Submarine manipulator shoulder joint

An underwater manipulator and shoulder joint technology, which is applied to manipulators, underwater operation equipment, ships, etc., can solve the problems of unfavorable hydraulic oil pipe pipeline layout, large volume of manipulator, and non-compact structure, and achieves favorable pipeline layout and rotation. Flexible, compact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in more detail below in conjunction with accompanying drawing example:

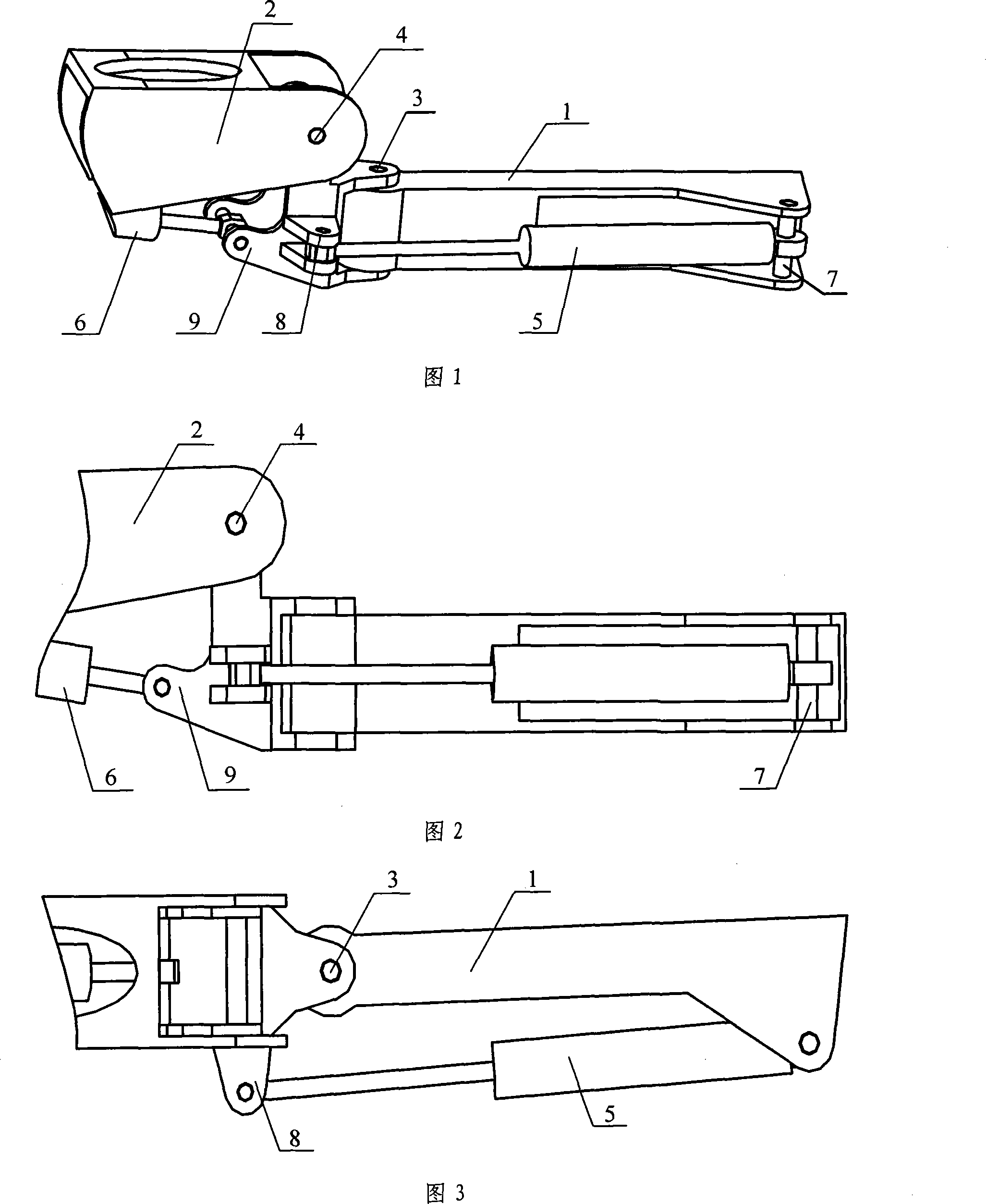

[0017] Combined with Figures 1-3, the shoulder joint of the underwater manipulator is connected by a base frame 1, an upper arm 2, a yaw shaft 3, a pitch shaft 4, a hydraulic cylinder 5, a hydraulic cylinder 6, a hydraulic cylinder bottom connecting shaft 7, and a hydraulic cylinder piston rod. The hinge seat 8 and the hydraulic cylinder piston rod joint hinge seat 9 are composed of the base frame 1 and the shoulder joint through the yaw shaft 3, and the upper arm 2 is connected with the shoulder joint through the pitch shaft 4; the bottom of the hydraulic cylinder 5 is connected through the bottom of the hydraulic cylinder. The end connecting shaft 7 is connected with the base frame 1, the piston rod end of the hydraulic cylinder 5 is connected with the shoulder joint through the hydraulic cylinder piston rod connecting hinge seat 8; the piston rod end of the hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com