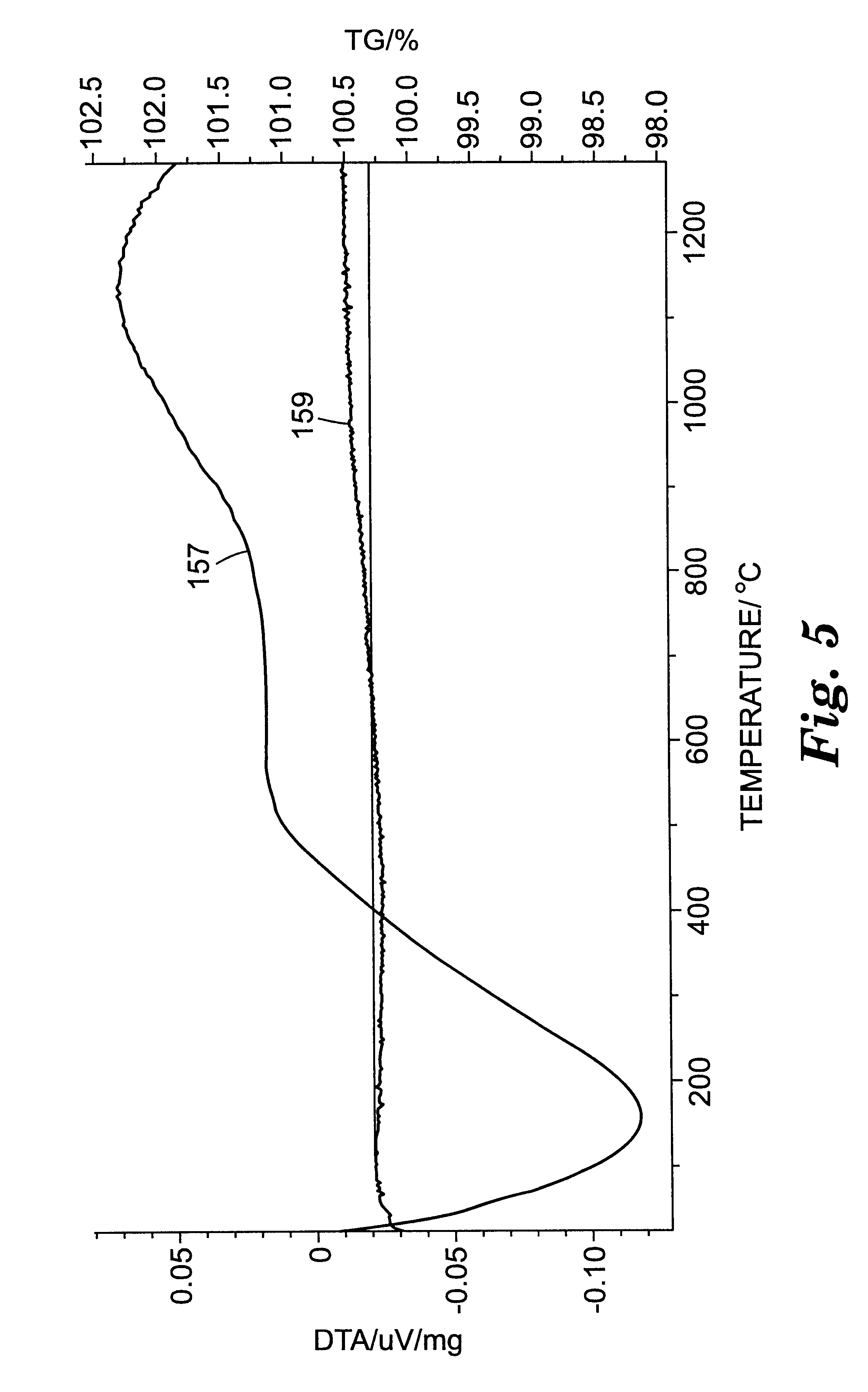

InactiveCN105622071AGood application effectGood grinding performanceLamellar crystalsCrystal morphology

The invention relates to alpha-Al2O3 ceramic particles containing lamellar microcrystals as well as a preparation method for the ceramic particles and an application of the ceramic particles. The alpha-Al2O3 ceramic particles comprises magnetoplumbite lamellar crystals and aluminum oxide crystals, and the magnetoplumbite lamellar crystals are inserted in the aluminum oxide crystals in a penetration manner. The specific preparation method comprises the following steps: 1) dispersing low-cost industrial grade pseudo-boehmite to form slurry, then adding aqueous solutions of acid and additives, and stirring uniformly; 2) performing heat treatment on the slurry at 180-240 DEG C for 24-72 hours to obtain gel; 3) drying the gel, and grinding and screening the gel to form semi-finished products with different particle sizes; and 4) slowly heating the semi-finished products to 1,500-1,600 DEG C in a vacuum state, and keeping a target temperature for 2-4 hours to obtain the alpha-Al2O3 ceramic particles containing the lamellar microcrystals. The alpha-Al2O3 ceramic particles containing the lamellar microcrystals are good in toughness and good in primary crystal morphology controllability, and have excellent grinding performance; and the hardness value of the ceramic particles is greater than 20GPa and the ball-milling toughness of the ceramic particles is greater than 76%.

Owner:SHANDONG UNIV

Polygonal superhard abrasive compound and method for manufacturing abrasive tool with same

ActiveCN104440605AHigh hardnessGood toughnessOther chemical processesAbrasion apparatusHardnessHigh pressure

The invention discloses a polygonal superhard abrasive compound and a method for manufacturing an abrasive tool with the same. The polygonal superhard abrasive compound is synthesized through high temperature and high pressure after polygonal grooves of a graphite die are filled with abrasive powder and synthesis blocks are assembled. Due to the fact that the polygonal superhard abrasive compound is the abrasive material which is regular in shape and synthesized through high temperature and high pressure after the polygonal grooves of the graphite die are filled with the abrasive powder and the synthesis blocks are assembled, the hardness is high, and the toughness is good; the size dimension is controllable, the particle size is uniform, and good grinding performance is achieved; the shape is regular, the sharpness of the abrasive material is further improved, the abrasive tool with abrasive material cutting edges evenly distributed in a space can be obtained conveniently, the grinding quality and the grinding effect of the abrasive tool can be improved, and the polygonal superhard abrasive compound and the abrasive tool are suitable for application and popularization.

Owner:FUNIK ULTRAHARD MATERIAL

High-efficiency composite grinding sheet and manufacturing method thereof

ActiveCN103612217AHigh bonding strengthImprove acid resistanceAbrasion apparatusGrinding devicesFiberPost curing

The invention discloses a high-efficiency composite grinding sheet and a manufacturing method thereof. The high-efficiency composite grinding sheet comprises a base material, base gel, an abrasive material and composite gel. The abrasive material is attached to the base material through the base gel and the composite gel, the back of selected steel vulcanized fiber paper is coated with the base gel through at least one of the methods of roller painting, blade coating and flat coating; the selected abrasive material is ground into abrasive material particles which are evenly mixed with the composite gel, and then the back of the selected steel vulcanized fiber paper with the base gel is coated with the mixture; a semi-finished product coated with the base gel and the composite gel is detached and sequentially undergoes a post curing process, a flexure and water entrainment process, a laser cutting process, a steel vulcanized fiber paper anti-deformation processing process and a storing process so as to support a grinding sheet finished product. The grinding sheet is sharp, long in service life, resistant to high temperature after being ground, and good in moisture resistance. The manufacturing method can effectively prevent deformation, and the product is large in tensile strength, good in adhesion and strong in grinding performance.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

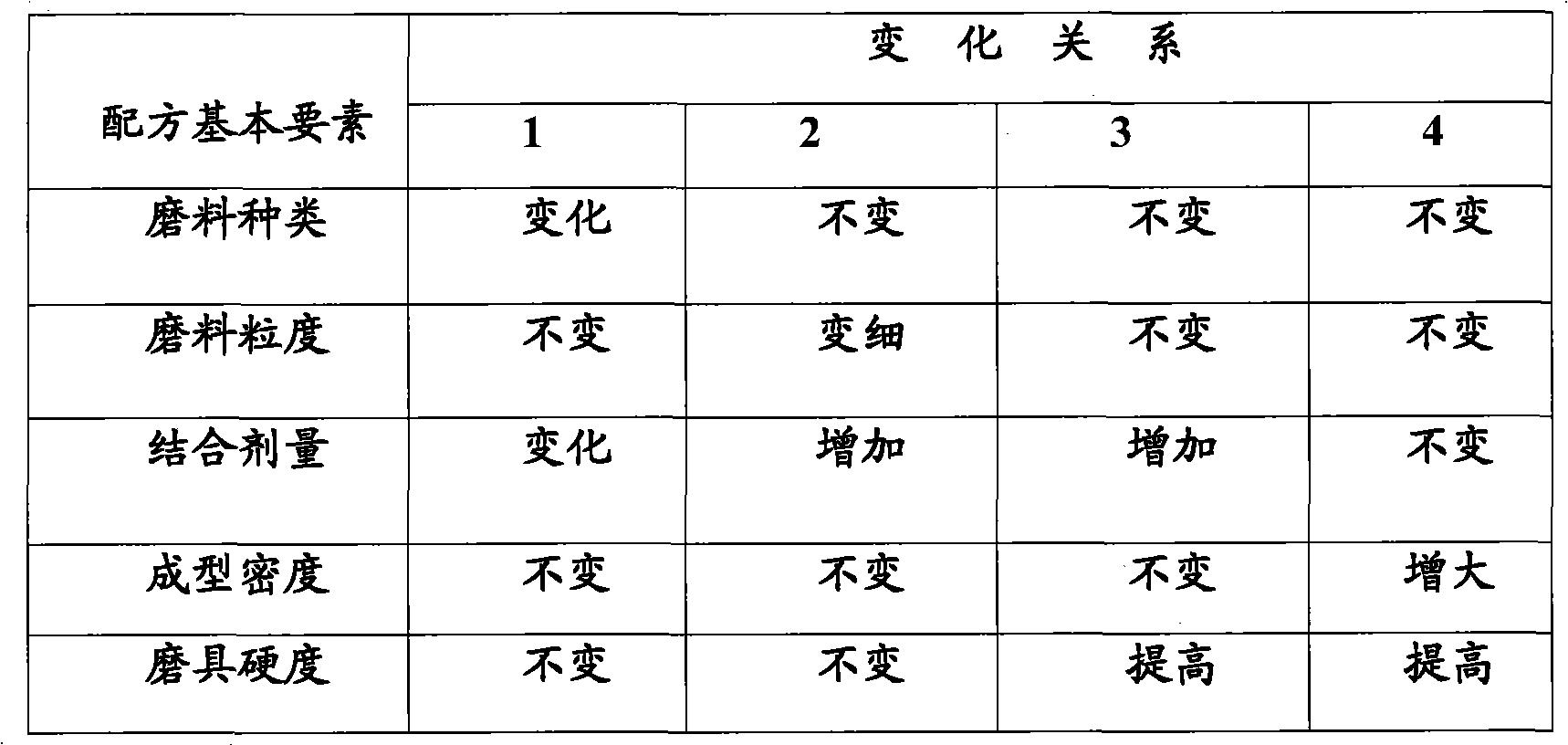

Preparing method of ceramic bonding agent CBN (Cubic Boron Nitride) grinding wheel with precisely adjustable and controllable hardness attenuation value

InactiveCN104002250AReduce the gripSolve the problem that the hardness is difficult to adjust preciselyAbrasion apparatusGrinding devicesBoron nitrideGrinding wheel

The invention discloses a preparing method of a ceramic bonding agent CBN (Cubic Boron Nitride) grinding wheel with a precisely adjustable and controllable hardness attenuation value. The preparing method comprises the following steps that: 16 to 20 weight percent of boric acid, 9 weight percent of sodium carbonate, 5 weight percent of potassium carbonate, 8 weight percent of aluminum oxide, 4 weight percent of titanium dioxide, and 54 to 58 weight percent of silicon dioxide are pretreated; bonding agents are prepared through smelting; the bonding agents are crushed; the bonding agents are subjected to ball milling; 15 to 23 weight percent of bonding agent powder, 72 to 80 weight percent of CBN grinding materials, 3 weight percent of yellow dextrin powder and 2 weight percent of deionized water are poured into a grinding jar, ball milling is carried out, and grinding wheel forming materials are prepared; a grinding wheel is formed after pressurizing and drying; the grinding wheel is sintered; a buffer solution is prepared; and the buffer solution is utilized for adjusting and controlling the hardness of the grinding wheel, and the ceramic bonding agent CBN grinding wheel with the precisely adjustable and controllable hardness attenuation value is prepared. The preparing method has the advantages that the hardness of the prepared ceramic CBN grinding wheel is precise and controllable, the ceramic CBN grinding wheels which have different hardness and are suitable for being used for grinding different materials are obtained, and the grinding performance of the ceramic CBN grinding wheel is improved.

Owner:HUNAN UNIV

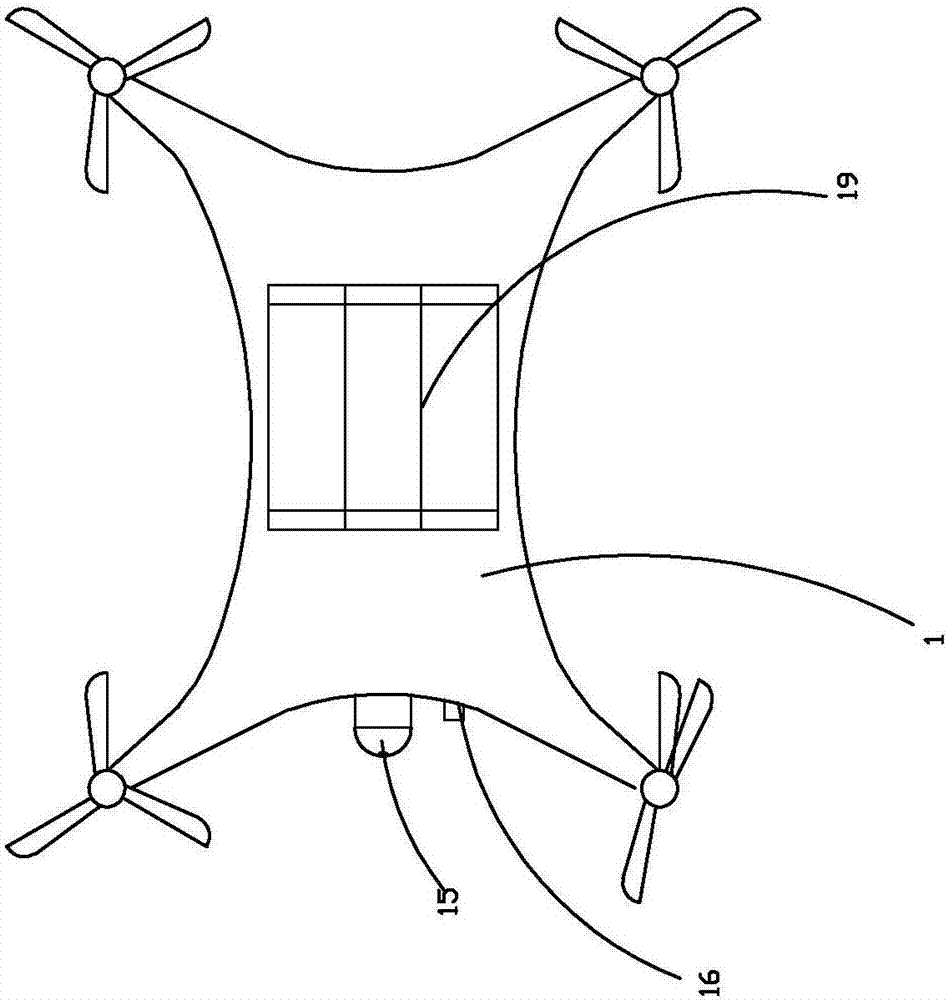

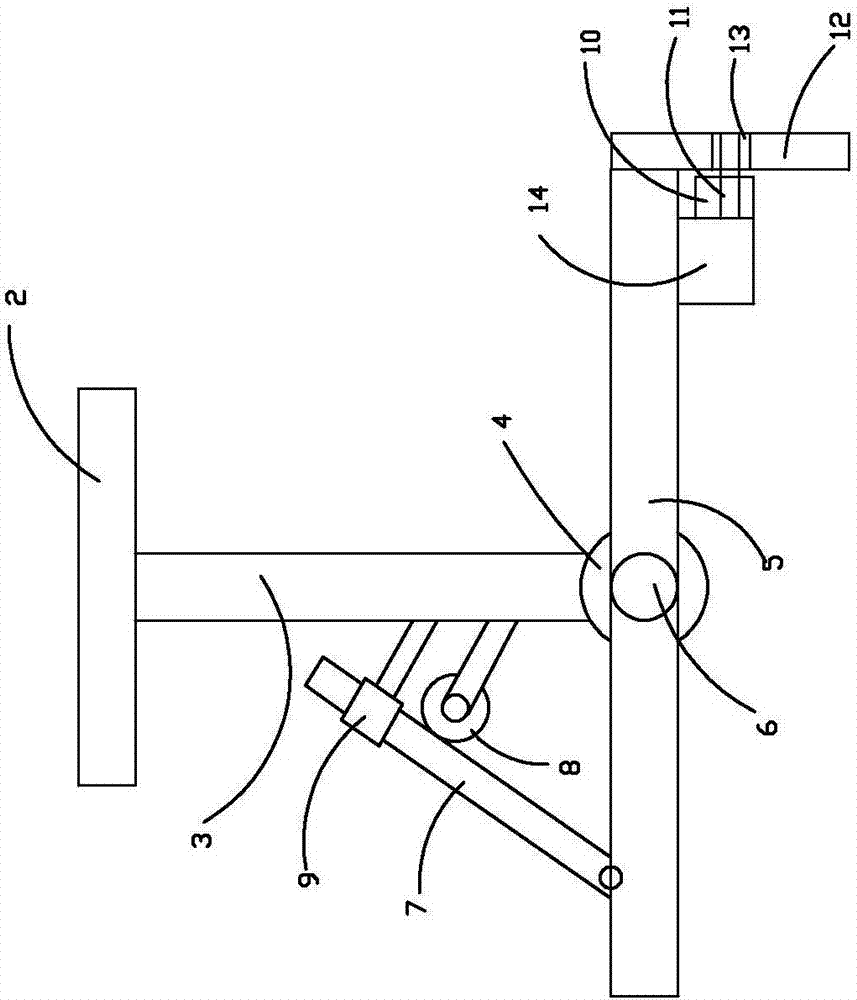

Unmanned aerial vehicle used for cleaning stain on photovoltaic plate roof face

PendingCN106995054AImprove grinding performancePhotovoltaicsRemote controlled aircraftControl systemUncrewed vehicle

The invention provides an unmanned aerial vehicle used for cleaning a stain on photovoltaic plate roof face. The unmanned aerial vehicle comprises an unmanned aerial vehicle body, a control system for controlling the unmanned aerial vehicle body and a storage battery supplying power, a chassis is fixed to the bottom of the unmanned aerial vehicle body, a connecting rod is vertically mounted on the lower end portion of the chassis, a shock absorbing sleeve is arranged in the lower end portion of the connecting rod, a mounting plate is connected to the lower end portion of the connecting rod, the mounting plate is arranged relative to the connecting rod in a rotary mode, a hinge shaft is fixedly arranged in the middle of the mounting plate, a rotating shaft is inserted in the shock absorbing sleeve, an angle adjusting mechanism is arranged between one side of the mounting plate and the connecting rod, a grinding mechanism is arranged on the other side of the mounting plate, an imaging device for detecting the stain on the photovoltaic roof face is arranged on the front portion of the unmanned aerial vehicle body, an angle sensor for detecting the inclination angle of the photovoltaic roof face is arranged at the bottom of the unmanned aerial vehicle body, the unmanned aerial vehicle is adopted to clean the photovoltaic roof face automatically, and cleaning is convenient.

Owner:广东大粤新能源科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com