Screw assembling unit for reliable line-pressing of alternating-current contactor

An AC contactor and assembly technology, applied in the direction of screws, connecting components, threaded fasteners, etc., can solve the problems of falling off, screw assemblies can not be reliably pressed, AC contactors can not work normally, etc., to achieve reliable pressing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

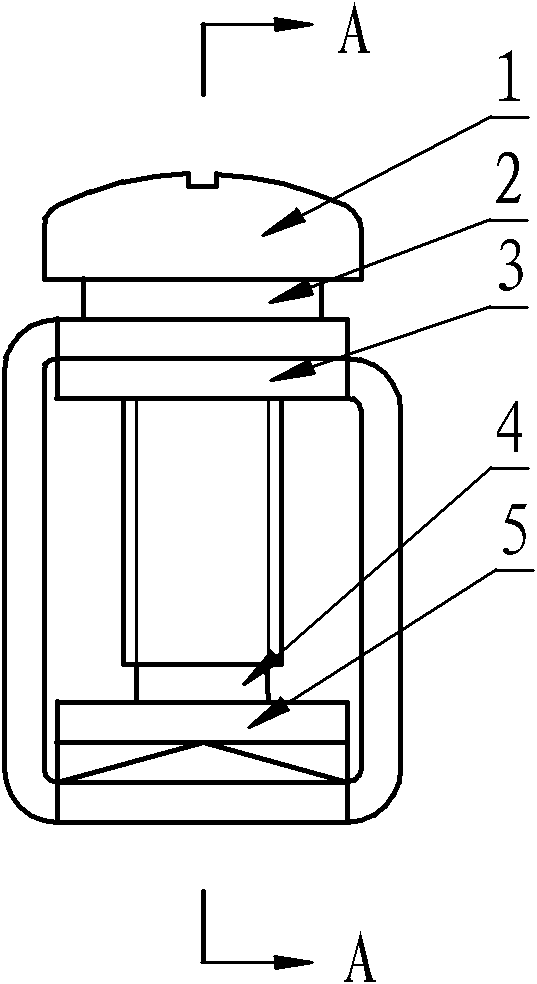

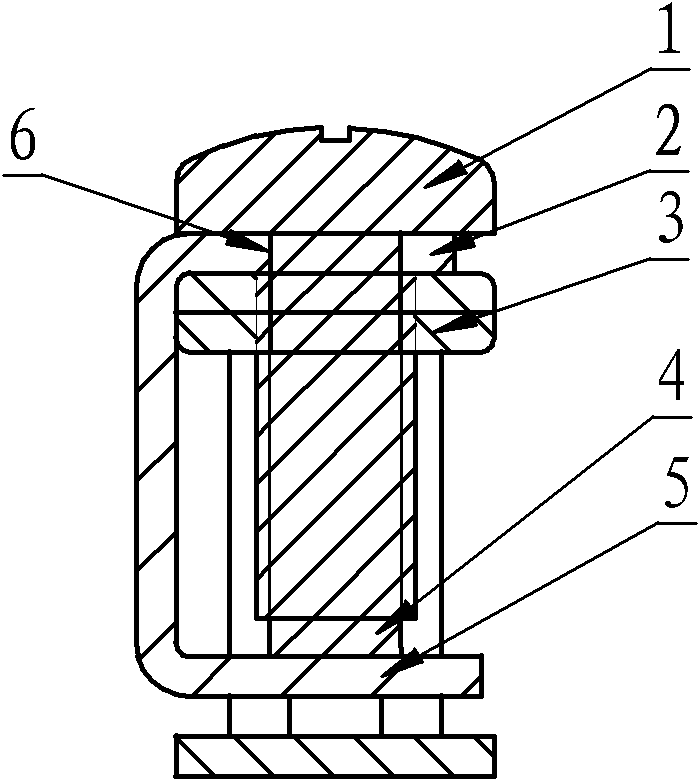

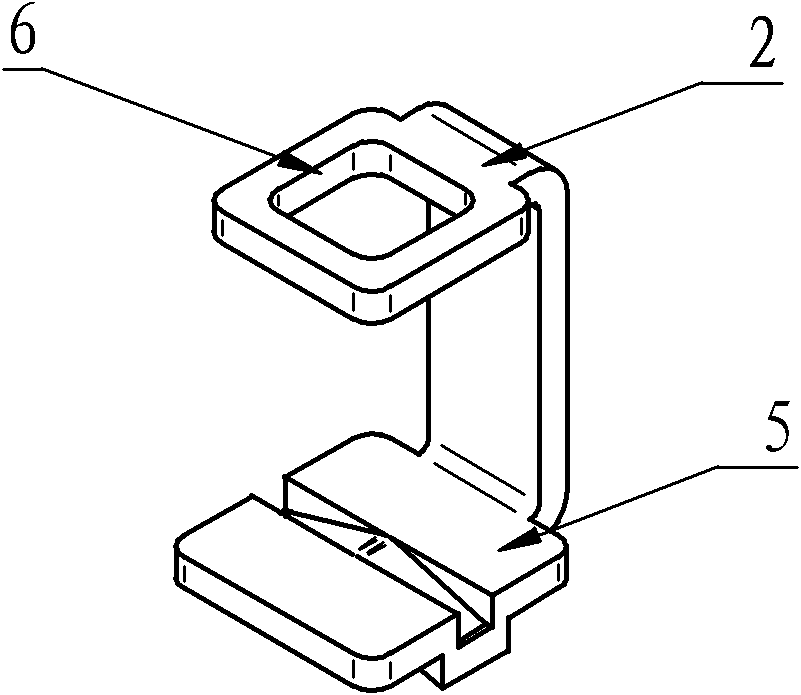

[0010] Such as figure 1 , 2 As shown, there is a threaded hole in the stack of clamp members 3. There is a square hole 6 on a vertical part of the U of a U font gasket plate 2, and the middle part of three limits of the square hole 6 protrudes to the center of the hole, and this has a vertical part of the square hole 6 It is placed on the threaded hole of the clip-shaped part 3 stack; on the other vertical part of the U-shaped of the gasket plate 2 is a flat plate 5 whose lower plane is tile-shaped, and this flat plate 5 part is on the clip-shaped part 3. In the space surrounded by four sides, the U-shaped bottom of the washer plate 2 is just on one side of the opening of the space surrounded by the clip-shaped piece; the screw 1 is a neck without th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com