Molding method of terminal

A molding method and terminal technology, applied in the manufacture of contacts, etc., can solve problems such as increased production costs, scrapped terminals, unstable terminal dimensions, etc., and achieve the effects of saving production costs and stabilizing the terminal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

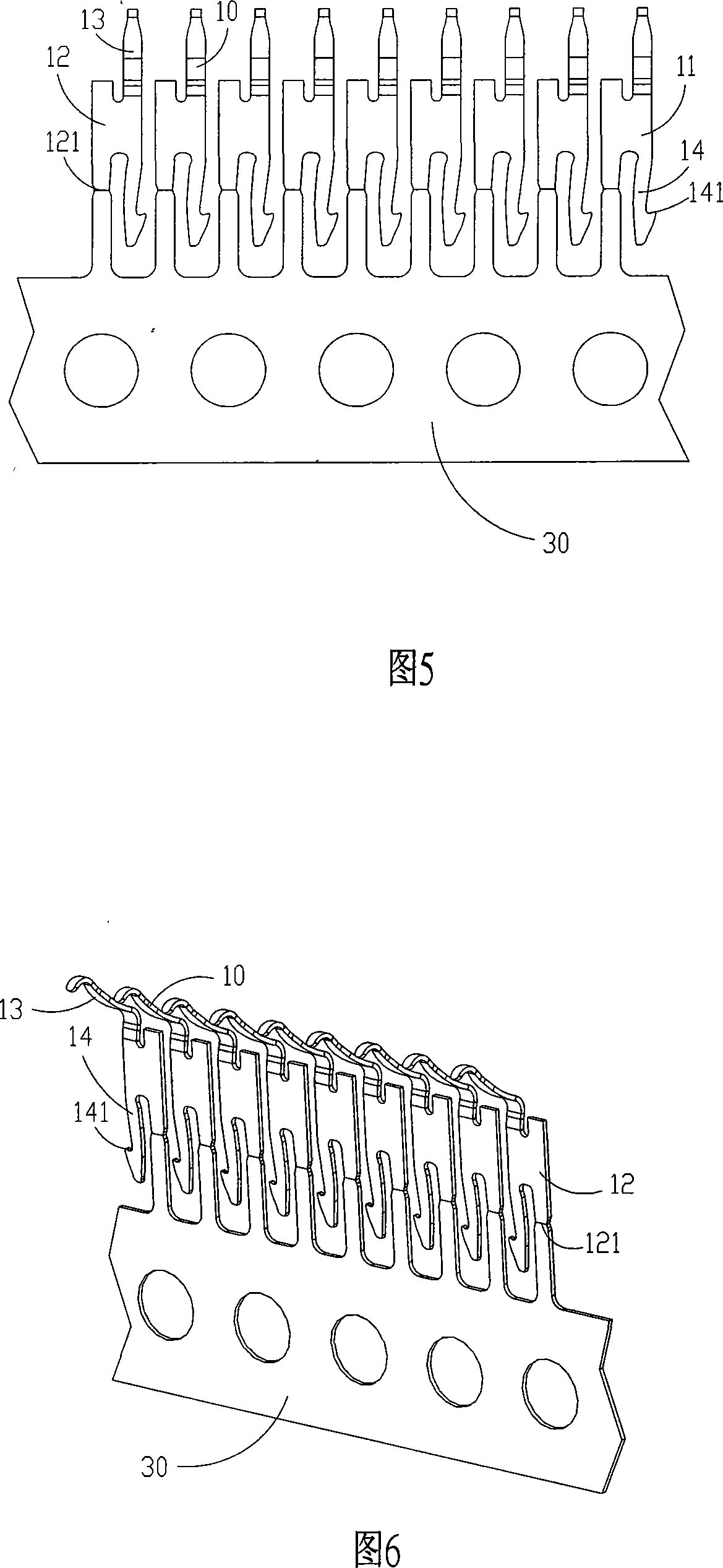

[0025] Please refer to FIG. 3 to FIG. 10 , the forming method of the terminal 10 of the present invention is to twist or rotate the terminal 10 by a certain angle in a certain way, so that the front-to-back distance between adjacent terminals 10 is increased, and the left-to-right distance is reduced, and then the terminal is accommodated. In an insulating body 20, the terminal density effect is achieved, and the process will be discussed in detail below.

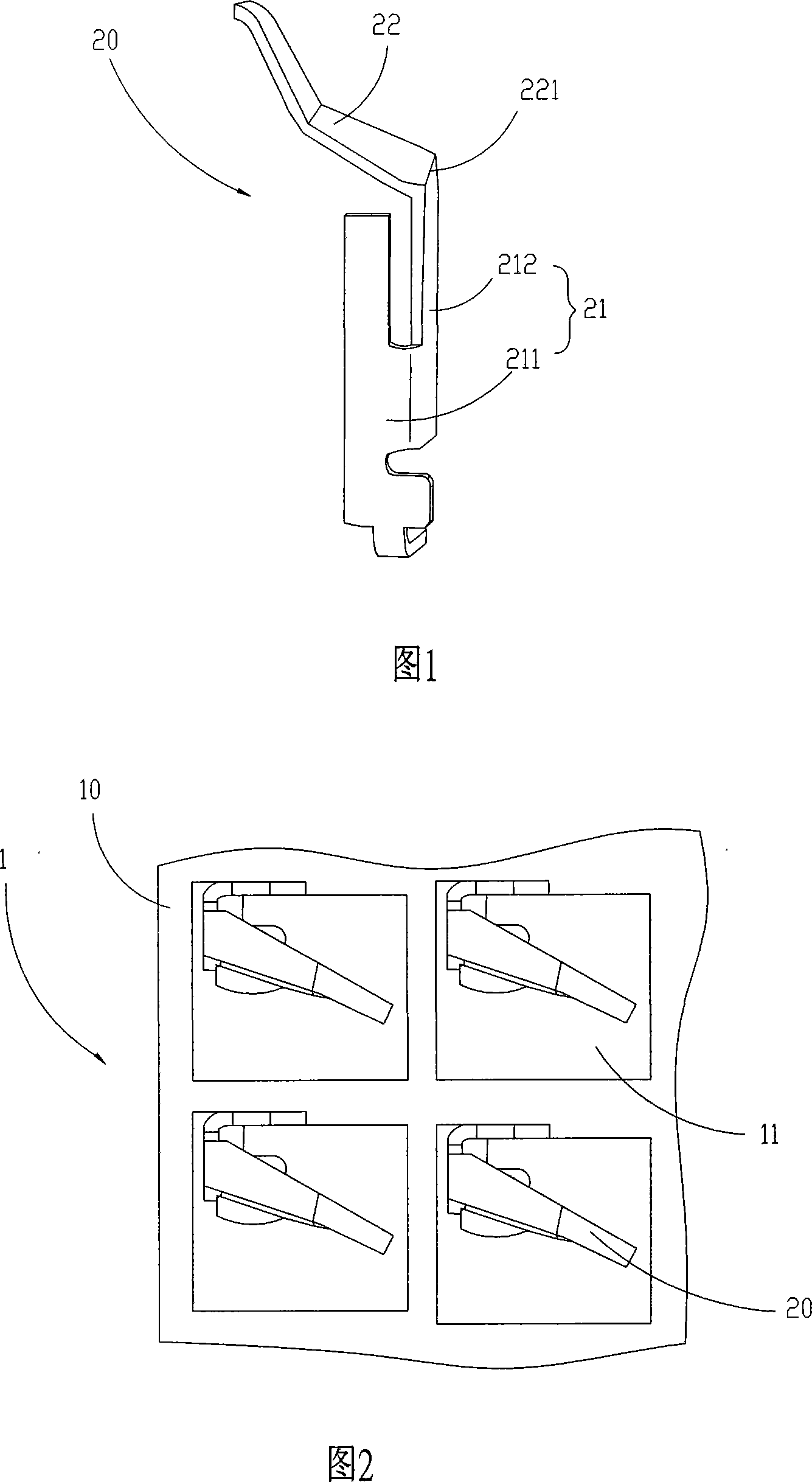

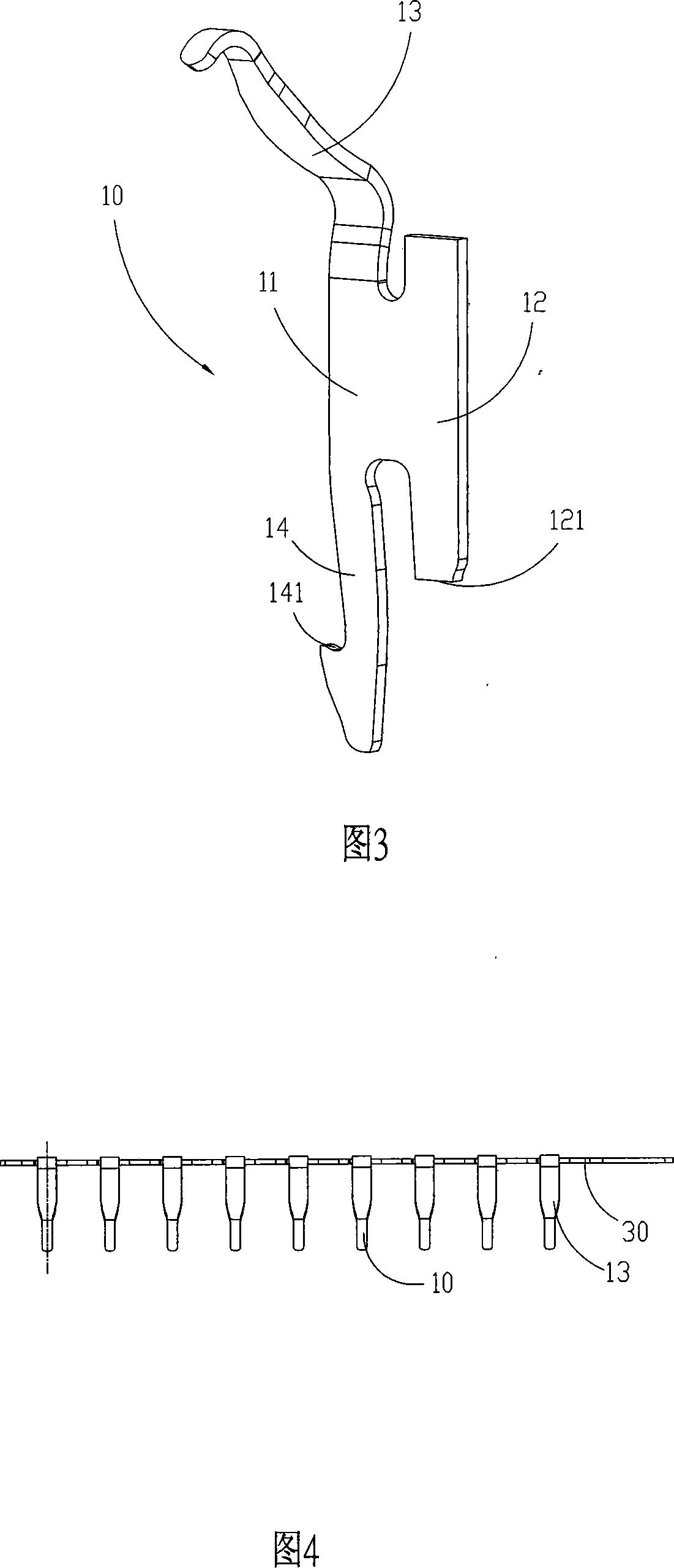

[0026] Please refer to FIG. 3 to FIG. 6, and FIG. 3 to FIG. 6 are schematic diagrams of the structure of the terminal 10 before rotation or twisting. A plurality of terminals 10 are integrally stamped and formed on a terminal strip 30. Each terminal 10 includes a main body 11 and consists of The base portion 12 , the elastic arm 13 and the welding portion 14 extend from the main body portion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com