Patents

Literature

126results about How to "Guaranteed gripping force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

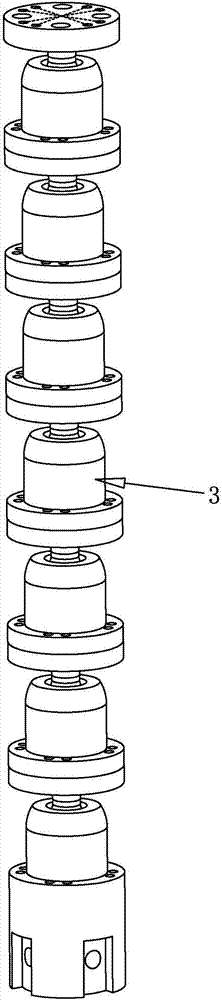

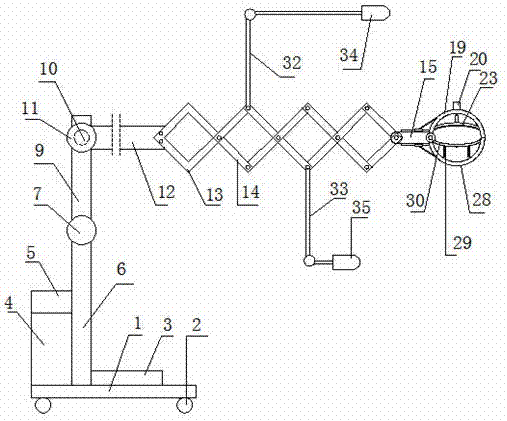

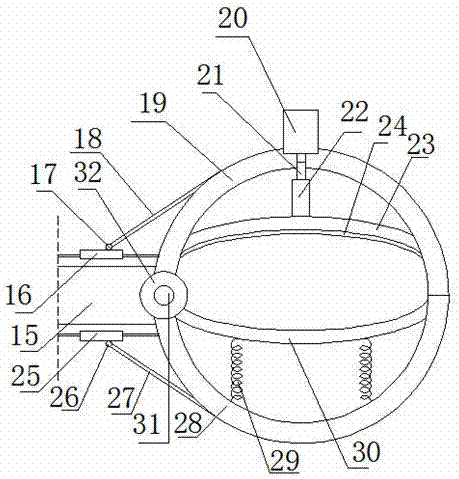

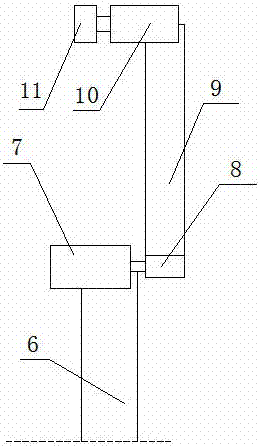

Flexible multi-joint surgical instrument for robot assisted minimally invasive surgery

ActiveCN107468339ARealize opening and closing movementAchieve bending motionSurgical manipulatorsSurgical robotsSurgical operationForceps

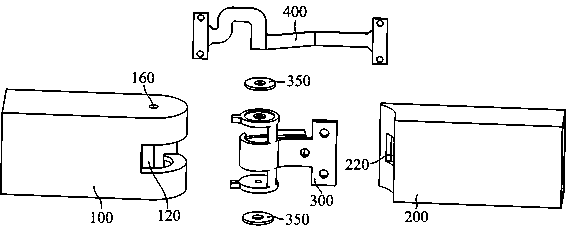

The invention discloses a flexible multi-joint surgical instrument for robot assisted minimally invasive surgery, and relates to the technical field of enterocoelia minimally invasive surgery department medical facilities. The instrument can achieve spatial displacement and positioning of tail end operating forceps by itself inside a patient, the tail end gesture adjusting capability of the surgical instrument is enhanced, the good flexibility is achieved, and the tissue surgical operation is completed inside the small space; by means of a self-rotation joint designed between the wrist of the surgical instrument and the tail end operating forceps, and the problem that joint restoration is needed during autorotation is avoided; the instrument comprises the tail end operating forceps mechanism, the autorotation joint, the wrist flexible joint and a power driving box; the power driving box comprises a wiring pipe, a shell, an upper base plate, a lower base plate, five sets of motor rope sheave devices, a rope guiding wheel set and a rope guiding column set; one end of the wiring pipe is connected with the tail end ball hinge structure of the wrist flexible joint, and the other end of the wiring pipe is fixed to the lower base plate. The instrument is used for the robot assisted minimally invasive surgery.

Owner:JILIN UNIV

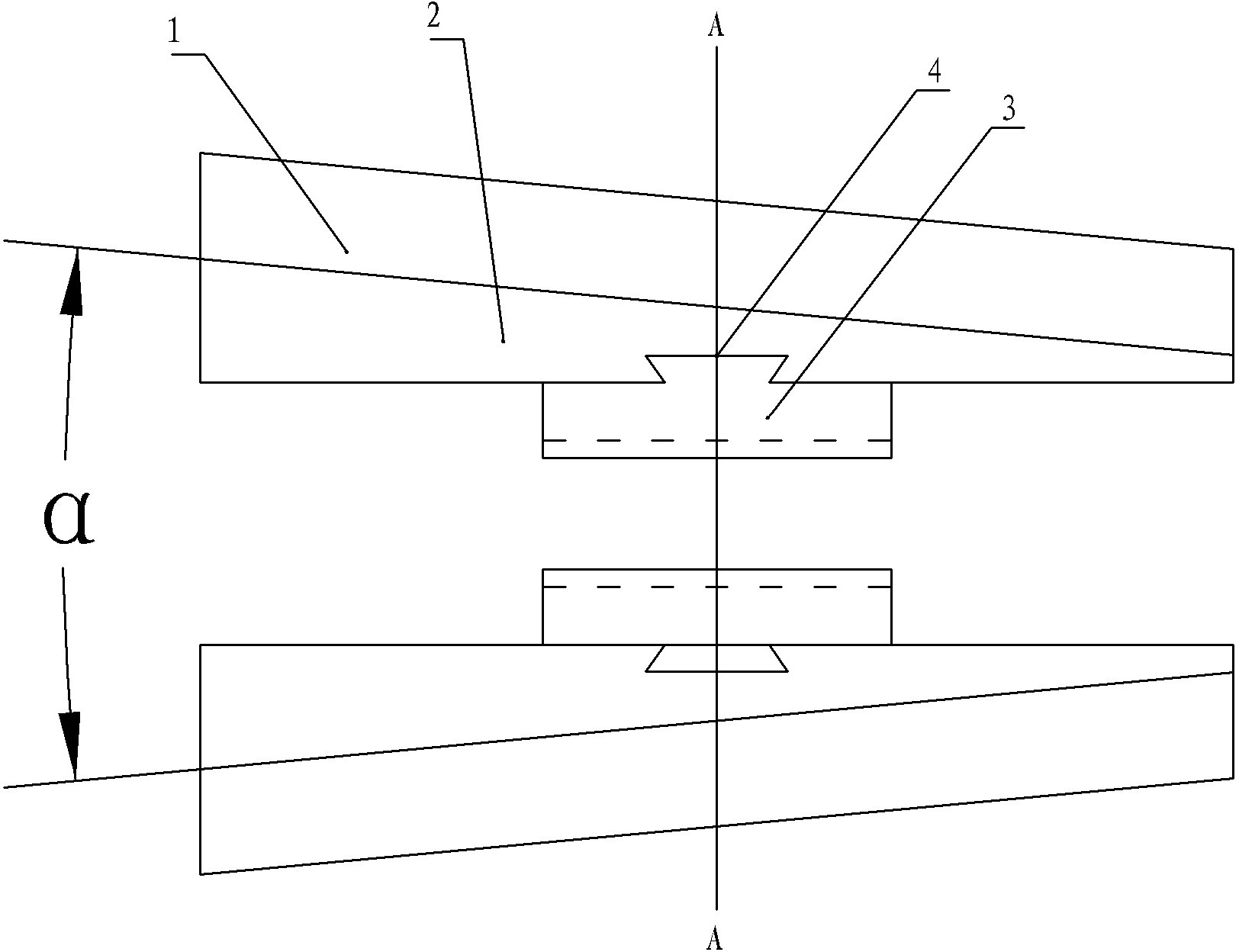

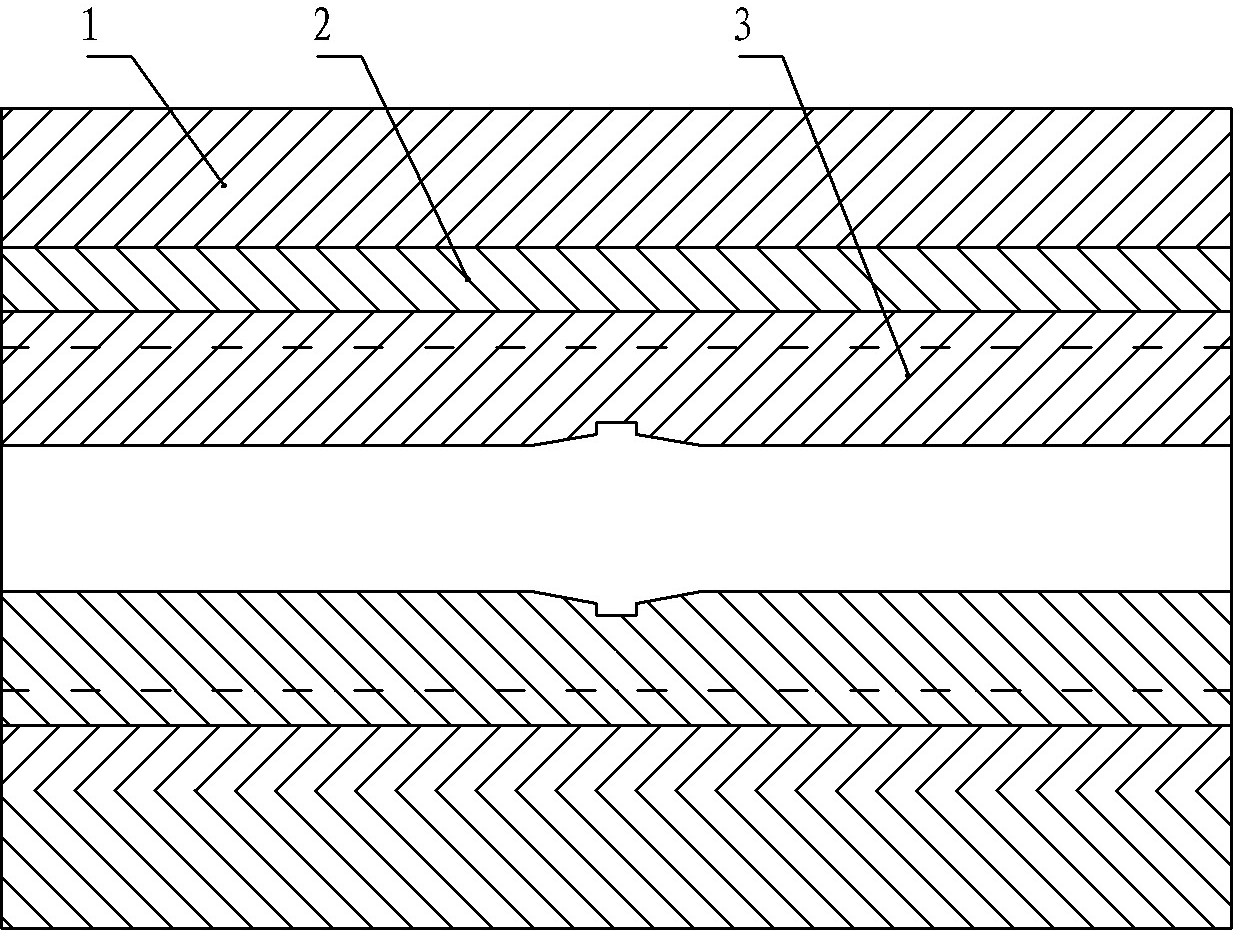

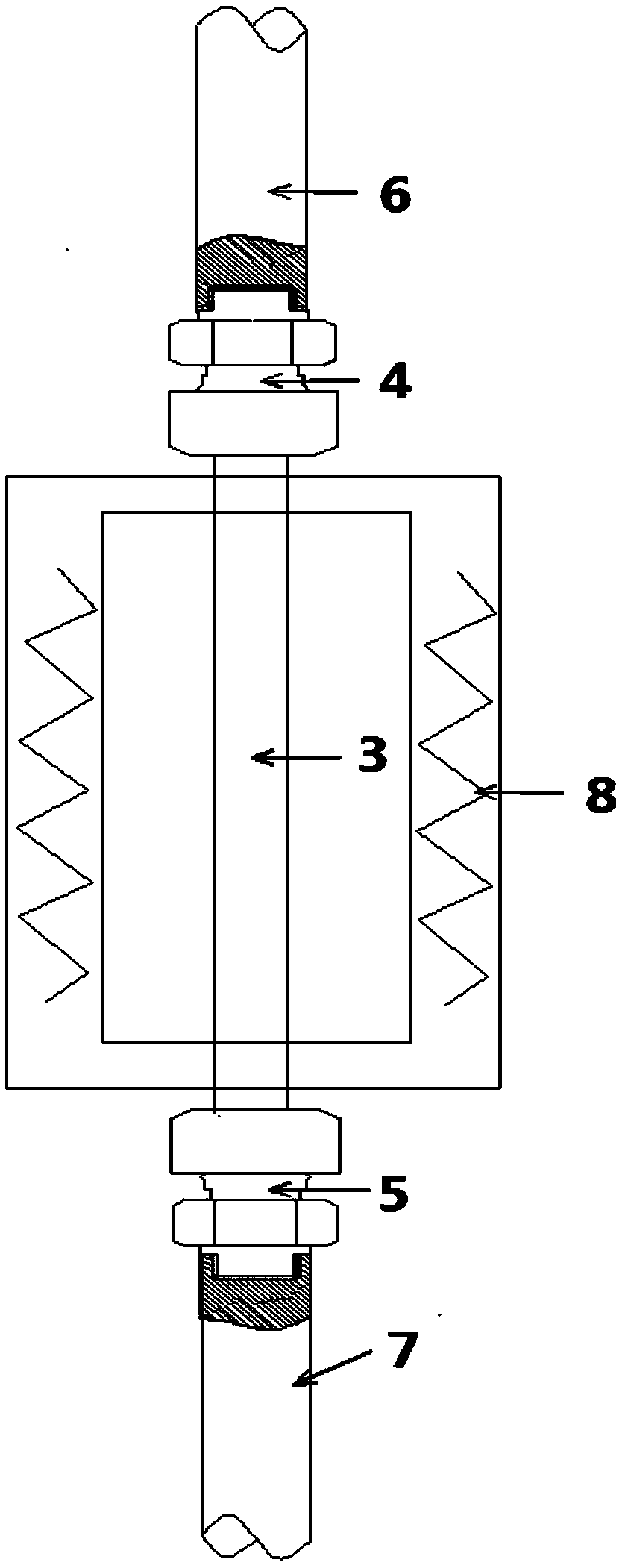

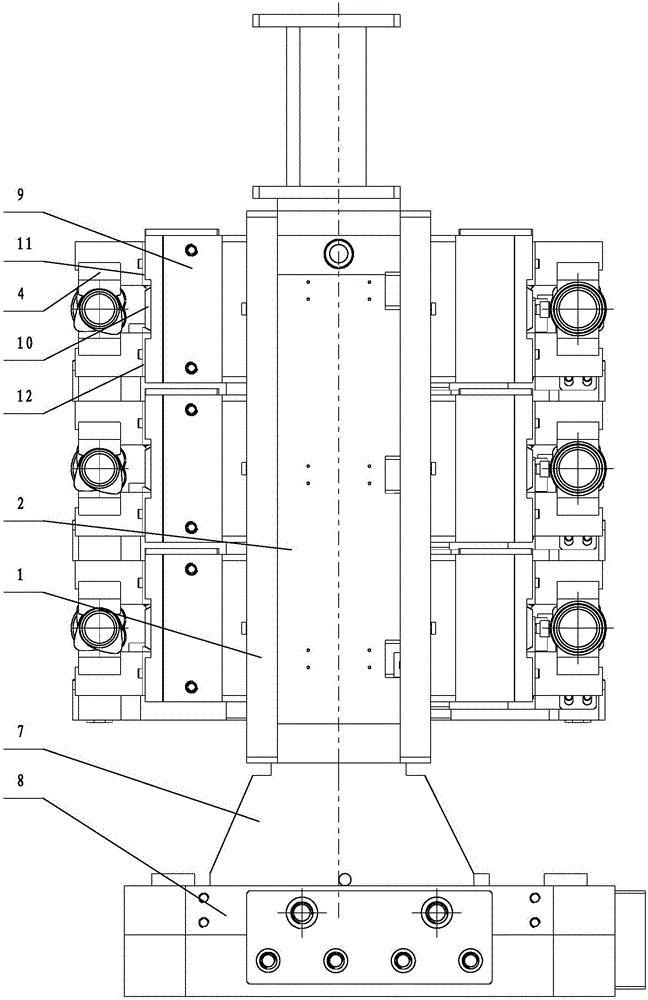

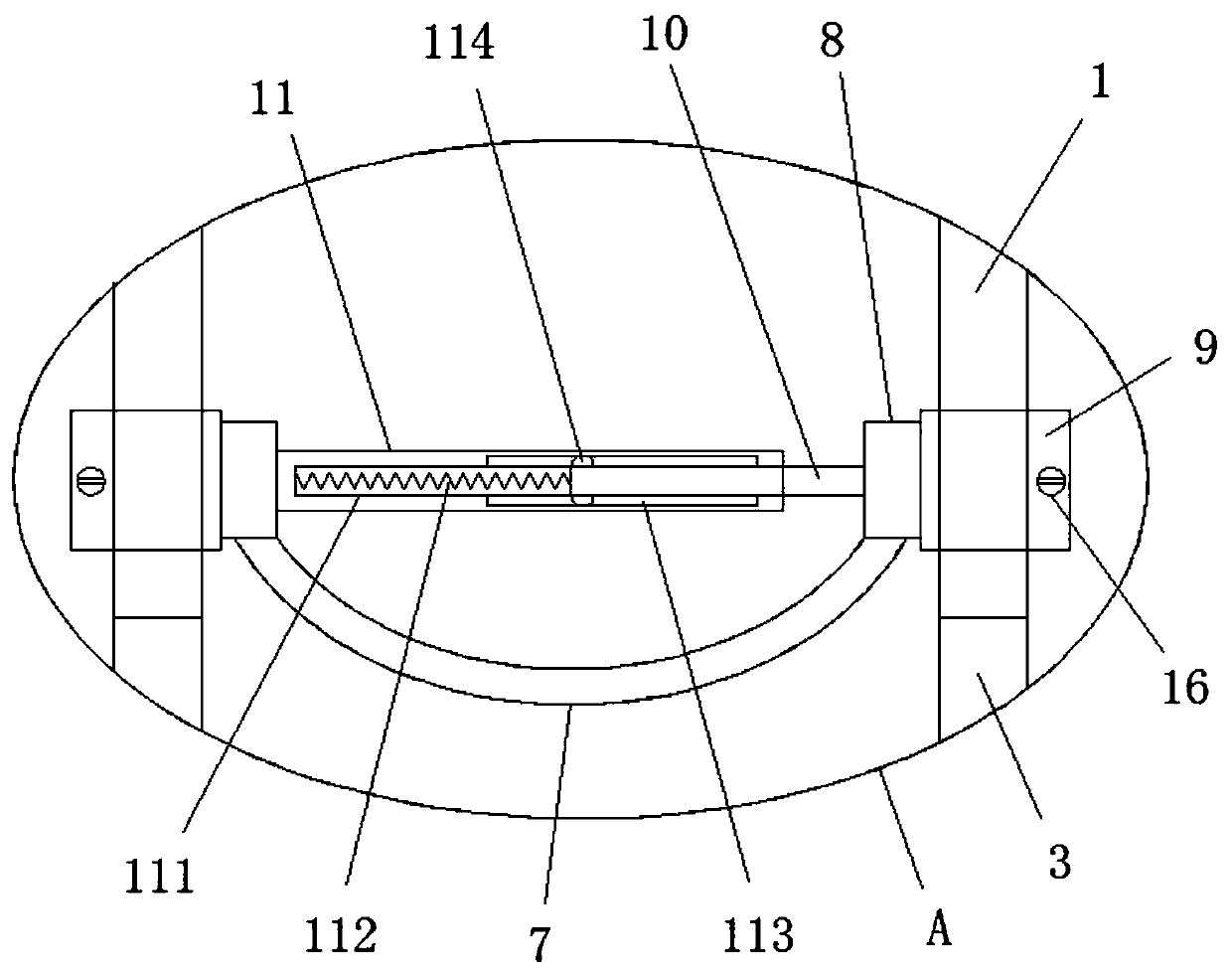

Steel wire rope tensile fixture and horizontal steel wire rope tensile testing machine thereof

ActiveCN102323144ARealize breaking testLarge clamping forceMaterial strength using tensile/compressive forcesEngineeringSlide plate

The invention discloses a steel wire rope tensile fixture and a horizontal steel wire rope tensile testing machine thereof. The steel wire rope tensile fixture comprises frame bodies, wedged sliding plates and friction blocks which are arranged symmetrically, wherein each frame body comprises two vertical plates of which the inner surfaces are arranged by forming an included angle alpha; the inclination angle of each wedged sliding plate is matched with the included angle alpha; the inner surface of each wedge sliding plate is connected with each friction block through a vertical dovetail groove structure; the included angle alpha is more than or equal to 13 degrees and less than or equal to 23 degrees; and the width L of each friction block is 190-340 millimeters. The horizontal steel wire rope tensile testing machine comprises a pressure sensor, a power device, a fixed steel wire rope tensile fixture and a movable steel wire rope tensile fixture, wherein the pressure sensor is arranged horizontally; the fixed steel wire rope tensile fixture comprises an upper fixture; and the power device is connected with the movable steel wire rope tensile fixture through a pull rod. The horizontal steel wire rope tensile testing machine has a simple structure, and is convenient to operate; the horizontal steel wire rope tensile testing machine is only required to be fixed on the ground, and the operation of the entire test process can be completed by one person, so that the labor intensity of detection test can be reduced greatly; and compared with the conventional testing machine, the horizontal steel wire rope tensile testing machine has the advantages of energy-saving test process, safety, environmental friendliness, mobility, low manufacturing cost and low test cost.

Owner:河南省煤科院检测技术有限公司

Clamp head and processing process of clamp head

InactiveCN103072029AImprove wear resistanceExtended service lifePositioning apparatusMetal-working holdersAlloyMachining process

The invention relates to a clamp head, which comprises a clamp head body, wherein the clamp head body is provided with an inner hole in the axial direction. The clamp head is characterized in that the part of the inner hole positioned at the front end of the clamp head body is also fixed and embedded with a hard alloy sleeve pipe, and the hard alloy sleeve pipe is provided with a pipe hole for a workpiece to penetrate in a rotating way. The clamp head has the advantages that the hard alloy sleeve pipe is fixedly arranged in the inner hole of the clamp head, the abrasion of the inner hole of the clamp head in the processing process is reduced, and the abrasion performance of the clamp head is improved; the head part of the clamp head adopts the uniform equant structure, so the head part of the clamp head has a certain elasticity, and tight locking caused by tight workpiece clamping is prevented; and the clamp head adopts the novel processing process, the uniformity of the clamp head material can be ensured, the deformation of the clamp head is reduced, the concentricity and the roughness of the clamp head are improved, in addition, the cost of the whole process flow is low, the realization is easy, and the quality of the clamp head obtained through processing is good, so the workpiece processed through the fixation of the clamp head is enabled to have higher precision and better quality.

Owner:ZHEJIANG BUSINESS TECH INST

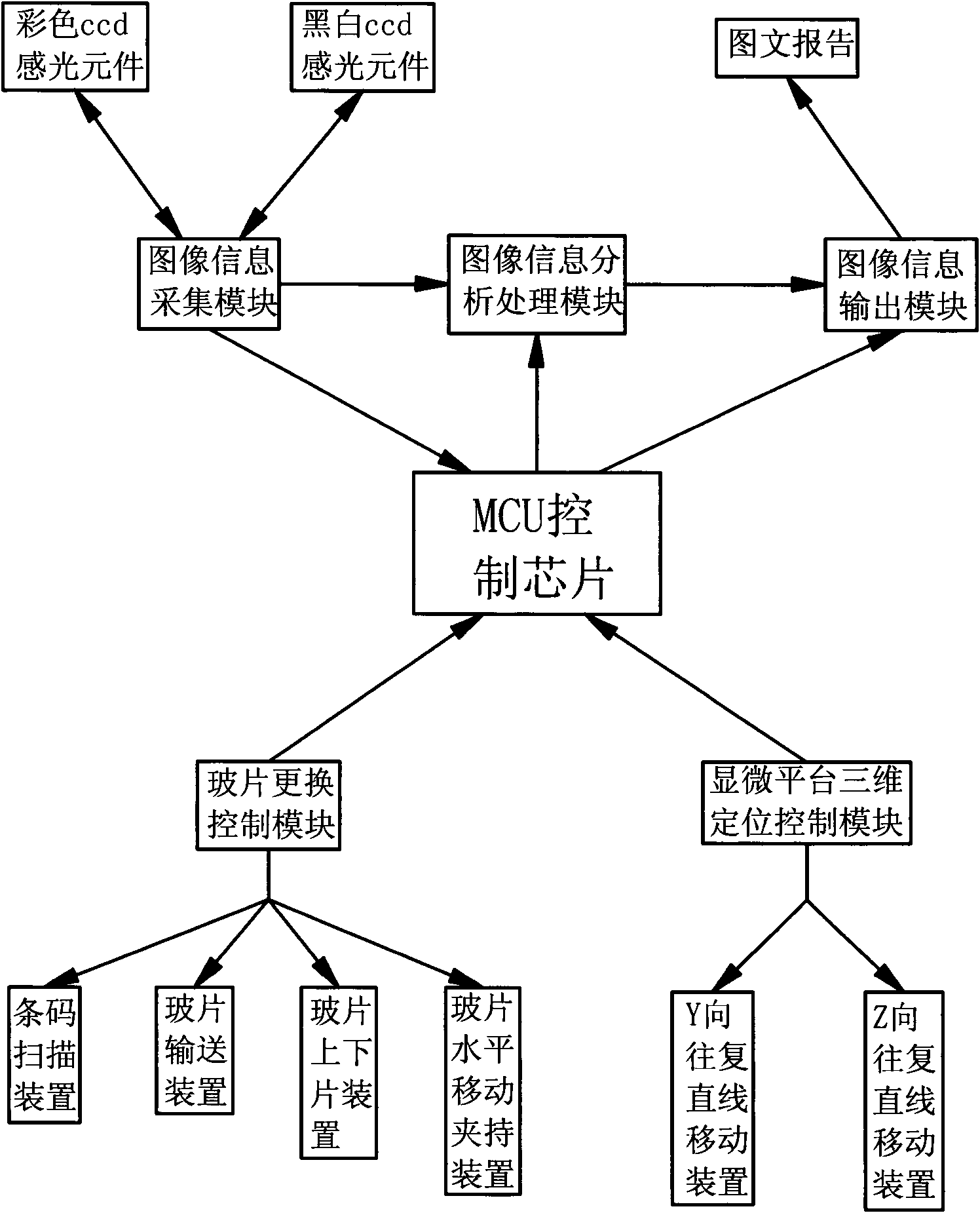

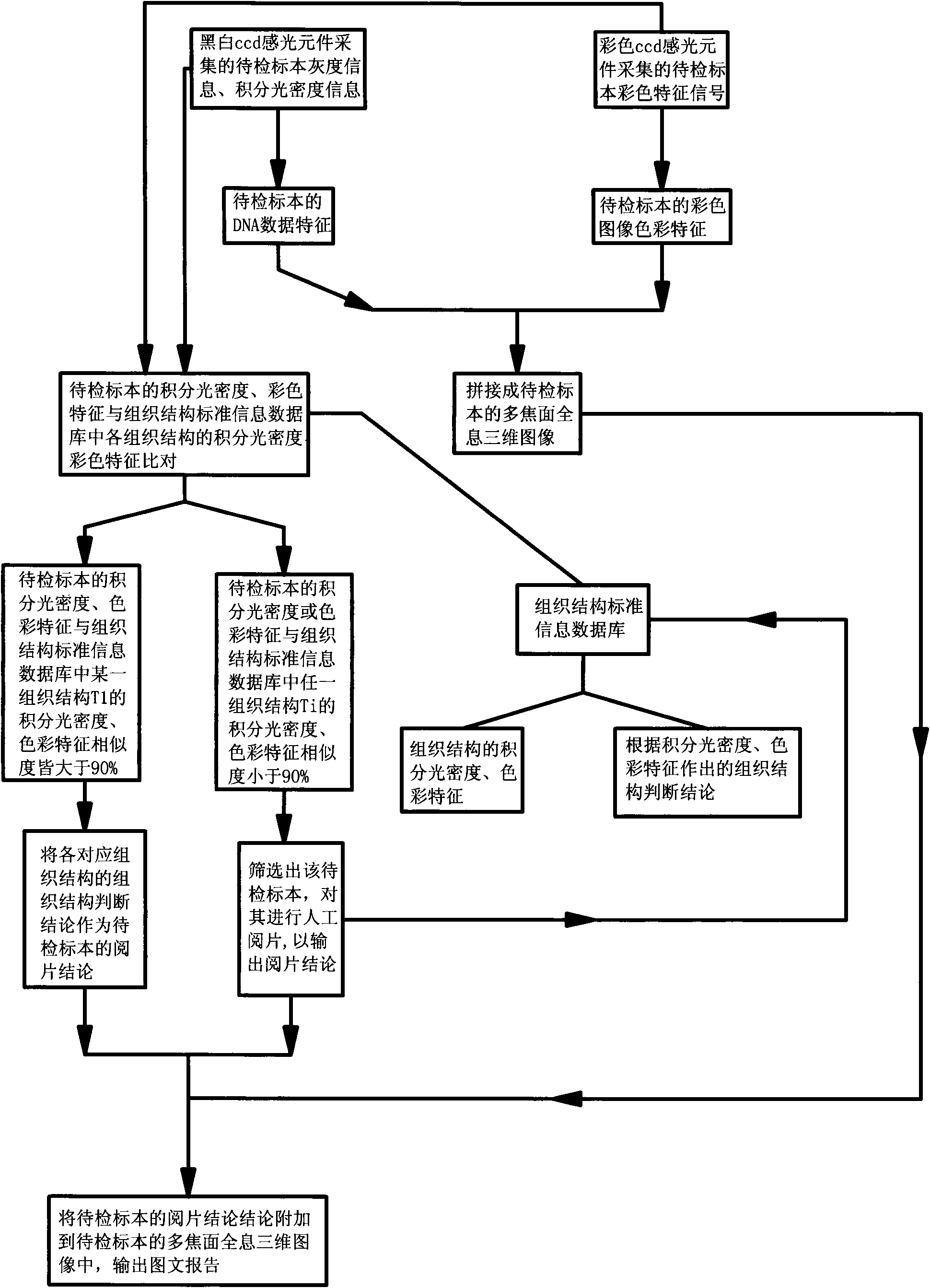

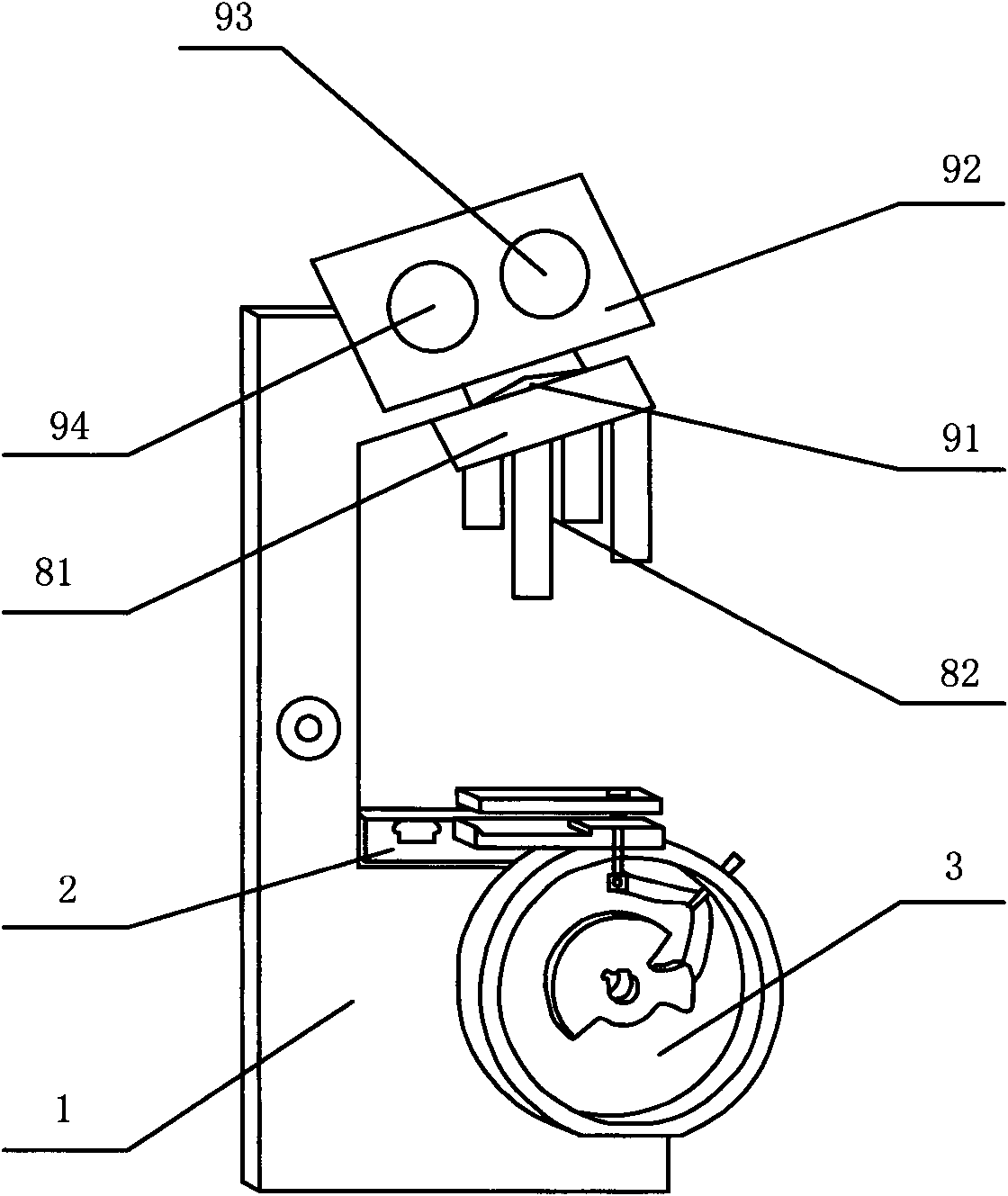

Full-automatic double-ccd photosensitive element digital microscope

ActiveCN102122066ATo achieve the purpose of intelligent screeningGuaranteed effectMicroscopesDigital imageOptical density

The invention discloses a full-automatic double-ccd (charge-coupled device) photosensitive element digital microscope, which is used for acquiring specimen image information by synchronously using a colored ccd photosensitive element and a black-and-white ccd photosensitive element so as to obtain a multifocal plane holographic three-dimensional image, synchronously outputting a specimen reading result according to nucleus integral optical density acquired by the black-and-white ccd photosensitive element, and finally outputting a specimen picture and text report. Additionally, the full-automatic double-ccd photosensitive element digital microscope comprises a slide uploading and unloading device and a horizontal migration clamping device for automatically changing the specimen slide, and then, the slide is located in three dimensions through a three-dimensional frame, so that the colored ccd photosensitive element and the black-and-white ccd photosensitive element can conveniently acquire the image information of the specimen. Thus, the full-automatic double-ccd photosensitive element digital microscope can be used for not only performing morphological observation on the specimen, but also taking digital images for a dyed tissue section so as to form the multi-focal plane holographic three-dimensional image, so that all the information of the cell can be observed in multiple layers and multiple focal planes, and accuracy of early diagnosis is greatly improved.

Owner:湖南港湾科学仪器有限公司

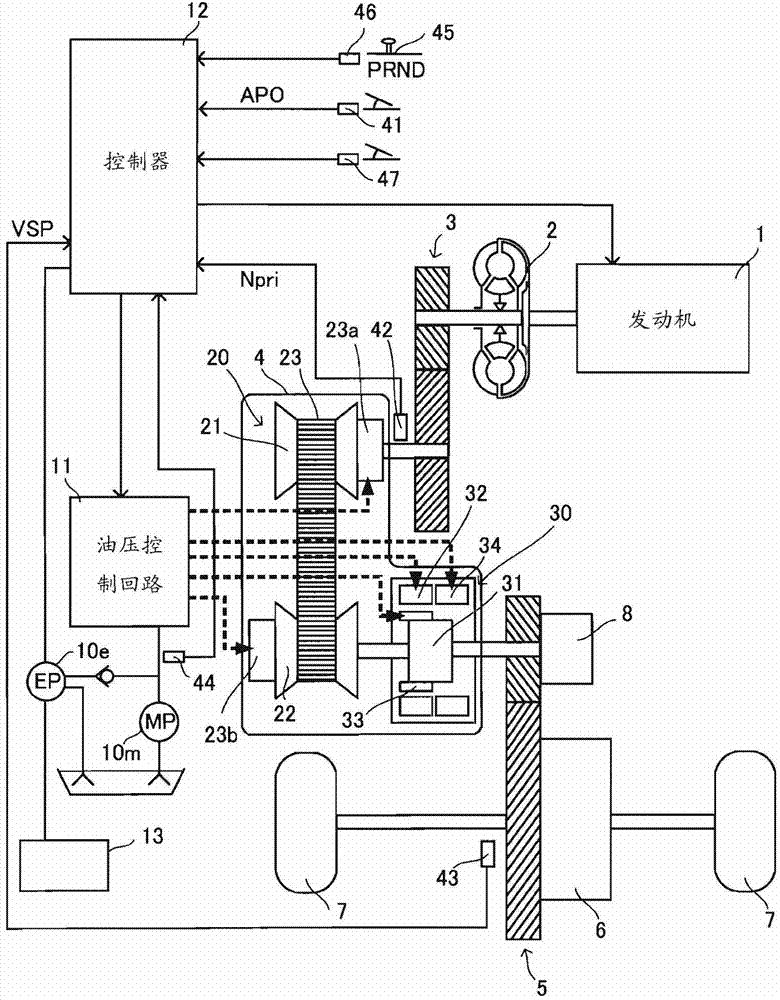

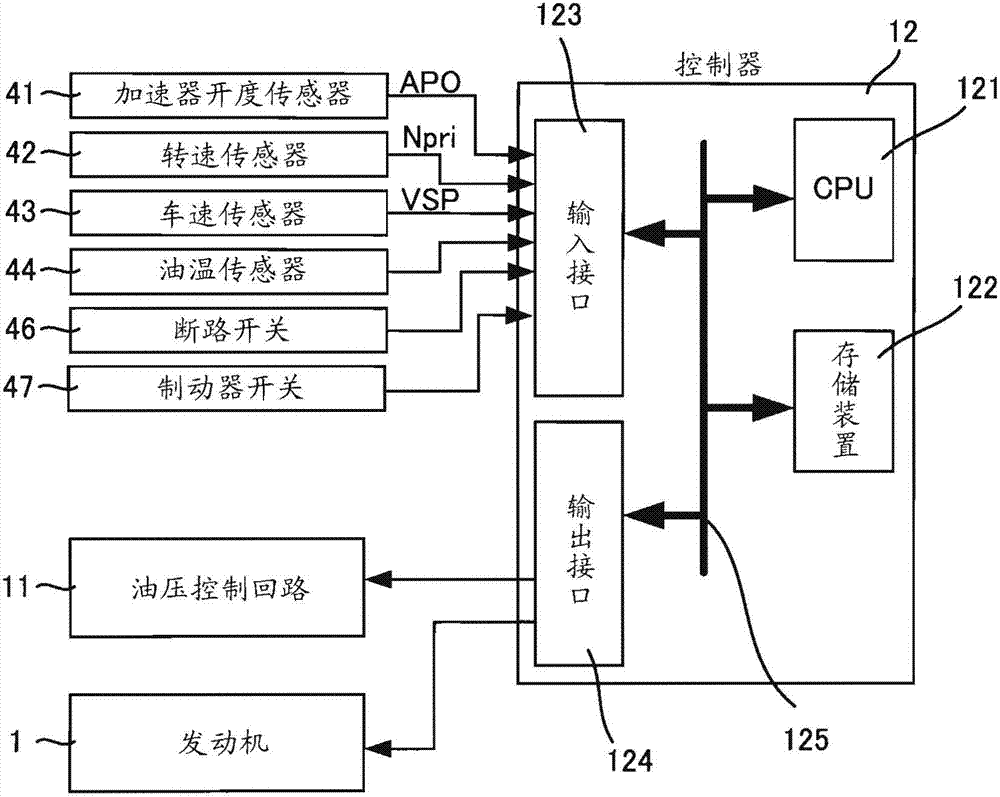

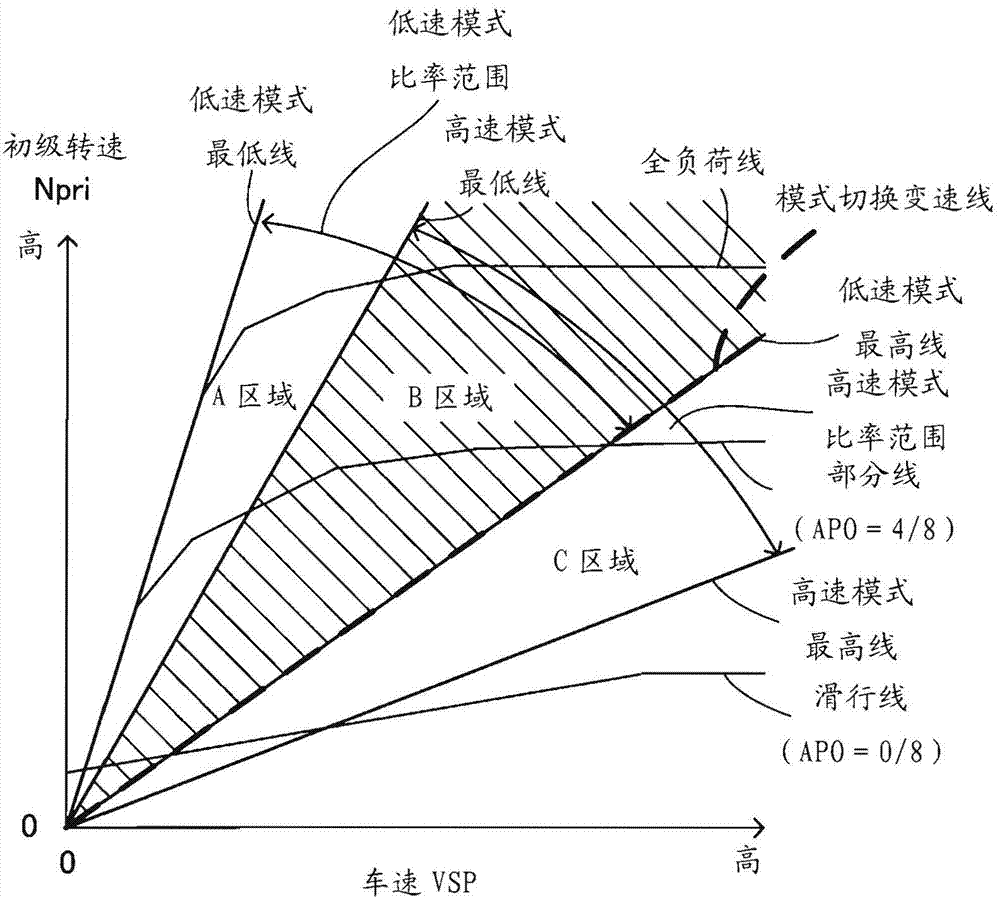

Control device for continuously variable transmission

InactiveCN103363102AGuaranteed gripping forcePrevent slidingGearingRoad transportHydraulic circuitHydraulic pump

The present invention is provided with a hydraulic control circuit including a hydraulic pump driven by a driving power source in order to supply an oil pressure to a hydraulic circuit, a hydraulic auxiliary unit for supplying an accumulated oil pressure to the hydraulic circuit, and a control valve for supplying at least one of oil pressures of the hydraulic pump and the hydraulic auxiliary unit to pulleys, and a control unit for executing a coast stop control to stop the driving power source while traveling and controlling, when an increase of torque inputted to the continuously variable transmission is detected or predicted during the coast stop control, the control valve so as to supply an oil pressure of the hydraulic auxiliary unit to the pulleys.

Owner:JATCO LTD

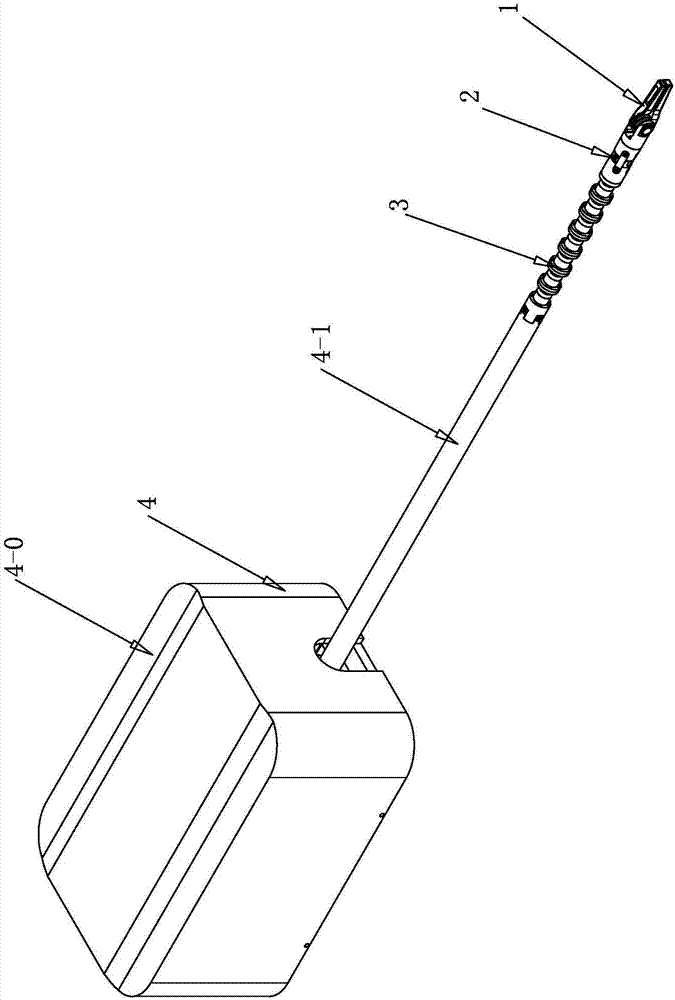

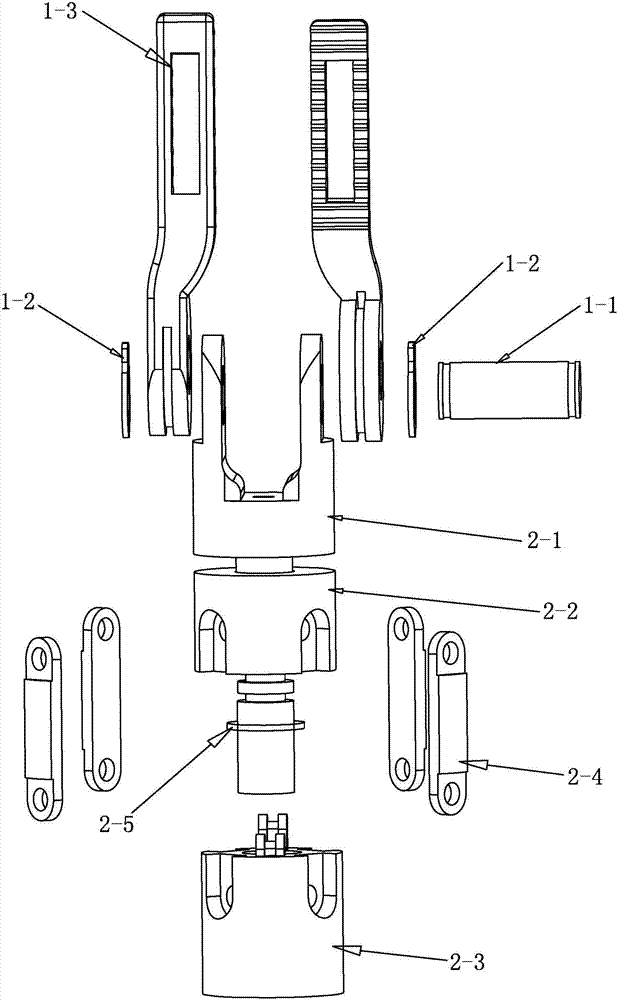

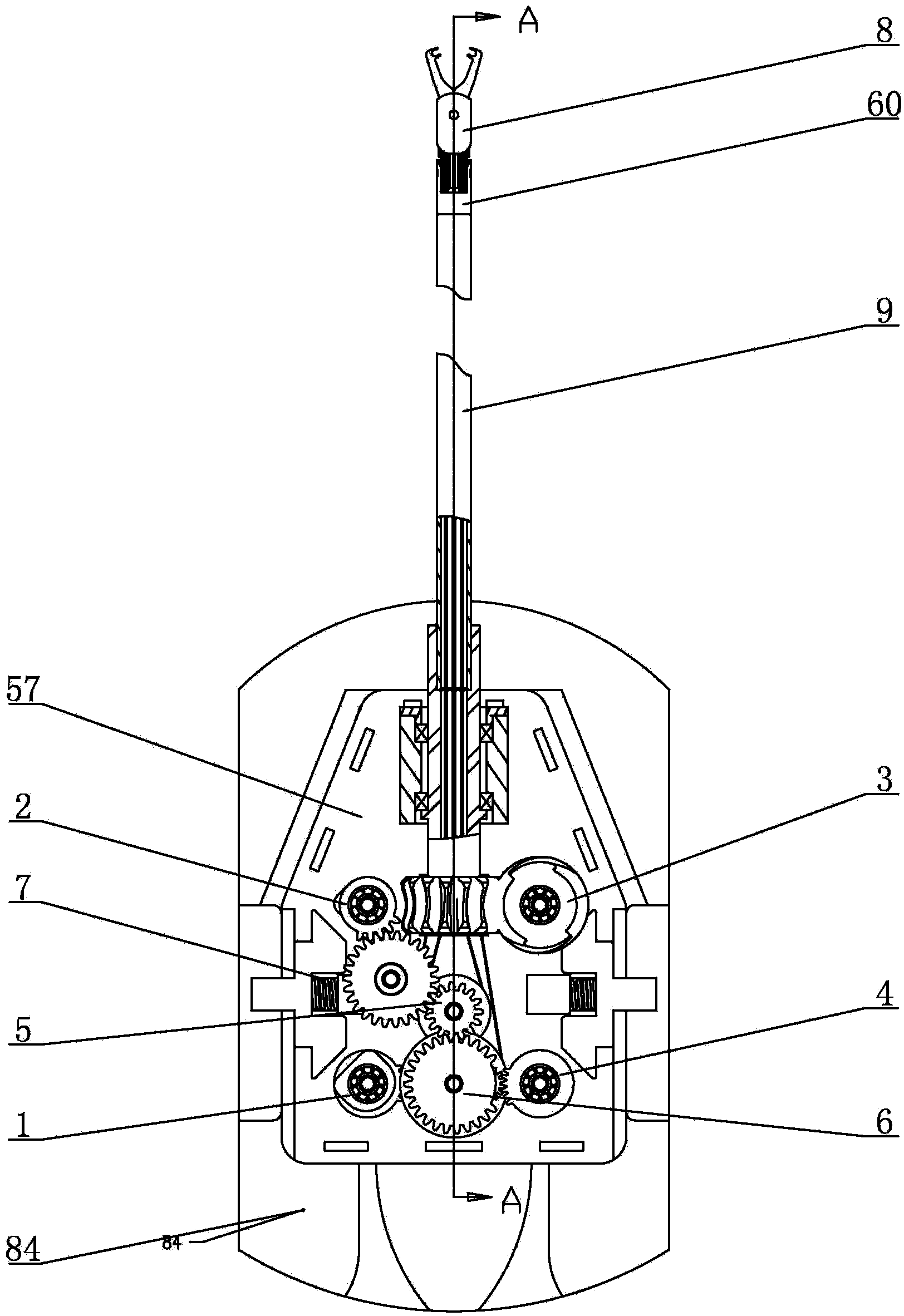

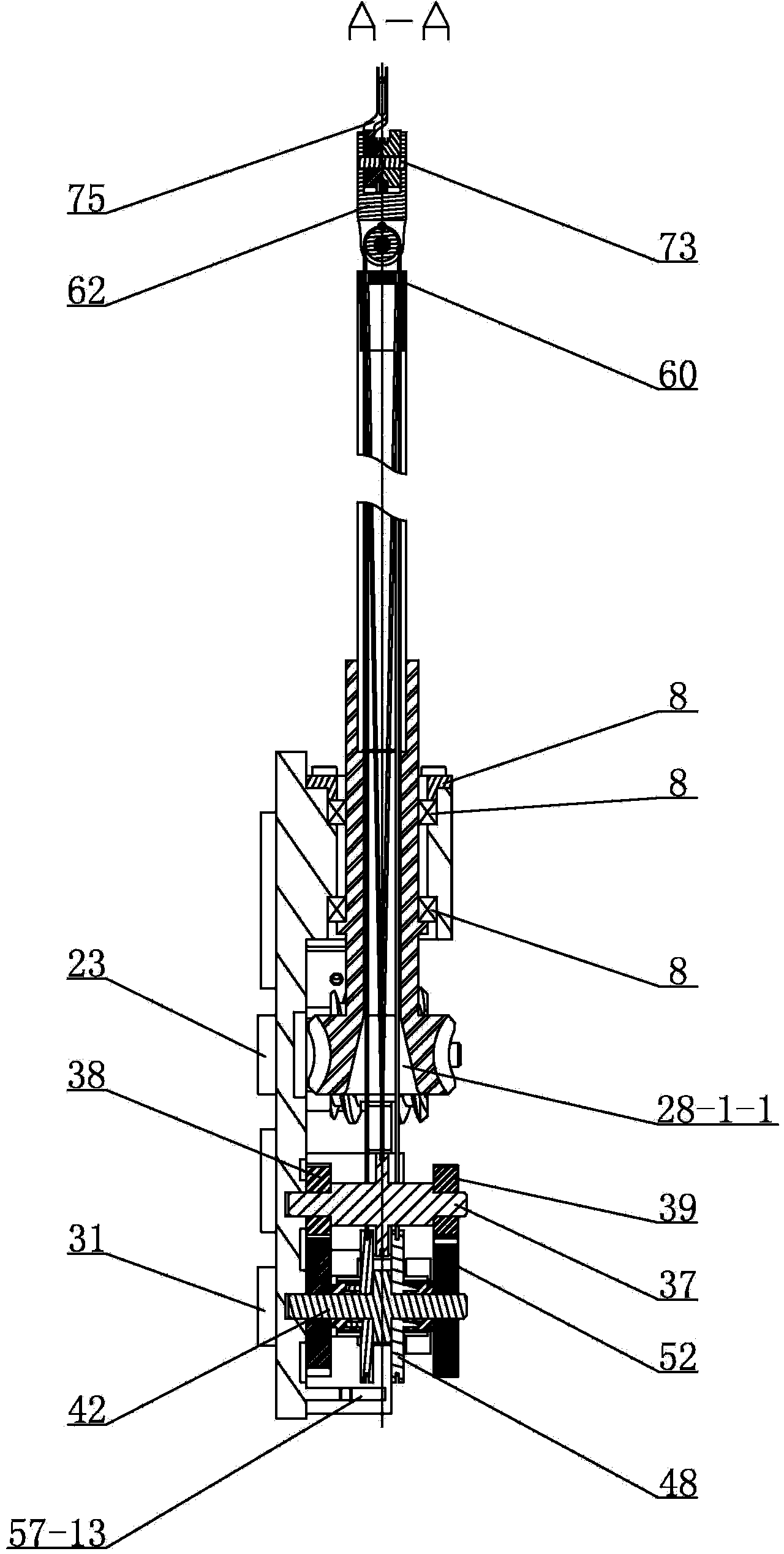

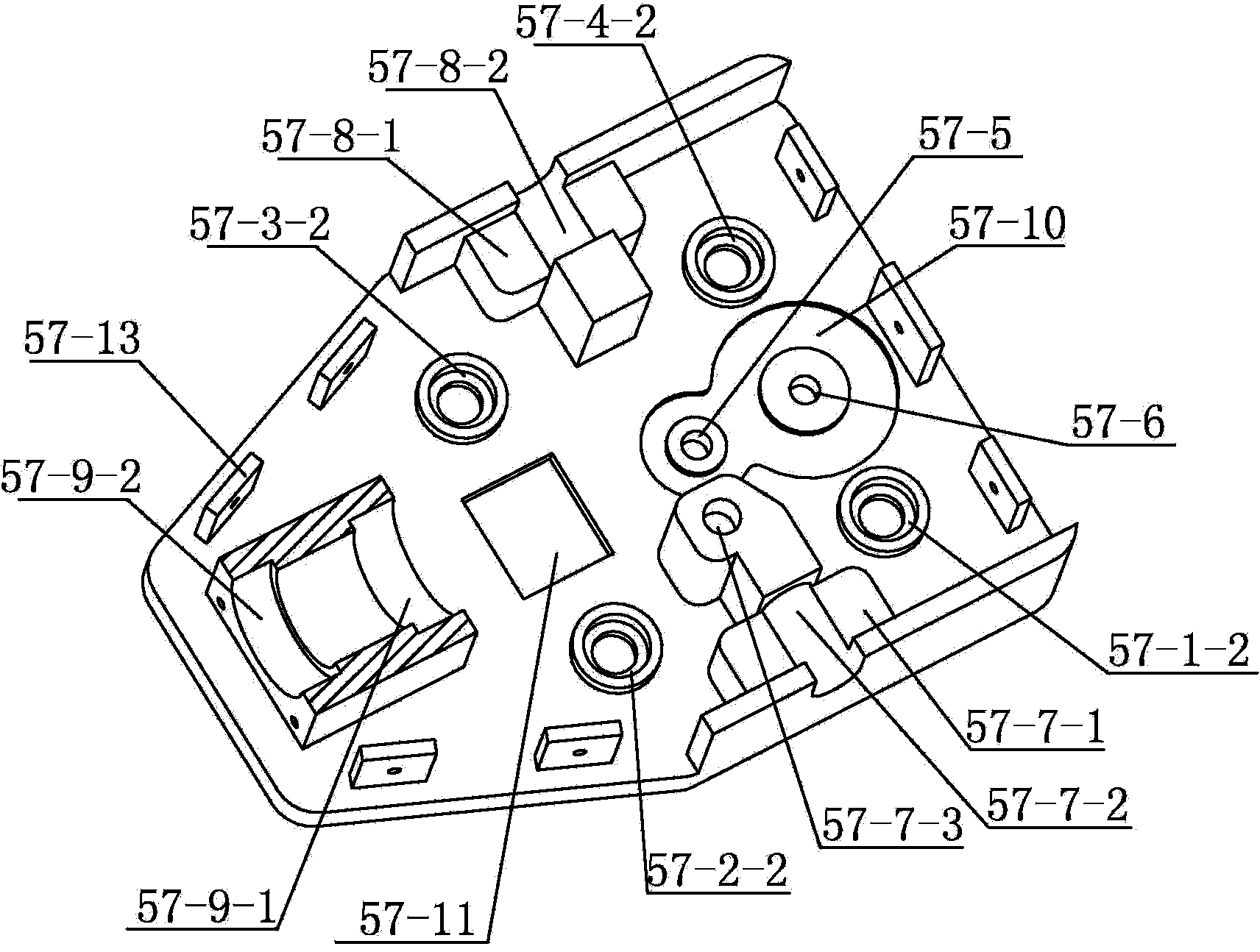

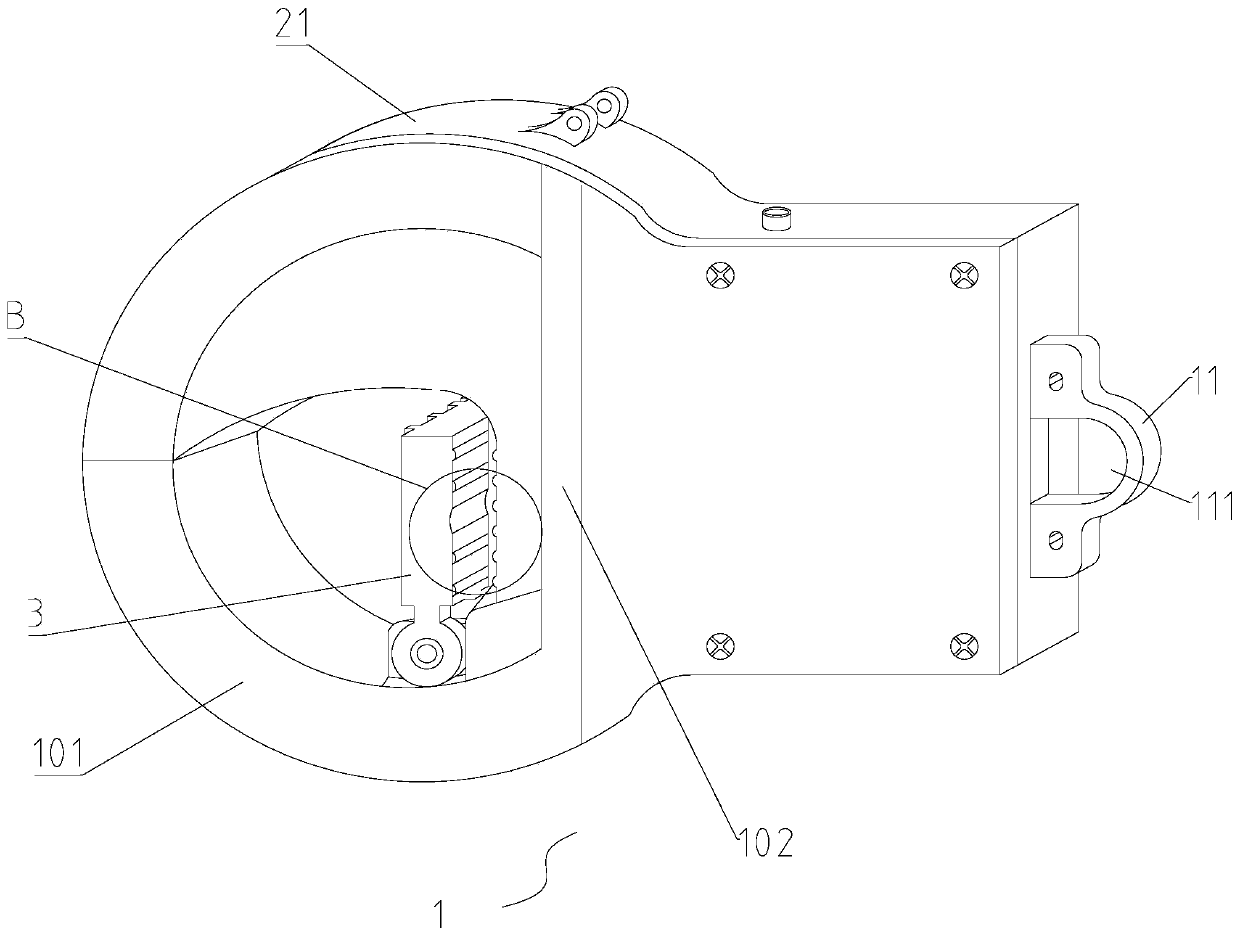

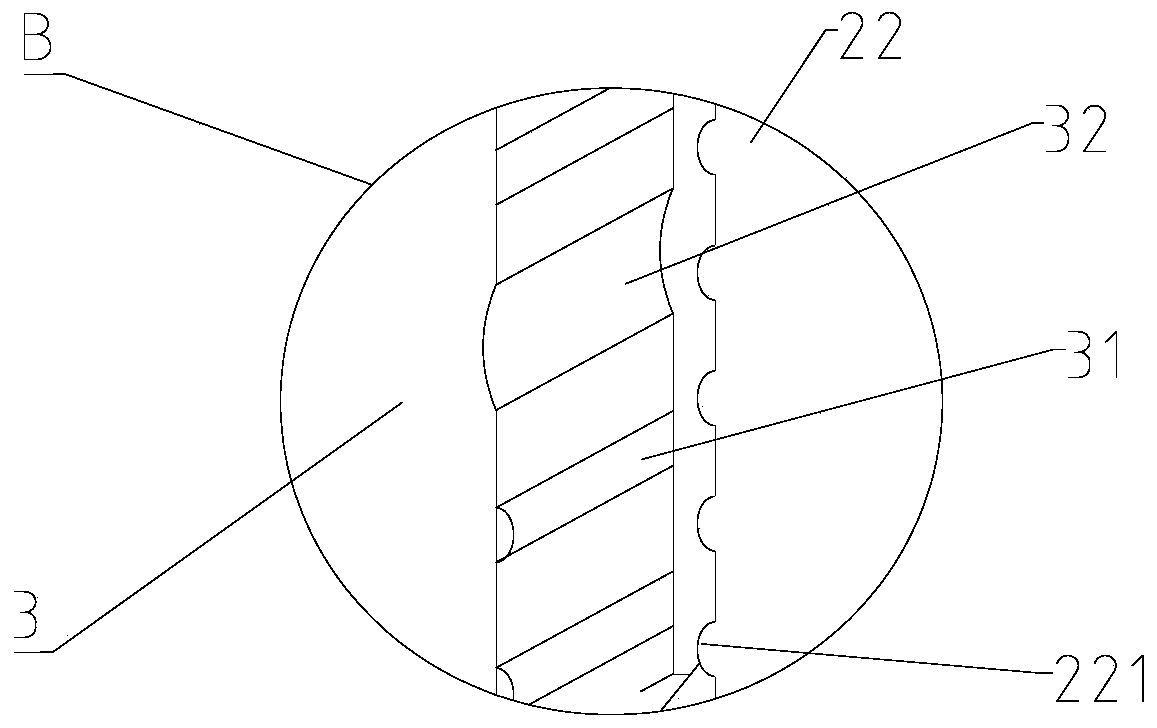

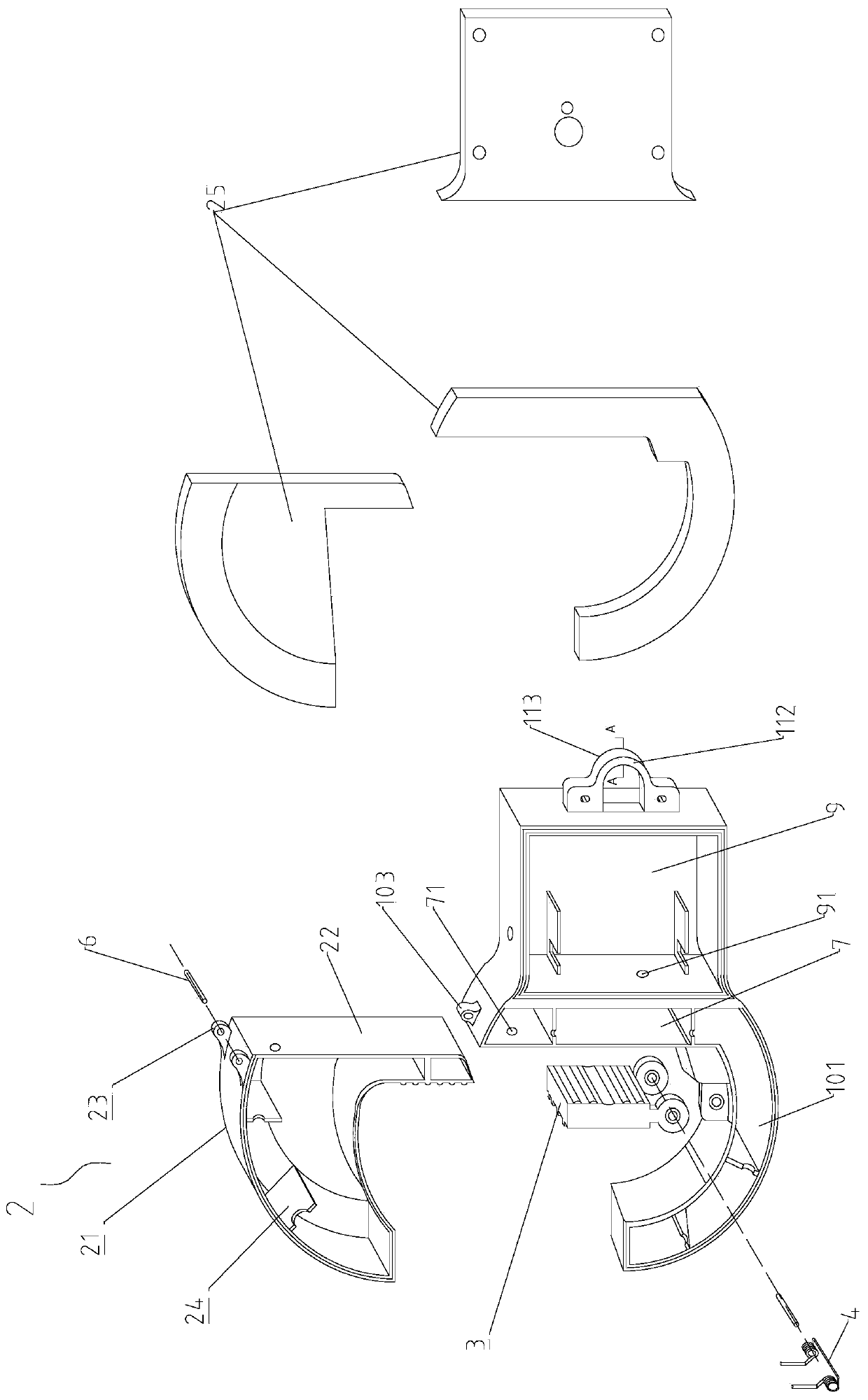

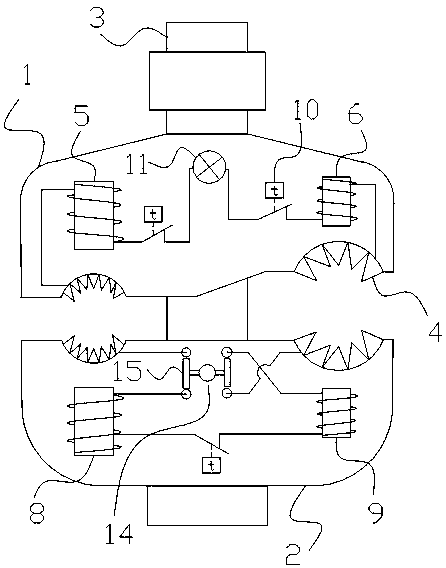

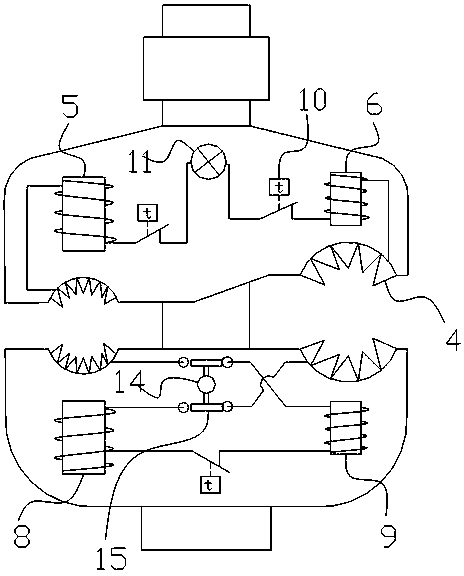

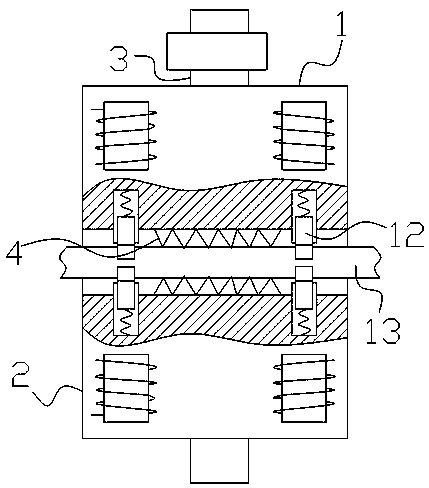

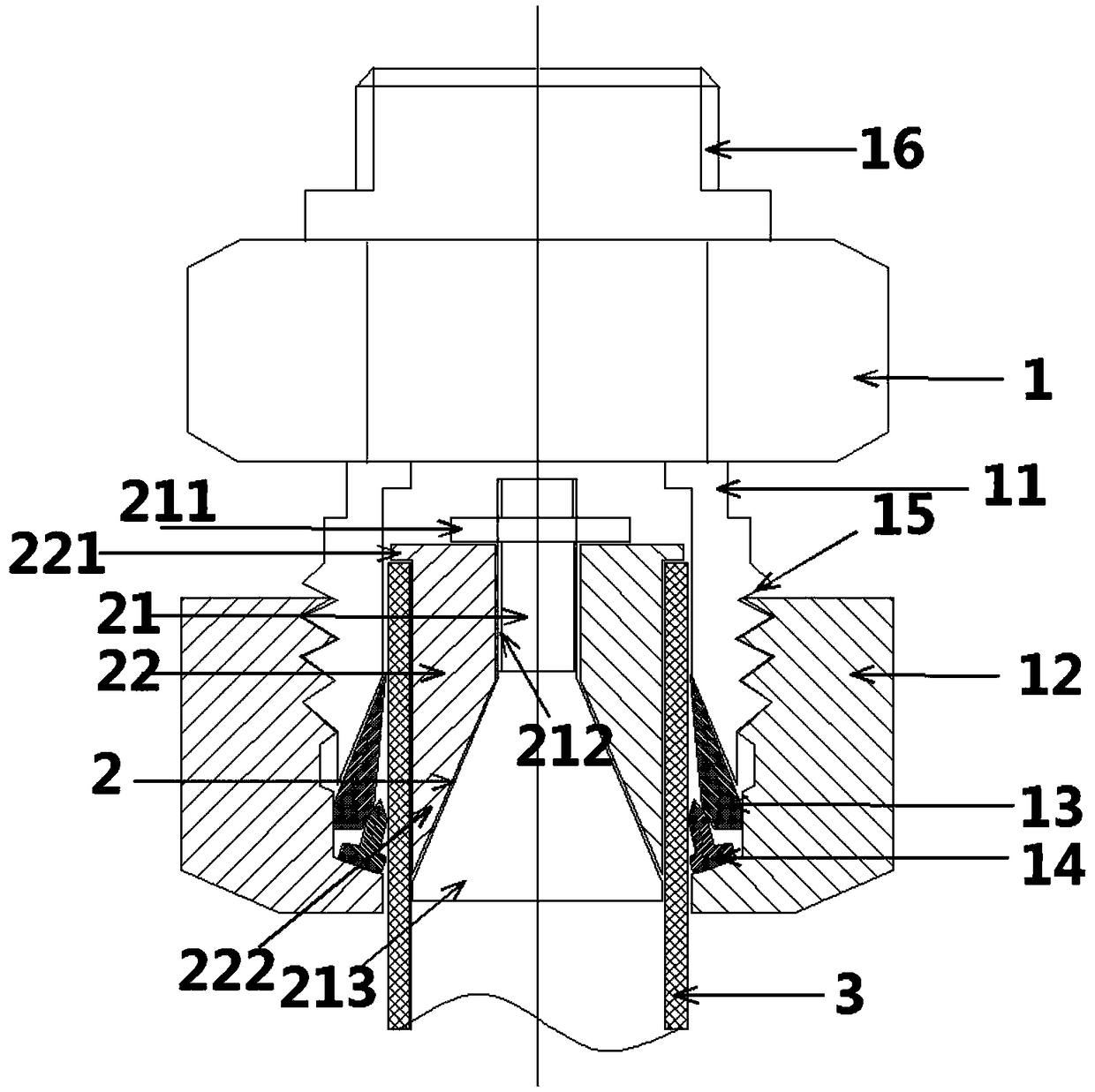

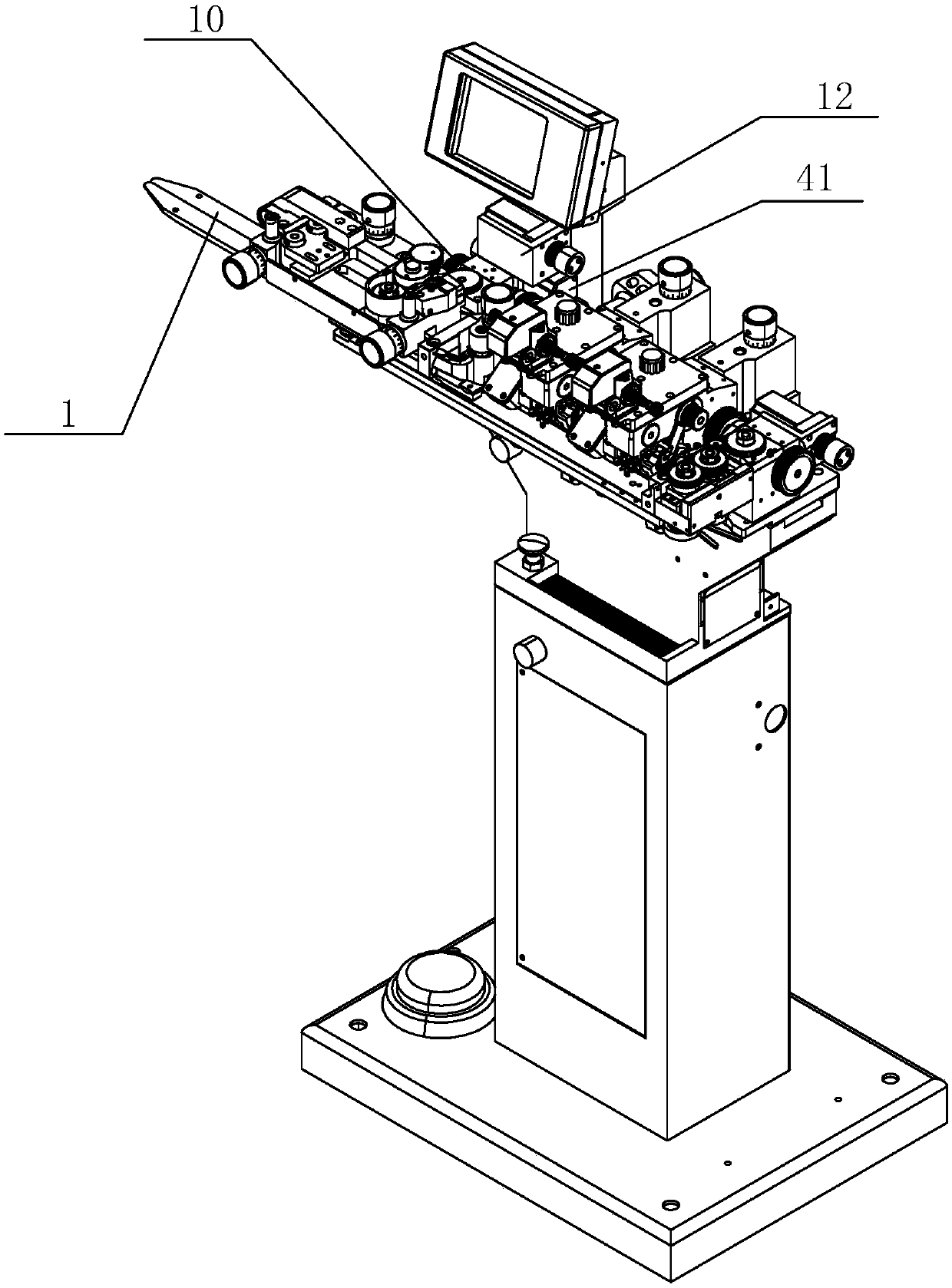

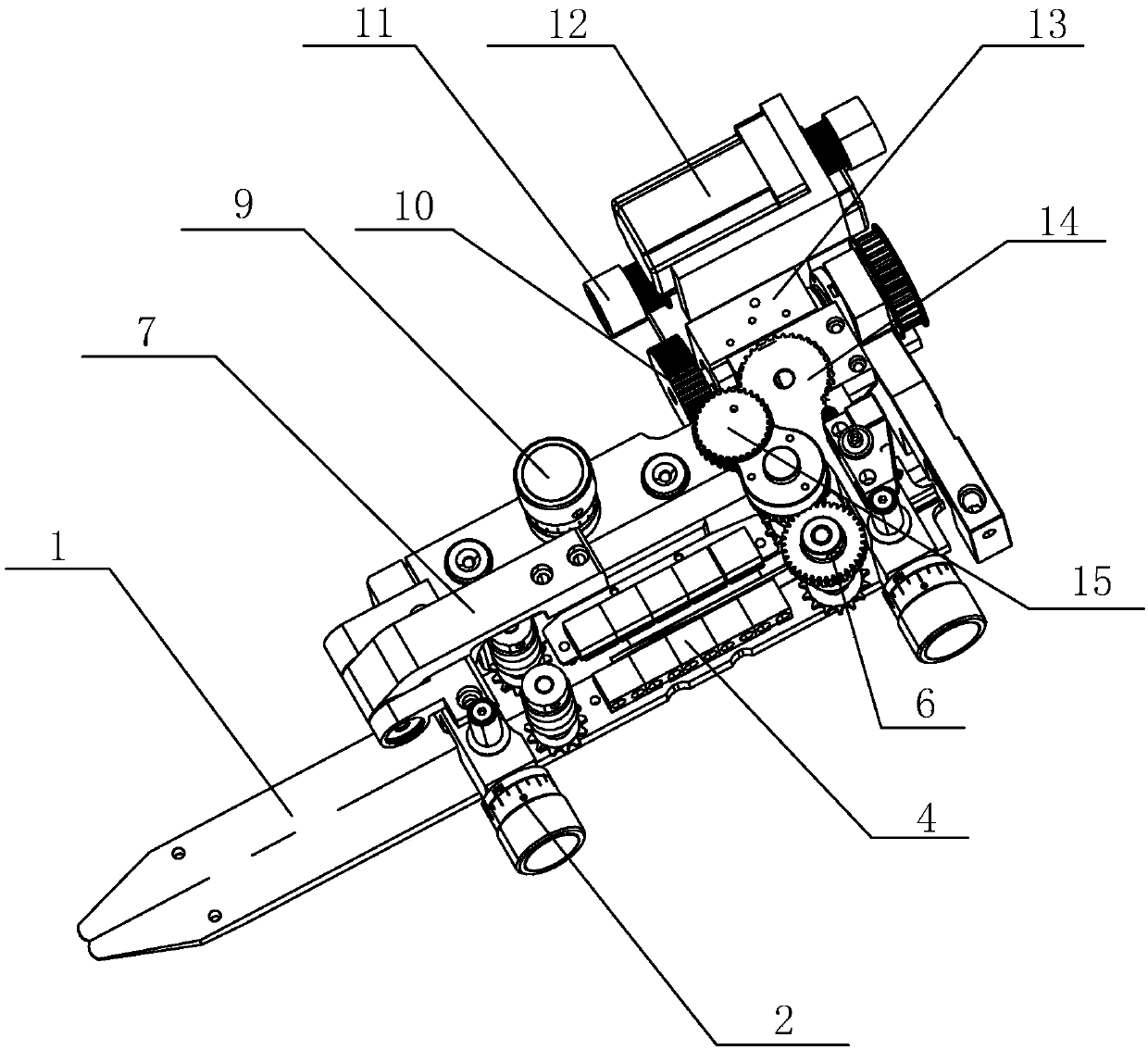

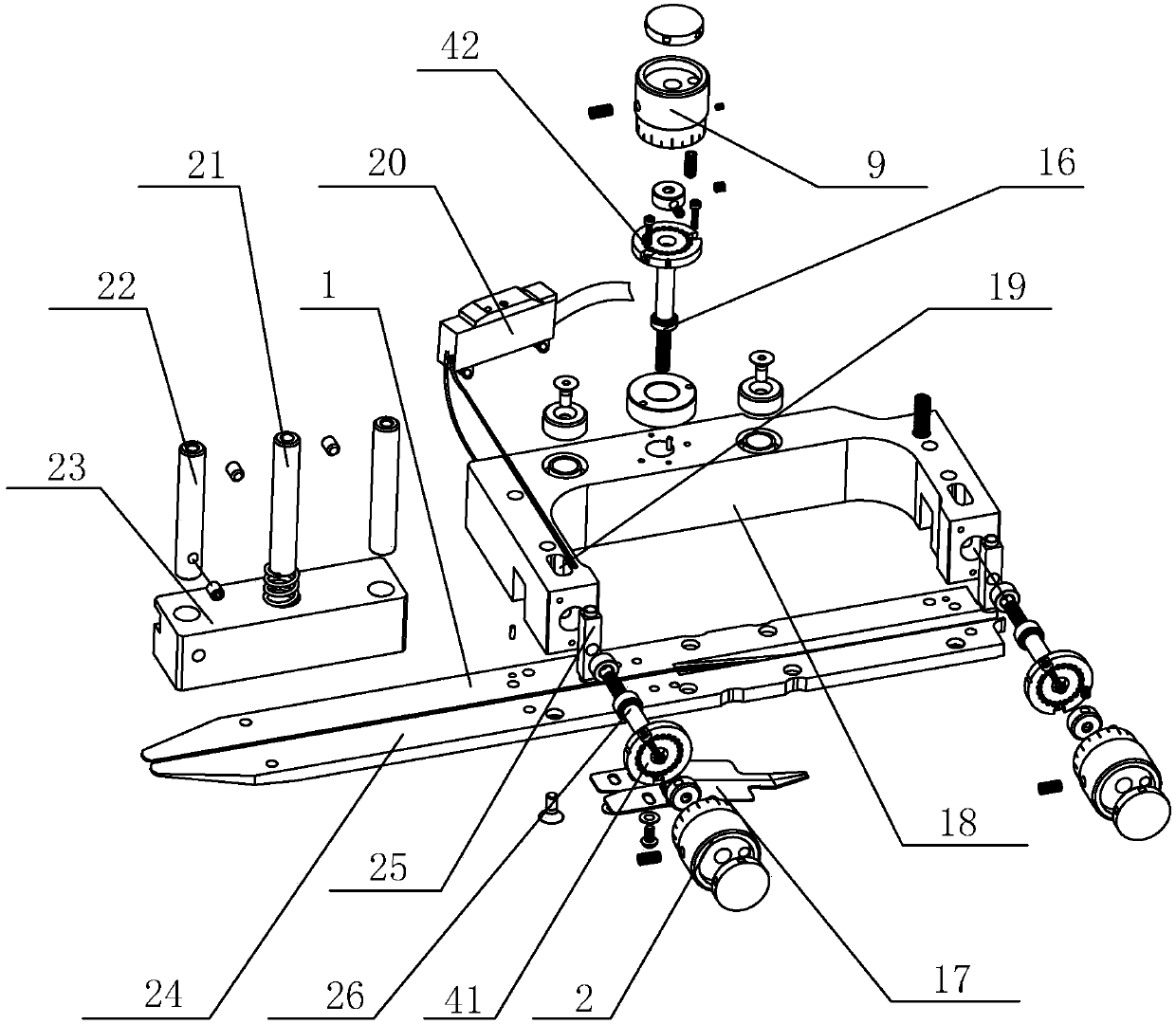

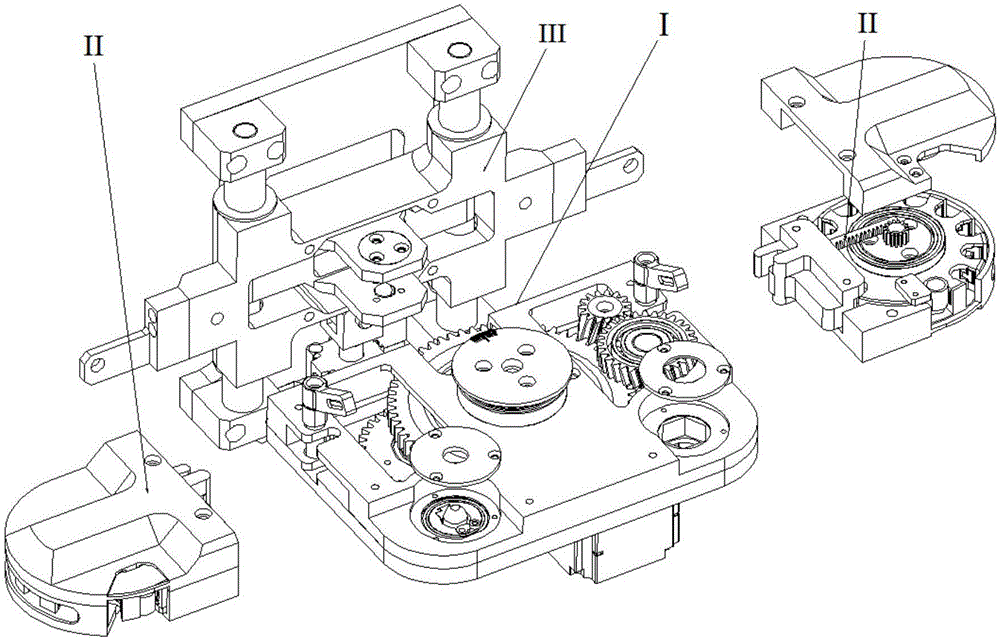

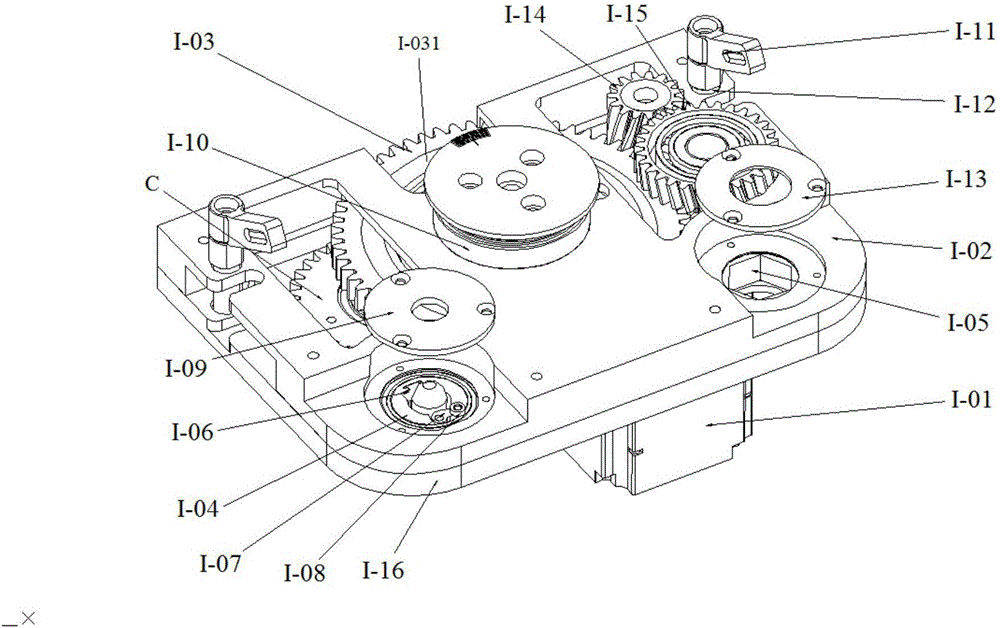

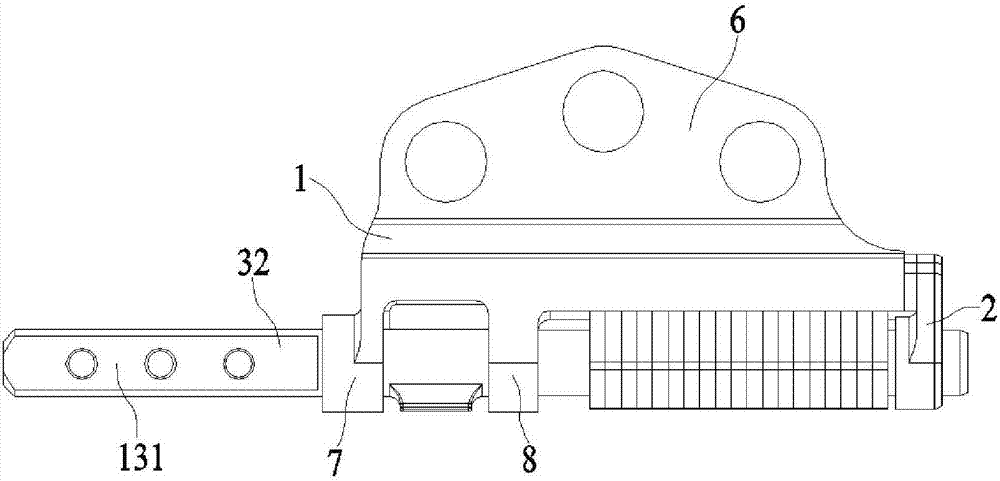

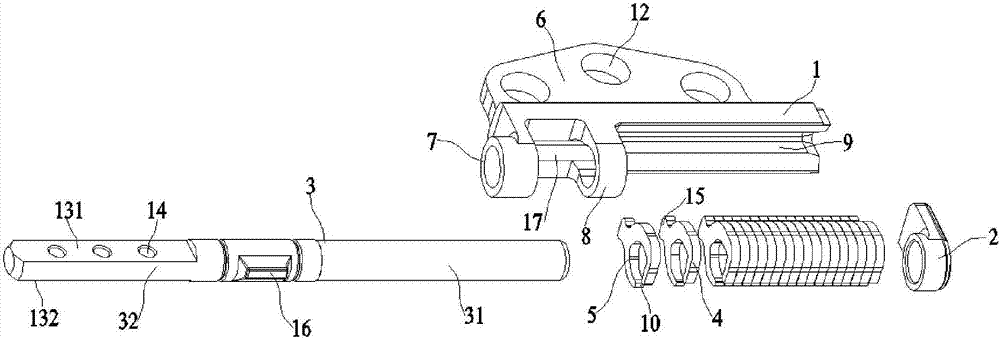

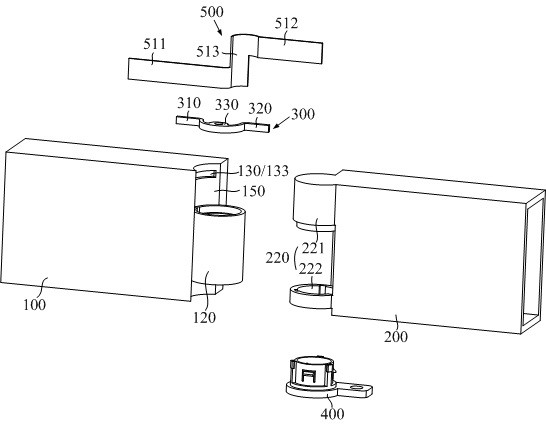

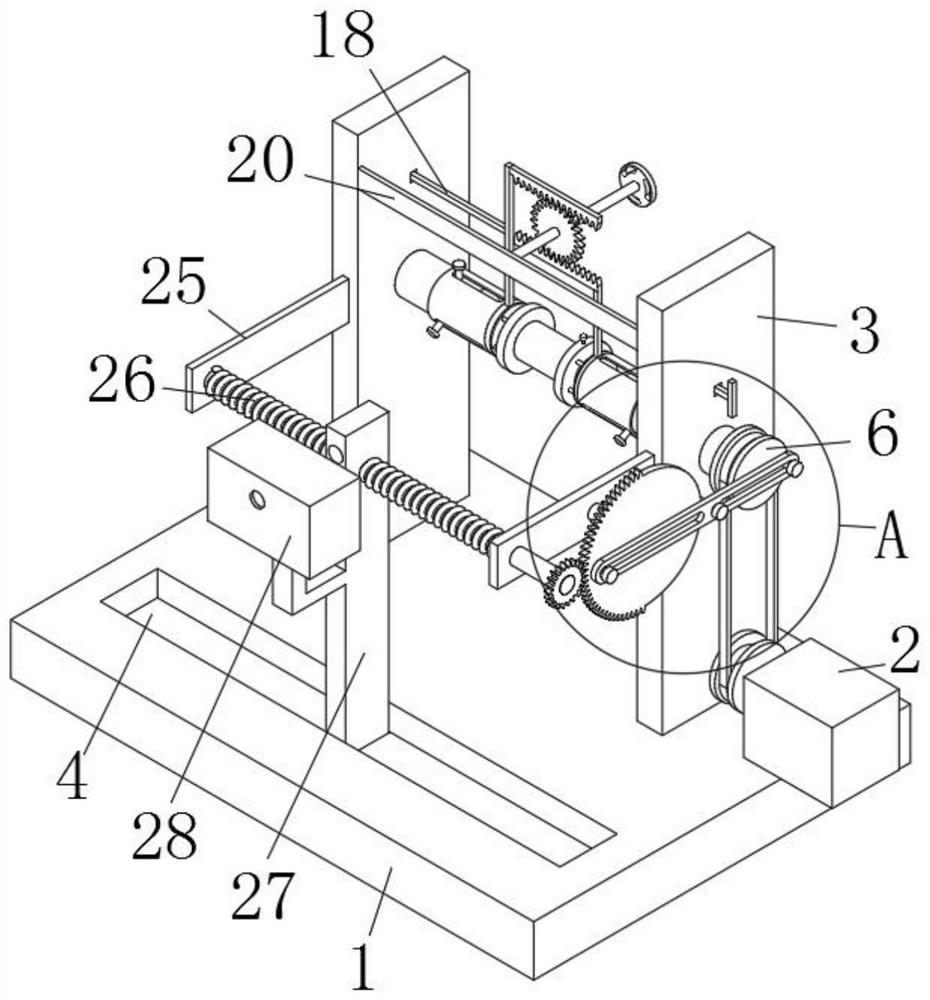

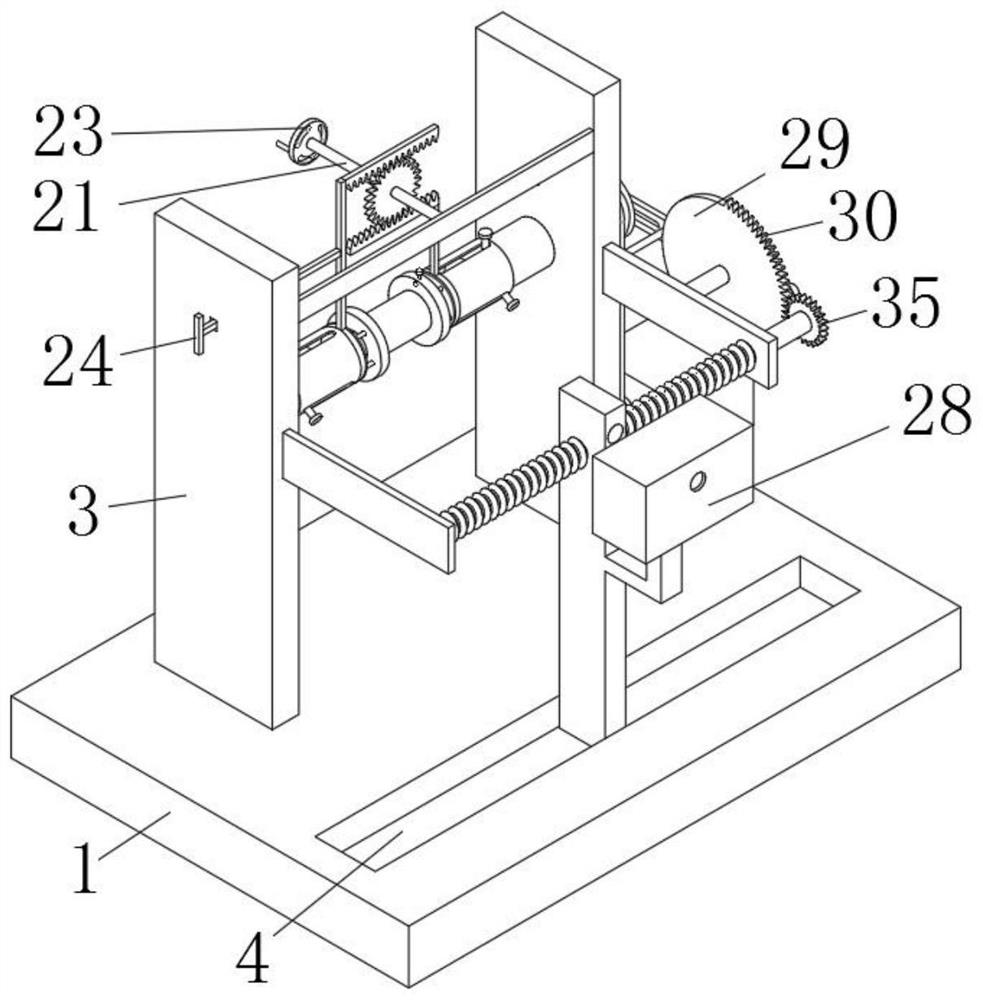

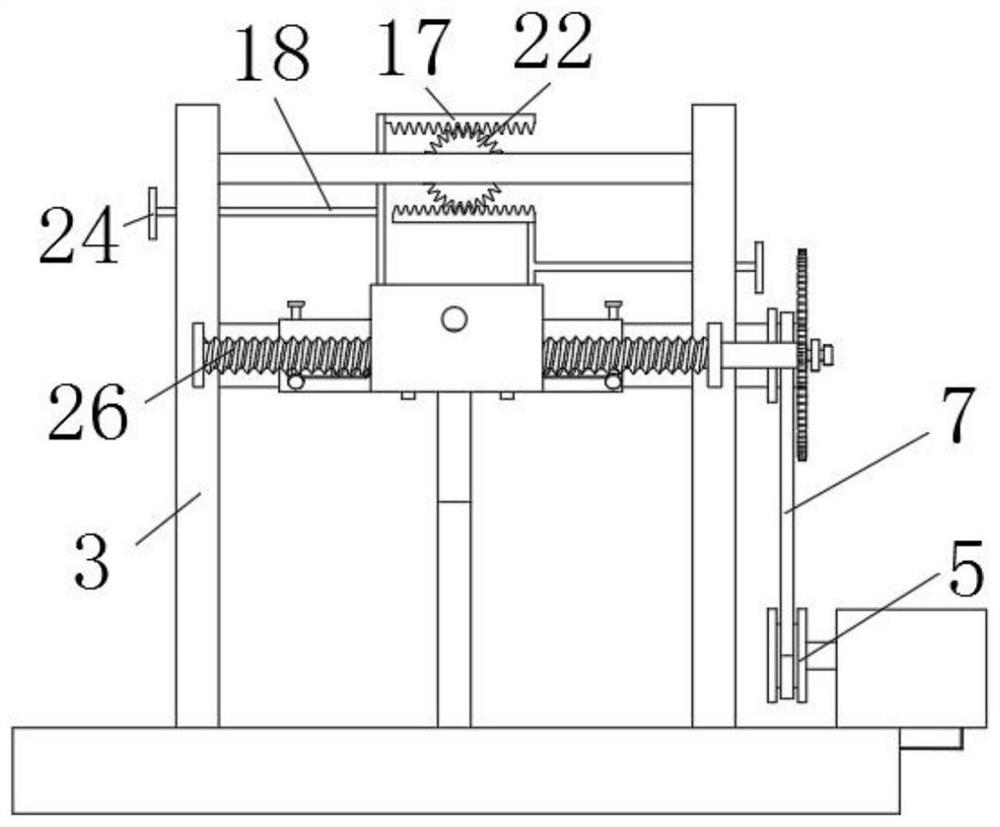

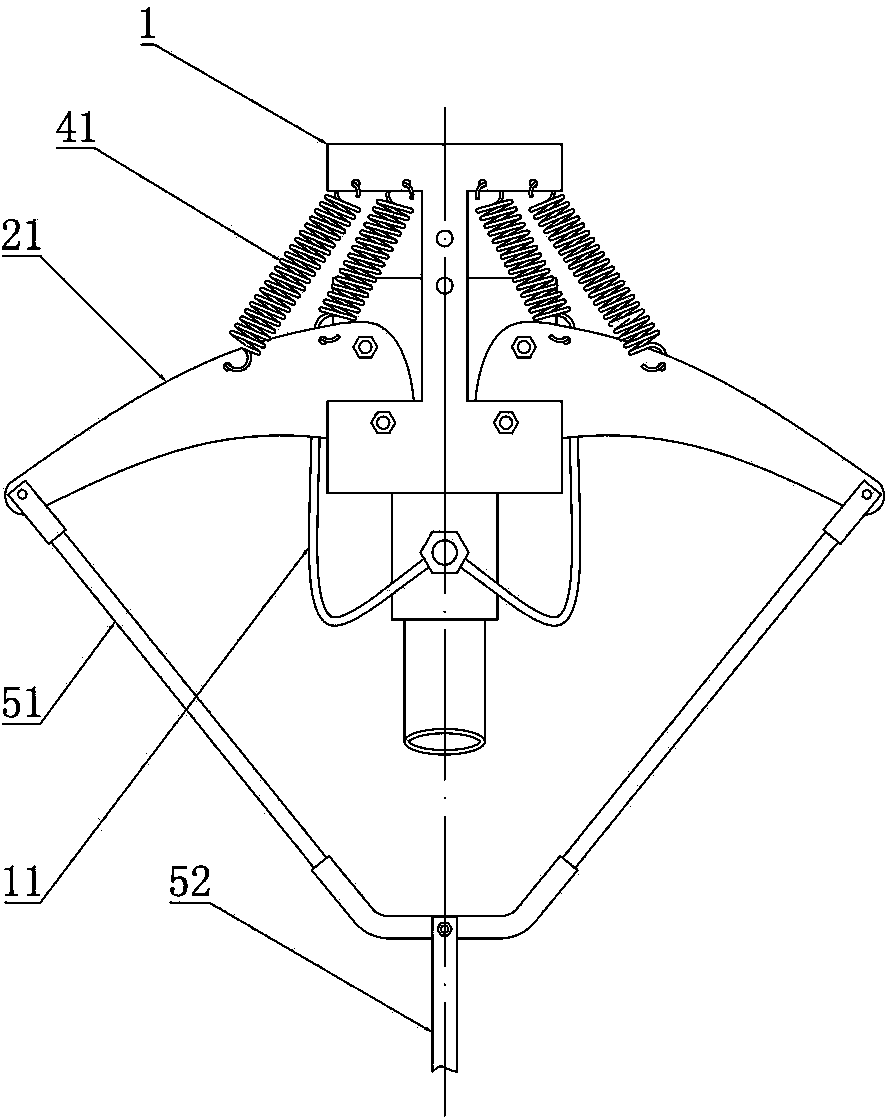

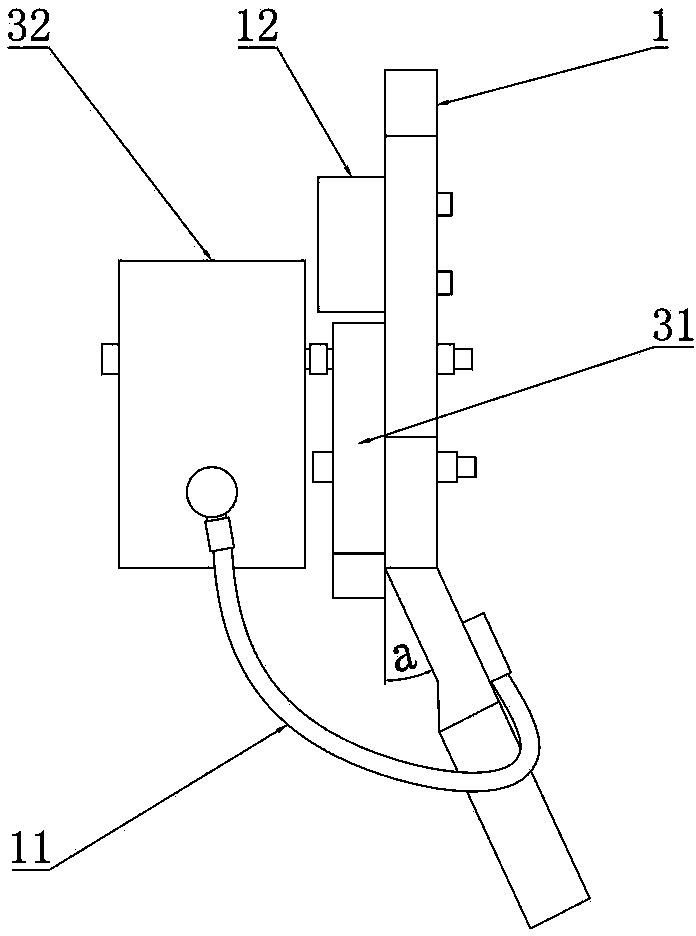

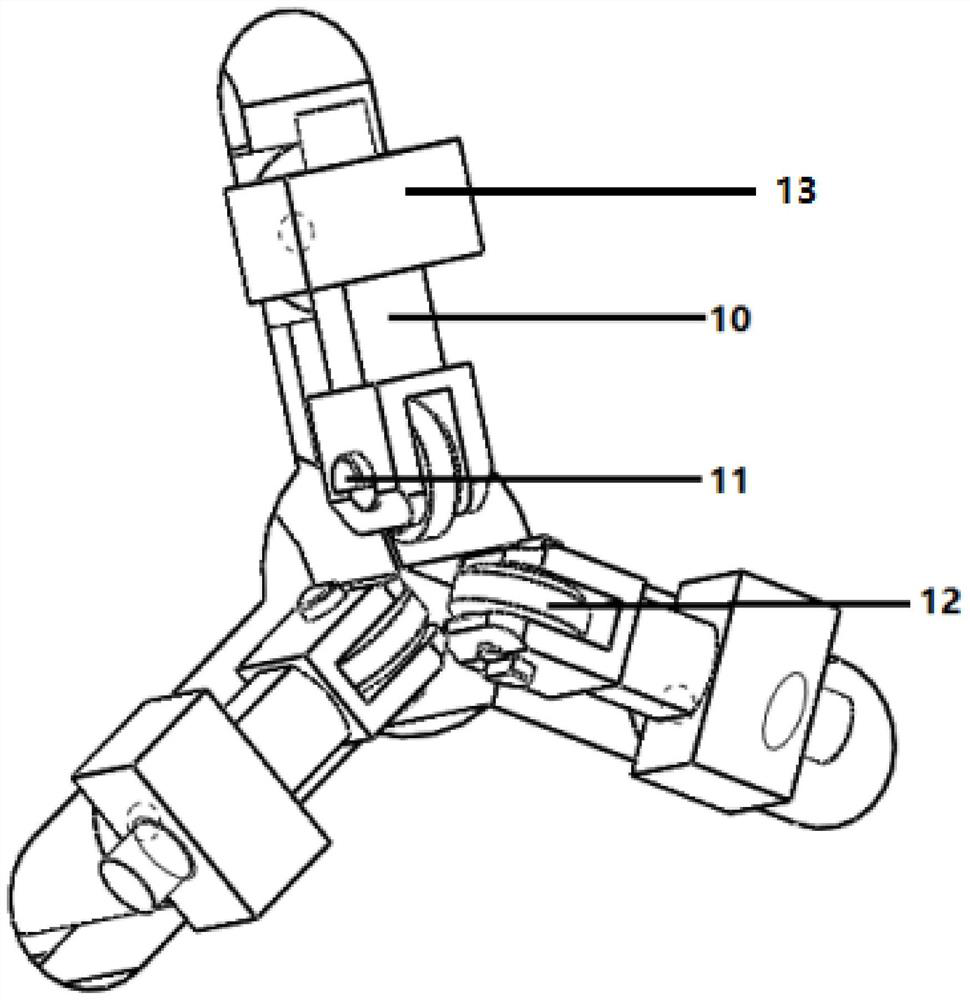

Robot-assisted no-coupling fast-changing titanium clamp surgical device for minimally invasive surgery

ActiveCN103892924AGuaranteed gripping forceQuick change replacementDiagnosticsWound clampsLess invasive surgeryTitanium

The invention relates to a robot-assisted titanium clamp surgical device for minimally invasive surgery, in particular to a robot-assisted no-coupling fast-changing titanium clamp surgical device for minimally invasive surgery in order to solve the problem that currently, the robot-assisted titanium clamp surgical device for minimally invasive surgery is in shortage in China. A tail end executing mechanism of the device is connected with one end of a sleeve tube through a wrist connecting part, the other end of the sleeve tube is connected with a base of an adapter, a left small-jaw transmission mechanism, a wrist transmission mechanism, a sleeve tube transmission mechanism and a right small-jaw transmission mechanism are arranged on the upper surface of the base of the adapter in the shape of a rectangle, a transmission return mechanism is installed on the base of the adapter, the wrist transmission mechanism is connected with the wrist connecting part through a lower wrist traction steel wire and an upper wrist traction steel wire, and the left small-jaw transmission mechanism is connected with the tail end executing mechanism through a left small-jaw traction left steel wire and a left small-jaw traction right steel wire. The device is applied to the field of medical care.

Owner:吉林省金博弘智能科技有限责任公司

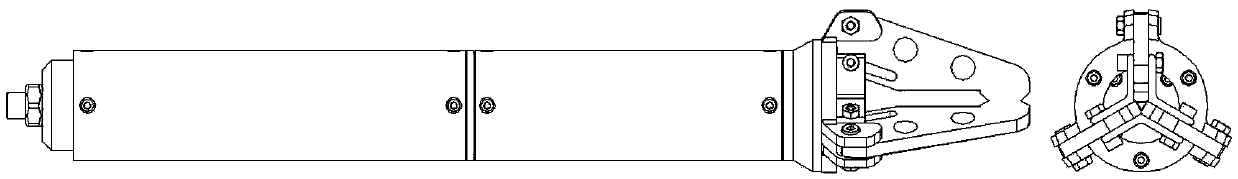

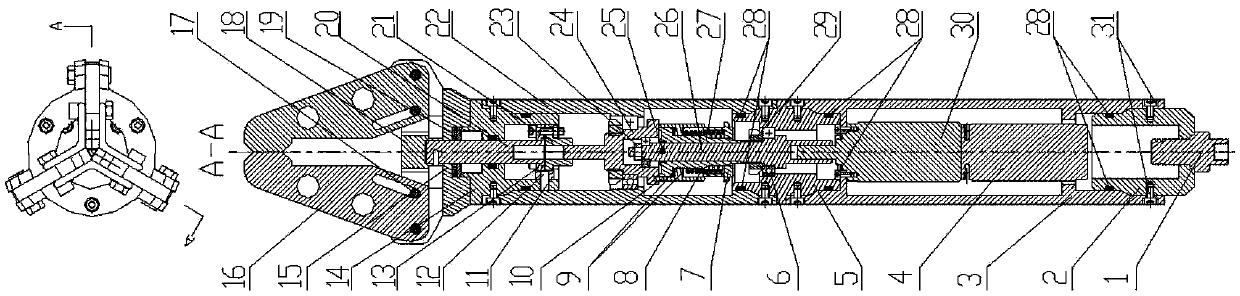

Small-scale underwater electric manipulator

InactiveCN103386678AImprove securityGuaranteed gripping forceMicromanipulatorFailure rateForeign matter

The invention relates to the field of operation of a microminiature ROV (remote operated vehicle), in particular to a small-scale underwater electric manipulator which is arranged on an ROV and is used for realizing the functions of salvaging foreign matter underwater and the like. The manipulator comprises a motor installing sleeve, a connecting sleeve, a driven shaft installing sleeve and a clamping jaw support, wherein a direct-current motor and a planetary reducer are arranged on the motor installing sleeve; a driving shaft and a rolling bearing are arranged on the connecting sleeve; the driven shaft installing sleeve is used for installing a driven shaft; and the clamping jaw support is used for installing clamping jaw fingers. After the speed of the motor is reduced by the planetary reducer, the torque of an output shaft of the motor is increased, and the output shaft is connected onto the driving shaft by a key; the driving shaft is connected onto the driven shaft through a torque limiter, and the driven shaft is linked with a pull rod through a lead screw nut; and the pull rod pulls the clamping jaw fingers through a pin roll to perform capturing action. The small-scale underwater electric manipulator has the characteristics of high safety, miniaturization, low failure rate, wide application range and the like.

Owner:BEIHANG UNIV

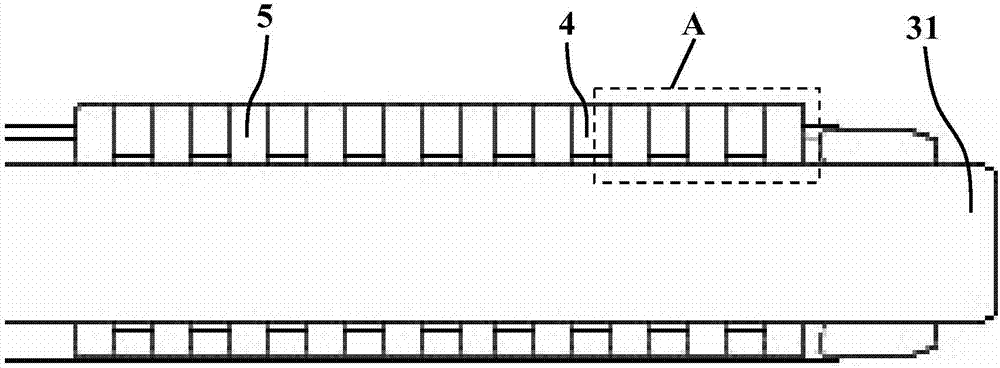

Medium-voltage load monitoring system

ActiveCN111521852ASolve the problem of difficult monitoringEasy to operateElectrical testingTime integral measurementMonitoring systemStructural engineering

The invention belongs to the technical field of power distribution automation, and provides a medium-voltage load monitoring system, which comprises a current acquisition device. The current acquisition device comprises a main housing, which comprises a first caliper housing and a limiting part which are connected in sequence; a second caliper housing, which comprises a jaw part and a clamping part which are connected with each other, wherein the jaw part is hinged to the main housing, the jaw part, the limiting part and the first caliper housing are sequentially arranged along an annular path; a wire pressing plate, one end of which is hinged to the first caliper housing, the clamping part and the wire pressing plate being both located in a space defined by the jaw part, the limiting partand the first caliper housing; a torsional spring, which is arranged on the rotating shaft of the wire pressing plate in a sleeving mode, wherein one acting end of the torsional spring acts on the wire pressing plate, and the other acting end of the torsional spring acts on the first caliper housing; and a Rogowski coil which is sequentially arranged in the jaw part, the limiting part and the first caliper housing along the annular path. According to the technical scheme, the problem of high difficulty in medium-voltage line loss monitoring in the prior art is solved.

Owner:保定市宇创电气科技有限公司

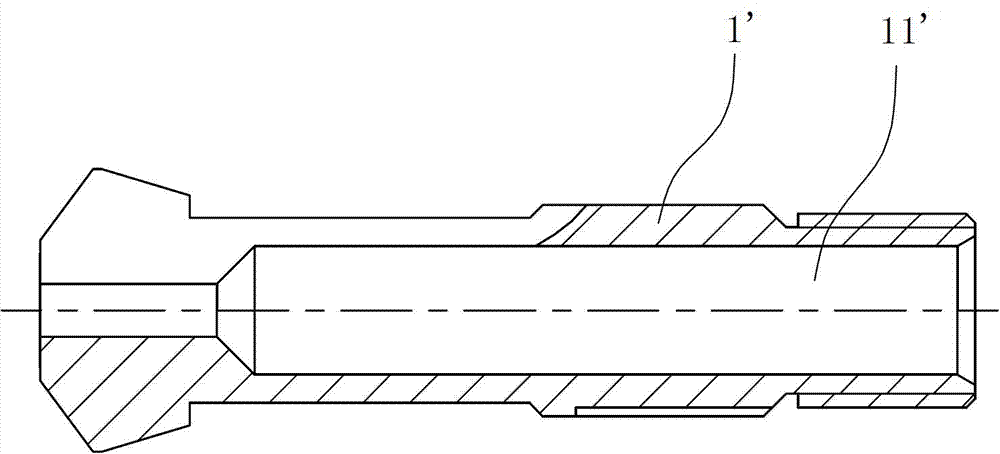

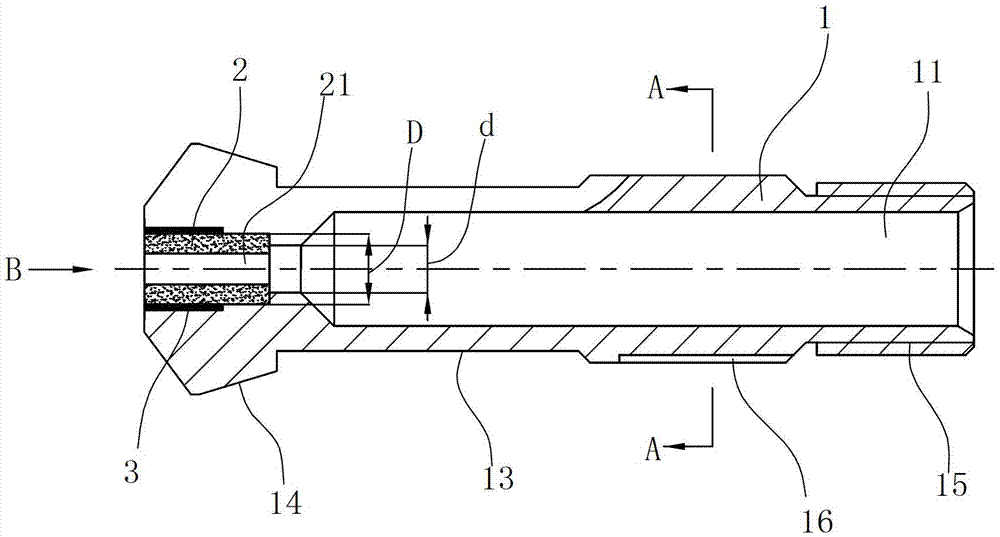

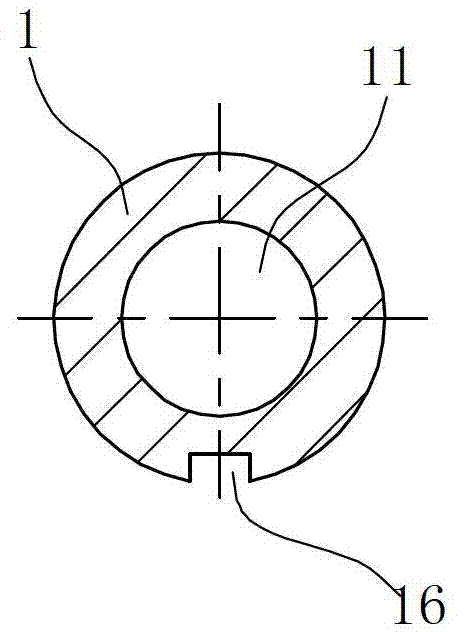

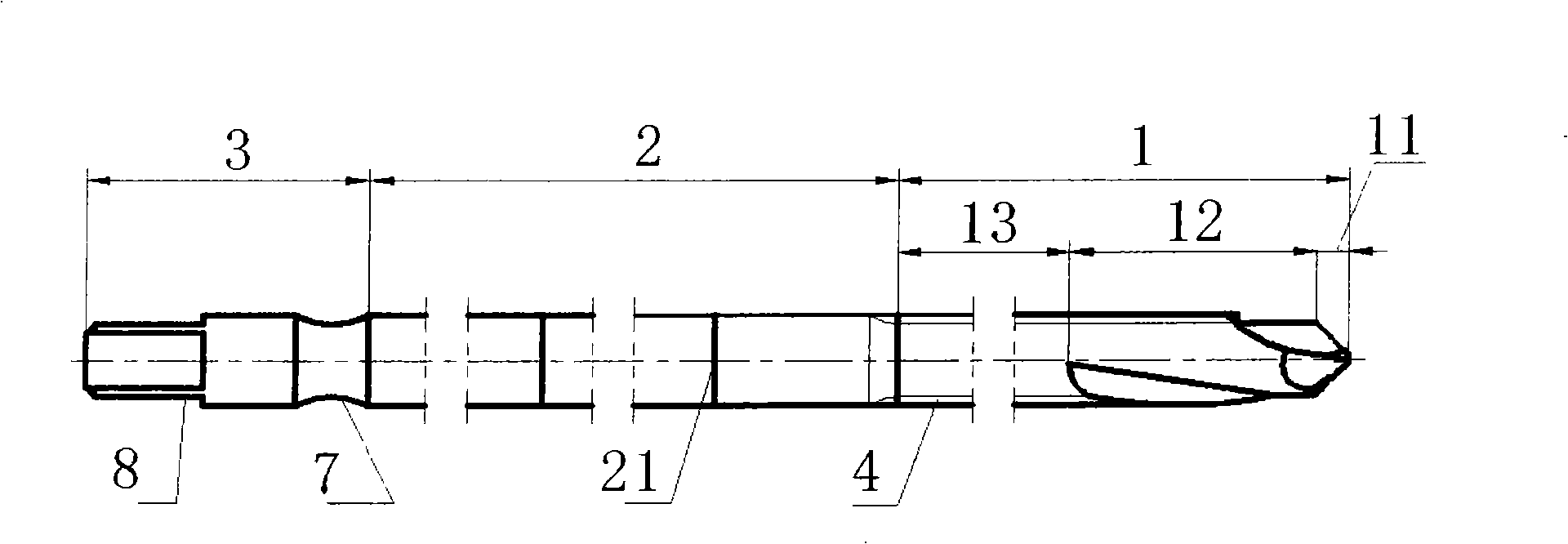

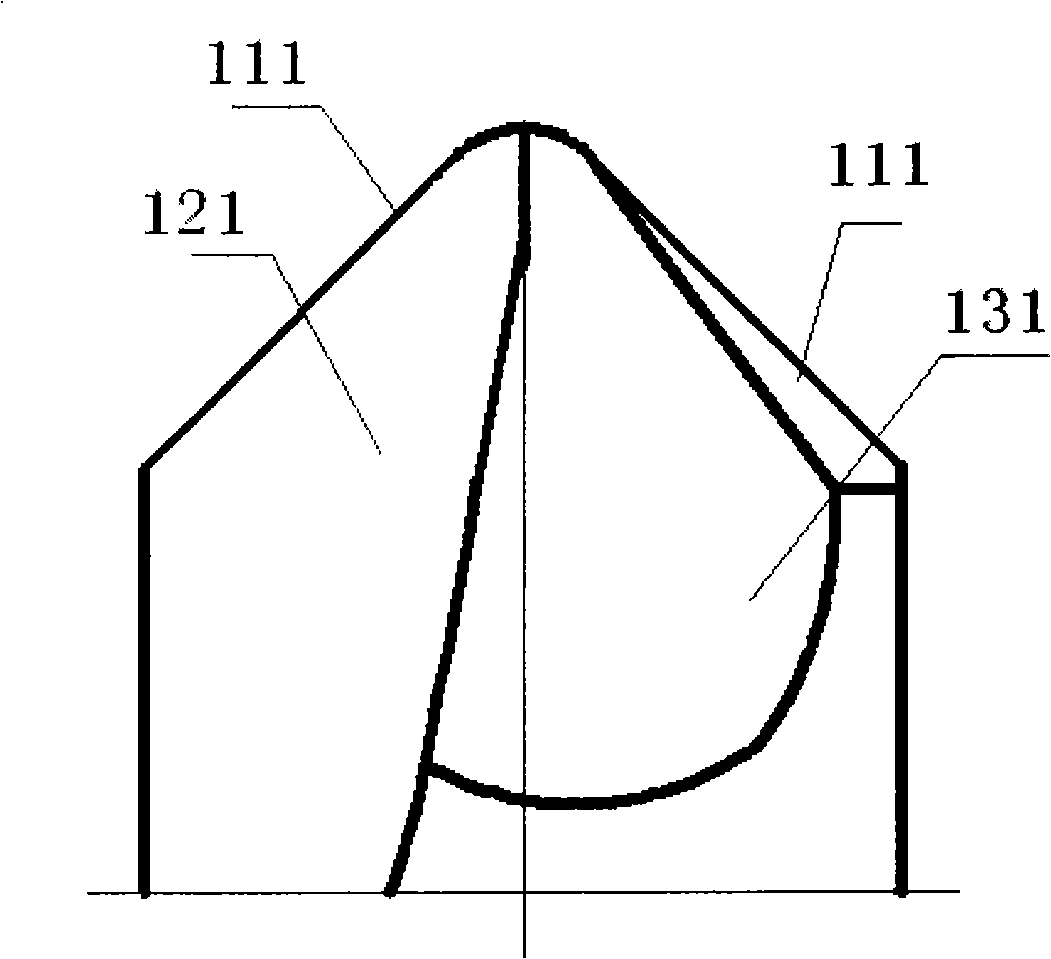

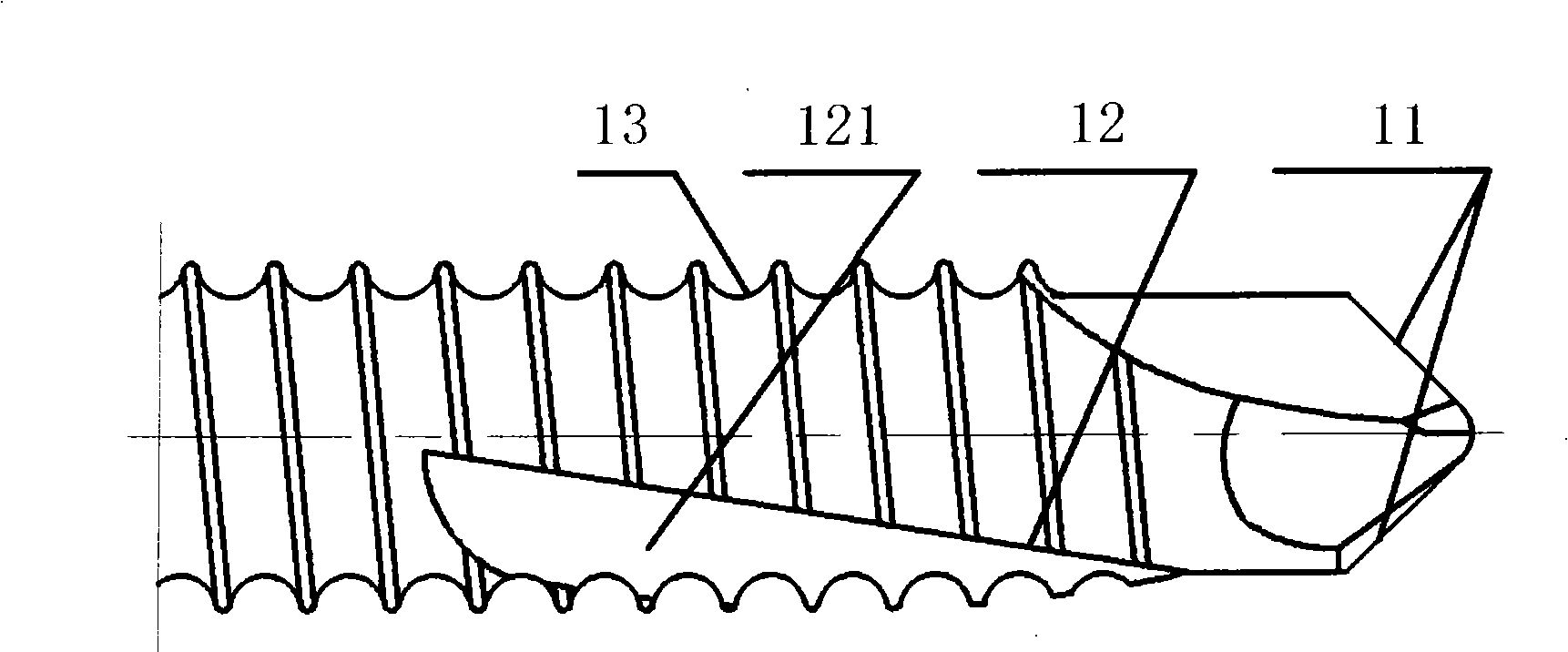

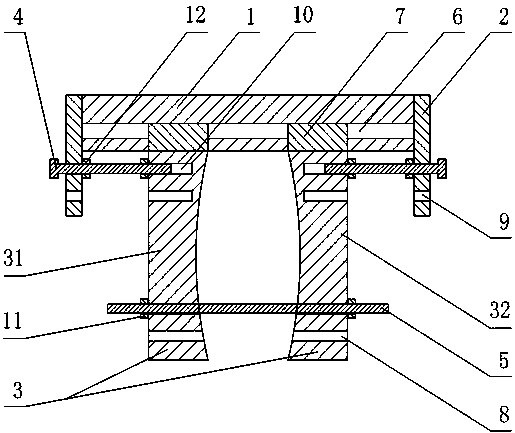

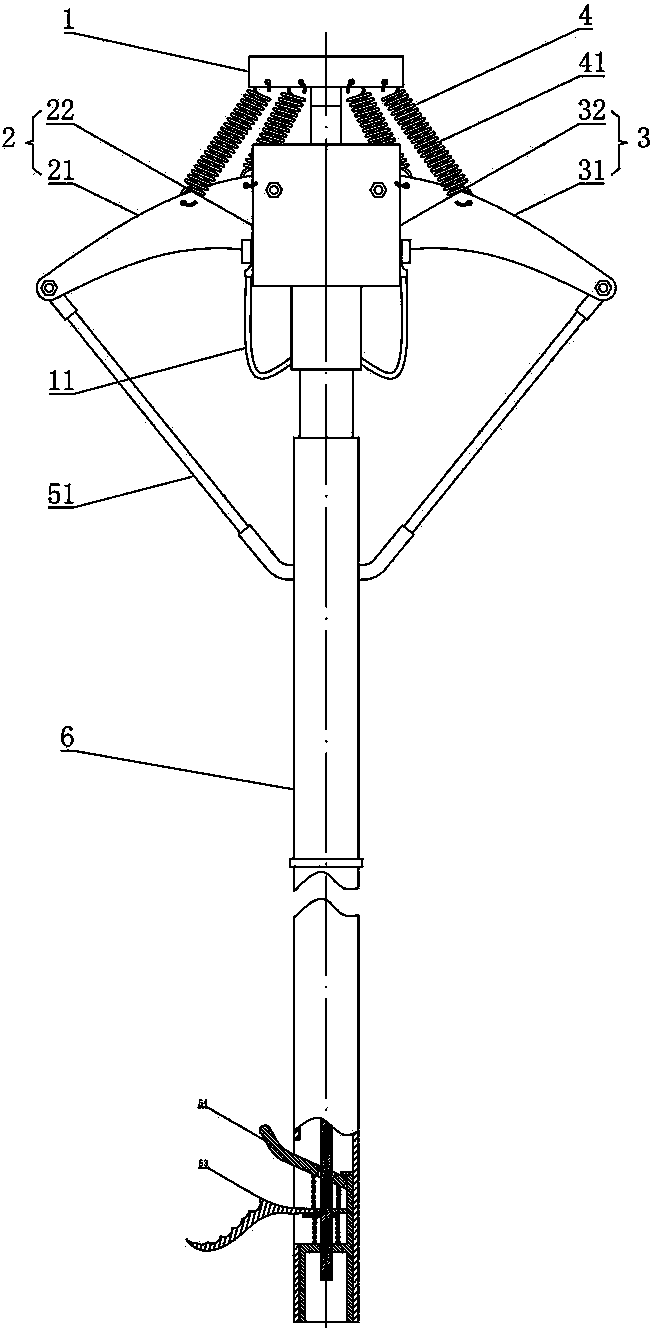

Medical self-drilling self-tapping fixed bone spicule

ActiveCN101352368AHigh strengthBest anchoring conditionFastenersBiomedical engineeringOperative time

The invention provides a medical self-drilling and self-tapping fixed bone needle, comprising an end drill edge part (1) with integrated structure, a middle cylinder part (2) and an interface part (3) at the tail end; the drill edge part (1) comprises a drill edge (11), a tapping edge (12) and a fixed thread (13); the tapping edge (12) is arranged between the drill edge (11) and the fixed thread (13); the shape of the tapping edge (12) is gradually transited from low and flat drill edge (11) to an edge identical to the fixed thread (13). The medical self-drilling and self-tapping fixed bone needle overcomes the shortages that the existing bone needle operation has complex process and inconvenient operation and the operation time and blood outgoing quantity of the patient are increased, etc. The medical self-drilling and self-tapping fixed bone needle can complete the operations of drilling, tapping and bone needle fixing.

Owner:WUHAN CONSTANT SCI & TECH

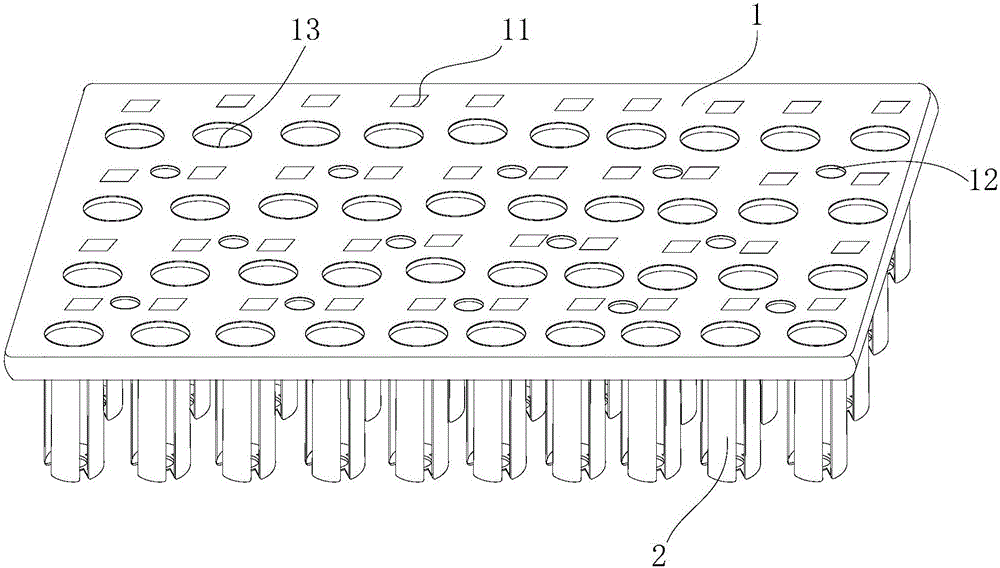

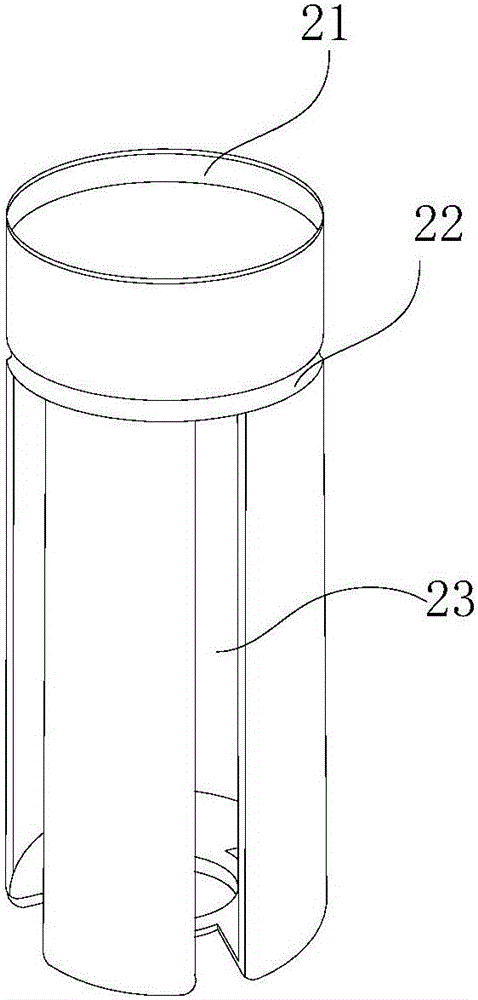

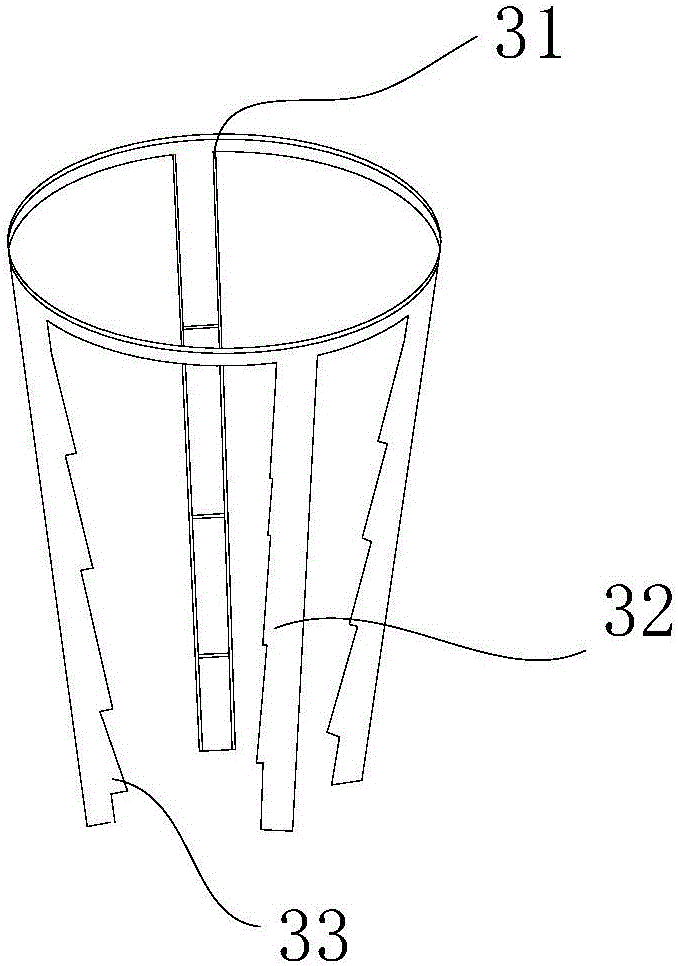

Medical test tube rack

The invention relates to a medical test tube rack which comprises a locating plate, locating pipes and clamping parts. An annular groove is formed in the outer side wall of each locating pipe, and long-strip-shaped strip clamping holes are vertically and symmetrically formed in the portion, below each groove, of the side wall; each clamping part is provided with a circular buckle matched with the corresponding groove, strip clamping buckles which correspond to the strip clamping holes and are used for clamping test tubes are arranged on the circular buckles, the tail ends of the strip clamping buckles are folded inwards and can clamp the test tubes, and the strip clamping buckles are provided with sawtooth-shaped protrusions. According to the medical test tube rack, by means of exquisite design of the locating pipes and the clamping parts, the clamping parts are provided with the strip clamping buckles corresponding to the strip clamping holes of the locating pipes, and the strip clamping buckles are provided with the sawtooth-shaped protrusions; by means of the flexible connection mode of the clamping parts and the locating pipes, clamping force to the test tubes can be guaranteed, the cost is low, replacement of the clamping parts is convenient, the application range is wide, and wide popularization significance is achieved.

Owner:QINGDAO BLOOD CENT

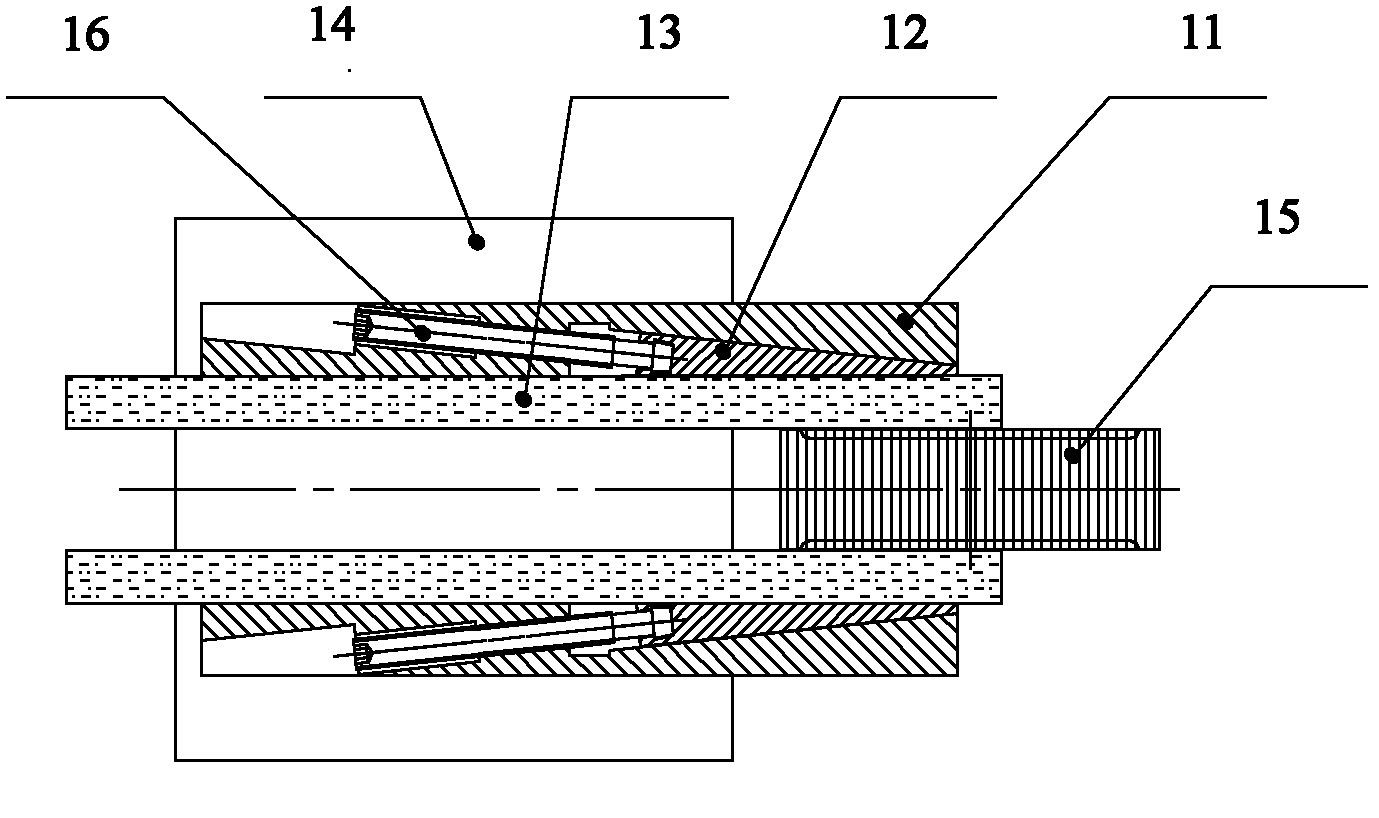

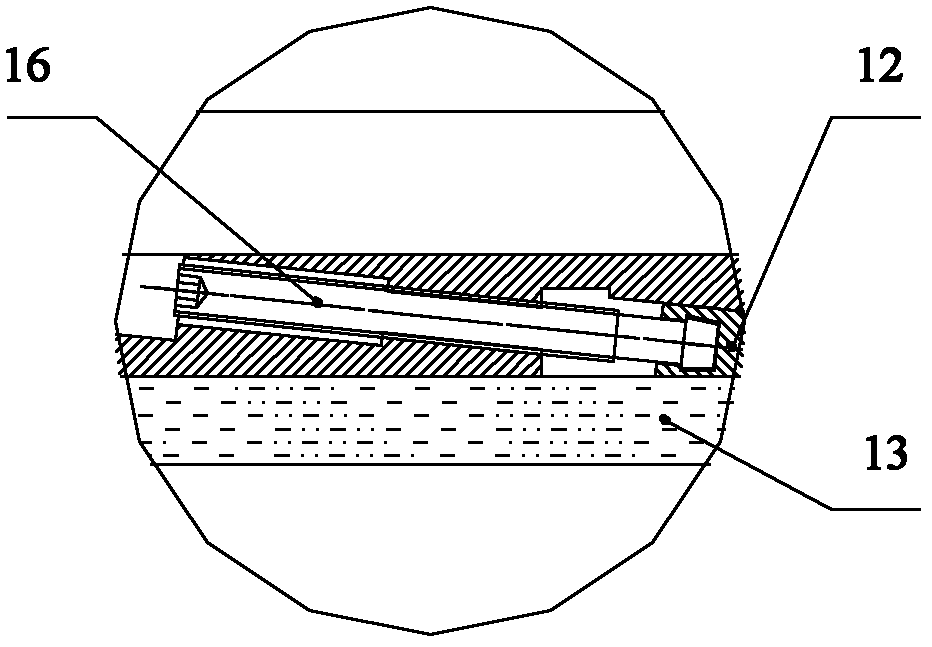

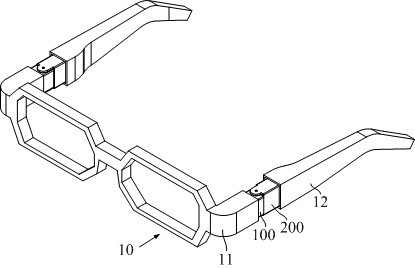

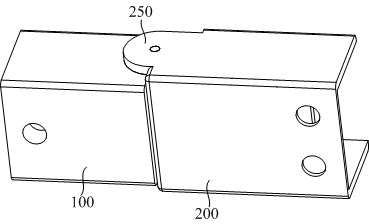

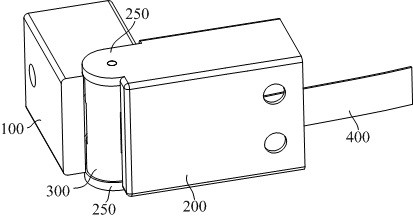

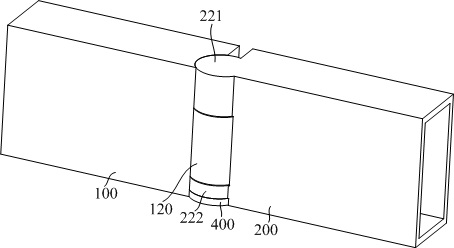

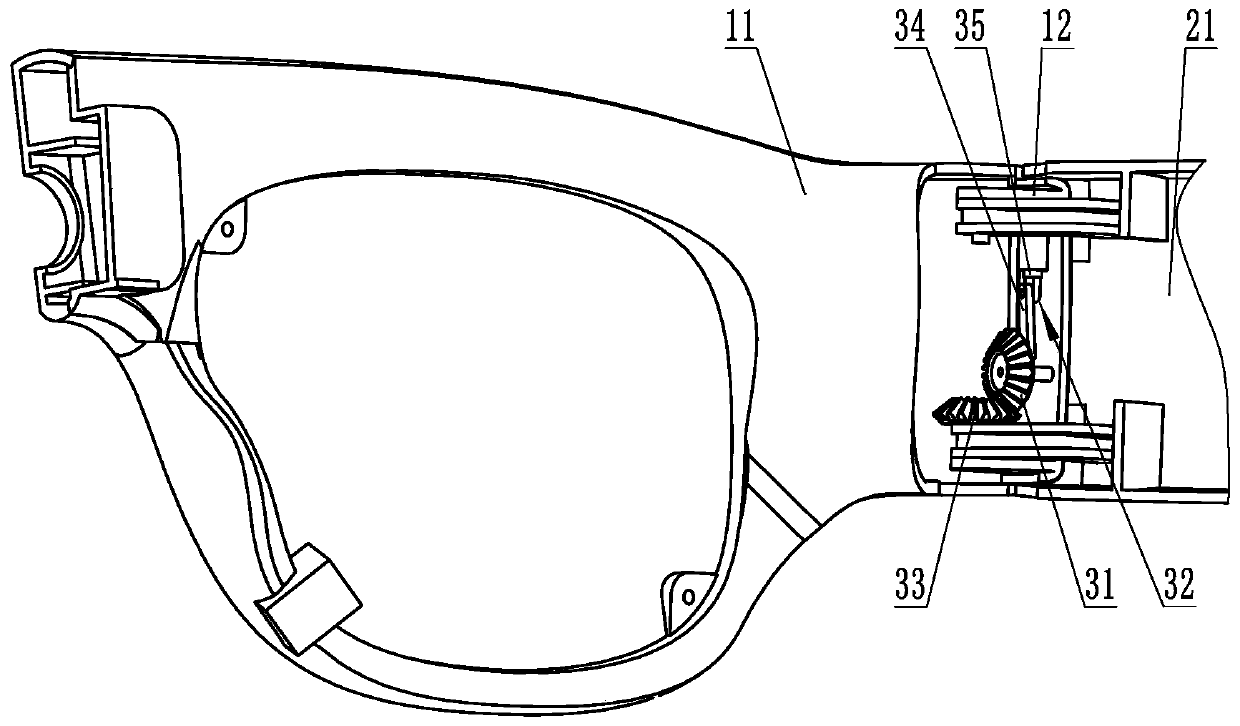

Foldable glasses leg assembly and head-mounted equipment

PendingCN111552084ARealize rotary connectionAvoid exposed and easy to wearOptical elementsEngineeringMechanical engineering

The invention discloses a foldable glasses leg assembly and head-mounted equipment. A rotating shaft part in the foldable glasses leg assembly comprises a glasses frame connecting part, a glasses legconnecting part and an elastic part; the glasses frame connecting part extends into the first cavity of the glasses frame through the glasses frame opening part to be rotatably connected with the inner wall of the glasses frame, and the glasses leg connecting part extends into the second cavity of the glasses leg through the glasses leg opening part to be fixedly connected with the inner wall of the glasses leg; when the glasses leg is bent towards the outer side of the glasses frame, the elastic part abuts against the peripheral wall where the opening part of the glasses frame is located so as to limit the reverse bending angles of the glasses leg, the elastic part is stressed and compressed to deform so that the glasses legs can have the tendency of moving towards the inner side of the glasses frame, certain clamping force can be kept when the glasses legs are bent reversely, and the wearing comfort is improved. The FPC assembly in the head-mounted device is arranged in the glasses frame, the gaps between the elastic deformation arms and the glasses leg connecting parts and in the glasses legs in a penetrating mode, the FPC assembly is not exposed when the glasses leg is folded,and the product reliability is improved.

Owner:GEER TECH CO LTD

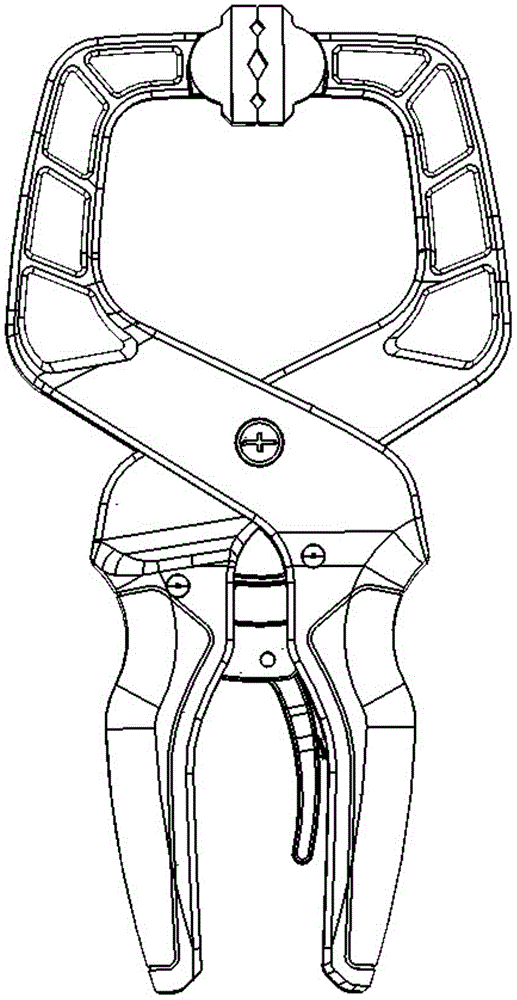

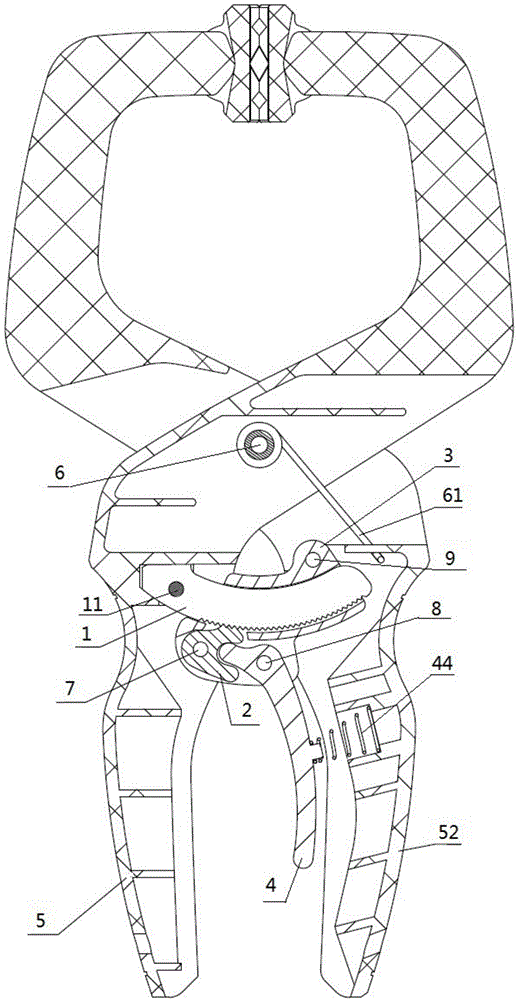

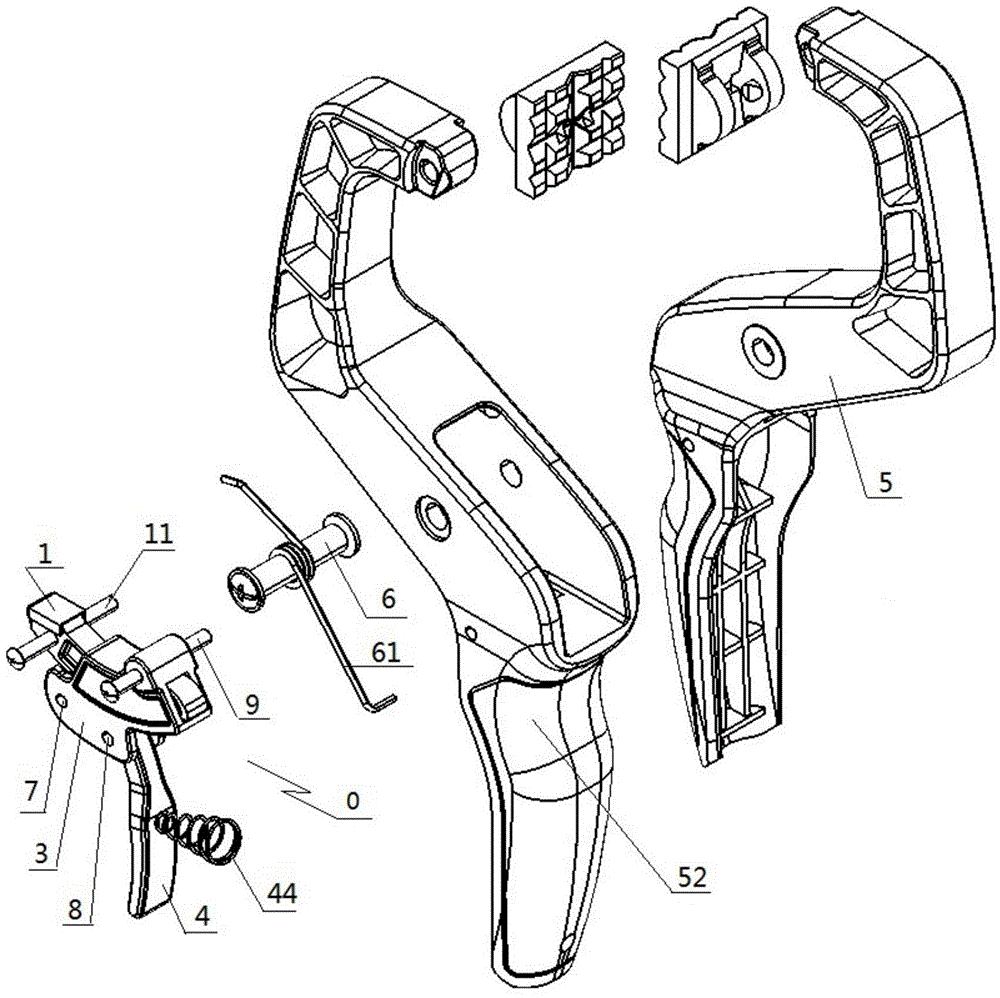

Ratchet clamp

The invention discloses a ratchet clamp and relates to the field of manual tools. The ratchet clamp comprises a first clamp arm, a second clamp arm and a ratchet mechanism disposed between the first clamp arm and the second clamp arm. An elastic part is disposed between the ratchet mechanism and the second clamp arm. The ratchet mechanism comprises a rack and a rocking part, and the rocking part comprises rocking teeth, a rocking tooth holder and a lever. In clamping, the rocking part wholly rocks in a range under the action of the elastic part, the rack and the rocking teeth engage mutually and reversely to hold clamping force, and the elastic part maintains engagement of the rock and rocking teeth from slipping; in opening, interference fit between the rack and the rocking teeth enables a user to pull the lever with little effort so as to disengage the rocking teeth and prevent the ratchet mechanism from being opened by accidental relief. The ratchet clamp is very secure and reliable in a self-locking state, and a jaw of the clamp is up to about 50 kg in maximum clamping force, with higher than 85% of maximum clamping force maintained after a user relieves the clamp arms.

Owner:HANGZHOU GREAT STAR TOOLS +1

Intelligent insulated cable piercing clip

ActiveCN107681295AEasy clamping operationGuaranteed gripping forceContact members penetrating/cutting insulation/cable strandsClamped/spring connectionsEngineeringMechanical engineering

The invention provides an intelligent insulated cable piercing clip, which relates to an insulated cable piercing clip and aims at solving the problems that the insulated piercing clip is laboursome in tightening a gland and the clamping force is loose in the case of use. The intelligent insulated cable piercing clip comprises a first gland and a second gland which are arranged oppositely, a fastening bolt passing through the gland, and a left clamping groove and a right clamping groove which are located at two sides of the fastening bolt for clamping the cable, wherein each clamping groove iscomposed of two oppositely-arranged half clamping grooves located on the first gland and the second gland, each half clamping groove is internally provided with a piercing blade, a first left electromagnet and a first right electromagnet are arranged above the left clamping groove and the right clamping groove on the first gland, the two electromagnets are serially connected, and iron blocks or magnets corresponding to the electromagnets on the first gland are arranged on the second gland. After the piercing blade and the wire are contacted, the tightening force of the two glands is increasedautomatically, and the clamping force is kept constantly during the use process.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD QUZHOU POWER SUPPLY CO +2

High-temperature endurance test fixture for full pipe sample of small-diameter metal thin-walled pipe

The invention discloses a high-temperature endurance test fixture for a full pipe sample of a small-diameter metal thin-walled pipe. The fixture is used for clamping the full pipe sample of the small-diameter metal thin-walled pipe during a high-temperature endurance test. The fixture comprises an outer fixture and an inner fixture; the outer fixture comprises an adapter body, a clamping nut, a front clamping sleeve, a back clamping sleeve, an adapter outer thread and a connecting thread; and the inner fixture comprises a shaft bar and a shaft sleeve. During use, the sample of the thin-walledpipe are sunken inwards by the aid of the front and back metal clamping sleeves, so that external clamping of the pipe is realized; and internal clamping of the pipe is realized through matching of the shaft bar and the shaft sleeve. Compared with the prior art, the fixture has the advantages that the clamping force on the sample is increased through internal and external clamping, and meanwhile,damage caused by machining of threads to the sample is avoided. Besides, the fixture is ingenious in design, is simple and convenient to operate and can be mounted on various common high-temperature endurance test machines in laboratories, the cost is low, and test results are accurate.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

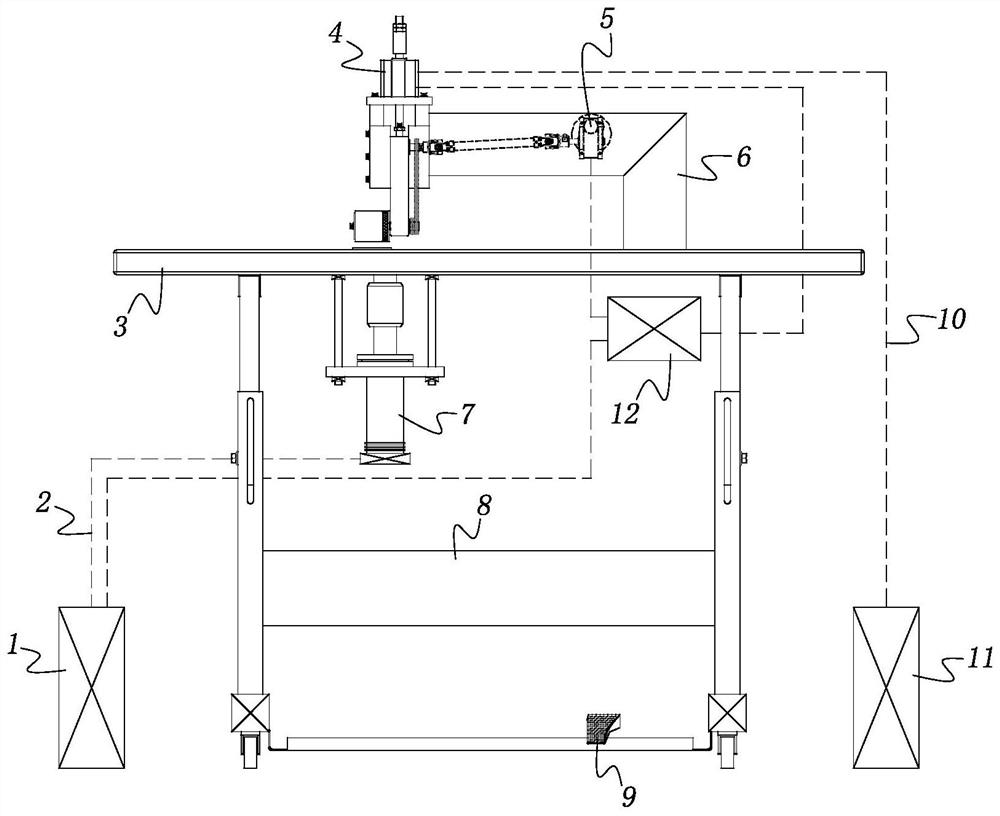

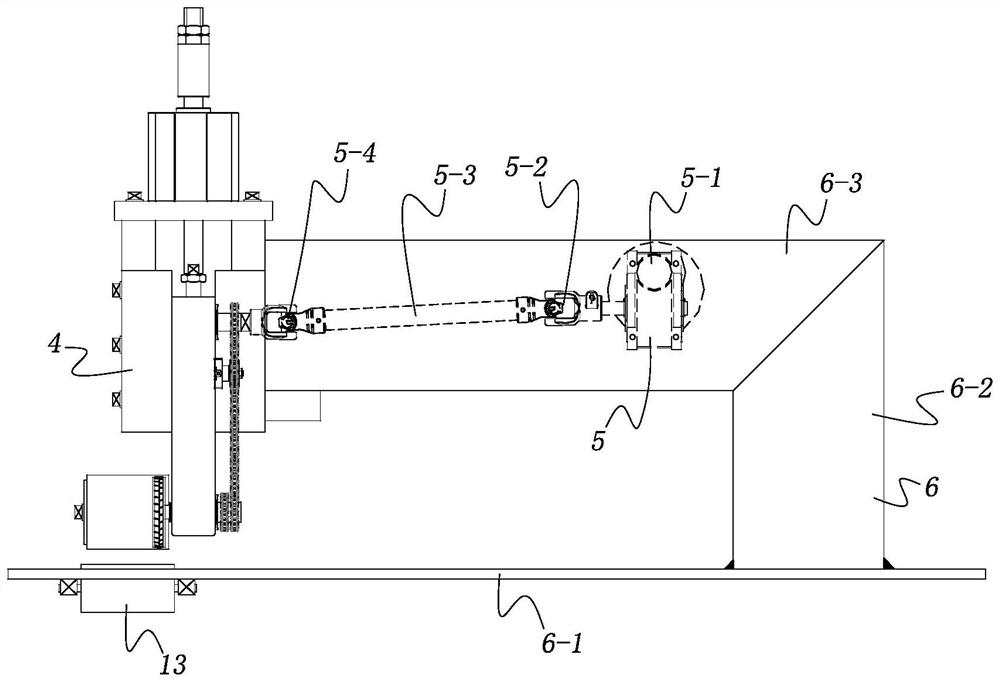

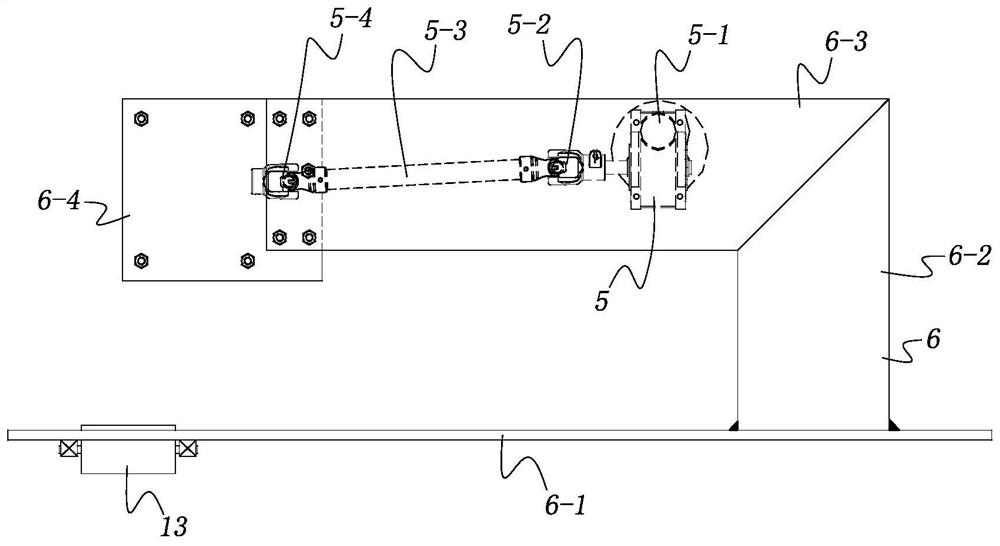

Efficient sock butend sewing machine rivaling manual butend sewing

ActiveCN107761262AReduce widthLow failure rateWork-feeding meansCombination sewing machinesIndustrial engineeringSewing machine

The invention discloses an efficient sock butend sewing machine rivaling manual butend sewing. The efficient sock butend sewing machine comprises a butend sewing motor for driving the sock butend sewing machine and a conveying motor for driving a sock conveying system; the efficient sock butend sewing machine is characterized in that the sock conveying system comprises a front-section conveying system body, a rear-section conveying system body, a butend sewing machine body, two machine heads and two lifting systems, wherein the butend sewing machine body, the two machines head and the two lifting systems are arranged on a mounting platform board. According to the efficient sock butend sewing machine rivaling manual butend sewing, the sewing width is small, the sewing speed ratio is adjustable, and the two machine heads share one center shaft, so that sewing lines of secondary sewing are highly consistent in coaxality.

Owner:ZHEJIANG ROSSO EQUIP MFG

Clamp for machining round thin-walled workpiece

The invention relates to a clamp for machining a round thin-walled workpiece. The clamp comprises a chuck body, fixing bases annularly arrayed on the chuck body and clamping jaws arranged on the fixing bases, wherein the front portion of each clamping jaw is folded to form a hooking jaw used for clamping, the end of each hooking jaw is provided with an inclination face, a cushion block for abutting against the end face of the workpiece is installed on each fixing base at the inner side of the corresponding hooking jaw, annular grooves are formed in the side walls of the workpiece, the ends ofthe hooking jaws stretch into the grooves, the inclination faces of the hooking jaws abut against notches of the grooves, and then the workpiece is driven to abut against the cushion blocks. Accordingto the technical scheme, the inclination faces are utilized for abutting against the ports of the grooves in the side walls of the workpiece, and then radial clamping force and axial thrust force towards the cushion blocks can be provided for the workpiece. In this way, it is guaranteed that the clamping jaws can firmly clamp the workpiece, the clamp applies acting force to the workpiece throughthe inclination faces, the acting force can be broken down into small component force in the axial direction and radial direction of the workpiece, the risk of radial deformation of the workpiece canbe effectively lowered, the circularity of the workpiece is guaranteed, and the yield is increased.

Owner:重庆和烁精密锻造有限公司

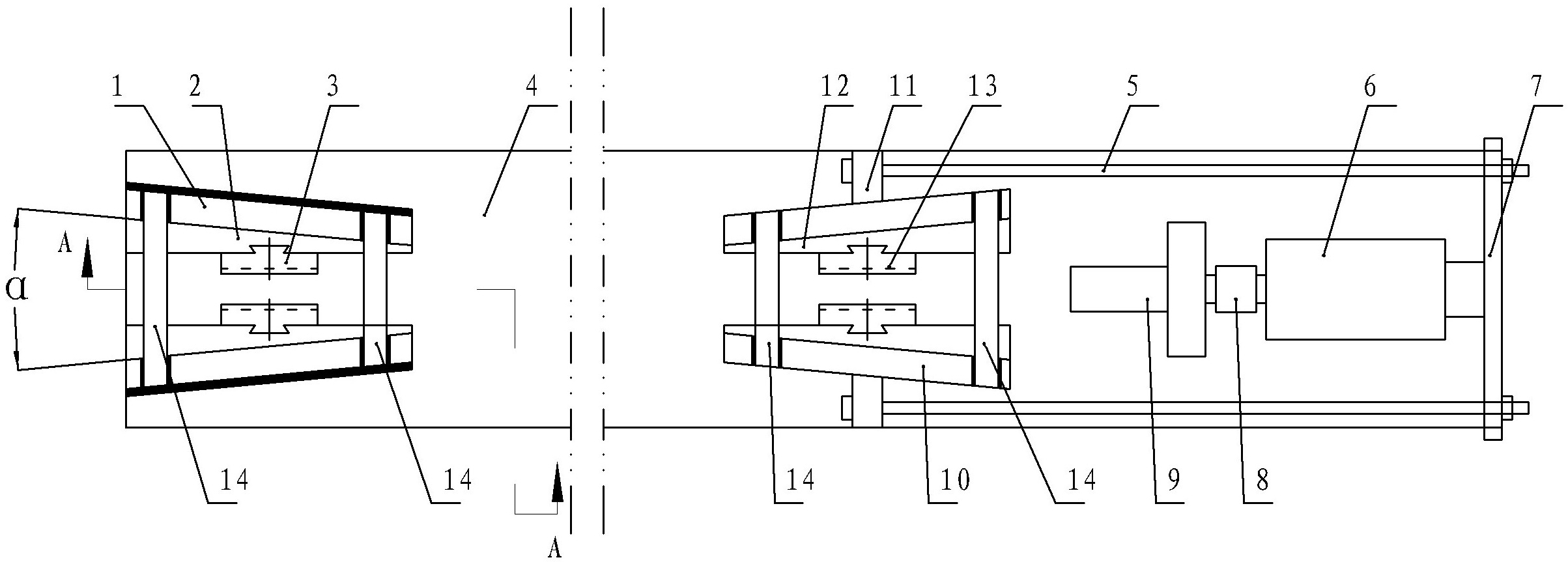

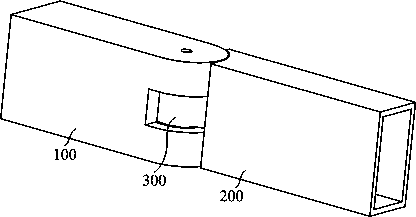

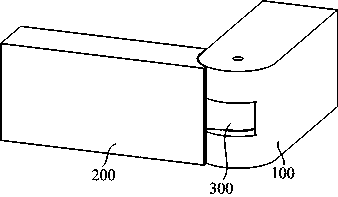

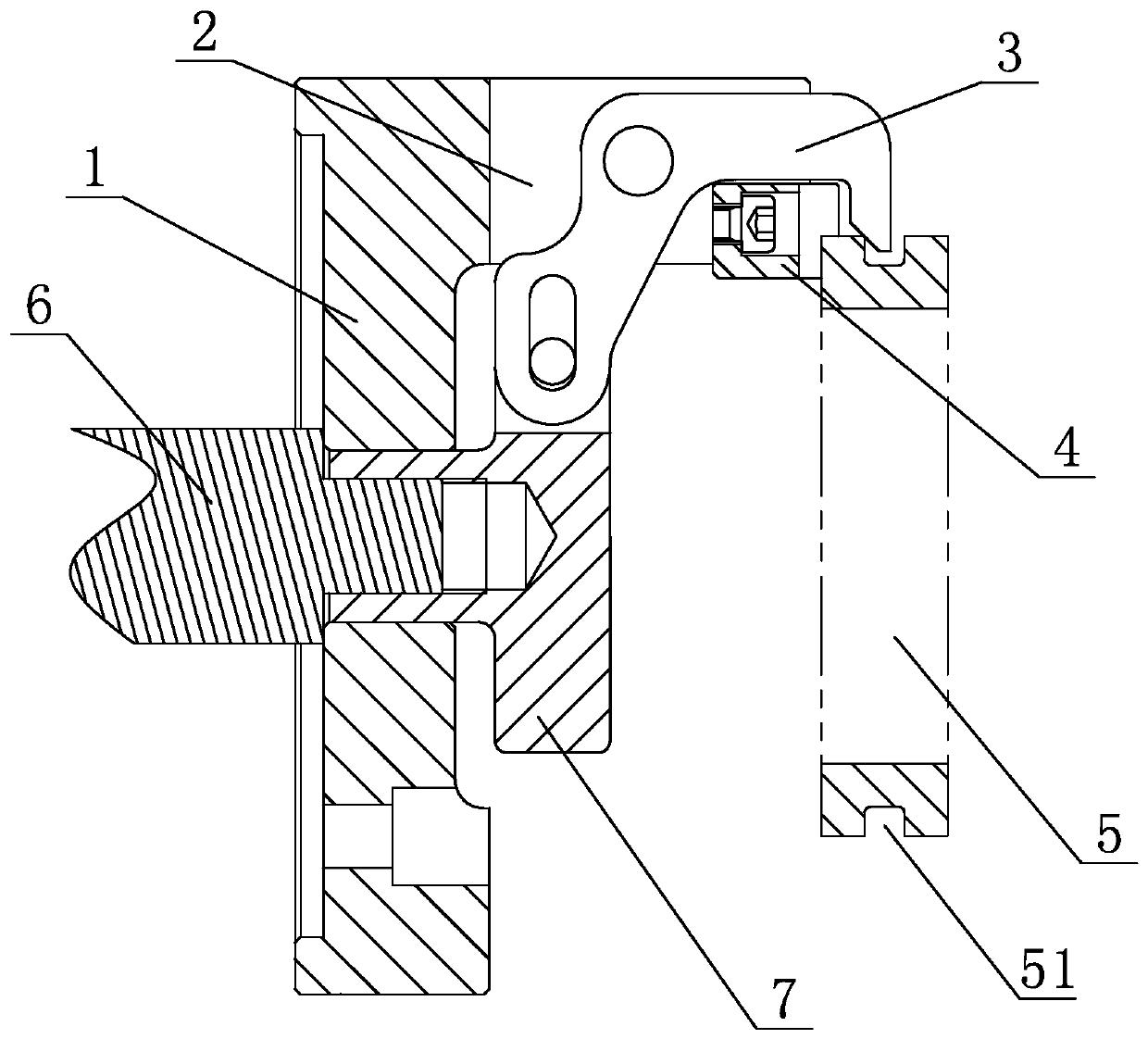

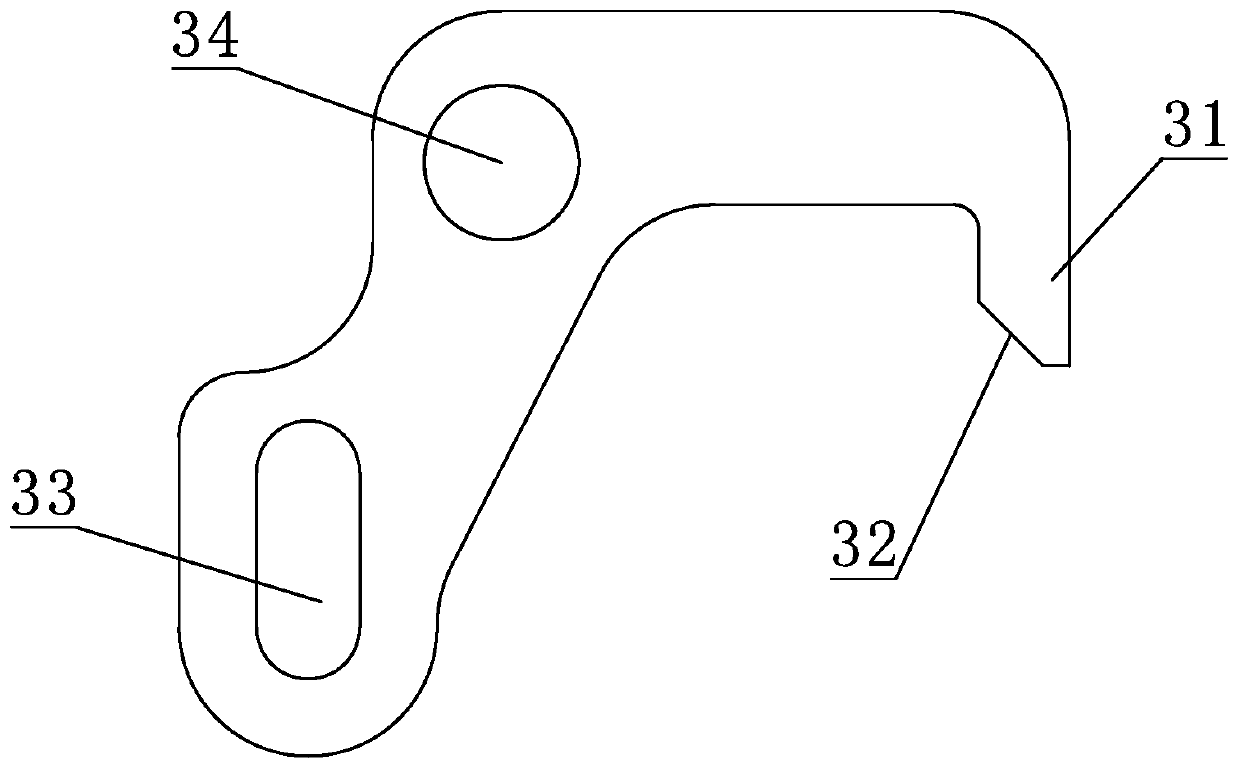

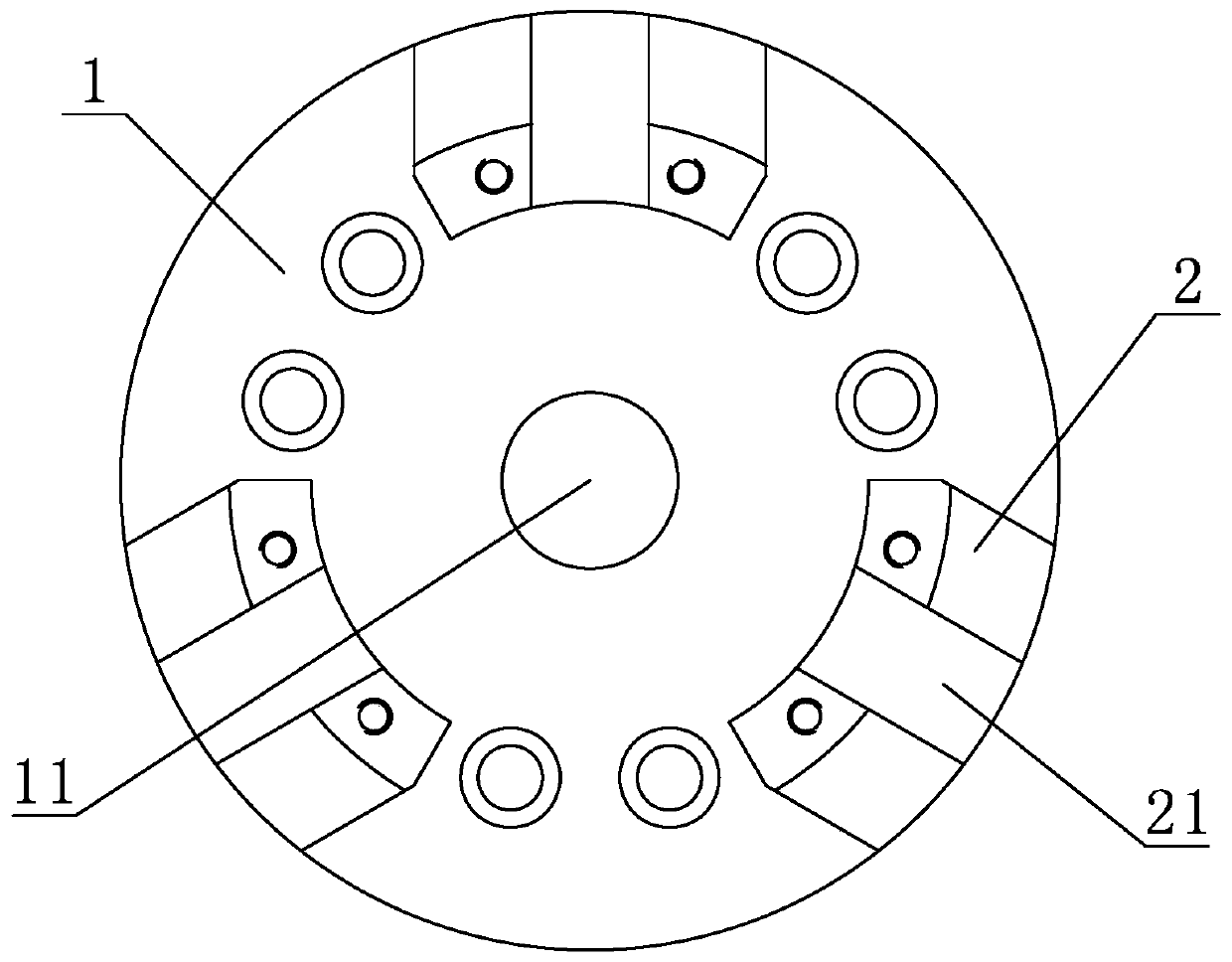

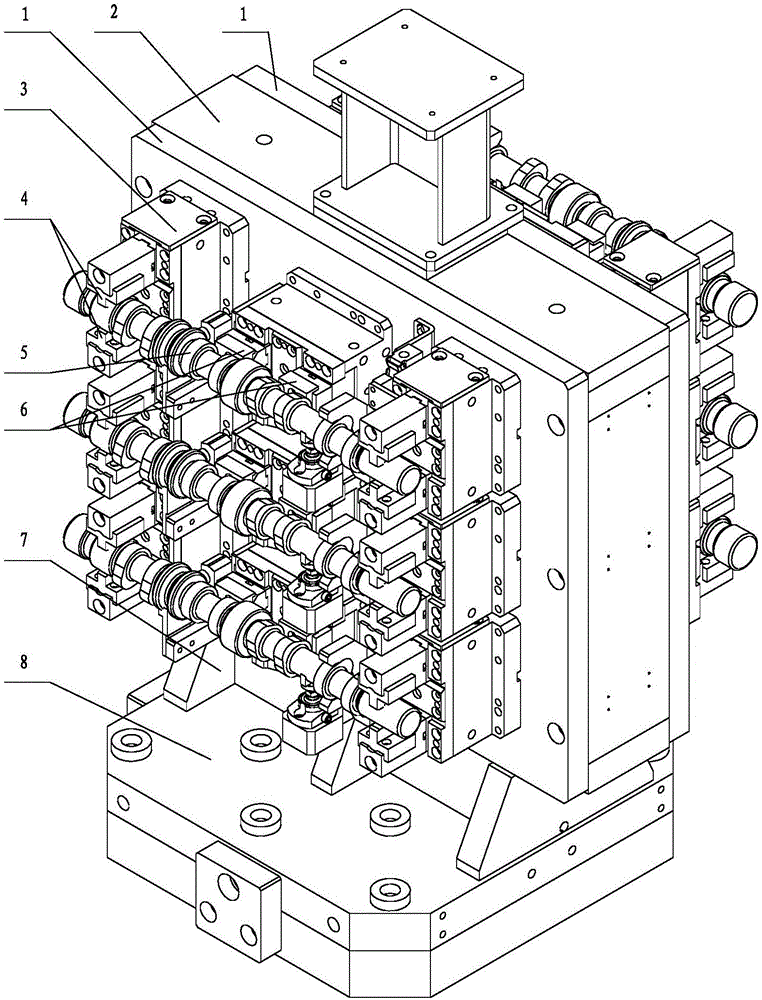

Tool for processing central hole in end part of camshaft

ActiveCN106271753AGuaranteed gripping forceUniform clamping forcePositioning apparatusMetal-working holdersCamProduct processing

The invention discloses a tool for processing a center hole in an end shaft of a camshaft. The tool comprises a supporting frame assembly, a plurality of clamping units (3), pre-positioning devices and gas inspecting devices; the lower end of the supporting frame assembly is connected onto a workbench of a machine tool through a rotary cylinder; each clamping unit (3) is used for clamping one camshaft (5) which is horizontally arranged; the plurality of the clamping units (3) are in parallel arranged at equal distance from top to bottom, and are symmetrically connected onto two end surfaces of the supporting frame assembly; each clamping unit (3) is equipped with one pre-positioning device and one gas inspecting device; and the pre-positioning devices and the gas inspecting devices are connected onto the supporting frame assembly. With the adoption of the structure, force borne on the camshaft is more balanced when the central hole is processed in the end part of the camshaft, so that deformation of the camshaft is avoided, and product processing quality is improved.

Owner:宁波圣龙智造凸轮轴有限公司

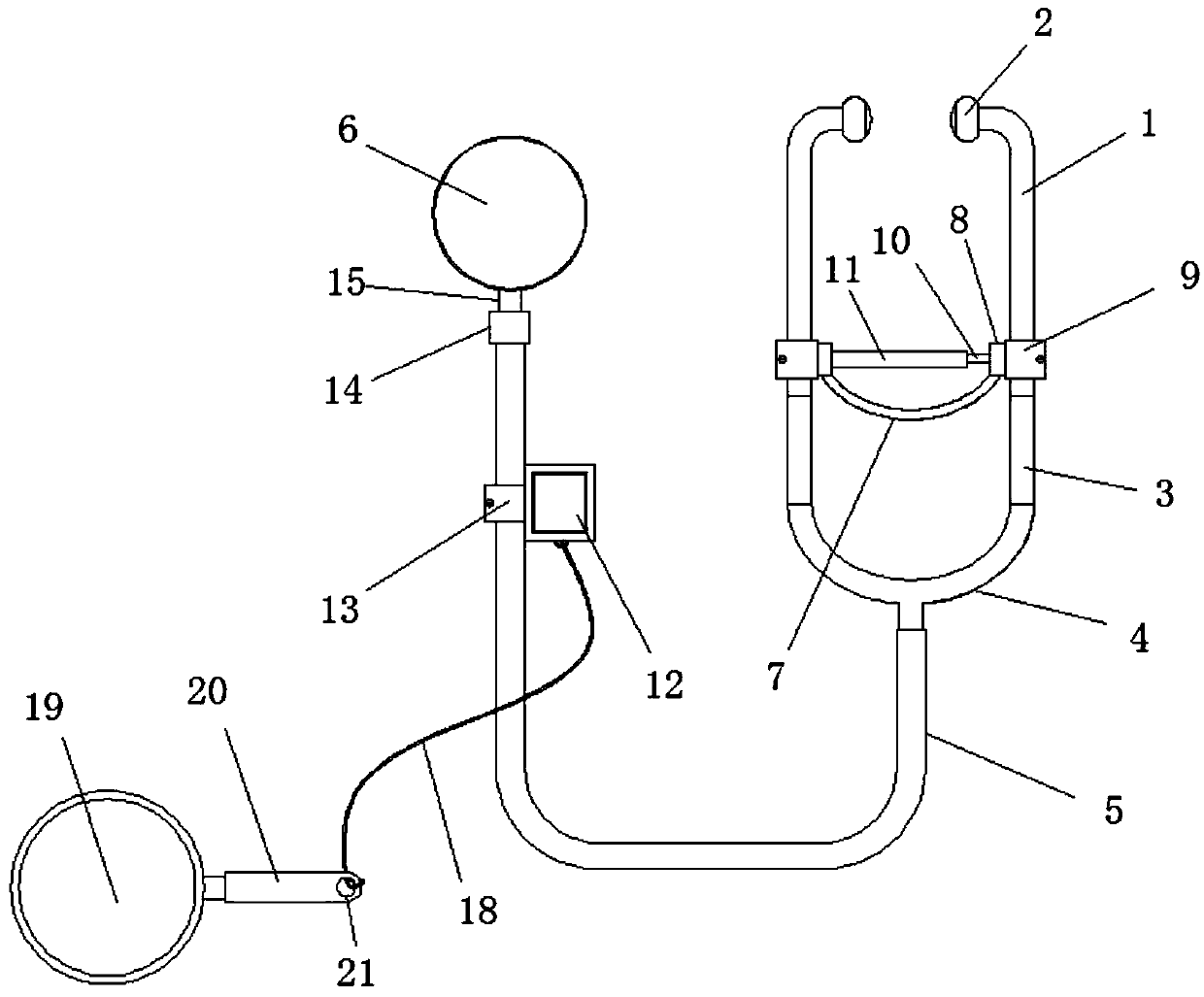

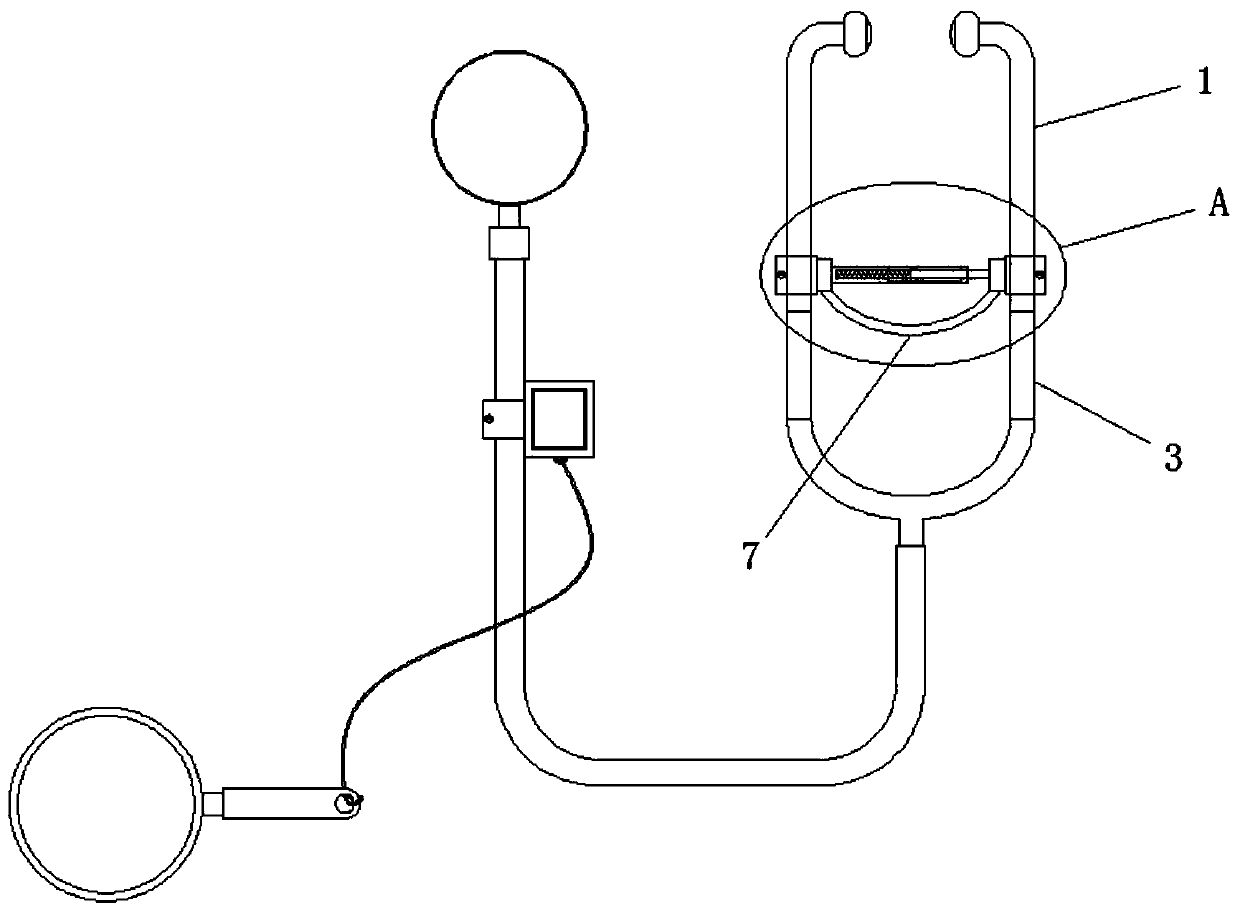

Clinical medical multi-functional stethoscope used in department of cardiology

InactiveCN109620284AEasy to disassemble and replaceGuaranteed gripping forceDiagnostics using lightStethoscopeAuscultationGuide tube

The invention discloses a clinical medical multi-functional stethoscope used in the department of cardiology. The clinical medical multi-functional stethoscope comprises two earring catheters with hollow structures, wherein the tops of the opposite sides of the two earring catheters are provided with auscultation earplugs, the bottom ends of the two earring catheters are both provided with short catheters, the bottom ends of the two short catheters are both connected with a three-way tube, a bottom interface of the three-way tube is connected with a long catheter, and the other end of the longcatheter is provided with a flat auscultation head. In the clinical medical multi-functional stethoscope, the flat auscultation head is convenient to disassemble and replace, the clamping force provided by an existing stethoscope only by relying on a spring is changed through the joint cooperation of a spring and a spring piece, the clamping force needed when a doctor wears the earplugs of the stethoscope is ensured, and clamping is firmer; by adjusting the tightness of nuts, integral movement adjustment of the spring piece and a spring assembly on the two earring catheters can be achieved; by arranging a magnifying lens, the doctor conveniently and accurately observe and judge patients' conditions.

Owner:孙瑶

Outdoor AP embracing fixer

InactiveCN104389862AHigh strengthImprove rigidityFriction grip releasable fasteningsScrew threadIndustrial engineering

Owner:成都开能科技发展有限公司

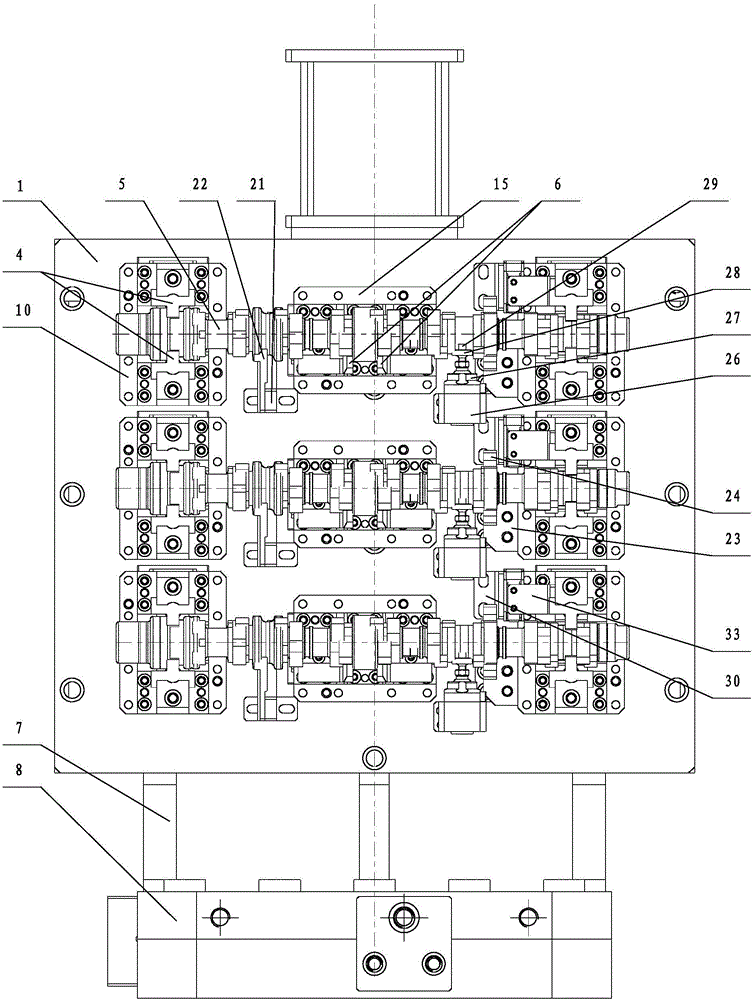

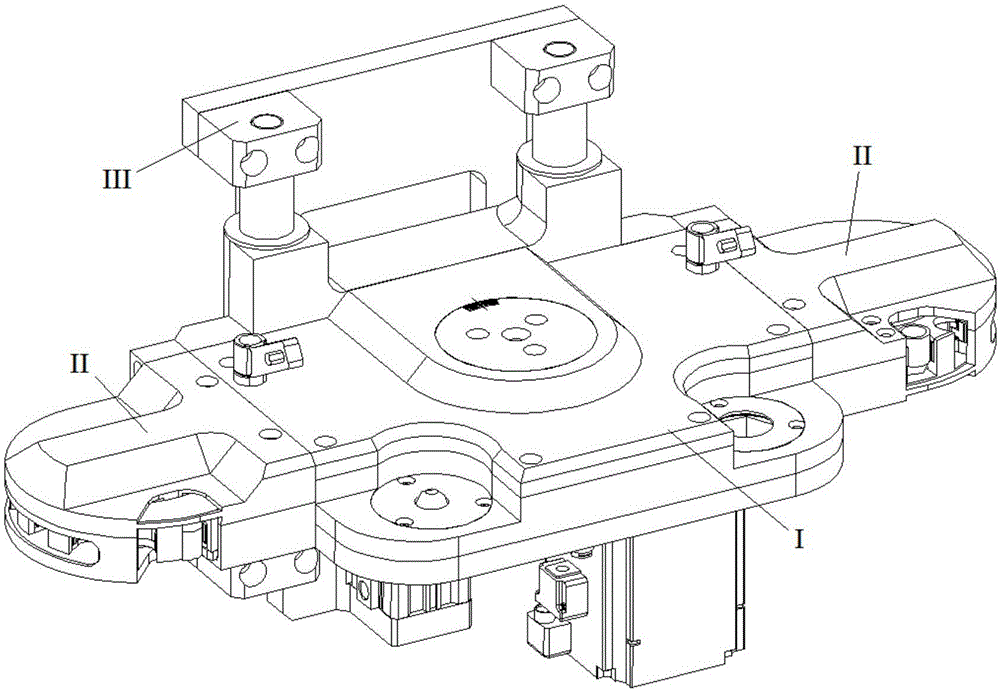

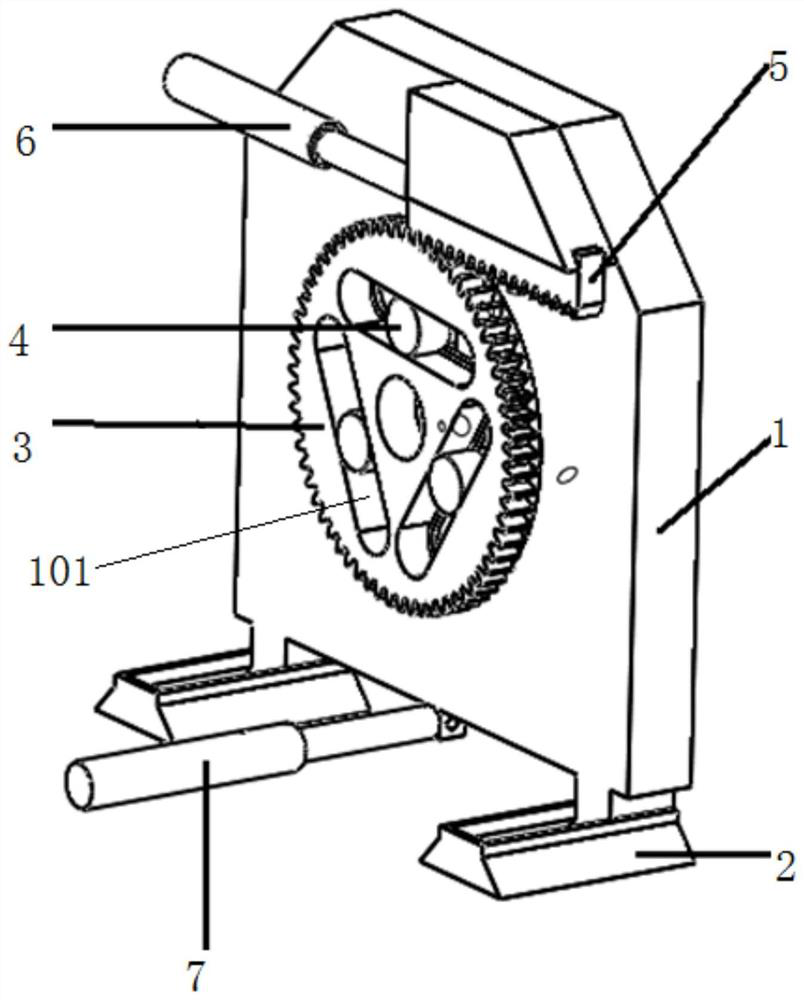

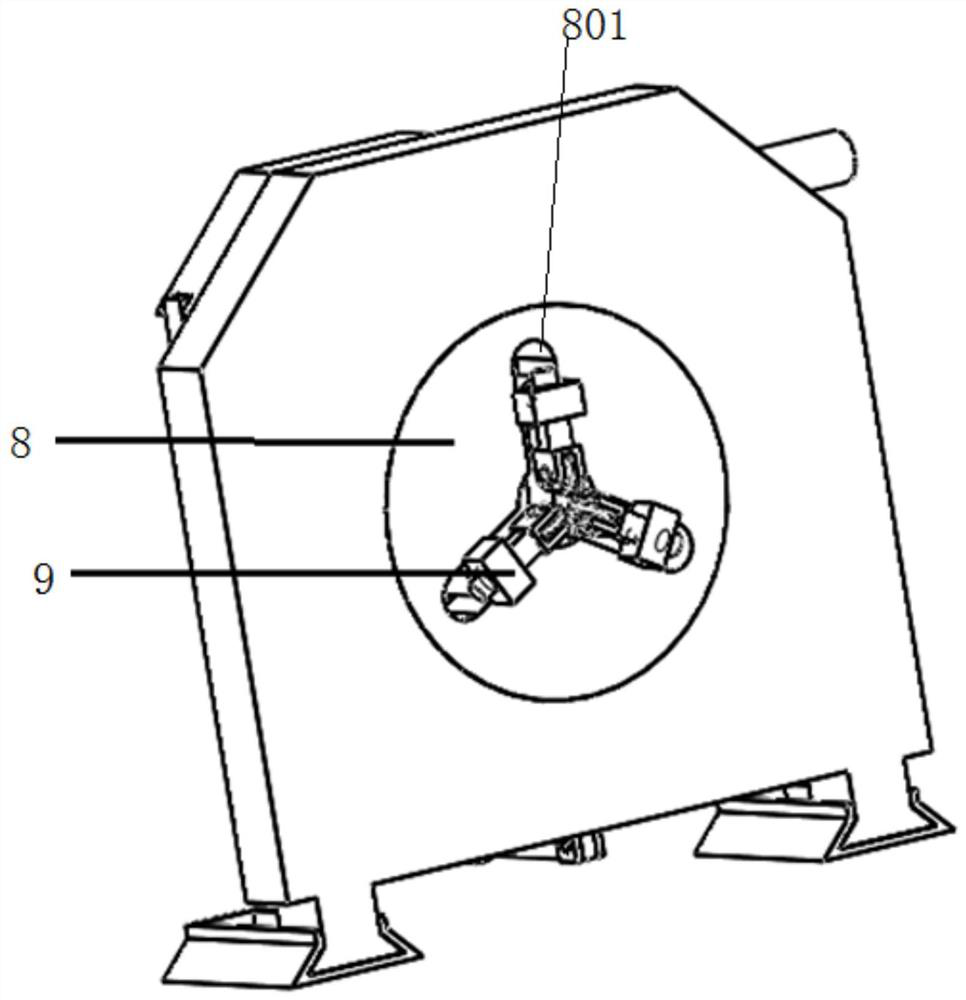

Servo-driven automatic mold repair and electrode cap replacement integrated mechanism

ActiveCN107520532ASimple structureEasy to useWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSpherical form

The invention discloses a servo-driven automatic mold repair and electrode cap replacement integrated mechanism. The servo-driven automatic mold repair and electrode cap replacement integrated mechanism comprises an electrode cap mold repair and cap detachment unit, an electrode cap storage unit and a buffer unit. The electrode cap mold repair and cap detachment unit comprises a power source, a cap detachment unit, a mold repair unit and a transmission gear set. The transmission gear set at least comprises a fourth gear with spiral guide grooves correspondingly formed in the end faces of the two sides. A ball support is fixedly connected to the buffer unit. An upper ear plate portion and a lower ear plate portion are arranged on the ball support. A ball capable of being matched with the corresponding spherical spiral groove is arranged on the lower end face of the upper ear plate portion. A ball matched with the corresponding spherical spiral groove is arranged on the upper end face of the lower ear plate portion. The two balls are coaxially arranged. The fourth gear is mounted between the upper ear plate portion and the lower ear plate portion. The servo-driven automatic mold repair and electrode cap replacement integrated mechanism is simple in structure and convenient to use. Compared with an independent mold repair device or a cap replacement machine, the servo-driven automatic mold repair and electrode cap replacement integrated mechanism has the beneficial effects that the integration is high, the drive force is more stable, the control over the mold repair amount is more accurate, and cap taking is more reliable.

Owner:南京君哲工业自动化有限公司

Mechanical gripping device

ActiveCN107363826AAvoid damageGuaranteed gripping forceProgramme-controlled manipulatorGripping headsCouplingElectric control

The invention discloses a mechanical gripping device which is characterized in that a supporting rod (6) is arranged between a control box I (3) and a power supply box (4); a motor I (7) is connected with the top end of the supporting rod (6); a coupling I (8) is connected with the output shaft of the motor I (7); an extension rod I (9) is fixedly connected with the outer surface of the coupling I (8); a motor II (10) is connected with the top end of the extension rod (9); a coupling II (11) is connected with the output shaft of the motor II (10); an extension rod (12) is connected onto the coupling II (11); a fixing rhombus (13) is connected with the outer end of the extension rod II (12) through fixing nails; an electric rhombus extension block (14) is connected with the transverse outer end of the fixing rhombus (13); and a supporting block (15) is connected with the transverse outer end of the electric rhombus extension block (14). By adoption of the mechanical gripping device disclosed by the invention, the clamping force can be increased, the electric control can be achieved, and the use scope is broad.

Owner:沭阳宏业机械有限公司

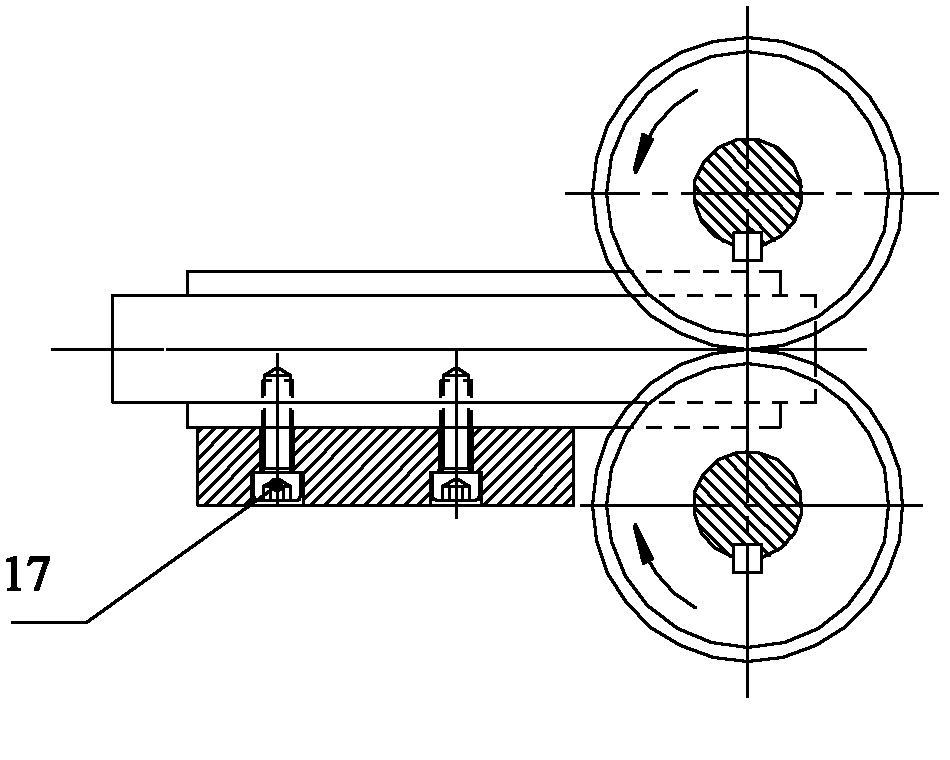

Wear-resistant clamp plate device of stuffing box crimping machine

ActiveCN102828294AEasy to processEasy to installFriction grip releasable fasteningsTextiles and paperWear resistantMechanical wear

The invention discloses a wear-resistant clamp plate device of a stuffing box crimping machine. The wear-resistant clamp plate device comprises brackets, adjusting mechanisms, wear-resistant clamp plates, a base and paired crimping rollers; the adjusting mechanisms capable of relatively sliding are arranged on the brackets; the wear-resistant clamp plates are arranged at the inner sides of the adjusting mechanisms; the two same brackets, the two adjusting mechanisms and the two wear-resistant clamp plates are symmetrically mounted at two sides of the paired crimping rollers and arranged on the base; the wear-resistant clamp plate device further comprises a fluid thrust device; a fluid inlet and a cylinder body are arranged on each bracket; one end of each adjusting mechanism extends into the cylinder body and cooperates with the cylinder body; and the fluid of the fluid thrust device enters the cylinder body from the fluid inlet and drives the wear-resistant clamp plates to move in the direction close to the side of the paired crimping rollers by means of the adjusting mechanisms. The fluid thrust device can be realized by liquid or gas. The device provided by the invention not only can conveniently and accurately adjust the clamping force of the wear-resistant clamp plates and both sides of the paired crimping rollers to be a preset value, but also can automatically compensate the mechanical wear of of the wear-resistant clamp plates or both sides of the paired crimping rollers, generated in the running of the machine, and can keep the preset clamping force all along.

Owner:NANTONG CELLULOSE FIBERS CO LTD

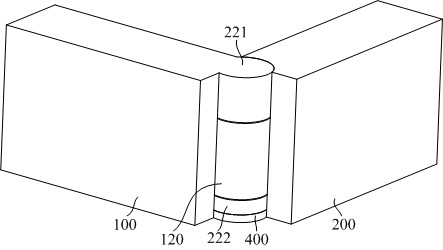

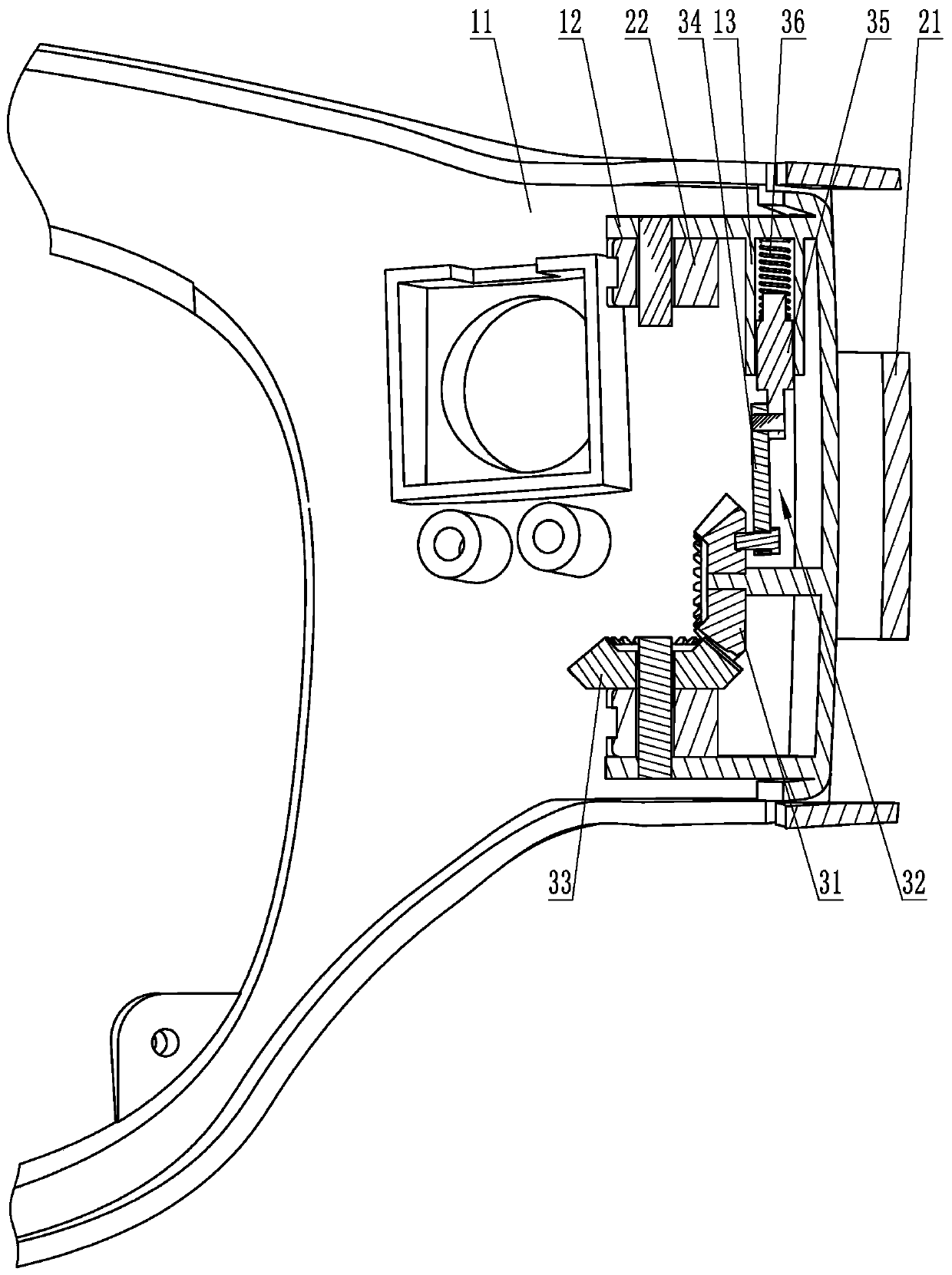

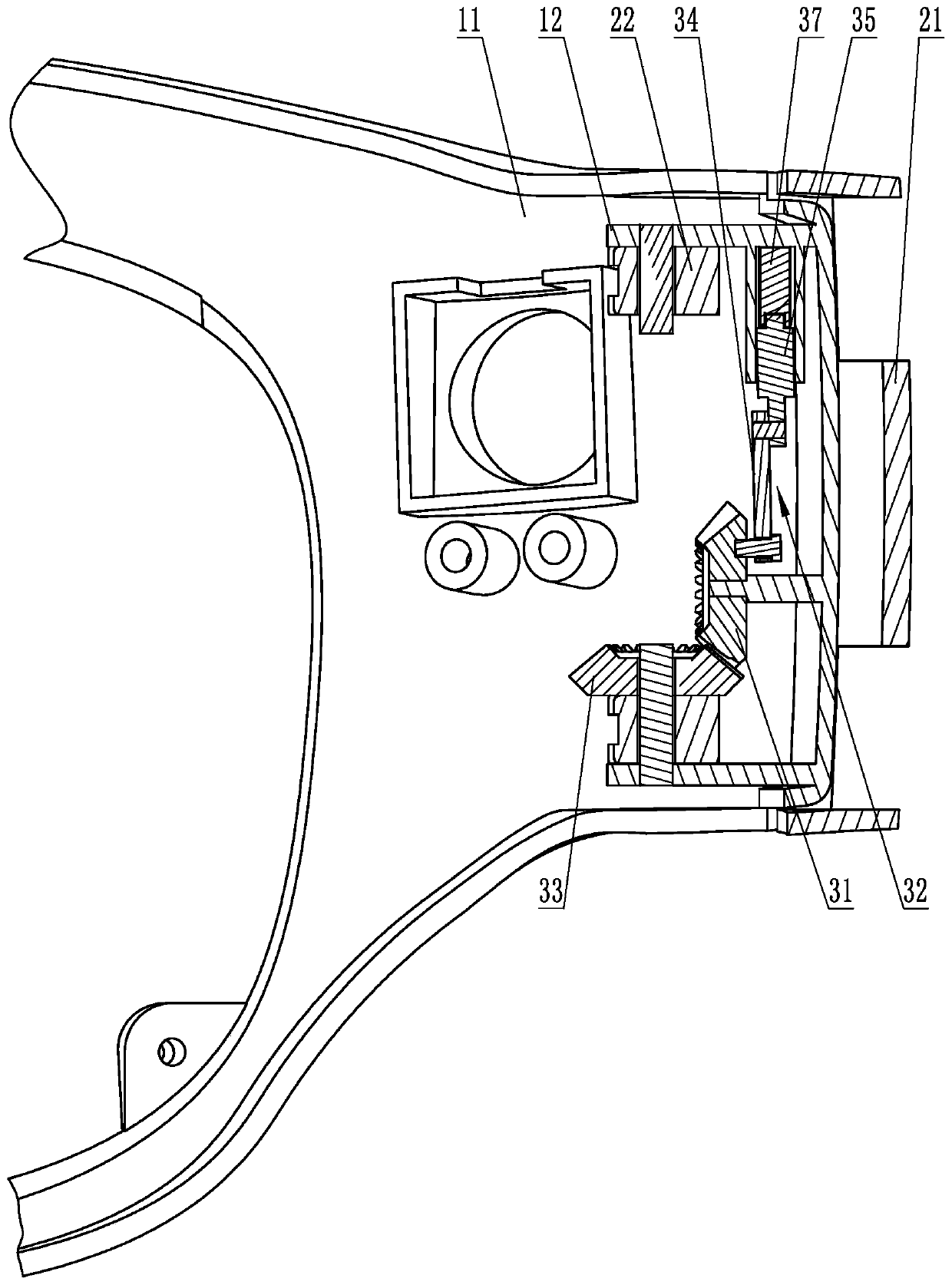

Glasses leg assembly and head-mounted equipment

PendingCN111624773ANot easy to slip offGuaranteed gripping forceOptical elementsMechanical engineeringPhysics

The invention discloses a glasses leg assembly and head-mounted equipment. The glasses leg assembly comprises a first rotating arm, a second rotating arm and a rotating shaft assembly, wherein the rotating shaft assembly is used for rotatably connecting the first rotating arm and the second rotating arm; the rotating shaft assembly is connected with the first rotating arm and can move in the length direction of the first rotating arm under the action of external force; meanwhile, the rotating shaft assembly is rotatably connected with the second rotating arm. When the second rotating arm rotates towards the outer side of the first rotating arm, the rotating shaft assembly moves in the length direction of the first rotating arm, and the rotating shaft assembly applies acting force enablingthe second rotating arm to move towards the inner side of the first rotating arm. Due to the reverse bending function of the glasses leg assembly, the glasses leg assembly can be suitable for being worn by users with different head circumferences, a certain clamping force can be kept when the second rotating arm is reversely bent, and the glasses leg assembly is comfortable and reliable to wear.

Owner:GEER TECH CO LTD

Laptop positioning rotary shaft

ActiveCN107131203AReduce spillageImprove the lubrication effectPivotal connectionsEngine lubricationEngineeringLubrication

The invention discloses a laptop positioning rotary shaft. A rotary bracket of the laptop positioning rotary shaft further comprises a supporting part, a first shaft sleeve and a second shaft sleeve. The area, between the other end of the rotary bracket and the second shaft sleeve, of the lower end face of the rotary bracket is provided with a dove-shaped groove. Loose fin rings and tight fin rings are each provided with a notched groove. A smooth rod part of an axis rod is sleeved with the loose fin rings and the tight fin rings. Gaps are reserved between the loose fin rings and the smooth rod part, and the tail ends of the loose fin rings are in tight fit contact with the smooth rod part. The inner walls of the loose fin rings and the tight fin rings are each provided with two inward sunken grooves which are separately located in the two sides of the corresponding notched groove. The gap part of each loose fin ring communicates with the two inward sunken grooves of the corresponding loose fin ring. The loose fin rings and the tight fin rings are alternately arranged. The middle area between the smooth rod part and the unsmooth rod part of the axis rod is provided with a protruding strip. The laptop positioning rotary shaft is good in stability and uniformity of torsion and friction force, and floating of the torsion and the friction force are controlled within 7%, so that torsion attenuation is reduced, and lubrication continuity and durability between the smooth rod part and the inner walls of the fin rings are further ensured.

Owner:KUNSHAN KERSEN SCI & TECH

Foldable glasses leg assembly and head-mounted equipment

ActiveCN111665632AGuaranteed gripping forceImprove wearing comfortOptical elementsStructural engineeringMechanical engineering

The invention discloses a foldable glasses leg assembly and head-mounted equipment. One end of a glasses frame is provided with a first rotary connecting part, and the glasses frame is provided with afirst limiting part; a second rotary connecting part is arranged at one end of each glasses leg, and the second rotary connecting part is rotatably connected with the first rotary connecting part; asecond limiting part is arranged on the glasses leg; elastic sheets are rotationally connected with the glasses legs; the first ends of the elastic sheets are located in the first limiting parts, andthe second ends of the elastic sheets are located in the second limiting parts; the elastic pieces can rotate along with the glasses legs; and when the first ends of the elastic pieces abut against the ends of the first limiting parts and the second ends of the elastic pieces abut against the ends of the second limiting parts, the elastic pieces can provide acting force for the glasses legs to move towards the inner side of the glasses frame. The glasses legs can keep a certain clamping force through the elastic pieces, the glasses can be suitable for being worn by heads with different head circumferences, and the wearing comfort of users is improved; and circuits such as an FPC assembly are not exposed when the head-mounted equipment is folded, and the product reliability is improved.

Owner:GEER TECH CO LTD

Novel cable recovery device for ocean engineering

The invention discloses a novel cable recovery device for ocean engineering, and relates to the field of cable recovery. The novel cable recovery device for the ocean engineering comprises a base, the top side of the base is fixedly provided with a motor, two installing plates and a sliding groove, wherein one sides of the installing plates are provided with through groove openings, and rotating shafts are rotationally installed on the sides, close to each other, of the two installing plates correspondingly, and the output end of the motor is connected to one end of one of the rotating shafts through a transmission part. According to the novel cable recovery device, the motor is started to drive a driving wheel, so that a belt can drive a driven rotating wheel to enable the rotating shafts to rotate, then a linkage shaft drives a rod and an inserting rod to enable a winding reel to automatically wind a cable, meanwhile, the driven rotating wheel rotates to drive a round rod to displace, a swing rod is driven to generate angle change during displacement, a rotating plate is pushed to displace teeth, and a linkage gear enables a threaded rod to rotate, so that a moving part moves in a reciprocating manner, and the cable is uniformly wound in the recycling process.

Owner:广州从益网络科技有限公司

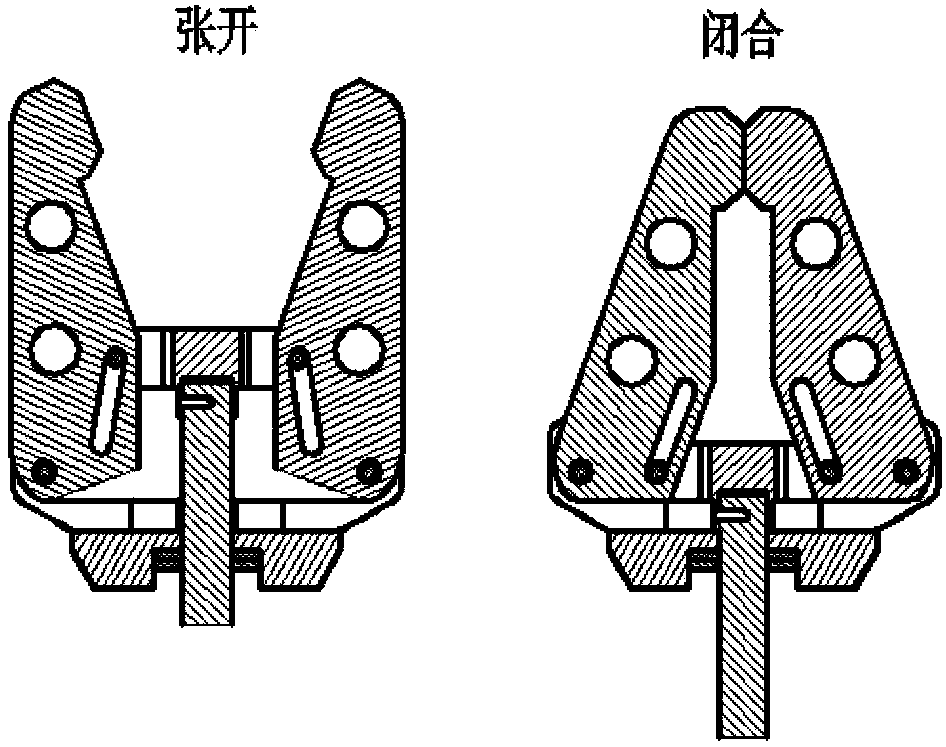

Ground wire device for vertical high-voltage lead

ActiveCN104332732AGuaranteed reliabilityGuaranteed gripping forceElectric connection structural associationsGround lineEngineering

The invention discloses a ground wire device for a vertical high-voltage lead. The ground wire device for the vertical high-voltage lead comprises a bottom plate, a first clamp piece, a second clamp piece and an insulating rod, the bottom plate is arranged vertically, the first clamp piece is symmetrical to the second clamp piece, the first clamp piece and second clamp piece are rotationally arranged at two sides of the bottom plate, the bottom plate is provided with a closing mechanism for driving the first clamp piece and second clamp piece to rotate to contact with each other to tightly hold the high-voltage lead, one end of the insulating rod is connected with the bottom plate, and the other end of the insulating rod is provided with a separating mechanism for driving the first clamp piece and second clamp piece to rotate to separate from each other to loosen the high-voltage lead. The ground wire device for the vertical high-voltage lead has advantages of simple structure, easiness in clamping and disassembling, and firm clamping.

Owner:STATE GRID CORP OF CHINA +2

Automatic centering guide mechanism and method

PendingCN112059649AAccurate clampingRealize the clamping effectLarge fixed membersCircular discGear wheel

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Glasses leg damping mechanism and AR (Augmented Reality) glasses

The invention belongs to the technical field of AR (Augmented Reality) glasses, in particular to a glasses leg damping mechanism and AR (Augmented Reality) glasses. The glasses leg damping mechanism comprises a driven gear rotatably installed on a glasses body, an elastic stretching mechanism arranged between the driven gear and the glasses body, and a stirring element fixedly installed on the glasses leg, wherein one end of the elastic stretching mechanism is connected to the side edge of the first spindle of the driven gear, and the other end of the elastic stretching mechanism is fixed on the glasses body. The AR glasses comprise the glasses body and two glasses leg independently rotatably connected to two sides of the glasses body, wherein the glasses leg damping mechanism is independently arranged between the glasses leg on each side and the glasses body part on the corresponding side. Through the stirring element, the driven gear is stirred to rotate, so that the elastic stretching structure is compressed or stretched to enable the elastic stretching structure to generate elastic force, and under the elastic force function of the elastic stretching mechanism, two glasses legsof the AR glasses are tightly clamped on the head of a user. When the user wears the AR glasses, clamping force between the glasses legs and the head of the user can be guaranteed so as to be convenient in wearing.

Owner:GEER TECH CO LTD

Ultrasonic stitching and embossing machine

The invention relates to an ultrasonic stitching and embossing machine. The ultrasonic stitching and embossing machine comprises an operation platform face supported by a support; an ultrasonic deviceis mounted below the operation platform face; the ultrasonic stitching and embossing machine further comprises an ultrasonic generator; a supporting seat is mounted on the operation platform face, and a stitching and embossing device and a driving device providing power for the stitching and embossing device are mounted on the supporting seat; the ultrasonic stitching and embossing machine further comprises an air compressor; the stitching and embossing device comprises a sliding rail mounted and fixed to the supporting seat; a lifting sliding block is mounted on the front part of the slidingrail, a top plate is mounted at the top of the sliding rail, an adjustable air cylinder is mounted on the top plate, and the lower end of a piston rod of the adjustable air cylinder is connected withthe top of the lifting sliding block in a hinged mode; a mounting base plate is mounted on the lifting sliding block, a pressure roller base is mounted on the front part of the bottom of the mountingbase plate in a hinged mode, a pattern wheel is mounted on the lower part of the mounting base plate, and a pressure roller synchronously rotating with the pattern wheel is mounted on the pressure roller base; and a carrier roller is further arranged below the pressure roller. The ultrasonic stitching and embossing machine is reasonable in structural design, the stitching and embossing flatness of a product is high, and adjusting is convenient.

Owner:TIANJIN CITY BAOJIA CLOTHING MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com