Rubber thin sheet grinding wheel and preparation method thereof

A technology of rubber and flakes, which is applied in the field of grinding wheels, can solve the problems of lack of self-sharpening, poor corrosion resistance, and poor heat resistance, and achieve good self-sharpening, good heat resistance, and increased grinding ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

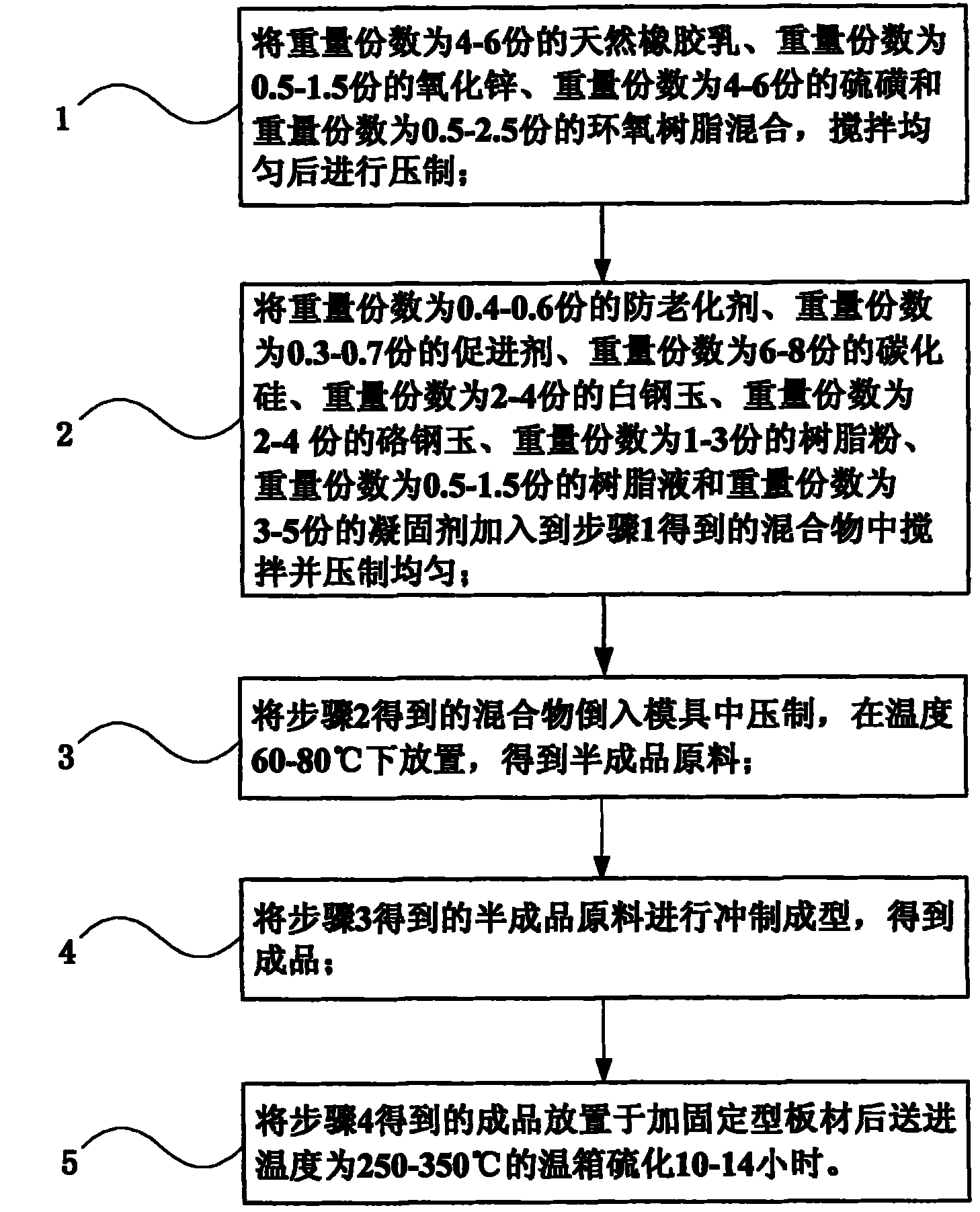

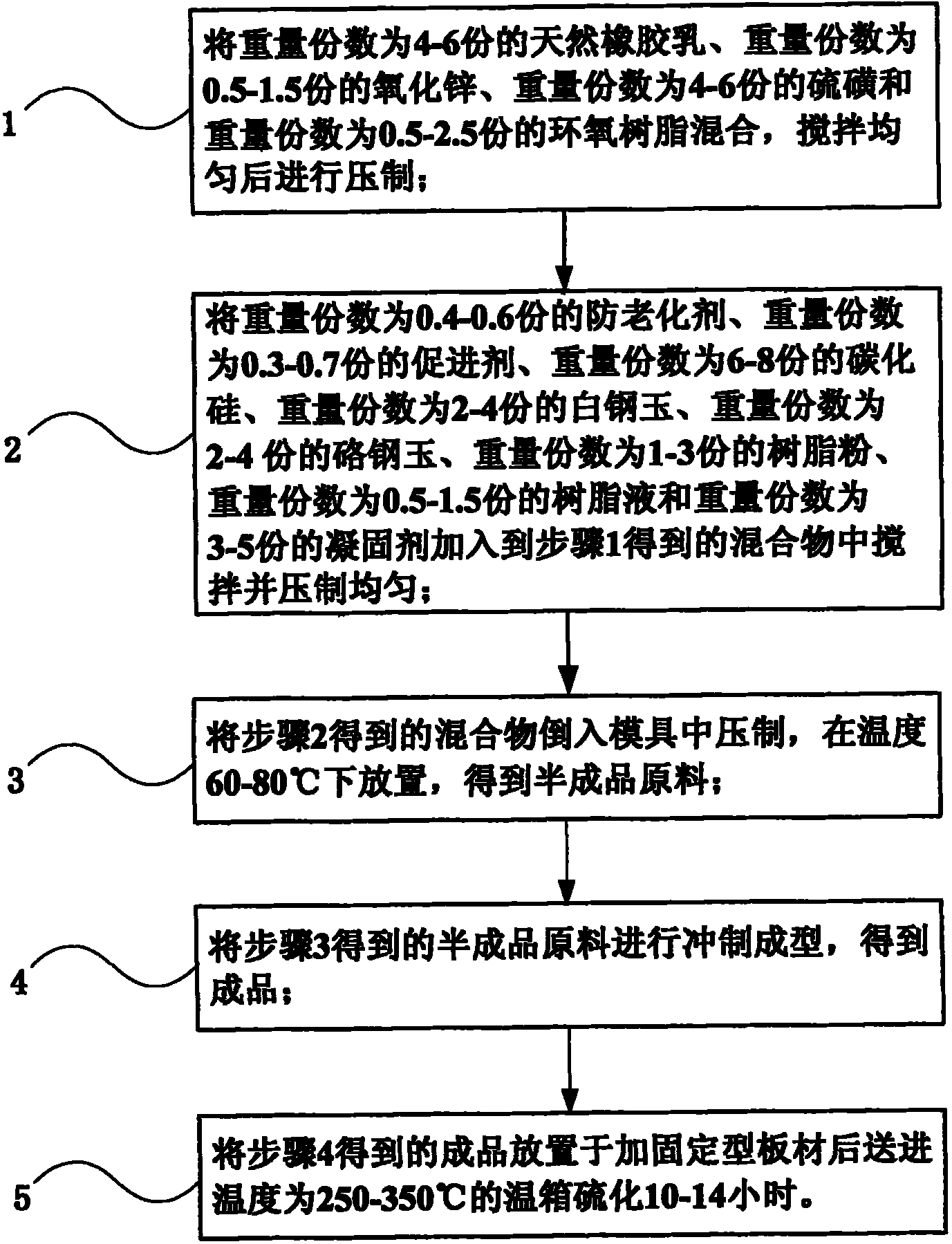

[0026] figure 1 It is a flow chart of the preparation method of a kind of rubber sheet grinding wheel of the present invention, specifically:

[0027] Step 1, the natural rubber latex that is 4-6 parts by weight, the zinc oxide that is 0.5-1.5 parts by weight, the sulfur that is 4-6 parts by weight and the ring that is 0.5-2.5 parts by weight are Oxygen resin mixed, stirred evenly and then pressed;

[0028] Step 2, the anti-aging agent that is 0.4-0.6 parts by weight, the accelerator that is 0.3-0.7 parts by weight, the silicon carbide that is 6-8 parts by weight, the White corundum, 2-4 parts by weight of steel jade, 1-3 parts by weight of resin powder, 0.5-1.5 parts by weight of resin liquid and 3-5 parts by weight of coagulant are added Stir in the mixture obtained in step 1 and press evenly;

[0029] Step 3. Pour the mixture obtained in step 2 into a mold for pressing, and place it at a temperature of 60-80° C. to obtain semi-finished raw materials;

[0030] Step 4, pu...

Embodiment 1

[0035] Step 11, the natural rubber latex that is 4 parts by weight, the zinc oxide that is 1.5 parts by weight, the sulfur that is 6 parts by weight and the epoxy resin that is 0.5 part by weight are mixed;

[0036] Step 12, pressing the mixture obtained in step 11 after being uniformly stirred in a mixer;

[0037] Step 13, be 0.4 parts by weight of 2,6-di-tert-butyl-4 methylphenol (antiaging agent 264), 0.7 parts by weight of tetrabase thiuram disulfide (accelerator TMTD) , parts by weight are 6 parts of silicon carbide, parts by weight are 4 parts of white corundum, parts by weight are 2 parts of corundum, parts by weight are 3 parts of phenolic resin powder, parts by weight are 0.5 parts of phenolic The resin liquid and 5 parts of coagulant are added to the mixture obtained in step 12, stirred and pressed evenly;

[0038] Step 14. Pour the mixture obtained in Step 13 into a sheet-shaped mold for pressing, and place it at a temperature of 60° C. to obtain semi-finished raw ...

Embodiment 2

[0043] Step 21, being 5 parts by weight of natural rubber latex, 1 part by weight of zinc oxide, 5 parts by weight of sulfur and 1.5 parts by weight of epoxy resin;

[0044] Step 22, pressing the mixture obtained in step 21 after being uniformly stirred in a mixer;

[0045] Step 23, the hexamethylenetetramine (hexamethamine) that is 0.5 parts by weight, the TH-DN nickel low-level accelerator (Dn) that is 0.5 parts by weight, the carbonization that is 7 parts by weight Silicon, parts by weight are 3 parts of white corundum, 3 parts by weight of corundum corundum, 2 parts by weight of phenolic resin powder, 1 part by weight of phenolic resin liquid and 4 parts of coagulant are added to Stir in the mixture obtained in step 22 and press evenly;

[0046] Step 24. Pour the mixture obtained in step 23 into a sheet-shaped mold for pressing, and place it at a temperature of 80° C. to obtain semi-finished raw materials;

[0047] Step 25, punching the semi-finished raw material obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com