Transverse type manual speed variator reverse gear safe device

A technology of manual transmission and reverse insurance, which is applied in the direction of transmission control, components with teeth, belts/chains/gears, etc., can solve problems such as high assembly requirements, no reverse gear, failure of automobile reverse gear insurance, etc., to achieve The effect of reliable assembly, simplified assembly, and elimination of assembly risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

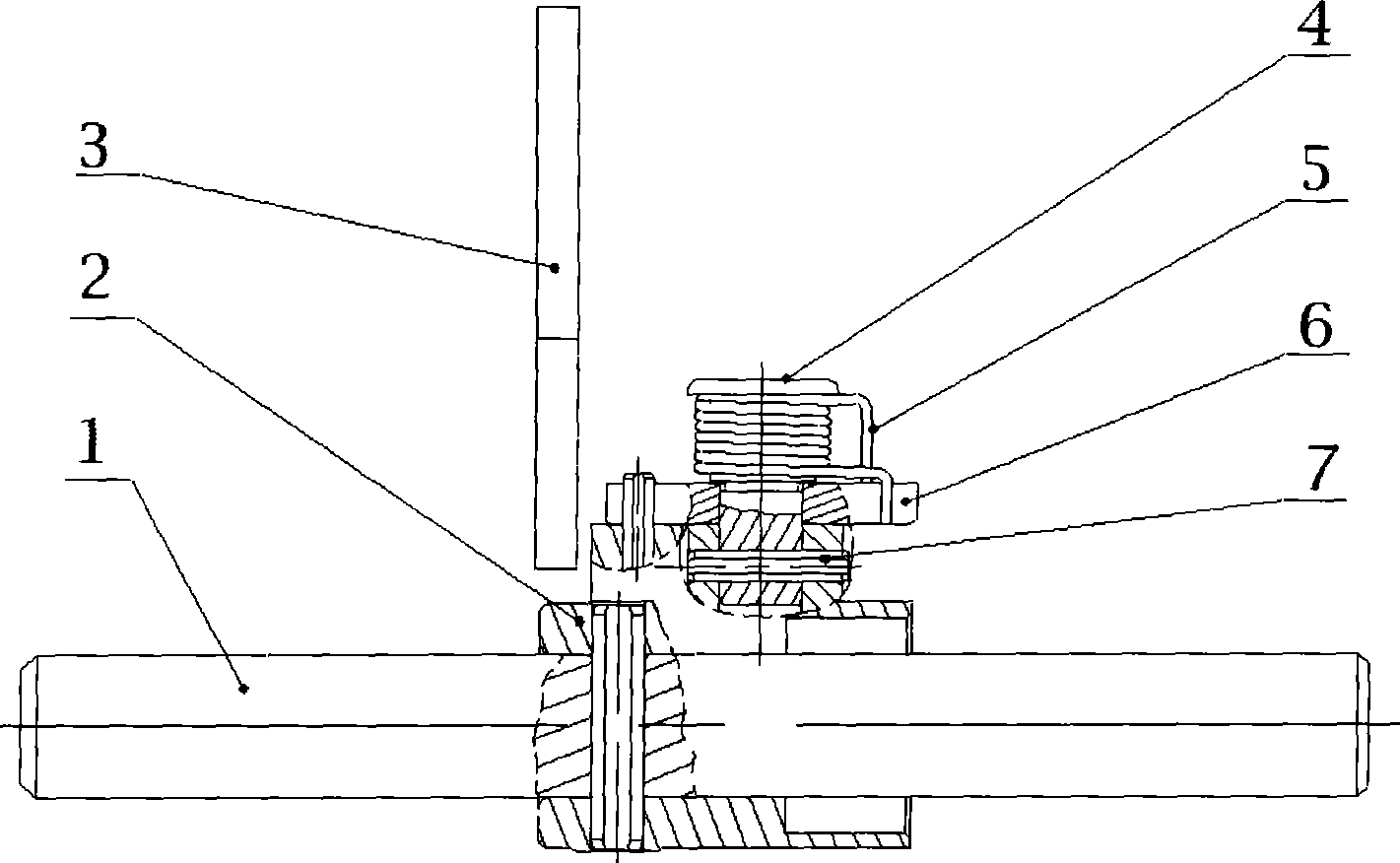

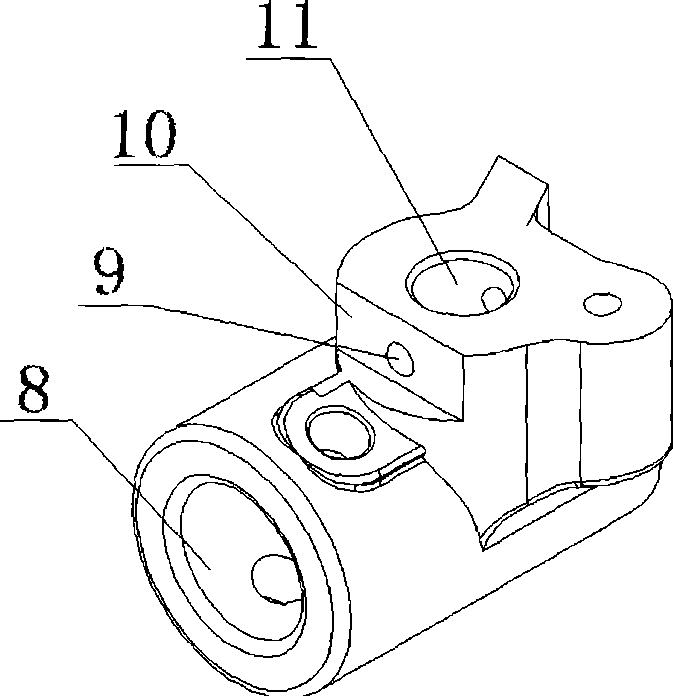

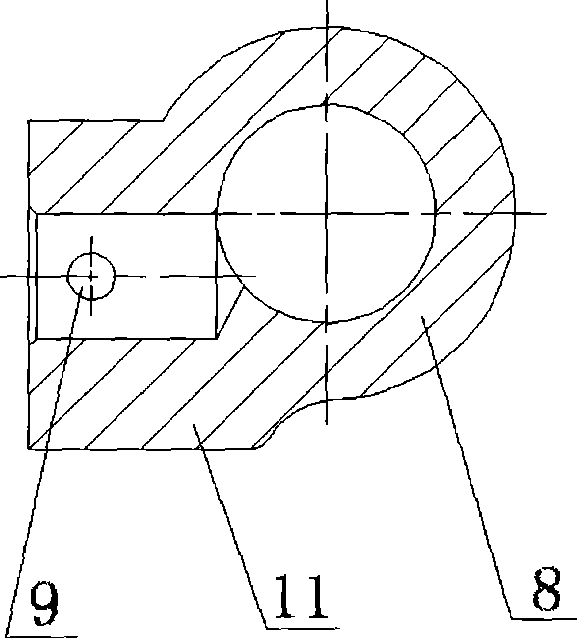

[0018] Such as figure 1 As shown, the present embodiment includes: a selector shift shaft 1, an insurance seat 2, a catch 3, a shift block shaft 4, a torsion spring 5, a shift block 6 and an elastic pin 7, wherein: the safety seat 2 is socketed on the select shift shaft On the shaft 1, the blocking piece 3 is fixedly arranged above the safety seat 2 and is perpendicular to the shifting shaft 1, the shift block shaft 4 passes through the shift block 6 and is vertically fixed on the safety seat 2 through the elastic pin 7, and the torsion spring 5 is wound around the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com