Patents

Literature

241results about "Combination sewing machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Towel machine

ActiveCN103498291AReduce manufacturing costIncrease productivityWorkpiece carriersWork-feeding meansIndustrial engineering

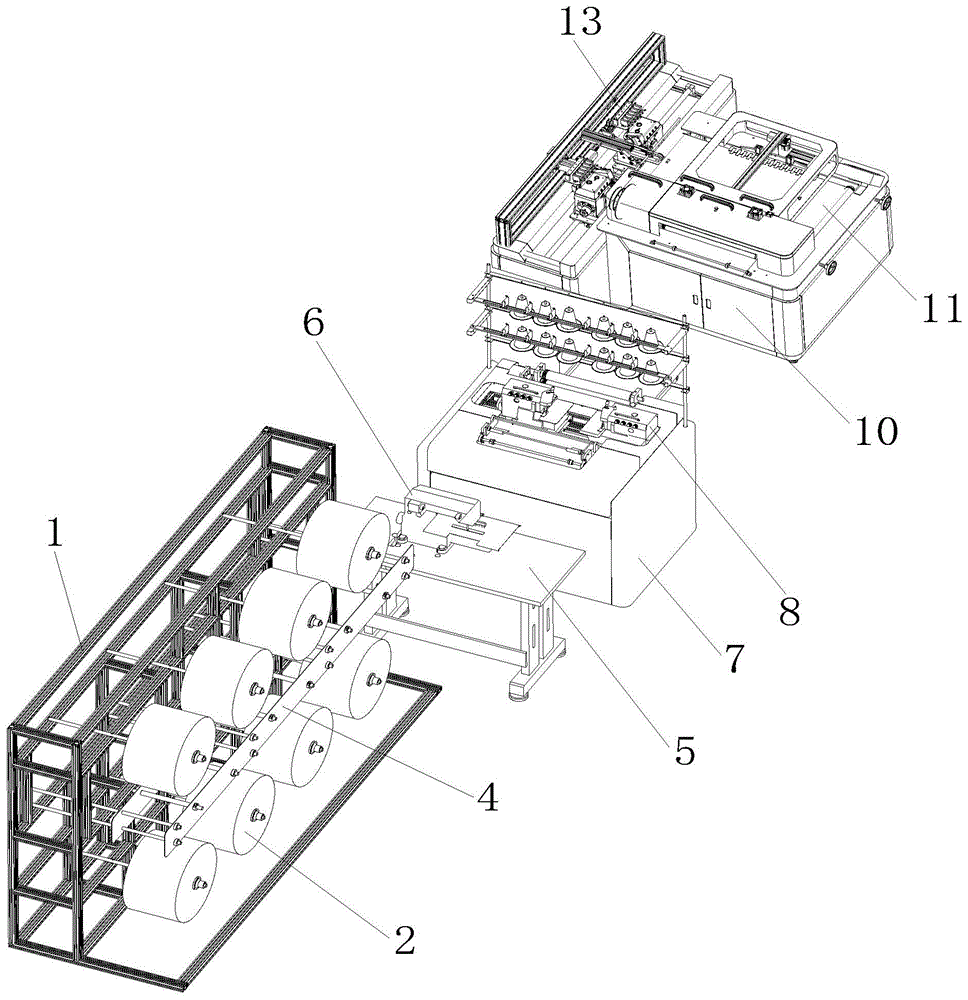

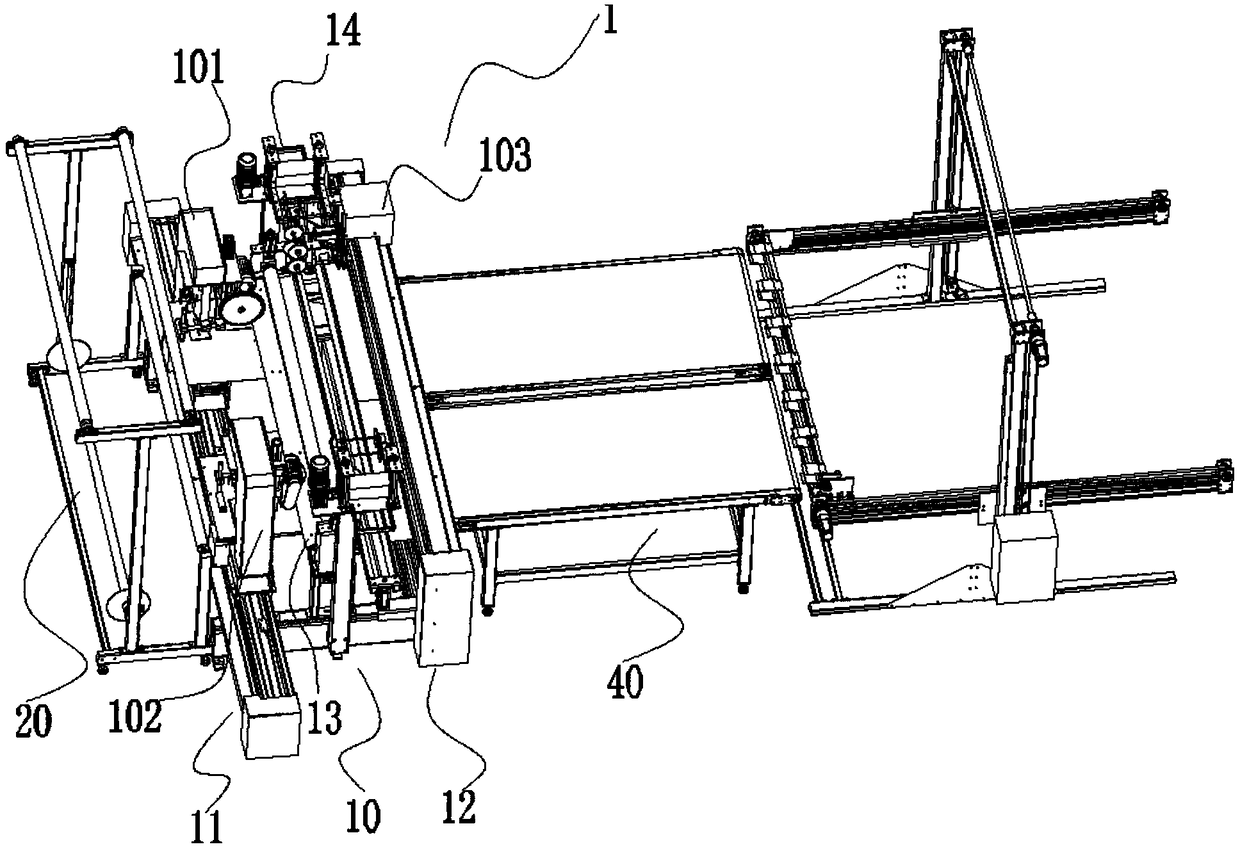

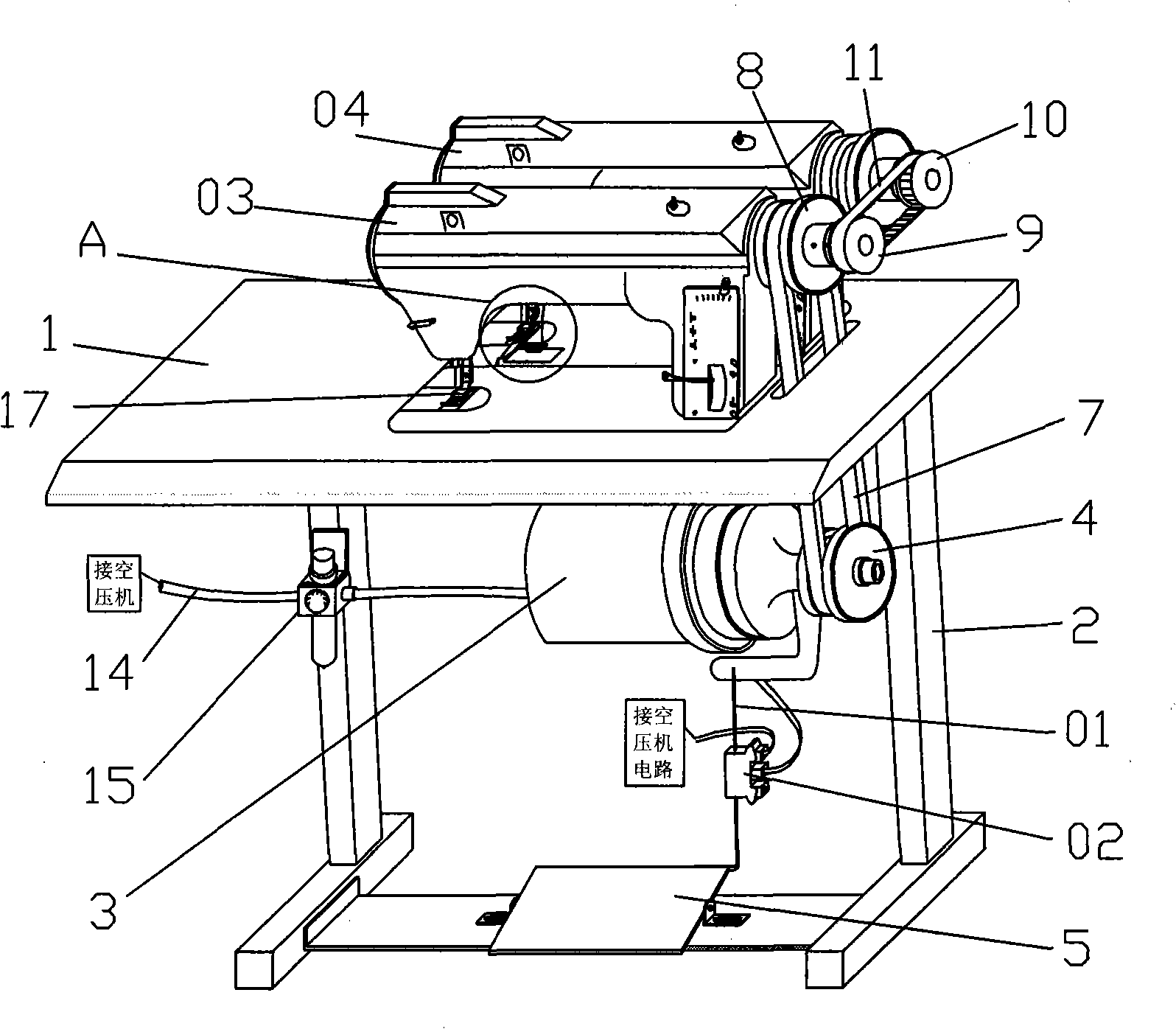

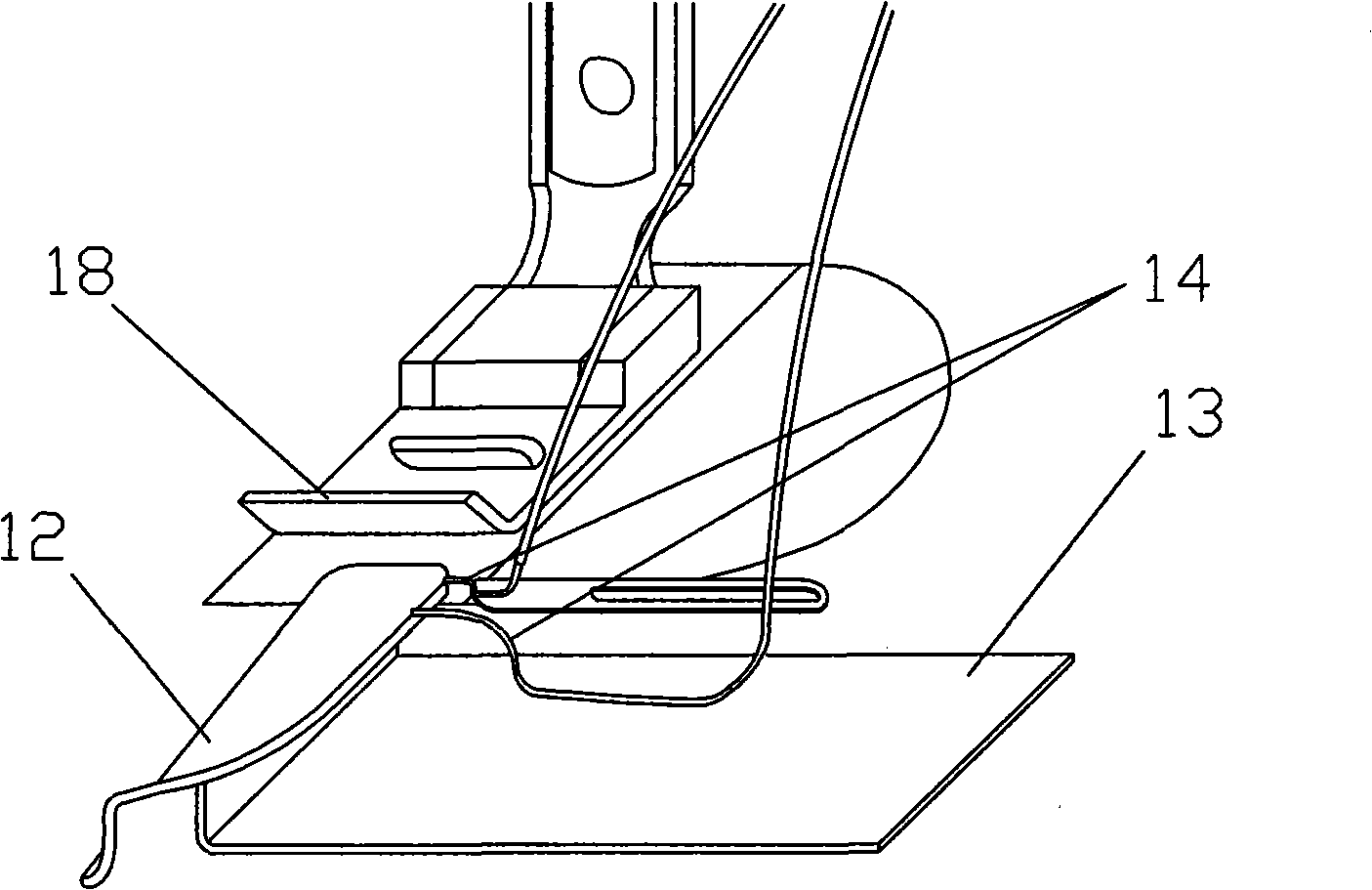

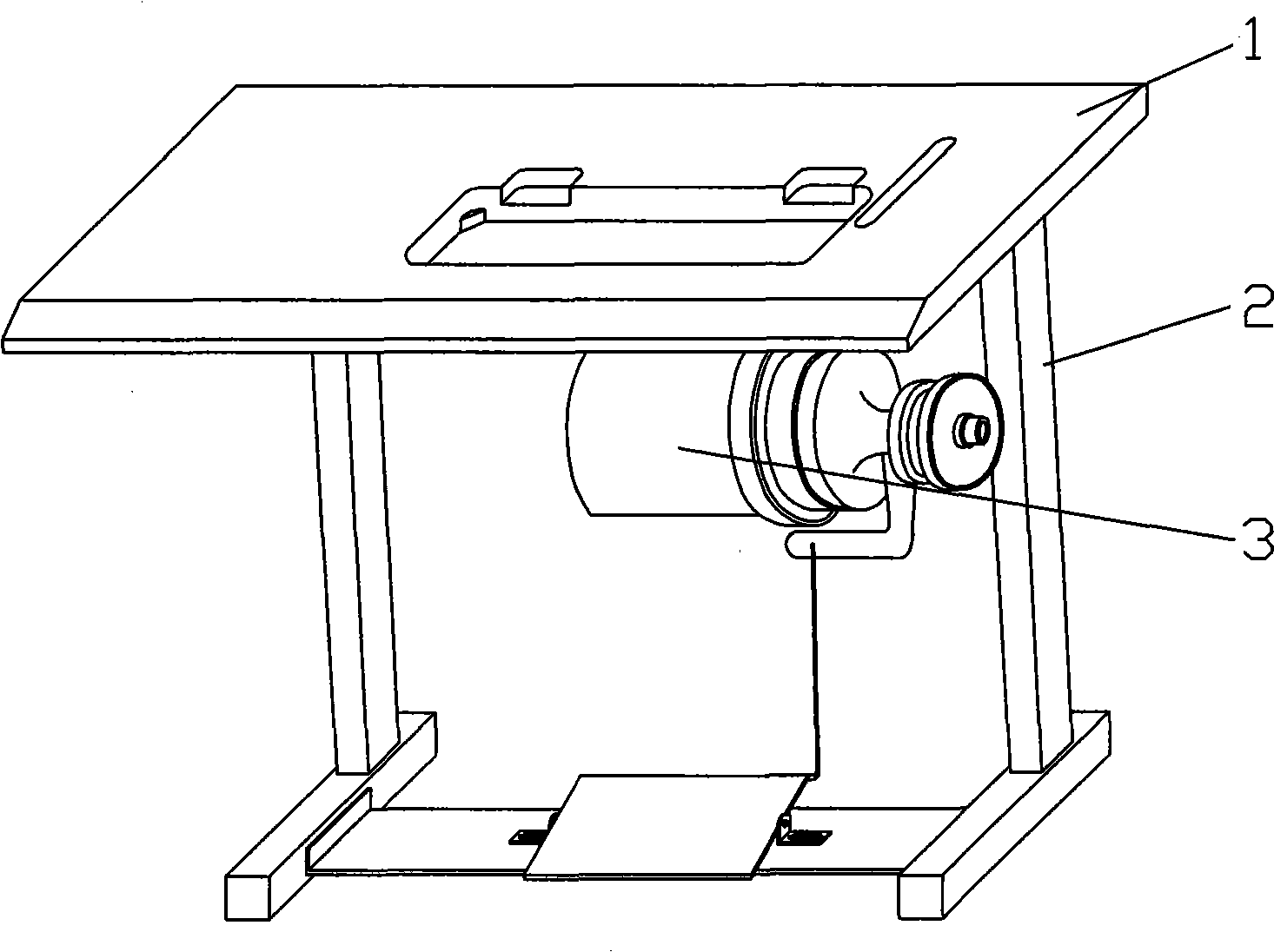

The invention discloses a towel machine. The towel machine comprises a feeding device, a first processing device and a second processing device. The feeding device, the first processing device and the second processing device are oppositely and fixedly placed in sequence. The feeding device is used for feeding cloth to the first processing device; the first processing device is used for binding off the two edges of the cloth fed by the feeding device for the first time; the second processing device is used for cutting off the cloth fed by the first processing device and then binding off the two edges of the cloth for the second time. According to the towel machine, original manual operation is replaced by mechanical automatic operation for towel production, so that labor intensity is greatly reduced for workers, the production mode that a single worker operates multiple machines can be realized in production, production efficiency of the product is improved, production cost is lowered, effective production management is facilitated, and the production value of the product is maximized.

Owner:SUZHOU TRANSPARENT TECH CO LTD

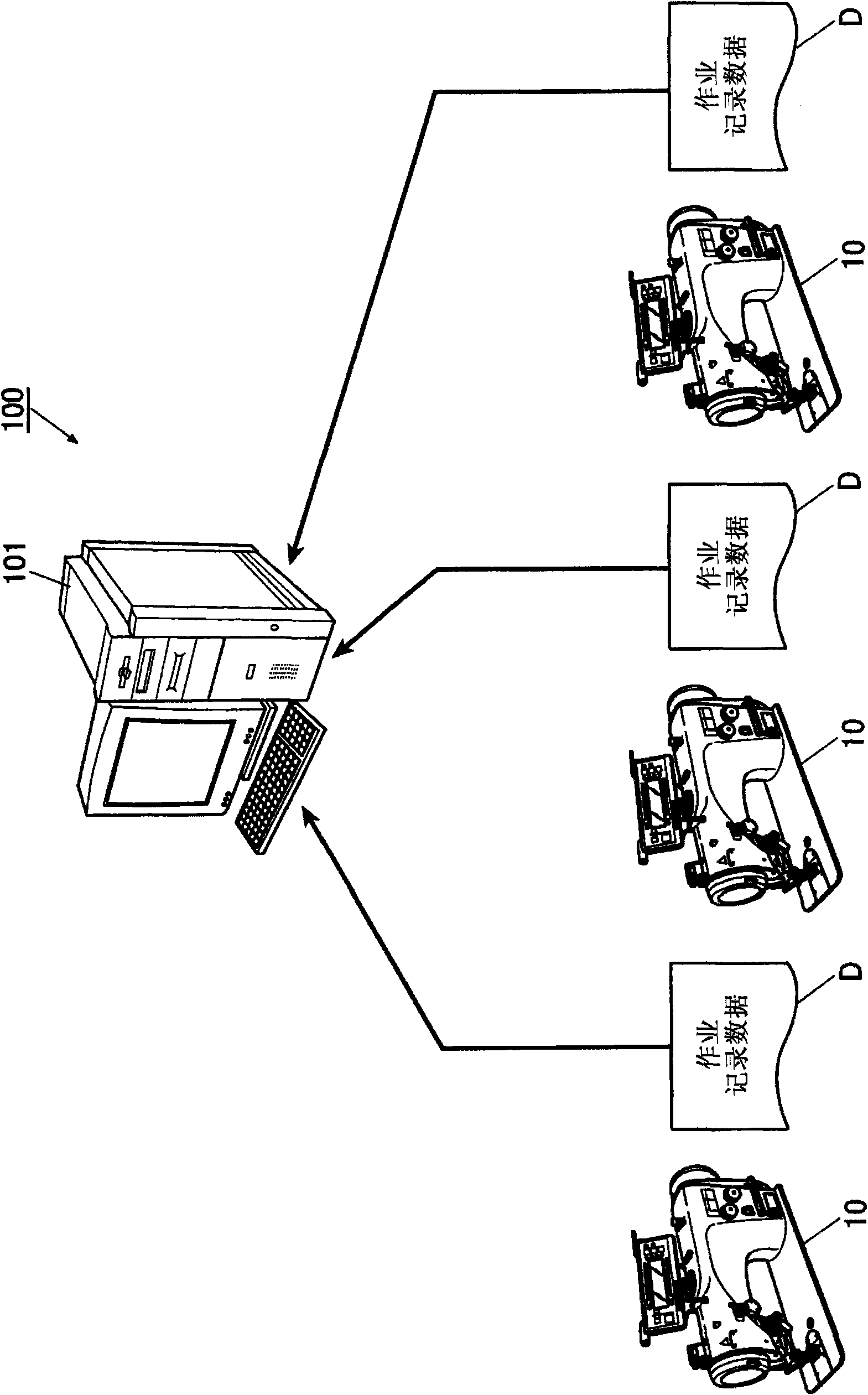

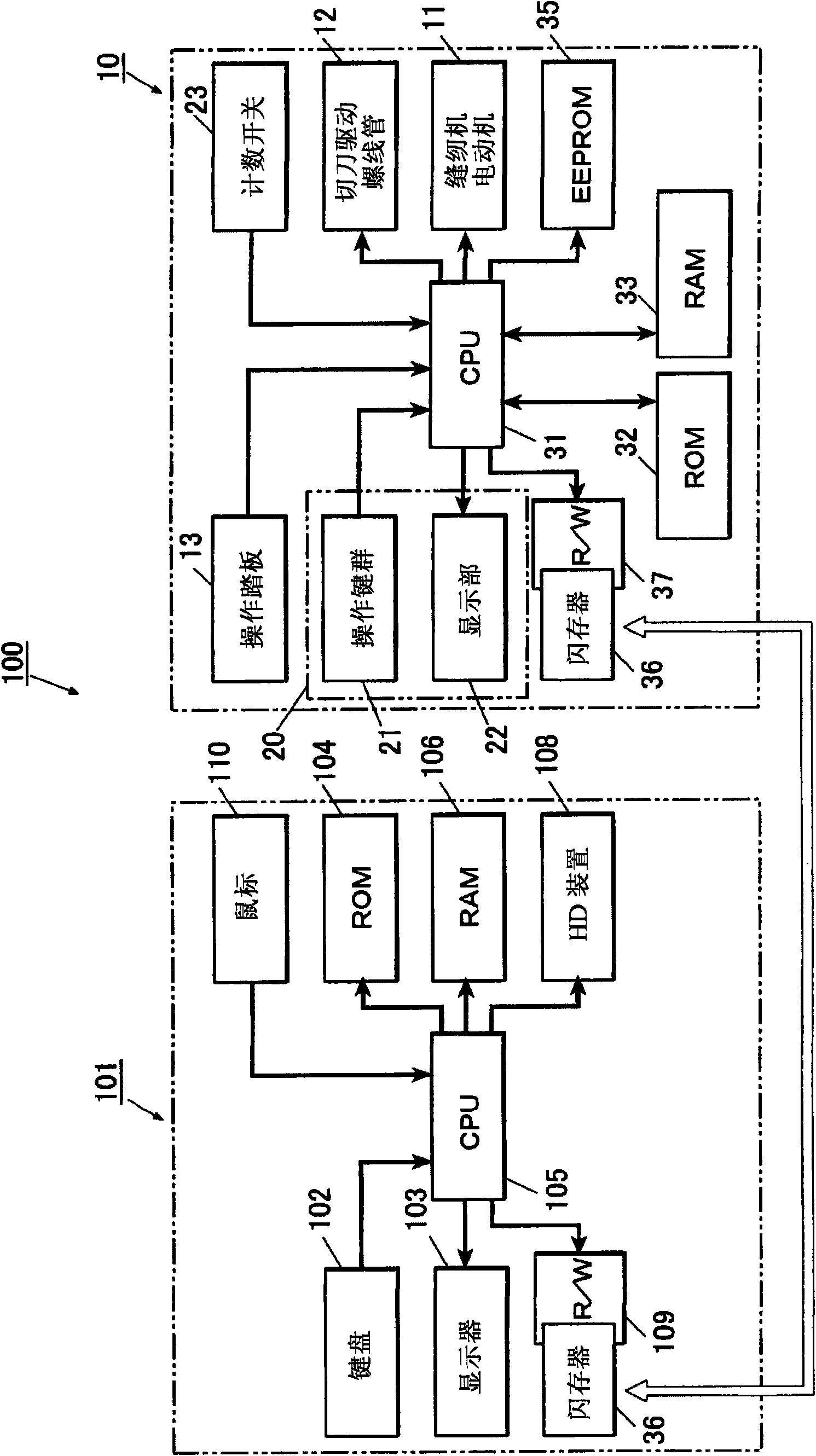

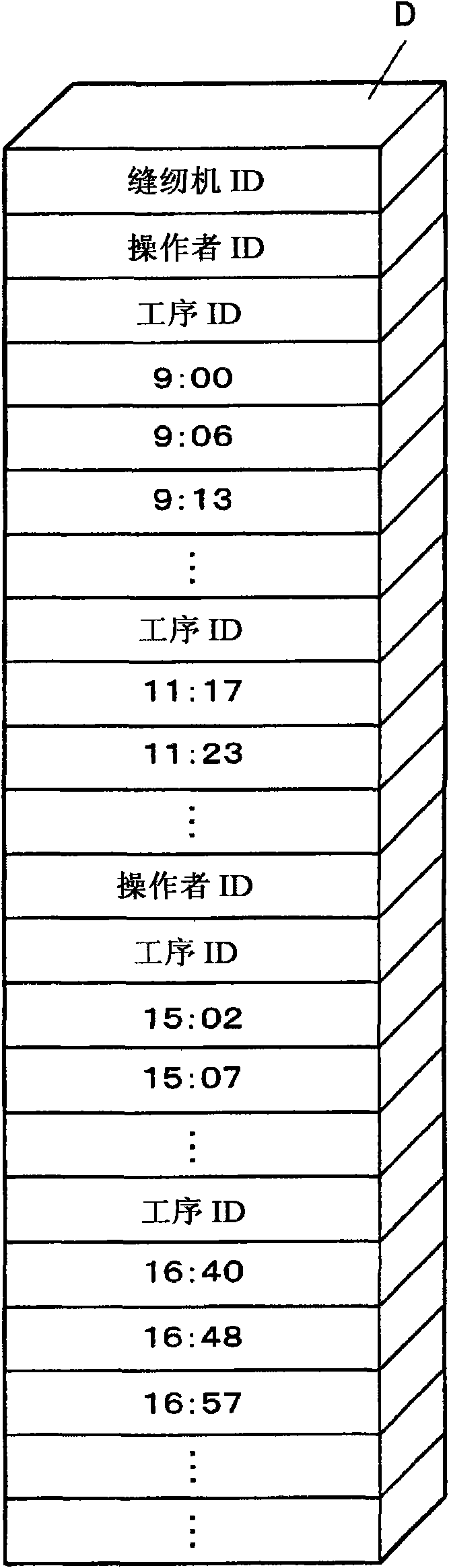

Operation analysis apparatus

InactiveCN101667283AAdjust process assignmentIncrease productivityData processing applicationsCombination sewing machinesOperator IDTime data

The invention relates to an operating analysis apparatus, which can correctly adjust process distribution of operator, and realize improvement of the production efficiency. The invention includes: a data acquiring unit, which acquires operation recording data D including operator ID, process ID and production pitch time data from each sewing machine; a operation requiring time calculation unit, inthe integral or part of the range of each operation recording data, production pitch time of each operator is calculated for each operation process; as well as actual job time calculation unit, against each operator, the production pitch time of each operation process is totaled for calculating an actual job time; an actual job time calculation unit, an operation process exists in each operationrecording data, that is under the instance of division of operation by multiple operators, the required time specific information is the averaged required time of the operation process operated by operators through conciliation and equilibration, based on the required time of each operation for calculating actual job time.

Owner:JUKI CORP

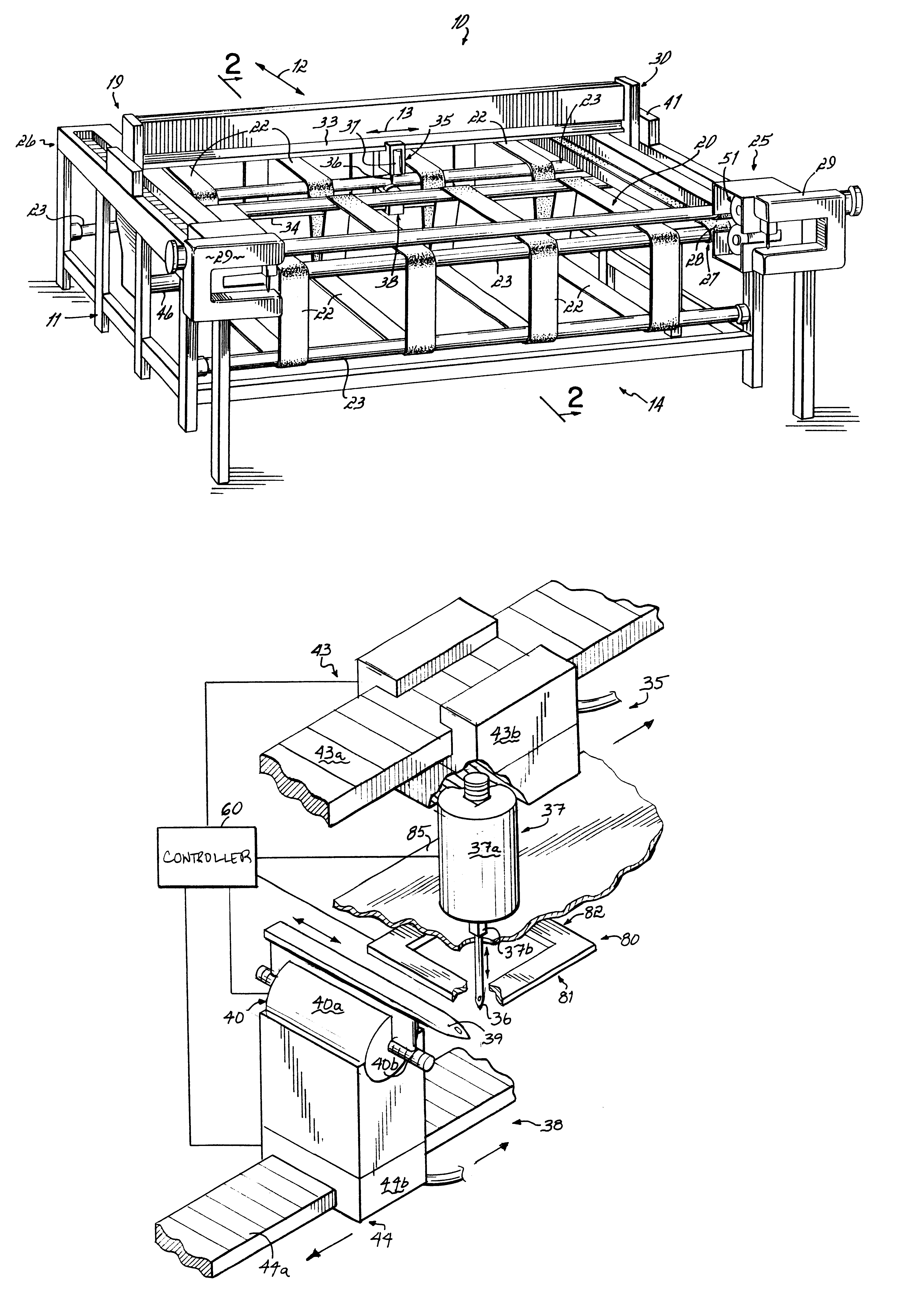

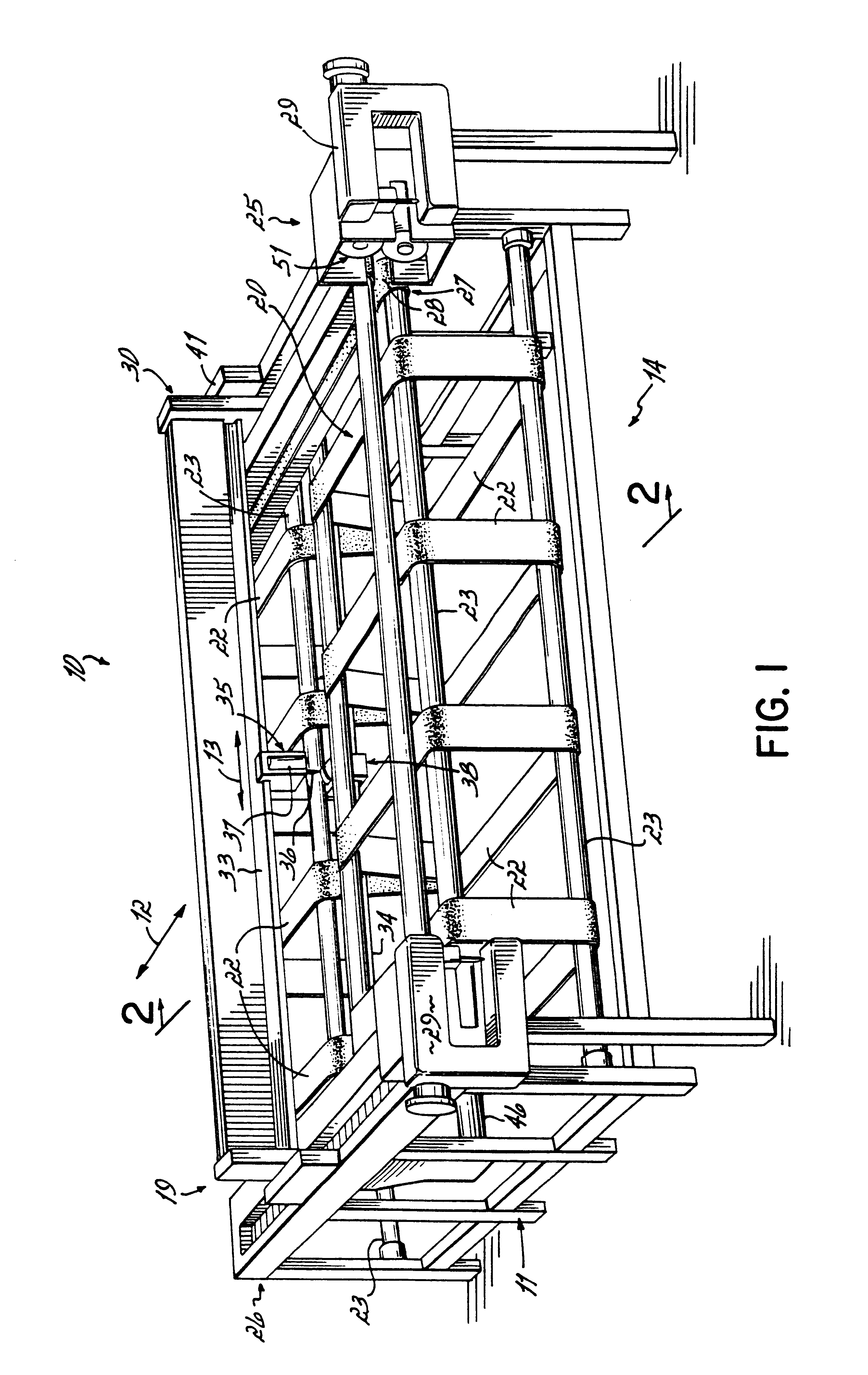

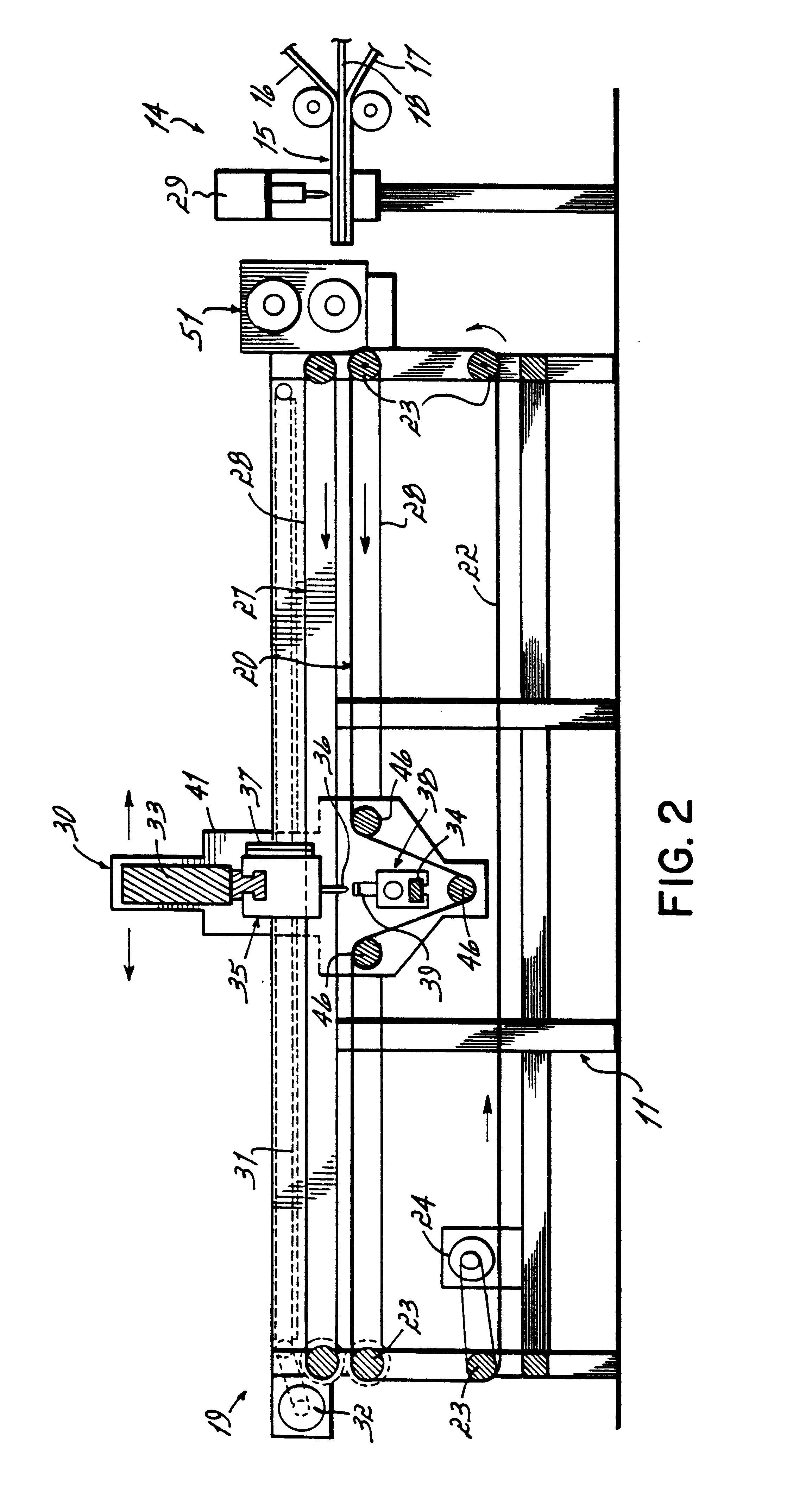

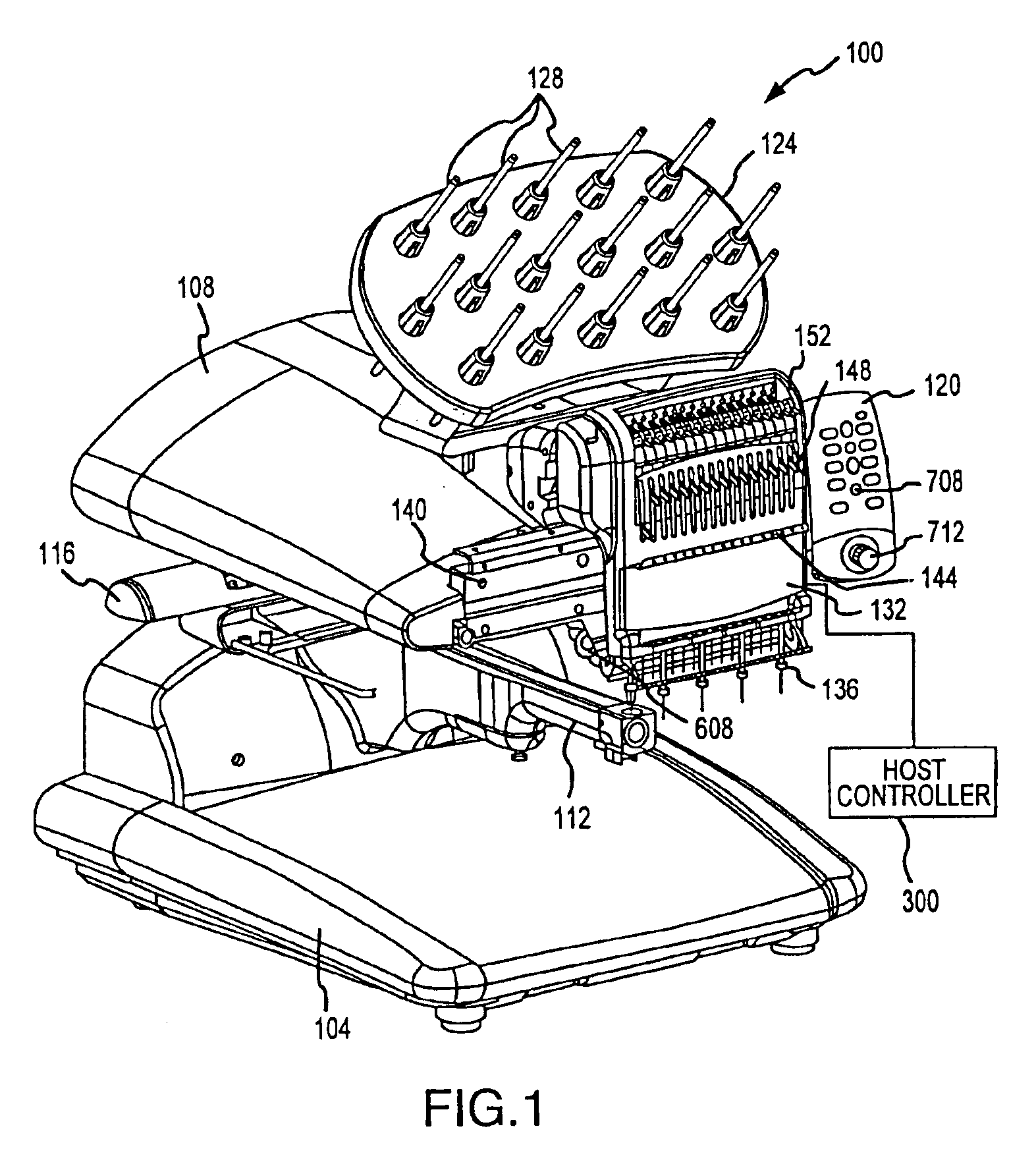

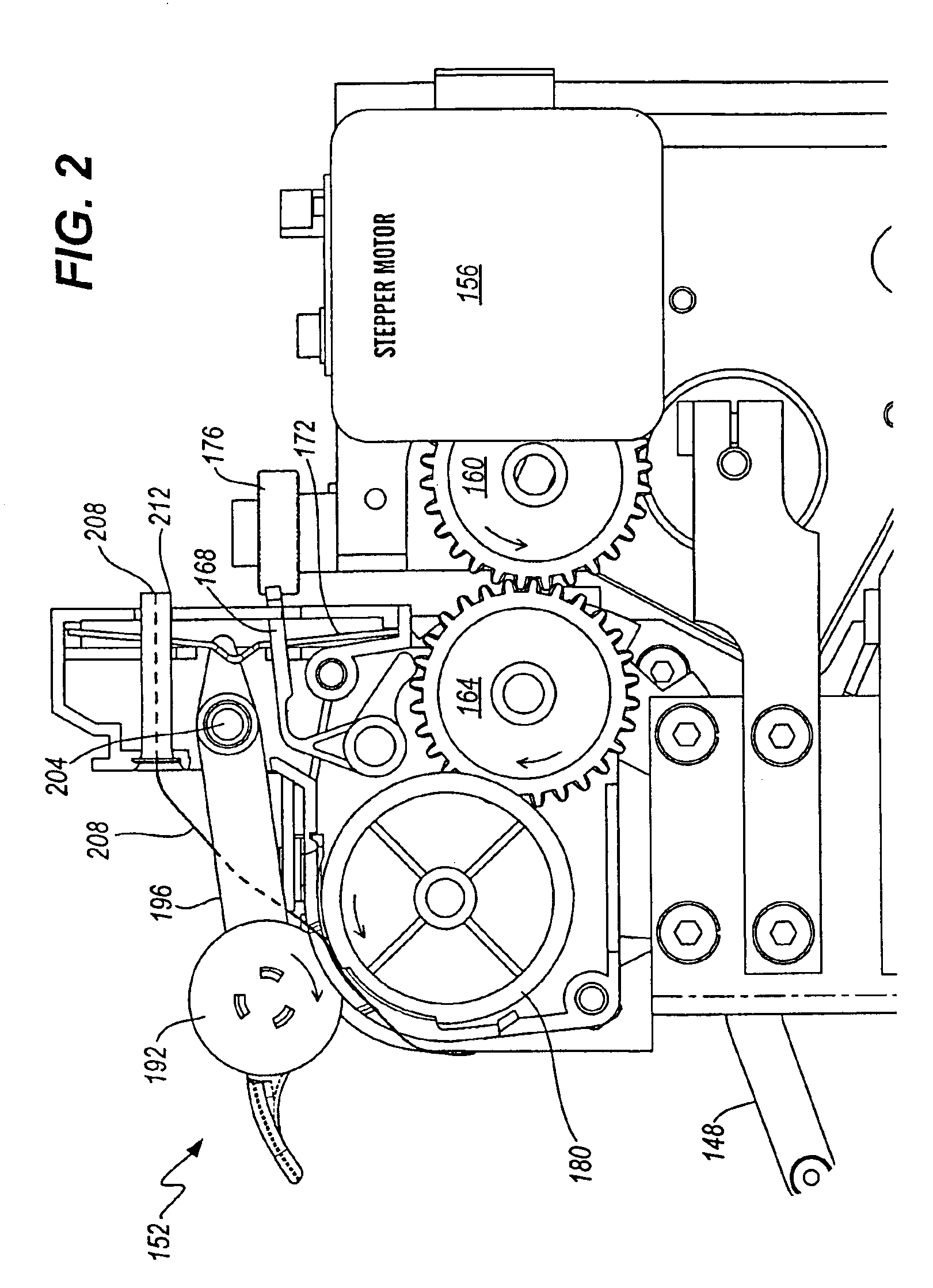

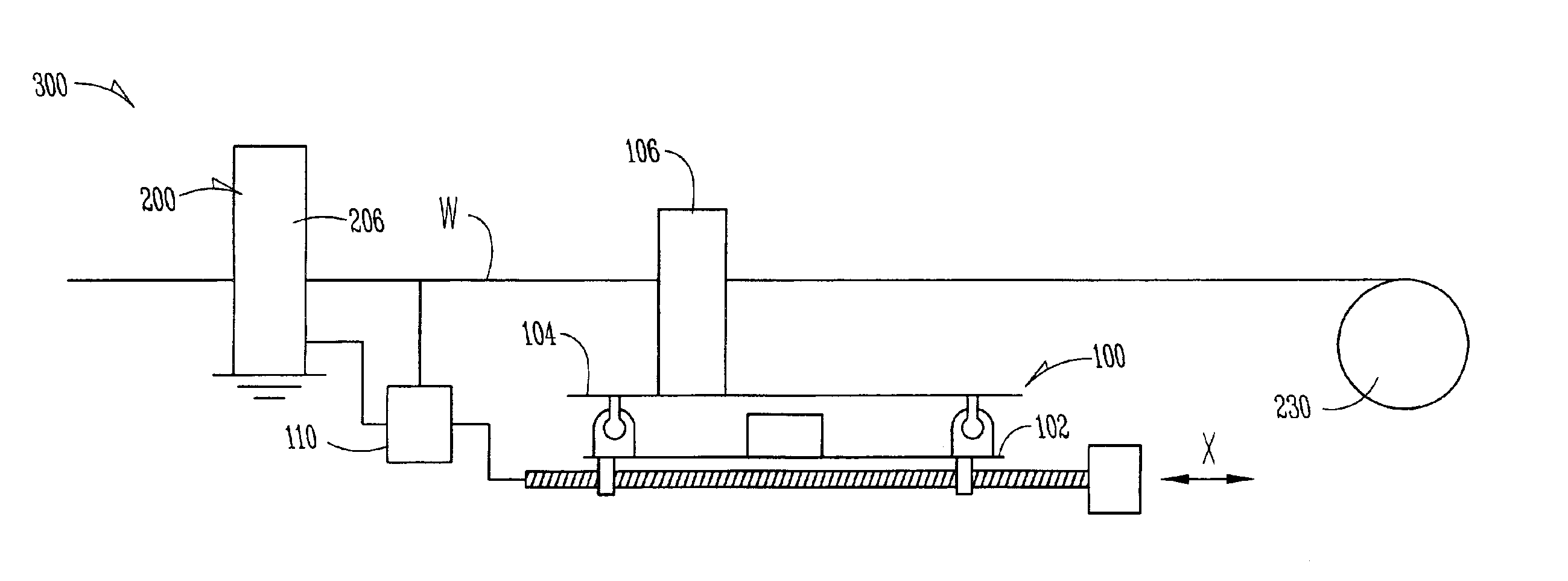

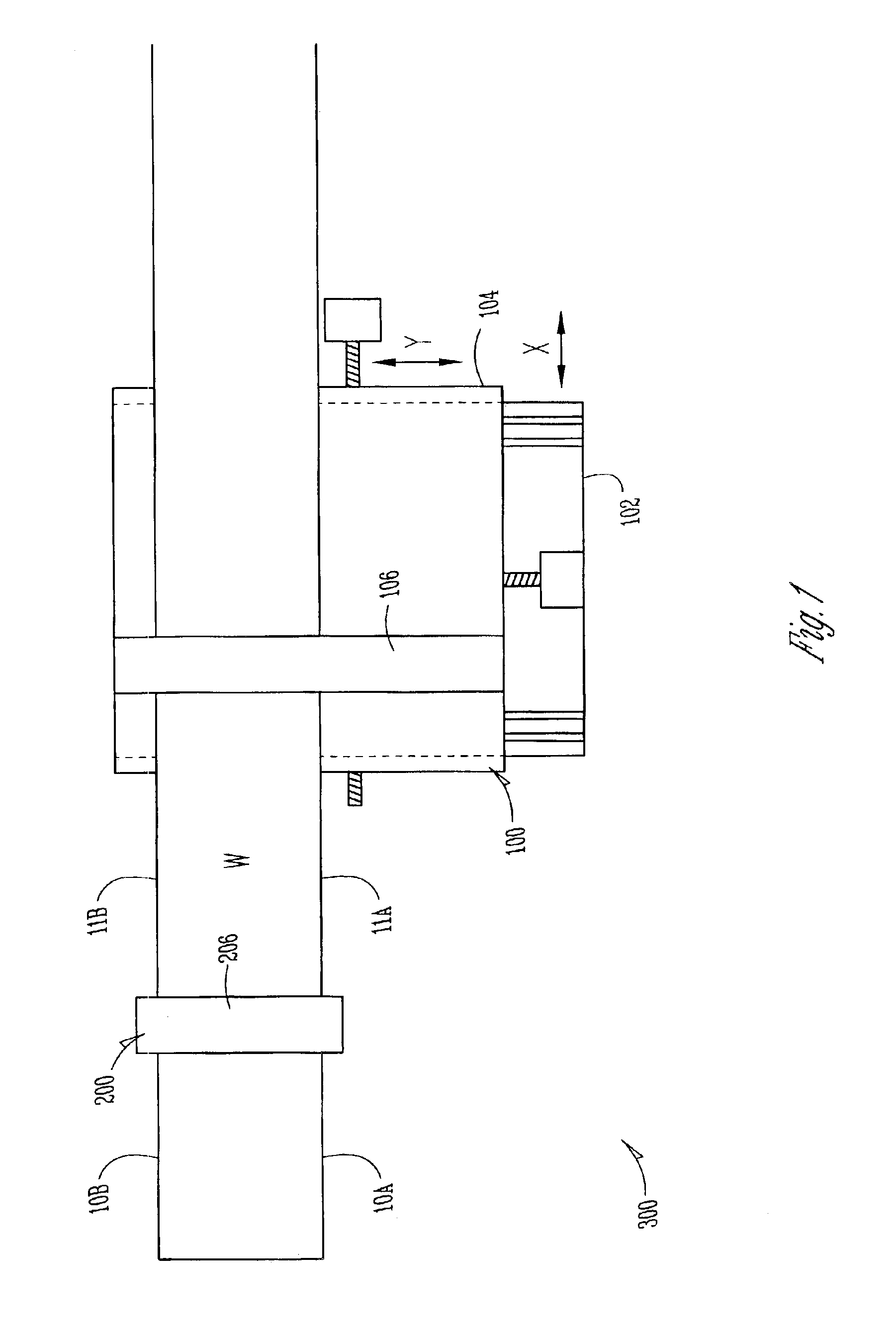

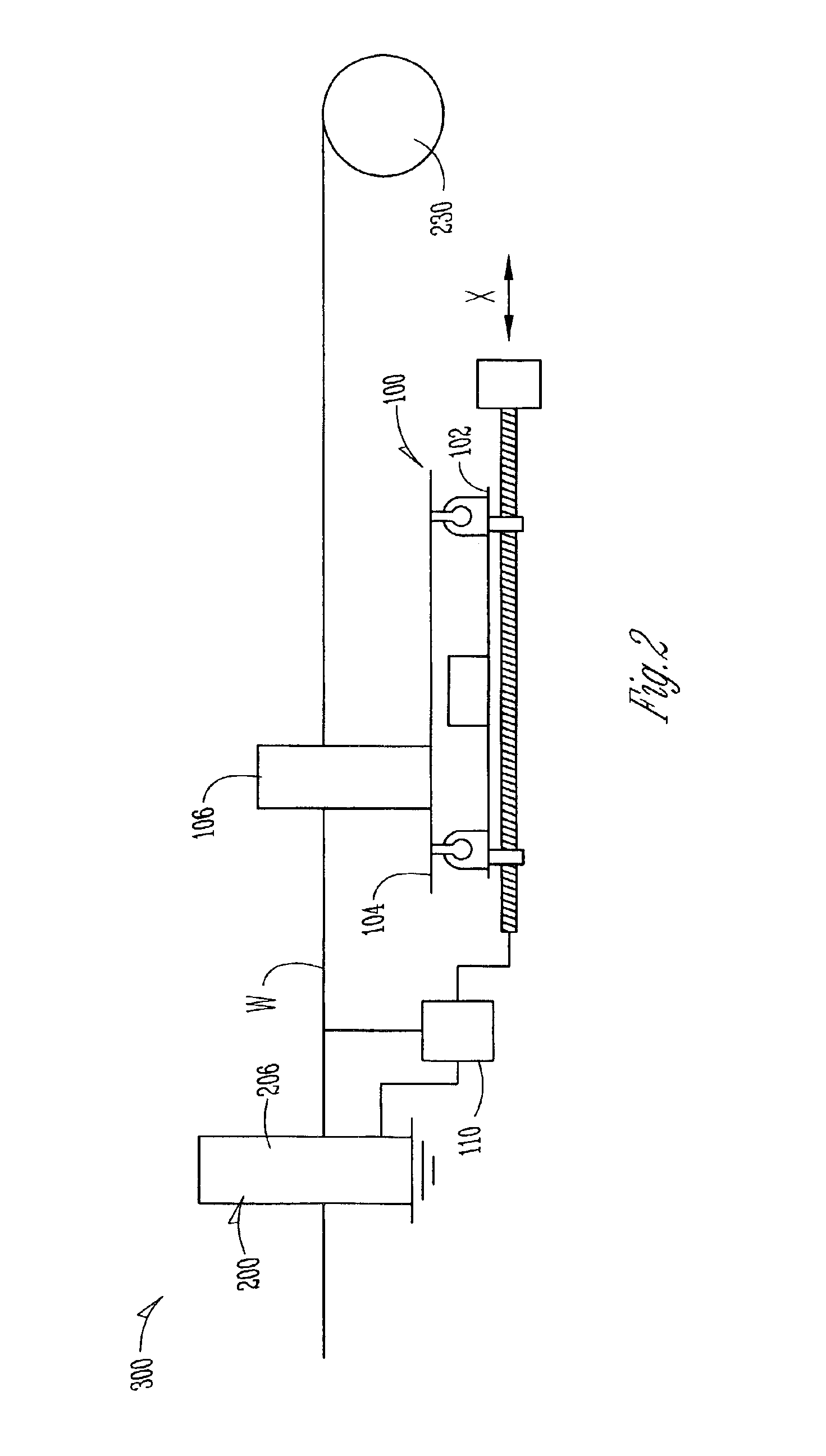

Servo driven quilter

InactiveUS7191718B1Easy to viewIncrease speedProgramme-controlled sewing machinesCombination sewing machinesReciprocating motionEngineering

A quilting machine has at least one needle and looper set for forming chain-stitched patterns on a thick multilayered material such as a mattress ticking, preferably a panel of the continuous web clamped stationary on a frame. The stitch forming elements are mounted on separate heads that move independently transversely relative to the panel on a bridge that moves longitudinally relative to the panel. The bridge is longitudinally moved by a servo and the heads are transversely moved on the bridge by separate linear servos. The needle and looper are each driven by a linear servo having an armature to which the element is directly fixed to reciprocate without intervening mechanical linkage assemblies. A controller drives the servos to chain-stitch patterns, differentially move the heads transversely to account for transverse needle deflection and to phase the needle and looper to compensate for longitudinal needle deflection. The controller determines or predicts needle deflection, either based on stored empirically determined data or optical sensing, and generates deflection compensation signals to drive the servos.

Owner:L & P PROPERTY MANAGEMENT CO

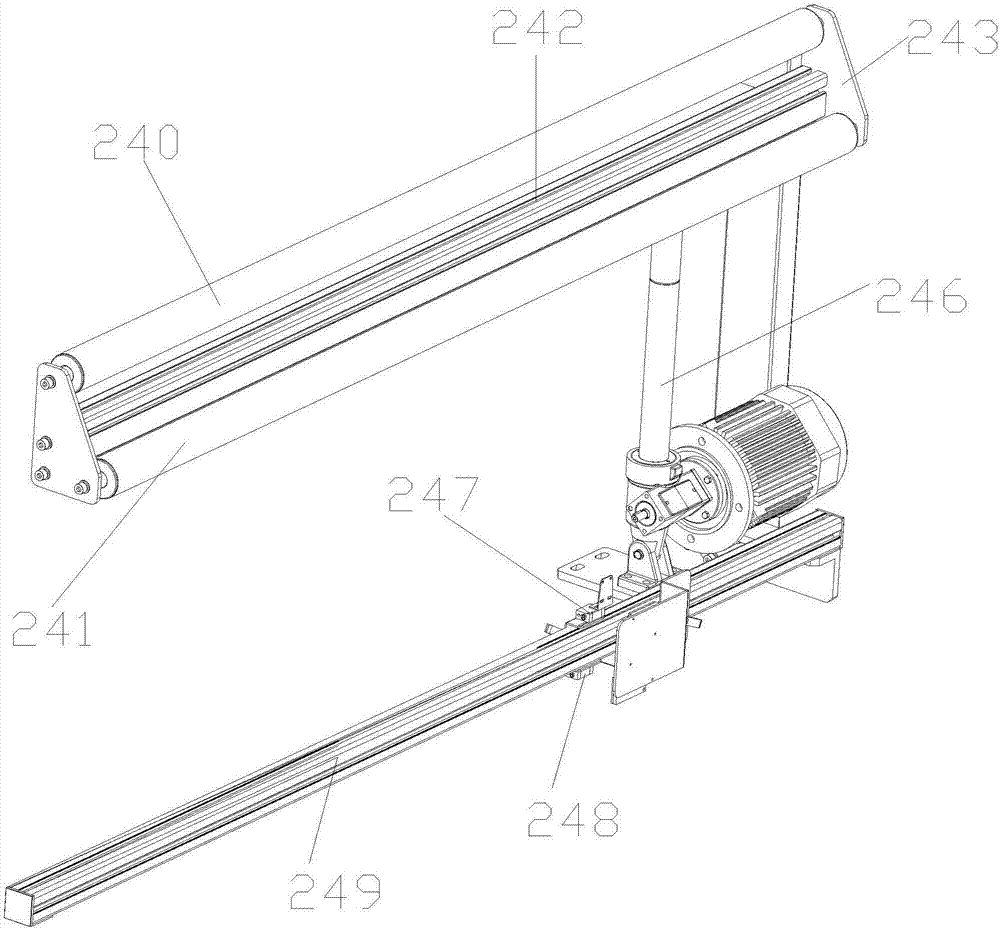

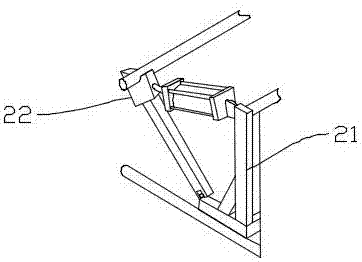

Left and right two-way edge sealer

InactiveCN105420935AExquisite and beautiful processingImprove work efficiencyWork-feeding meansCombination sewing machinesLeft directionCotton material

The invention discloses a left and right two-way edge sealer. The edge sealer comprises an edge sealer rack. Thread releasing rollers are arranged at one end of the edge sealer rack, columns are arranged on the edge sealer rack, a rotary shaft is connected to the top ends of the columns, and a material expanding roller is arranged on the rotary shaft. A motor is arranged at the lower end of the edge sealer rack, a compression roller A and a compression roller B are arranged at the upper end of the middle of the edge sealer rack, and a left sewing machine and a right sewing machine are arranged on the edge sealer rack. By means of the left and right two-way edge sealer, cloth in processing can be sewn in two directions, so that work efficiency is improved, sewing is performed in the left direction and the right direction simultaneously, and materials are processed to be more exquisite and beautiful.

Owner:常熟市古里镇淼泉利达机械厂

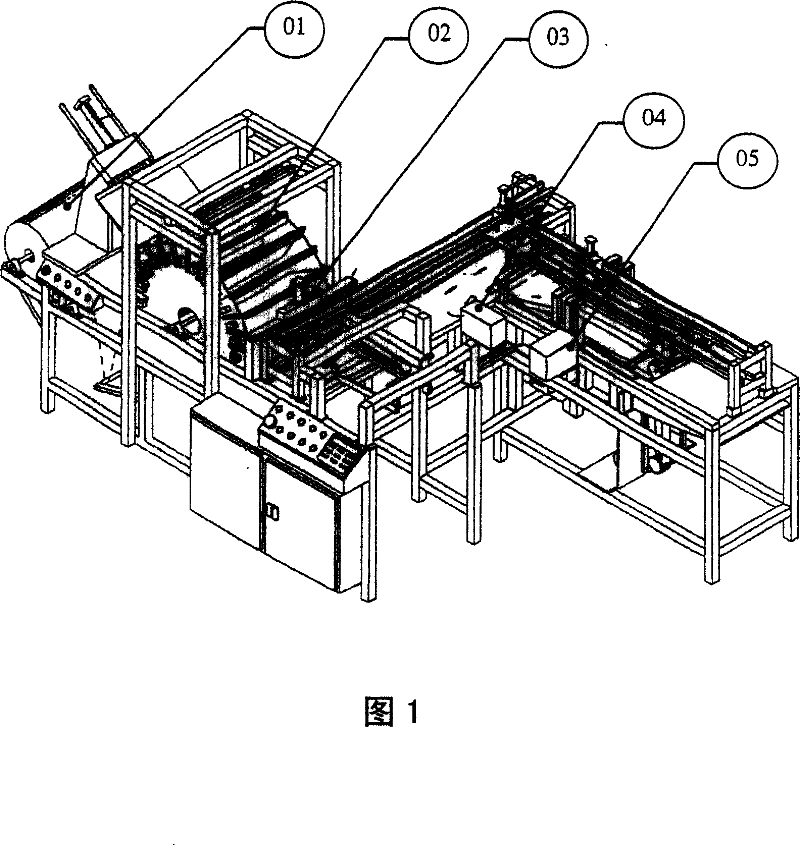

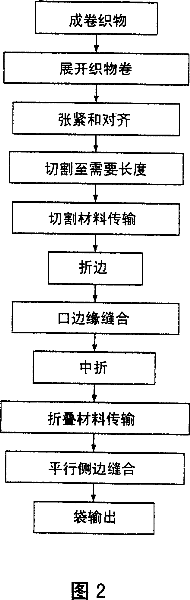

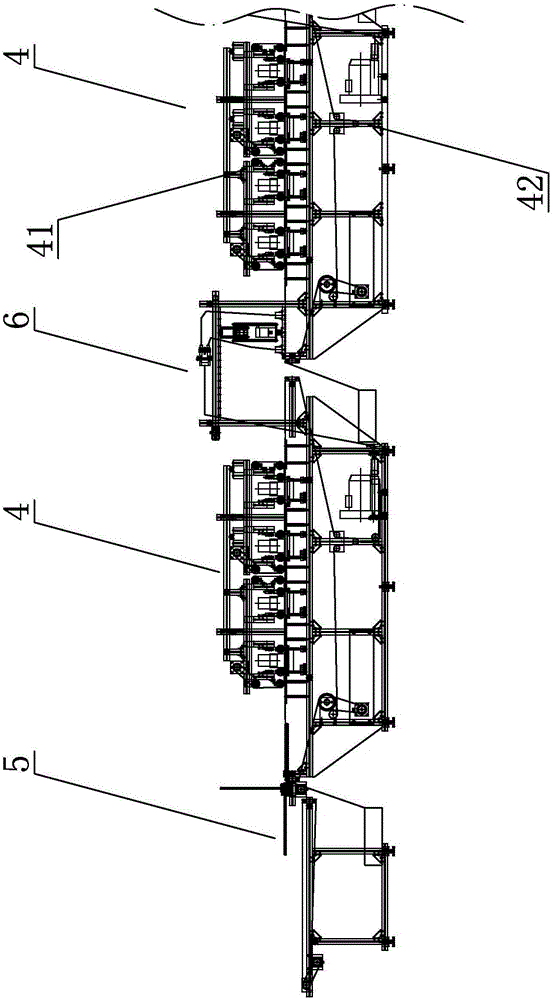

Machine for making textile bags

InactiveCN101041926AFully automatedImprove qualityProgramme-controlled sewing machinesWorkpiece carriersSemi automaticAutomation

A fabric bag making machine is the combination of a fabric cutting and conveying unit (FCCU) and a hemming table assembly which comprises a simultaneous multi-edge folding and sewing unit (SMESU), a middle folding and material guiding unit (MMGU) and a simultaneous parellel side sewing unit (SPSS) and carries out operations like cutting, hemming, middle folding and simultaneous parellel side sewing in synchronization mode. The sequential assembly operation of the combination unit is controlled by computer to achieve complete automation of all the manual, semi-automatic or partial-automatic processes. The bag making machine of the invention enables bag manufacturing in a single device; the fabric material is fed continuously by controlled expanding process, cut to required length, hem folded and sewn to form a hem opening, and then middle folded and parellel side sewn. The bag after parellel side sewing and opening folding is preferably used as bag with bottom and one side sewn for they have excellent qualities.

Owner:COUNCIL OF SCI & IND RES

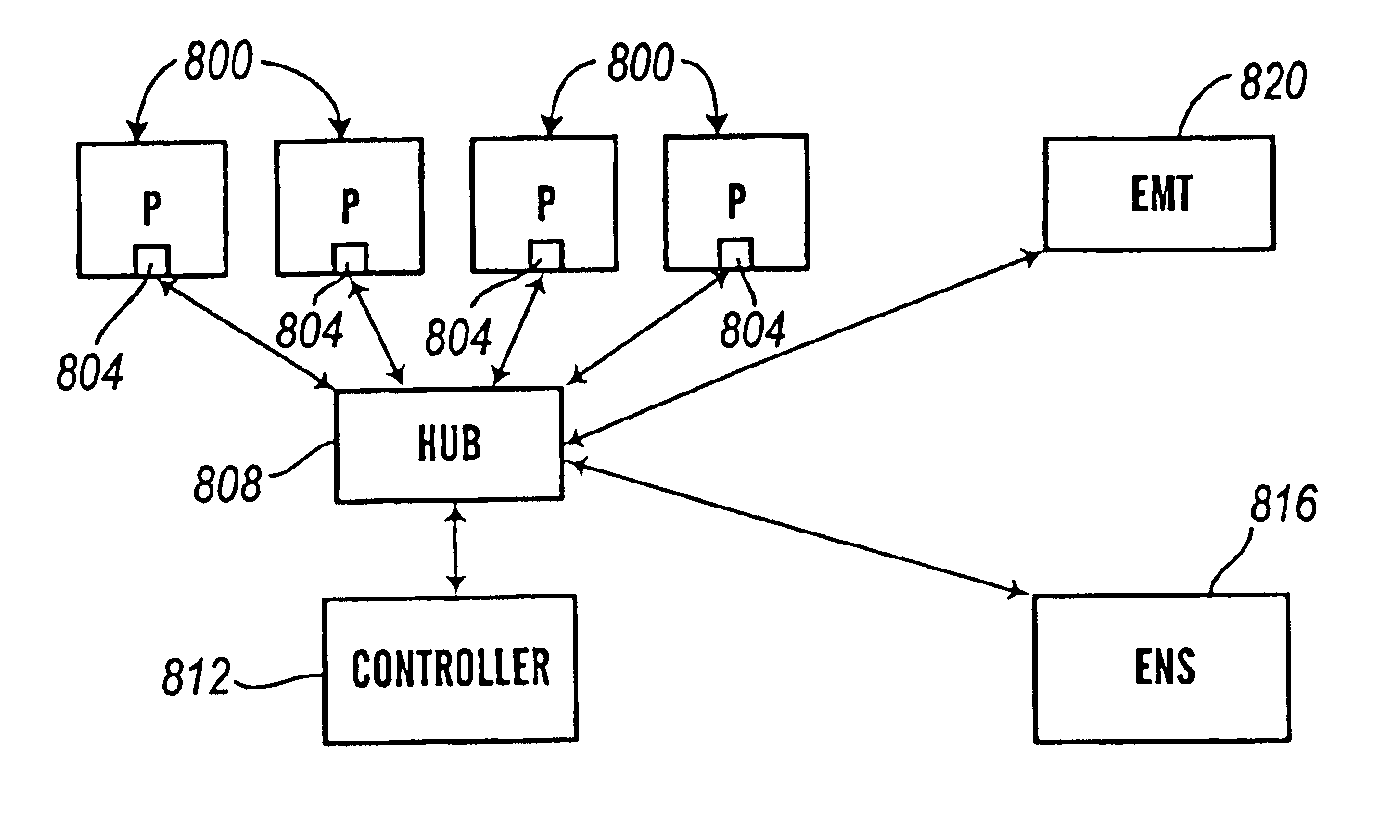

Computerized stitching including embroidering

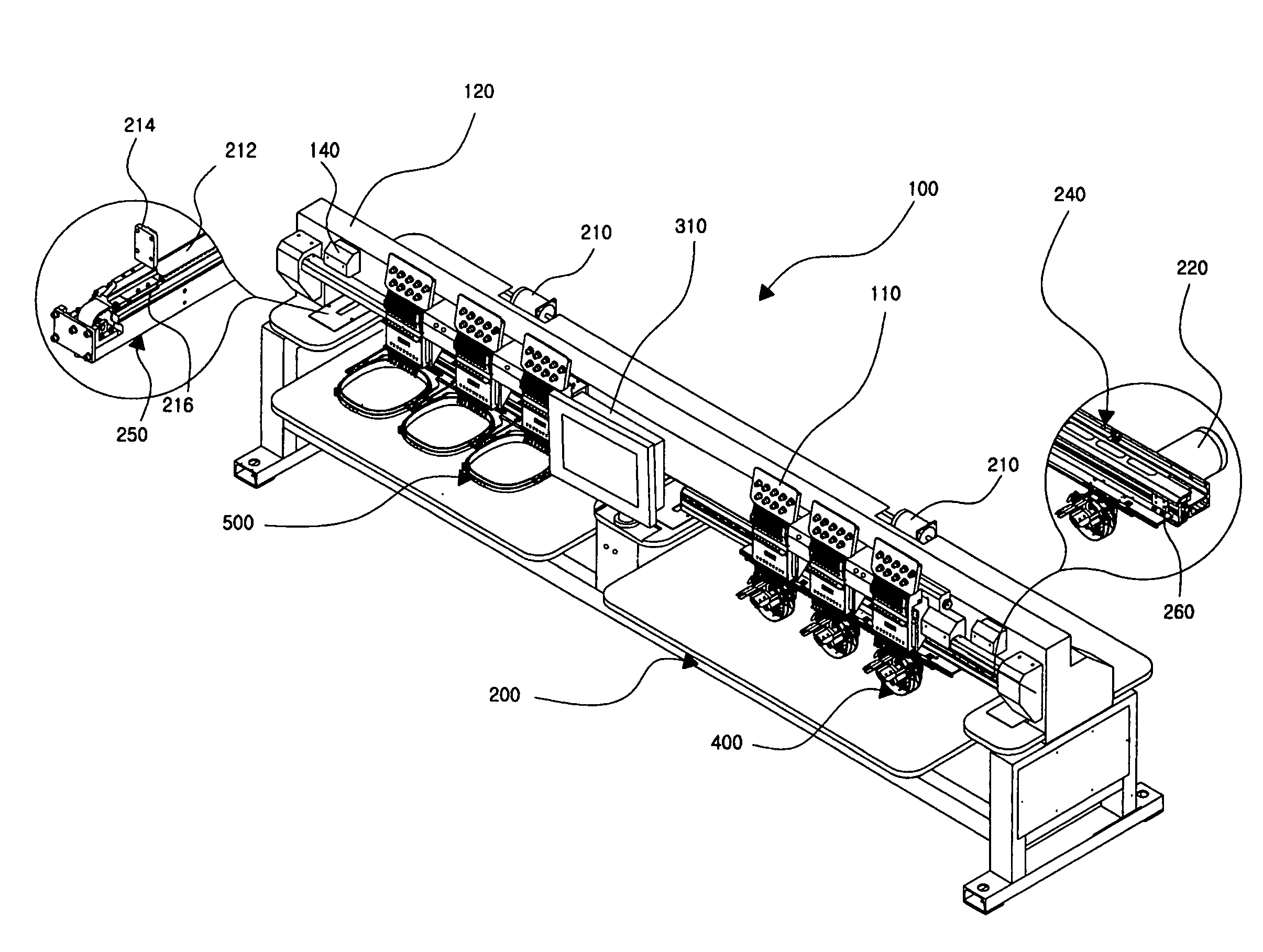

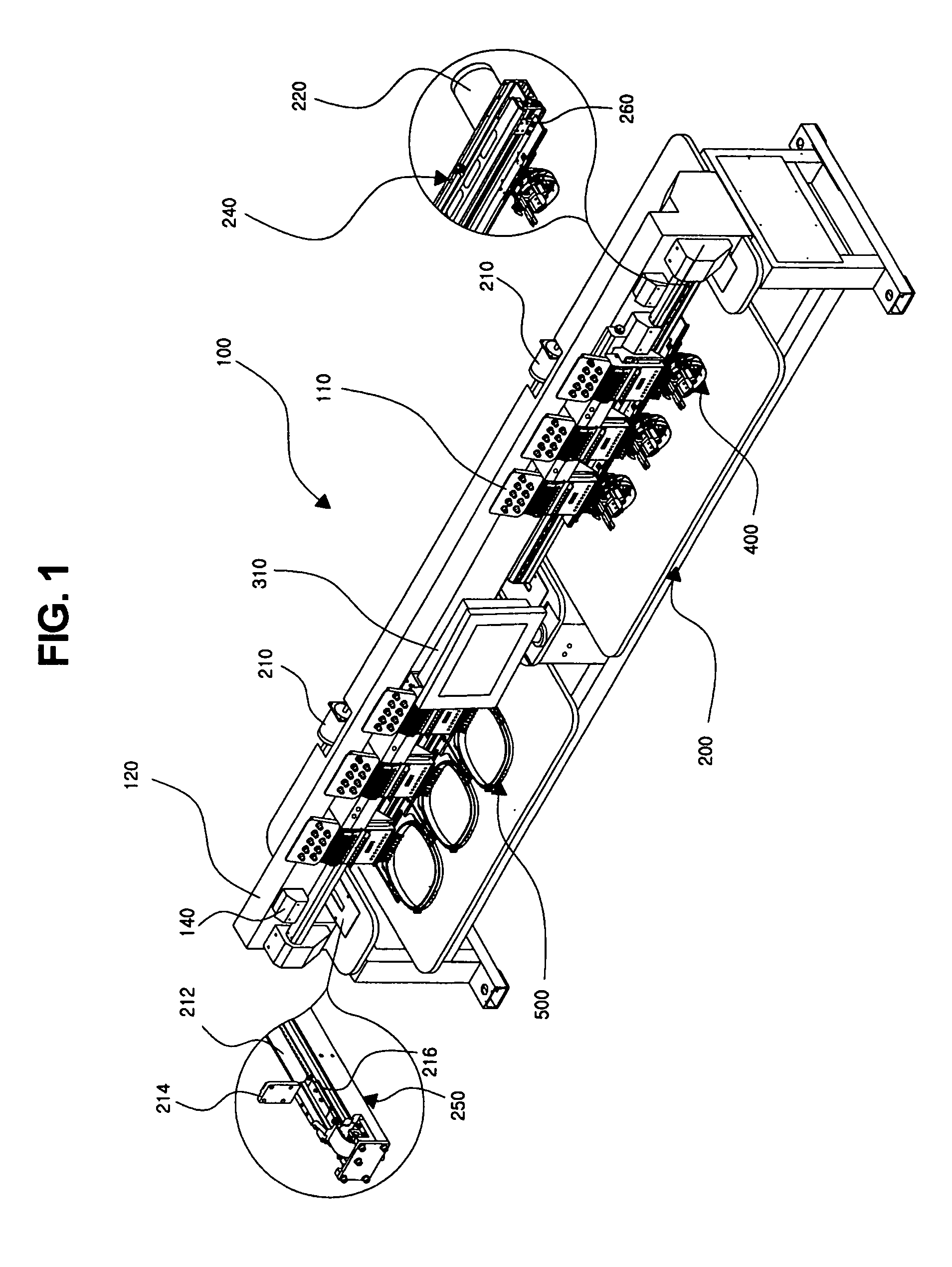

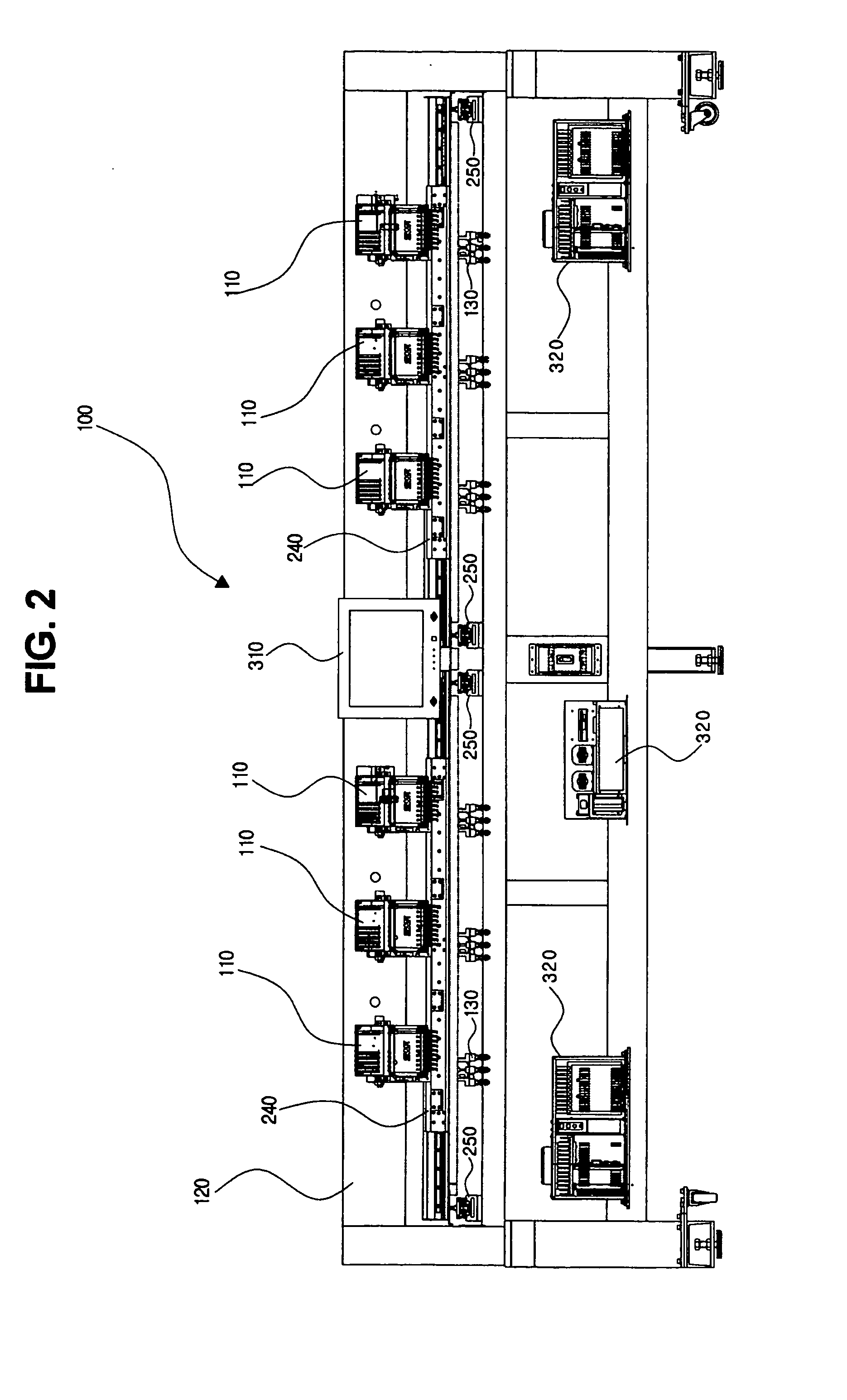

InactiveUS6983192B2Reduce in quantityIncrease flexibilityProgramme-controlled sewing machinesCombination sewing machinesControl systemEngineering

A plurality of stitching machines and a control system used in stitching patterns into a plurality of items is capable of flexible control. The plurality of stitching machines may include one or more clusters of stitching machines, with each cluster able to stitch patterns into items independently of other clusters. Stitching machines within the plurality of stitching machines, or within the clusters of stitching machines, may be set to stitch patterns into items using one of a synchronized mode and an unsynchronized mode. When in the synchronized mode, the stitching machines perform stitching substantially synchronously with other stitching machines, and when in the unsynchronized mode the stitching machines perform stitching independently of the status of other stitching machines.

Owner:MELCO INT

Embroidery machine

InactiveUS6925946B1Reduce manufacturing costEasy to produceCombination sewing machinesAutomatic machinesEngineeringMechanical engineering

An embroidery machine can simultaneously embroider sewing objects having various shapes, including a flat object, an object having a shape of a usual processed cloth, an object having a shape of a cap, etc. The embroidery machine comprises a plurality of sewing heads grouped into at least two working groups, and the embroidering frames, each of which is arranged for one of the working groups. The embroidering frames have structures either identical to each other or different from each other. Therefore, one conventional embroidery machine can simultaneously embroider more than one kind of sewing objects, including at least two of a flat sewing object, a tubular sewing object, and a cap-shaped sewing object.

Owner:SUSR PRECISION CO LTD

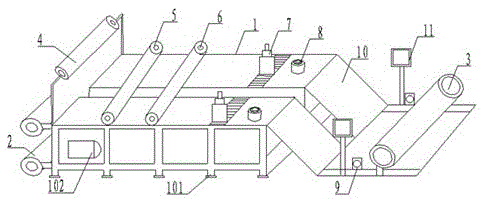

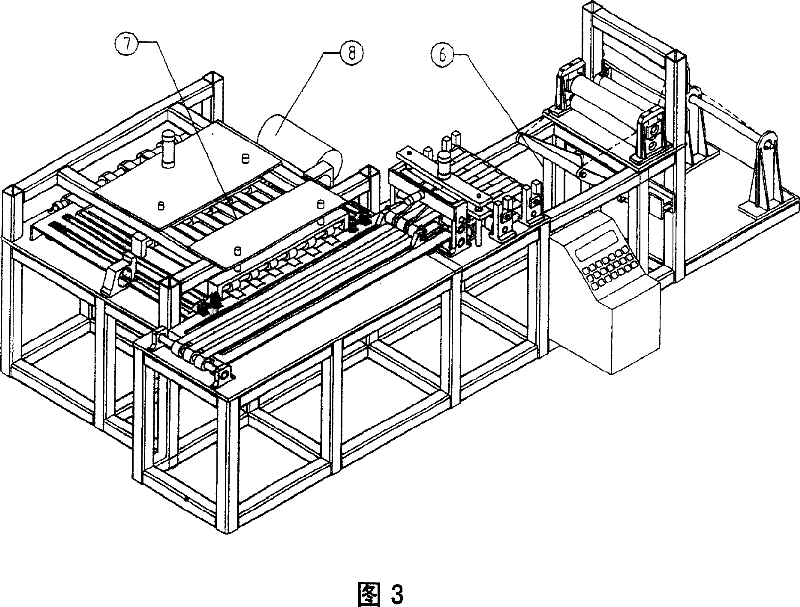

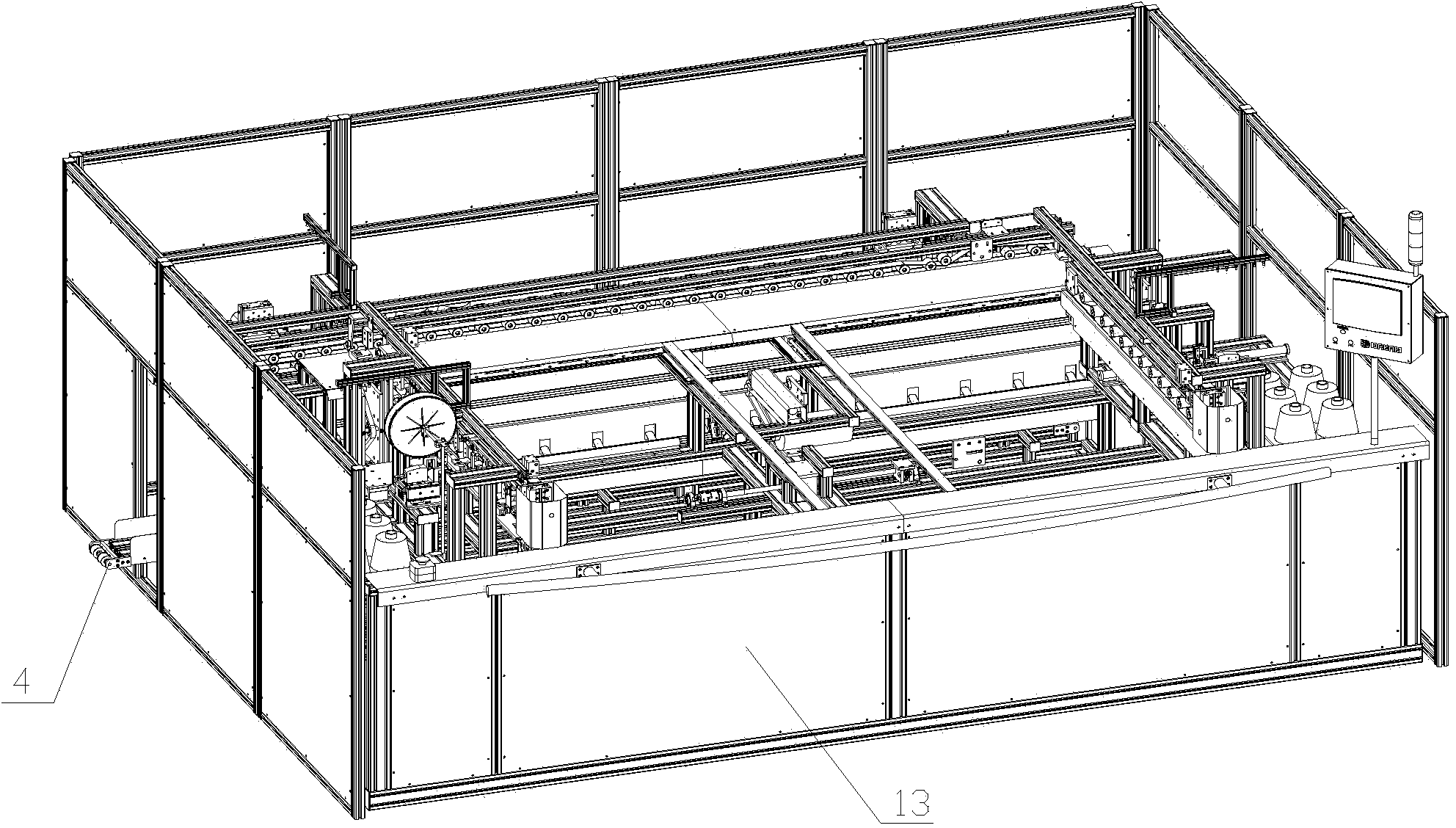

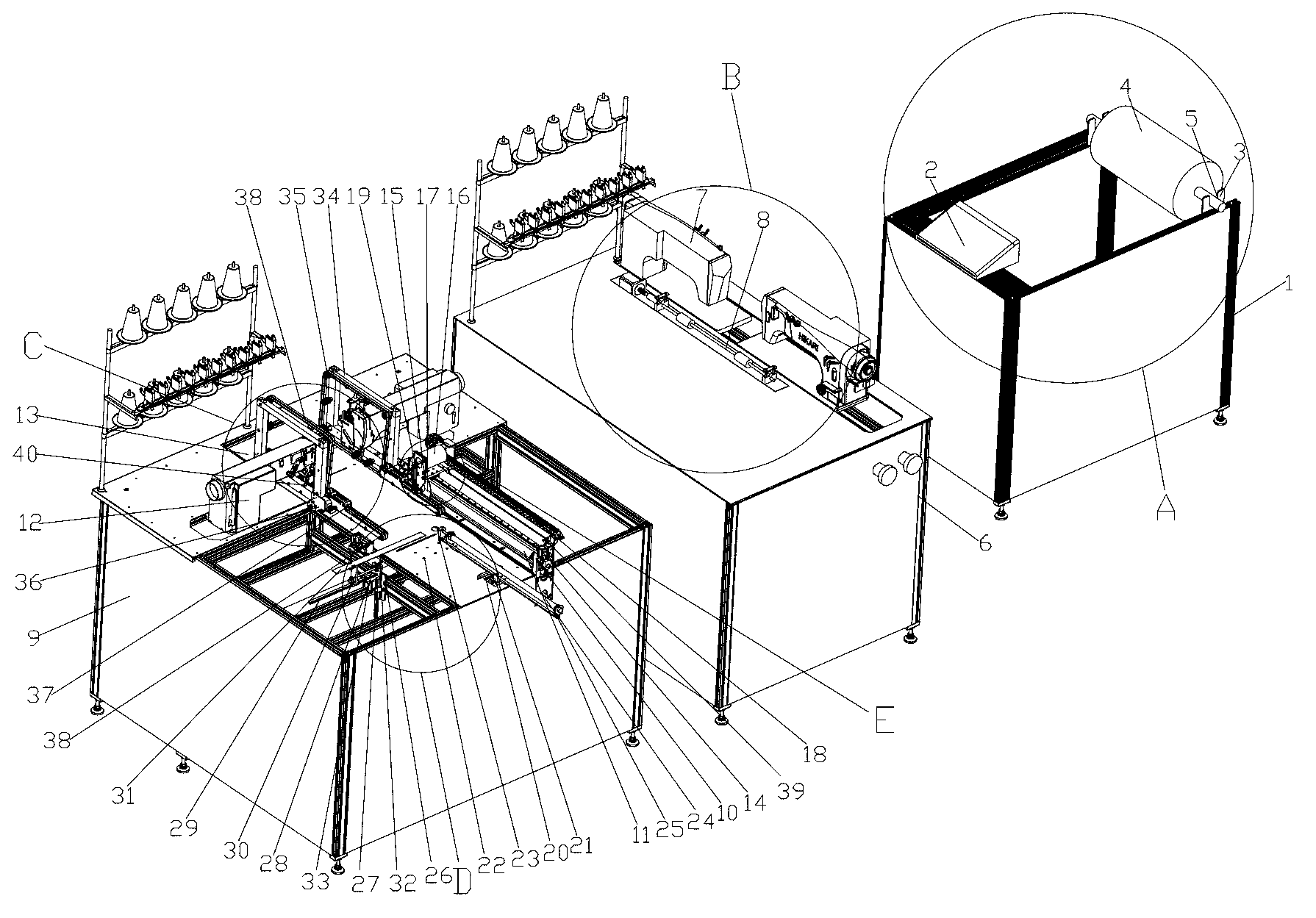

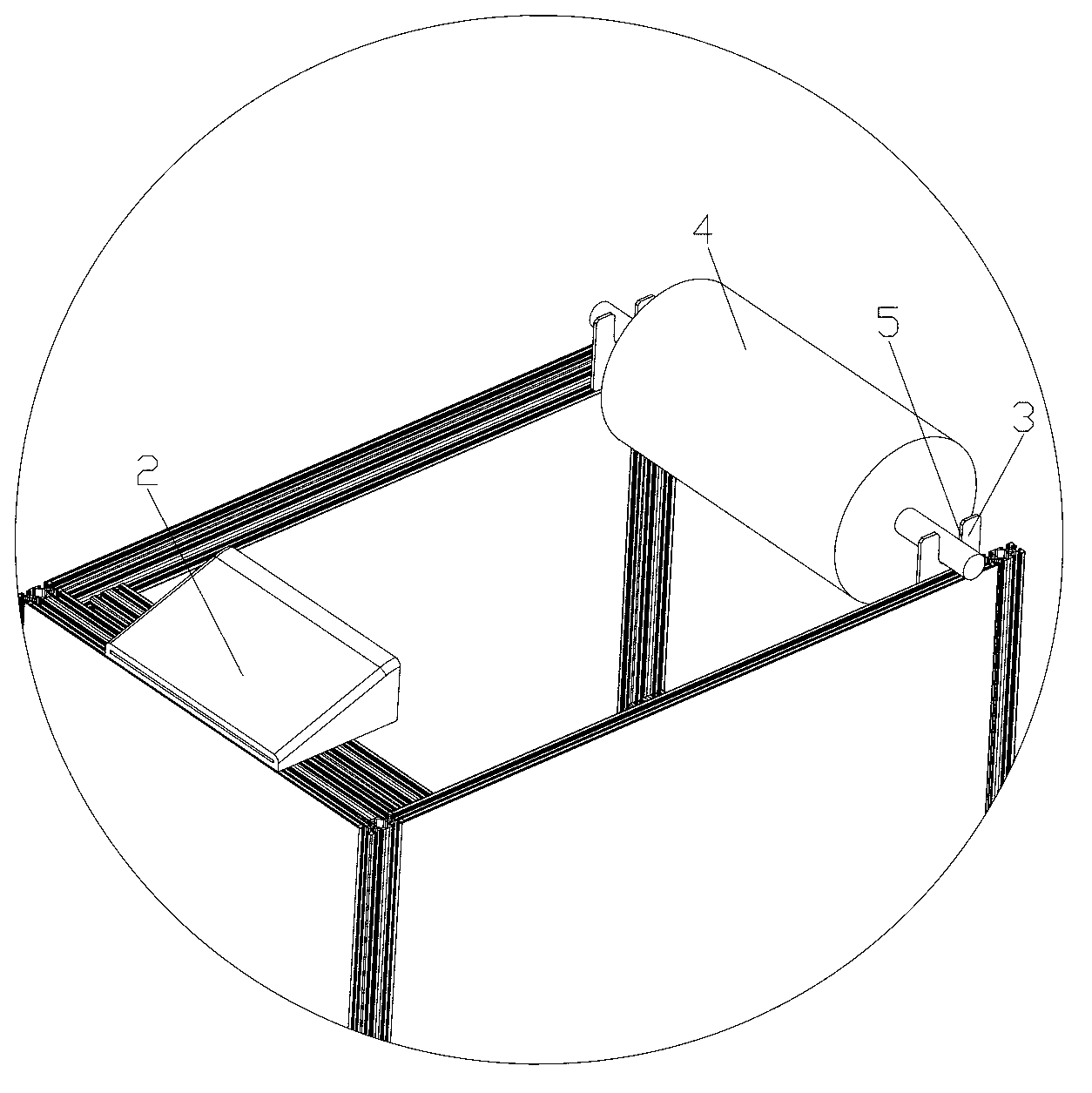

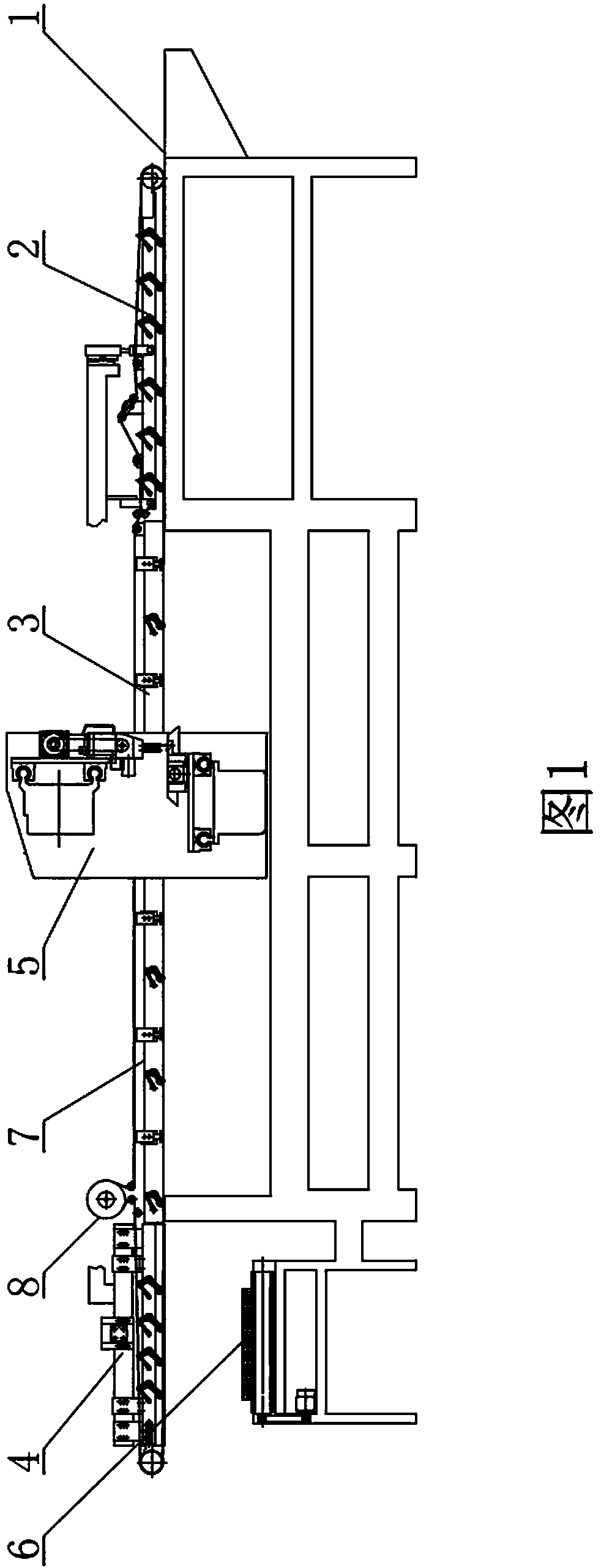

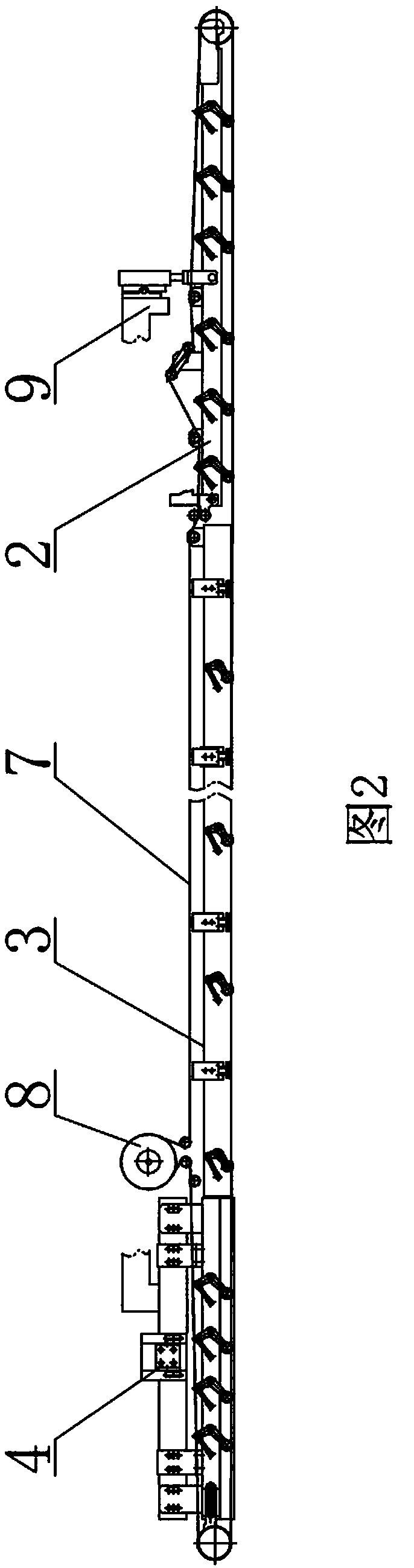

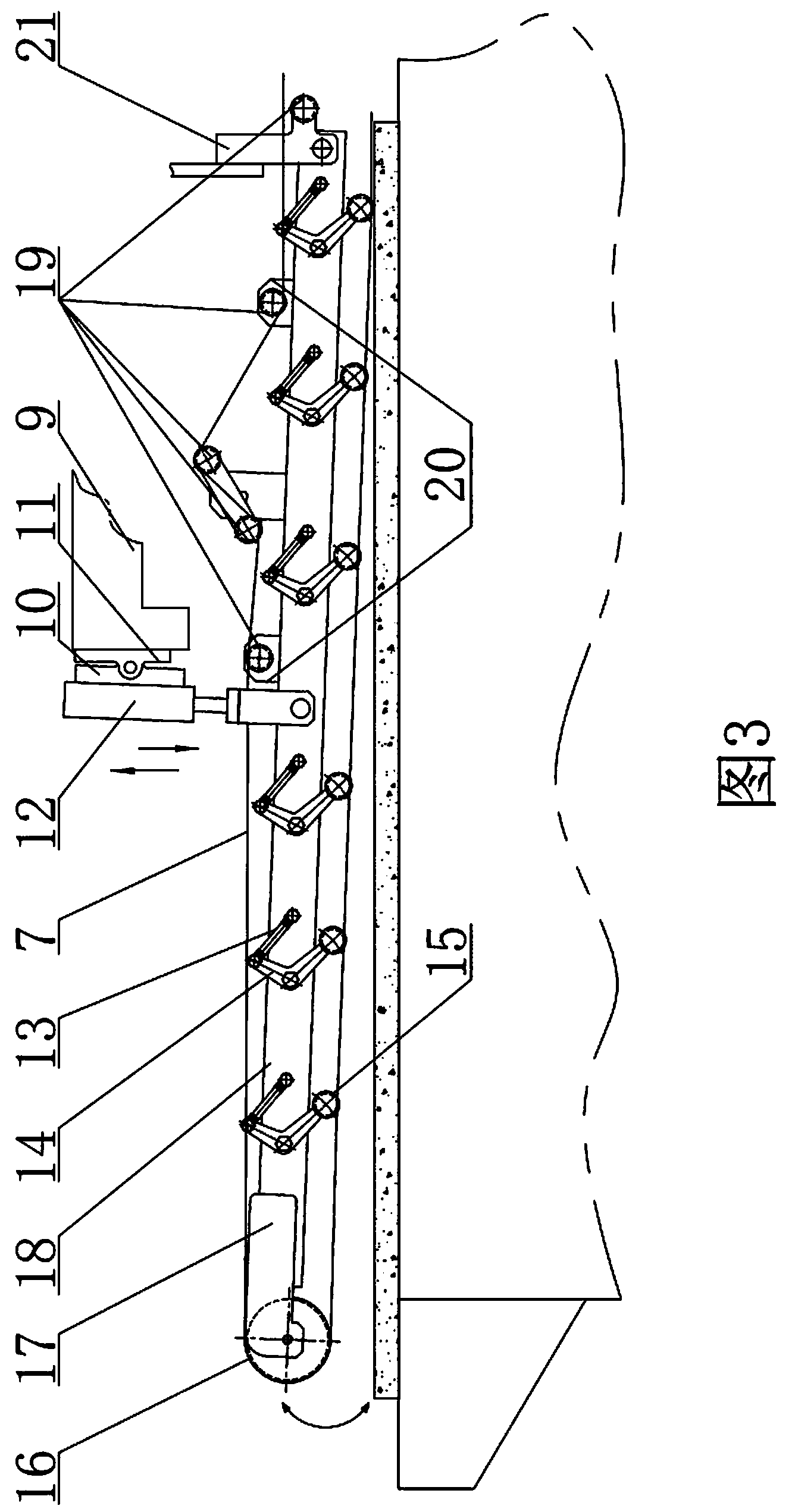

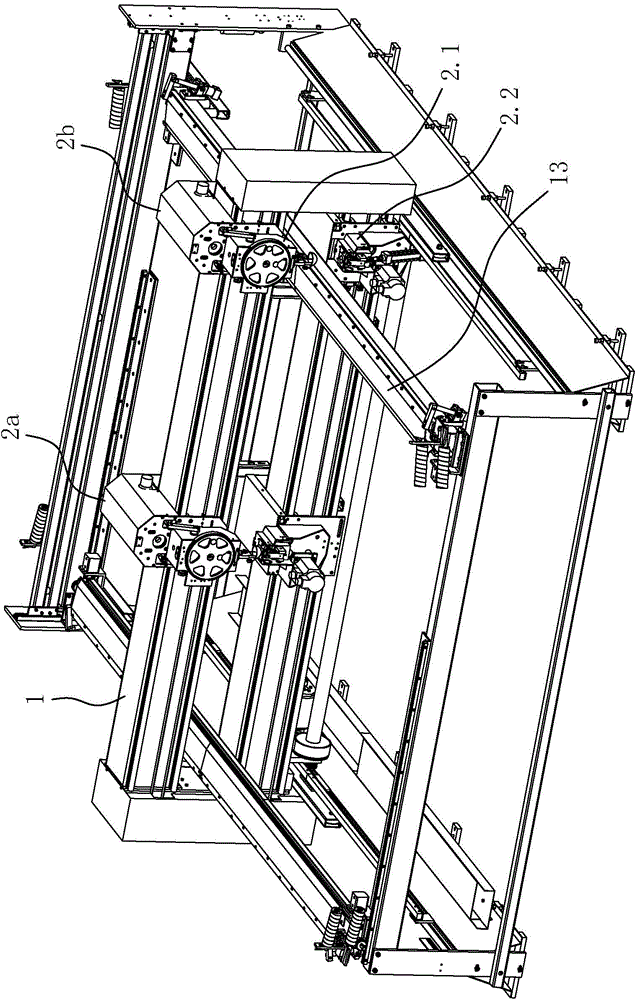

Automated production line for carpet flat seams

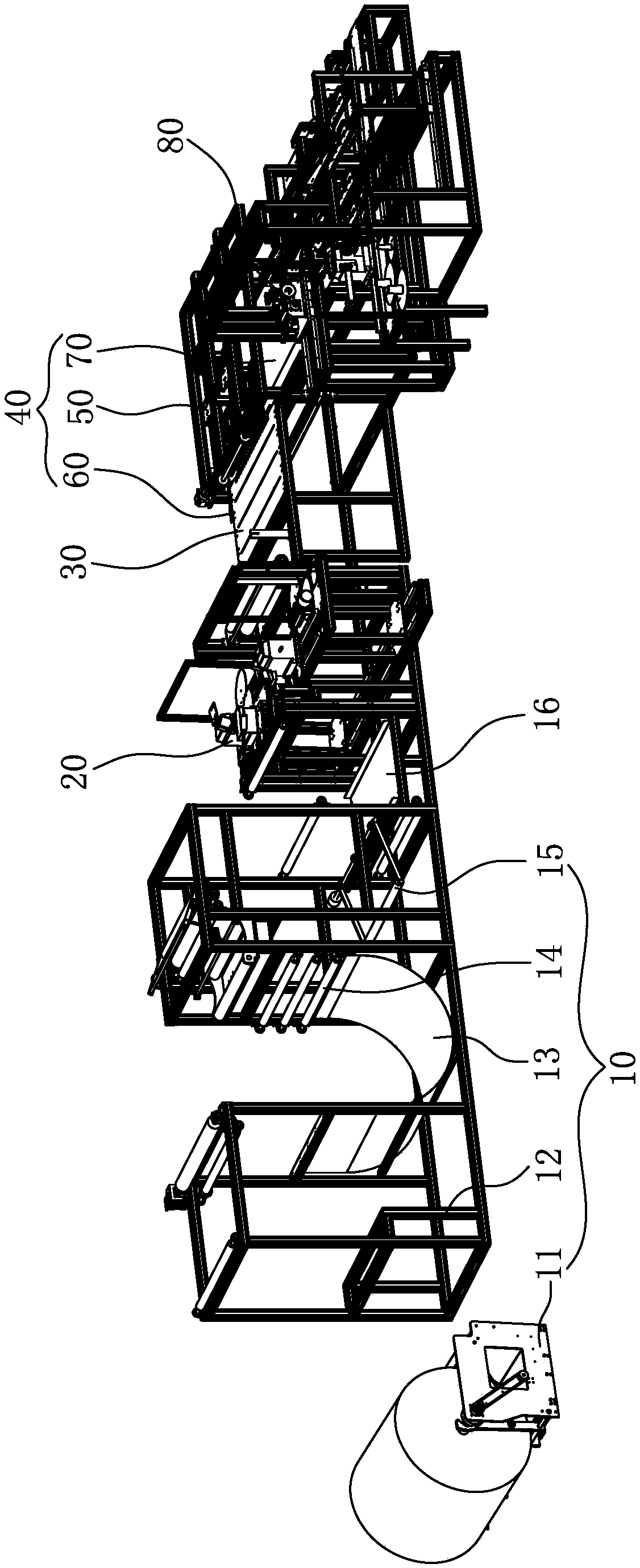

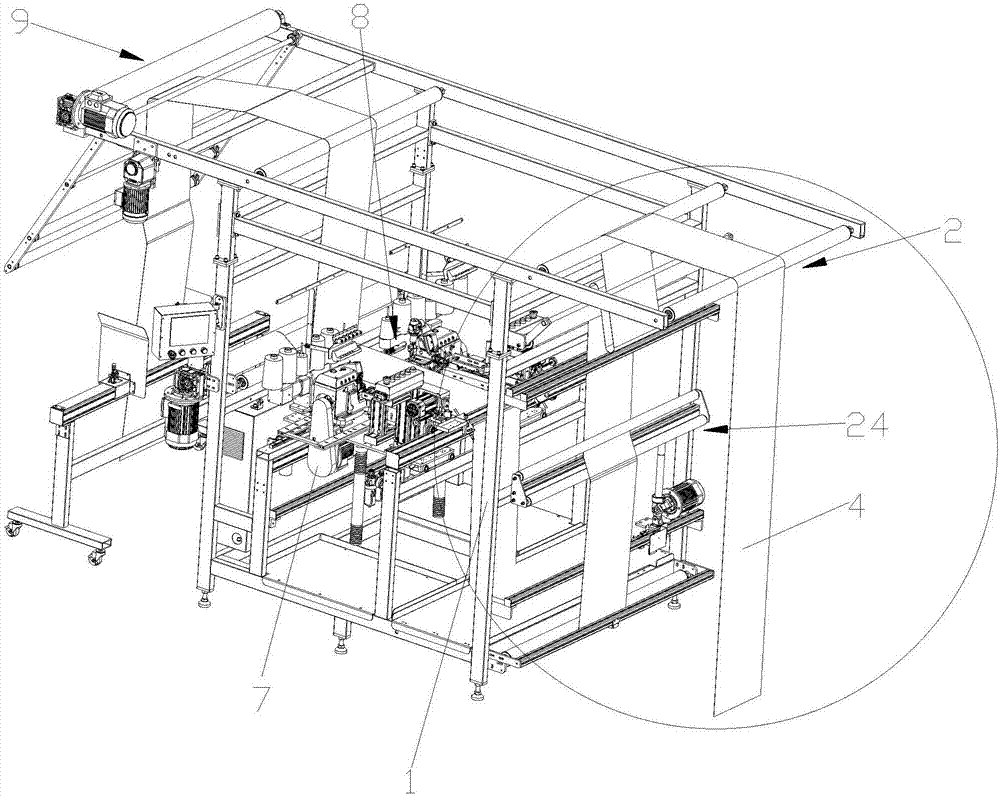

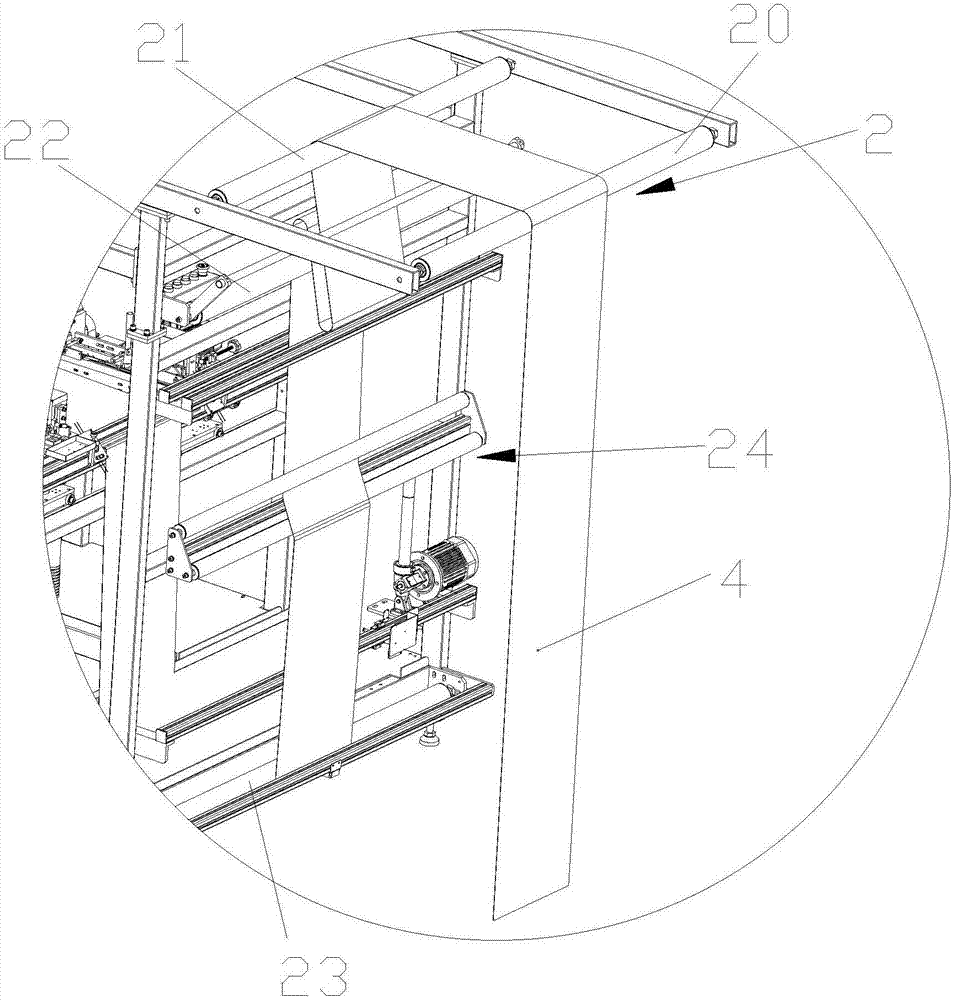

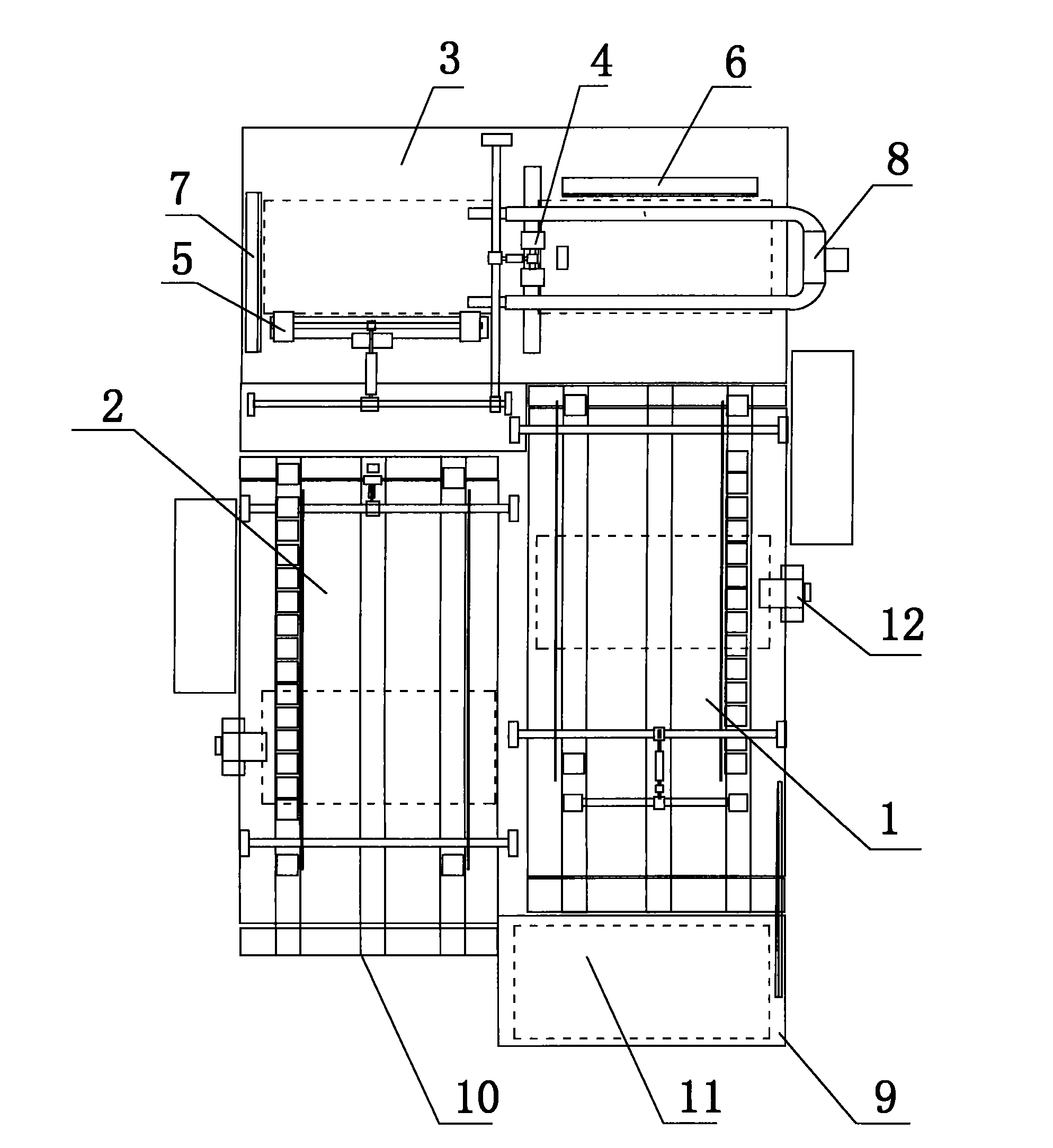

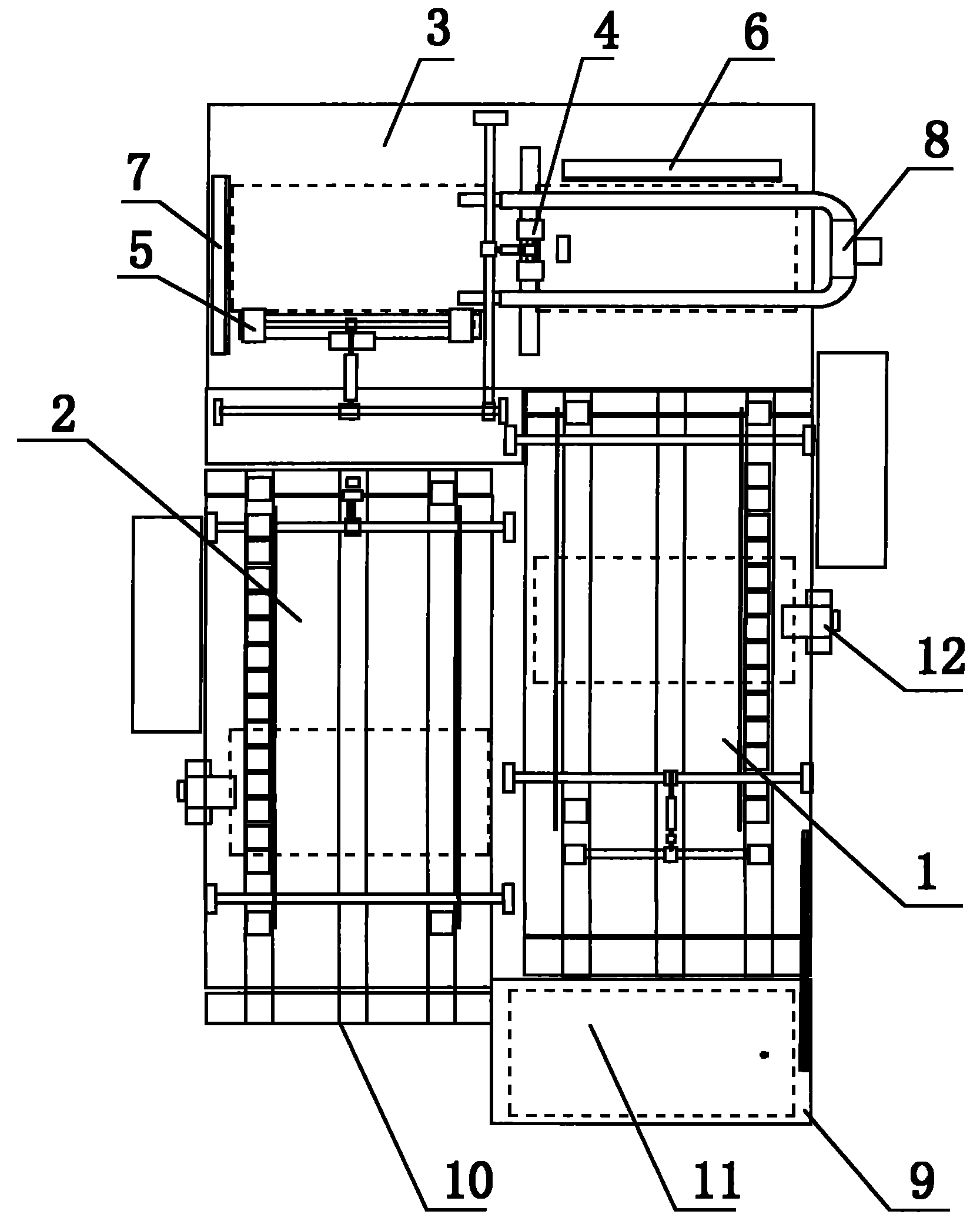

ActiveCN103015046ASimple structureGuaranteed uptimeWorkpiece carriersCombination sewing machinesProduction lineConveyor belt

The invention discloses an automated production line for carpet flat seams. The automated production line comprises a coiled carpet, a carpet feeding mechanism, a conveyor belt mechanism, and more than two automatic carpet flat seam stages, wherein the more than two automatic carpet flat seam stages are respectively arranged at two sides of the conveyor belt mechanism. The automated production line for carpet flat seams can automatically complete the technique processes of feeding of the coiled carpet, shearing into strips, automatic conveying, automatic capturing, shearing of residual corners of the carpet, automatic flat seam of straight lines and fillets of the carpet, and the like, multiple middle links on traditionally manually processing the flat seams of the carpet can be omitted, the fast and high-efficiency automatic streamlined production for carpet flat seams can be realized, the labor force can be liberated, and the production efficiency can be improved.

Owner:716TH RES INST OF CHINA SHIPBUILDING INDAL CORP +1

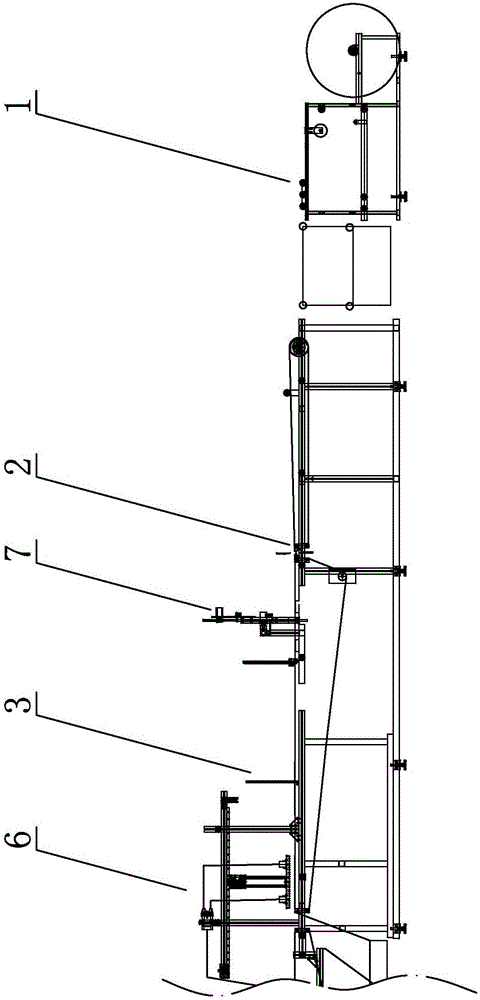

Full-automatic top fly sewing machine

InactiveCN105525445AEasy to operateImprove processing efficiencyCombination sewing machinesInterliningPulp and paper industry

The invention discloses a full-automatic top fly sewing machine. The sewing machine comprises a rack, an interlining fusing machine, an overlocking machine, a flat seaming machine, a cutting machine and a control device, wherein the control device controls the interlining fusing machine, the overlocking machine, the flat seaming machine and the cutting machine to operate; the interlining fusing machine, the overlocking machine, the flat seaming machine and the cutting machine are sequentially fixed on a workbench on the upper surface of the rack; fabric and an interlining enter the interlining fusing machine after being folded, enter the overlocking machine for overlocking, then enter the flat seaming machine for pressing and finally enter the cutting machine for cutting forming. With the adoption of the full-automatic top fly sewing machine, procedures of fusing, overlocking, pressing, cutting and the like required by traditional top fly production are adopted for processing simultaneously, the processing efficiency is effectively improved, the production technology is simplified, the manpower resource is saved, and the sewing machine is suitable for popularization.

Owner:FAR EAST CLOTHES SUZHOU CO LTD

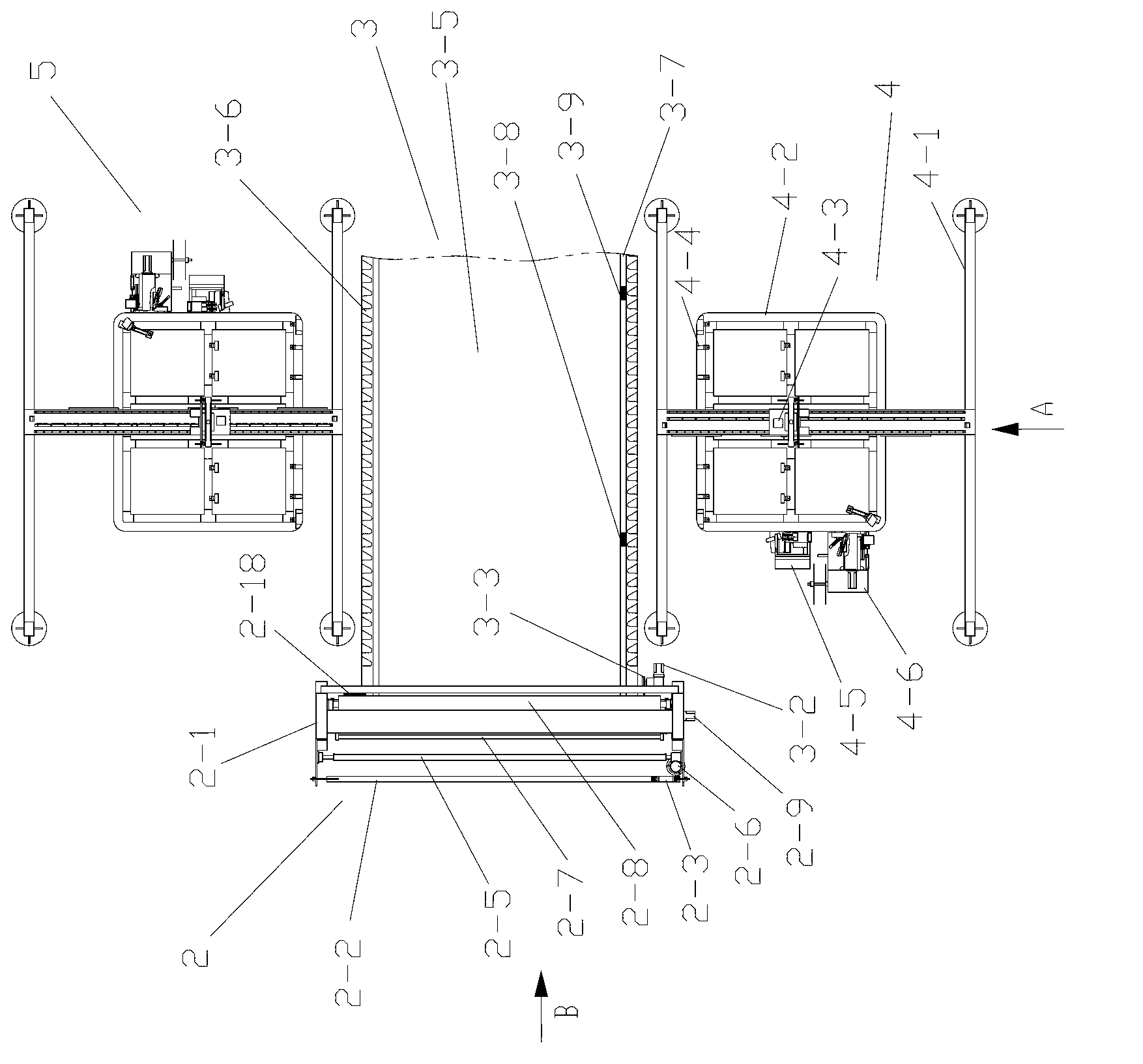

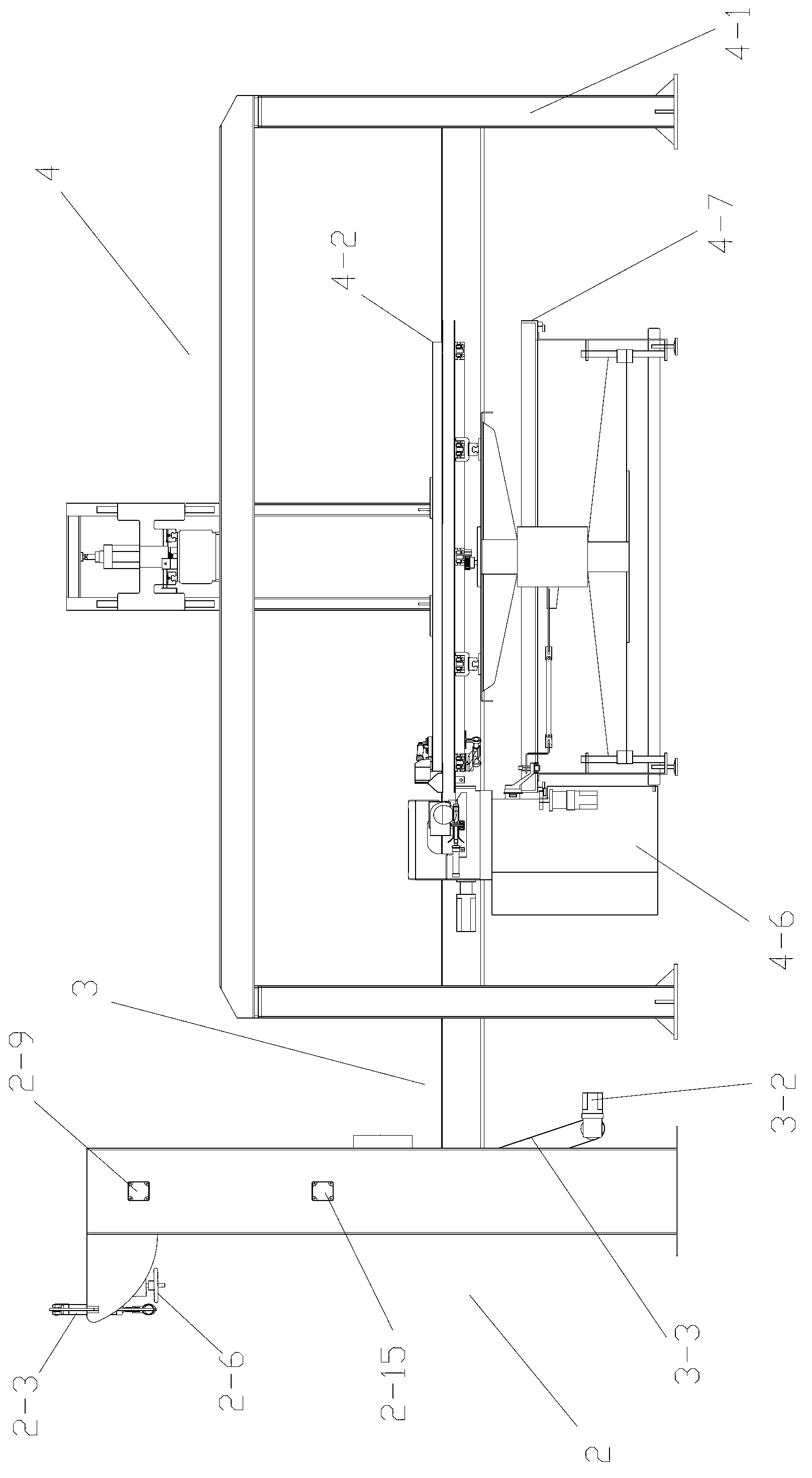

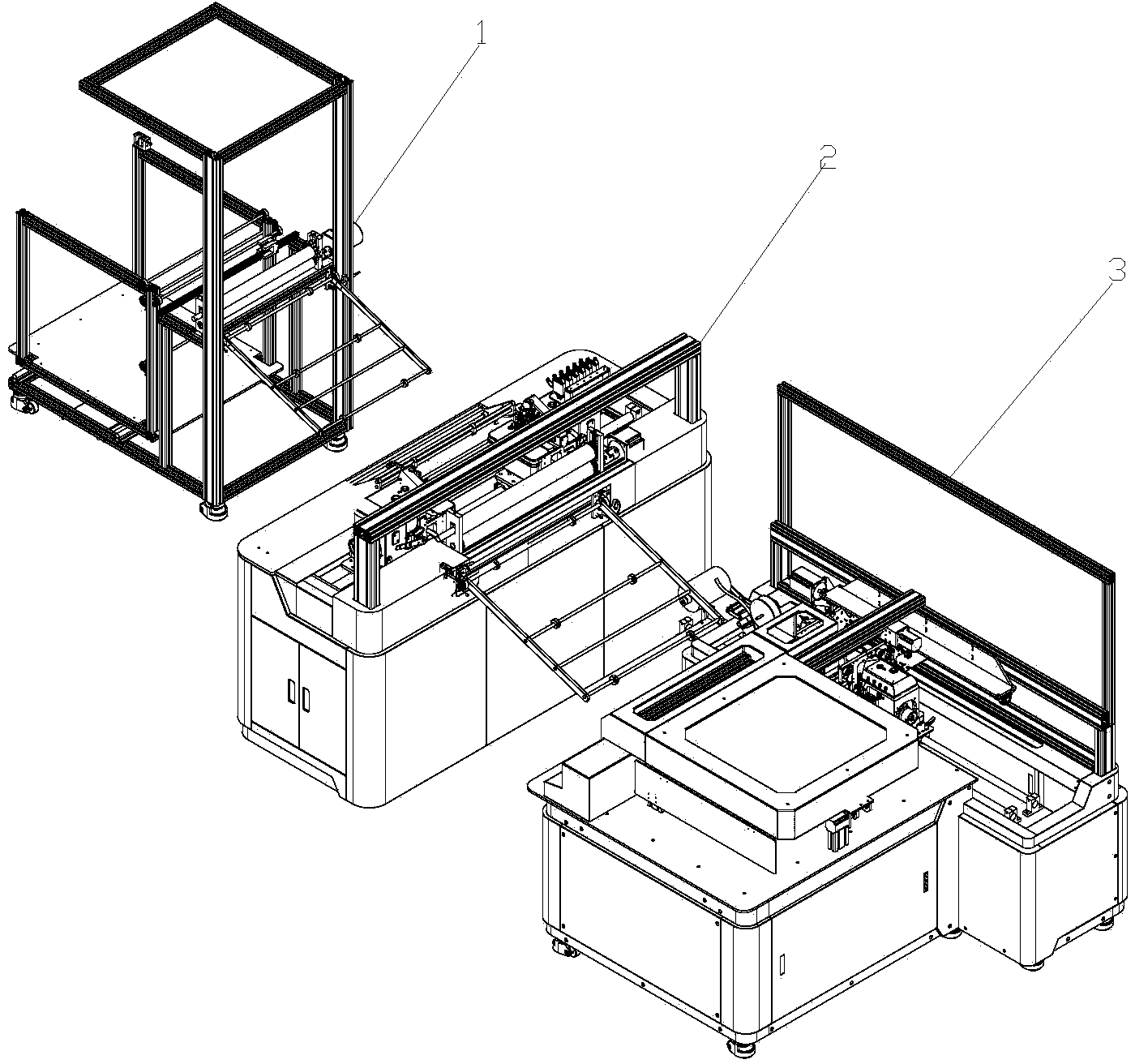

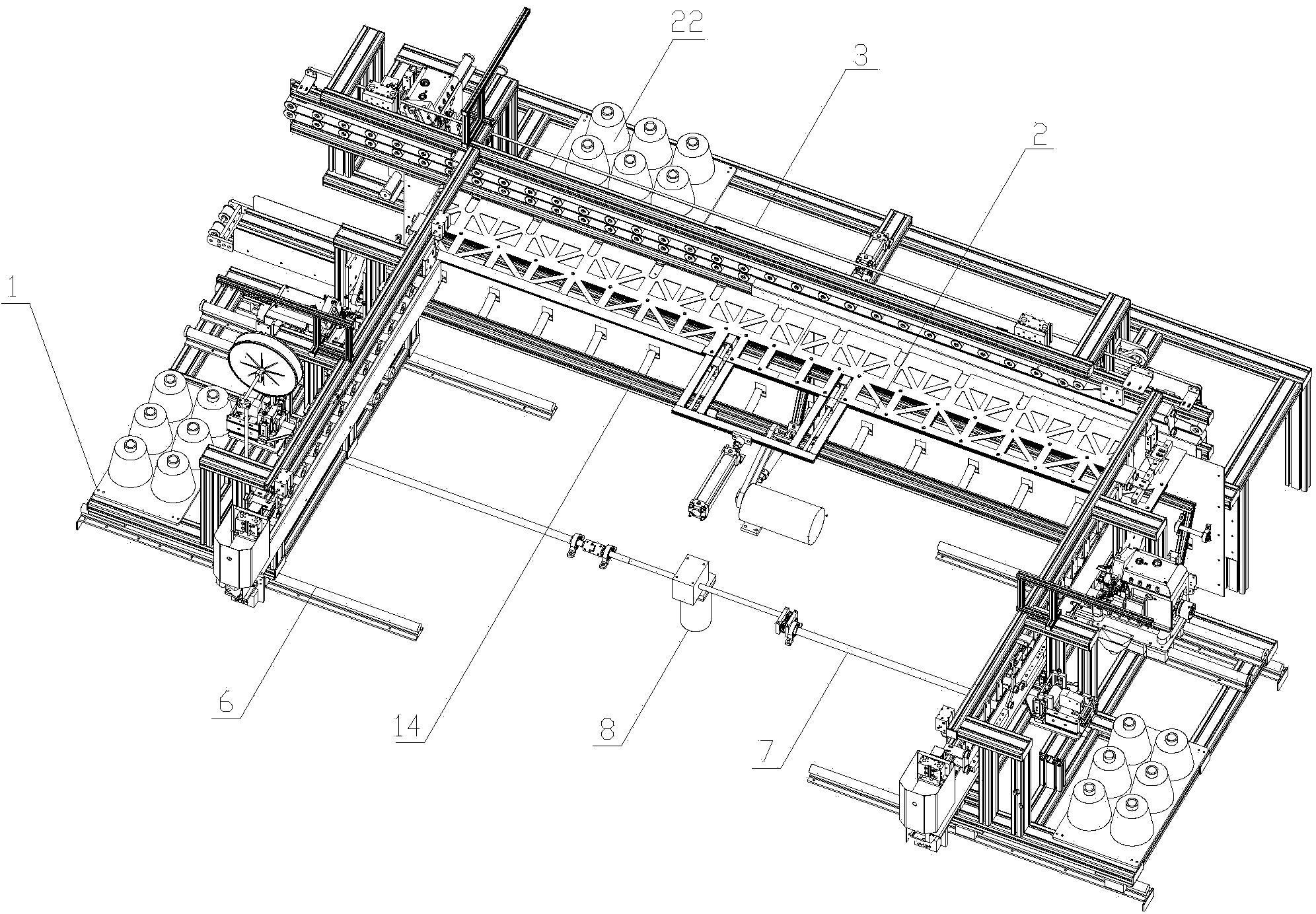

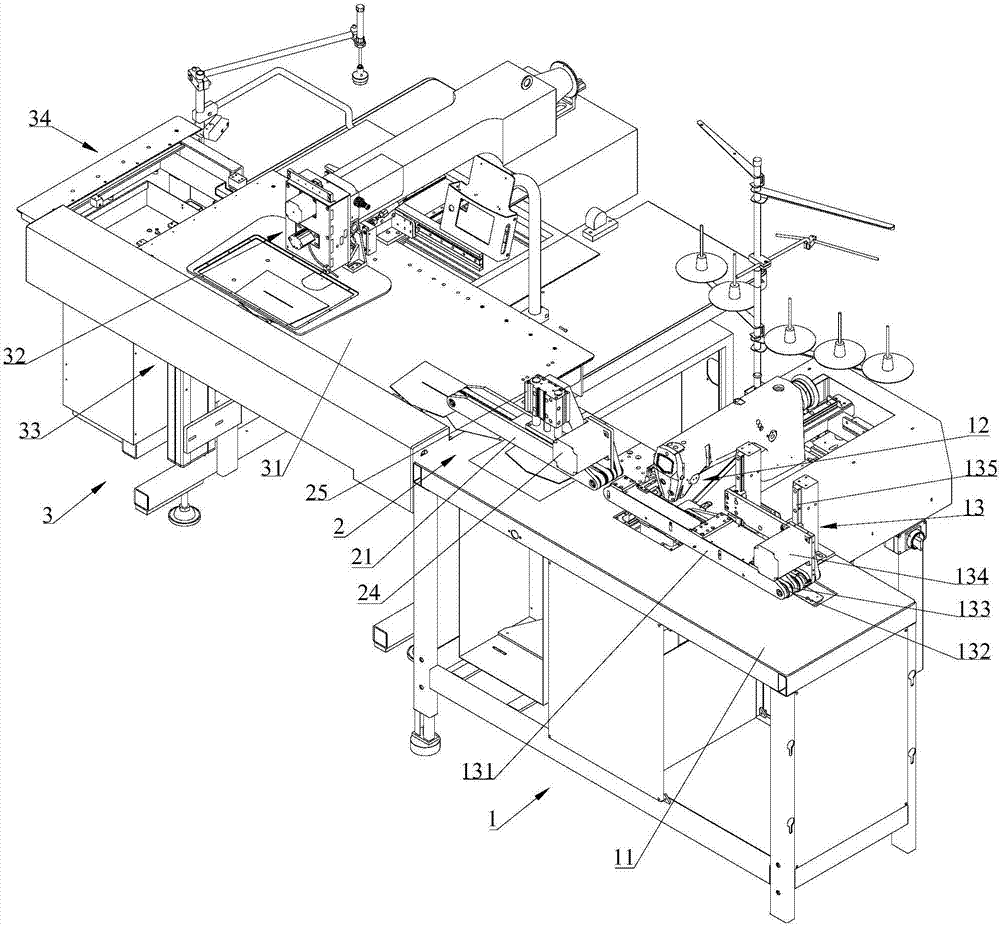

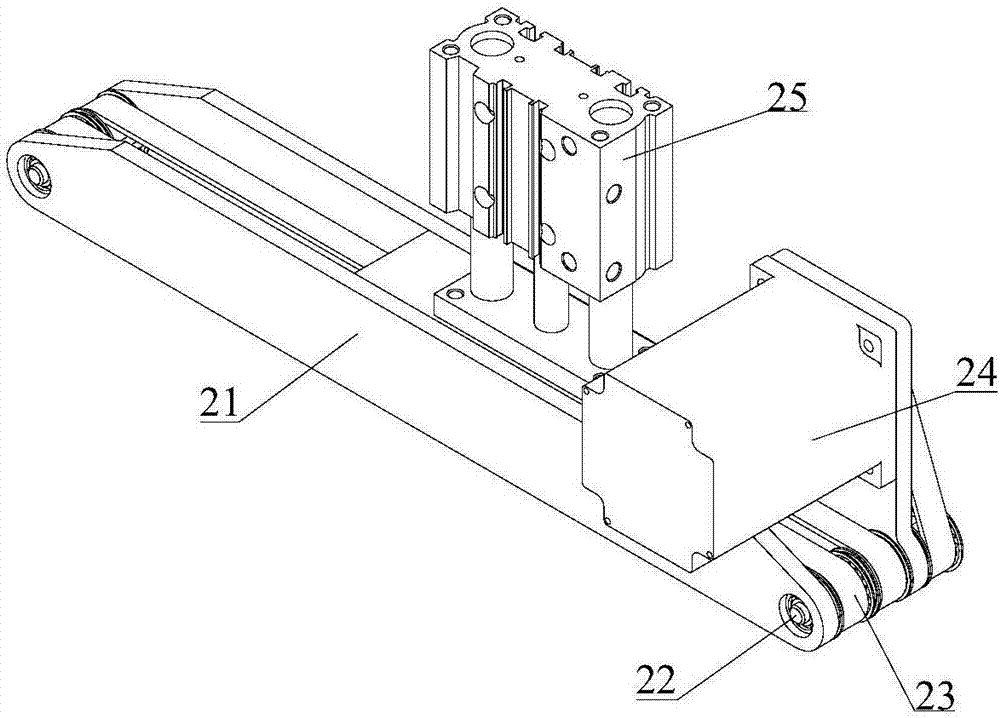

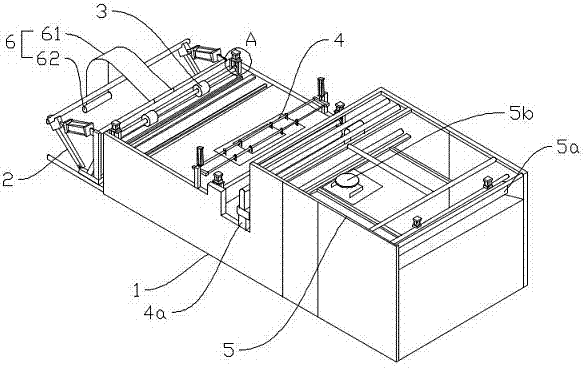

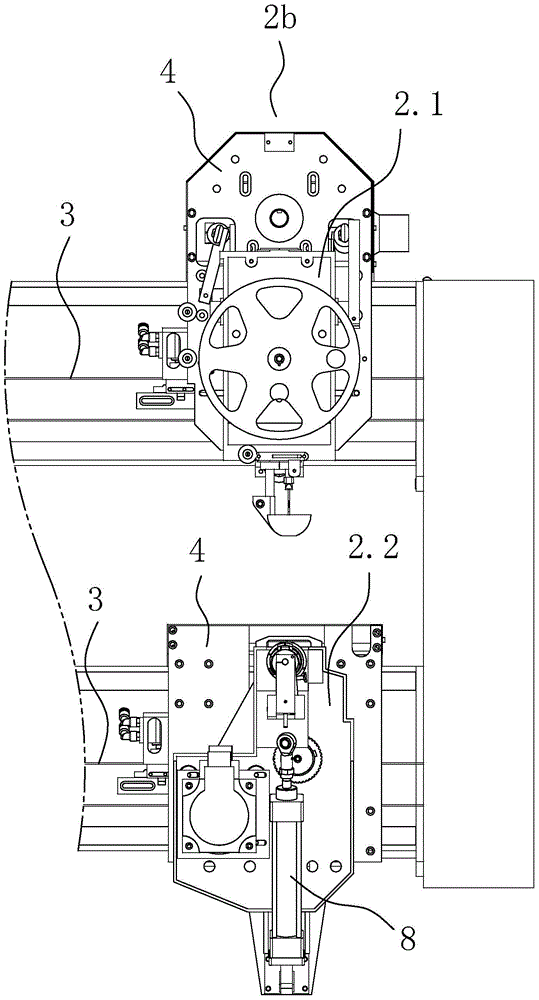

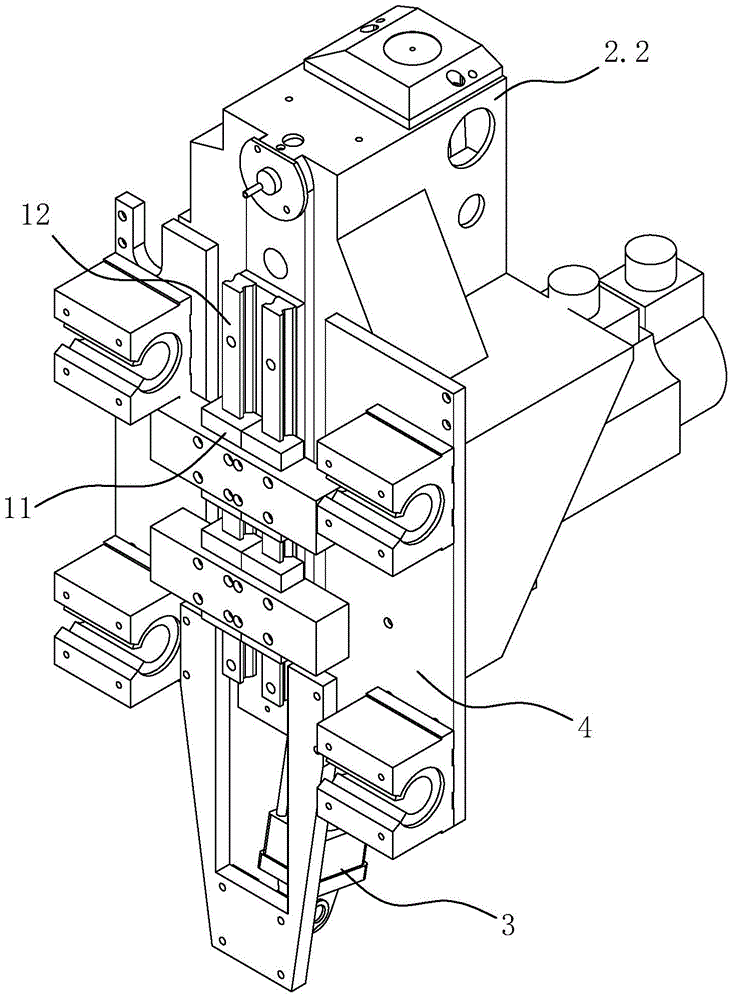

Improved towel machine

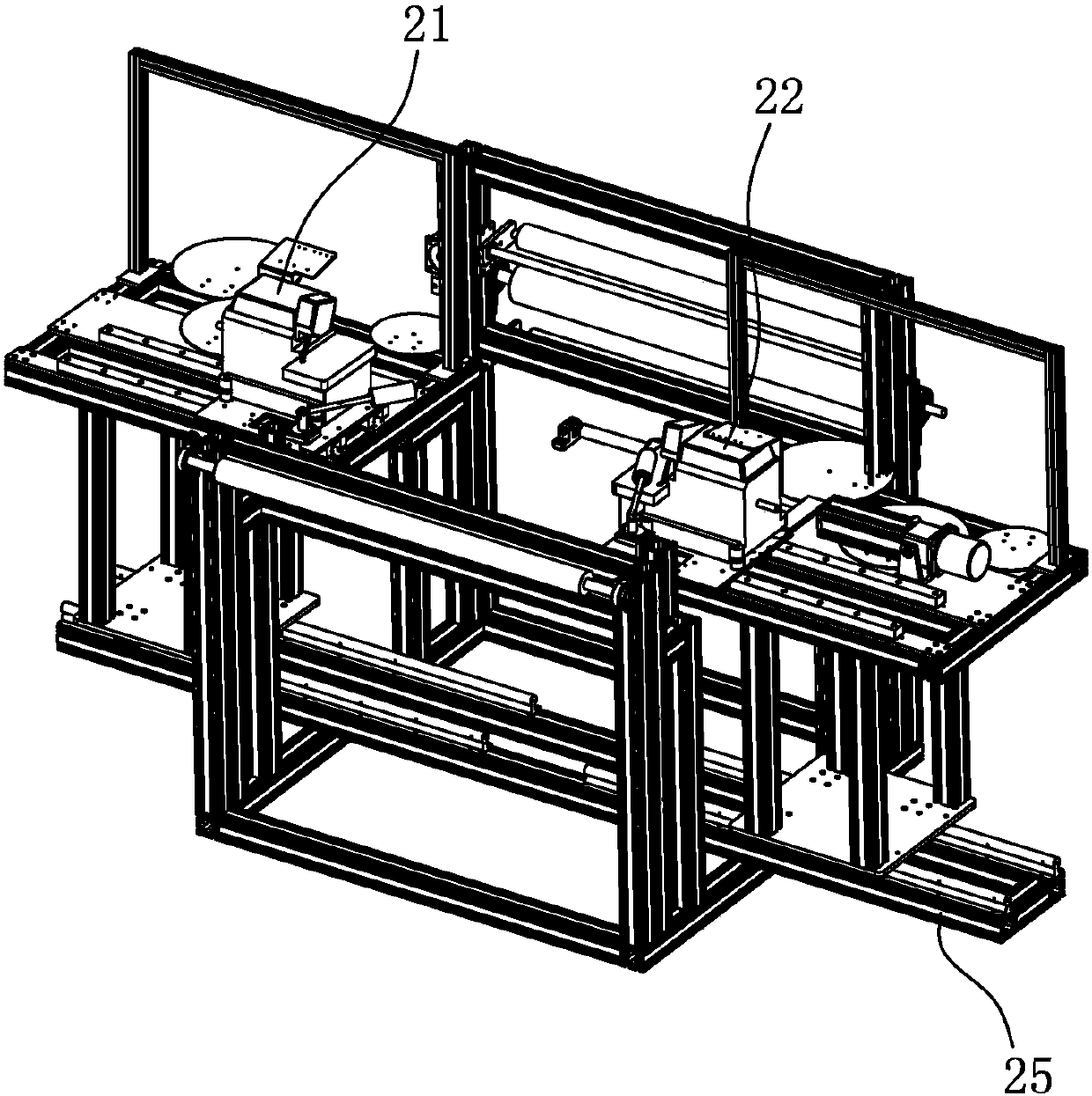

InactiveCN104611846AImprove processing efficiencyWorkpiece carriersWork-feeding meansEngineeringAutomation

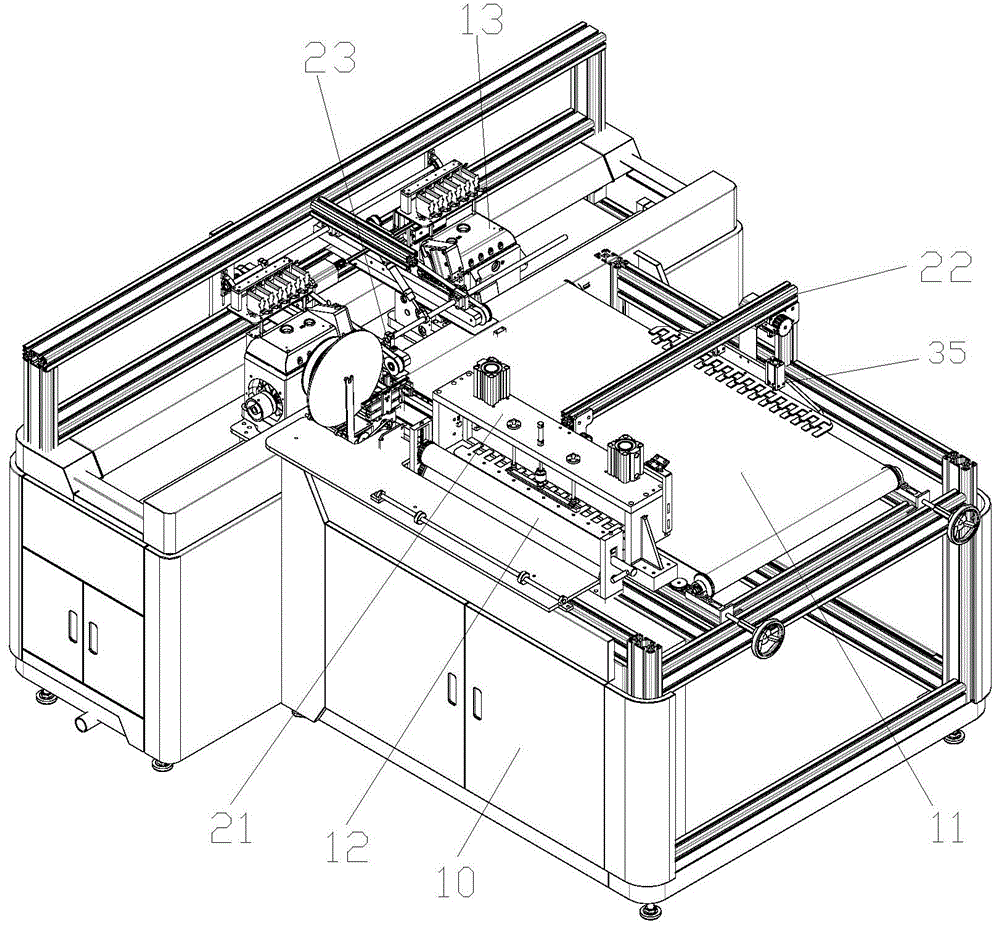

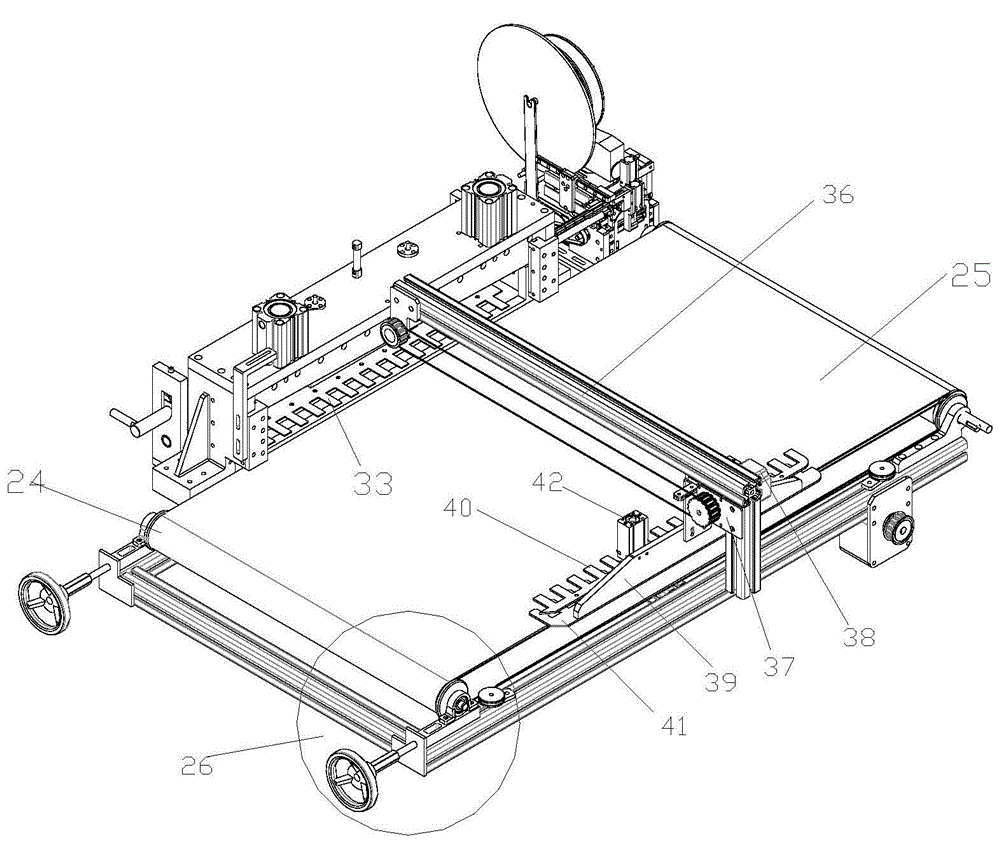

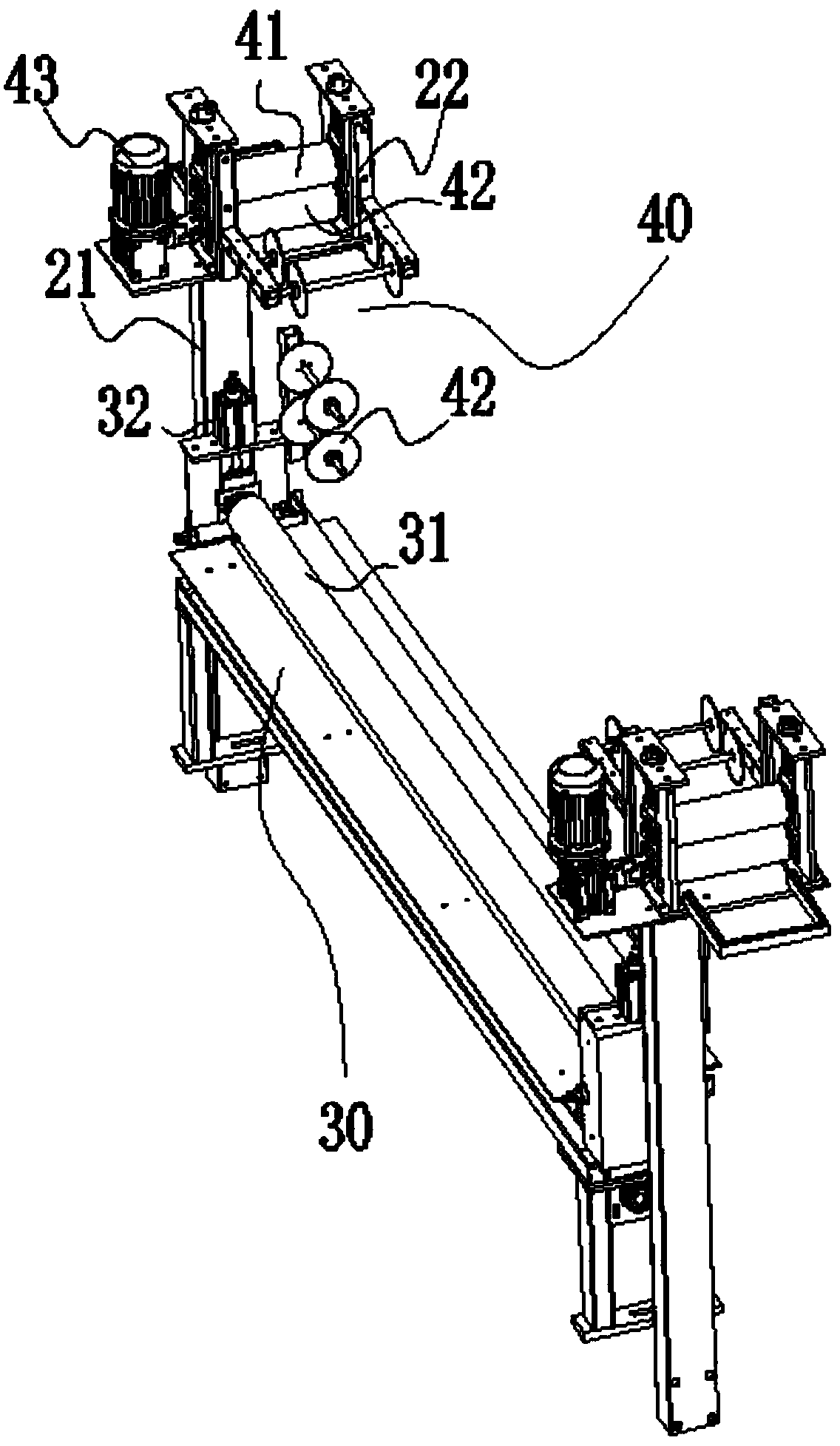

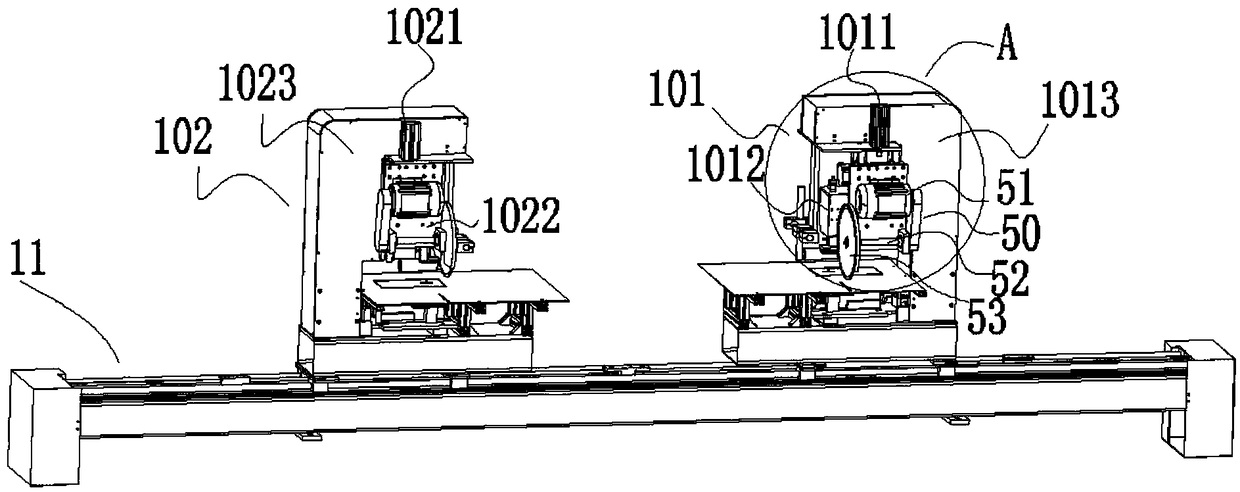

The invention relates to an improved towel machine which comprises a first processing device and a second processing device. A feeding device, the first processing device and the second processing device are oppositely and fixedly arranged in sequence. The second processing device comprises a third machine table, a belt conveying mechanism, a pair of synchronous second rubber rollers, a cutting mechanism, a clamping mechanism, a mark folding and sending mechanism and a second double-needle machine. The belt conveying mechanism, the pair of synchronous second rubber rollers, the cutting mechanism, the clamping mechanism, the mark folding and sending mechanism and the second double-needle machine are fixed to the third machine table. The cutting mechanism is arranged between the synchronous second rubber rollers and the belt conveying mechanism. The clamping mechanism is fixedly hung above the belt conveying mechanism and clamps cloth to the belt conveying mechanism. The discharging outlet of the belt conveying mechanism is fixedly provided with the second double-needle machine. The mark folding and sending mechanism is fixedly arranged on one side of the belt conveying mechanism and located between the synchronous second rubber rollers and the double-needle machine. The improved towel machine produces towels through mechanical automation instead of manual operation, the labor intensity of workers is lowered, and the processing efficiency of the improved towel machine is effectively improved.

Owner:SUZHOU JUKANG SEWING ROBOT

Automatic coverseam four-edge machine

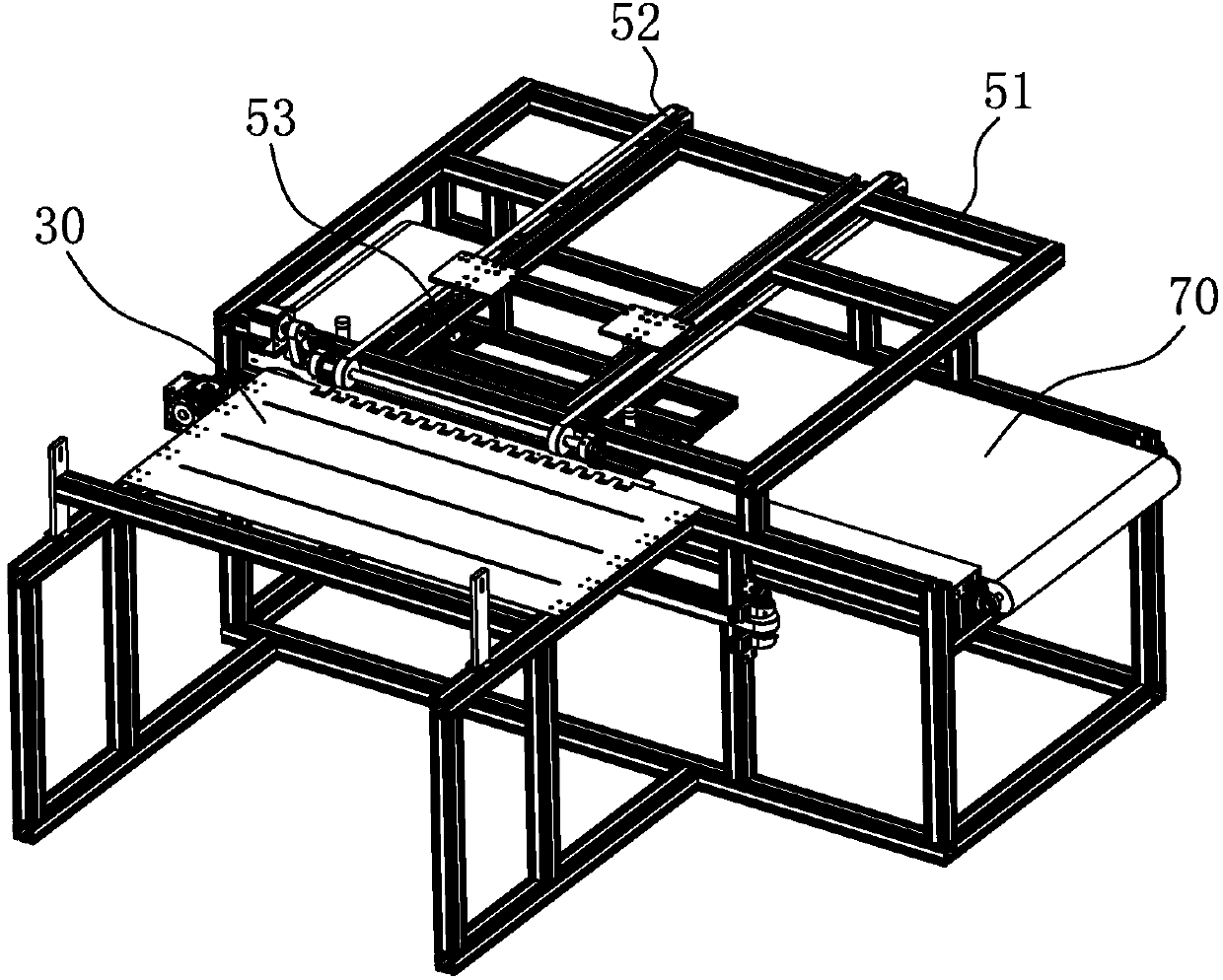

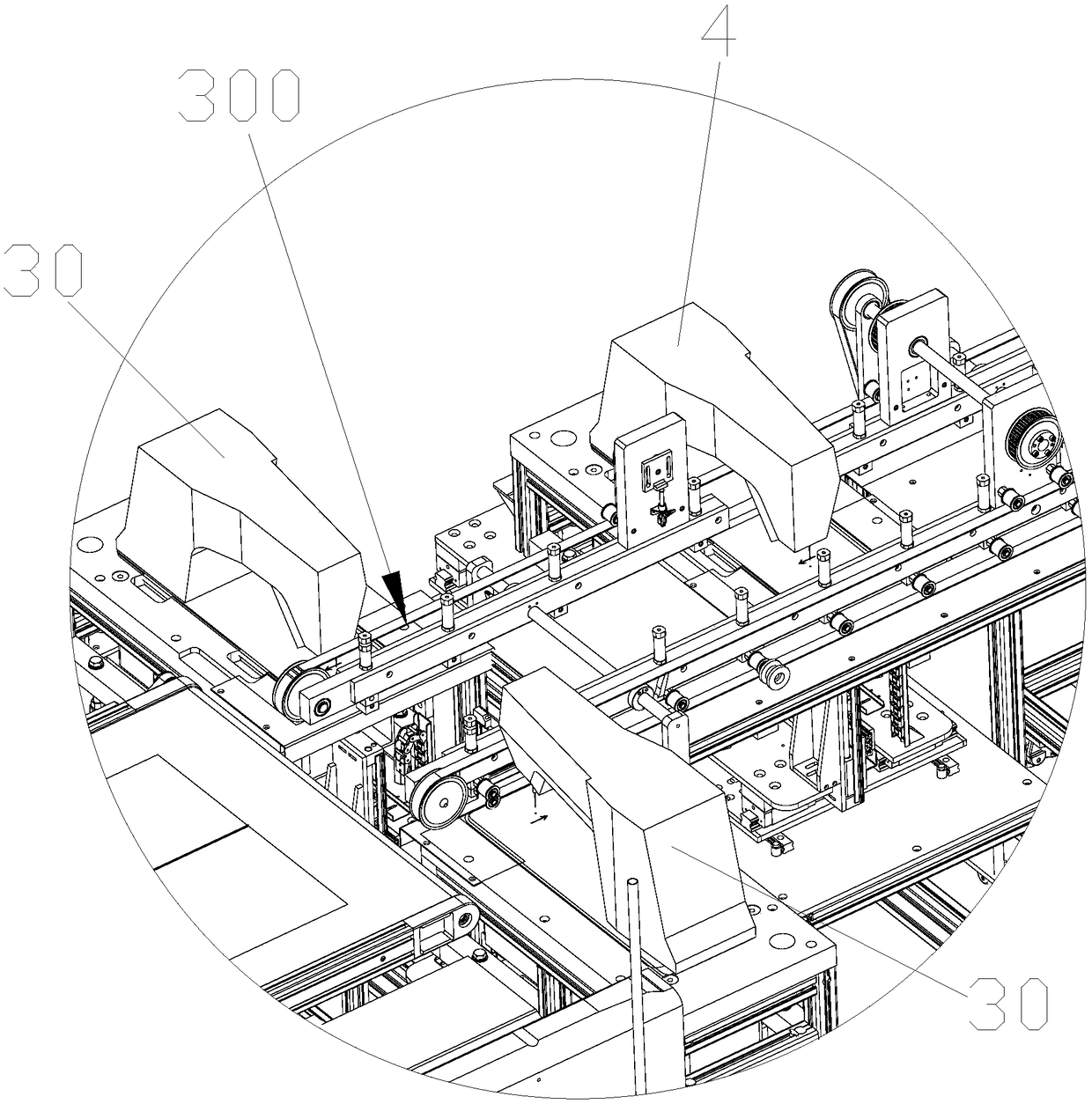

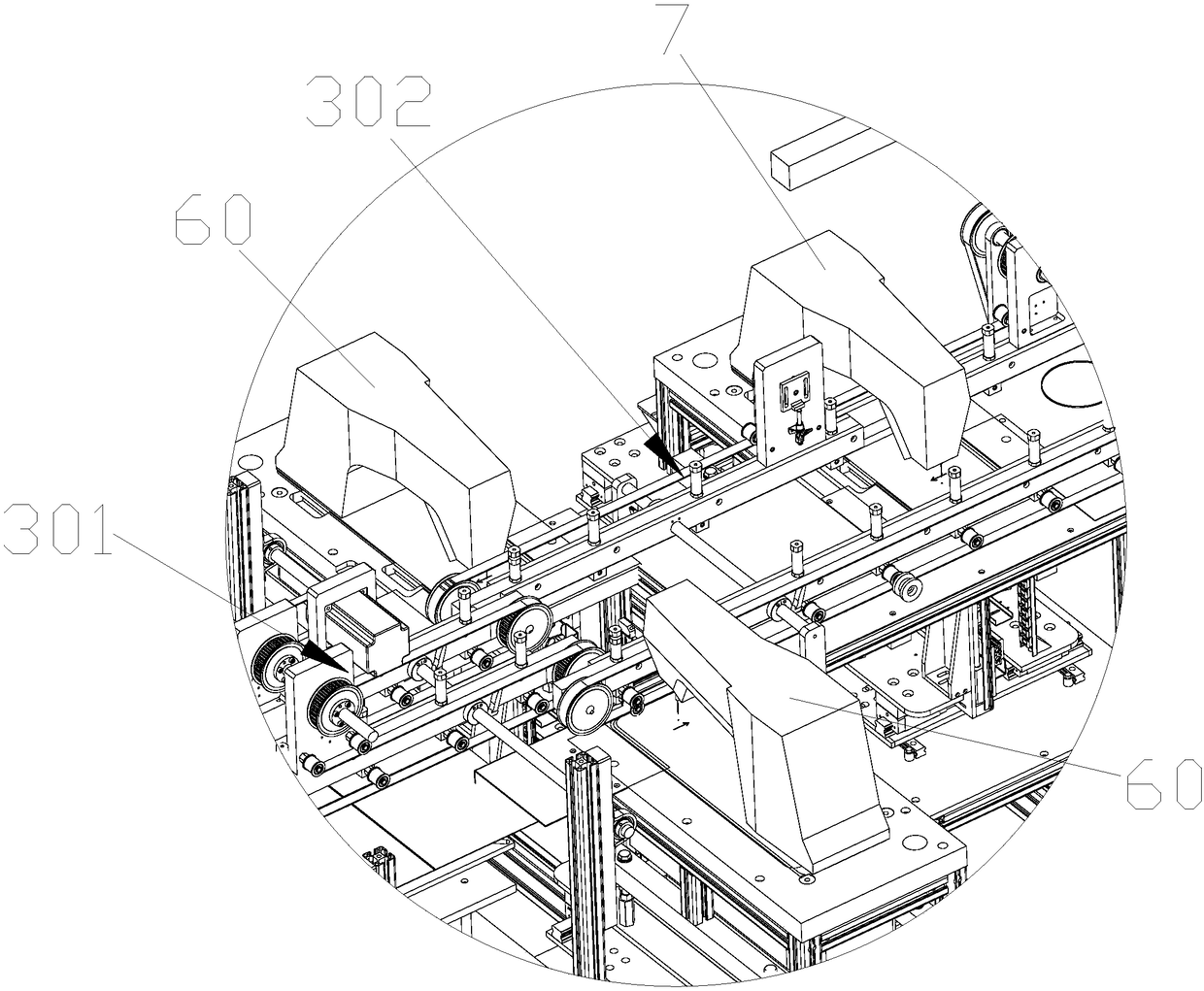

ActiveCN107829223AIncrease productivityReduce labor costsWorkpiece carriersCombination sewing machinesProduction lineEngineering

The invention discloses an automatic coverseam four-edge machine. The machine includes a feeding device, a first sewing device, a cloth storage device, a conveying device and a second sewing device which are arranged at the front and rear sides in sequence along a production line; the first sewing device is provided with a first planishing mechanism and a first horizontal coverseam machine; the second sewing device is provided with a second planishing mechanism and a second horizontal coverseam machine; the included angle between the cloth conveying direction in the first sewing device and thecloth conveying direction in the second sewing device is 90 degrees; the conveying device is provided with a cloth clamping mechanism used for clamping and horizontally transferring cloth sewn by thefirst sewing device, a trimming mechanism for trimming cloth when the cloth clamping mechanism clamps the cloth from a first position to a second position, and a belt conveying mechanism used for conveying the cloth formed by the trimming mechanism to the second sewing device. The clamping direction of the cloth clamping mechanism is perpendicular to the conveying direction of the belt conveyingmechanism.

Owner:JINJIANG LIDA MACHINERY

Full-automatic material distribution machine capable of achieving longitudinal sewing

PendingCN107164882AMeet development needsCompact structureWorkpiece carriersWork-feeding meansCardingEngineering

The invention relates to a full-automatic material distribution machine capable of achieving longitudinal sewing. A material feeding component is arranged on one side of a machine frame, and a material feeding deviation rectifying device is arranged in the material feeding component; a left and right deviation rectifying device is arranged on one side of the material feeding component; an edge trimming device, a hemming device, a sewing machine and a main material dragging device are sequentially arranged on the left and right deviation rectifying device; a material receiving mechanism is arranged on one side of the main material dragging device. After entering from the from the material feeding component through the main material dragging device, a fabric is first subjected to material feeding deviation rectification through the material feeding deviation rectifying device and then enters the left and right deviation rectifying device, and the fabric is subjected to left and right deviation rectification through the mutual cooperation of pile loop detection components and a deviation rectifying component; next, the fabric passes through the edge trimming device and the hemming device in sequence, excessive parts at the edge of the fabric are subjected to trimming and hemming, then the fabric is sewn through the sewing machine, and finally, the sewn towels is subjected to stacked carding and finishing. Be means of the full-automatic material distribution machine, operation is convenient and saves labor, the longitudinal sewing of the fabric can be automatically achieved, the overall process is fully automatic, and development requirements of enterprises are met.

Owner:SUZHOU TRANSPARENT TECH CO LTD

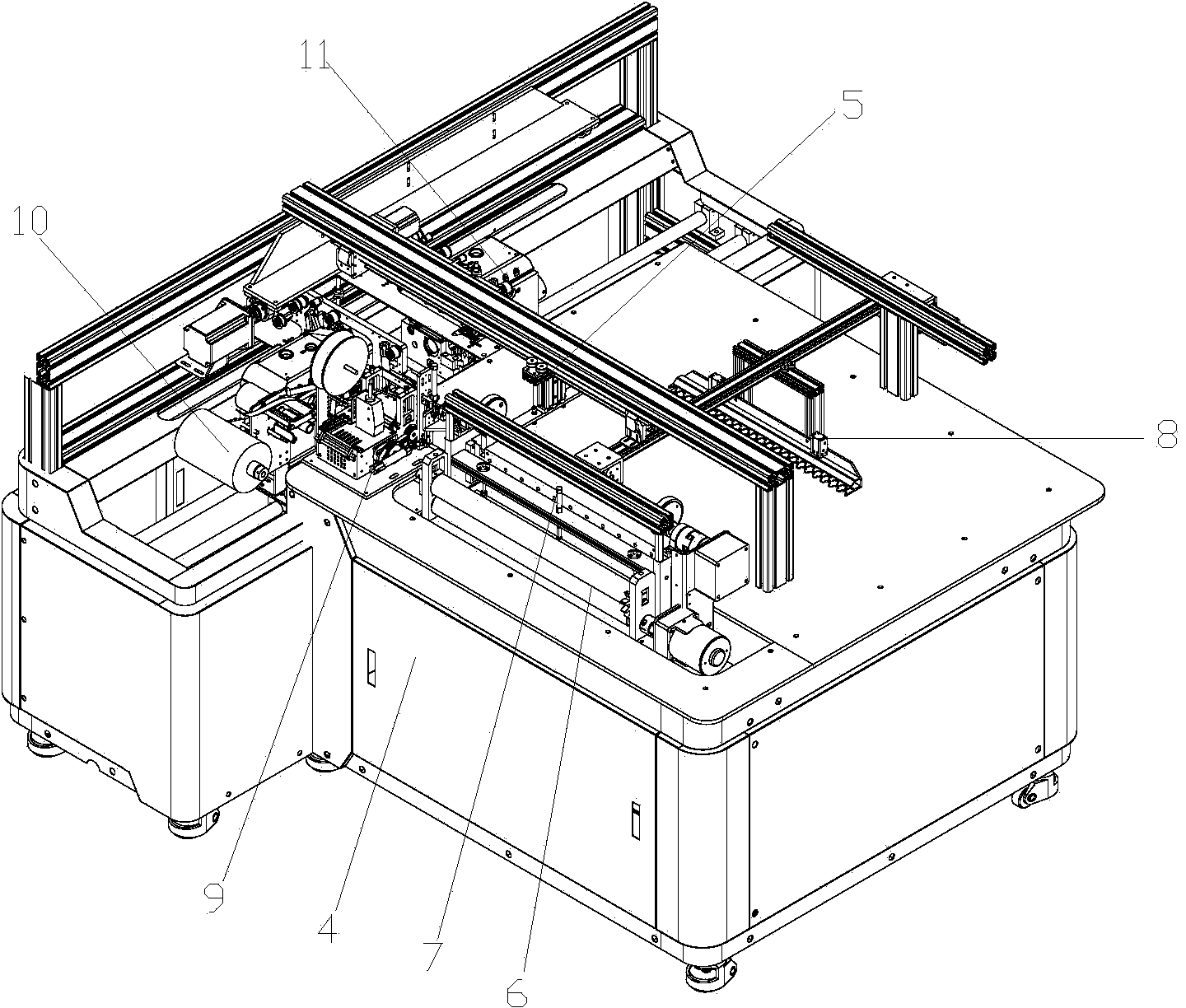

High-efficiency towel machine

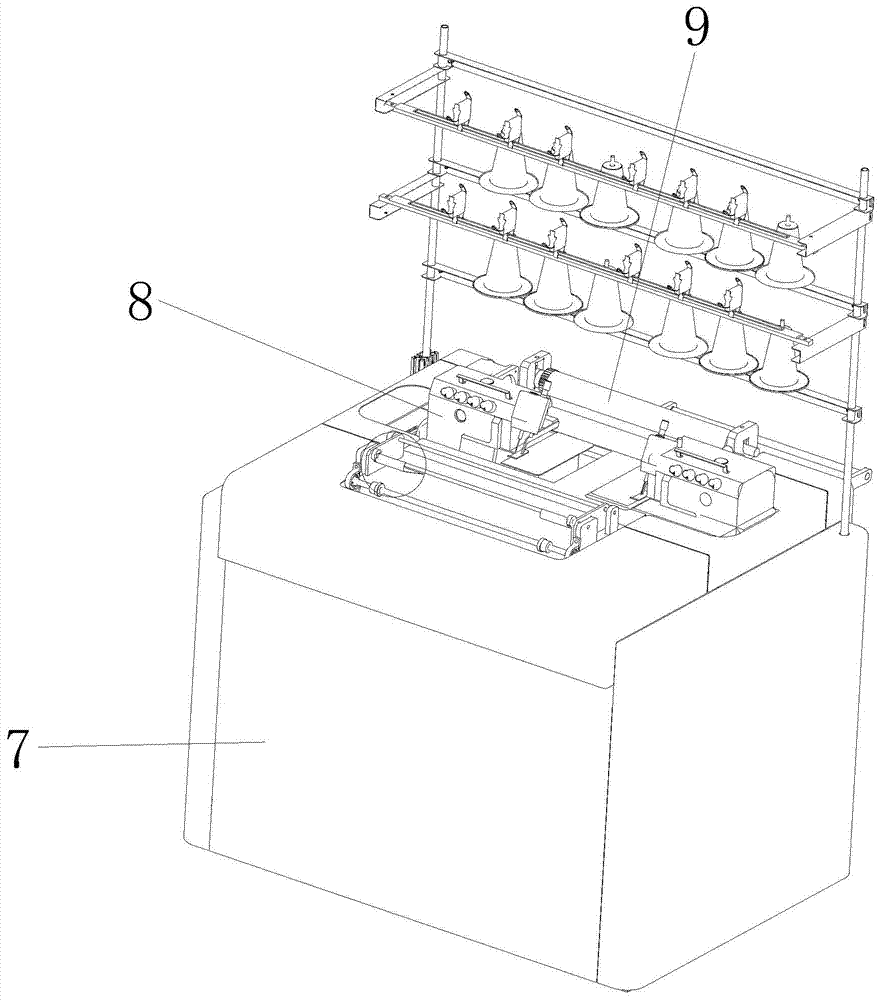

ActiveCN104250888AGood transmission effectHigh precisionProgramme-controlled sewing machinesCombination sewing machinesElectric machineryEngineering

The invention relates to a high-efficiency towel machine. The high-efficiency towel machine comprises a control center, a feed device, a first machining device and a second machining device. The feed device feeds cloth into the first machining device for first double-side binding, and the processed cloth of the first machining device is fed into the second machining device. The second machining device cuts off the cloth for second double-side binding. The second machining device comprises a second machine table, a sucker conveying mechanism, a second synchronous wheel, a cutting mechanism, a clamping mechanism, a label folding and sending mechanism, a belt loosening device and a second double-needle sewing machine, wherein the sucker conveying mechanism, the second synchronous wheel, the cutting mechanism, the clamping mechanism, the label folding and sending mechanism, the belt loosening device and the second double-needle sewing machine are fixed on the second machine table. The cutting mechanism comprises a first cutter rest, a first cutter, a first cutter motor, a spindle and an eccentric bearing, wherein the first cutter rest is provided with a vertical guide groove, the vertical side of the first cutter is matched in the guide groove, the spindle is horizontally fixed on the first cutter rest, the spindle is arranged above the guide groove, the eccentric bearing is sleeved with the spindle and is radially and movably connected with the first cutter, and one end of the spindle is connected with the first cutter motor. According to the above technical scheme of the high-efficiency tower machine provided, production efficiency and machining quality are greatly improved.

Owner:SUZHOU TRANSPARENT TECH CO LTD

Lamellar cloth sewing machine

ActiveCN104047120AReduce consumptionQuality assuranceWork-feeding meansCombination sewing machinesEngineeringOutput device

The invention discloses a lamellar cloth sewing machine, comprising two bilaterally symmetrical front end overlocking devices, a cloth overturning device, a back end overlocking device and a finished-product output device. The two front end overlocking devices carry out two-side synchronous overlocking processing on lamellar cloth and then discharge the lamellar cloth into the cloth overturning device, and the cloth overturning device overturns the cloth and feeds the cloth into the back end overlocking device; the finished-product output device is arranged below the back end overlocking device and conveys the processed lamellar cloth out of the machine. Through the above manner, the lamellar cloth sewing machine is provided; according to the cloth sewing machine, by utilizing processing steps of general products as starting points, an advantageous structure of two-side overlocking and end overlocking is designed on purpose; in addition, for improving the mechanical property, a relatively low-consumption transmission structure is optimized; based on the working efficiency of the machine, the working process of the cloth in the sewing machine is very continuous, and by utilizing multiple process assisting structures, the quality of finished-products is also guaranteed.

Owner:SUZHOU TRANSPARENT TECH CO LTD

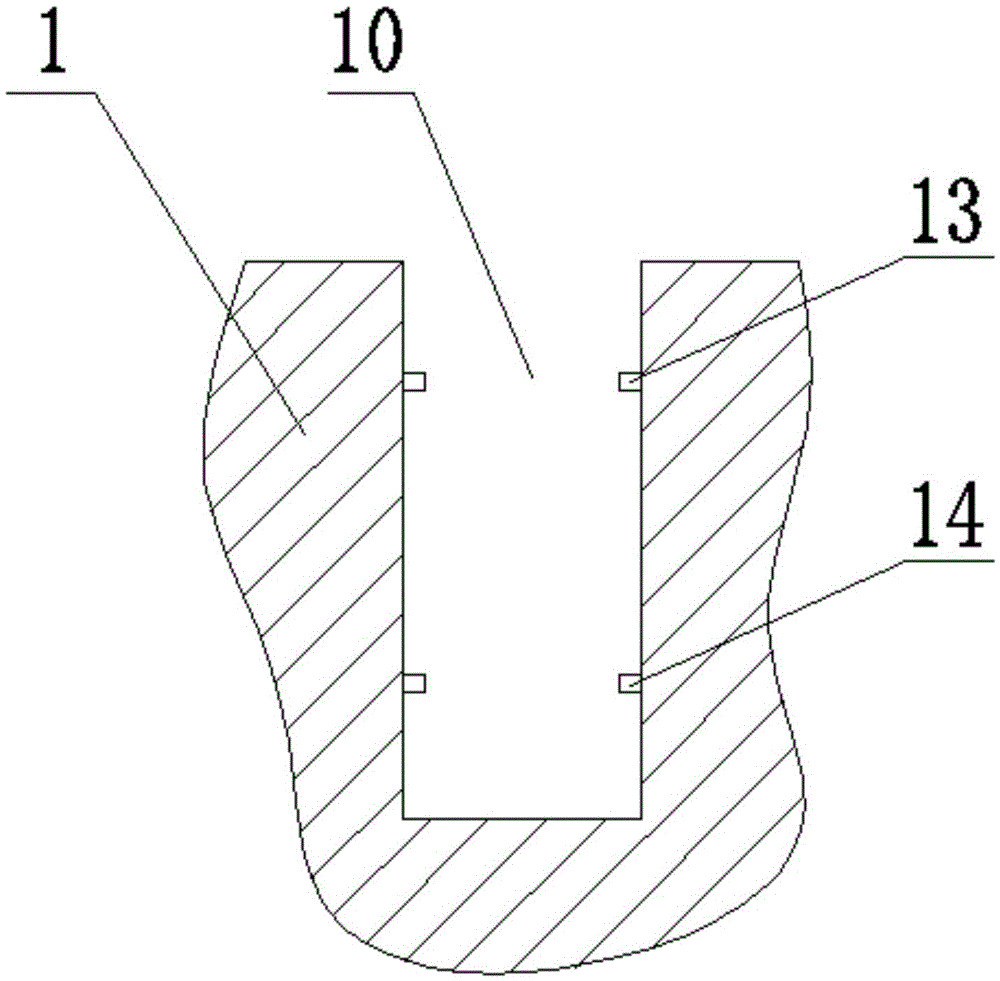

Abdomen pad machine

PendingCN109183286AMeet needsCompact structureWork-feeding meansCombination sewing machinesChinese charactersEngineering

The invention relates to an abdomen pad machine, which comprises a frame, a working table on the frame, a label feeding device located at one side of the working table on the frame for feeding two stitched labels to a cloth on the working table, a longitudinal stitching device, a first stitching device, a rotating mechanism, a transverse stitching device, a second stitching device and a pattern stitching device arranged on the frame and sequentially located at the front end of the working table, a first conveying mechanism located above the longitudinal stitching device and the first stitchingdevice for driving the cloth to be sequentially conveyed to the longitudinal stitching device, the first stitching device and the rotating mechanism, a second conveying mechanism located above the rotating mechanism and a third conveying mechanism located above the transverse stitching device and the second stitching device. Label placing on the cloth can be automatically realized, the stitchingline for the abdomen pad can be processed to be in multiple shapes such as a shape like a Chinese character wang, a shape like a Chinese character tian and a patterned shape according to actual needs,and various needs of the abdomen pad during production and processing are met.

Owner:SUZHOU TRANSPARENT TECH CO LTD

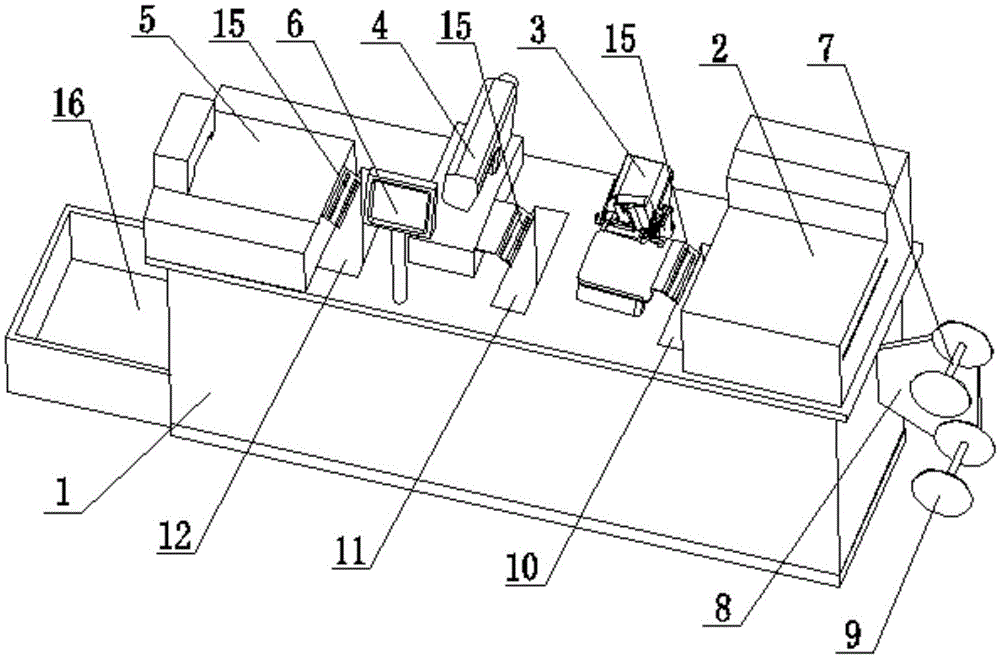

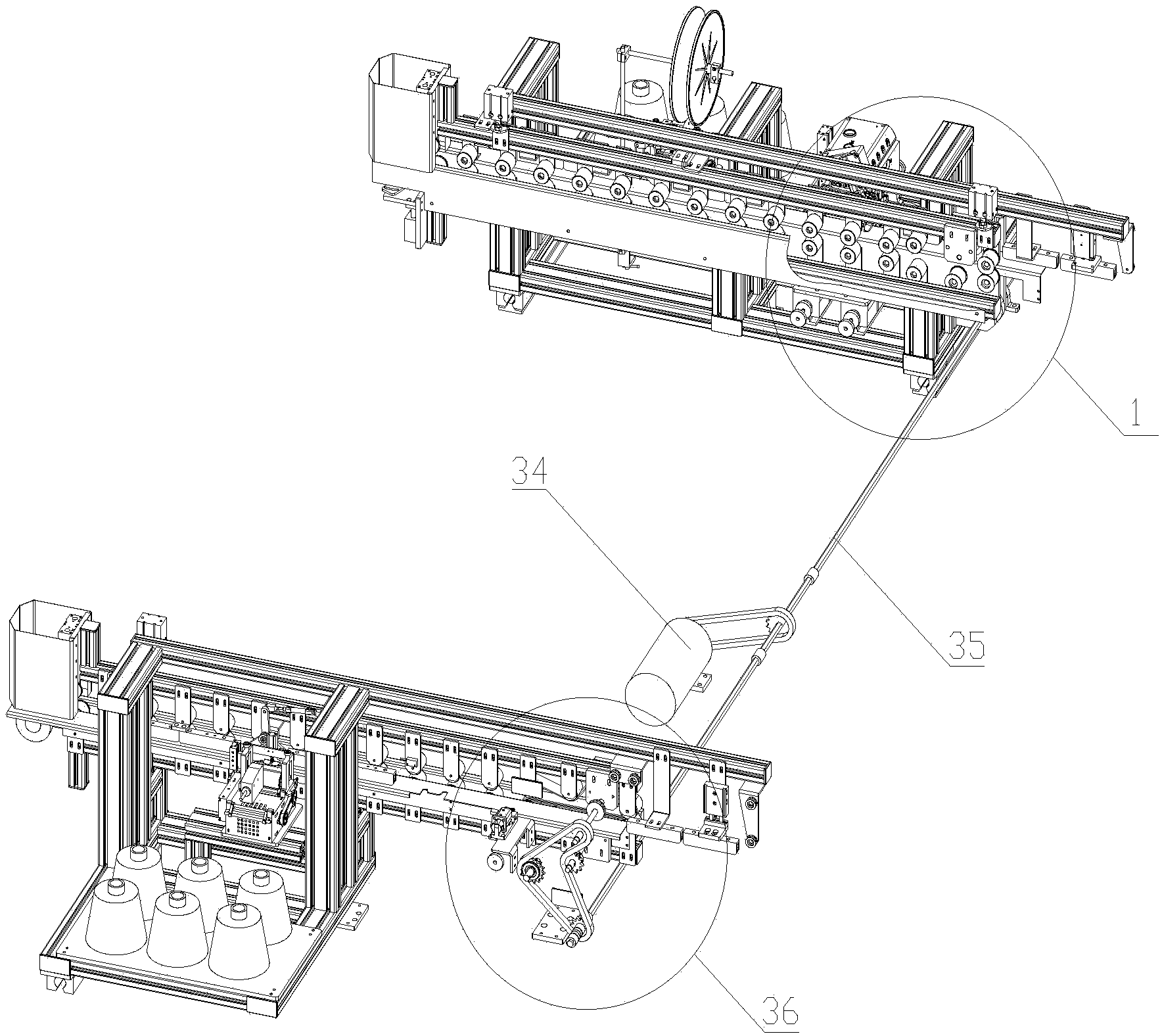

Yarn bag machine

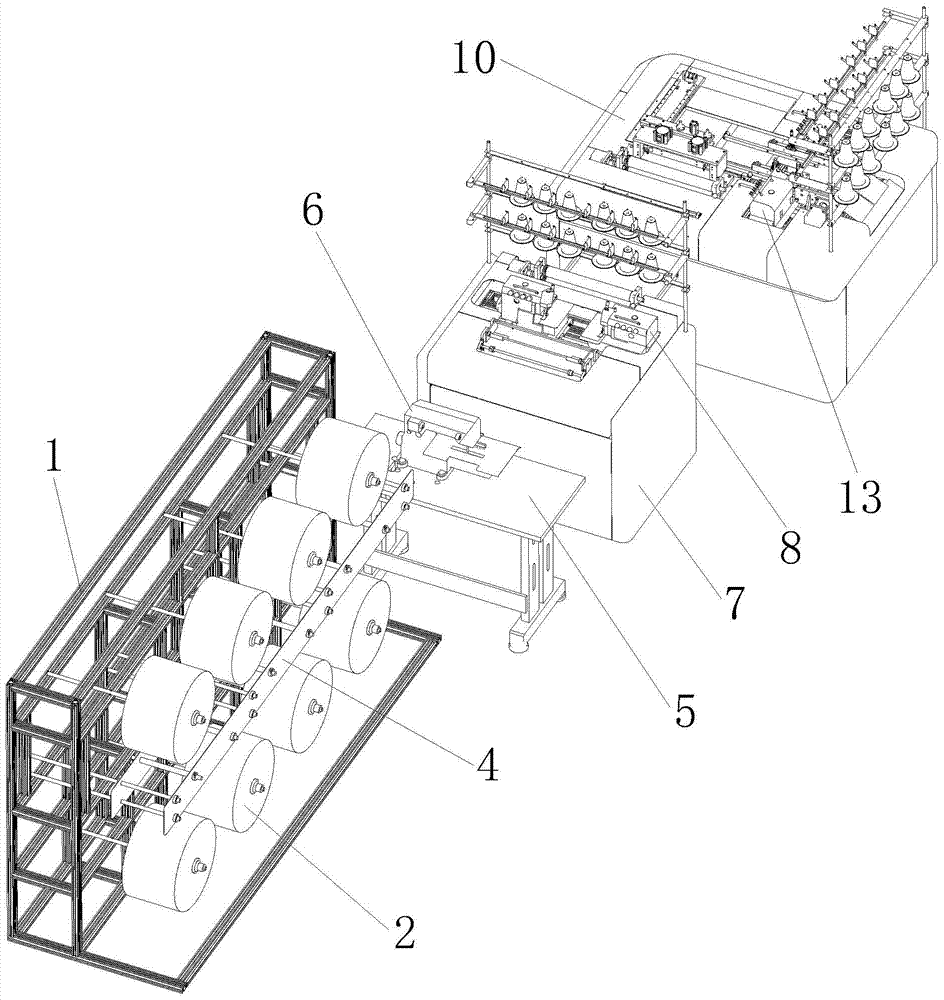

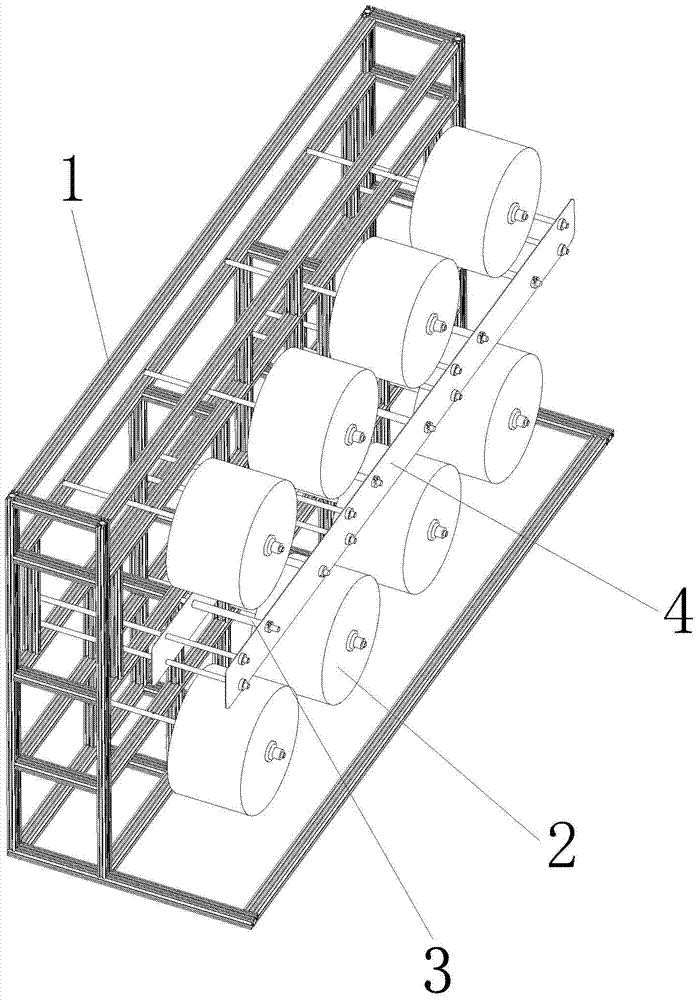

ActiveCN103320973AReduce manufacturing costIncrease productivityCombination sewing machinesYarnUltimate tensile strength

The invention discloses a yarn bag machine which comprises a feeding device, a first processing device and a second processing device. The feeding device, the first processing device and the second processing device are oppositely and fixedly disposed in sequence. The feeding device feeds shell fabric to the first processing device. The first processing device sews two ends of the shell fabric sent by the feeding device. The second processing device sews the two ends of the shell fabric sent by the first processing device after folding the shell fabric. Manual operation is replaced by mechanical automation operation to produce yarn bags, so that labor intensity of workers is greatly reduced, a production mode in which one person can operate multiple machines can be realized during production, product production efficiency is improved, production cost is reduced, effective management on production is facilitated, and product output value can be maximized.

Owner:SUZHOU TRANSPARENT TECH CO LTD

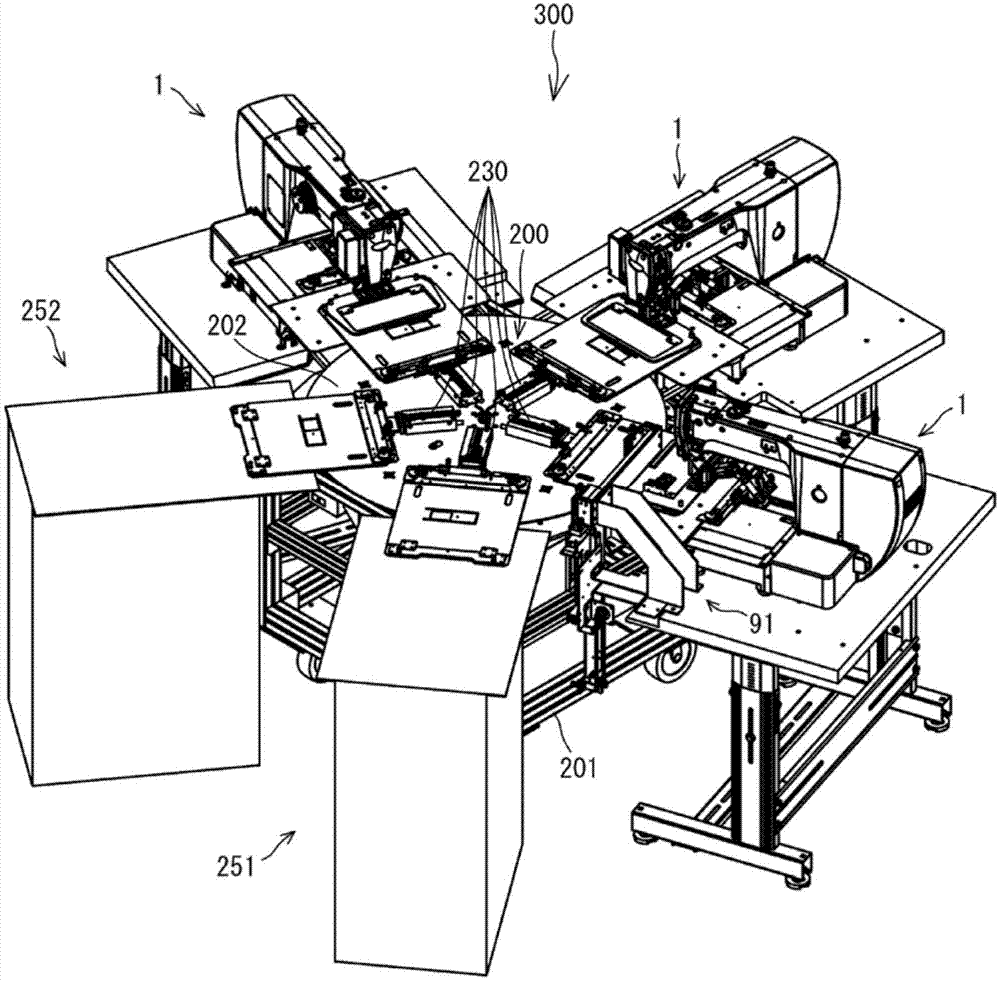

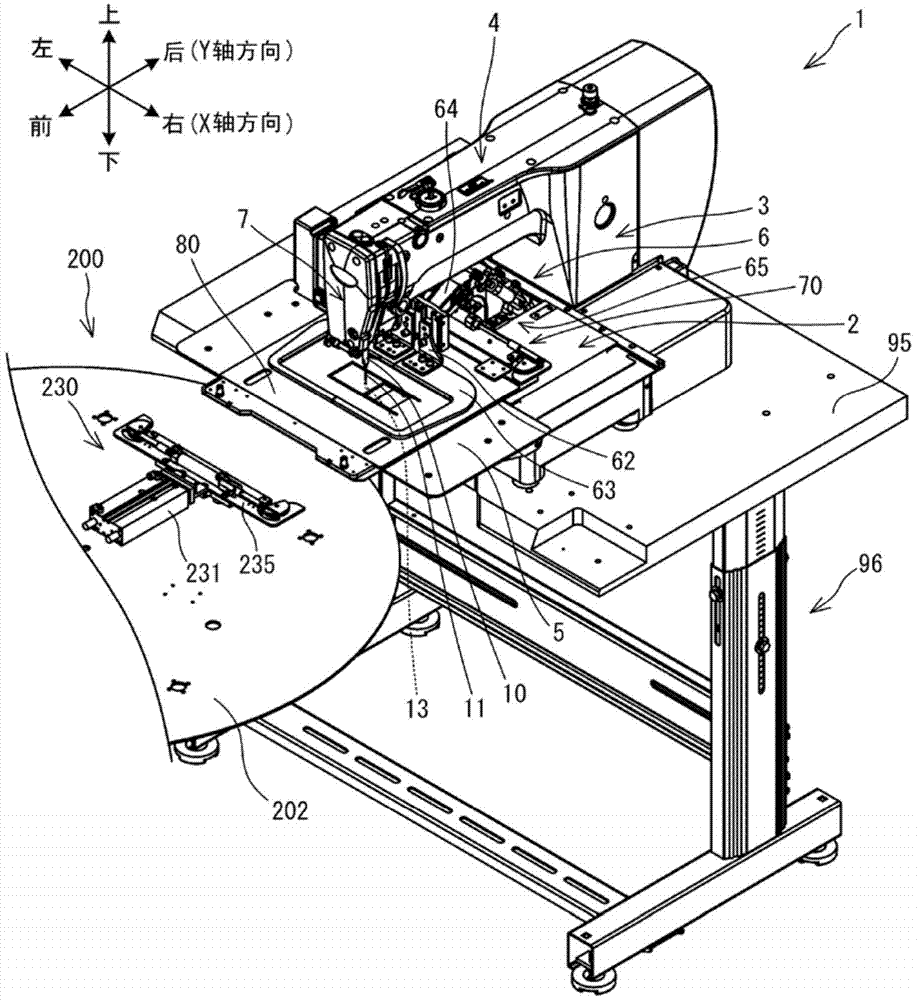

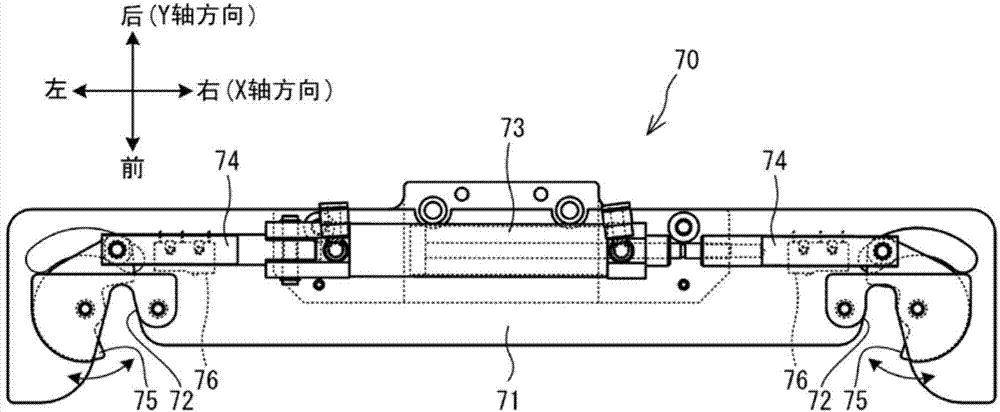

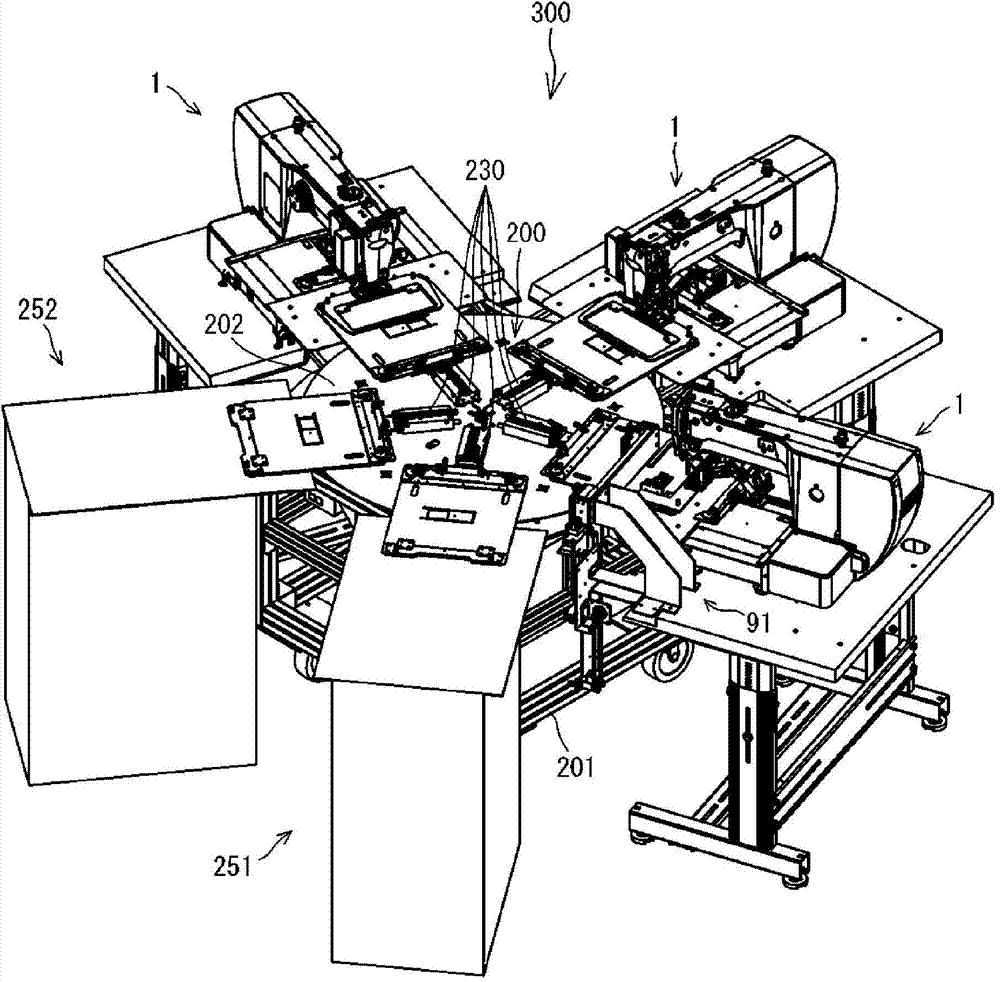

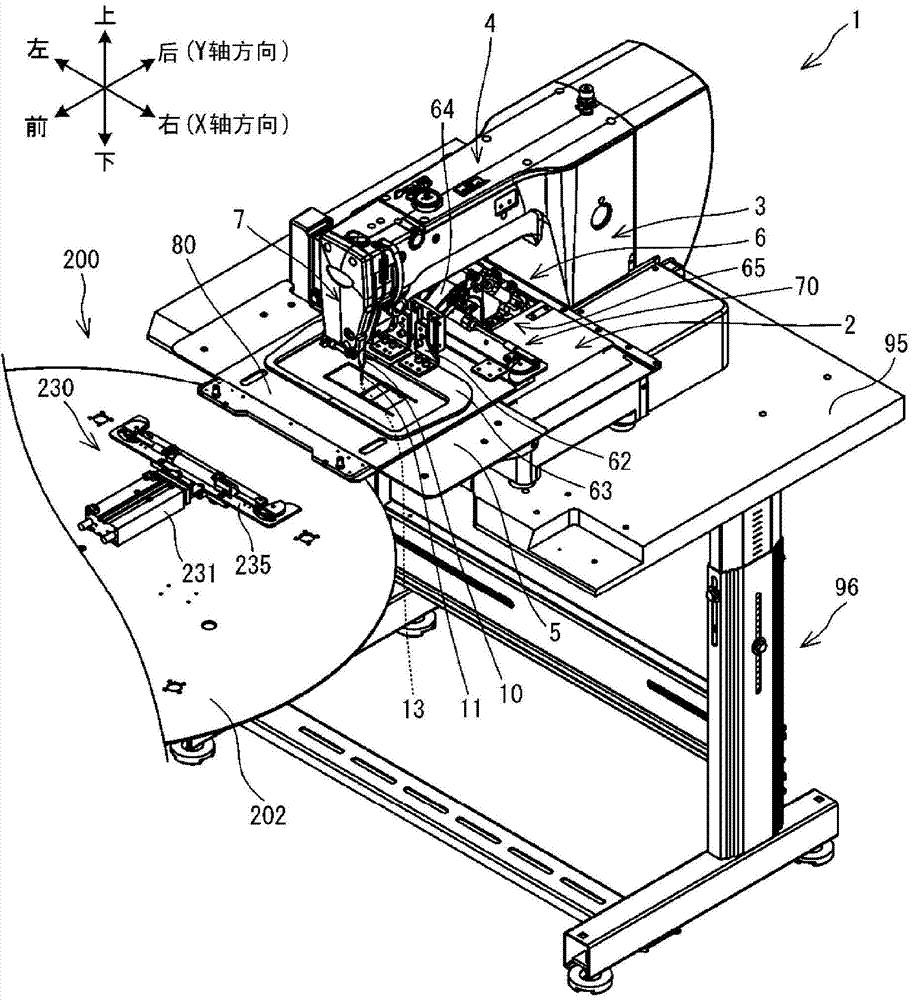

Sewing machine and sewing system

InactiveCN104514097AEfficient sewingReliable receptionProgramme-controlled sewing machinesCombination sewing machinesStart signalSewing machine

The present invention relates to a sewing machine and a sewing system. An object of the invention is to correct positional deviation of a reception position of a sewing machine relative to a supply position where a supply device supplies a holder, and reduce loads applied to the sewing machine and the holder, so that the sewing machine and the holder are prevented from damage. A CPU moves a frame support unit and a holder plate holding unit to a reception position (S38). During a time period started by receiving a receipt start signal (S42) and stopped by receiving a receipt request signal (S56), a holder plate supply device moves the holder plate holding unit which holds a holder plate to a supply position. The CPU repeatedly calculates a first deviation between the current position of the holder plate holding unit and the reception position (S47). If the first deviation exceeds a first specified value because of the push of the holder plate supply device (S48, S52), the CPU sets a holding position as a new reception position to make the first deviation become lower than the first specified value (S51, S55).

Owner:BROTHER KOGYO KK

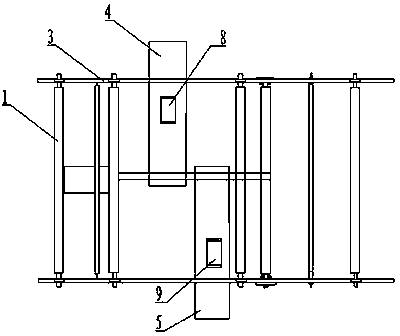

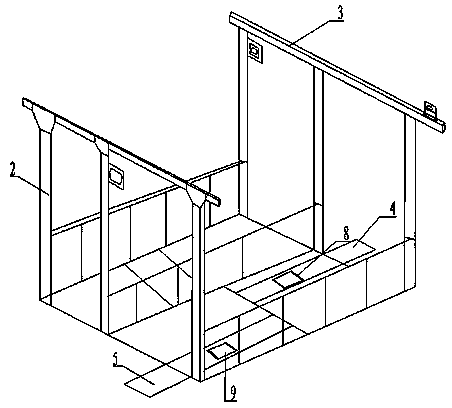

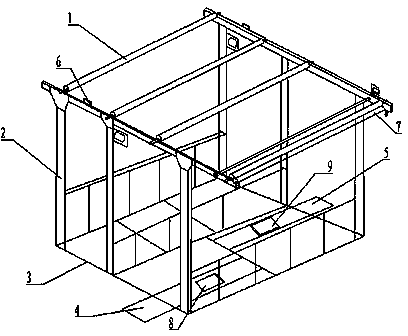

Full-automatic four-side sewing machine

ActiveCN109338602AIncrease flexibilityAvoid scratchesWorkpiece carriersWork-feeding meansProcessing accuracyCotton material

The invention belongs to the technical field of cloth processing, and particularly discloses a full-automatic four-side sewing machine, which comprises a frame, a workbench, a cloth pressing and feeding device, a cloth output device, a residual material discharge device, a first fixing seat, a second fixing seat, a first station, a second station and a third station, a cutting device and a automatic positioning device, after the cloth to be processed is placed on the workbench, the fabric to be processed is pressed and is pushed to move, and then a first processing surface and second processing surface of the cloth to be processed are processed through the first working station and the second working station. Then a third processing surface is measured and positioned by the automatic positioning device, and the third processing surface is processed through the third working station. The cutting device cuts the processed cloth, and the residual material is discharged by the residual material discharge device, after finishing the processing of the cloth to be processed. The cloth is conveyed out of the frame by the cloth output device. The full-automatic four-side sewing machine improves the processing accuracy and the working efficiency.

Owner:佛山市科华智缝设备有限公司

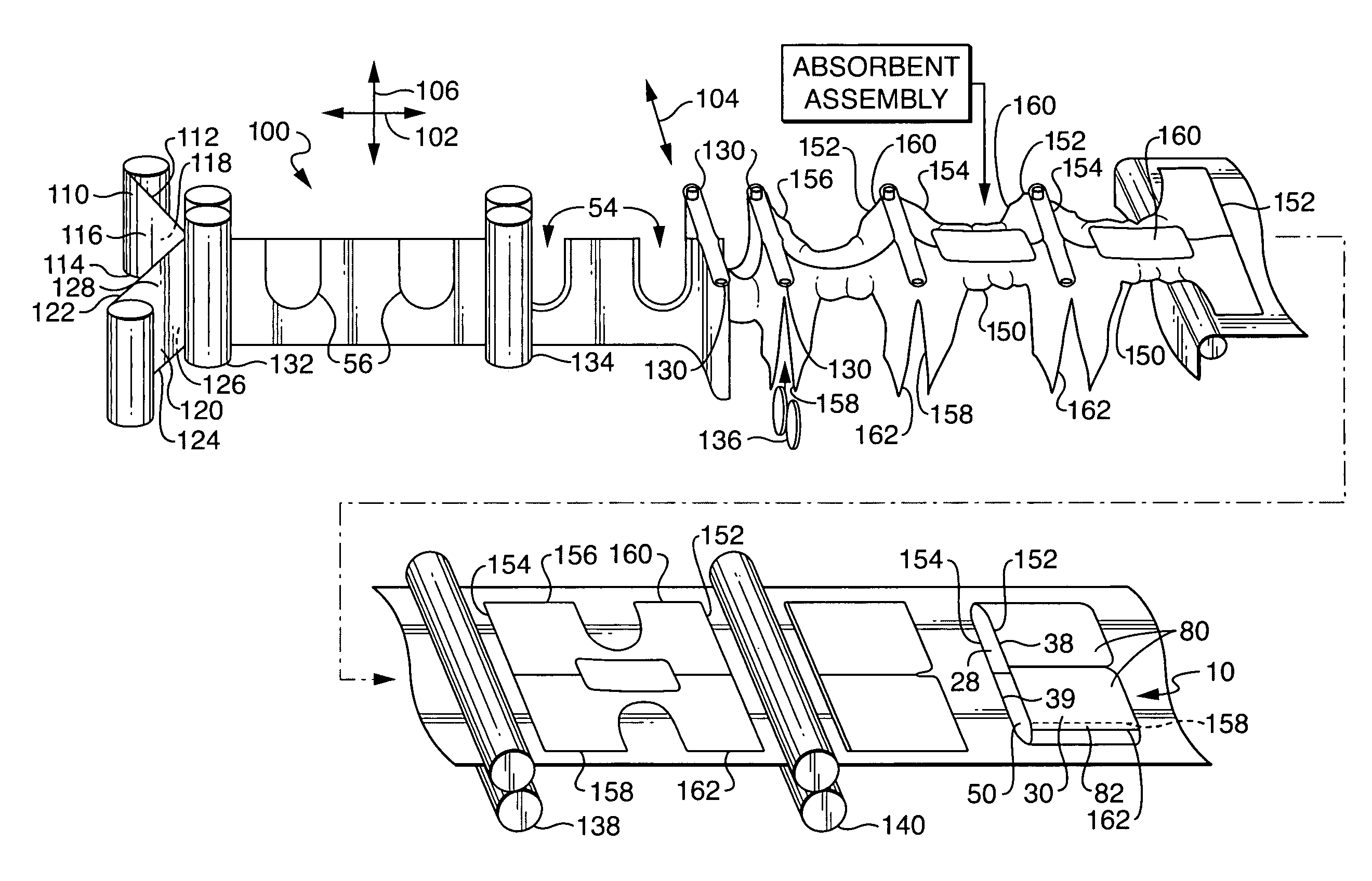

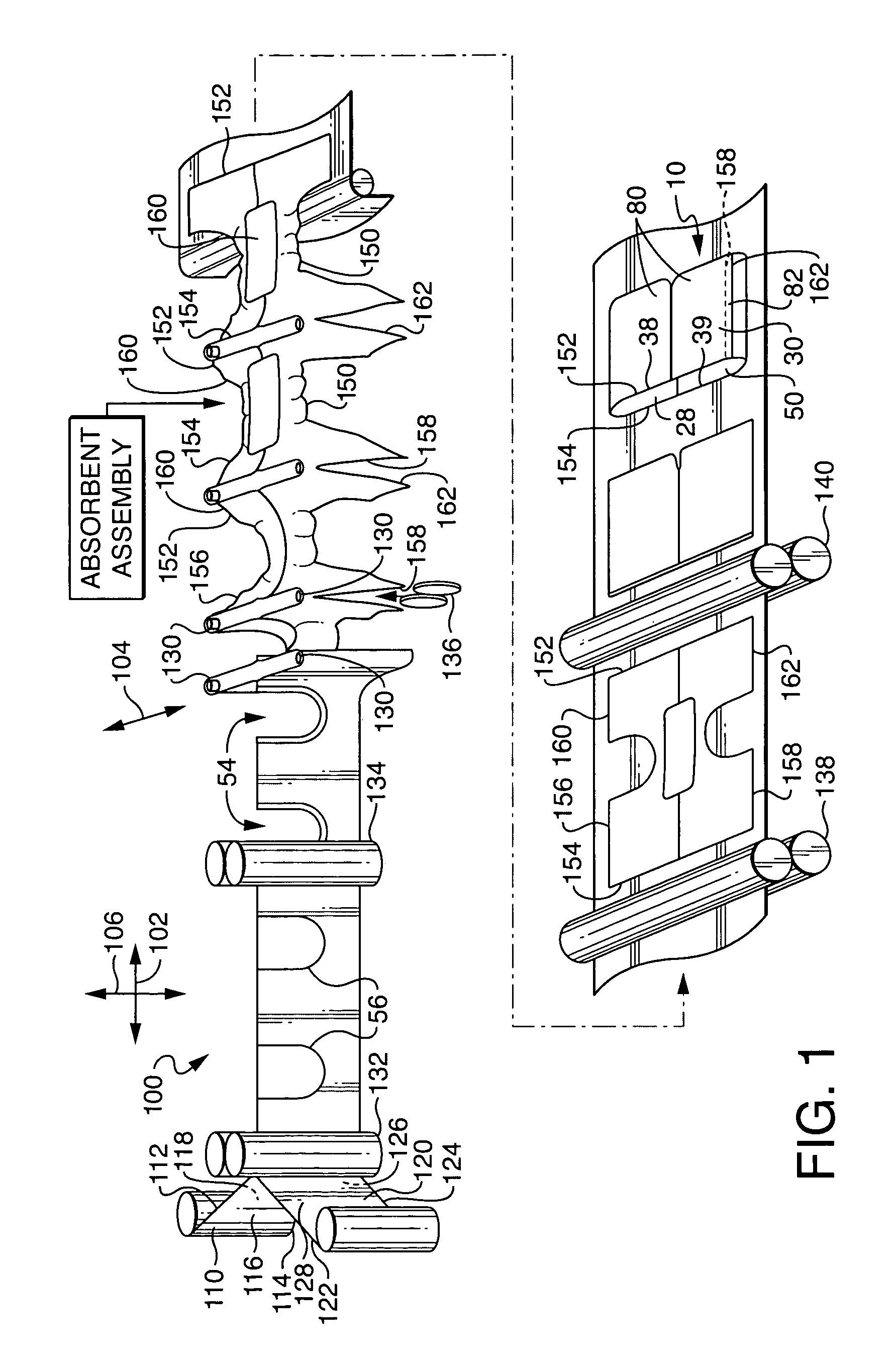

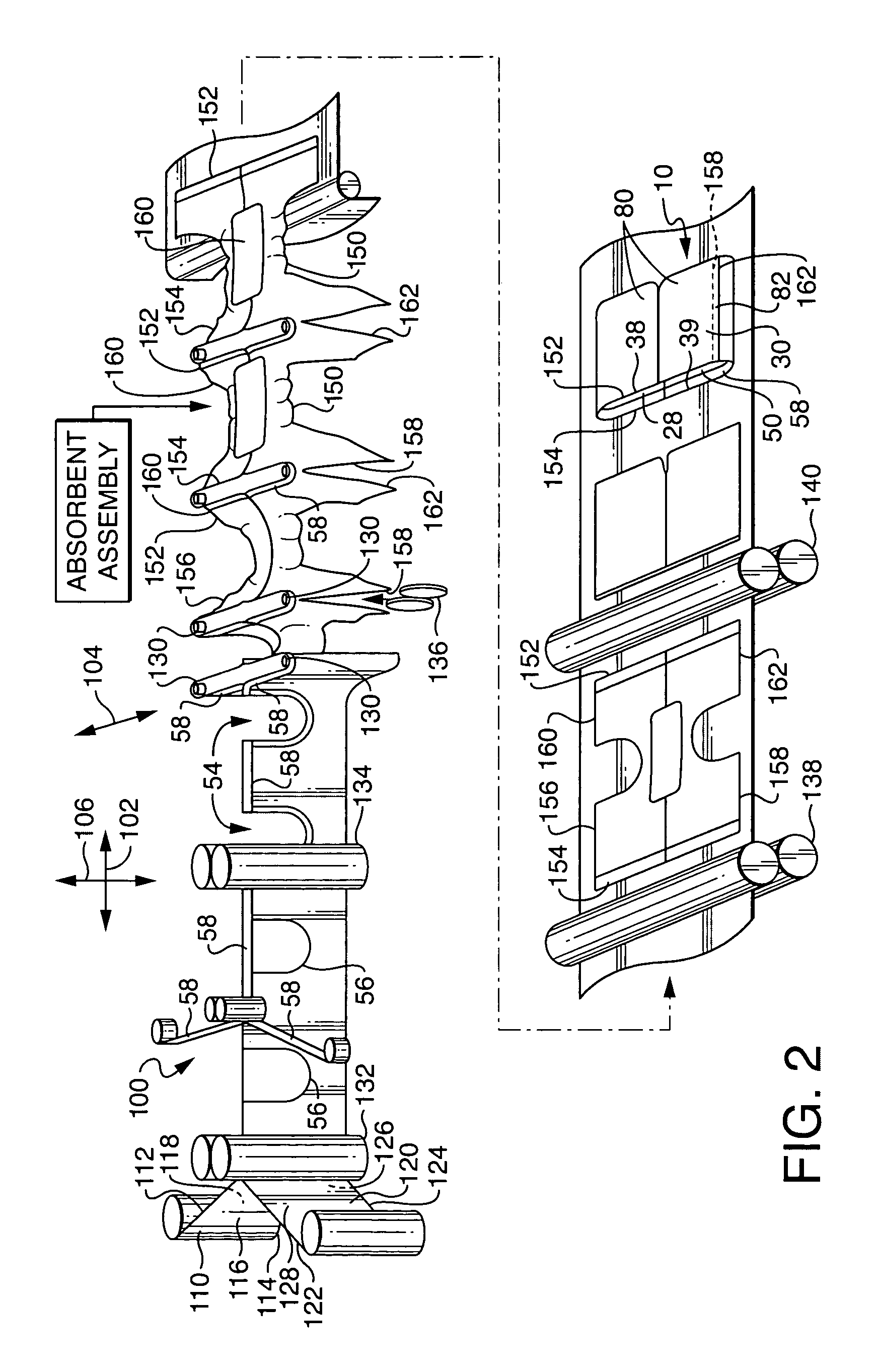

Process for making a garment having hanging legs

Owner:KIMBERLY-CLARK WORLDWIDE INC

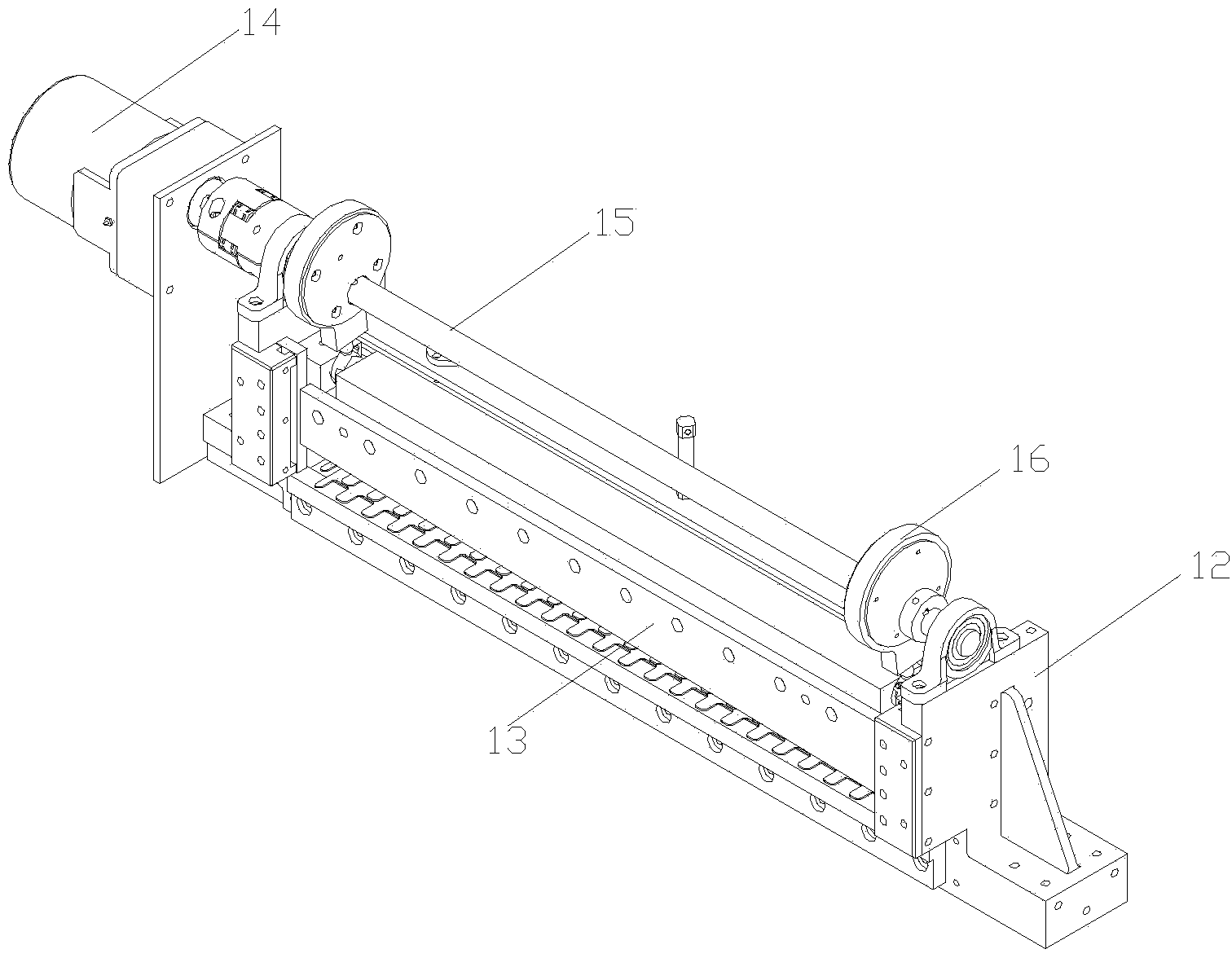

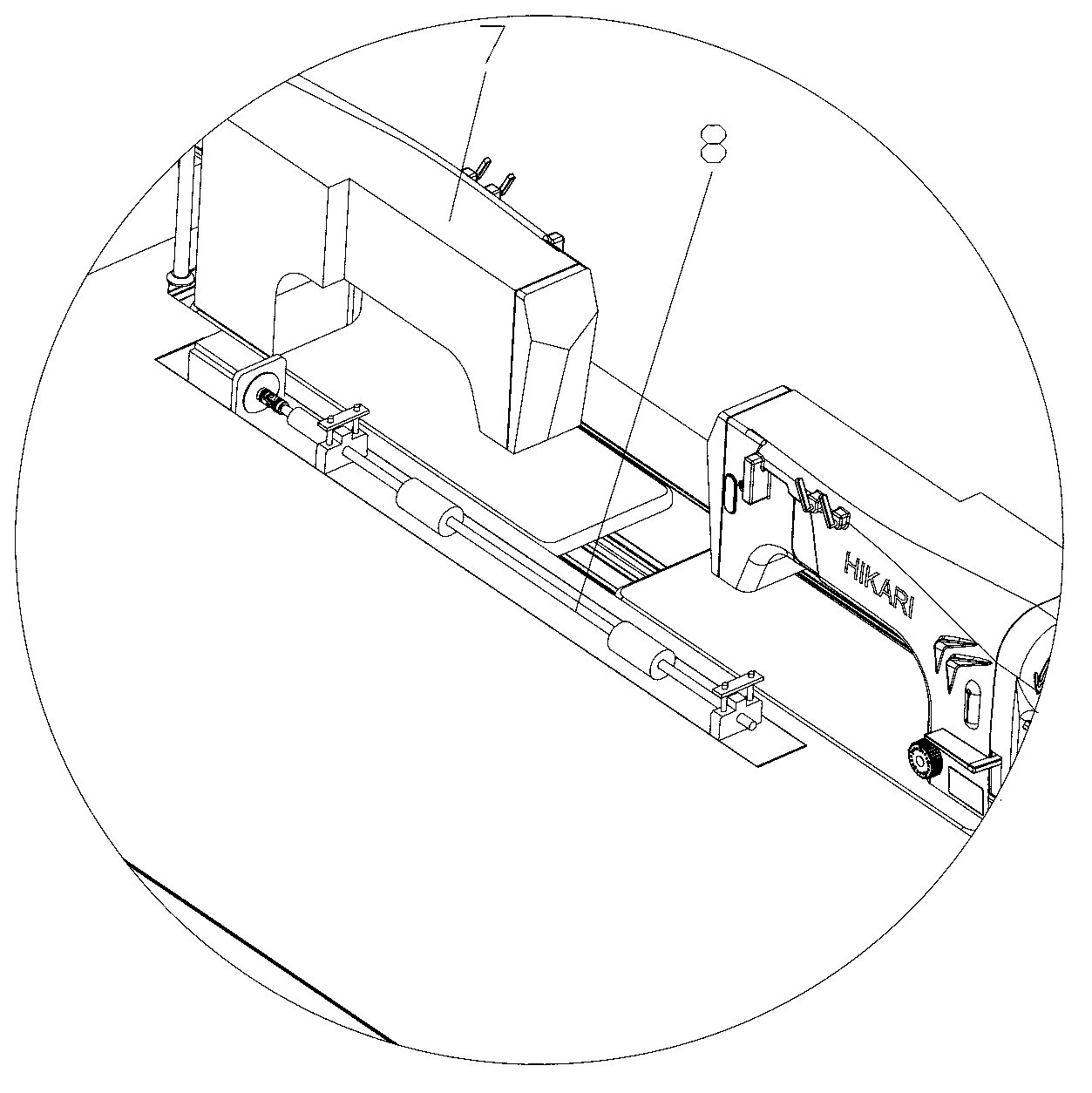

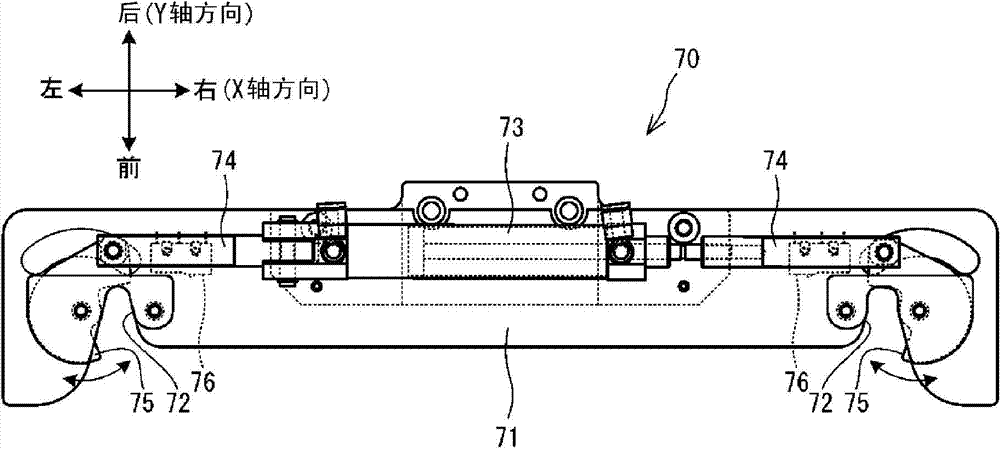

Sewing system and conveying device for connecting sewing equipment

PendingCN107881667AEasy to processReduce loading stepsCombination sewing machinesElectric machineryEngineering

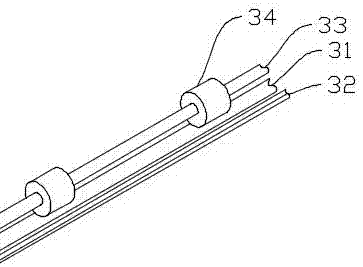

The invention discloses a sewing system and a conveying device for connecting sewing equipment. Cloth pieces can be automatically fed and continuously processed, and the efficiency is high. The conveying device for connecting the sewing equipment is provided with an input end which is used for being connected with first sewing equipment for completing a last process and an output end which is usedfor being connected with second sewing equipment for completing a next process, the conveying device comprises a mounting base, a plurality of synchronous wheels which are rotatably arranged on the mounting base, a synchronous belt which is arranged on the synchronous wheels and a motor which is arranged on the mounting base, the motor is in transmission connection with one or more synchronous wheels to drive the synchronous wheels to rotate, and the synchronous wheels are arranged at the input end and the output end respectively.

Owner:SUZHOU HANDLEY ELECTROMECHANICAL TECH CO LTD

Apparatus, seaming assembly and method for placing seams in a continuously moving web

Owner:KIMBERLY-CLARK WORLDWIDE INC

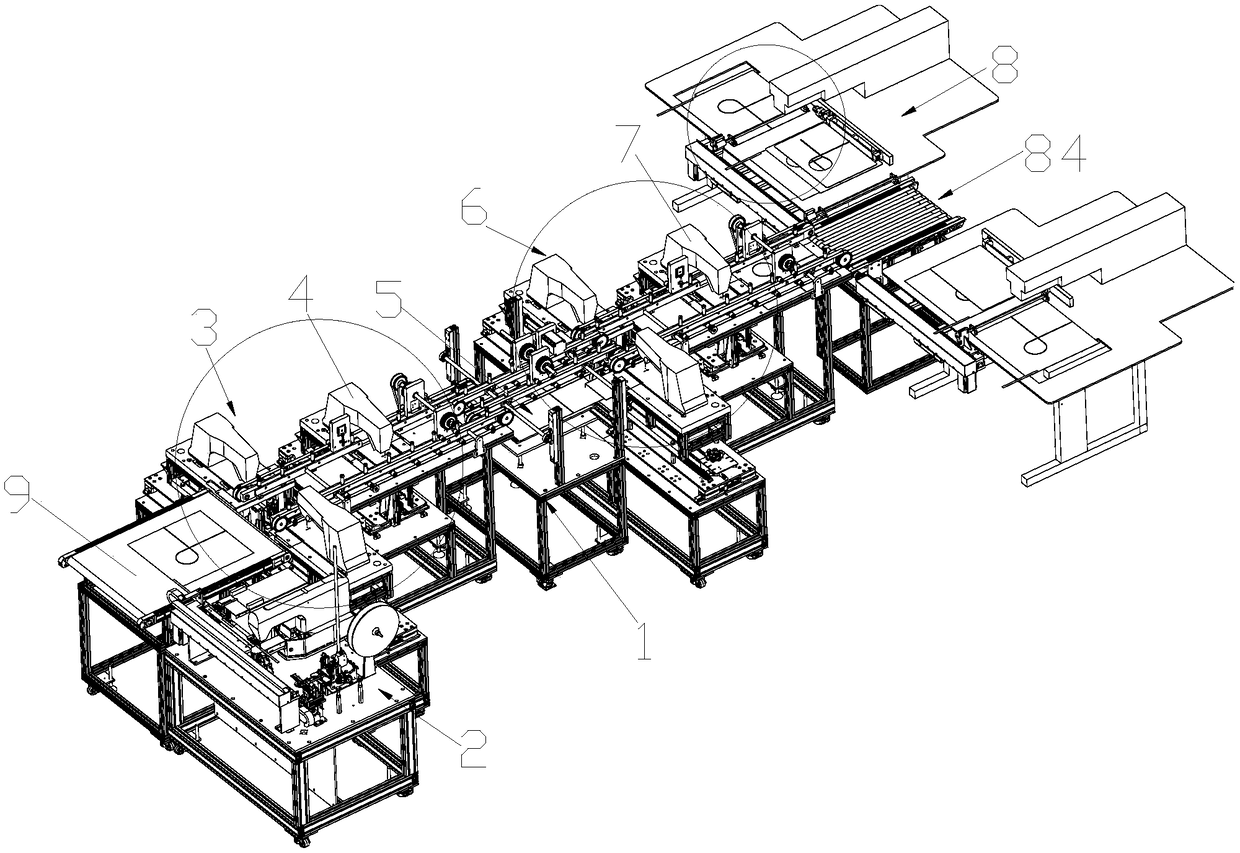

Automatic production line of medical gauze

ActiveCN106087270AIncrease productivityReduce human resource costsWork-feeding meansCombination sewing machinesProduction lineEngineering

The invention discloses an automatic production line of medical gauze, which sequentially comprises an unreeling mechanism, a cutting mechanism, a gauze folding mechanism, a sewing mechanism and a discharging mechanism, wherein all mechanisms are connected through conveying belts, and a transport passage for enabling gauze / gauze prefabricated parts to pass through is arranged. The automatic production line can automatically finish unreeling, cutting, folding, sewing and discharging steps of reeled gauze, a finished product of the medical gauze can be obtained without hand participation, the existing handmade mode is replaced, the production efficiency is increased, and the human resource cost is reduced. According to the invention, the structure is skillful, and the automatic production line is specially provided aiming at the requirements of the automatic production line of the medical gauze.

Owner:佛山市宾宏设备有限公司

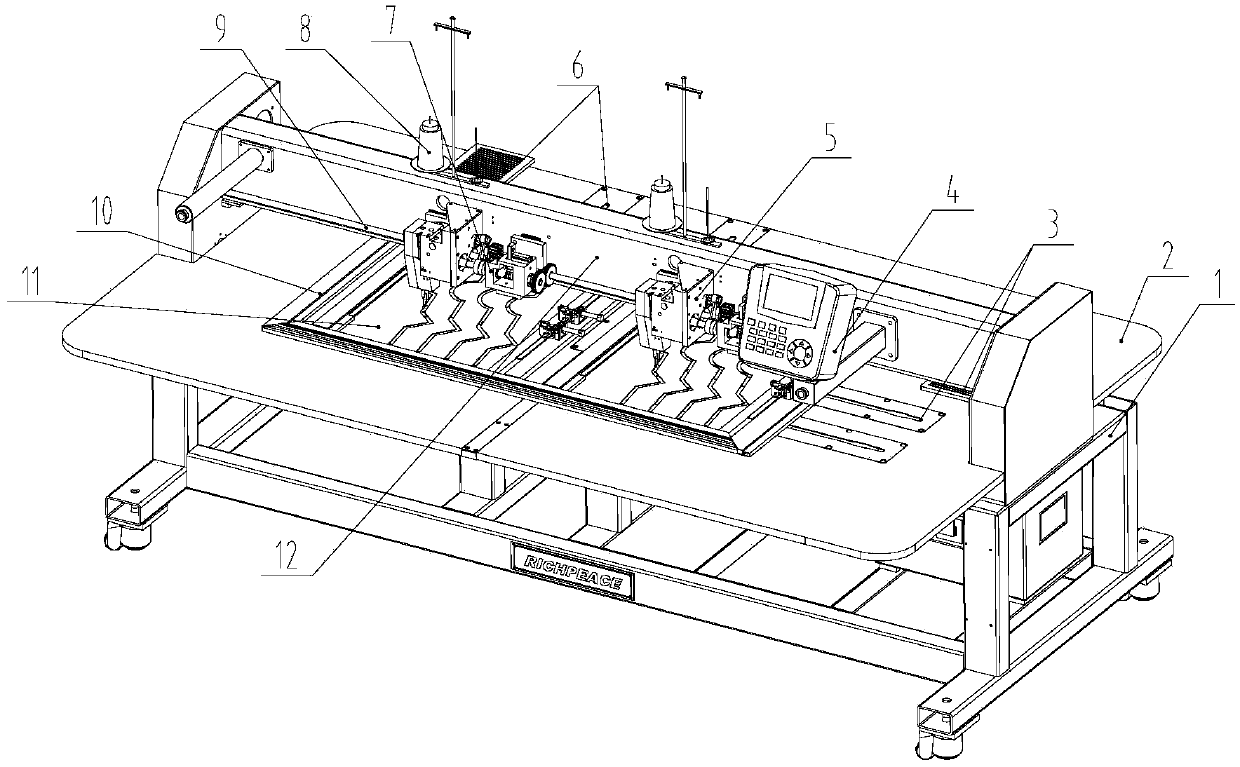

Full-automatic multi-head template sewing machine

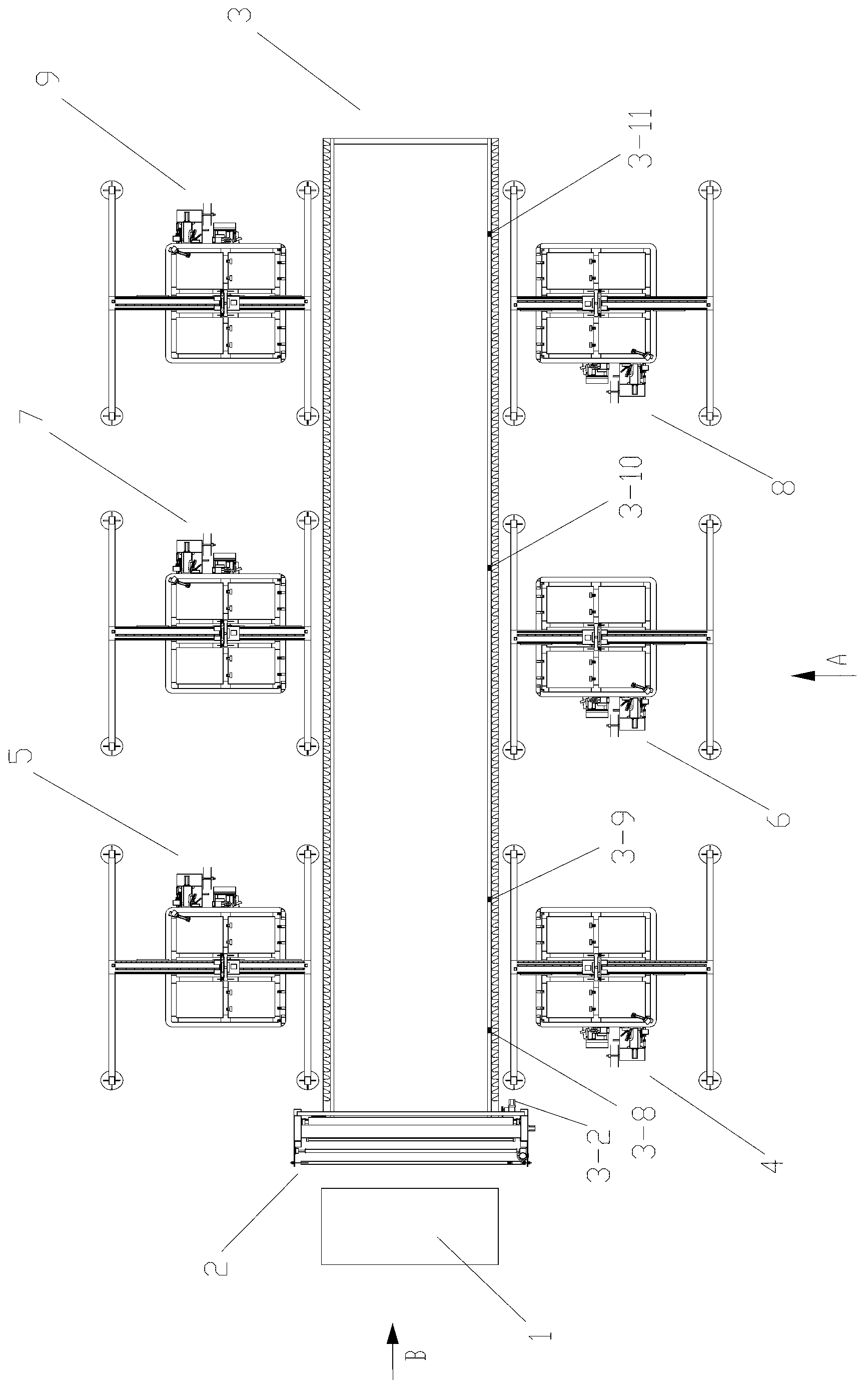

InactiveCN103628258AMeet a wide range of job requirementsMeet job requirementsProgramme-controlled sewing machinesCombination sewing machinesAutomatic controlControl system

The invention discloses a full-automatic multi-head template sewing machine which comprises a machine frame, a platen, X orientation tabouret driving parts, Y orientation tabouret driving parts, a tabouret, machine heads, a clutch, a thread stand and an automatic control system. A bridge type structural frame is arranged above the platen, the number of the machine heads is multiple, and the multiple machine heads are installed on the bridge type structural frame and driven by a main shaft transmission part to move on the bridge type structural frame. The multiple heads are used for sewing synchronously, so conformance to standards, such as needle pitches of all products and sewing orientations is guaranteed; meanwhile, production efficiency is improved, complex processes are simplified and standardized, the quality defective rate is reduced, working breadth is large, the distance between the X-axis and the Y-axis can be adjusted, the breadth of the tabouret is set according to requirements of clients, and wider working requirements of the clients are met.

Owner:上工富怡智能制造(天津)有限公司

Automatic production device for bed cloth

InactiveCN107151871AAchieve replacementReduce replacementWork-feeding meansCombination sewing machinesFuselageBiomedical engineering

The invention discloses an automatic production equipment for bedcloths, comprising a machine body, a cloth feeding device, a cloth hemming device, a cloth hemming device, and a cloth cutting device which are connected in sequence, wherein the cloth feeding device comprises a cloth upper frame As with the cloth pressing device, the cloth hemming device is arranged on both sides of the fuselage and is symmetrical to each other, and the cloth hemming device includes a flattening mechanism in the middle and a hemming mechanism arranged on both sides of the flattening mechanism; The cutting device includes a cloth cutting mechanism and a cloth cutting mechanism, the cloth cutting mechanism is used for cutting the length of the cloth, and the cloth cutting mechanism is used for cutting and modeling on the cloth. The automatic production equipment for bedcloth provided by the present invention changes the operation process of manual hemming and sewing in the past, realizes integration and automation, greatly improves the production efficiency and product precision, and the production efficiency achieved by the present invention is less labor-intensive At the same time, the qualified rate of products reaches 99%, which is far greater than the qualified rate of manual operation.

Owner:JIAXING REST FURNITURE & APPLIANCE CO LTD

Horizontal retracing woven bag mouth and bottom sewer

InactiveCN102140735AHigh degree of automationLow costCombination sewing machinesSack sewingEngineeringAutomation

The invention provides a horizontal retracing woven bag mouth and bottom sewer which simultaneously adopts two general woven bag bottom sewers. In order to reduce the length of equipment and bring convenience for feeding and collecting materials, the front ends of two parallel bottom sewers are provided with woven bag transferring platforms; after the mouth of the woven bag is sewn after the woven bag horizontally moves on a mouth sewer, the woven bag is horizontally sent to the transferring platforms from a discharging end and is then horizontally transferred to the feeding end of the bottom sewer from the transferring platforms; then, the woven bag horizontally enters the bottom sewer to sew the bottom mouth edge of the woven bag; and finally, the woven bag is discharged, bunched and packaged from the discharging end of the bottom sewers. Compared with the prior art, the horizontal retracing woven bag mouth and bottom sewer disclosed by the invention has the characteristics of high degree of automation, high production efficiency, no waste and the like, is reasonable to design and is convenient to operate. The parts of the sewer are made in China, so that the parts are easy to purchase, thereby greatly lowering the cost of construction of equipment and the like. Thus, the sewer has good popularization and use value.

Owner:陈华

Sewing machine and sewing machine control method

The present invention relates to a sewing machine and a sewing machine control method. The sewing machine has two standby positions between the sewing machine and a holder plate supply mechanism. An operator uses an operation disc of the sewing machine to move a holder plate holding part. The holder plate holding part is positioned according to a holder plate holding part supply position of the holder plate supply mechanism. The sewing machine sets the position of the positioned holder plate holding plate as the first standby position, and sets a position closer to the sewing machine side than the first standby position as the second standby position. The holder plate holding part receives a holder plate at the first standby position and moves to the second standby position. After the holder plate holding part has moved to the second standby position, the sewing machine carries out sewing only when the holder plate is detected by a holder plate sensor.

Owner:BROTHER KOGYO KK

Single-needle quilting machine

InactiveCN104294482AReduce the process of changing the frame back and forthLower demand costCombination sewing machinesPressersEngineeringPulley

The invention discloses a single-needle quilting machine. The single-needle quilting machine comprises a feeding workbench, a conveying belt, a material conveying mechanism, a quilting mechanism and a material automatically outputting mechanism. The material conveying mechanism comprises an automatic feeding mechanism, a pressing and tension mechanism and an unloading mechanism which are sequentially arranged; the automatic feeding mechanism comprises a feeding support, a feeding air cylinder, a feeding large pulley and a feeding arm, wherein the feeding support is connected with the feeding air cylinder through an air cylinder fixing seat b and an air cylinder fixing seat a, the air cylinder fixing seat b and the air cylinder fixing seat a are hinged, the feeding large pulley is arranged on a feeding large pulley fixing plate, both ends of the feeding arm are connected with a feeding connecting seat and the feeding large pulley, and the middle of the feeding arm is connected with the extending end of the feeding air cylinder; the pressing and tension mechanism and the unloading mechanism are connected with the feeding connecting seat through the conveying belt; the material automatically outputting mechanism is arranged under the unloading mechanism. The single-needle quilting machine achieves feeding, quilting and discharging in one step, thereby being simple and rapid in working process and capable of improving the working efficiency.

Owner:海门市昊泽机械科技有限公司

Multifunctional edge seamer

ActiveCN104250889AImprove work efficiencyRealize synchronous sewingWork-feeding meansCombination sewing machinesSewing machineTextile

Owner:中山港渊科技股份有限公司

Double-head herringbone thread sewing machine and method for making same

InactiveCN101255637AReduce labor costsIncrease productivityWork-feeding meansCombination sewing machinesElectric machineryEngineering

A double-head herringbone line sewing machine is disclosed, comprising a frame, a panel, a foot pedal and a connecting rod, an electric engine equipped on an output shaft below the panel and provided with a driving belt pulley, and a foot pedal switch connected with the connecting rod of the foot pedal and used for starting the electric engine. Two herringbone line sewing machine heads are mounted on the panel in parallel, wherein the rotating shaft of a first herringbone line sewing machine is sequentially provided with a driven synchronous belt pulley and a first synchronous belt pulley, the rotating shaft of a second herringbone line sewing machine is provided with a second synchronous belt pulley matching with the first synchronous belt pulley; the first synchronous belt pulley and the second synchronous belt pulley are interconnected through a synchronous belt; the driven belt pulley and the driving belt pulley are interconnected through a belt; the panel between the first and the second herringbone line sewing machine heads is provided with a turnover mechanism and a blowing device. The invention also discloses a manufacturing method of the double-head herringbone line sewing machine. It can not only efficiently solve the problem about high cost, but also greatly improve the production efficiency by using the device.

Owner:东莞合迅服装设计有限公司

Quilting mechanism provided with double machine heads

InactiveCN104404720ASimple and flexible operationIncrease productivityCombination sewing machinesSewing-machine control devicesEngineeringSewing machine

The invention discloses a quilting mechanism provided with double machine heads. The quilting mechanism comprises two groups of sewing machine heads and synchronous belts driving an upper sewing machine head and a lower sewing machine head of each group of sewing machine heads to move respectively, wherein an upper side press plate provided with synchronous belt and a lower side press plate provided with a synchronous belt are fixed on a side mounting plate of the upper sewing machine head and the lower sewing machine head of one group of sewing machine heads, the lower side press plate is driven by a first cylinder to go up and down, the first cylinder is fixed on the side mounting plate, synchronous teeth meshed with the synchronous belt are formed in the lower side press plate, the lower sewing machine head of the group of sewing machine heads is in vertical slide connection with the side mounting plate, and a second cylinder used for driving the lower sewing machine head to slide is mounted between the lower sewing machine head and the side mounting plate. A clamping mechanism is adopted in one group of quilting machine heads for clamping the synchronous belts, and the lower sewing machine head of the quilting mechanism can go up and down, so that the working state of a single machine head or double machine heads can be selected as required, the operation is simple and flexible, and the production efficiency can be greatly improved.

Owner:FOSHAN YUANTIAN MATTRESS MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com