Tobacco box

A technology for a cut tobacco box and a box body is applied in the field of cut tobacco boxes, which can solve the problems of inability to apply automatic production, cumbersome manufacturing process, and high manufacturing cost, and achieve the effects of simple and fast factory production, reduced production cost, and easy loading and unloading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

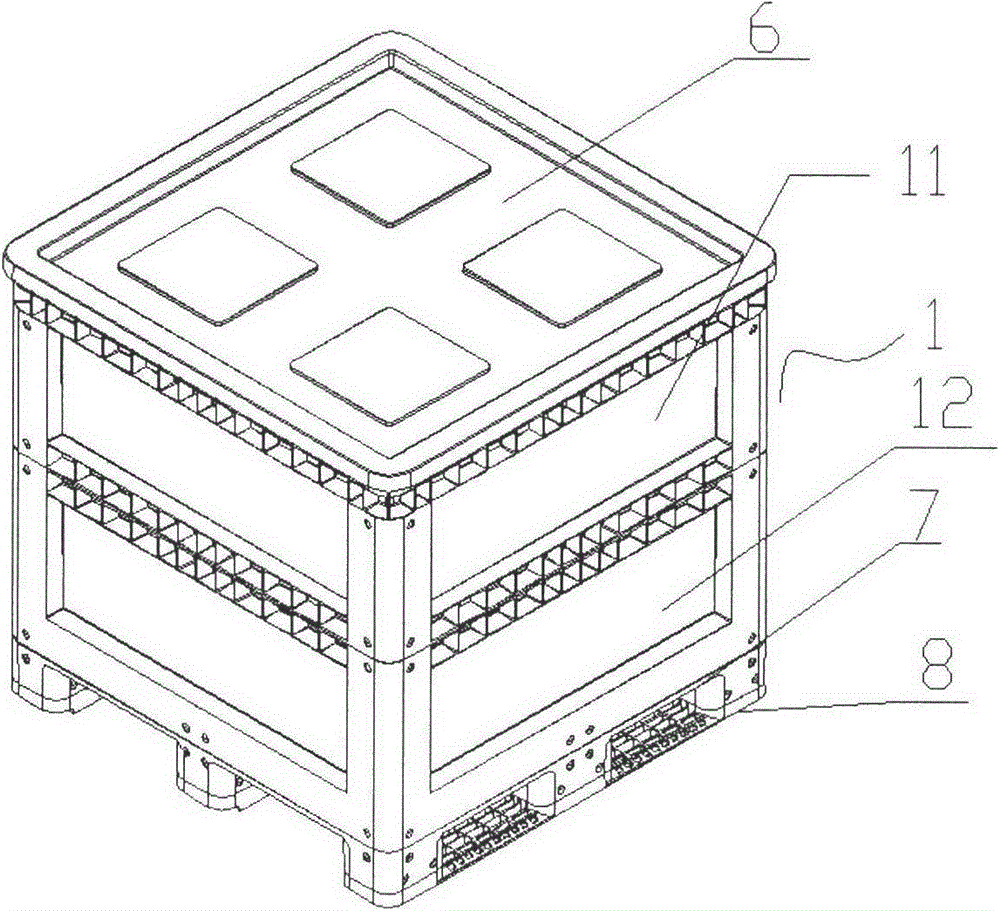

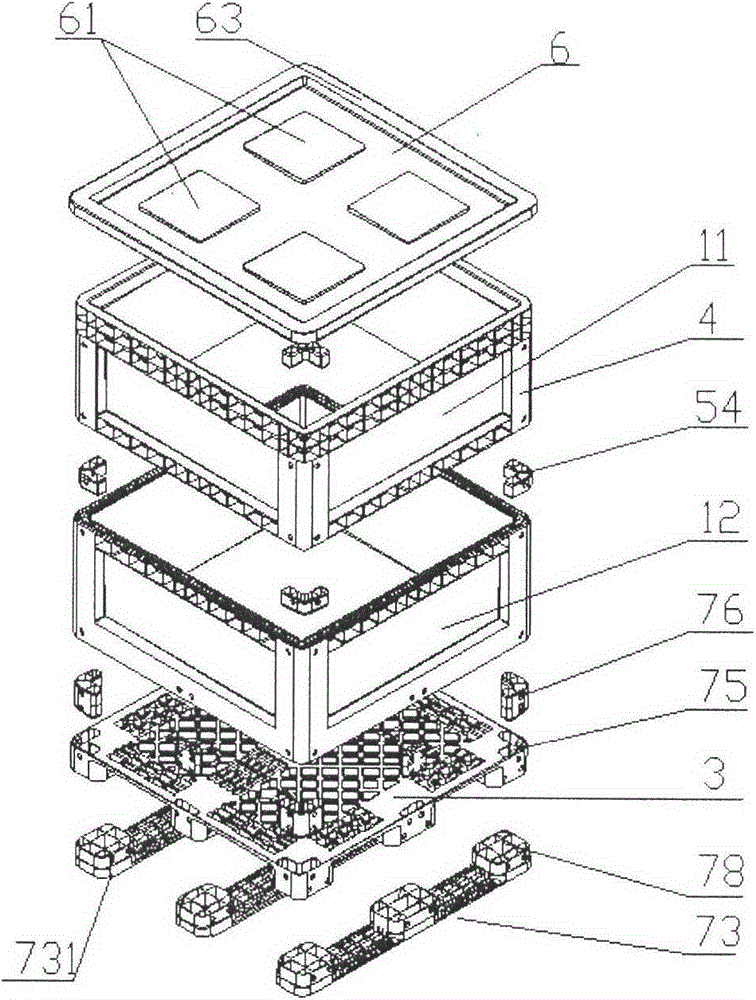

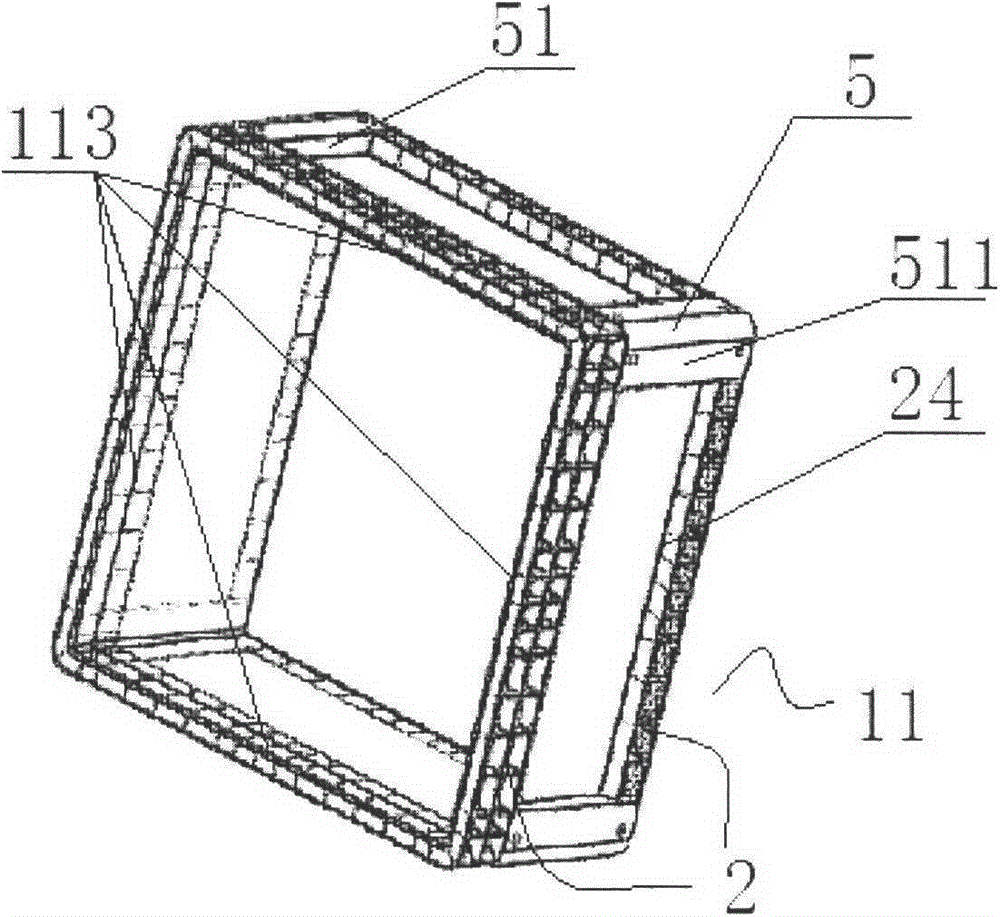

[0113] This embodiment provides a shredded tobacco box, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 7 and Figure 8 As shown, it includes an upper box 11 and a lower box 12, the upper box 11 has a first open end and a second open end oppositely arranged, the lower box 12 has a third open end, the second The open end is sealed and fixedly connected with the third open end to form the shredded tobacco box, the upper box 11 and the lower box 12 are molded parts, and the size of the shredded tobacco box is 1100cm×1100cm×1100cm.

[0114] The second open end has a second end face 112 (such as Figure 4 shown), the third open end has a third end face 121 (as Figure 8 As shown), the second end surface 112 is aligned with the third end surface 121 and then sealed and fixedly connected by welding, and a smooth connection surface is formed inside the shredded tobacco box. In specific welding connection, the second end surface 112 and the third end surface 121 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com