Efficient sock butend sewing machine rivaling manual butend sewing

A technology for stitching machines and socks, which is applied in the direction of sewing machines, sewing machine components, sewing machine control devices, etc. It can solve the problems of small space occupation, regular vibration, small vibration amplitude, and low sewing quality, so as to reduce the failure rate and improve the sewing quality. The seam effect, the effect of reducing the vibration amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

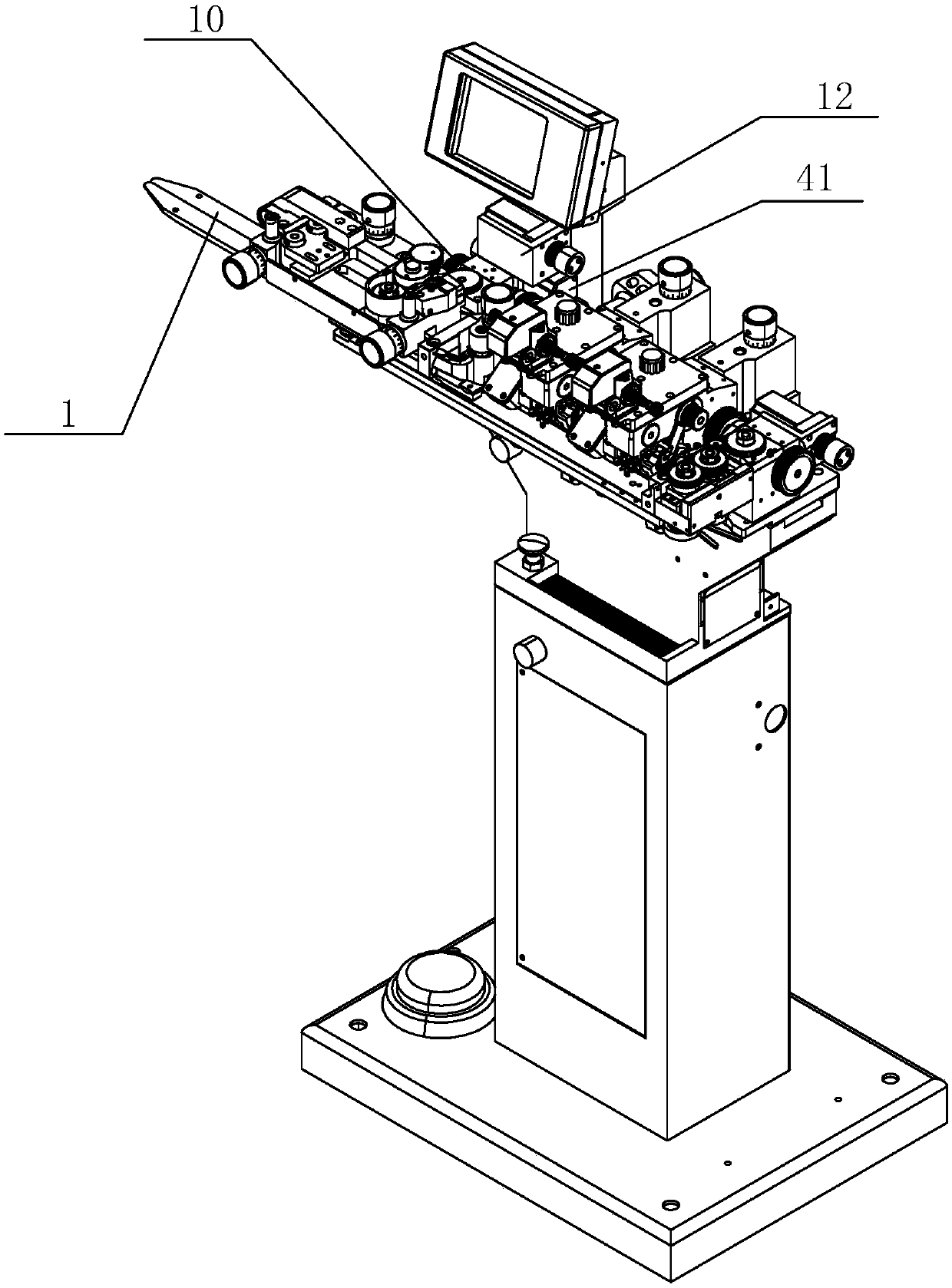

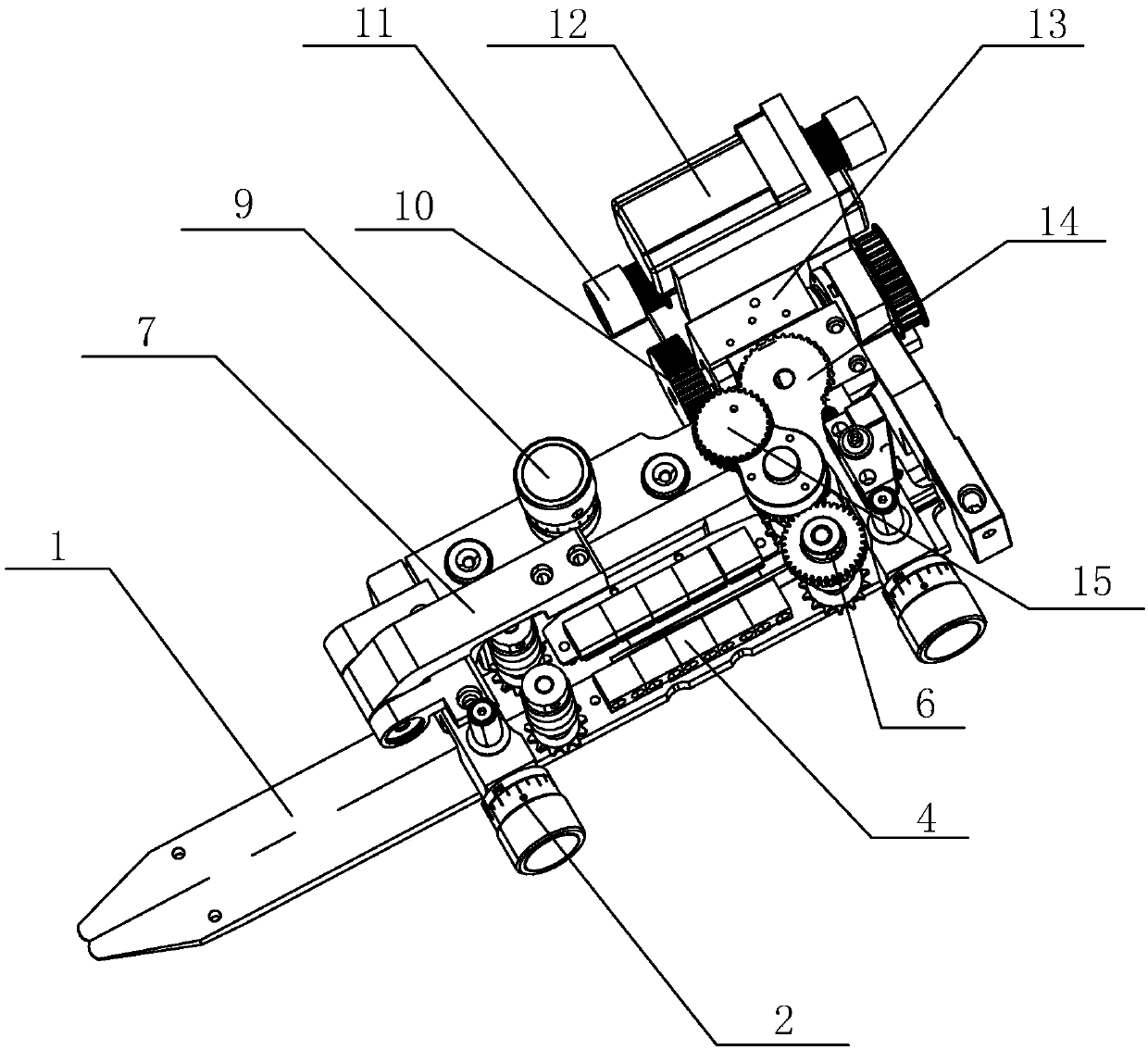

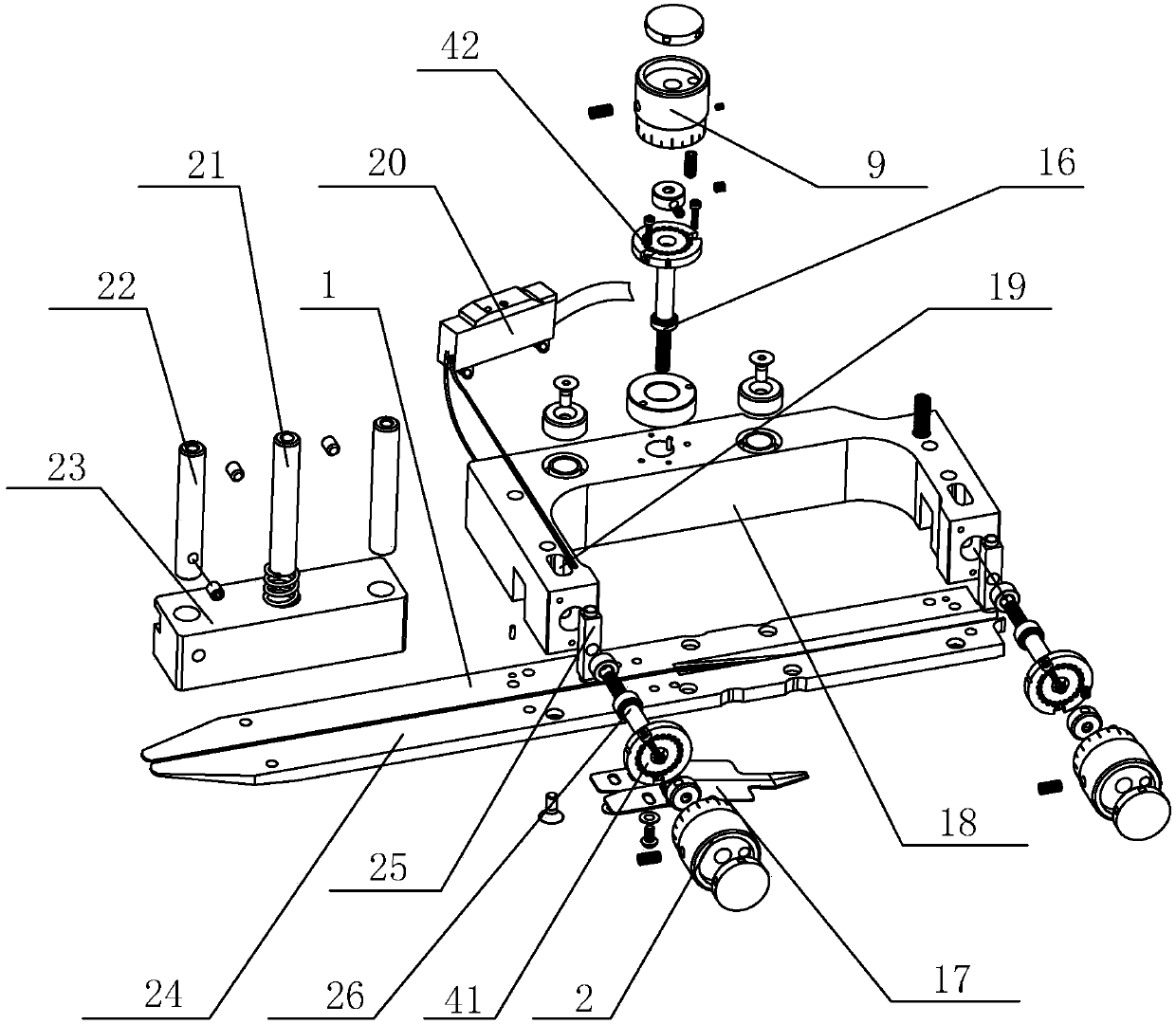

[0030] Such as Figure 1-9 Shown is a sock sewing machine that is as efficient as manual sewing, including a sewing motor that drives the sock sewing machine and a transmission motor that drives the sock transmission system. The sock transmission system includes a front transmission system and a rear transmission system, and The head sewing machine installed on the installation table, double head, double lifting system.

[0031] The front section transmission system includes the seam end motor 12 and the transmission motor 41 that drive the sock sewing machine, and the front section transmission system includes the front section clamping mechanism and the front section clamping mechanism of socks. The front clamping mechanism contains the elastic device and lifting device for clamping socks. The front clamping mechanism includes a worm driven by a transmission motor 41. The worm is installed in the worm box 13. The worm drives two front chain gears through a gear set. The two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com