Patents

Literature

156results about How to "Will not be scrapped" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

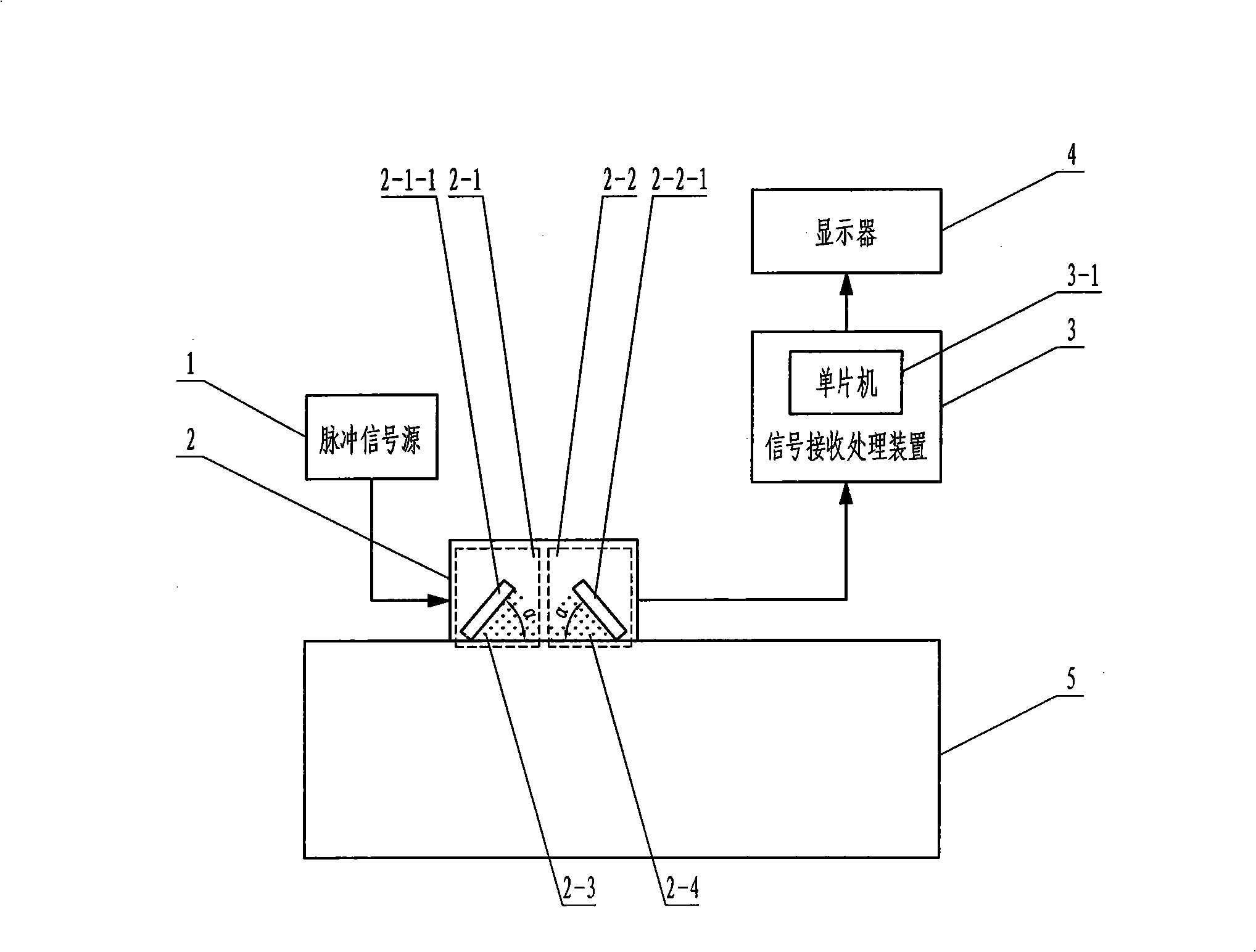

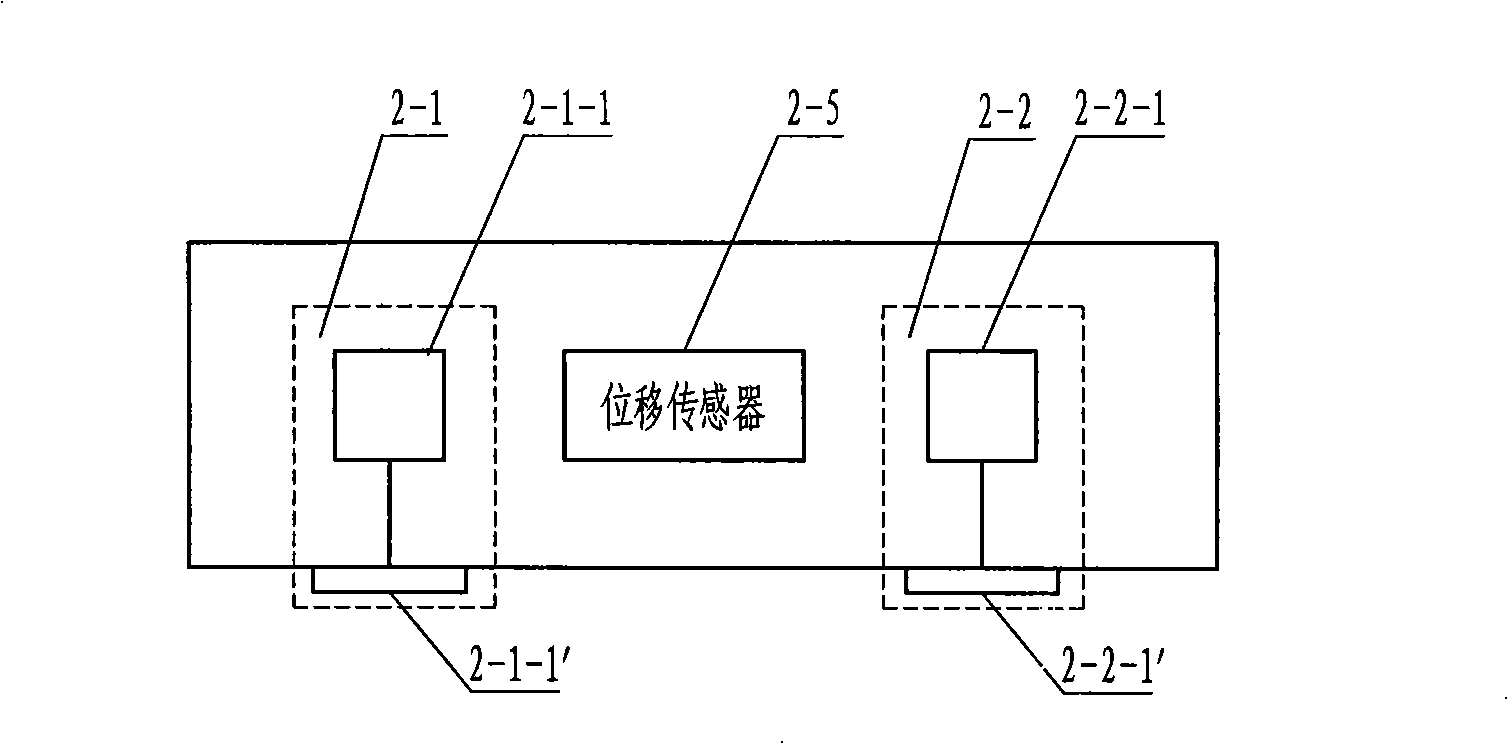

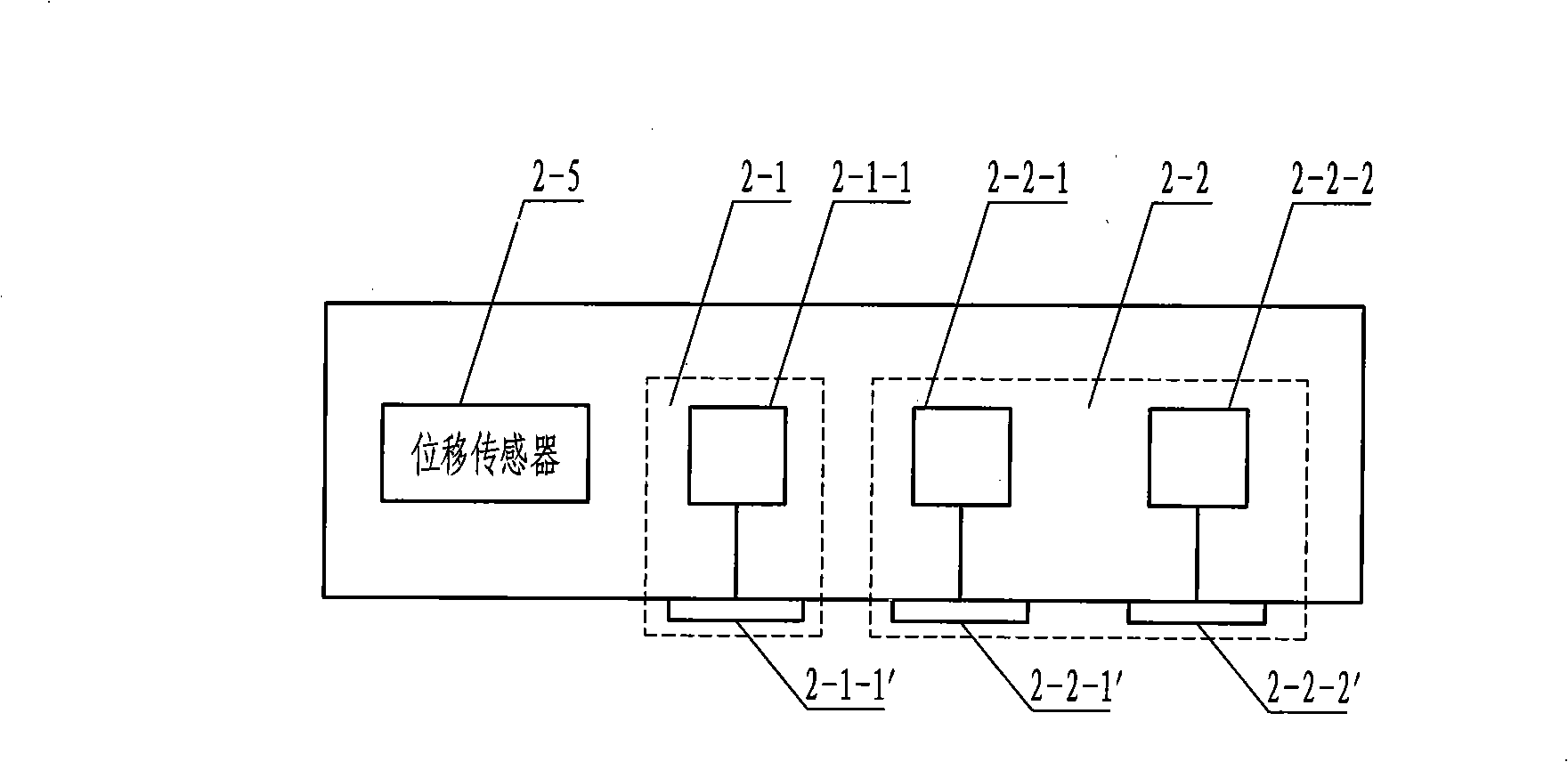

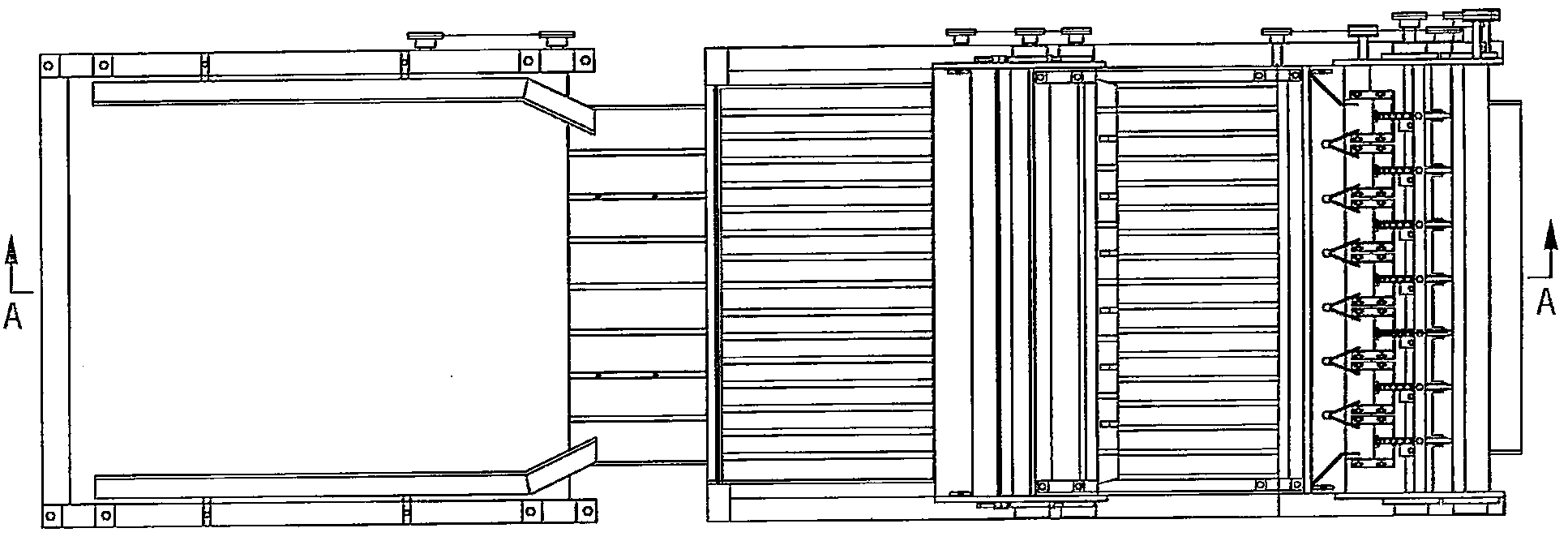

Ultrasonic wave nondestructive apparatus and method for measuring residual stress of welded structure

InactiveCN101320018AWill not be scrappedHigh measurement accuracyAnalysing solids using sonic/ultrasonic/infrasonic wavesMicrocontrollerMeasurement device

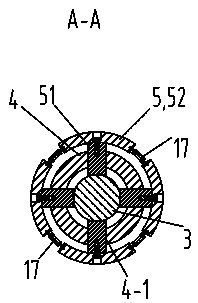

The invention relates to a welding structure residual stress ultrasonic lossless measurement device and a method, in particular to a device and a method using ultrasonic for measuring the residual stress of a welding structure, belonging to the residual stress measurement field. The method aims at overcoming the problems of a traditional stress measurement method that work pieces are destroyed, time is consumed and the residual stress measurement can not be satisfied under the service condition of the welding structure. The two ends of a probe group of the invention are respectively connected with an impulse signal source and a signal receiving processing device which is connected with a display. And a microcontroller is embedded in the signal receiving processing device. In said method, the coordinate of a measured point is determined; the probe group emits impulse signals sent out from the impulse signal source into a work piece through a first critical refraction angle to generate critically refracted longitudinal waves, wherein, enveloping data are read by the signal receiving processing device and are discretized into digital signals and FIR filtering waves; total enveloping weight eigenvalue Mn is worked out; abnormal data are removed according to Brubbs criterion after one measured point is measured for a plurality of times, measuring position is changed for measuring again, and Mn and Mn+1 are worked out according to two measuring points to calculate the residual stress Delta of the work piece.

Owner:HARBIN INST OF TECH

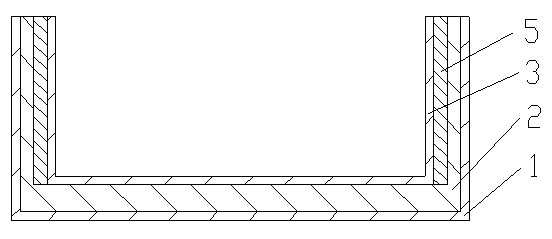

Fluororubber cloth clamp combination V seal ring and method for producing the same

The invention provides a V-shaped seal ring with a fluororubber canvas combination which is characterized in that the seal ring is produced by materials with the following portions by weight: 100 portions of peroxide vulcanized fluororubber, 20-50 portions of light-colored filler, 3-5 portions of zinc oxide, 2-5 portions of iron oxide red, 3-5 portions of 2,5-dimethyl-2,5-di-(tert-butyl peroxide) hexane, 4-6 portions of triallyl glycicy isocyanuratel and 0.5-1.5 portion of processing agent. A preparation method of the invention indicates that the materials with the portions by weight are first made into fluororubber dry mix which is then dissolved in mixed solvent so as to prepare adhesive cement; then the adhesive cement is dip coated on glass fiber cloth to prepared the fluororubber glass fiber canvas which is then die pressed by a vulcanized product combination to prepare the V-shaped seal ring with the fluororubber canvas combination. In addition, the obtained V-shaped seal ring with the fluororubber canvas combination has long service life and is resistant to high temperature, high pressure and hydraulic safety fluid.

Owner:GUANGZHOU MECHANICAL ENG RES INST

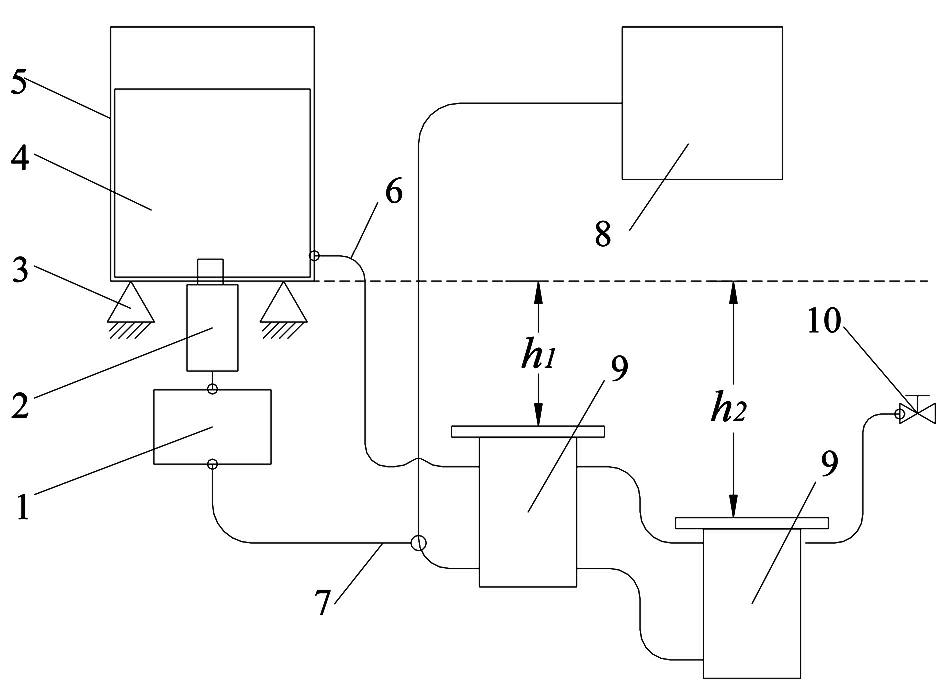

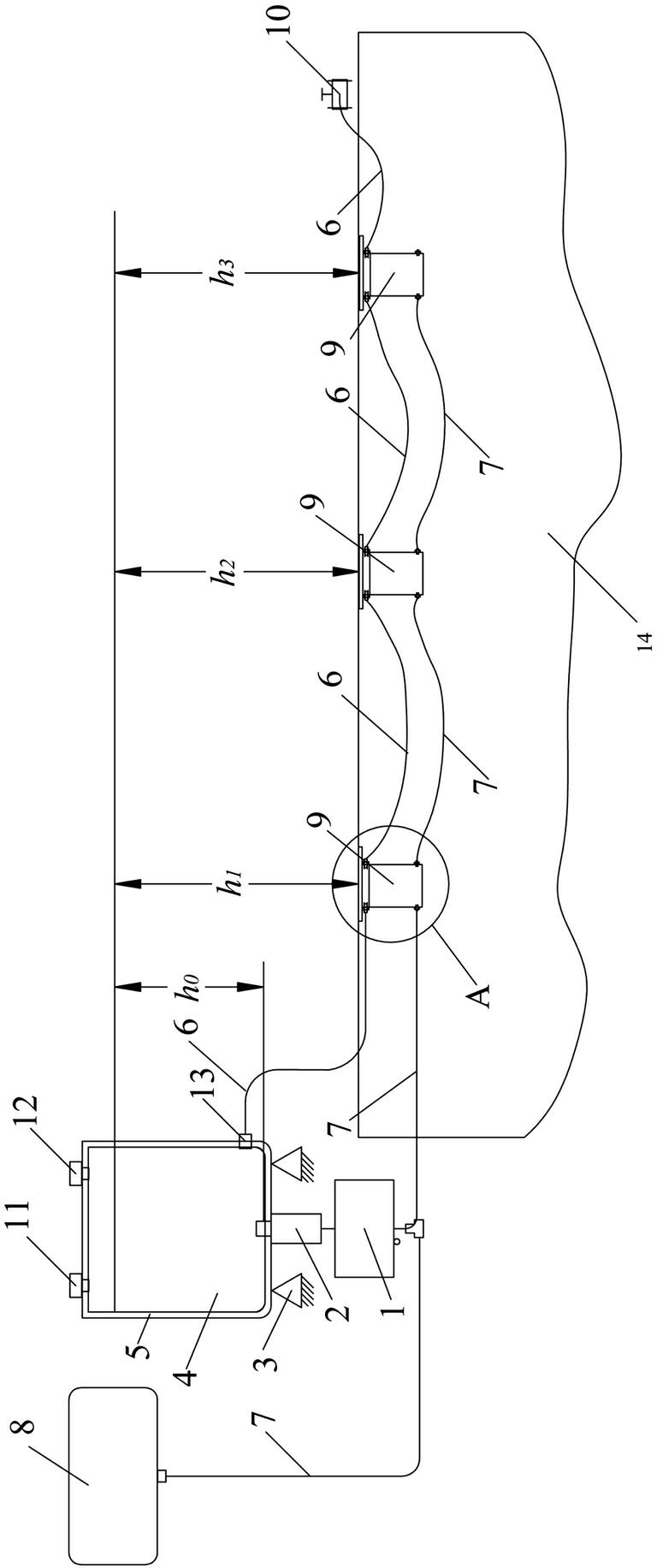

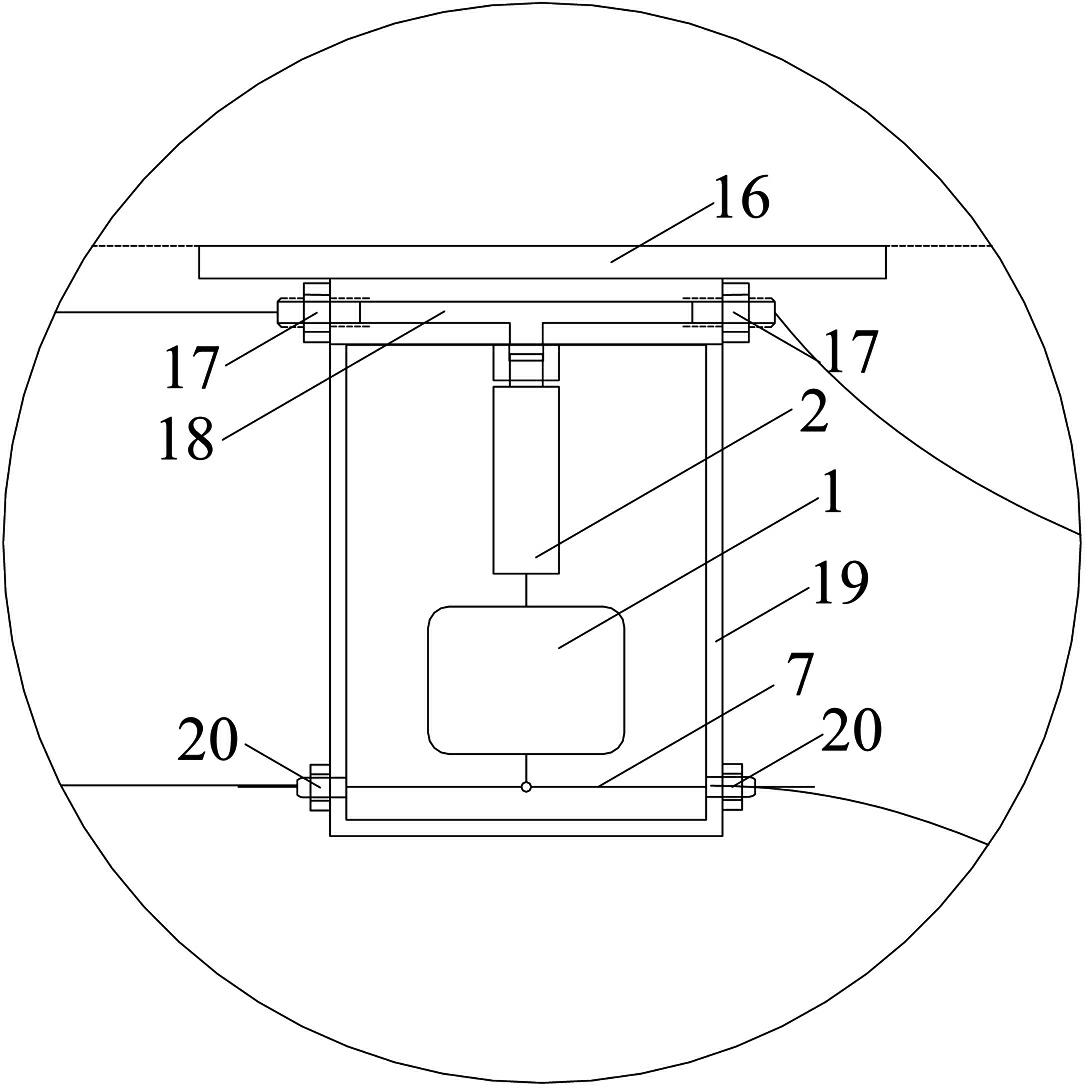

A method for monitoring deep foundation subsidence

ActiveCN102288157ASmall temperature changeReduce the effects of temperature changesHydrostatic levellingControl systemCurve fitting

The invention relates to a method for monitoring the deep settlement of a foundation, which is characterized in that: a liquid level static pressure monitoring method is adopted; in the liquid level static pressure monitoring method, a container provided with a pressure sensor and a secondary instrument is adopted, taken as a pressure measuring reference container and fixed on the ground which isnot influenced by the foundation settlement; the height of a pressure sensing surface of the pressure sensor is greater than that of any one embedded settlement instrument; the embedded settlement instrument consists of a shell, a three-way joint, a pressure sensor, a secondary instrument circuit and a serial bus circuit and is electrically connected with other embedded settlement instruments anda ground measurement and control system through an electric serial bus; and the measurement and control system records a pressure value of each detection point, converts the pressure value into a foundation settlement value, and performs curve fitting to obtain a foundation section settlement outline.

Owner:上海同禾工程科技股份有限公司

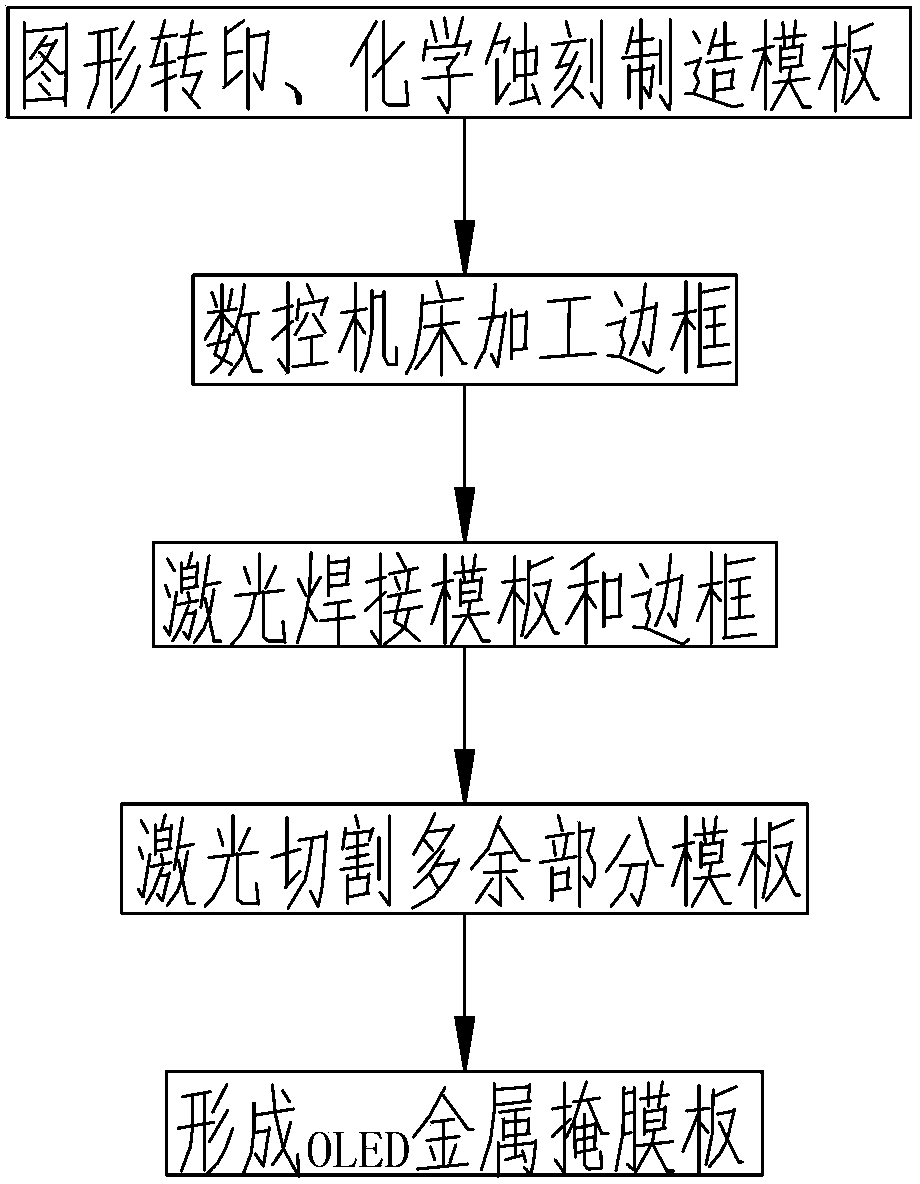

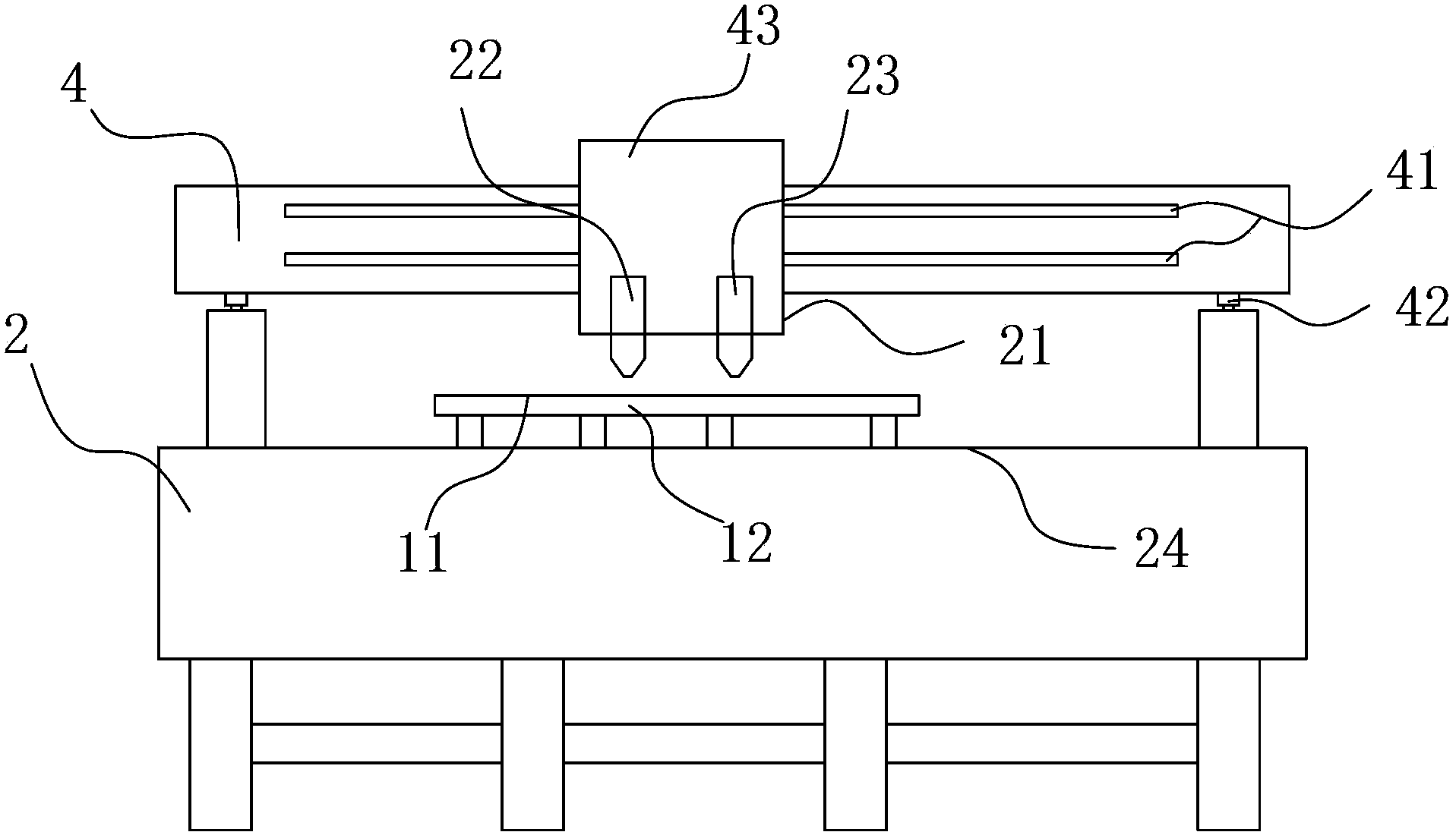

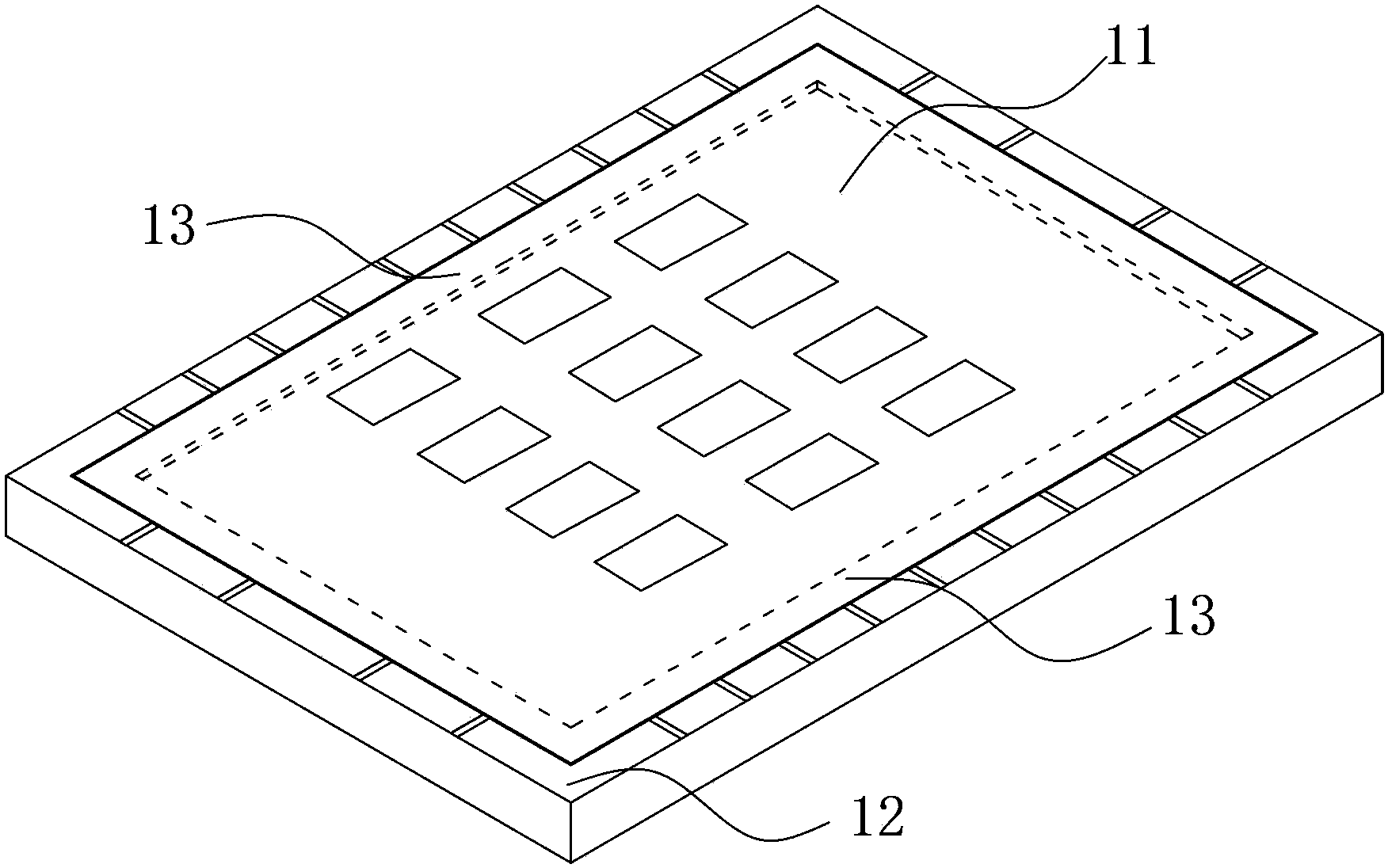

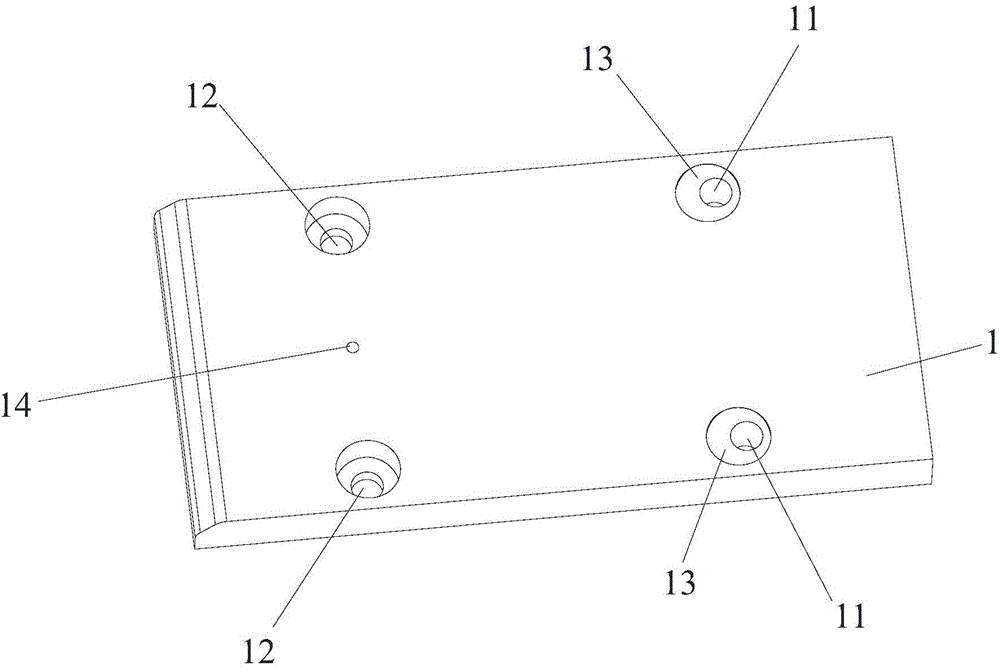

Manufacturing method of OLED (Organic Light Emitting Diode) metal mask plate

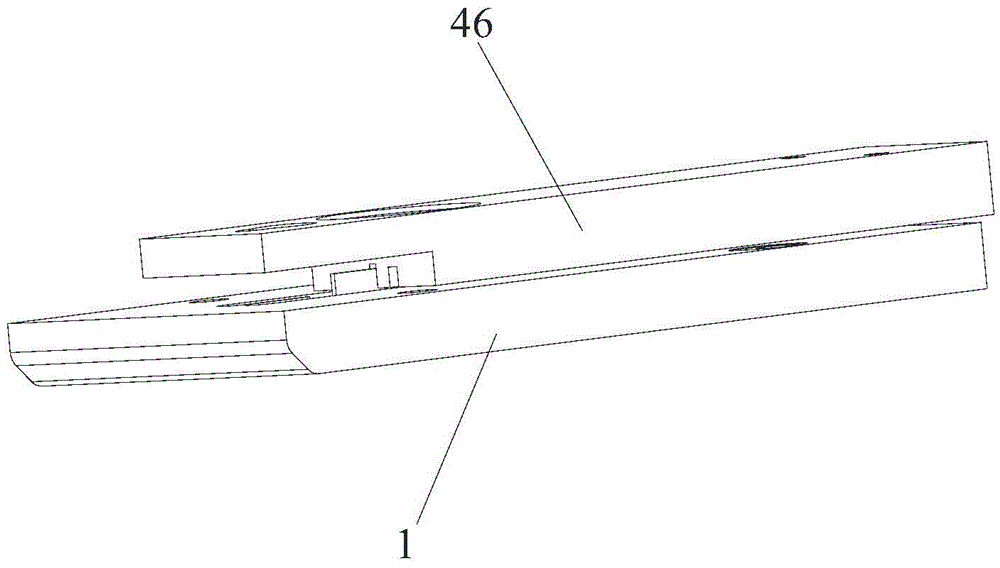

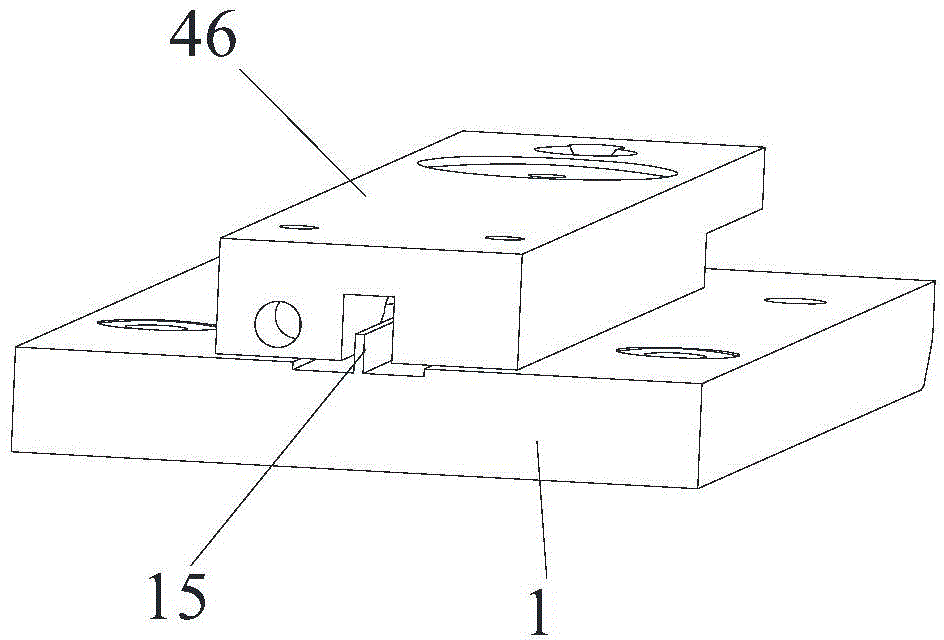

InactiveCN104097027AHigh precisionWill not be scrappedVacuum evaporation coatingSputtering coatingNumerical controlEtching

The invention provides a manufacturing method of an OLED (Organic Light Emitting Diode) metal mask plate. The manufacturing method comprises the following steps: carrying out pattern transfer and chemical etching on a metal sheet by photochemical etching to manufacture a prefabricated template; machining the metal sheet by using a numerically controlled machine tool to manufacture a frame; further machining the prefabricated template and the frame by using a laser welding machine, wherein the laser welding machine is provided with a laser welding head and a laser cutting head, and the frame is fixed on a welding platform of the laser welding machine; putting the prefabricated template on the frame, tightly pressing by a pressing device, and welding and cutting the prefabricated template and the frame by using the laser welding head and the laser cutting head. In addition, a control file is edited according to motion paths of the laser welding head and the laser cutting head to automatically finish welding and cutting. According to the manufacturing method of the OLED metal mask plate, the metal mask plate is manufactured by laser welding and cutting, so that the quality of a product is well ensured, the problems of burrs, trimmings and the like are avoided, and convenience is provided for use of a subsequent evaporation process.

Owner:KUNSHAN THETA MICRO

Aluminum Alloy Hard Anodic Oxidation Film and Its Process Method

InactiveCN102286766AImprove performanceHigh hardnessSurface reaction electrolytic coatingHigh current densityHardness

The invention relates to an aluminum alloy hard anodized film and a process method thereof. After degreasing and degreasing, the surface of the aluminum alloy workpiece is shot peened with clean stainless steel shot, and then hard anodized in an electrolyte with low sulfuric acid concentration, and hard anodized with low current density and then high current density The hard oxide film is obtained after treatment, the thickness of the oxide film is 340-374 μm, and the hardness is high, the film layer is dense, and it is beneficial to environmental protection and cost reduction.

Owner:XIHUA UNIV

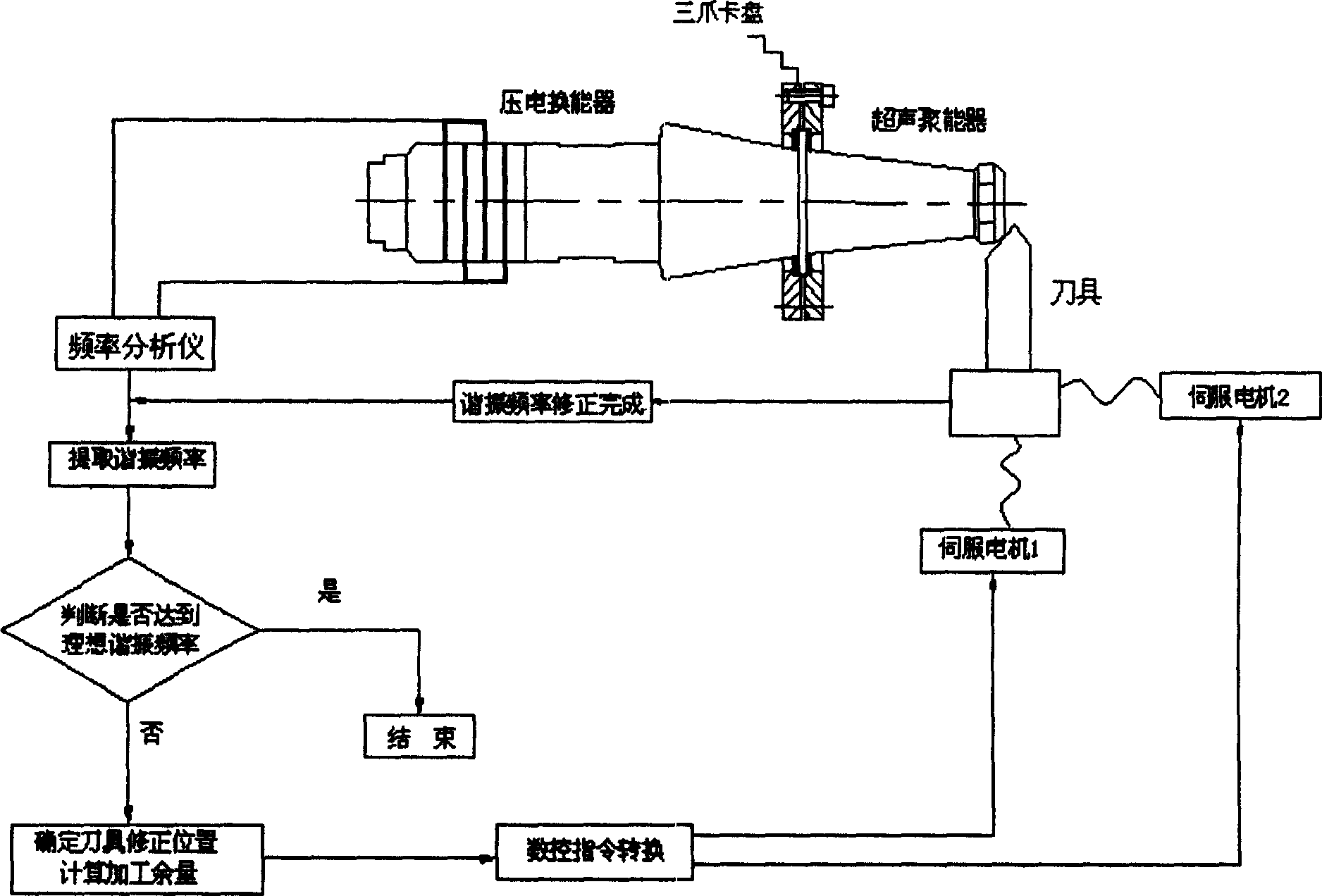

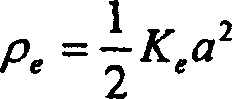

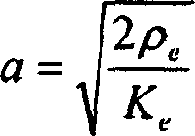

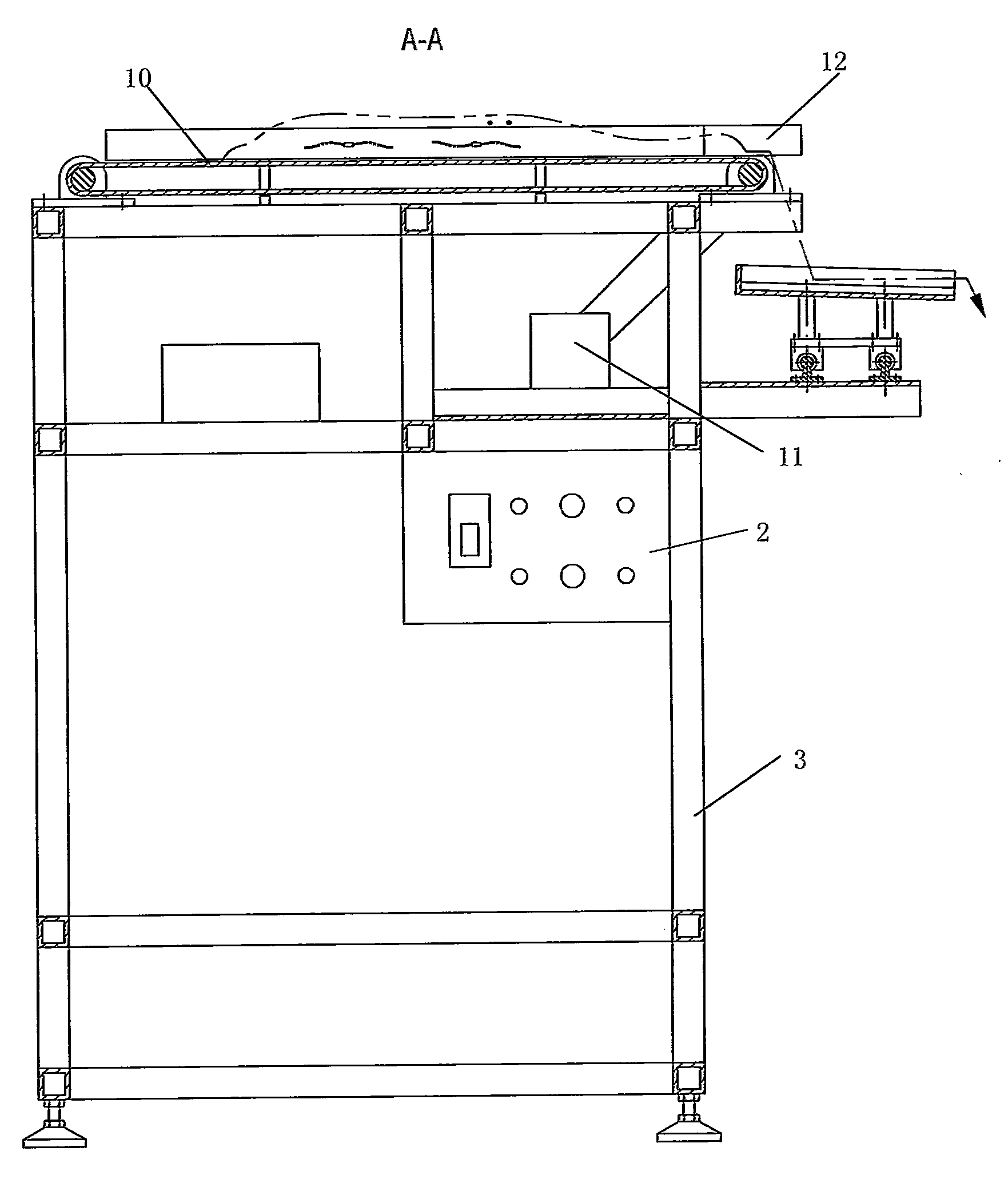

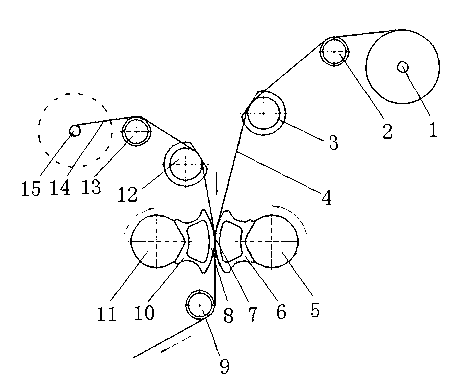

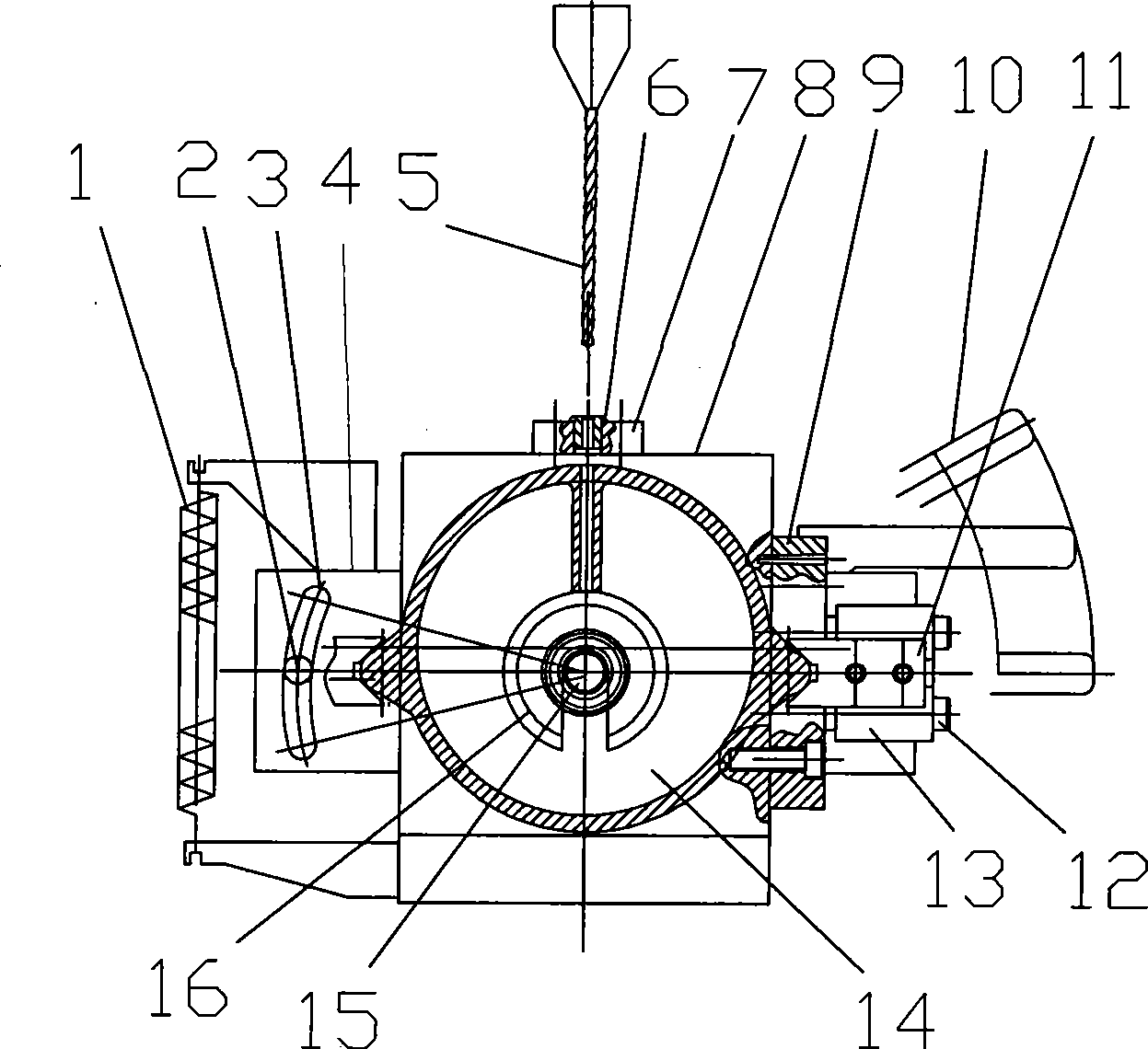

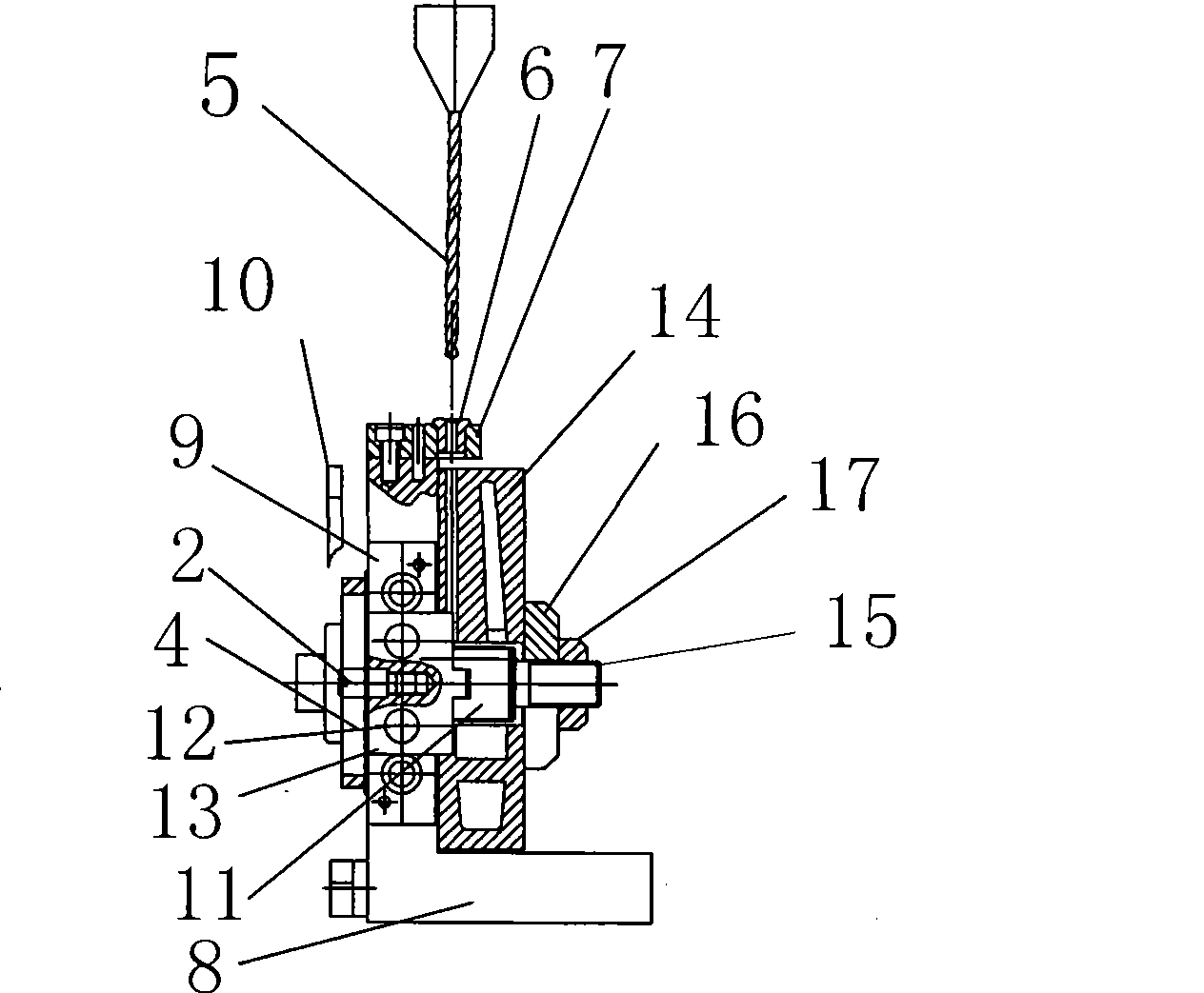

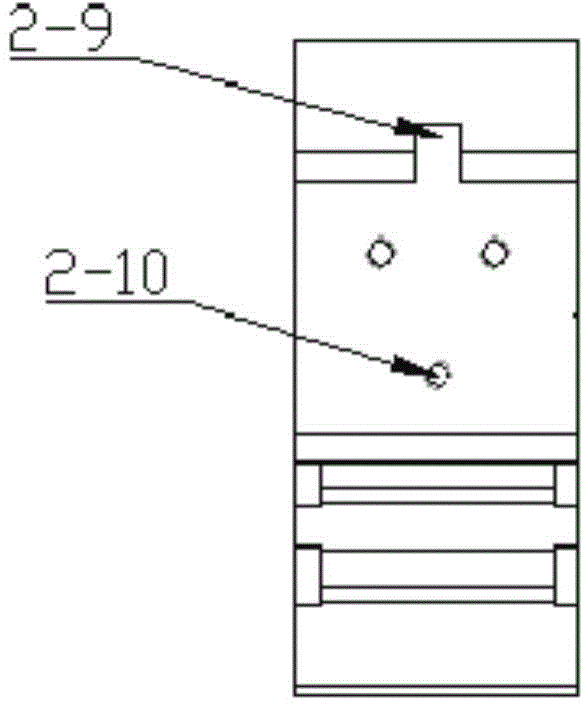

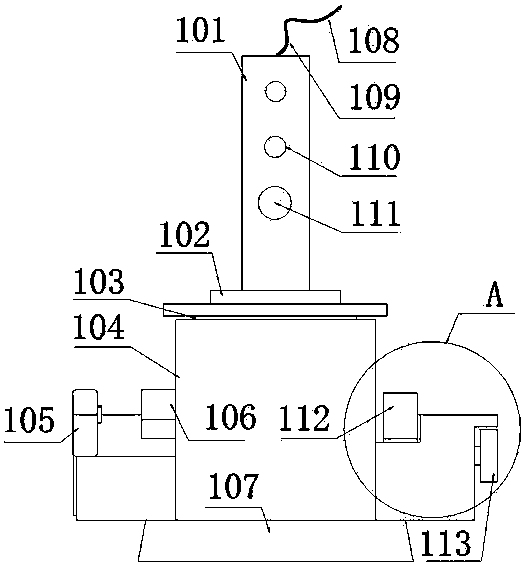

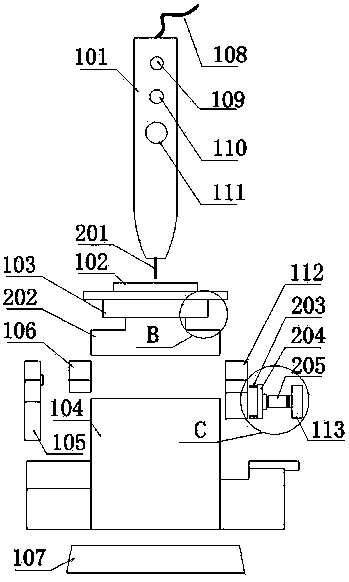

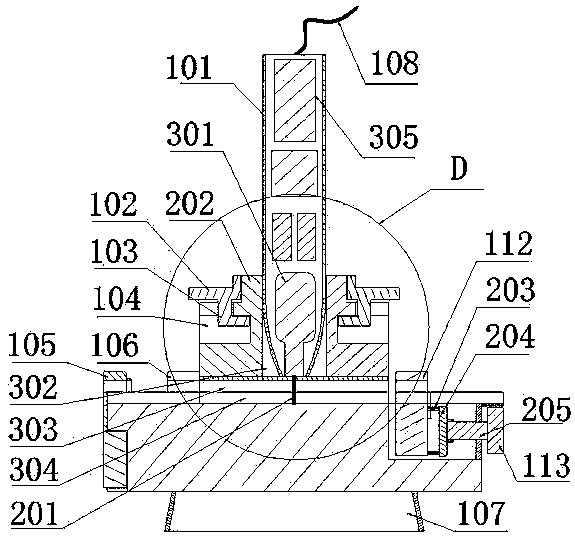

Digital control correcting method for resonance frequency of piezoelectric transducer and supersonic concentrator

InactiveCN1603065AAccurate resonant frequency correctionAccurate correctionProgramme controlAutomatic control devicesElectricityMotor drive

The invention discloses a resonance frequency digital control amendment method of the piezoelectric transducer and super-sound concentrator. The piezoelectric transducer and super-sound concentrator assembled together are installed at the digital control lathe by the flange at the pitch point of the super-sound concentrator. The anode and the cathode of the piezoelectric transducer are respectively connected to the anode and the cathode of the frequency analyzer. The frequency analyzer is measured the resonance frequency of the piezoelectric transducer and super-sound concentrator at real time, and transferred the tested actual resonance frequency parameter to the computer to calculate out the difference value of the actual and theoretical resonance frequency, the amendment position and the amendment allowance of the piezoelectric transducer and super-sound concentrator. The piezoelectric transducer and super-sound concentrator are practiced precision finishing ultra-precision machining by the servo motor drive cutter to change their shape and size. The advantage of the invention are that the amendment efficiency is high; the amendment frequency is accurate; the piezoelectric transducer and super-sound concentrator will not be discarded as useless; the cost is low; the operation is simple; and the automatic amendment can be realize.

Owner:HANGZHOU DIANZI UNIV

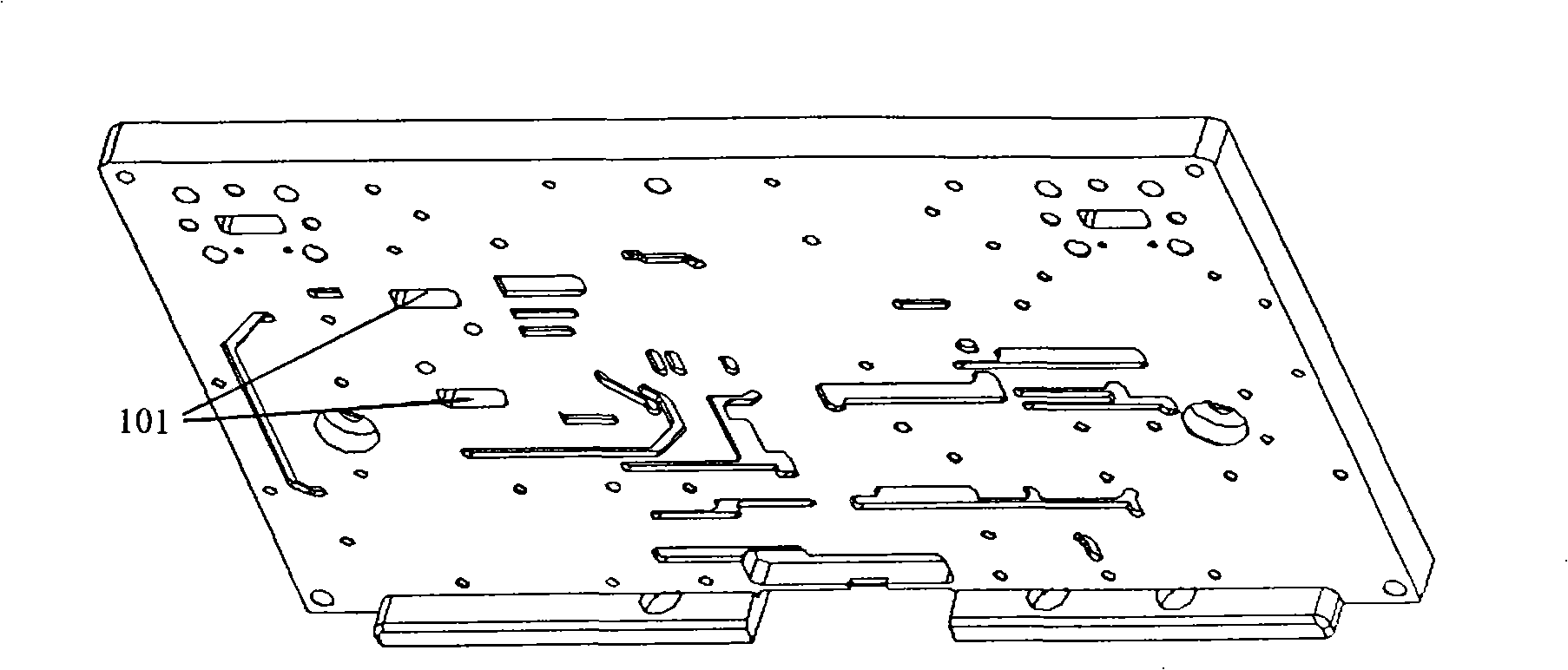

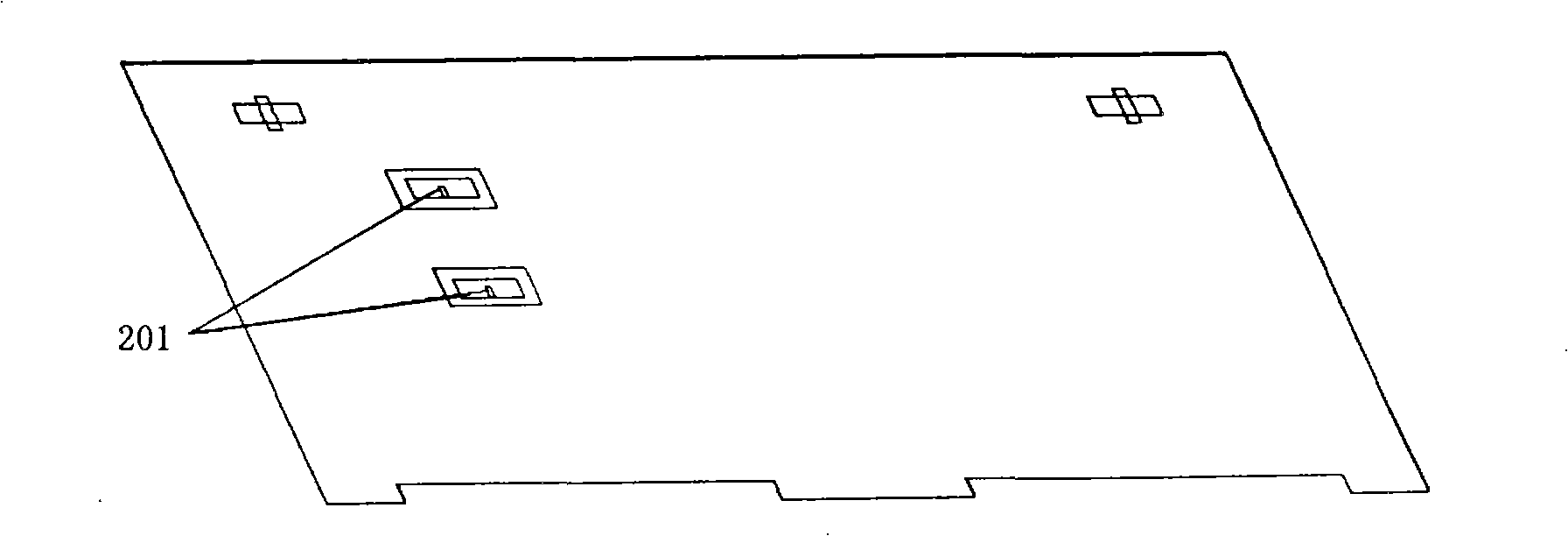

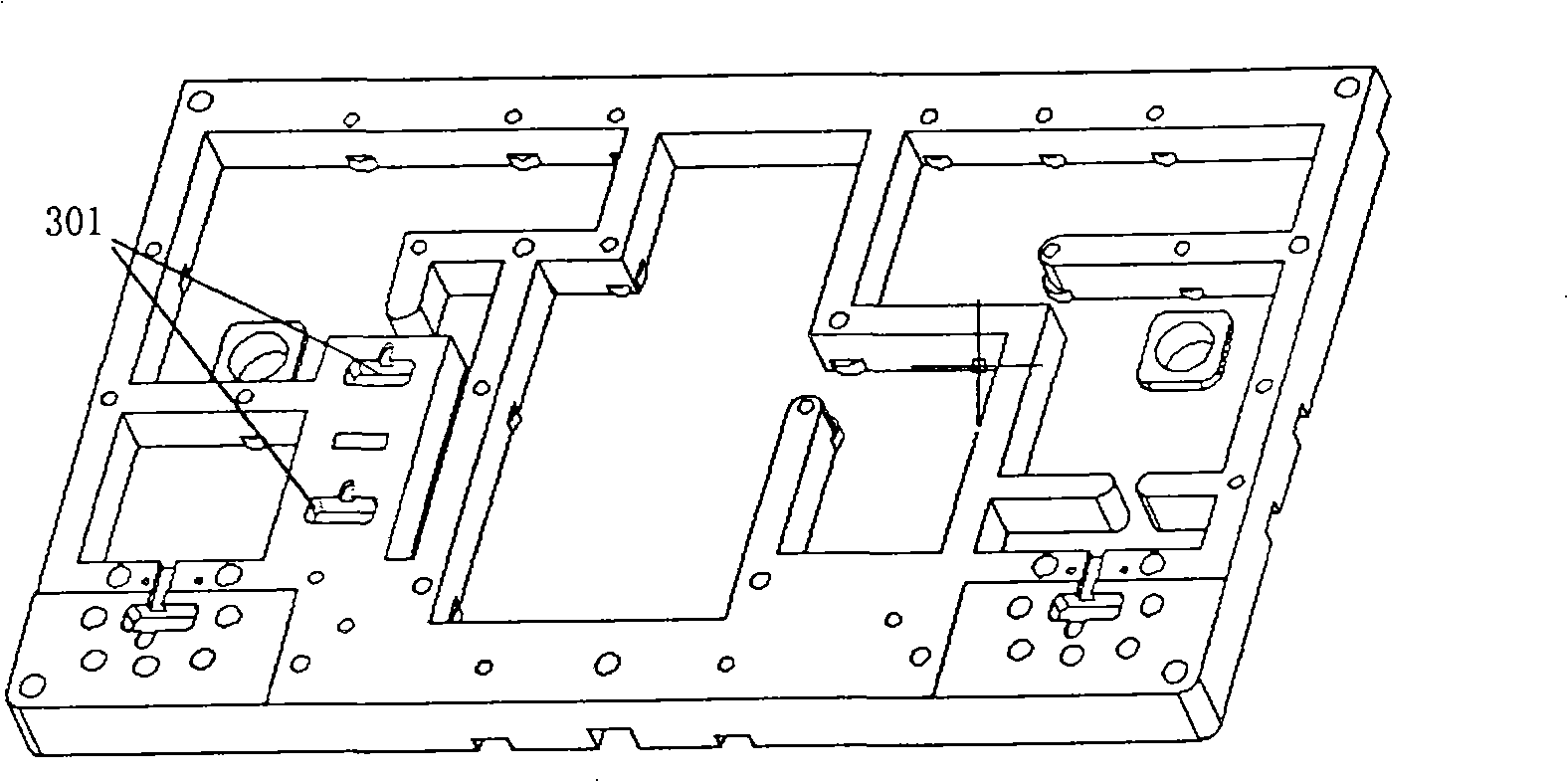

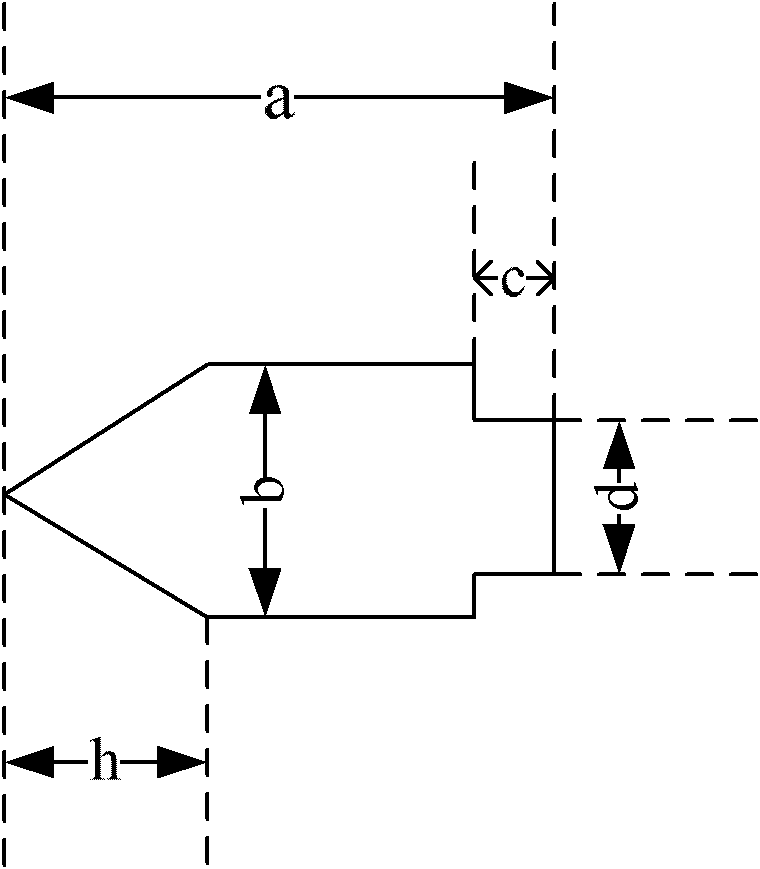

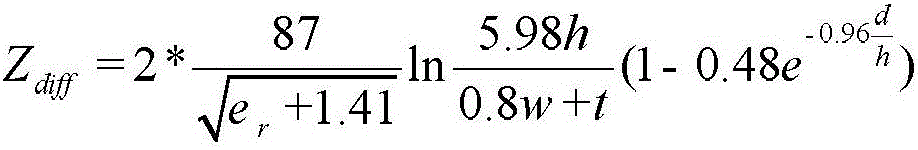

Wave-guide coupling microstrip/strip line filter

InactiveCN101355189AWill not be scrappedAvoid Surface Mount ProcessCoupling devicesBand shapeSignal on

The invention provides a waveguide coupling micro-strip / band-shaped line filter, comprising a cover board for a shielding box in a microwave transceiving module, a microwave mixing circuit board, a base plate for the shielding box, a plate for a filter and a cover board for the filter, wherein the plate for the filter is separated from the microwave mixing circuit board and is coupled with the microwave mixing circuit board in a waveguide way, that is, the cover board for the shielding box is provided with two rectangular waveguide openings, the plate for the filter is provided with a micro-strip or strip-shaped line-waveguide converter corresponding to the microwave mixing circuit board; and a signal on the microwave mixing circuit board is coupled to the plate for the filter through the strip-shaped line-waveguide converter, and microwave mixing circuit board is filtered, strip-shaped line-waveguide converted and coupled so as to realize the micro-strip filter function. The waveguide coupling micro-strip / band-shaped line filter has the advantages of improving the maintainability, producibility and debugging performance of the product, improving the spurious suppression, solving the problems of microwave transmission line and the power cord intersection in the routing process of the double-surface circuit board, and improving the performance of the product.

Owner:上海杰盛无线通讯设备有限公司

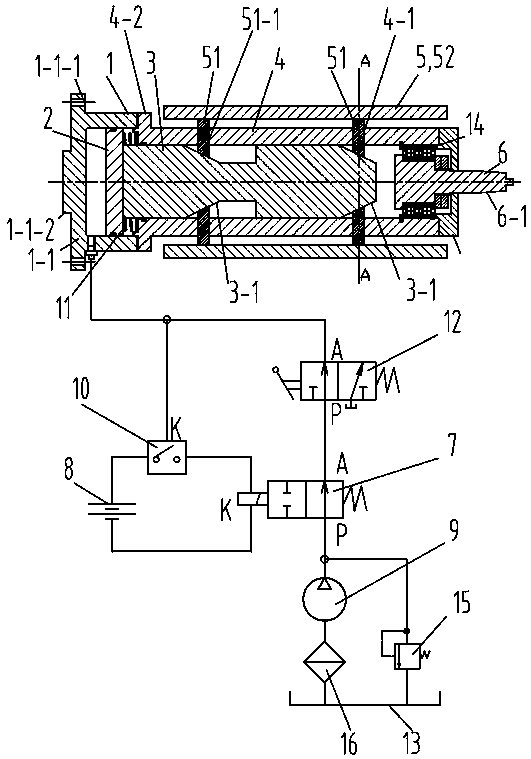

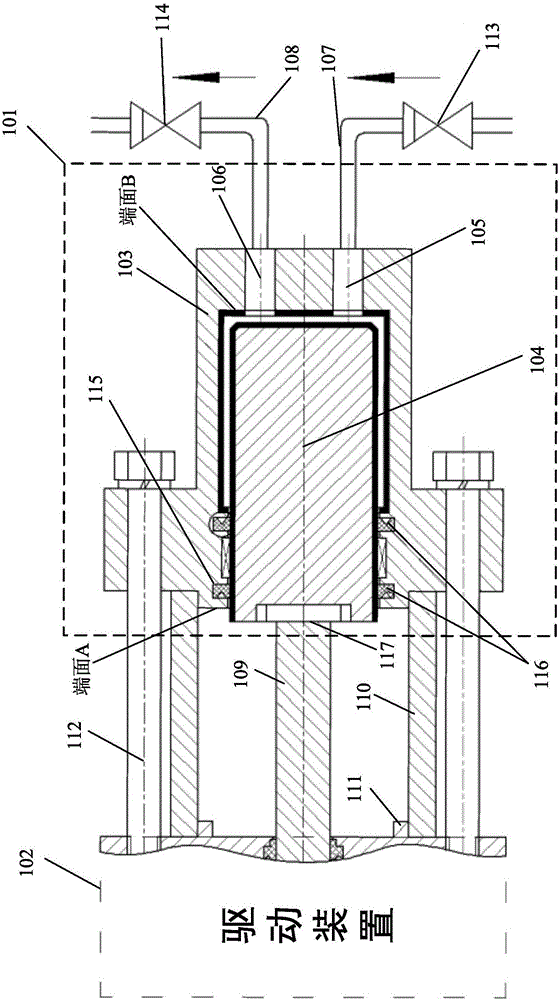

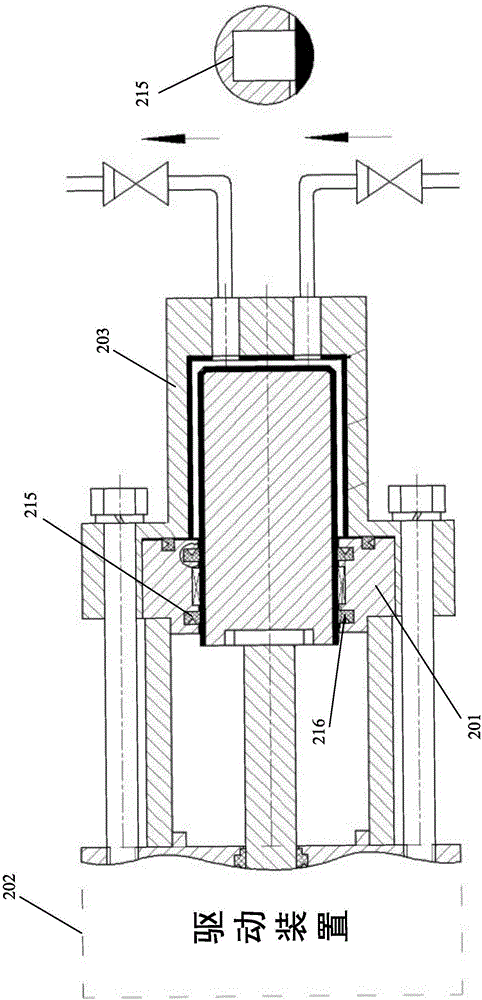

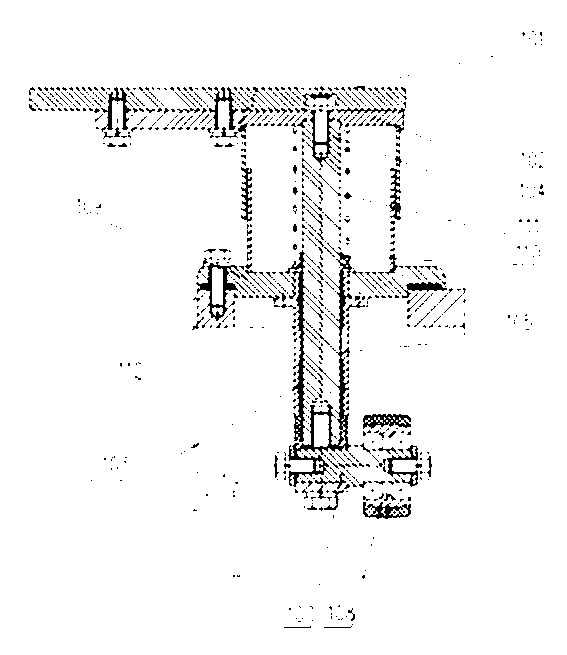

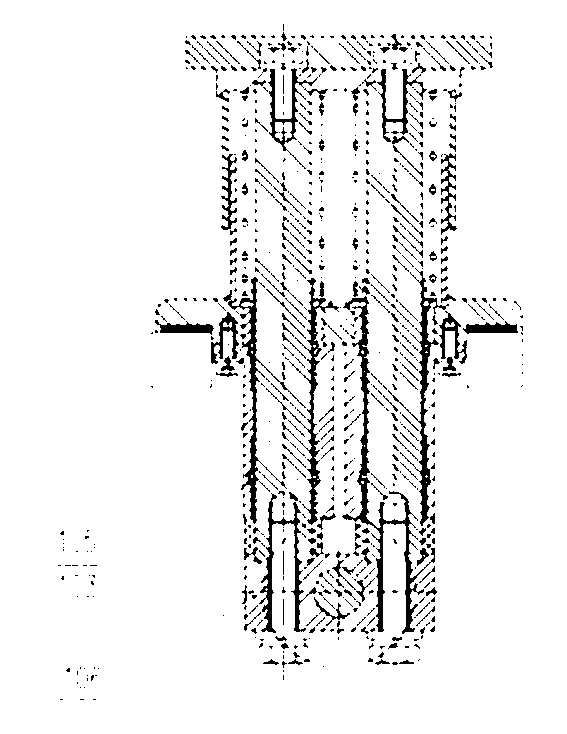

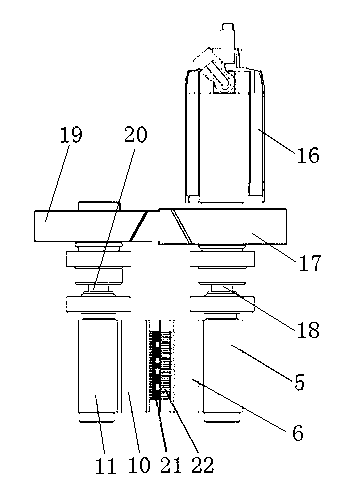

Hydraulic expansion device

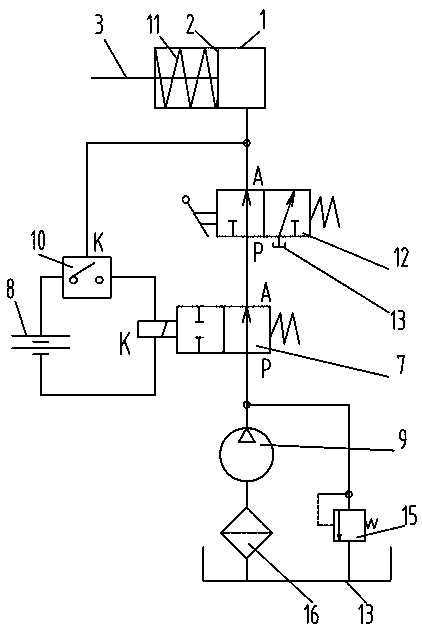

InactiveCN109396907AWill not be scrappedPrevent looseningExpansion mandrelsPositioning apparatusHydraulic pumpFuel tank

The invention discloses a hydraulic expansion device. The hydraulic expansion device comprises a cylinder body, a piston, a piston rod, an expansion block installing seat, expansion block mechanisms,a mandrel, an electromagnetic valve, a power supply, a hydraulic pump, a pressure relay, springs, a manual reversing valve and an oil box; the piston is slidably connected to the inner cavity of the cylinder body; the piston rod is fixedly connected with the piston, and cone parts are axially arranged on the piston rod; sliding grooves are formed in the expansion block installing seat; expansion blocks are fixedly connected with radial-direction sliding blocks, the radial-direction sliding blocks are slidably connected to the sliding grooves in the expansion block installing seat, and cone faces are arranged on the radial-direction sliding blocks; the mandrel is rotatably connected with the expansion block installing seat, an oil outlet port of the hydraulic pump communicates with an oil inlet port P of the electromagnetic valve, an execution port A of the electromagnetic valve communicates with an oil inlet port P of the manual reversing valve, and an execution port A of the manual reversing valve communicates with a non-rod cavity of the cylinder body; and the power supply, the pressure relay and a terminal of the electromagnetic valve are electrically connected in sequence and form a circuit. The hydraulic expansion device cannot make parts be scrapped because of big expansion force, and cannot make the parts be loosened because of small expansion force when the parts are machined.

Owner:刘剑

Nail catcher leading-out cover plate of bead nailing machine

InactiveCN104153223AQuick installationFast fixationTextile decorationPulp and paper industryFixed time

The invention discloses a nail catcher leading-out cover plate of a bead nailing machine. The nail catcher leading-out cover plate of the bead nailing machine comprises a main cover plate body, wherein the main cover plate body covers a conveying groove block; a nail catcher guide rail is arranged on a covering surface of the main cover plate body; when being covered, the nail catcher guide rail is arranged in the middle of a main groove of the conveying groove block; surplus grooves are formed in two sides of the nail catcher guide rail of the main cover plate body; a nail catcher hole is formed in the main cover plate and located in the end of the nail catcher guide rail; four fixing holes are formed in the main cover plate body, and are respectively pairwise formed in two sides of the main cover plate body; the two fixing holes close to a nail catcher inlet are eccentrically formed in a rotation block respectively; the rotation block is embedded in the main cover plate body. Compared with the prior art, the nail catcher leading-out cover plate of the bead nailing machine can be quickly mounted and fixed, the mounting time and the fixing time are saved; the efficiency is improved; meanwhile, the scrapping of the nail catcher leading-out cover plate is avoided even if the machining accuracy has a slight deviation.

Owner:林尧宇

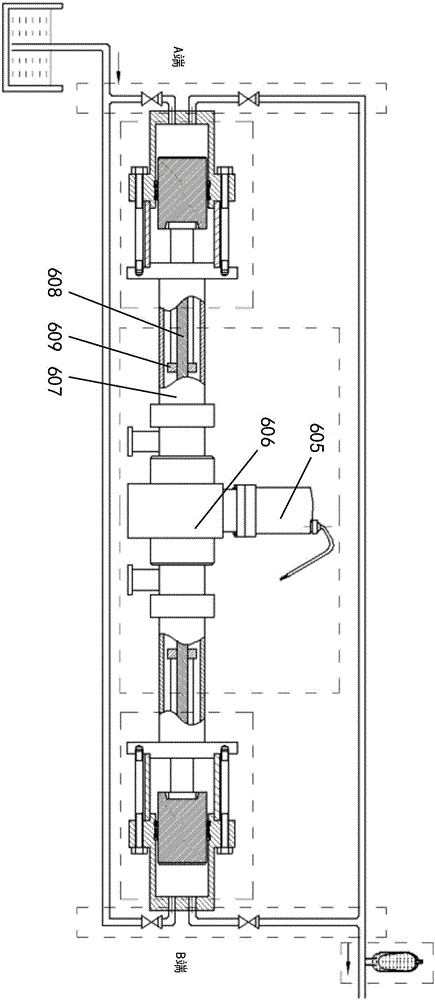

Device and system for liquid transformation and conveying

InactiveCN106468252AWill not be scrappedLow costPositive displacement pump componentsPiston pumpsCouplingReciprocating motion

The invention provides a device and system for liquid transformation and conveying. The device comprises a pressure transmitting device, a liquid inlet check valve and a liquid outlet check valve and a power driving device. The pressure transmitting device comprises a cylinder tube and a plunger located in the cylinder tube, the plunder can axially moves inside the cylinder tube along the cylinder tube, and a liquid inlet hole and a liquid outlet hole are formed in the tube; the liquid inlet check valve and the liquid outlet check valve are independent of the pressure transmitting device and are connected to the liquid inlet hole and the liquid outlet hole through pipelines; the power driving device is arranged at the other end of the cylinder tube by being isolated from the cylinder tube, the power driving device comprises a transmitting push-pull rod capable of making upward to-and-fro movement on the cylinder tube, and the transmitting push-pull rod is coupled with the plunder through a coupling so as to make the power driving device provide power for the to-and-fro movement of the plunger via the transmitting push-pull rod. The system for the liquid transformation and conveying comprises a large amount of the equipment.

Owner:舟山梅朋水处理有限公司

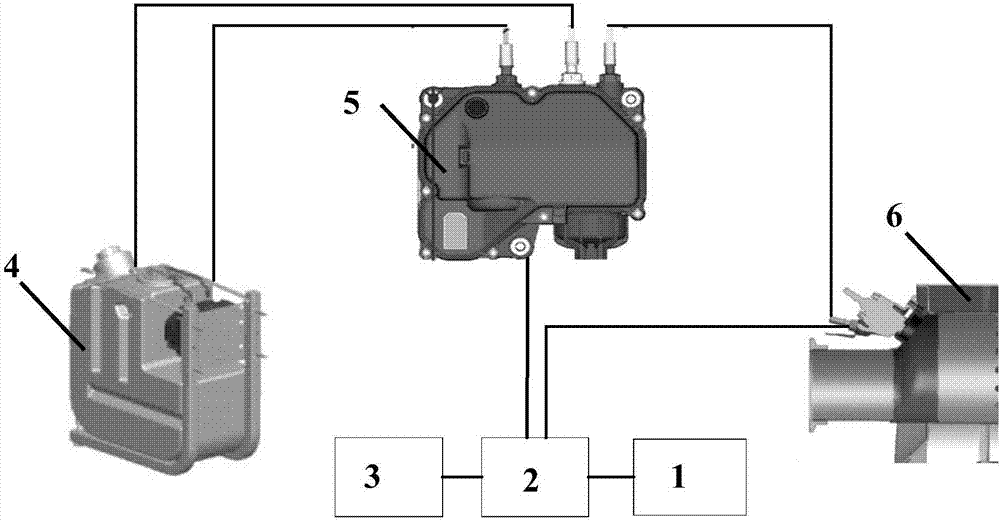

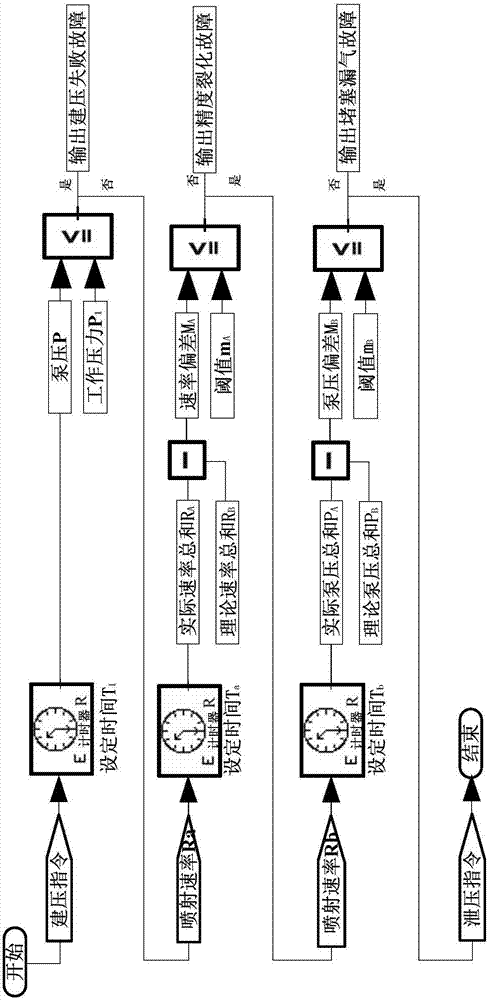

SCR injection system testing device and method

InactiveCN107060969ANo delay in normal operationsAvoid complexityInternal combustion piston enginesExhaust treatment electric controlSystem testingPump pressure

The invention provides a SCR injection system testing device and a method. The method comprises the following steps: (S1) an electronic control unit sends a pressure building instruction to an urea pump of a SCR injection system; the urea pump sucks urea from an urea box of the SCR injection system through an urea pipeline to start the pressure building; the electronic control unit obtains a pressure result through a signal of the urea pump; if a pump pressure P built by the SCR injection system in a set time T1 reaches a working pressure P1, the pressure building is successful; and otherwise, the pressure building failure is output; and (S2) after the working pressure P1 of the urea pump is stabilized, the electronic control unit sends an injection instruction of injecting the urea at an injection speed Ra by a set time Ta to the urea pump; an actual speed sum Ra detected in the set time Ta and a theoretic injection speed sum RA are calculated; the theoretic injection speed sum RA is equal to a product between the injection speed Ra and the set time Ta; if a deviation MA between the theoretic injection speed sum RA and the actual speed sum Ra is not more than a thread mA, the success is achieved; and otherwise, the precision cracking failure of the SCR injection system is output.

Owner:WEICHAI POWER CO LTD +1

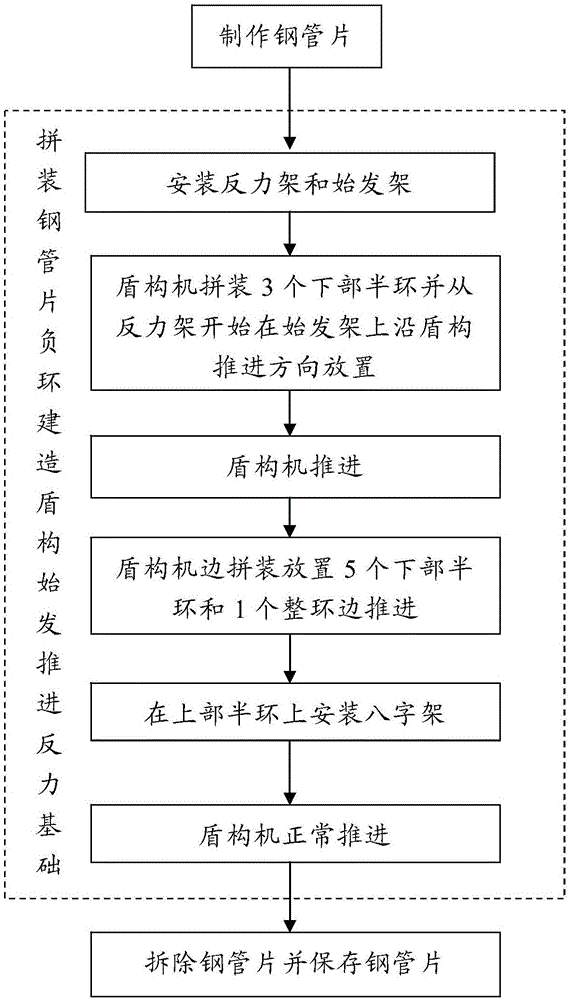

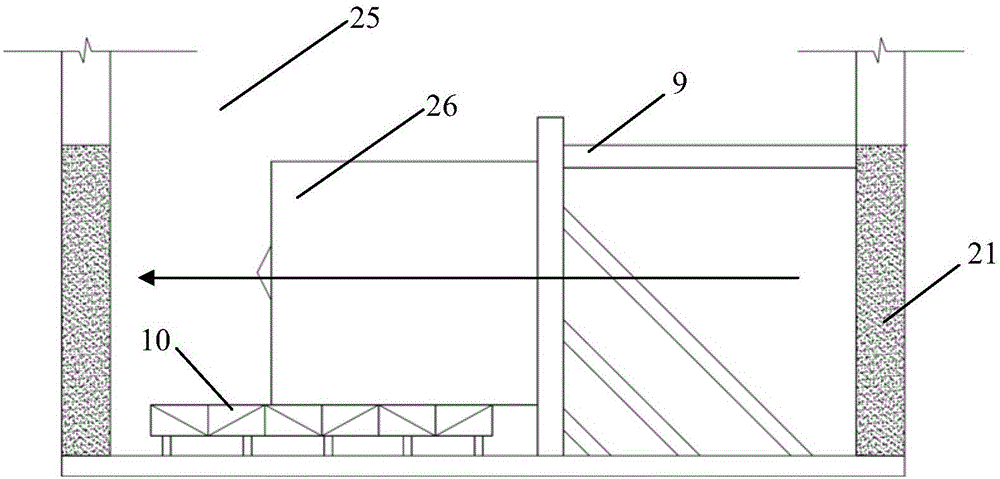

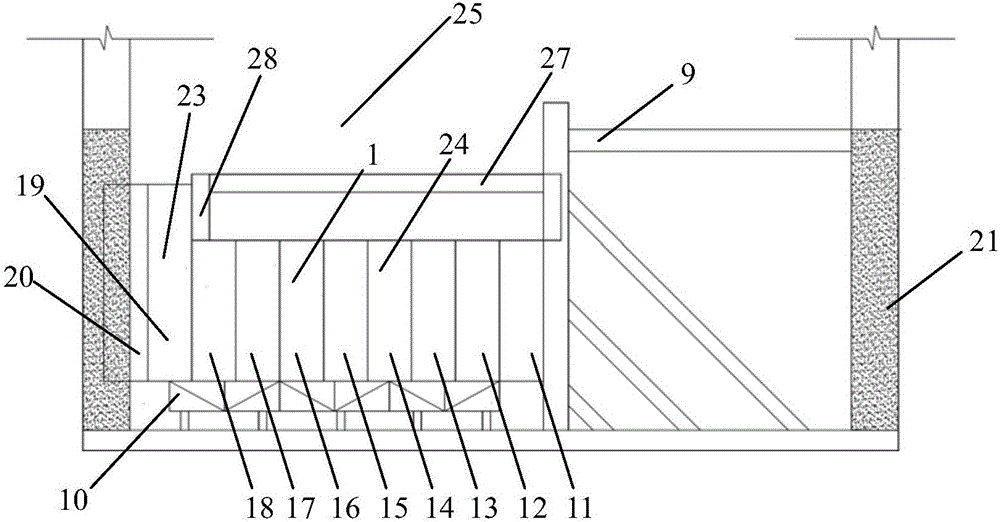

Minus-circled flake construction method for shield tunnel construction

ActiveCN106677808AWill not be scrappedHigh reuse rateUnderground chambersTunnel liningLine segmentMaterials science

The invention provides a minus-circled flake construction method for shield tunnel construction. Minus-circled flakes which are used are steel segment minus-circled flakes. Preferably, the minus-circled flake construction method for shield tunnel construction particularly comprises the following steps that (1), steel segments are manufactured; (2), the steel segments are used for splicing the steel segment minus-circled flakes and the steel segment minus-circled flakes are used for building a shield launching thrust counter-force foundation; and (3), the steel segments are dismounted from the shield launching thrust counter-force foundation and then are stored. The steel segments comprise the bottom steel segment, the lower left steel segment, the upper left steel segment, the top steel segment, the upper right steel segment and the lower right steel segment. Except for the final steel segment minus-circled flake, only lower half rings of other steel segment minus-circled flakes are spliced. The minus-circled flake segments used in the minus-circled flake construction method for shield tunnel construction are not scrapped after being used, the repeating utilization rate is high, resources are saved, environmental pollution is avoided, design is ingenious, operation is easy and convenient, cost is low, and the method is suitable for large-scale application and popularization.

Owner:SHANGHAI TUNNEL ENG CO LTD

Magnetic type intelligent building block, system, control method and using method

PendingCN106890458AHigh degree of modularitySimple stitchingToysModel driven codeElectricityGyroscope

The invention discloses a magnetic type intelligent building block, an intelligent building block system, a control method thereof and an intelligent building block using method. The magnetic type intelligent building block mainly comprises a core module, function modules and magnetic type connecting pieces. The core module and the function modules are in electricity and communication connection through the magnetic type connecting pieces, and the function modules are in electricity and communication connection through the magnetic type connecting pieces. The intelligent building block system mainly comprises the core module and the function modules. The function modules include one or more of the WiFi module, the gyroscope module, the display screen module, a steering engine module, a stepping motor module and a control arm module. When in use, a user modifies a program as needed, and codes are downloaded into the core module; then, building blocks are freely spliced, and a power switch is turned on; finally, the core module operates the program and executes corresponding functions, and the user can also directly operate the building block system at a mobile terminal. The magnetic type intelligent building block has the advantages of being intelligent, high in modularization degree, easy to splice and convenient to operate.

Owner:李峰 +2

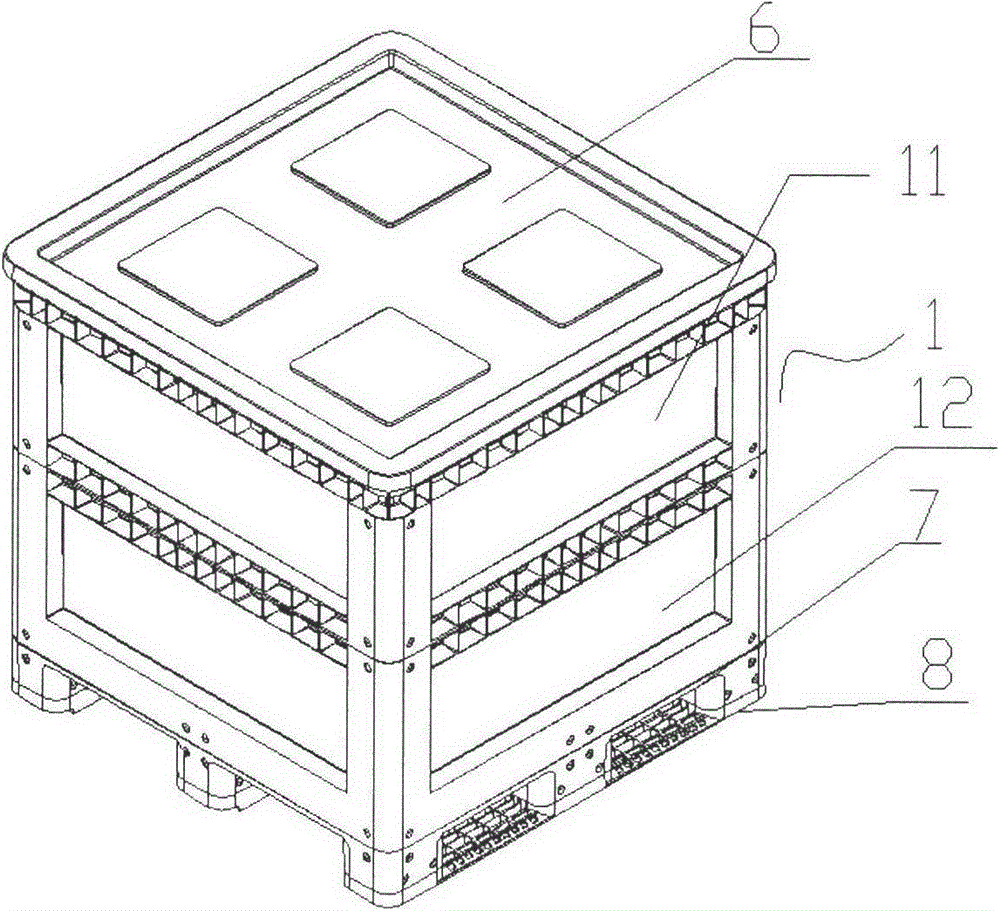

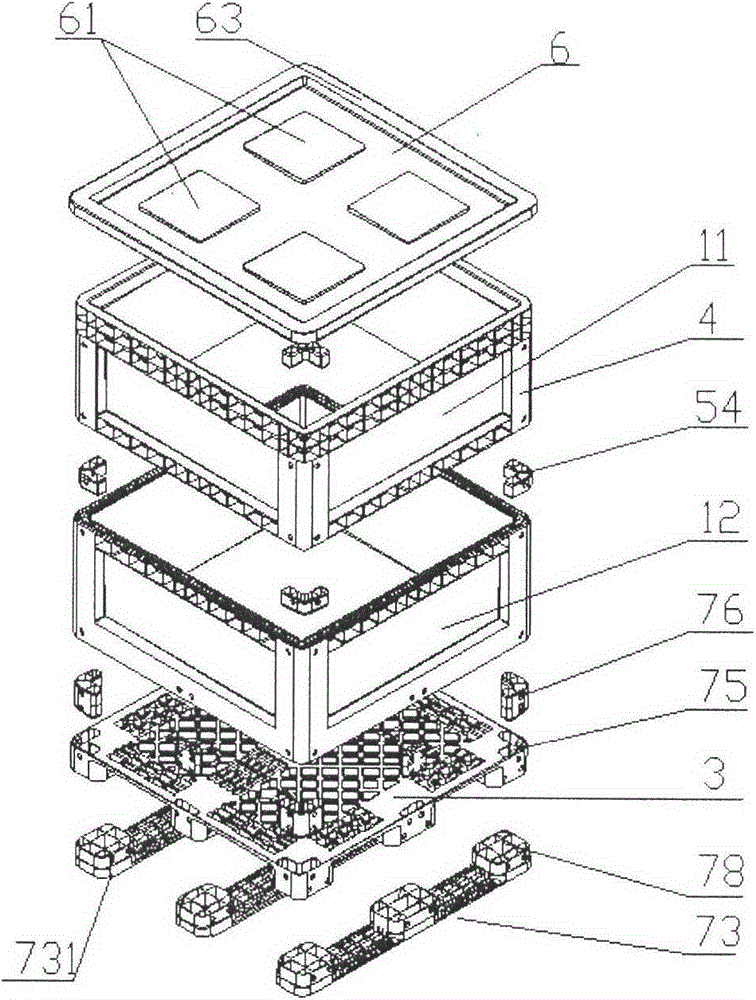

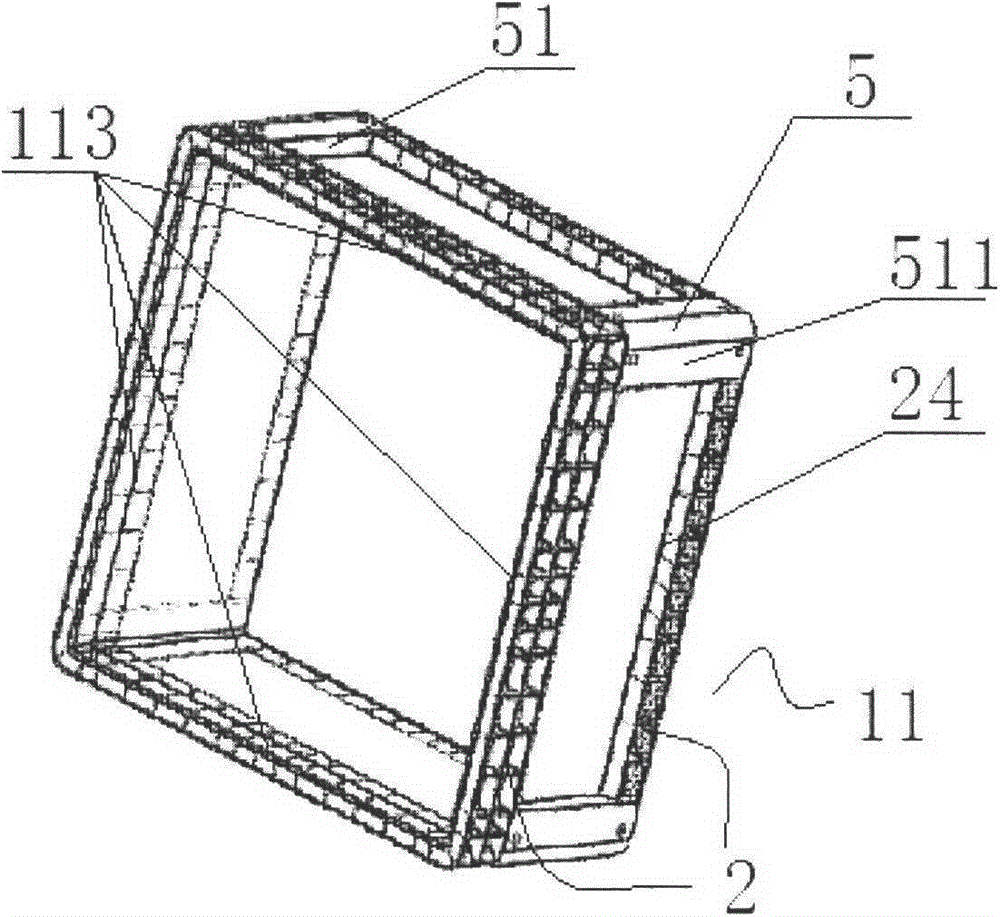

Tobacco box

The invention provides a tobacco box. The tobacco box comprises an upper box body and a lower box body, the upper box body is provided with a first opening end and a second opening end which are oppositely arranged, the lower box body is provided with a third opening end, and the second opening end and the third opening end are hermetically and fixedly connected to form the tobacco box. The upper box body and the lower box body are molding parts, the tobacco box is 700 cm by 700 cm by 700 to 1300 cm by 1300 cm by 1300 cm and is applicable to the fields of automatic production lines and storage and transport and the like; the tobacco box is manufactured by molding, industrial batch production is easy to realize, production cost can be reduced, and the tobacco box has high functional expansibility.

Owner:青岛冠宇工业设备有限公司 +1

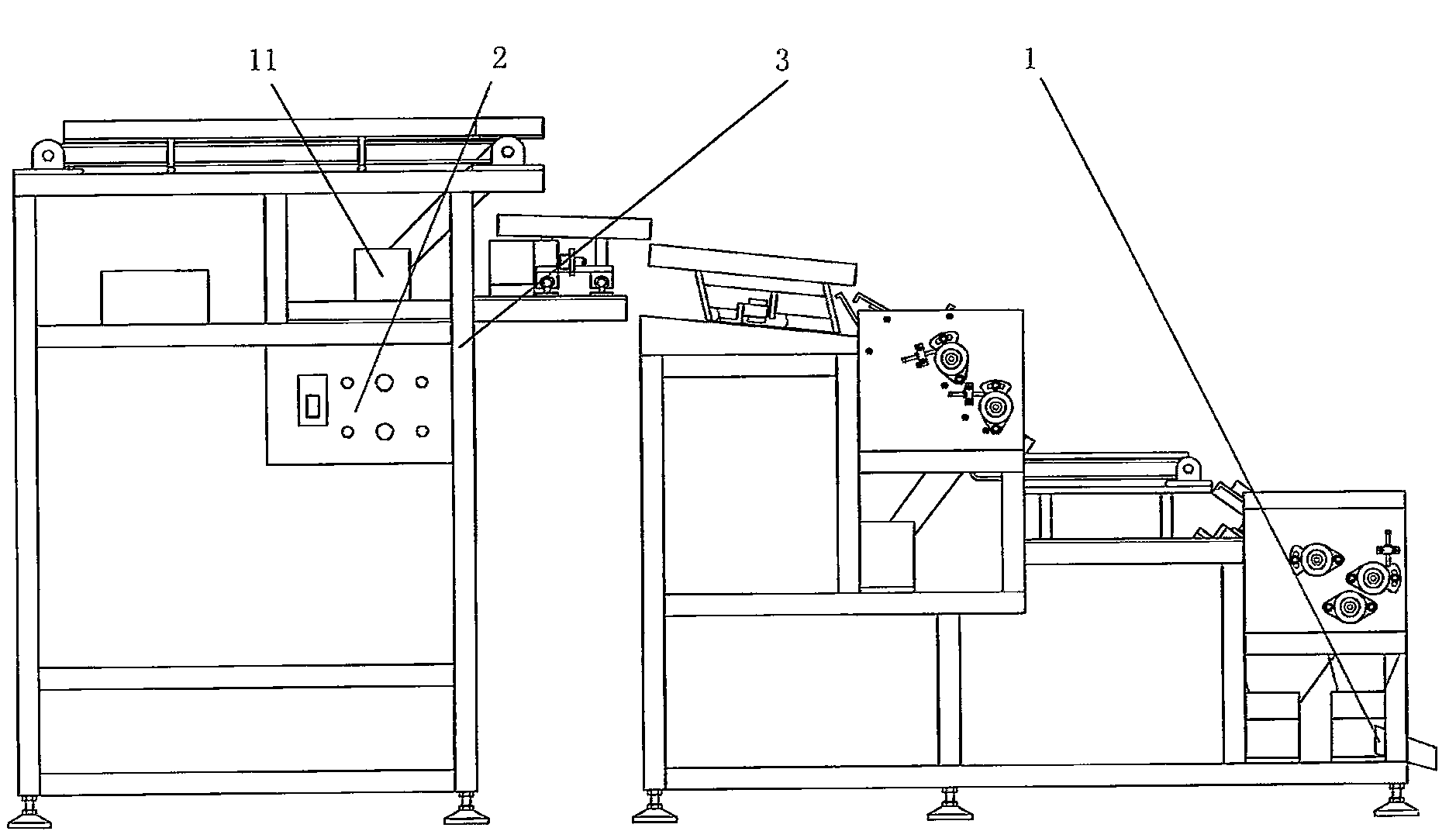

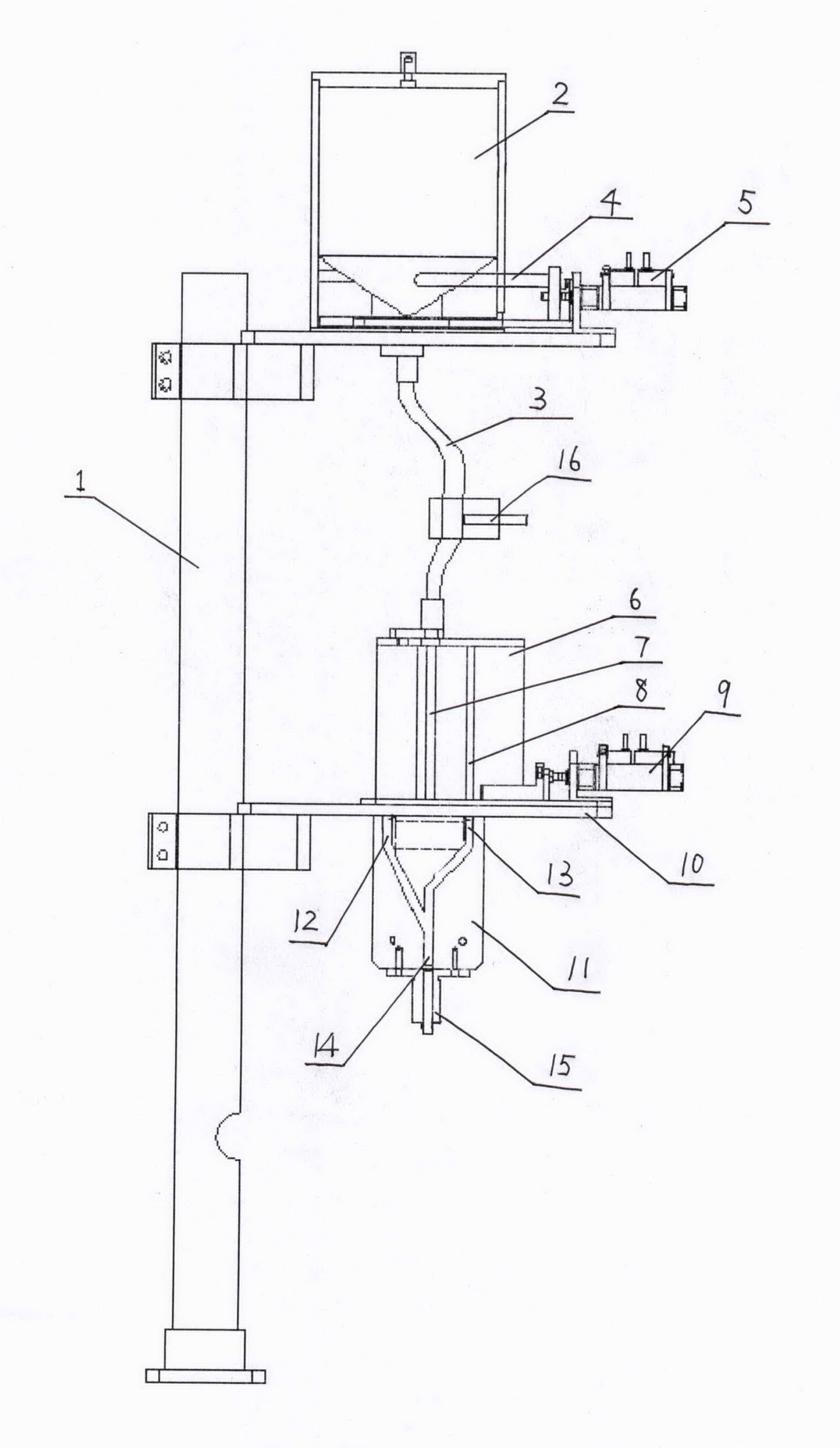

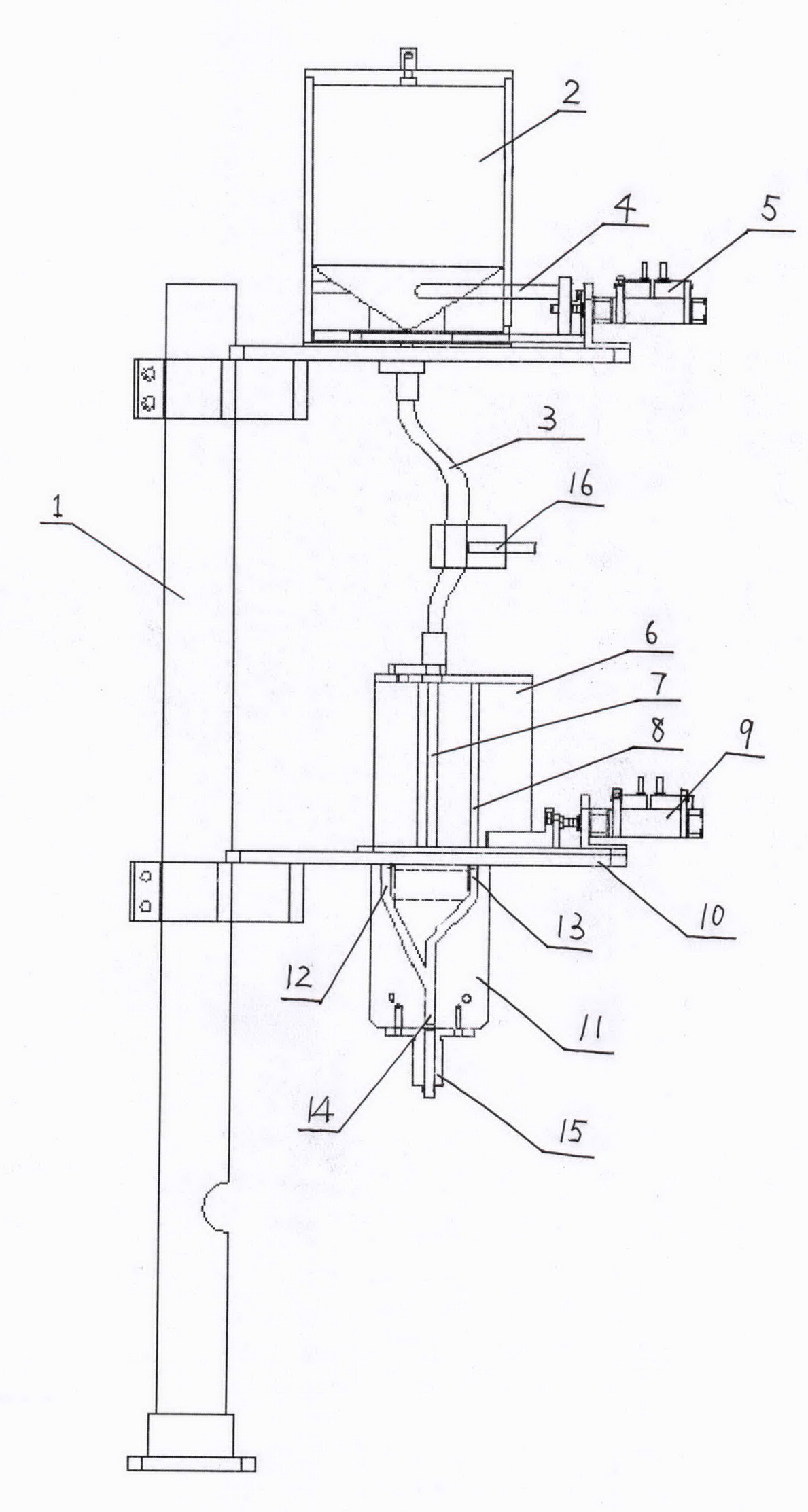

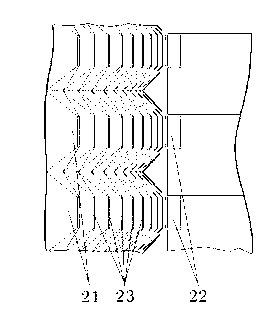

Diode lead-out line straightening machine

InactiveCN103071738AIncrease productivityAvoid blackeningSemiconductor/solid-state device manufacturingControl systemMechanical engineering

The invention discloses a diode lead-out line straightening machine, which comprises a primary straightening device, a transmission conveying device, an oscillation orientation precise straightening device, a finished product gathering hopper, a control system, a stander and a supply device enabling the diodes to be sequentially arranged at intervals. The supply device, the primary straightening device, the transmission conveying device and the oscillation orientation precise straightening device are sequentially connected with one another, the oscillation orientation precise straightening device comprises a first straightening roll, a second straightening roll, a material uniformly-distributing mechanism, a reversing device enabling the orientation of lead-out liens of the diodes to be in consistency, a second drive mechanism for driving the first straightening roll to rotate and supplying power to the material uniformly-distributing mechanism and a third drive mechanism for driving the second straightening roll to rotate, the first straightening roll and the second straightening roll make relative differential movement, and a precise straightening passage with an adjustable gap and capable of dropping the diodes processed by the material uniformly-distributing mechanism is arranged between the first straightening roll and the second straightening roll. Through twice screening, the twisting, broken pin and reject phenomenon of the diodes in the straightening process can be avoided, and the phenomenon that the diode misses the straightening also can be avoided.

Owner:张成骏

Bottle supporting device

The invention provides a bottle supporting device. The bottle supporting device comprises a bottle supporting plate, wherein a connecting block for driving the bottle supporting plate to lift is connected with one end of a guide column penetrating through a shaft cylinder; the other end of the guide column is integrally connected with a limiting plate; a lifting device is arranged on the connecting block; the lifting device moves to drive the connecting block to lift, so that the bottle supporting plate, the guide column and the limiting plate are driven to lift. As the bottle supporting device provided by the invention is small in volume and simple in structure, and does not need a flange plate, the bottle supporting device provided by the invention has the advantages of low cost, small space usage, and simplicity in mounting and maintenance; and meanwhile, as objects can be fixed without welding, the objects cannot be deformed and declared worthless due to welding, therefore, the cost is further reduced.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

Secondary explosion-proof device of storage battery

The invention discloses a secondary explosion-proof device of a storage battery, relates to a safety protection device of the storage battery, in particular to an explosion-proof exhaust device of the storage device, and mainly solves the known problems that the battery is blown up or even explodes due to temperature generated in the use or charge-discharge processes of the storage battery and the storage battery with the capacity larger than 50Ah is scrapped once the explosion-proof device arranged on the storage battery is started due to the fact that the explosion-proof device is disposable. The secondary explosion-proof device is characterized in that a valve body is fixed on a battery cover plate, a middle hole communicated with the interior of the battery is arranged on the valve body, and an explosion-proof cover is connected onto the valve body; a sealing gasket, a press plate and a spring are arranged between the explosion-proof cover and the valve body; and a through hole is formed in the explosion-proof cover in the axial direction. An explosion-proof valve is arranged on the storage cover plate, the middle hole formed in the valve body is opened to discharge air in the battery when pressure in the battery is larger than the set value and is sealed when pressure in the battery is smaller than the set value, and therefore scrapping of the battery due to explosion caused by too much pressure in the battery is avoided.

Owner:XIANGYANG ZHENGXIN AVIATION TECH

Positioning device, sticking system and sticking method

InactiveCN102130209AQuality assuranceReduce manufacturing costFinal product manufactureSemiconductor/solid-state device manufacturingFixed frameEngineering

The embodiment of the invention discloses a positioning device, a sticking system and a sticking method. The sticking system and the sticking method are used for sticking a single crystal silicon rod and a crystal support, and the sticking system comprises the positioning device and a sticking device, wherein the positioning device comprises a clamping mechanism for clamping the single crystal silicon rod, a crystal support fixing frame for fixing the crystal support and a positioning pin, one end of the positioning pin is mounted at the center of the crystal support, the other end of the positioning pin is in the shape of a cone. By adopting the positioning device, the sticking system and the sticking method, the center of the single crystal silicon rod and the center of the crystal support can be strictly aligned before sticking the single crystal silicon rod with the crystal support, thereby further ensuring that the center of the single crystal silicon rod and the center of the crystal support can be strictly aligned after completing the follow-up sticking work, being conductive to ensuring the quality of silicon blocks after square cutting, further reducing the number of the scrapped silicon blocks, and reducing the production cost.

Owner:ZHEJIANG YUHUI SOLAR ENERGY SOURCE

Structure for dropping steel balls

ActiveCN102062153AWill not be scrappedImprove efficiencyBearing componentsSteel ballMechanical engineering

The invention provides a structure for dropping steel balls, which ensures that the number of the steel balls required by the corresponding bearing can be accurately given and the bearing cannot be scraped due to a small number of the steel balls, and continuously feeds balls and has high efficiency. The structure for dropping the steel balls comprises a vertical shaft; a ball placing device is connected with the upper part of the vertical shaft; an inlet of a ball falling pipe is connected with an inlet of the ball placing device; and the structure is characterized in that: a slide block is arranged below the ball falling pipe; an outlet of the ball falling pipe corresponds to ball dropping through holes in the slide block; two vertical ball dropping through holes with the same diameter are formed in the slide block; a linear cylinder is connected with one side of the slide block; a connection line of the ball dropping through holes is parallel to an advance straight line of the linear cylinder; the slide block is supported on a middle beam; the linear cylinder is supported on the middle beam; a ball falling block is fastened below the middle beam; two inlets are formed on the upper part of the ball falling block and an outlet is formed on the lower part of the ball falling block; the inlets are communicated with the outlet respectively; a guide sleeve is arranged below the outlet; and a sensor is arranged in the middle of the ball falling pipe.

Owner:WUXI SHUANGYI PRECISION MACHINERY

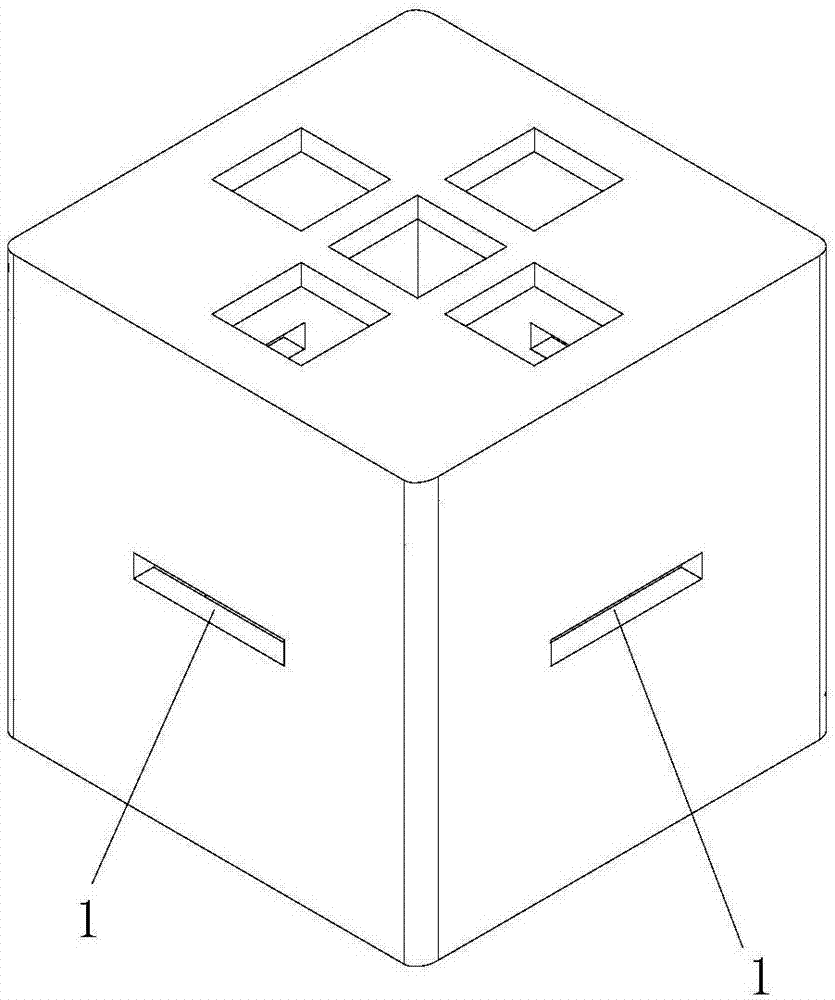

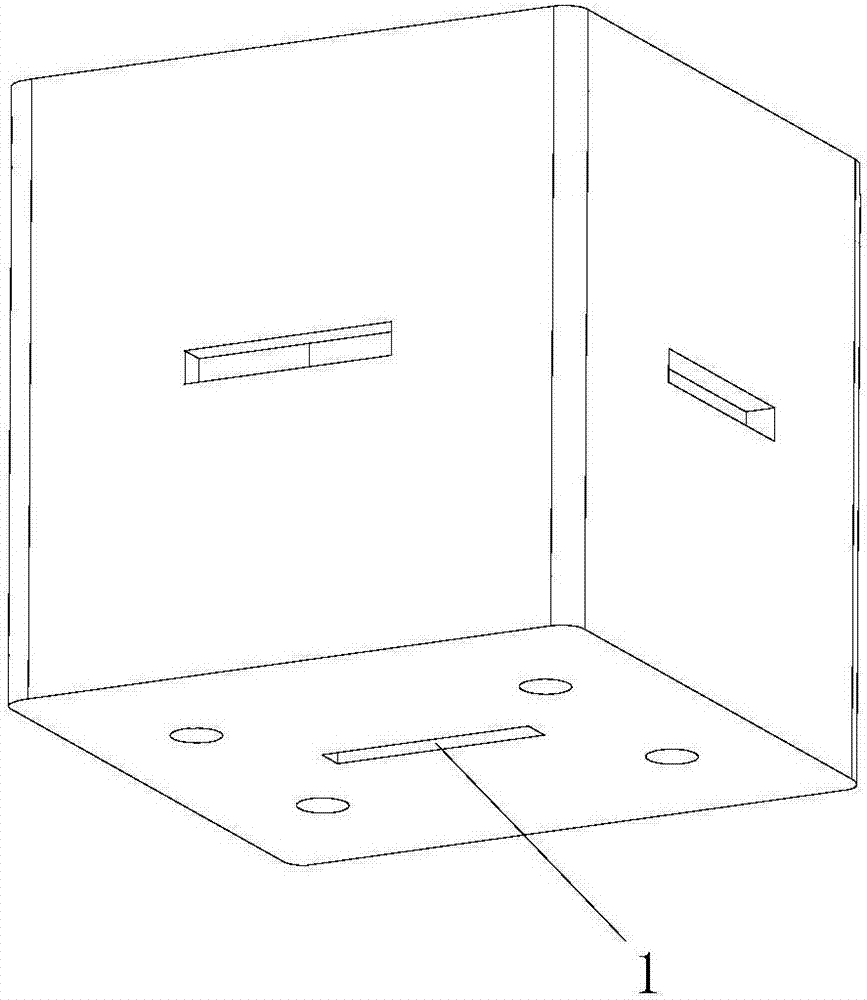

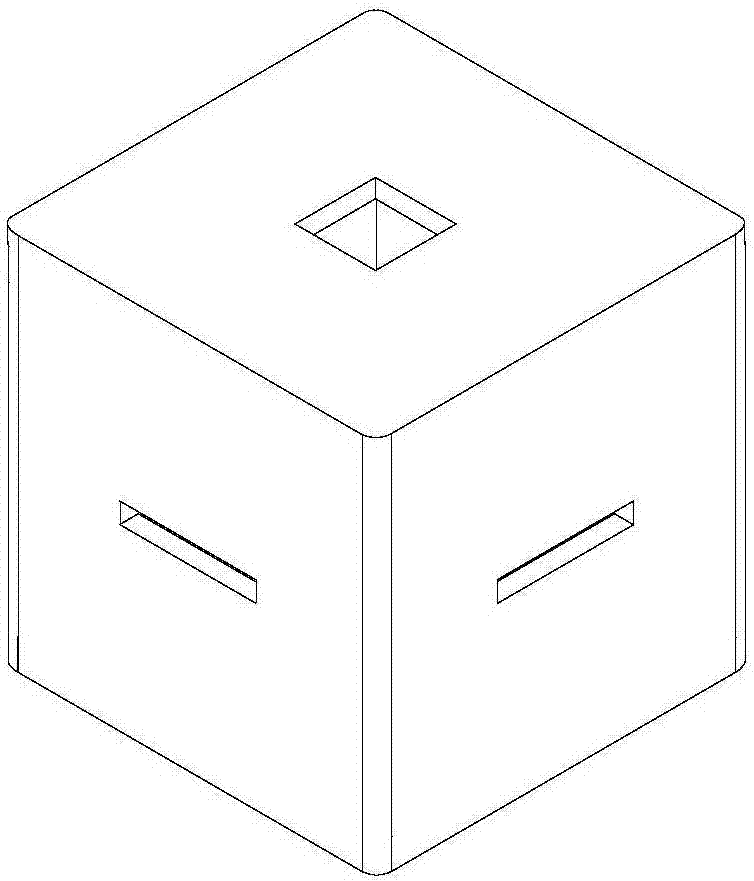

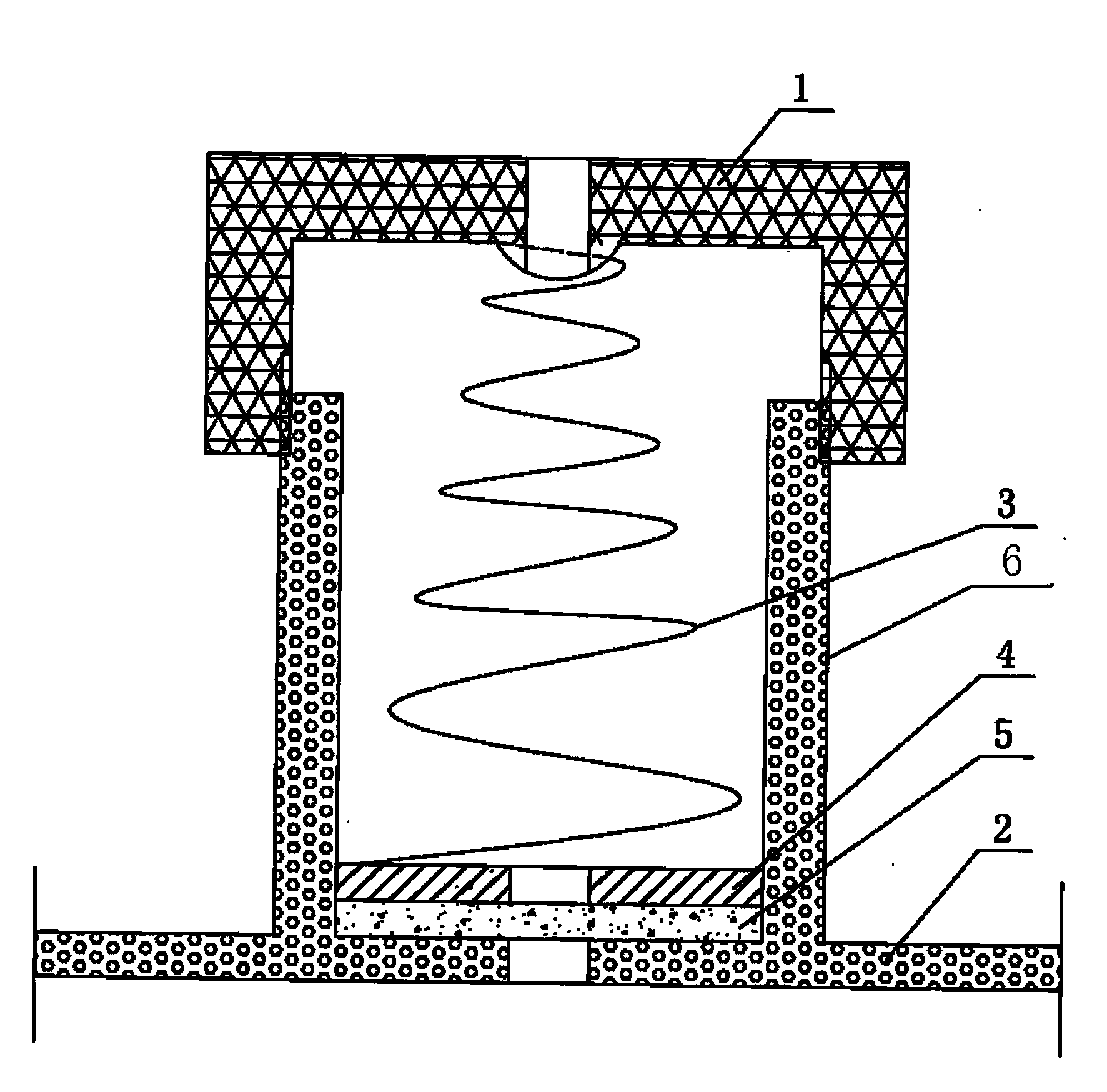

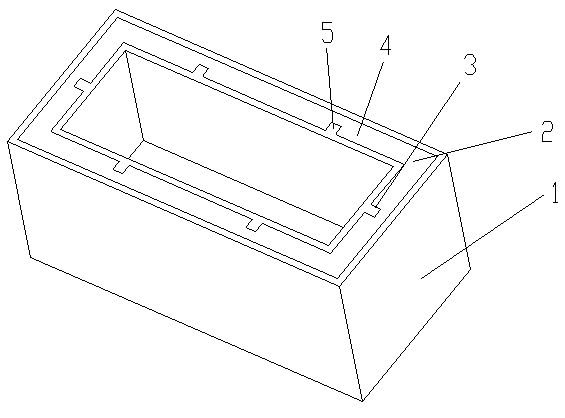

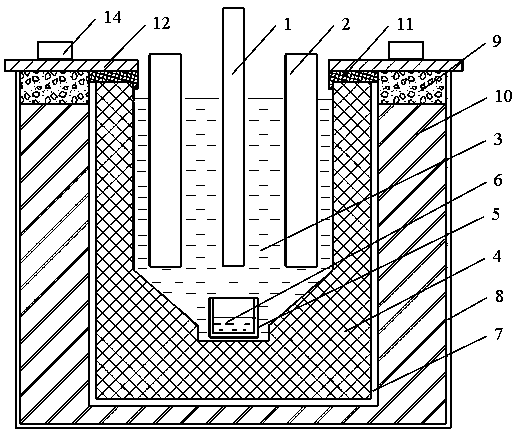

Electrolytic cell

An electrolytic cell comprises a steel frame and a metal shell disposed outside the steel frame, wherein grooves are disposed in left-right symmetry on the steel frame; inside the steel frame, a lead bladder is mounted; ridges matched with the grooves are disposed on the lead bladder; the ridges are inserted in the grooves, which facilitates the mounting of the lead bladder inside the steel frame; a groove is disposed symmetrically on the left and right side surfaces of the steel frame; and two grooves are disposed symmetrically on the upper and lower side surfaces of the steel frame. By substituting the lead bladder for the original plastic bladder, the bulging of bladder due to thermal expansion is prevented, and a better corrosion protection effect is achieved; the detachable arrangement of the lead bladder in the steel frame facilitates maintenance in case that the lead bladder is damaged, so that the electrolytic cell is prevented from being rejected due to the damage of lead bladder, and the production cost is reduced.

Owner:SUZHOU TIANHUA NONFERROUS METAL PROD

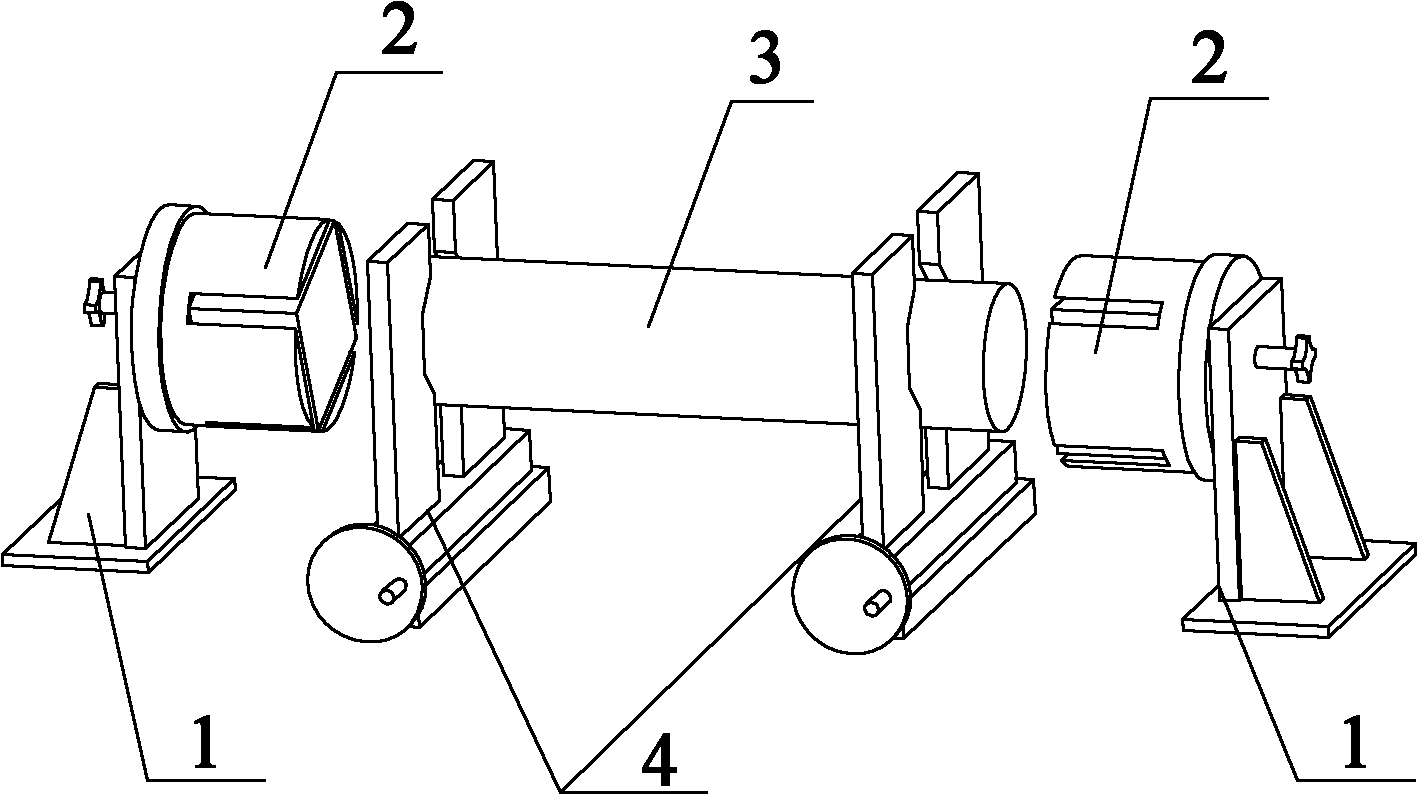

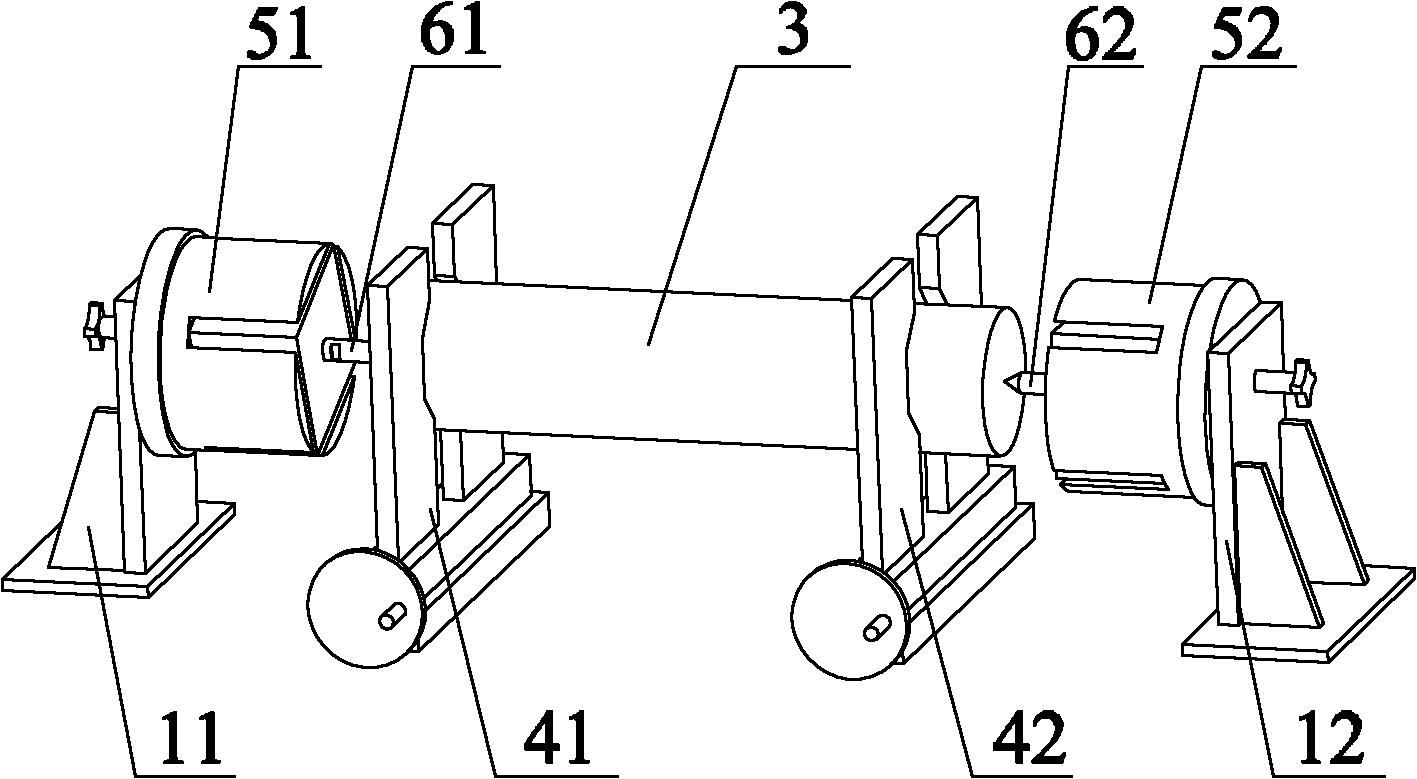

Strip direct splicing device

The invention provides a strip direct splicing device. The strip direct splicing device comprises a new strip coil supporting mechanism and an old strip coil supporting mechanism, and is characterized in that a crimping mechanism is arranged between the new and the old strip coil supporting mechanisms, the crimping mechanism comprises a roll pair which is respectively provided with a terrace die and a concave die, both a new strip and an old strip are respectively arranged between the terrace die and the concave die, each roll shaft of the roll pair is provided with a gear, the two gears are engaged with each other, and a wheel shaft of one gear is connected with a power machine. Under the situation that no splicing auxiliary material is used, the new strip can be spliced onto the old strip on line so as to continuously supply a packing strip to a main production unit and complete the alternation between the new packing strip and the old packing strip. The strip direct splicing device is simple in structure, free from polluting main materials for producing cigarettes, free from breaking and folding the strips, reliable in crimping, high in automation degree, flexible to arrange, convenient to maintain and repair, and not only applicable to the splicing of cigarette paper and filter rod paper, but also applicable to the splicing of the packing strips in any width or any length.

Owner:KUNMING DINGCHENG TECH

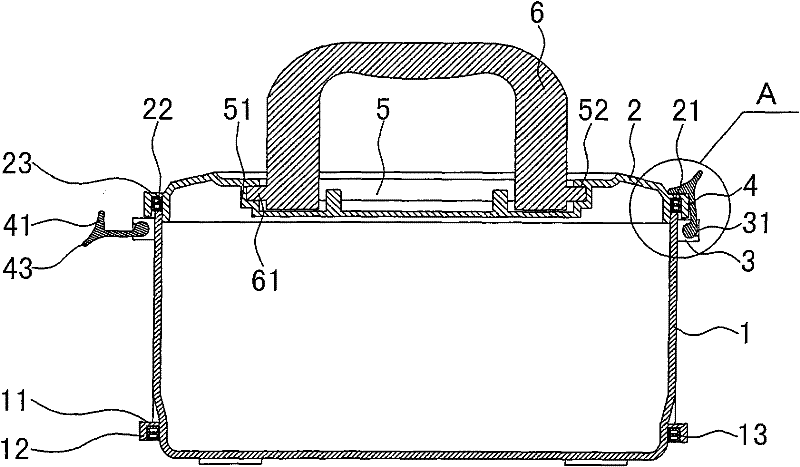

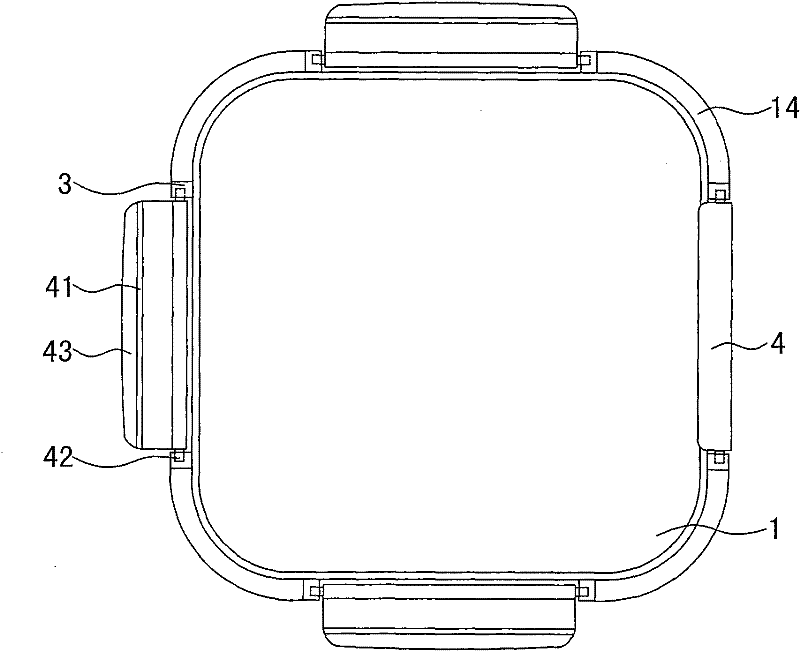

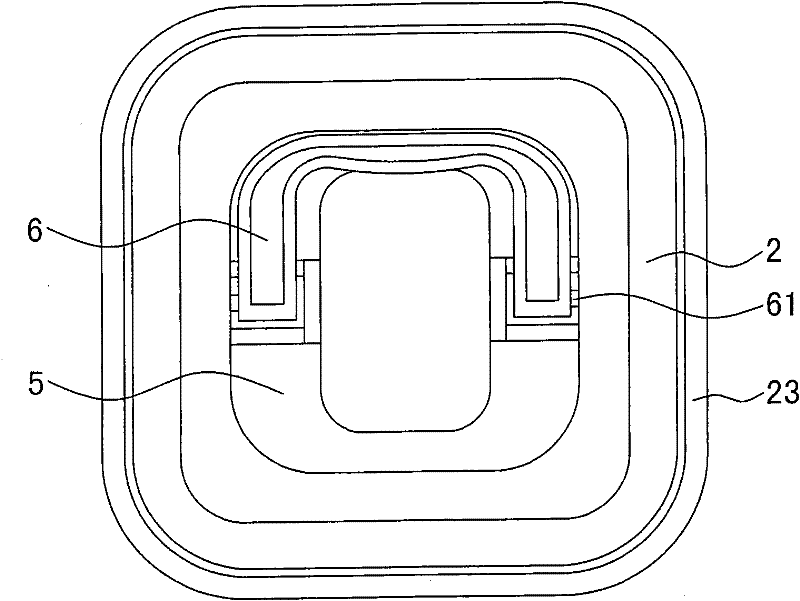

Split-type wrenching-type preservation box

InactiveCN102219082AWill not be scrappedWill not cause scrapSealingRigid containersEngineeringInjection moulding

The invention relates to a split-type wrenching-type preservation box, comprising a box body and a box cover, wherein a fixed slot is arranged below the box cover, the fixed slot is provided with a seal ring, and the seal ring is sealed with the opening of the box body. The split-type wrenching-type preservation box is characterized in that the outer wall of the box body is provided with a connection block, the connection block is provided with a connecting slot, the connecting slot is internally provided with a wrench, the two ends of the wrench are provided with blocking tenons, the blocking tenons are movably connected with the connecting slot in the connection block, the wrench is provided with a clip, the box cover is provided with a fixed side, and the clip of the wrench is clamped and matched with the fixed side. The outer side of the box body is provided with the connection block, the connection block is provided with the connecting slot, the connecting slot and the wrench are connected, the wrench is independently injected and moulded, the two ends of the wrench are provided with the blocking tenons, and the wrench is arranged in the connecting slot of the box body by virtue of the blocking tenons, thus mounting is convenient, the generality is good, the blocking tenons and the connecting slot are connected in a rotating way by virtue of spindle and can not rebound or slip off, the influence of repeated rotation is avoided, the service life is long, the wrench and the box body or box cover are in a split structure, a die is easy to make, a demoulding mechanism is simple, the rejection rate is low, and the production efficiency is high.

Owner:张胜伟

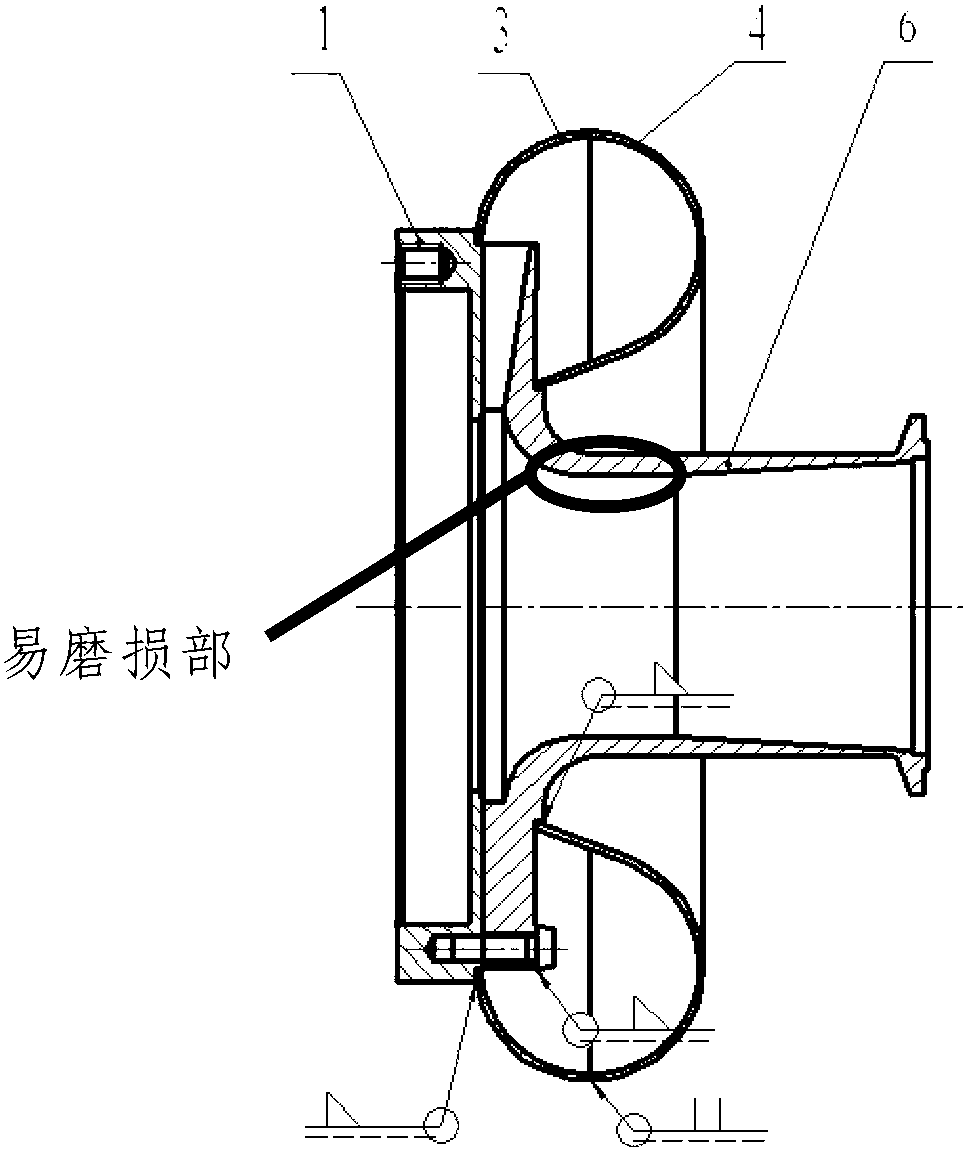

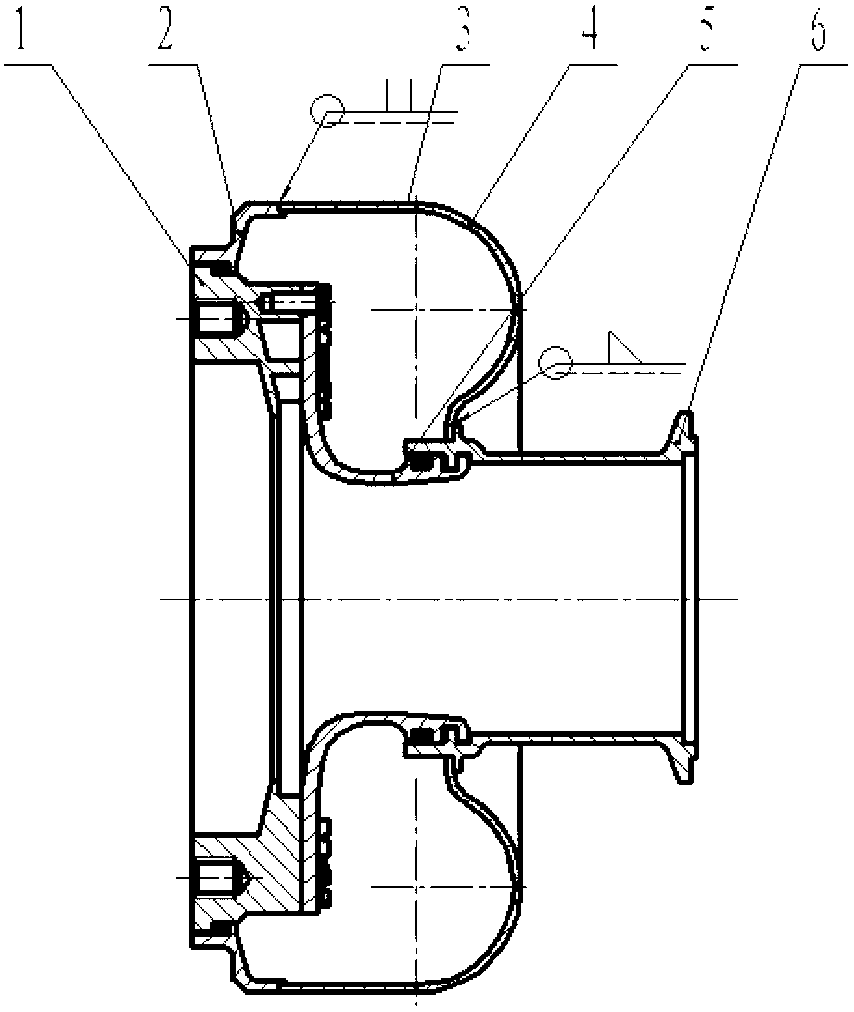

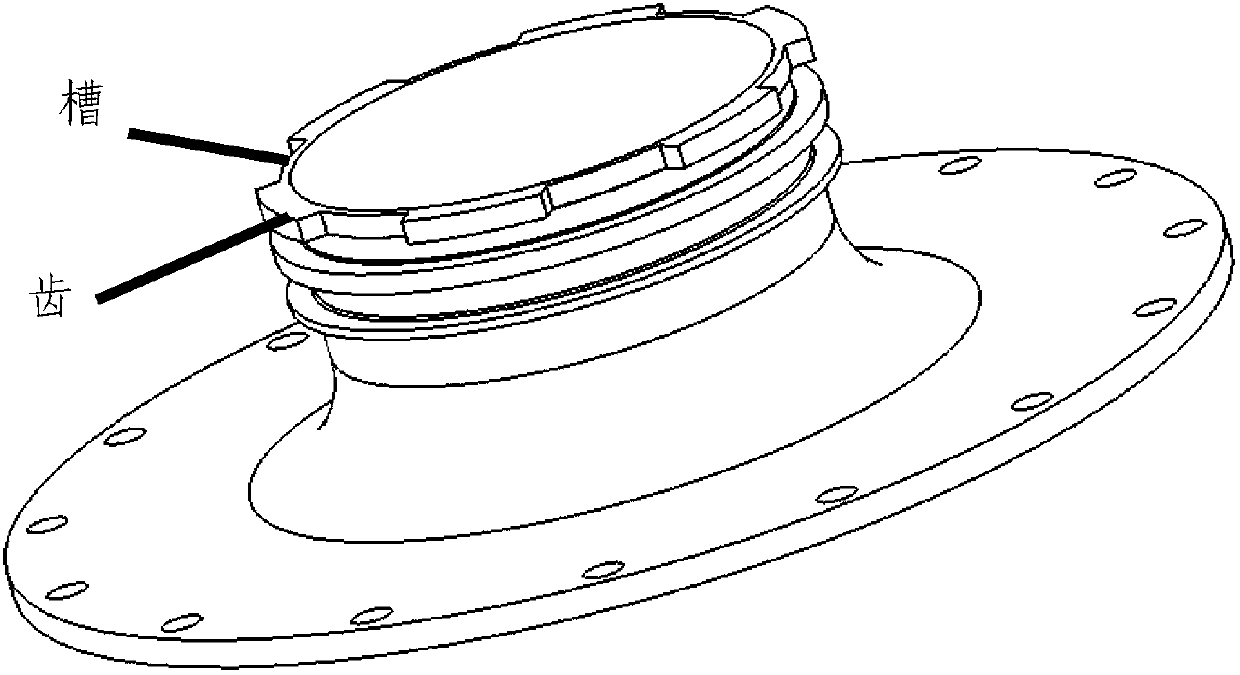

Housing structure of centrifugal compressor

InactiveCN102996520AWill not be scrappedWill not lead to scrappingPump componentsPumpsWeld seamEngineering

The invention relates to a housing structure of a centrifugal compressor. The housing of the compressor is detachable and convenient to maintain and process. The technical scheme includes that a diffuser is detached to a diffuser blade and a diffuser covering plate, wherein a tooth slot of the diffuser covering plate and a tooth slot of a compressor volute are connected, an O-shaped sealing ring is arranged at the connection position of the compressor volute and the diffuser, and the leakage is avoided. By the aid of the structure of the compressor, the welding seam number is reduced, the whole machine processing is omitted, the processing difficulty and the processing cost are reduced effectively, the diffuser covering plate is easy to wear, the diffuser covering plate can be replaced during maintenance after being designed to a part separately, the whole compressor housing cannot be wasted and the maintenance cost and the maintenance period are greatly reduced.

Owner:JINCHENG NANJING ELECTROMECHANICAL HYDRAULIC PRESSURE ENG RES CENT AVIATION IND OF CHINA

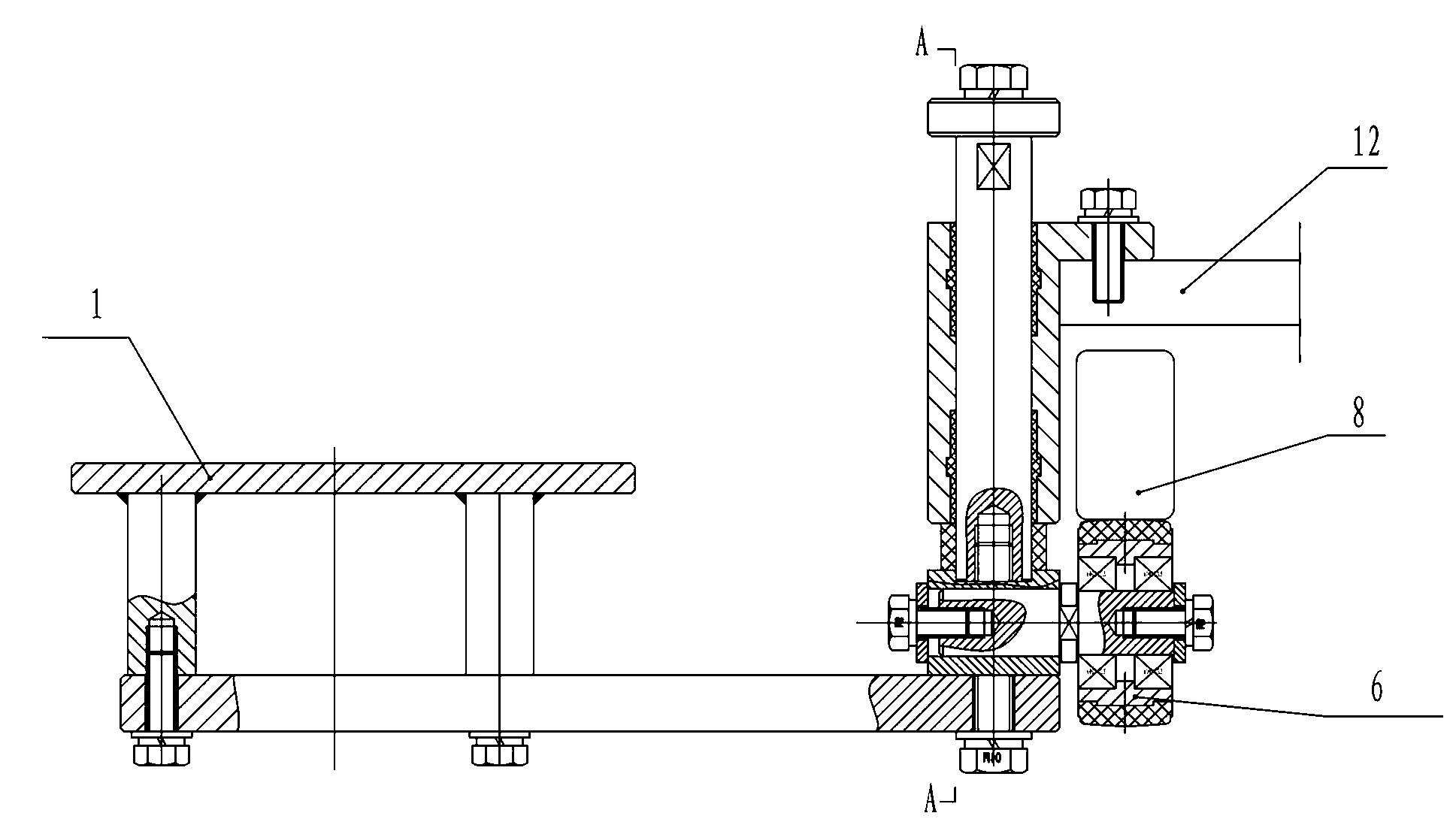

Drilling jig for drilling deep hole on medium-thickness reinforcement bar in vacuum pump

The invention provides a drilling die which drills deep holes on a stiffener of internal casting of middle wall of a vacuum pump. Two sides of a vertical plate are respectively provided with a guiding frame; the guiding frame is provided with a guiding column which is provided with a sliding block which is provided with a V-shaped positioning block; the rear part of the vertical plate is provided with a cam plate; the center of the cam plate is sleeved on the shaft of a pulling rod; two sides of the cam plate are provided with a curved slot respectively; two pins are fixed at two V-shaped positioning blocks respectively and are respectively sheathed in the curved slot; the cam plate at one side is provided with a cam plate handle and a spring is arranged between the cam plate at the other side and the vertical plate; the upper part of the vertical plate is provided with a drilling die block and the middle of which is provided with a drilling sleeve; the upper part of the drilling sleeve is provided with a drilling bit; the middle part of the vertical plate is provided with a pulling rod which is provided with a slotted washer and a nut; the drilling die has the advantages that the drilled holes can be ensured to be at the central position of the whole length of the stiffener and not to lead the middle wall of the vacuum pump to be abandoned caused by misaligned drilling or drilling through.

Owner:KEHUA HLDG

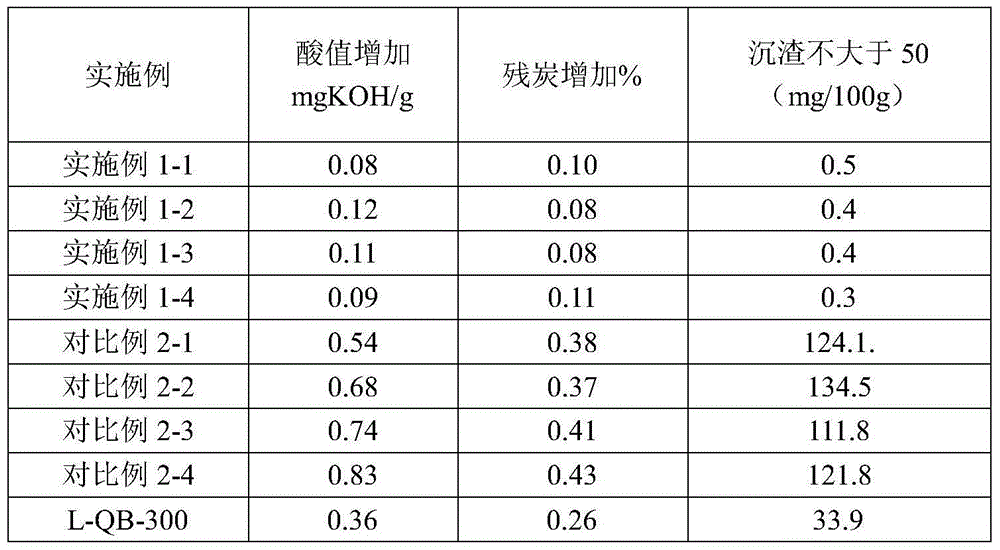

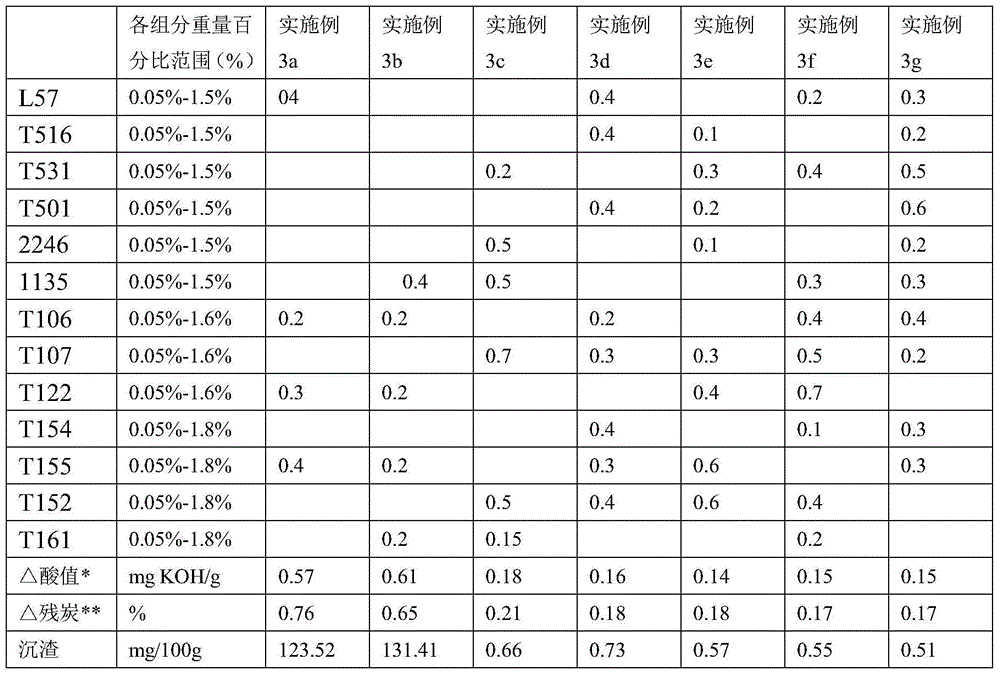

Anti-coking alkylbenzene synthesis heat conduction oil and preparation method thereof

ActiveCN104893683AExcellent detergency and dispersibilityReduce high temperature degradationHeat-exchange elementsOxidation resistantComponents of crude oil

The invention discloses anti-coking alkylbenzene synthesis heat conduction oil. The anti-coking alkylbenzene synthesis heat conduction oil mainly comprises the following ingredients: alkylbenzene base oil, amine antioxidants, phenolic antioxidants, clearing agents and dispersing agents, wherein the content of the alkylbenzene base oil is not lower than 95 in percentage by weight; the initial boiling point of the alkylbenzene base oil is greater than 320 DEG C; the density of the alkylbenzene base oil is greater than 0.83g / cm(3); the flashing point of the alkylbenzene base oil is greater than 180 DEG C; the carbon residue of the alkylbenzene base oil is smaller than 0.02%; the acid value of the alkylbenzene base oil is smaller than 0.02mg KOH / g; the pour point of the alkylbenzene base oil is smaller than minus 55 DEG C; and copper corrosion is smaller than 1 level. The anti-coking alkylbenzene synthesis heat conduction oil has the advantages of high clearing performance, high dispersing performance, low high-temperature degradation, high oxidation resistance, high coking resistance, high sedimentation resistance and long service life. The self-cleaning property is high, and the high cleanliness of the anti-coking alkylbenzene synthesis heat conduction oil can be kept for a long time.

Owner:CHENGDU MAX TOP NEW ENERGY LUBRICATING MATERIALS

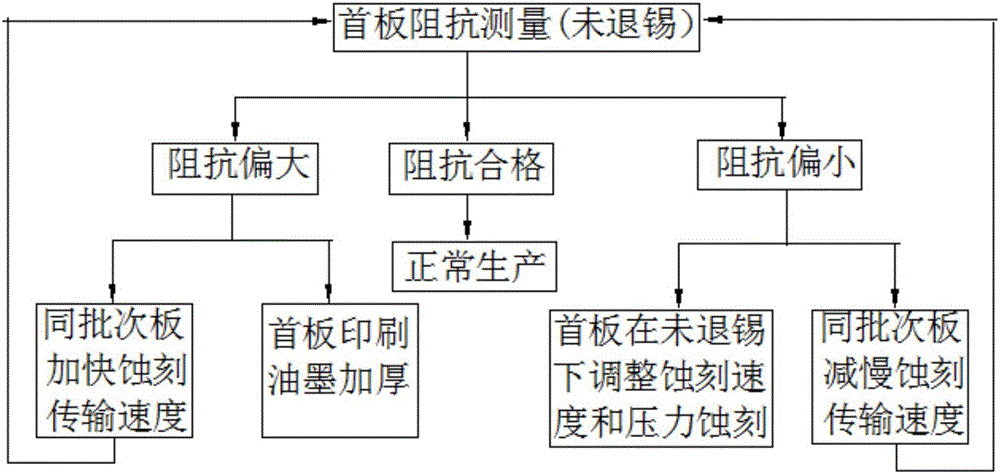

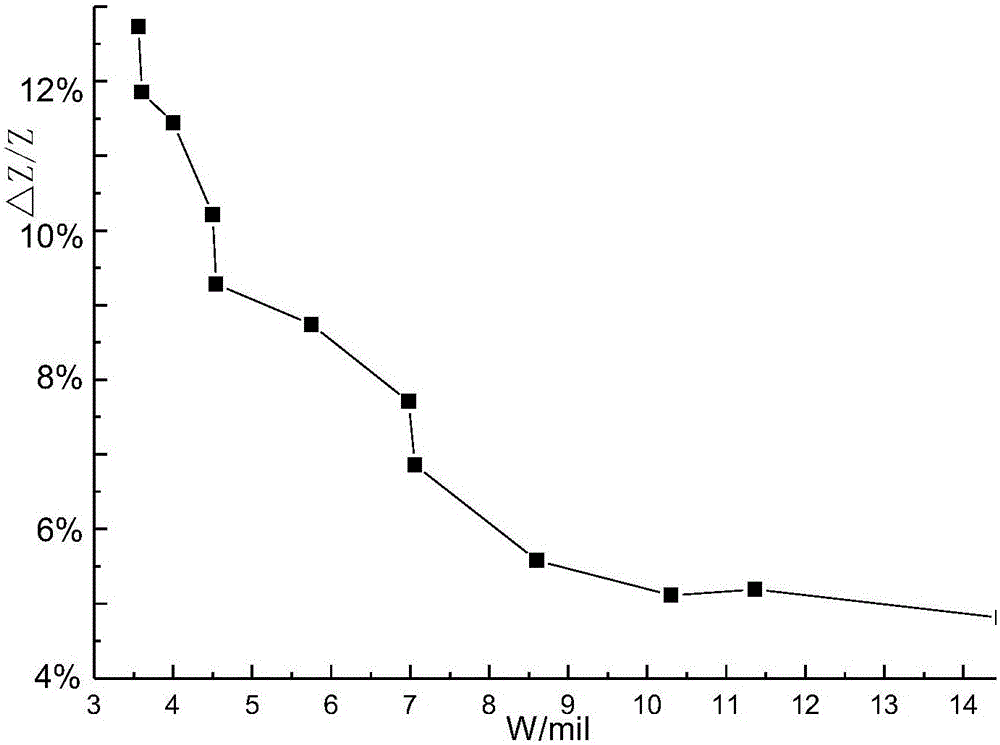

Control method for impedance of outer layer

ActiveCN105813374AWill not be scrappedWill not lead to scrappingPrinted circuit detailsConductive material chemical/electrolytical removalElectrical impedancePrinted circuit board

A control method for the impedance of an outer layer comprises the following steps of selecting a circuit board from circuit boards in the same batch, making an initial board according to a certain etching speed, and carrying out an impedance test before tin stripping after etching of the initial board; selecting another circuit board from the circuit boards in the same batch when the actually-measured impedance value of the initial board is greater than a set range, increasing the etching speed to remake a new initial board until the actually-measured impedance value of the new initial board is within the set range, and judging that the new initial board is a qualified initial board; and selecting another circuit board from the circuit boards in the same batch when the actually-measured impedance value is smaller than the set range, reducing the etching speed to remake a new initial board until the actually-measured impedance value of the new initial board is within the set range, and judging the new initial board is a qualified initial board. By the control method, the impedance of the outer layer of a printed circuit board (PCB) can be more accurately controlled, and the impedance qualified rate of the outer layer is greatly improved.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

High-yield and energy-saving electrolytic furnace for rare-earth metals

The invention discloses a high-yield and energy-saving electrolytic furnace for rare-earth metals. The high-yield and energy-saving electrolytic furnace comprises a cathode, a graphite anode, electrolyte, a graphite groove, a crucible, an inner steel sleeve, an outer steel sleeve, a filler layer, diamantane and a furnace panel. The high-yield and energy-saving electrolytic furnace has the characteristics that the furnace building cost is low, the service life is long, the heat balance is good, the content of impurities in a product is less, the yield is high, the energy is saved and the operation is convenient and the like.

Owner:GANZHOU SANYOU RARE EARTH NEW MATERIAL

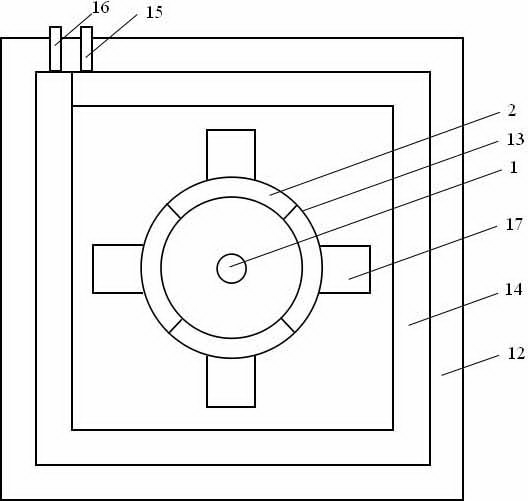

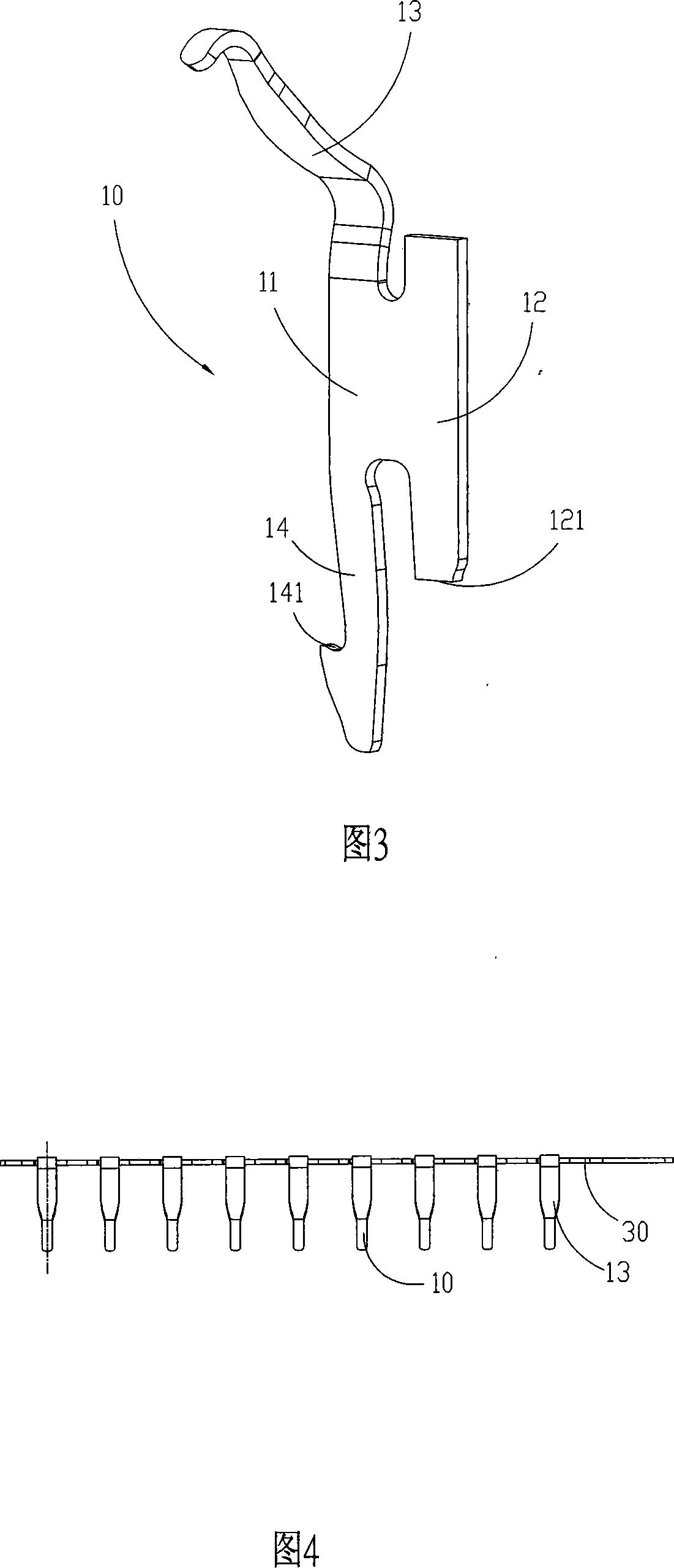

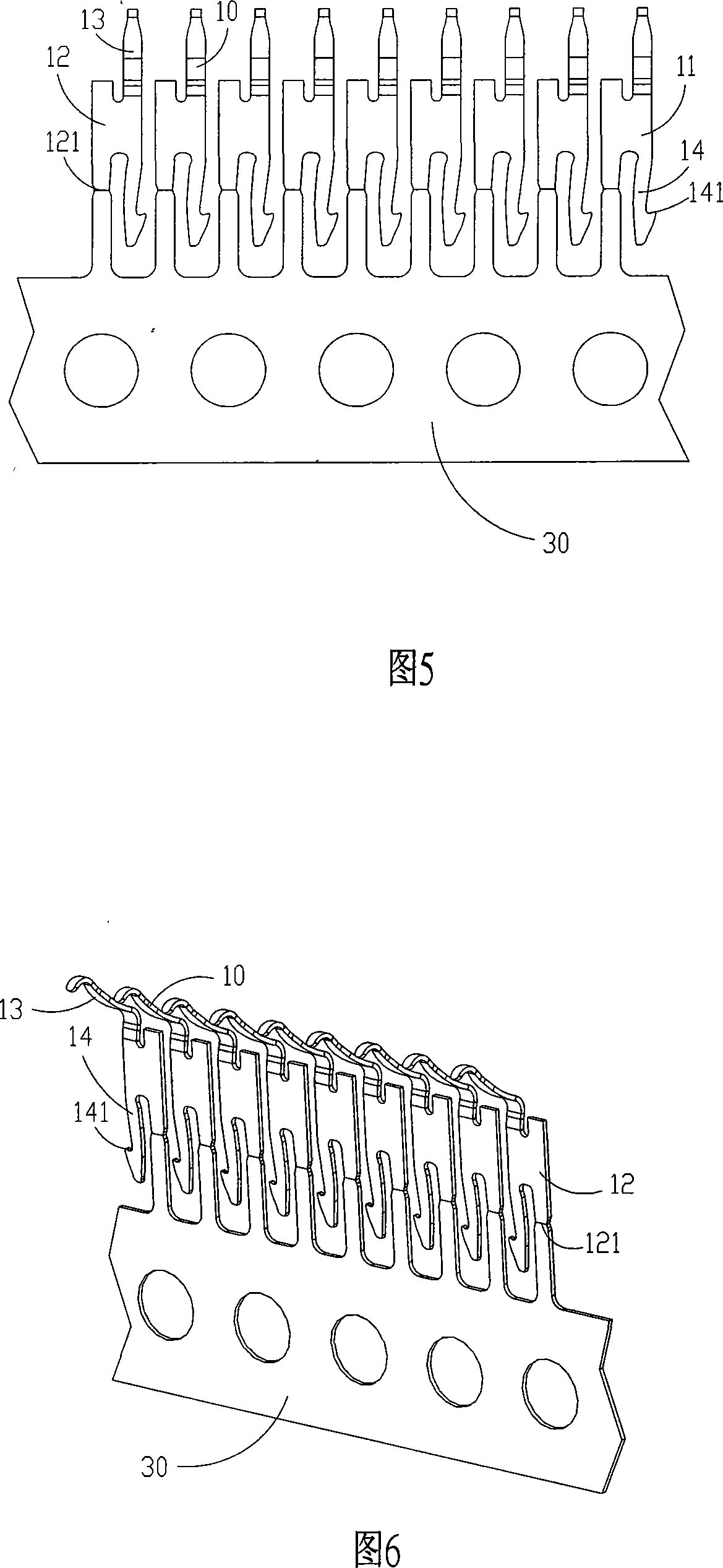

Molding method of terminal

InactiveCN101119007AAchieve the effect of densificationStable structureContact member manufacturingElectrical and Electronics engineering

The invention relates to a terminal shaping method, comprising the following steps: (1) a plurality of terminals and a terminal material belt are shape integrally; (2) a first device is provided to fix the terminal material belt; (3) providing a second device which has a plurality of clamping claws clamping on a plurality of terminals on the other end of the terminal material belt; (4) the first device and the second device fix the two opposite ends of the terminals and the terminal material belt, and the terminals are made to return or rotate at a certain angle so as to cut off the terminals and the terminal material belt; (5) the clamping claws clamp the terminals and put the terminals into an insulating body. The present invention fixes the two opposite ends of the terminals and the terminal material belt through the two devices so as to make the terminals return or rotate at a certain angle to increase the longitudinal distance between two adjacent terminals and reduce the horizontal distance so as to reach the terminal intensification effect.

Owner:DEYI PRECISION ELECTRONIC IND CO LTD PANYU

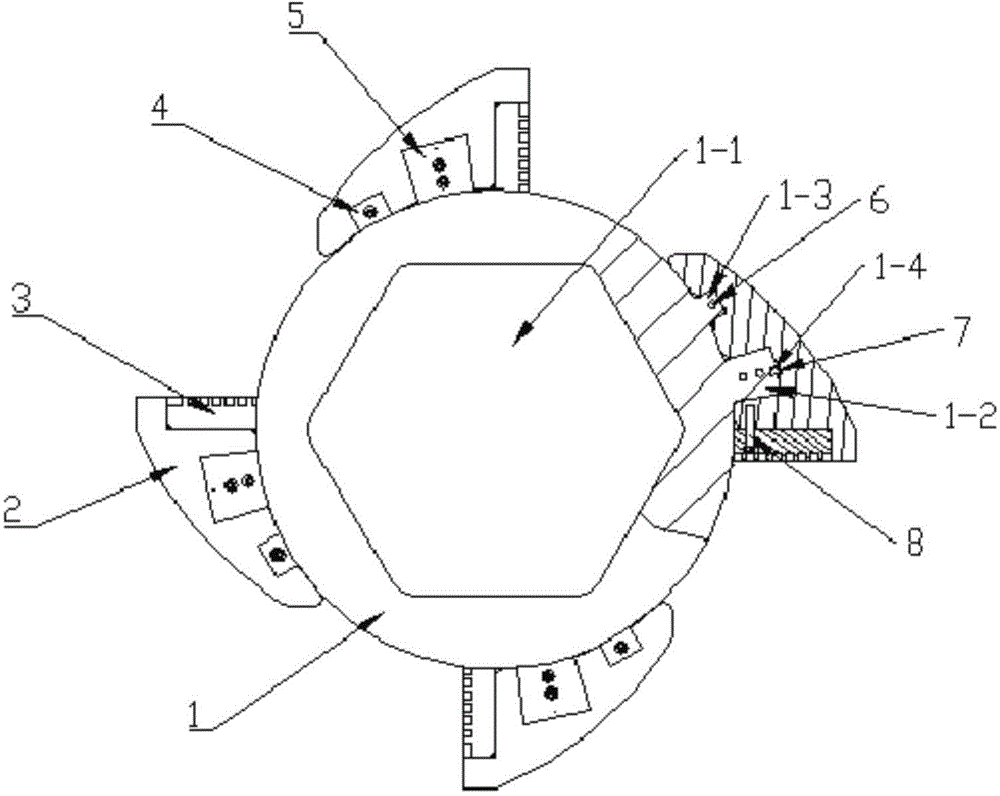

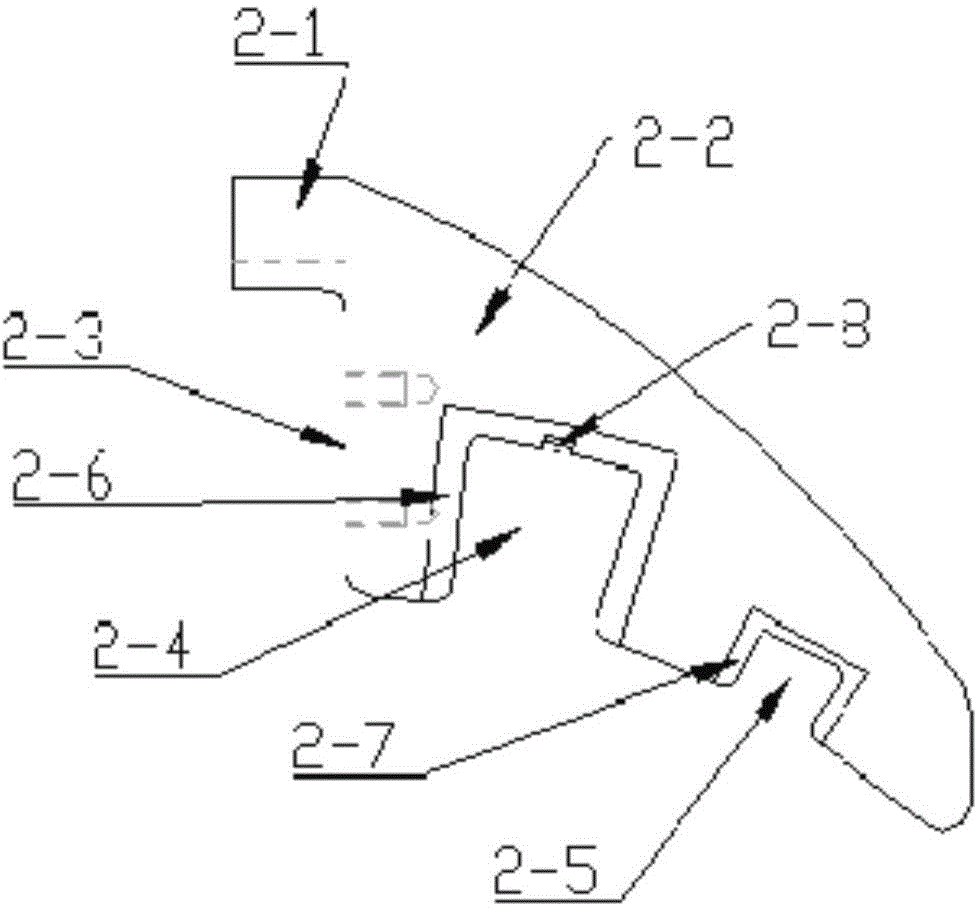

Attapulgite coarse crushing cutter

InactiveCN104785340AFulfil requirementsSmall and uniform particle sizeGrain treatmentsTool bitBearing surface

The invention discloses an attapulgite coarse crushing cutter, which comprises a cutter head and 3-6 sets of combined tool bits, wherein the cutter head is in a circular table form; a mounting hole combined with a roll shaft is formed in the center part of the cutter head; dovetail block bodies which are matched with the combined tool bits in quantity are arranged on the cylindrical surface of the cutter head; the dovetail block bodies are evenly distributed around the cylindrical surface of the cutter head; each combined tool bit comprises a primary tool bit and a secondary tool bit; each primary tool bit comprises an attapulgite crushing head and a connecting body; each secondary tool bit is a plate-shaped body; a bump which is matched with a limiting groove in the attapulgite crushing head is arranged on the top surface of each secondary tool bit; the bottom surface is an arc surface matched with the cylindrical surface of the cutter head; the front surface is a working surface; a cycloidal tooth and a cycloidal groove are formed in the working surface; each secondary tool bit is fixedly arranged on the bearing surface of the connecting body in each primary tool bit, and is located below each attapulgite crushing head; each secondary tool bit is detachably connected with each primary tool bit; various combined tool bits are respectively arranged at the positions, with the dovetail block bodies, on the cylindrical surface of the cutter head, are fixed through baffle plates and bolts, and are detachably connected with the cylindrical surface.

Owner:XIHUA UNIV

Fusion splicer for broken ends of hot melt wires

InactiveCN107584756AAvoid wastingWill not be scrappedAdditive manufacturing apparatusManufacturing material handlingEngineeringSizing

The invention discloses a fusion splicer for broken ends of hot melt wires. The fusion splicer is used for fusing, lengthening and utilizing broken wires of the hot melt wires or remnant wires, and particularly brings great convenience to three-dimensional printers taking hot melt linear materials as raw materials. Three-dimensional printing wires are fused and lengthened without limitation in advance, so that the problem that automatic pause and replacement of splicing wires are not supported in the three-dimensional printing can be effectively solved, and waste of a large amount of remnant wires is avoided; more importantly, the condition that three-dimensional printing parts are scraped caused by feeding interruption of consumable materials is prevented. According to the fusion splicerdisclosed by the invention, hot melt butting, extrusion and sizing of broken end sections of to-be-fused wires are realized by a heating rod, a heating head and a movable clamping lock; the fusion splicer has the advantages of good welding effect, high strength, simplicity and convenience in operation and high efficiency; a clamping groove base, an upper clamping groove member and a heating deviceare arranged and are simple in structure, convenient to use, low in construction cost, economical and practical; clamping groove gaskets are additionally arranged on an upper clamping groove and a lower clamping groove, so that the fusion splicer is suitable for welding and lengthening operation of wires with different model numbers and specifications and has a broader market application prospect.

Owner:于卫华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com