Patents

Literature

45 results about "Diamantane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diamantane (also called congressane) is an organic compound that is a member of the diamondoids. These are cage hydrocarbons with structures similar to a subunit of the diamond lattice. It is a colorless solid that has been a topic of research since its discovery in oil and separation from deep natural gas condensates. Diamondoids such as diamantane exhibit unusual properties, including low surface energies, high densities, high hydrophobicities, and resistance to oxidation.

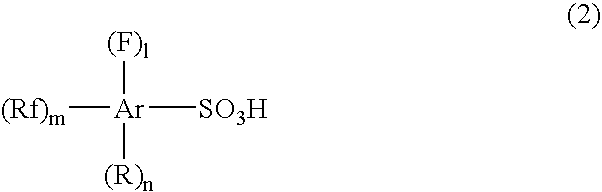

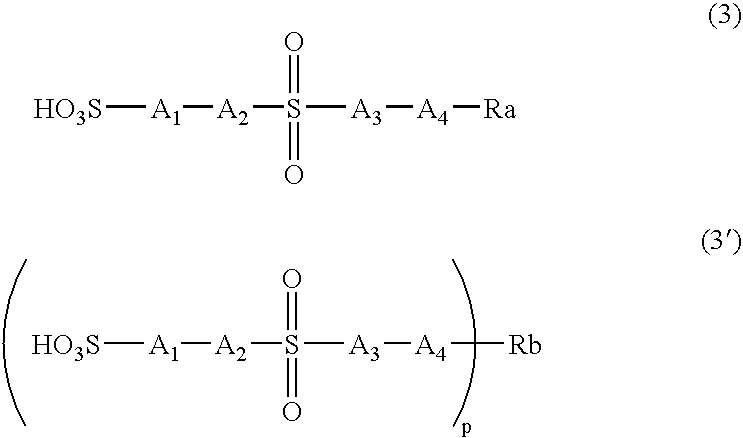

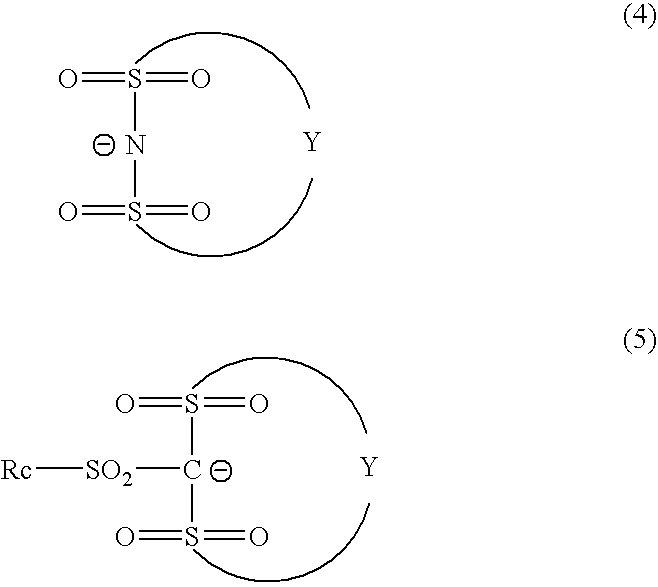

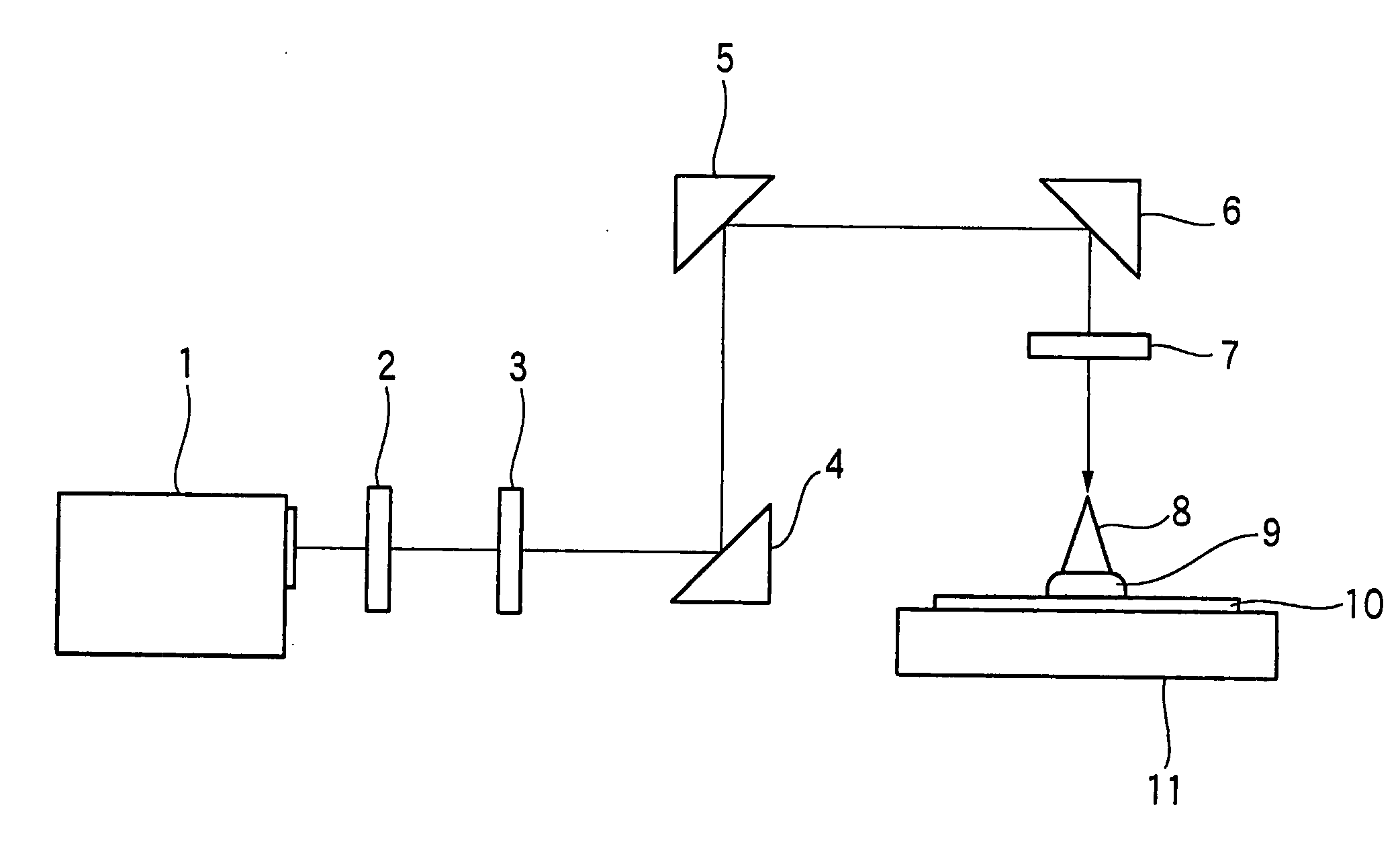

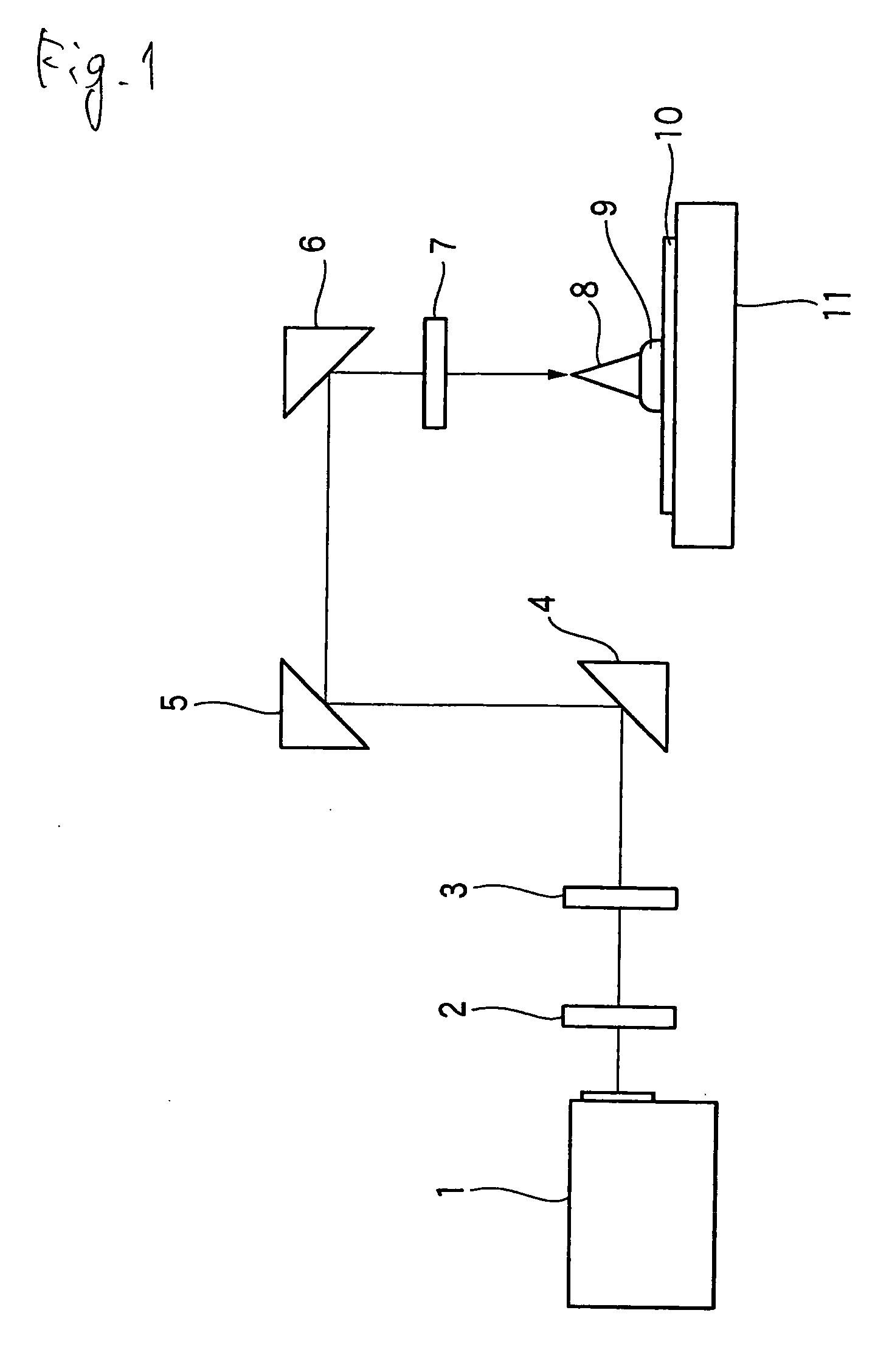

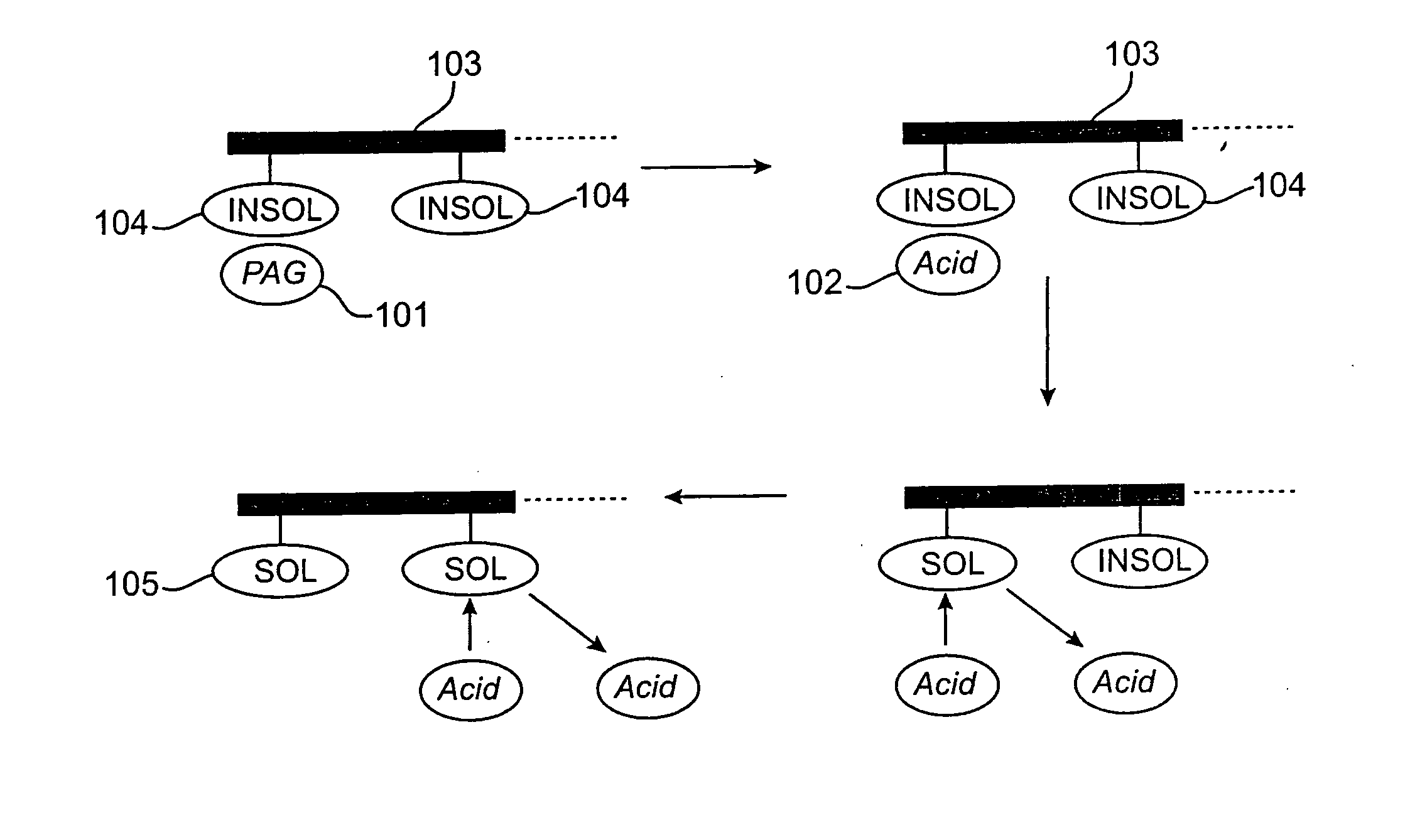

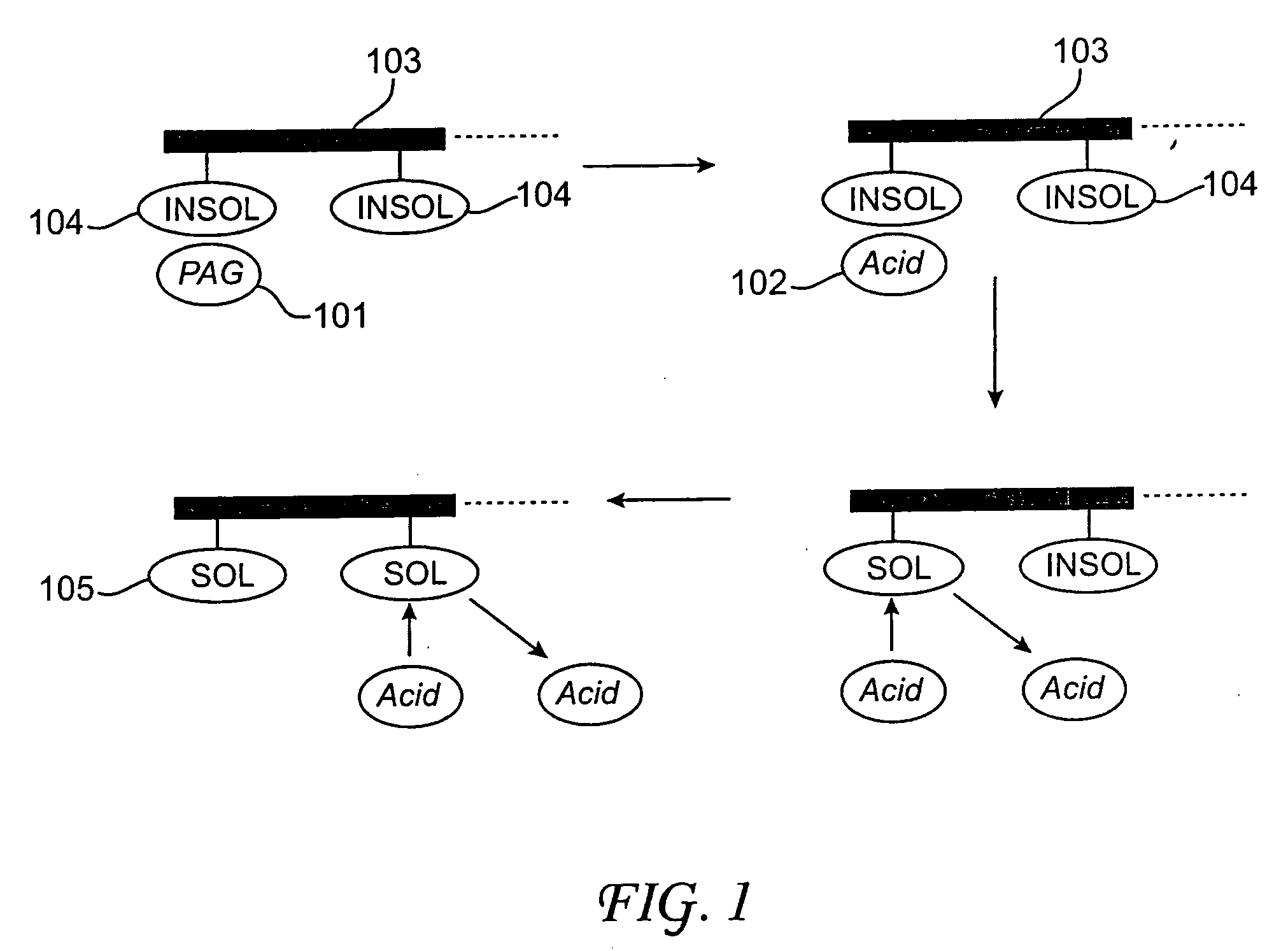

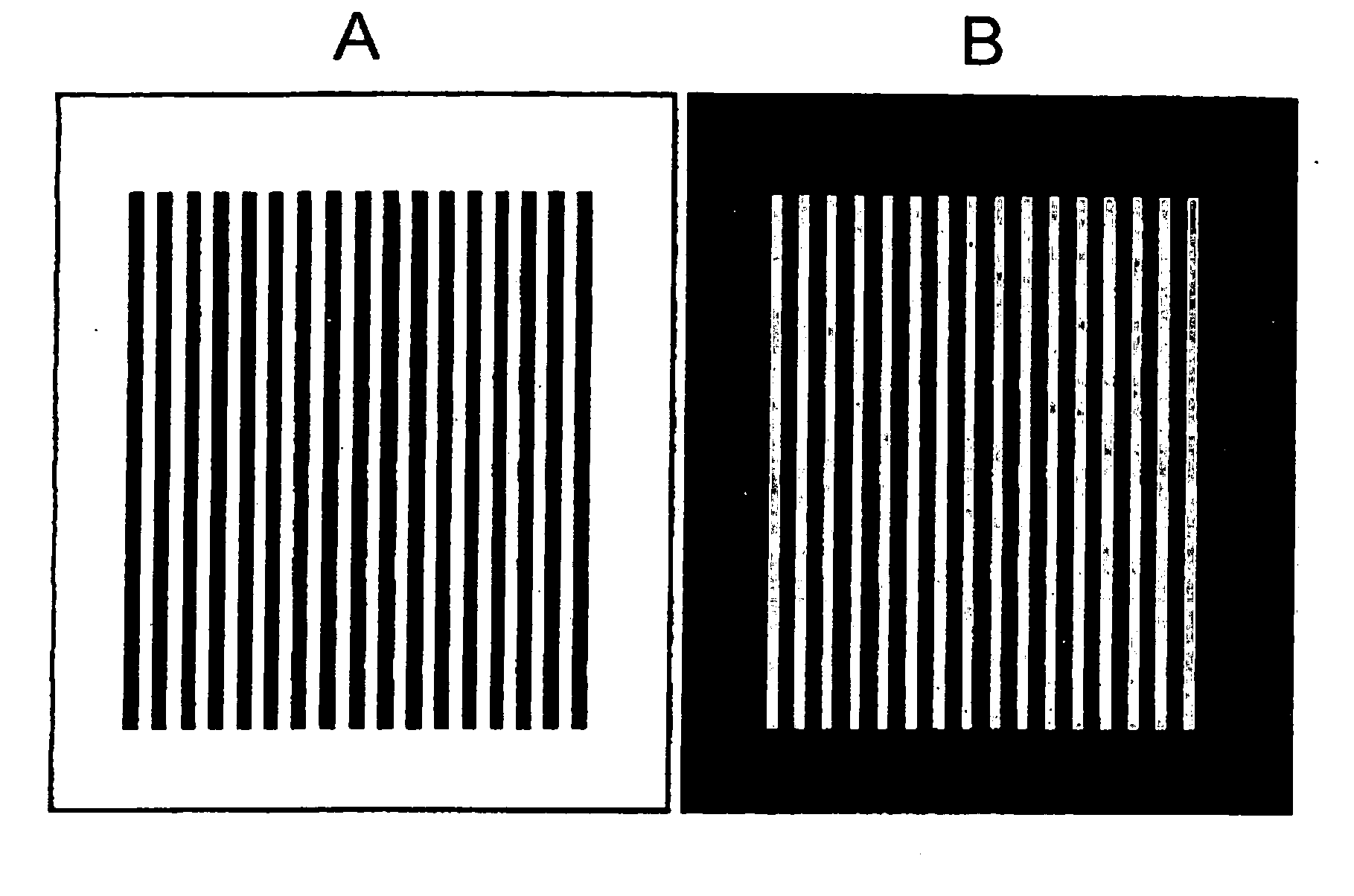

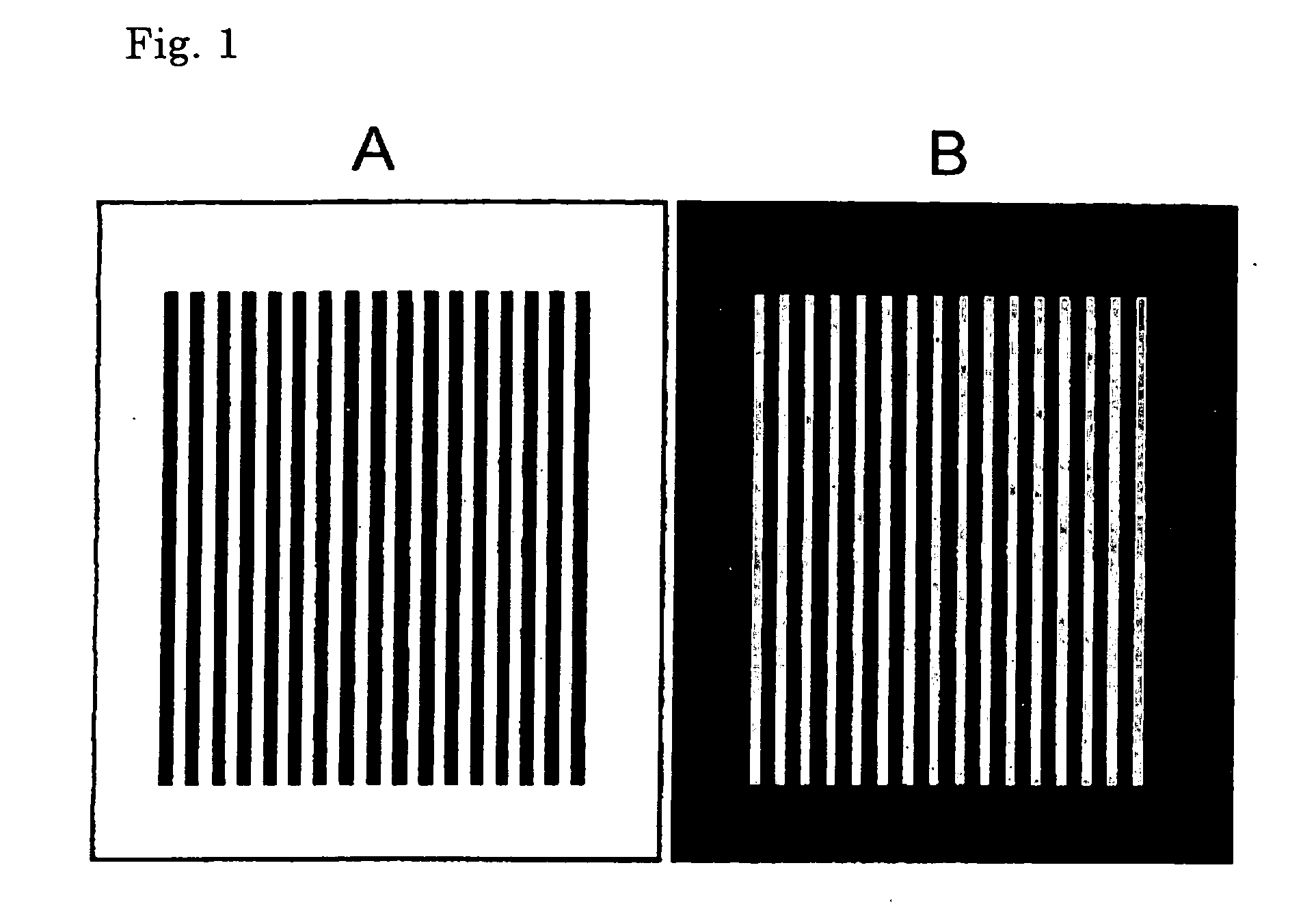

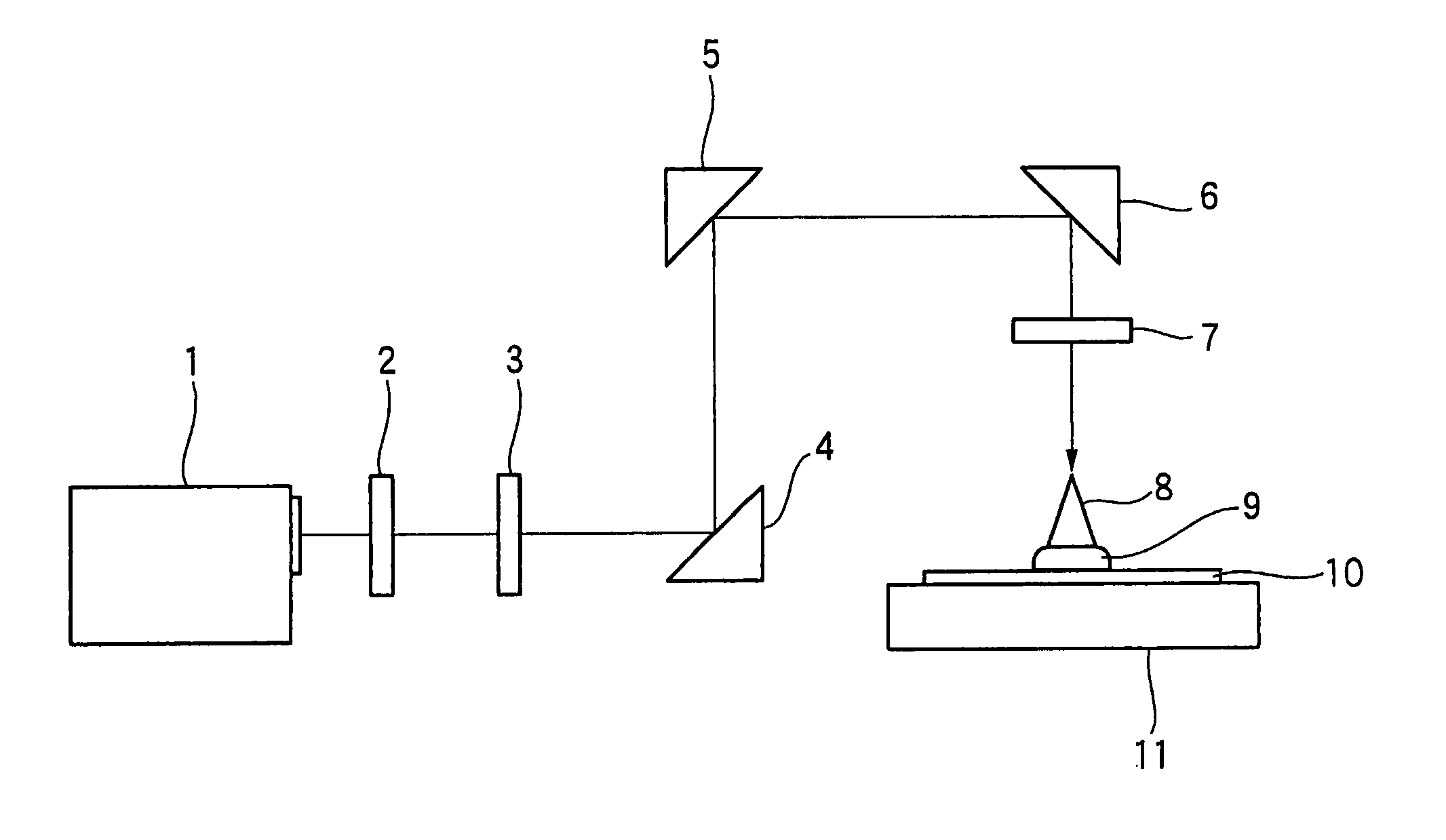

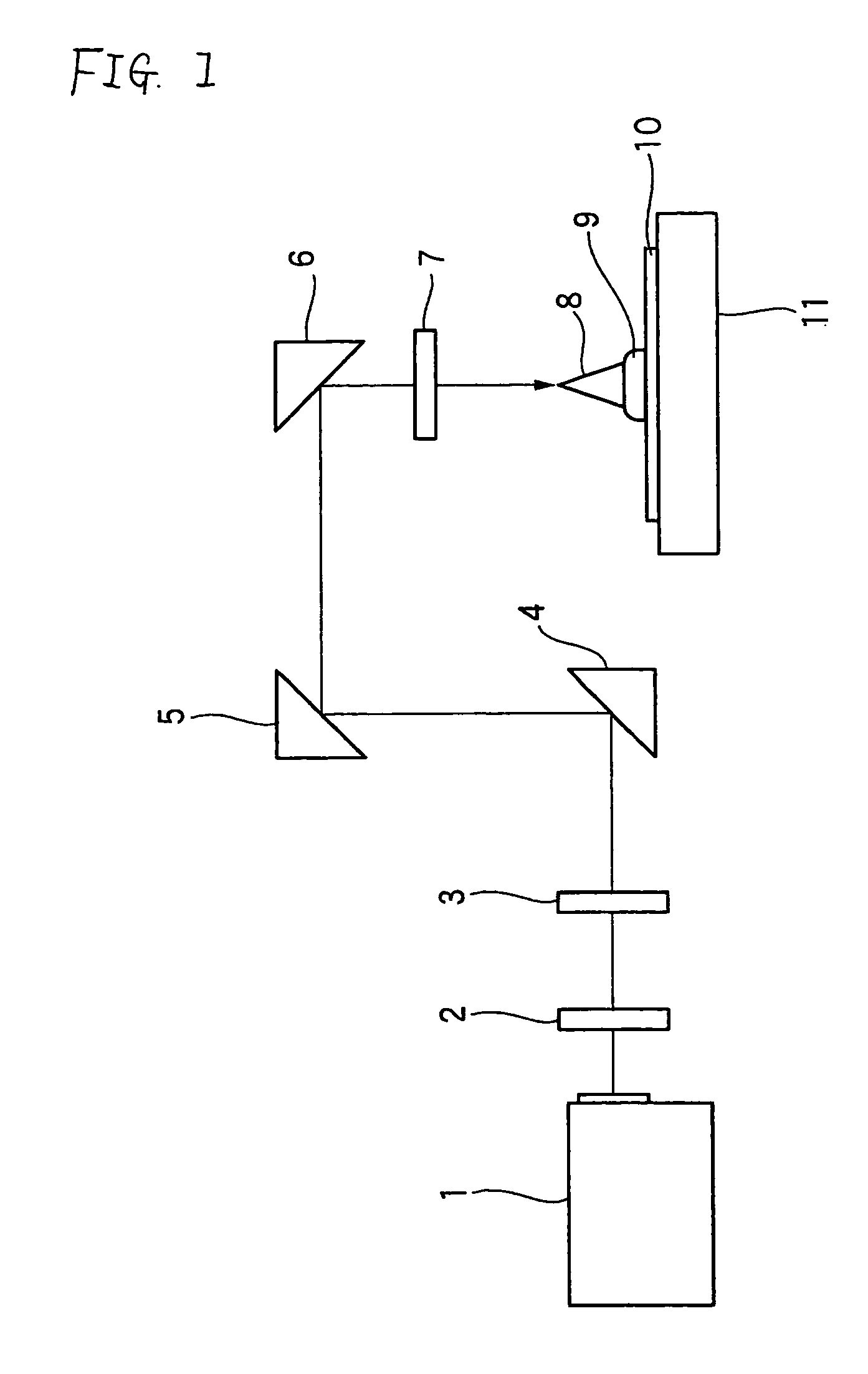

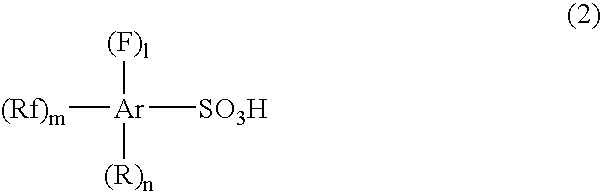

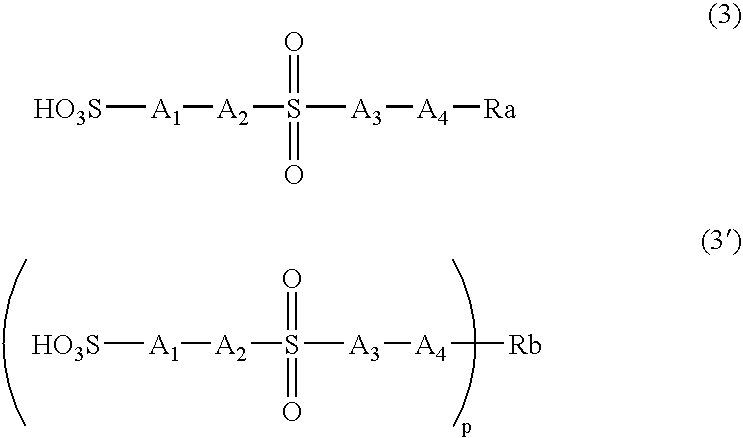

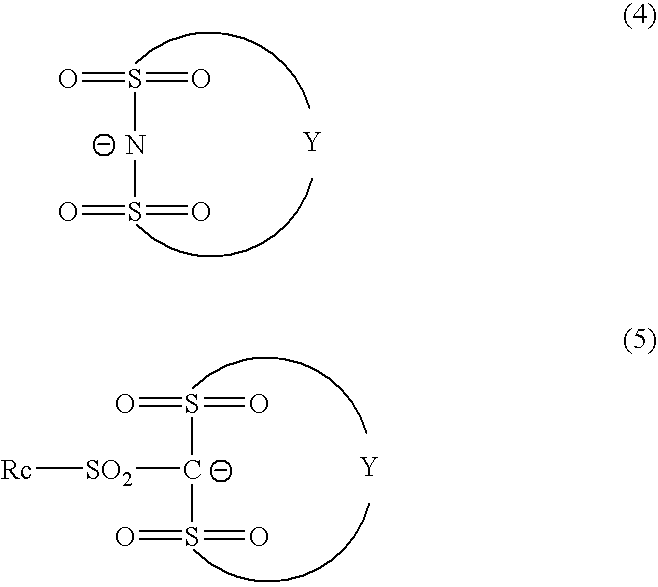

Positive-working photosensitive composition and pattern forming method using the same

ActiveUS20070087288A1Improve errorPhotosensitive materialsRadiation applicationsOrganic acidActinic Rays

A positive-working photosensitive composition that includes (A) a resin containing repeating units having diamantane structures and capable of decomposing under action of an acid to increase solubility in an alkali developer, (B) a compound capable of generating a specific organic acid upon irradiation with an actinic ray or radiation, and (C) a solvent.

Owner:FUJIFILM CORP

Positive photosensitive composition and pattern-forming method using the same

InactiveUS20070054217A1Positive photosensitive compositionIncrease exposurePhotosensitive materialsPhotomechanical apparatusMethacrylateActinic Rays

A positive photosensitive composition comprises: (A) a compound capable of generating an acid upon irradiation with actinic ray or radiation; and (B) a resin having a group capable of decomposing by action of an acid to increase solubility of the group in an alkali developer, wherein the resin (B) comprises: at least one methacrylate repeating unit; at least one acrylate repeating unit; and at least one repeating unit (Ba) having a diamantane structure.

Owner:FUJIFILM CORP +1

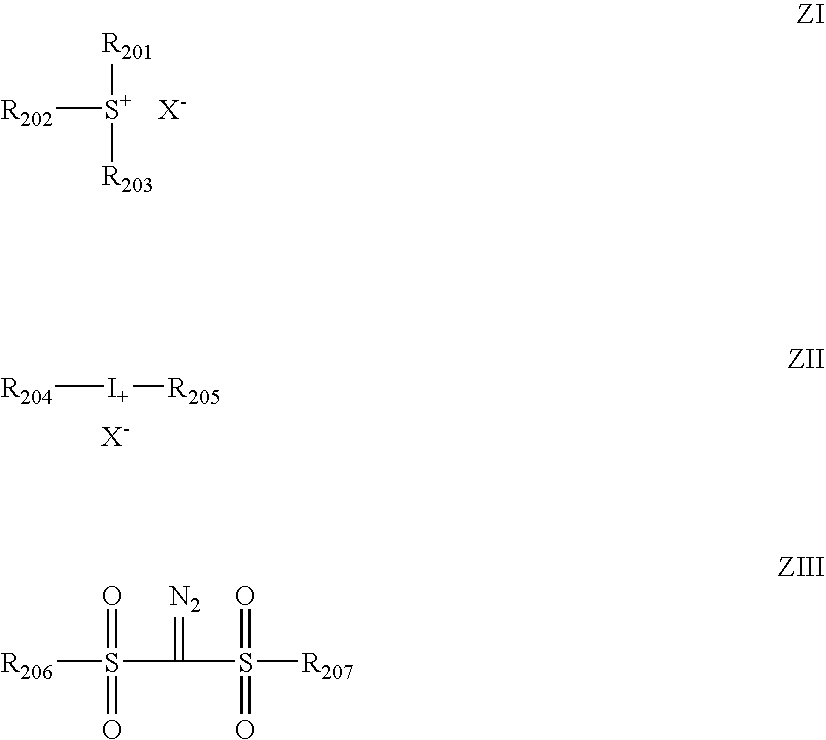

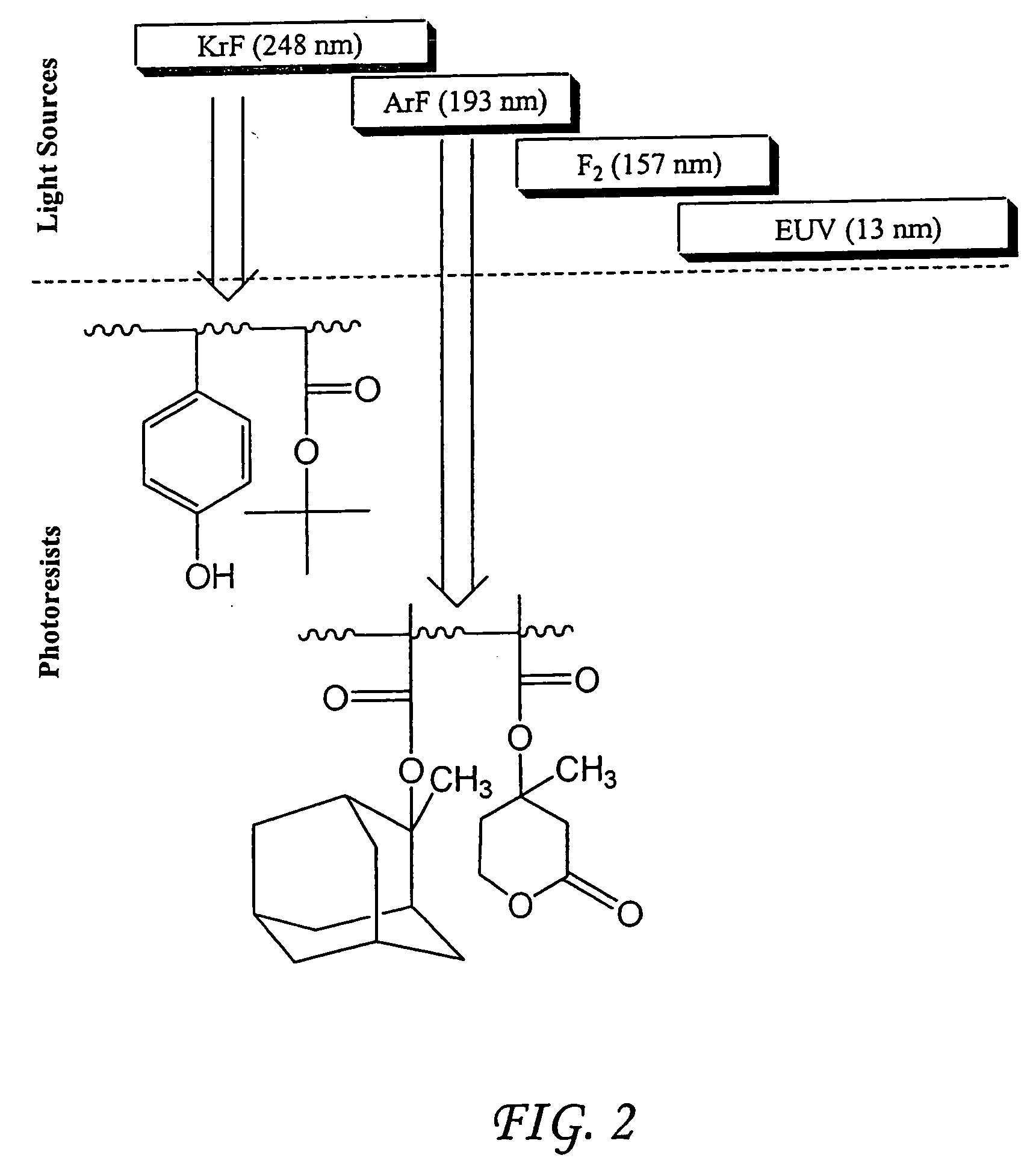

Photoresist compositions comprising diamondoid derivatives

InactiveUS20050074690A1Improve hydrophilicityMore solubleOrganic compound preparationRadiation applicationsResistDiamantane

Novel positive-working photoresist compositions are disclosed. The monomers of the base resin of the resist contain diamondoid-containing pendant groups higher than adamantane in the polymantane series; for example, diamantane, triamantane, tetramantane, pentamantane, hexamantane, etc. The diamondoid-containing pendant group may have hydrophilic-enhancing substituents such as a hydroxyl group, and may contain a lactone group. Advantages of the present compositions include enhanced resolution, sensitivity, and adhesion to the substrate.

Owner:CHEVROU USA INC

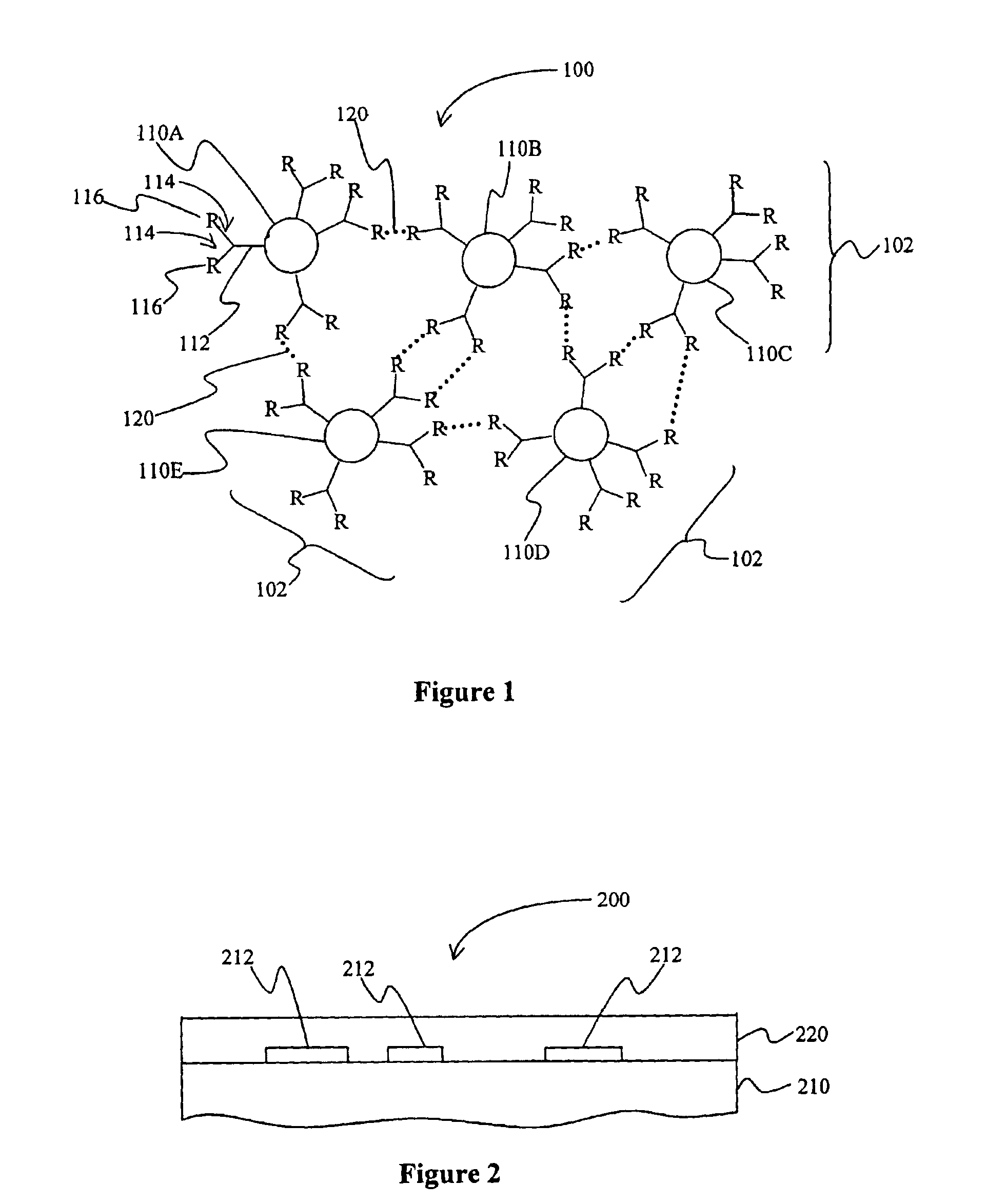

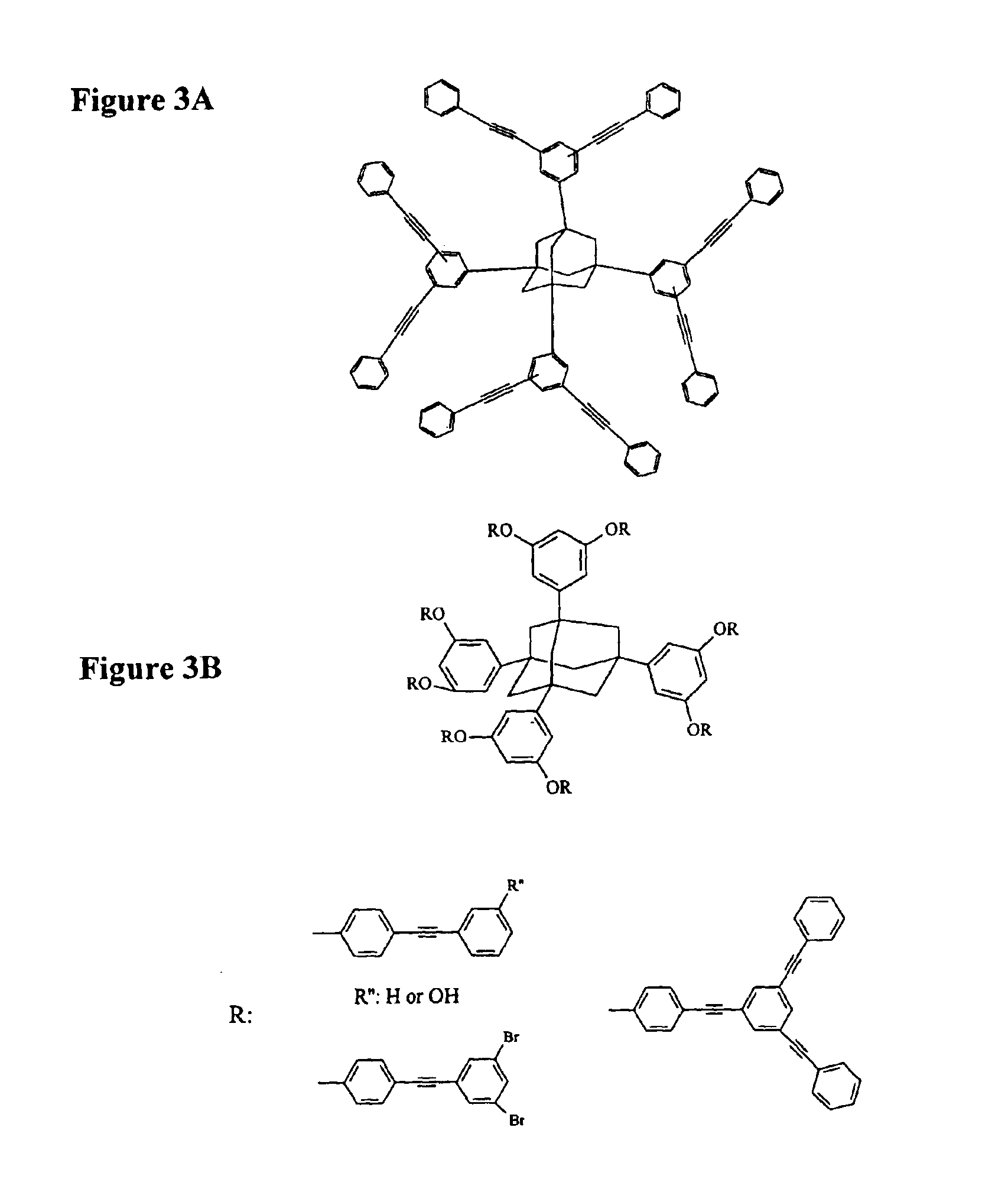

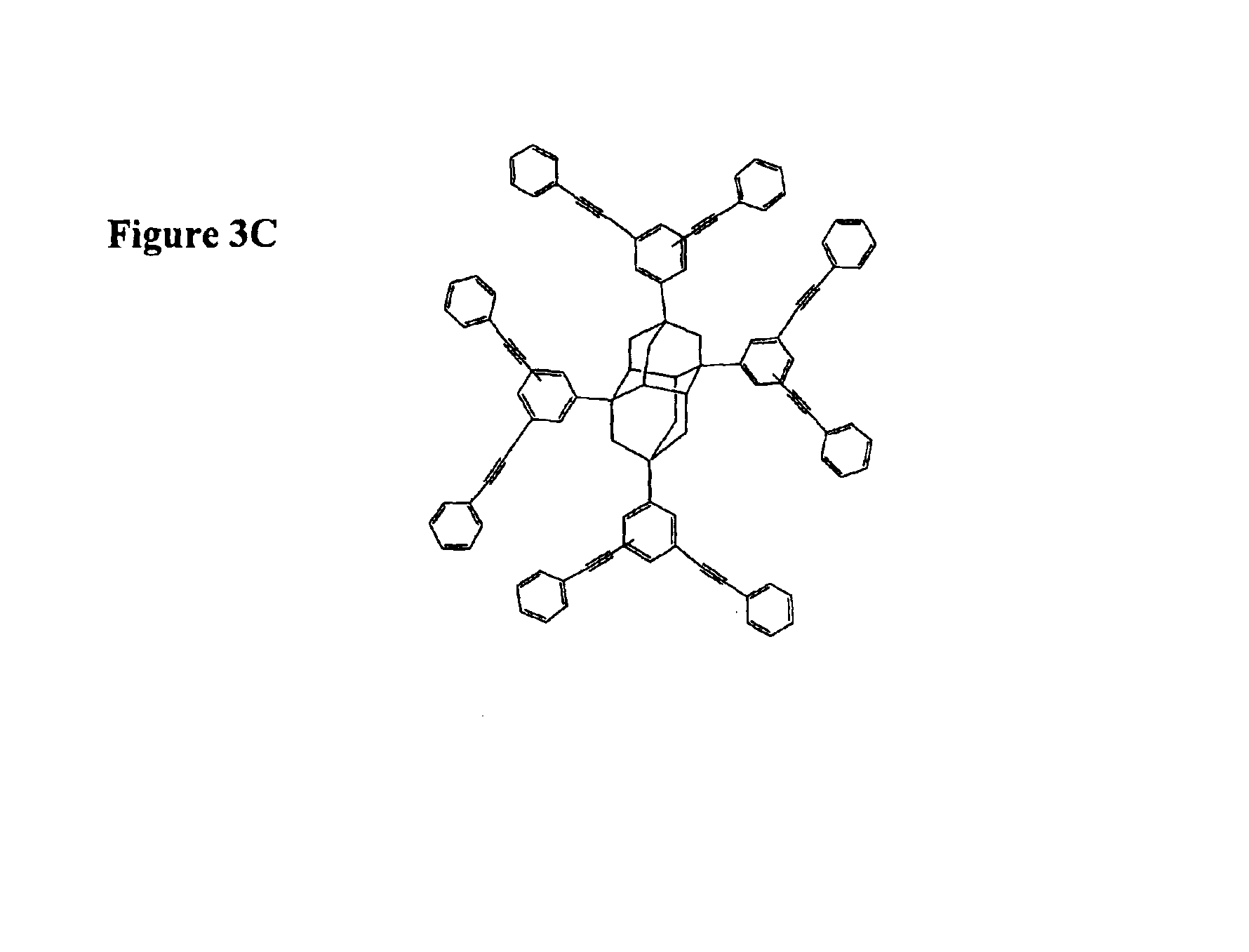

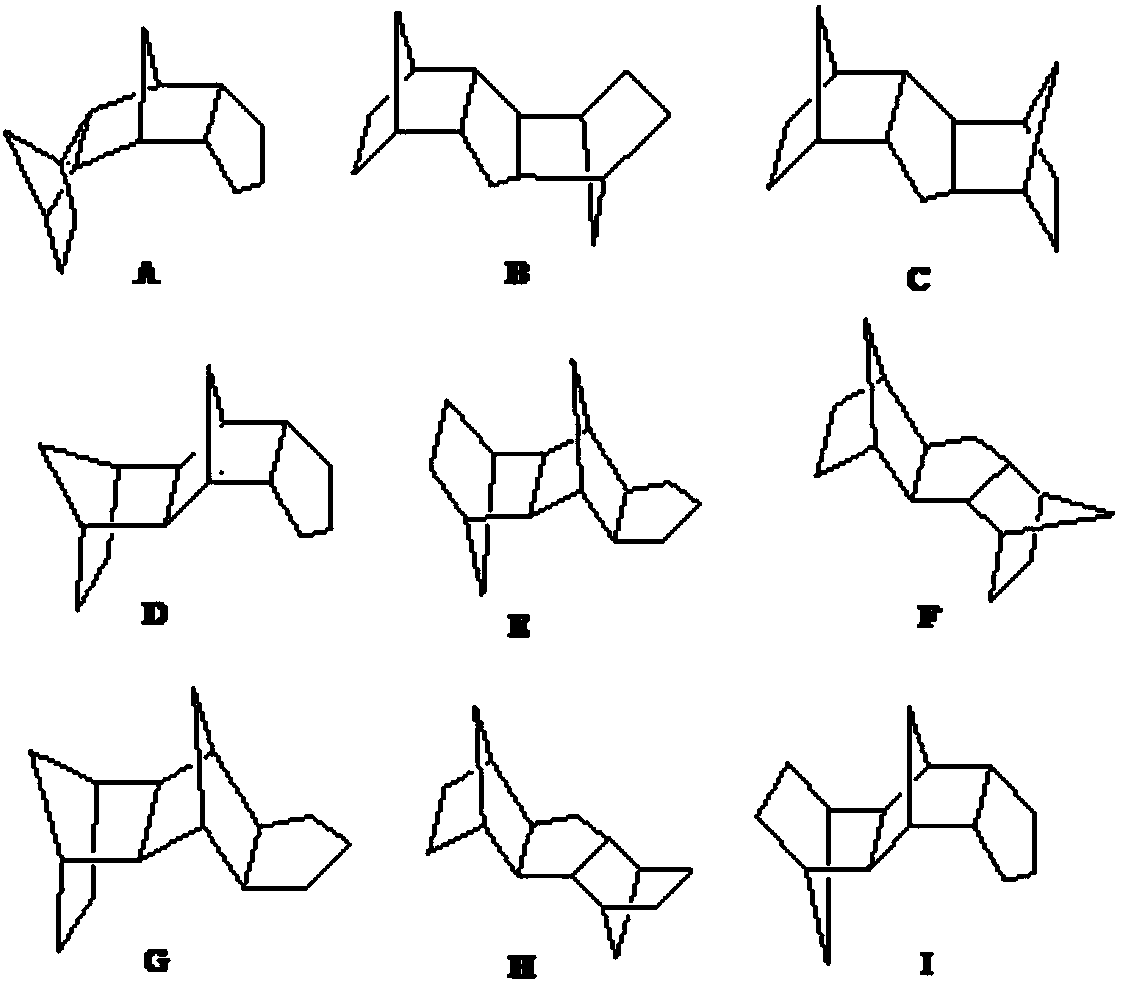

Low dielectric constant materials with improved thermo-mechanical strength and processability

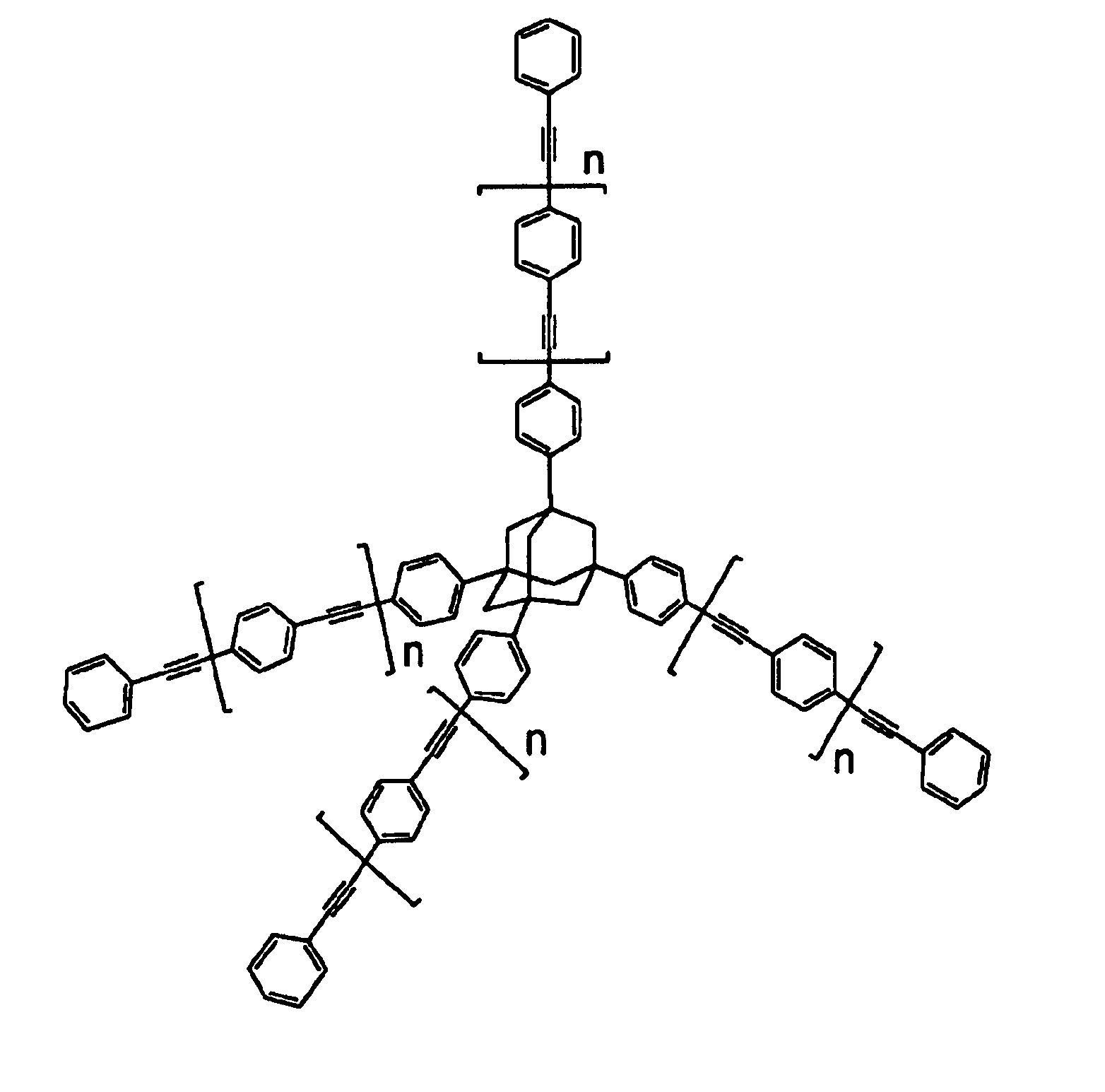

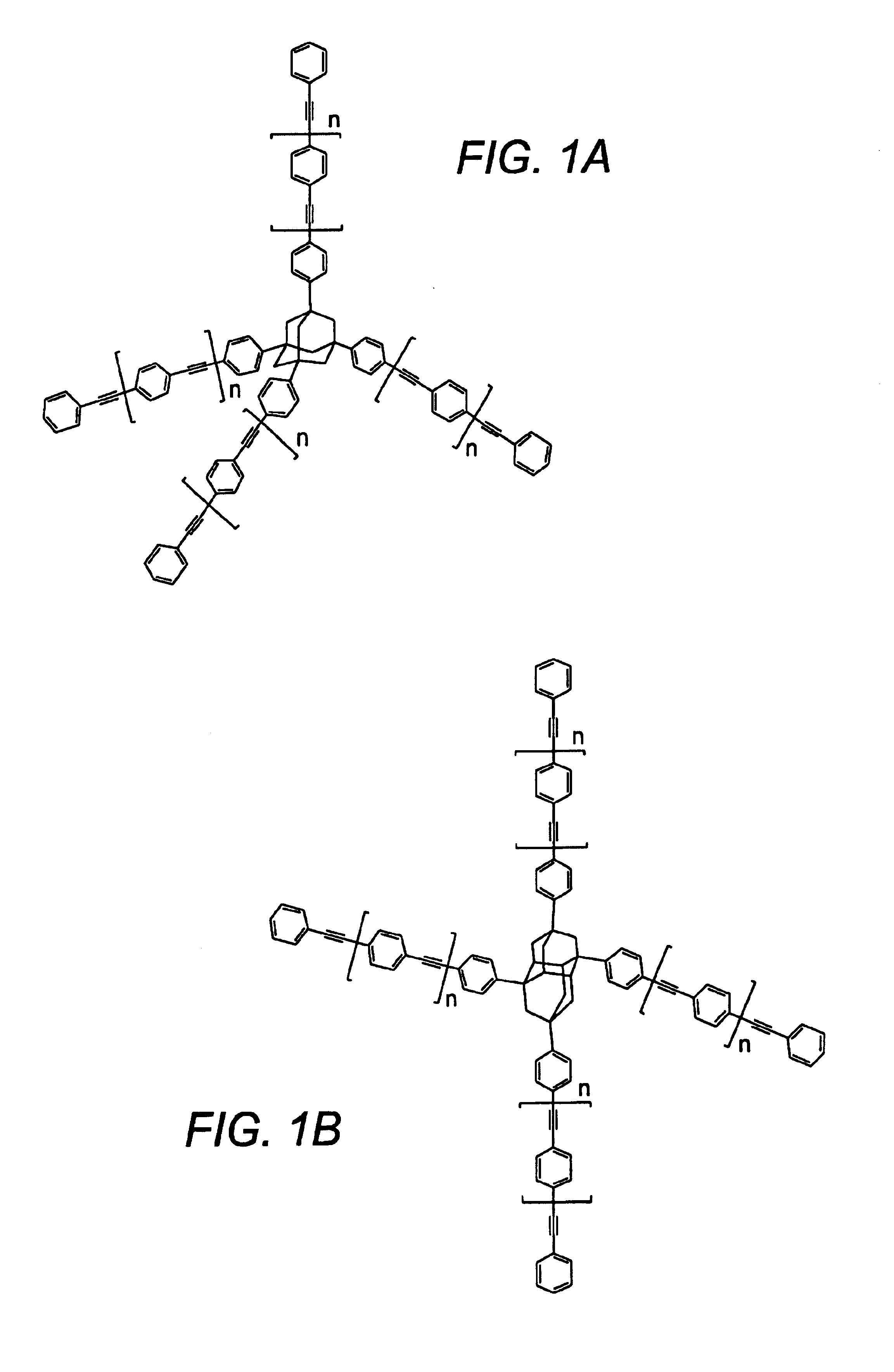

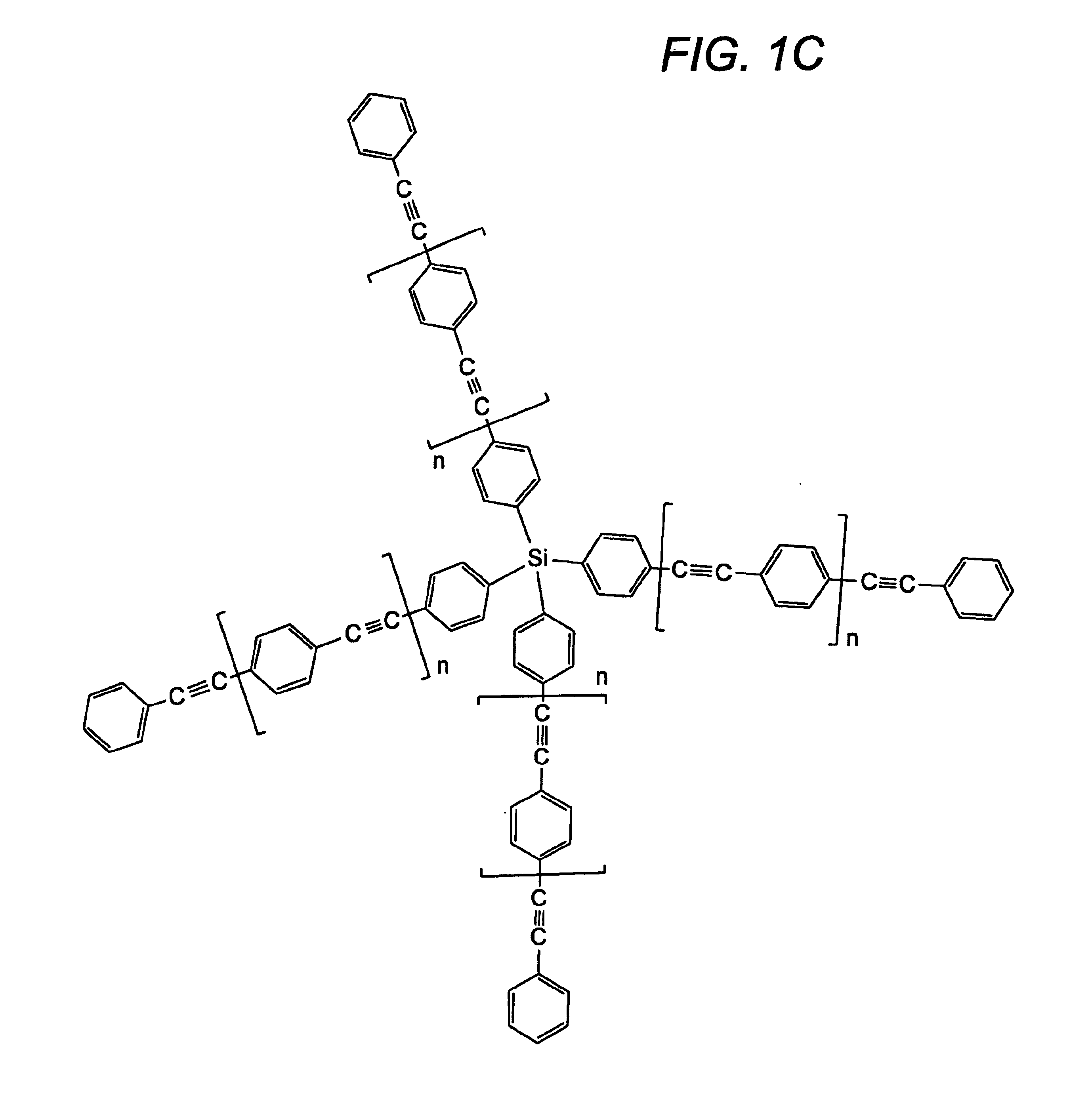

InactiveUS6987147B2Synthetic resin layered productsSemiconductor/solid-state device manufacturingPolymer networkDiamantane

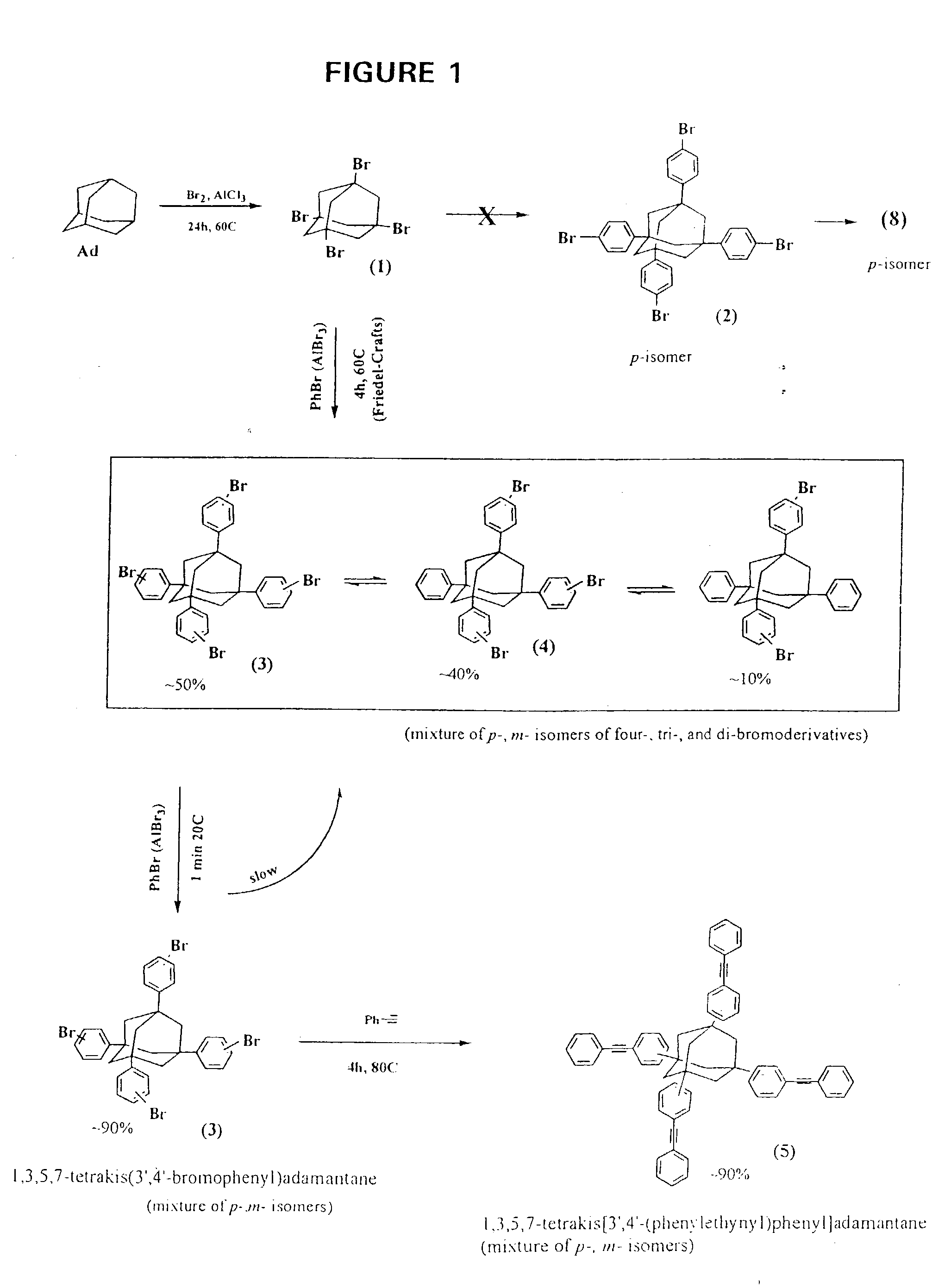

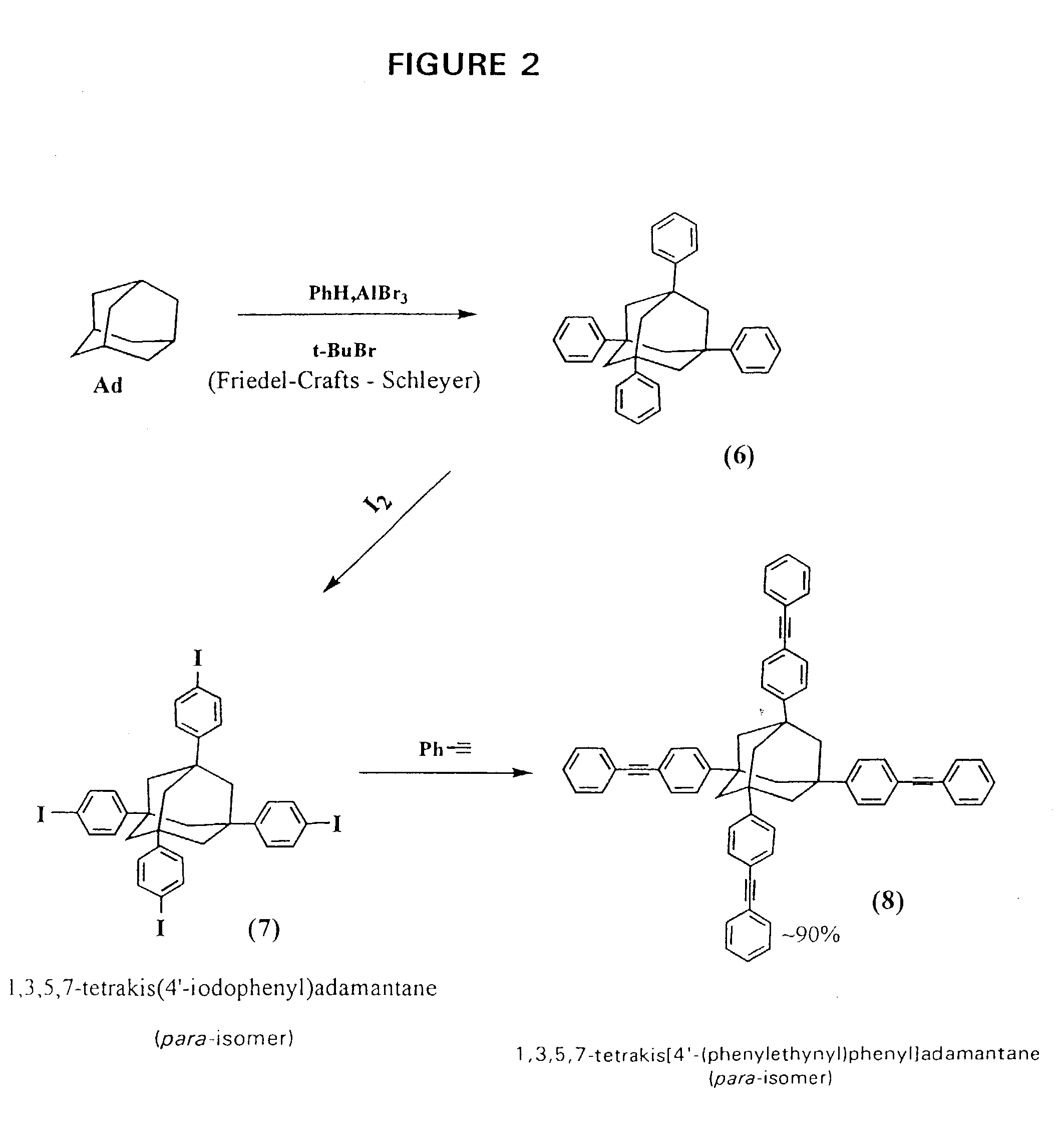

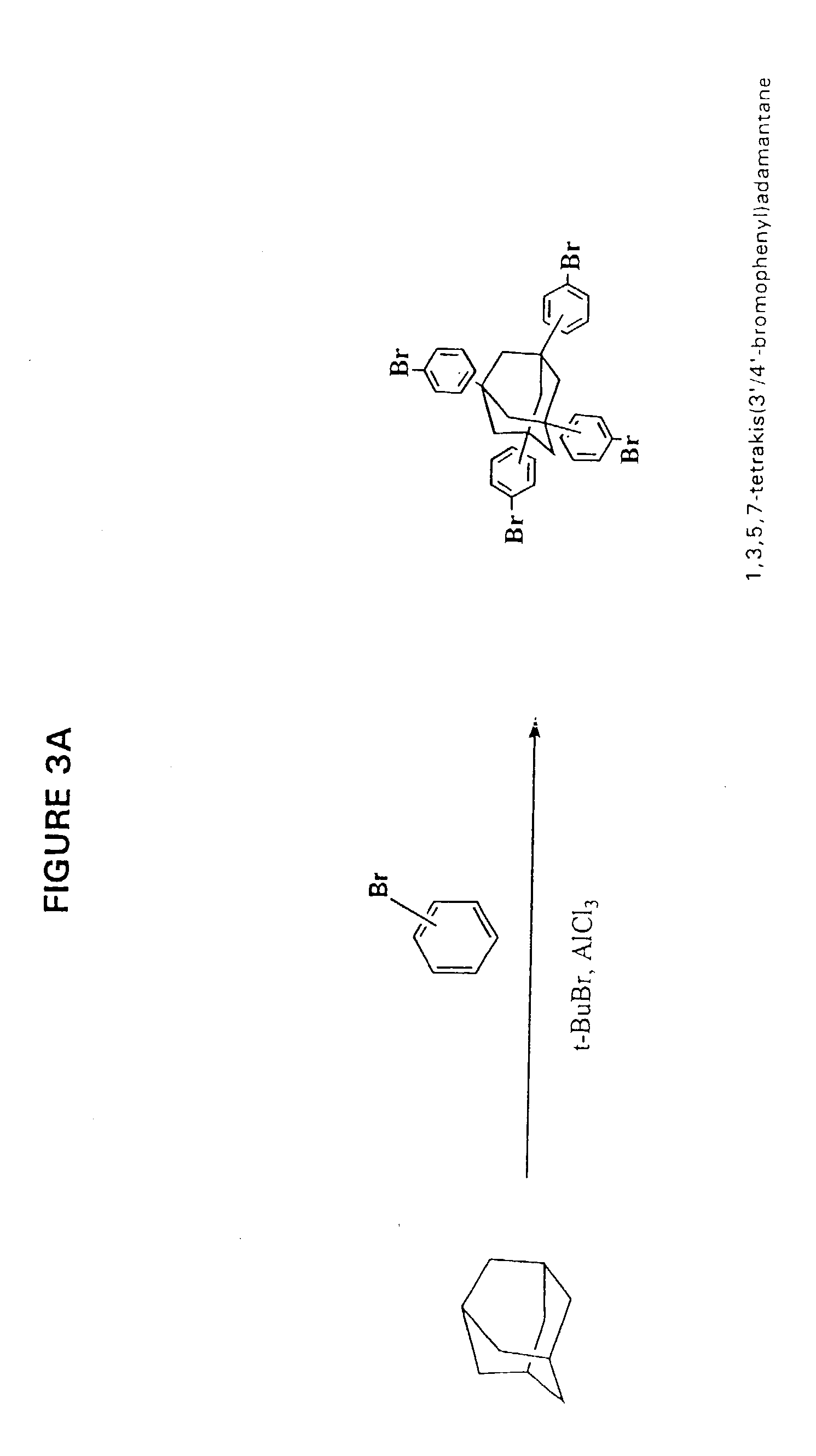

A polymeric network comprises a plurality of monomers that include a cage compound with at least three arms, wherein at least one of the arms has two or more branches, and wherein each of the branches further comprises a reactive group. Monomers in contemplated polymeric networks are covalently coupled to each other via the reactive groups. Particularly contemplated cage compounds include adamantane and diamantane, and especially contemplated branched arms comprise ortho-bis(phenylethynyl)phenyl. Especially contemplated polymeric networks have a dielectric constant of no more than 3.0, and are formed on the surface of a substrate.

Owner:HONEYWELL INT INC

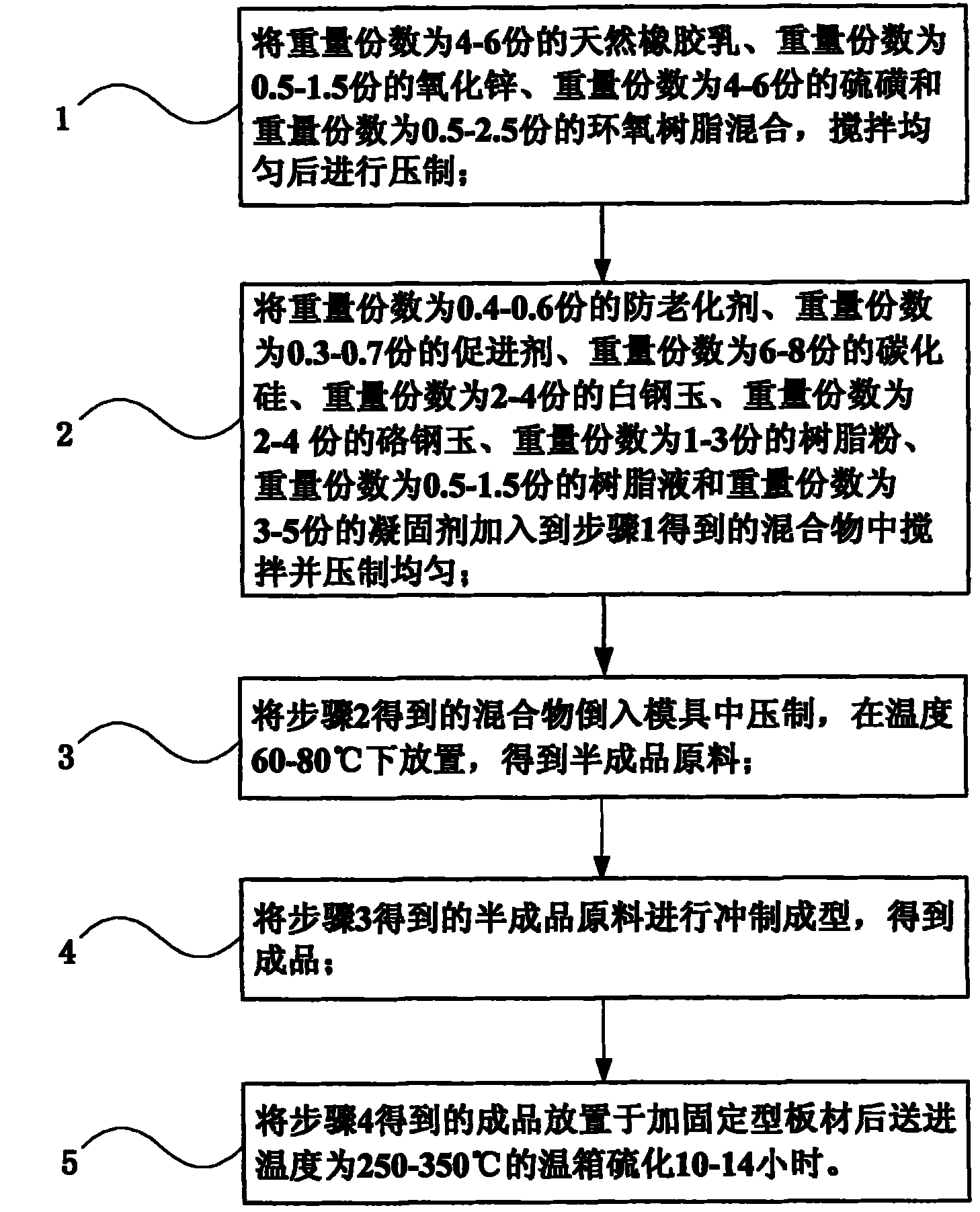

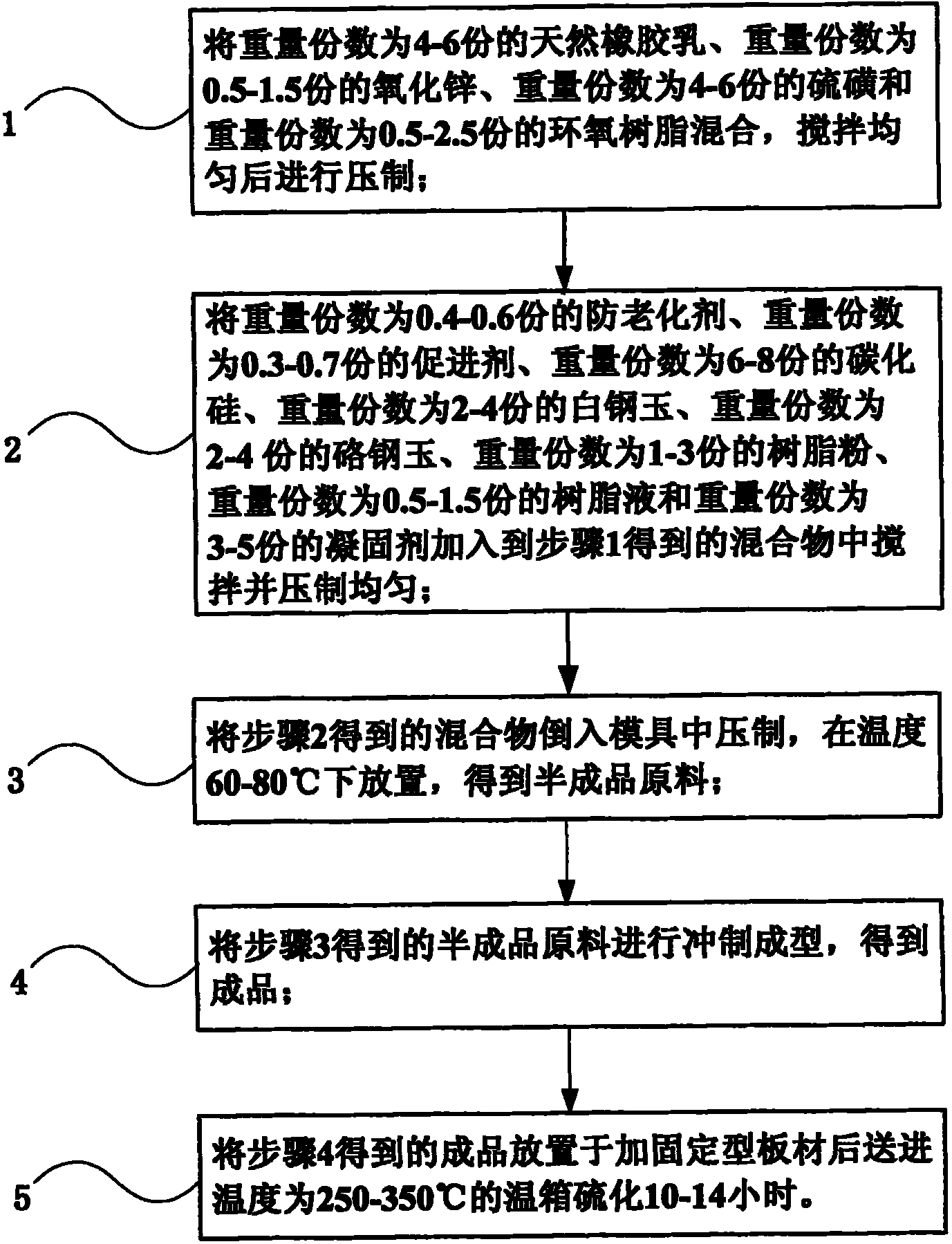

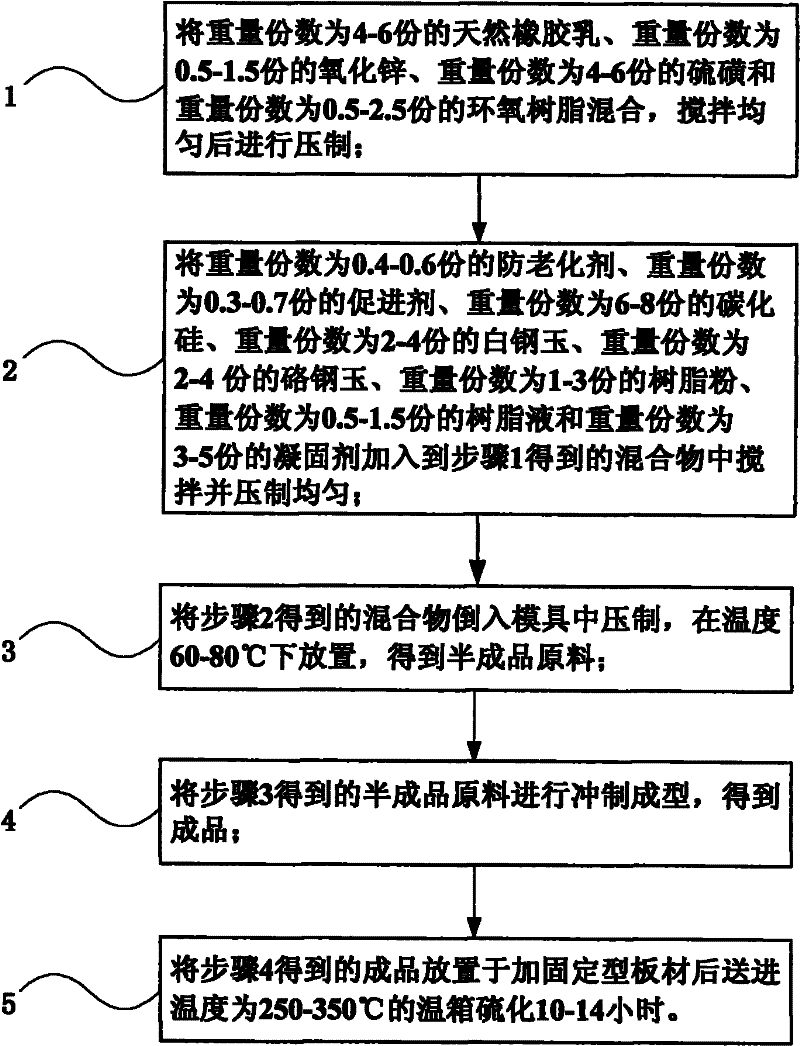

Rubber thin sheet grinding wheel and preparation method thereof

InactiveCN102001057AImprove wear resistanceHigh hardnessAbrasion apparatusGrinding devicesEpoxyPolymer science

The invention relates to a rubber thin sheet grinding wheel and a preparation method thereof. The rubber thin sheet grinding wheel comprises the following raw materials in part by weight: 4 to 6 parts of natural rubber emulsion, 0.5 to 1.5 parts of zinc oxide, 4 to 6 parts of sulfur, 0.5 to 2.5 parts of epoxy resin, 0.4 to 0.6 part of anti-ager, 0.3 to 0.7 part of accelerant, 6 to 8 parts of silicon carbide, 2 to 4 parts of diamantane, 2 to 4 parts of chromium corundum, 1 to 3 parts of resin powder, 0.5 to 1.5 parts of resin liquid and 3 to 5 parts of coagulator. The rubber thin sheet grinding wheel of the invention has the advantages of high wear resistance, heat resistance, self-sharpening property, heat conductivity, corrosion resistance, toughness, hardness and working efficiency and long service life; in addition, the rubber thin sheet grinding wheel prepared by the preparation method of the rubber thin sheet grinding wheel of the invention is very thin and has low loss and high accuracy during cutting.

Owner:施镇源

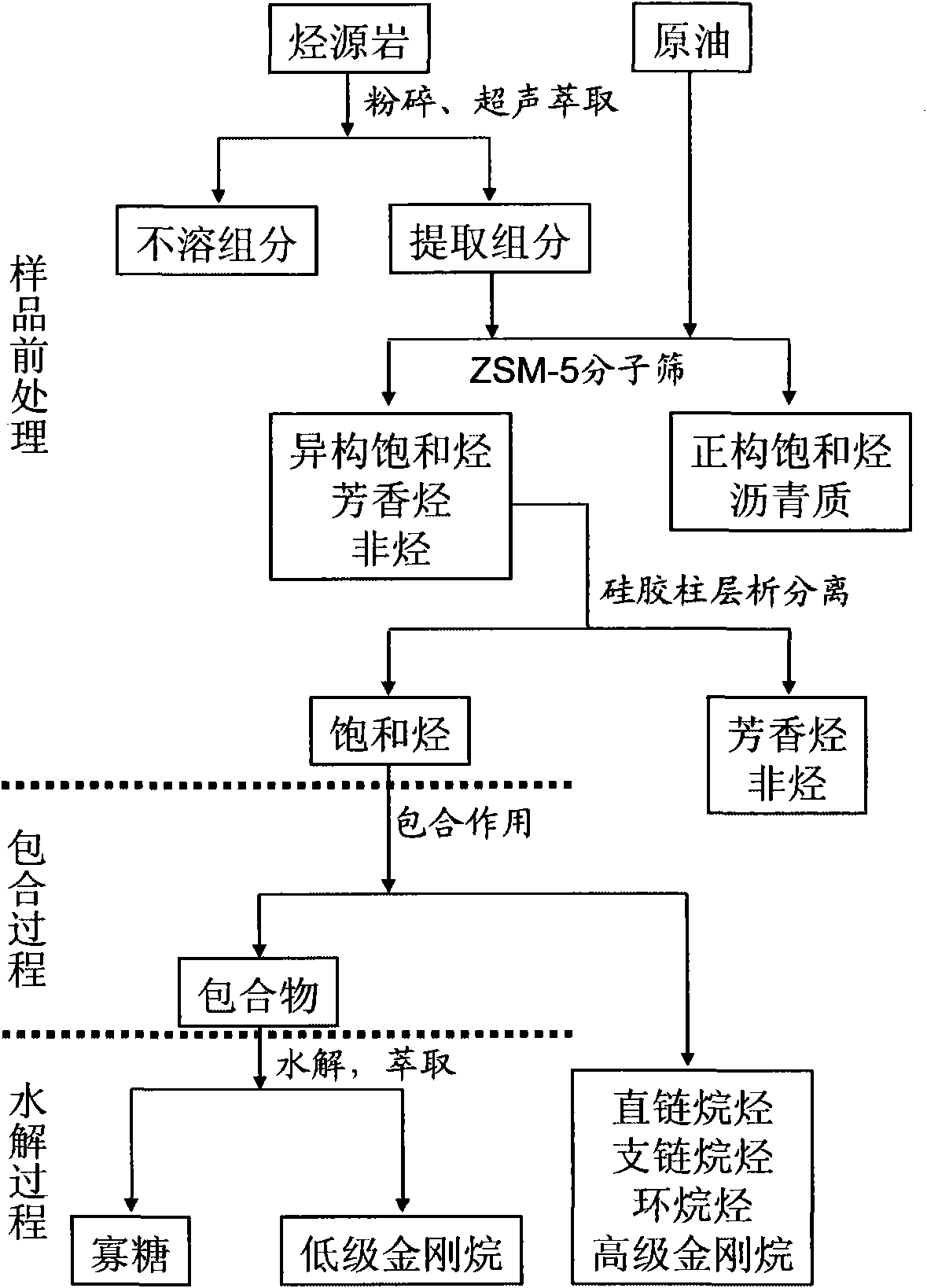

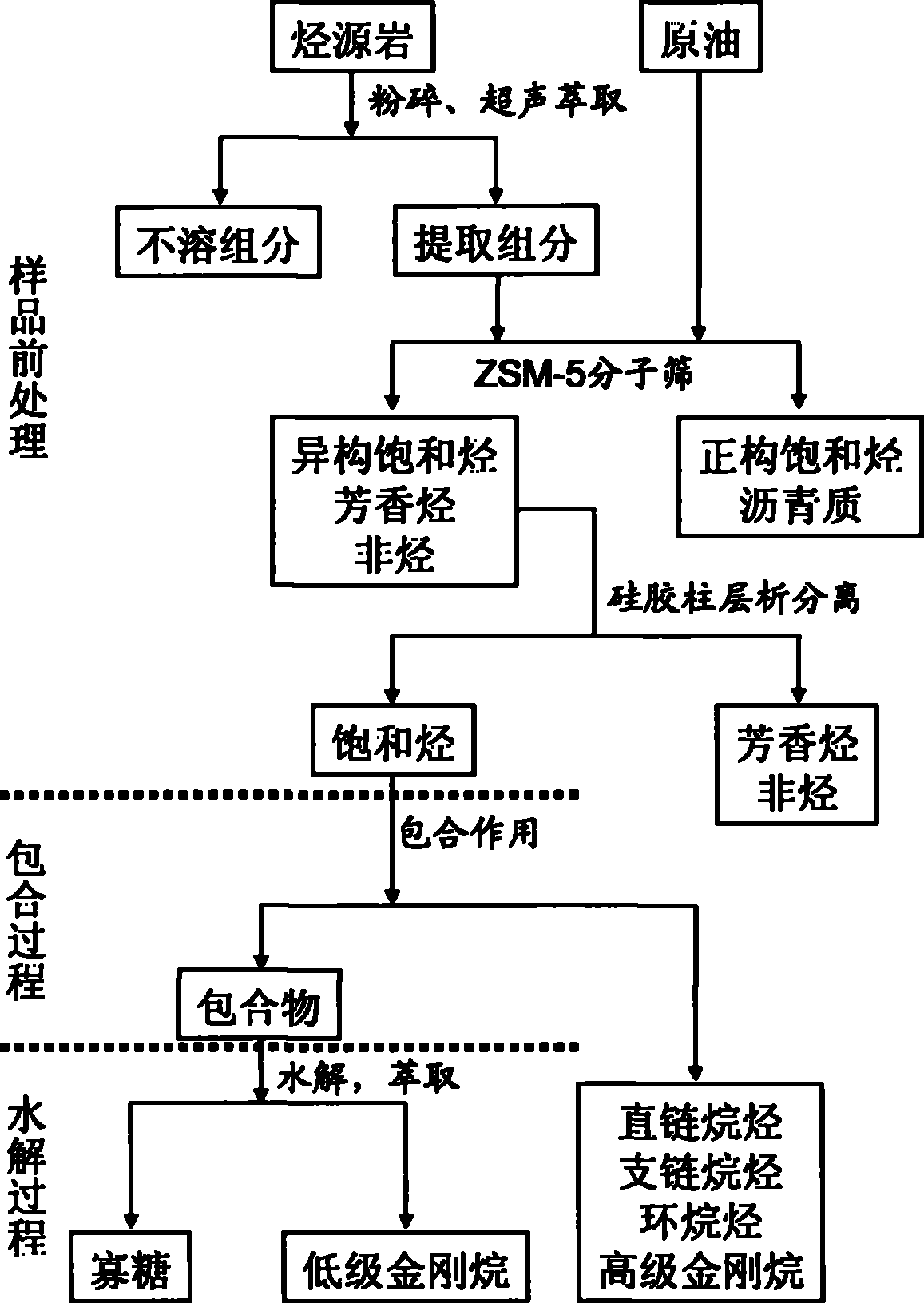

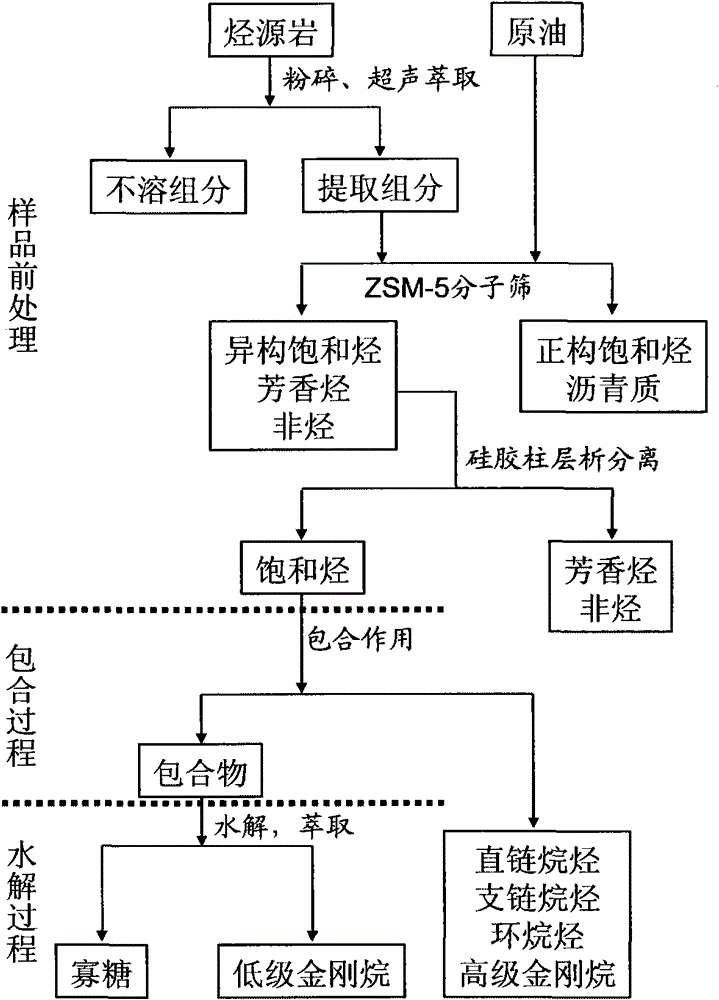

Method for separating and enriching low-grade adamantane compounds in petroleum and hydrocarbon source rocks

ActiveCN102101817AHigh recovery rateEasy to operateOrganic compound preparationHydrocarbonsCooking & bakingDiamantane

The invention relates to a method for separating and enriching low-grade adamantane compounds in petroleum and hydrocarbon source rocks, which comprises the following steps: extracting a hydrocarbon source rock sample with dichloromethane and methanol solution to obtain a hydrocarbon source rock extract; removing normal saturated hydrocarbons and asphaltene components in the hydrocarbon source rock extract or crude oil sample by using a ZSM-5 molecular sieve, passing through silicagel columns to obtain isomeric saturated hydrocarbon components, adding beta-cyclodextrin solution into the isomeric saturated hydrocarbon solution, and separating the suspension to obtain a precipitate; moving the precipitate into a hydrochloric acid solution, putting into a baking oven at 40-95 DEG C, and keeping the temperature; and after the acid-catalysis hydrolysis reaction of the beta-cyclodextrin finishes, cooling to room temperature, and extracting with a saturated hydrocarbon solvent to obtain the low-grade adamantane compounds. By using the method, the recovery rate of the single-adamantane compounds can maximally reach higher than 18%, the recovery rate of the double-adamantane compounds can maximally reach higher than 35%, and the recovery rate of the tertiary-adamantane compounds can maximally reach higher than 1.5%.

Owner:PETROCHINA CO LTD

Ph reversible response mesoporous silicon oxide composite medicament-carrying system, preparation method thereof and application thereof

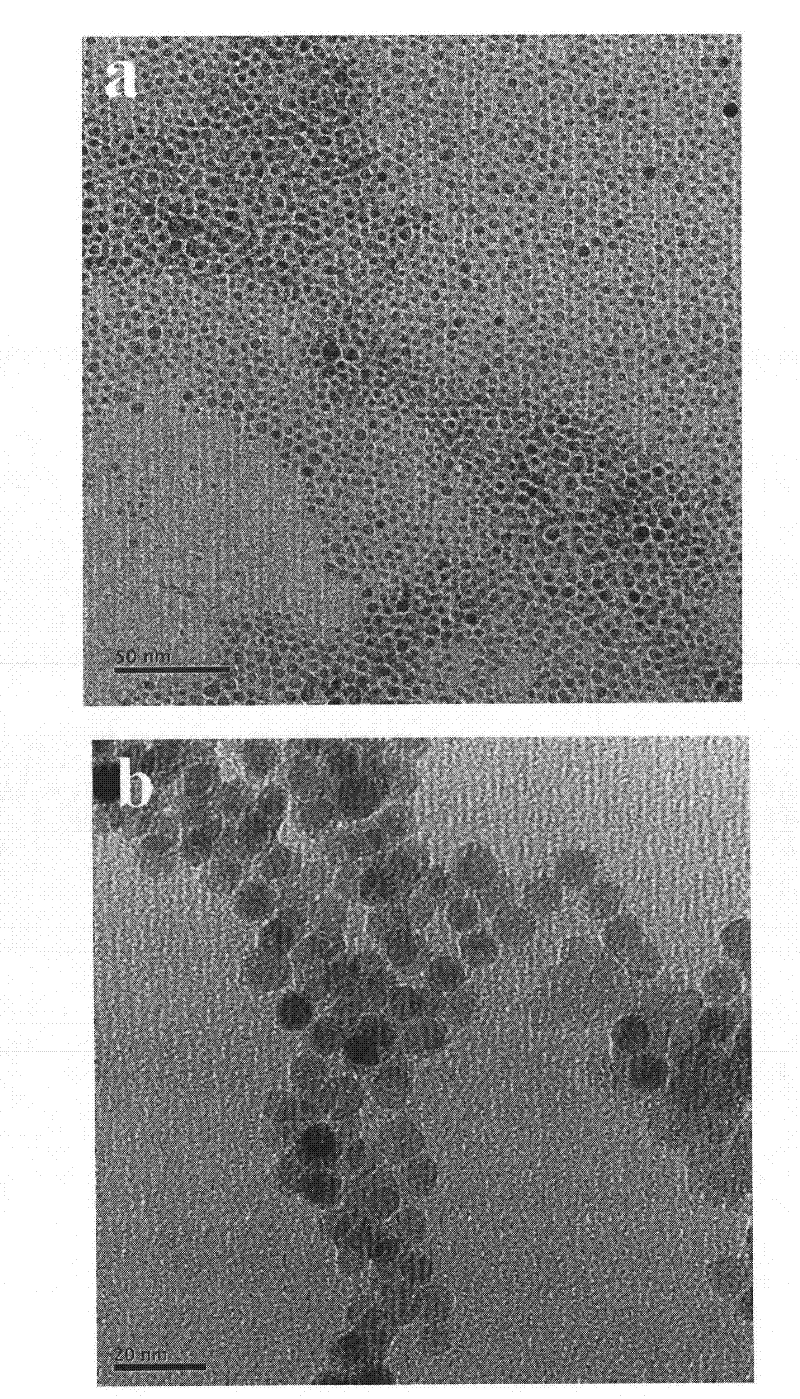

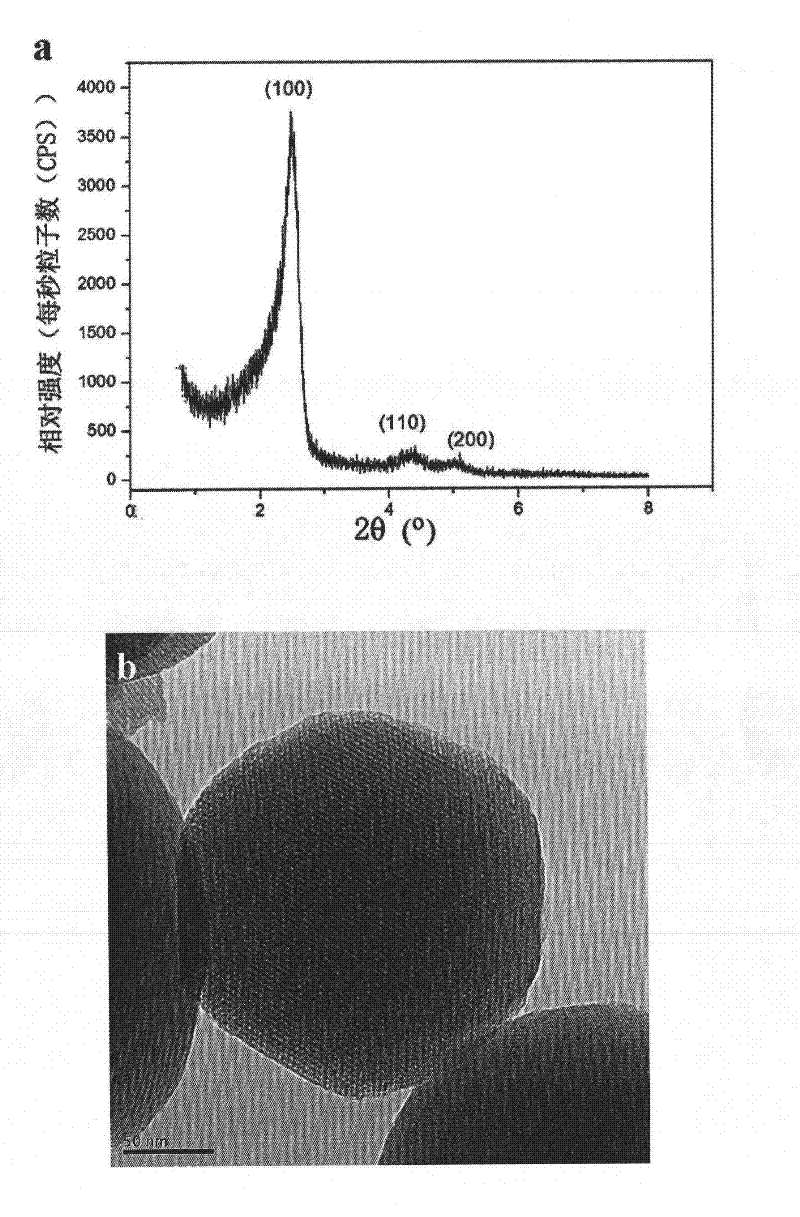

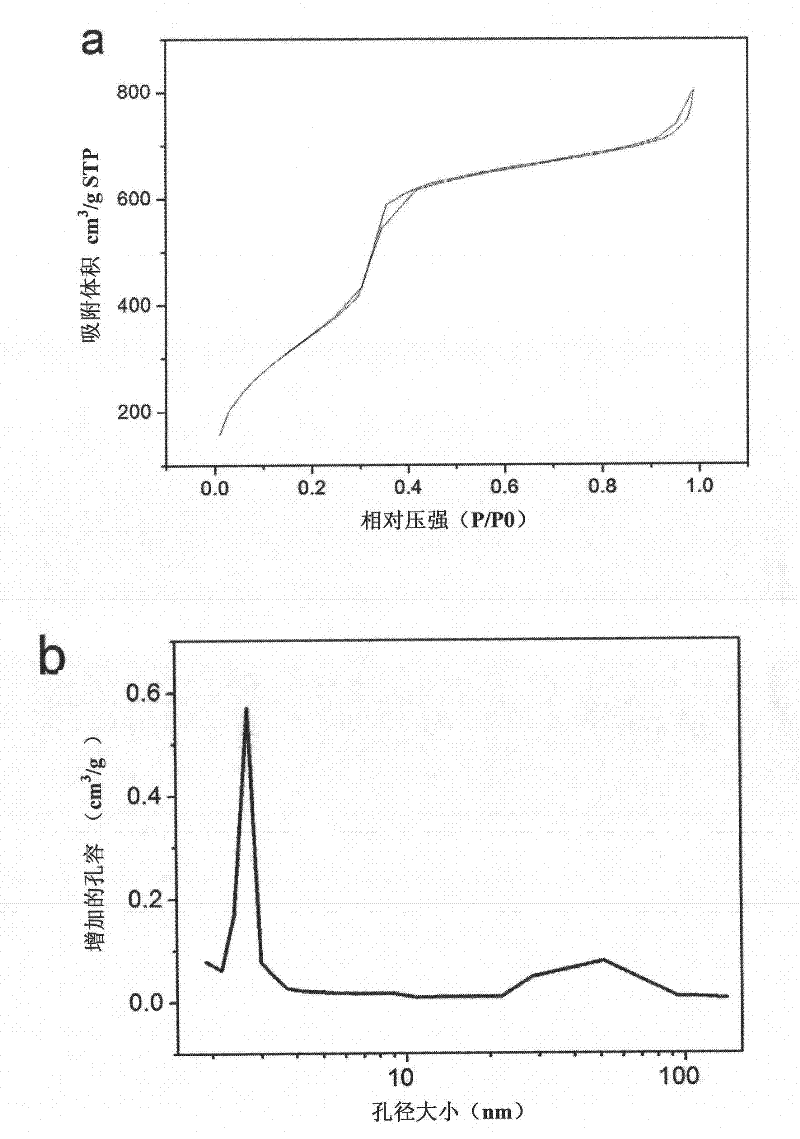

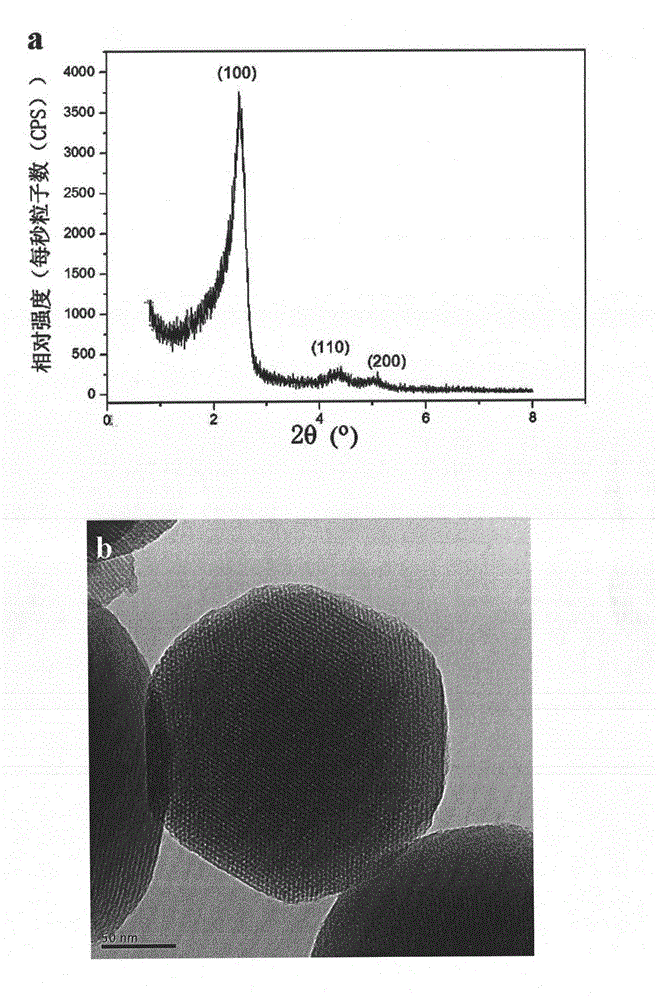

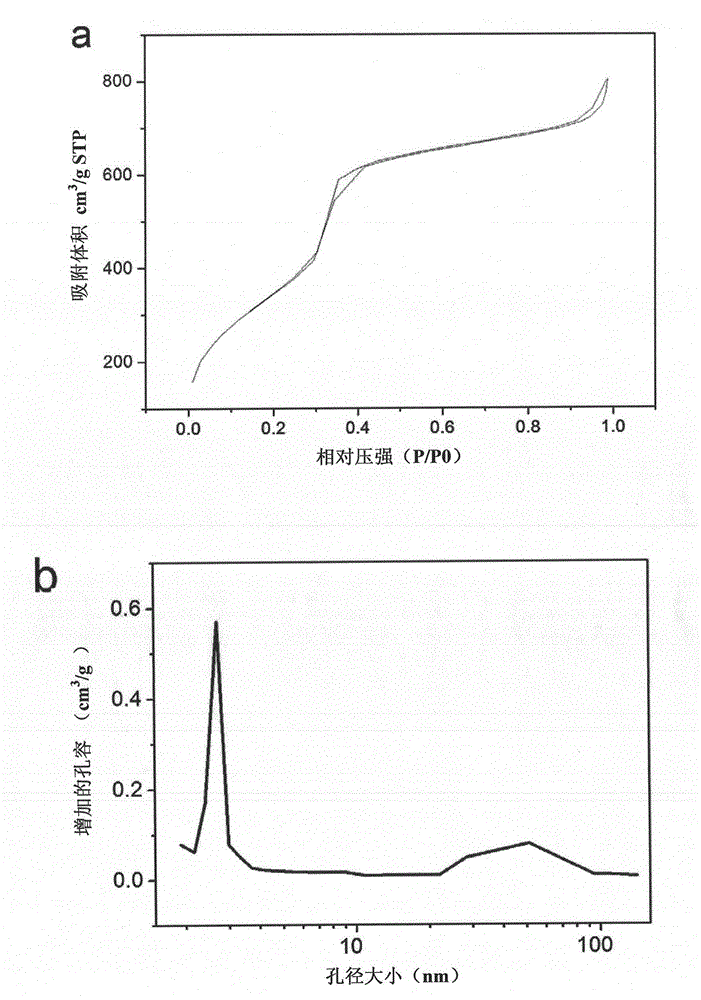

InactiveCN102210867AGood biocompatibilityFacilitated releaseGenetic material ingredientsInorganic non-active ingredientsSilicon oxideMesoporous silica

The invention discloses a pH reversible response mesoporous silicon oxide composite medicament-carrying system, a preparation method thereof and application thereof. The preparation method comprises the following steps of: preparing mesoporous silicon oxide nano particles by a sol-gel process; and modifying surfaces of mesoporous silicon oxide and nanometer magnetic particles respectively by using triaminomethyl ethane and 4-carboxybenzaldehyde, and reacting in alkalescent environment to generate pH sensitive triaza diamantane groups, so that the magnetic nano particles are covered on the surface of a mesoporous silicon oxide porous channel to obtain the pH reversible response mesoporous silicon oxide composite medicament-carrying system. The pH reversible response mesoporous silicon oxide composite medicament-carrying system has the excellent magnetic targeting and biocompatibility, and can realize pH response pulse release.

Owner:EAST CHINA UNIV OF SCI & TECH

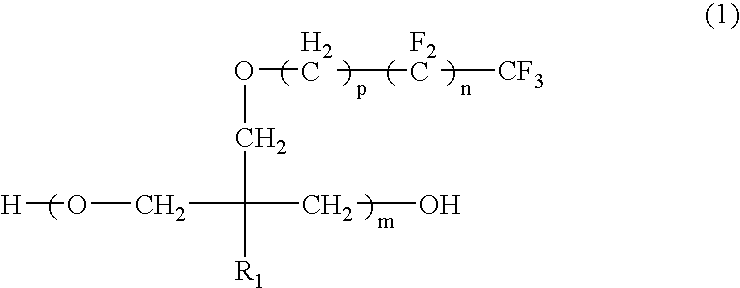

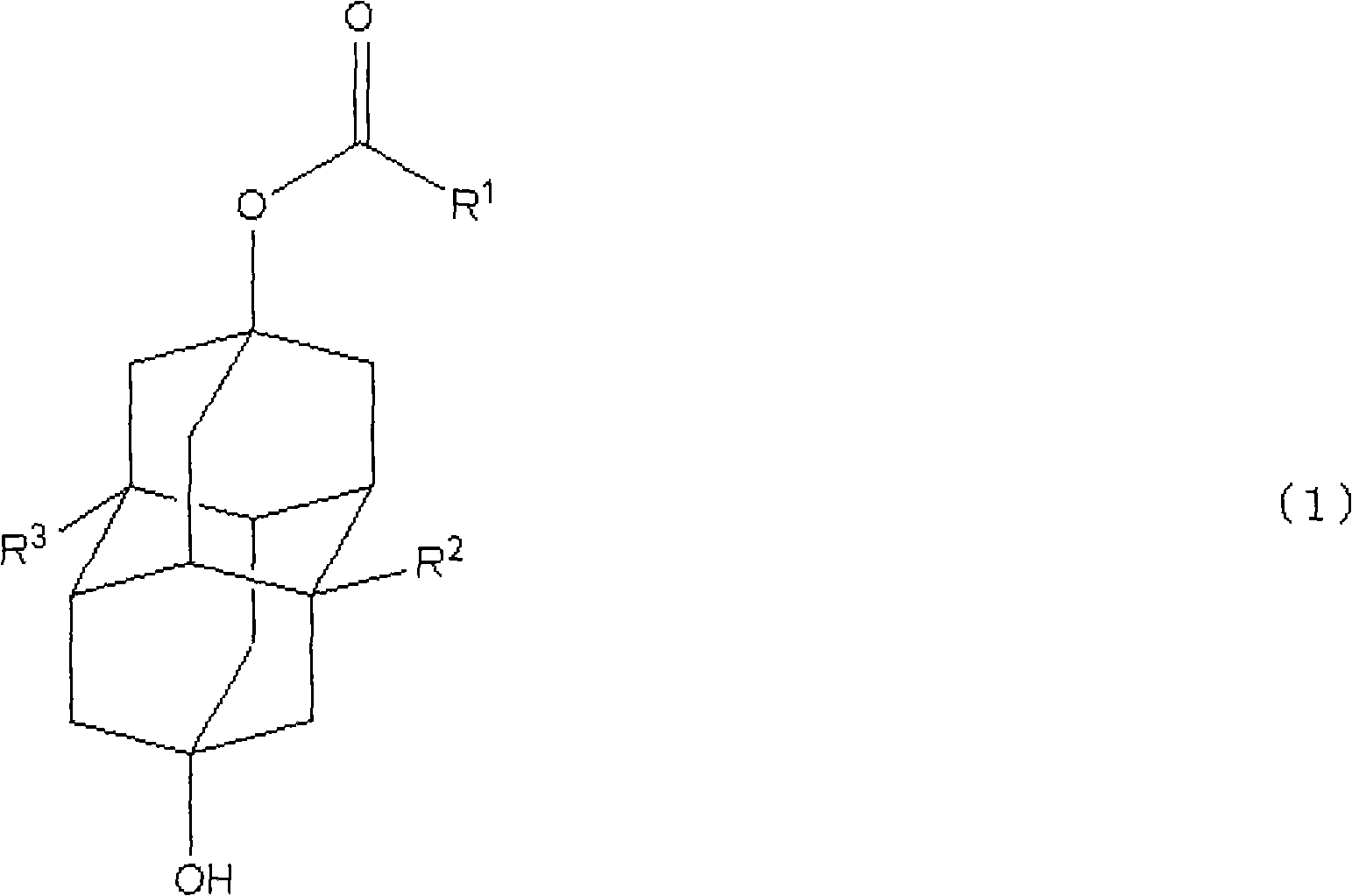

Positive photosensitive composition and pattern forming method using the same

InactiveUS20070072118A1Increase the differenceSame exposure amountPhotosensitive materialsPhotomechanical apparatusHydrogen atomActinic Rays

A positive photosensitive composition comprising: a resin which comprises a repeating unit having a diamantane structure and decomposes under an action of an acid to increase a solubility in an alkali developer; a compound capable of generating an acid upon irradiation with actinic rays or radiation; a compound represented by the following formula (1); and a solvent: wherein R1 represents a hydrogen atom or an alkyl group, m represents an integer of from 1 to 30, n represents an integer of from 0 to 3, and p represents an integer of from 0 to 5.

Owner:FUJIFILM CORP +1

Preparation method of shell with long and thin blades of investment casting aero-engine

ActiveCN104353786ANo metallurgical defectsGrain refinementFoundry mouldsFoundry coresInvestment castingRoom temperature

The invention discloses a preparation method of a shell with long and thin blades of an investment casting aero-engine. The preparation method comprises the following steps: mixing 5%-10% of cobaltous oxide powder and 90%-95% of electric smelting diamantane, roasting at 1200 DEG C-1350 DEG C, cooling to room temperature, and grinding so as to prepare a nucleating agent; preparing a mixed powder material from the nucleating agent and diamantane powder, adding silica sol into the mixed powder material so as to prepare slurry, coating the first layer of the shell with the slurry, coating the second layer to the eighth layer of the shell with the slurry prepared from the diamantane powder and silica sol, carrying out sand-lining on the first and second layers with No.80-No.100 emery, carrying out sand-lining on the third and fourth layers with No.46-No.60 emery, and carrying out sand-lining on the fifth-eighth layers with No.16-No.25 emery. Compared with a traditional shell preparation method, the shell prepared by the method disclosed by the invention is compact and smooth in surface; the long and thin blades of the aero-engine, which are prepared from the shell, are smooth in surface, and are refined in crystal grain, and can reach the technique requirements.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Positive photosensitive composition and method of pattern formation with the same

InactiveUS20070031757A1Excellent in development defectImprove line edge roughnessPhotosensitive materialsPhotomechanical apparatusDispersityActinic Rays

A positive photosensitive composition comprising: (A) a compound which generates an acid upon irradiation with actinic rays or a radiation; (B) a resin which decomposes by an action of an acid to come to have an enhanced solubility in an alkaline developing solution; and (F) a solvent, wherein the resin as the component (B) is a resin that has a repeating unit (Ba) having a diamantane structure, and wherein the resin as the component (B) has a weight-average molecular weight of from 3,000 to 30,000 and a dispersity ratio of from 1.1 to 3.0; and a method of pattern formation using the positive photosensitive composition.

Owner:FUJIFILM CORP +1

Organic composition

The present invention provides adamantane or diamantane compositions that are useful as a dielectric material in microelectronic applications such as microchips.

Owner:HONEYWELL INT INC

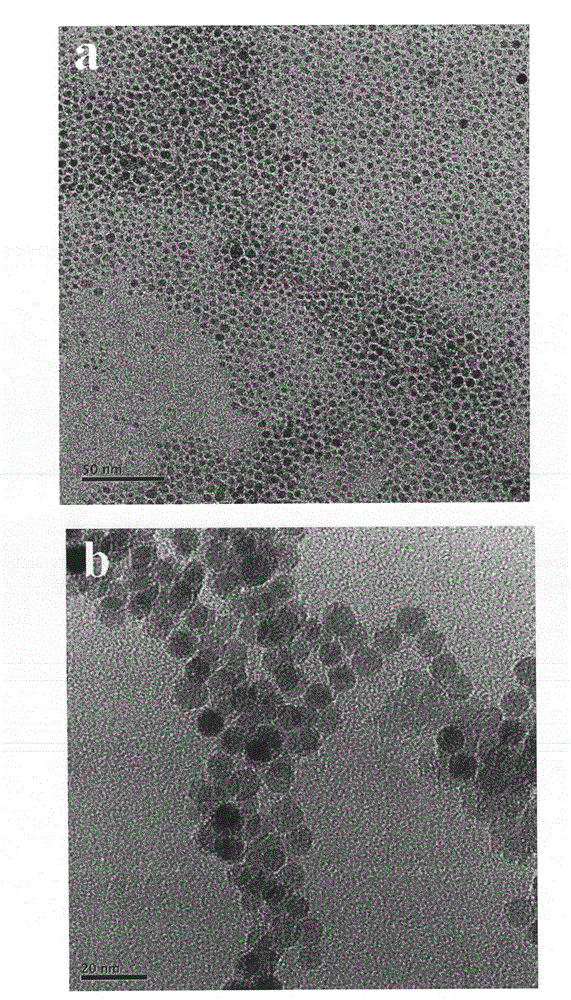

Diamondoid stabilized fine-grained metals

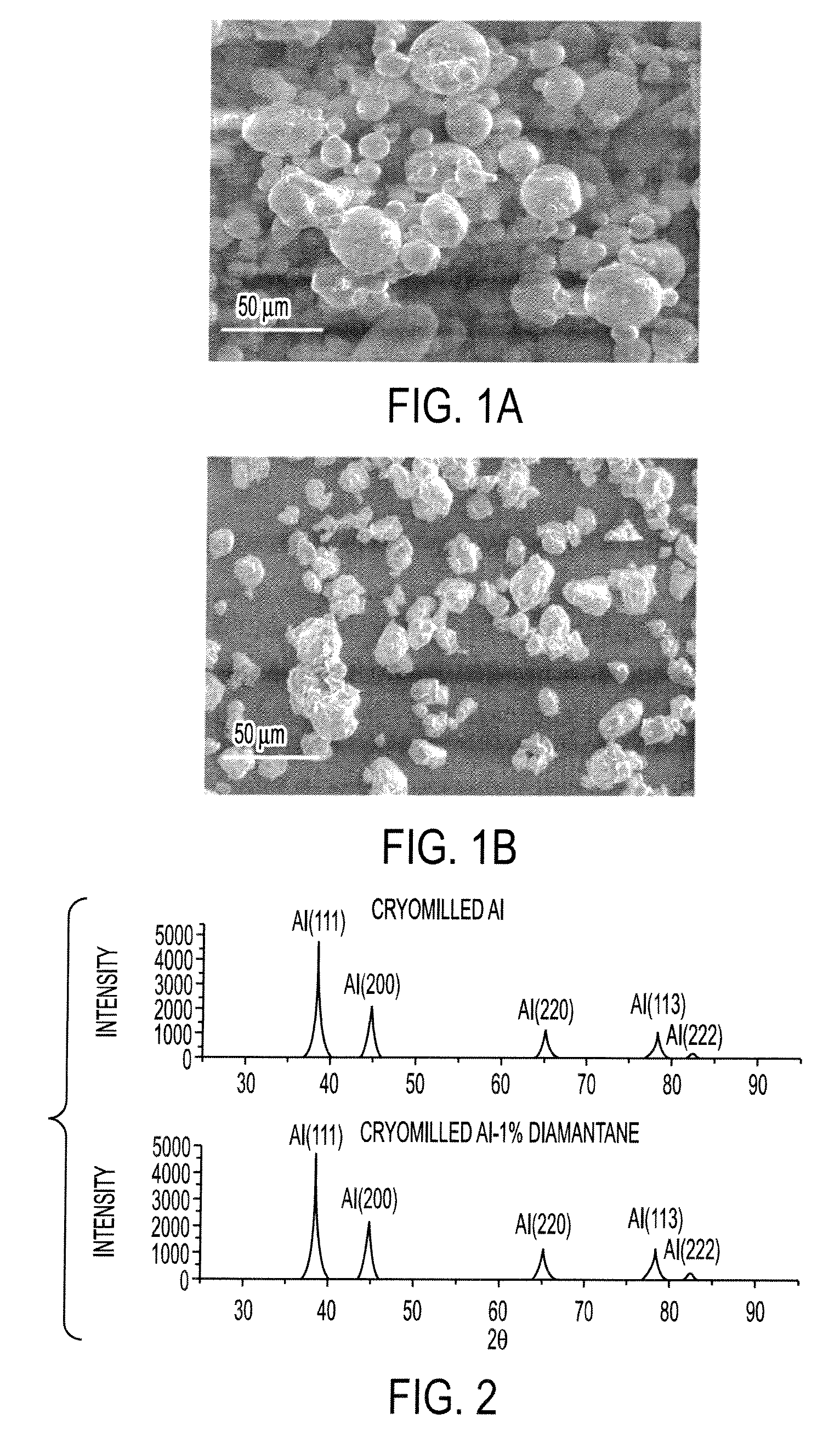

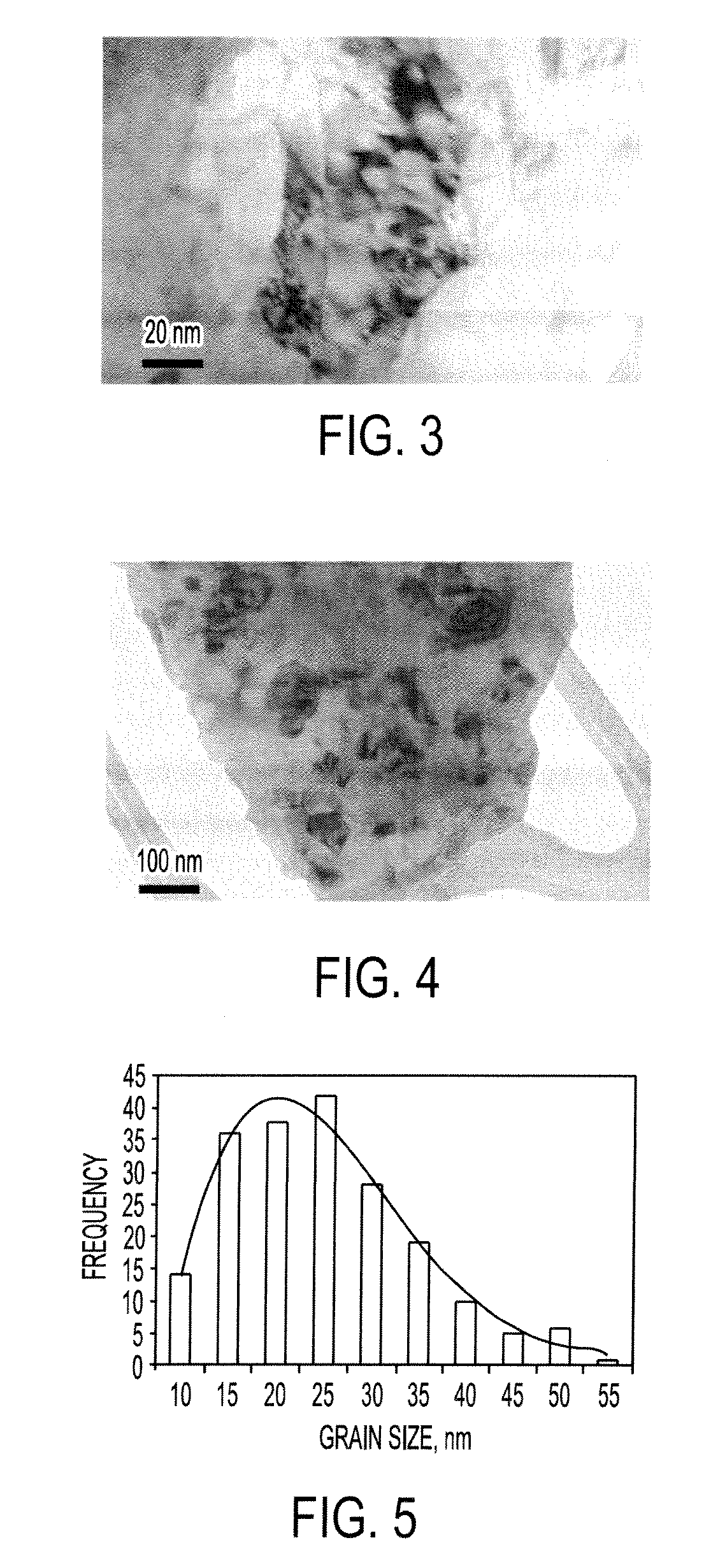

ActiveUS20090061229A1Improve stabilityHigh strengthSynthetic resin layered productsMetal-working apparatusAl powderX-ray

Thermal stability of cryomilled Al+1% diamantane was investigated in the temperature range of 423 to 773K. Diamantane is a nanosized hydrocarbon molecule with a 14 carbon atom diamond cubic framework that is terminated by hydrogen atoms. Following the cryomilling of the Al powders and diamantane cages, the average grain size characterized using transmission electron microscopy (TEM) and X-ray diffraction (XRD). The as-cryomilled grain sized was found to be of the order of 22 nm, essentially the same as that for Al cryomilled without diamantane. To determine thermal stability, the powders were sealed in glass tubes in an Ar atmosphere to avoid oxidation and contamination and annealed at different temperatures between 423 and 773K for different holding times. Following these treatments, the grain size of cryomilled Al+1% diamantane was consistently less than that for cryomilled Al by about a factor of two. Preliminary investigations indicate that the grain growth exponent n decreased with increasing temperature, reaching a value of approximately 35 at 423 K. Such a high value of n suggests the operation of strong pinning forces on boundaries during annealing treatment. The thermal stability data were found to be consistent with Burke's model based on drag forces exerted by dispersion particles.

Owner:RGT UNIV OF CALIFORNIA

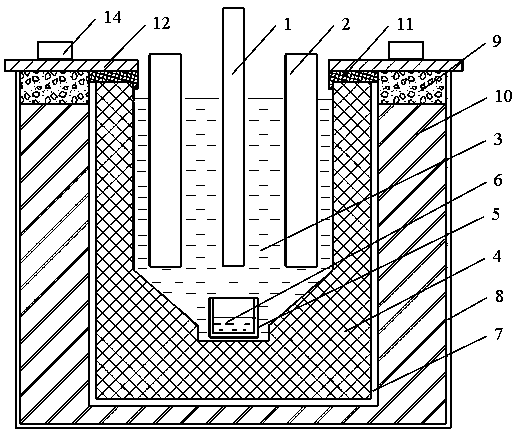

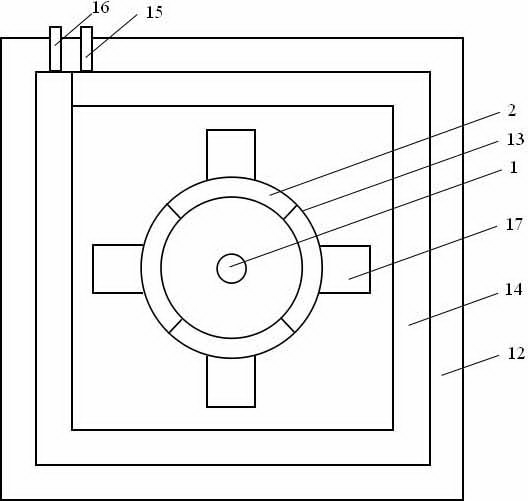

High-yield and energy-saving electrolytic furnace for rare-earth metals

The invention discloses a high-yield and energy-saving electrolytic furnace for rare-earth metals. The high-yield and energy-saving electrolytic furnace comprises a cathode, a graphite anode, electrolyte, a graphite groove, a crucible, an inner steel sleeve, an outer steel sleeve, a filler layer, diamantane and a furnace panel. The high-yield and energy-saving electrolytic furnace has the characteristics that the furnace building cost is low, the service life is long, the heat balance is good, the content of impurities in a product is less, the yield is high, the energy is saved and the operation is convenient and the like.

Owner:GANZHOU SANYOU RARE EARTH NEW MATERIAL

Positive-working photosensitive composition and pattern forming method using the same

ActiveUS7465528B2Improve errorPhotosensitive materialsRadiation applicationsOrganic acidActinic Rays

A positive-working photosensitive composition that includes (A) a resin containing repeating units having diamantane structures and capable of decomposing under action of an acid to increase solubility in an alkali developer, (B) a compound capable of generating a specific organic acid upon irradiation with an actinic ray or radiation, and (C) a solvent.

Owner:FUJIFILM CORP

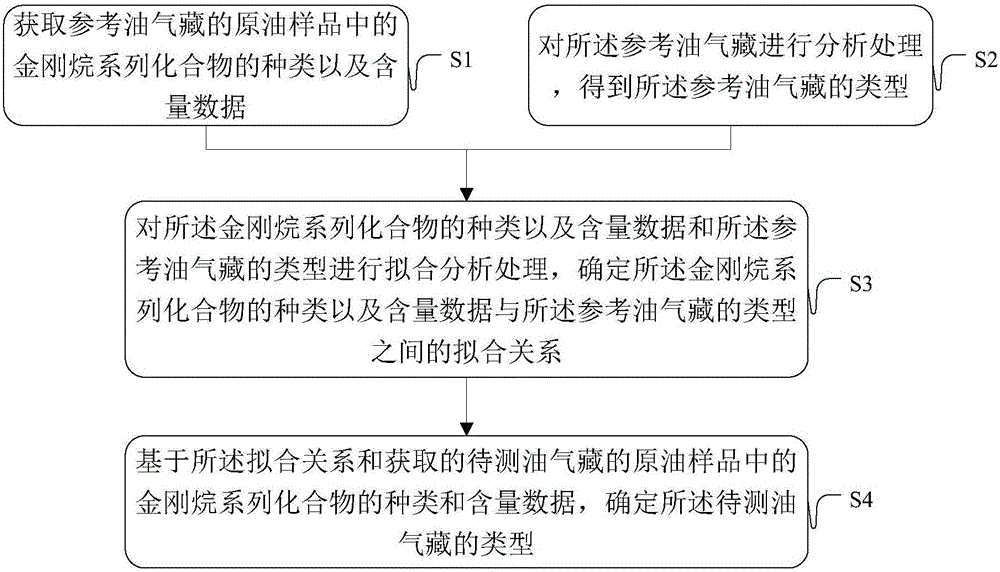

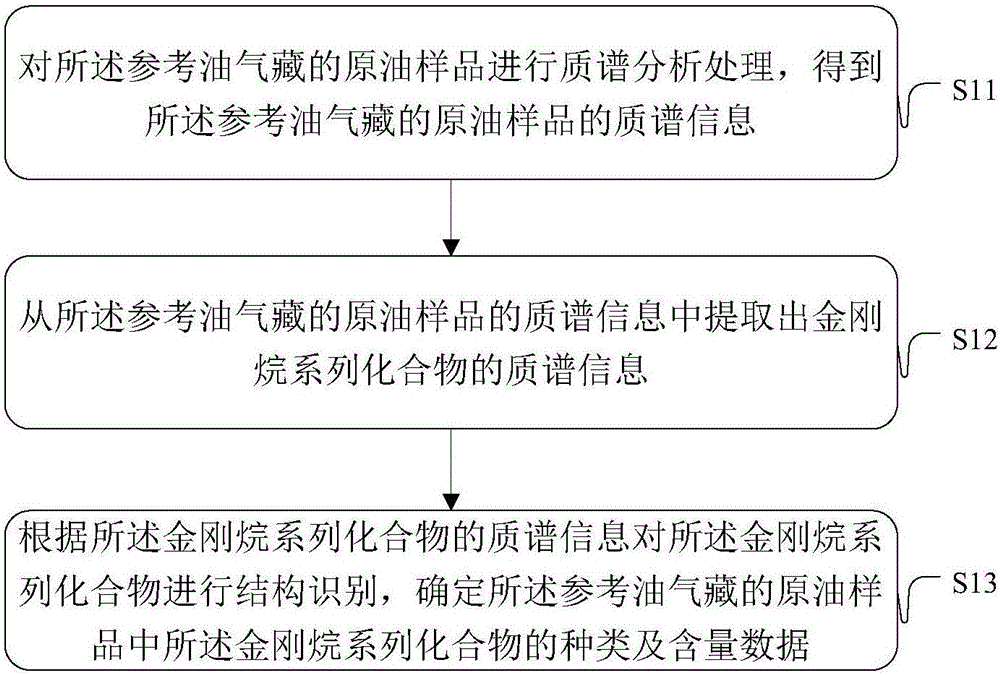

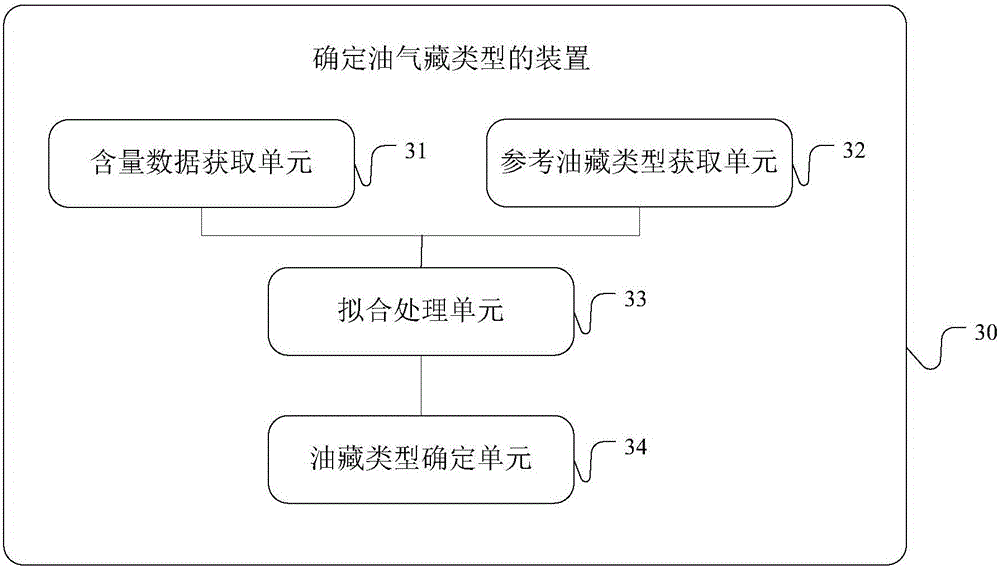

Method and device for determining type of oil and gas reservoir

ActiveCN105975761ASimplify analytical processingReduce analysis costsSpecial data processing applicationsInformaticsReservoir typeDiamantane

Embodiments of the invention provide a method and a device for determining the type of an oil and gas reservoir. The method comprises the following steps of obtaining type and content data of diamantane series compounds in a crude oil sample of a reference oil and gas reservoir; carrying out analysis and processing on the reference oil and gas reservoir to obtain the type of the reference oil and gas reservoir; and carrying out fitting analysis and processing on the type and content data of the diamantane series compounds and the type of the reference oil and gas reservoir and determining a fitting relation between the type and content data of the diamantane series compounds and the type of the reference oil and gas reservoir; and determining the type of a to-be-tested oil and gas reservoir based on the fitting relation and the type and content data of the diamantane series compounds in the obtained crude oil sample of the to-be-tested oil and gas reservoir. Through utilizing the technical scheme provided by the embodiments of the invention, the reservoir type of the to-be-tested oil and gas reservoir can be determined quickly and accurately.

Owner:PETROCHINA CO LTD

Ph reversible response mesoporous silicon oxide composite medicament-carrying system, preparation method thereof and application thereof

InactiveCN102210867BGood biocompatibilityFacilitated releaseGenetic material ingredientsInorganic non-active ingredientsSilicon oxideMesoporous silica

The invention discloses a pH reversible response mesoporous silicon oxide composite medicament-carrying system, a preparation method thereof and application thereof. The preparation method comprises the following steps of: preparing mesoporous silicon oxide nano particles by a sol-gel process; and modifying surfaces of mesoporous silicon oxide and nanometer magnetic particles respectively by using triaminomethyl ethane and 4-carboxybenzaldehyde, and reacting in alkalescent environment to generate pH sensitive triaza diamantane groups, so that the magnetic nano particles are covered on the surface of a mesoporous silicon oxide porous channel to obtain the pH reversible response mesoporous silicon oxide composite medicament-carrying system. The pH reversible response mesoporous silicon oxide composite medicament-carrying system has the excellent magnetic targeting and biocompatibility, and can realize pH response pulse release.

Owner:EAST CHINA UNIV OF SCI & TECH

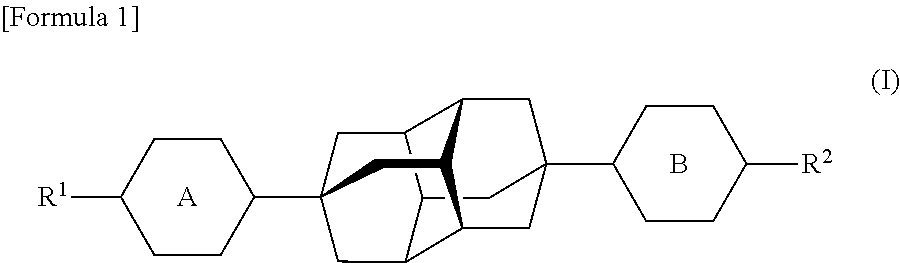

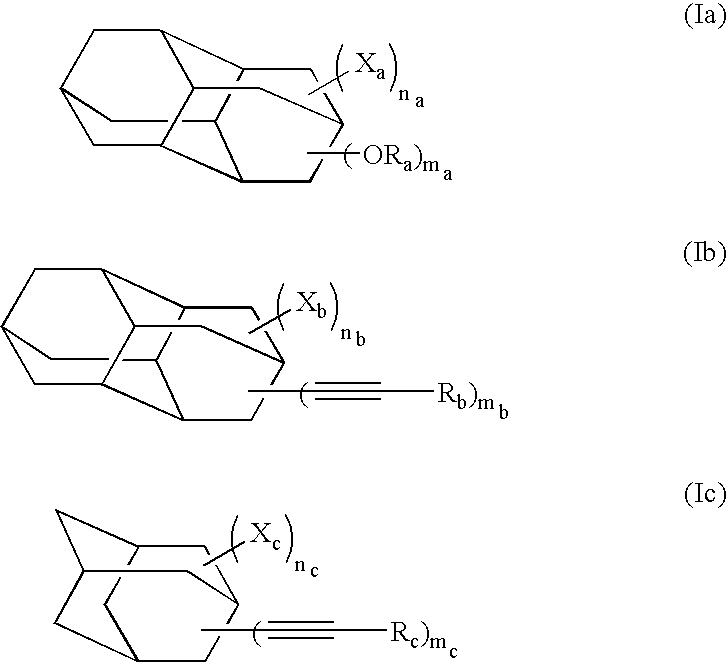

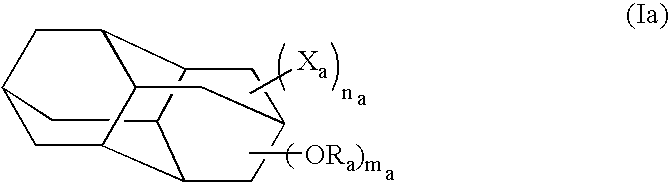

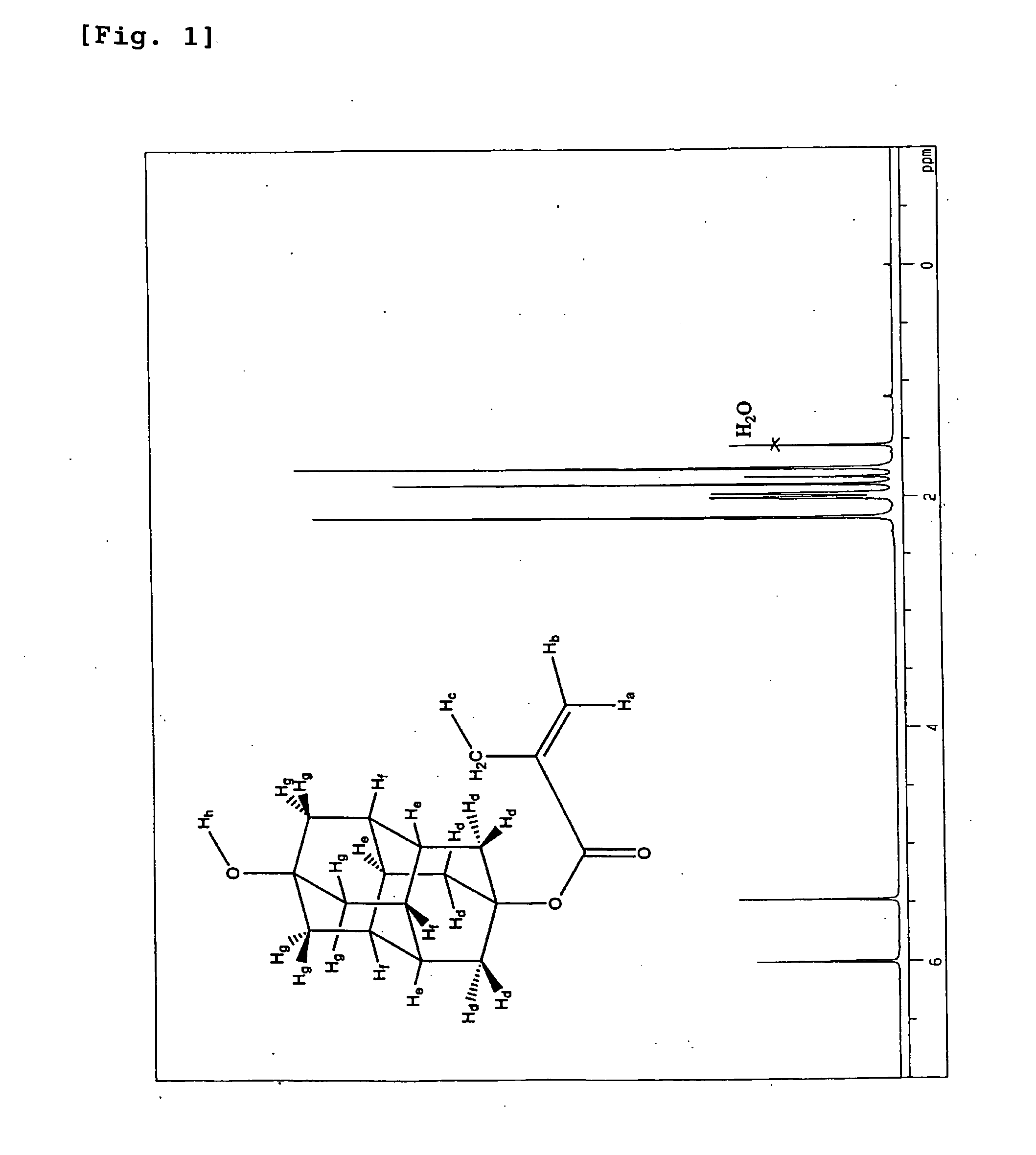

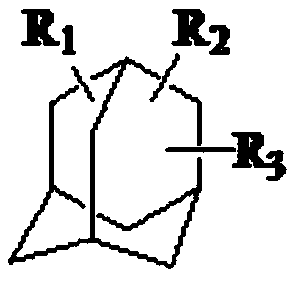

Novel diamantane compounds, liquid crystalline compounds, and liquid crystalline compositions

InactiveUS20110015426A1Easy to synthesizeImprove thermal stabilityLiquid crystal compositionsOrganic chemistryLiquid crystallineCrystallography

A liquid crystalline compound has excellent liquid crystal properties, particularly high phase transition temperature. Diamantane compounds are represented by the general formula (I):(I) wherein A and B are each a six-membered, saturated or unsaturated, carbo- or hetero-cycle, and these cycles may have substituents, which substituents may be united to form a ring; and R1 and R2 are each a hydrocarbon group having 1 to 18 carbon atoms, and part of the carbon atoms of the hydrocarbon group may be replaced by heteroatoms or heteroatom-containing groups, while part of the hydrogen atoms thereof may be replaced by halogen atoms or heteroatom-containing groups.

Owner:NAT UNIV CORP YOKOHAMA NAT UNIV +1

Compositions and methods for thermosetting molecules in organic compositions

In a method of producing a low dielectric constant polymer, a thermosetting monomer is provided, wherein the thermosetting monomer has a cage compound or aryl core structure, and a plurality of arms that are covalently bound to the cage compound or core structure. In a subsequent step, the thermosetting monomer is incorporated into a polymer to form the low dielectric constant polymer, wherein the incorporation into the polymer comprises a chemical reaction of a triple bond that is located in at least one of the arms. Contemplated cage compounds and core structures include adamantane, diamantane, silicon, a phenyl group and a sexiphenylene group, while preferred arms include an arlyene, a branched arylene, and an arylene ether. The thermosetting monomers may advantageously be employed to produce low-k dielectric material in electronic devices, and the dielectric constant of the polymer can be controlled by varying the overall length of the arms.

Owner:HONEYWELL INT INC

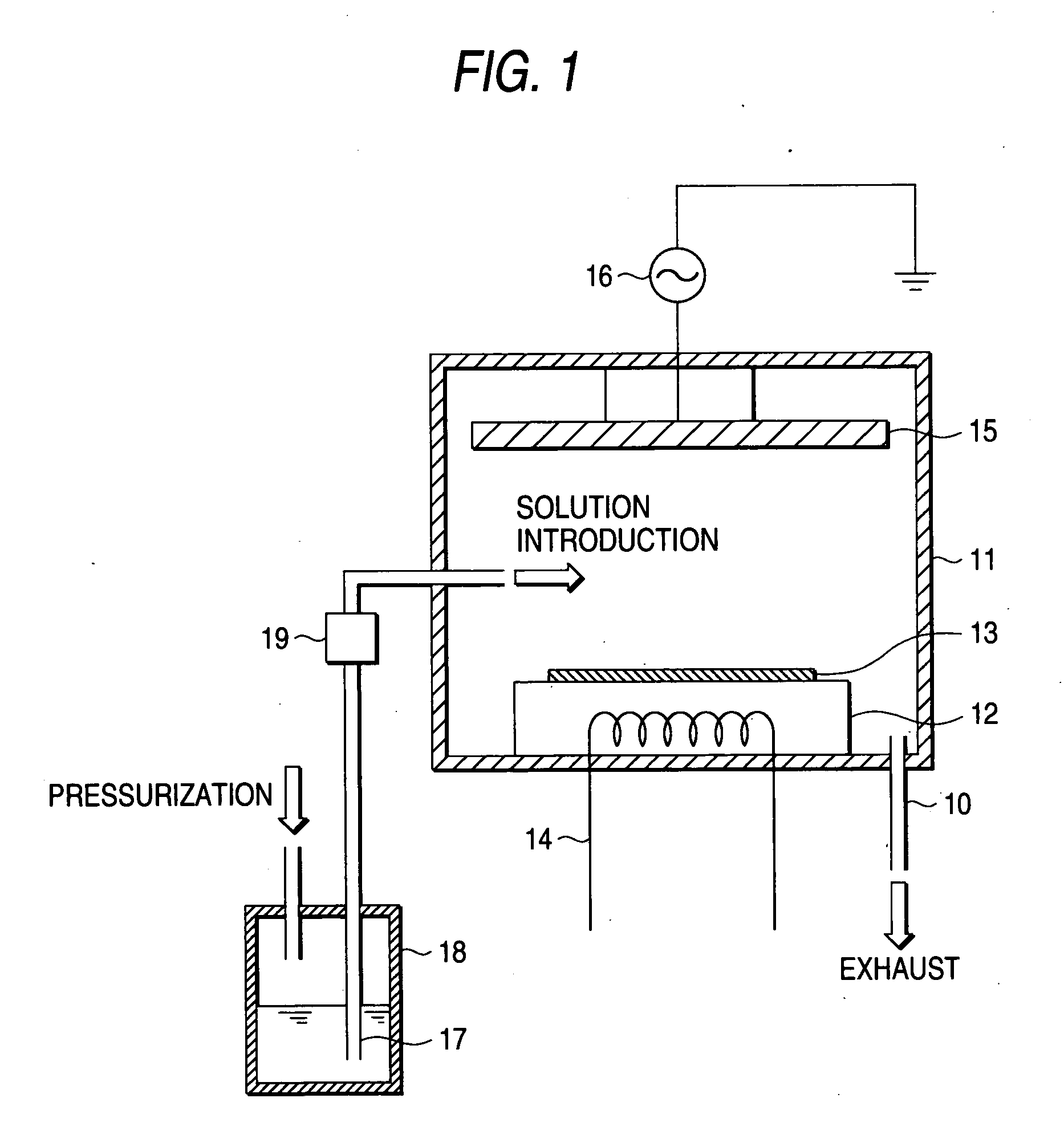

Film

A film formed by chemical vapor deposition of a diamantane or adamantane compound having a particular substituent or a composition containing the compound.

Owner:FUJIFILM CORP +1

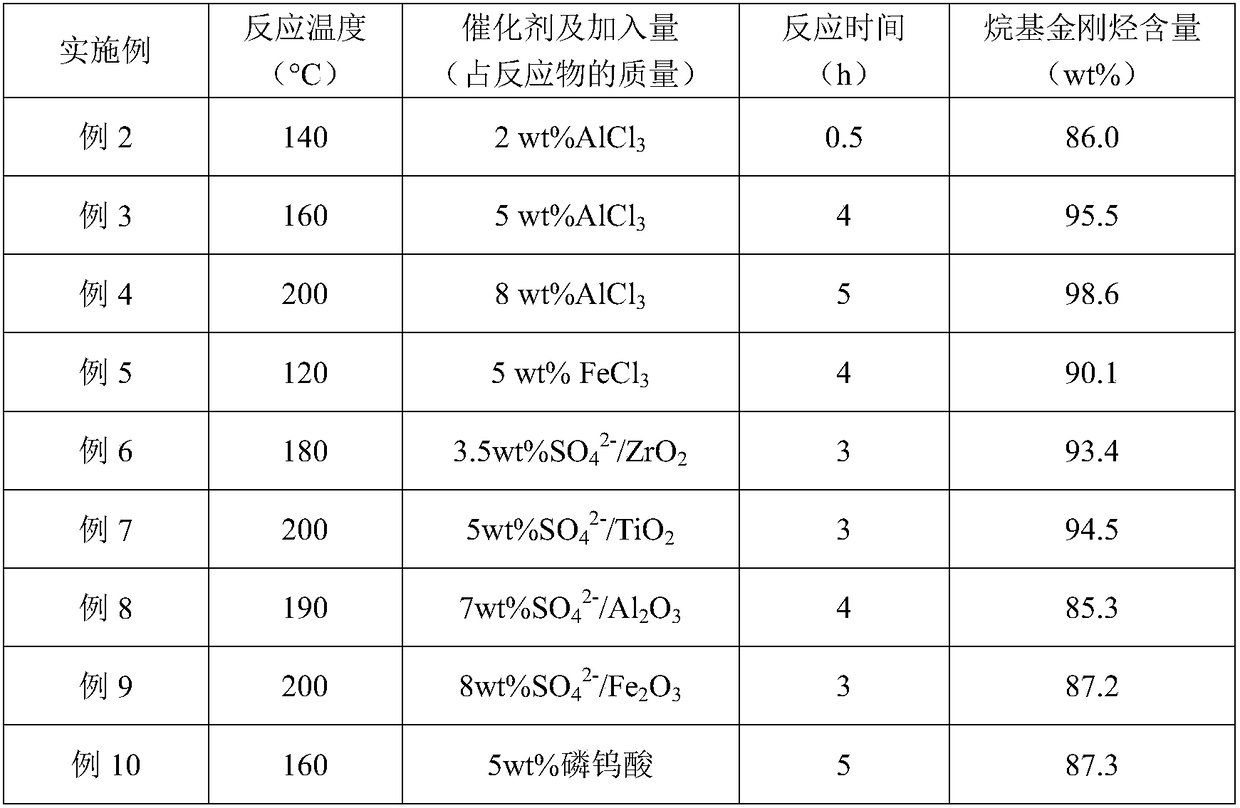

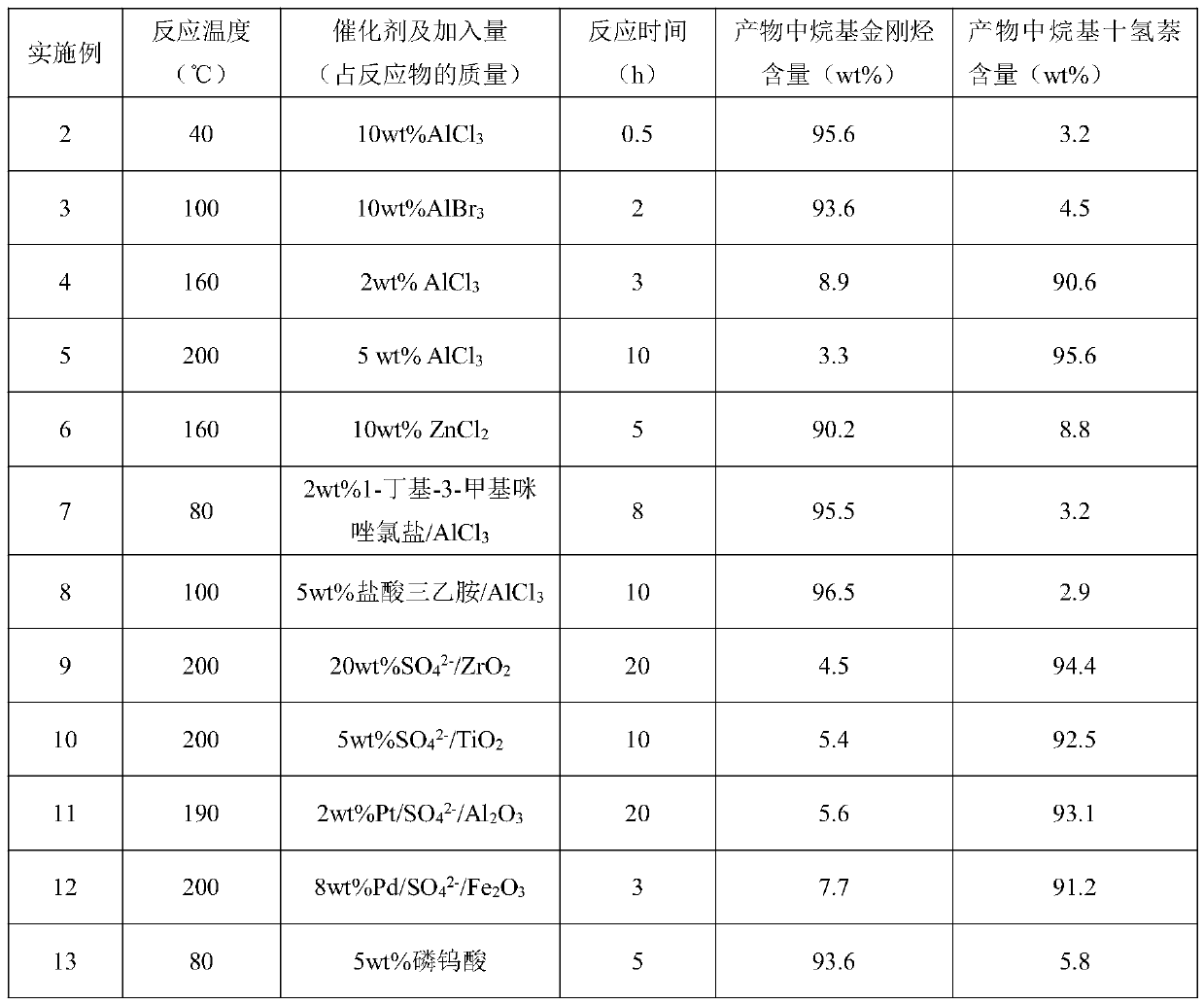

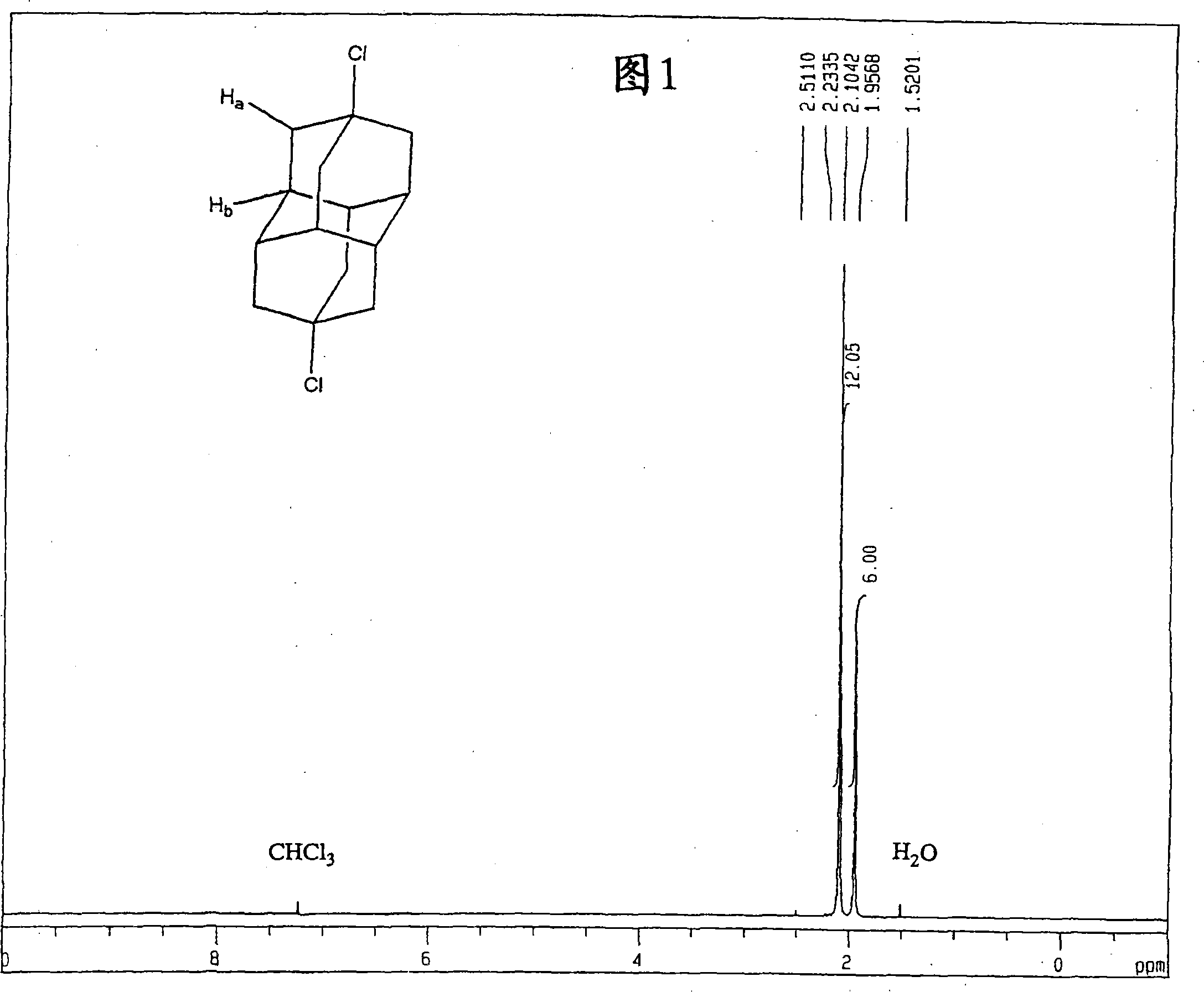

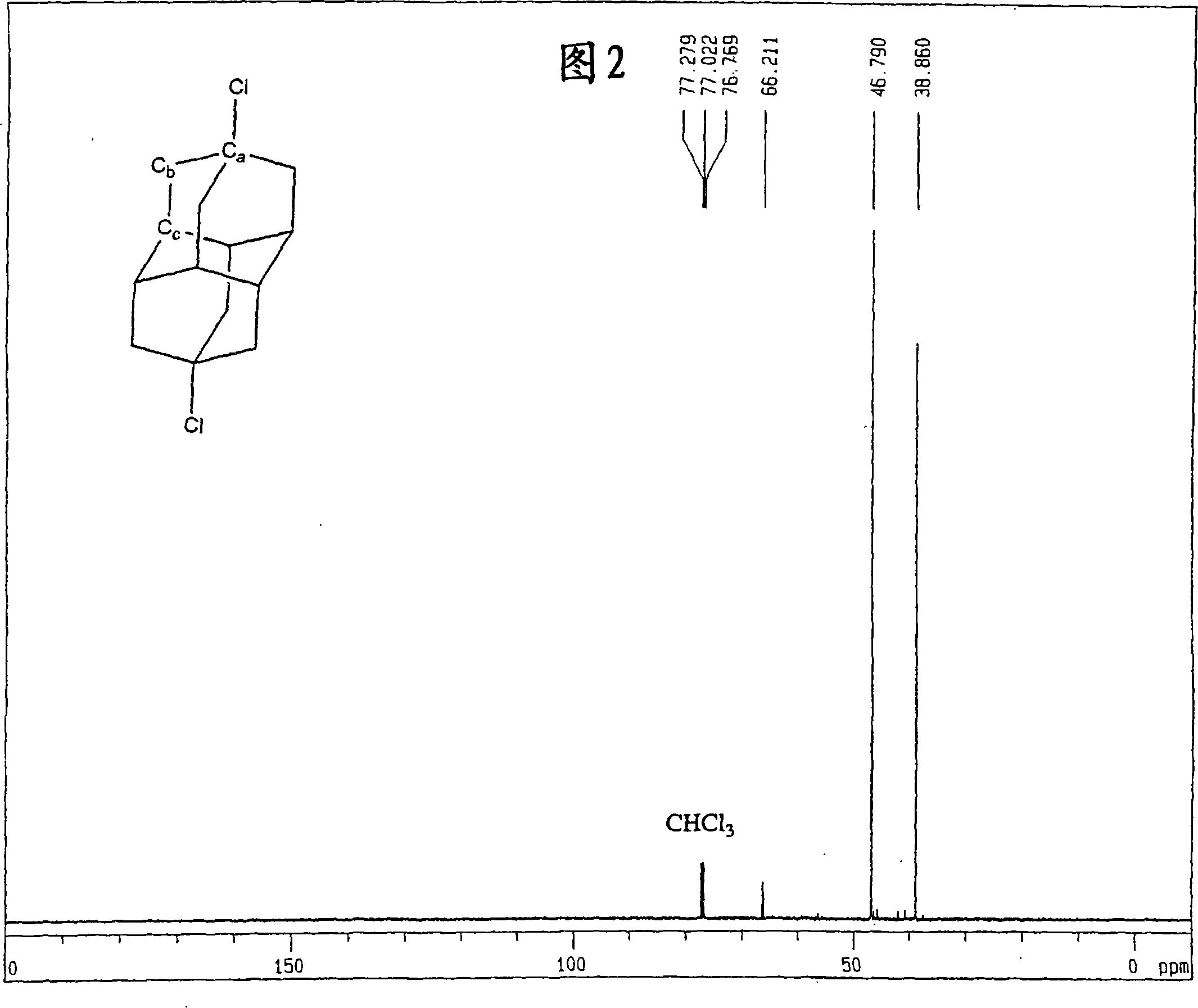

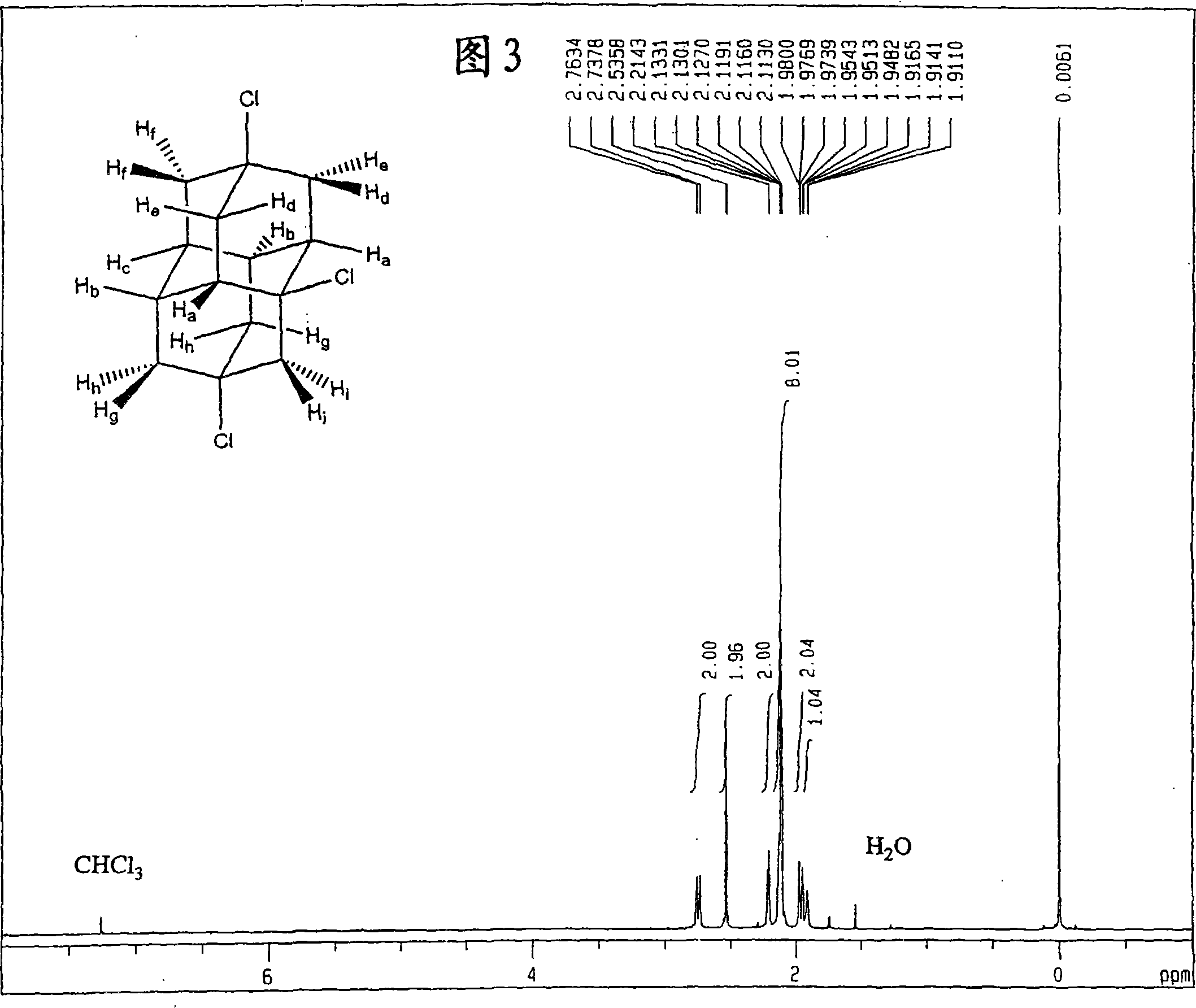

Diamantane fuel and method for preparing same

ActiveCN108410499AReduce usageSimple processRefining to change hydrocarbon structural skeletonLiquid carbonaceous fuelsDiamantaneFreezing point

The invention discloses diamantane fuel. The content of alkyl diamantane in the diamantane fuel is higher than 85.0 wt%, the freezing point of the diamantane fuel is lower than -75 DEG C, and the density of the diamantane fuel is higher than 0.98 g / cm<3>; one or a plurality of types of the alkyl diamantane is shown. The invention further discloses a method for preparing the diamantane fuel.

Owner:TIANJIN UNIV

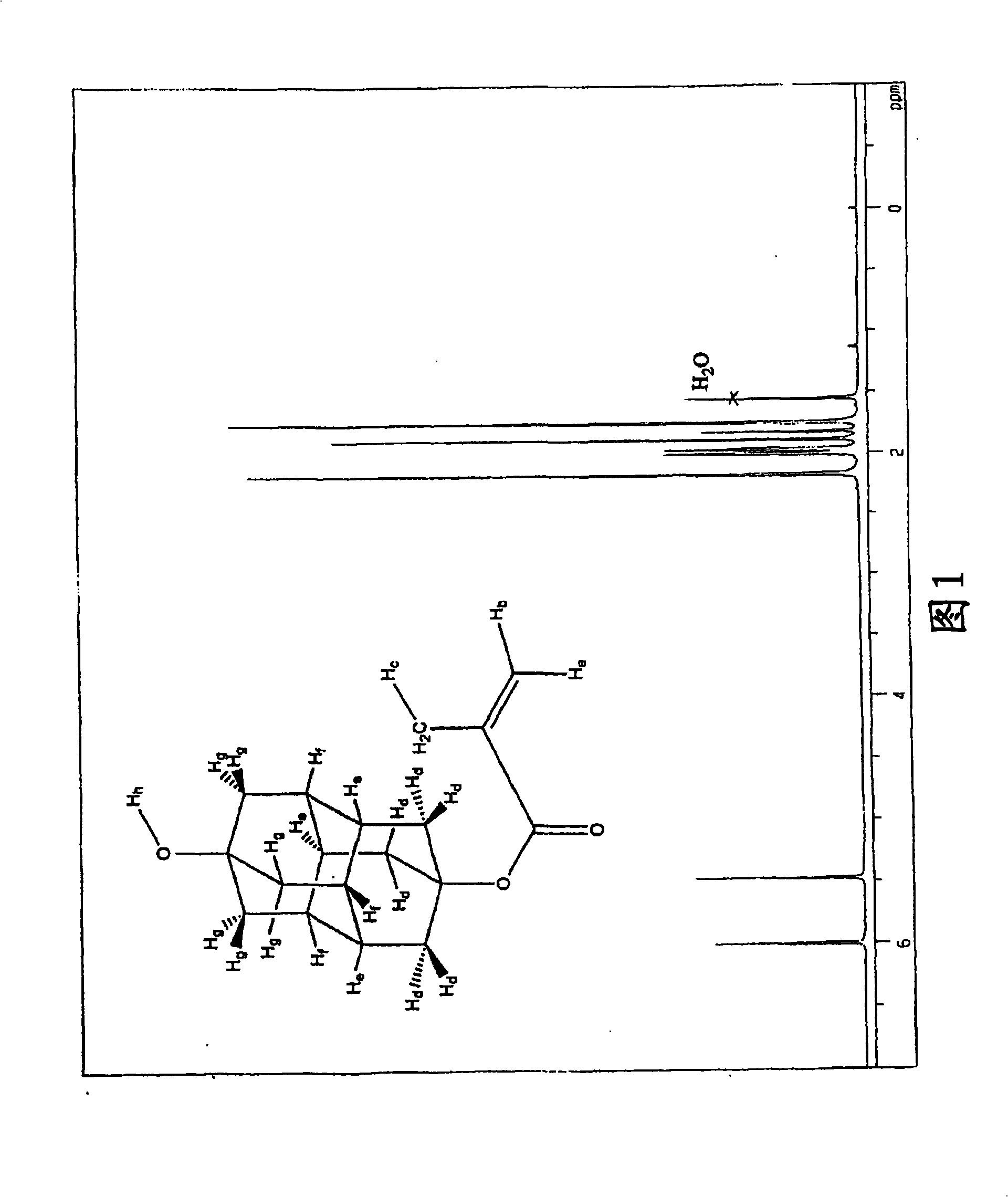

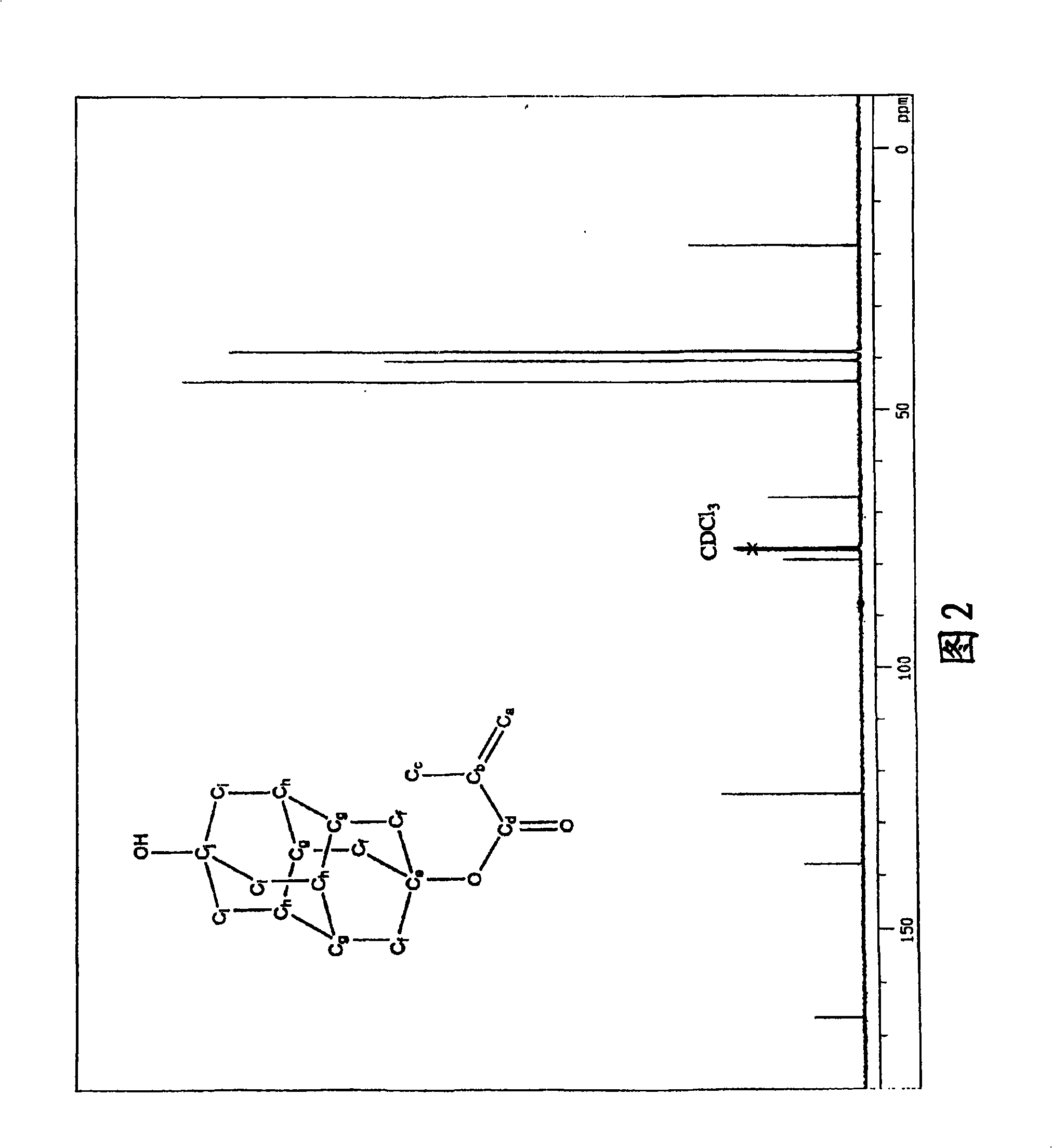

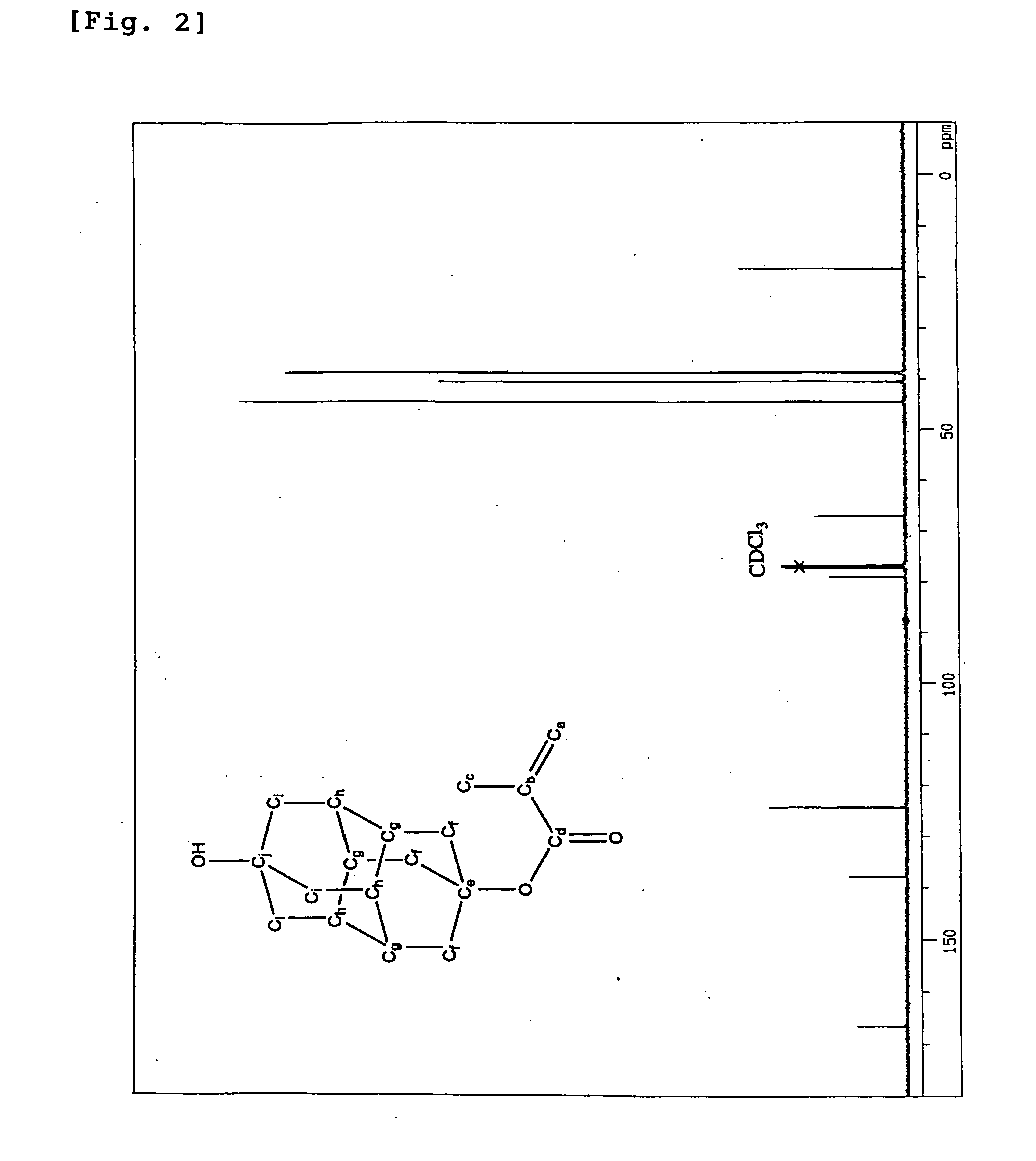

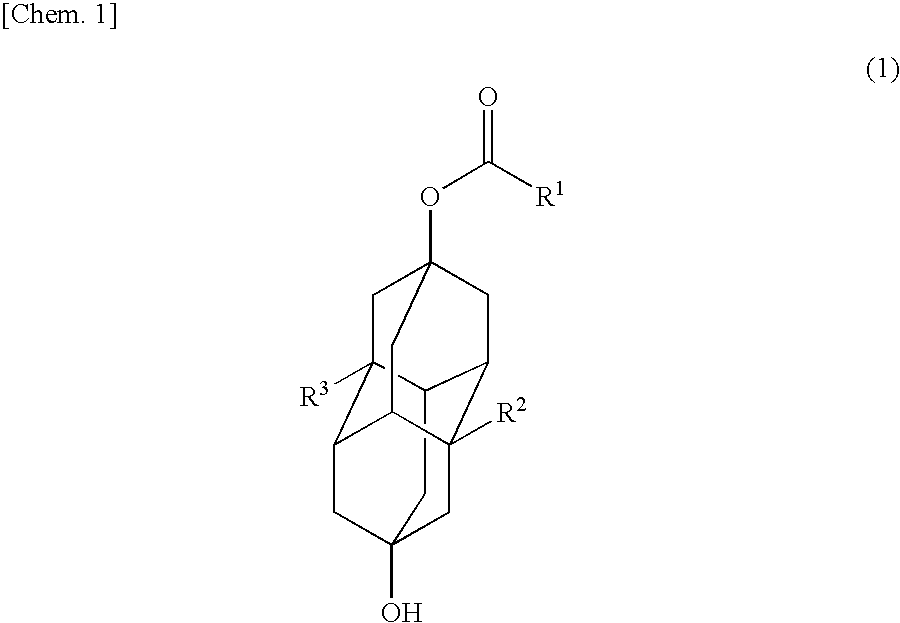

Method for producing polymerizable hydroxydiamantyl ester compound

InactiveCN101321721AHigh yieldHigh purityOrganic compound preparationCarboxylic acid esters preparationDiamantaneEsterification reaction

Disclosed is a method for producing a polymerizable hydroxydiamantyl ester compound wherein a 4,9-diamantanediol compound is produced by dihalogenating and then hydrolyzing a raw material compound having a diamantane backbone such as diamantane, and then the 4,9-diamantanediol compound is esterified in the mixture of a polymerizable unsaturated carboxylic acid and a polymerizable unsaturated carboxylic acid anhydride in the presence of a polymerization inhibitor and an acid catalyst.

Owner:TOKUYAMA CORP

Process for producing 4,9-dibromodiamantane

A process for selectively producing 4,9-dibromodiamantane includes a step of reacting diamantane with bromine in the presence of a Lewis acid and a solvent, wherein the solvent comprises a substituted or unsubstituted, straight-chain, branched-chain or cyclic saturated hydrocarbon containing from 3 to 10 carbon atoms, and a reaction solution after the step satisfies Formula (1):A / (A+B+C+D+E)>0.80 Formula (1)wherein A represents an area ratio (%) of 4,9-dibromodiamantane obtained by gas chromatography of the reaction solution, B represents an area ratio of diamantane, C represents a sum of an area ratio of 1-bromodiamantane and an area ratio of 4-bromodiamantane, D represents an area ratio of tribromodiamantane, and E represents a sum of an area ratio of 1,6-dibromodiamantane and an area ratio of 1,4-dibromodiamantane.

Owner:FUJIFILM CORP

A kind of preparation method of 1-bromoadamantane

ActiveCN106928018BPrevent volatilizationEfficient recyclingHalogenated hydrocarbon preparationAcetic acidDistillation

The invention discloses a preparation method of 1-bromoadamantane. The method comprises the steps that diamantane is added into a reactor, the temperature inside the reactor is controlled to be 10-15 DEG C, then, a mixed solution of bromine and an organic solvent A is added dropwise into the reactor, dropping is completed in 1-3 h, then, the temperature is increased to 40 DEG C, the temperature is kept constant for 1 h, then, the temperature inside the reactor is gradually increased to 110 DEG C within 7 h in the 10 DEG C / h temperature programming mode, and after the temperature is kept constant for 4-6 h, reduced pressure distillation is performed to recycle a mixed solution of bromine and the organic solvent A; then, an organic solvent B is added into the reactor to perform cooling crystallization, after filtering, filter cakes are washed with distilled water till the pH value is 6-7, and airing is performed to obtain the 1-bromoadamantane. According to the method, in a bromination reaction, organic solvent glacial acetic acid (organic solvent A) is introduced, compared with a traditional method, on the premise that the reactions are not affected, the organic solvents are added to restrain volatilization of the bromine, the bromine can be effectively recycled, the recycling rate is larger than 90%, the cost is reduced, and discharge of waste gas, water and industrial residues is reduced.

Owner:CHINA CATALYST HLDG CO LTD

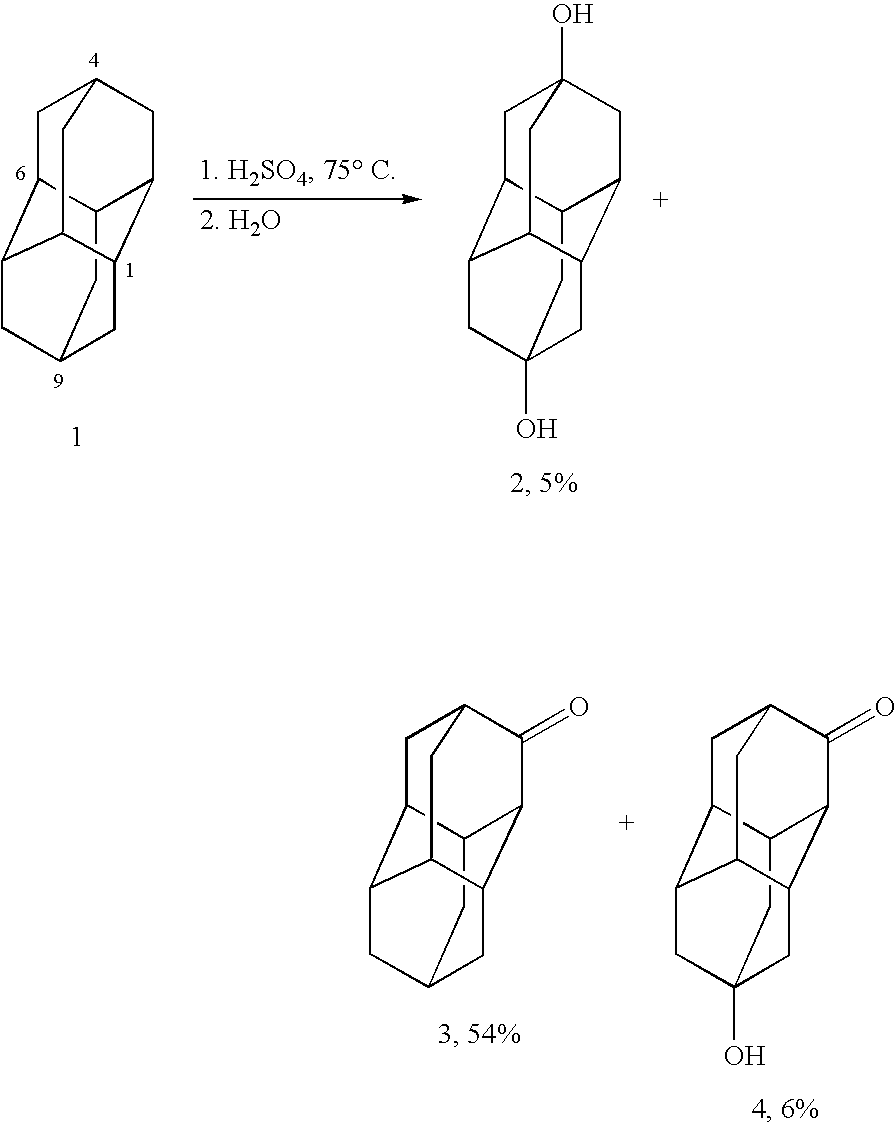

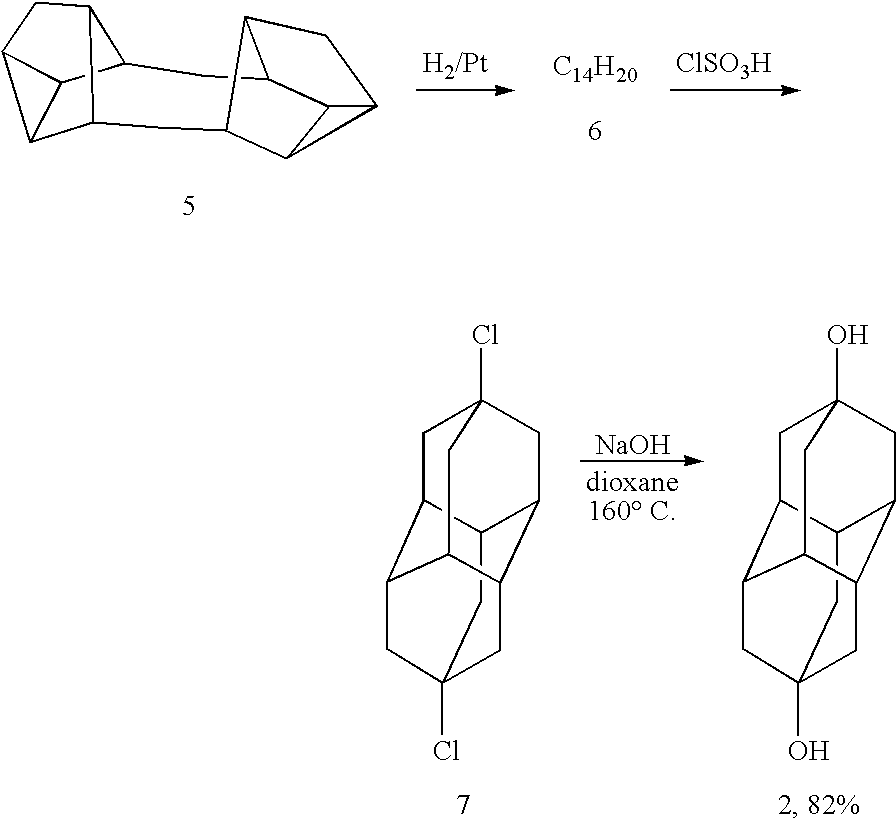

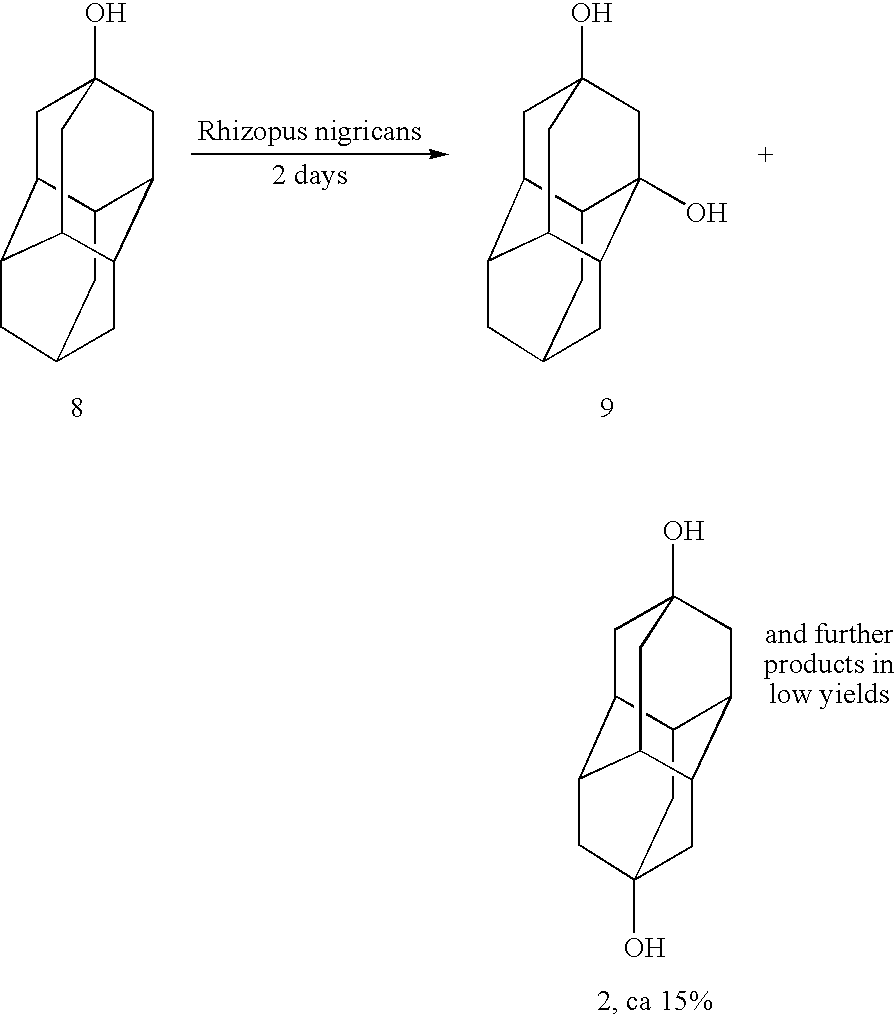

Method for producing substituted diamantanes

InactiveUS8716539B2Inhibition formationOrganic compound preparationCarboxylic acid esters preparationStrong acidsDiamantane

Owner:JUSTUS LIEBIG UNIV

Method for Producing Polymerizable Hydroxydiamantyl Ester Compound

InactiveUS20100217033A1Reduce solubilityHigh purityOrganic compound preparationPreparation by ester-hydroxy reactionPolymer scienceAcid catalyzed

The present invention discloses a method for producing a polymerizable hydroxydiamantyl ester compound, which comprises di-halogenating a raw material compound having a diamantane skeleton, such as diamantane or the like, then hydrolyzing the di-halogenation product to produce a 4,9-diamantanediol compound, thereafter esterifying the 4,9-diamantanediol compound in a mixture of a polymerizable unsaturated carboxylic acid and a polymerizable unsaturated carboxylic acid anhydride in the presence of a polymerization inhibitor and an acid catalyst, to obtain a polymerizable hydroxydiamantyl ester compound.

Owner:TOKUYAMA CORP

A fuel containing alkyl decahydronaphthalene and alkyl adamantane, its preparation method and application

ActiveCN109797015BExcellent high thermal stabilityReduce usageLiquid carbonaceous fuelsDiamantaneDecalin

Owner:TIANJIN UNIV

Method for producing polyhalogenated diamantane and derivative thereof

InactiveCN1972886AHigh purityIndustrial manufacturing methods are usefulOrganic compound preparationOrganic chemistry methodsPolyolOrganic solvent

Disclosed is a method for producing polyhalogenated diamantanes which is characterized by reacting diamantanes with a halosulfonic acid. Also disclosed is a method for producing diamantane polyols which is characterized in that the polyhalogenated diamantanes obtained by the above-described method are reacted with water in the presence of a water-soluble organic solvent and a carboxylate.

Owner:TOKUYAMA CORP

Method for separating and enriching low-grade adamantane compounds in petroleum and hydrocarbon source rocks

ActiveCN102101817BHigh recovery rateEasy to operateOrganic compound preparationHydrocarbonsCyclodextrinSilica gel

Disclosed is a method for separating and enriching lower diamondoid compounds from petroleum and source rock, which includes: extracting the source rock sample with a solution of dichloromethane and methanol to give a source rock extract; removing normal saturated hydrocarbons and asphaltic components from the source rock extract or a crude oil sample with ZSM-5 molecular sieve, obtaining isomeric saturated hydrocarbons components through silica-gel column; adding a solution of ß-cyclodextrin into the solution of the isomeric saturated hydrocarbons, separating the mixed suspension to obtain a deposit, adding the deposit into a solution of hydrochloric acid, maintaining the temperature from 40 to 95? in an oven, cooling to room temperature after the hydrolysis of ß-cyclodextrin catalyzed by an acid is completed, and extracting with a saturated hydrocarbon solvent to obtain lower diamondoid compounds. In this method, the rate of recovery of mono-diamondoid compounds is up to 18%, the rate of recovery of di-diamondoid compounds is up to 35%, and the rate of recovery of tri-diamondoid compounds is up to 1.5%.

Owner:PETROCHINA CO LTD

Material for preservative formation

InactiveCN1388414ASemiconductor/solid-state device manufacturingThin material handlingTectorial membraneOrganic solvent

Owner:TOKYO OHKA KOGYO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com