A device and method for preparing graphene nano water-based slurry for concrete

A water-based slurry and graphene technology, applied in the field of building materials, can solve the problems of limited intrinsic properties of graphene, incompatible production processes, and high cost of graphene oxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

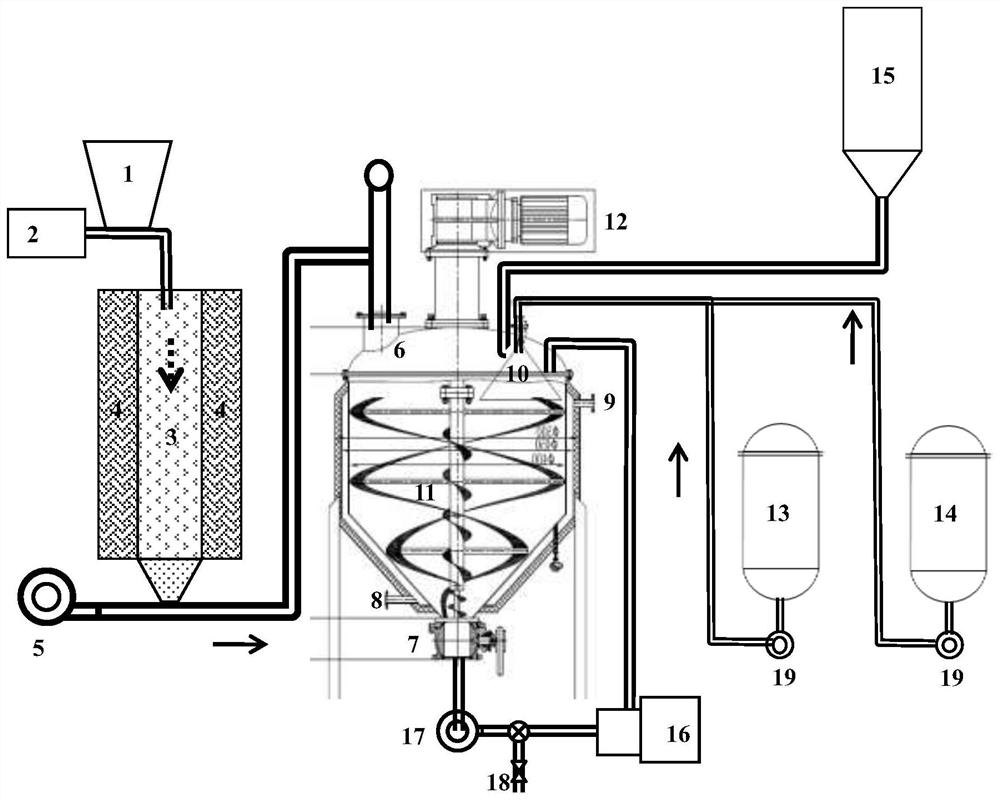

Method used

Image

Examples

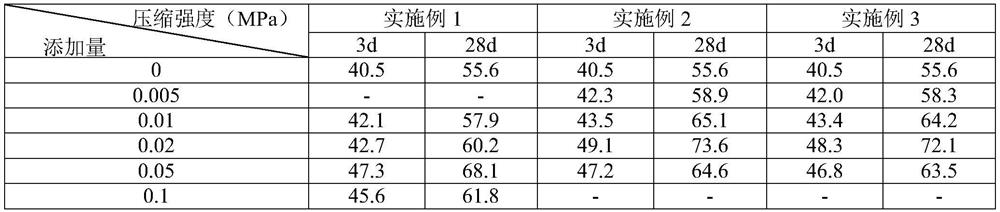

Embodiment 1

[0039] (1) Put 50-mesh high-expansion expandable graphite in the hopper, push the material into the high-temperature electric heating expansion furnace through the screw feeder, and heat it to 600°C with the silicon carbide heating rod to expand, and the expansion multiple is 250 times , specific surface area 62m 2 / g of graphite worms, and blown into the reactor by air pump;

[0040] (2) Open the stirring mechanism of the reaction kettle to make the vertical spiral belt rotate in the direction of the pointer, put the hydrogen peroxide with a volume concentration of 30% into the oxidized water storage tank, control the feed flow rate through the flow meter, and spray it through the feeder Mix with graphite worm spray in the reaction kettle, the weight ratio of graphite worm and hydrogen peroxide is 1:0.2, oxidize the surface of graphite worm, first react for 10 minutes, heat up to 100°C, continue stirring for 60 minutes to complete oxidation, continue stirring to cool down to ...

Embodiment 2

[0045] (1) Put the 50-mesh high expansion multiple expandable graphite in the hopper, push the material into the high-temperature electric heating expansion furnace through the screw feeder, and heat it to 1800°C with the silicon carbide heating rod for expansion, and the expansion multiple is 650 times , specific surface area 81m 2 / g of graphite worms, and blown into the reactor by air pump;

[0046] (2) Open the stirring mechanism of the reactor to rotate the vertical spiral belt in the direction of the pointer, put the hydrogen peroxide with a volume concentration of 50% into the oxidized water storage tank, and spray the graphite worms in the reactor with the spray feeder Mixing, the weight ratio of graphite worms to hydrogen peroxide is 1:0.01, oxidize the surface of graphite worms, first react for 120 minutes, heat up to 80°C, continue stirring for 10 minutes to complete oxidation, and obtain hydrophilic graphite worms;

[0047] (3) the aminopropyltrimethoxysilane aque...

Embodiment 3

[0051] (1) Put 50-mesh expandable graphite with high expansion multiple in the hopper, push the material into the high-temperature electric heating expansion furnace through the screw feeder, and heat it to 950°C with the silicon carbide heating rod for expansion, and the expansion multiple is 400 times , The specific surface area is greater than 78m 2 / g of graphite worms, and blown into the reactor by air pump;

[0052] (2) Open the stirring mechanism of the reactor to rotate the vertical spiral belt in the direction of the pointer, put the hydrogen peroxide with a volume concentration of 50% into the oxidized water storage tank, and spray the graphite worms in the reactor with the spray feeder Mixing, the weight ratio of graphite worms to hydrogen peroxide is 1:0.3, oxidize the surface of graphite worms, first react for 55 minutes, heat up to 90°C, continue to stir for 50 minutes and complete the oxidation to obtain hydrophilic graphite worms;

[0053] (3) The aqueous solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com