High-yield and energy-saving electrolytic furnace for rare-earth metals

A rare earth metal and electrolytic furnace technology, applied in the direction of cells, etc., can solve the problems of product quality fluctuation, short furnace life, high carbon content, etc., and achieve the effects of facilitating production operations, improving product quality, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

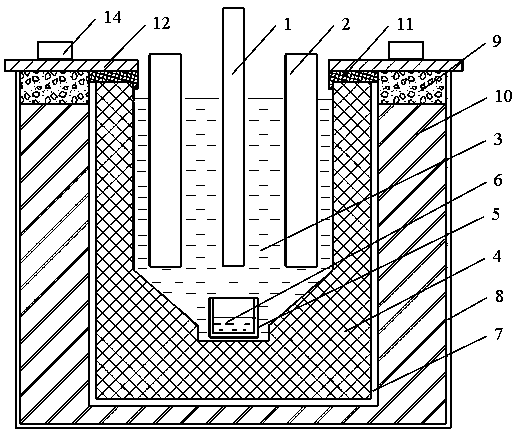

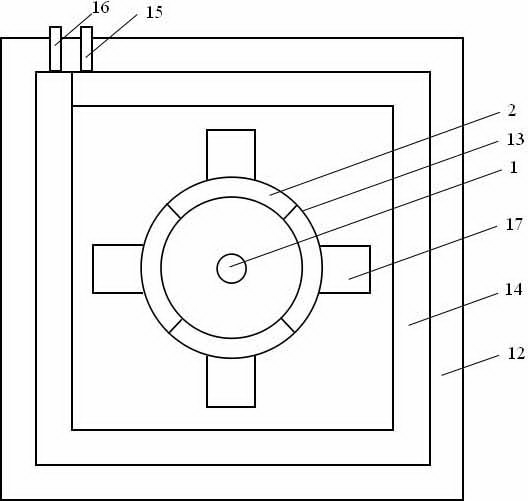

[0017] The invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0018] Such as figure 1 , 2 As shown, the high-yield and energy-saving rare earth metal electrolytic furnace proposed by the present invention comprises a drum-shaped outer steel jacket 8 and an inner steel jacket 7, both of which are drum-shaped, and the bottom and surroundings are completely sealed. The wall thickness is 5-10mm. The inner steel sleeve 7 is put into the outer steel sleeve 8, and the gap between the outer wall of the inner steel sleeve 7 and the inner wall of the outer steel sleeve 8 is filled with a filler layer; The upper layer 9 is formed, and the furnace roof plate 12 is adhered to the surface of the upper layer.

[0019] The inside of the inner steel sleeve 7 is provided with a graphite groove 4, the outer diameter of the graphite groove 4 is slightly smaller than the inner diameter of the inner steel sleeve, graphite powder is filled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com