A real-time dynamic prediction method for converter steelmaking quality based on data analysis

A converter steelmaking, real-time dynamic technology, applied in the direction of electrical digital data processing, special data processing applications, manufacturing converters, etc., can solve problems such as cost increase, reduce demand costs, improve detection accuracy, improve economic benefits and society benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

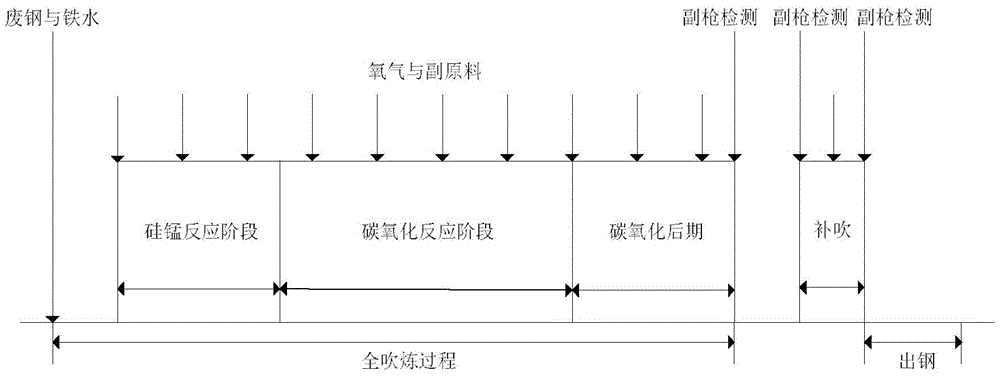

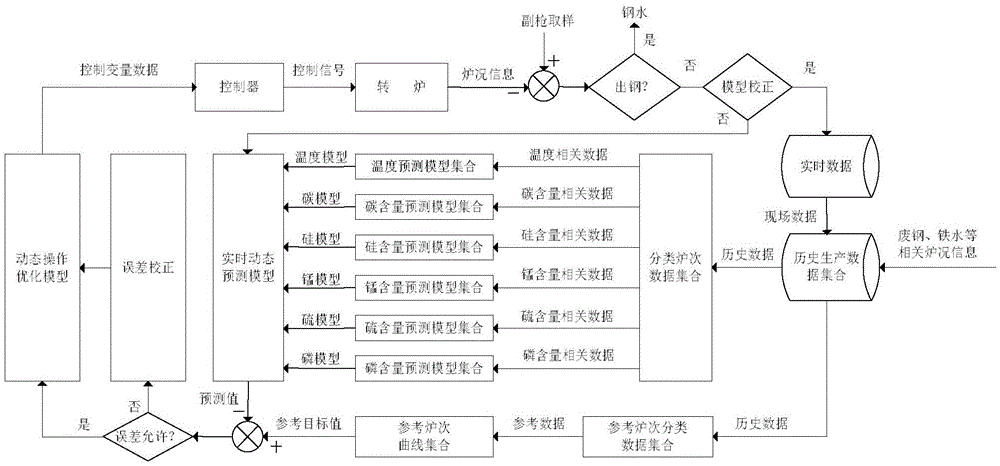

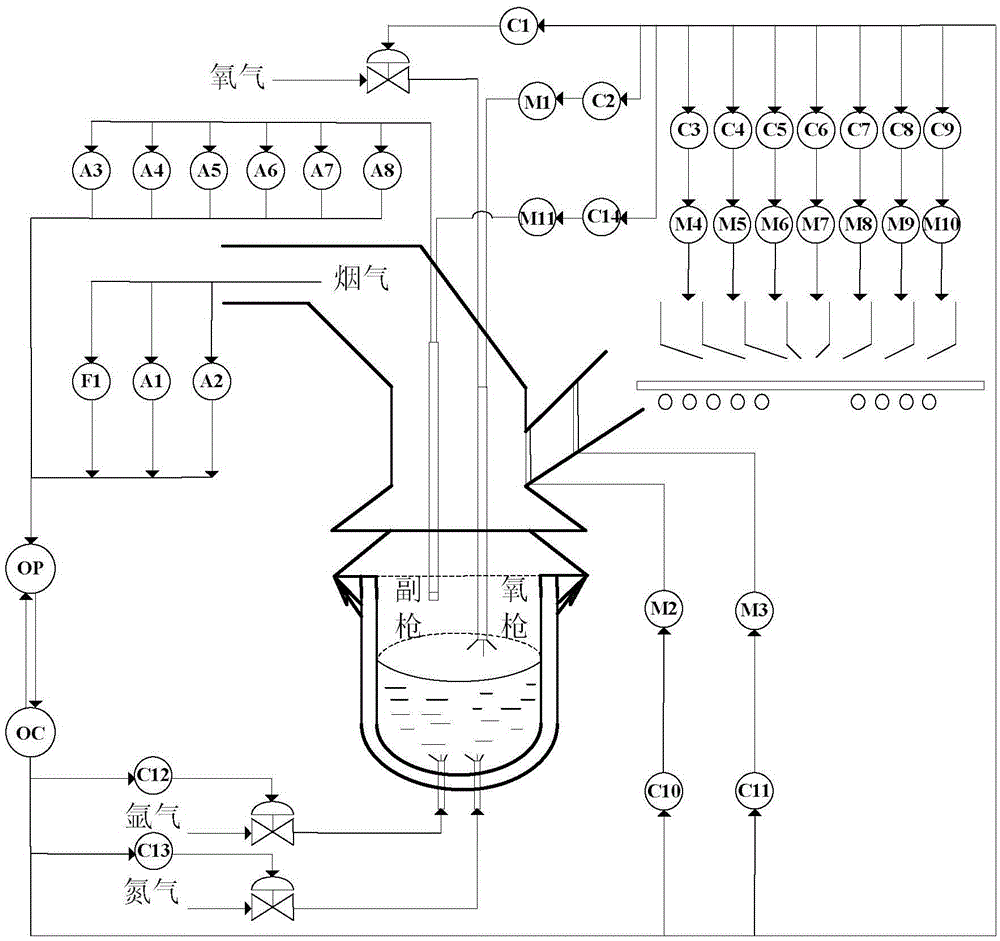

[0050] The purpose of the present invention is to accurately and dynamically predict the molten steel temperature and molten steel quality in the converter steelmaking production process, such as figure 2 As shown, the principle of real-time dynamic prediction of converter steelmaking quality based on data analysis is as follows: firstly, a prediction model database is established by collecting a large amount of historical data information, and relevant furnace condition information such as scrap steel and molten iron is used as historical data collection, and then different steel types are used to aggregate According to the method classification, find the reference heat sets belonging to different steel types as the reference standard for dynamic operation optimization, select relevant data sets that meet the conditions of molten steel temperature and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com