Single-needle quilting machine

A quilting machine and single-needle technology, which is applied to sewing units, sewing machine components, sewing machines for bedding, etc., can solve the problems of cumbersome operation process, low production efficiency, time-consuming, etc., achieve simple and fast work process, and improve work efficiency , the effect of reducing demand costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

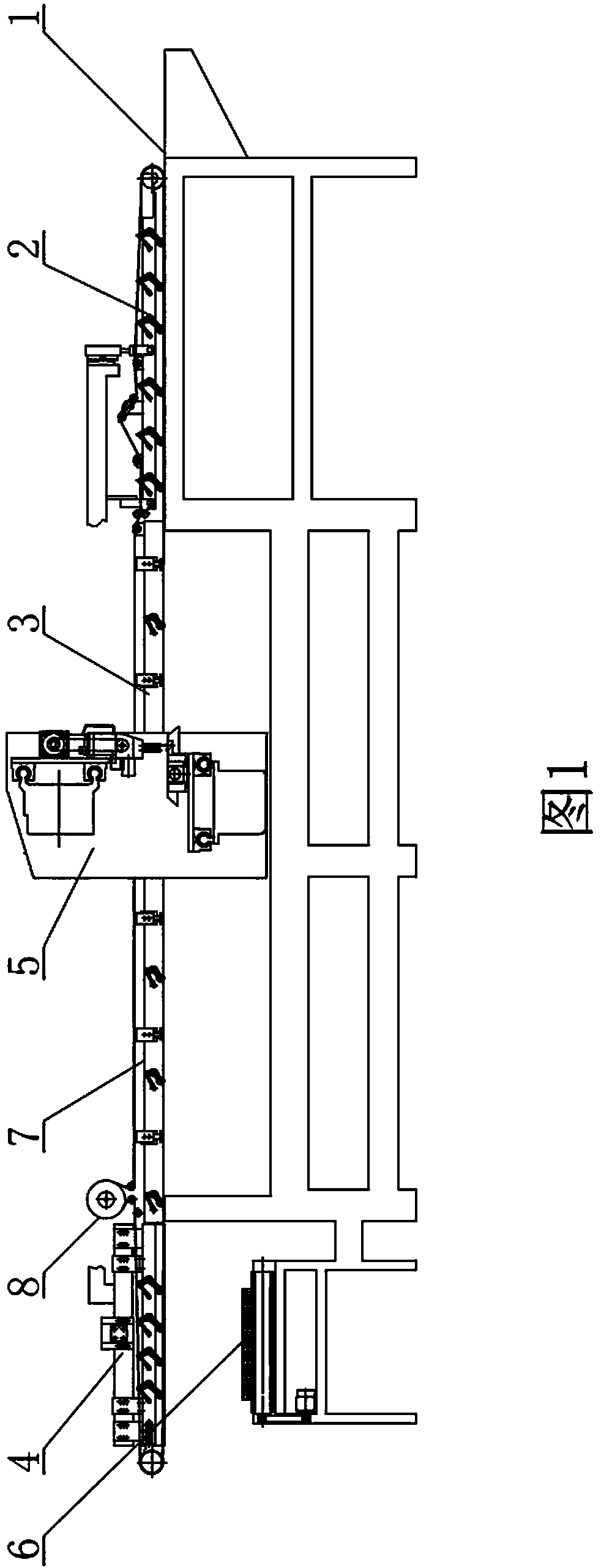

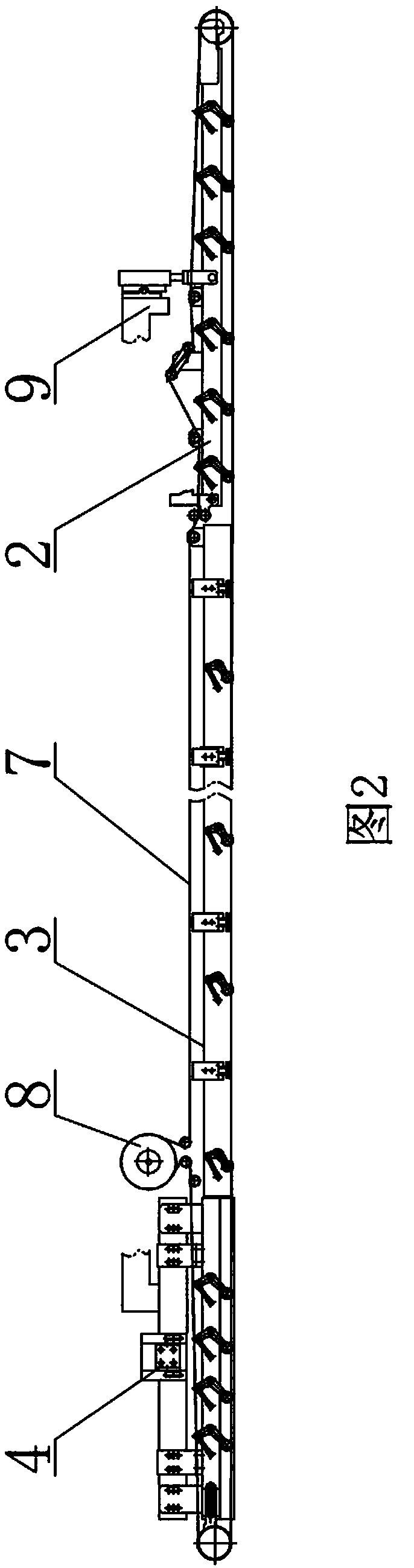

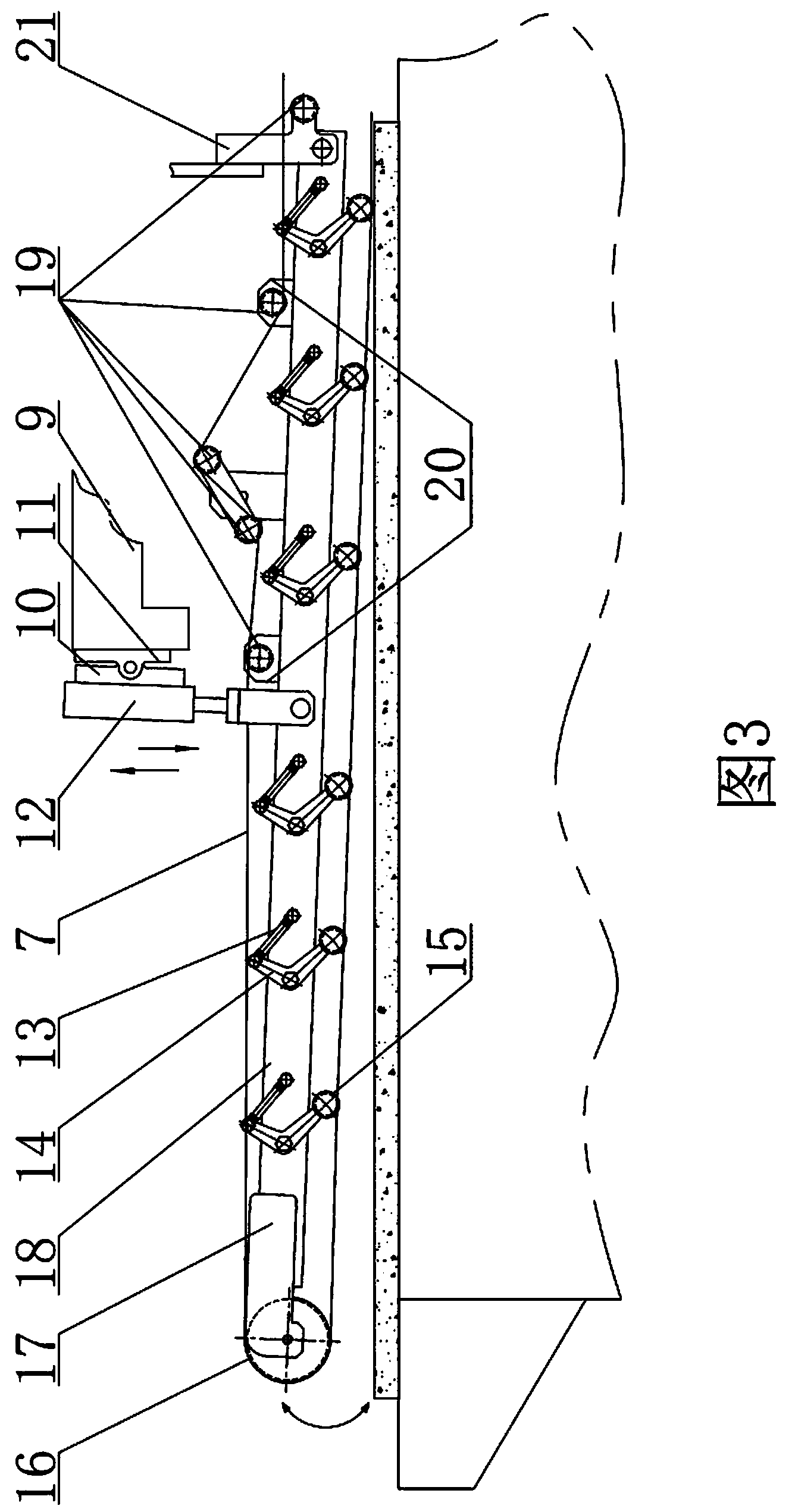

[0025] Such as figure 1 , figure 2 with image 3 As shown, a single-needle quilting machine includes a feed table 1 integrated with the fuselage, a frame 35, a conveying belt 7, a material conveying mechanism, a quilting mechanism 5 and a material arranged at one end of the frame 35 The automatic output mechanism 6, the material conveying mechanism includes the automatic feeding mechanism 2, the compression tension mechanism 3 and the unloading mechanism 4 arranged in sequence, the automatic feeding mechanism 2 includes the feeding bracket 9, the feeding cylinder 12, and the large feeding pulley 16 and the feed arm 18, the feed bracket 9 is connected with the feed cylinder 12 through the cylinder holder b11 and the cylinder holder a10, the cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com