Positioning device, sticking system and sticking method

A positioning device and glue technology, applied in the direction of sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve the problem of affecting the quality of silicon blocks, high production costs, and the center alignment of the center of the silicon rod and the crystal support Difficulties and other problems to achieve the effect of reducing production costs and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] As mentioned in the background technology section, it is still a very difficult technical problem to align the center of the single crystal silicon rod (silicon rod for short) with the center of the crystal support after controlling the glue in the prior art. If the center of the rod and the center of the crystal holder are not aligned, the quality of the subsequently formed silicon block will not meet the requirements, and then the silicon block will be scrapped, thereby increasing the production cost.

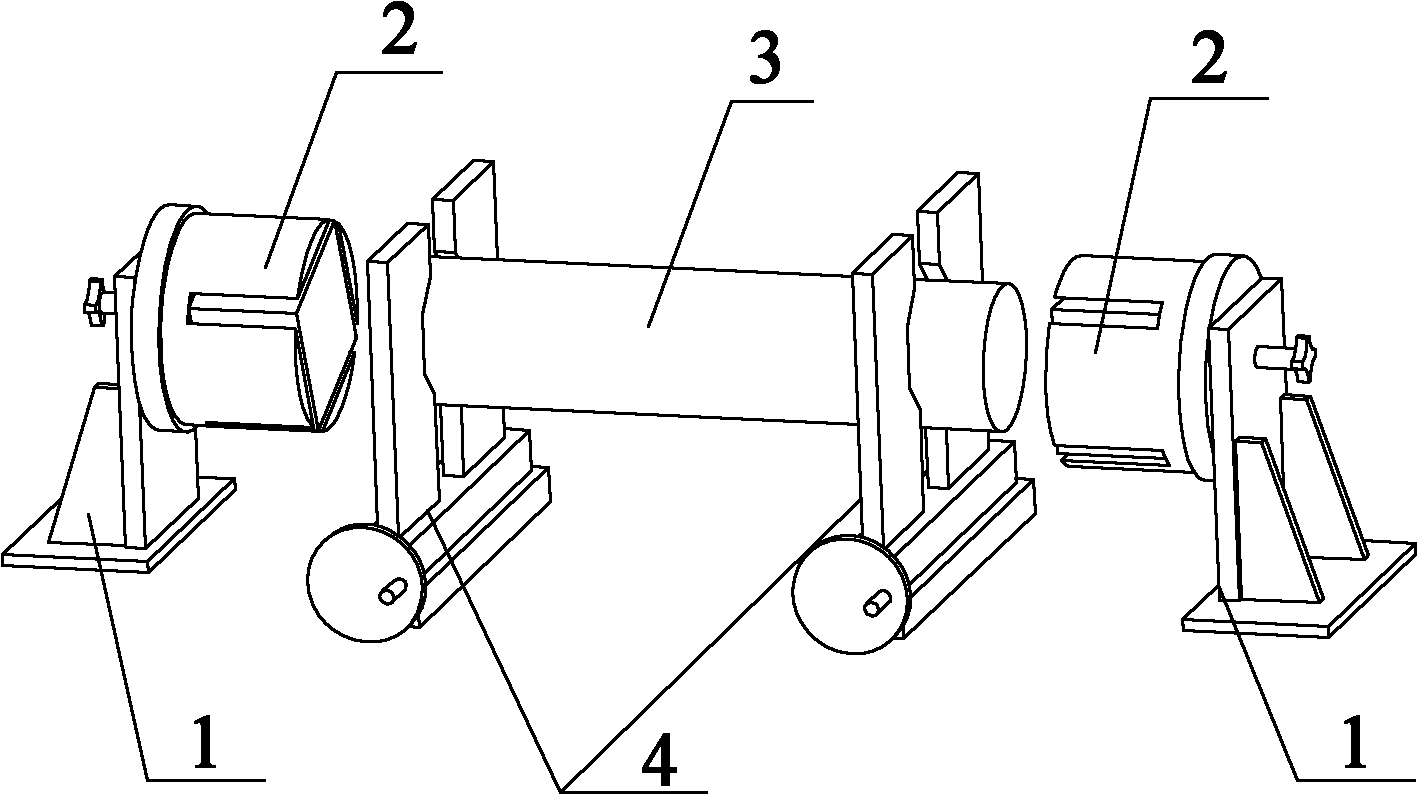

[0047] refer to figure 1 , figure 1 It is a structural schematic diagram of a positioning device in the prior art. The single crystal silicon rod 3 is shown in the figure, and the clamping mechanism 4 for clamping the single crystal silicon rod 3 has two clamping mechanisms 4, which respectively clamp the two ends of the single crystal silicon rod 3; The silicon rod 3 has two end faces, and one side of each end face is provided with a crystal holder fixing frame 1, a...

Embodiment 2

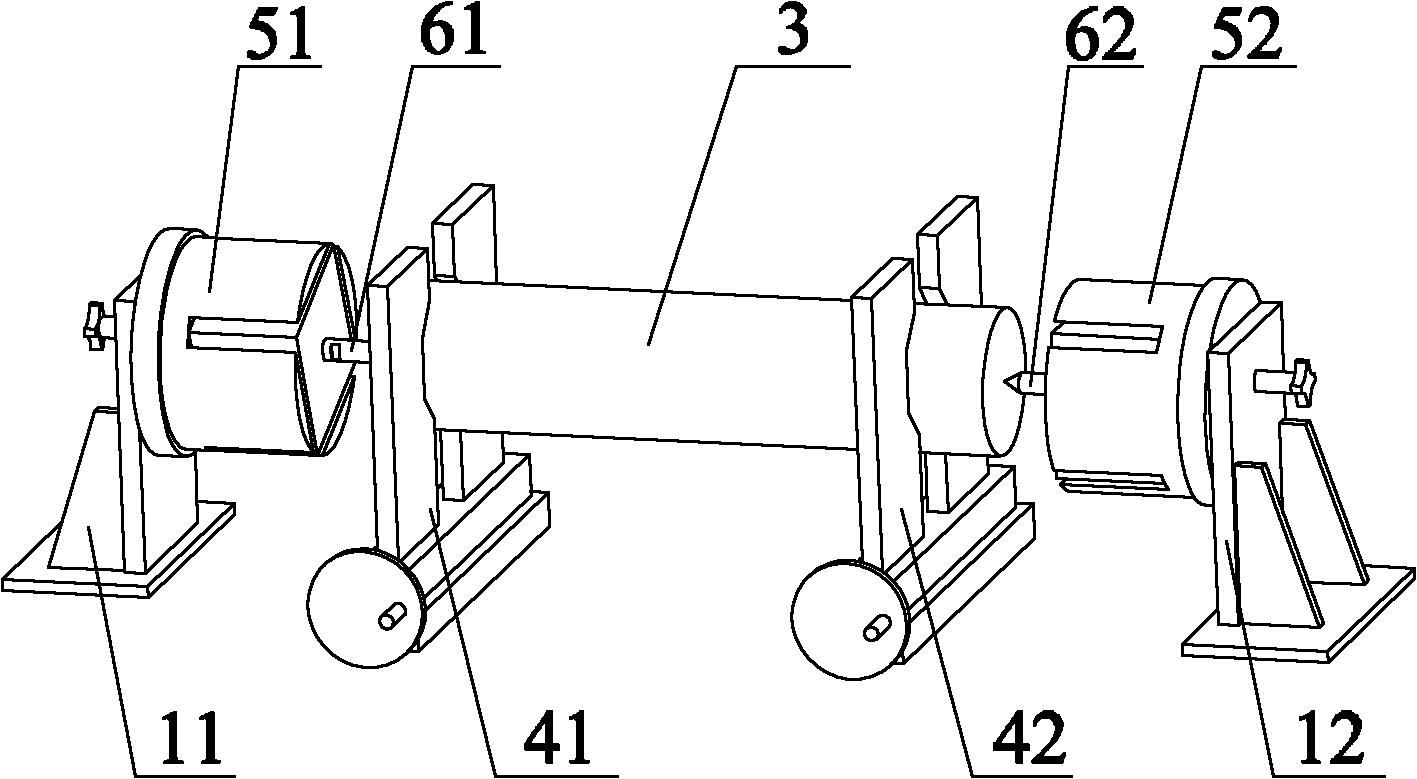

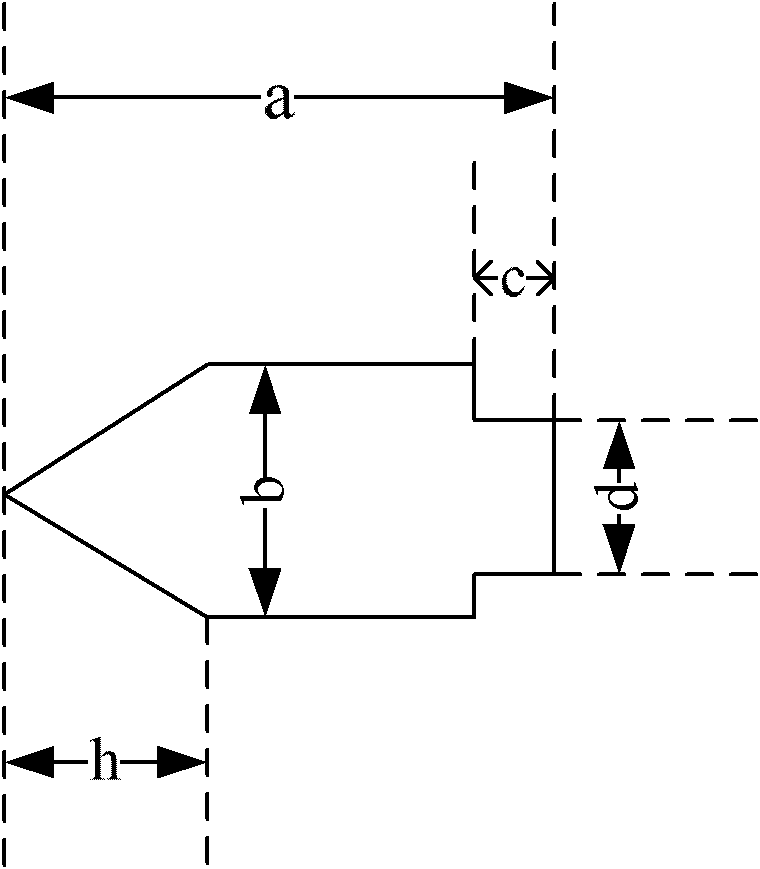

[0055] The present invention also provides a positioning device, which is used for aligning the center of the single crystal silicon rod with the center of the crystal support before bonding the single crystal silicon rod and the crystal support. The positioning device includes: a clamping mechanism for clamping a single crystal silicon rod; a crystal holder fixing frame for fixing the crystal holder; a positioning pin installed at the center of the crystal holder at one end, and the other end of the positioning pin is a cone.

[0056] In this embodiment, one end of the positioning pin installed in the center of the crystal holder is provided with a thread, and the center of the crystal holder is provided with a threaded hole, and one end of the positioning pin is installed in the threaded hole in the center of the crystal holder in the form of a thread.

[0057] During the specific implementation process, the clamping mechanism is adjusted so that the center of the single crys...

Embodiment 3

[0059] The present invention also provides a kind of viscose method, with reference to Figure 4 , Figure 4 It is a schematic flow chart of the viscose method provided by the present invention. combine figure 2 , the method specifically includes the following steps:

[0060] Step S1: Install a positioning pin at the center of the crystal support on the crystal support holder, and one end of the positioning pin exposed outside the center of the crystal support is a cone.

[0061] In the specific implementation process, at first the first crystal holder 51 is fixed on the first crystal holder holder 11, the second crystal holder 52 is fixed on the second crystal holder holder 12, the first crystal holder 51 and the second crystal holder 52 correspond to the two end surfaces of the single crystal silicon rod 3 respectively. Then a first alignment pin 61 is installed at the center of the first crystal holder 51 , and a second alignment pin 62 is installed at the center of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom diameter | aaaaa | aaaaa |

| Thread length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com