Improved towel machine

A technology of towel machine and machine table, which is applied in the direction of sewing unit, cloth pressing mechanism, cloth feeding mechanism, etc., and can solve problems such as delay in feeding, affecting production quality, and single function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

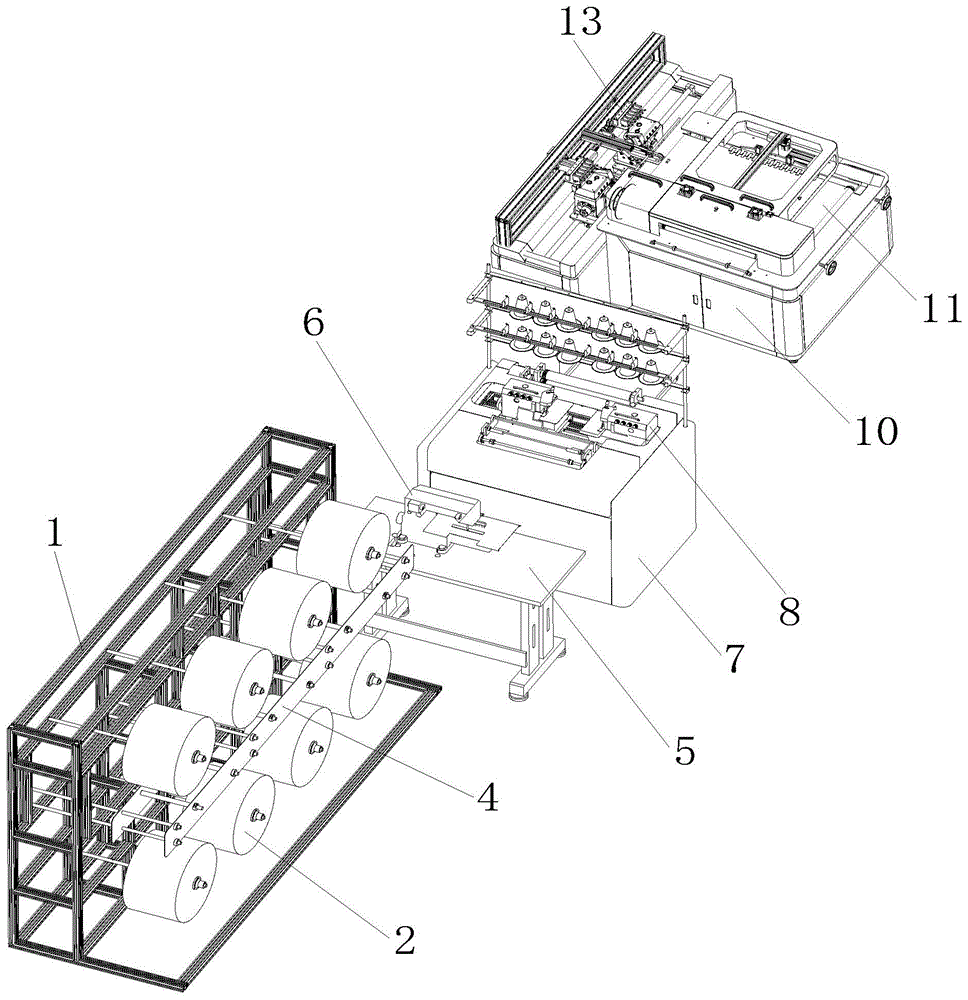

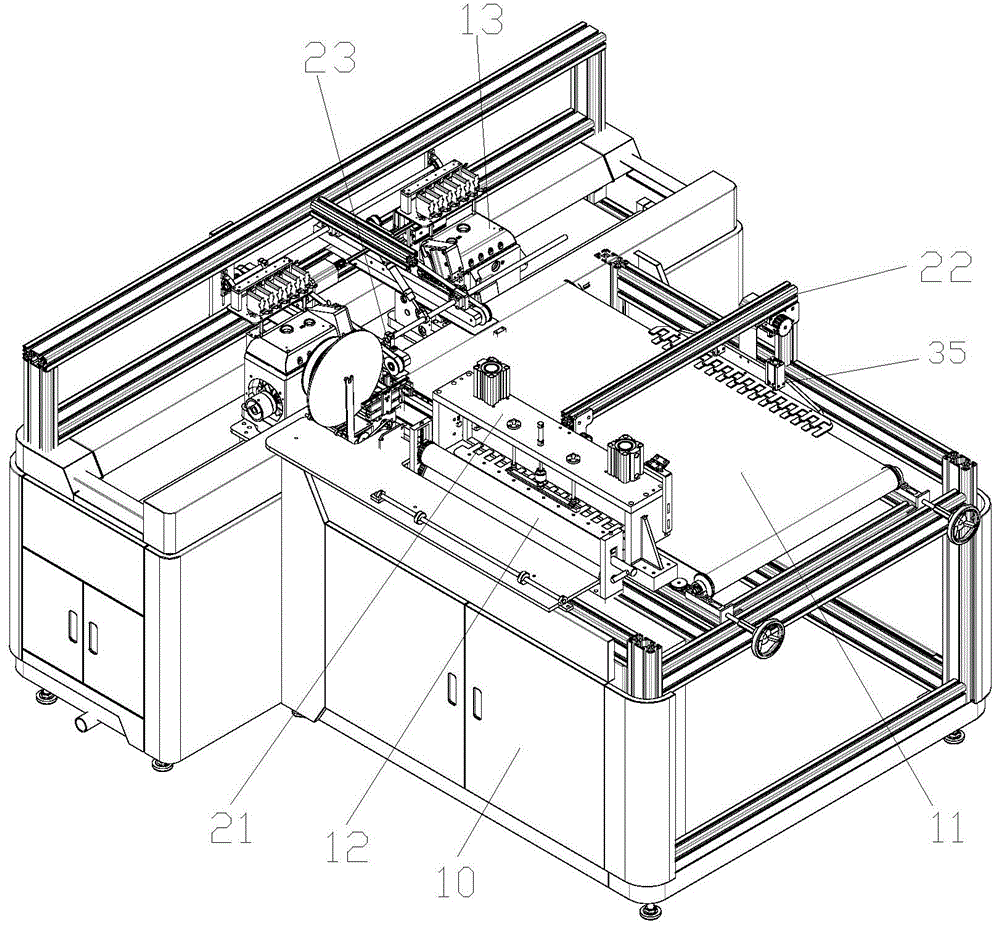

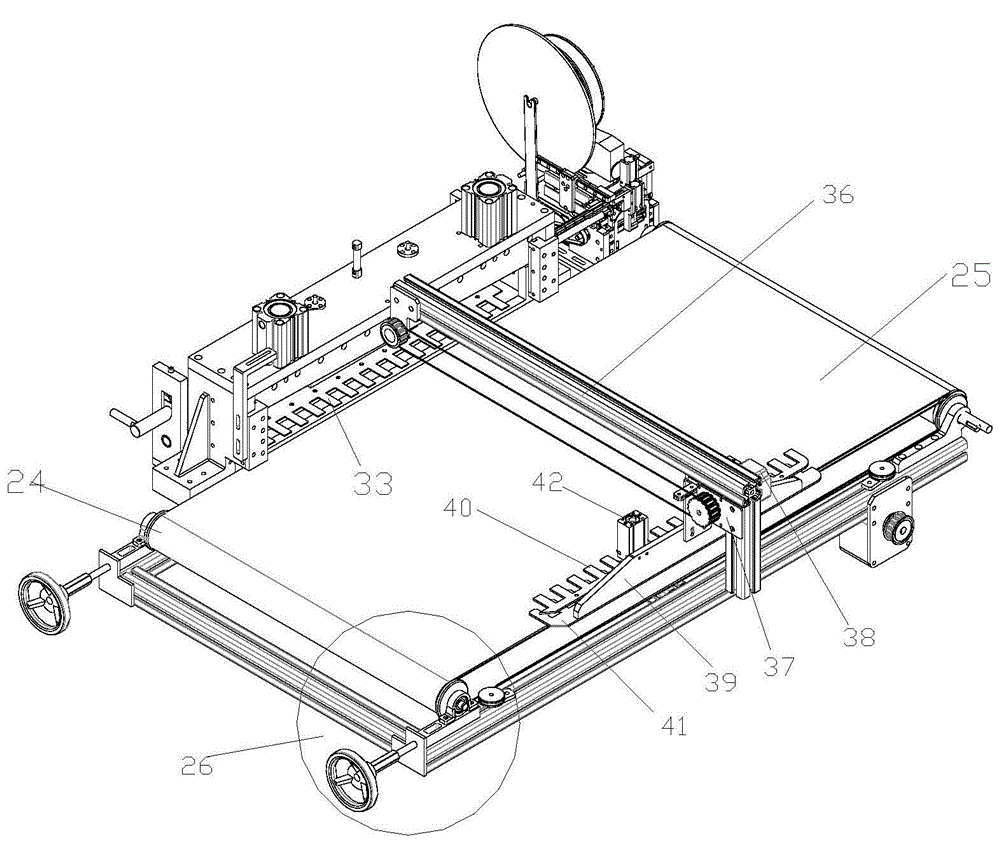

[0025] as attached Figure 1-7An improved towel machine according to the present invention is shown, the feeding device, the first processing device and the second processing device; the feeding device, the first processing device and the second processing device are relatively fixed in sequence; the feeding device sends the cloth into Into the first processing device; the first processing device performs a double-sided overlay on the cloth sent out by the feeding device; the second processing device cuts the cloth sent out from the first processing device and then performs a second double-side overside. The same as the working principle of general equipment, the overall structure of the equipment adopts this segmented processing method to complete the overall processing of towels. Among them, the feeding device includes a feeding fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com