Method for producing polymerizable hydroxydiamantyl ester compound

A technology of hydroxydiadamantyl ester and dihalogenated diamantane, which is applied in the field of preparation of polymeric hydroxydiadamantyl ester compounds, and can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

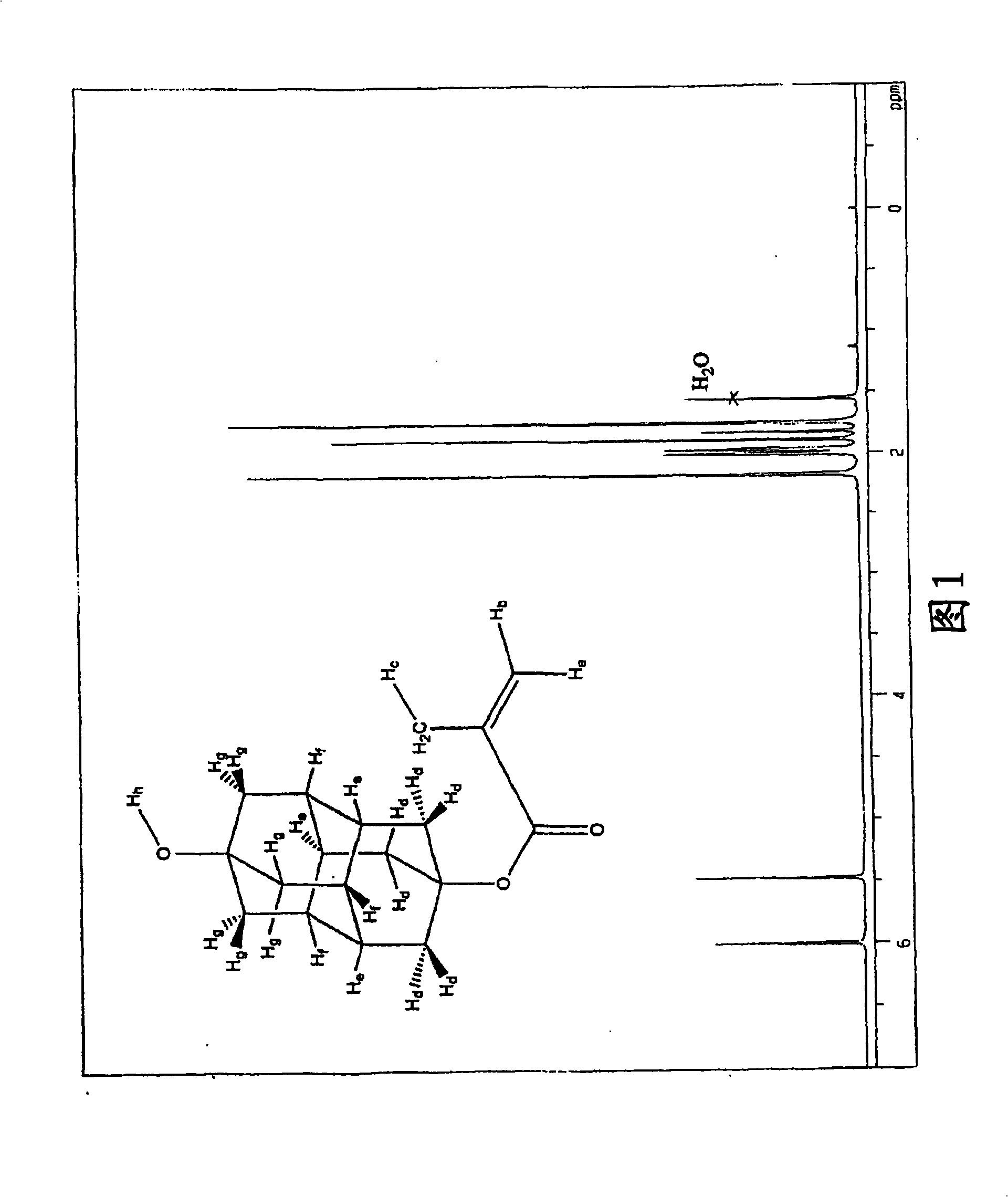

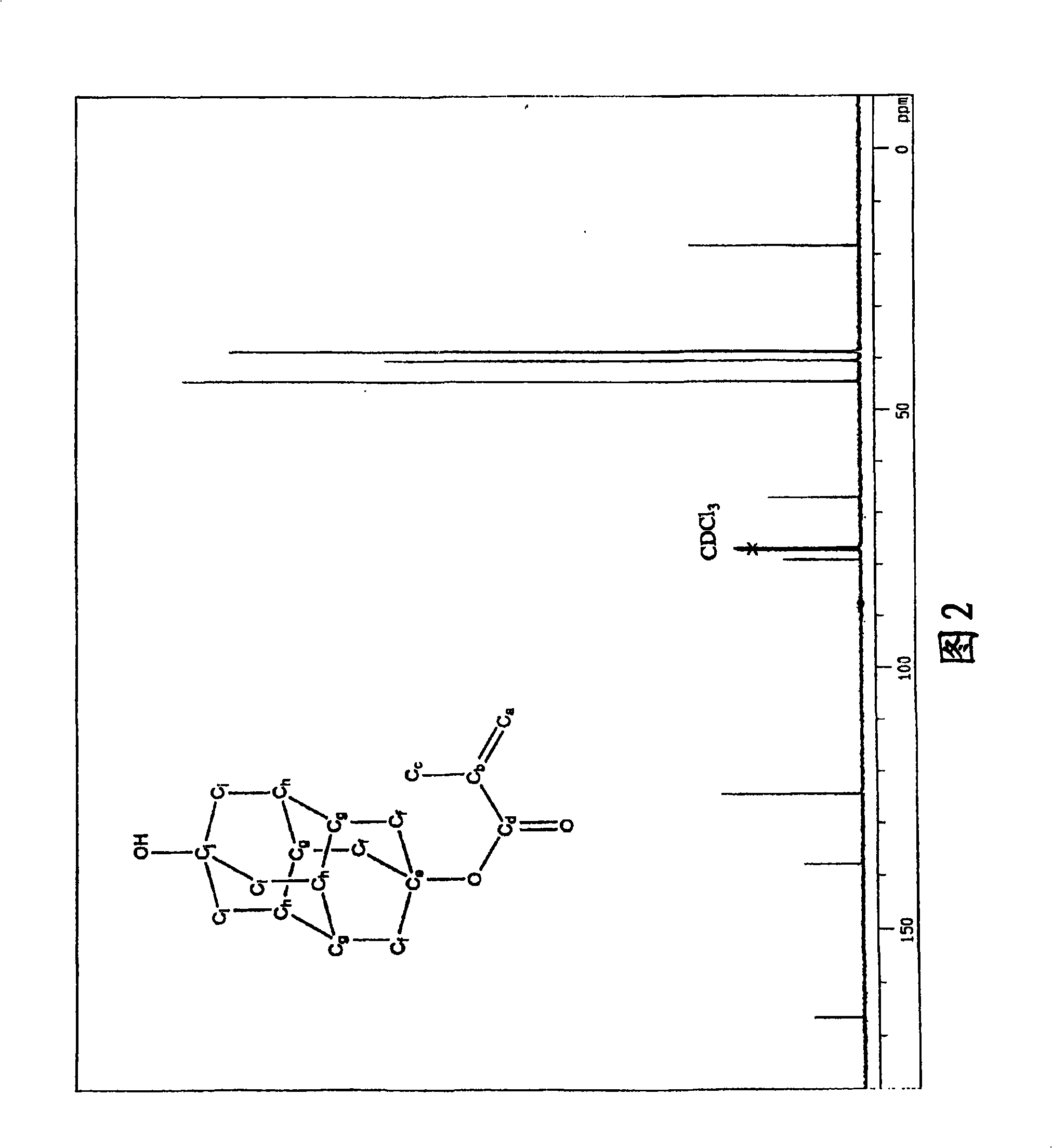

Image

Examples

preparation example Construction

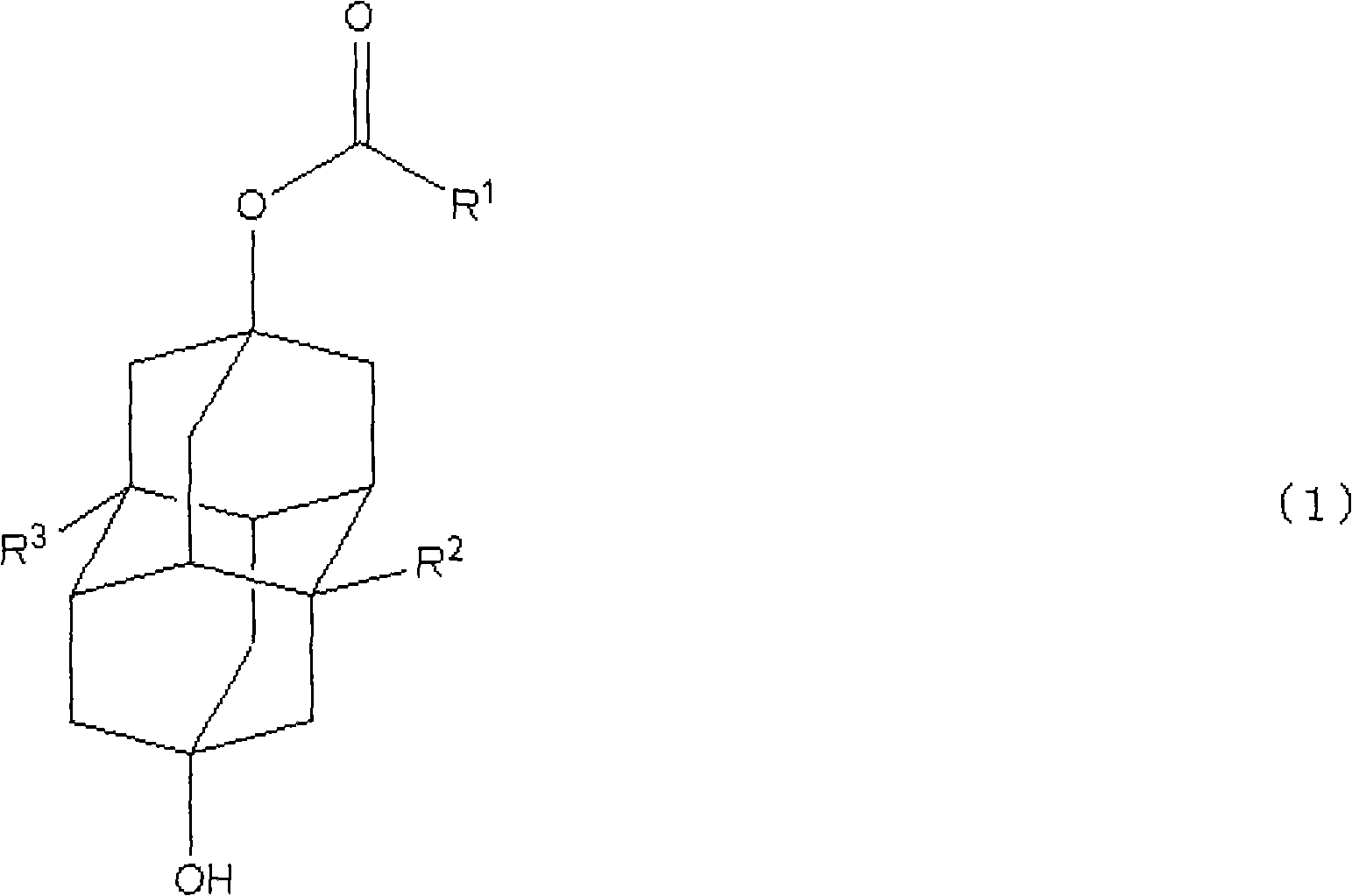

In the production method of the present invention, first, a diadamantane compound represented by the following formula (2) is subjected to a dihalogenation reaction to obtain a 4,9-dihalogenated diadamantane compound.

[0031] [chemical 4]

[0032] In the above formula (2), R 2 and R 3 Each independently represents a hydrogen atom or an alkyl group having 1 to 5 carbon atoms.

[0033] Specific examples of preferred groups among the alkyl groups having 1 to 5 carbon atoms include methyl, ethyl, n-propyl, isopropyl, n-butyl, sec-butyl, tert-butyl, n-pentyl Base, sec-pentyl, isopentyl, etc.

[0034] In this step (i), as R 2 and R 3 , as long as it matches with the target polymerizable hydroxydiamantyl ester compound and selects appropriately. Specific examples of diadamantane compounds that can be used include diadamantane, 1-methyldiamantane, 1-ethyldiamantane, 1,6-dimethyldiamantane, 1,6 -Diethyldiadamantane and the like. Among these, diamantane is particularly prefera...

Embodiment 1

[0133] Add chlorosulfonic acid 222.7g (1.912mol, be 3 mole times of raw material diadamantane) (total be 5 mole times of diadamantane) to wherein, stir again at 30 ℃ for 15 hours (reaction time of 18 hours in total) ). After 15 hours, GC analysis revealed that the product contained 1% of the raw materials diadamantane, 5% of monochlorodiamantane, 80% of dichlorodiamantane, and 14% of trichlorodiamantane. After cooling the reaction liquid to about 10°C, 262 g of water was dropped while keeping the reaction liquid at a temperature not higher than 30°C. 840 g of dichloromethane was added, stirred, left to stand, and liquid-separated, and the lower sulfuric acid aqueous solution layer was removed. Then, the organic layer was washed 2 times with 240 g of 10% aqueous sodium hydroxide solution, 1 time with 300 g of 7% aqueous sodium sulfate solution, and 2 times with 120 g of 7% aqueous sodium sulfate solution. At this time, the pH value of the organic layer had changed into neutra...

Embodiment 2~3

[0142] Table 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com