Oil path built-in swivel motor for underwater manipulator

An underwater manipulator and swing motor technology, which is applied in electromechanical devices, control mechanical energy, underwater operation equipment, etc., can solve the problems of not meeting the sealing requirements of underwater manipulators, affecting the flexibility of manipulator movements, and occupying space, etc. Conducive to protection, light weight and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in more detail below in conjunction with accompanying drawing example:

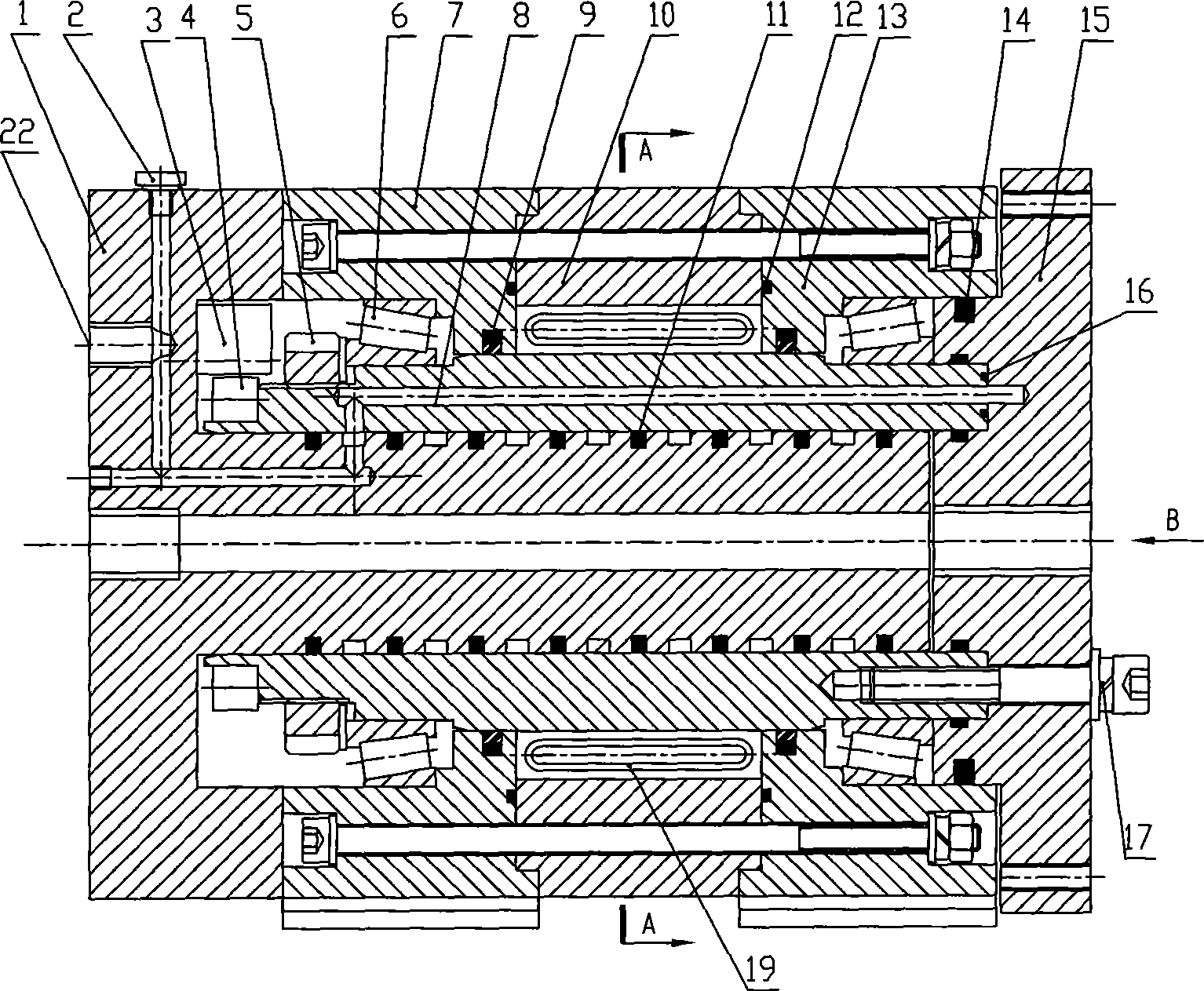

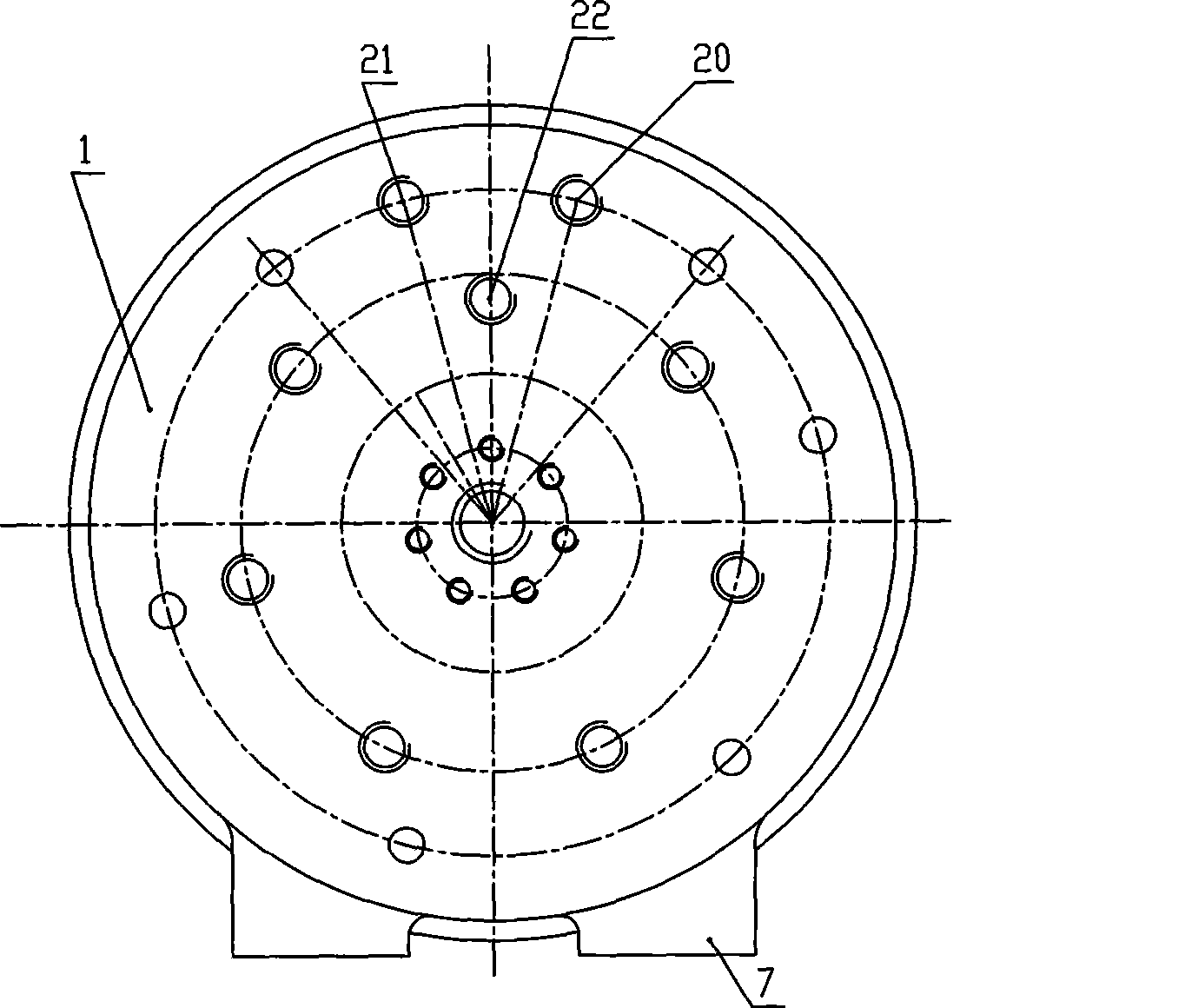

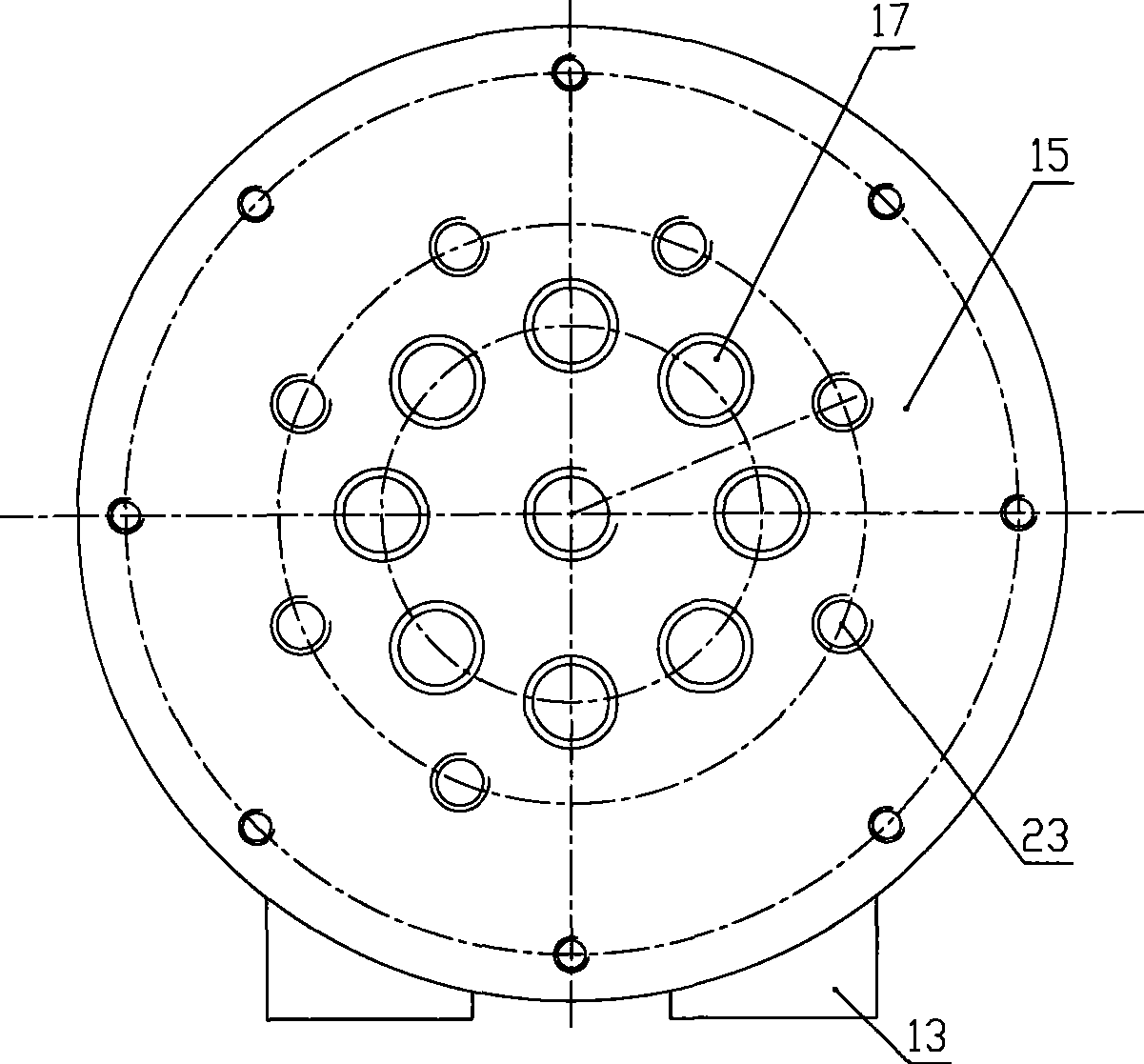

[0022] combine figure 1 and image 3 , the present invention is made up of swing motor shaft core 1, left end cover 7, stator 10, rotor 8, blade 18, right end cover 13, output flange 15, sensor 4, tapered roller bearing 6; The shaft core 1 is fixedly connected, and the other end is fixedly connected with the stator 10; the other end of the stator 10 is fixedly connected with the right end cover 13; the left end cover 7, the stator 10, and the right end cover 13 have cavities, and the rotor 8 is placed in the cavity, which can be Circumferential rotation; one end of the rotor 8 is fixedly connected to the output flange 15 by screws 17; the blade 18 is fixedly connected to the outer surface of the rotor 8; the sensor 4 is installed at one end of the rotor 8, and the sensor reading head 3 is installed in the cavity of the shaft core 1 inside, and firmly connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com