Hydraulic joint of underwater manipulator

An underwater manipulator and hydraulic technology, applied in the direction of manipulators, manufacturing tools, joints, etc., can solve the problems of large size and affect the movement of underwater manipulators, and achieve the effect of small internal leakage and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

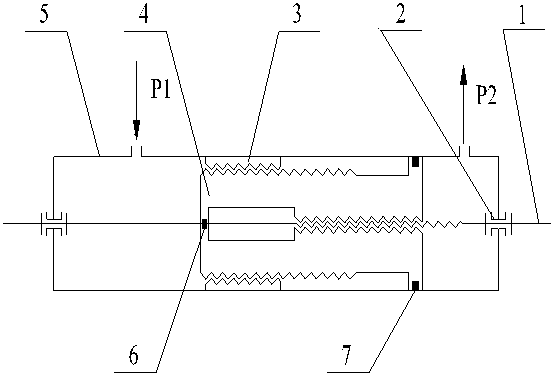

[0018] Embodiment 1: as figure 1 As shown, the device is composed of an output screw 1, a thrust bearing 2, a fixed nut 3, a hollow screw 4, a cylinder 5, a screw sealing ring 6 and a cylinder sealing ring 7. The materials are mostly made of seawater resistant stainless steel. The two ends of the output screw 1 are connected with the cylinder body 5 through the thrust bearing 2 . The fixing nut 3 is assembled with the cylinder body 5 as a whole through thread fastening or interference fit. The hollow screw 4 and the output screw 1 form the first-stage screw pair, and the hollow screw 4 and the fixed nut 3 form the second-stage screw pair. Through the two-stage screw pair, the hydraulic oil pressure at the oil inlet is converted into torque output, and by adjusting the oil pressure difference between the oil inlet and the oil outlet, the forward rotation and reverse rotation of the output screw can be realized, so that Realize large-angle swing motion. Working process of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com