Device and system for liquid transformation and conveying

A kind of equipment and liquid technology, which is applied in the field of equipment and systems for liquid pressure variable transmission, can solve the problems of only complete machine replacement and increase equipment operation and maintenance costs, and achieve the effects of cost saving and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

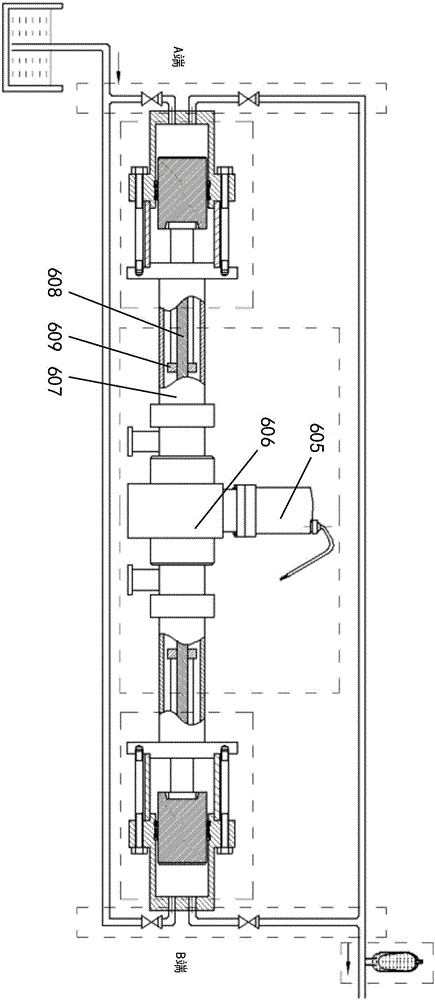

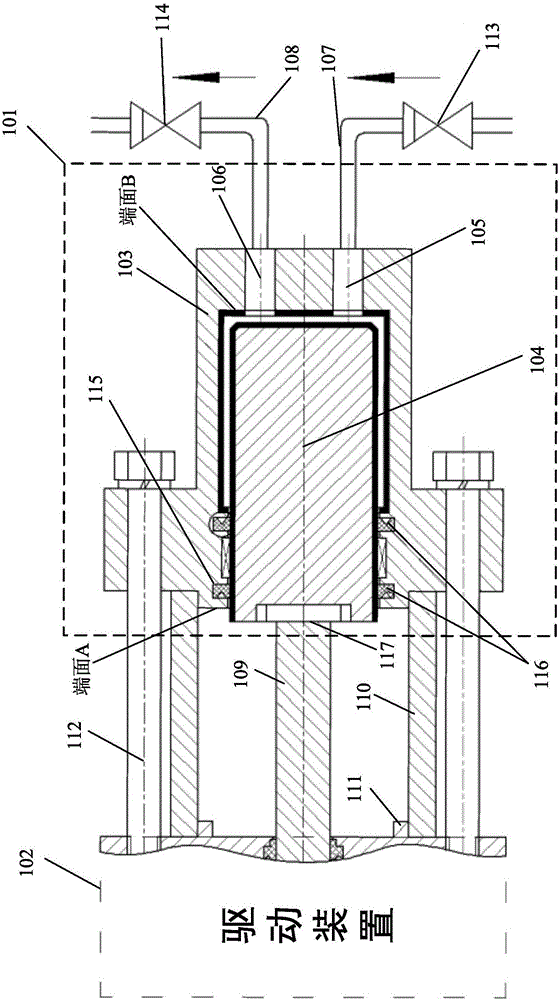

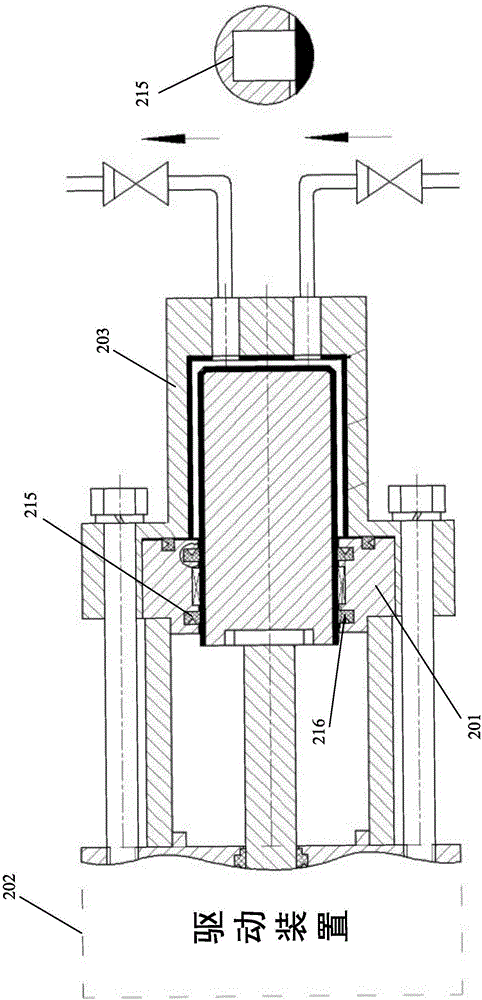

[0086] General design idea of the present invention is:

[0087] The "pump" which is highly integrated by multiple parts is disassembled and restored according to the functions of the parts, so that the structure of each part is fully simplified to improve the corrosion resistance and maintainability of the pressure transmitter.

[0088] Isolate the high-speed motion power drive device from the pressure transmitter device for corrosive liquids, reducing the corrosion resistance requirements for the overall equipment.

[0089] The devices that control the one-way flow of liquid (one-way valve, check valve, etc.) are separated from the pump body and used as independent devices to improve maintainability.

[0090] Based on: the degree of corrosion of parts with the same material in the same corrosive solution with the same composition is related to their relative motion state, that is, the degree of corrosion is different when they are placed at rest, moving at low speed, and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com