Wear-resistant clamp plate device of stuffing box crimping machine

A technology of crimping machine and stuffing box, which is used in mechanical equipment, friction-clamped detachable fasteners, textiles and papermaking, etc. Can not achieve timely automatic compensation and other problems, to achieve the effect of simple processing and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

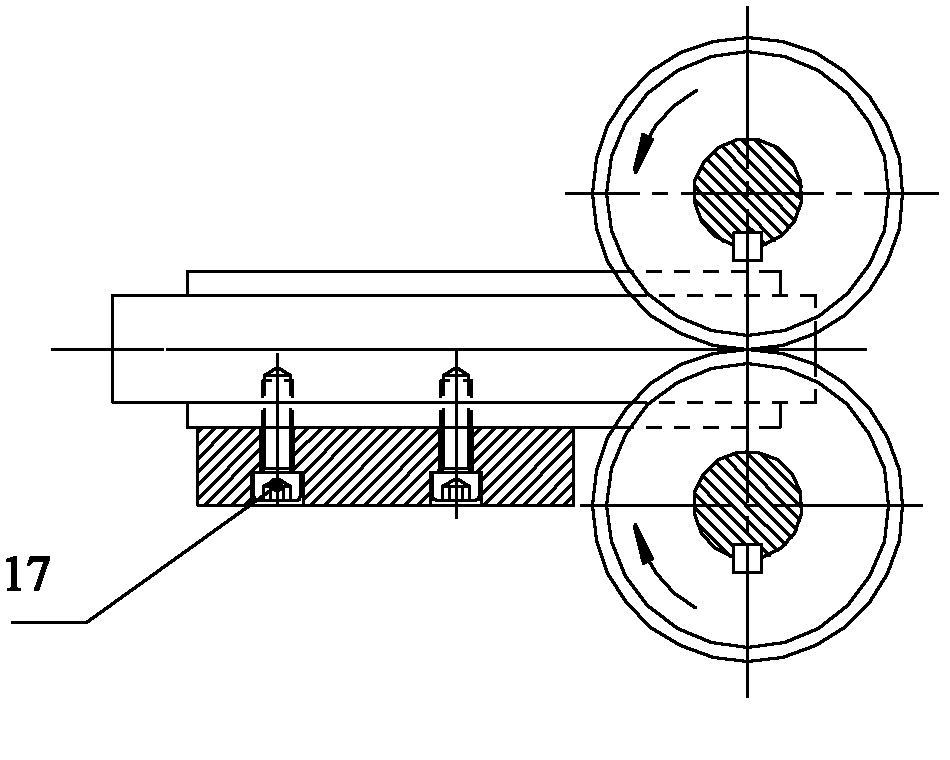

Embodiment 1

[0025] Such as Figure 4 As shown, a stuffing box crimping machine wear-resistant splint adjustment device includes a bracket 1, a relatively sliding adjustment block 2 is installed on the bracket 1, a wear-resistant splint 3 is installed on the inside of the adjustment block 2, two identical brackets 1, and the adjustment block 2. The wear-resistant splint 3 is symmetrically installed on both sides of the curling roller 5 . The adjustment block 2 is provided with a stepped part, one end of the stepped part is a cylindrical piston with a smaller diameter, and the cylindrical piston can slide back and forth along the cylinder axis in the cylinder of the bracket, and the other end of the stepped part is a cylindrical piston with a larger diameter The wedge-shaped body, the cylindrical piston and the wedge-shaped body are processed into one piece or assembled together after segmental processing; the surface of the wedge-shaped body is composed of multiple planes, and is composed ...

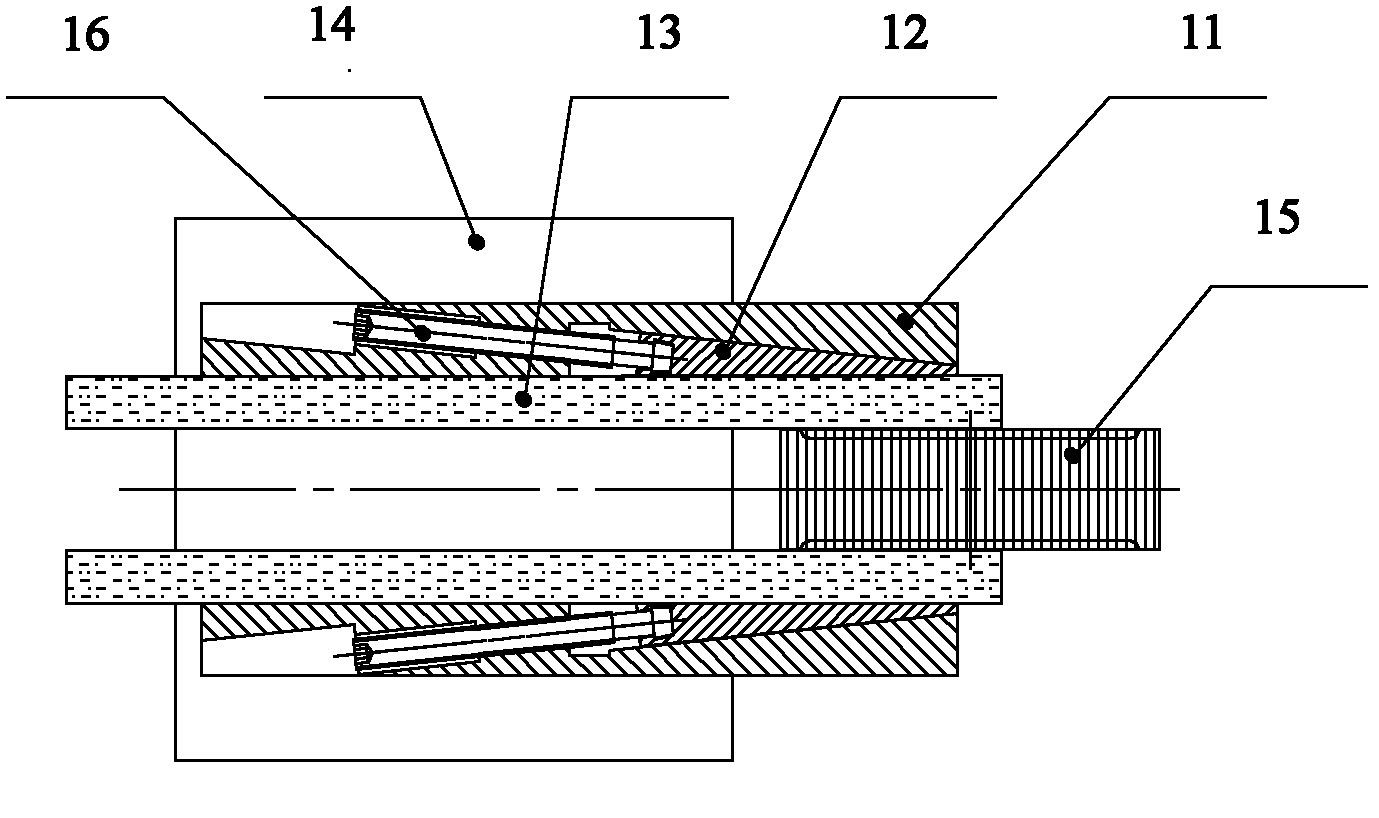

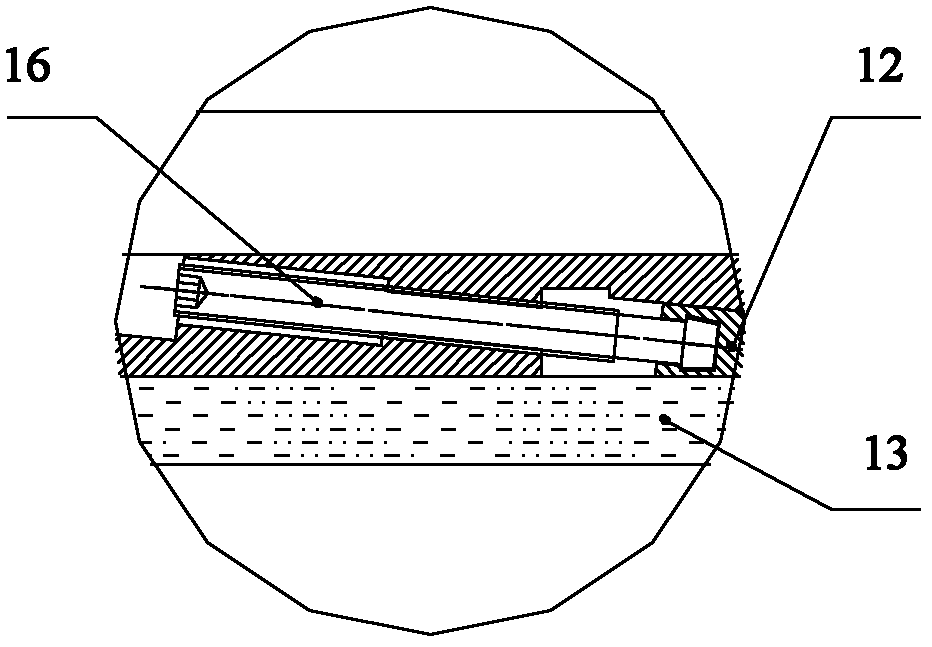

Embodiment 2

[0027] Such as Figure 5As shown, a stuffing box crimping machine wear-resistant splint adjustment device includes a bracket 1, a relatively sliding adjustment block 2 is installed on the bracket 1, a wear-resistant splint 3 is installed on the inside of the adjustment block 2, two identical brackets 1, and the adjustment block 2. The wear-resistant splint 3 is symmetrically installed on both sides of the curling roller 5 . The adjustment block 2 is provided with a stepped portion, one end of the stepped portion is a first cylindrical piston with a smaller diameter, the first cylindrical piston can slide back and forth in the cylinder of the bracket along the cylinder axis, the other end of the stepped portion is a diameter opposite The larger wedge body of the first cylindrical piston, the first cylindrical piston and the wedge body are processed as a whole or assembled together after segmental processing; the surface of the wedge body is composed of multiple planes, which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com