Attapulgite coarse crushing cutter

A kind of attapulgite and coarse crushing technology, which is applied in the direction of grain processing, etc., can solve the problems of difficult particle processing, unevenness, waste of labor, etc., and achieve the effect of reliable combination and connection, easy disassembly and installation, and saving purchase cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The attapulgite rough breaking tool of the present invention will be further described through examples below.

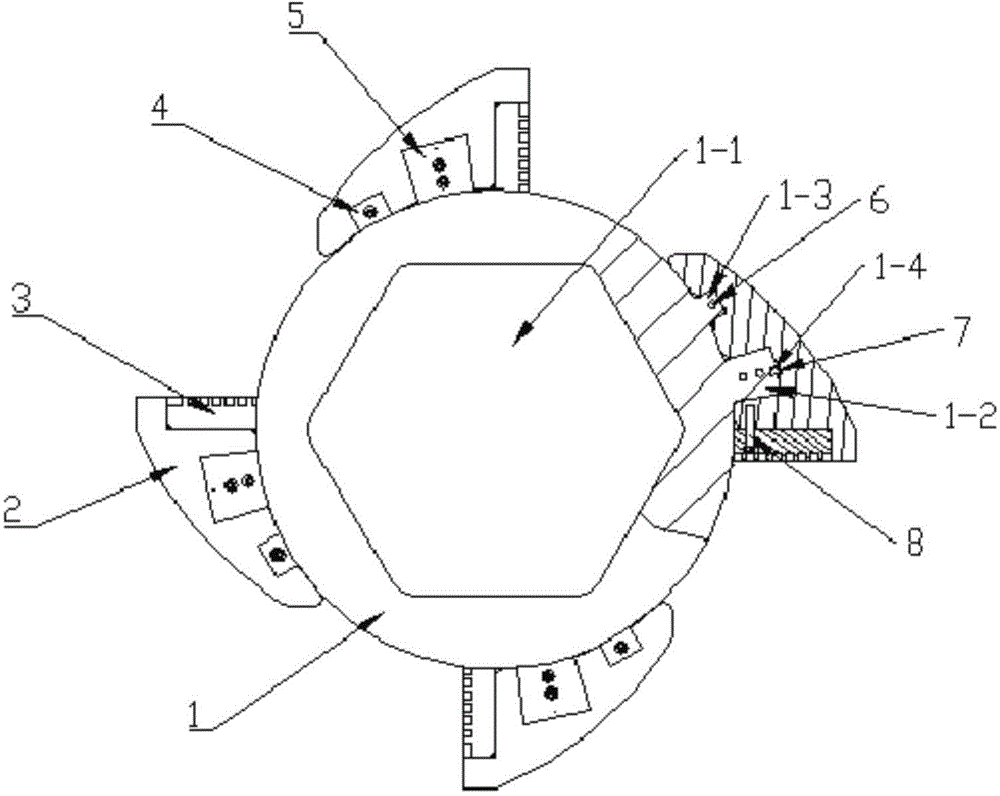

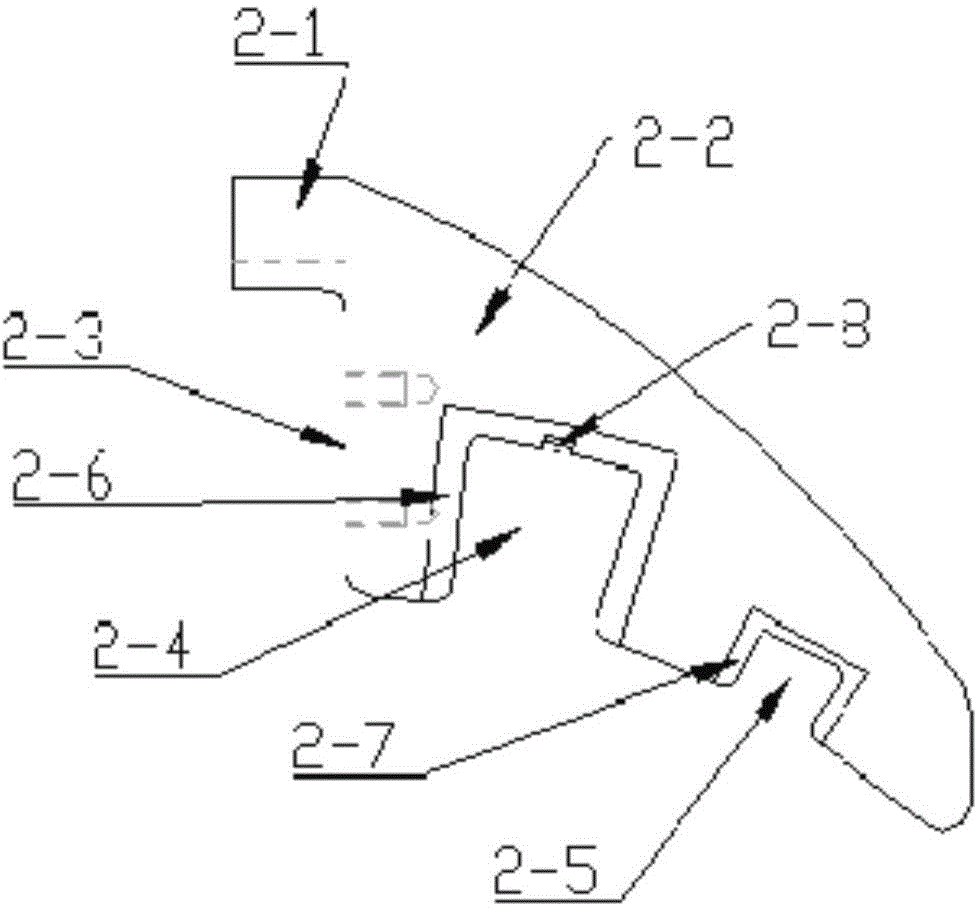

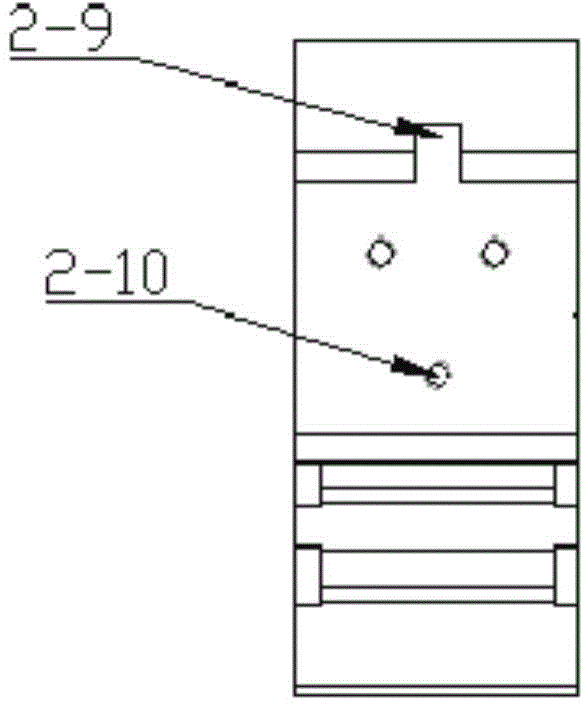

[0022] In the present embodiment, the structure of attapulgite rough breaking tool is as follows: figure 1 As shown, it is composed of a cutter head 1, four sets of combined cutter heads, a first baffle 5, a second baffle 4, a wedge key 7, a first bolt 6 and a second bolt 8. The cutterhead 1 is in the shape of a truncated cone, and the central part of the cutterhead is provided with a mounting hole 1-1 combined with the roller shaft. The mounting hole is a hexagonal hole, and eight dovetail-shaped blocks are arranged on the cylindrical surface of the cutterhead. body, wherein, four are the first dovetail-shaped block 1-2, four are the second dovetail-shaped block 1-3, the first dovetail-shaped block 1-2 is larger than the second dovetail-shaped block 1-3, A first dovetail-shaped block 1-2 and a second dovetail-shaped block 1-3 form a group, and the center po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com