Diamantane fuel and method for preparing same

A diamond hydrocarbon and fuel technology, which is applied to fuel, liquid carbon-containing fuel, refining to change the structure and skeleton of hydrocarbons, etc., can solve the problems of large amount of ionic liquid and solvent, and achieve small catalyst usage, environmental friendliness, and production low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Put 100g of tetrahydrotricyclopentadiene raw material in a round-bottomed three-neck flask, heat it to 130°C under continuous stirring, add 4g of anhydrous aluminum trichloride, continue stirring for 3h, cool to room temperature after reaction, and use dilute alkali solution respectively The reaction product was washed with water to neutrality, and impurities were removed by distillation to obtain 86 g of the product. The product was analyzed and characterized by gas chromatography, and the content of the component containing the adamantane structure in the product was 85.3 wt%, and the remainder was a mixture of multiple pendant tetrahydrotricyclopentadiene isomers.

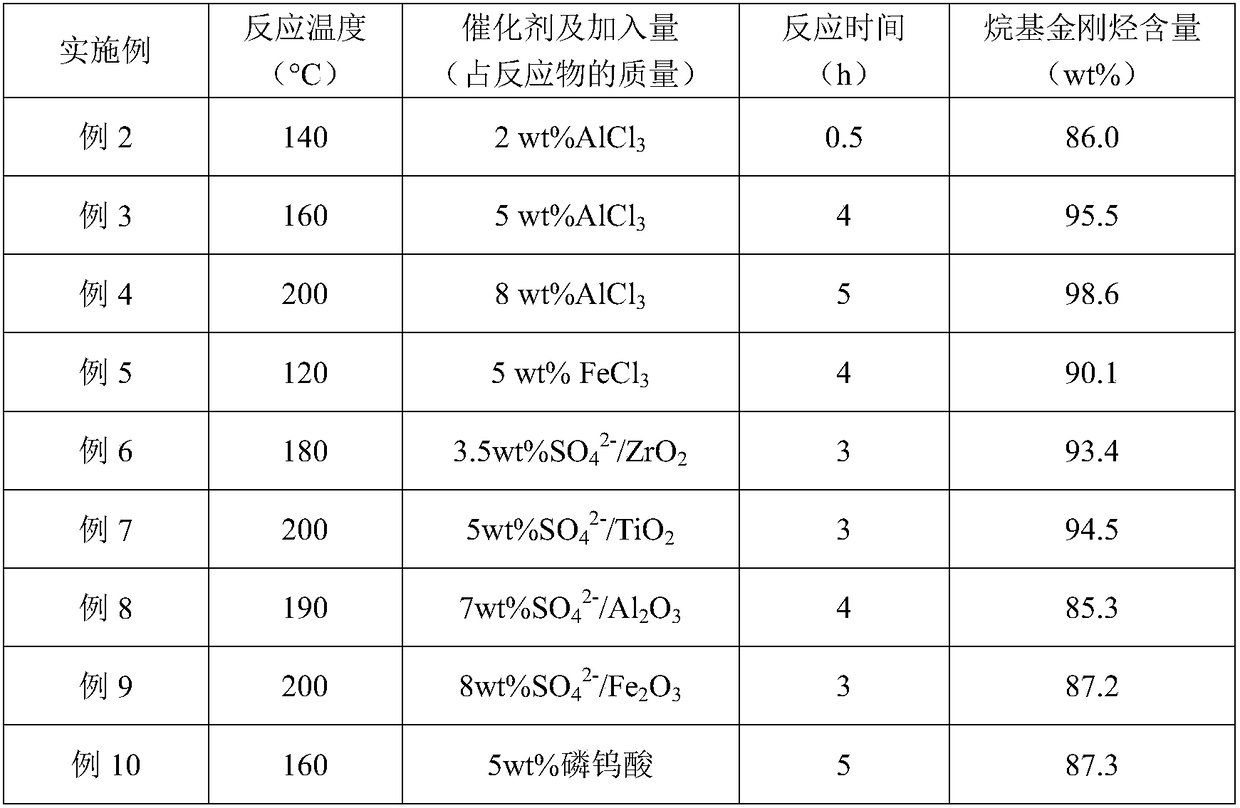

Embodiment 2-10

[0022] The steps of the isomerization reaction in each embodiment are the same as those in Example 1, except that the adjustment of the reaction conditions includes: reaction temperature, catalyst dosage and reaction time. See table below.

[0023]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com