Patents

Literature

57results about How to "Reliable crimping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

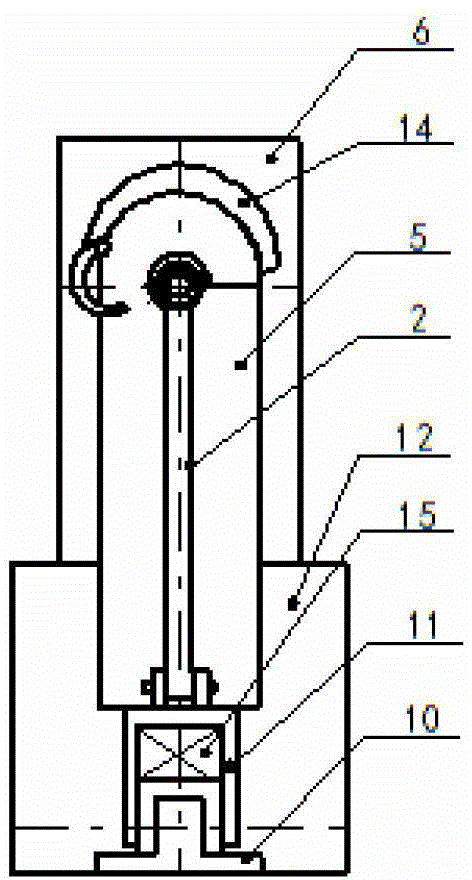

Air fuel ratio sensor

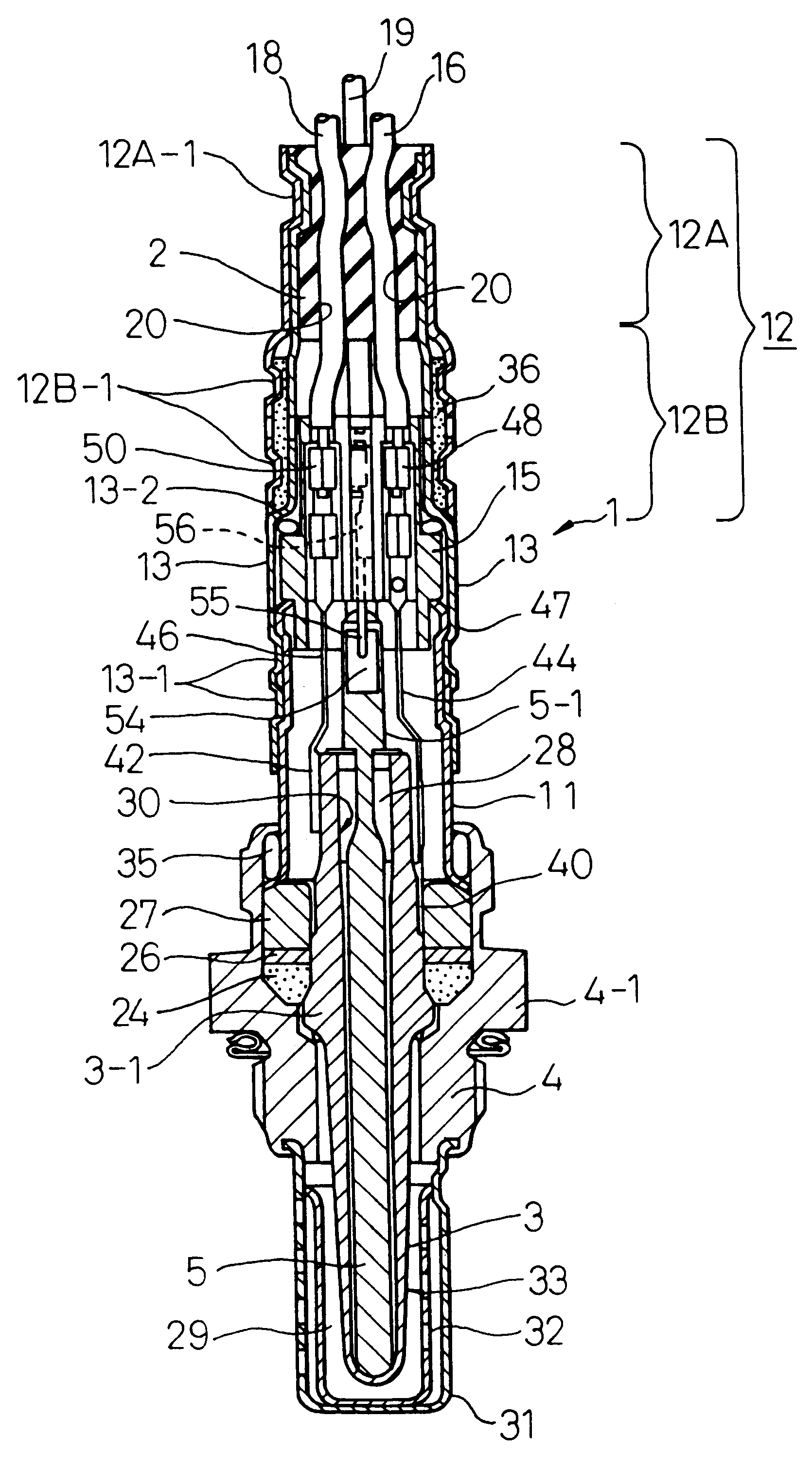

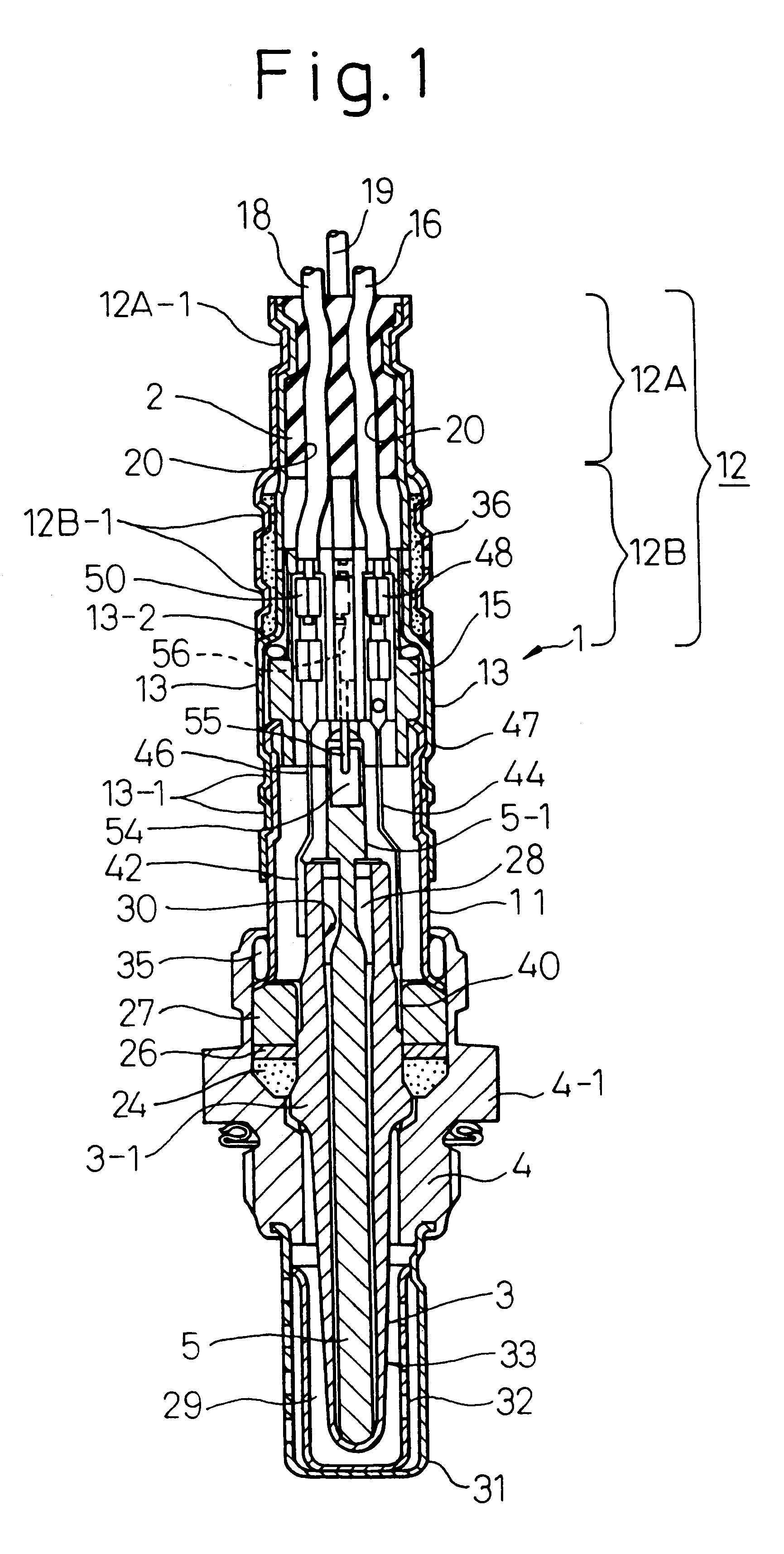

InactiveUS6258234B1Desired durabilityDesired waterproofnessMaterial electrochemical variablesEngineeringAir–fuel ratio

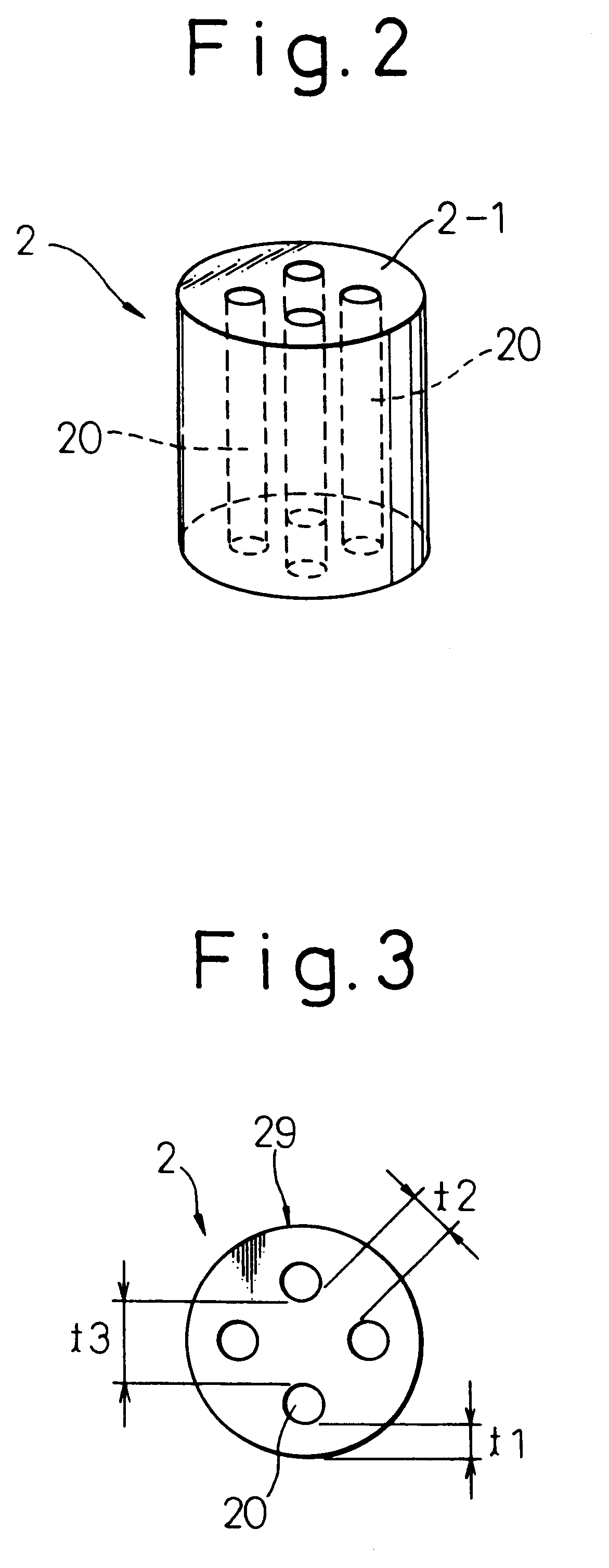

Air fuel ratio sensor for use in an exhaust gas purification system for an internal combustion engine. The sensor has an outer and inner cover 12 and 13 for protection of lead wires 16, 18 and 19 to a detecting element 3 and a heater 5 of the sensor, a rubber seal for 2 for obtaining a sealing between the covers and the lead wires and a water repellent filter 36 for obtaining a seal between the inner and outer covers 12 and 13, while keeping an air ventilation capability of the space inside the covers. For receiving the lead wires 16, 18 and 19, the seal 2 is formed with holes 20 such that the minimum thickness between the holes and the minimum thickness between the hole and an outer surface of the seal is 1 mm or more. A crimping of the outer cover 12 is done so that a deformation of the seal 2 in a range between 10 to 20% of the outer diameter is obtained.A crimping of the outer cover 12 is further done at a first section 12A at a larger force for fixation of the outer cover 12 to the inner cover 12 and at a second section 12B at a smaller force for holding the water repellent filter 36 between the outer and inner covers. In the crimping, the crimping at the first section is completed simultaneously or earlier from the completion of the crimping at the second section.

Owner:DENSO CORP

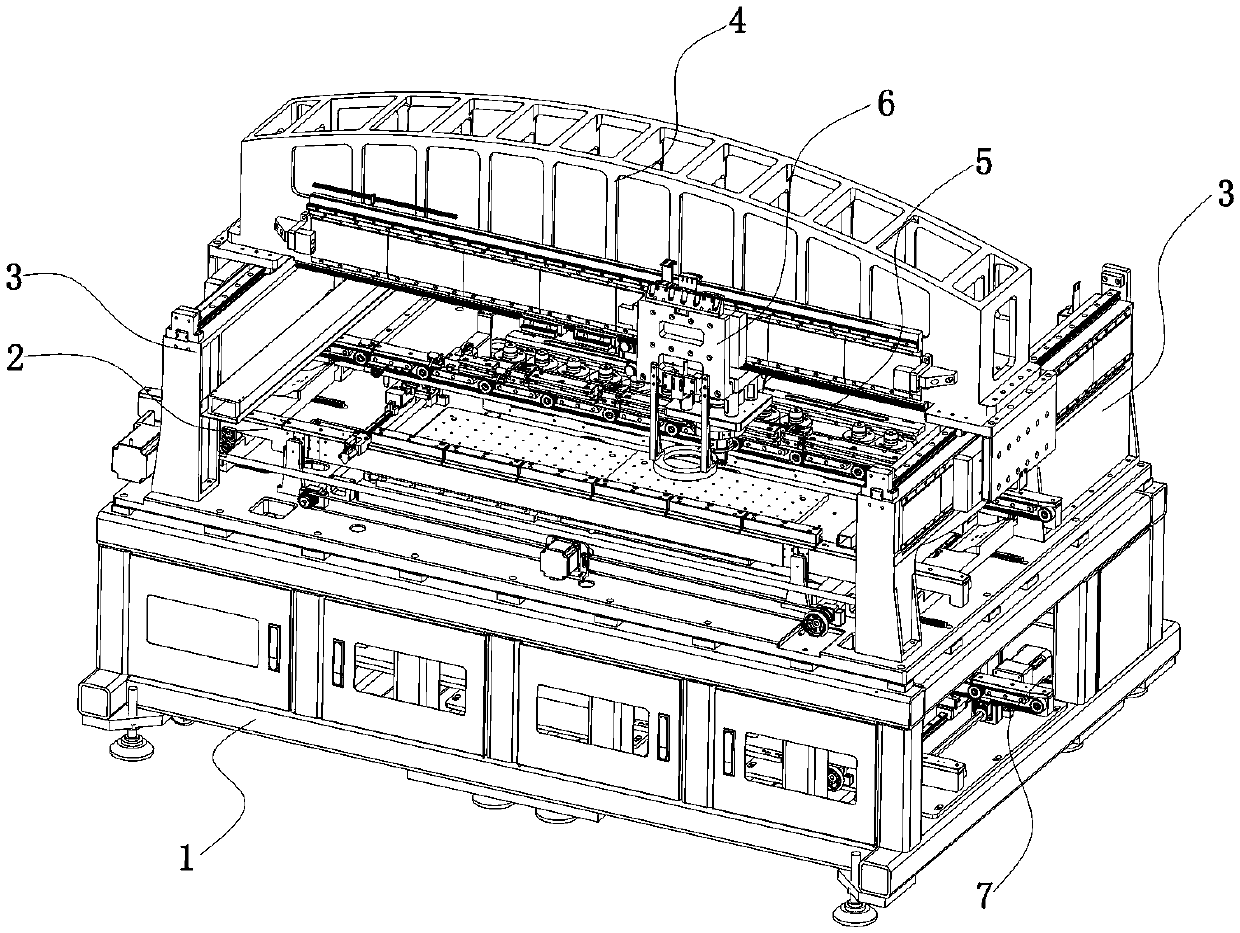

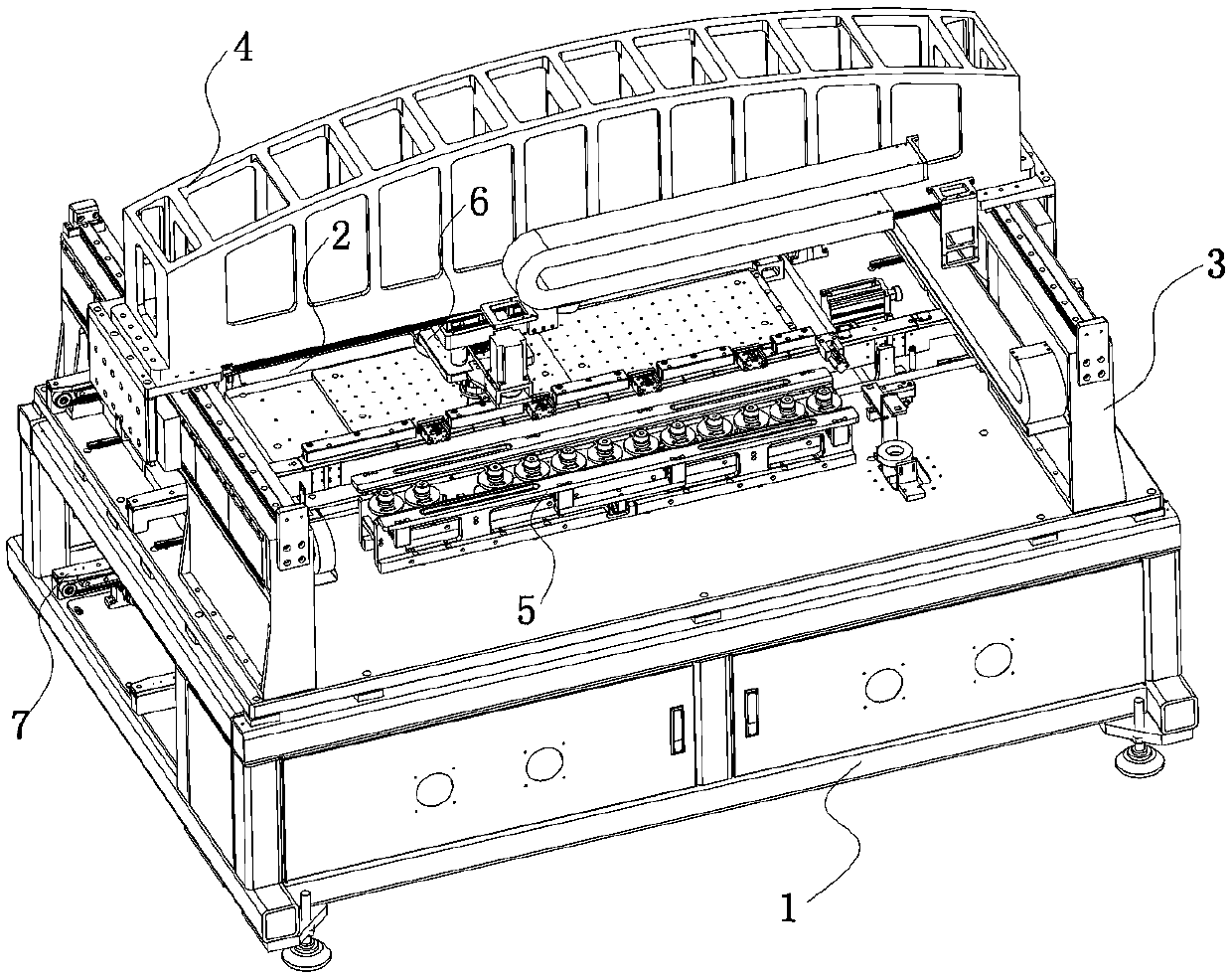

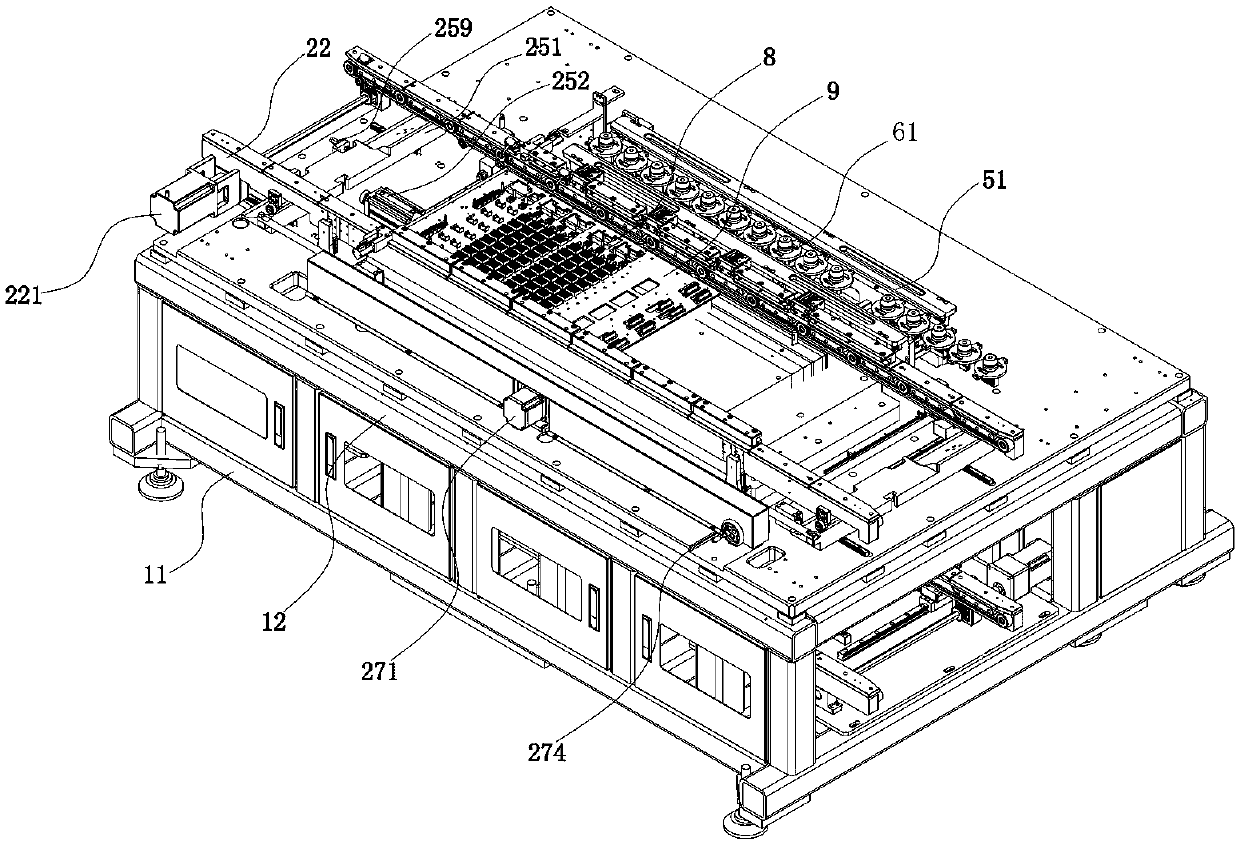

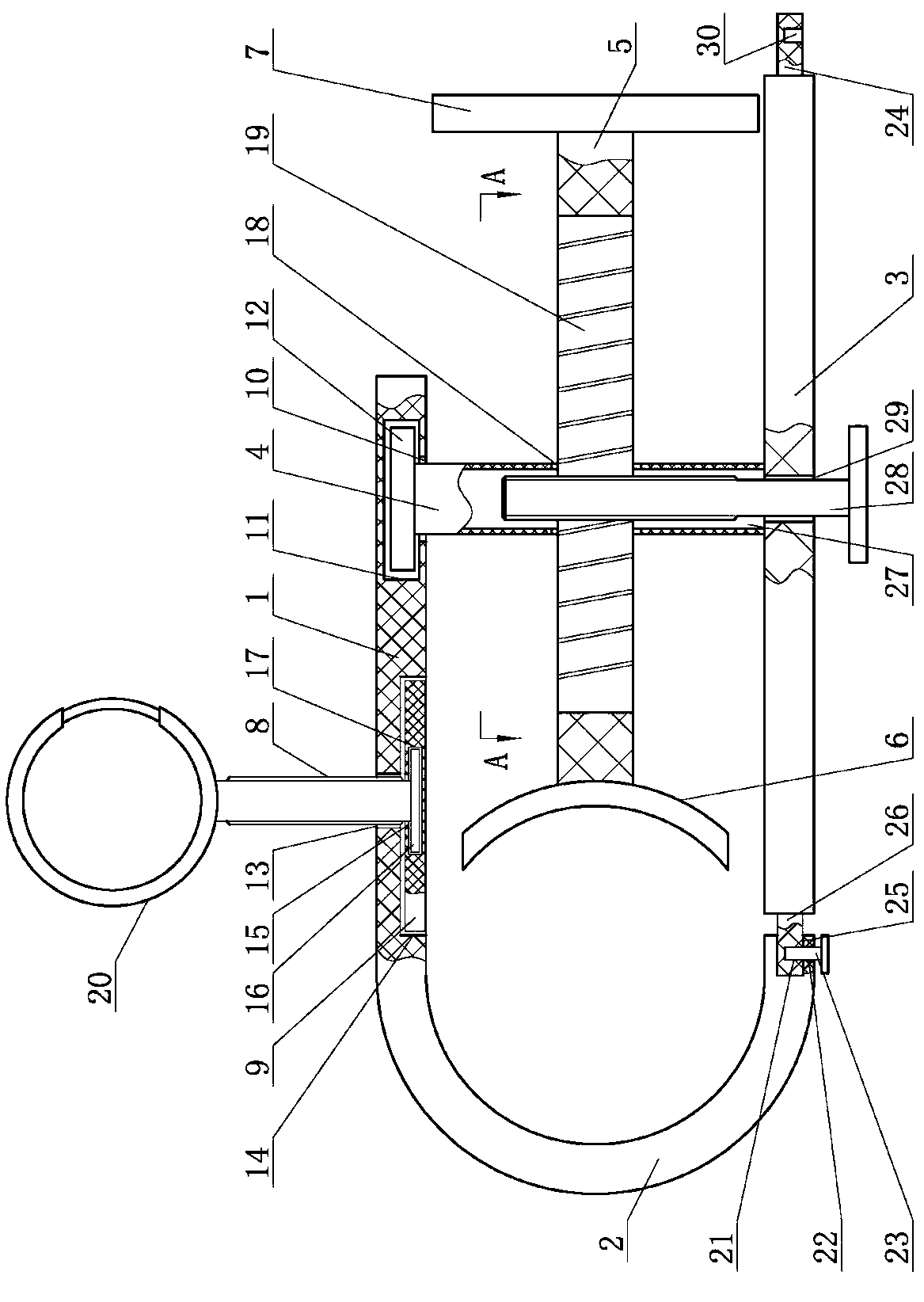

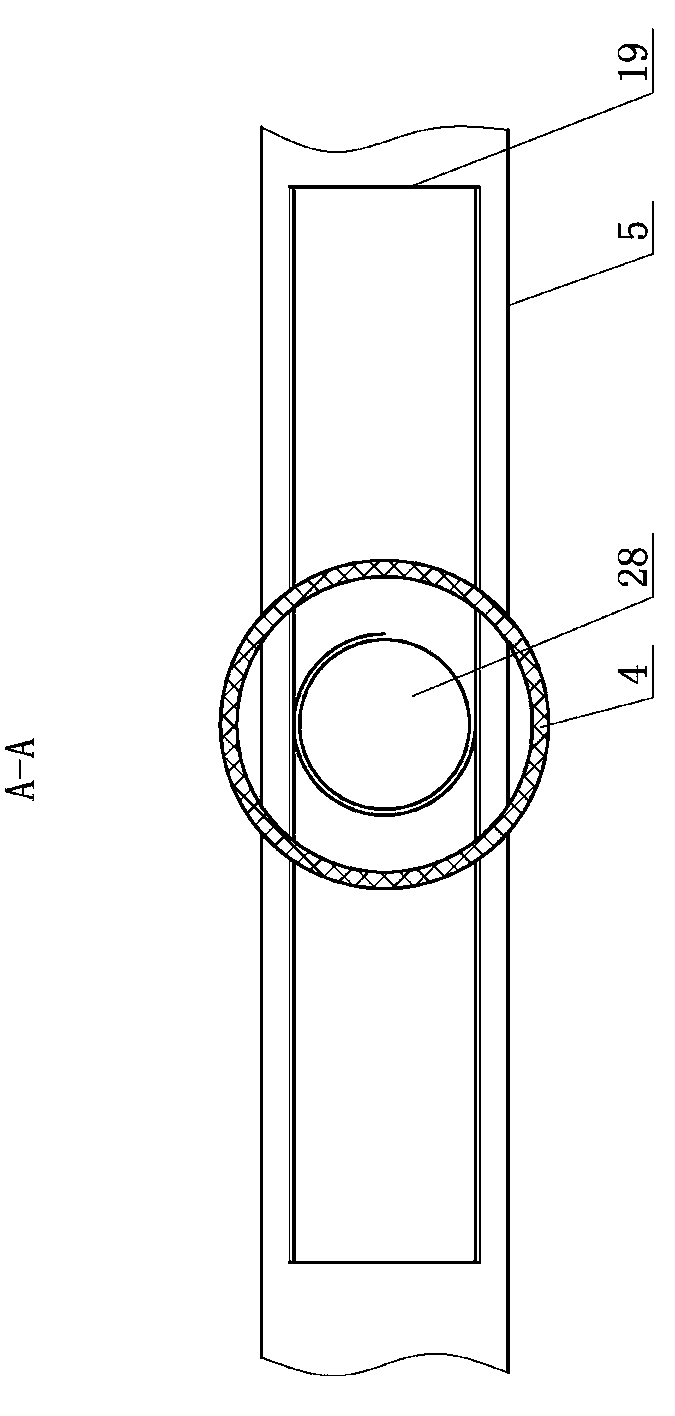

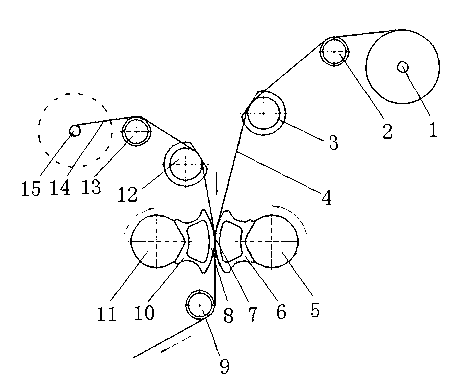

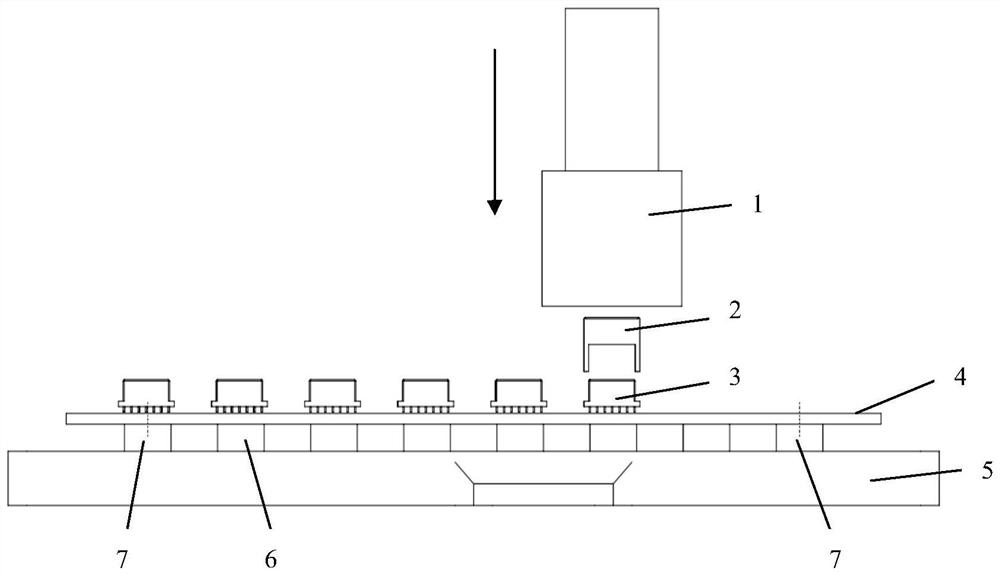

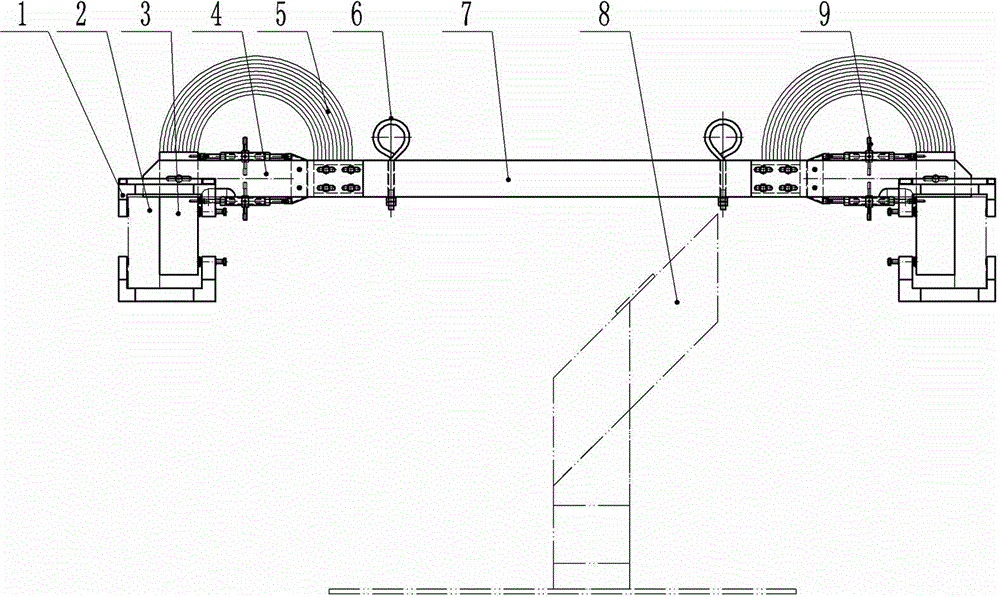

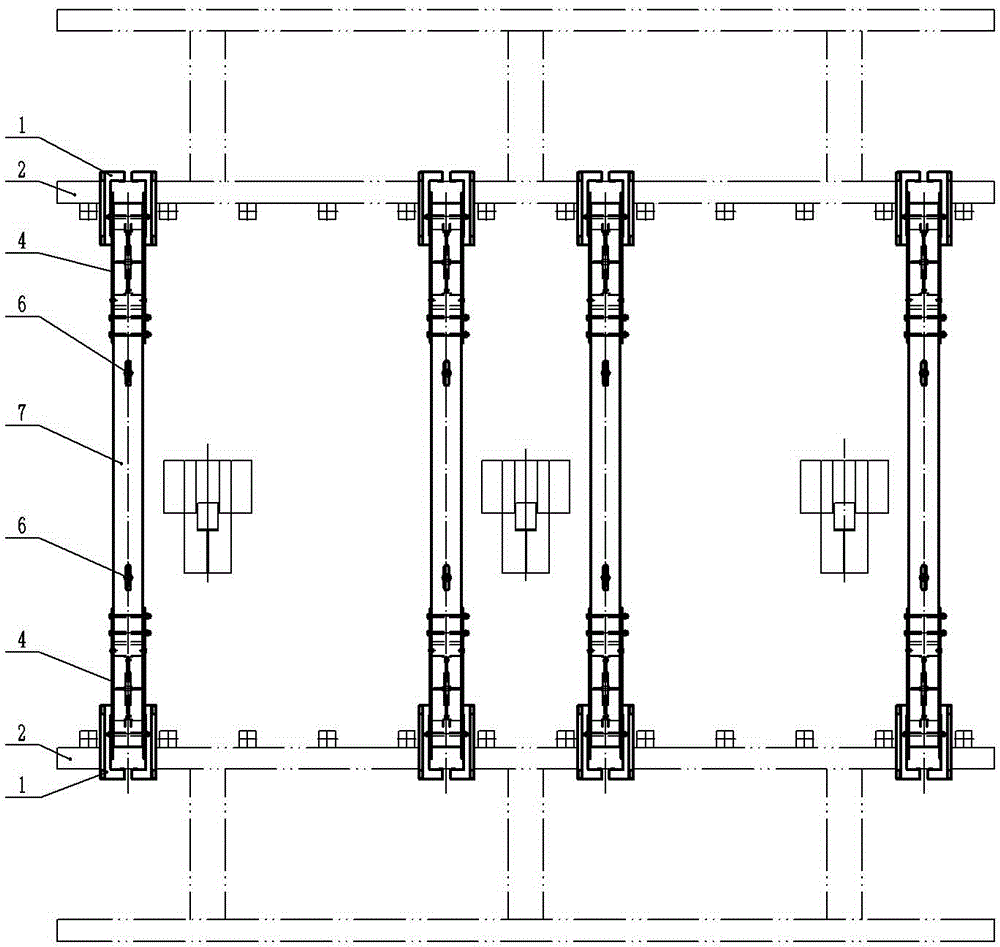

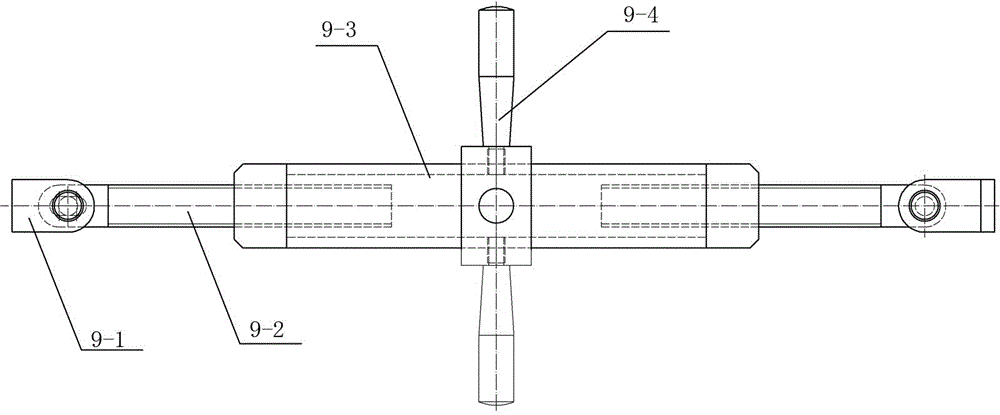

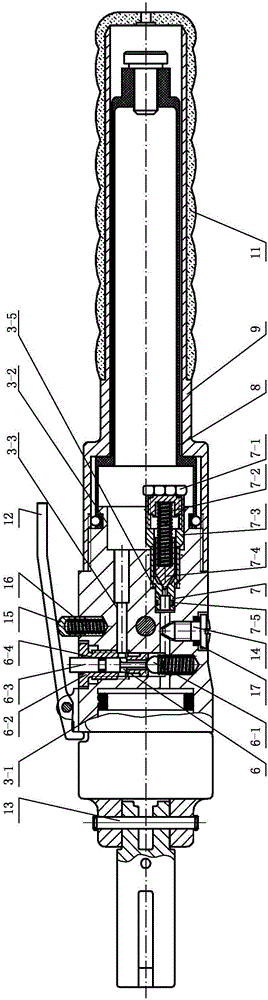

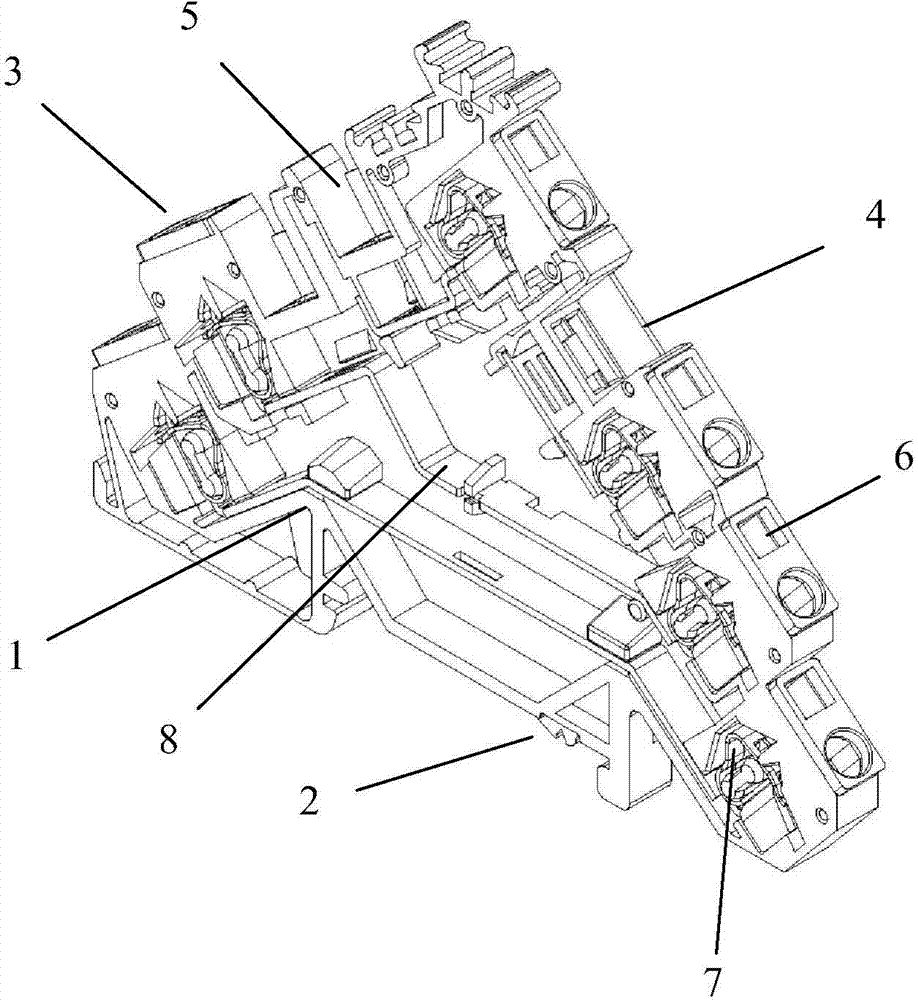

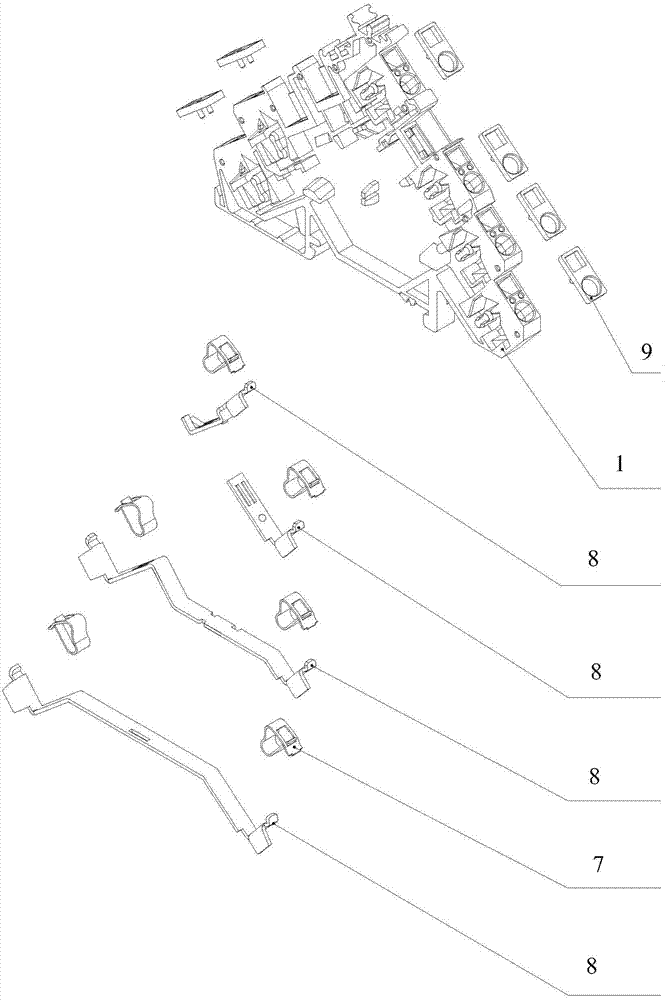

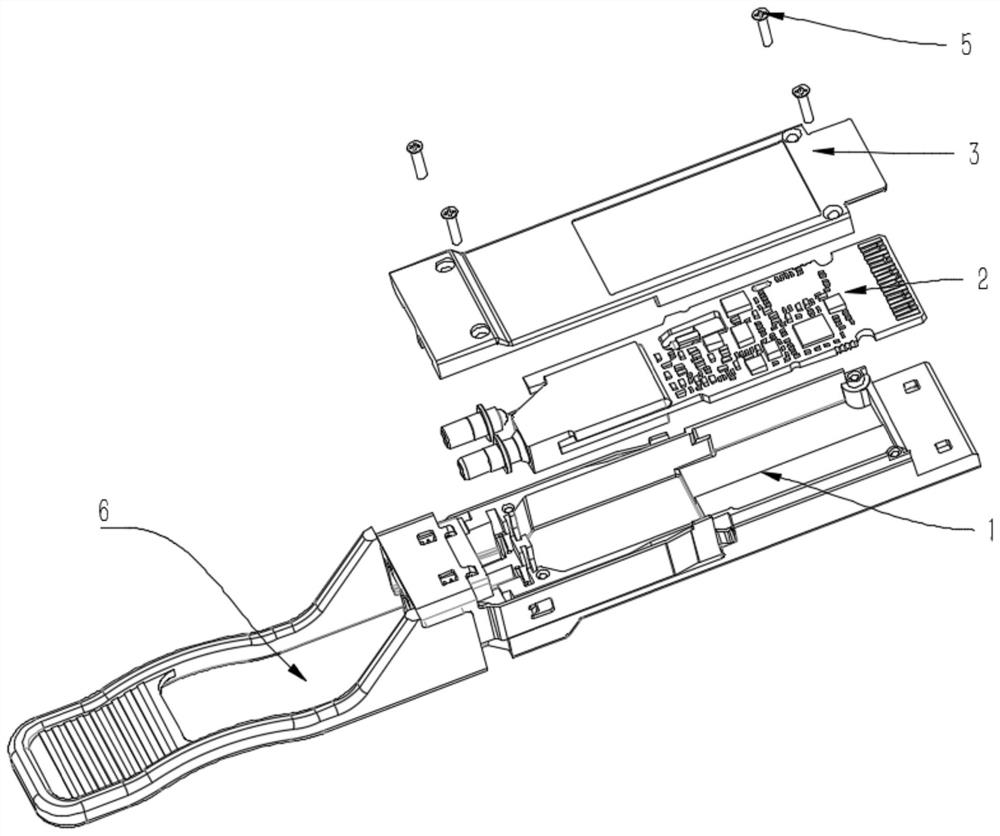

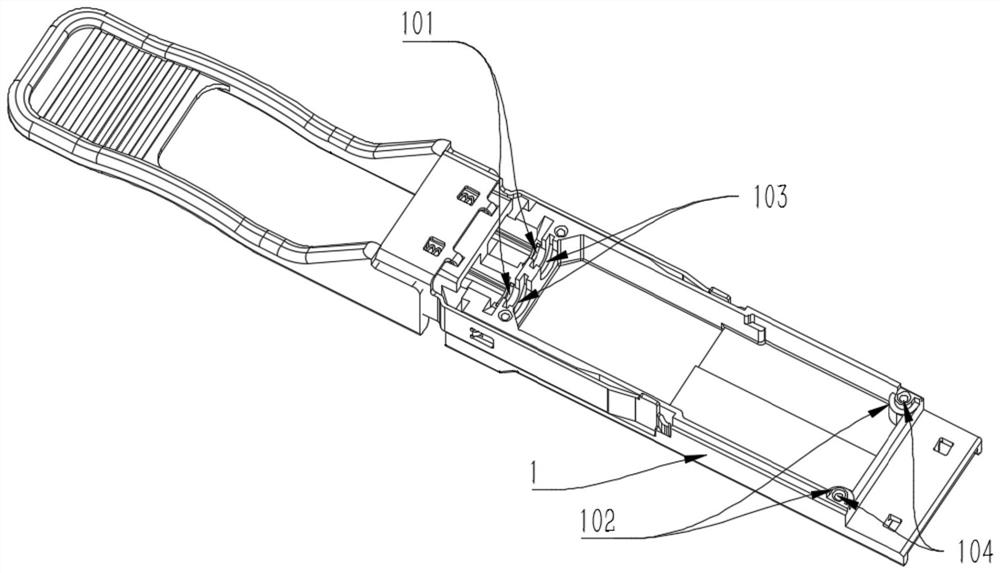

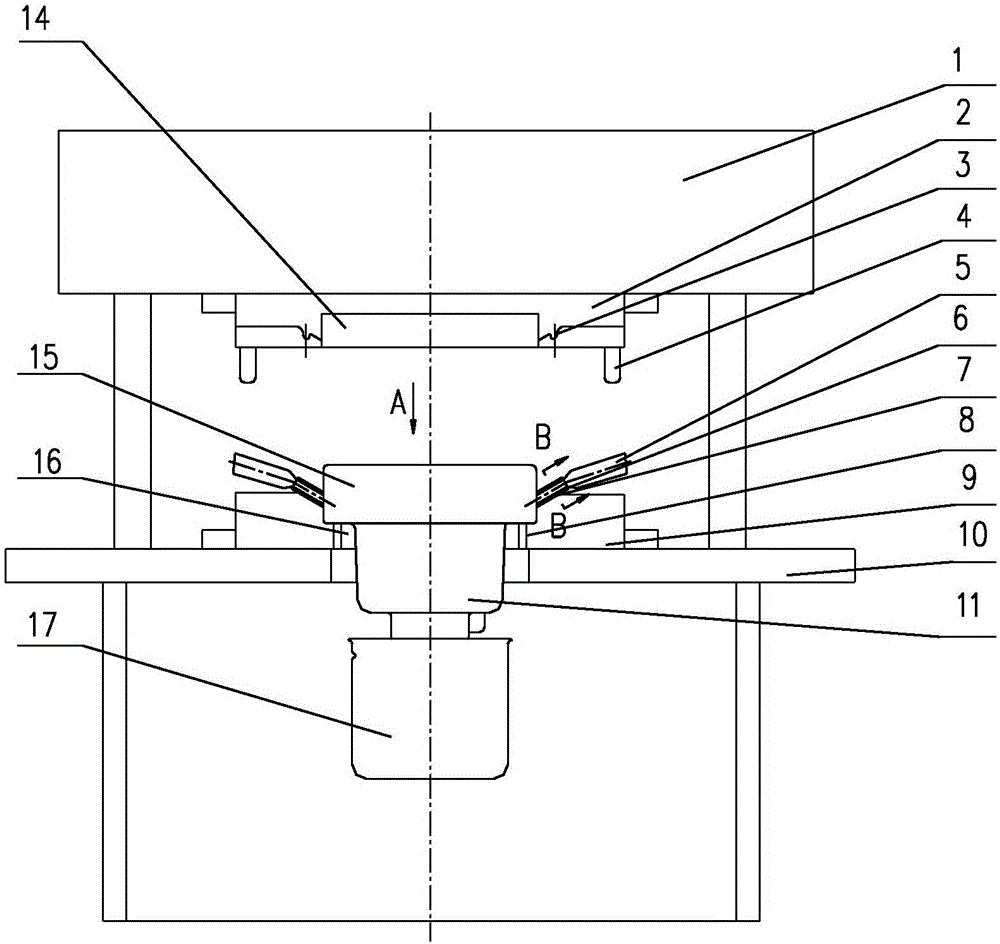

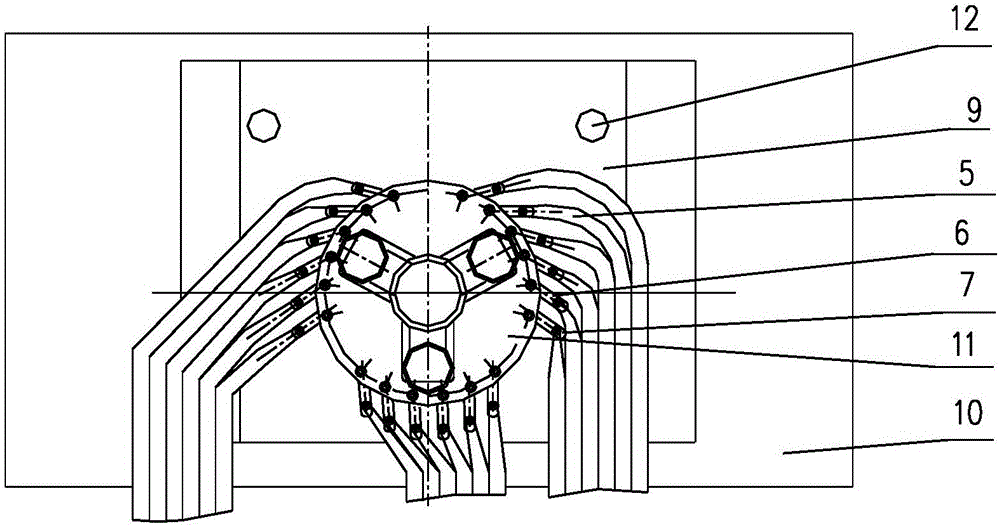

Automatic press-connection machine of connector and press-connection system and press-connection process thereof

ActiveCN105514754ACompact designAccurate crimp positioningLine/current collector detailsFixed connectionsComputer moduleData acquisition

The invention discloses an automatic press-connection machine of a connector and a press-connection system and press-connection process thereof. The automatic press-connection machine comprises a machine body, a portal frame supporting and guiding assembly, a material guiding assembly, a press-connection head replacing assembly and a press-connection assembly; the press-connection system comprises an IPC control chip, a height sensor connected with the IPC control chip, a CCD module, a movement control card, a linear motor and a data acquisition card; the press-connection process comprises a PARS press-connection module, a pressure press-connection module and a distance press-connection module. The automatic press-connection machine of the connector and the press-connection system and press-connection process thereof are applicable to a modern assembly line, fully-automatic material guiding control is adopted, a plurality of press-connection head components are arranged therein, multiple types of press-connection modes are correspondingly matched with the press-connection head components, in the press-connection process, pres-connection heads are replaced automatically, and product press-connection diversity is achieved.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

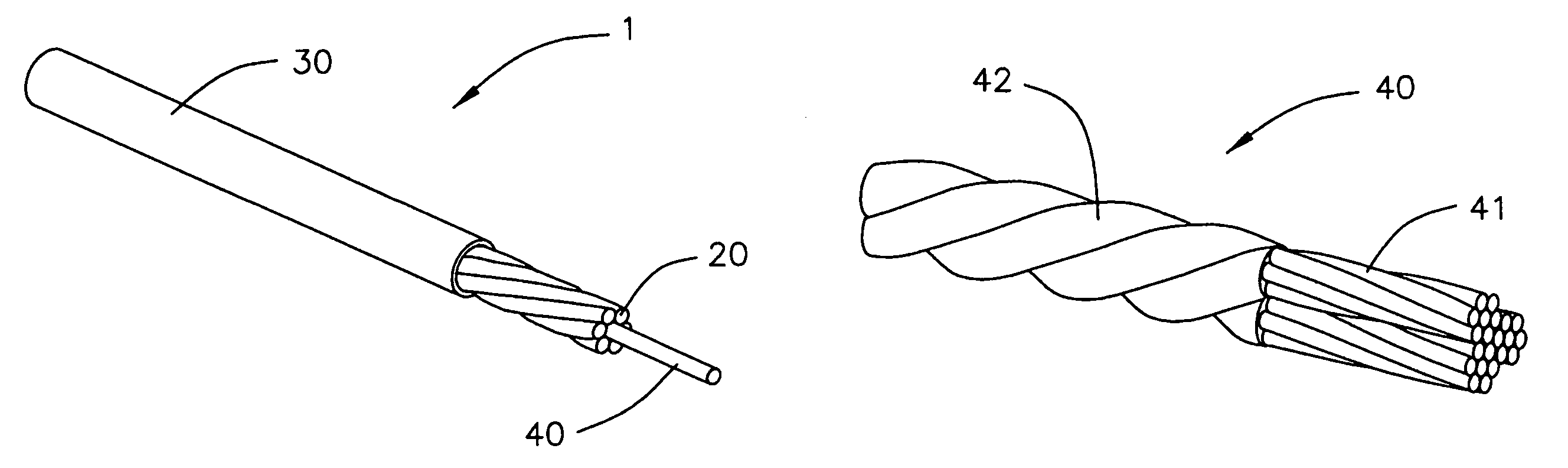

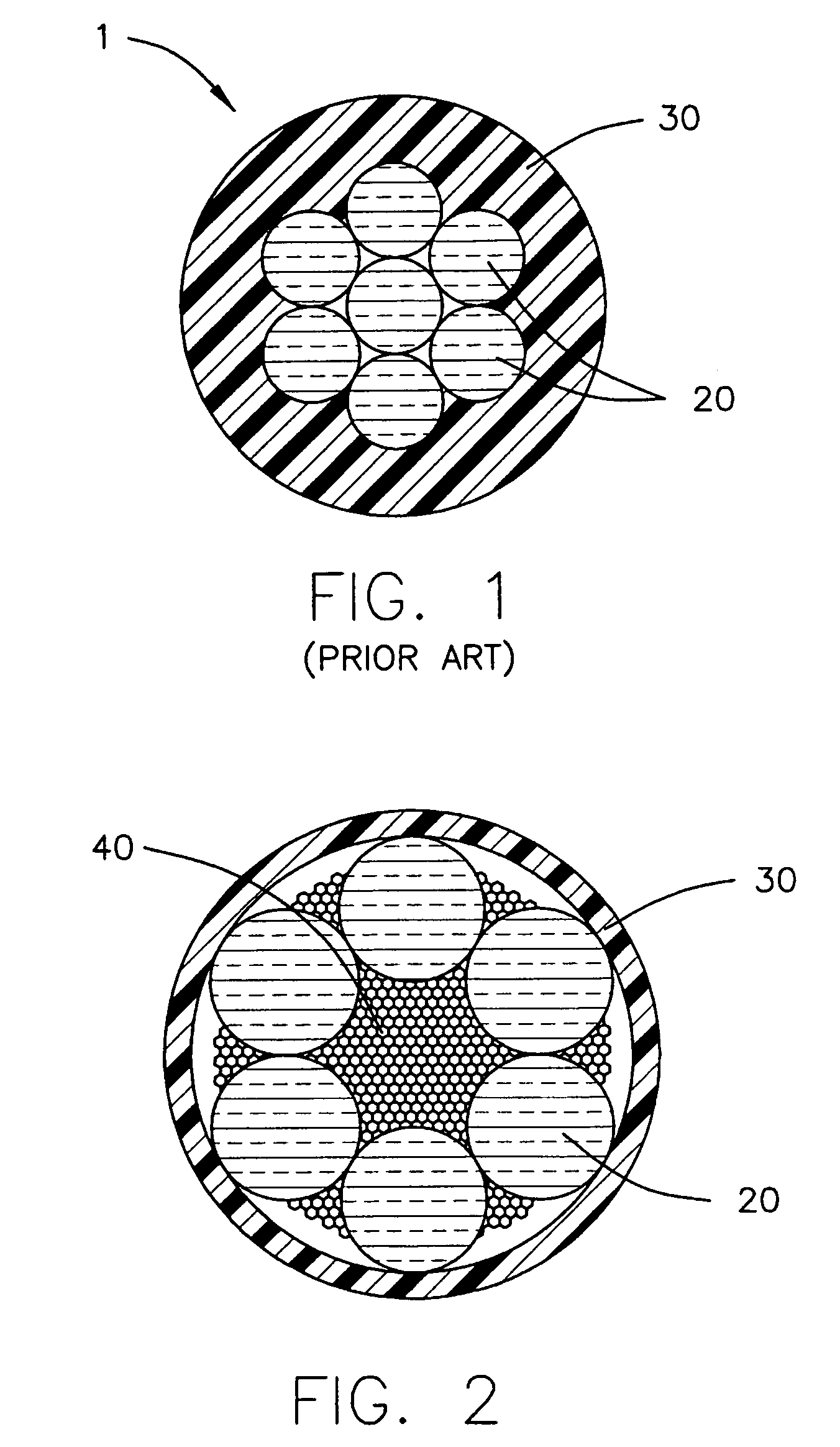

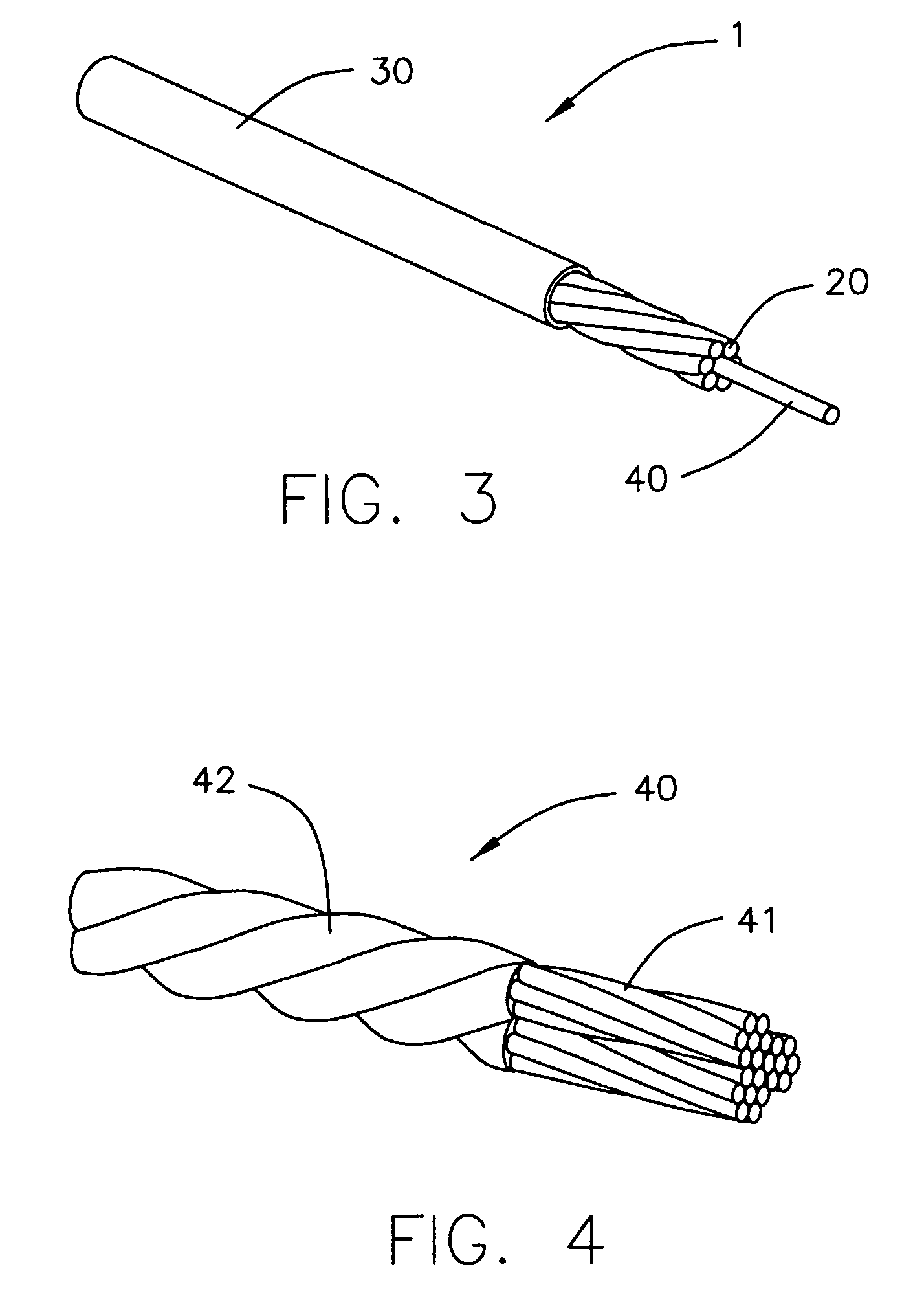

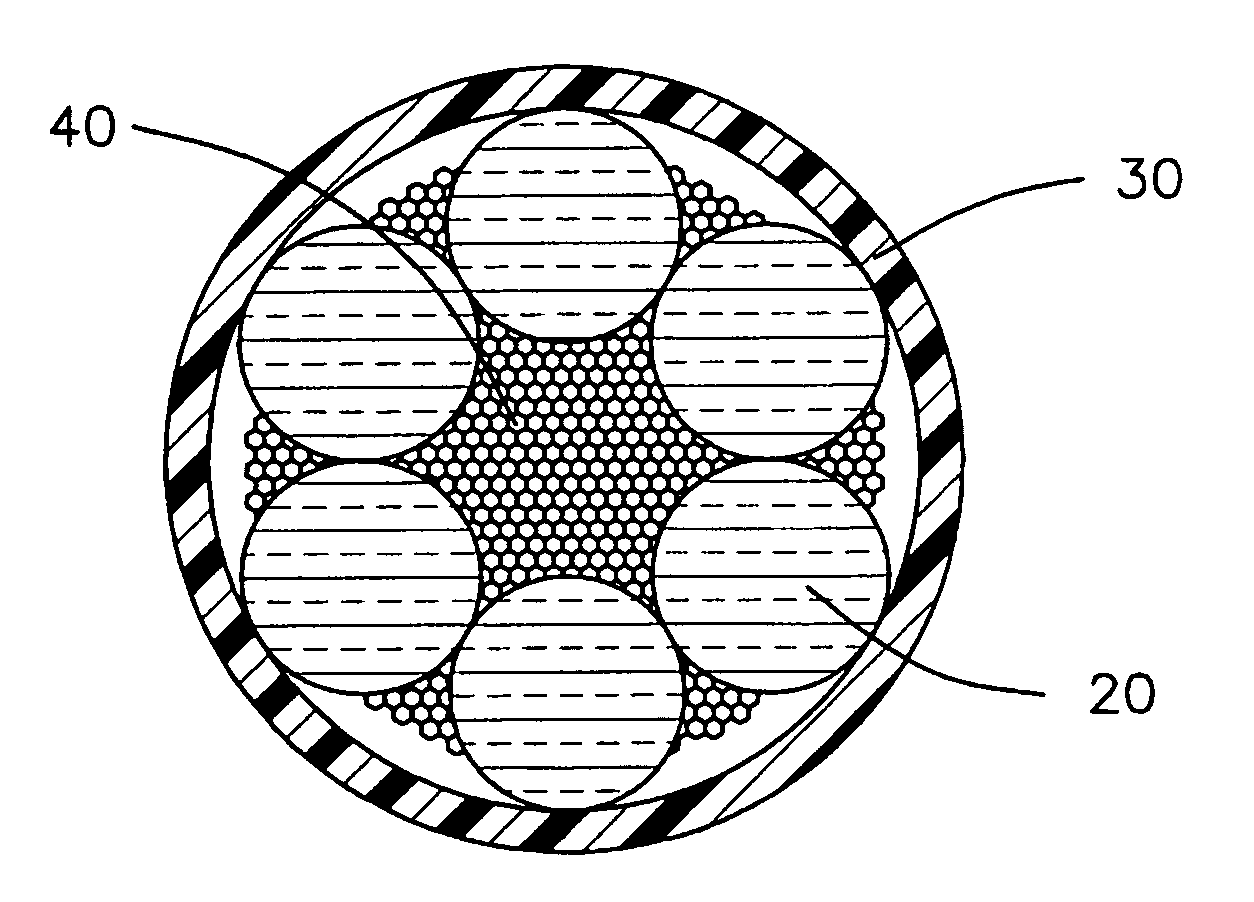

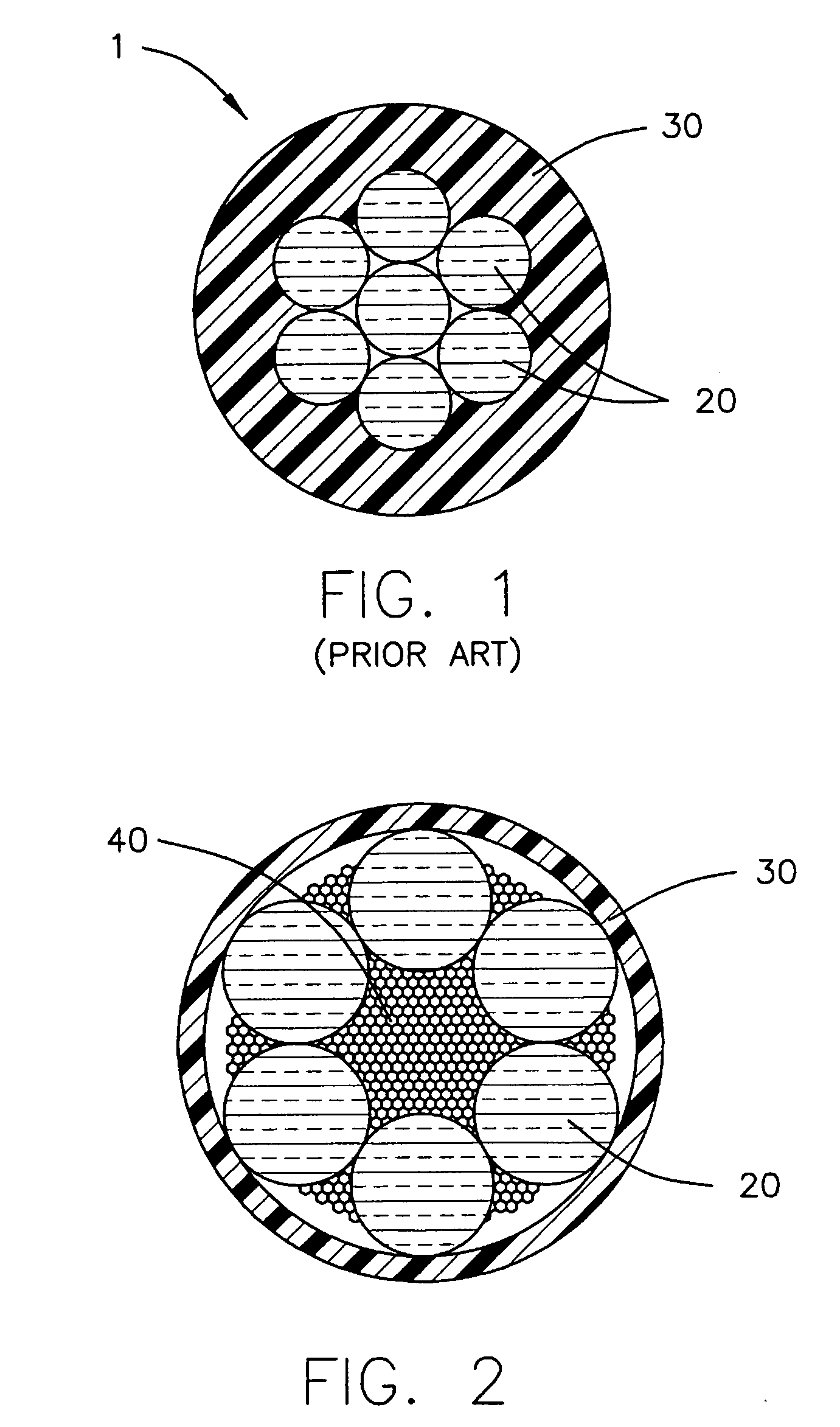

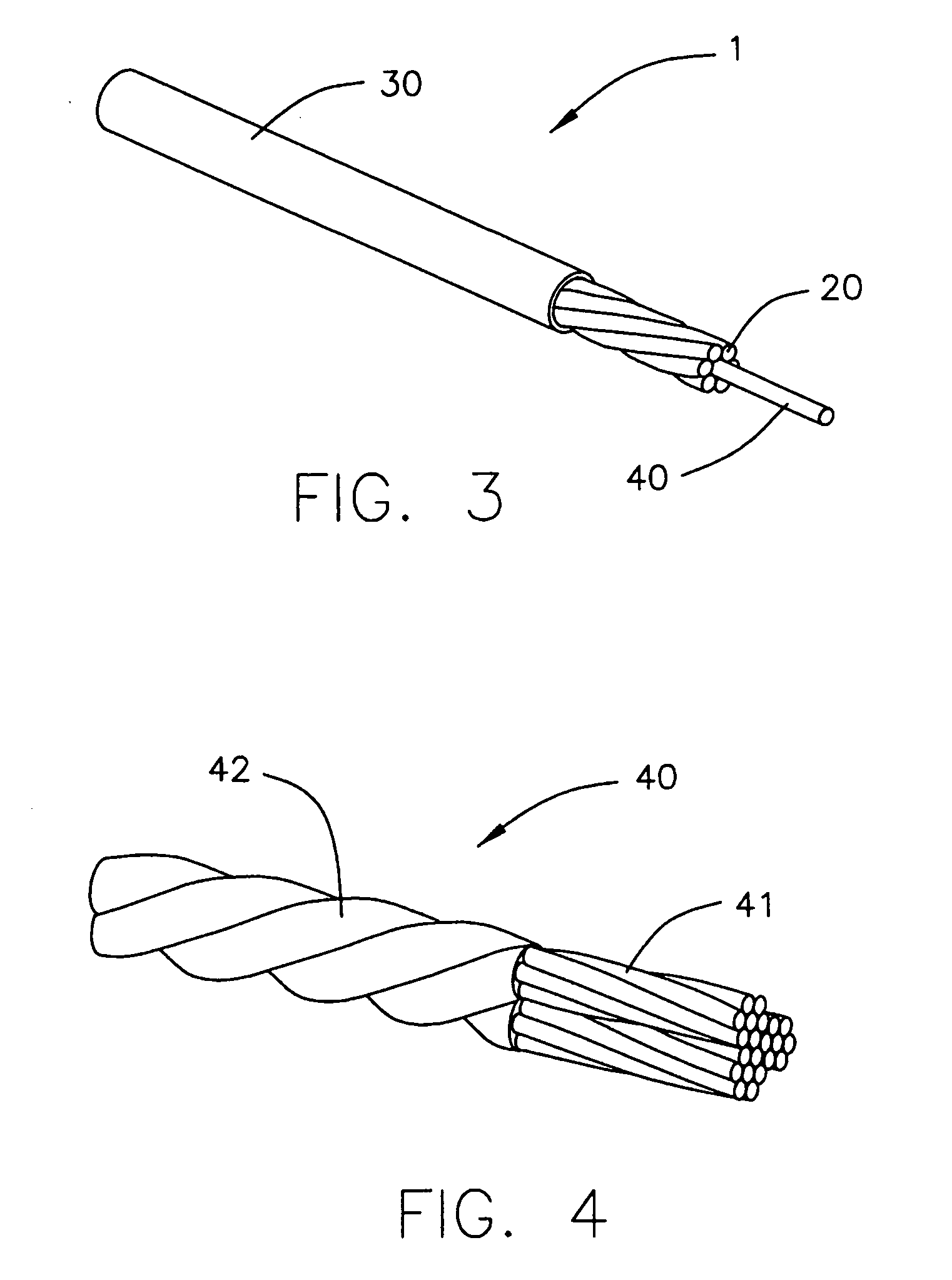

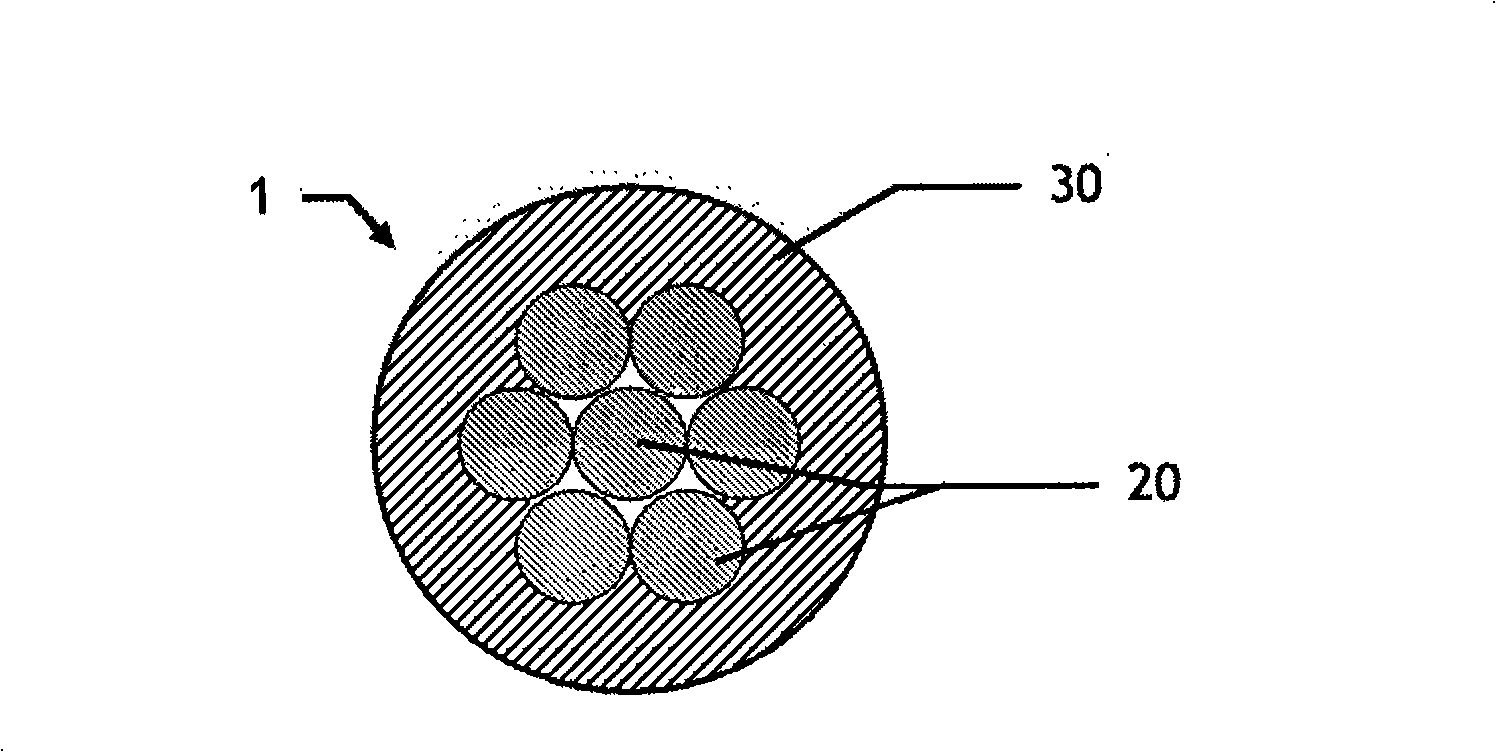

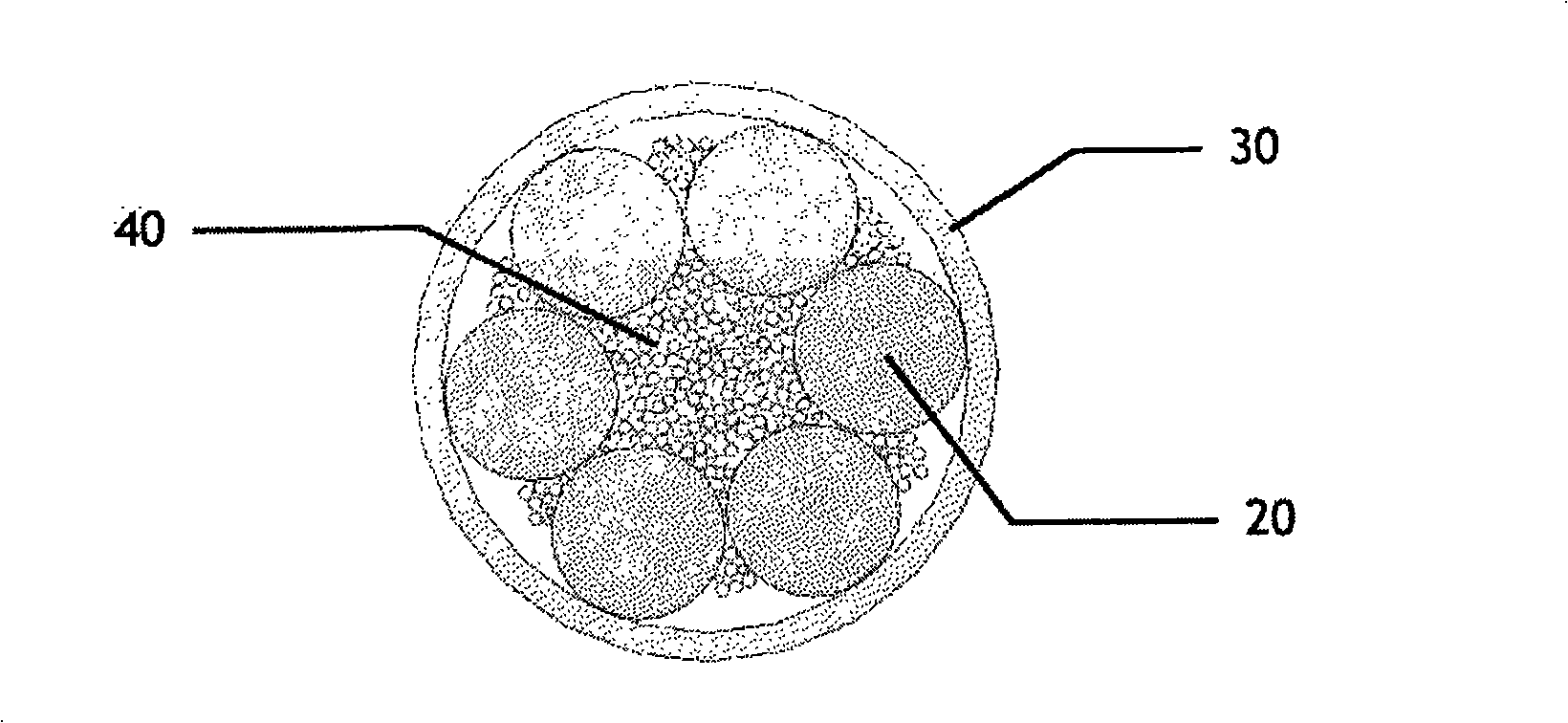

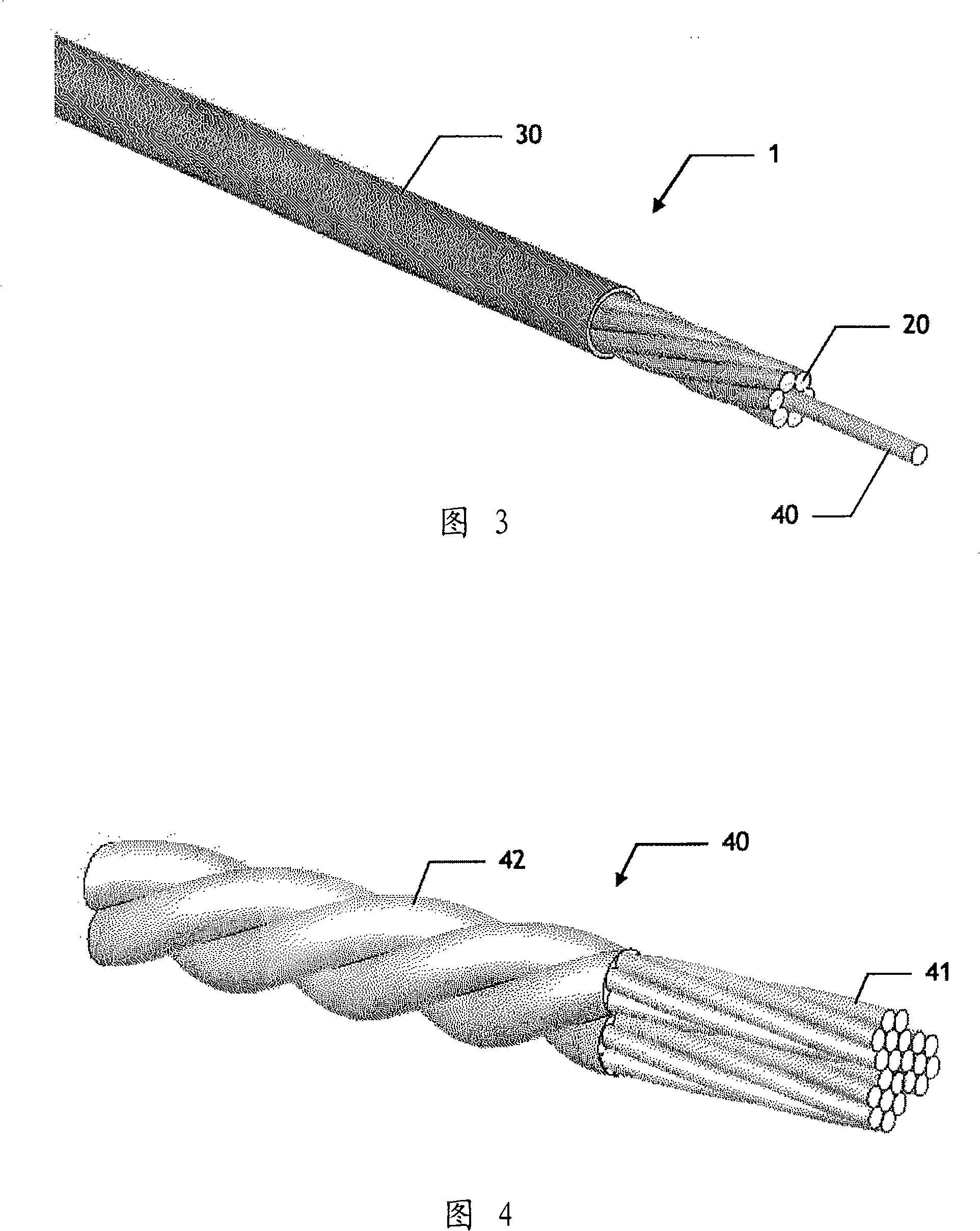

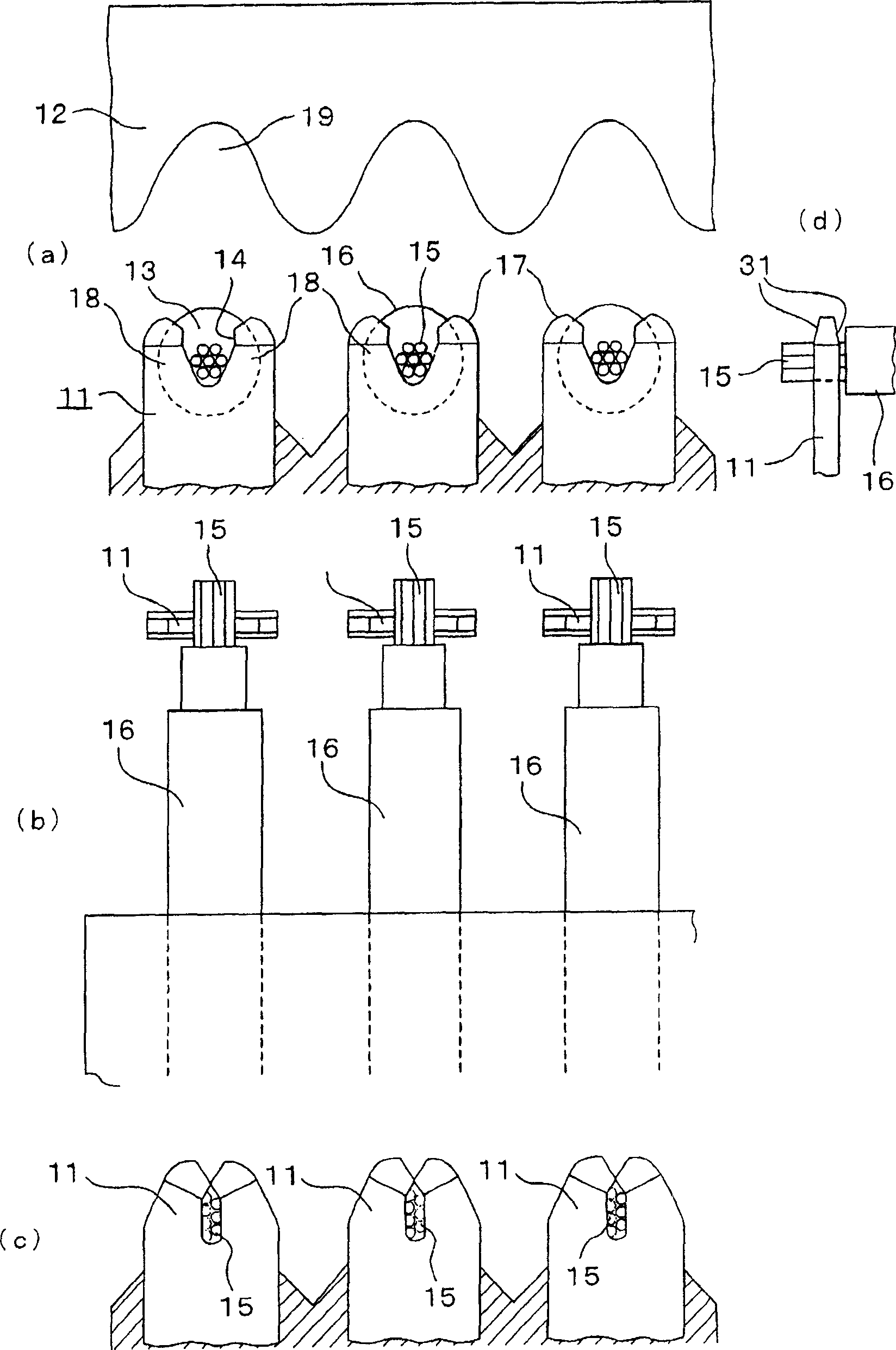

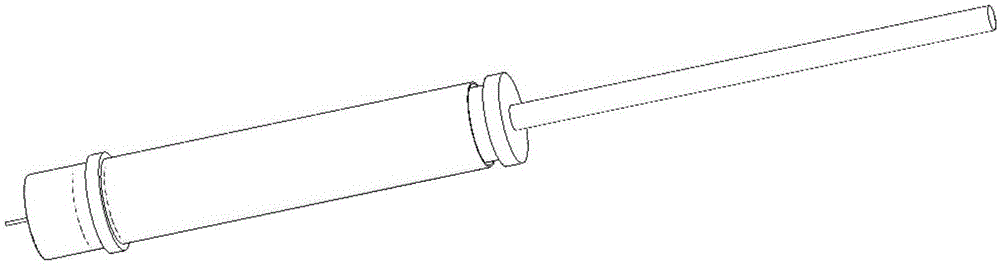

Electrical control cable

InactiveUS8692120B2Reliable crimpingInexpensive to fabricateNon-insulated conductorsInsulated cablesElectricityElectrical conductor

The present invention relates to an electrical control cable of the type comprising a core having a plurality of polymer filaments, a plurality of strands of conductor material extending in the longitudinal direction of said core, an outer insulating sheath. According to the invention, said strands are distributed uniformly and concentrically over the periphery of said core, in contact with one another in pairs and in contact with said core, and the filaments of said core are secured to one another to form a non-metallic unitary structure that is obtained by organizing said filaments into a plurality of subassemblies, the filaments in any one subassembly being twisted together helically, the subassemblies in turn being twisted with one another to form an overall helix. Advantage: the cable uses a limited number of copper strands while guaranteeing that crimping operations are reliable.

Owner:NEXANS

Electrical control cable

InactiveUS20090071688A1Inexpensive to fabricateReliable crimpingPlastic/resin/waxes insulatorsInsulated cablesElectrical conductorElectrical control

The present invention relates to an electrical control cable of the type comprising a core having a plurality of polymer filaments, a plurality of strands of conductor material extending in the longitudinal direction of said core, an outer insulating sheath. According to the invention, said strands are distributed uniformly and concentrically over the periphery of said core, in contact with one another in pairs and in contact with said core, and the filaments of said core are secured to one another to form a non-metallic unitary structure that is obtained by organizing said filaments into a plurality of subassemblies, the filaments in any one subassembly being twisted together helically, the subassemblies in turn being twisted with one another to form an overall helix. Advantage: the cable uses a limited number of copper strands while guaranteeing that crimping operations are reliable.

Owner:NEXANS

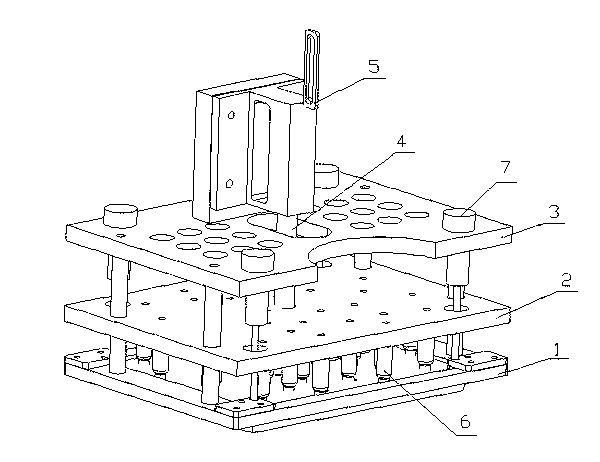

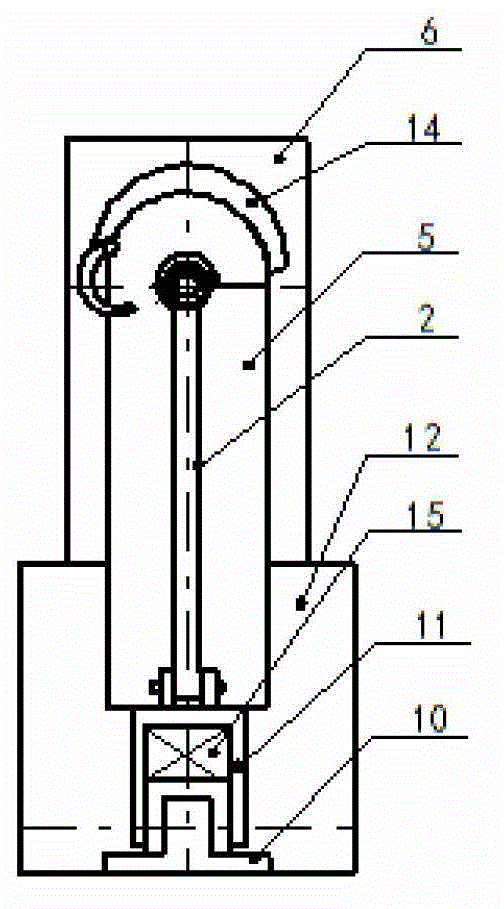

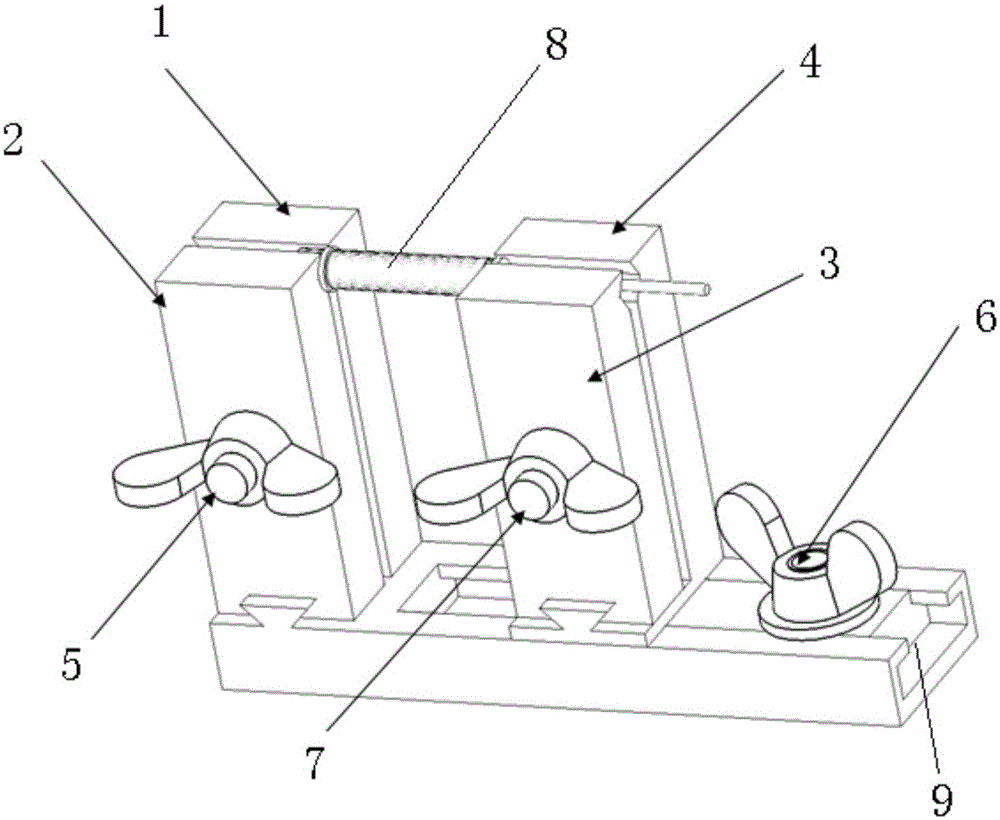

Assembly device for welding circuit board and heat sinking base plate and welding method thereof

InactiveCN102837099AReliable crimpingCrimp firmlySoldering auxillary devicesAudio power amplifierManufacturing technology

The invention discloses an assembly device for welding a circuit board and a heat sinking base plate and a welding method of the assembly device, relating to the emitting and manufacturing technical field of a radio and a television. The assembly device comprises clamping board layers consisting of a bottom board, a middle board and a top board which are horizontally arranged in sequence, and a clamping rod which is arranged on the centers of the clamping plate layers and penetrates through the three layers of the clamping plates, wherein a clamp handle capable of clamping or loosening the three layers of the clamping plates is arranged on the top end of the clamping rod; and bolts for fixing the three layers of the clamping plates are respectively arranged on four corners of the clamping plate layers. A welding piece consisting of a power amplifier module circuit board and the heat sinking base plate can be arranged on the bottom board; a plurality of pressing columns with pressure spring devices are fixedly connected below the middle board vertically; and a position of each pressing column is in one-to-one correspondence with the power amplifier module circuit board and a pressing hole on the heat sinking base plate respectively. Compared with the prior art, the assembly device can effectively ensure the power amplifier module circuit board to reliably connect with the heat sinking base plate for a long time, so as to achieve good electrical conductivity and thermal conductivity, and improve working stability and reliability of an amplifier.

Owner:BEIJING TONGFANG GIGAMEGA TECH

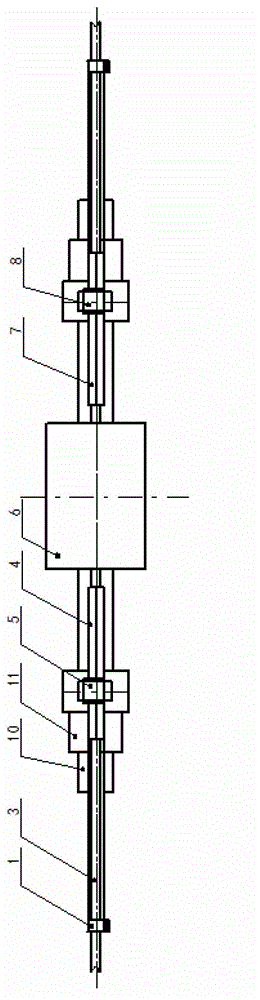

Special ground conducting wire hydraulic compression connection method for transmission line

ActiveCN103337808AHigh precisionAdvanced constructionConnection formation by deformationApparatus for overhead lines/cablesEngineeringTraveling block

The invention relates to a special ground conducting wire hydraulic compression connection method for a transmission line, which comprises the following steps: (1) mounting, before compression connection, a device is well assembled, a steel channel guide rail with a fixed middle area is lay flat on a leveling ground, a hydraulic plier is placed in the steel channel guide rail, a left pulley and a right pulley are mounted on the guide rail along a guide rail groove, and fixtures are mounted on the left pulley and the right pulley; (2) calibrating; (3) a steel pipe compression connection; (4) an aluminium pipe compression connection; and (5) a protection sleeve sleeving. According to the invention, the method is advanced in construction and simple to operate, can be suitable for the application of various compression connection tubes after a horizontal mid-partition limiting aluminium pipe is adopted, has high precision for horizontally compressing and connecting butted steel connecting pipes and connecting aluminium pipes, can support and hold aluminium conducting wires per se, automatically completes the straightening of ground conducting wires, completely avoids various problems existing in the manual compression and connection, and has the advantages that the compressing connection is reliable, the precision is high and the cost is low.

Owner:STATE GRID CORP OF CHINA +1

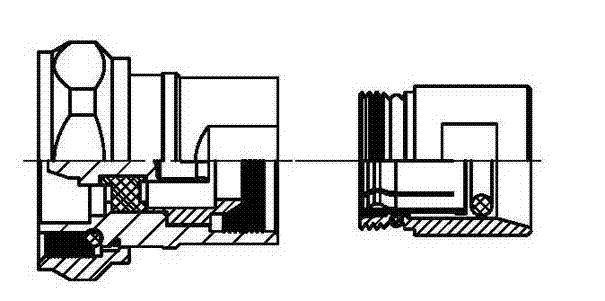

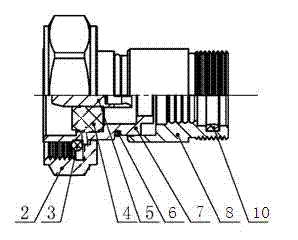

Integrated crimping connector

InactiveCN102832473AEasy to installReliable crimpingRelieving strain on wire connectionCoupling contact membersElectrical conductorInterference fit

The invention provides an integrated crimping connector, which comprises a screw sleeve, an insulator, a contact pin, a shell and a cable clamp. The insulator is arranged in the shell. The contact pin is fixed by the insulator. A first O-shaped ring is arranged between the insulator and the shell. The end part of the contact pin is grooved and closed to form an elastic structure. According to the integrated crimping connector, an inner conductor of a cable is clamped by the elastic structure of the contact pin, and reliable connection can be realized by interference fit and one-time crimping between the shell and the cable clamp or between the shell and a rear shell, so that the cable can be conveniently arranged and used; on the head part of the connector, during the interference fit connection of a front rubber shell and the rear plastic shell, the front rubber shell and the rear plastic shell are elastically deformed around, thereby sealing the connector; and on the tail part of the connector, the rear plastic shell is in threaded connection with the cable clamp to tightly press a middle threaded sealing ring, thereby sealing the connector to form a good waterproof structure.

Owner:CHANGZHOU AMPHENOL FUYANG COMM EQUIP CO LTD

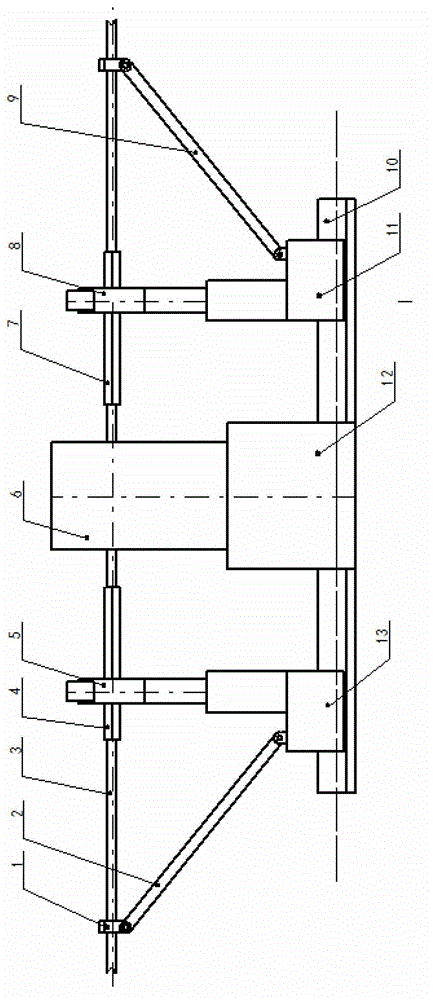

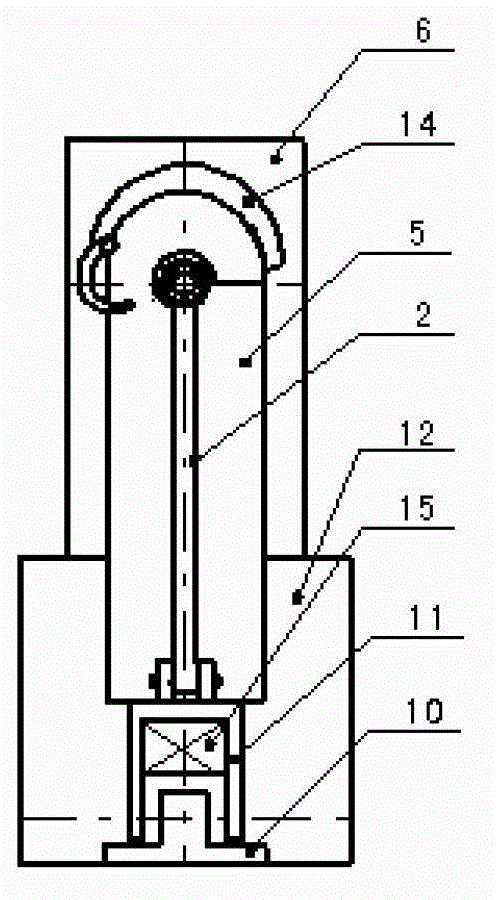

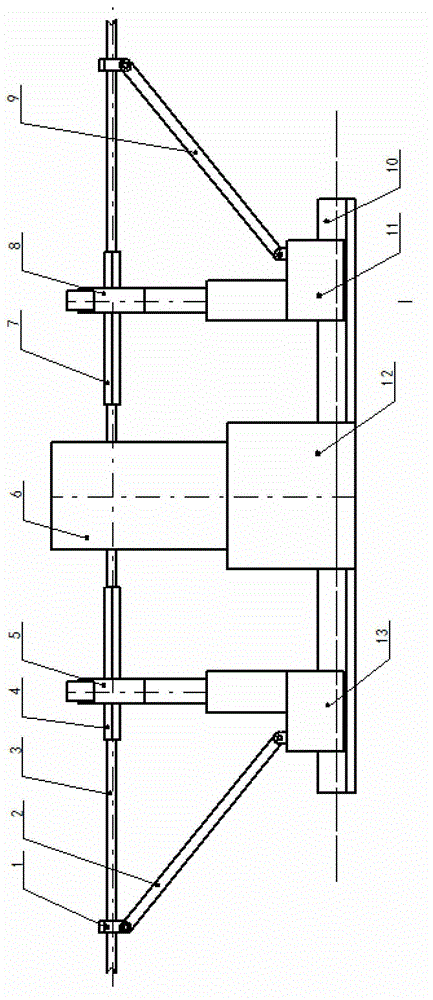

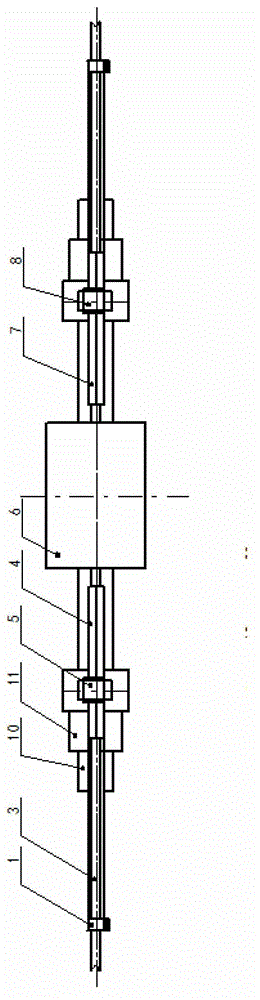

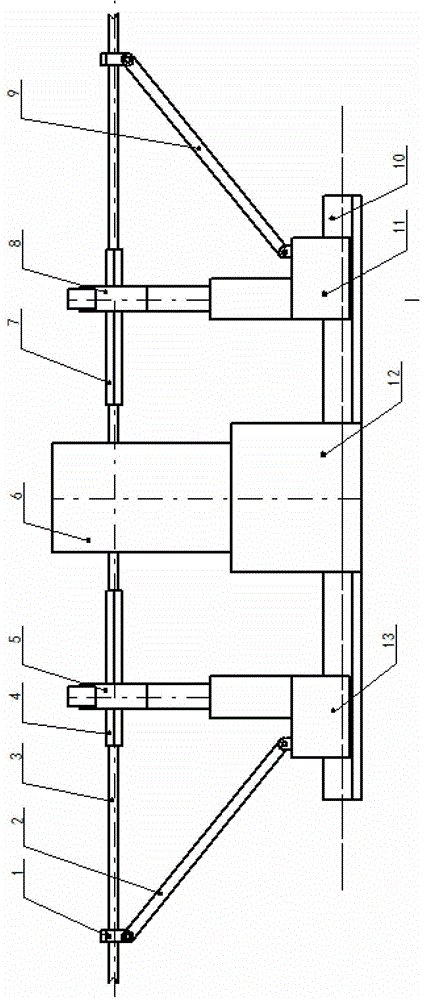

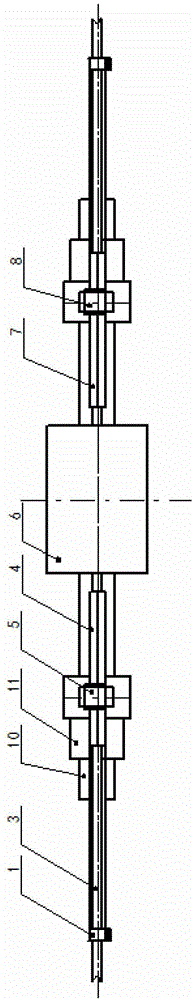

Special ground conducting wire hydraulic compression connector for transmission line

ActiveCN103337814AHigh precisionAdvanced constructionConnection formation by deformationApparatus for joining/termination cablesEngineeringTraveling block

The invention relates to a special ground conducting wire hydraulic compression connector for a transmission line, which comprising a hydraulic plier, a left fixture, a right fixture, a left supporting-holding rod, a right supporting-holding rod and a channel steel guide rail, wherein the hydraulic plier is mounted in the middle of the channel steel guide rail in a positioning manner through a positioning base; the left fixture and the right fixture are symmetrically arranged on the left side and the right side of the hydraulic plier, and operate in a sliding manner respectively through a left tackle and a right tackle both sliding on the channel steel guide rail; mounting holes respectively manufactured by the left fixture, the hydraulic plier and the right fixture are on the same axis; the left supporting-holding rod and the right supporting-holding rod are hinged to the left tackle and the right tackle respectively in a mirror symmetry manner. According to the invention, the special ground conducting wire hydraulic compression connector is advanced in construction and simple to operate, can be suitable for the application of various compression connection tubes after a horizontal mid-partition limiting aluminium pipe is adopted, has high precision for horizontally compressing and connecting butted steel connecting pipes and connecting aluminium pipes, can support and hold aluminium conducting wires per se, automatically completes the straightening of ground conducting wires, completely avoids various problems existing in the manual compression and connection, and has the advantages that the compressing connection is reliable, the precision is high and the cost is low.

Owner:STATE GRID CORP OF CHINA +1

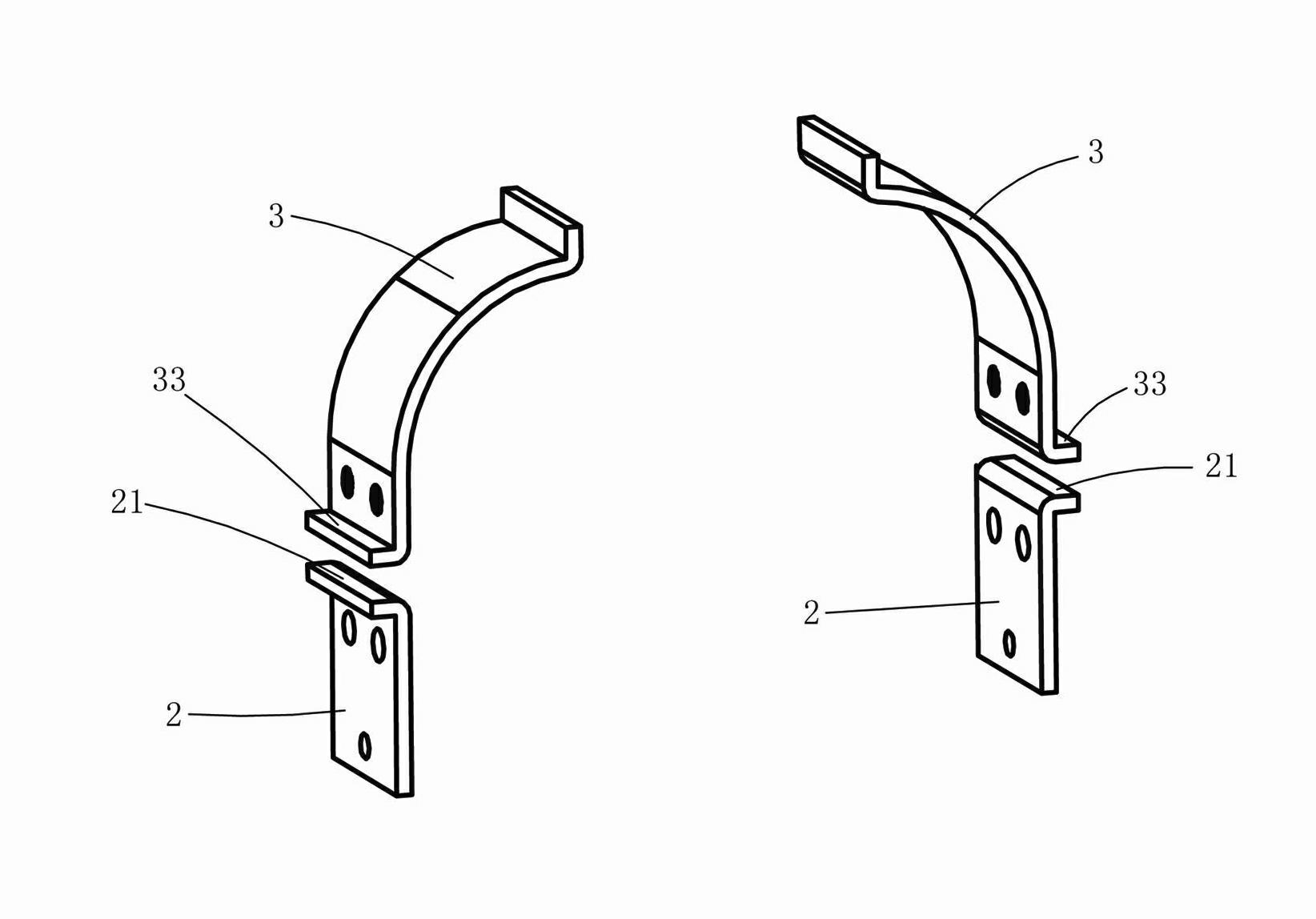

Ground wire clamp

ActiveCN103001022AEasy to fixNot easy to fall offElectric connection structural associationsClamped/spring connectionsElectrical conductorEngineering

The invention relates to a ground wire clamp which comprises a side plate and a top plate. The side plate is arc-shaped, one end of the side plate is connected with the top plate, a first fixing groove is arranged on the end face of the other end of the side plate, the side plate is connected with a base plate through the first fixing groove, and two fixing plates are installed at two ends of the base plate respectively. The fixing plates are matched with the first fixing groove, the middle of the base plate is provided with a sixth connecting hole, a connecting pipe is arranged on the sixth connecting hole, one end of the connecting pipe is fixed on the upper surface of the base plate, and a first limiting round block is installed at the other end of the connecting pipe. The ground wire clamp has the advantages that a round conductor can be fixed by enabling a press block to be matched with the side plate, a rectangular conductor can be fixed by enabling a press plate to be matched with the side plate, the press block is connected with the press plate, conductors of different shapes can not only be fixed respectively, but also be convenient to replace, a wire is pressed firmly and cannot be dropped easily, and the conductors are fixed on the base plate through an upper press plate, so that the conductors are fixed firmly. By using a hanging buckle, the ground wire clamp is convenient to carry and cannot be dropped easily.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

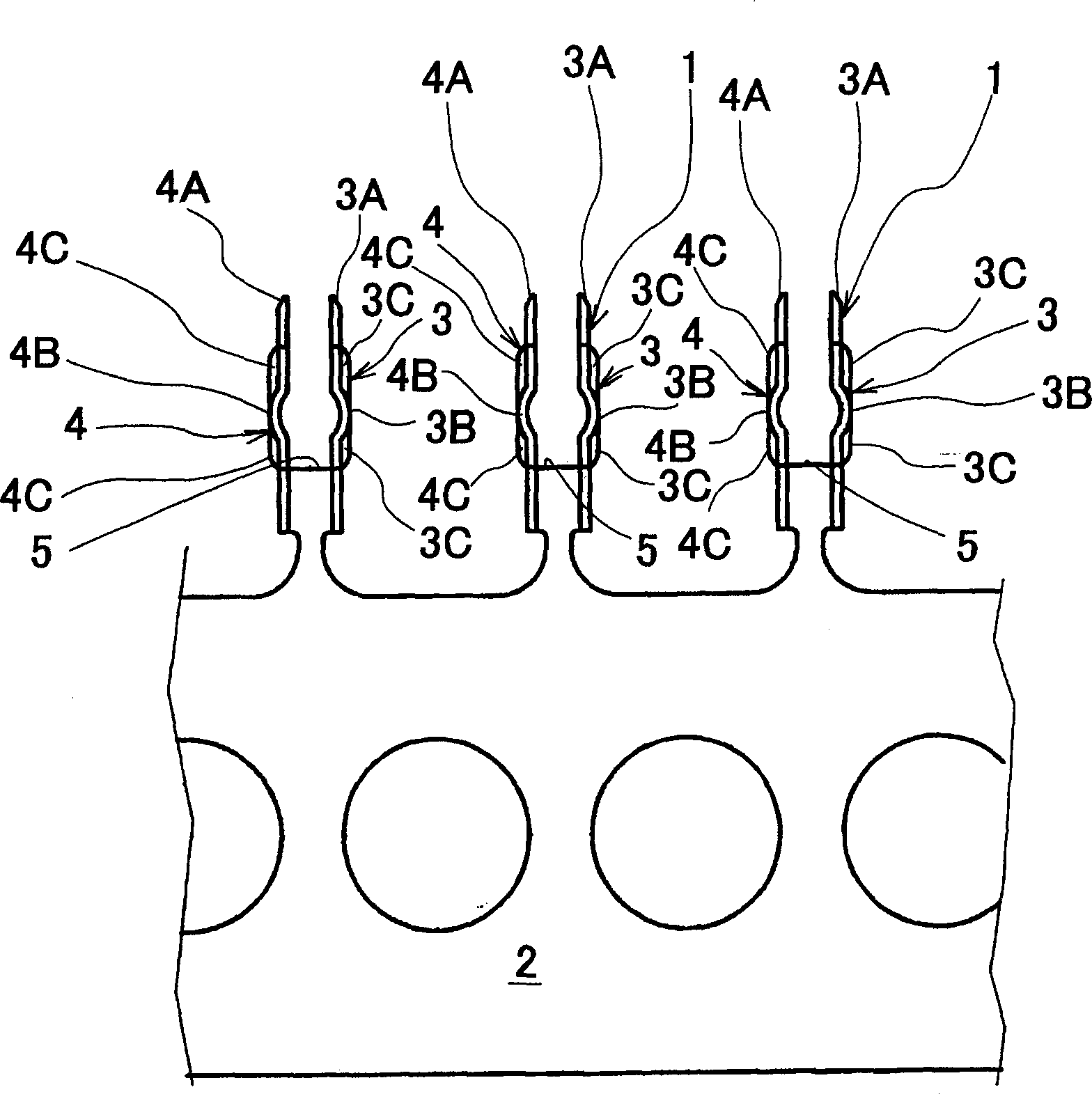

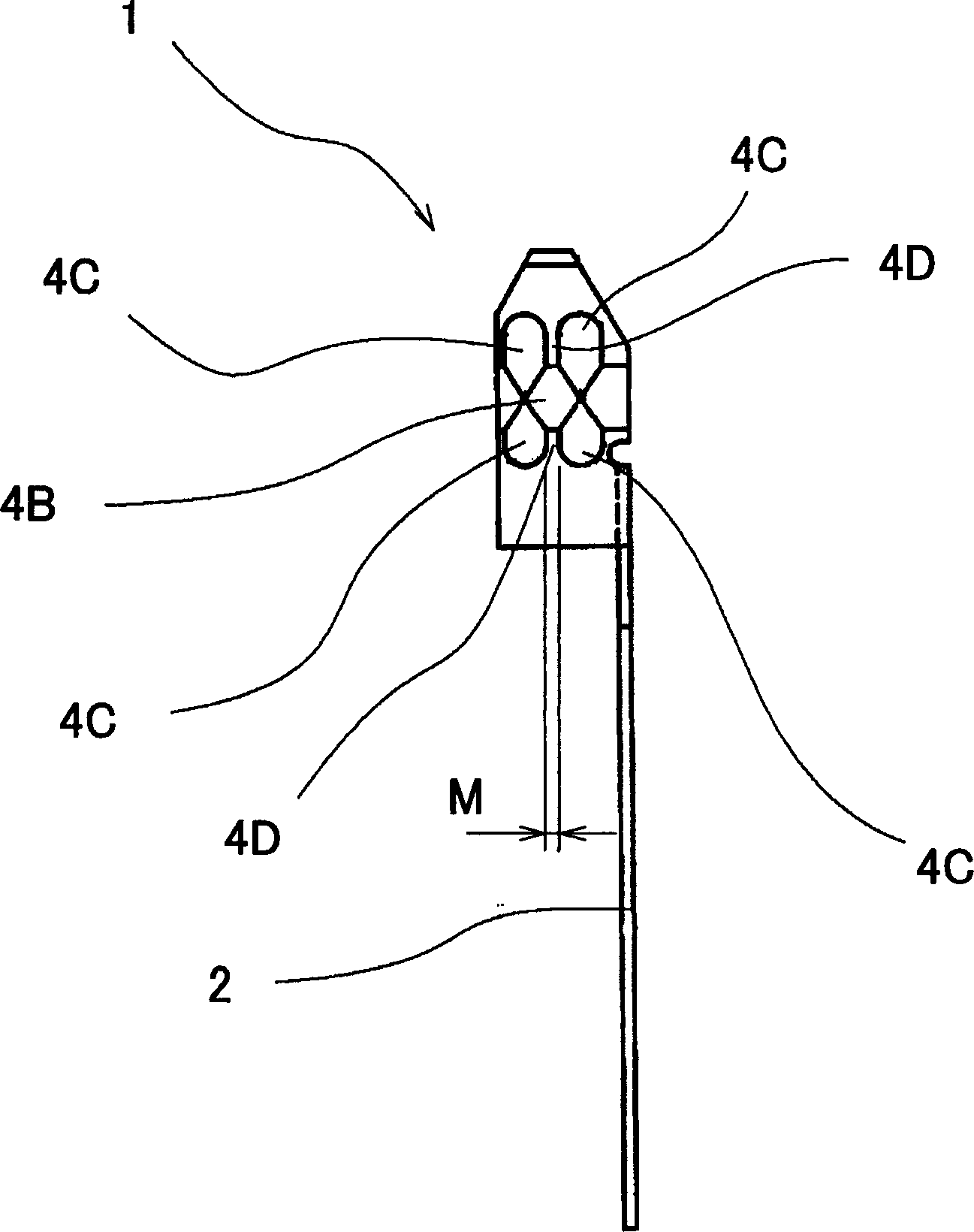

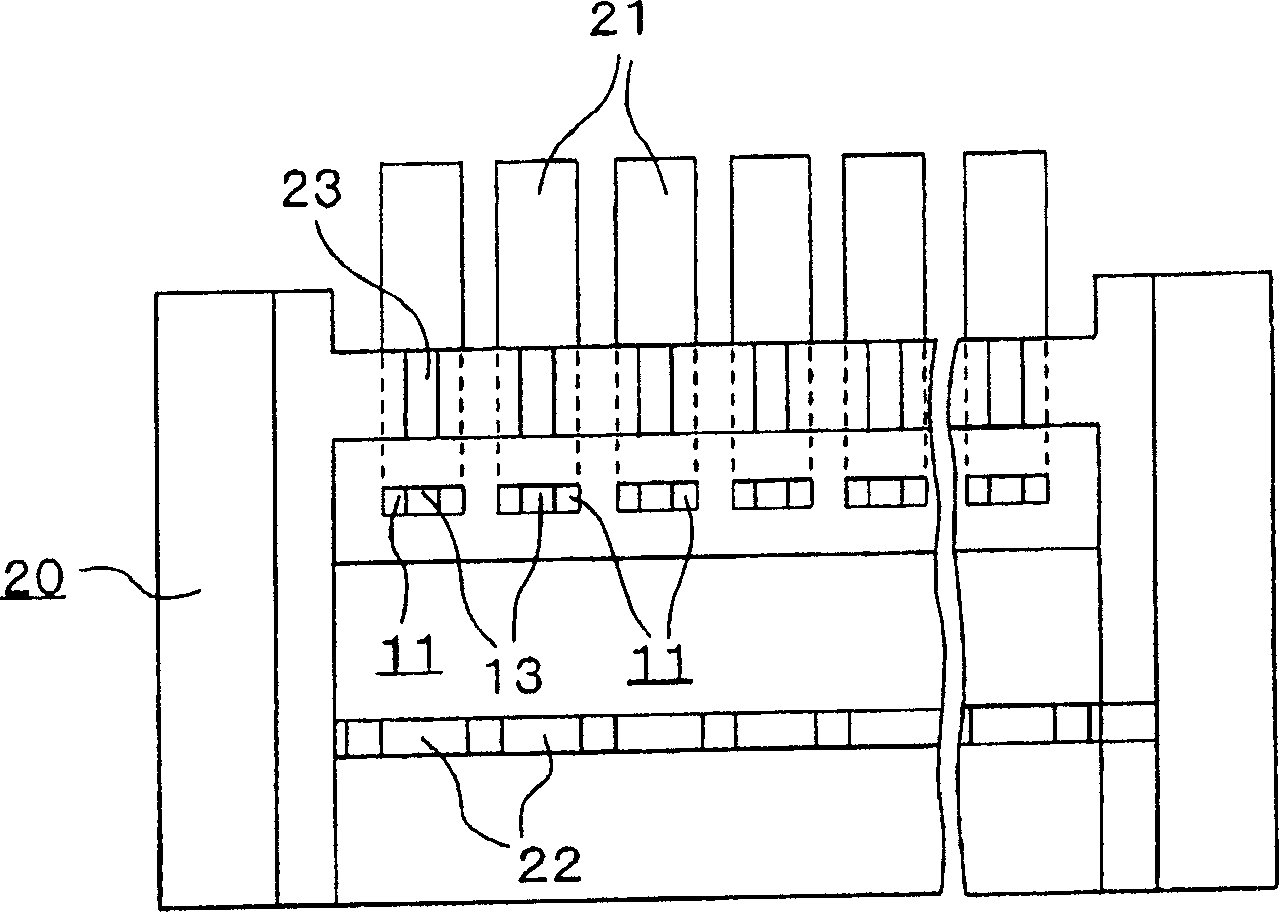

Pressure connection structure with coaxial cable

InactiveCN1619885ASimple homeworkReliable crimpingMulticonductor cable end piecesElectrical conductorCoaxial cable

Provides a coaxial cable crimping structure that can reduce the processing steps for the end of the coaxial cable 1 with an extremely thin outer diameter or simplify the processing. For a structure having a central conductor core, an inner insulating layer covering the central conductor core, an outer conductor shield covering the inner insulating layer, and an outer insulating layer covering the outer conductor shield, the aforementioned first housing member and the aforementioned first The two housing parts clamp the plurality of coaxial cables processed to a state in which the front end side removes the aforementioned outer conductor shielding layer and the outer insulating layer to expose the aforementioned inner insulating layer, and the aforementioned piercing terminal pierces the aforementioned outer The insulating layer is electrically connected to the outer conductor shielding layer. In addition, the U-shaped portion of the front end of the crimping contact pierces the inner insulating layer and is electrically connected to the central conductor core wire.

Owner:JST MFG CO LTD

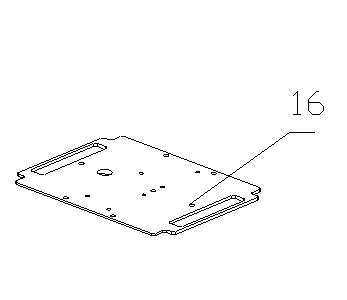

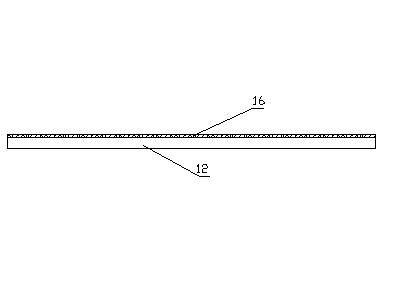

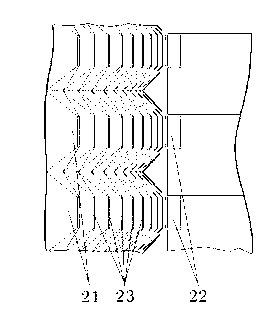

Electrical control cable

InactiveCN101350235AReliable crimpingCheap manufacturingInsulated cablesDetails of conductive coresFiberElectrical control

The application relates to an electric control cable (1), which comprises multiple polymer fiber cores (40), multiple cable strands (20) made of conducting material extended along the longitudinal direction of the cores and an exterior insulating sheath. According to the invention, the cable strands (20) are arranged around the cores uniformly and concentrically connecting to each other in pair while connecting to the cores; the fibers of the cores are fixed together to form a nonmetallic integral structure in the steps of arranging the fibers into multiple components, twisting the fibers in each component, and twisting the all the components one by one into a whole helical structure. The invention can keep the used copper cable strands in limited quantity, while ensure the pressure operation is reliable.

Owner:NEXANS

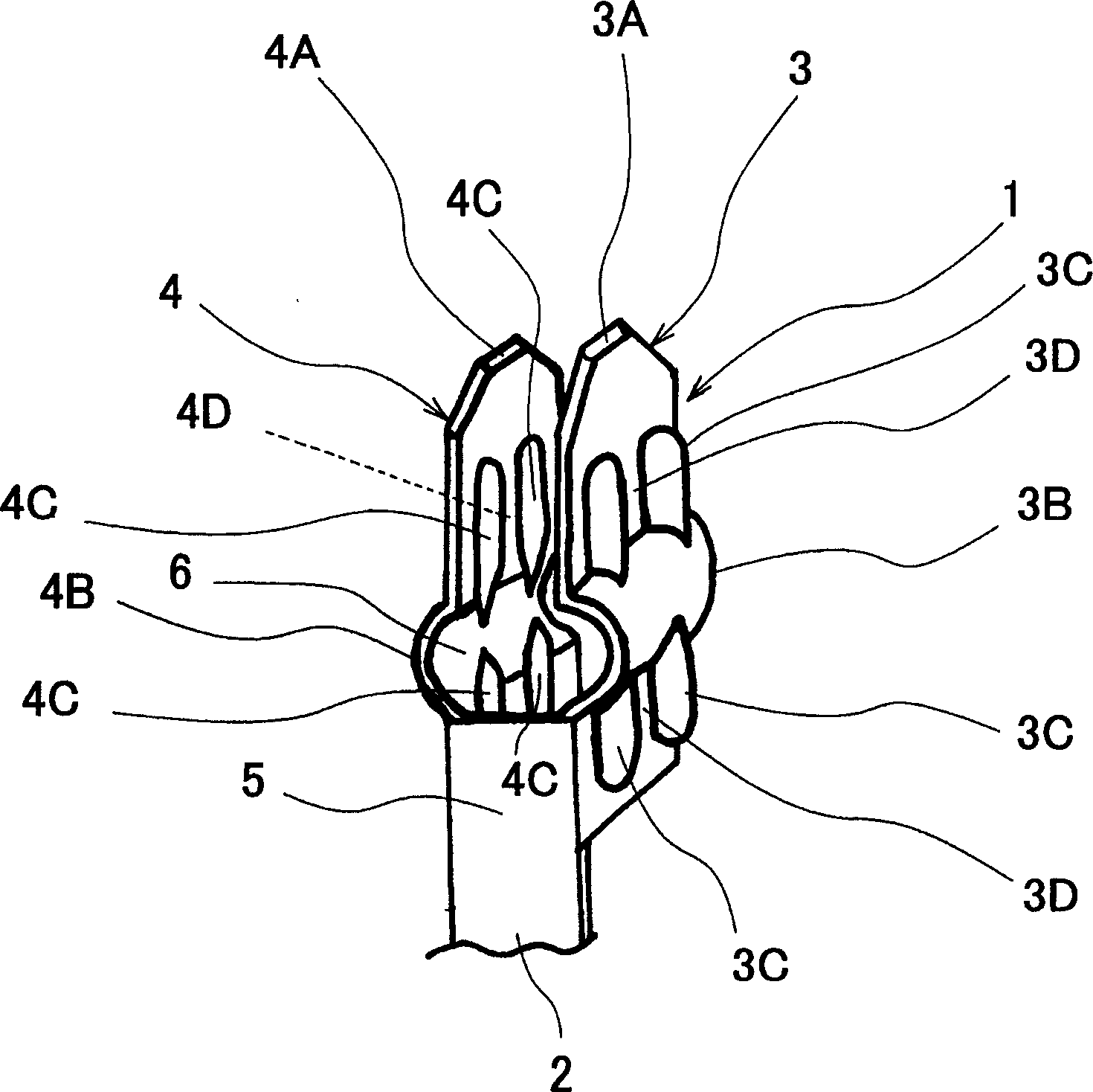

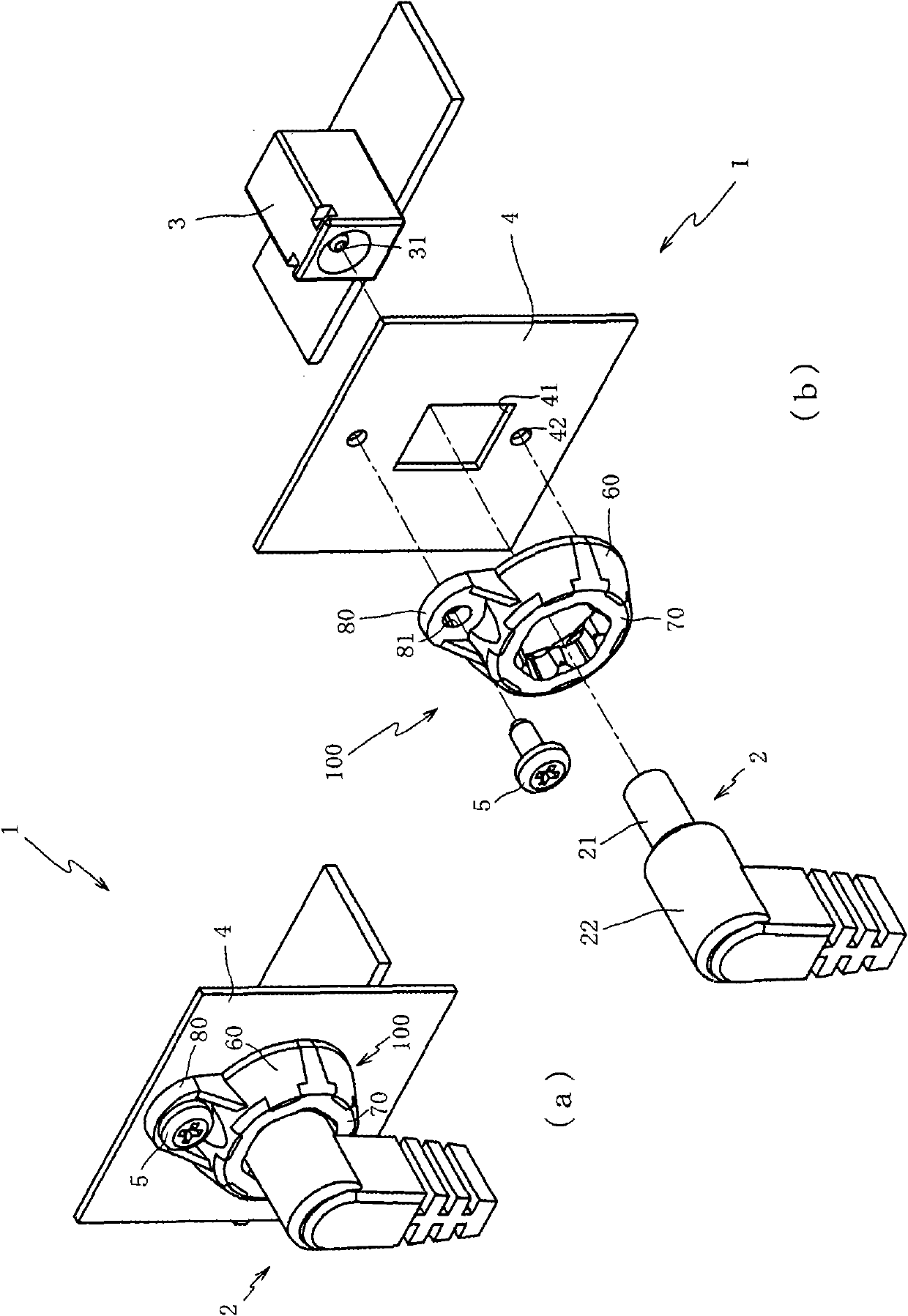

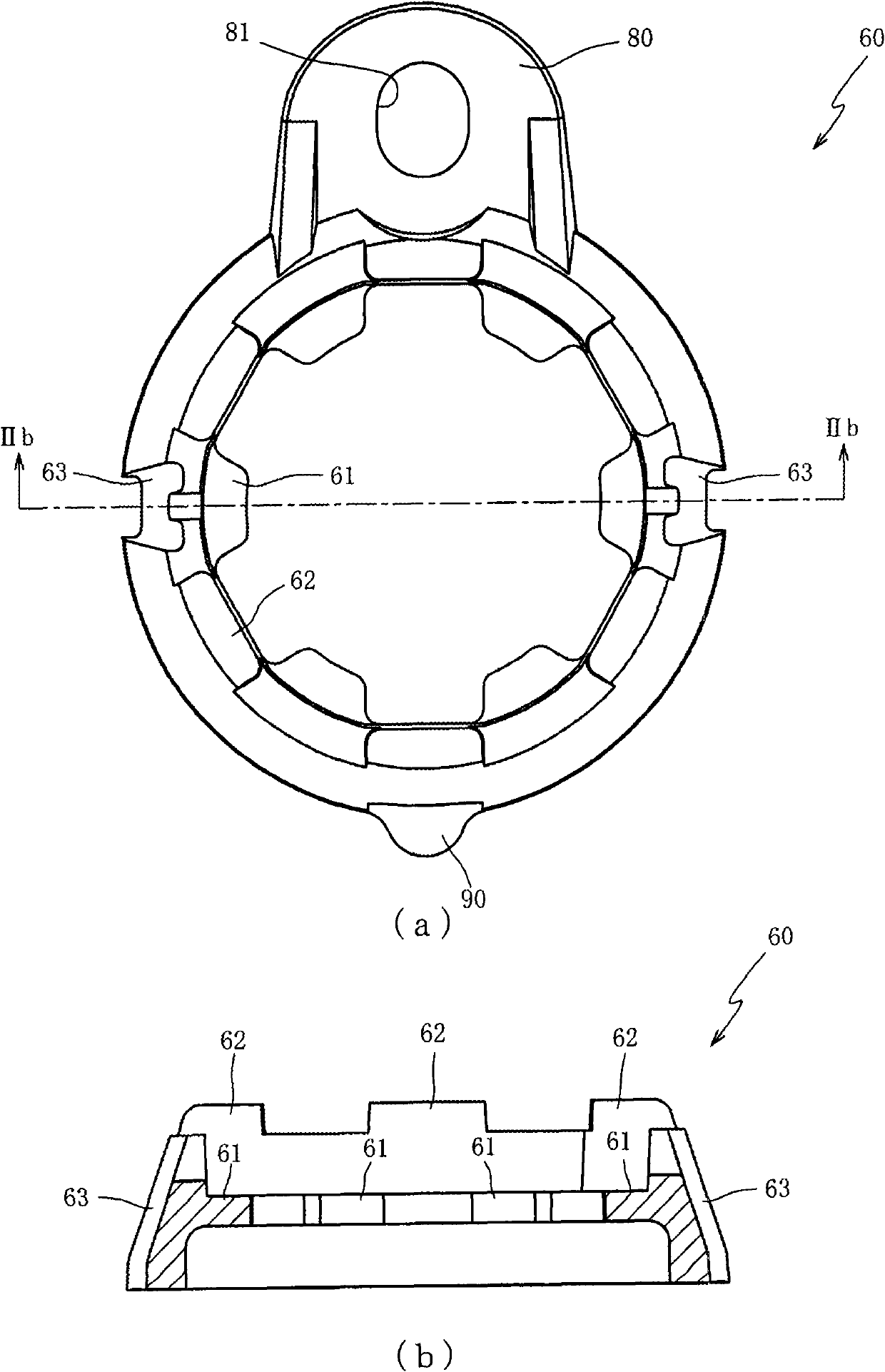

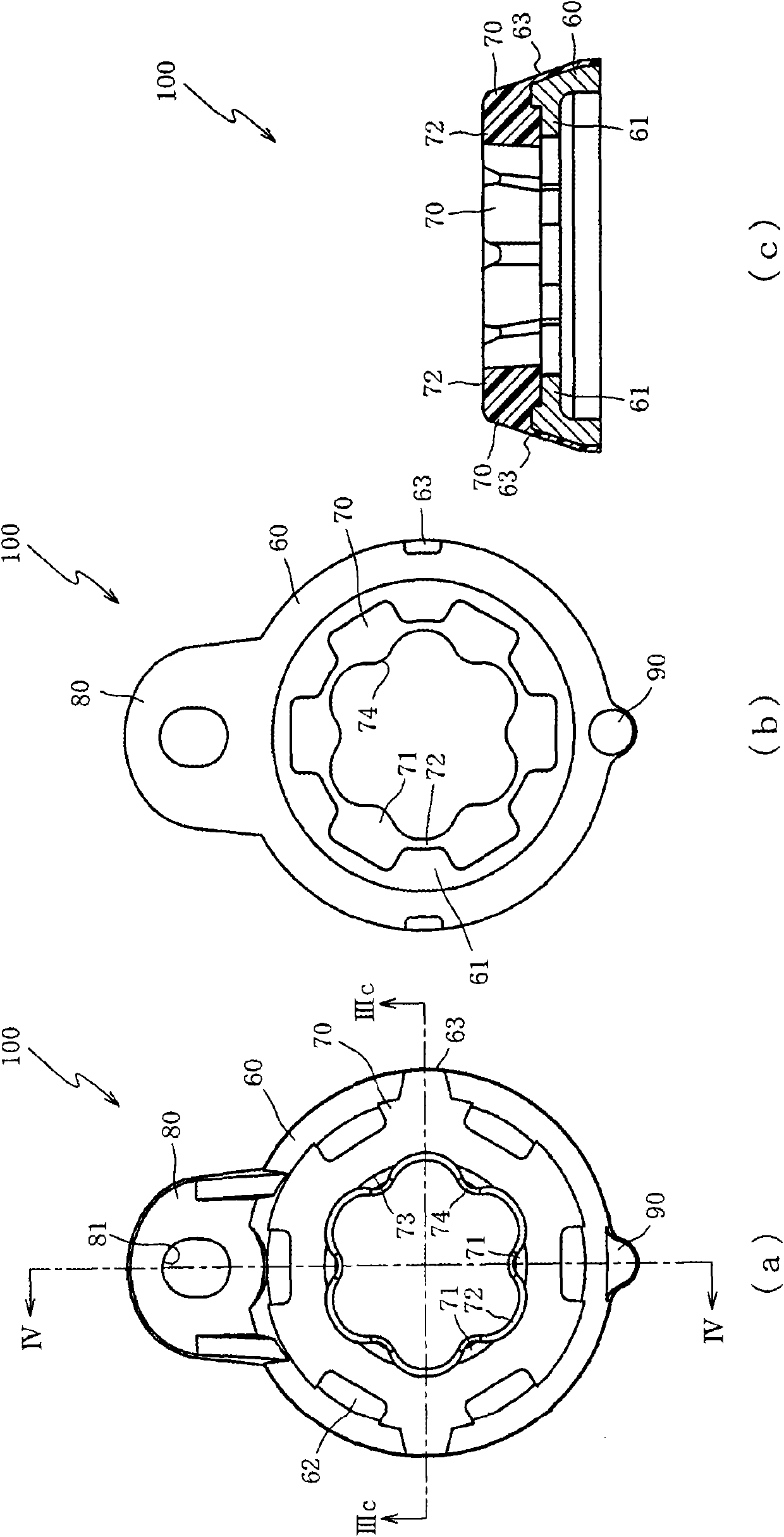

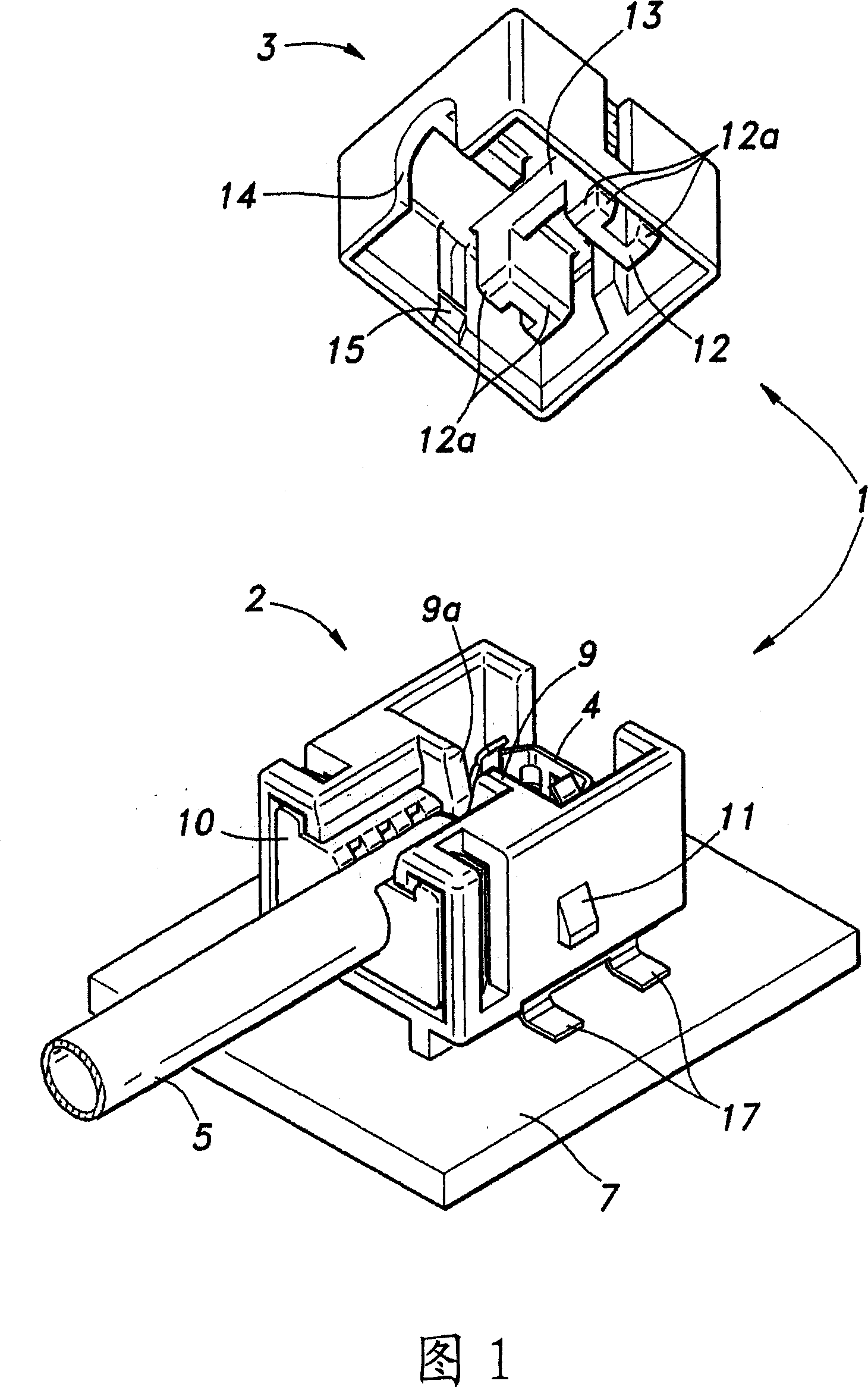

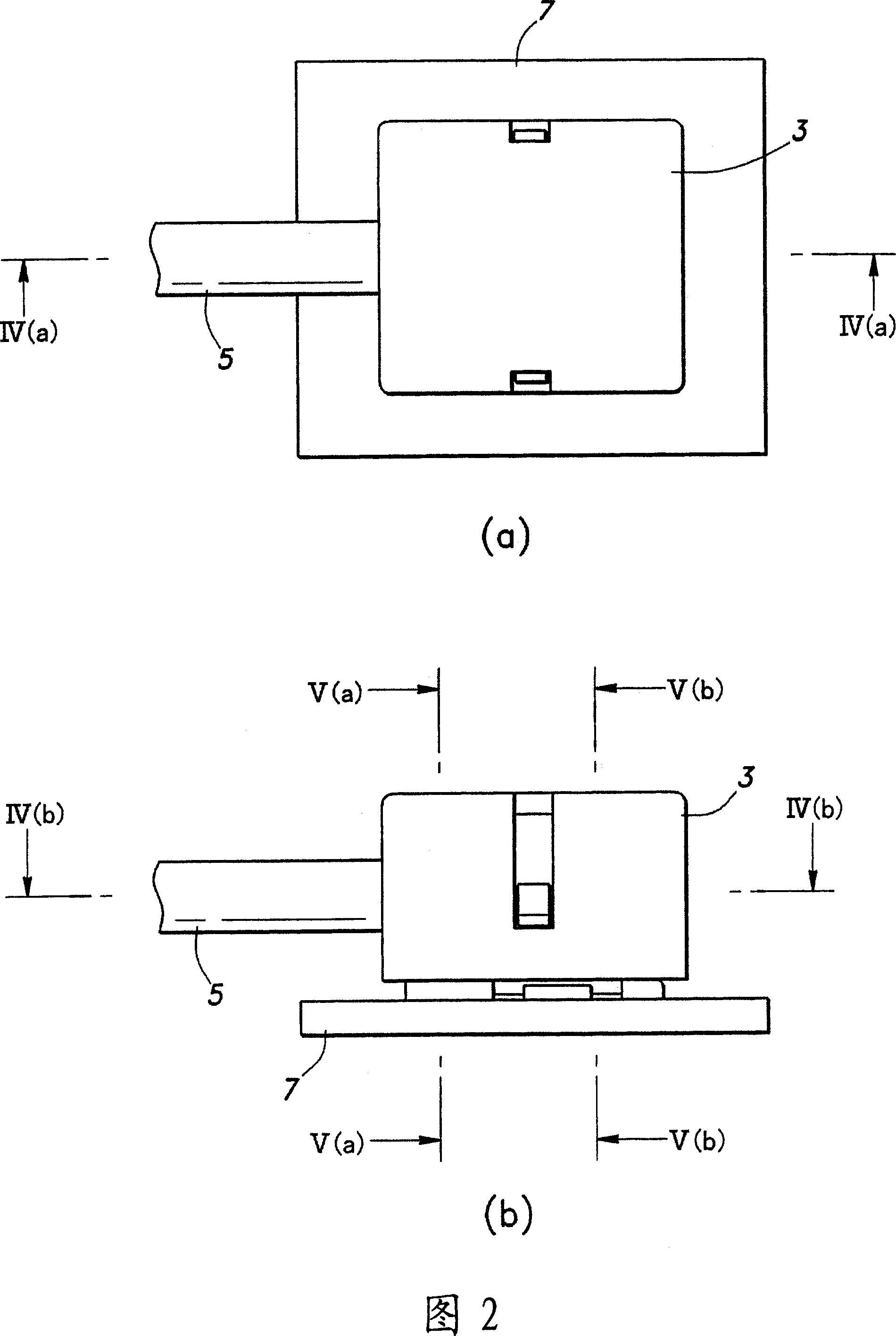

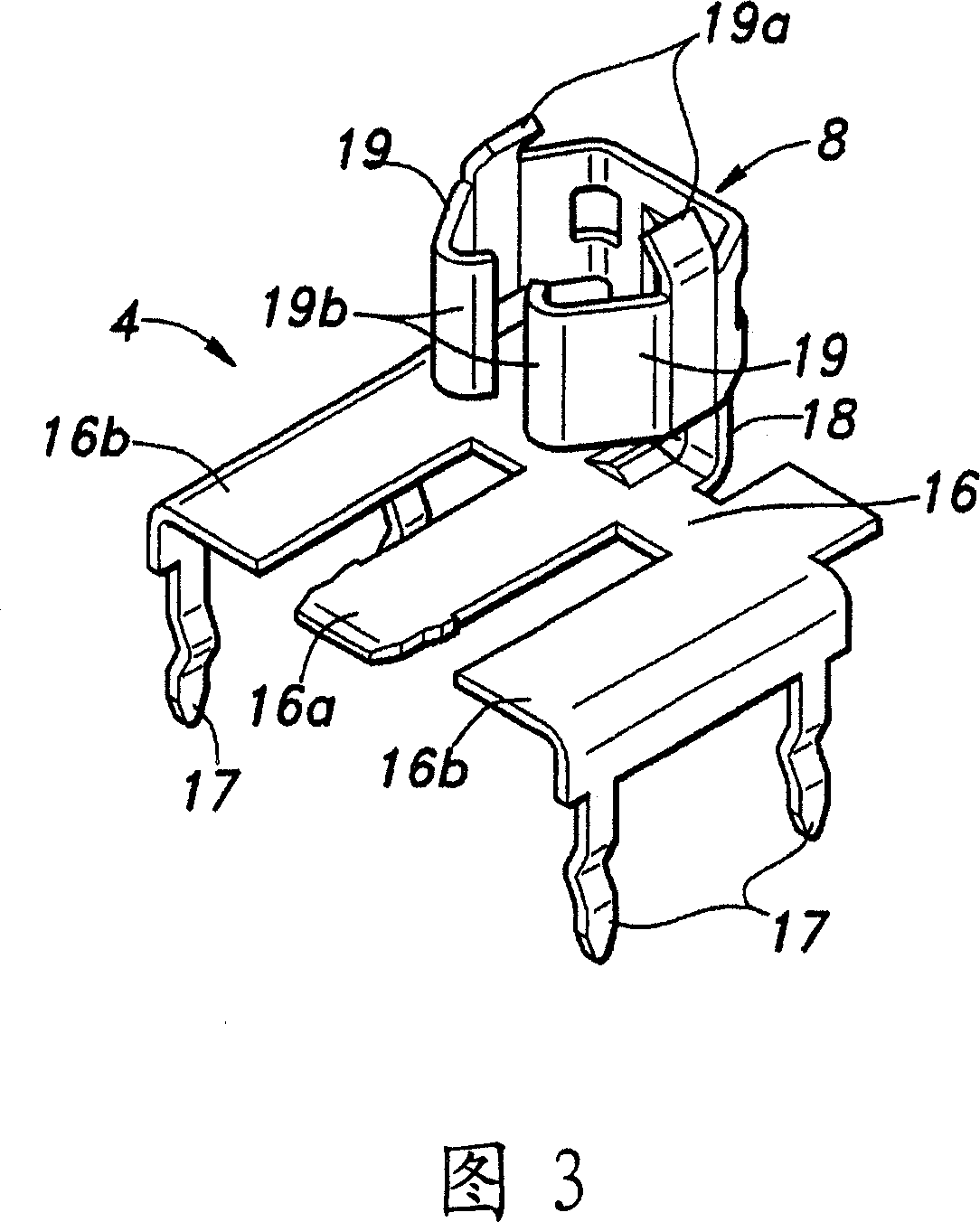

Plug detachment prevention structure

InactiveCN102005671ALarge margin of errorResilience inhibitionCoupling device detailsTwo-part coupling devicesEngineeringSynthetic rubber

The present invention relates to plug detachment prevention structures and, in particular, to plug detachment prevention structures that can provide greater tolerance for assembling accuracy among parts including plugs and jacks, as well as improve their general applicability. A plug fastener 100 is formed by a frame section 60 made of ABS resin and an elastic section 70 made of synthetic rubber. Thereby the plug fastener 100 is firmly fixed. It is noted that, when the plug fastener 100 is attached to the housing 4, and when an error is present in coaxial accuracy among the plug fastener 100, the plug 2 and the jack 3, the elastic section 70 may be elastically deformed thereby correcting the error in the coaxiality, whereby a tolerance can be given for assembling accuracy among the parts including the plug fastener 100, the plug 2 and the jack 3. Accordingly, it is not necessary to set the coaxial accuracy to a high degree at the time of attaching the frame section, such that the frame section can be effectively attached.

Owner:ROLAND CORP

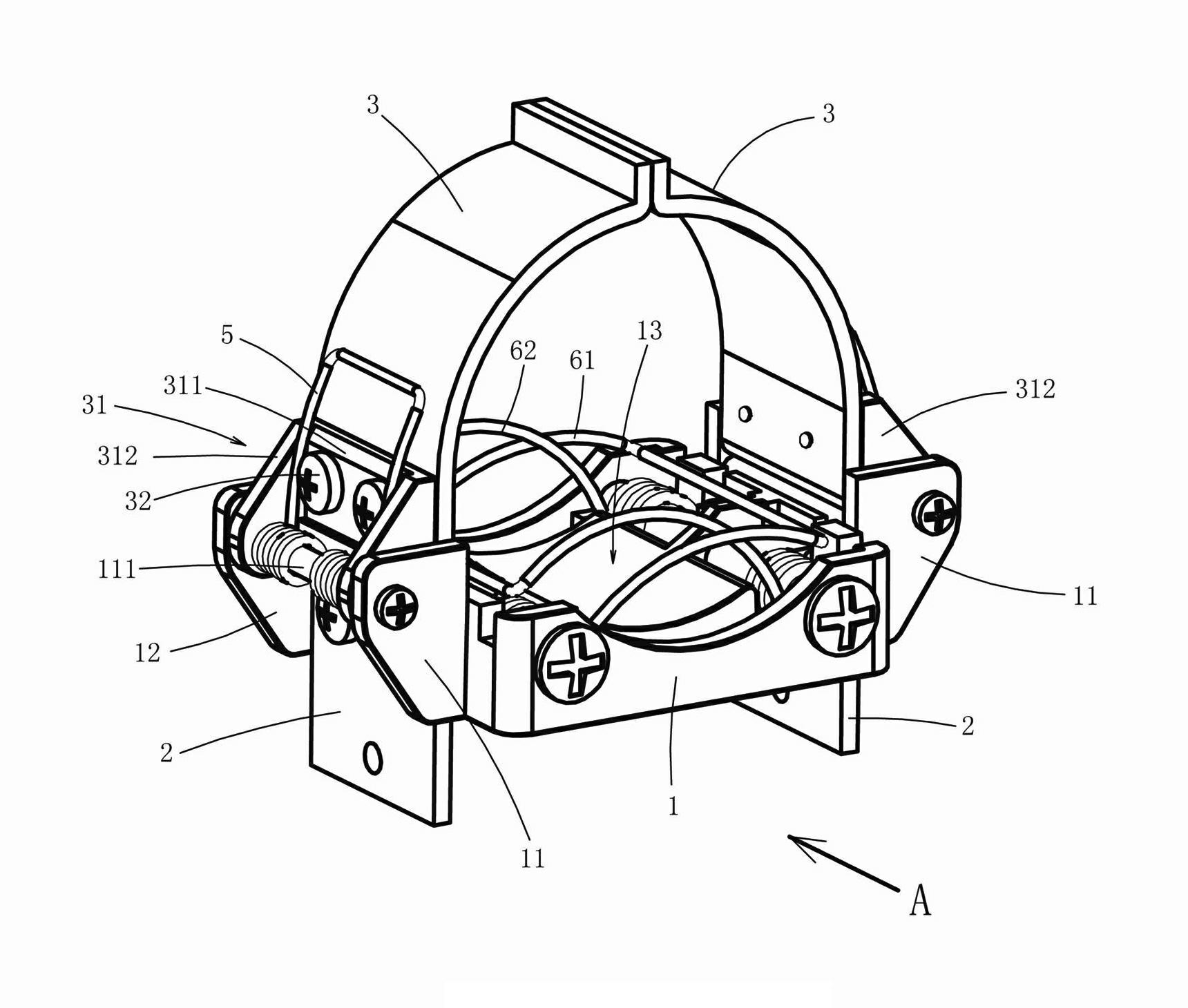

Cable clamping device of electric power circuit fault indicator

ActiveCN102141188ALow costEasy to make and installMachine supportsElectrical testingFault indicatorStructural engineering

The invention discloses a cable clamping device of an electric power circuit fault indicator. The device comprises a base, two vertical columns, two magnetic conduction plates capable of opening and closing and a resetting mechanism, wherein the vertical columns are oppositely arranged on the two sides of the base; the resetting mechanism is used for driving the magnetic conduction plates to be closed and pressed against each other; and a cable pressing device for pressing a working cable is arranged on the base. The device is characterized in that: the base is an integrated integral type base; the vertical columns are fixedly arranged on the two sides of the base; the magnetic conduction plates are arc-shaped panels; the lower end parts of the two magnetic conduction plates are fixedly connected with a pivoting seat respectively; pivoting seats are hinged on the base; the magnetic conduction plates are rotatably arranged on the corresponding part of the base through corresponding pivoting seats; the lower end part of each magnetic conduction plate is fixedly connected with one pivoting seat; two pairs of lug plates which are integrated with the base are correspondingly arranged on the two sides of the base; a pin shaft is inserted into the space between every two lug plates; and the pin shaft between the two lug plates are rotatably inserted into the pivoting seat. The lower ends of the magnetic conduction plates which are made of expensive materials are not required to be molded with pin seats, so that a large number of magnetic conduction materials are saved, and the cost is reduced; and the base is integrated, so that the device has high structural integrity and a reasonable design and is easy to mount and manufacture.

Owner:FUJIAN HONGKE ELECTRIC POWER SCI & TECH CO LTD

Strip direct splicing device

The invention provides a strip direct splicing device. The strip direct splicing device comprises a new strip coil supporting mechanism and an old strip coil supporting mechanism, and is characterized in that a crimping mechanism is arranged between the new and the old strip coil supporting mechanisms, the crimping mechanism comprises a roll pair which is respectively provided with a terrace die and a concave die, both a new strip and an old strip are respectively arranged between the terrace die and the concave die, each roll shaft of the roll pair is provided with a gear, the two gears are engaged with each other, and a wheel shaft of one gear is connected with a power machine. Under the situation that no splicing auxiliary material is used, the new strip can be spliced onto the old strip on line so as to continuously supply a packing strip to a main production unit and complete the alternation between the new packing strip and the old packing strip. The strip direct splicing device is simple in structure, free from polluting main materials for producing cigarettes, free from breaking and folding the strips, reliable in crimping, high in automation degree, flexible to arrange, convenient to maintain and repair, and not only applicable to the splicing of cigarette paper and filter rod paper, but also applicable to the splicing of the packing strips in any width or any length.

Owner:KUNMING DINGCHENG TECH

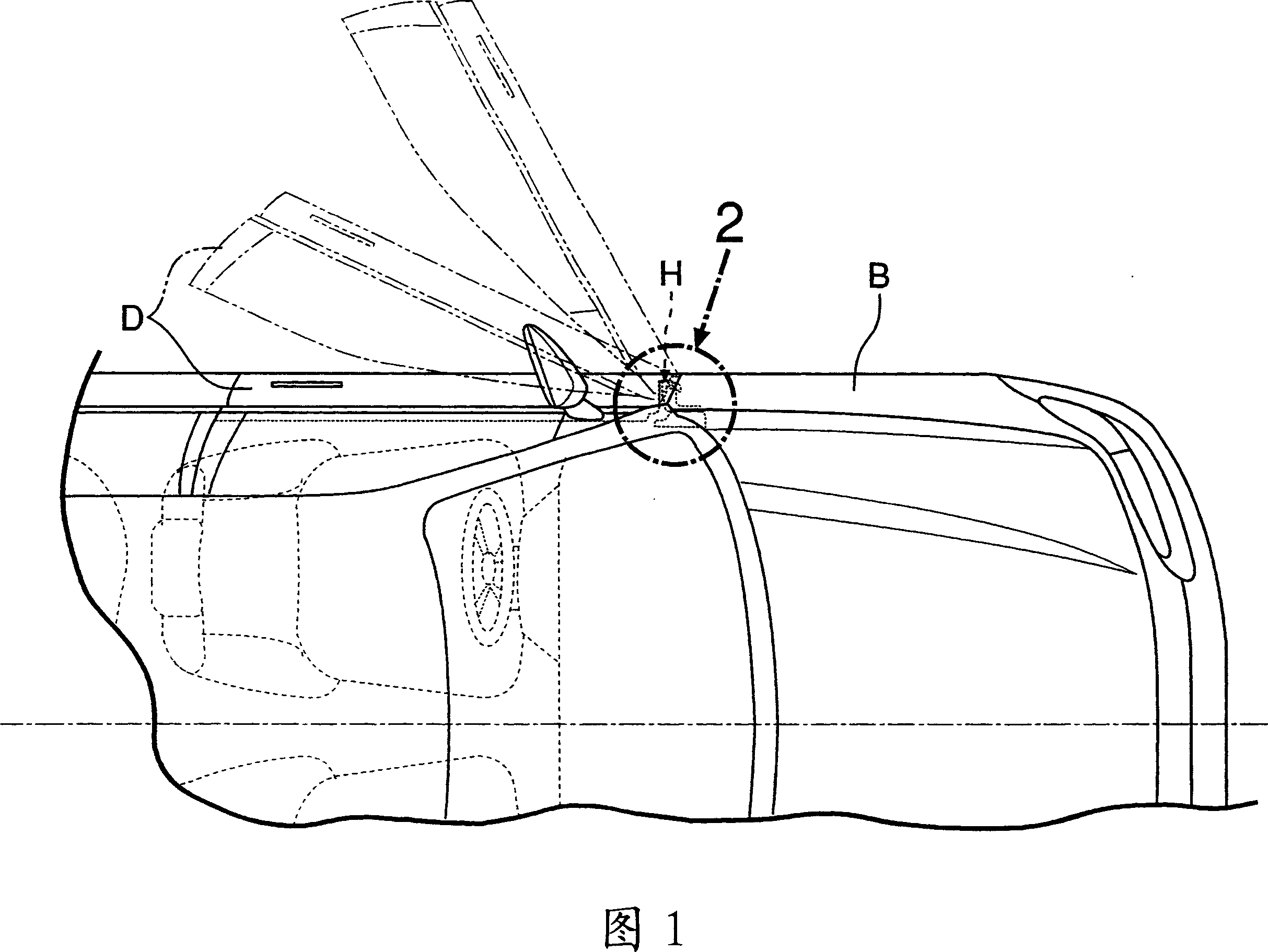

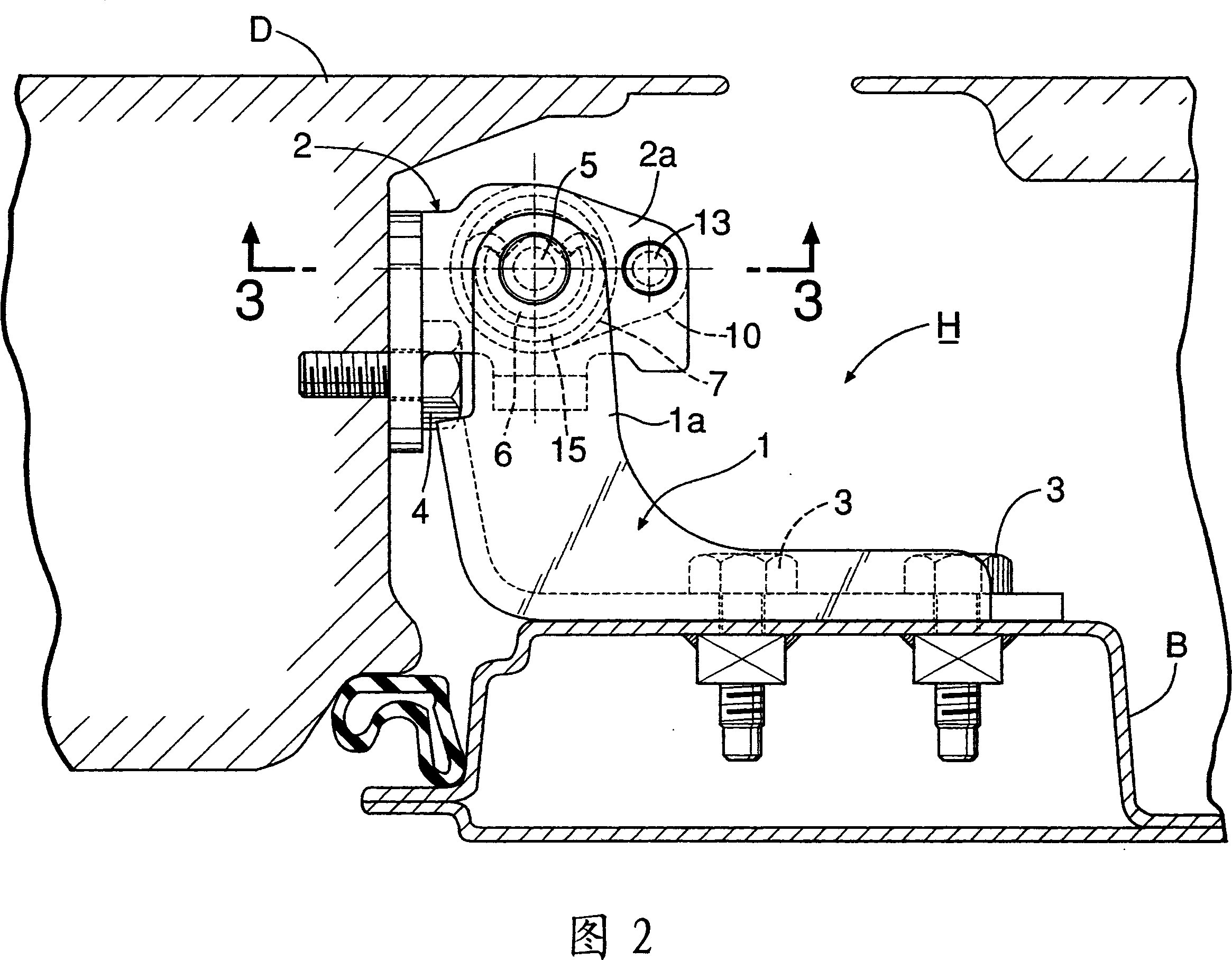

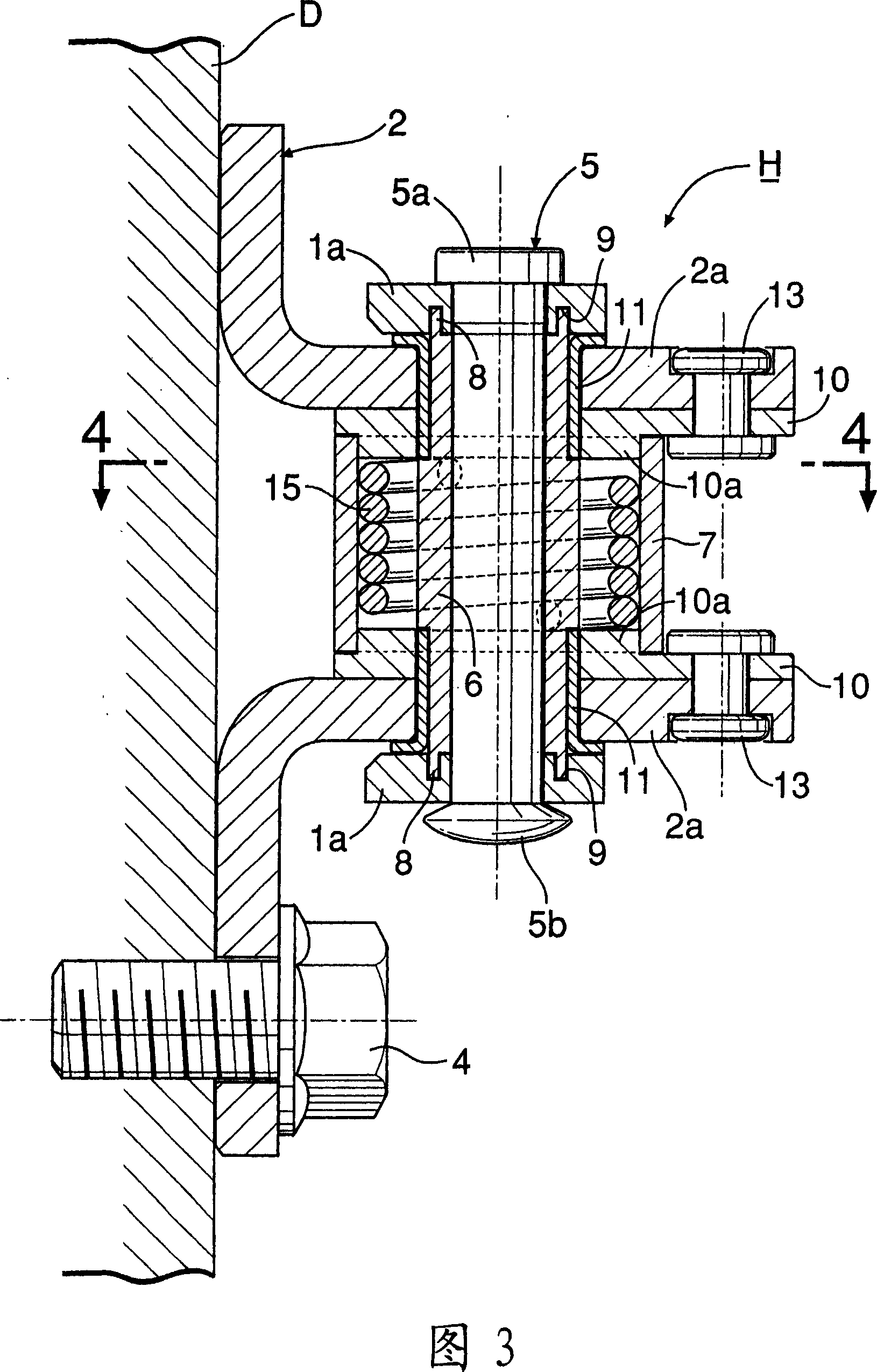

Automobile door hinge device

InactiveCN1970983AAvoid casual activitiesReduce the numberWing accessoriesWing fastenersEngineeringCar door

An automobile door hinge device includes: an inner cylindrical body integrally connected to a first bracket and rotatably fitted over an outer periphery of a hinge pin; an outer cylindrical body integrally connected to a second bracket to surround the inner cylindrical body; a check spring disposed between the inner cylindrical body and the outer cylindrical body to come into contact with an outer peripheral surface of the inner cylindrical body with a resilient force of the check spring; and first and second control portions that are provided in the inner cylindrical body to face first and second engaging portions, respectively, at opposite ends of the check spring, and displace the first and second engaging portions in directions releasing the contact of the check spring during relative rotation of the inner cylindrical body and the outer cylindrical body. Thus, the door hinge can exert a stepless door check function of holding a door at any opening degree.

Owner:RIKEN KAKI KOGYO CO LTD

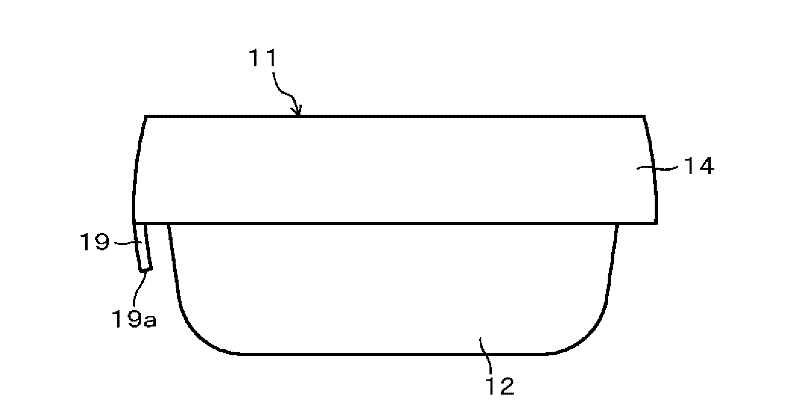

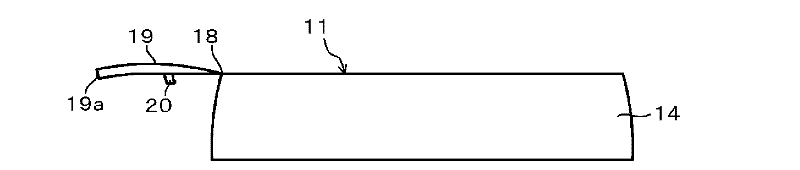

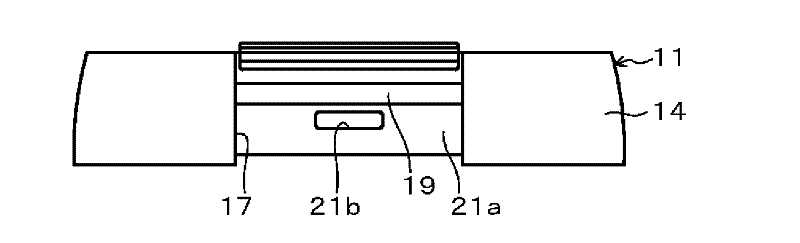

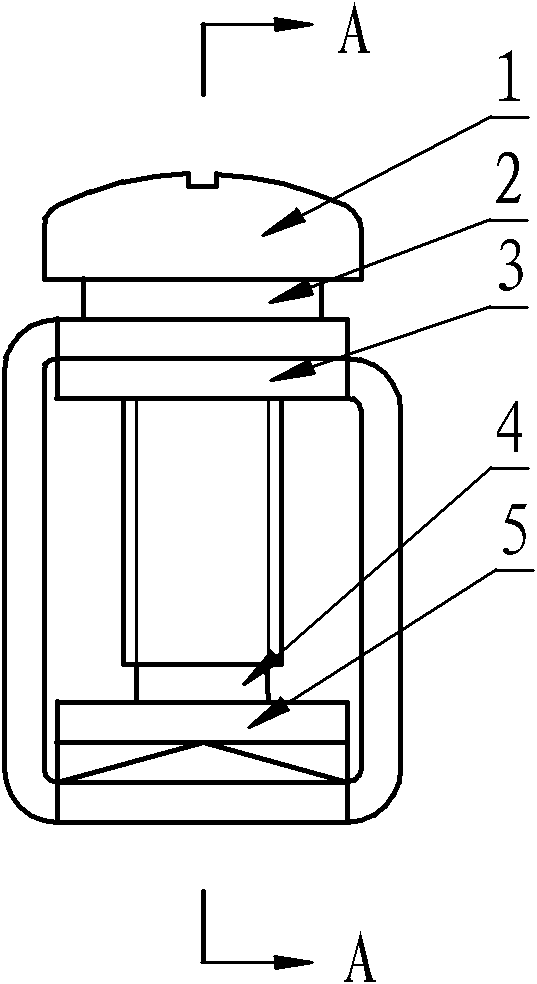

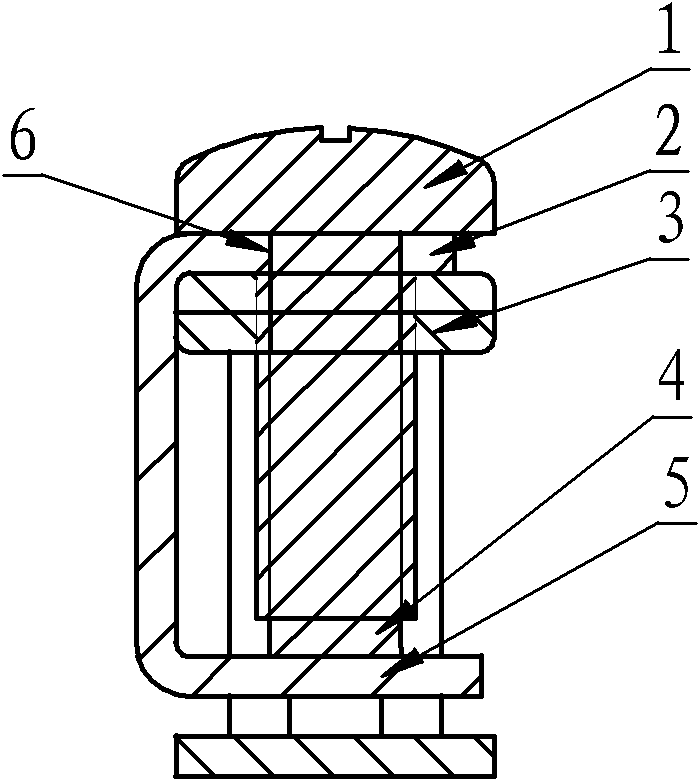

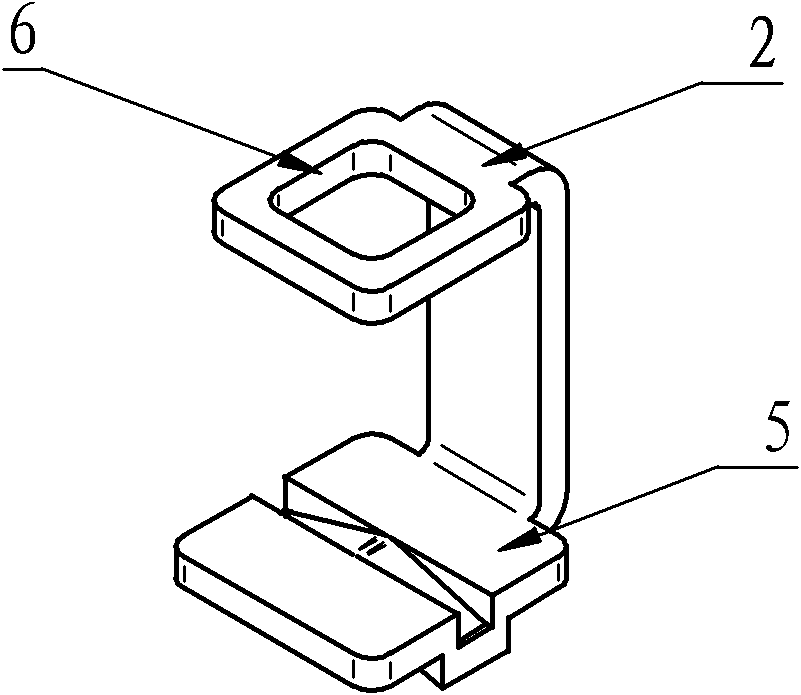

Container with opening and closing cover

The invention provides a container with an opening and closing cover. The container can realize sealing of the container body and the opening and closing cover via simple and single structure. The container with the opening and closing cover is structured in such a way that, namely, a clamping edge (25) is in a protruding disposing at the periphery of the opening of the container main body (12), the opening and closing cover (11) is provided with: a top part (13) covering the opening of the container main body (12), a flange (14) drooping from the periphery of the top part (13) in a mode of surrounding the side wall periphery of the container main body (12) and comprising the clamping edge (25), an annular sealing member (24) is installed at the lower surface of the top part (13) at the internal side of the flange (14), a clamping member (19) is disposed at a notch (17) forming a part of the flange (14), and the clamping member (19) is provided with a clamping projection (20) clamping with the clamping edge (25) of the container main body (12).

Owner:AGC TECHNO GLASS

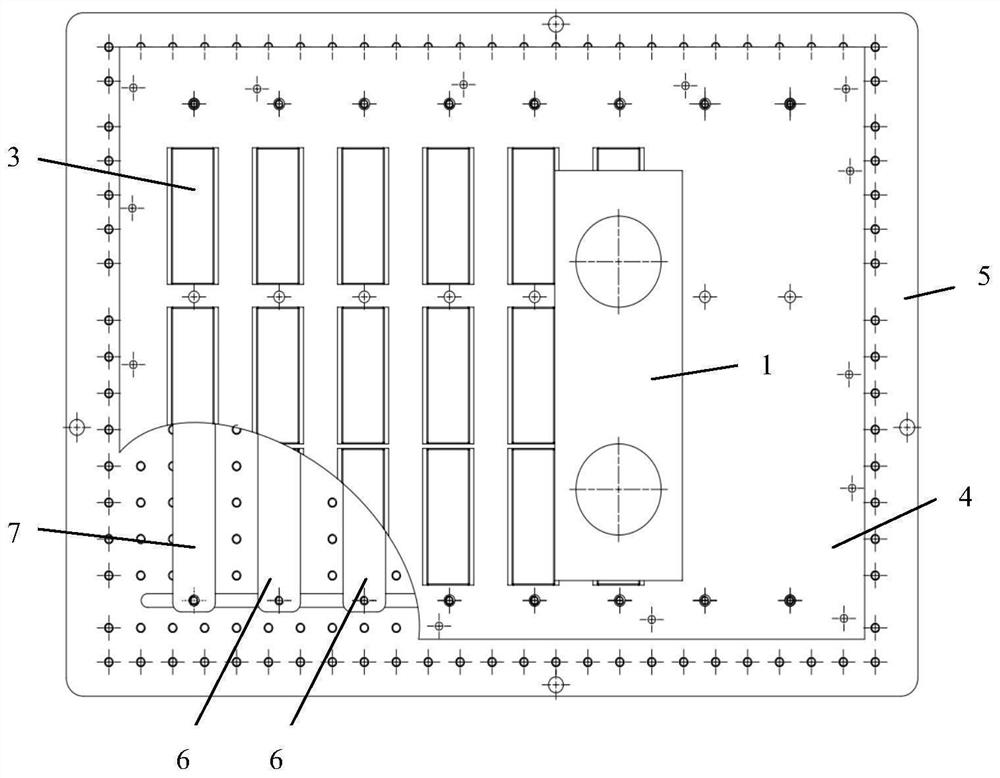

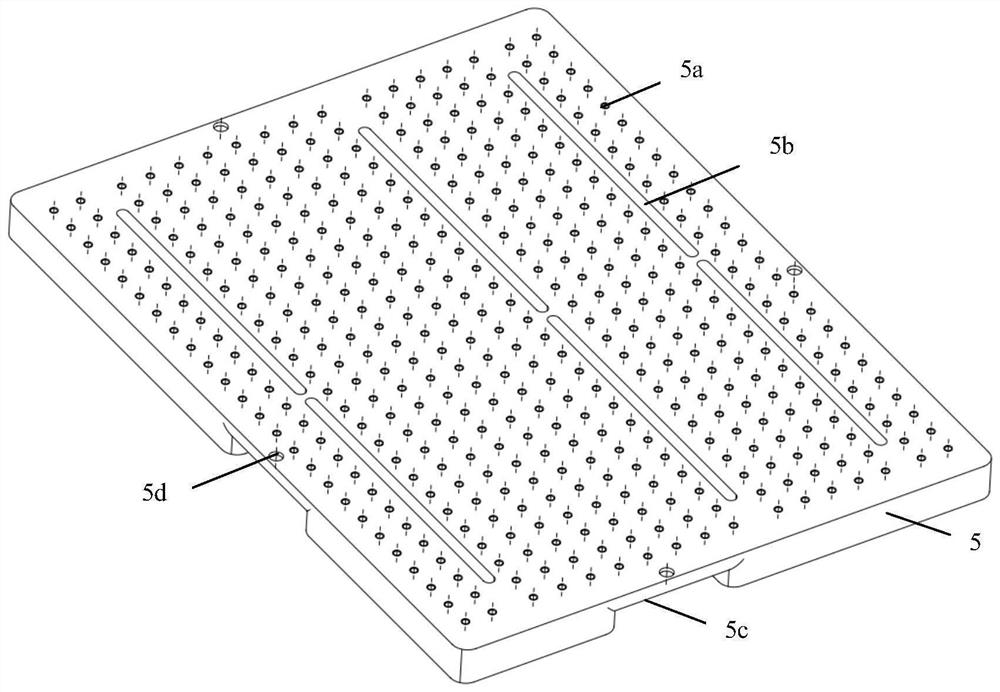

PCB and connector flat pressing type crimping tool

The invention discloses a PCB and a connector flat pressing type crimping tool, and aims to provide a crimping tool which is easy to align, rapid and convenient in crimping and high in one-time crimping qualification rate. The technical scheme comprises the steps that a lower die positioning plate provided with a positioning pin and a strip-shaped groove for separating a plurality of lower pressing dies is produced, the strip-shaped groove divides the lower pressing dies into a plurality of crimping areas, and the lower pressing dies are distributed in the separated crimping areas; during crimping, module pins of a connector pass through correspondingly prefabricated metallized plugging holes in a PCB mother board and are arranged in a matrix manner and inserted into the PCB mother board;and according to numerical control programming, a set crimping force and a crimping height, a crimping machine crimping head selects the number of the lower pressing dies on the support surface of thePCB mother board for the connector that has been positioned corresponding to the lower pressing dies to push a lower die positioning plate with an effective press-in force with single-pin pressure which does not exceed 35N to press the pin of the connector into the metallized plugging holes of the PCB mother board so as to complete crimping.

Owner:10TH RES INST OF CETC

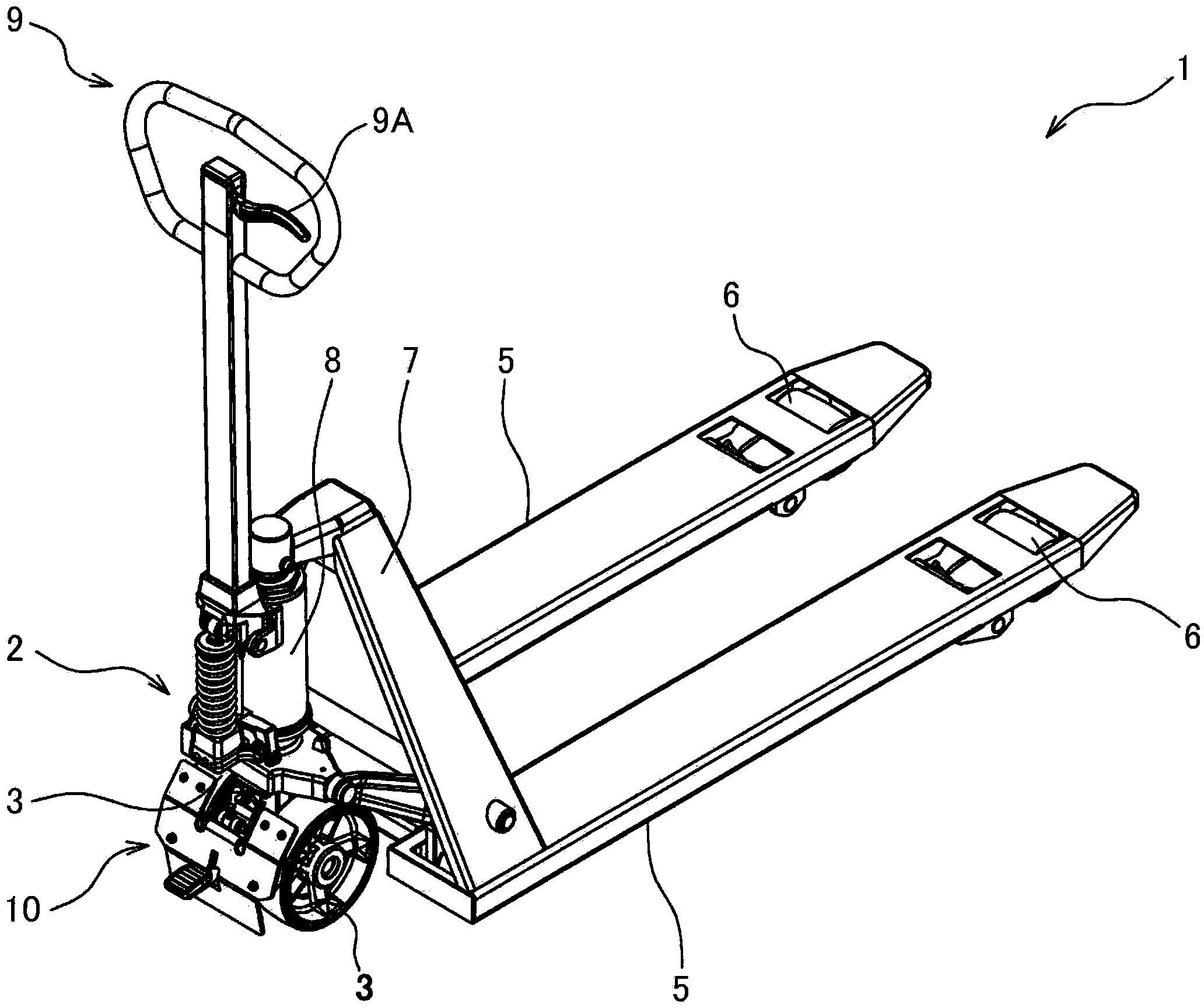

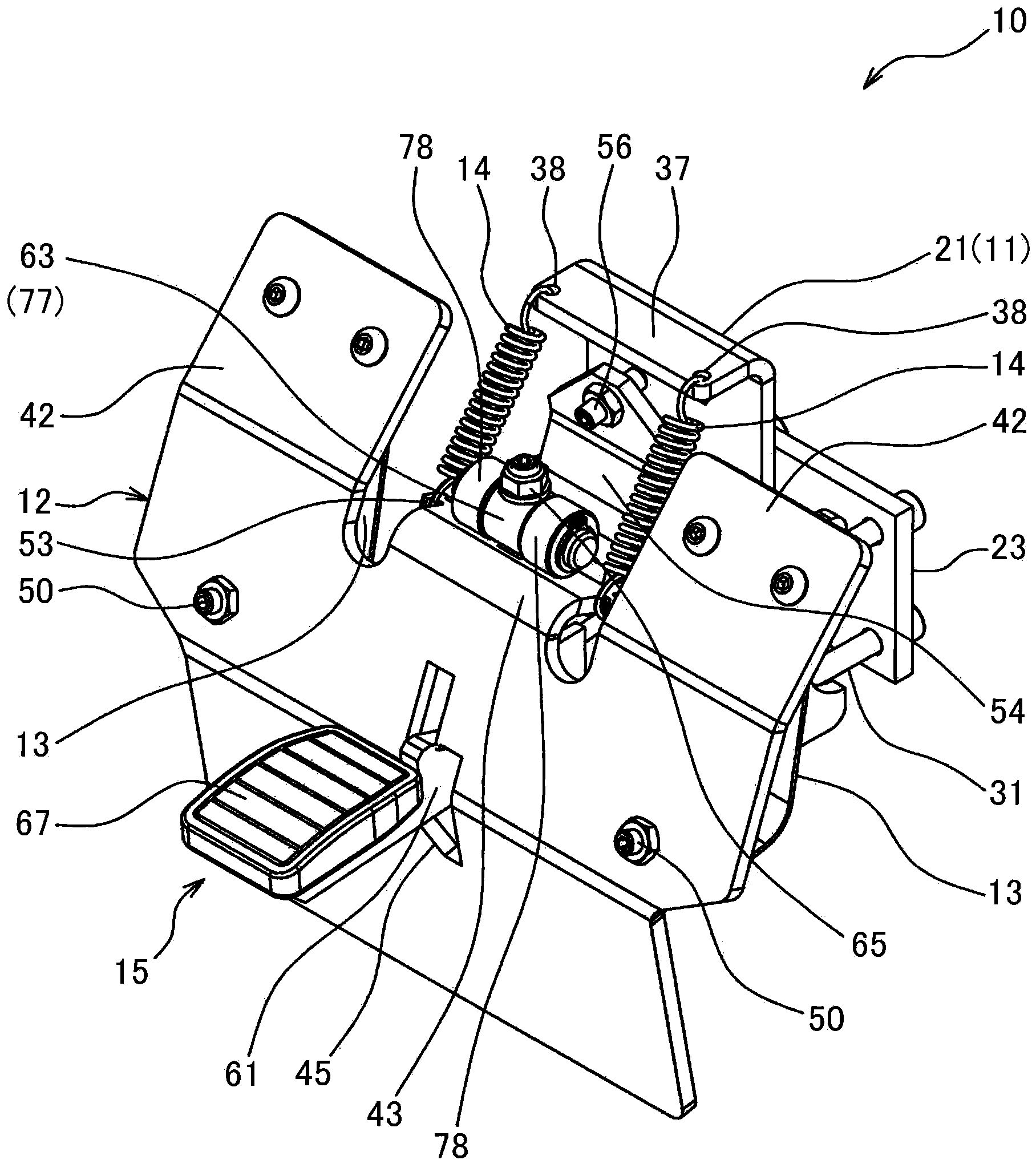

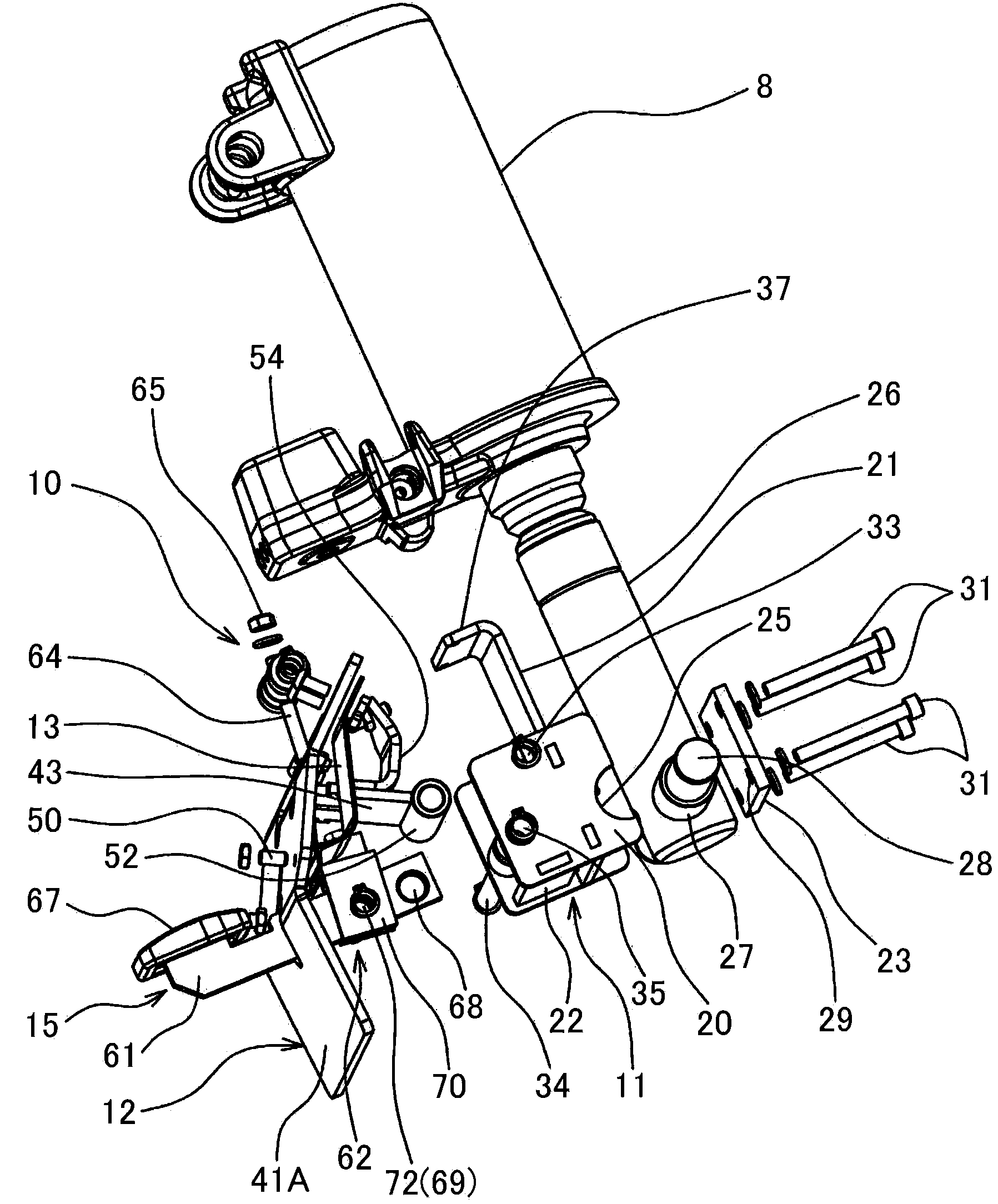

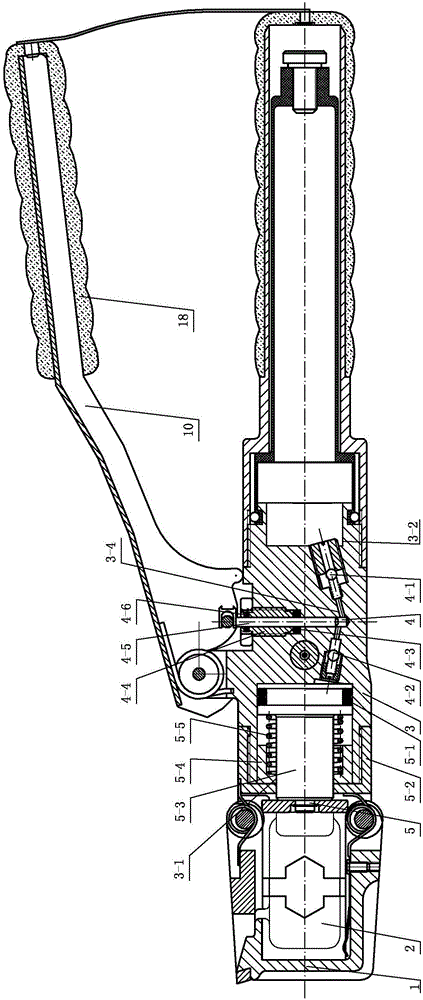

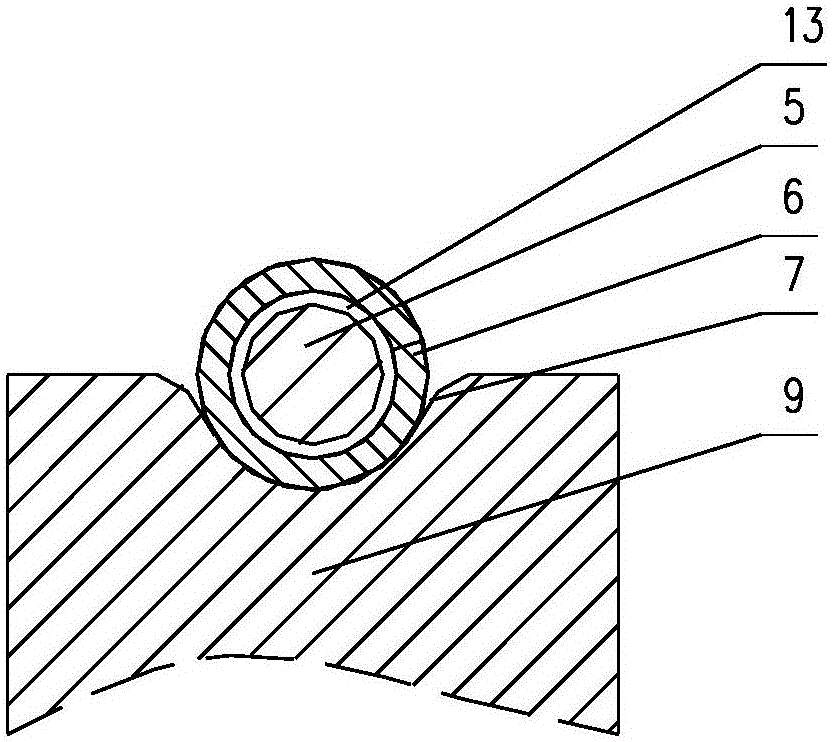

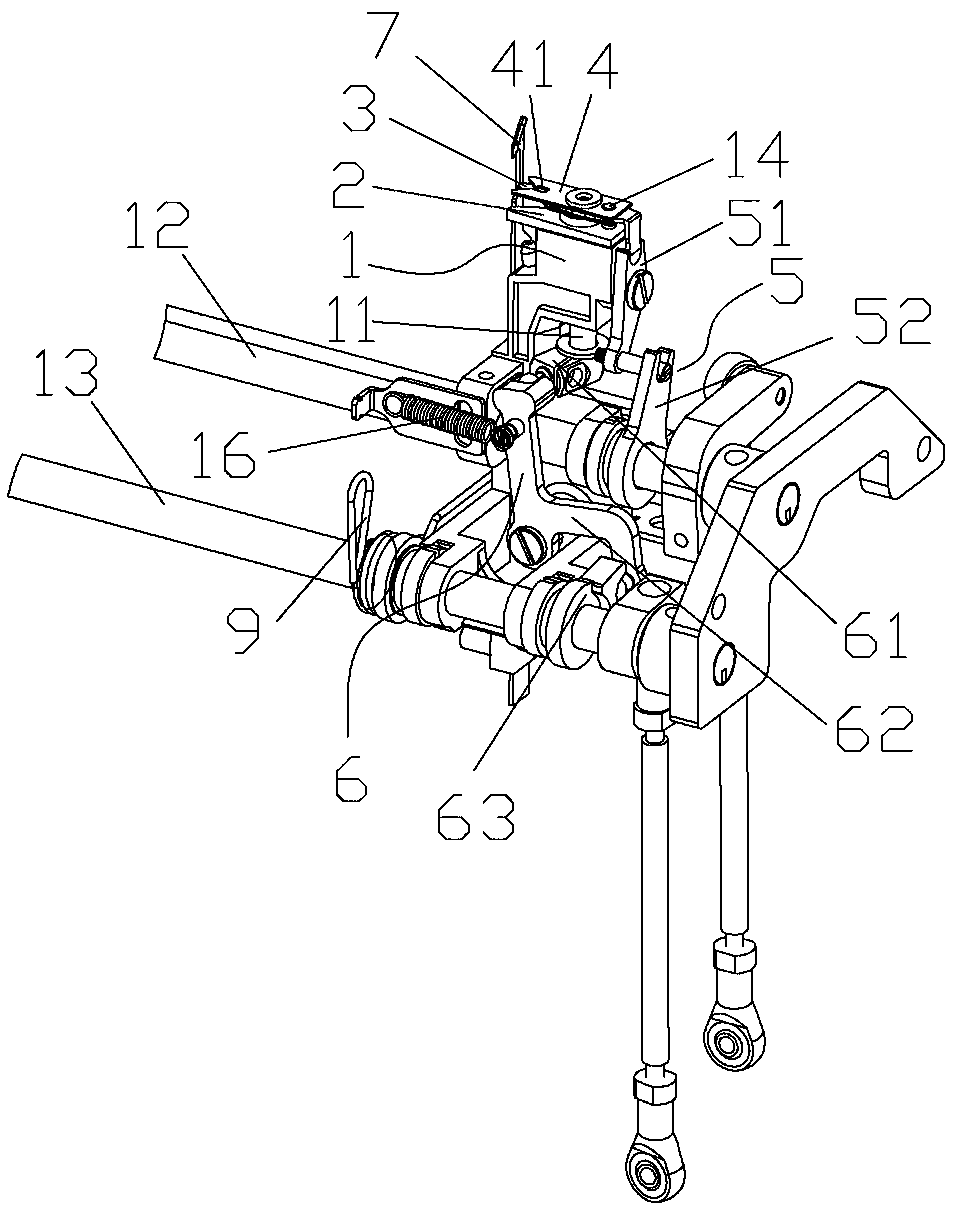

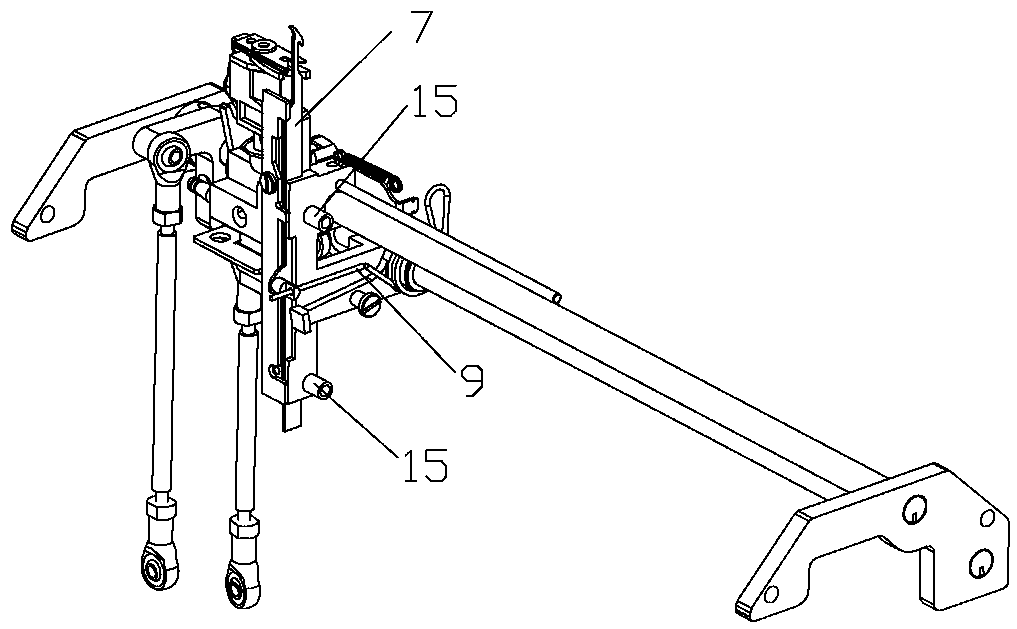

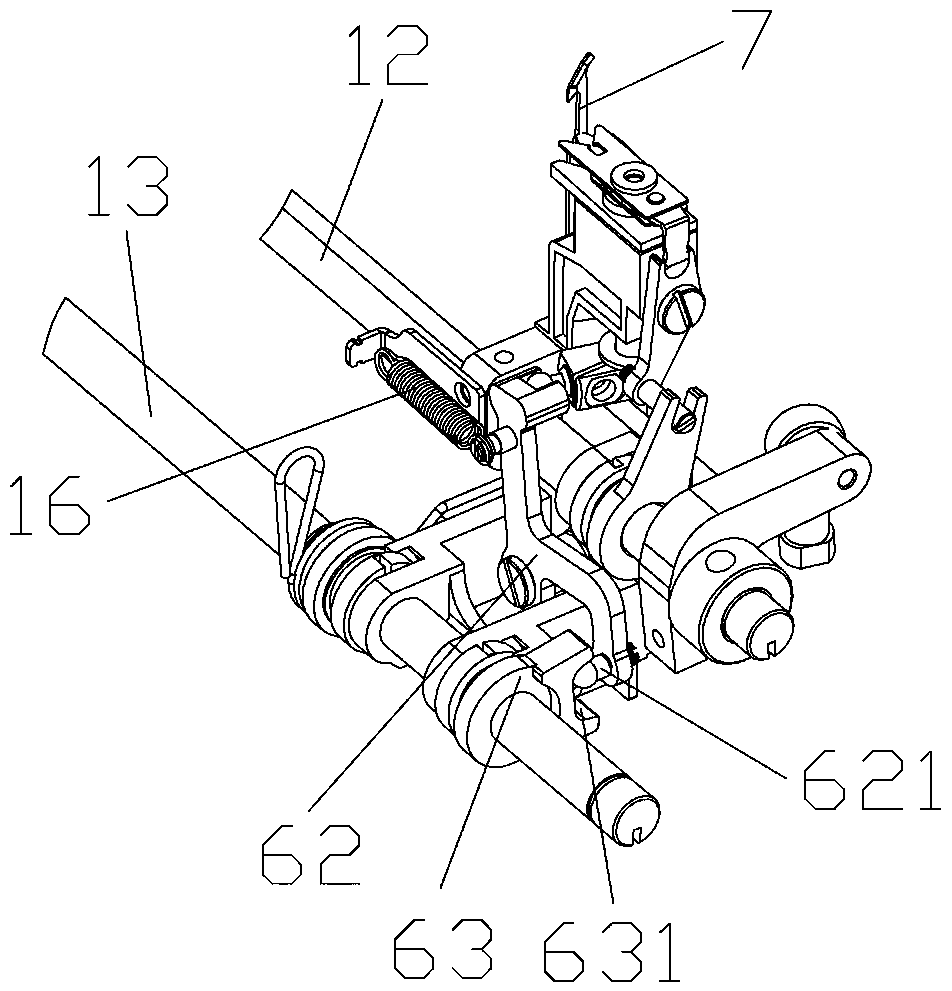

Brake apparatus of manual pallet truck

The invention provides a brake apparatus of a manual pallet truck. The brake apparatus is improved in operating performance. The manual pallet truck comprises a main body portion (26) and wheels for running. The main body portion (26) enables multiple forklifts to be connected and to be lifted. The wheels are arranged under the main body portion. The brake apparatus (10) of the manual pallet truck is disposed on the manual pallet truck and allows the wheels to brake. The brake apparatus (10) comprises an inclined rotation part (12) which is supported on the main body portion and can rotate toward the wheels in an inclined manner; a press connection portion which is disposed on the inclined rotation part and can be in pressed connection with the wheels; a force applying unit which is configured between the main body portion and the inclined rotation part, and usually applies force in a direction where the inclined rotation part is separated from the wheels; and a pedal part (15) which is jammed at the inclined rotation part. The pedal part is treaded by overcoming acting force of the force applying unit to enable the press connection portion to be in pressed connection with the wheels.

Owner:SUGIYASU

Emergency short-circuit device and method for aluminum electrolytic cell

The invention relates to the technical field of short circuit treatment of aluminum cells, and particularly relates to an emergency short circuit device and method of an aluminum cell. The emergency short circuit device disclosed by the invention comprises a guide bus, a crimping bus, a transitional soft connector and a clamp, wherein a support beam is supported and fixed together with the guide bus, the crimping bus and the transitional soft connector. The emergency short circuit device is simple in structure, convenient to install, reliable to crimp, and high in security, and can be accurately positioned. By adopting the device and the method disclosed by the invention, rapid short circuit operation of a worker is facilitated; the time is saved; the loss caused by power failure is reduced; the emergency short circuit device can be suitable for various accidents of the electrolytic cell; rapid recovery of production can be achieved; the time is saved; the connection part is easily dismantled; and the emergency short circuit device is simple to operate, fast and feasible, and has good maneuverability.

Owner:ZHENGZHOU LIGHT METAL TECH

Portable hydraulic pliers for crimping bead string joints

InactiveCN105127939ALabor-saving operationEasy to operatePliersMetal-working hand toolsComputer moduleMechanical engineering

A pair of portable hydraulic pliers for crimping bead string joints relates to a pair of portable hydraulic pliers and aims to solve the problems that no appropriate crimping operation tool is available for conventional crimping of bead string joints, a crimping force cannot be controlled within a reasonable range, and accordingly the connection between a bead string joint and a bead string is not stable. The pair of portable hydraulic pliers comprises a jaw, a pliers pump body, an oil inlet component, a compressing component, an oil draining component, a pressure setting component, an oil receiver, a main handle, a pressurizing moving handle, a pressure unlocking handle, a pressure measuring valve, an elastic load-bearing pin, crimping modules and pin shafts, wherein a first blind hole and a second blind hole are processed in two ends of the pliers pump body respectively; the oil receiver is sleeved with the main handle; the compressing component is mounted on the pliers pump body; the jaw is fixedly mounted on the compressing component; the crimping modules are mounted on the jaw in a sliding way; the pressure setting component is mounted in the second blind hole; the oil inlet component is mounted on the pliers pump body; and the oil draining component is fixedly mounted on the pliers pump body. The pair of portable hydraulic pliers is used in the field of crimping of bead string joints.

Owner:HEILONGJIANG UNIV

Contact for cable connection and cable connecting method using the contact

InactiveCN1913230AReliable crimpingSolution to short lifeContact members penetrating/cutting insulation/cable strandsProduction rateElectrical conductor

The invention provides a cable connecting contact and a method for connecting a cable using the contact capable of wiring certainly even if the cable is of very thin type, and of enhancing the productivity of terminals. The contact to generate electric connection through pressure attachment with the core part of the cable formed by covering one or more core wires consisting of conductor with an insulating material is provided with an opening in the center of the end face of a metal member in plate shape and a slit shaped as a groove with the width narrowing gradually in a position deeper than the opening, in which the two sides where the slits are formed serve as crimp terminals.

Owner:SMK CO LTD

Wiring module for sensor and actuator

InactiveCN104332729AFast horizontal connectionAvoid lostClamped/spring connectionsComputer moduleSingle strand

The invention relates to a wiring module for a sensor and an actuator, which comprises an insulated shell. The front upper side surface of the shell and the front lower side surface make up the front side surface of the wiring module for the sensor and the actuator; the front upper side surface and the front lower side surface form an included angle; jacks and wiring ports of the sensor and the actuator are respectively located in the front upper side surface and the front lower side surface, and wiring is clear; multiple wiring ports are respectively located on multiple steps in the front lower side face, thereby facilitating wiring; a connecting groove opening is arranged on a conductive element, the connecting groove opening can be matched with a pluggable connector for quickly realizing transverse connection among modules, and closing or disconnection among the modules is extremely convenient; each wiring port is provided with a sign box, colors or characters can be adopted for distinguishing, and features of the wiring port can be distinctly indicated; a filling cover plate can cover wiring ports which are free of wiring, and unnecessary loss due to momentary oversight of an operator can be prevented; and a wiring terminal adopts a cage-type spring, elastic deformation can be used for firmly crimping multiple strands or a single strand of wire, thereby being convenient and time-saving.

Owner:SHANGHAI UPUN ELECTRIC GRP

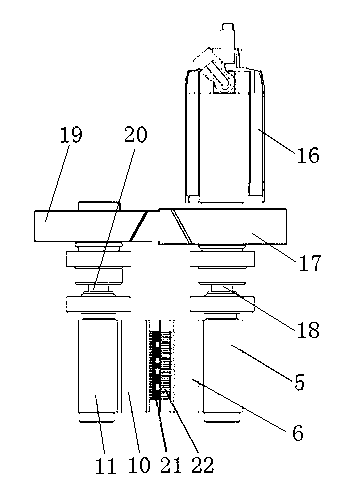

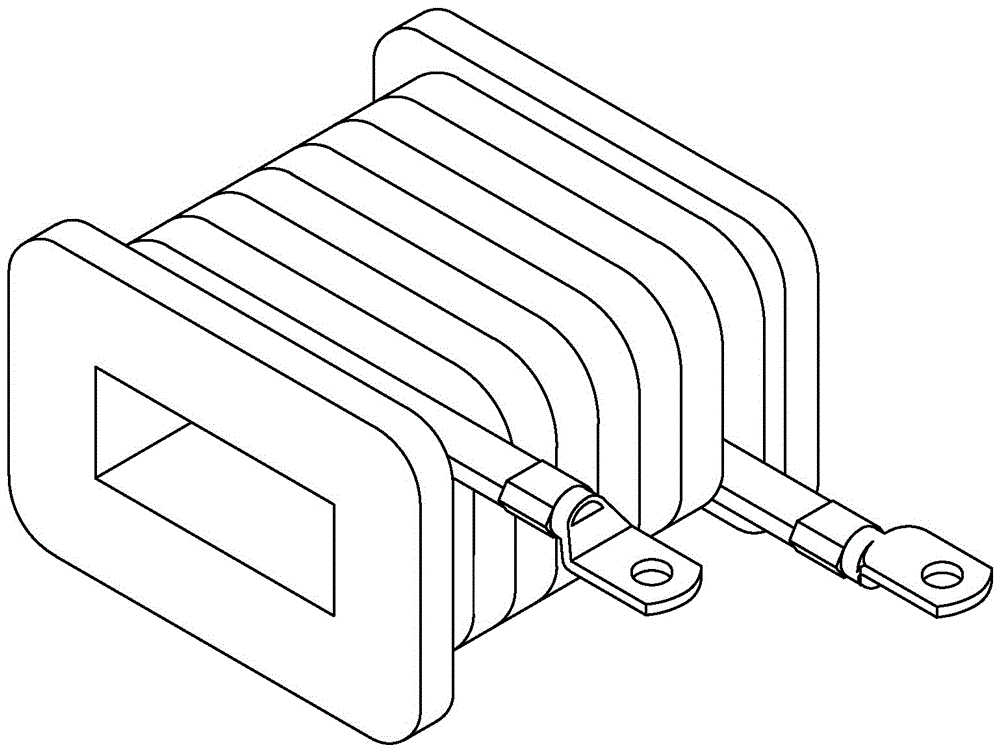

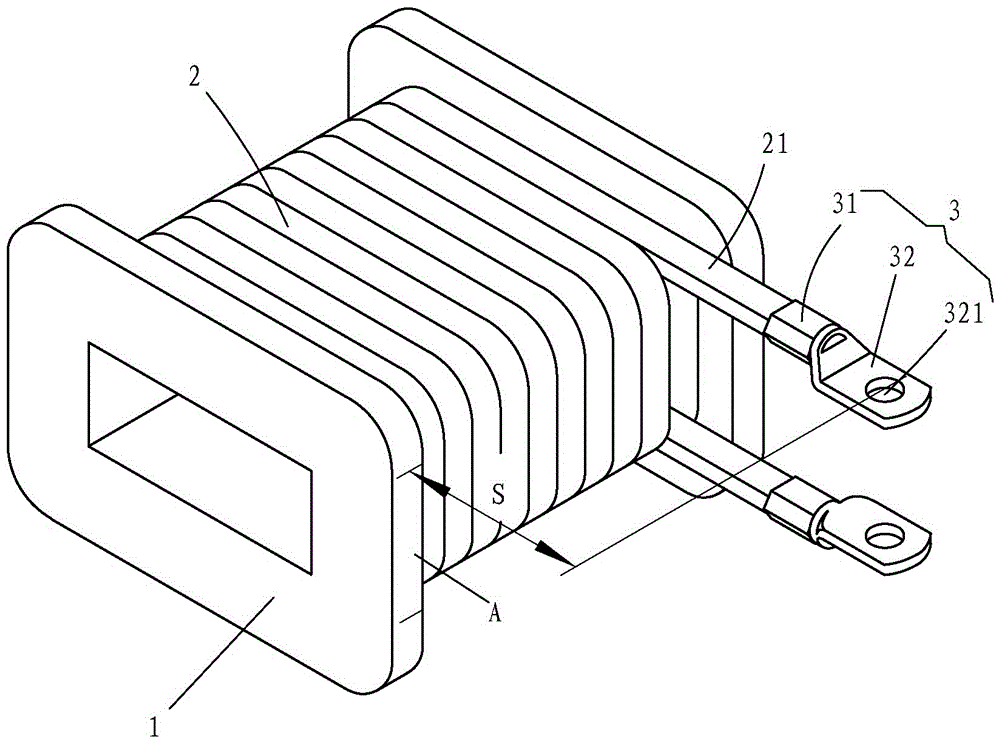

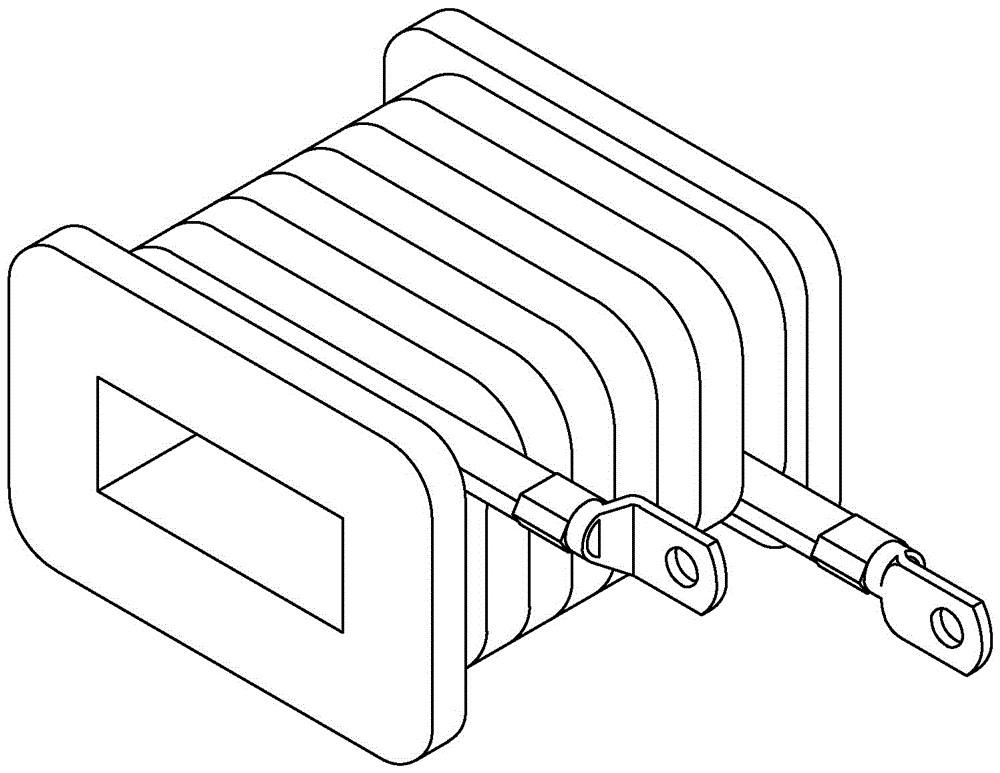

Crimping tool structure of electric reactor coil terminal

ActiveCN106683878AEasy to operateAccurate and uniform sizeLine/current collector detailsCoils manufactureEngineering

Disclosed is a crimping tool structure of an electric reactor coil terminal. The crimping tool structure comprises an upper tool body, a lower tool body, an upper pressing die and a lower pressing die, wherein the upper tool body comprises a column body and a guiding column; a counter bore is formed in the upper end plane of the column body; a piston rod is inserted in the counter bore; a mounting plate extends perpendicularly and backwardly at the bottom of the column body; the top of the guiding column is perpendicularly fixed on the mounting plate; the lower tool body comprises a bottom plate, a stand column and a guiding plate; the guiding plate is perpendicularly connected with the upper part of the stand column; a positioning hole is formed in the guiding plate; in a working state, the guiding column is inserted in the positioning hole; the upper pressing die is fixed at the bottom end of the column body, and the bottom end of the upper pressing die concaves inwardly to form a first trapezoid-shaped groove; the lower pressing die is fixed at the top end of the stand column; a second trapezoid-shaped groove is formed in the top end of the lower pressing die; and the first trapezoid-shaped groove and the second trapezoid-shaped groove are formed in a corresponding manner. The crimping tool structure is convenient and safe to operate, accurate and unified in dimensions, firm and reliable in crimping and high in working efficiency.

Owner:FUJIAN EVERSTRONG LEGA POWER EQUIP CO LTD

A kind of hydraulic crimper for ground wire dedicated to power transmission line

ActiveCN103337814BHigh precisionAdvanced constructionConnection formation by deformationApparatus for joining/termination cablesEngineeringTraveling block

The invention relates to a special ground conducting wire hydraulic compression connector for a transmission line, which comprising a hydraulic plier, a left fixture, a right fixture, a left supporting-holding rod, a right supporting-holding rod and a channel steel guide rail, wherein the hydraulic plier is mounted in the middle of the channel steel guide rail in a positioning manner through a positioning base; the left fixture and the right fixture are symmetrically arranged on the left side and the right side of the hydraulic plier, and operate in a sliding manner respectively through a left tackle and a right tackle both sliding on the channel steel guide rail; mounting holes respectively manufactured by the left fixture, the hydraulic plier and the right fixture are on the same axis; the left supporting-holding rod and the right supporting-holding rod are hinged to the left tackle and the right tackle respectively in a mirror symmetry manner. According to the invention, the special ground conducting wire hydraulic compression connector is advanced in construction and simple to operate, can be suitable for the application of various compression connection tubes after a horizontal mid-partition limiting aluminium pipe is adopted, has high precision for horizontally compressing and connecting butted steel connecting pipes and connecting aluminium pipes, can support and hold aluminium conducting wires per se, automatically completes the straightening of ground conducting wires, completely avoids various problems existing in the manual compression and connection, and has the advantages that the compressing connection is reliable, the precision is high and the cost is low.

Owner:STATE GRID CORP OF CHINA +1

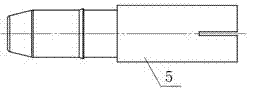

Tooling capable of improving dual coaxial crimping reliability

InactiveCN105098560AReliable crimpingTightly boundLine/current collector detailsCoaxial cableEngineering

The invention relates to a tooling capable of improving dual coaxial crimping reliability, and belongs to the technical field of connector clip crimping. By the tooling provided by the invention, the crimping reliability between a shielding layer of a coaxial cable and a crimping contact pin can be ensured; and a crimping sleeve is tightly combined with a tail nut, and does not displace any more. The dual coaxial crimping reliability can be improved; and the operating requirements of contact pins with variable diameters and lengths can be met.

Owner:NO 8357 RES INST OF THE THIRD ACADEMY OF CHINA AEROSPACE SCI & IND

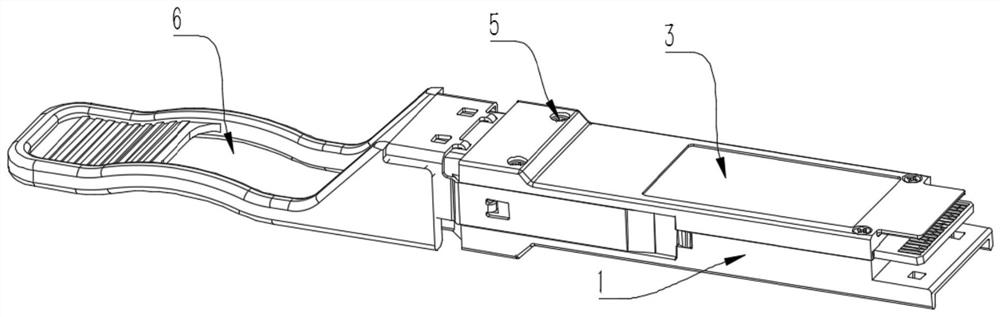

QSFP28 module

InactiveCN113341512AImprove EMI performanceReduce electromagnetic interferenceCoupling light guidesPhysicsElectromagnetic interference

The invention relates to a QSFP28 module which comprises an upper cover and a base which are fixedly connected to form a containing space, a photoelectric sub-module is arranged in the containing space, a port of the photoelectric sub-module extends out of the containing space, and conductive adhesive is further arranged in the containing space, and the conductive adhesive seals a connecting gap between the upper cover and the base and connecting gaps among the upper cover, the base and the port of the photoelectric sub-module. A conductive adhesive is dispensed at the seam of the upper cover and the base to block the connection gap between the upper cover and the base, and a conductive adhesive is dispensed at the port of the photoelectric sub-module and the connection gap between the upper cover and the base to block the connection gap between the port of the photoelectric sub-module and the connection gap between the upper cover and the base; the upper cover, the base and the conductive adhesive are matched with each other, so that the accommodating space forms a closed shielding space, electromagnetic signals are prevented from leaking from each connecting gap of the accommodating space, electromagnetic interference to external equipment is prevented, and the EMI performance of the QSFP28 module is improved.

Owner:武汉永鼎光通科技有限公司

Tap switch lead cold pressing equipment

ActiveCN106299959ASimple structureEasy to operateLine/current collector detailsEngineeringTap changer

Owner:WUHAN TAIPU TRANSFORMER CHANGER

Screw assembling unit for reliable line-pressing of alternating-current contactor

The invention relates to a screw assembling unit for reliable line-pressing of an alternating-current contactor; the screw assembling unit of the alternating-current contactor comprises a stacking clip-type part, a screw and a U-shaped washer plate, an internally-convex hole is arranged at one vertical part of the U-shaped washer plate, and the vertical part is arranged above a stacking screw hole of the clip-type part; a panel with lower tile-shaped plane is arranged at the other vertical part of the U-shaped washer plate, and the other vertical part is arranged in the space surrounded by the clip-type part, and the bottom part of the U-shaped washer plate is arranged at one side of the opening of the clip-type part; the screw is provided with a thin neck and a flat end, and the thin neck of the screw is arranged at the square hole position of the washer plate; three side surfaces of a square hole at the upper part of the washer plate are cold-headered on the screw neck, the screw can rotate in the washer plate and the clip-type part, the washer plate can not be taken off from the screw, the plane of the end of the screw props against to the plane of the lower surface of the washer plate and is connected by the U-shaped side wall and can not fall off and be inclined, so as to lead the crew assembling unit to press line reliably and to work normally.

Owner:TIANJIN BAILI ELECTRIC CO LTD

Novel scissor device and working control method thereof

The invention mainly relates to a novel scissor device. The novel scissor device comprises a scissor frame, wherein a rotating shaft is movably arranged on the scissor frame; scissors, a movable pieceand a pressing piece are sequentially arranged on the rotating shaft, and the rotating shaft can drive the scissors to rotate; the movable piece is movably mounted between the pressing piece and thescissors, the end of the pressing piece is provided with an opening, the opening is a yarn pressing opening, and the movable piece can rotate relative to the pressing piece; the movable piece is connected with a first connecting rod mechanism; the movable piece is connected with a first driving shaft through the first connecting rod mechanism; the two sides of the movable piece are matched with the yarn pressing opening to realize individual yarn pressing control of multiple yarns; the rotating shaft is connected with a second connecting rod mechanism. and the rotating shaft is connected witha second driving shaft through the second connecting rod mechanism; a hook cutter is glidingly mounted on the side of the scissor frame; and the second driving shaft can control and drive the scissorsand the hook cutter to move and work. The design structure is simple and ingenious, the control is stable, the various yarns can be individually pressed and controlled, and when multiple yarns are switched, the yarns do not need to be reconnected, and the working efficiency is improved.

Owner:ZHEJIANG RUIFENG INTELLIGENT TECH CO LTD

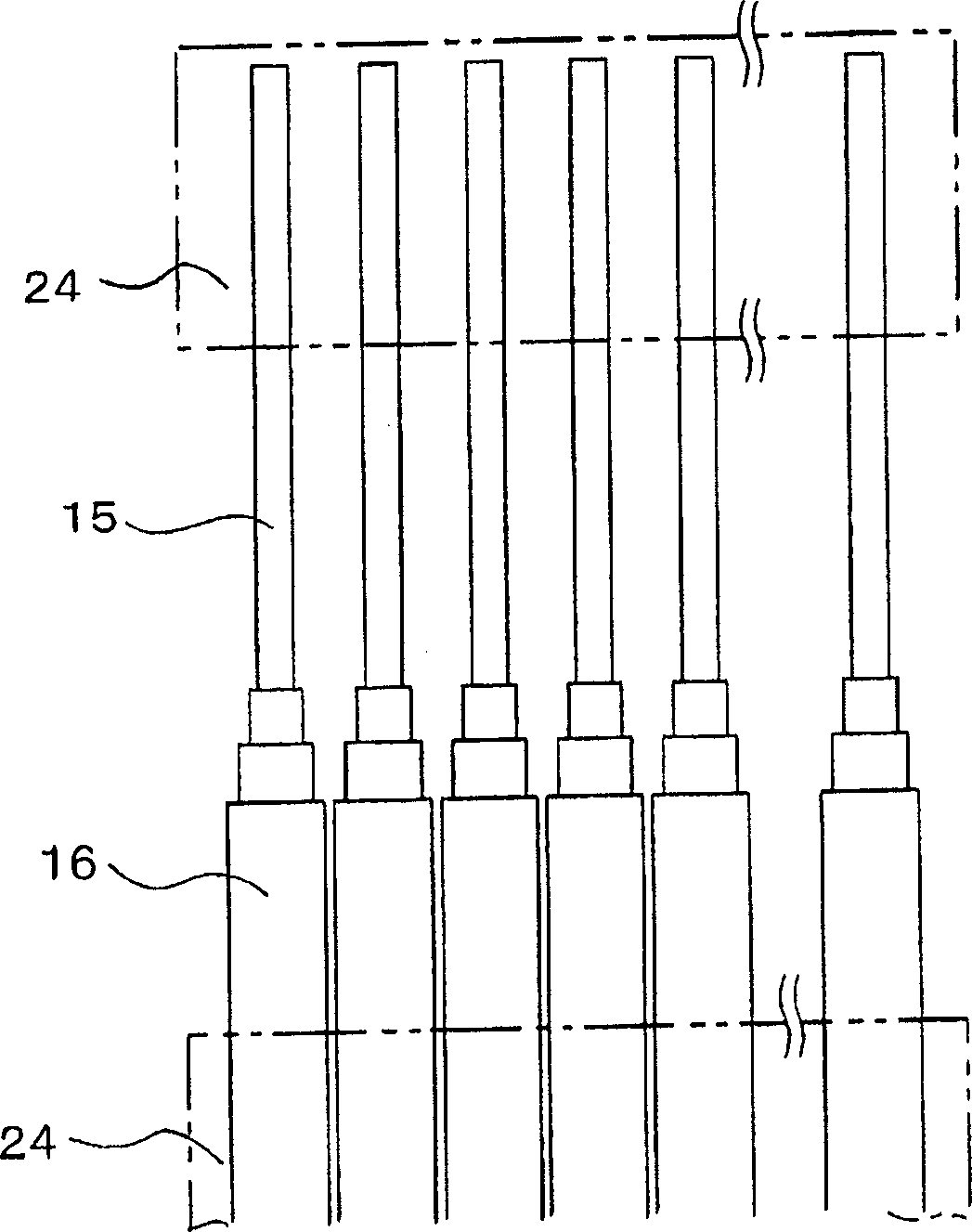

Connector for cold cathode tube

InactiveCN1983738AReliable crimpingEasy to operateEngagement/disengagement of coupling partsElectric discharge tubesMiniaturizationCold cathode

The present invention provides a connector for cold cathode fluorescent tube, which can dispose cold cathode fluorescent tube and electrode line, and can execute connection reliably even the electrode line has deviation without insert force and bending distortion, the connection can be executed easily, making the connector to minitype, the inner connecting status can be affirmed by eyes and the connection can be reliably executed, the connector can be easily applied to substrate fitting mode and guide lines mode. The case of the connector is formed by the casing (2) and top cover (3), a keep chamber for cold cathode and a connection chamber for receiving connection terminals (4) are disposed in the case, a pair of activation cards (19) with crimping part in the front side is disposed on the contact point (8), the electrode line (6) can be inserted between each activation card (9) with a wedging status when the top part of the cold cathode fluorescent tube (5) is fit into the keep chamber, a top cover having a pair of action doming (12) are covered on the opening part of the case, the activation cards (19) of the contact point (8) are pressed from outside, the electrode line (6) is clamped and crimped by the crimping part.

Owner:NIPPON TANSHI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com