Method for separating and enriching low-grade adamantane compounds in petroleum and hydrocarbon source rocks

A source rock and adamantane technology, which is applied in the field of separation and enrichment of low-level adamantane compounds from petroleum and source rocks, and can solve the problems of inability to enrich low-level adamantane compounds and single species of low-level adamantane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

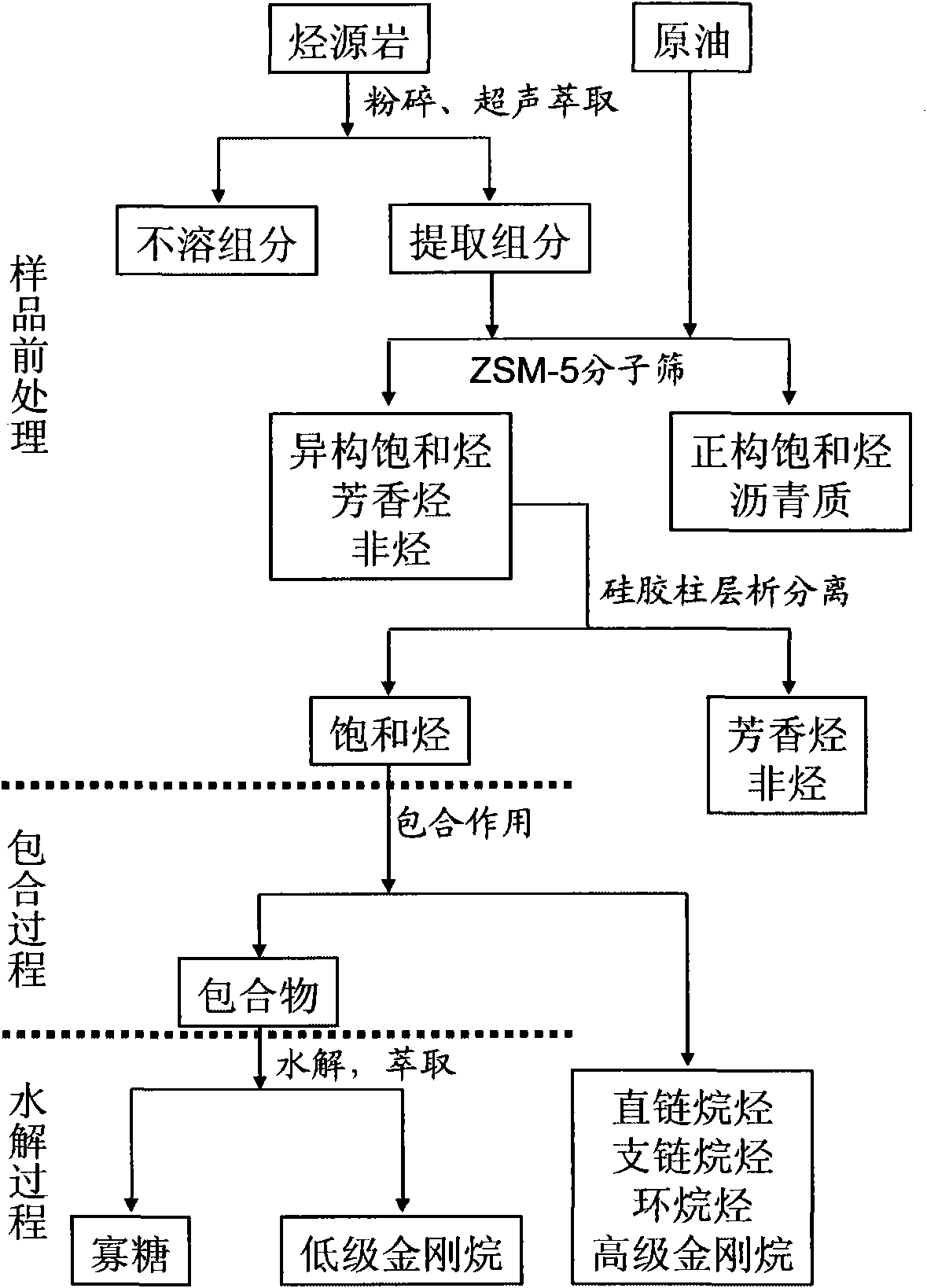

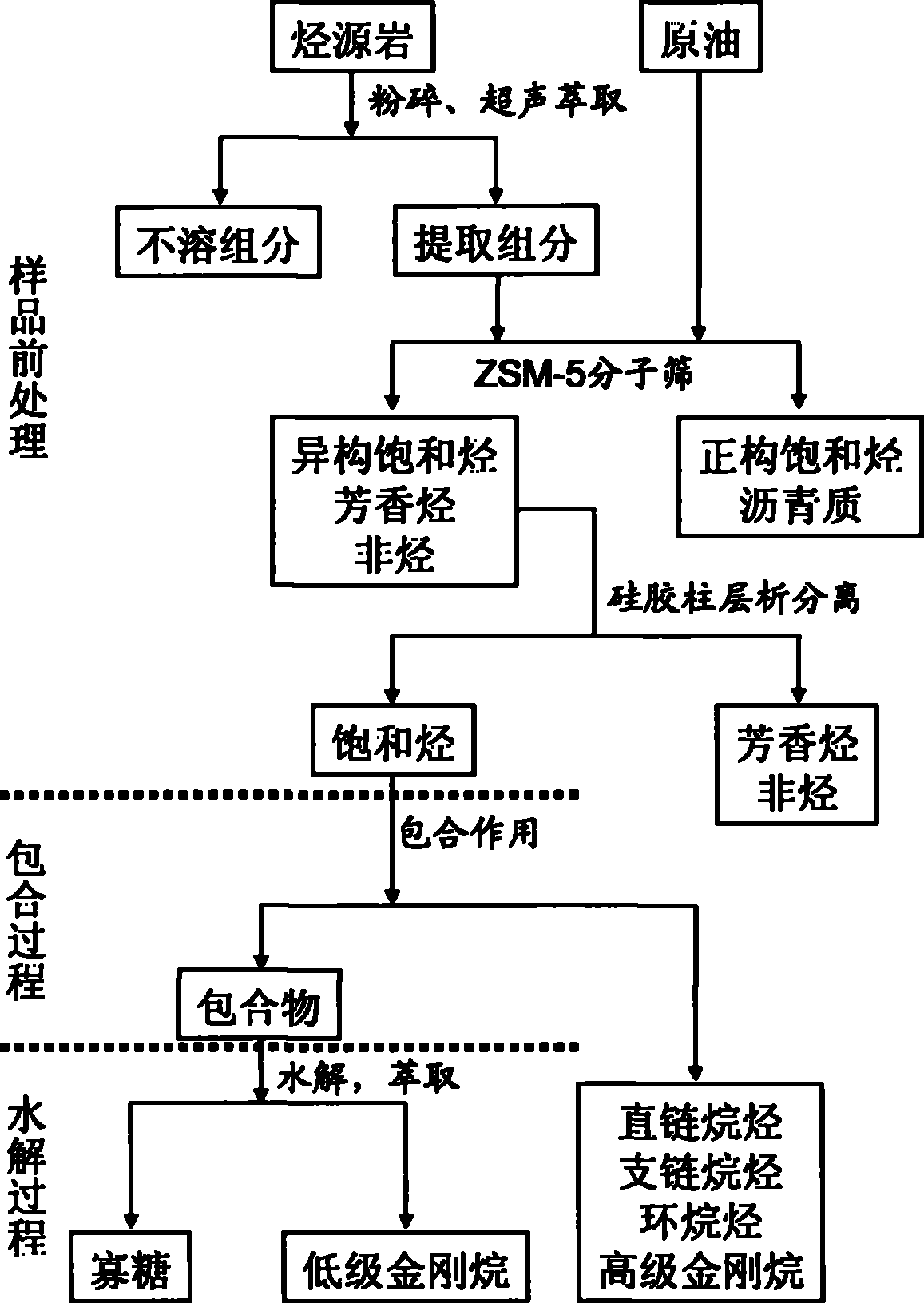

Image

Examples

Embodiment 1

[0019] 1 g of source rock samples crushed to 100 μm were placed in 25 mL of dichloromethane:methanol (1:1 v / v) solution for ultrasonic extraction for 24 hours. Filter the extract and pour it into a 100mL separatory funnel containing 25mL deionized water. The bottom aqueous phase was extracted three times with 10 mL of n-pentane:dichloromethane (2:1 v / v) solution, and the combined extracts were added with appropriate amount of sodium sulfate to remove water. Dry the sample with nitrogen at room temperature, dissolve it with a small amount of isooctane, and use isooctane as the eluent to remove normal saturated hydrocarbons and asphaltenes with a 6g ZSM-5 molecular sieve column, and then use n-hexane as the eluent to dissolve the sample The isooctane solution of the obtained isomeric saturated hydrocarbon component was obtained through a 12g silica gel column. The resulting solution was poured into 50 mL of an aqueous solution of β-cyclodextrin with a concentration of 5 mg / mL, ...

Embodiment 2

[0021] 1 g of source rock samples crushed to 100 μm were placed in 25 mL of dichloromethane:methanol (1:1 v / v) solution for ultrasonic extraction for 24 hours. Filter the extract and pour it into a 100mL separatory funnel containing 25mL deionized water. The bottom aqueous phase was extracted three times with 10 mL of n-pentane:dichloromethane (2:1 v / v) solution, and the combined extracts were added with appropriate amount of sodium sulfate to remove water. Dry the sample with nitrogen at room temperature and dissolve it with a small amount of cyclohexane, use cyclohexane as eluent, remove normal saturated hydrocarbons and asphaltenes with 6g ZSM-5 molecular sieve column, then use n-pentane as eluent, The n-hexane solution of the sample was passed through a 12g silica gel column to obtain isomeric saturated hydrocarbon components. The resulting solution was poured into 50 mL of 2 mg / mL β-cyclodextrin aqueous solution, and stirred rapidly for 4 hours. The resulting milky whit...

Embodiment 3

[0023] Take 100mg crude oil sample and dissolve it with a small amount of cyclohexane. Using cyclohexane as the eluent, use a 6g ZSM-5 molecular sieve column to remove normal saturated hydrocarbons and asphaltenes, and then use n-pentane as the eluent to pass the cyclohexane solution of the sample through a 12g silica gel column to obtain isomerization saturation hydrocarbon components. The resulting solution was poured into 50 mL of β-cyclodextrin aqueous solution with a concentration of 1 mg / mL, and stirred rapidly for 1 hour. The resulting milky white suspension was centrifuged for 20 minutes (3000 rpm) to obtain a precipitate, which was washed three times with 10 mL of n-pentane. The resulting precipitate was transferred to a glass bottle filled with 30 mL of 0.1 mol / L hydrochloric acid solution, sealed and placed in an oven at 80°C for 24 hours at a constant temperature. After the sample is cooled to room temperature, add 20 mL of n-pentane to extract the lower adamanta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com