Novel scissor device and working control method thereof

A scissors, a new type of technology, applied in textile and papermaking, weft knitting, knitting and other directions, can solve the problems of complex structure of the thread pressing mechanism, affecting work efficiency, unstable control, etc., to facilitate access to the thread pressing port and improve work efficiency. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

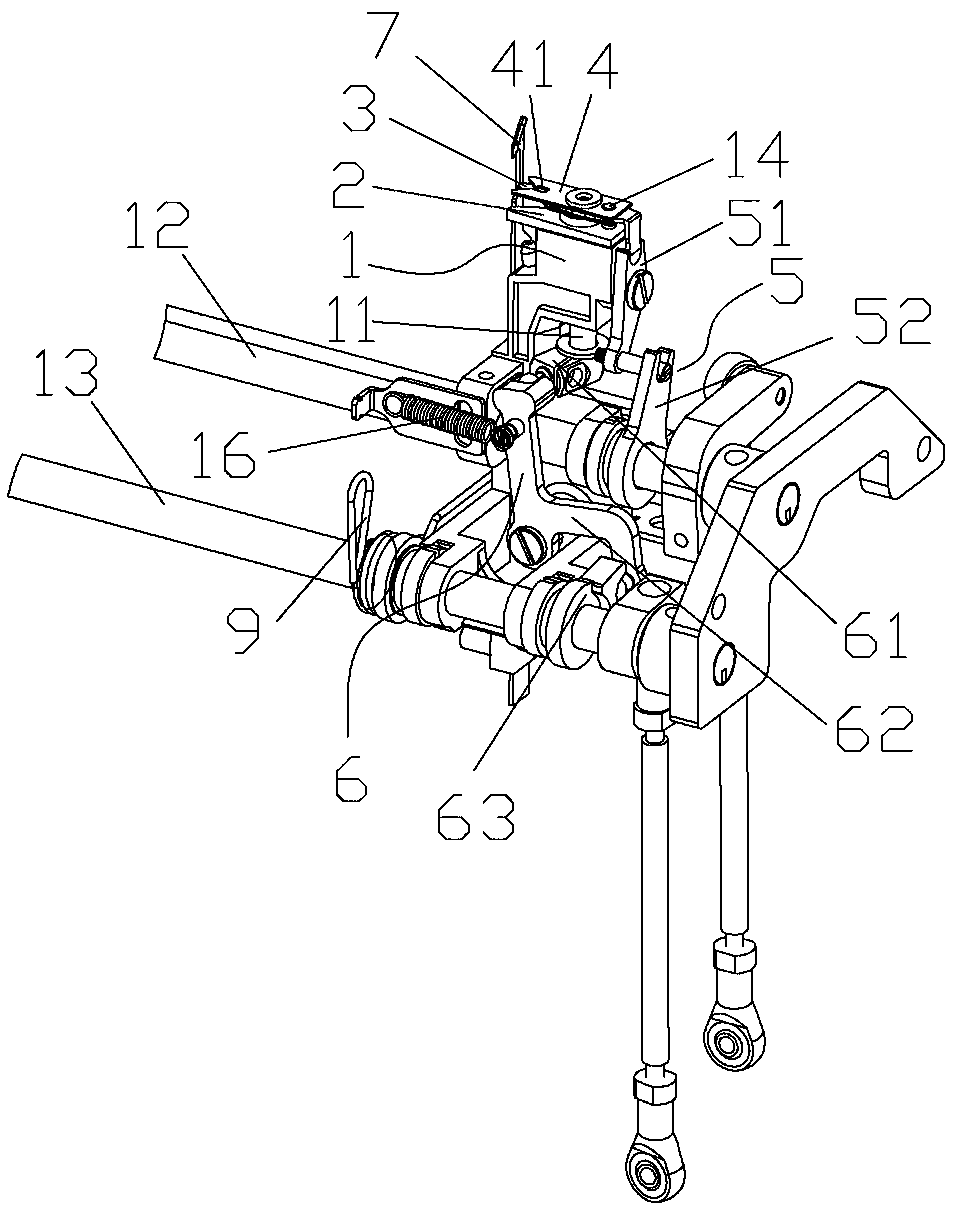

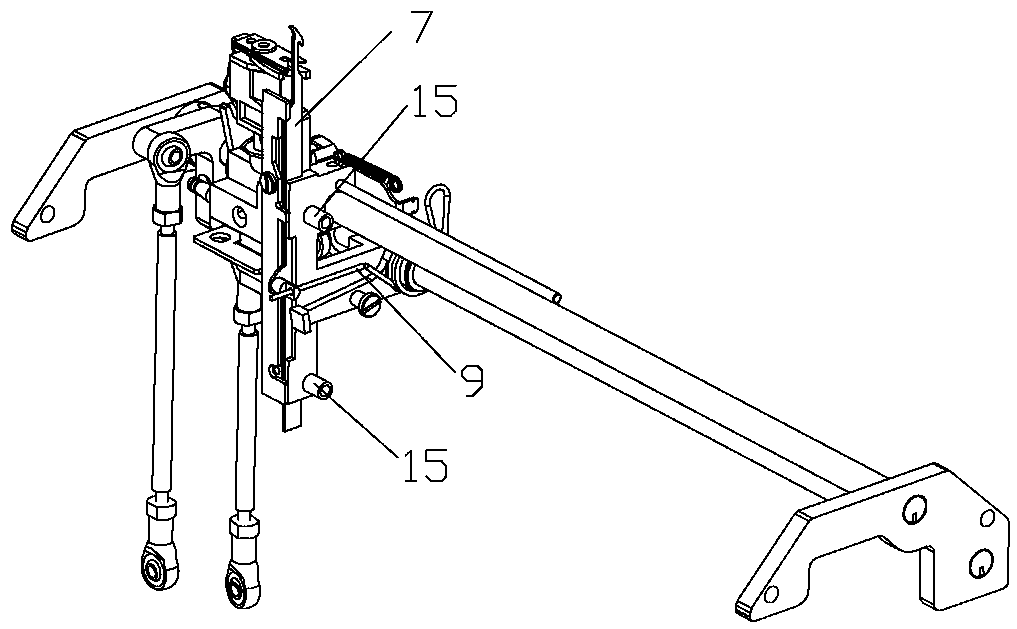

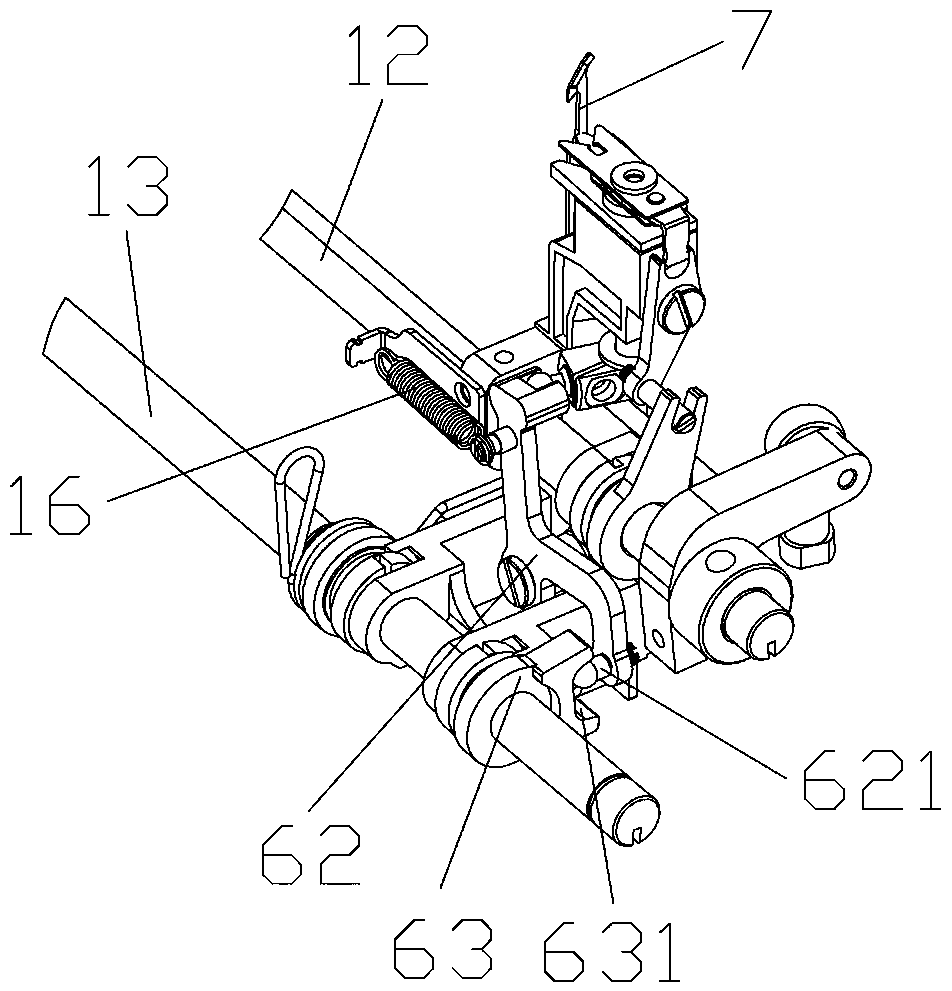

[0038] Such as figure 1 , 2 , shown in 3, 4, a kind of novel scissors device comprises scissors frame 1, is provided with rotating shaft 11 movablely on the scissors frame 1, is provided with scissors 2, movable sheet 3 and pressing sheet 4 successively on rotating shaft 11, and rotating shaft 11 can drive scissors 2 Rotate to realize cutting the yarn; the movable piece 3 is movably installed between the pressing piece 4 and the scissors 2, the end of the pressing piece 4 is provided with an opening, and the opening is a crimping port 41, and the movable piece 3 can rotate relative to the pressing piece 4 The movable piece 3 is connected with the first linkage mechanism 5, and the movable piece 3 is connected with the first drive shaft 12 by the first linkage mechanism 5, so as to realize the rotation control of the movable piece 3; when the movable piece 3 rotates, the movable piece 3 both sides respectively Cooperate with crimping port 41 to realize individual crimping cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com