Four-bar-linkage feed-screw-nut electrically-driven underwater mechanical arm gripper

An underwater manipulator, screw nut technology, applied in the directions of manipulators, chucks, manufacturing tools, etc., can solve the problems of small gripping force of the gripper structure, complex driving system, low applicability, etc. High precision and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

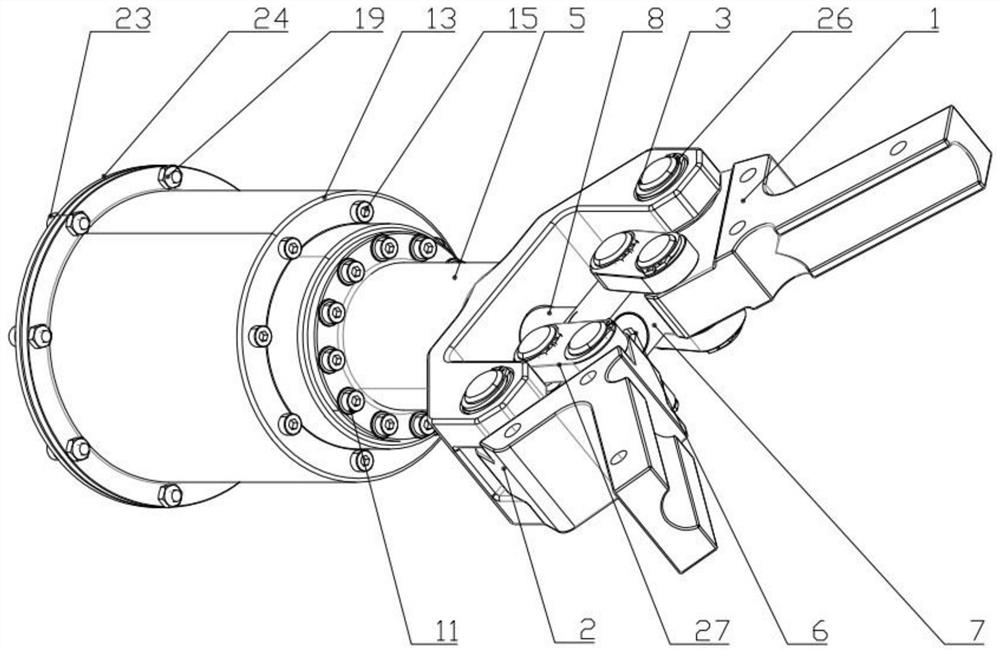

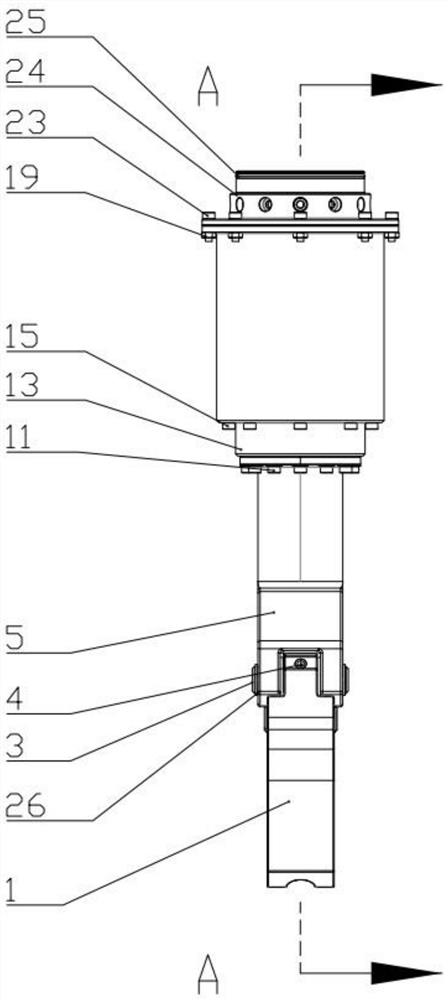

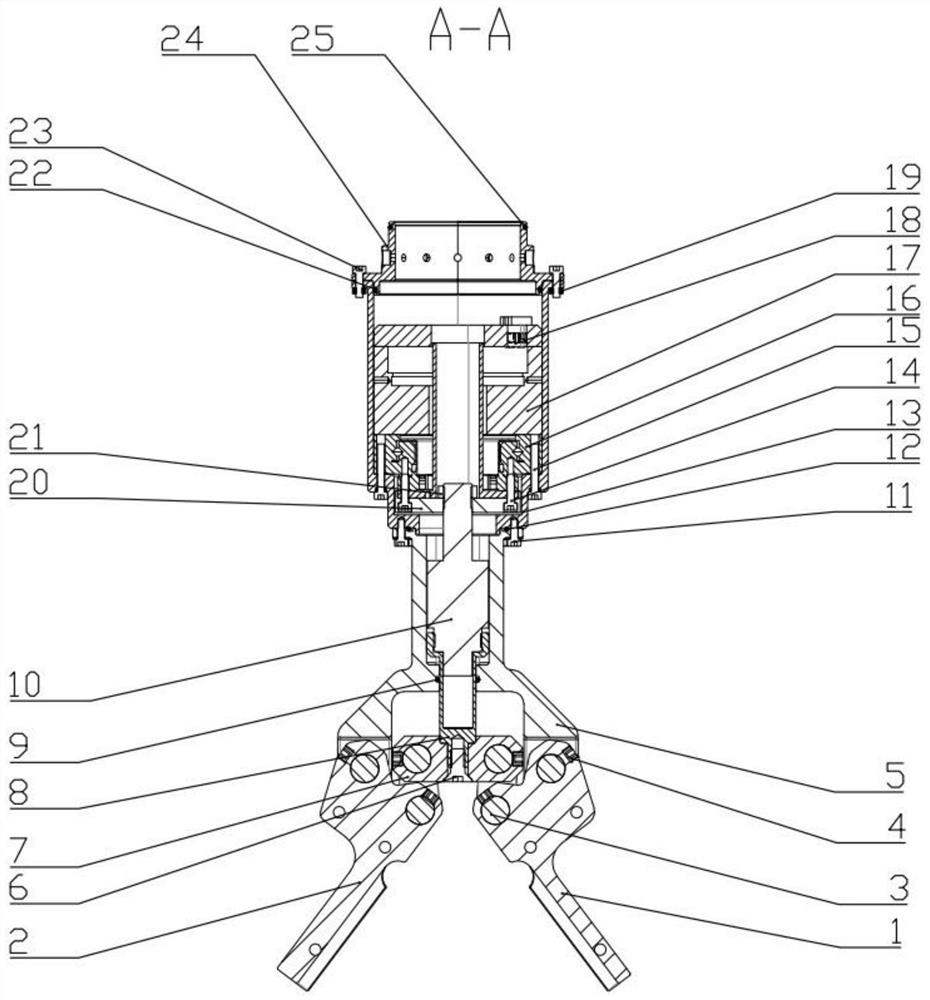

[0058] Such as Figure 1-Figure 11 As shown, a four-link screw nut electric drive type underwater manipulator gripper, including finger actuator structure components, four-link drive structure, screw nut drive components, motor drive system, seals and fasteners, etc.; The finger actuator structure assembly is composed of a first external gripper 1 and a second external gripper 2. The grippers are L-shaped, symmetrically distributed on both sides of the axis of the gripper, and are the parts that are in direct contact with the gripped object. , and the grasping surfaces of the first external clamper 1 and the second external clamper 2 are processed with semi-cylindrical grooves for grabbing T-shaped handles; the four-link driving structure is clamped by an L-shaped device, one side of jaw support 5, positioning rod end 7, square drive rod 8, and connecting rod; the motor, as a power source, transmits the rotational motion to the screw nut, and the rolling nut of the screw nut a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com