A kind of composite antistatic plastic concentrated masterbatch and preparation method thereof

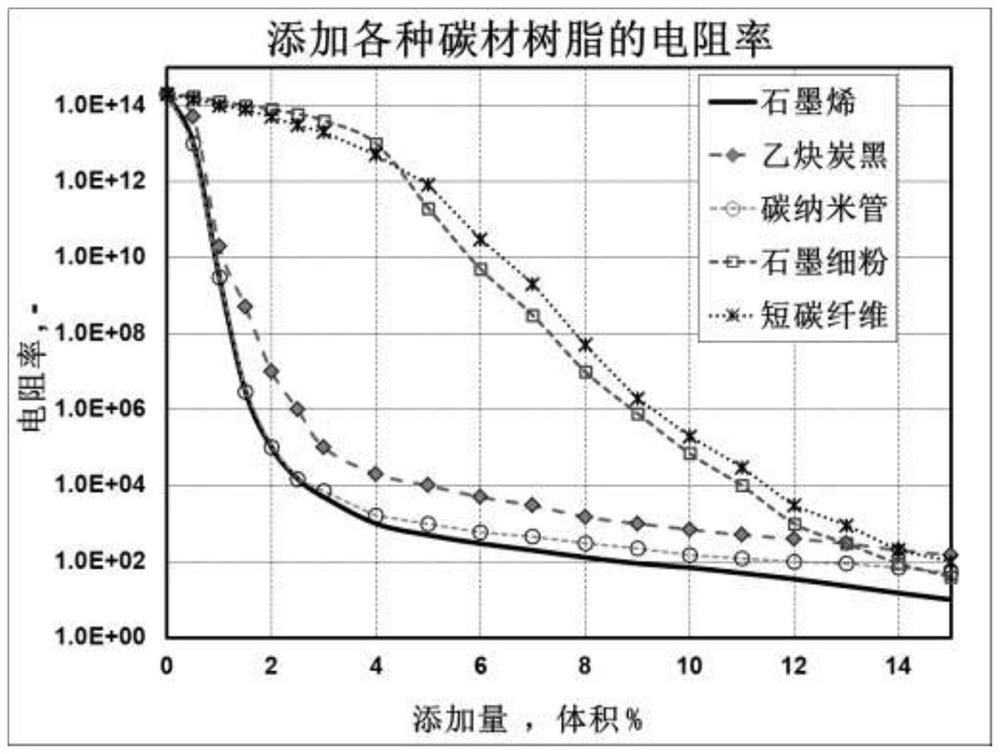

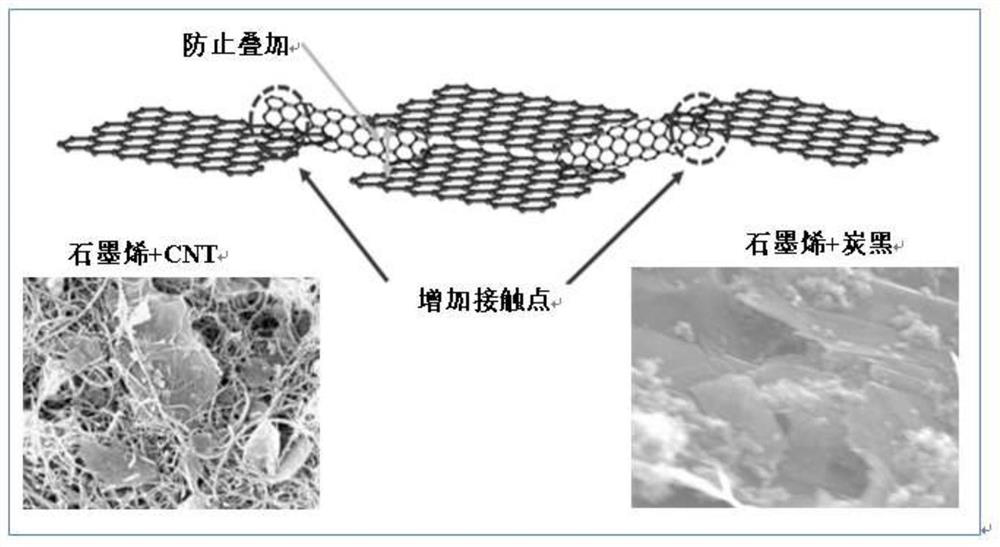

An antistatic plastic and composite slurry technology, applied in the field of composite materials, can solve the problems of difficult and uniform dispersion of carbon black, low cost performance, low mechanical strength, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

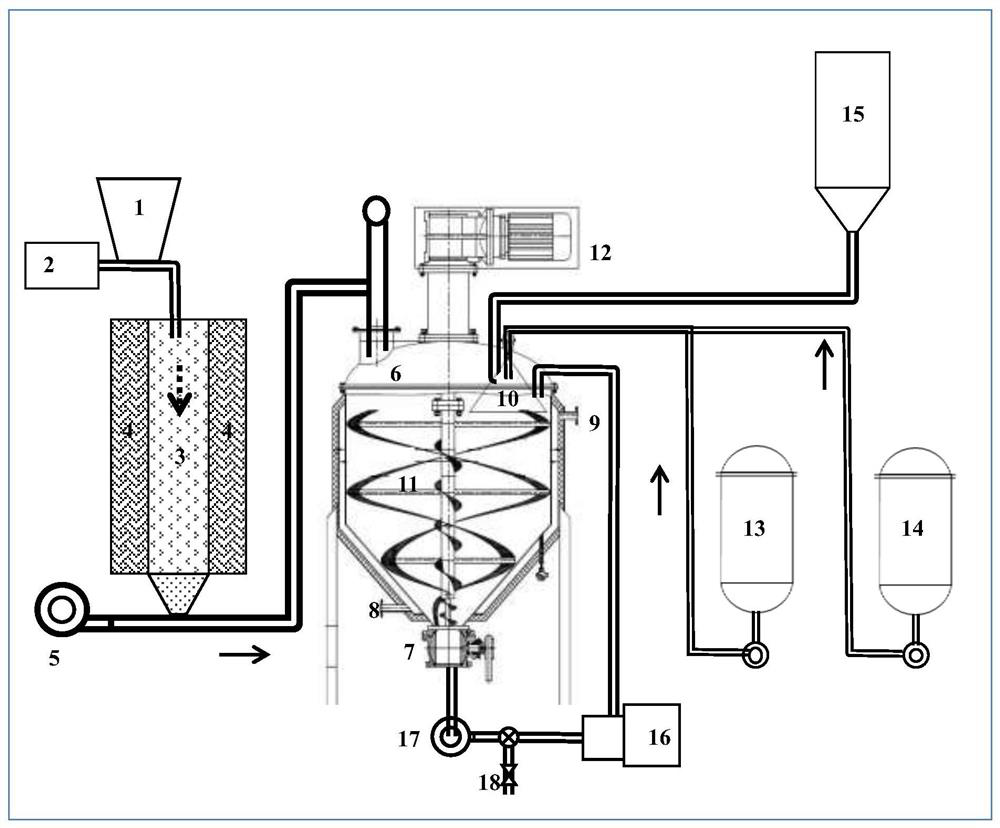

Method used

Image

Examples

Embodiment 1

[0047] (1) Put the 50-mesh expandable graphite in the hopper and send it into the electric heating high-temperature expansion furnace through the screw feed, and heat and expand at a high temperature of 1000°C to obtain graphite worms with high specific surface area and high carbon content, and the expansion ratio of worms About 610 times, specific surface area 71m 2 / g, the graphite worms are directly blown into the vertical ribbon heating stirring tank through the fan until the tank is full, and 30% hydrogen peroxide is sprayed while stirring. The weight ratio of worms to hydrogen peroxide is 1:0.2. Control, keep stirring for 30 minutes, raise the temperature to 105°C within one hour and maintain it for 50 minutes, keep stirring and cool down to below 50°C;

[0048] (2) Continue to stir the worms, spray into 15wt% aminopropyltrimethoxysilane hydrolysis ethanol solution, the weight ratio of worms to coupling agent solution is 1:0.3, the flow rate of coupling agent solution ca...

Embodiment 2

[0054] (1) Put 50 meshes of 630 times expandable graphite in the hopper and feed it through the screw into the electric heating high temperature expansion furnace, and heat and expand at 950°C to obtain a specific surface area of 70m 2 Graphite worms / g are blown into a vertical ribbon heating stirring tank, and 50% hydrogen peroxide is sprayed while stirring. The weight ratio of worms to hydrogen peroxide is 1:0.15. Minutes, within one hour, the temperature was raised to 105°C and maintained for 60 minutes, and the temperature was lowered to below 50°C with continuous stirring;

[0055] (2) Continue to stir the worms, spray into 20% aminopropyltriethoxysilane hydrolysis ethanol solution, the weight ratio of worms to coupling agent solution is 1:0.35, the flow rate of coupling agent solution can be controlled by flow pump, stir After reacting for 60 minutes, raise the temperature to 70°C within one hour, and continue stirring for 60 minutes to complete the surface modificatio...

Embodiment 3

[0061] (1) Put 50-mesh 800-times expandable graphite in the hopper and feed it into the electric heating high-temperature expansion furnace through the screw feed, and heat and expand at 1100°C to obtain a specific surface area of 81m 2 Graphite worms / g are blown into a vertical ribbon heating stirring tank, and 30% hydrogen peroxide is sprayed while stirring. The weight ratio of worms to hydrogen peroxide is 1:0.2. The flow rate of hydrogen peroxide can be controlled by a flow pump, and the continuous stirring is 60 Minutes, within one hour, the temperature was raised to 105°C and maintained for 50 minutes, and the temperature was lowered to below 50°C with continuous stirring;

[0062] (2) Continue to stir the worms, spray into 25% N-B (aminoethyl)-C-aminopropyltriethoxysilane ethanol solution, the weight ratio of worms to the coupling agent solution is 1:0.4, the coupling agent solution The flow rate can be controlled by a flow pump. After stirring for 60 minutes, the tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com