Patents

Literature

75 results about "Underwater manipulator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

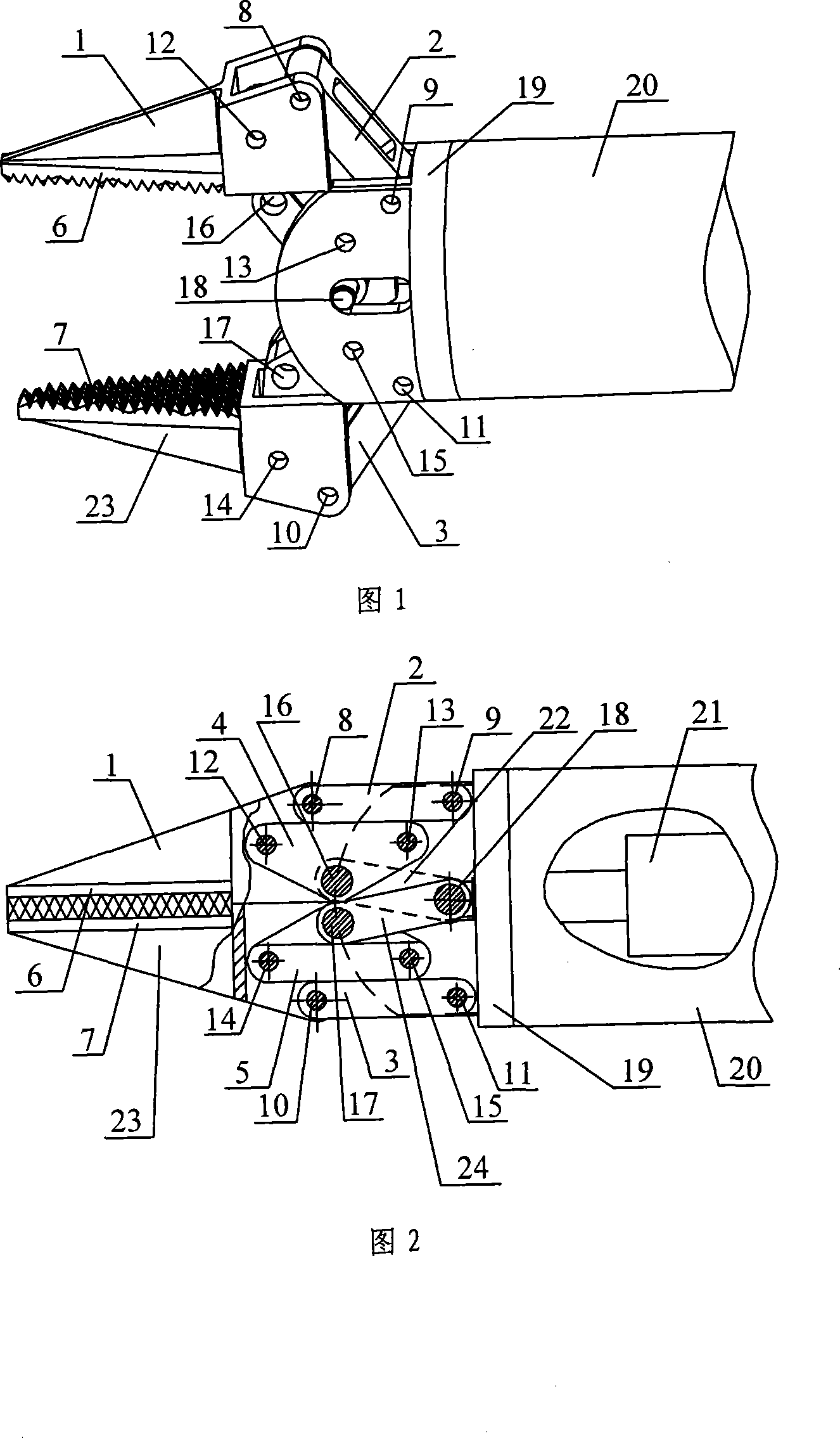

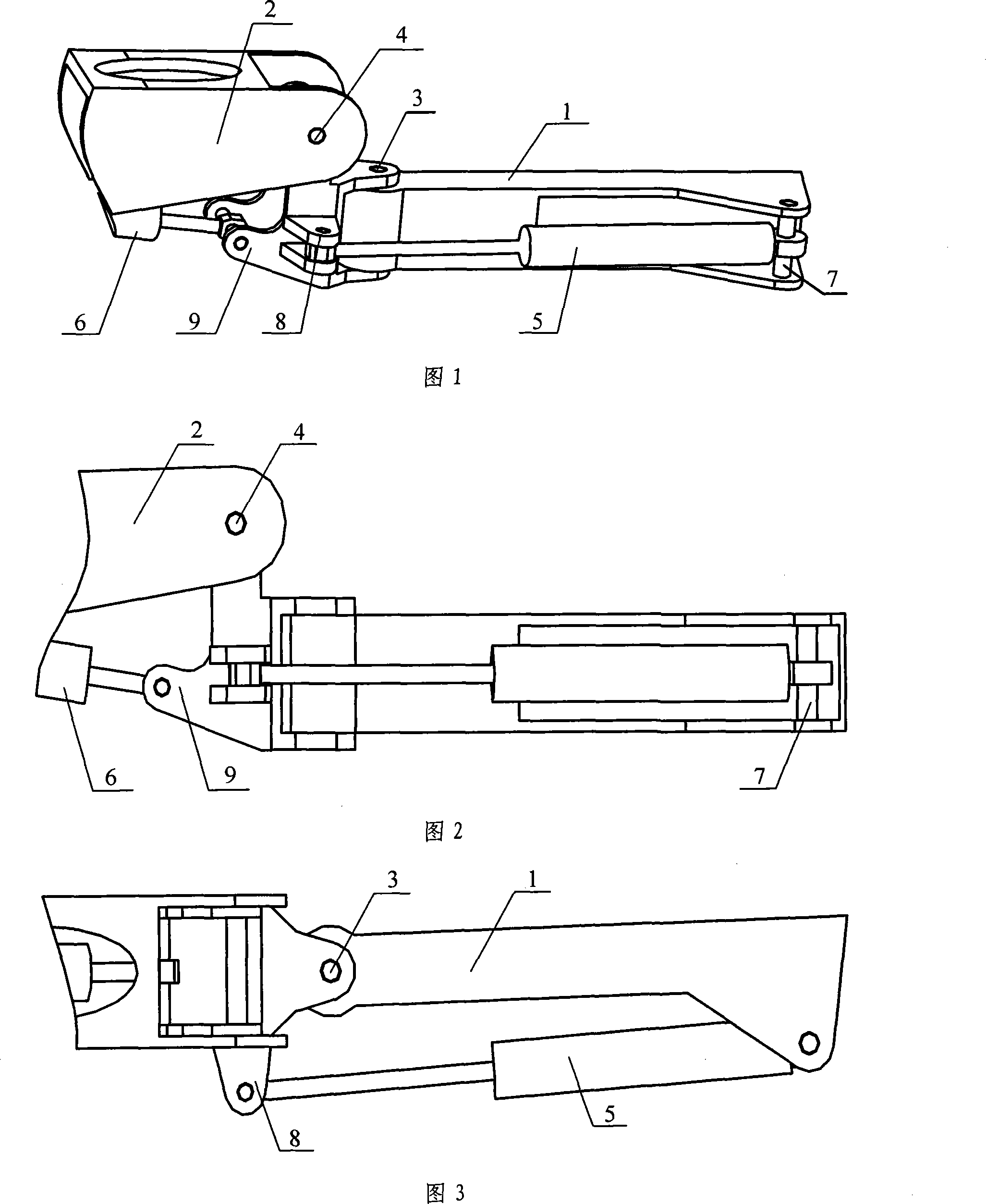

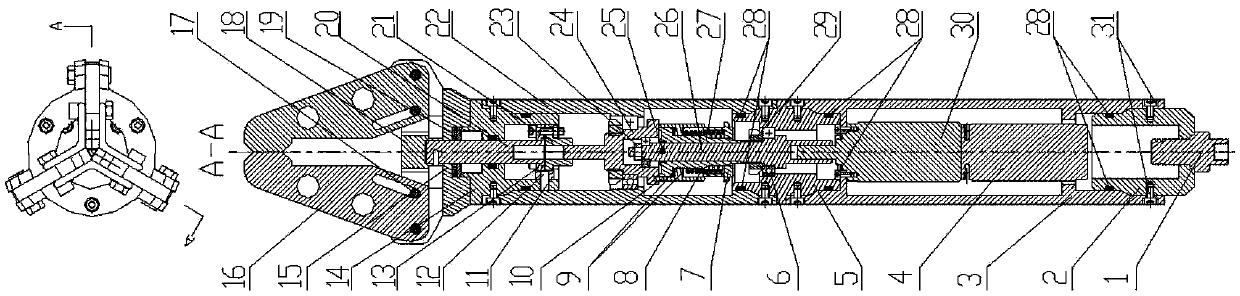

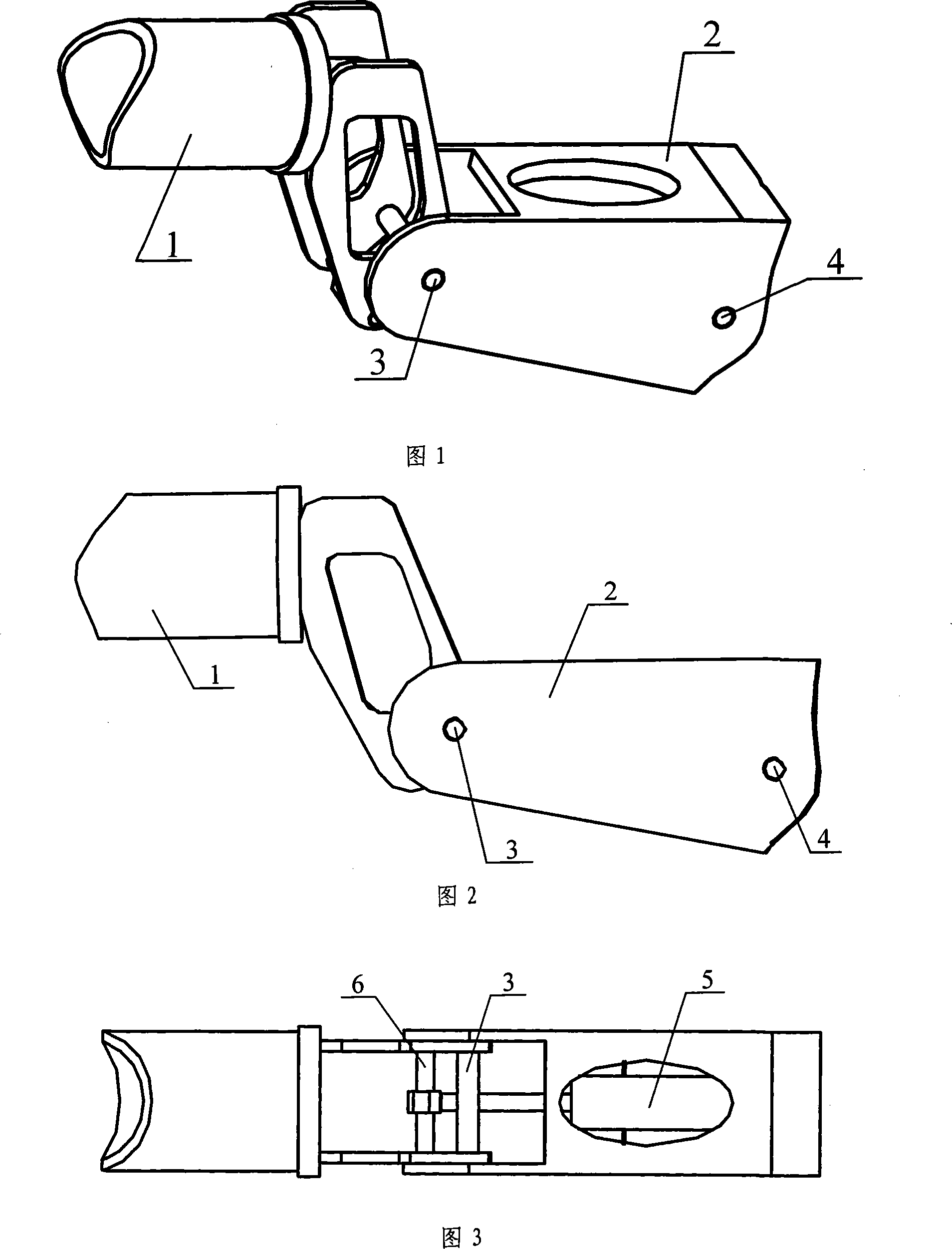

Submarine mechanical claw structure

InactiveCN101224579ASimple structureReduce weightGripping headsUnderwater equipmentHydraulic cylinderUnderwater manipulator

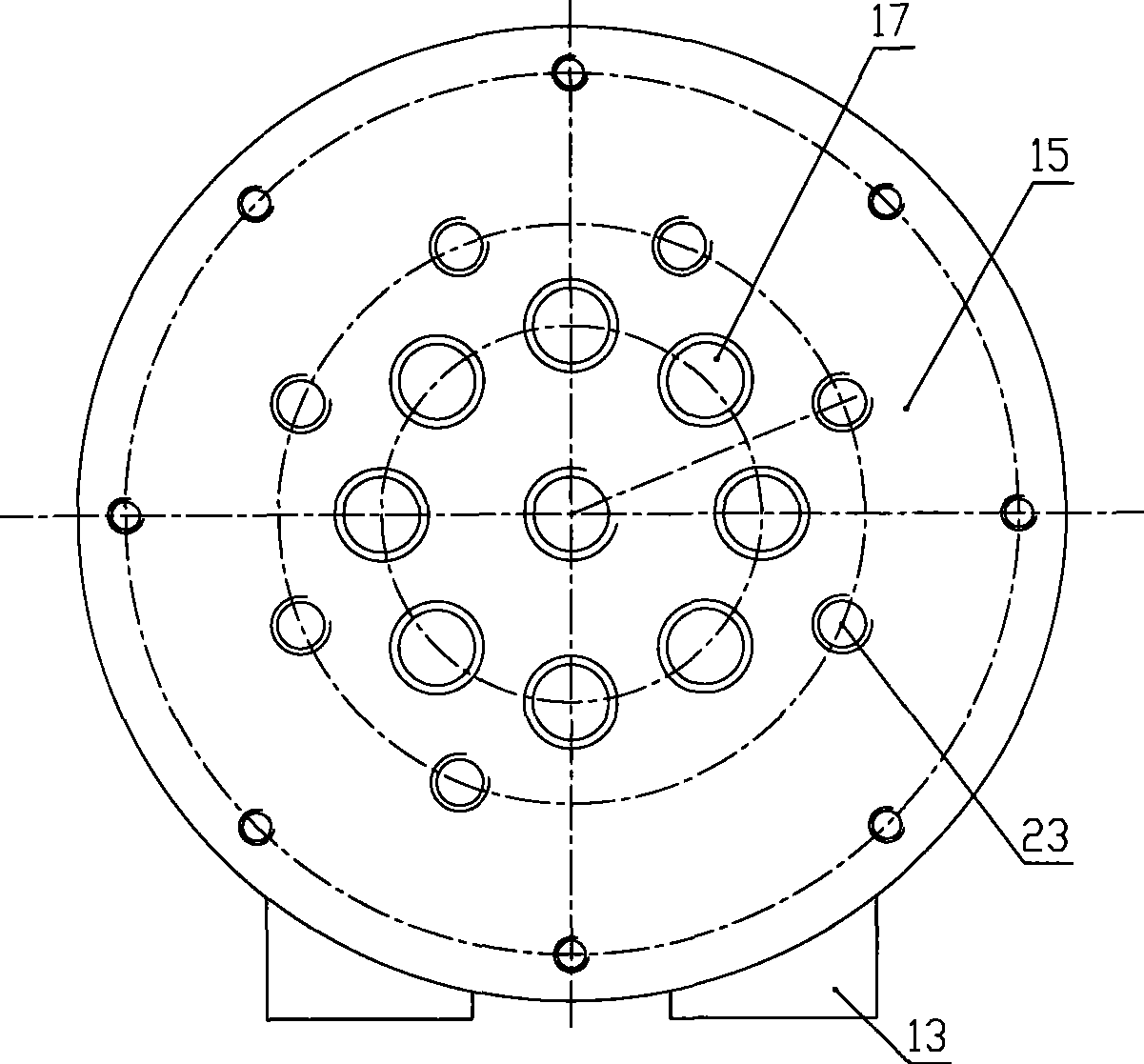

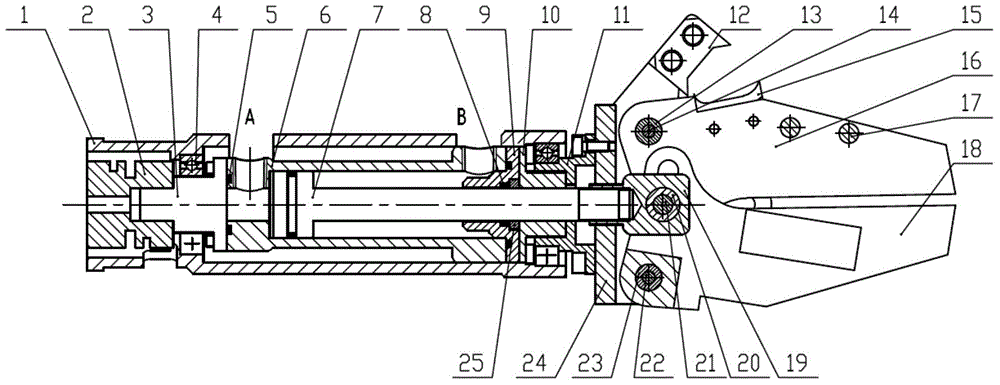

The invention provides an underwater manipulator clamping jaw structure, which consists of a claw I1, a claw II 23, an external connecting rod I 2, an external connecting rod II 3, an internal connecting rod I 4, an internal connecting rod II 5, a rubber layer I 6, a rubber layer II 7, an external connecting rod pin I 8, an external connecting rod pin II 9, an external connecting rod pin III 10, an external connecting rod pin IV 11, an internal connecting rod little pin II 13, an internal connecting rod little pin III 14, an internal connecting rod little pin IV 15, an internal connecting rod large pin II 17, a hydraulic cylinder pin 18, a base 19, a wrist 20, a hydraulic cylinder 21, a connecting rod I 22, and a connecting rod II 24.The invention is used for an underwater robot and has the advantages of simple structure, light weight, and agile movement. By the driving of the hydraulic pressure, the opening / closing movement of the clamping jaw is realized, and the clamping jaw is provided with the capability of clamping lager load; by the small range movement of the hydraulic cylinder piston, the opening / closing movement in large range of the clamping jaw is realized.

Owner:HARBIN ENG UNIV

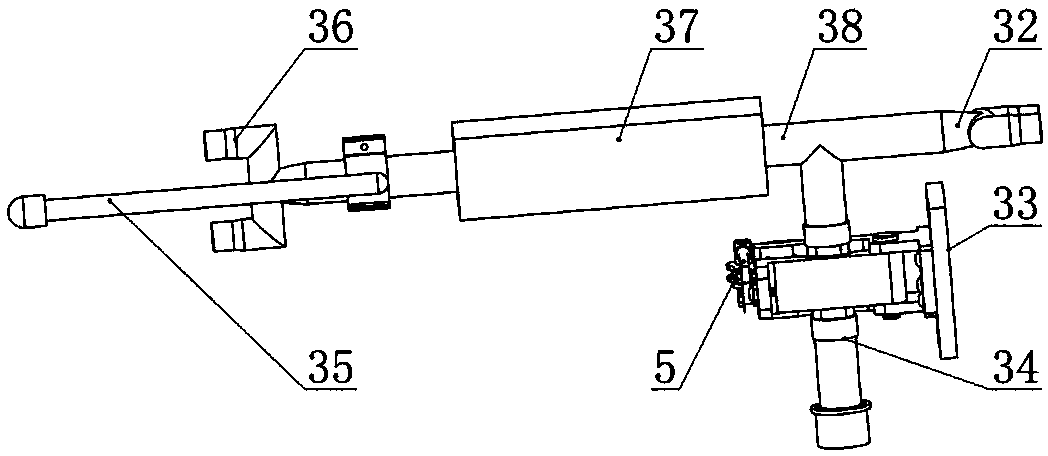

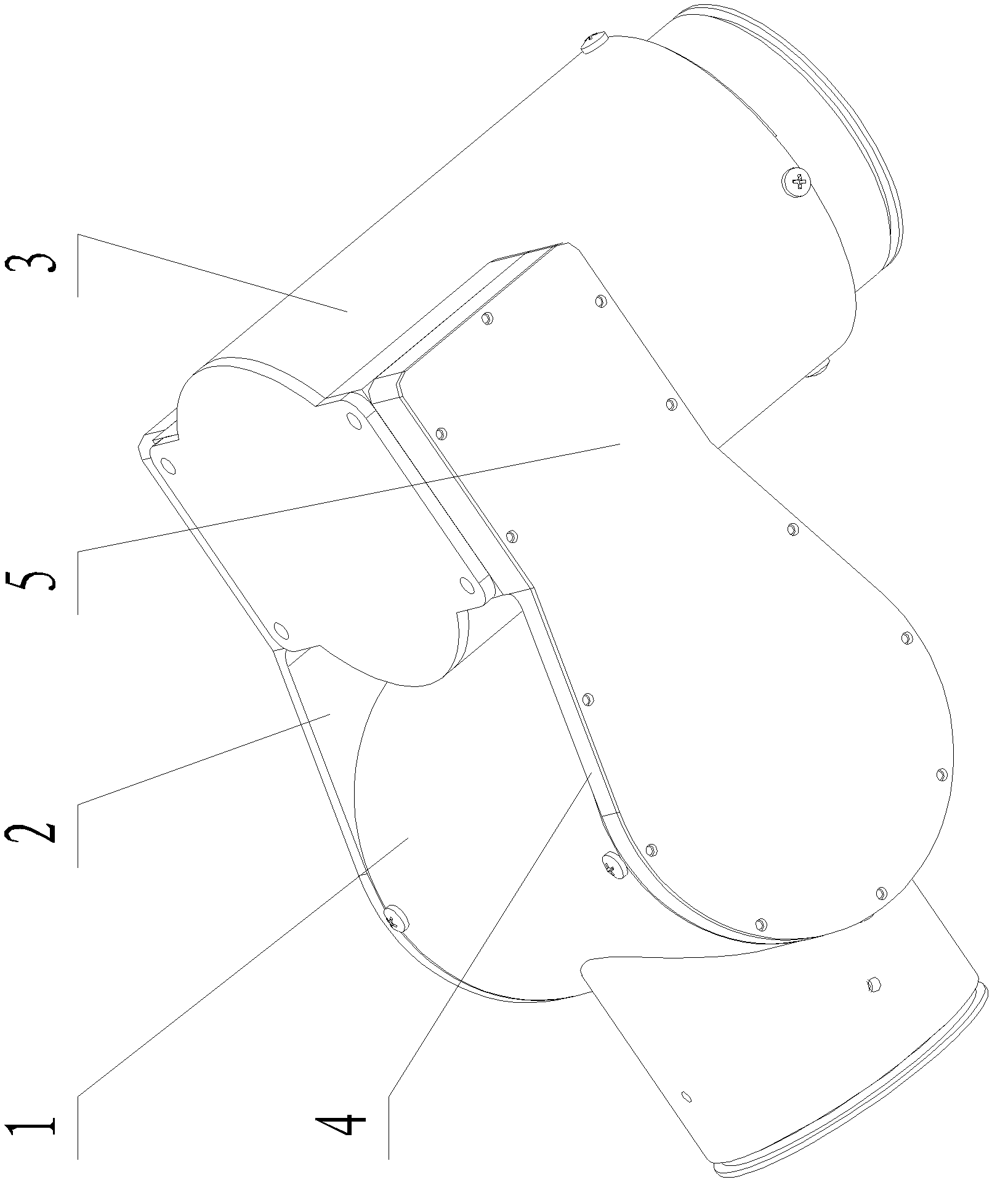

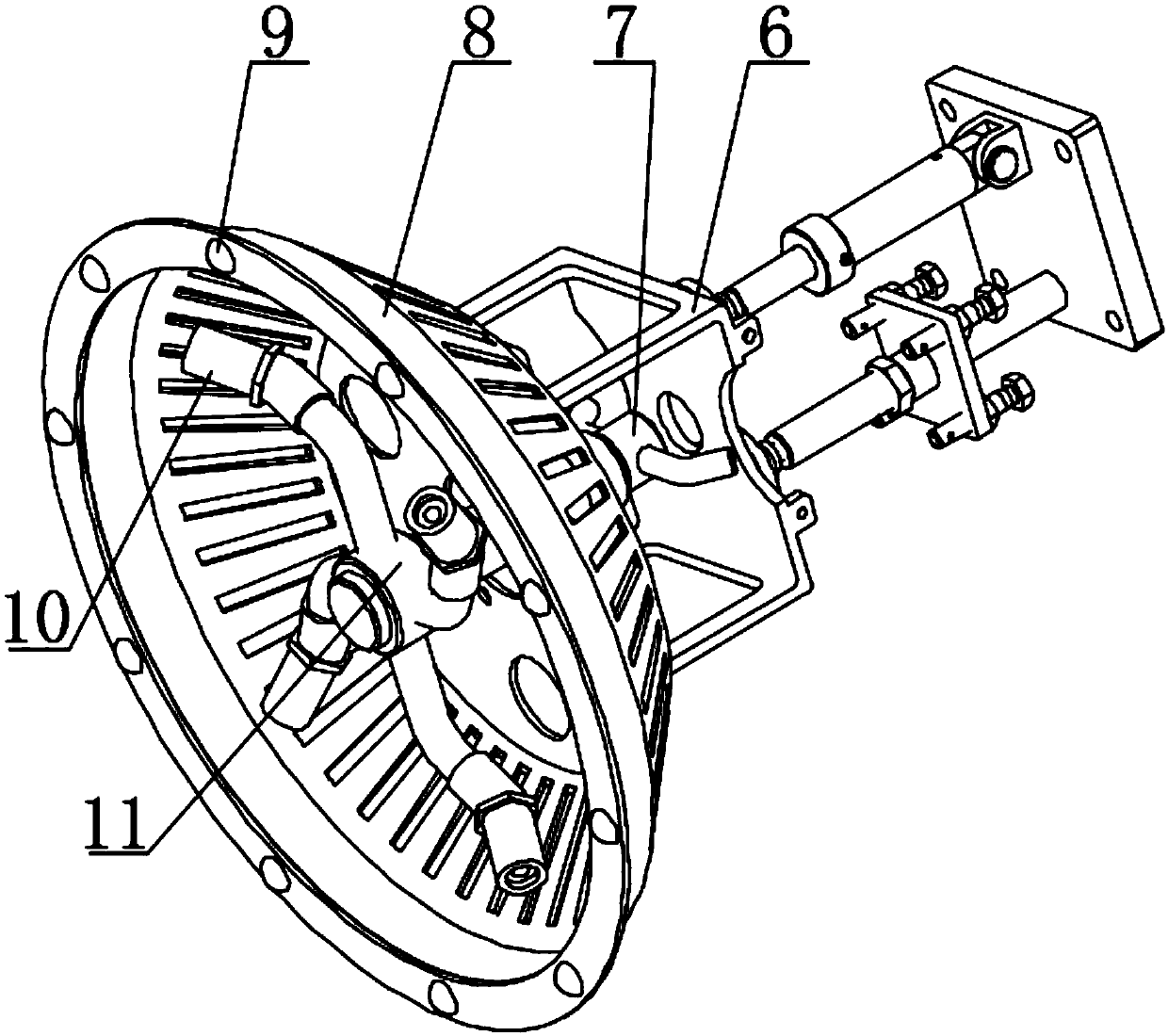

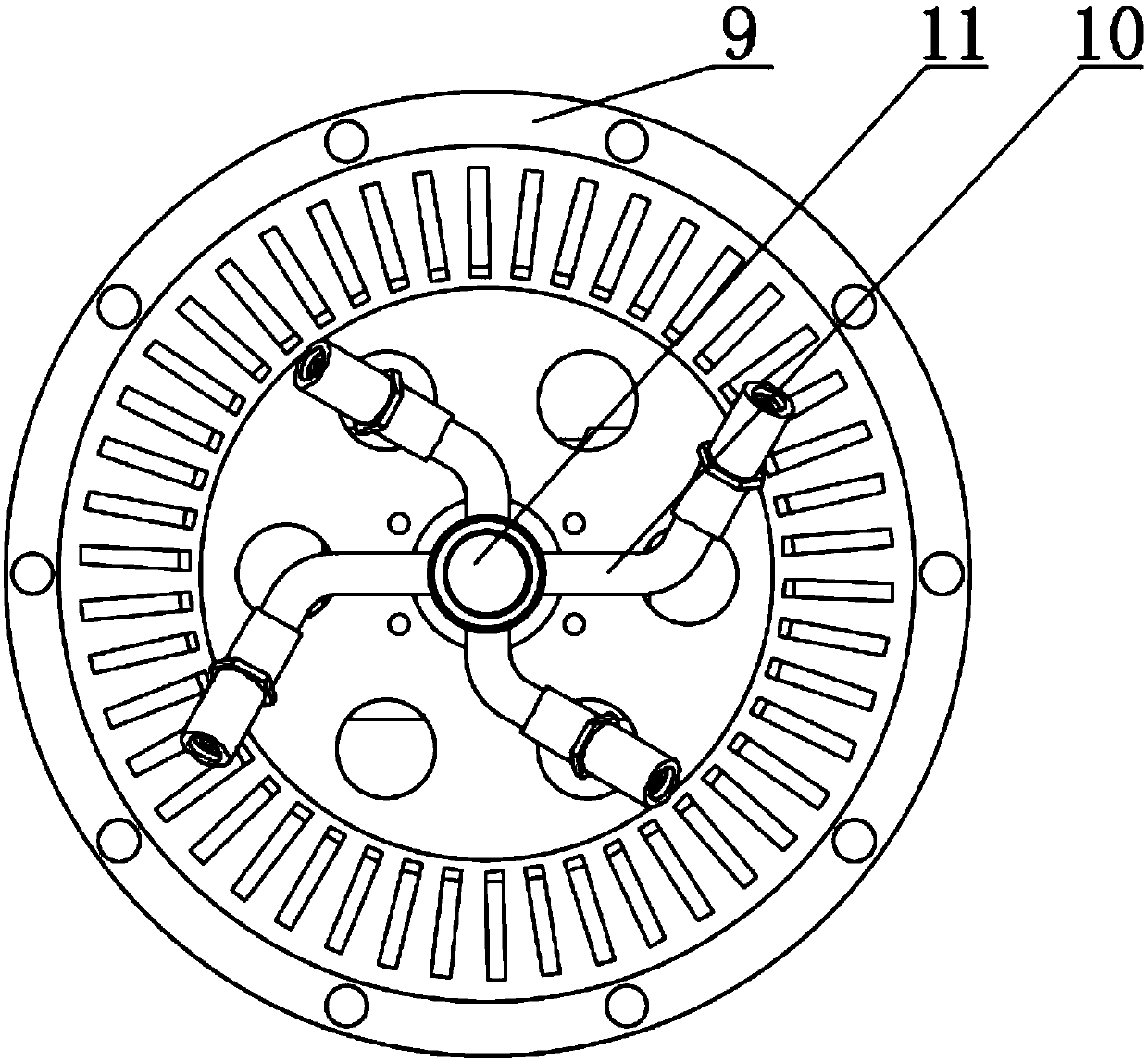

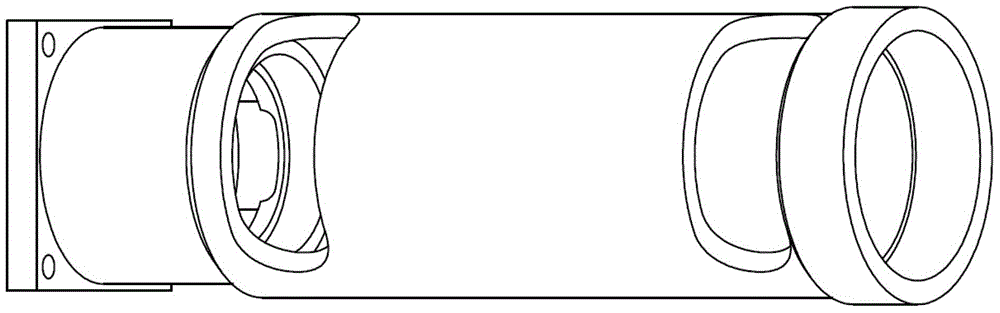

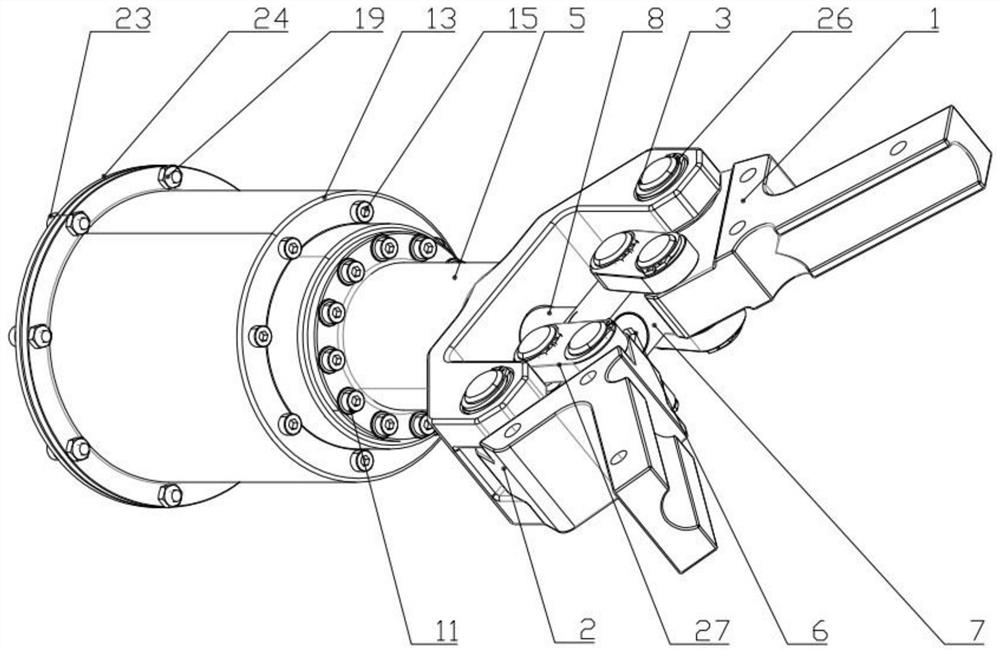

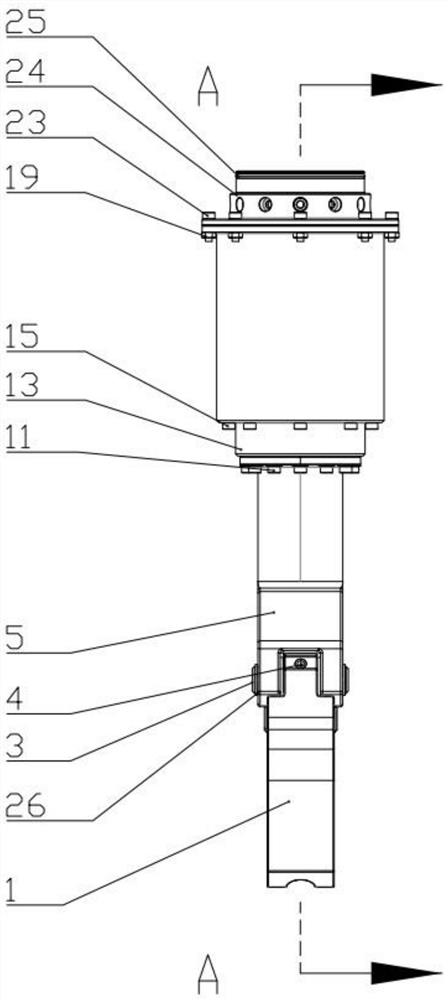

Transportable type device applicable to capturing and butt joint of underwater moving target

ActiveCN108502129AImprove power efficiencyImprove capture efficiencyUnderwater equipmentUnderwater manipulatorMarine engineering

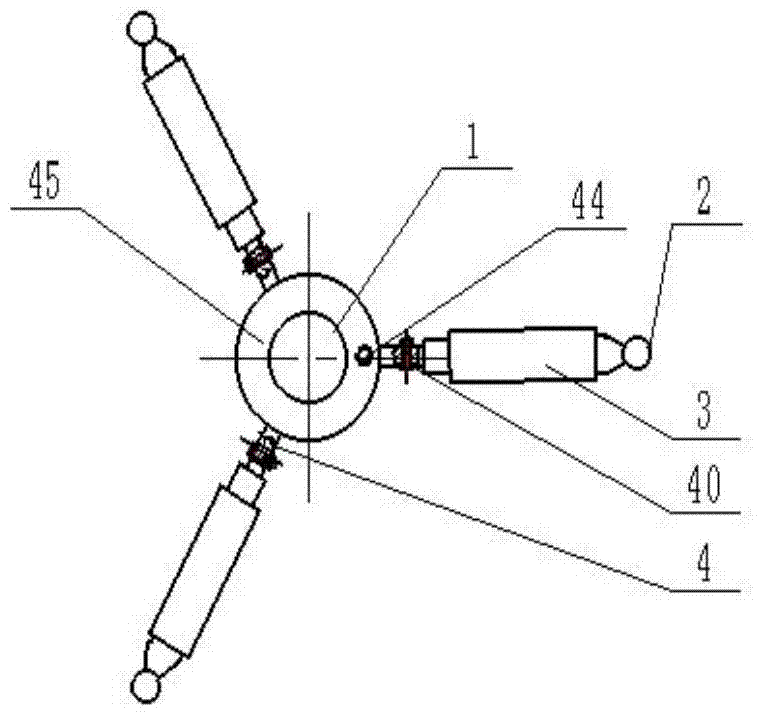

The invention belongs to the field of related equipment of deep sea rendezvous and docking and discloses a transportable type device applicable to capturing and butt joint of an underwater moving target. The transportable type device comprises a mechanical arm, a guide cover capturing unit, a light source guide unit and a butt joint unit, wherein the mechanical arm is designed into a multi-joint type underwater mechanical arm and can be folded and stored after operation is finished; the guide cover capturing unit is mounted at the tail end of the mechanical arm and has opening and closing functions, so that the capturing of the underwater moving target is finished; the light source guide unit is used for sensing a position and a posture of the underwater moving target; the butt joint unitis used for carrying out mutual and accurate butt joint on a butt joint socket for the underwater moving target through a plug manner. With the adoption of the transportable type device disclosed by the invention, capturing and butt joint operation of the underwater moving target can be finished under a moving state in a higher-precision manner; meanwhile, influences caused by seawater interference are effectively overcome, the capturing success rate and the capturing efficiency are remarkably improved, and the accuracy and applicability of the butt joint operation are ensured.

Owner:HUAZHONG UNIV OF SCI & TECH

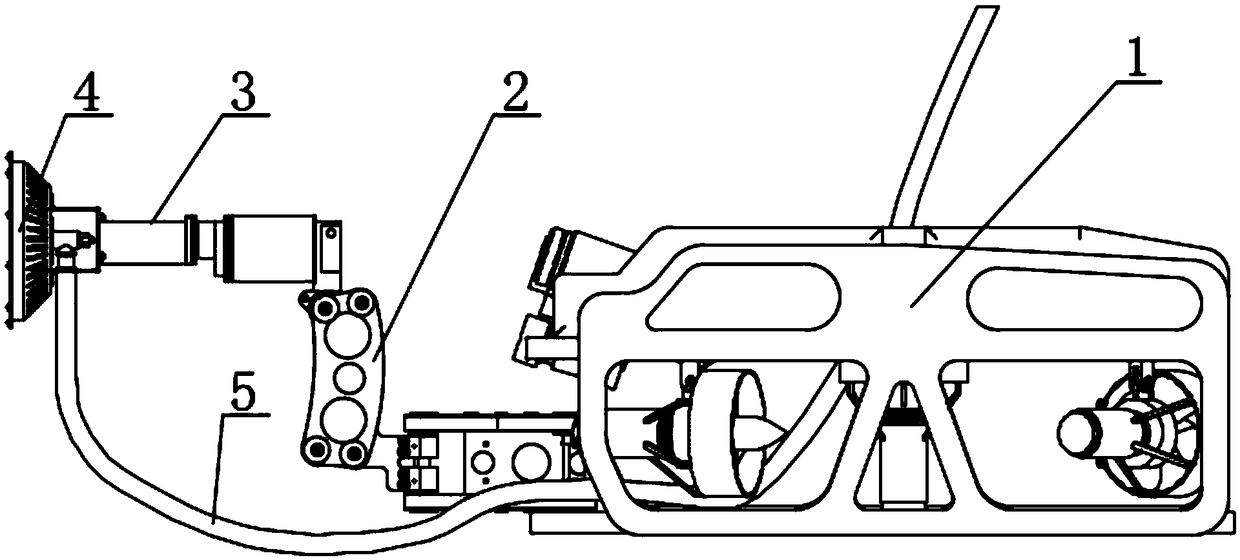

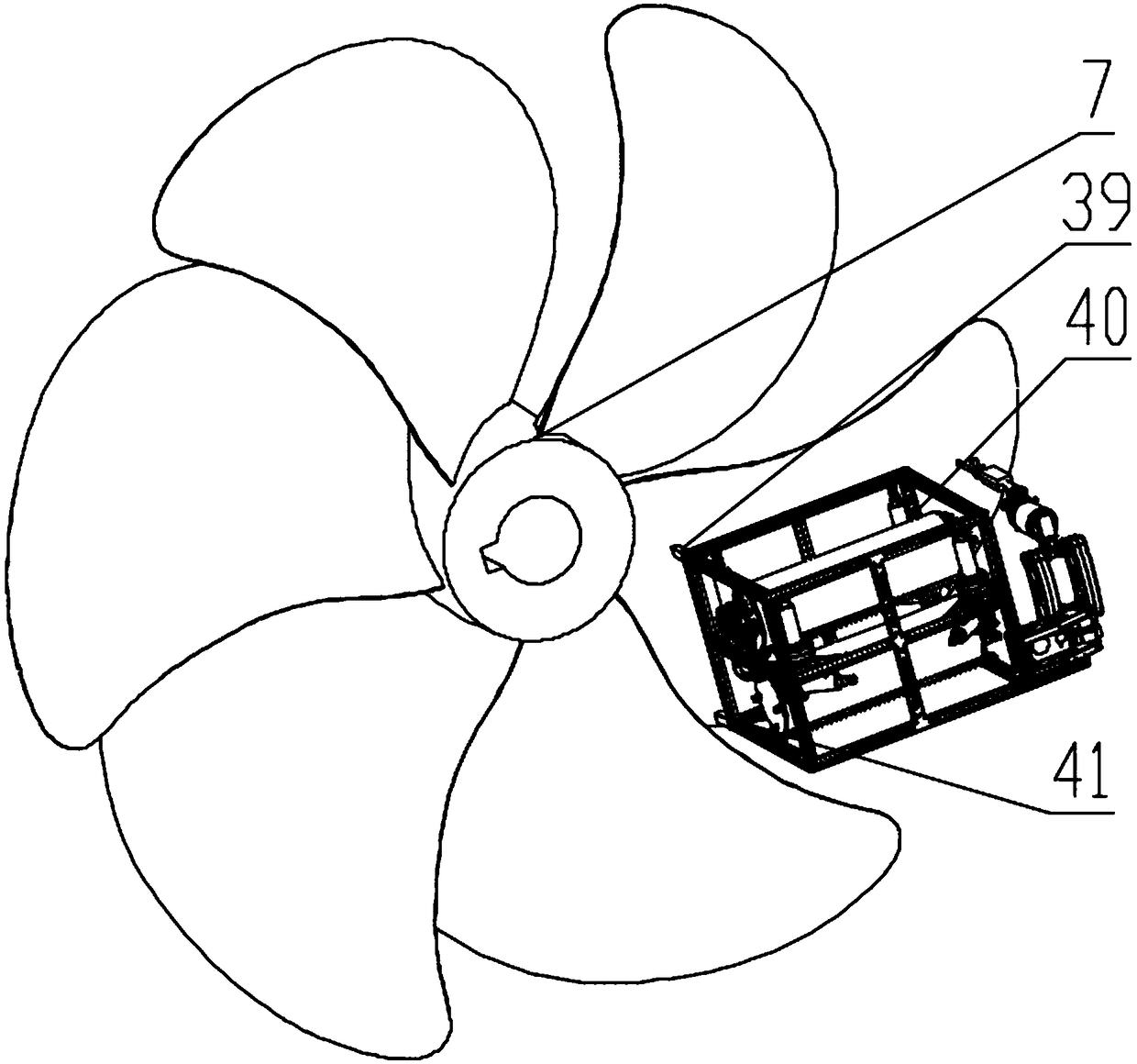

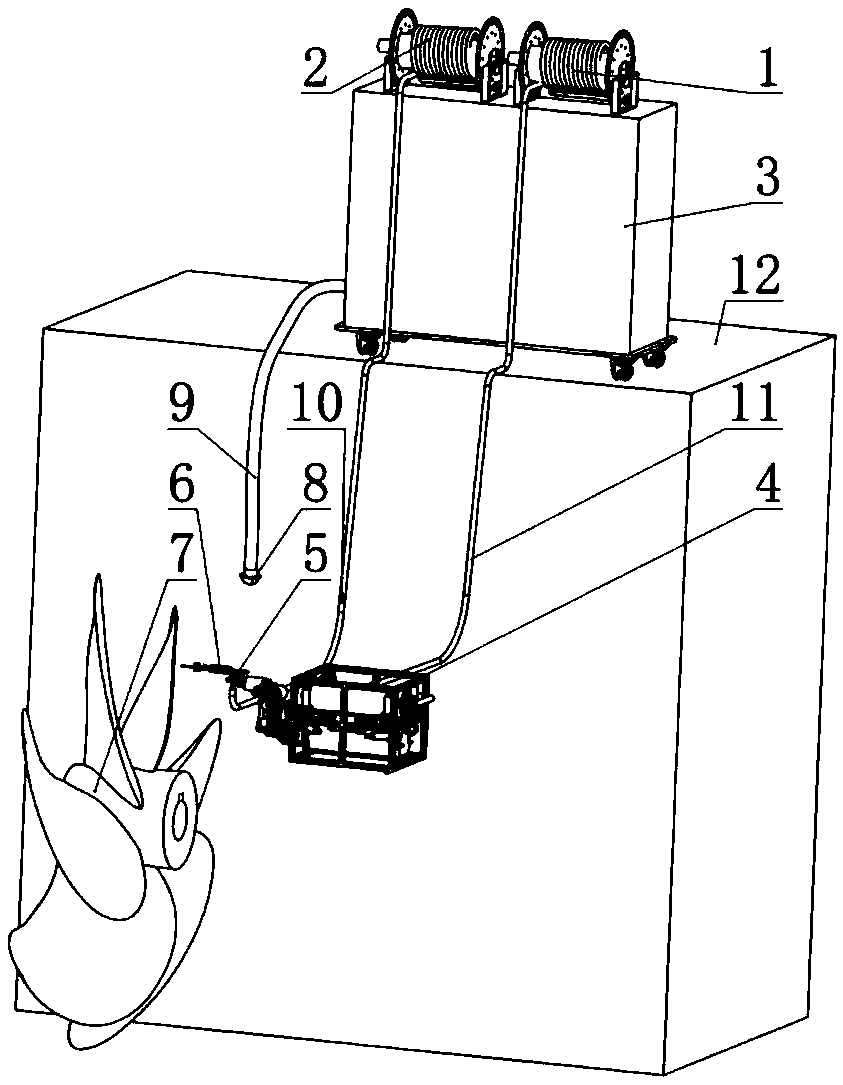

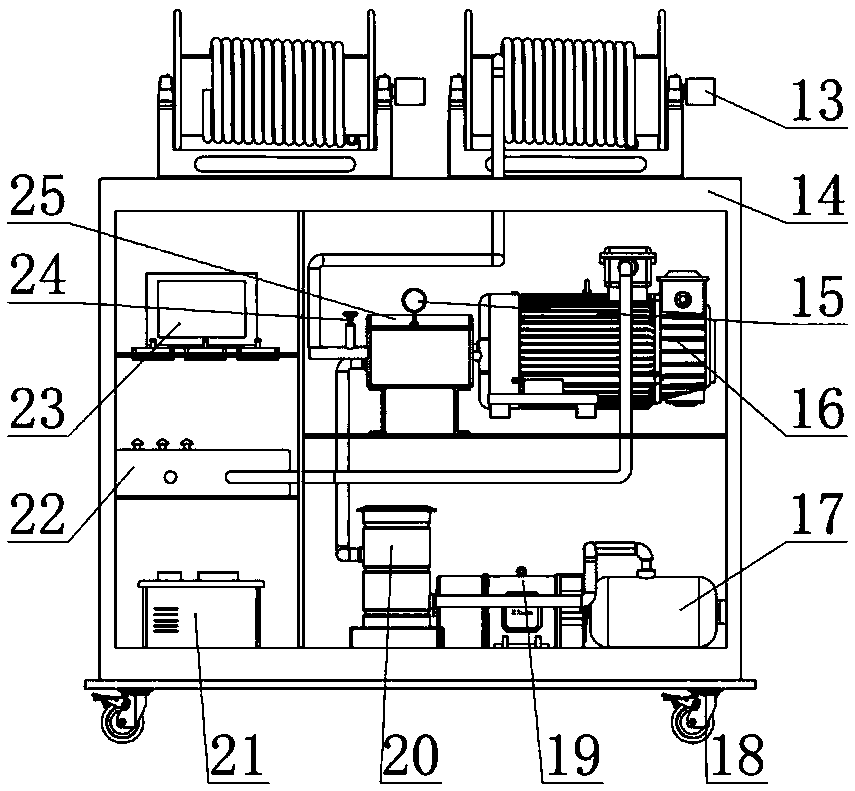

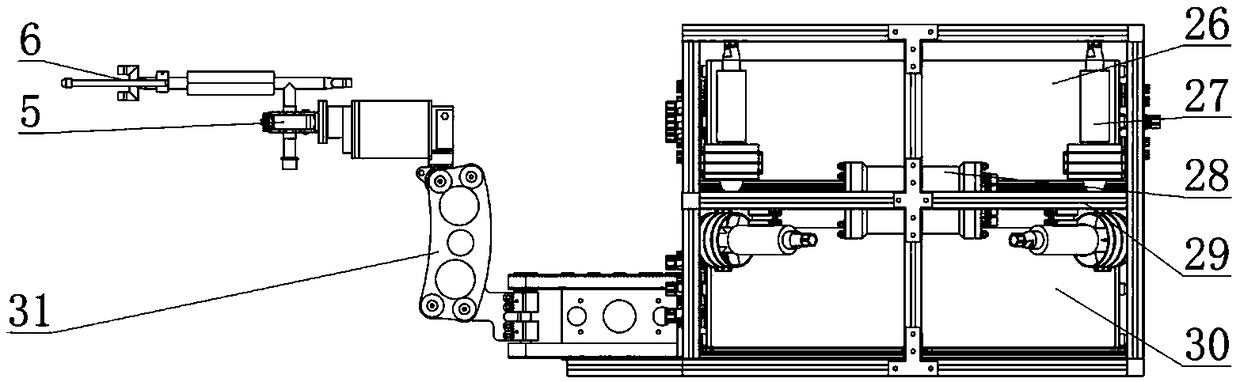

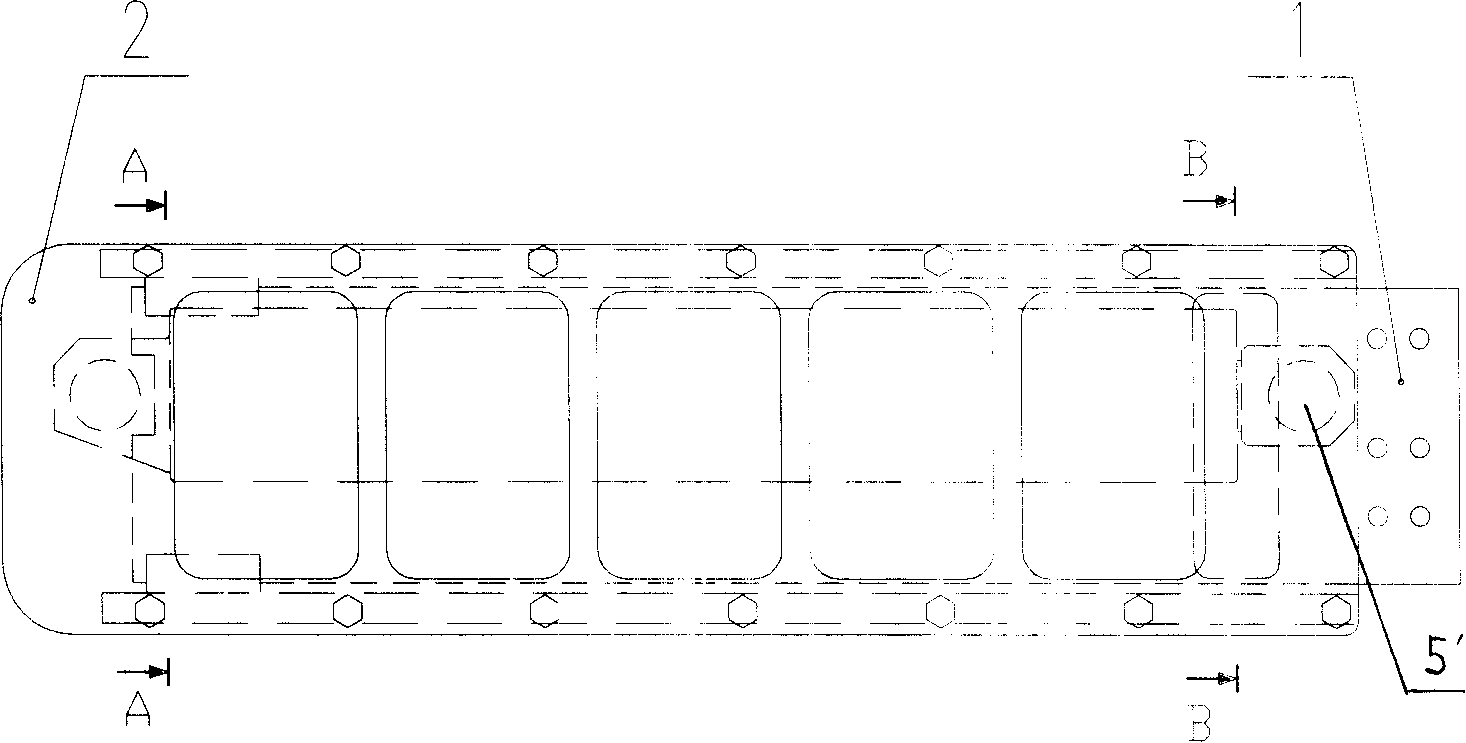

Underwater cavitation cleaning device for propeller and use method thereof

InactiveCN109050823AConvenient underwater automatic cleaningCompact structureVessel cleaningHullsCavitationUnderwater manipulator

The invention relates to an underwater cavitation cleaning device for a propeller, comprising an underwater robot, wherein one end of the underwater robot is provided with an underwater manipulator, an output end of the underwater manipulator is provided with a cavitation cleaning device through a connecting device, a water pipe is penetrated into the underwater robot, and the water pipe is connected with the cavitation cleaning device; The cavitation cleaning device is structured as follows: including mounting brackets, the mounting bracket is formed into a frame-type structure, At one end ofthat mount bracket, shell is mount at that other end, A plurality of convex spherical surfaces are evenly spaced apart in the circumferential direction of the outer end surface of the housing, A central rotating body is installed in the middle of the casing, the central rotating body passes through the central hole of the casing and is fixedly connected with the casing through screws, a recoil nozzle is installed at one end of the central rotating body, the recoil nozzle is located in the mounting frame, and an abnormal nozzle is installed at the other end of the central rotating body. Work reliably.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

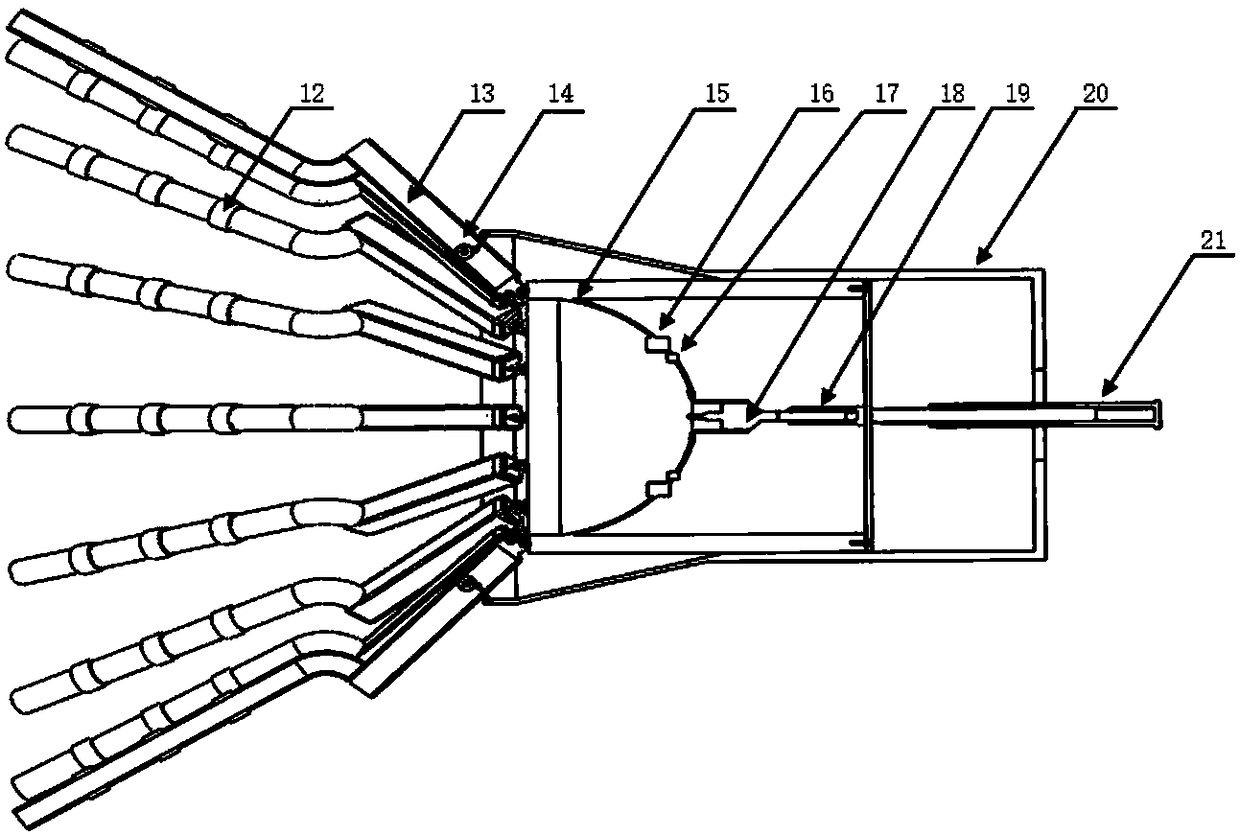

Sucking-type underwater manipulator and sucking method thereof

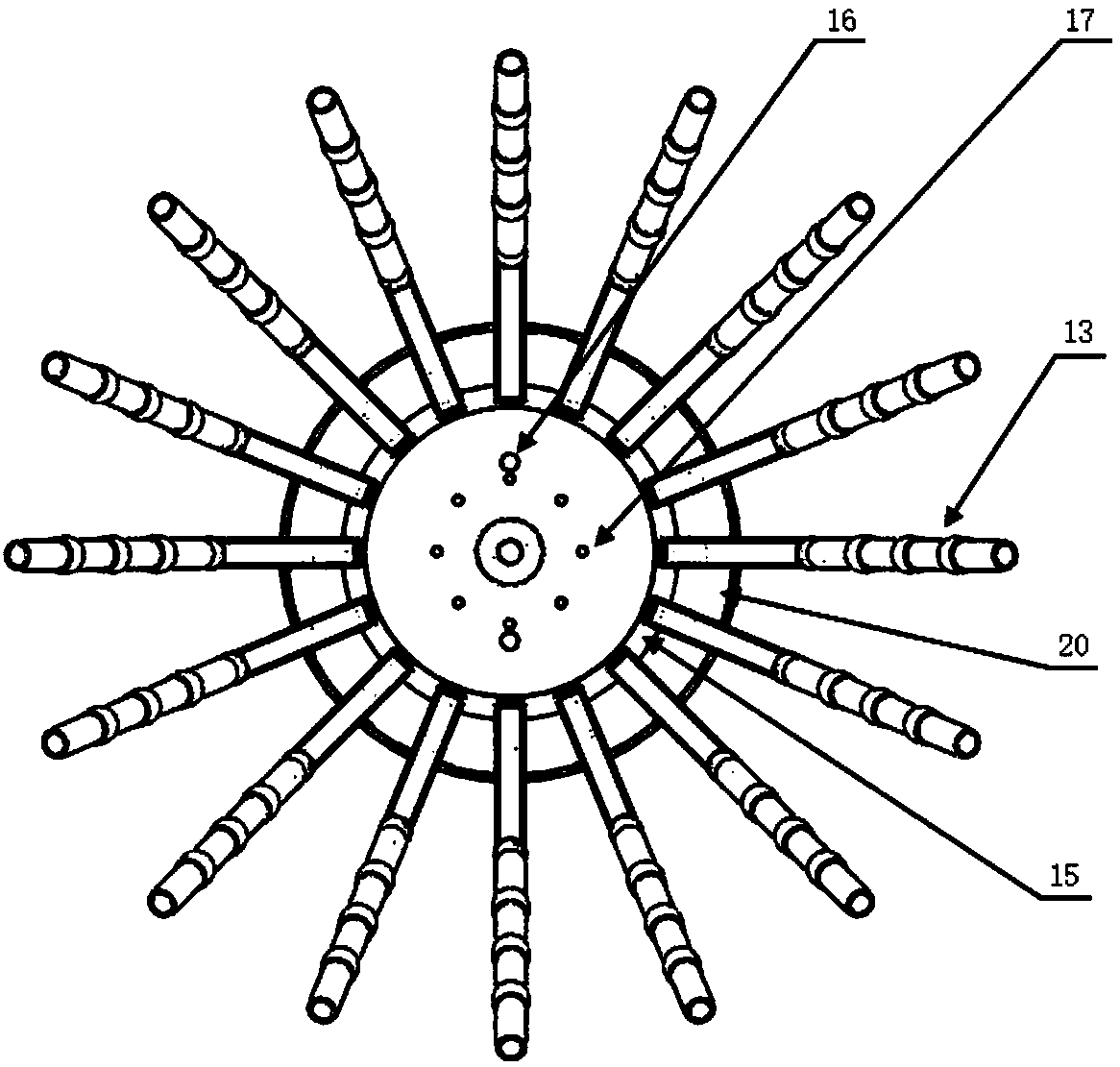

InactiveCN103921277AImprove efficiencyGuaranteed firmnessGripping headsUnderwater equipmentHydraulic motorHydraulic cylinder

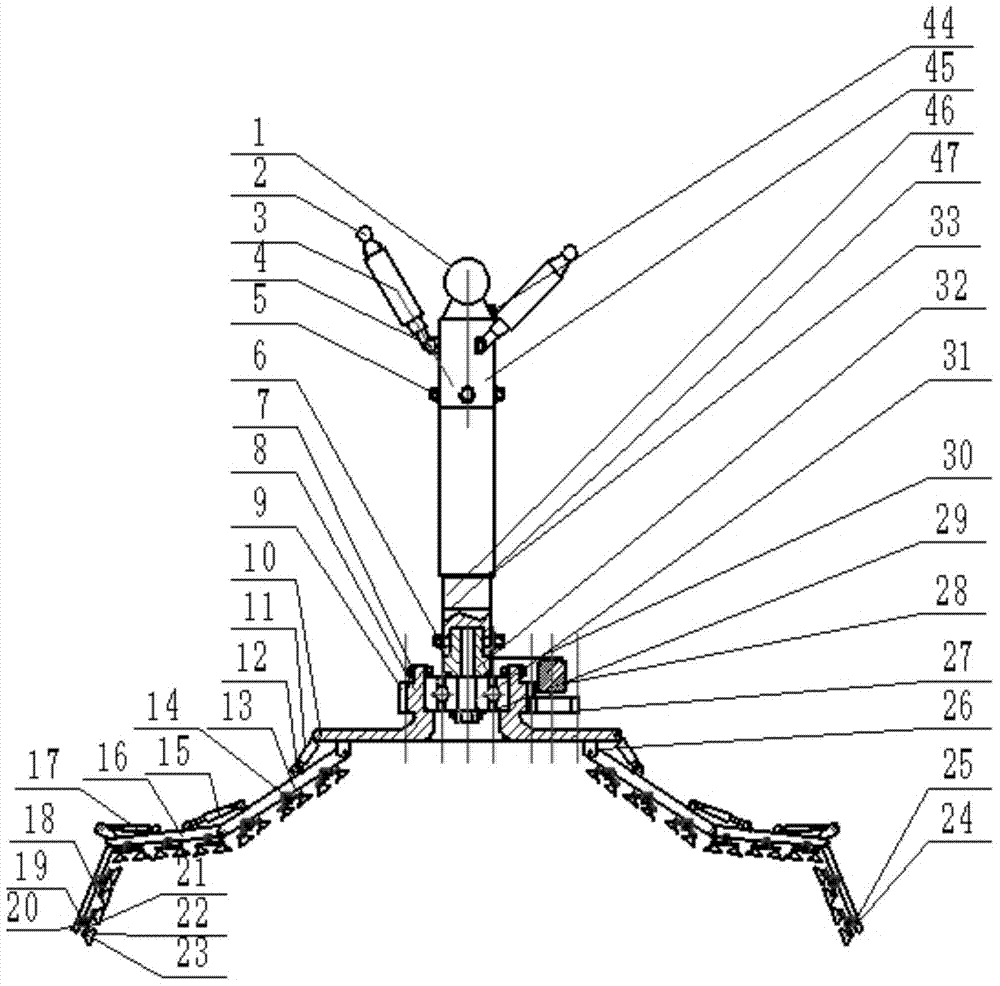

The invention relates to a sucking-type underwater manipulator and a sucking method thereof. A main oil pump of a robot hull provides hydraulic oil for hydraulic cylinders and hydraulic motors of the manipulator through multilevel flexible hydraulic oil pipes. A manipulator base is connected with the hull through a universal ball at the top and is connected with three hydraulic cylinders which control the manipulator base. A single-level hydraulic cylinder is fixed on the lower portion of the manipulator base. A telescopic shaft of the single-level hydraulic cylinder is connected with the base through a sleeve shaft. A hydraulic motor is mounted on the sleeve shaft and is used for driving the manipulator base to rotate. Eight manipulator wrists controlled by the hydraulic cylinders are mounted on the base. A certain quantity of sucking disc rod groups are mounted on the bottom surface of each manipulator wrist. The object grabbing and adsorbing method of the sucking-type underwater manipulator is similar to that of an octopus living under the sea, sucking discs are squeezed and liquid in cavities of the sucking discs is drained under the acting force of the manipulator wrists to objects, and the sucking discs are enabled to be adsorbed to the surfaces of the objects. Under the joint action of grabbing force of the manipulator wrists and adsorbing force of the sucking discs, the manipulator has a better object grabbing capability.

Owner:JILIN UNIV

A cleaning device for propeller underwater automatic cleaning equipment

InactiveCN109080789AReduce cleaning costsSimple structureVessel cleaningHullsCavitationUnderwater manipulator

The invention relates to a cleaning device for propeller underwater automatic cleaning equipment of a propeller, including underwater vehicles, A first cleaning device positioning rod is respectivelyinstalled at three positions on the left side of the underwater robot frame of the underwater robot, a second cleaning device positioning lever and a third cleaning device positioning lever, The firstcleaning device positioning rod, the second cleaning device positioning rod and the third cleaning device positioning rod position the propeller, and the underwater manipulator of the underwater robot is provided with a cavitation cleaning device through a connecting device, and the output port of the cavitation cleaning device is butted with the propeller. The underwater robot is equipped with an underwater robot hand, and the cavitation cleaning device is clamped by a connecting device, and the high-pressure water supplied by the high-pressure water supply device is injected to clean the propeller according to the cavitation principle. The underwater vehicle moves along a preset path to clean the entire propeller blade surface, and rotates the propeller to clean all the blade surfaces of the propeller.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

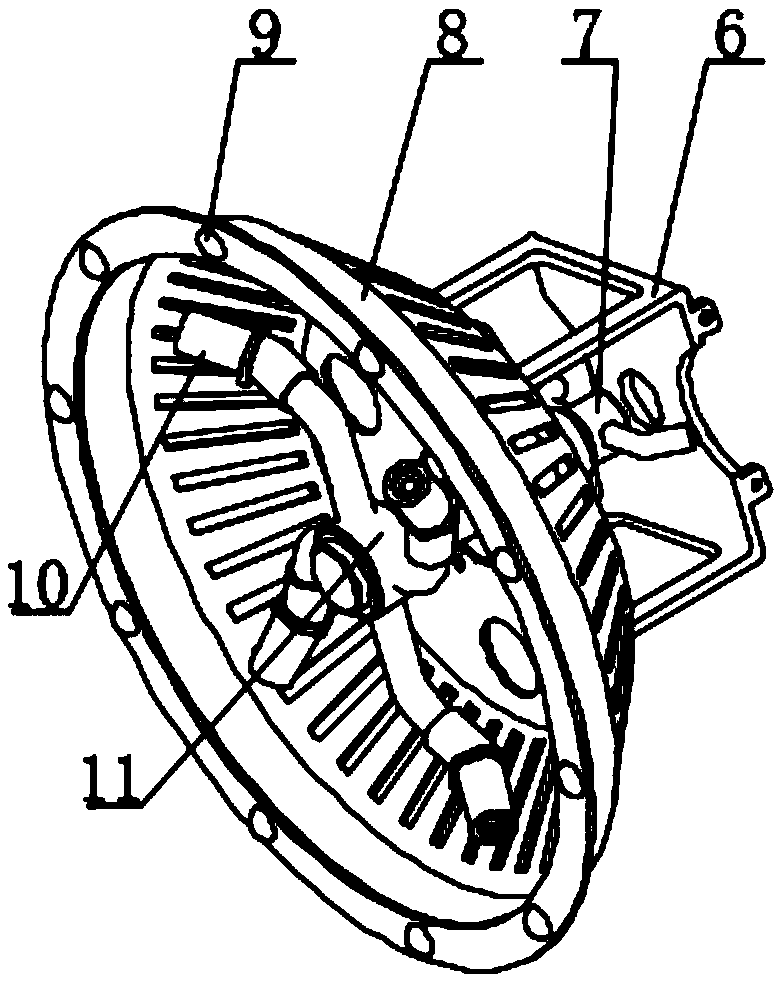

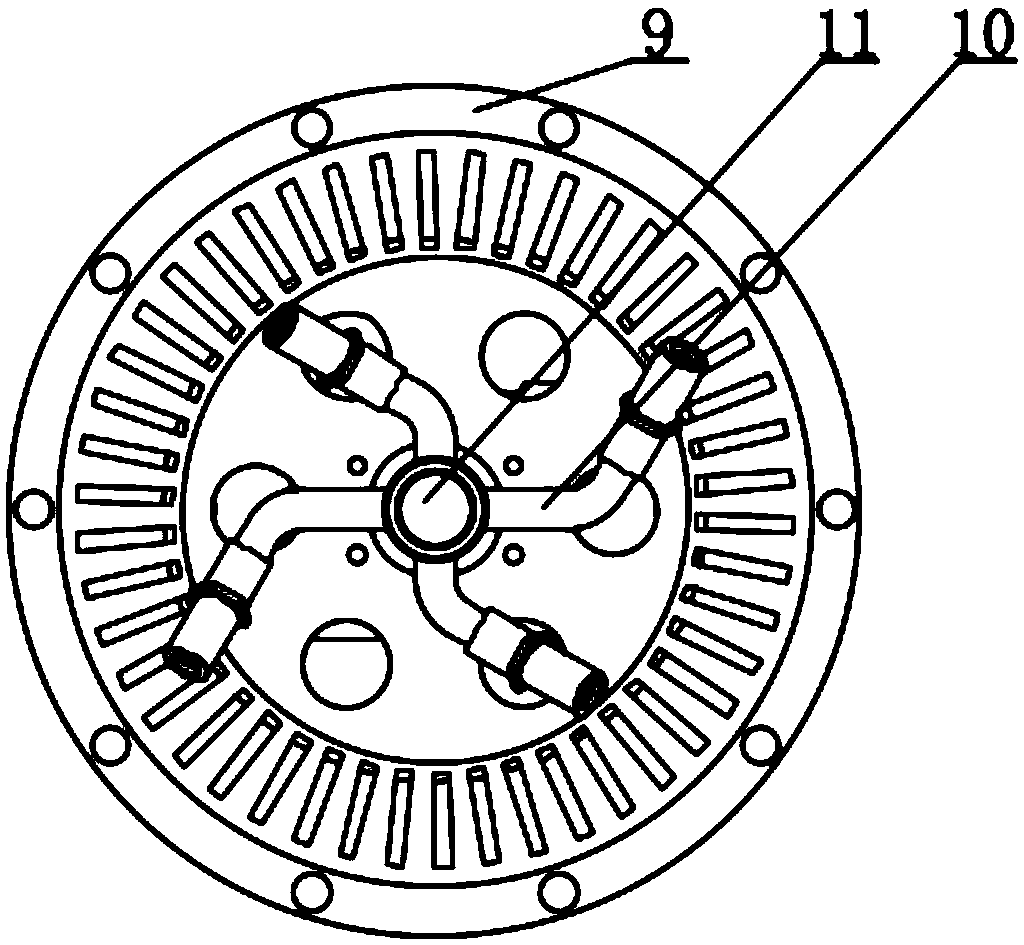

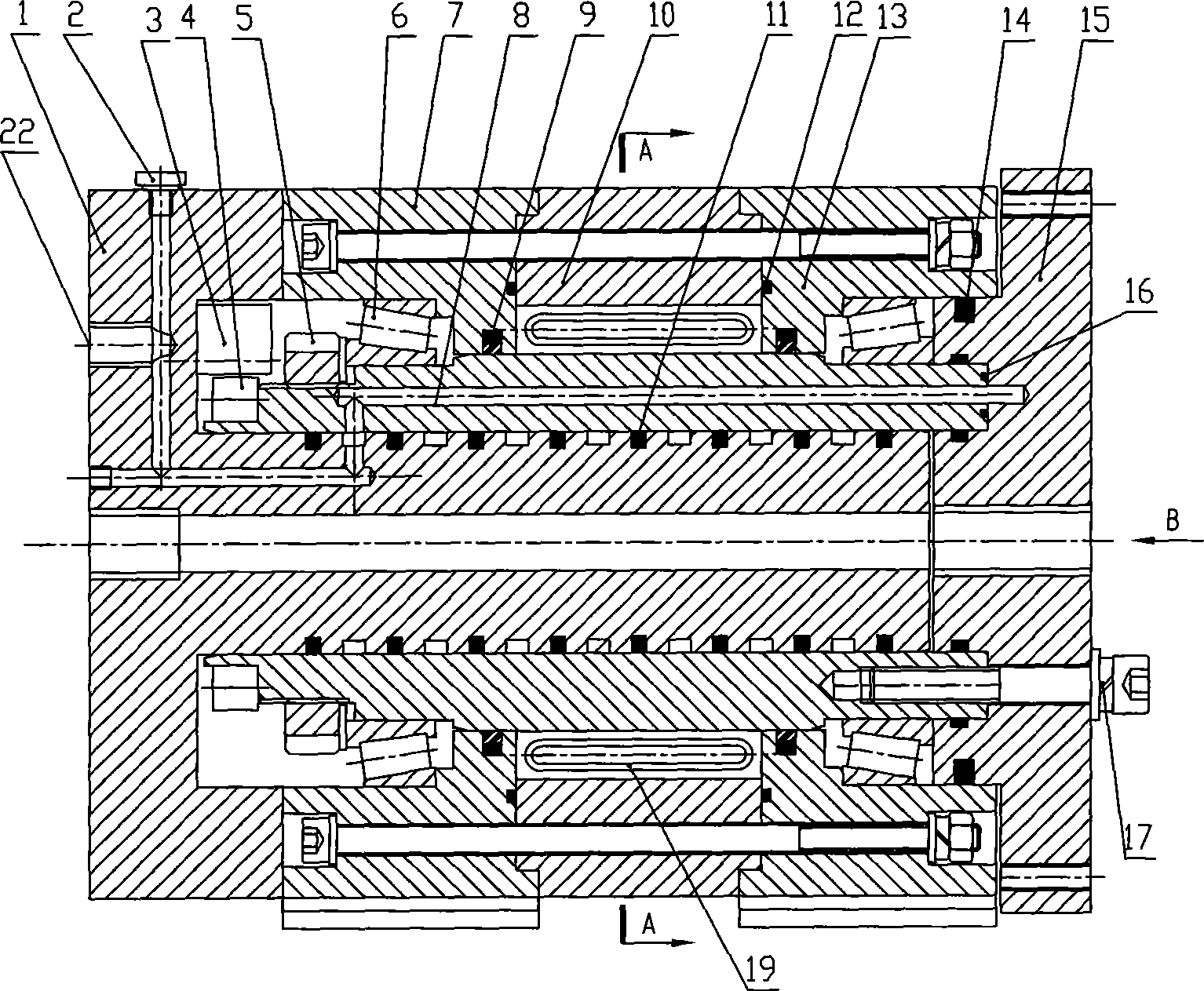

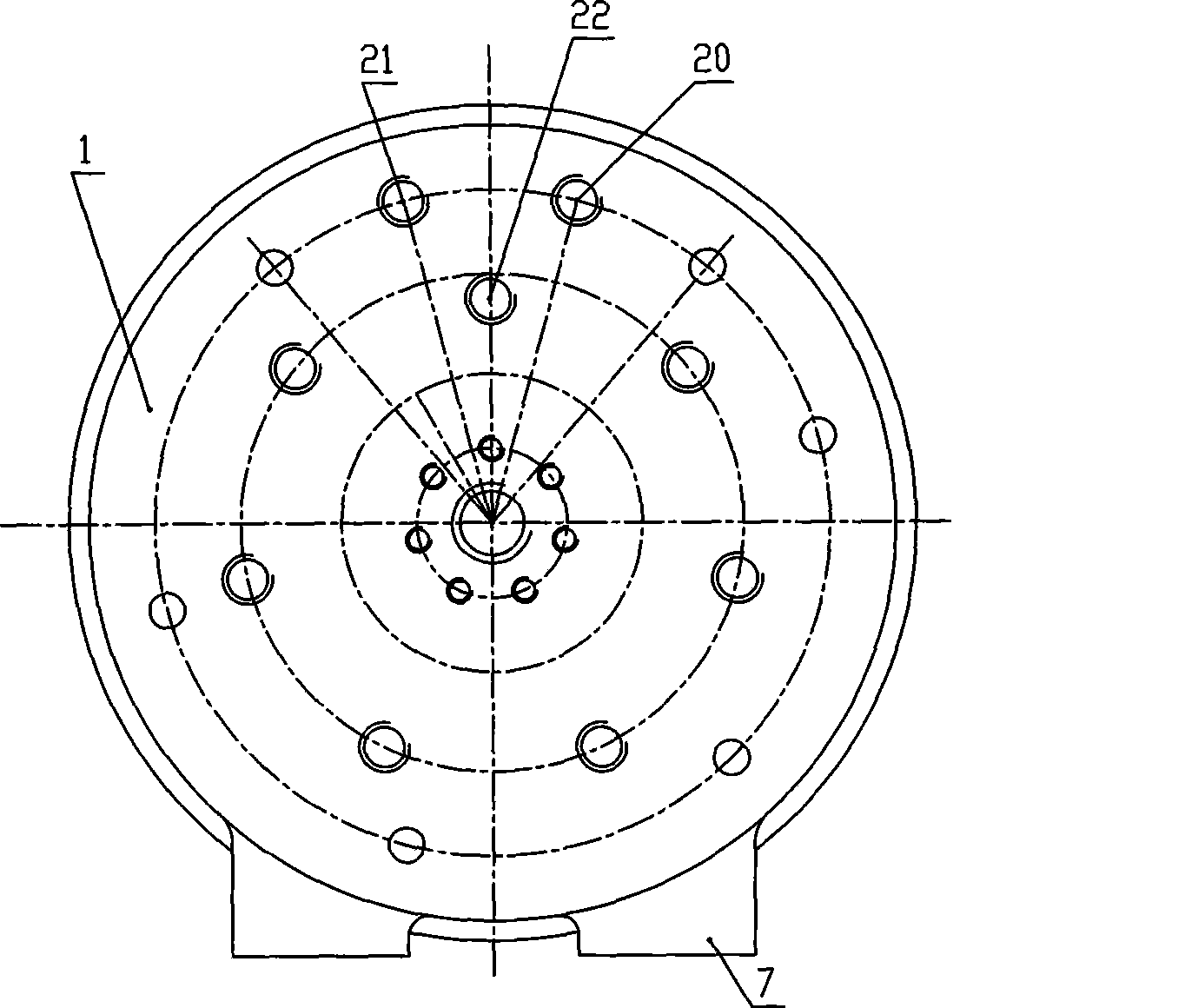

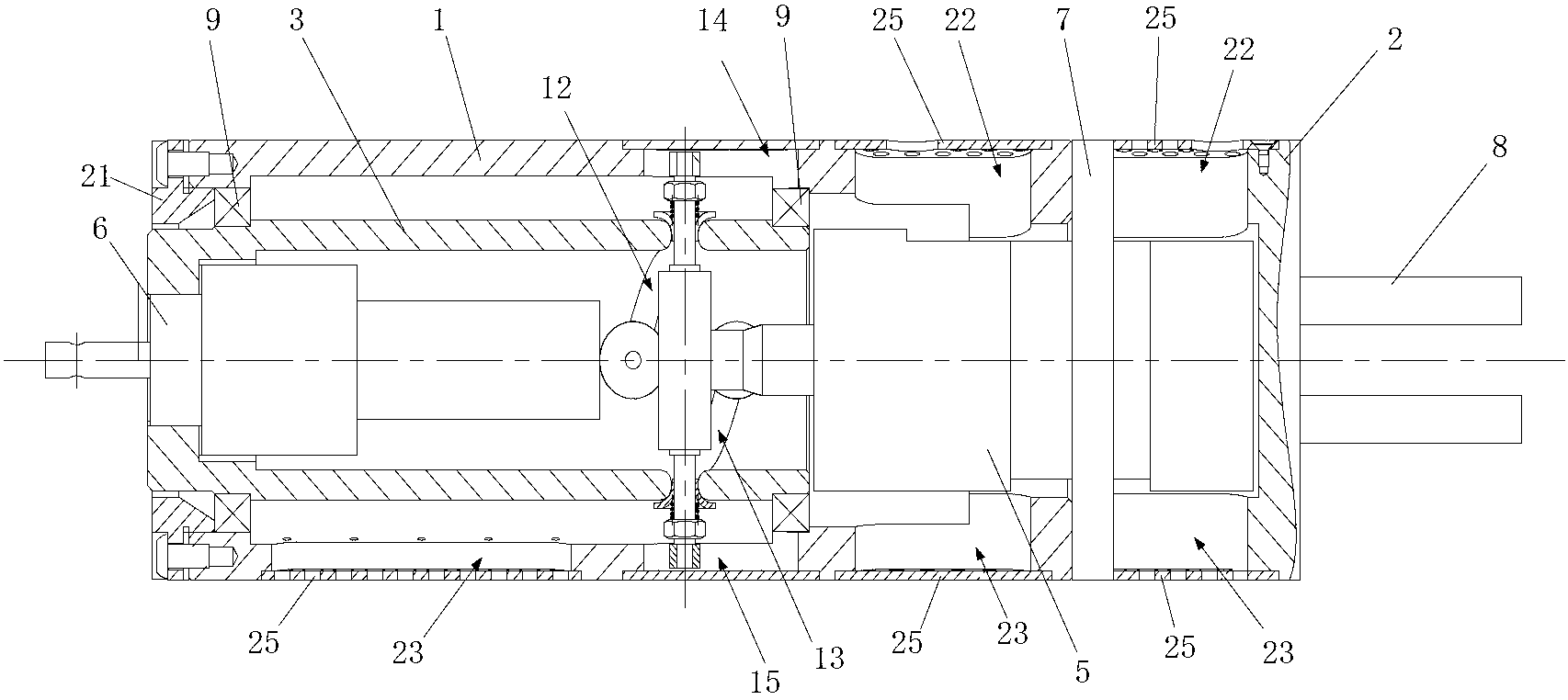

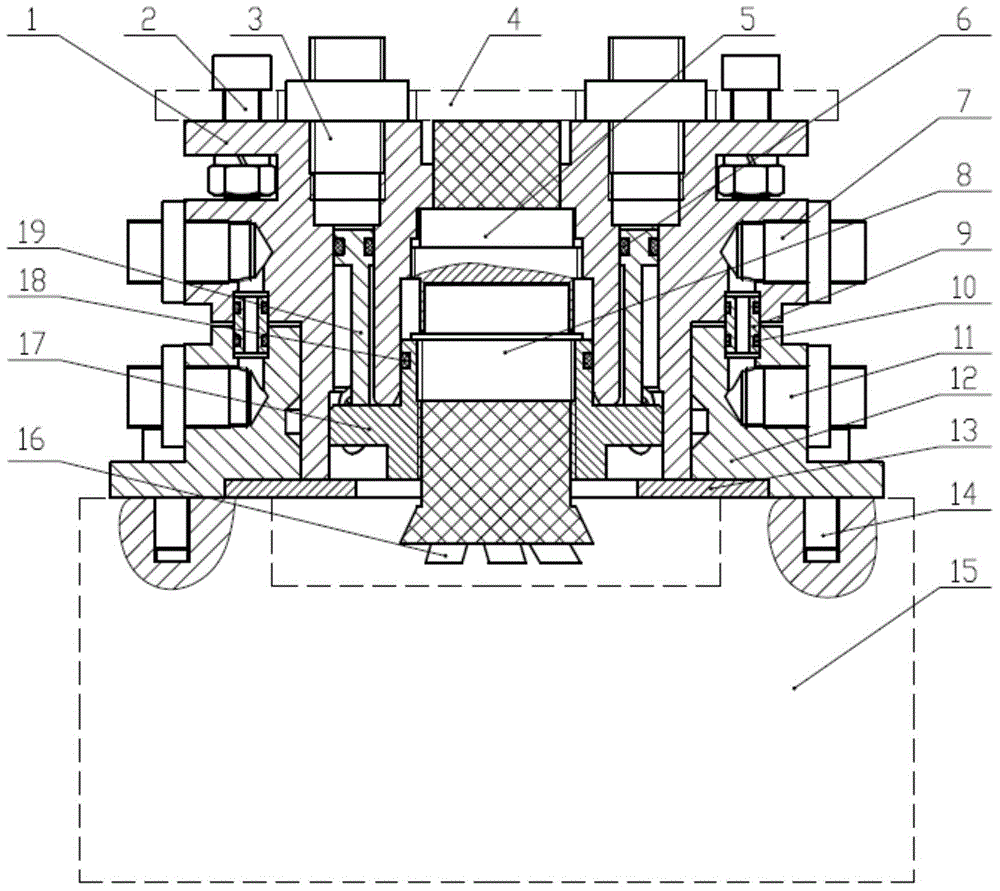

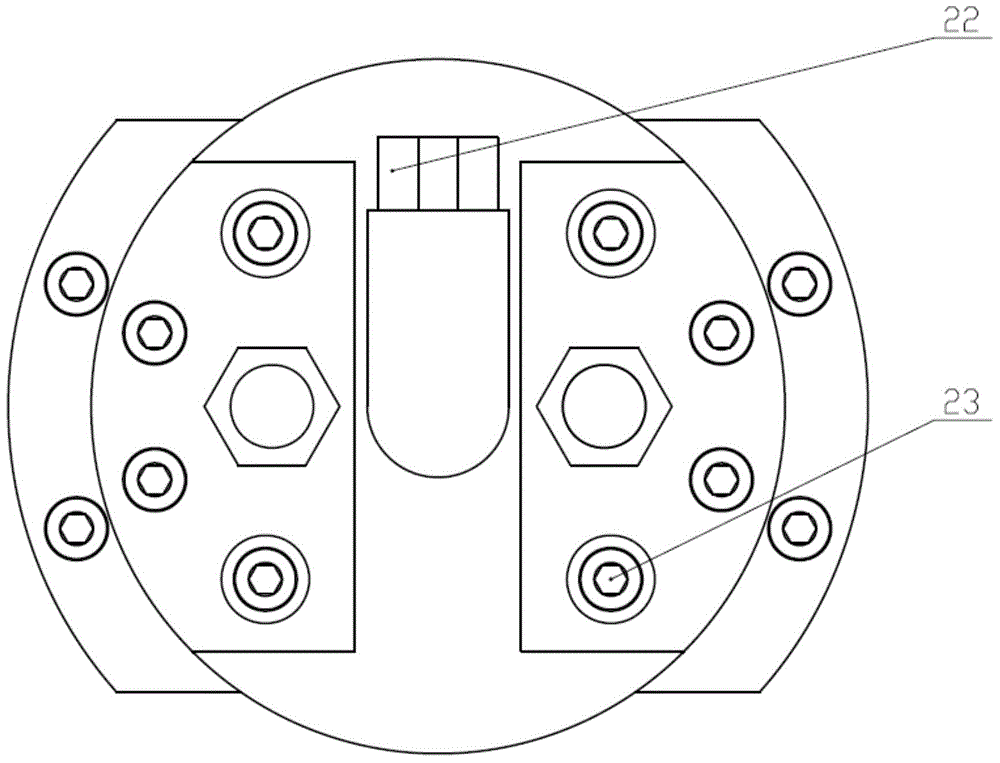

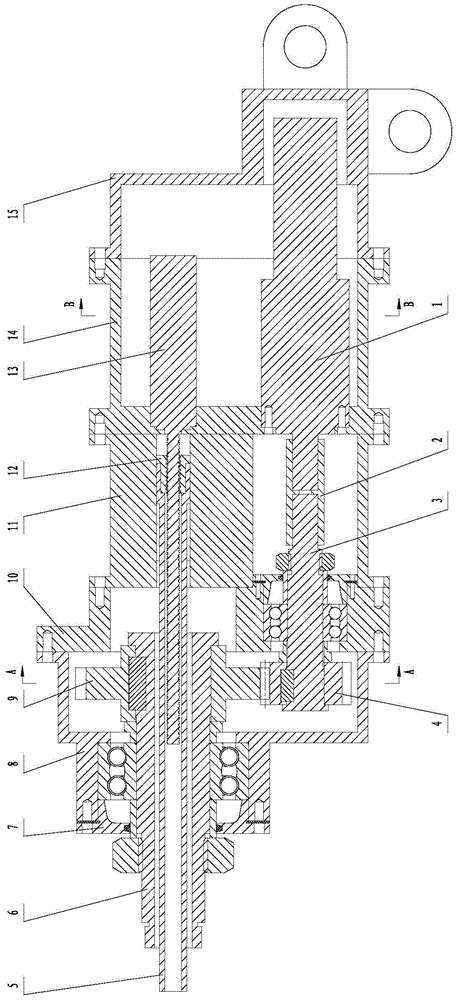

Oil path built-in swivel motor for underwater manipulator

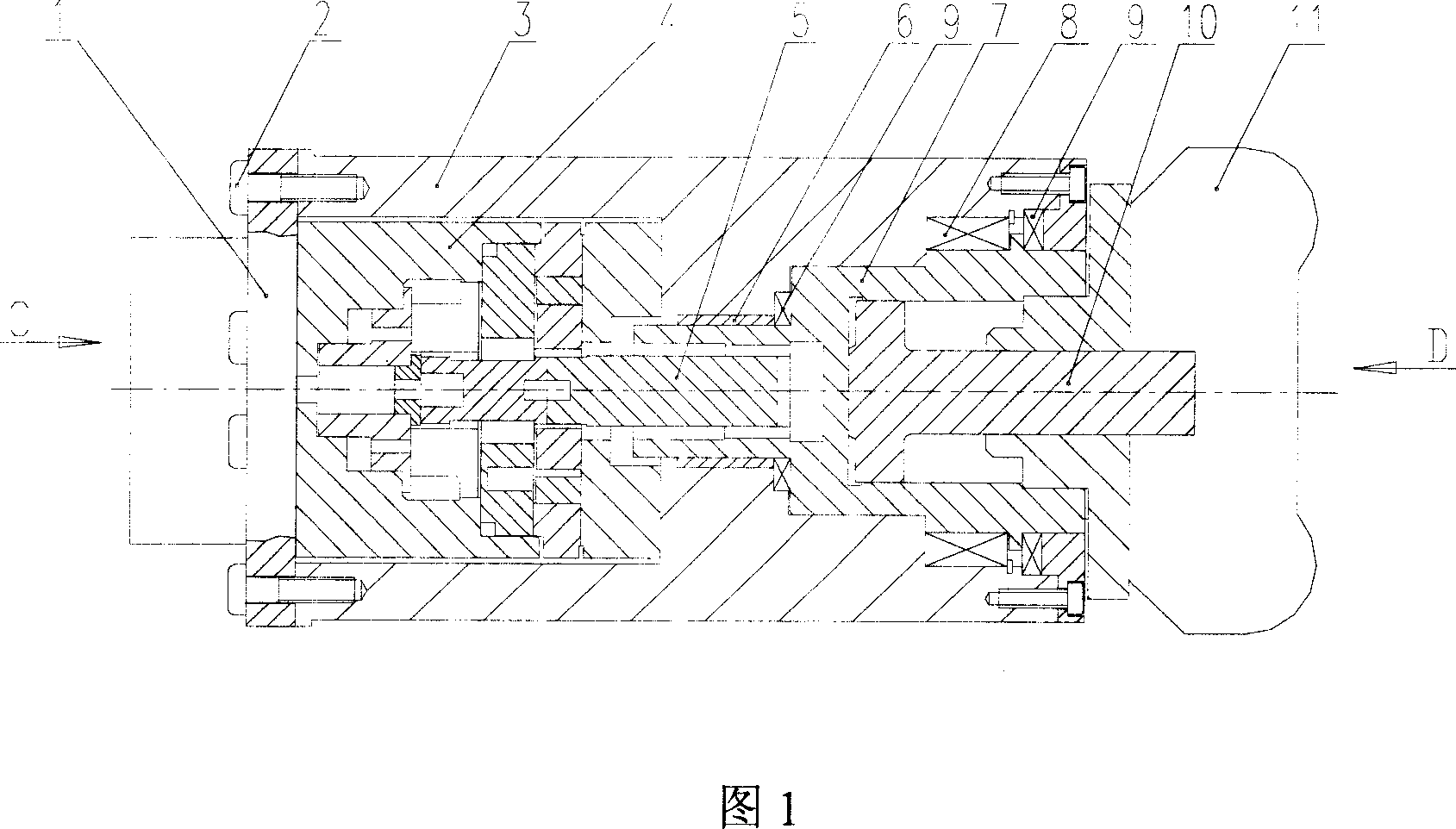

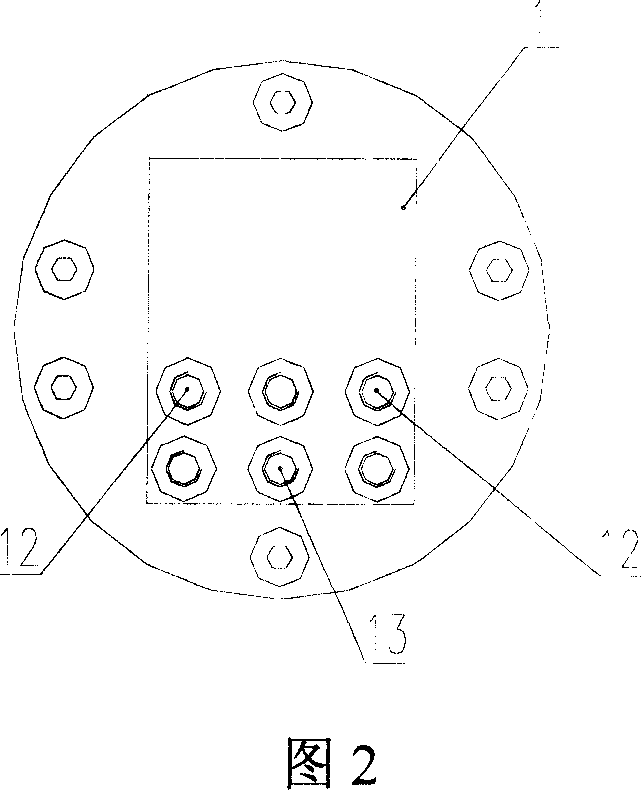

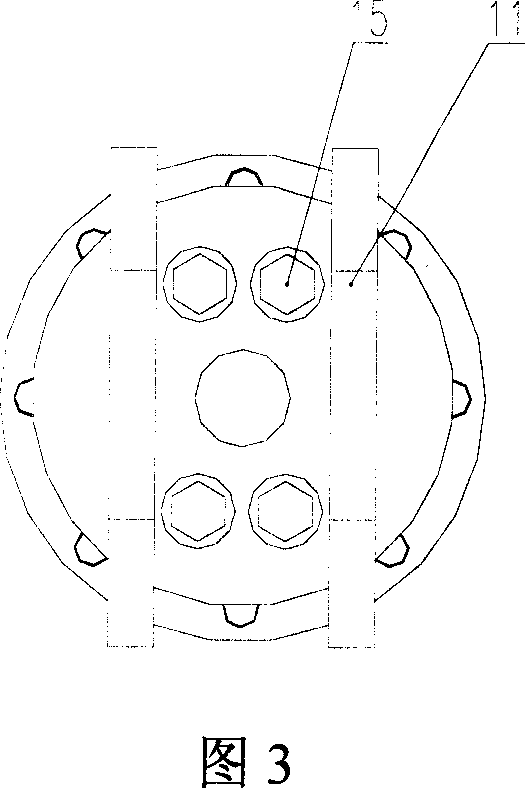

InactiveCN101499693AAvoid interferenceCompact structureStructural associationMechanical energy handlingUnderwater manipulatorEngineering

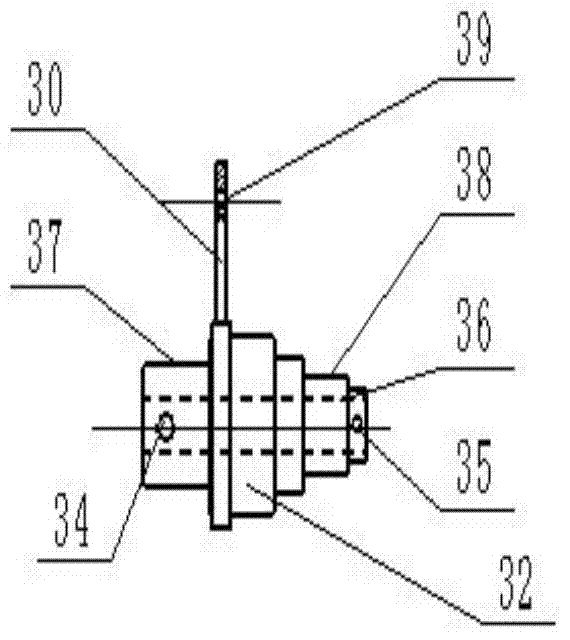

The invention provides a swing motor which is provided with a built-in oil passage and used for an underwater manipulator. The swing motor comprises a swing motor shaft core, a left end cover, a stator, a rotor, a vane, a right end cover, an output flange, a sensor and a conical roller bearing; one end of the left end cover is fixedly connected with the swing motor shaft core and the other end thereof is fixedly connected with the stator; the other end of the stator is fixedly connected with the right end cover; the left end cover, the stator and the right end cover are respectively provided with a cavity; the rotor is arranged in the cavity and can rotate in the circumferential direction; one end of the rotor is fixedly connected with the output flange; the vane is fixedly connected with the external round surface of the rotor; the sensor is arranged at one end of the rotor; the reading head of the sensor is arranged in the cavity of the motor shaft core and fixedly connected with the motor shaft core; the conical roller bearing is sleeved on the external round surface of the rotor; the motor shaft core, the rotor and the output flange are provided with an oil passage respectively. The swing motor has compact structure and light weight, simultaneously avoids the interference with the environmental article due to the exteriorization of the oil pipe and increases the operation range of the manipulator.

Owner:HARBIN ENG UNIV

A hydrodynamic analysis method for a grabbing movement process of an underwater robot and a manipulator system

ActiveCN109558694AReduce disturbanceImprove stabilitySustainable transportationHydrodynamic testingUnderwater manipulatorEngineering

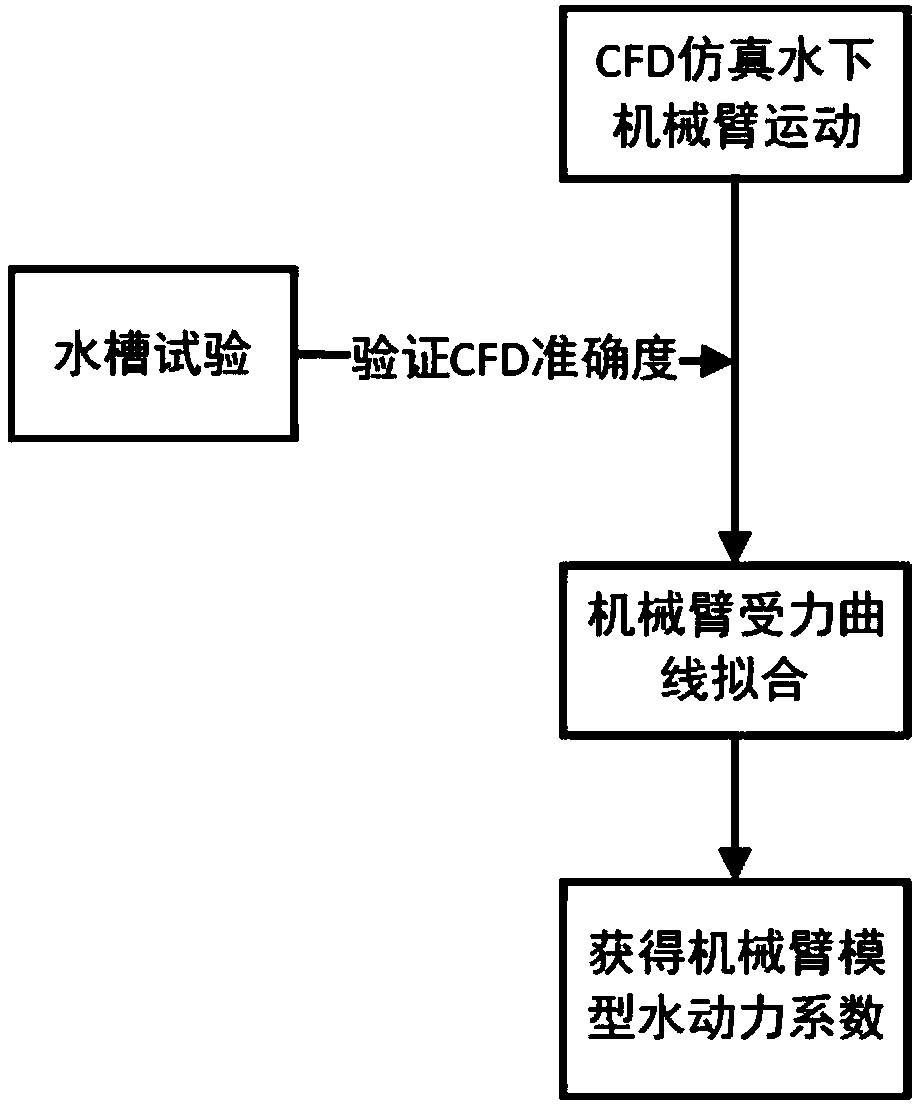

The invention belongs to the field of underwater robots, and particularly relates to a hydrodynamic analysis method for a grabbing movement process of an underwater robot and a manipulator system. Themethod comprises a UVMS system circulating water tank test and CFD numerical simulation. The UVMS circulating water tank test comprises the steps that a plane movement mechanism is used for measuringthe stress of the UVMS in a flow field, wherein different mechanical arm postures of the UVMS are kept in the flow field; and the water tank test is reproduced by using a CFD method, and the accuracyof the CFD method is verified. CFD software is used for conducting numerical simulation on the underwater movement process of the UVMS mechanical arm, and the hydrodynamic coefficient of the underwater mechanical arm is obtained through fitting. A part of complexity can be replaced at the initial design stage of the UVMS system; according to the method, a high pool test is carried out, qualitative and quantitative analysis is carried out on the disturbance effect of the designed mechanical arm on the stress and moment of the UVMS system, the hydrodynamic coefficient of the mechanical arm based on the slice theory is obtained, then an accurate underwater mechanical arm hydrodynamic model is established, and a reference is provided for further optimization design and motion simulation of the UVMS system.

Owner:HARBIN ENG UNIV

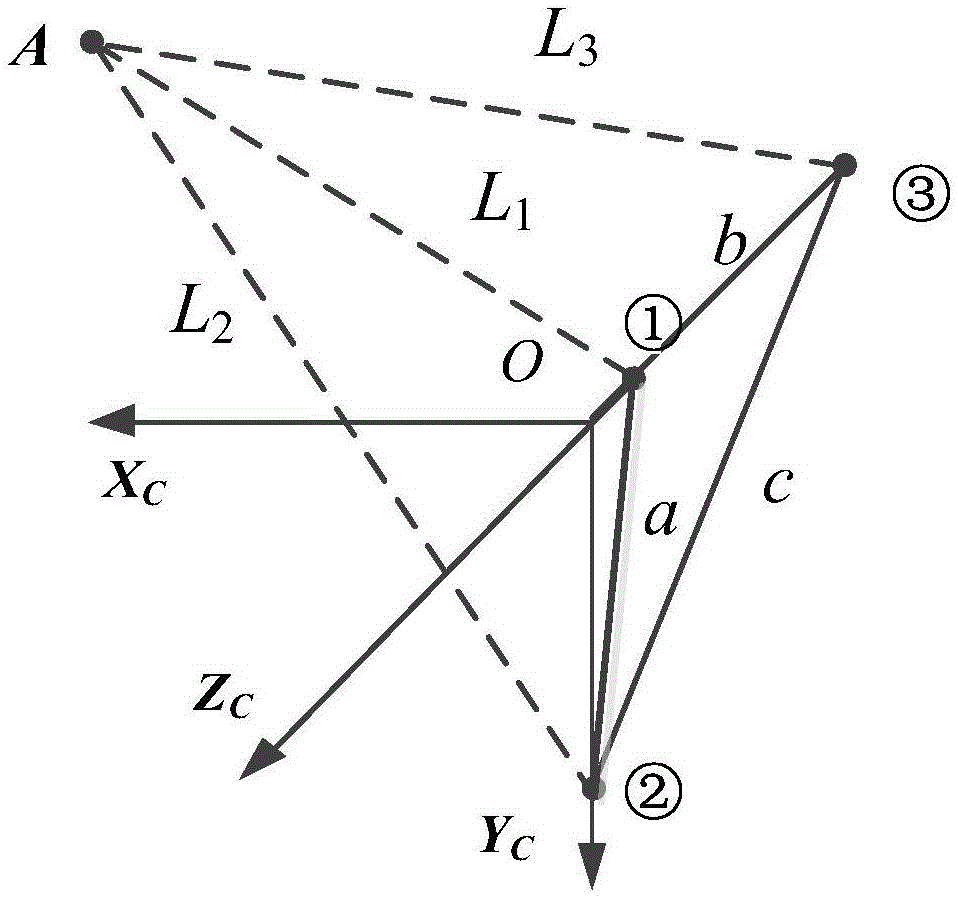

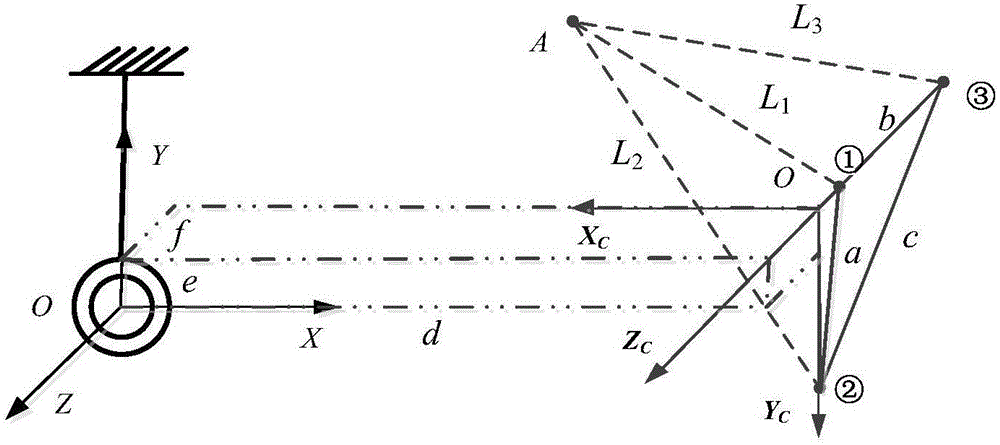

Miniaturized underwater manipulator position angle measuring method

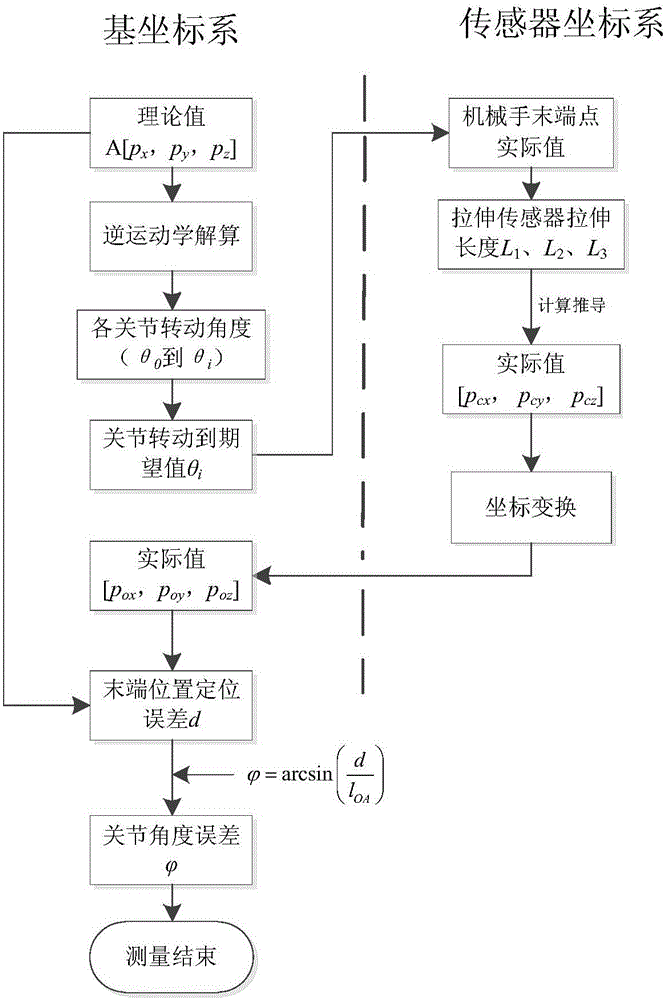

The invention provides a miniaturized underwater manipulator position angle measuring method. Based on a three-dimensional position measuring apparatus formed by installing three stay rope displacement sensors, a measuring coordinate system (O-XCYCZC) is established, and a base coordinate system (O-XYZ) is established at a manipulator installation fixed point. The principle of the method is as follows: actual value coordinates of the tail end of a manipulator under the measuring coordinate system are obtained through the three-dimensional measuring apparatus, the actual value coordinates are converted into the base coordinate system through coordinate conversion, and motion position errors of the tail end of the manipulator are obtained through comparison. The underwater manipulator position angle measuring method provided by the invention is convenient and simple in measuring process, concise in calculation processing process and low in cost, thereby being suitable for three-dimensional position measurement and tail-end angle precision measurement carried out by an underwater manipulator in a pool environment.

Owner:HARBIN ENG UNIV

Wrist joint structure of underwater mechanical arm

InactiveCN103317524ARealize limited angular rotation movementSimple structureJointsHydraulic cylinderUnderwater manipulator

Owner:BEIHANG UNIV

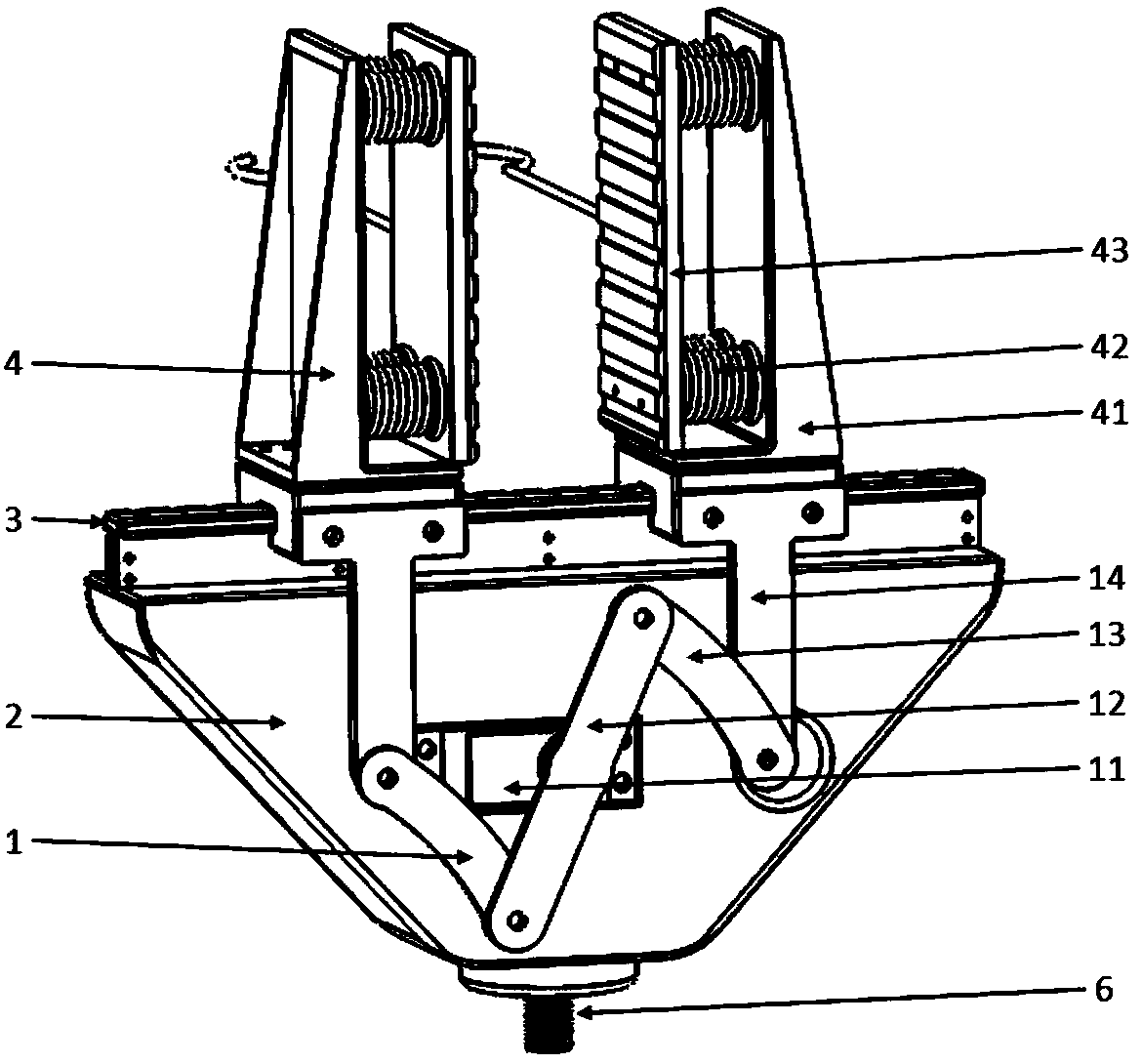

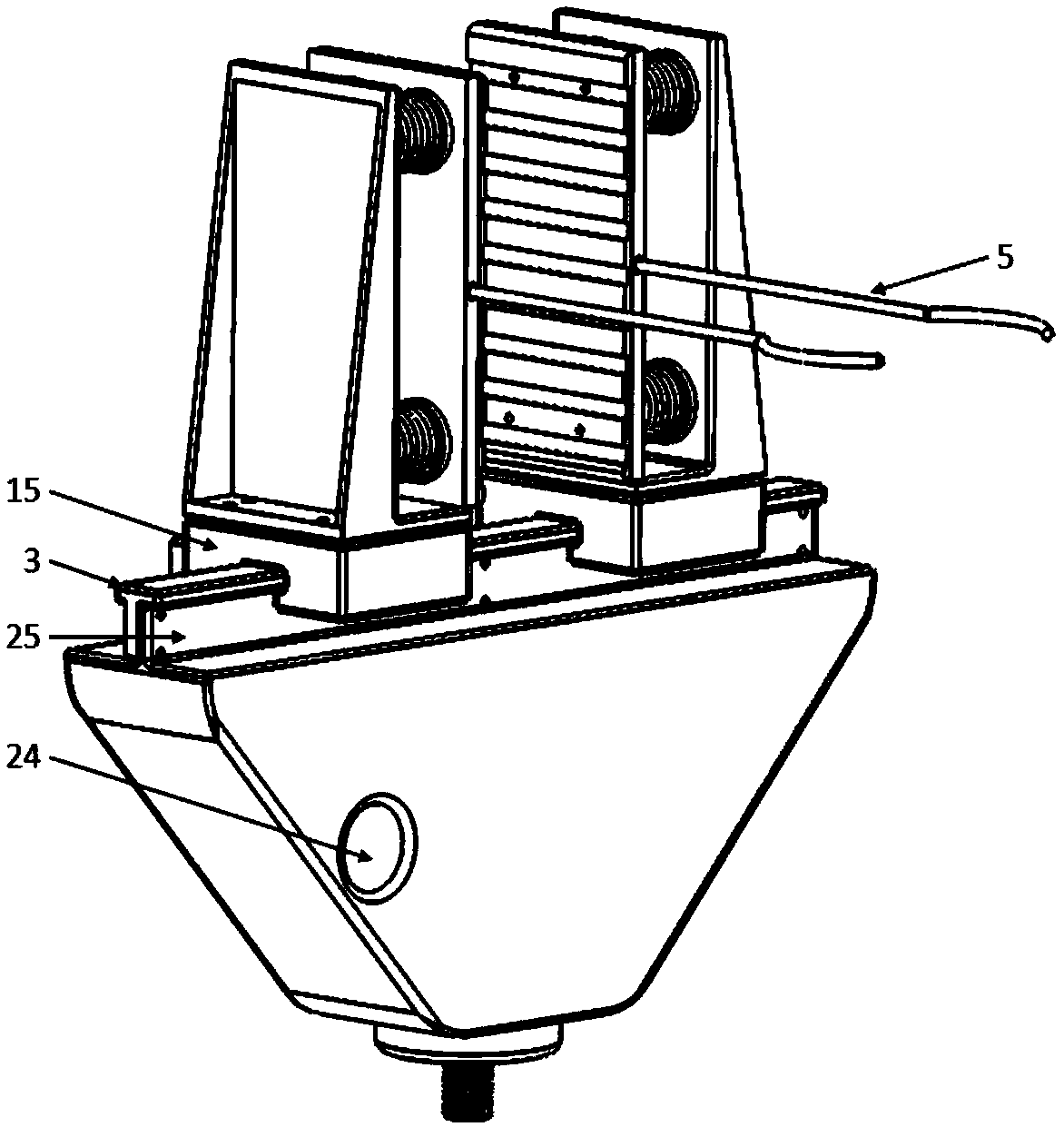

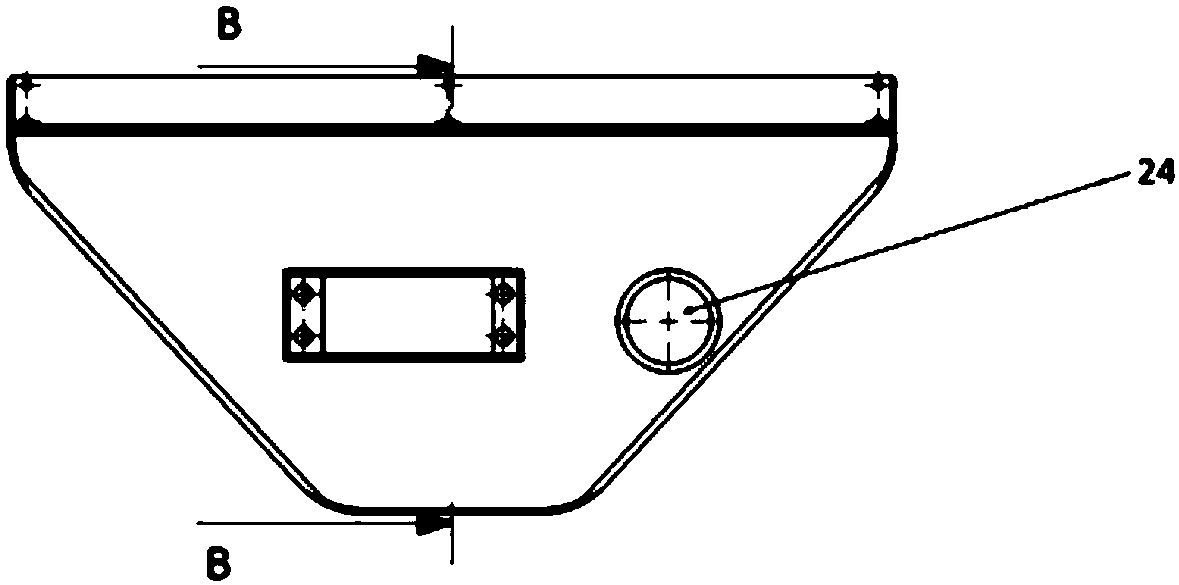

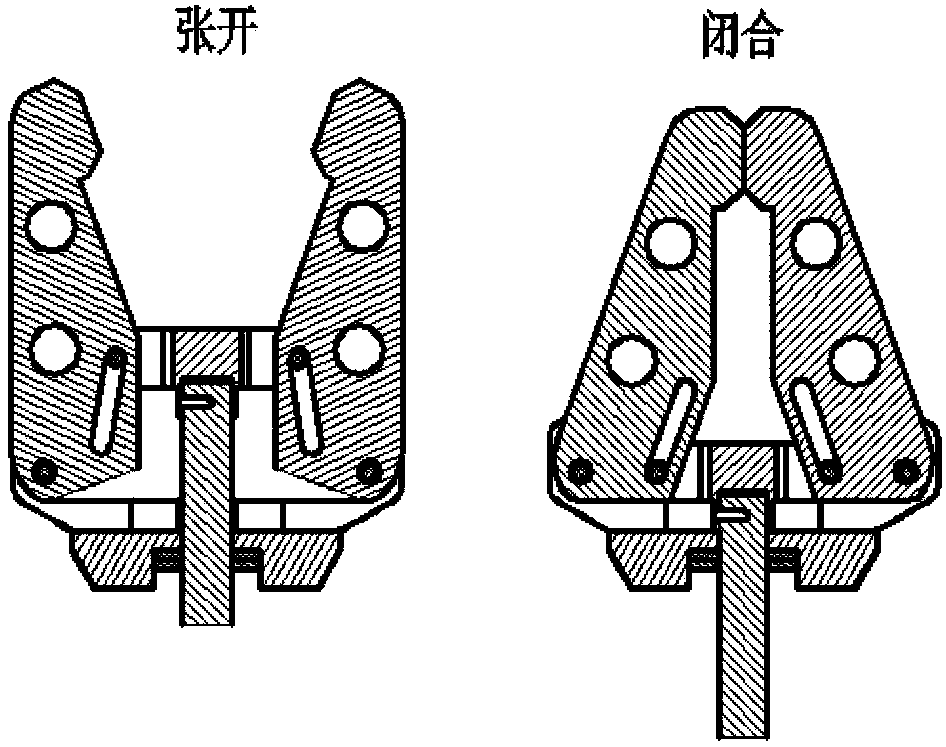

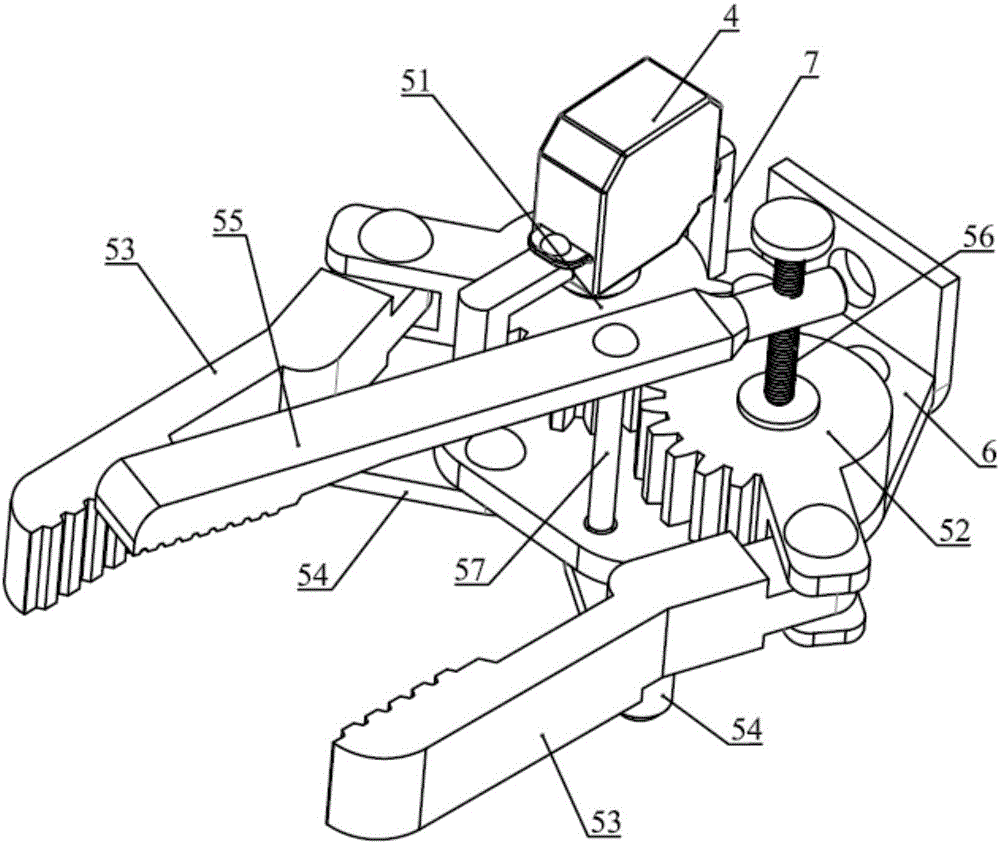

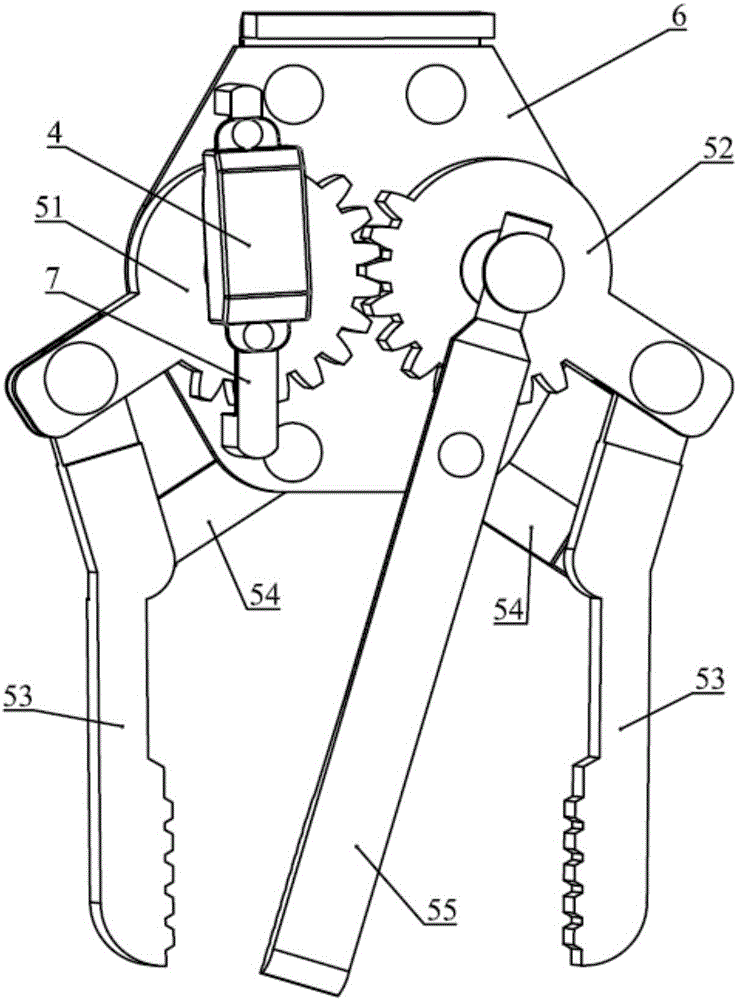

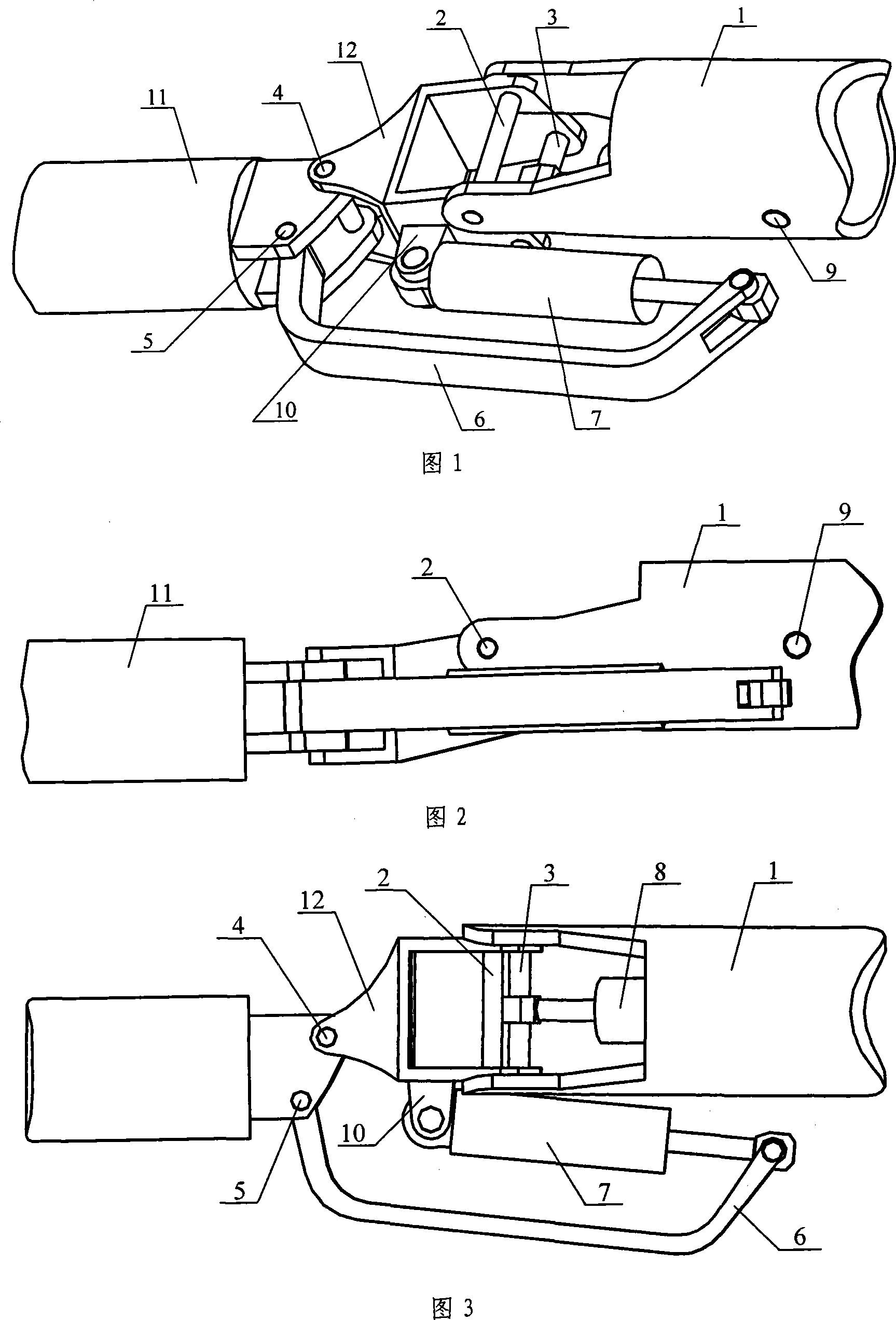

Underwater target grabbing manipulator and grabbing method

PendingCN108098823AImprove general performanceEasy to controlGripping headsMarine engineeringUnderwater manipulator

The invention discloses an underwater target grabbing manipulator and a grabbing method. The problems that an underwater manipulator is poor in balance performance, grabbing objects can be damaged easily and target objects in a narrow space cannot be grabbed in the prior art are solved. The underwater target grabbing manipulator has the effects of being high in universality, wide in applied range,easy to control, good in grabbing effect, high in grabbing efficiency and capable of reducing cost. According to the technical scheme, the underwater target grabbing manipulator comprises clamping jaws, a manipulator base body and a transmission mechanism. The clamping jaws are connected to the upper portion of the manipulator base body in a sliding mode. The transmission mechanism is used for driving the clamping jaws to make opening and closing movement on the manipulator base body so that underwater targets can be grabbed. Auxiliary clamping jaws used for grabbing the underwater targets inthe narrow space are installed at one sides of the clamping jaws.

Owner:SHANDONG UNIV

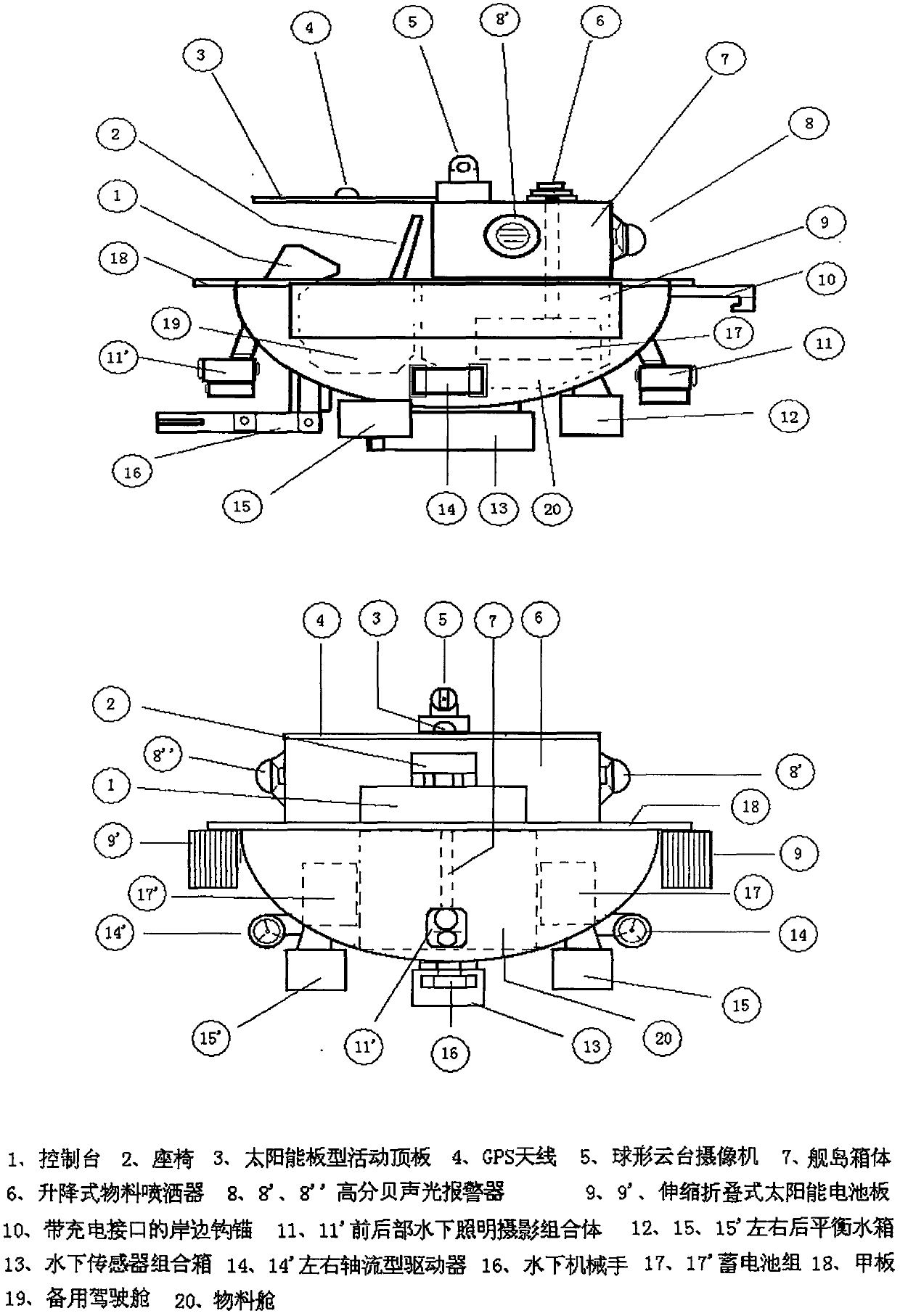

Completely-intelligent unmanned fishing boat

InactiveCN109649593AReal-time observation of growthPhotovoltaic supportsPropulsion power plantsDynamic balanceWater quality

The invention relates to a completely-intelligent unmanned fishing boat. The completely-intelligent unmanned fishing boat is characterized in that under control of an artificial intelligent control system, all unmanned fishery operations including real-time positioning, regional setting, path planning, fixed-time feeding, oxygenation as needed, fry releasing, fishing, water plant removing, water quality monitoring, risk prevention, theft prevention and the like are executed; running states and operating states can be remotely monitored and controlled; data of images inside the boat, outside the boat, under the water, on the water surface and around the shore are all transmitted to a user platform (such as a computer and a mobile phone) in real time; solar energy is taken as a main energy source while other energy sources are used for auxiliary supplementation, and solar panels are telescopically foldable and has self-protection and self-cleaning functions; a boat body is provided witha self-stabilizing and self-balancing system, and balance water tanks distributed in three directions guarantee dynamic balance of the boat body at any time; a biaxial flow type boat body propeller provides sufficient advancing power and flexible direction control; a multifunctional underwater manipulator completes various underwater operations.

Owner:韩立春 +1

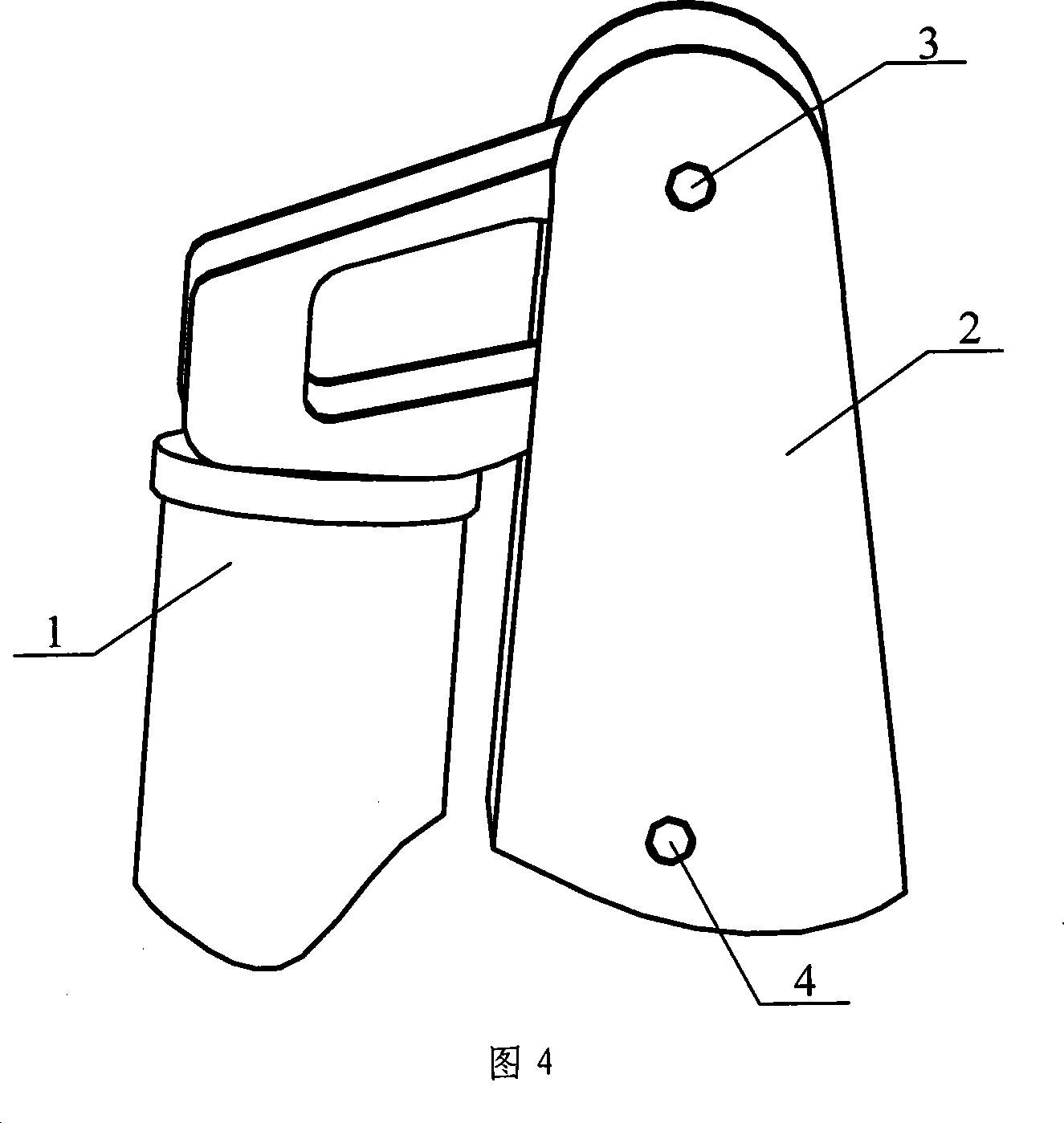

Submarine manipulator shoulder joint

InactiveCN101224581ASimple organizationReduce weightJointsUnderwater equipmentHydraulic cylinderUnderwater manipulator

The invention provides an underwater manipulator shoulder joint, consisting of a foundation frame, an upper arm, a yaw rotating shaft, a pitching rotating shaft, a hydraulic cylinder, a coupling spindle at the bottom of the hydraulic cylinder and a piston rod hinge base of the hydraulic cylinder; wherein, the foundation frame is linked to a shoulder joint through the yaw rotating shaft; the upper arm is linked to the shoulder joint through the pitching rotating shaft; the shoulder joint is provided with two piston rod hinge bases of the hydraulic cylinder which are respectively linked to two hydraulic cylinders; wherein, one hydraulic cylinder is arranged on the foundation frame, and the other hydraulic cylinder is arranged in a cavity of the upper arm. The invention is used for the underwater robot and has the advantages of simple structure, light weight, and flexible rotation. The invention realizes the motion of two DOFs rotation of the shoulder joint; furthermore, the distance between the two rotating shafts is extremely close, thus leading the structure to be compact.

Owner:HARBIN ENG UNIV

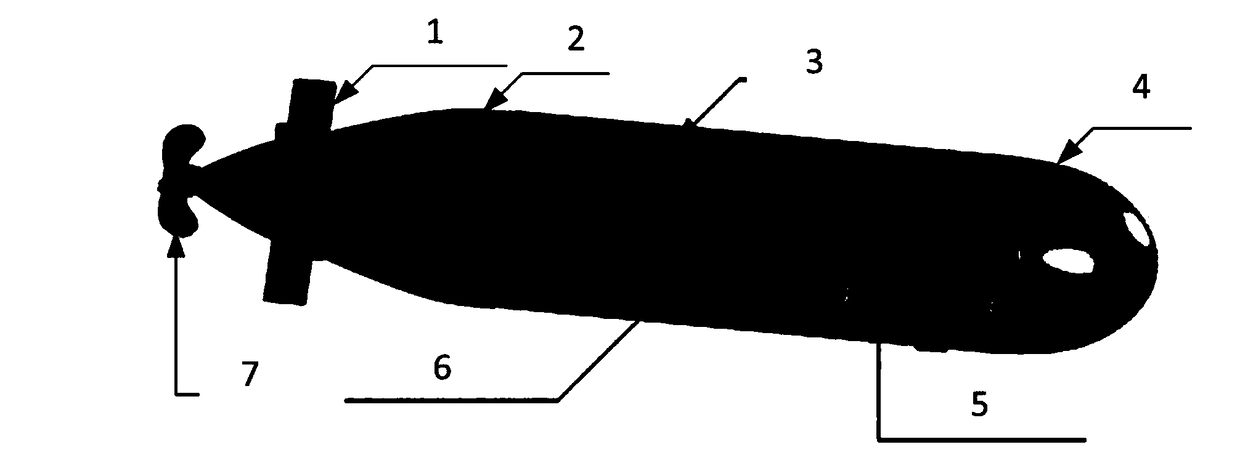

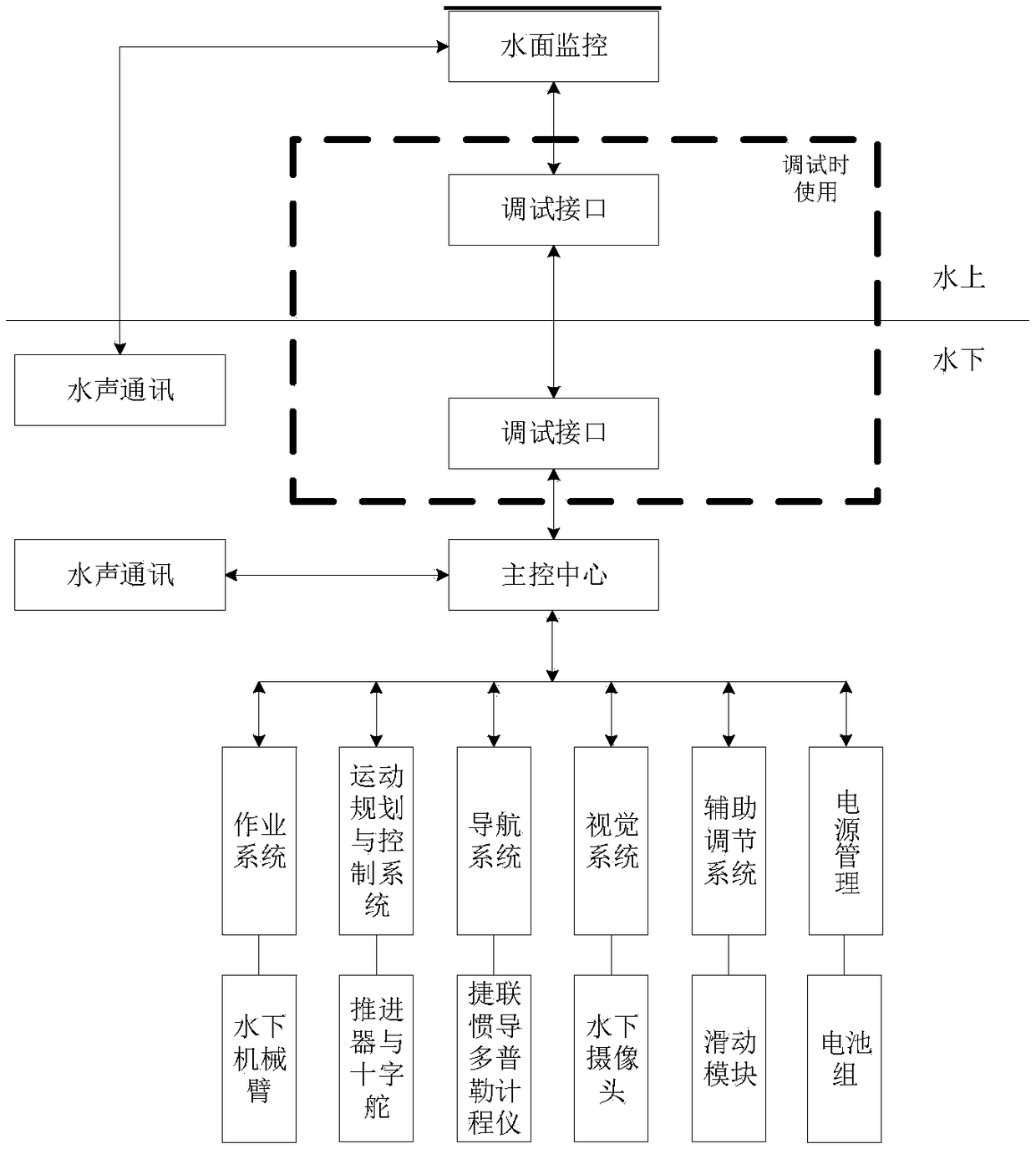

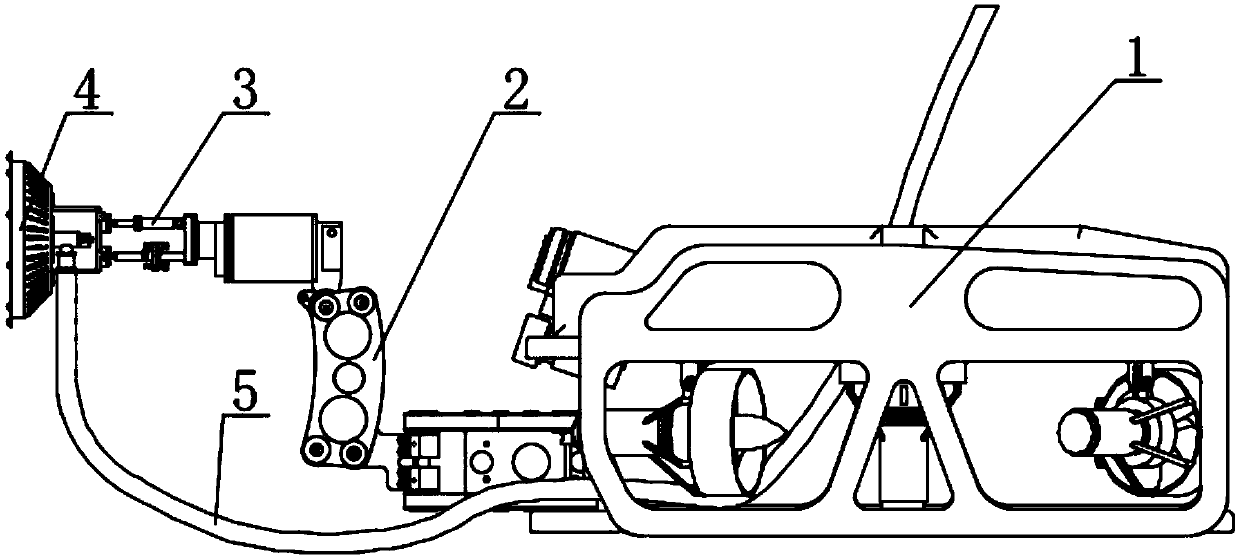

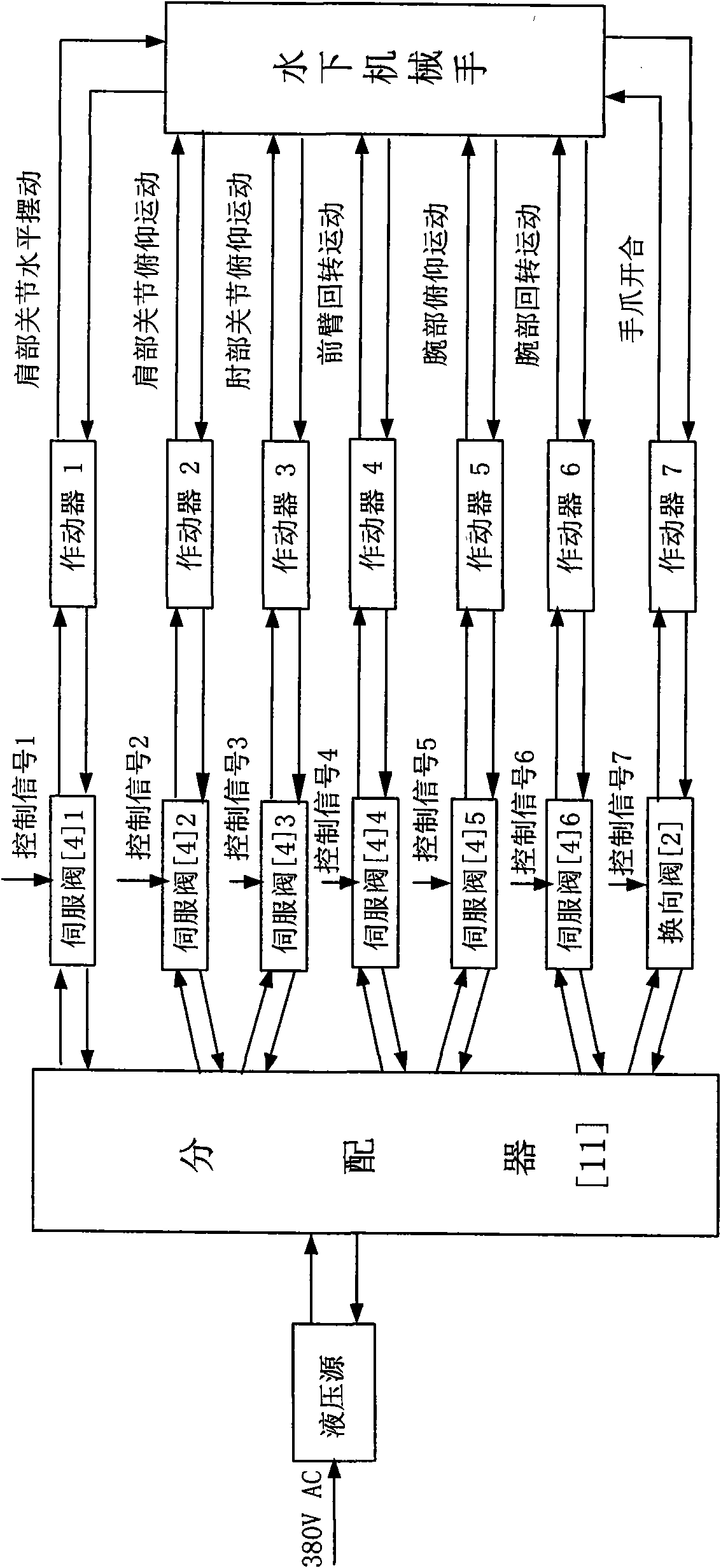

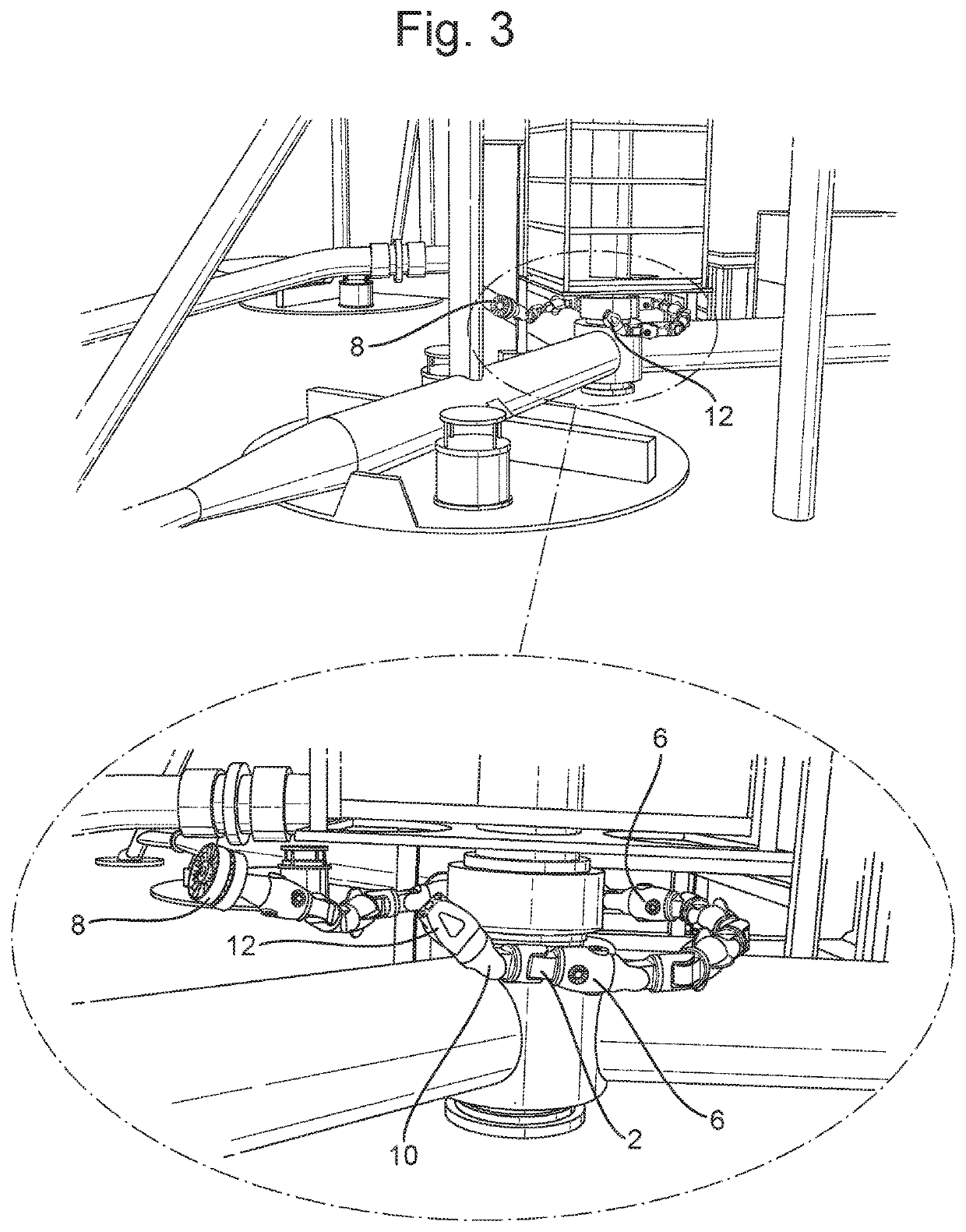

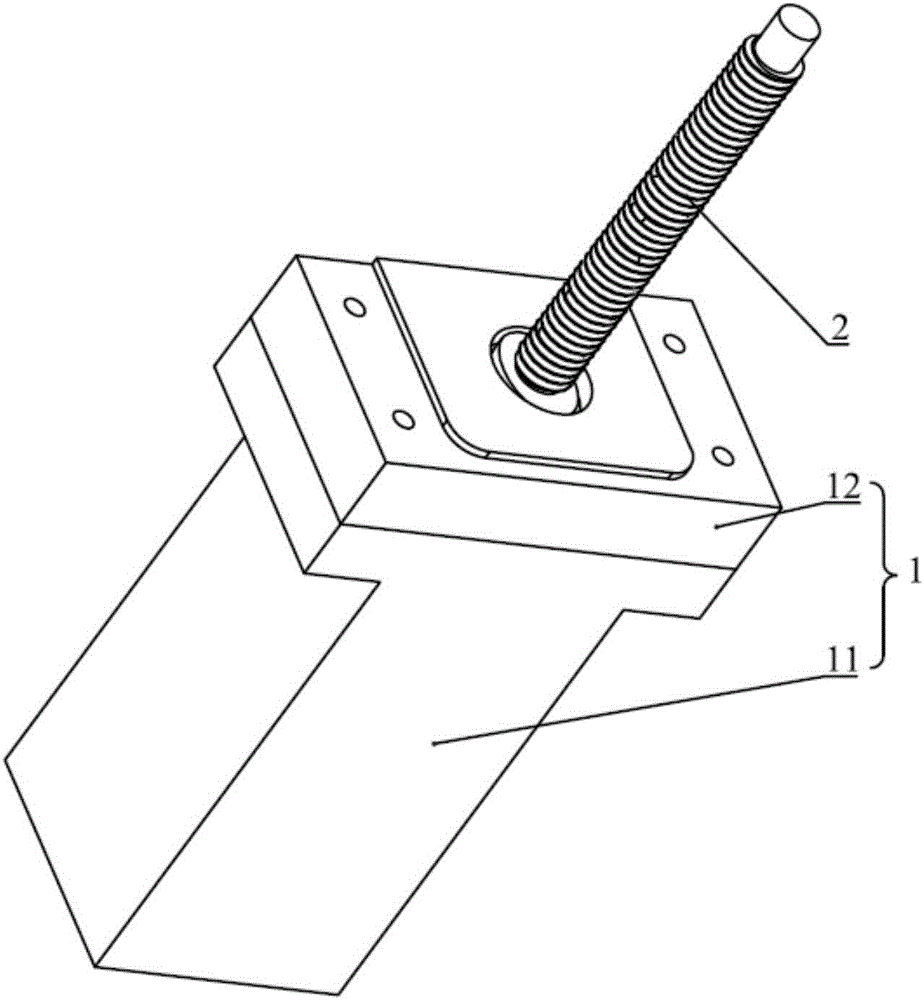

Underwater robot-underwater manipulator system

ActiveCN108860527AHighlight substantiveGuaranteed reliabilityProgramme-controlled manipulatorUnderwater vesselsUnderwater manipulatorPropeller

The invention relates to an underwater robot-underwater robot arm system, belonging to the field of underwater robots and comprising three parts: an underwater robot body, an underwater manipulator and an auxiliary adjusting device; the underwater robot body is an autonomous underwater robot without cables, and the power system of the underwater robot body uses the under-actuated mode to control the attitude and motion of the underwater robot, and the drive system of the underwater robot body consists of single propellers and one cruciform of rudder, which are installed at the stern of the underwater robot body; the system uses the underwater manipulator with four degrees of freedom and five functions, and the underwater manipulator consists of two rotative joints and two pendulum joint and one manipulator grasp, and the auxiliary adjustment device is installed directly below the underwater robot and is close to the stern. The device is driven by a lead screw slider mechanism and a servo motor. By moving the slider, the adjustment of the center of gravity of the underwater robot can be achieved, which compensates the influence of the underwater manipulator on the longitudinal change of the center of gravity of the underwater robot during the movement, thereby achieving the attitude stability of the underwater robot.

Owner:HARBIN ENG UNIV

Underwater mechanical arm wrist portion structure for high strength operation underwater robot

The invention discloses a submerged mechanic wrist structure of strong-operation submerged robot, which is characterized by the following: the motor component of cycloid is assembled on one side of cavity, which seals the end surface of wrist through back seat; one end of long-spline connecting cardo is plugged in the motor component of cycloid and the other end is sleeved in the inner-spline groove; the sleeve is set on the exterior of rotary jacket, which lies one end of long-spline connecting cardo; one end of rotary jacket possesses column-shaped cavity, which contains short piston rod; the chuck rotary seat is loaded in the column cavity, which seals short piston rod in the column cavity; the centripetal rolling needle bearing sleeve is set on the exterior of rotary jacket; the push rolling bearing is set between centripetal rolling bearing and chuck rotary seat, which is between rotary jacket and sleeve.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

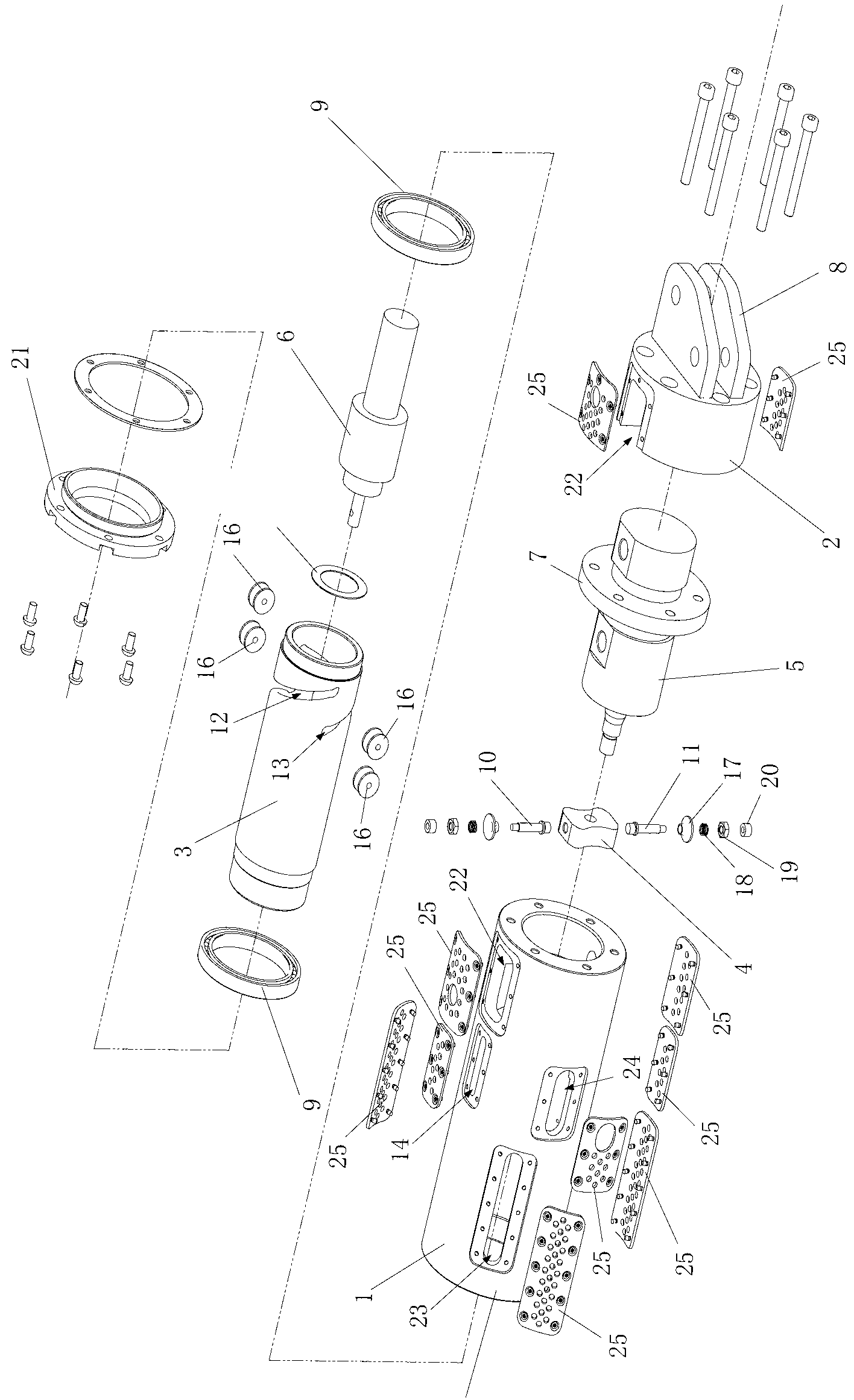

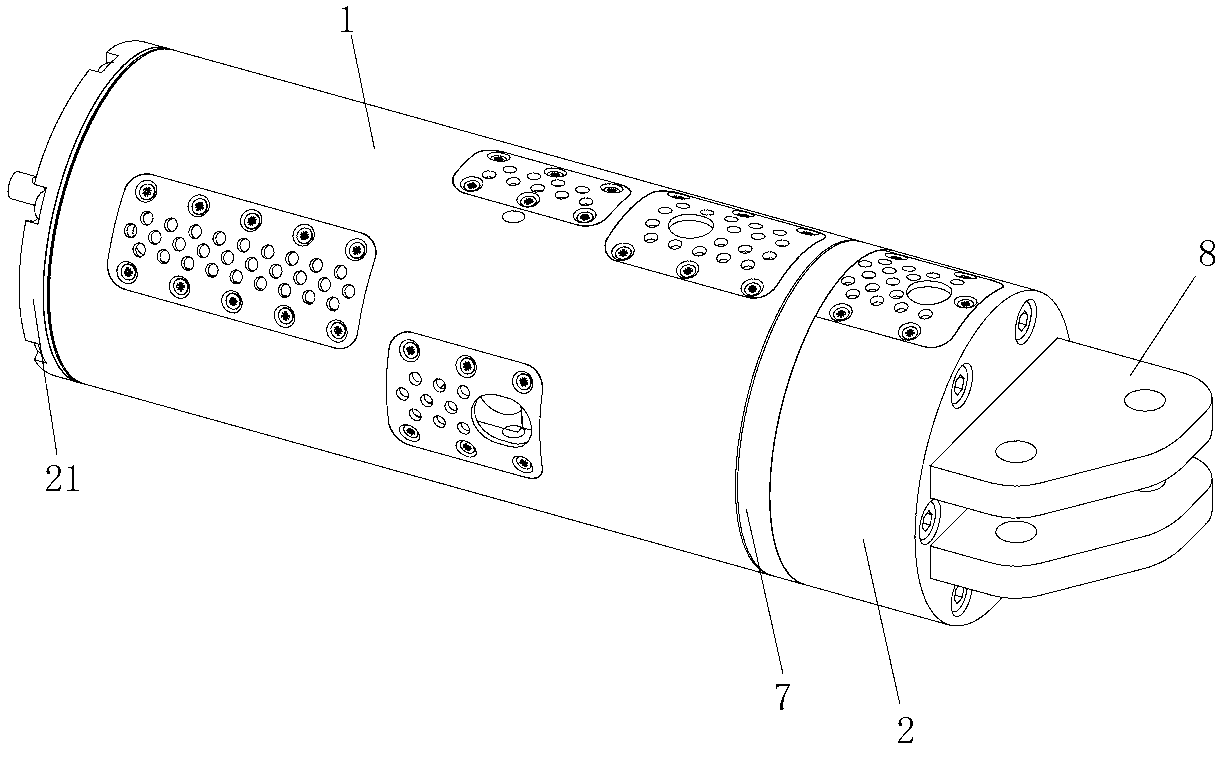

Drive module for constructing underwater electric manipulator

The invention relates to the technical field of underwater robot operation, in particular to a drive module for constructing an underwater electric manipulator. The drive module comprises a pitching joint, an auxiliary connecting plate, a wrist rotating joint, a wire routing connecting plate and a wire routing seal plate, two axial ends of the pitching joint are connected with the wrist rotating joint respectively through the auxiliary connecting plate and the wire routing connecting plate so as to transmit pitching motion to the wrist rotating joint, a joint connecting piece is internally driven by the wrist rotating joint to rotate, routing wires between the pitching joint and the wrist rotating joint are accommodated in the wire routing connecting plate, and the wire routing connecting plate is sealed through the wire routing seal plate. According to the drive module for constructing the underwater electric manipulator, the internal wire routing is achieved, the problem that external wire routing is prone to break down is solved, the underwater application is facilitated, the connection with external machinery is simple, the underwater manipulator with different degrees of freedom can be rapidly and flexibly constructed so as to meet different needs, the generality is good, the application range is wide, and the design of the underwater electric manipulator can be simplified.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Propeller underwater cleaning device and method thereof

InactiveCN109080791AConvenient underwater automatic cleaningCompact structureVessel cleaningHullsCavitationUnderwater manipulator

The invention relates to an underwater cleaning device for propeller, comprising an underwater robot, wherein one end of the underwater robot is provided with an underwater manipulator, an output endof the underwater manipulator is provided with a cavitation cleaning device through a connecting device, a water pipe is penetrated into the underwater robot, and the water pipe is connected with thecavitation cleaning device. The utility model has the advantages of compact structure, reasonable structure and convenient operation. The underwater automatic cleaning work of the propeller can be conveniently realized through the cooperation of the underwater robot, the underwater manipulator, the connecting device and the cavitation cleaning device, and the underwater automatic cleaning work ofthe propeller is convenient to clean, the working efficiency is high and the cleaning cost is low.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

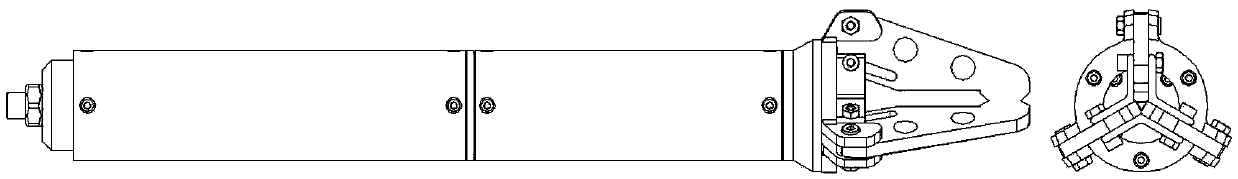

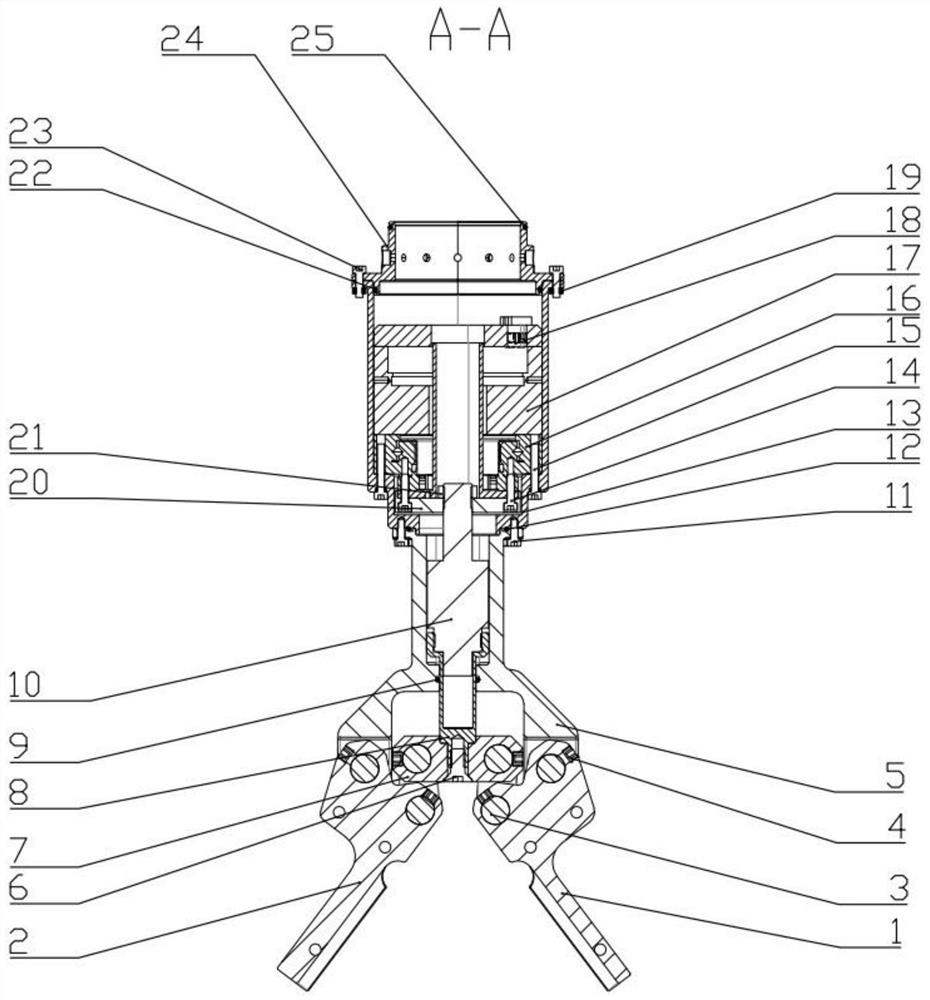

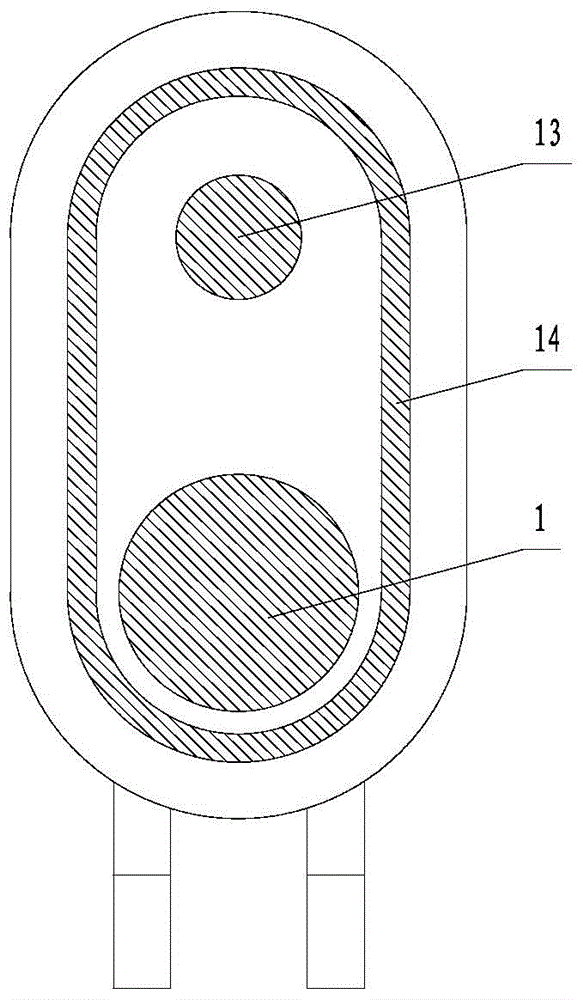

Small-sized underwater hydraulic manipulator paw joint structure

InactiveCN104858888ACompact structureReduce size and weightJointsGripping headsHydraulic cylinderUnderwater manipulator

The invention provides a small-sized underwater hydraulic manipulator paw joint structure. The small-sized underwater hydraulic manipulator paw joint structure comprises three groups of shear blade blades, three groups of shear fingers on which the shear blades are mounted, a group of catching fingers, a paw driving hydraulic cylinder, a driving connecting part and a paw base, and is an underwater manipulator end actuator for cable clamping, cable shearing and article clamping. The fingers of a manipulator adopt pivot rotary type structures, and transmit driving force through sliding chute levers; the three groups of shear blades are respectively mounted at different positions of a manipulator paw, and are used for providing different shearing force for cables in different types; meanwhile, the group of catching fingers for clamping cables and rods is provided; relative to motor driving, the paw adopts hydraulic drive to provide larger shearing force and catching force. The small-sized underwater hydraulic manipulator paw joint structure provides a manipulator end actuator structure which is used for a small-sized underwater hydraulic manipulator, skilful, compact, and suitable for driving of water and hydraulic oil, and has catching and shearing functions.

Owner:HARBIN ENG UNIV

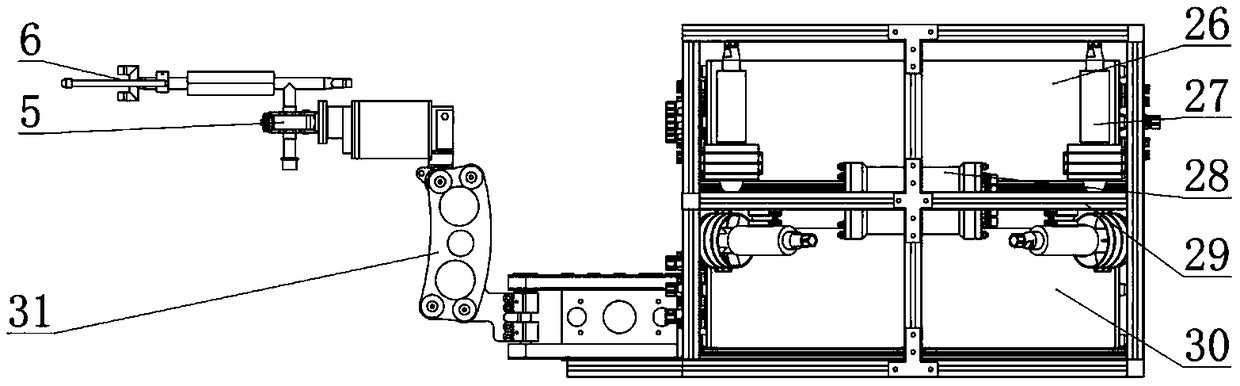

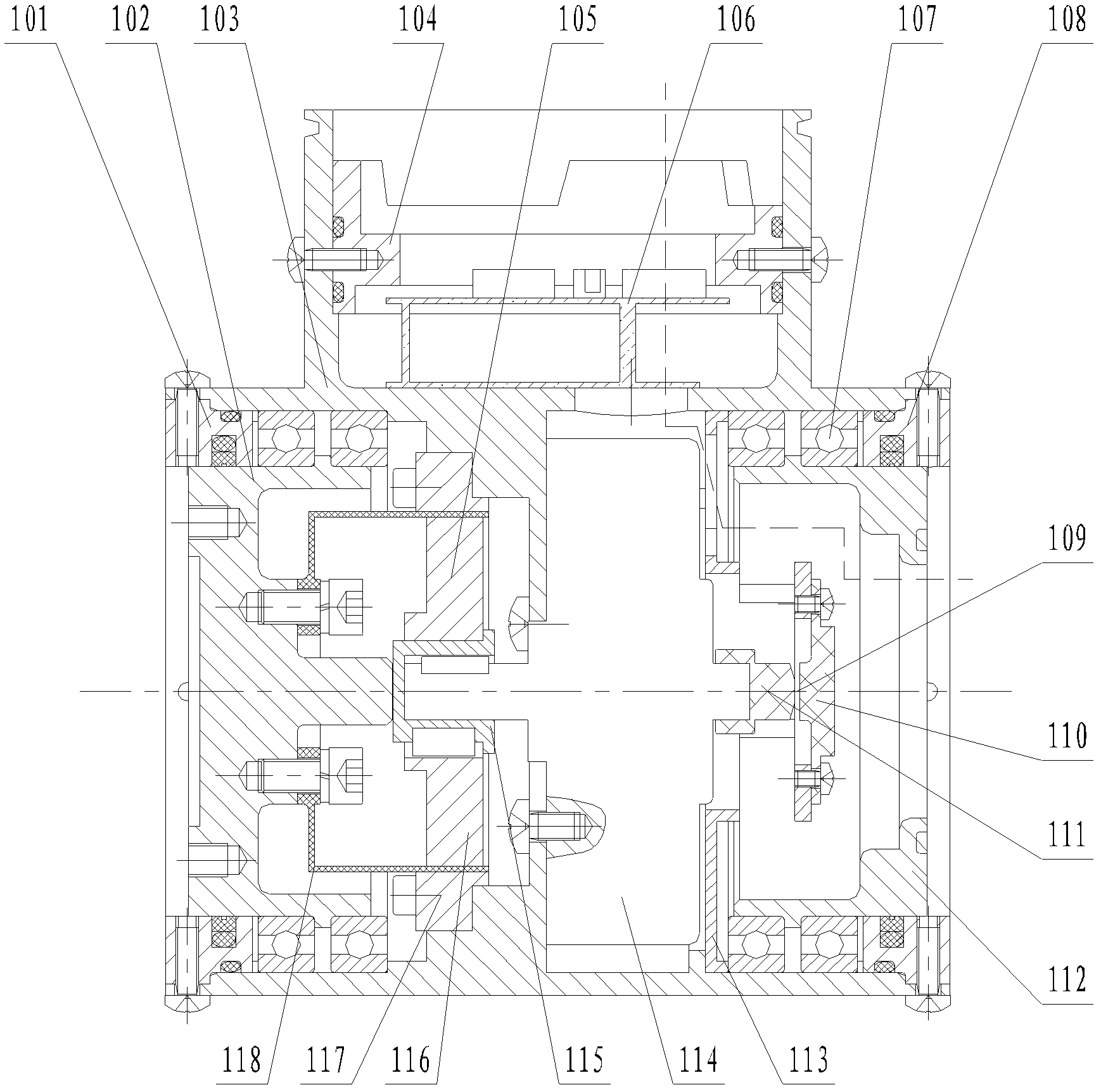

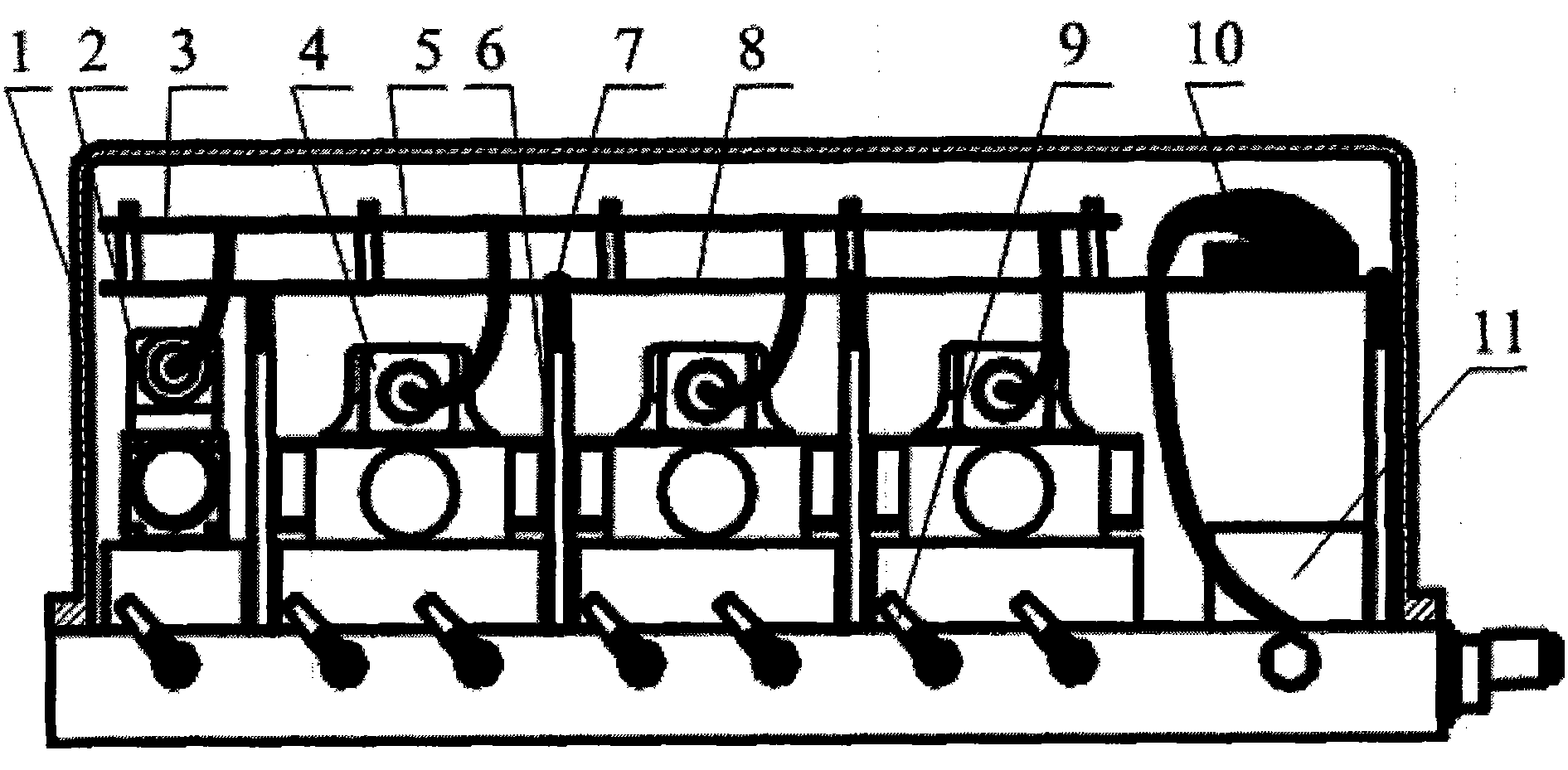

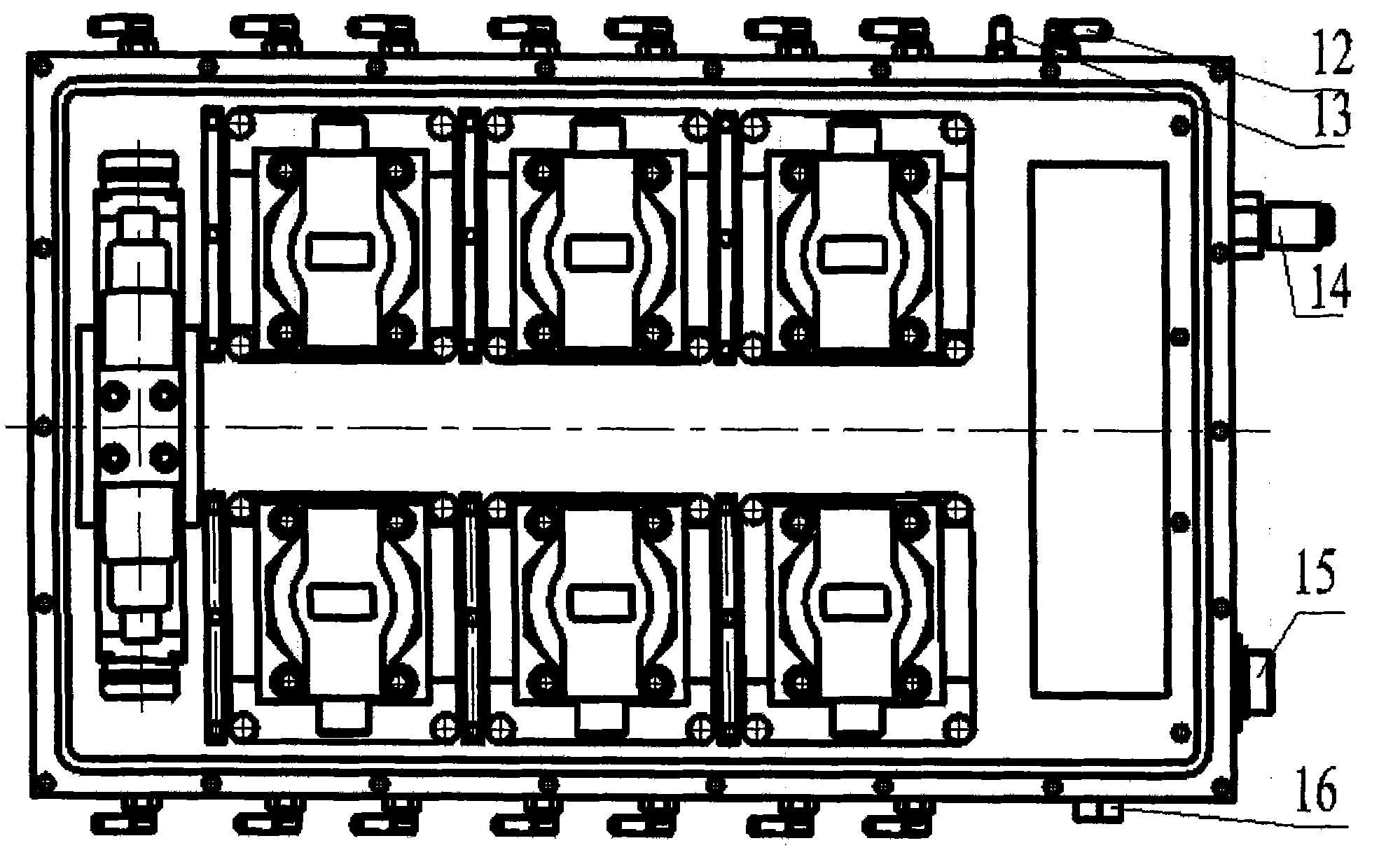

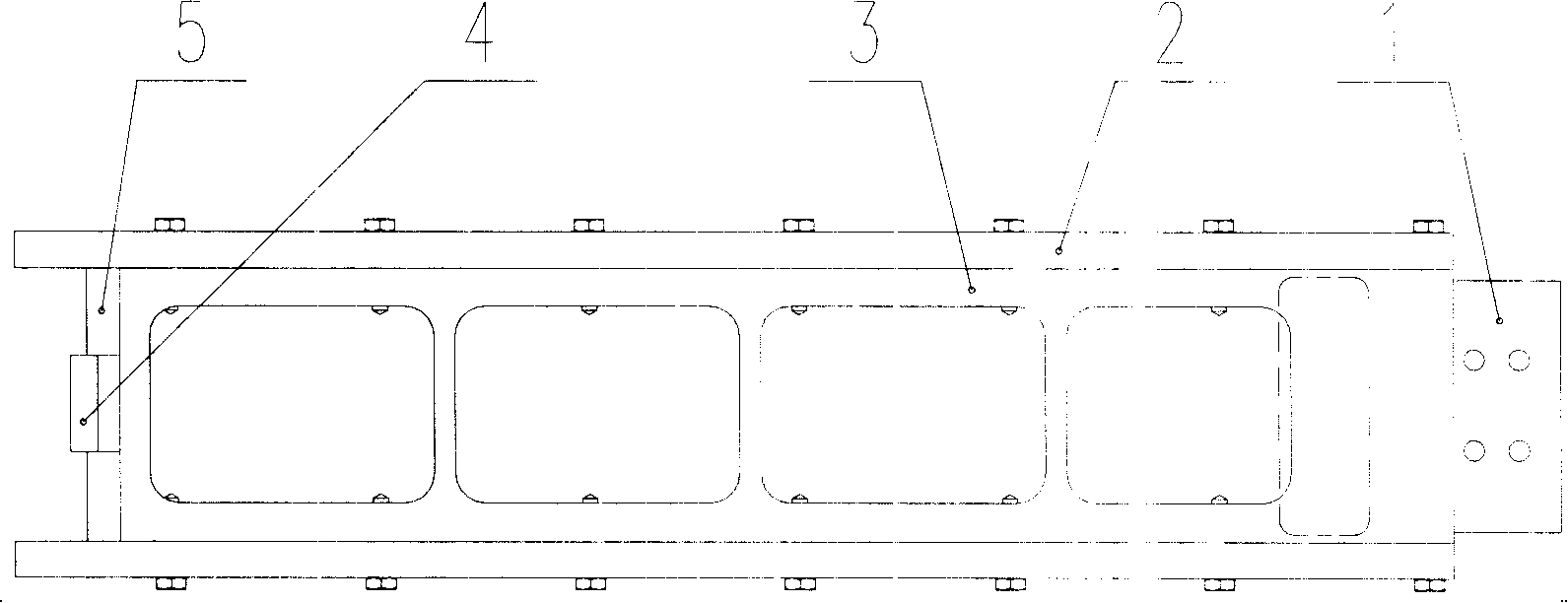

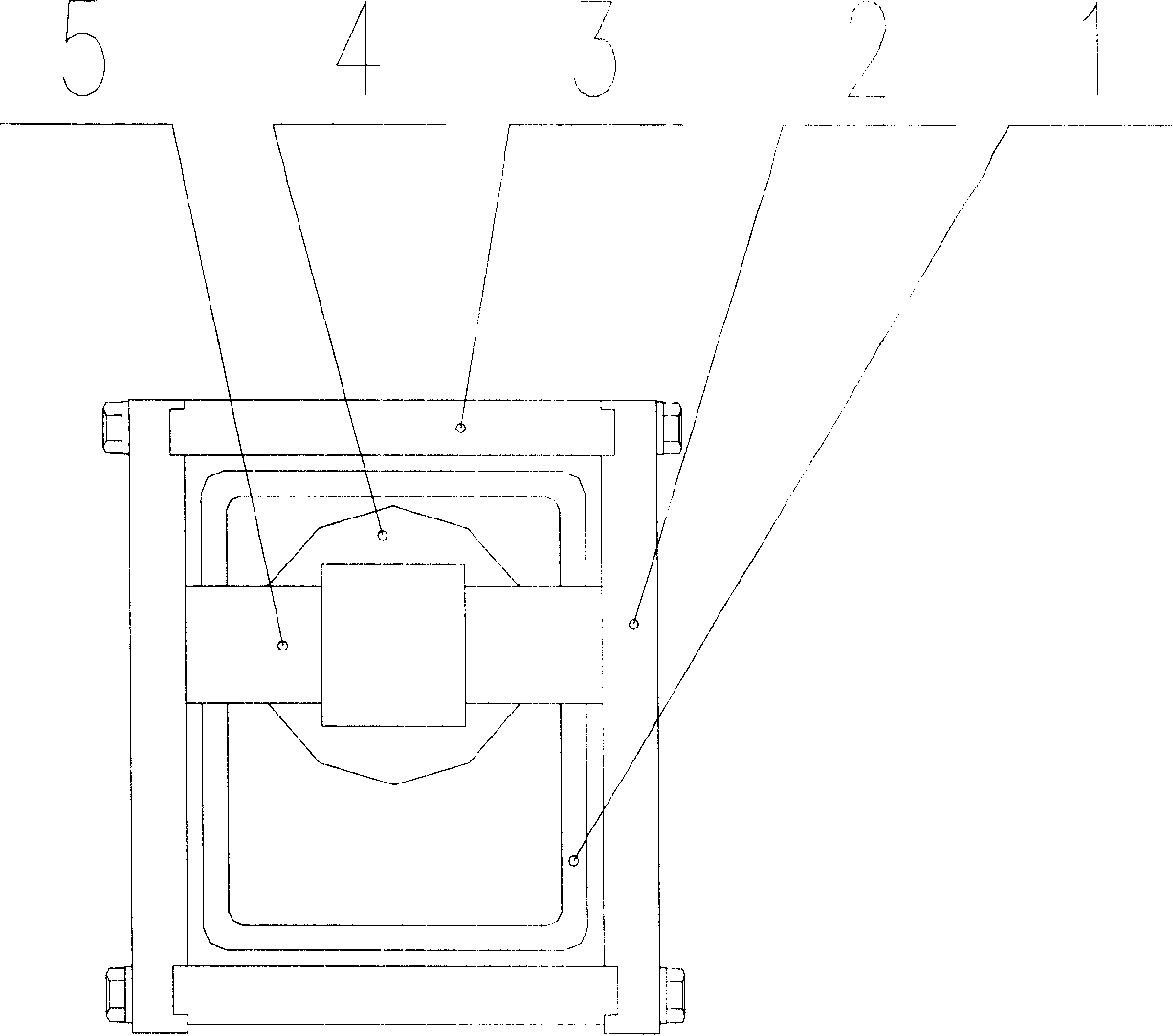

Valve box structure for underwater machine hand

The invention provides a valve box structure for an underwater machine hand. A plurality of control valves and a plurality of control circuit module boards are mounted in a box body, in which a distributor and a wiring terminal are arranged; the box body is provided with a plurality of oil pipe connectors, oil supply pipe connectors, pressure compensator connectors, oil return pipe connectors and electric wire connectors, wherein a base board of the box body is provided with a plurality of upper posts; the upper post is mounted with a control circuit main board; a plurality of control valves are mounted on the base board of the box body; a plurality of control circuit module boards are mounted on the control circuit main board; the inner ends of the plurality of oil pipe connectors are respectively connected with a plurality of control valves through oil pipes; the inner ends of the oil supply pipe connectors are connected with the distributors which are respectively connected with the plurality of control valves; the plurality of control valves are respectively connected with oil return ports of the distributors; and the electric wire connectors are respectively connected with the control circuit module boards which are respectively connected with the control valves. The structure causes the box body structure to be more compact, and improves the efficiency and sealing performance controlled by the underwater work. Therefore, the use is safer.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Small-scale underwater electric manipulator

InactiveCN103386678AImprove securityGuaranteed gripping forceMicromanipulatorFailure rateForeign matter

The invention relates to the field of operation of a microminiature ROV (remote operated vehicle), in particular to a small-scale underwater electric manipulator which is arranged on an ROV and is used for realizing the functions of salvaging foreign matter underwater and the like. The manipulator comprises a motor installing sleeve, a connecting sleeve, a driven shaft installing sleeve and a clamping jaw support, wherein a direct-current motor and a planetary reducer are arranged on the motor installing sleeve; a driving shaft and a rolling bearing are arranged on the connecting sleeve; the driven shaft installing sleeve is used for installing a driven shaft; and the clamping jaw support is used for installing clamping jaw fingers. After the speed of the motor is reduced by the planetary reducer, the torque of an output shaft of the motor is increased, and the output shaft is connected onto the driving shaft by a key; the driving shaft is connected onto the driven shaft through a torque limiter, and the driven shaft is linked with a pull rod through a lead screw nut; and the pull rod pulls the clamping jaw fingers through a pin roll to perform capturing action. The small-scale underwater electric manipulator has the characteristics of high safety, miniaturization, low failure rate, wide application range and the like.

Owner:BEIHANG UNIV

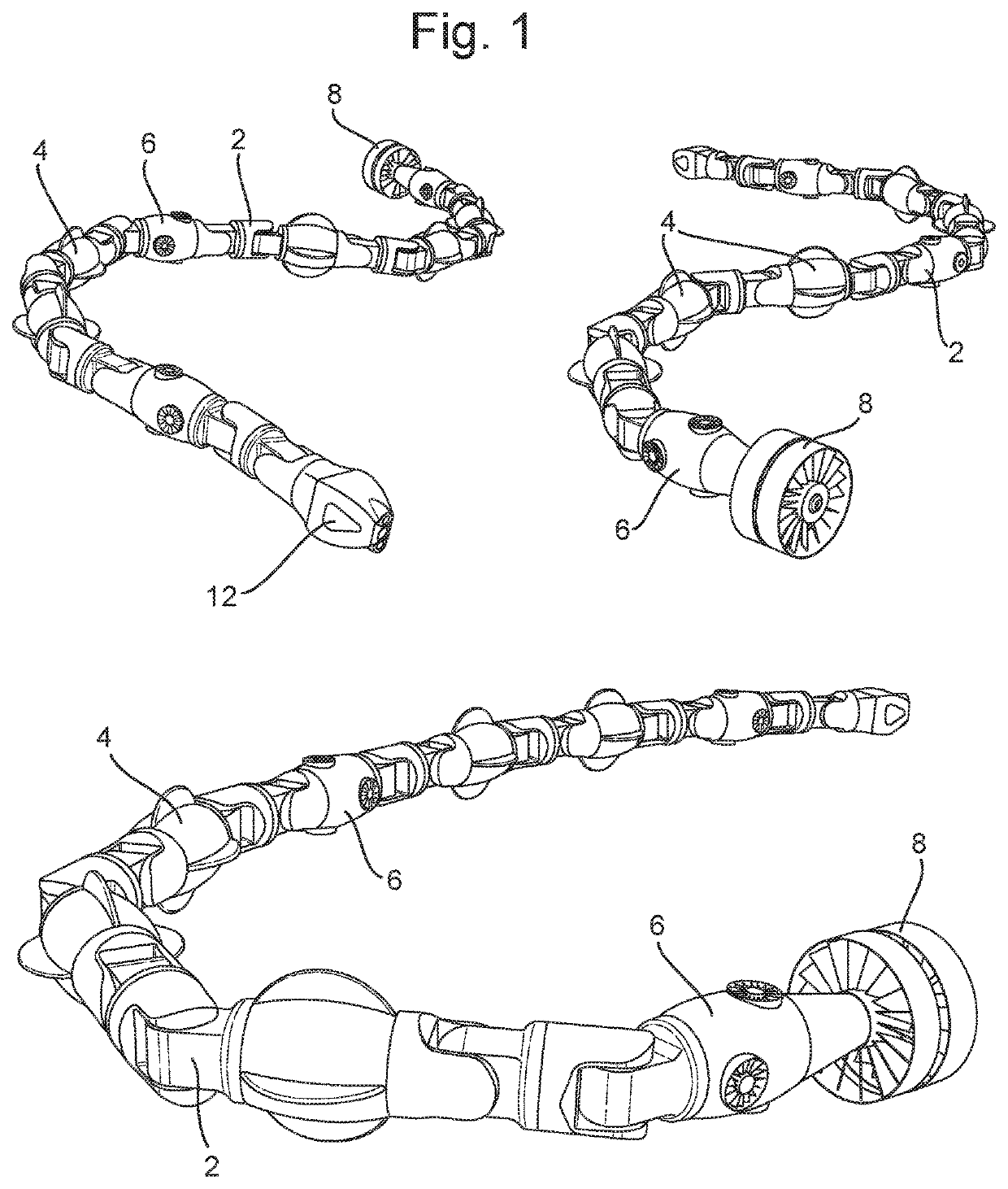

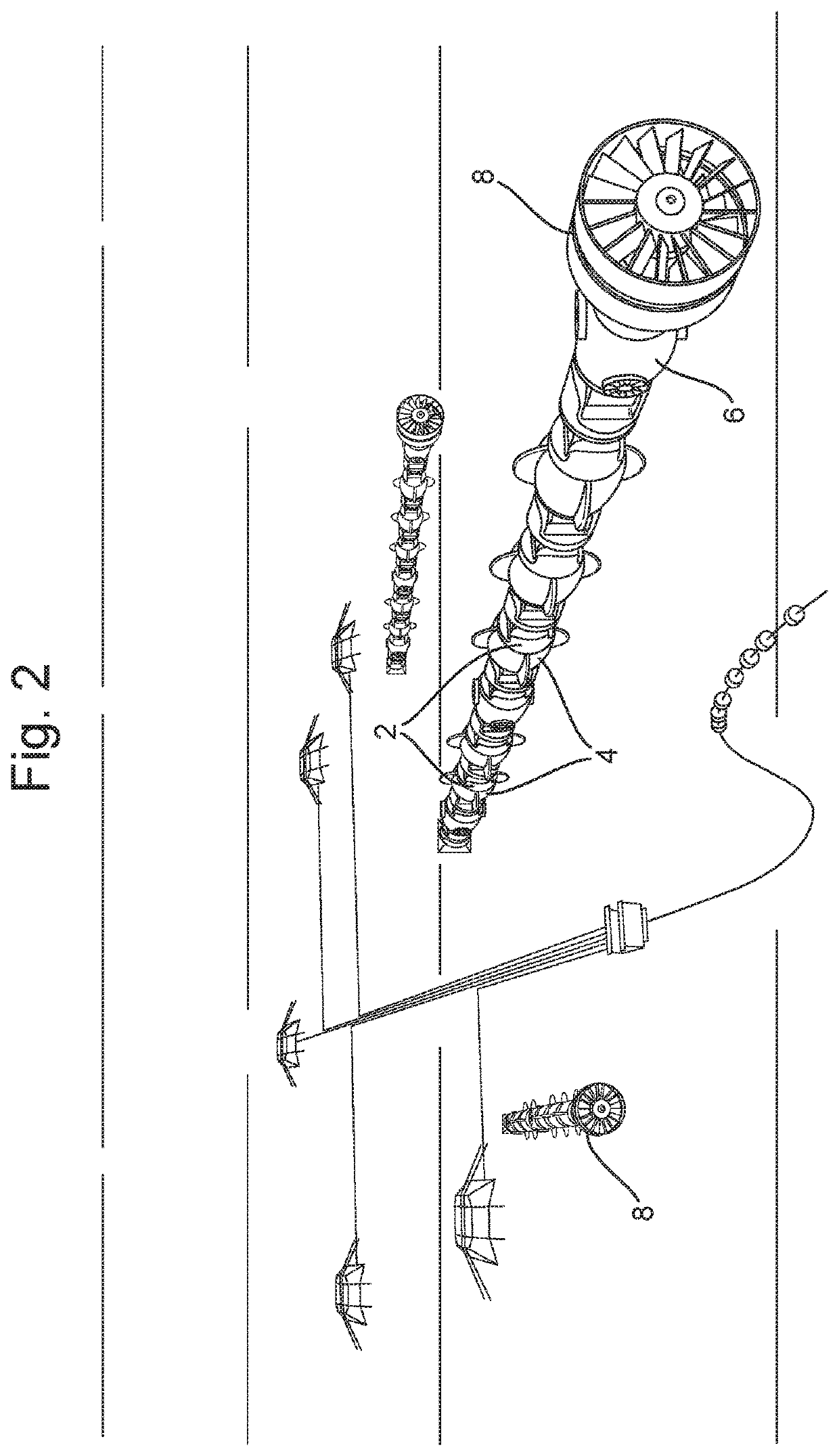

Underwater manipulator arm robot

An underwater manipulator arm robot comprises: a plurality of links that are connected to one another by joint modules for generating a flexural motion of the robot; multiple thrust devices located at different points along the length of the robot for applying thrust to the robot for propulsion and / or guidance; and at least one tool, or at least one connection point for a tool, attached to the robot; wherein the flexural motion and / or thrust devices enable movement of the robot and control of the orientation and / or location of the tool.

Owner:EELUME AS

Hydraulic driving type underwater emergency release device

InactiveCN103978497AAvoid carryingSave spaceManipulatorUnderwater equipmentLoad rejectionPower cable

The invention aims to provide a hydraulic driving type underwater emergency release device, wherein hydraulic oil or water is taken as a driving medium. The hydraulic driving type underwater emergency release device comprises a mechanical body, a signal cable release part and a power cable release part. The mechanical body is used for providing a connecting platform between an underwater aircraft and an underwater manipulator. When the underwater aircraft works normally, the device can ensure safe and reliable connection between the aircraft and the underwater manipulator. When serious failures of the underwater aircraft and the underwater manipulator occur, for example serious winding or blocking failure of each driving joint of the manipulator occurs, or an actuator at the tail end of the manipulator is wound by an underwater entanglement, conventional fault-tolerant control cannot meet the working requirement, and load rejection is necessary to ensure the safety of the underwater aircraft. A release command is given by a control system, and disengaging between a hydraulic manipulator and the underwater aircraft is quickly realized so as to ensure the safety of the aircraft. The hydraulic driving type underwater emergency release device can realize underwater release of a hydraulic manipulator body, power cables and signal cables.

Owner:HARBIN ENG UNIV

Underwater manipulator structure and robot

ActiveCN106826891AImprove gripInhibit sheddingNuclear energy generationGripping headsUnderwater manipulatorGear wheel

The invention discloses an underwater manipulator structure and a robot, relates to the technical field of robots and is intended to improve the watertightness. The underwater manipulator structure comprises a watertight steering engine and an actuator, the watertight steering engine drives the actuator to grip an object, the actuator comprises two first manipulators arranged in symmetry and a transmission mechanism, the transmission mechanism comprises first and second gears engaging with each other, the first gear is connected to an output shaft of the watertight steering engine, each of the first gear and the second gear is connected with a first manipulator, the actuator also comprises a worm or screw connected with the second gear and a second manipulator connected with the worm or screw, and an end of the second manipulator sleeves the worm or screw. The watertight steering engine drives the first gear and the second gear to engage for transmission, the two first manipulators and the second manipulator are driven to move to clamp an object from three directions, the object is avoided falling, and the underwater manipulator structure is simple in structure and reliable in transmission.

Owner:SHANGHAI XPARTNER ROBOTICS +1

An underwater automatic clean device for propeller and a cleaning method thereof

An underwater automatic clean device for a propeller and a cleaning method thereof, includes a high-pressure water supply device positioned on the shore, The high-pressure water supply device is connected with the underwater robot through a communication cable of the underwater robot and a high-pressure water pipe, the output end of the underwater robot is provided with an underwater manipulator,the underwater manipulator is provided with a cavitation cleaning device through a connecting device, and the output port of the cavitation cleaning device is butted with the blade of the propeller. The underwater robot is equipped with an underwater robot hand, and the cavitation cleaning device is clamped by a connecting device, and the high-pressure water supplied by the high-pressure water supply device is injected to clean the propeller according to the cavitation principle. The three positioning rods of the underwater vehicle are positioned relative to the propeller by the lateral thrustforce generated by the self-propeller, An underwater manipulator clam that cavitation cleaning device to complete the partial area clean of the propeller blade surface, an underwater robot moves according to a preset path to clean the entire propeller blade surface, and rotate the propeller to complete all the blade surface cleaning of the propeller. The underwater vehicle clamps the cavitation cleaning device to complete the local area cleaning of the propeller blade surfaces.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

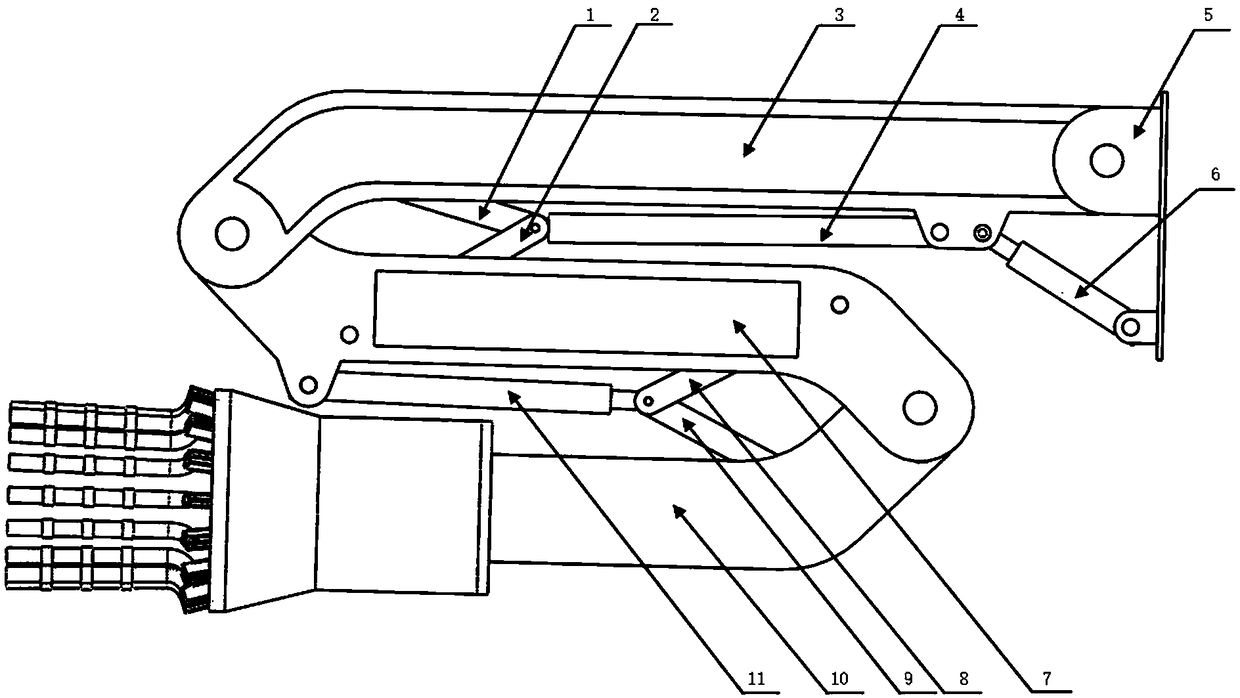

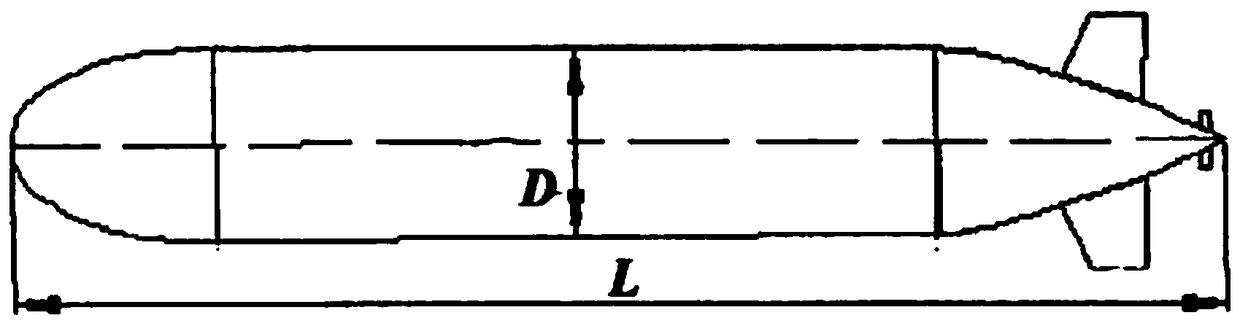

Underwater mechanical arm telescopic joint for strong operation type underwater robot

The invention discloses a strong-operation underwater manipulator telescopic joint used for an underwater robot, comprising a telescopic arm, a guide square sleeve and a telescopic oil cylinder; the telescopic arm is a hollow rectangle podetium with uniform wall thickness and rectangle section; the podetium at one end of the telescopic arm is connected with a front joint, which is used for driving the front joint to carry out telescopic motion; at the vertex angle of the four edges of the podetium at the other end of the telescopic arm, right angle-shaped troughs are arranged along the edges and used for placing a rear angle supporting; the guide square sleeve is composed of a front baffle, a rear baffle, an upper baffle and a lower baffle and is sheathed on the external surface of the telescopic arm; the telescopic oil cylinder is arranged in the chamber of the telescopic arm; the centre of the telescopic oil cylinder is in the same lead vertical plane with the centre of the telescopic arm; the telescopic arm is connected with a rear supporting shaft and a front supporting shaft which is used for supporting the telescopic oil cylinder. The invention is the underwater manipulator telescopic joint which can be applied to strong-operation underwater robots and has the advantages of great bearing capacity, long telescopic length, light weight and simple structure.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

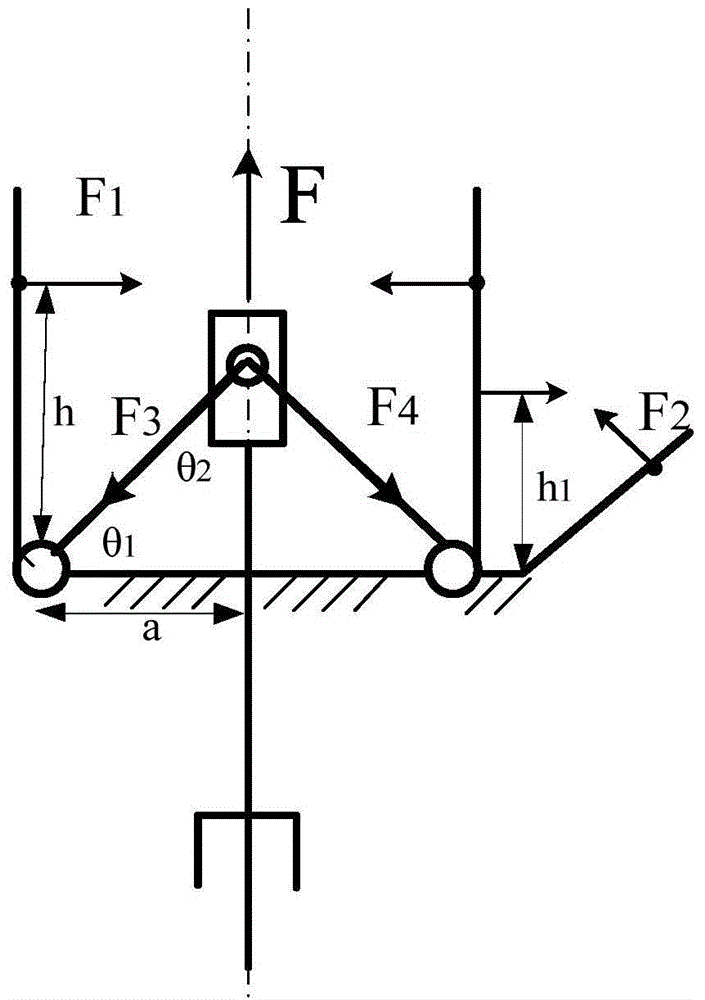

Four-bar-linkage feed-screw-nut electrically-driven underwater mechanical arm gripper

PendingCN112692861ASimple compositionHigh control precisionGripping headsNuclear energy generationMarine engineeringElectric machine

The invention discloses a four-bar-linkage feed-screw-nut electrically-driven underwater mechanical arm gripper. The four-bar-linkage feed-screw-nut electrically-driven underwater mechanical arm gripper comprises a finger execution structure assembly, a four-bar-linkage driving structure, a feed-screw-nut transmission assembly, a motor driving system, a sealing part and a fastening part; the finger execution structure assembly is a finger-shaped structure assembly, and is used for grabbing and clamping objects; the four-bar-linkage driving structure is connected with the finger execution structure assembly, and is used for driving the finger execution structure assembly to conduct opening and closing movement; the feed-screw-nut transmission assembly is connected with the four-bar-linkage driving structure and the motor driving system separately, and is used for driving the four-bar-linkage driving structure to move; and the motor driving system is used for driving the feed-screw-nut transmission assembly to move. According to the four-bar-linkage feed-screw-nut electrically-driven underwater mechanical arm gripper, feed screw nut transmission and a four bar linkage structure are adopted, and through feed screw nut transmission, rotating movement of a motor is converted into linear movement needed for driving the four-bar-linkage structure, so that the two-finger mechanical gripper is driven to be opened and closed, and the four-bar-linkage feed-screw-nut electrically-driven underwater mechanical arm gripper has the advantages that the structure is compact, rotation is flexible, the carrying capacity is high, the four-bar-linkage feed-screw-nut electrically-driven underwater mechanical arm gripper is not liable to be jammed, and the like.

Owner:SHANGHAI OCEAN UNIV +1

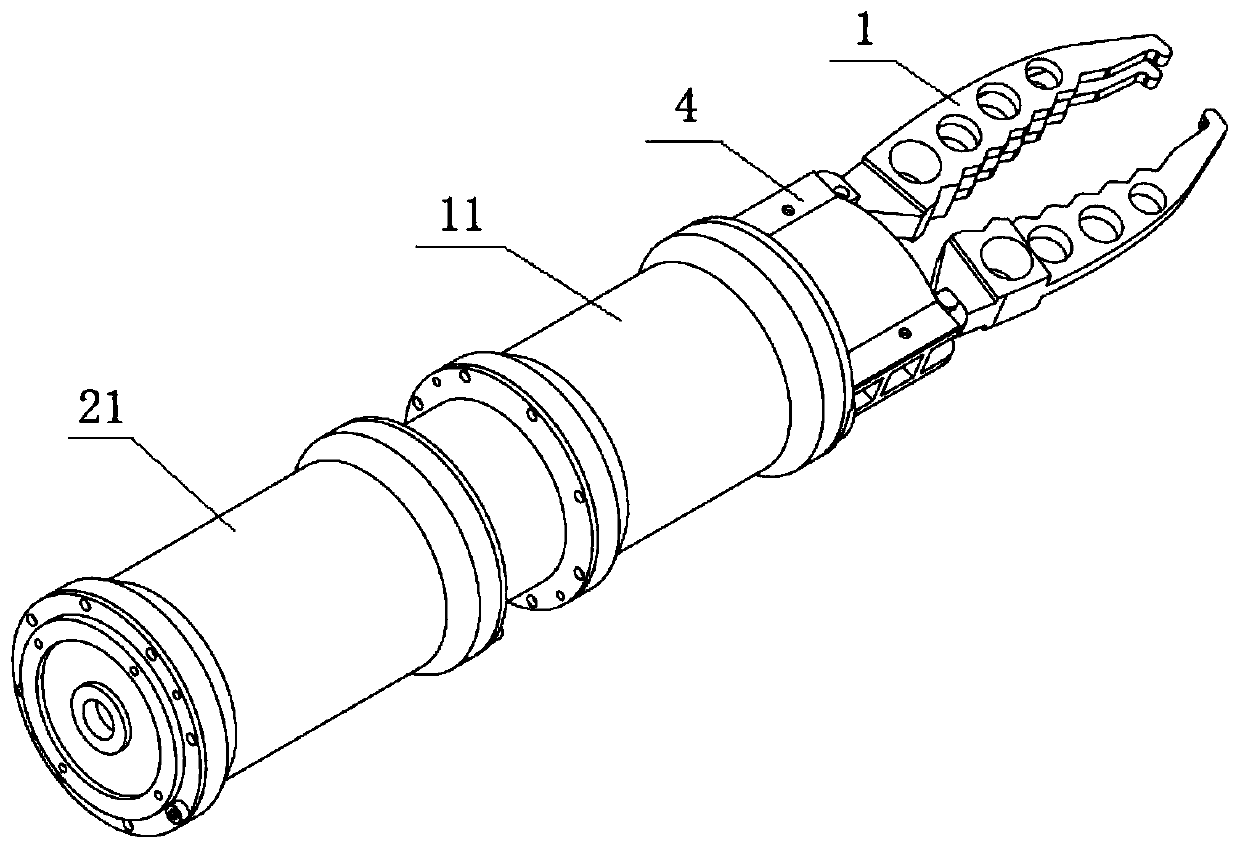

Two-degree-of-freedom underwater manipulator

PendingCN110978038ACompact structureFlexible operationGripping headsVessel salvagingSet screwUnderwater manipulator

The invention discloses a two-degree-of-freedom underwater manipulator. The two-degree-of-freedom underwater manipulator comprises a clamping joint and a rotating joint. The clamping joint comprises aclaw, a claw bracket, a lead screw and a first motor cover. The claw is fastened on the claw bracket by screws, and the claw and a sliding nut are connected by the screws, the sliding nut is installed on the lead screw, a first brushless direct-current motor and a first driving plate are arranged in the first motor cover, the output end of the first brushless direct-current motor is fixed to thelead screw, a sealing movable sleeve is connected to the lead screw through a set screw, a first sealing static sleeve seat is installed on the inner wall of the claw bracket, and a connection flangeis installed at the end, away from the claw, of the first motor cover. According to the two-degree-of-freedom underwater manipulator, the functions of clamping and rotating two-degree-of-freedom of the underwater manipulator are achieved, the structure is compact, the operation is flexible, and the reliability is high; and a complete waterproof design is adopted in the whole machine, and the requirements of long-term underwater work can be met.

Owner:南京华研动密封科技有限公司

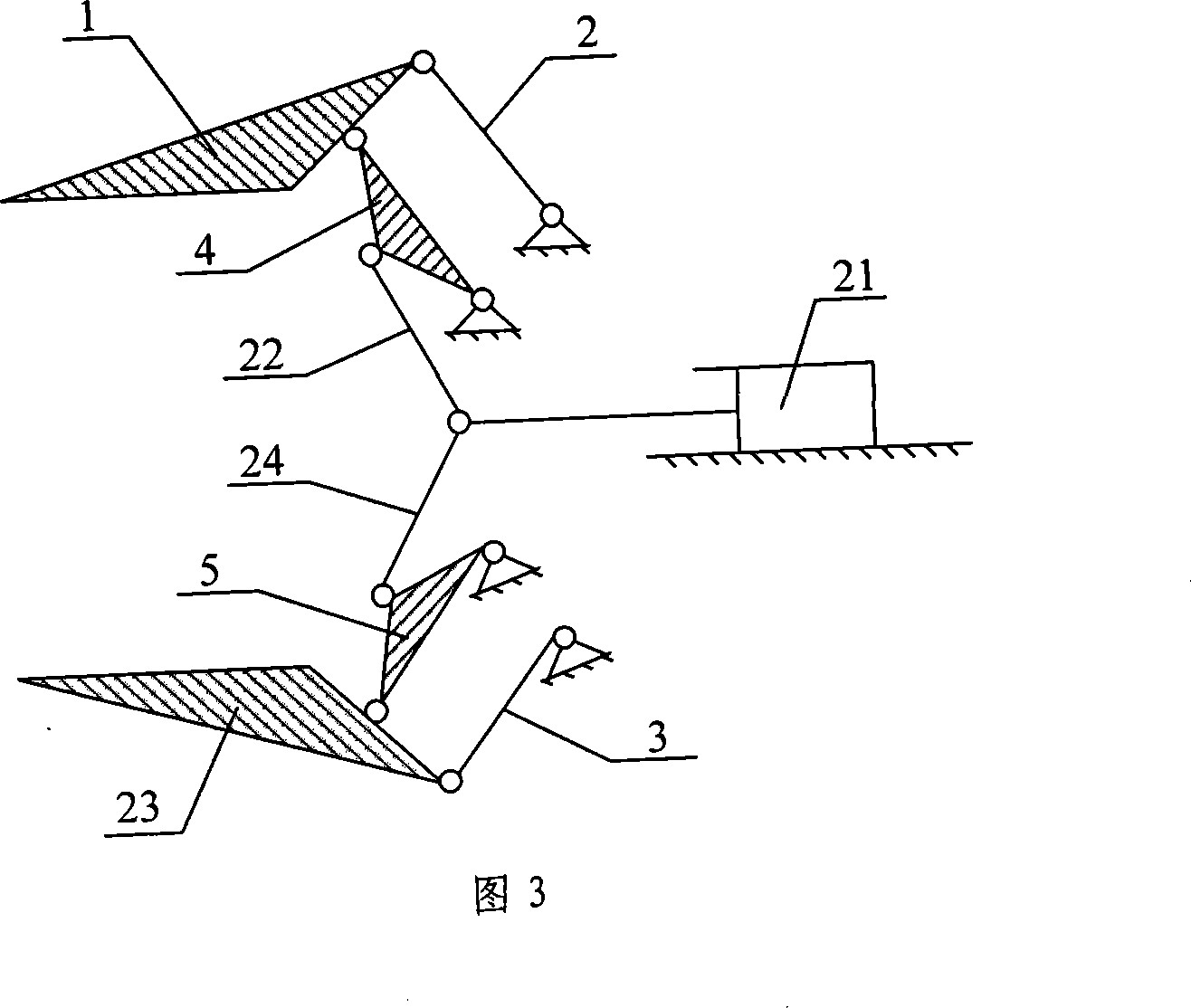

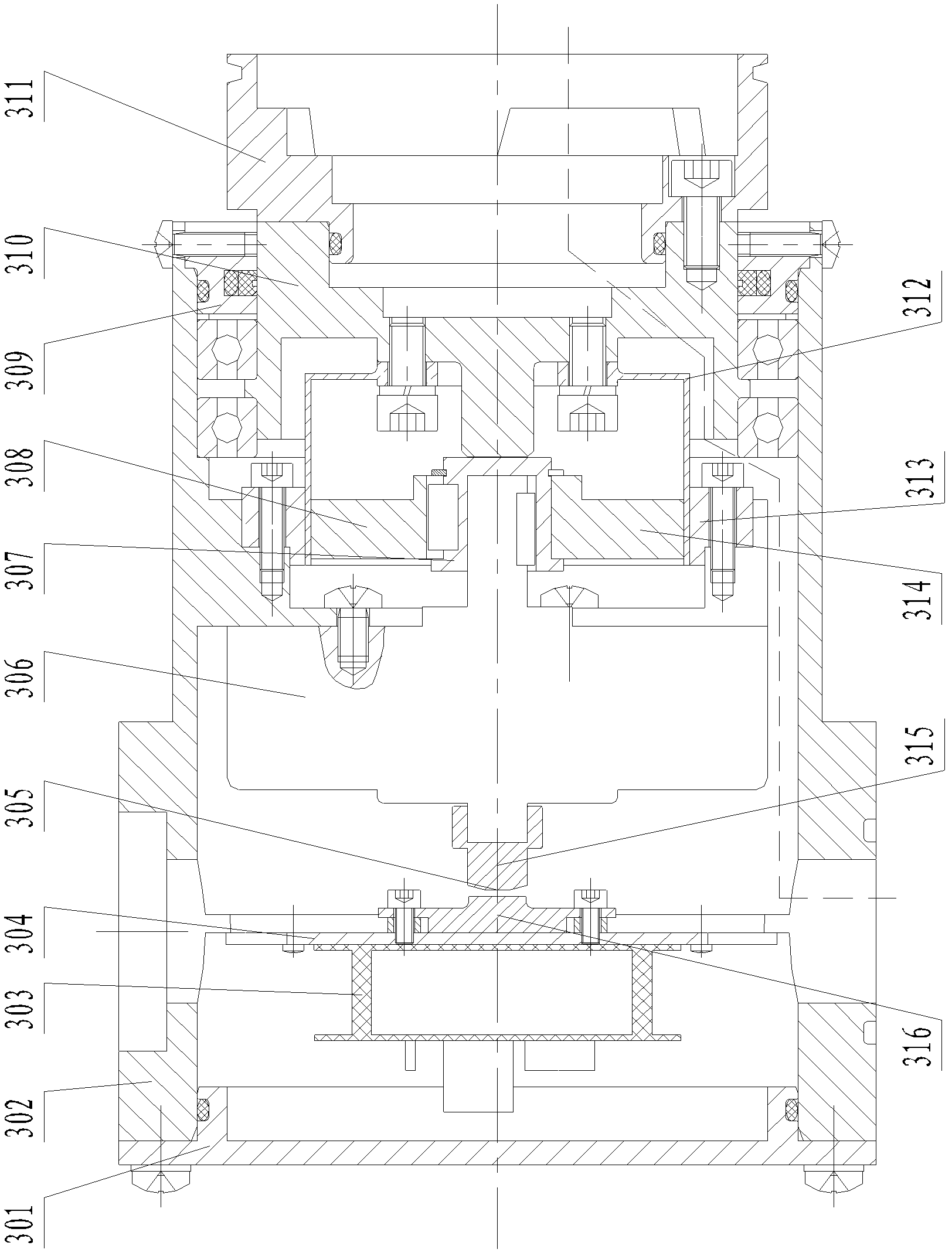

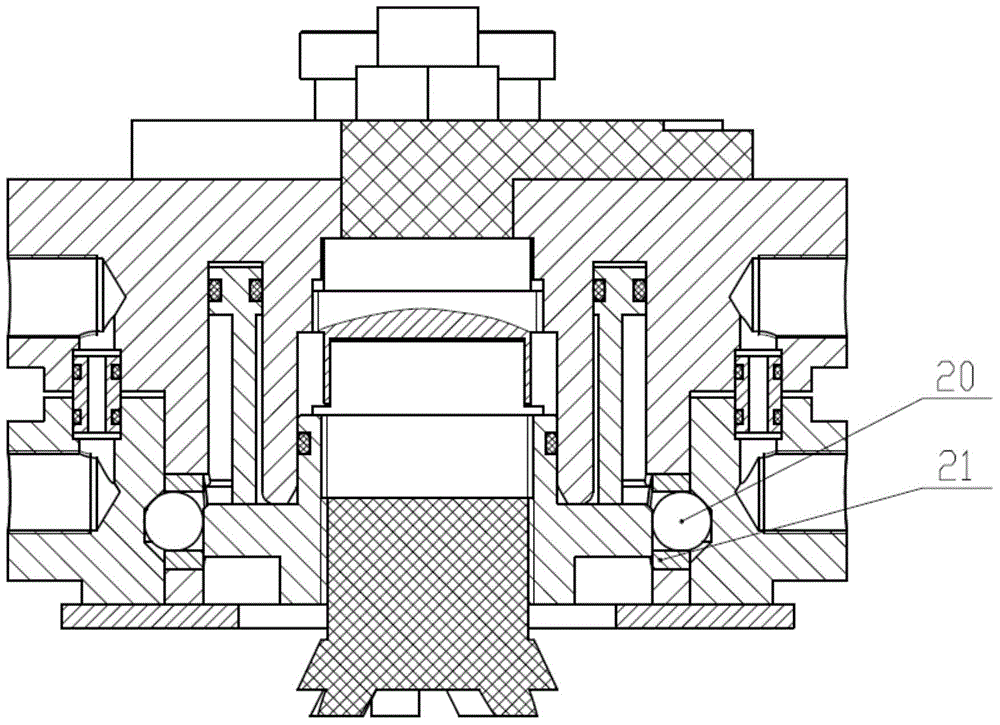

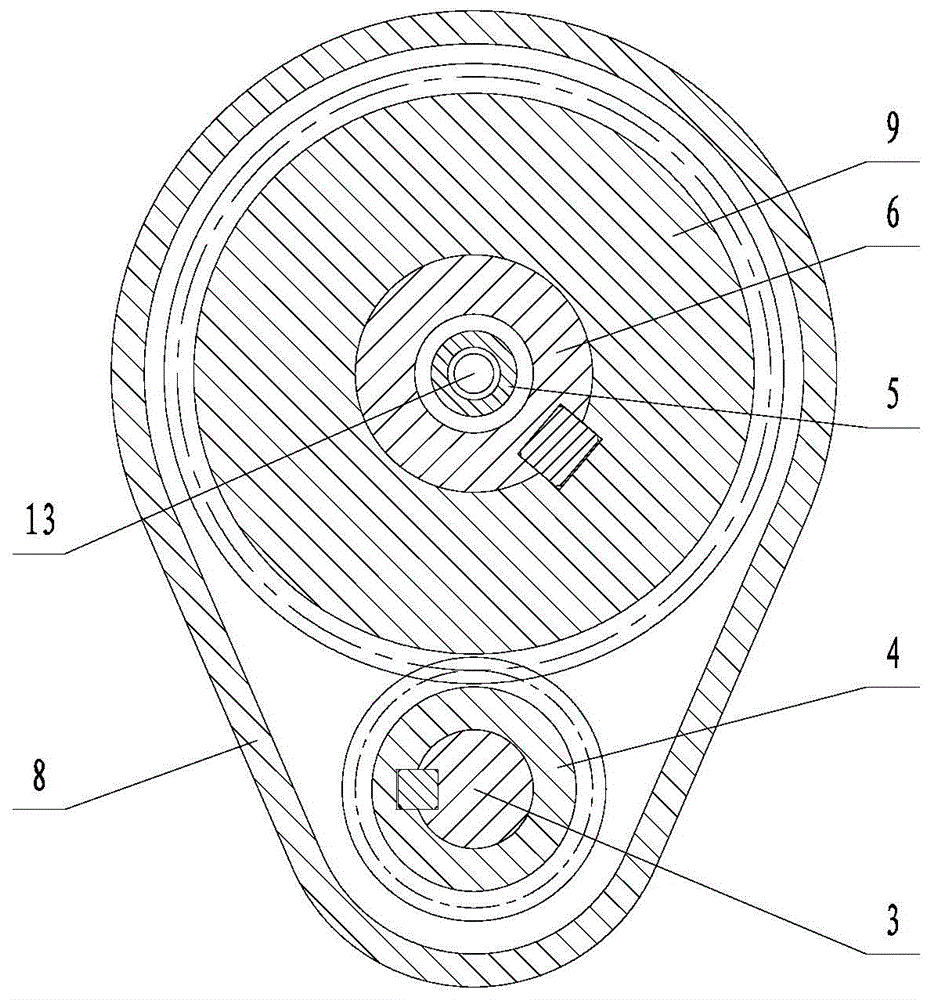

Submarine manipulator wrist joint structure with three degrees of freedom

InactiveCN101224582ACompact designRealize three degrees of freedom movementJointsUnderwater equipmentHydraulic cylinderHydraulic motor

The invention provides an underwater manipulator three degrees of freedom(DOFs) wrist structure. A connecting frame 12 is respectively connected with a front arm 1 and a wrist 11 through a wrist pitching rotating shaft 2 and a wrist yaw rotating shaft 4; the bottom end of a second hydraulic cylinder 8 in the front arm 1 is arranged on a coupling spindle 9 at the bottom of the hydraulic cylinder in a cavity of the front arm 1; the end of the piston rod of the second hydraulic cylinder 8 is connected with a piston rod coupling spindle 3 of the hydraulic cylinder on the connecting frame 12; one end of a connecting rod 6 is connected with a connecting rod coupling spindle 5 of the wrist 11; the other end of the connecting rod 6 is connected with a piston rod of a first hydraulic cylinder 7; the bottom of the hydraulic cylinder is fixed on the connecting frame 12; a hydraulic motor is arranged inside the wrist 11. The whole wrist has compact structural design, can realize the three DOFs motion of the wrist, and has the advantages of flexible operation, improving the operation space, reducing the operation dead areas of the underwater manipulator, etc.

Owner:HARBIN ENG UNIV

Submarine manipulator elbow joint structure

InactiveCN101224583ASimple organizationCompact structureJointsUnderwater equipmentHydraulic cylinderUnderwater manipulator

The invention provides an elbow joint structure for an underwater manipulator, which consists of a forearm 1, an upper arm 2, an elbow joint pitching rotating shaft 3, a hydraulic cylinder bottom coupling shaft 4 arranged on the upper arm 2 and a hydraulic cylinder piston rod coupling shaft 6 arranged on the forearm 1 and the hydraulic cylinder 5. The forearm 1 is connected with the upper arm 2 by the elbow joint pitching rotating shaft 3; the bottom of a hydraulic cylinder 5 is connected with the hydraulic cylinder bottom coupling shaft 4 arranged on the upper arm 2, the end of the piston rod of the hydraulic cylinder 5 is connected with the hydraulic cylinder piston rod coupling shaft 6 arranged on the forearm 1. The invention can be applied to an underwater robot, is characterized by simple mechanism, compact structure and reasonable arrangement, can realize the wide range pitching rotation of the elbow joint and can considerably reduce the dead zone of the operation space of the underwater manipulator.

Owner:HARBIN ENG UNIV

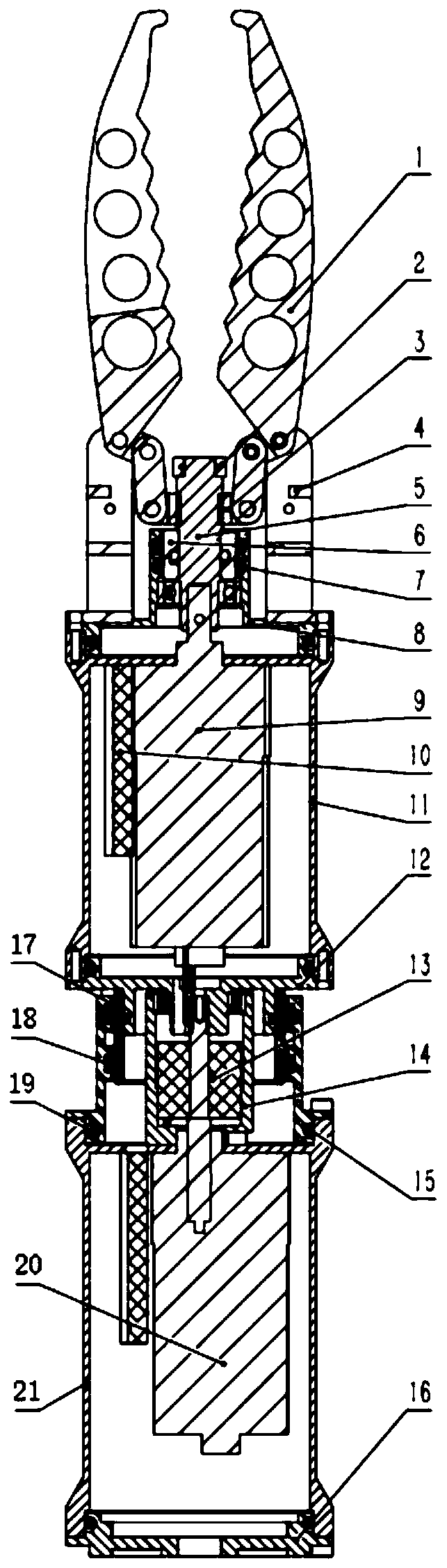

Underwater electromechanical wrist turning and clamping drive structure

ActiveCN104669262AReliable transmissionSmooth transmissionProgramme-controlled manipulatorJointsUnderwater manipulatorBall screw

The invention belongs to the field of underwater manipulators of robot engineering and particularly relates to an underwater electromechanical wrist turning and clamping drive structure. The underwater electromechanical wrist turning and clamping drive structure comprises a wrist turning drive module for achieving an underwater electromechanical wrist turning function, a clamping drive module for achieving an underwater electromechanical wrist clamping function and a joint housing, wherein the wrist turning drive module and the clamping drive module are accommodated in the joint housing respectively. The wrist turning drive module uses gear transmission. The clamping drive module uses ball screw transmission. A second shaft of the wrist turning module is of a hollow structure, a ball screw nut connecting rod for driving a clamp can penetrate through the second shaft of the wrist turning module, and the wrist turning module and the clamping module can be integrated into the joint housing and avoid mutual interference to achieve two functions of an underwater electromechanical arm. The underwater electromechanical wrist turning and clamping drive structure has the advantages of being reliable in performance, compact in structure, easy to maintain and debug and the like.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

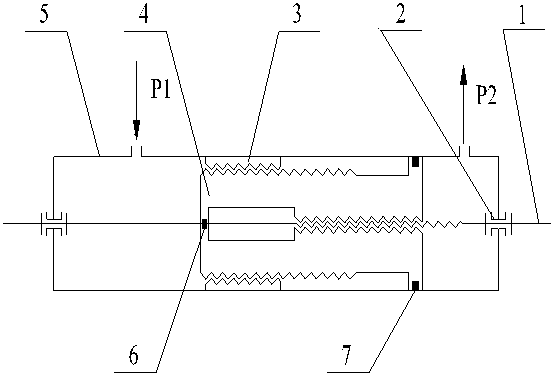

Hydraulic joint of underwater manipulator

The invention relates to a hydraulic joint of an underwater manipulator, which comprises an output screw, a cylinder body, a cored screw, a fixing nut and thrust bearings, wherein the two ends of the output screw are connected with the cylinder body via the thrust bearings; the fixing nut is assembled with the cylinder body into a whole via threaded fastening or interference fit; the output screw is inserted into a middle hollow part of the cored screw; the cored screw and the output screw form a first stage helical pair; the cored screw and the fixing nut form a second stage helical pair; hydraulic oil pressure at an oil inlet is converted into a torque for output by the two helical pairs; and forward rotation and reverse rotation of the output screw can be achieved by adjusting an oil pressure difference between the oil inlet and an oil outlet, so that large angle pendulum motion is achieved.According to the joint, very small internal leakage can be ensured via a unique helical structure and high precision processing; a stable rotation angle can be kept for a long time without external control; and most of the hydraulic joint is made of seawater corrosion-resisting stainless steel, so that the hydraulic joint is good in corrosion resistance and can operate underwater for a long term.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com