Patents

Literature

382results about "Tensioning devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

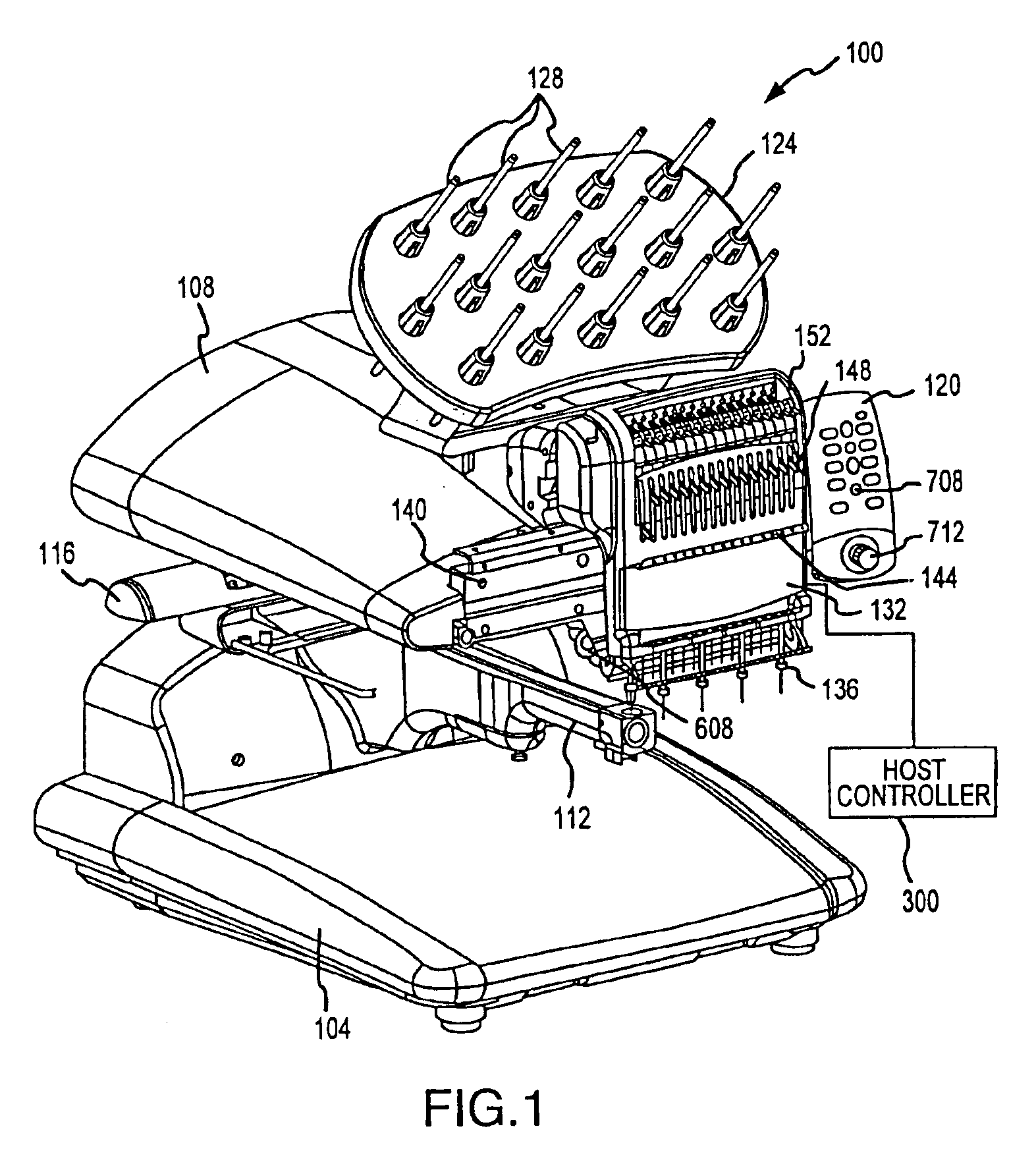

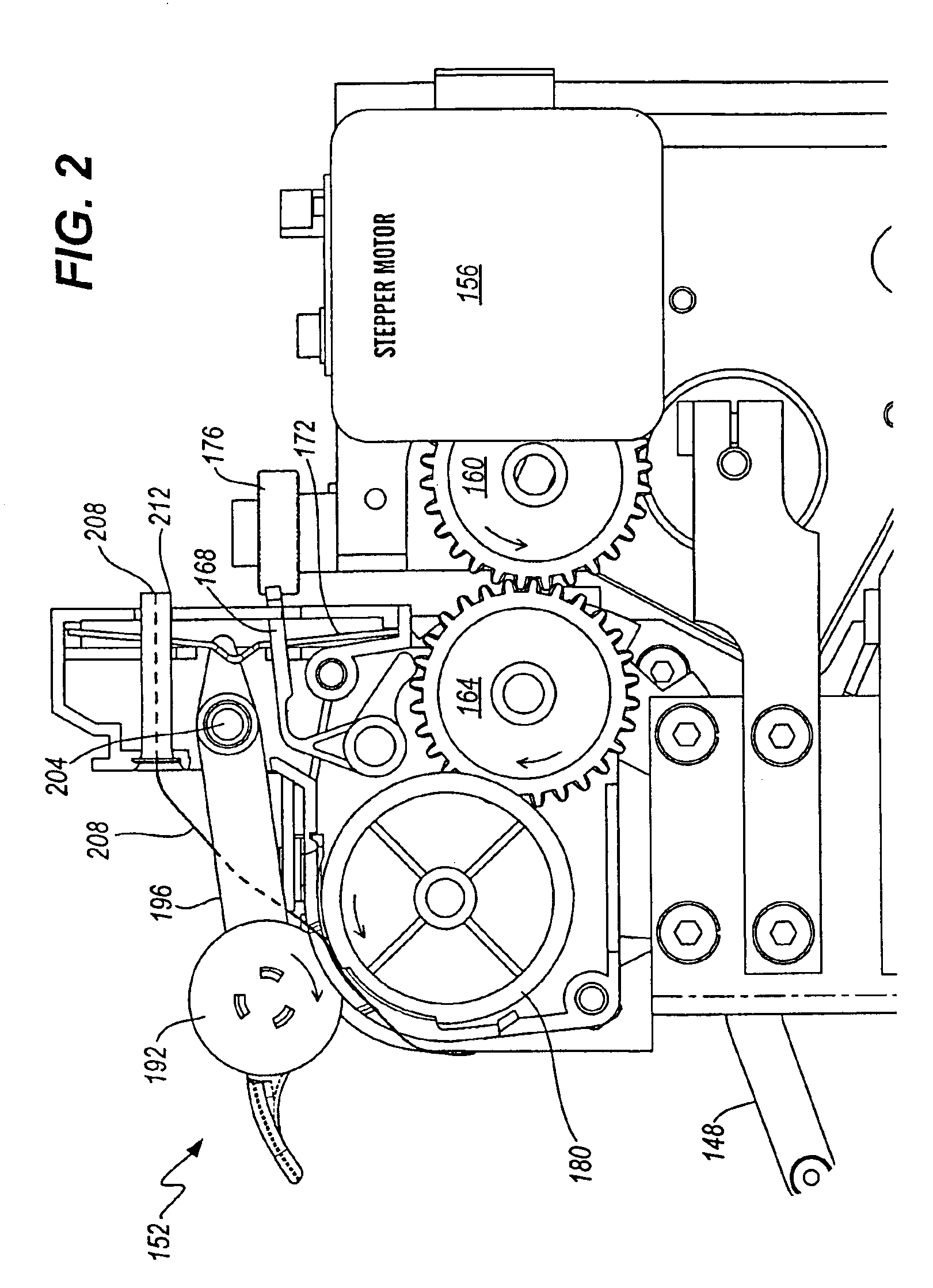

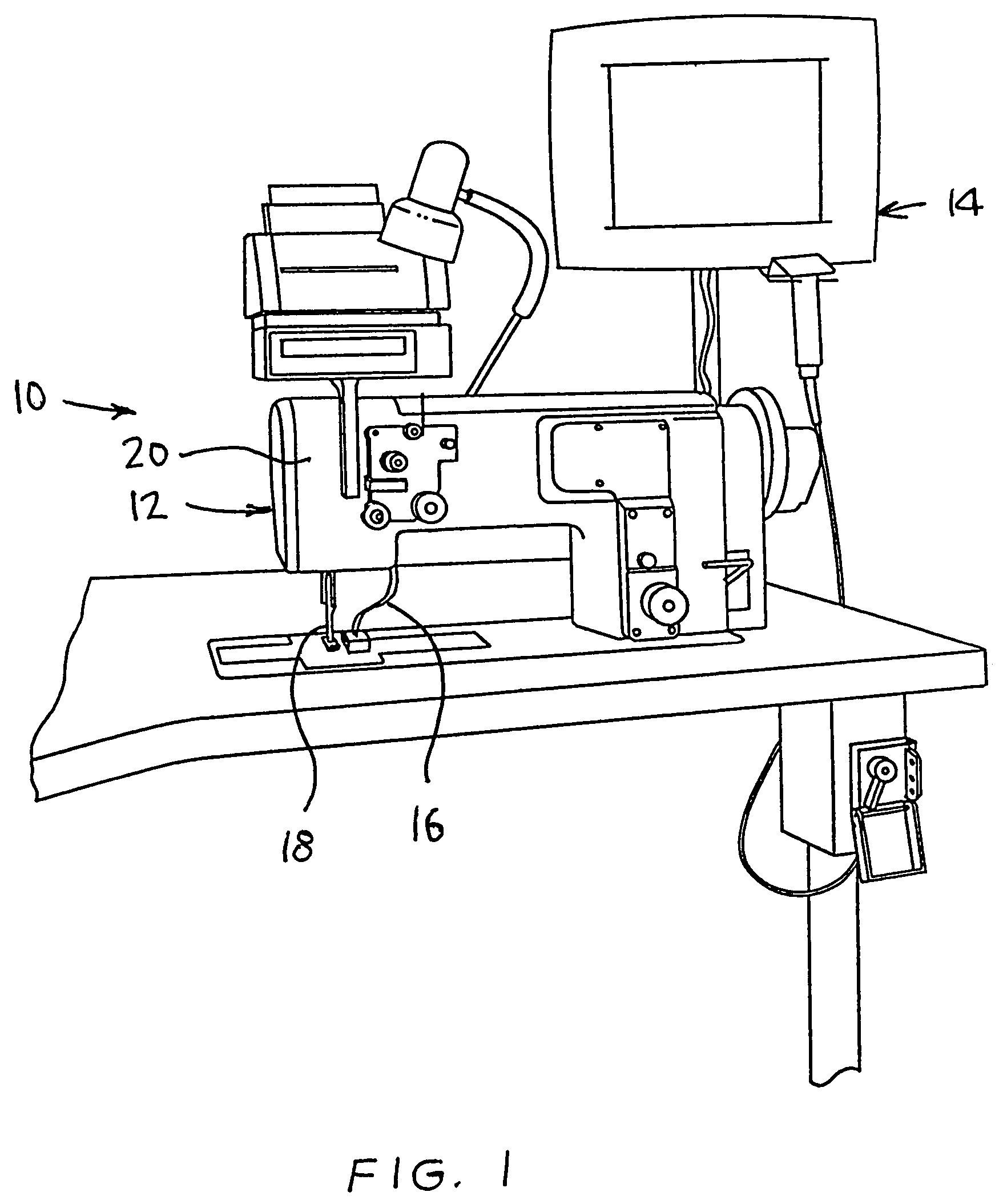

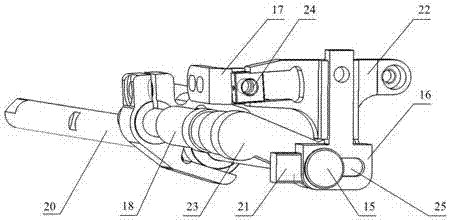

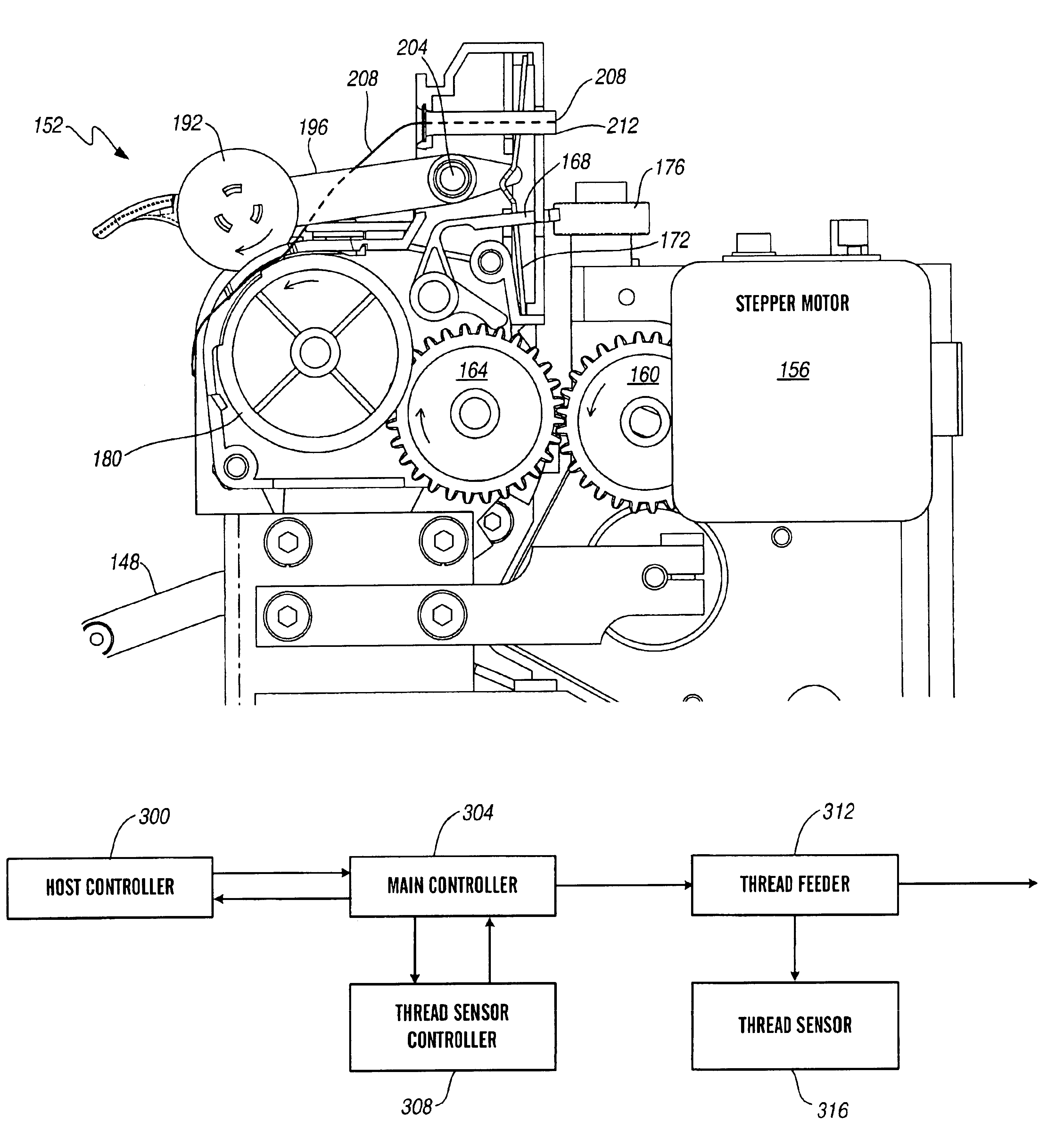

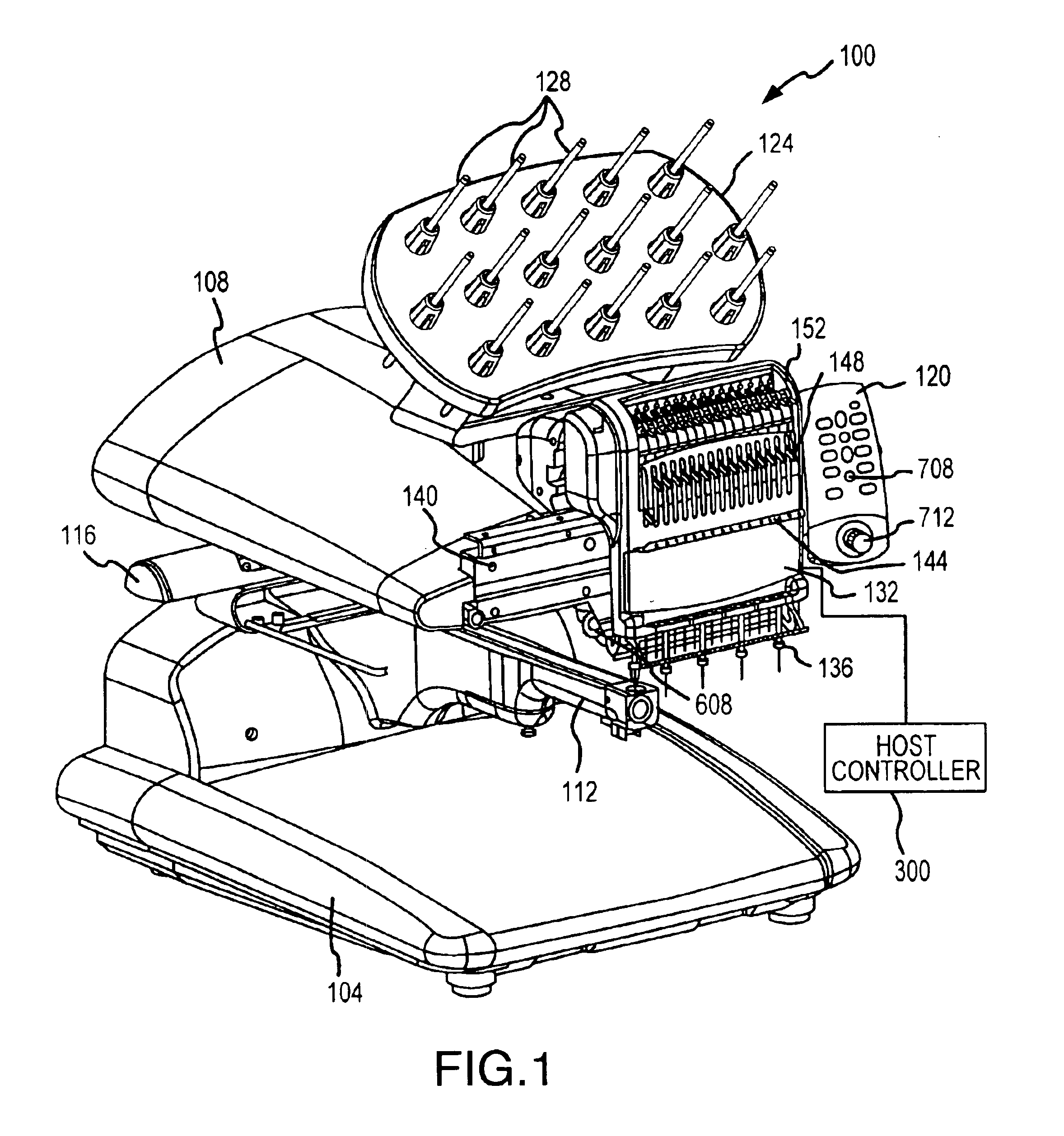

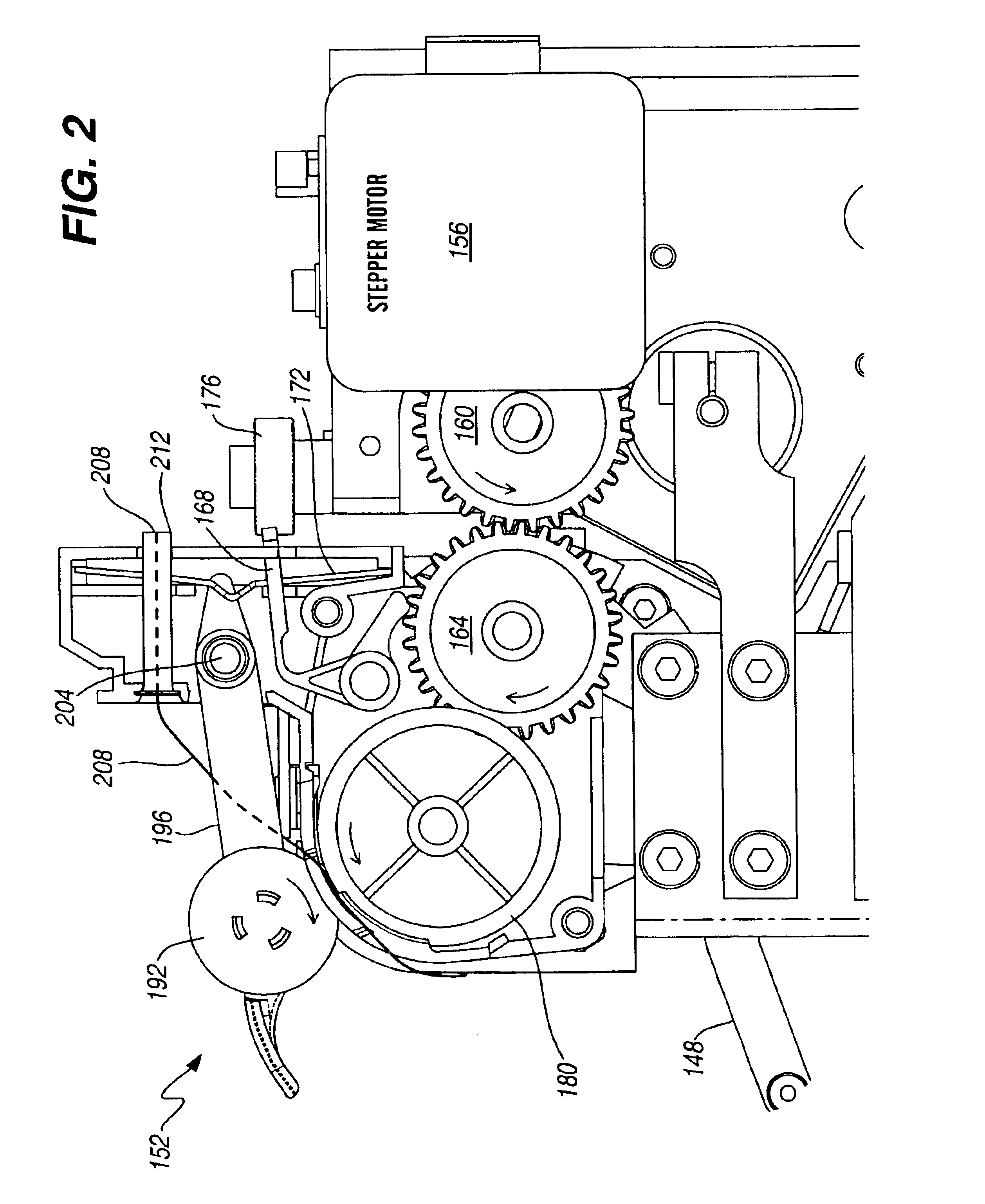

Computerized stitching including embroidering

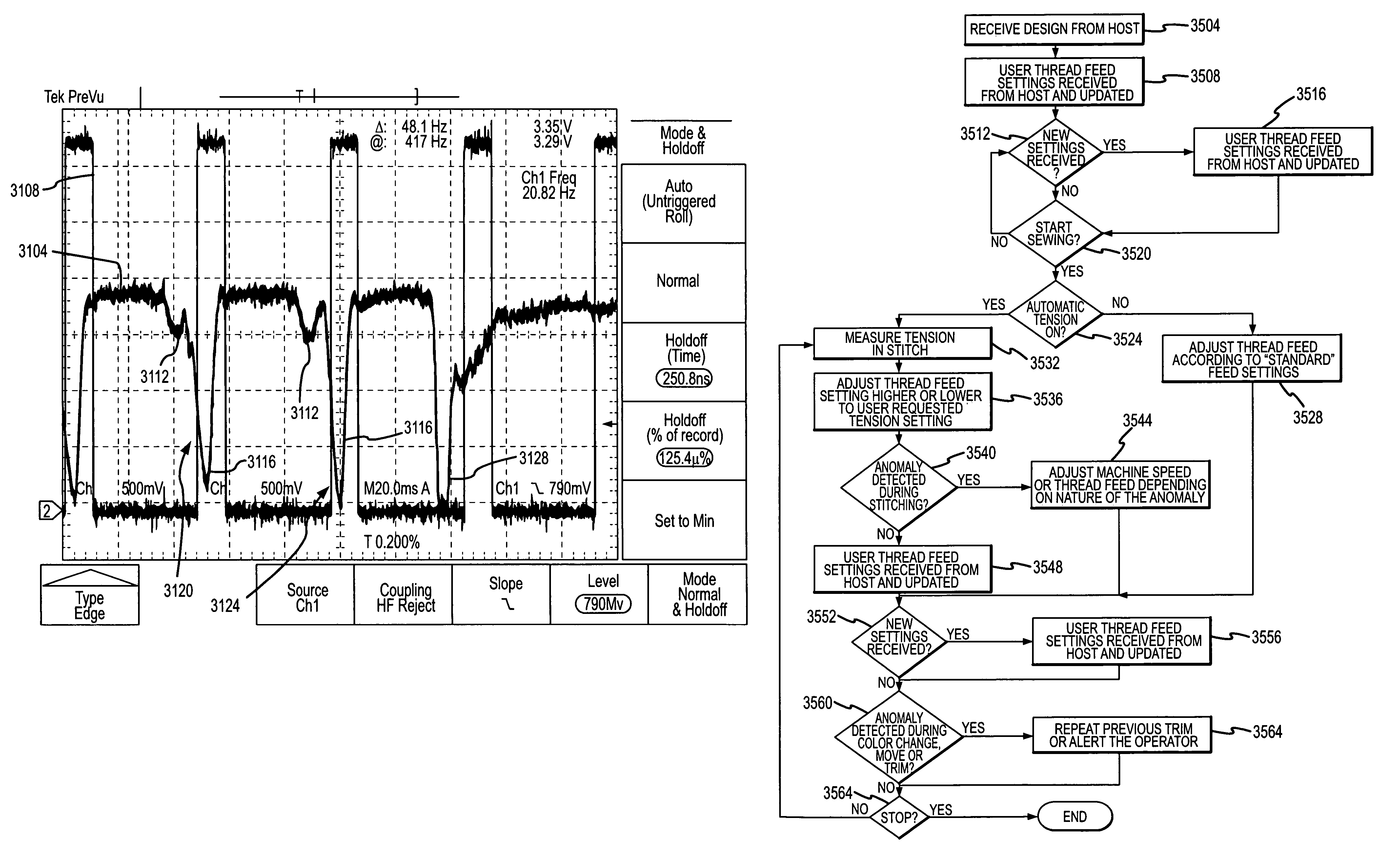

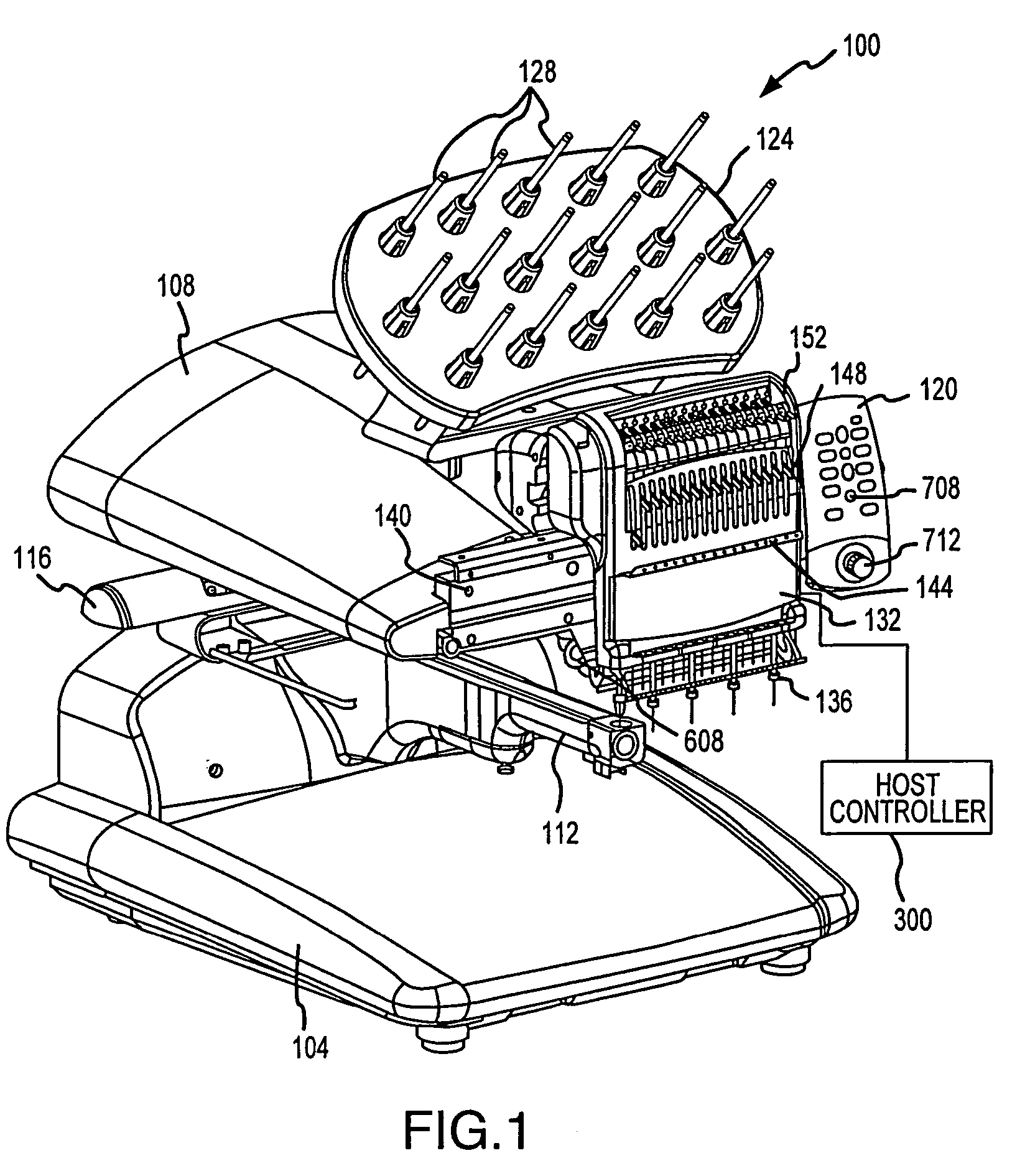

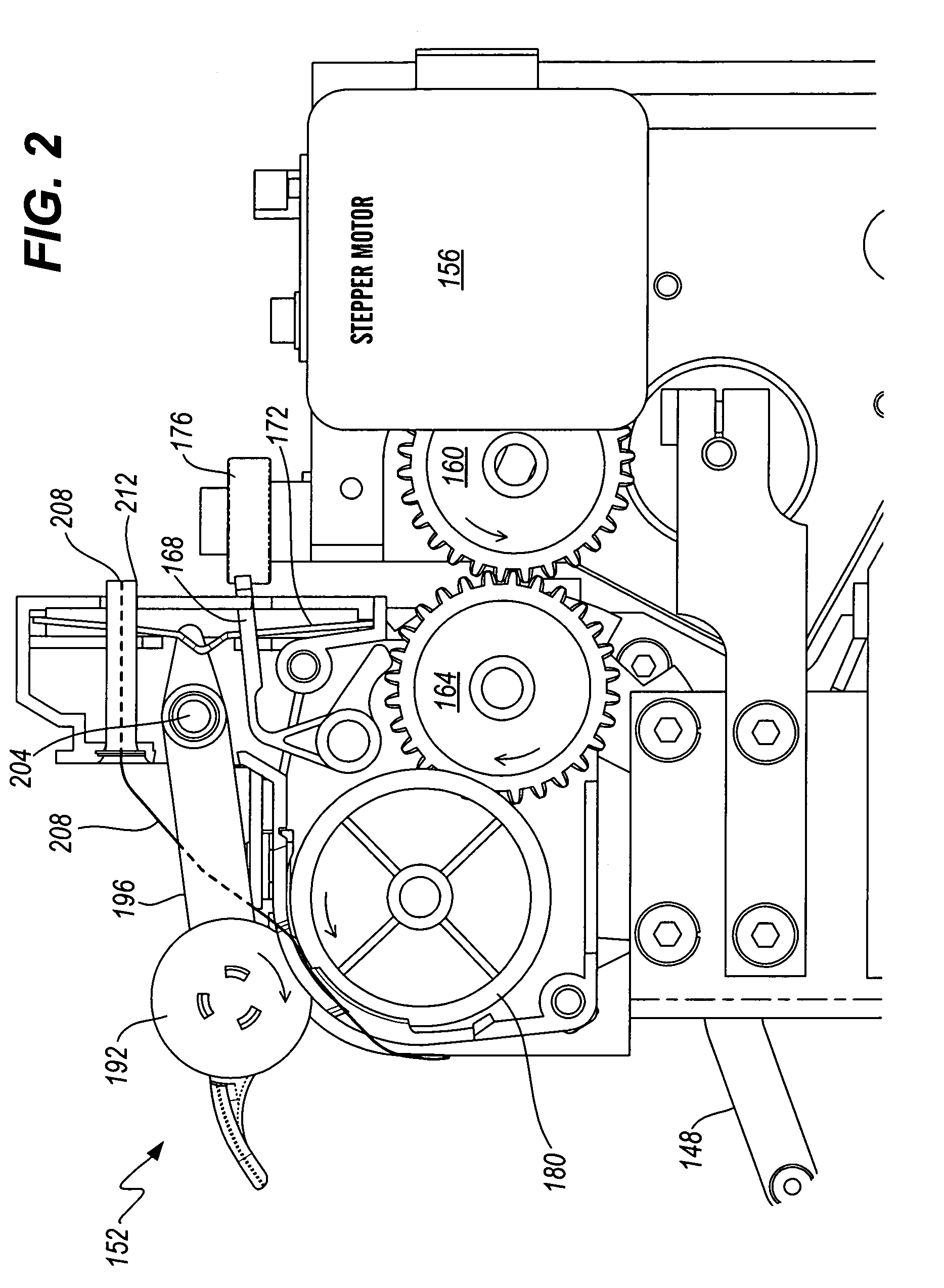

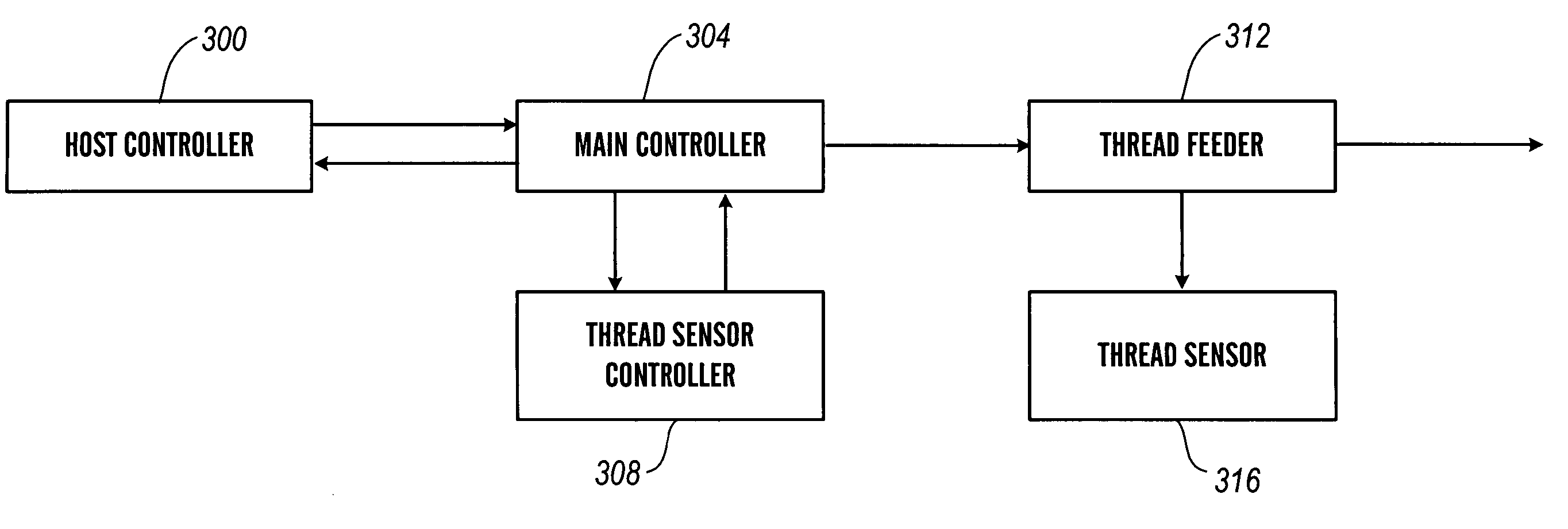

InactiveUS7308333B2Easy to controlProgramme-controlled sewing machinesPressersAnomaly detectionRemedial action

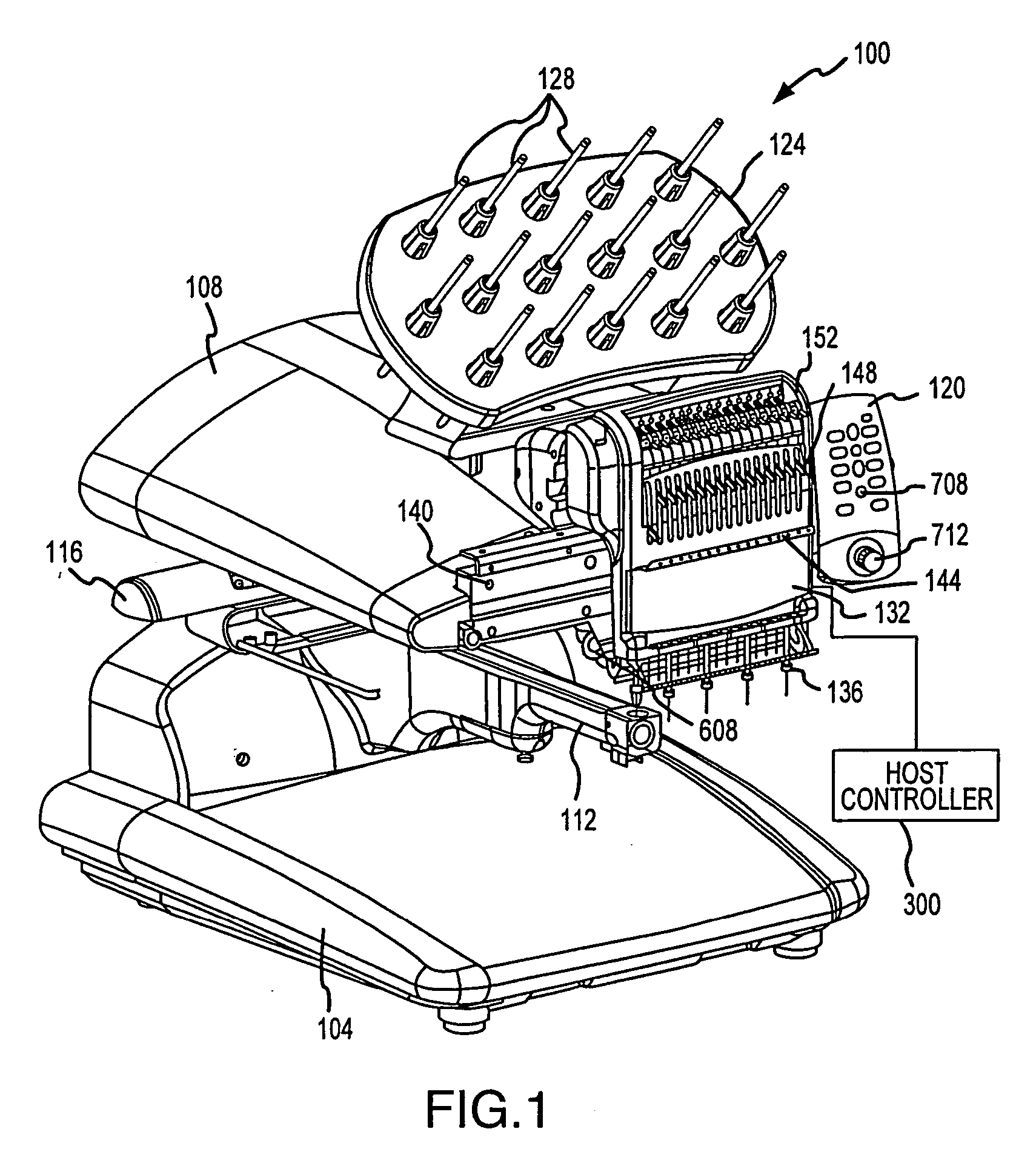

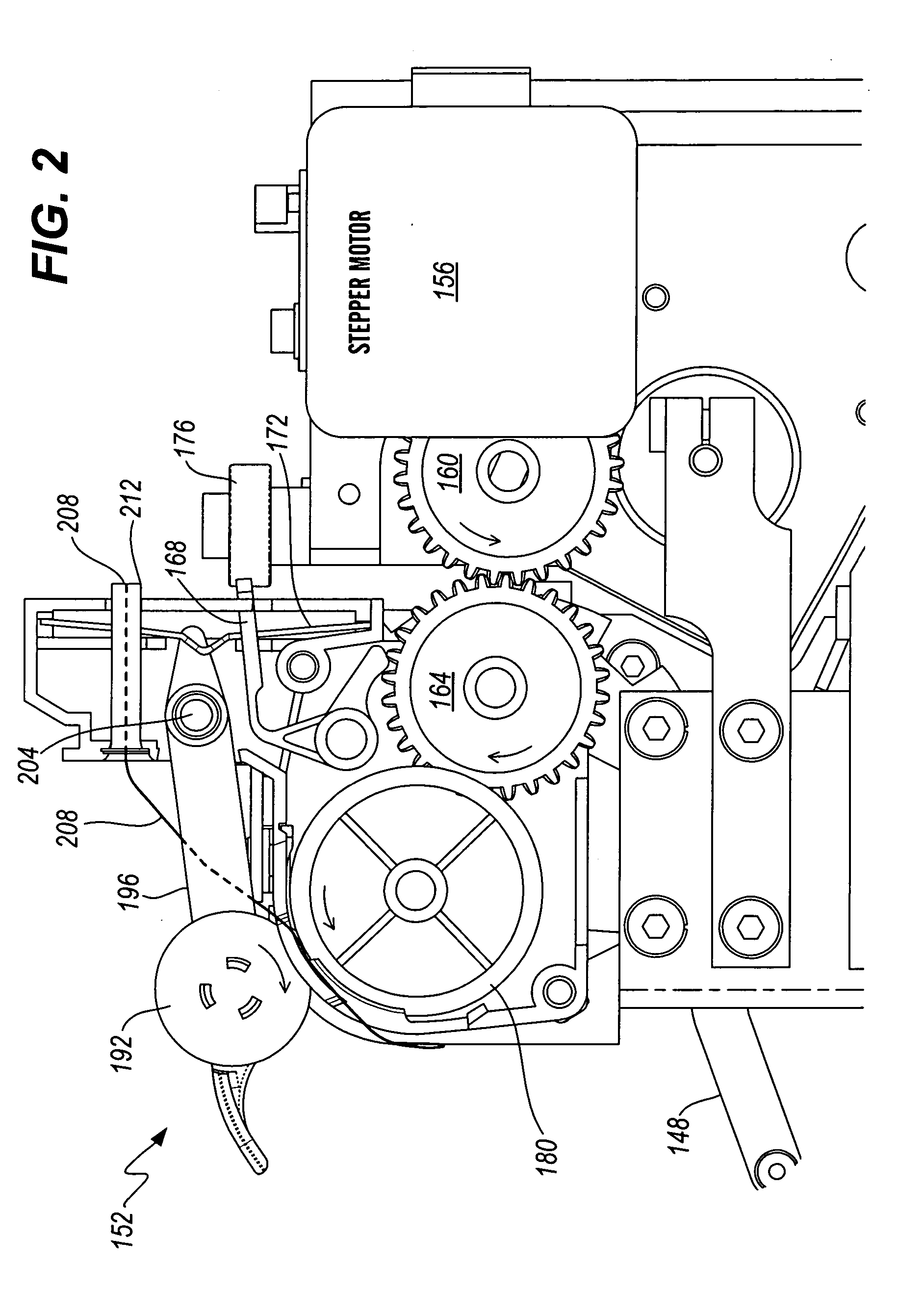

A stitching apparatus with thread tension control is provided. Tension in a thread is monitored during stitching apparatus operations, and remedial action is taken in response to the detection of an anomaly in the thread tension profile. The remedial action can include altering a feed rate of the thread in order to adjust the thread tension, and / or repeating a previous operation. Anomaly detection can be performed with respect to stitching or sewing operations, and also with respect to trim operations performed in connection with moving between elements and / or thread color changes.

Owner:MELCO INT

Computerized stitching including embroidering

InactiveUS20060064195A1Easy to controlProgramme-controlled sewing machinesPressersAnomaly detectionRemedial action

A stitching apparatus with thread tension control is provided. Tension in a thread is monitored during stitching apparatus operations, and remedial action is taken in response to the detection of an anomaly in the thread tension profile. The remedial action can include altering a feed rate of the thread in order to adjust the thread tension, and / or repeating a previous operation. Anomaly detection can be performed with respect to stitching or sewing operations, and also with respect to trim operations performed in connection with moving between elements and / or thread color changes.

Owner:MELCO INT

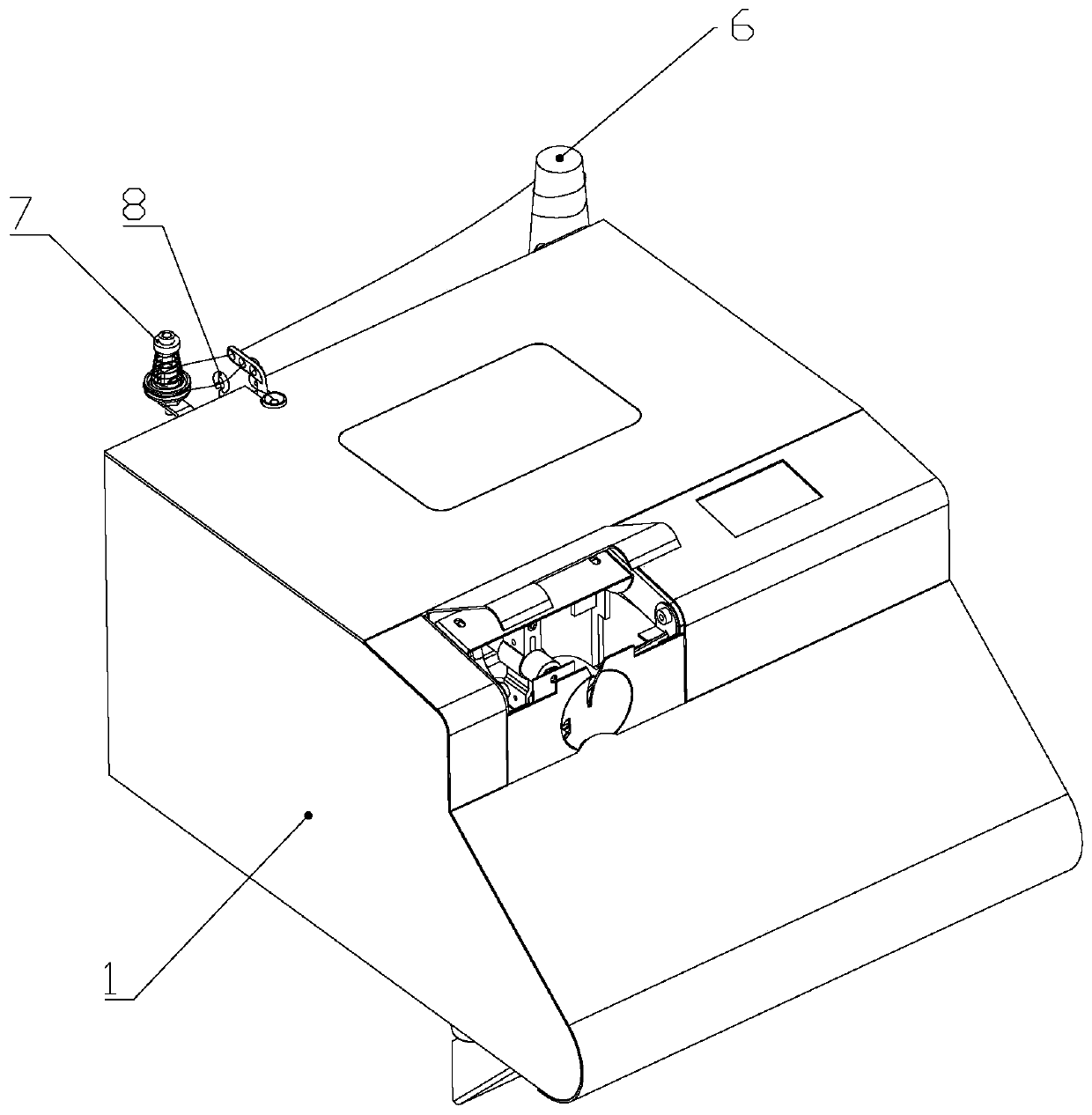

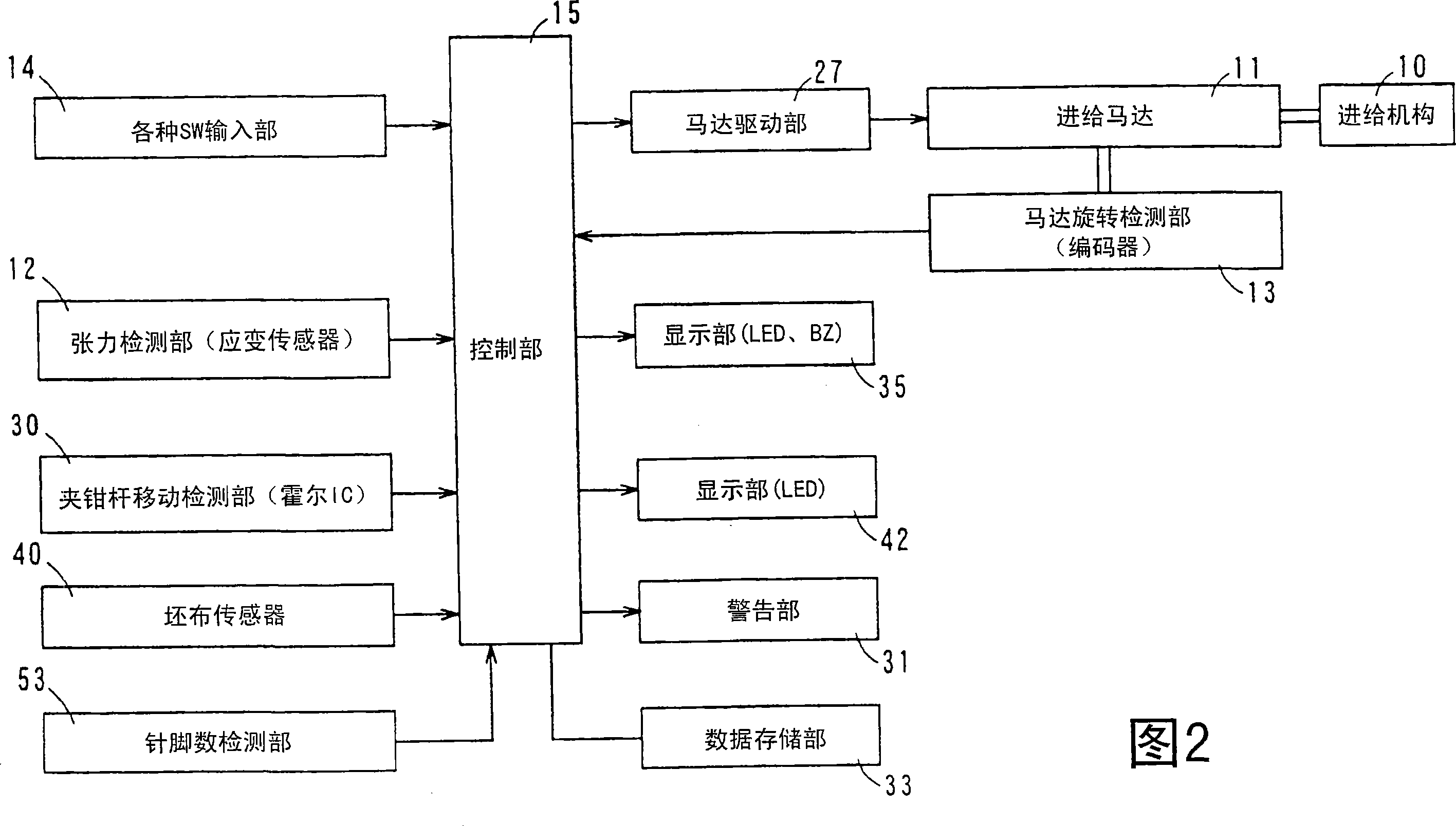

Automatic thread feeding system of sewing machine and control method thereof

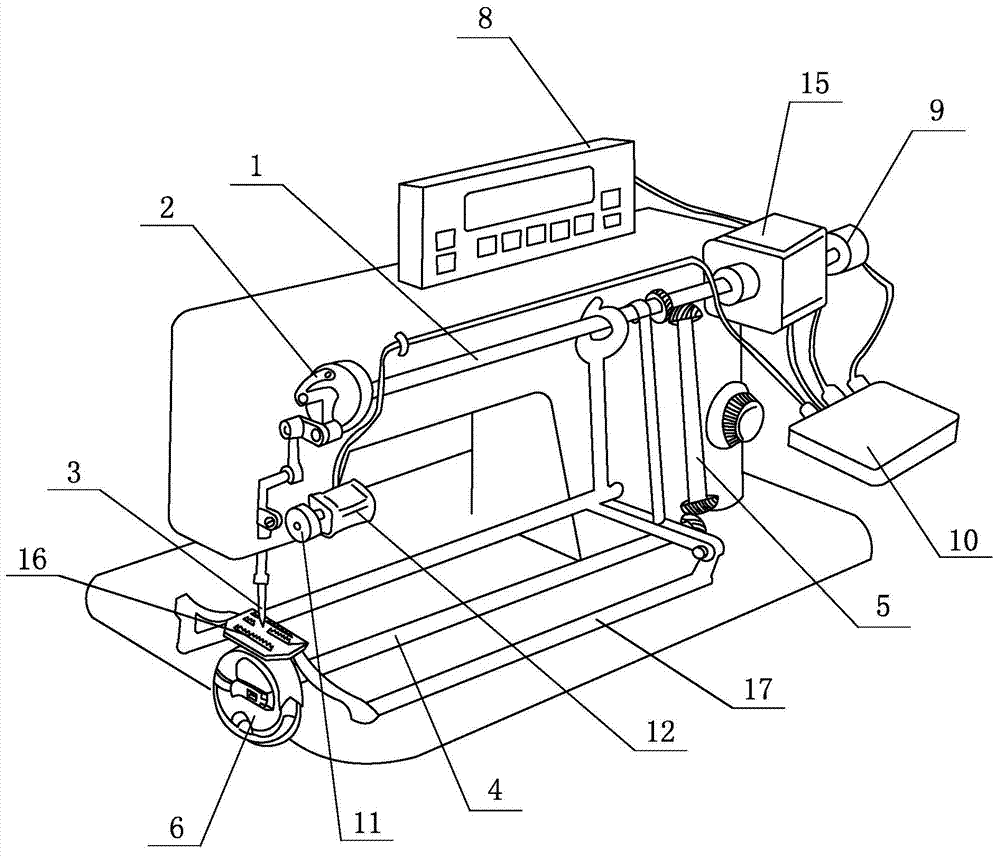

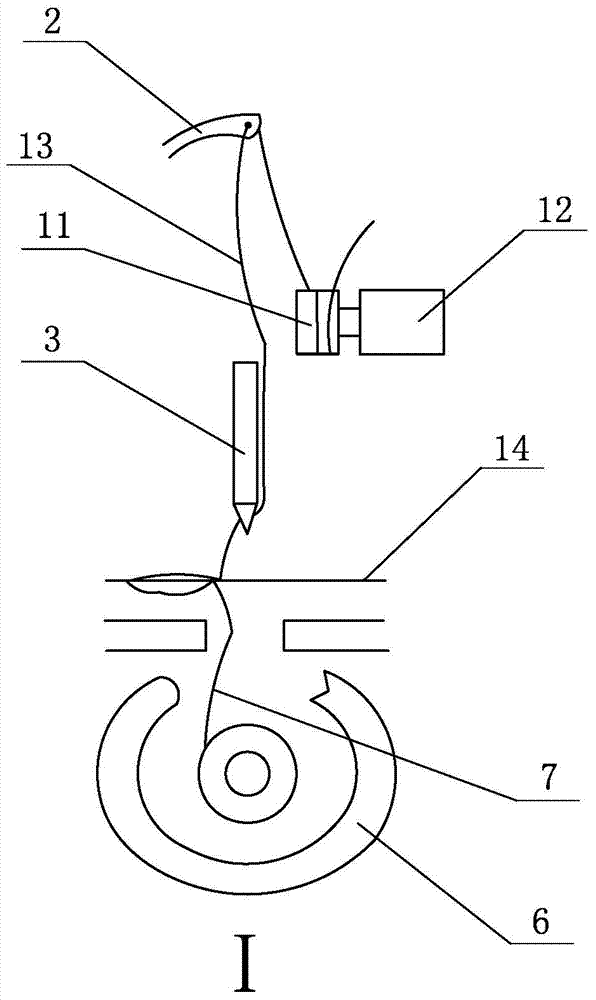

InactiveCN104120547AConsistent outputConsistent pitchProgramme-controlled sewing machinesSewing-machine control devicesDrive shaftElectric machinery

The invention discloses an automatic thread feeding system of a sewing machine. The automatic thread feeding system comprises an upper shaft, a lower shaft, a control device, a cloth feeding system and a sewing thread tension adjusting device. One end of the upper shaft is connected with a sewing machine driving mechanism, and the other end of the upper shaft is connected with a thread take-up lever and a sewing needle; one end of the lower shaft is connected with the upper shaft through a transmission shaft, and a rotating shuttle is arranged at the other end of the lower shaft and wound with a sewing bottom thread. The automatic thread feeding system is characterized in that the sewing thread tension adjusting device comprises a rotating body and a stepping motor, the rotating body is connected with an output end of the stepping motor, the sewing machine driving mechanism and a control end of the stepping motor are connected with the control device, the rotating body is wound with a sewing upper thread, and the sewing upper thread penetrates through the thread take-up lever and is connected with the sewing needle. The control method includes the steps of parameter setting, sewing needle sewing, rotating body taking up, cloth moving and rotating body paying off. The sewn stitches are in order, and sewing quality is high.

Owner:SUZHOU HAOJIE MACHINERY ELECTRONICS EQUIP

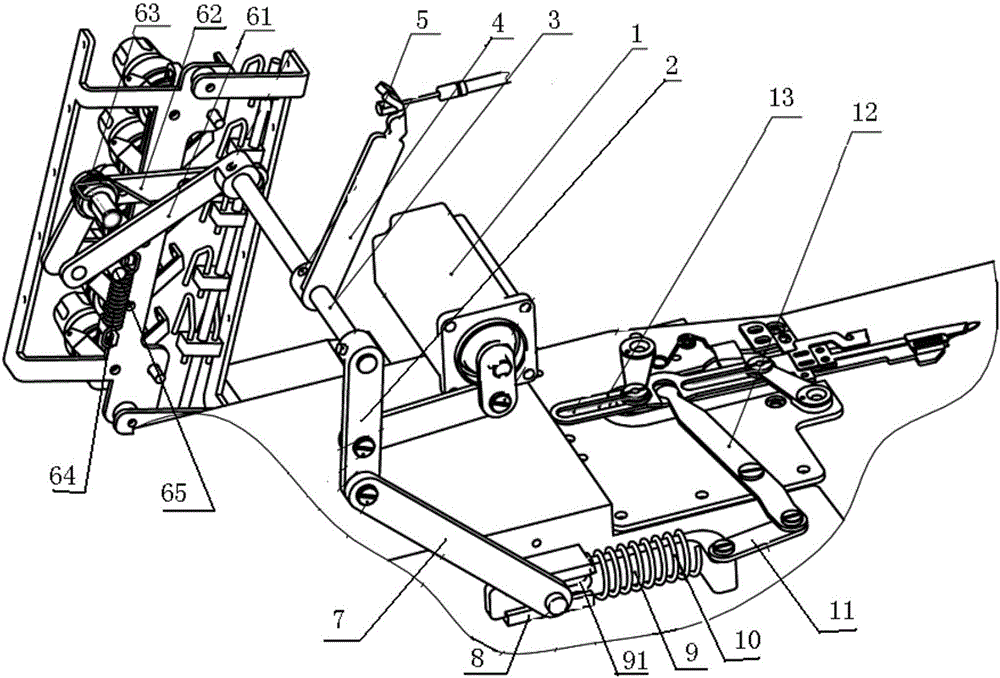

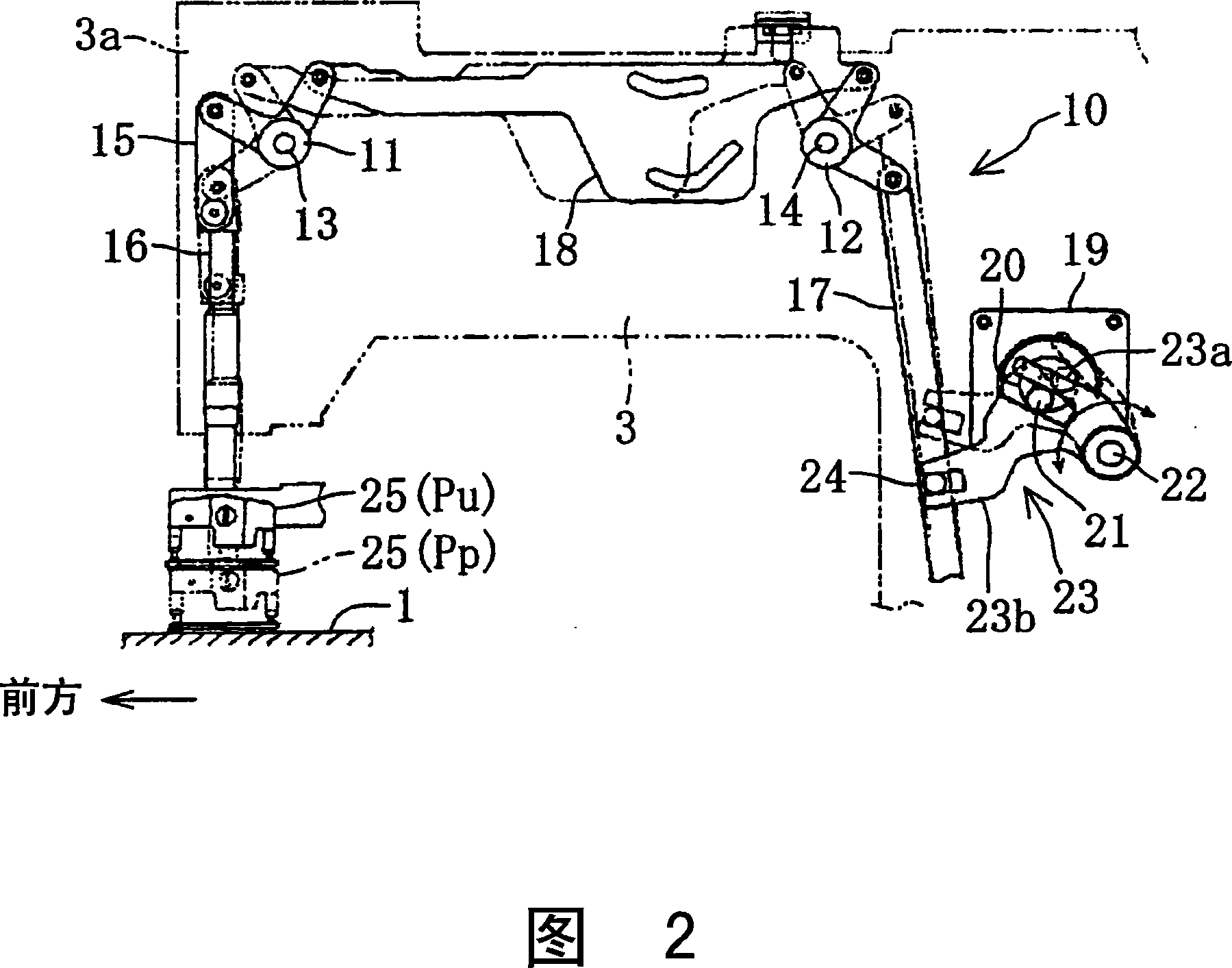

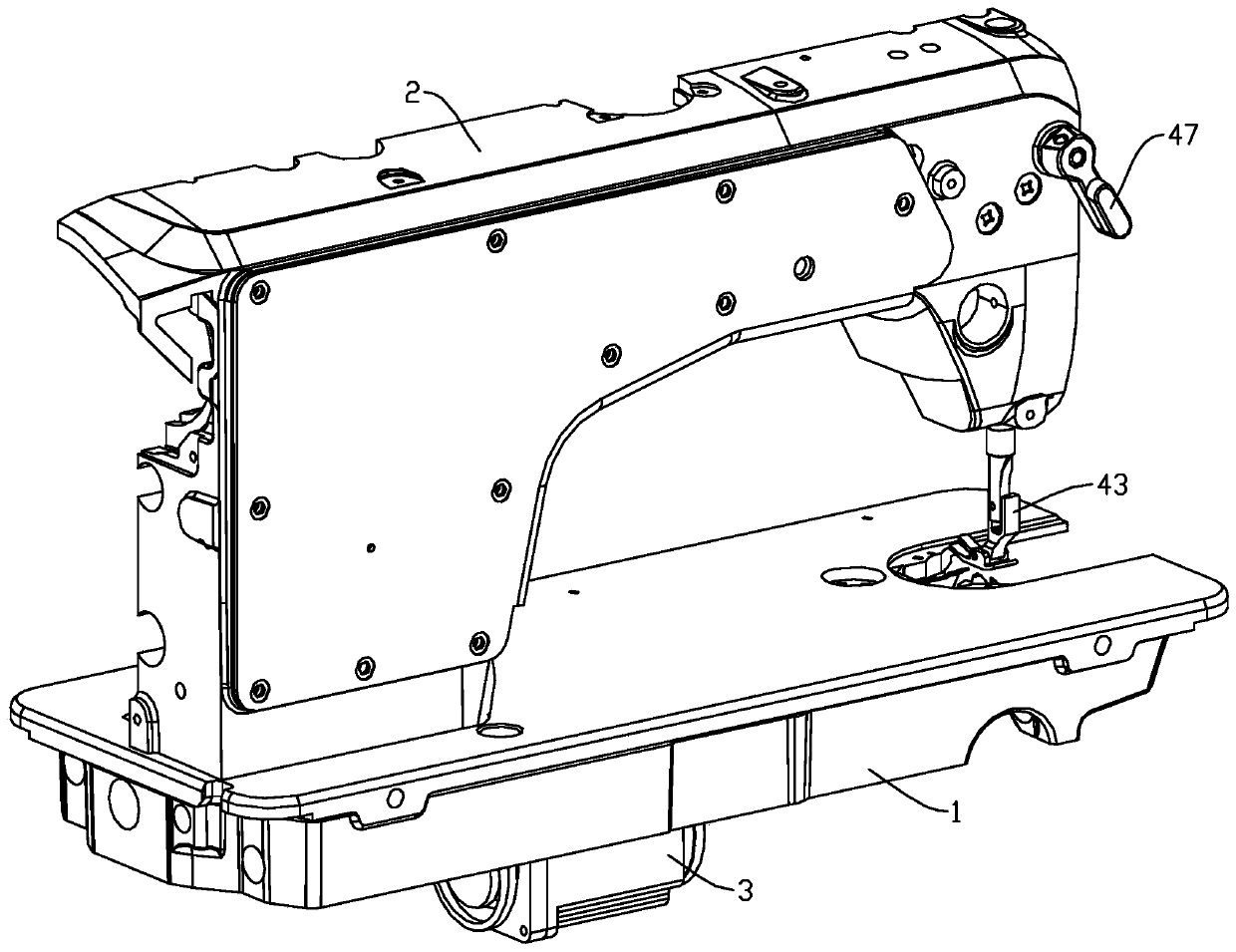

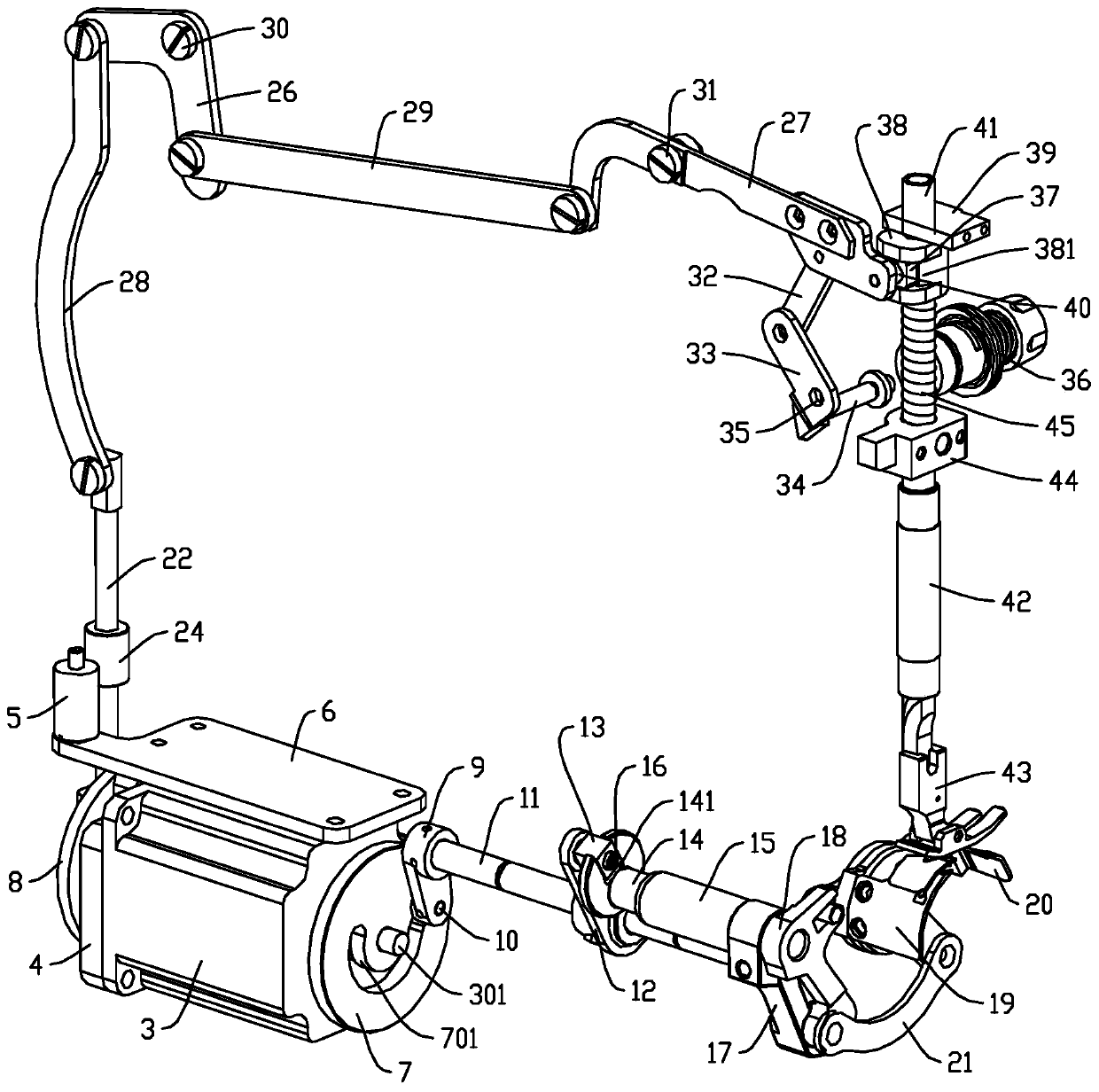

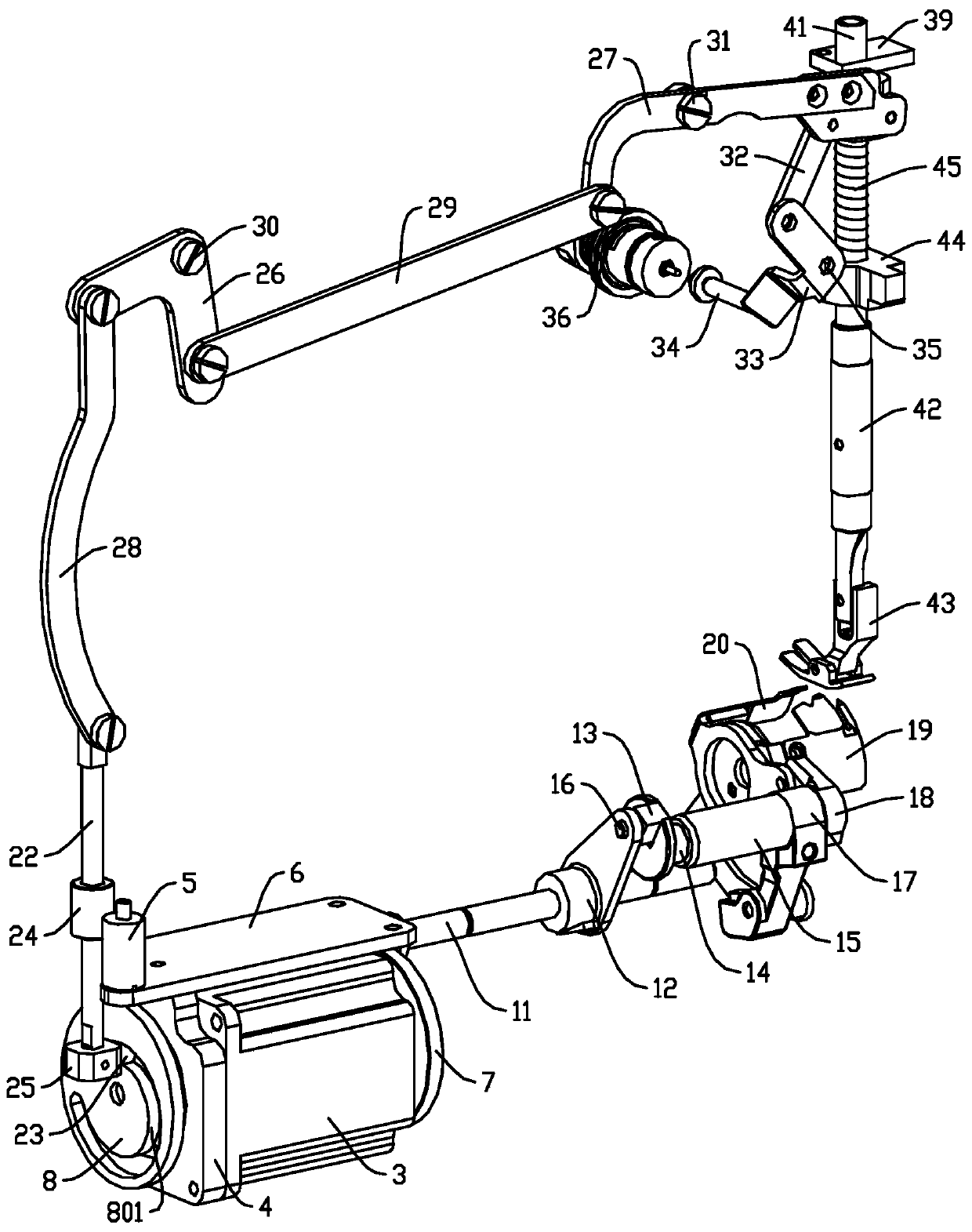

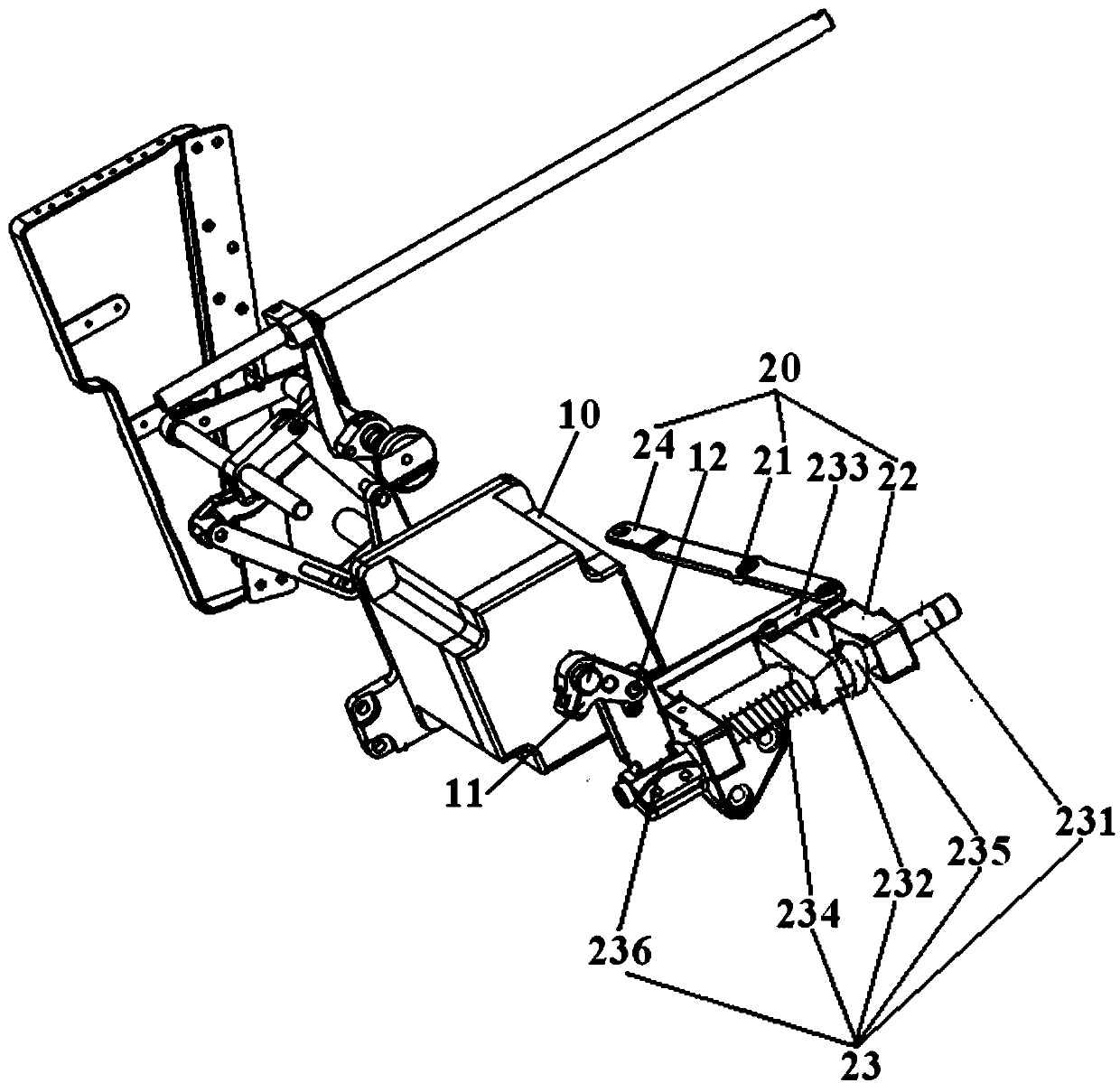

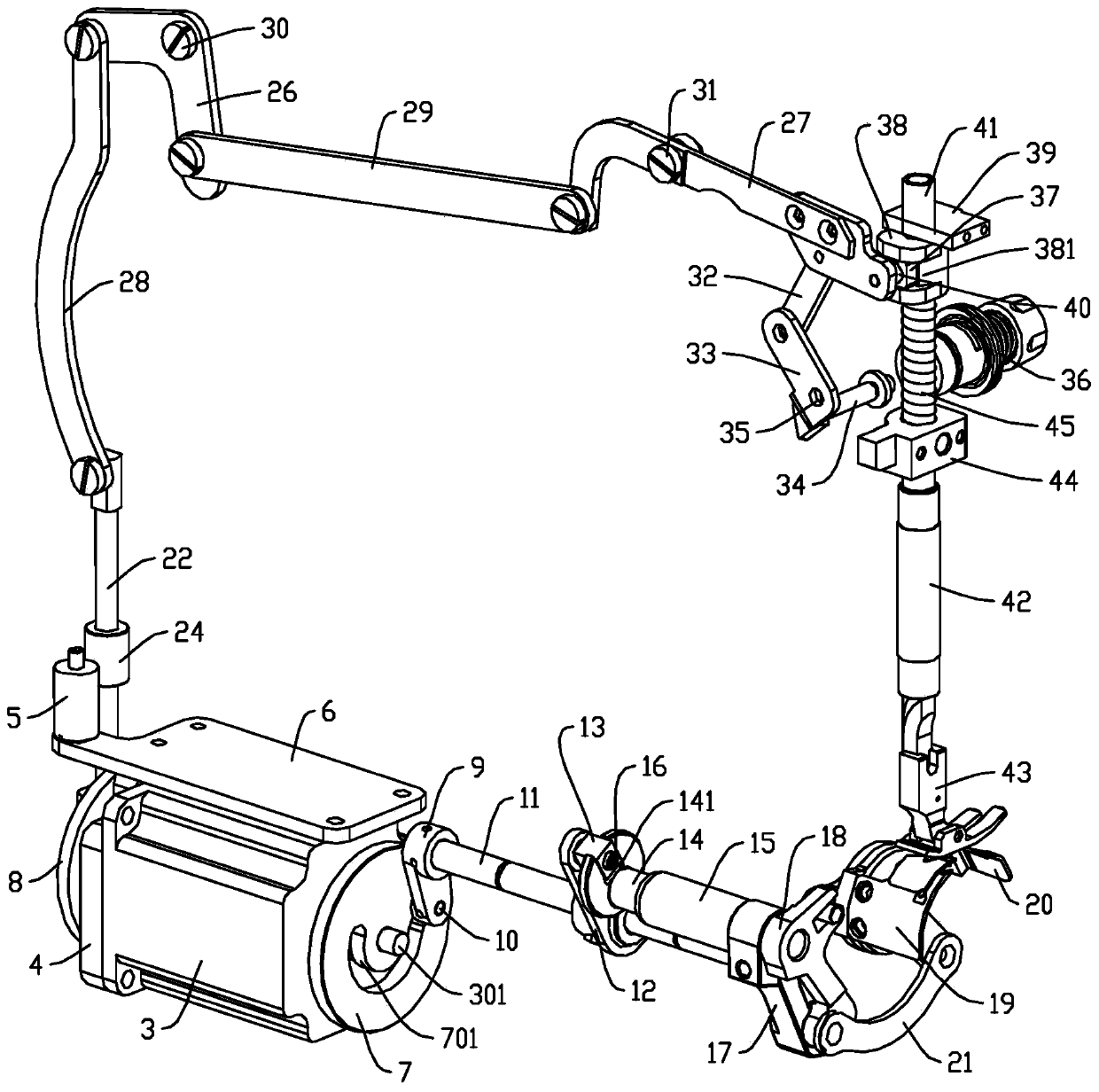

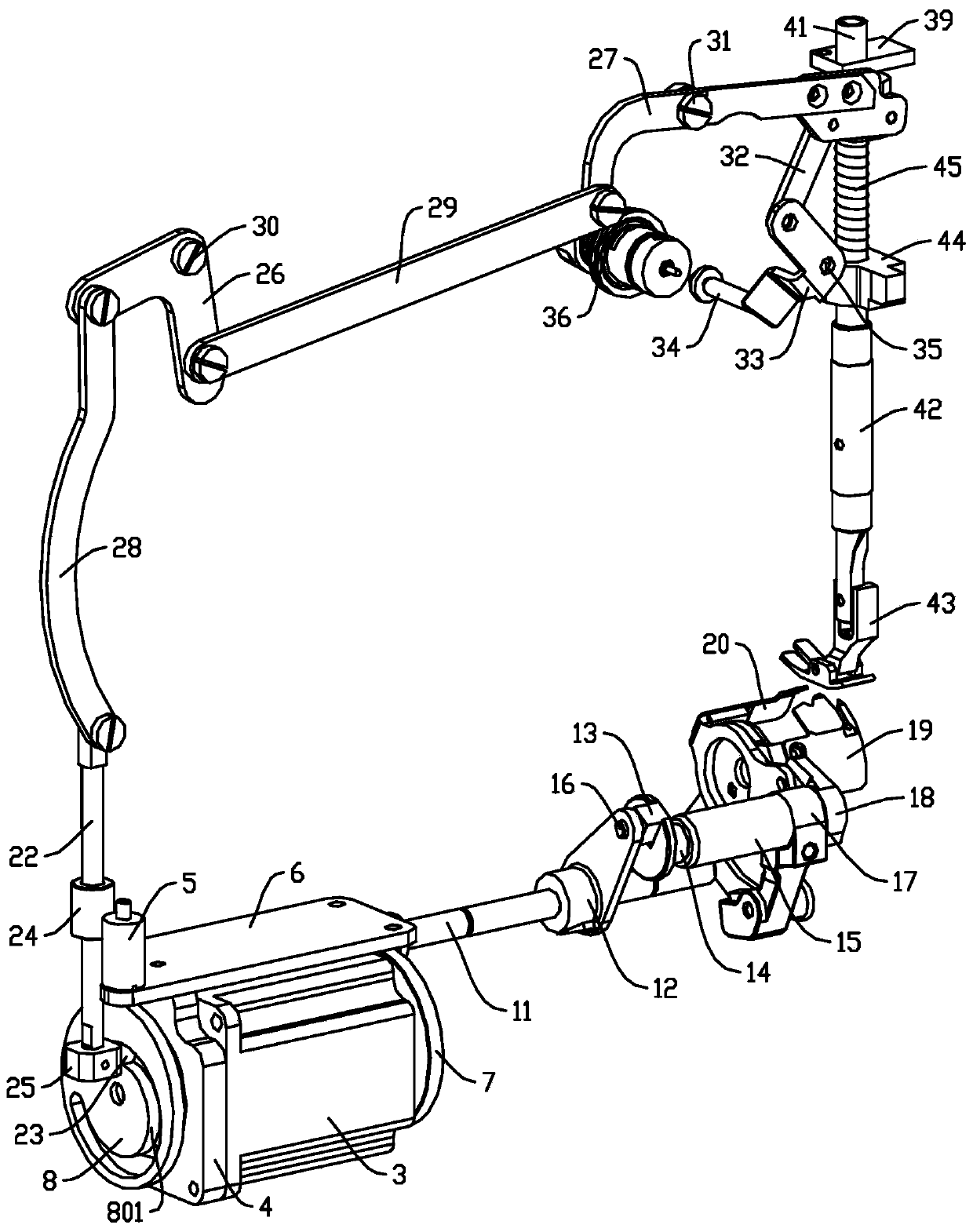

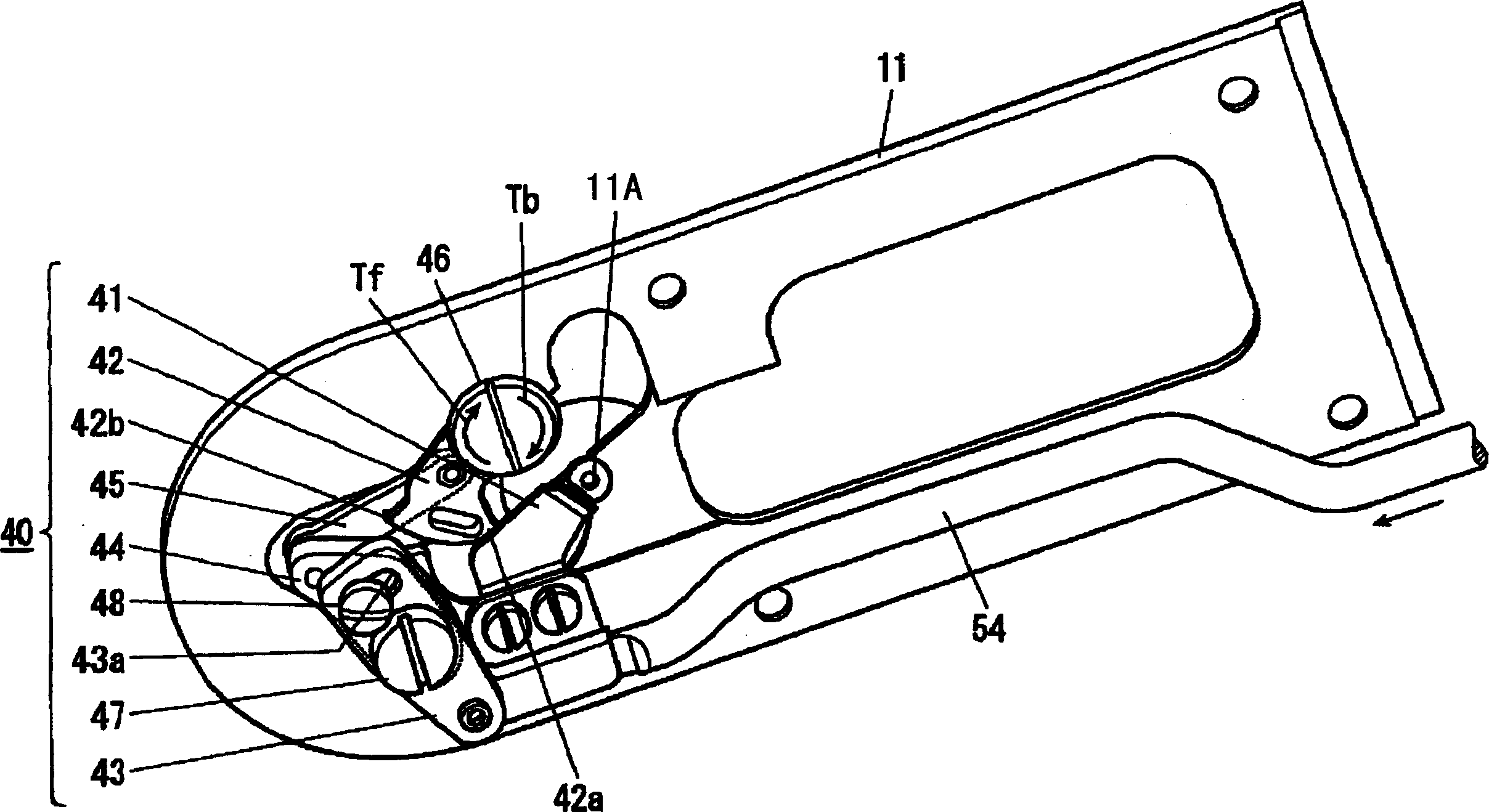

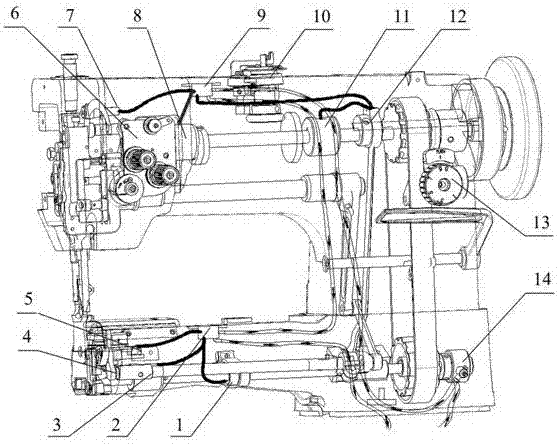

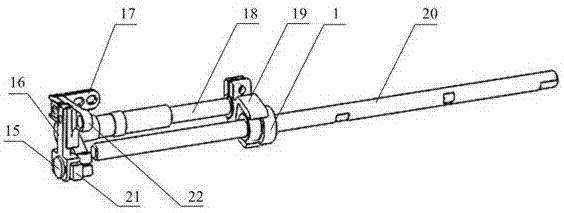

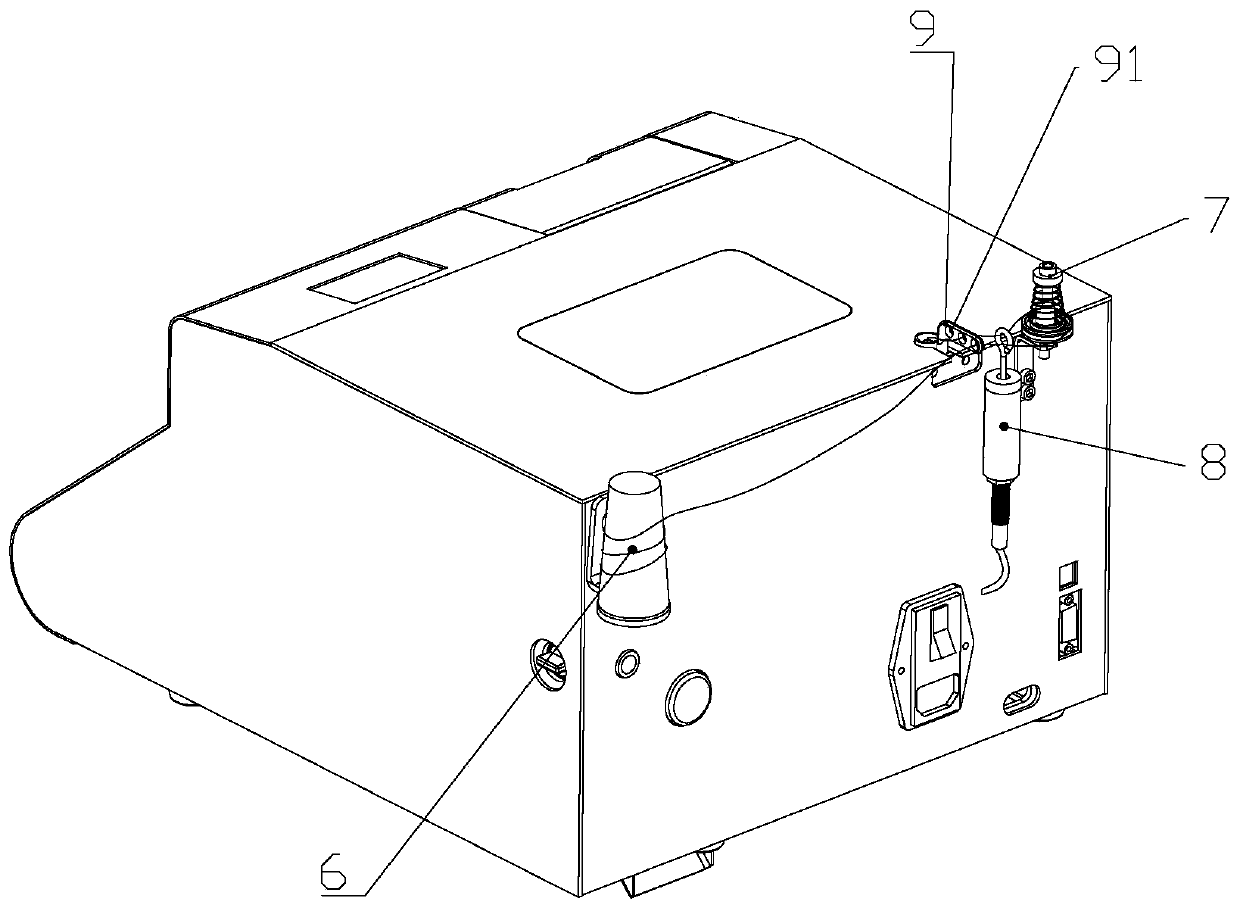

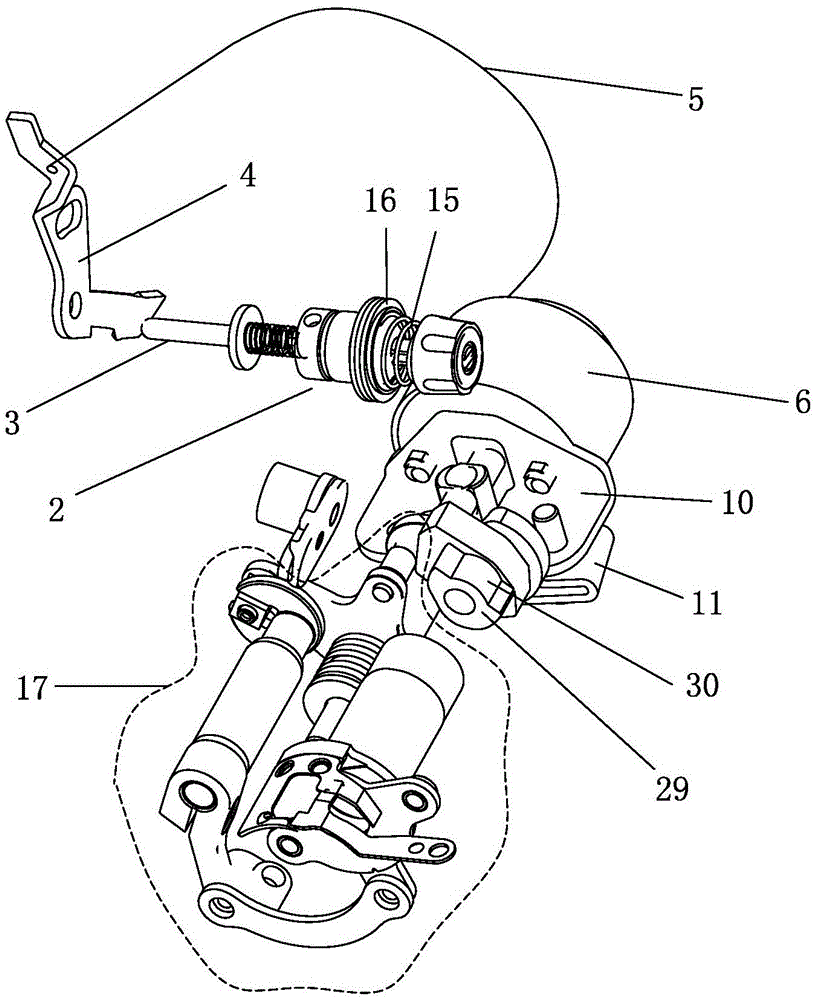

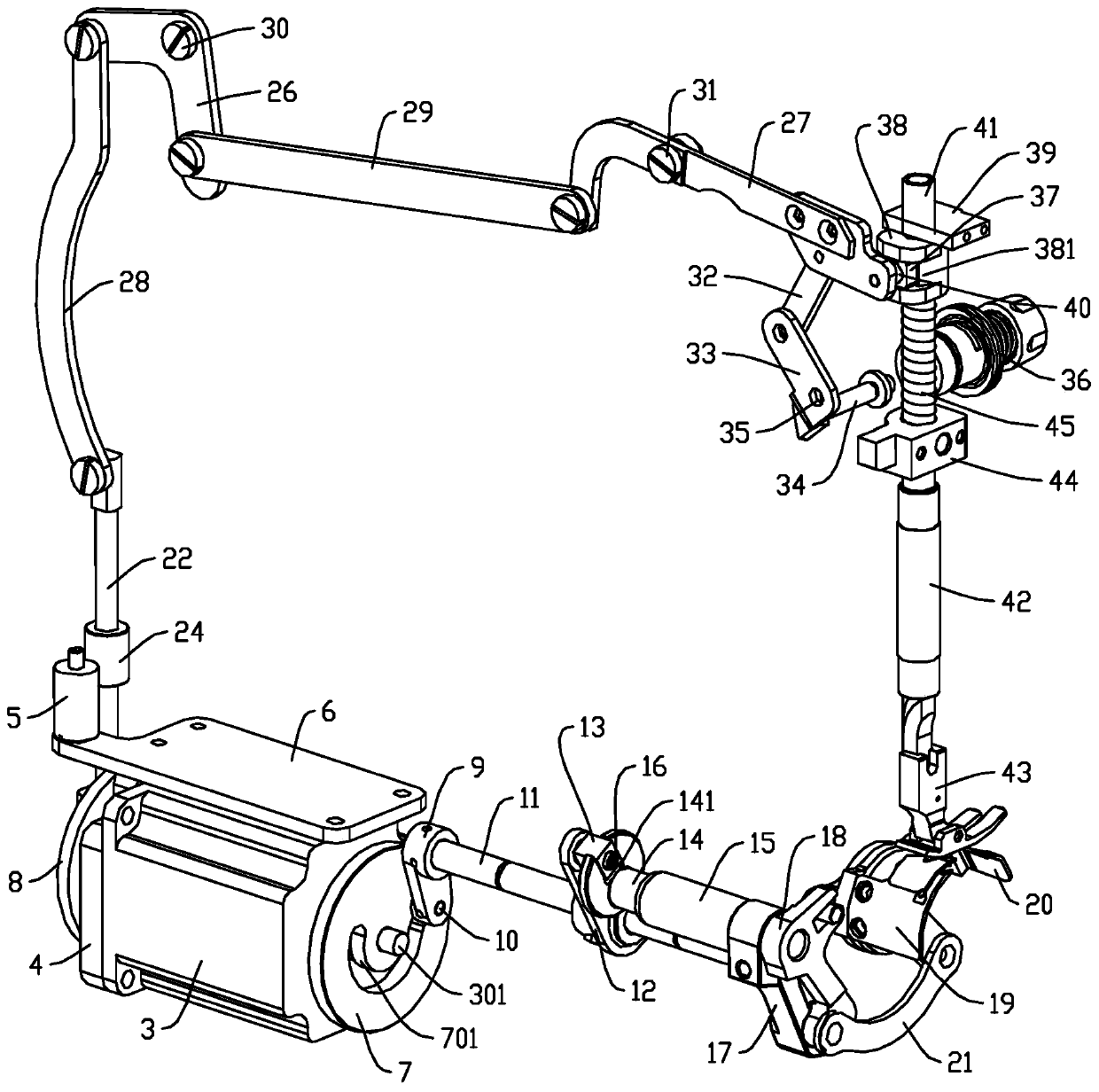

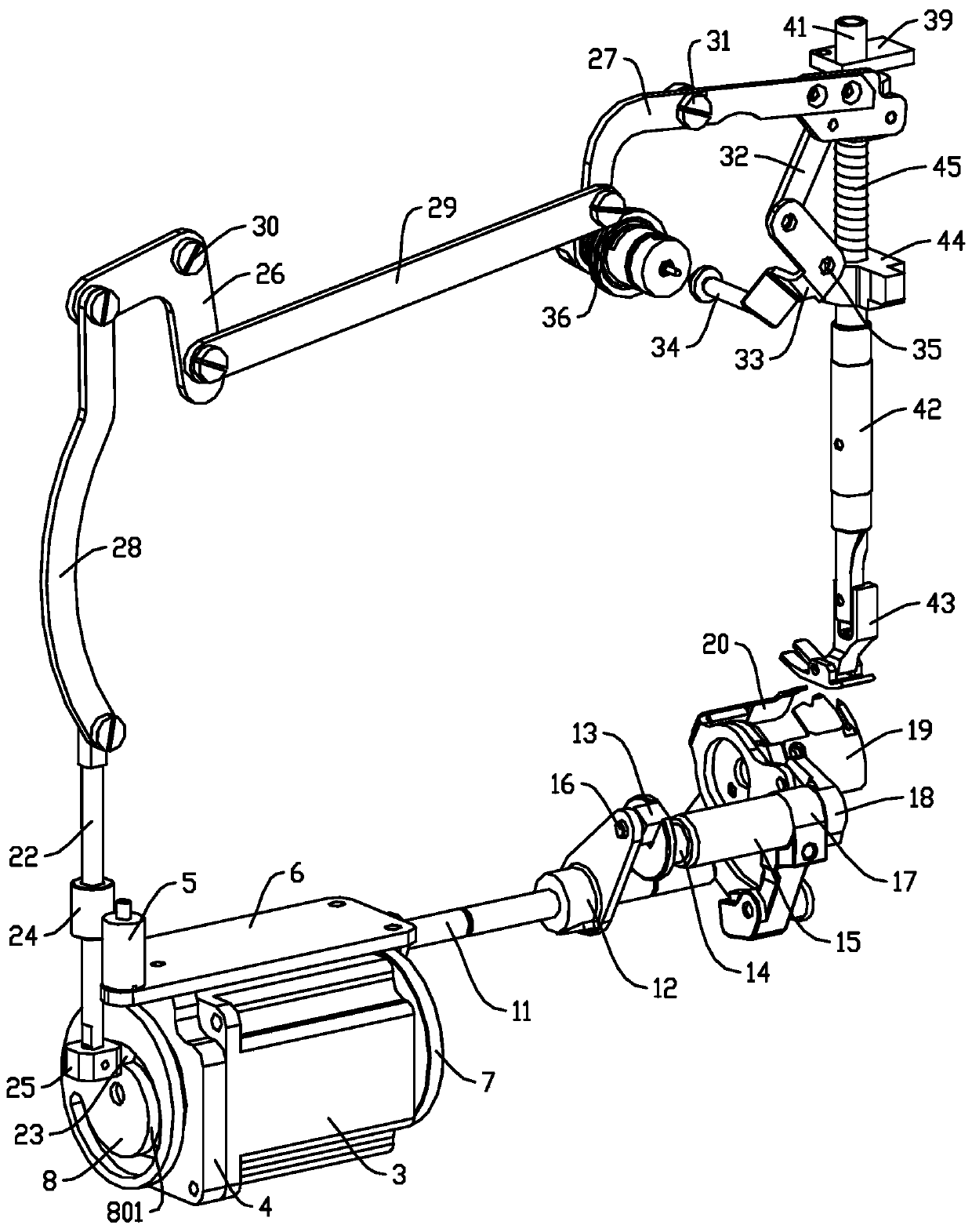

Drive mechanism integrating trimming, thread slacking, routing and presser foot lifting and sewing machine

ActiveCN105839300AEasy to controlMovement precisionNeedle severing devicesSewing-machine control devicesDrive motorEngineering

The invention provides a drive mechanism integrating trimming, thread slacking, routing and presser foot lifting and a sewing machine. The drive mechanism comprises a drive motor, a thread slacking shaft in transmission connection with the drive motor, a presser foot lifting transmission assembly connected with a presser foot lifting assembly, and a thread slacking transmission part connected with a thread slacking and routing assembly. The presser foot lifting transmission assembly comprises a presser foot lifting transmission rod and a presser foot lifting transmission part which are in sliding connection, the presser foot lifting transmission rod is fixedly connected with the thread slacking shaft, the presser foot lifting transmission part is connected with the presser foot lifting assembly, and the thread slacking transmission part is connected with the thread slacking shaft. One power source, namely the drive motor is adopted, so that the drive mechanism is simplified; meanwhile, the drive motor can control movement positions more accurately, routing and thread slacking actions and presser foot lifting and thread slacking actions are more accurate, and adjustment is more convenient.

Owner:JACK SEWING MASCH CO LTD

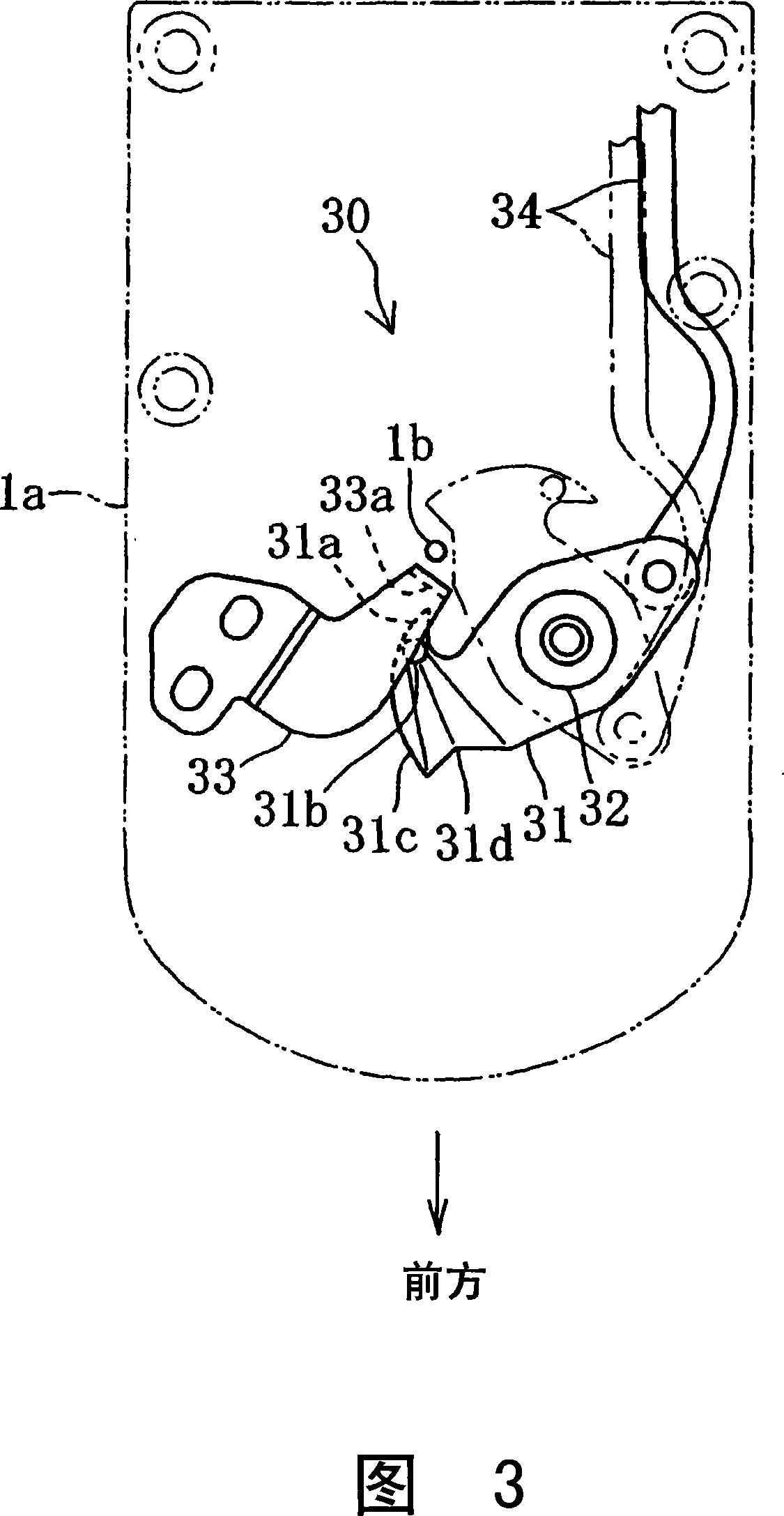

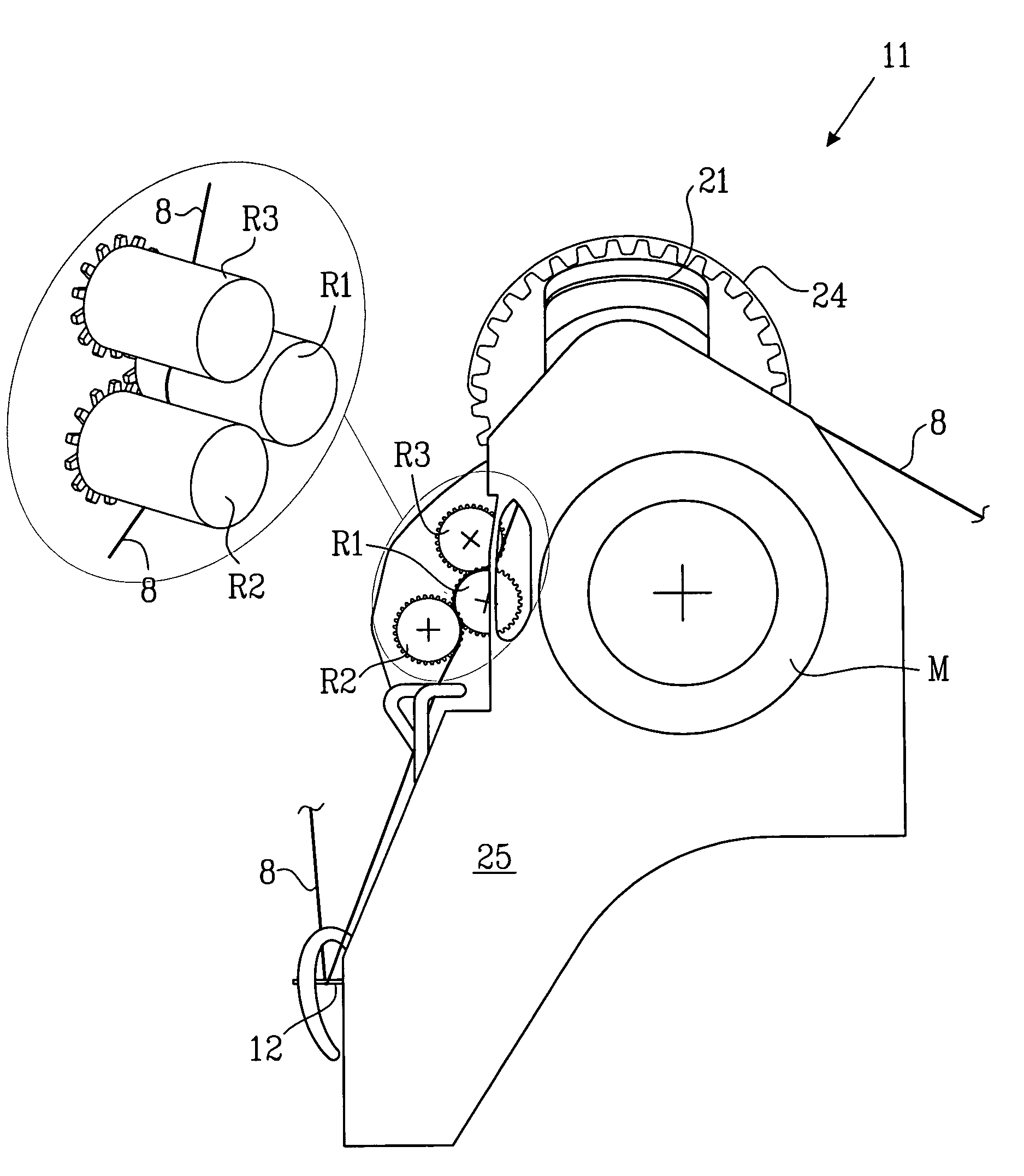

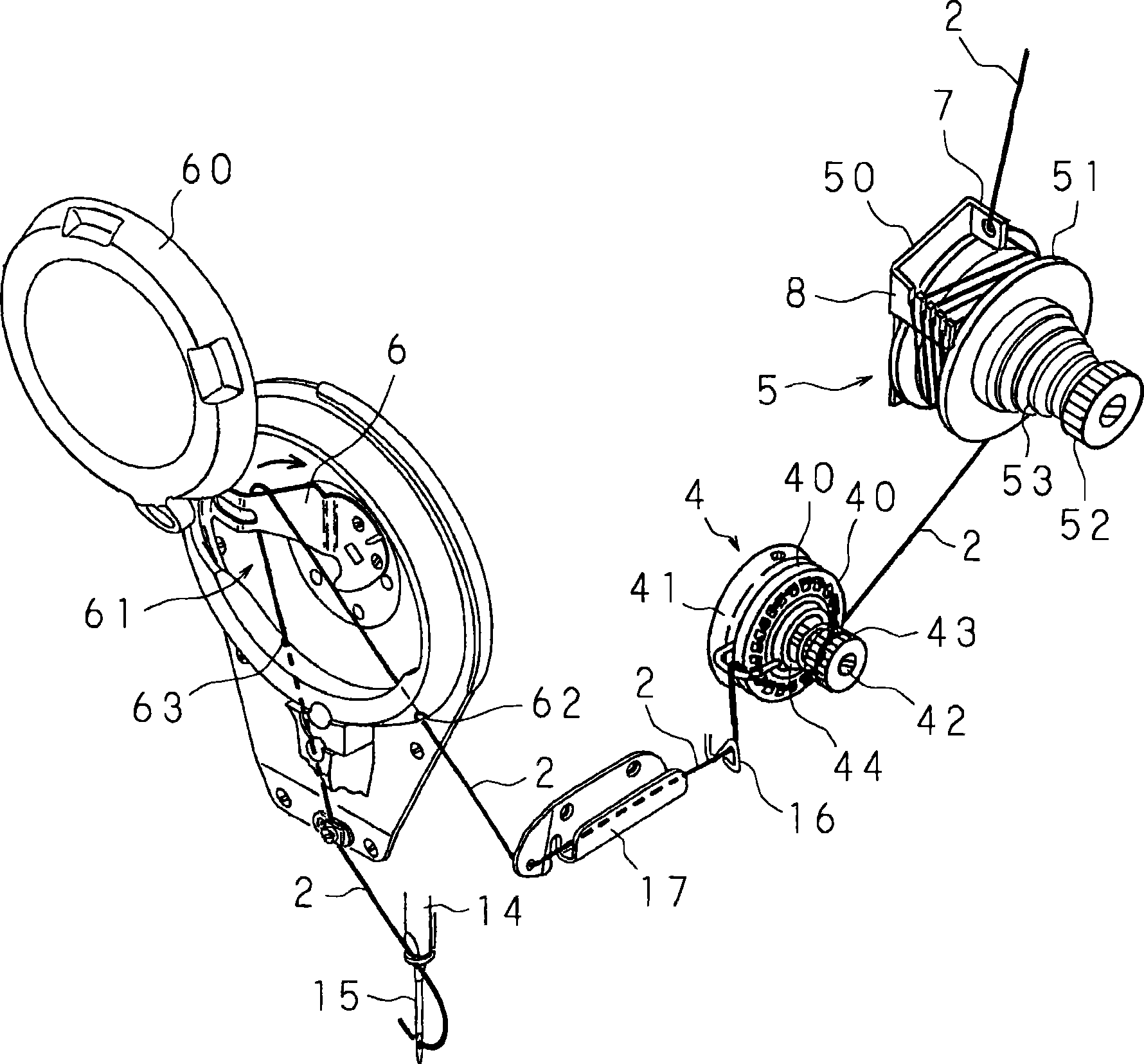

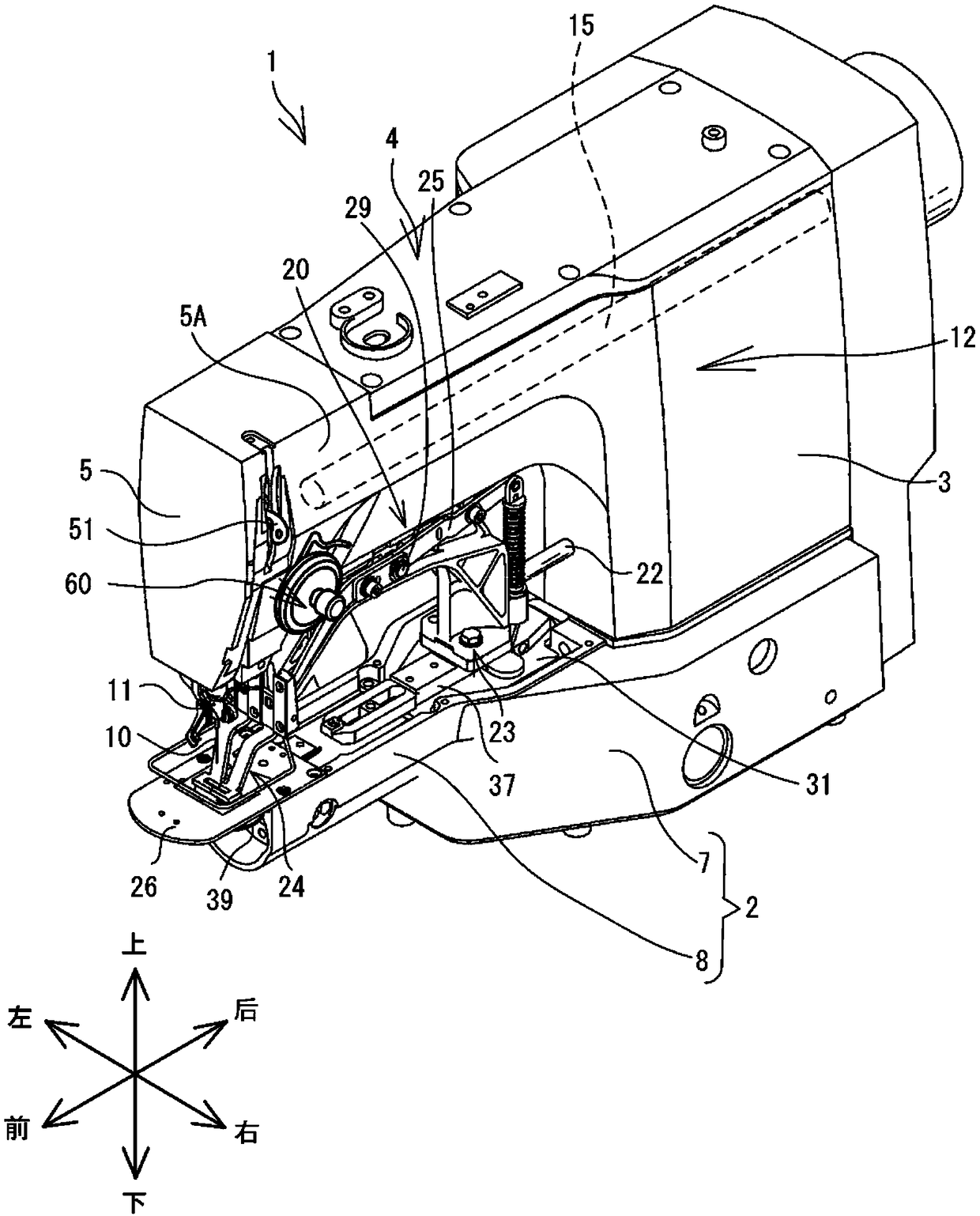

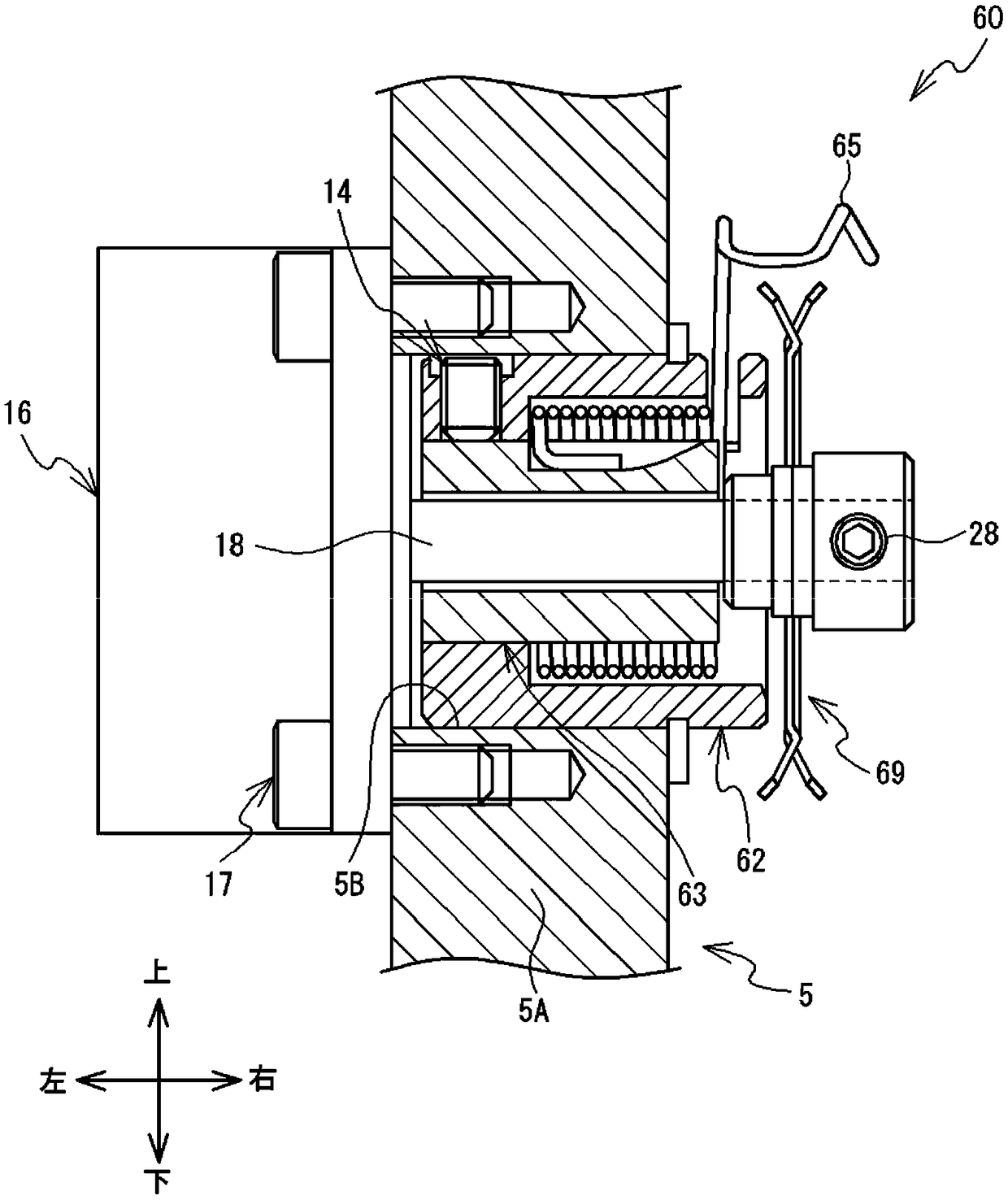

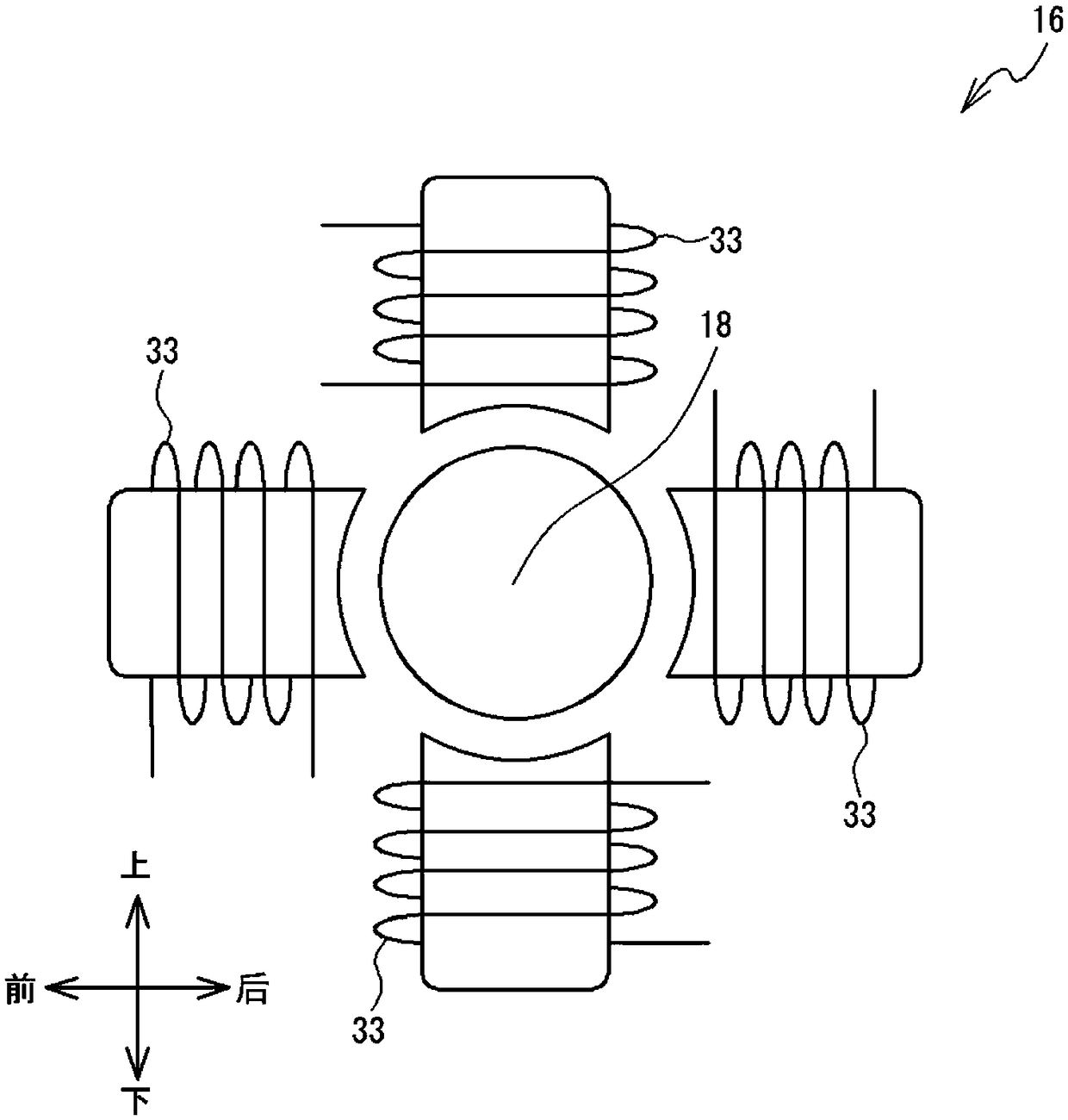

Stitch Outlet Detection Device, Sewing Machine And Stitch Outlet Detection Method

The invention provides a stitch outlet detecting device of a sewing machine which can detect a stitching with high accuracy and is unaffected by elongation of a thread or sewing unevenness. The stitch outlet detecting device (21) of a sewing machine forms a stitch by detecting a top thread loop formed by a sewing needle by using a rotary kettle and by causing a top thread and a bottom thread to cross each other. The device comprises: a rotary member (33), which rolls the top thread to the center of a thread path extending from a thread reel of the top thread; a motor (29) which causes the rotary member to rotate so as to apply a tension to the top thread upon feeding the top thread from the thread reel; and a detection unit (22) which monitors a predetermined portion immediately before the upper top loop is released from the rotary kettle, and detects the stitch outlet of the behavior of the motor in the predetermined portion.

Owner:JUKI CORP

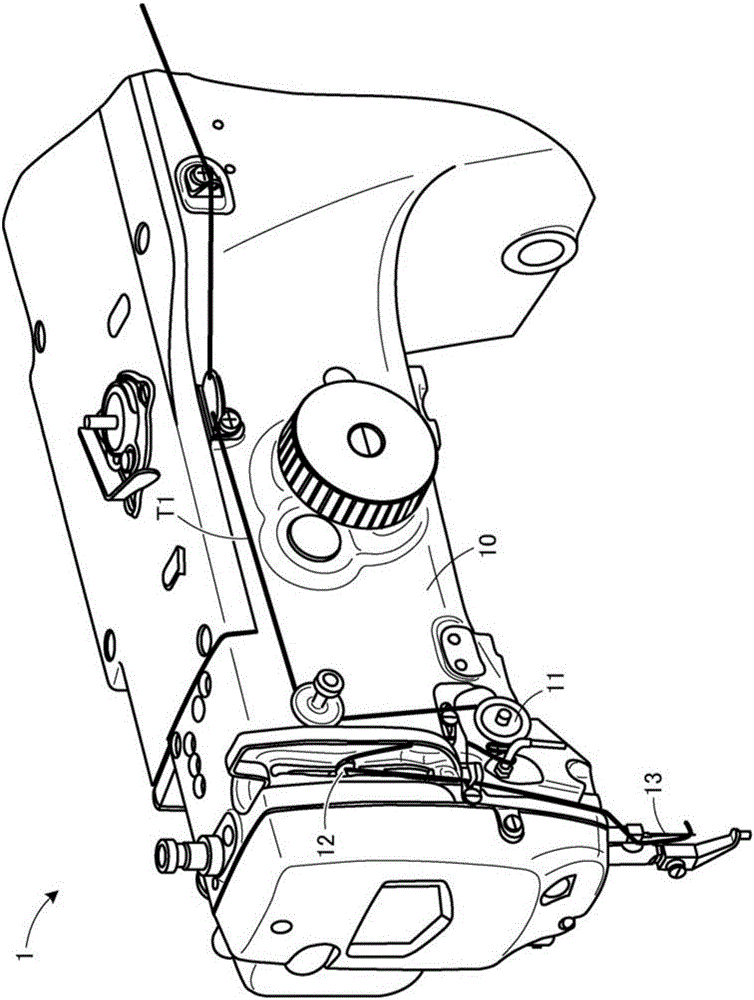

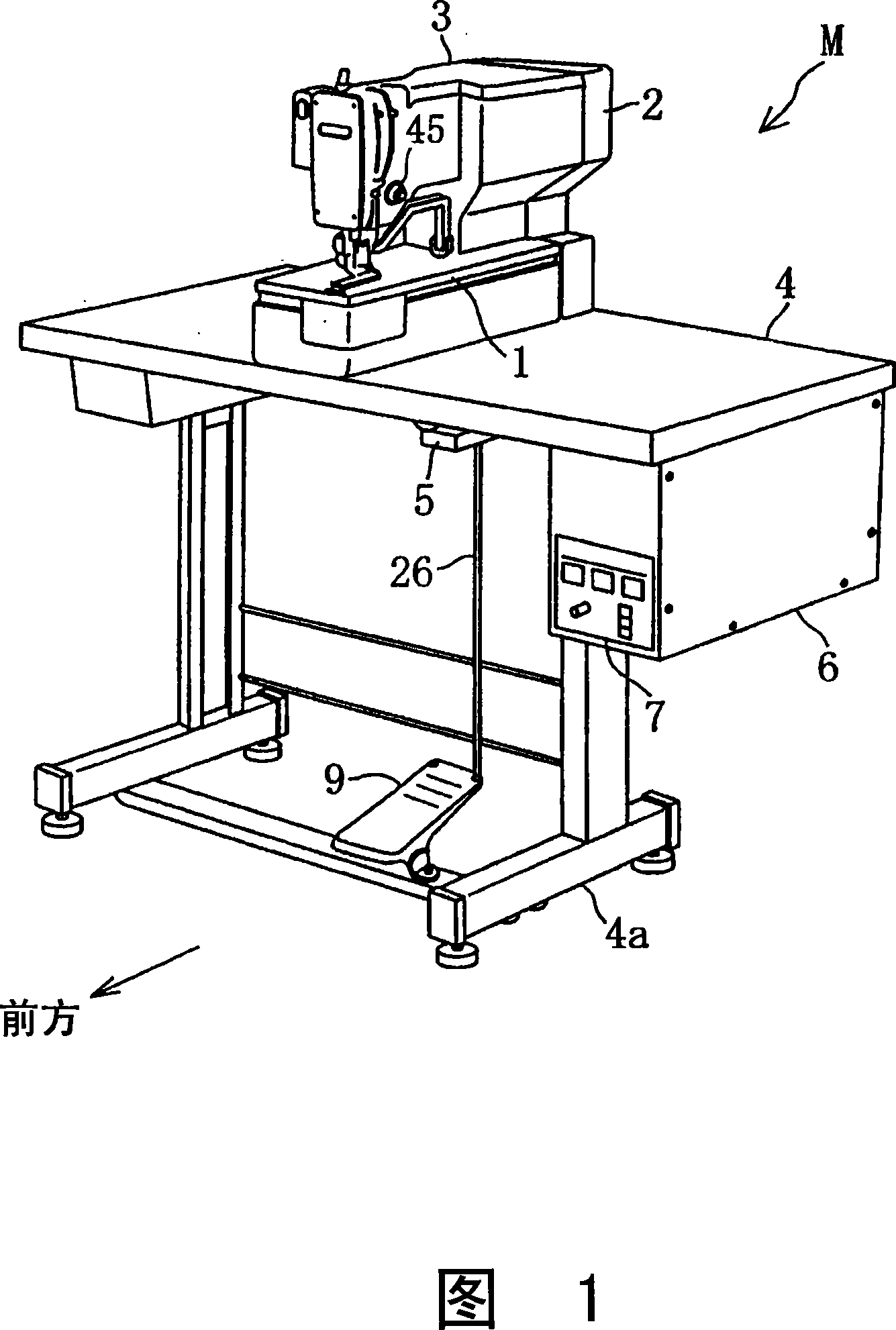

Thread adjusting device for sewing machine

InactiveCN101122071ASuppress feverEliminate operational interruptionsProgramme-controlled sewing machinesSewing-machine control devicesEngineeringStops device

A thread tension guide apparatus for a sewing machine is provided to inhibit the heat emission of a tension discharge actuator, thereby enhancing the efficiency of the sewing work. The thread tension guide apparatus comprises a tension releasing device. In the tension releasing device, an output shaft protruded by the operation of a tension releasing solenoid separates a pair of thread control dishes and releases the tension of the upper thread. In the thread control dish, the tension releasing device drives to the tension release state and thereafter the tension release state is maintained by a tension maintaining device. At the state that the tension releasing state is continuously maintained by the tension releasing device, a stop device stops the operation of the tension releasing solenoid. The tension maintaining device comprises a tension releasing actuator for switching a combination member. A control box(6) is installed at the lower right end of a sewing machine table(4).

Owner:BROTHER KOGYO KK

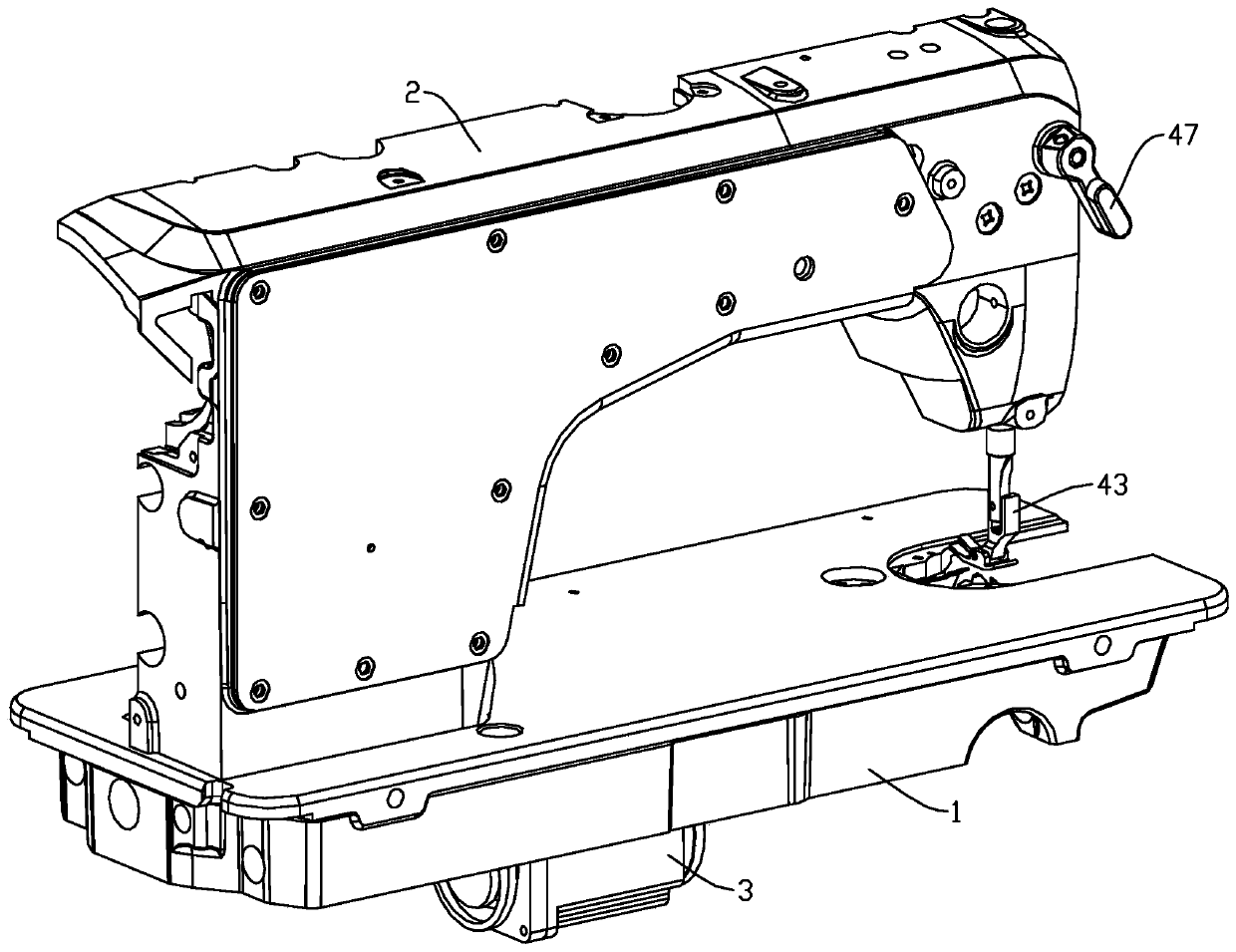

Industrial sewing machine

ActiveCN104141201ASuitable for sewingThe stitches are strong and beautifulProgramme-controlled sewing machinesNeedle severing devicesProgrammable logic controllerReciprocating motion

The invention belongs to the technical field of machinery and discloses an industrial sewing machine. A needle holder is driven to do vertical reciprocation by a swing rod and is driven to rotate around the needle holder axis by a needle holder rotation motor. A rotary hook and a hook carrier are mounted on a hook carrier assembly which comprises a shell, a rotary disc, a circular rotary seat, a belt pulley ring, a rotary hook motor, an assembly bearing and a slip ring. The rotary hook assembly is driven to do horizontal rotation by a rotary hook motor. Cloth to be sewn is clamped by a cloth feeding mechanism to do plane moving between the needle holder and the rotary hook. The needle holder rotation motor, the rotary hook carrier motor and the rotary hook motor are connected to a programmable logic controller on a table through the slip ring. The programmable logic controller drives the needle holder and the rotary hook carrier assembly to do rotation with same phase and same angular velocity. Products sewn by the industrial sewing machine have stable and firm stitches, and the industrial sewing machine is particularly suitable for sewing leather / cloth products in variable curved shapes.

Owner:广州明志电脑花样缝纫机械有限公司

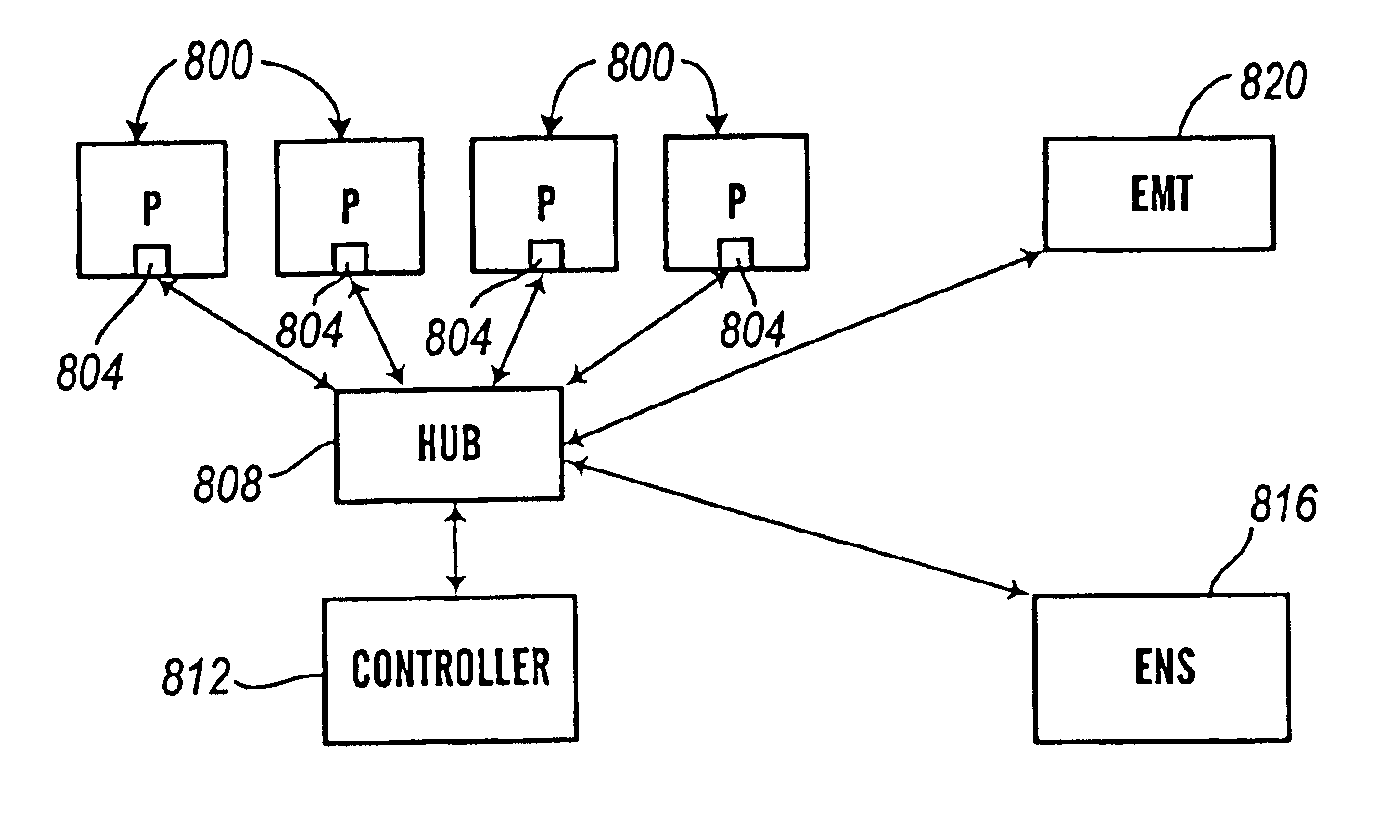

Computerized stitching including embroidering

InactiveUS6983192B2Reduce in quantityIncrease flexibilityProgramme-controlled sewing machinesCombination sewing machinesControl systemEngineering

A plurality of stitching machines and a control system used in stitching patterns into a plurality of items is capable of flexible control. The plurality of stitching machines may include one or more clusters of stitching machines, with each cluster able to stitch patterns into items independently of other clusters. Stitching machines within the plurality of stitching machines, or within the clusters of stitching machines, may be set to stitch patterns into items using one of a synchronized mode and an unsynchronized mode. When in the synchronized mode, the stitching machines perform stitching substantially synchronously with other stitching machines, and when in the unsynchronized mode the stitching machines perform stitching independently of the status of other stitching machines.

Owner:MELCO INT

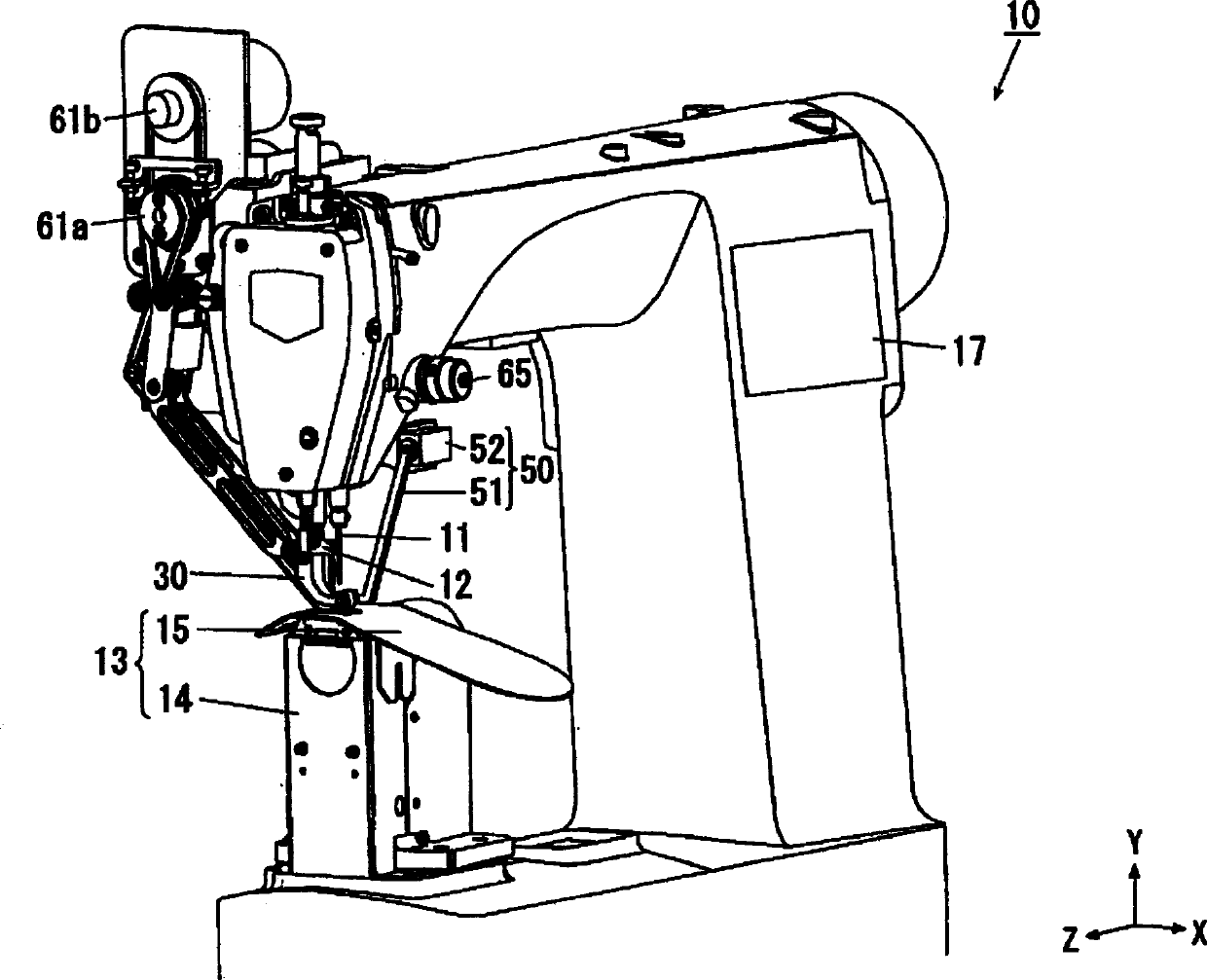

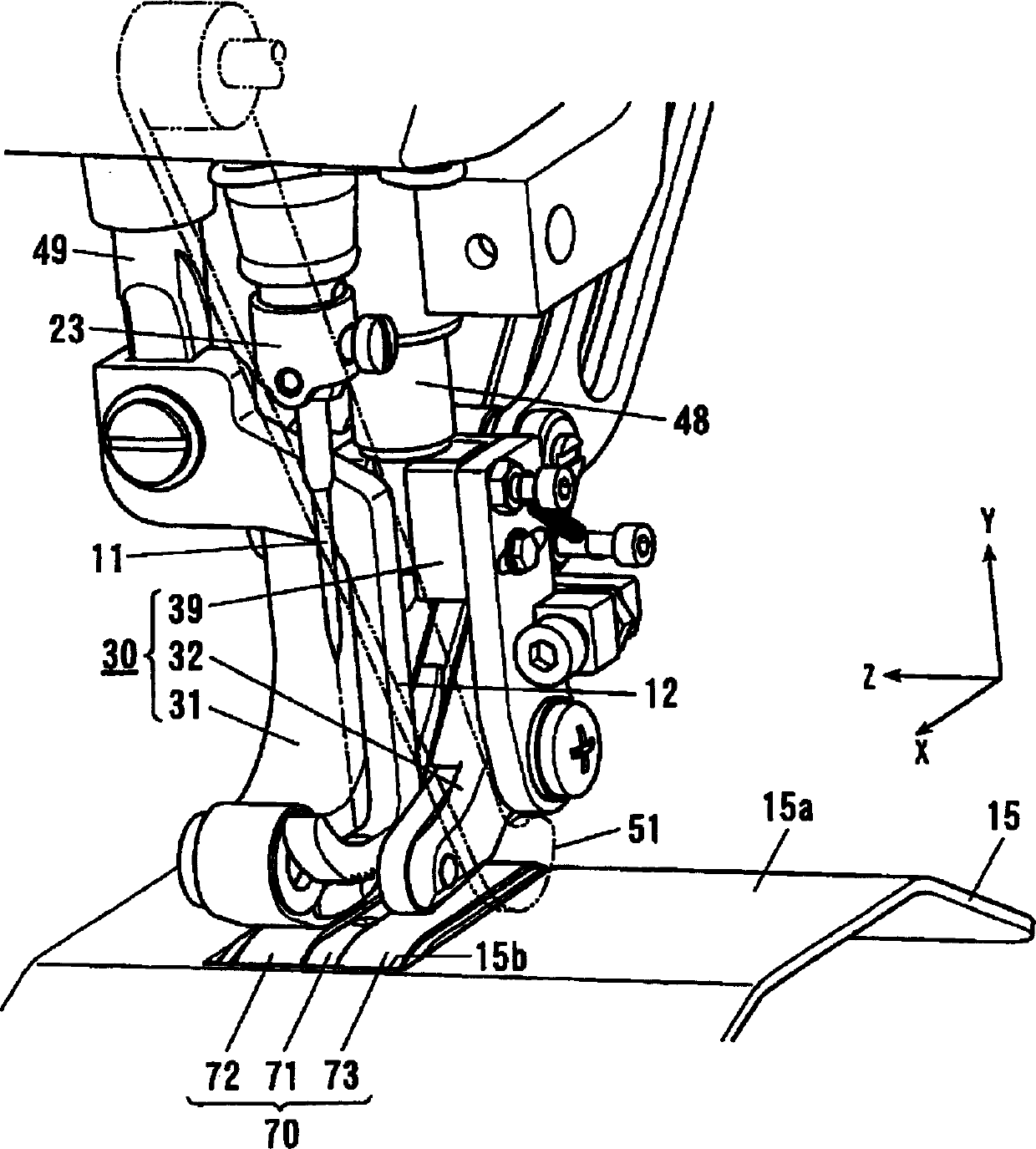

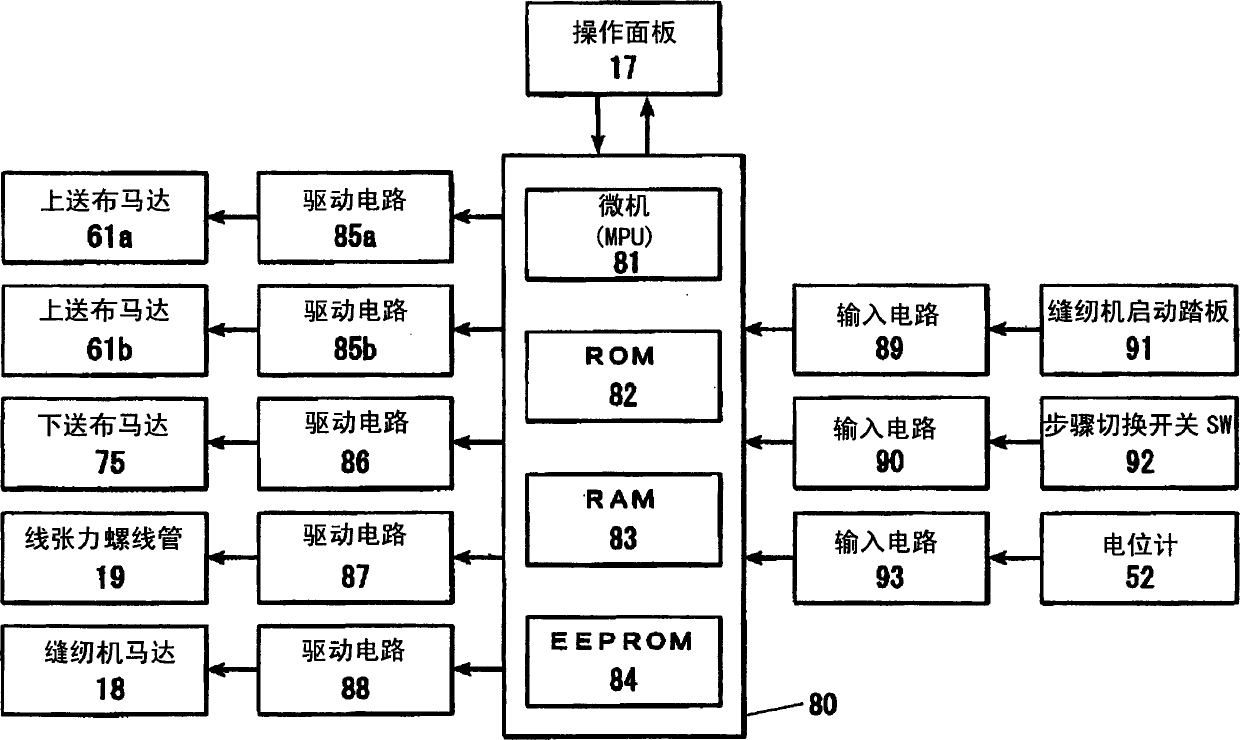

Up and down feeding cloth sewing machine

InactiveCN1782160AImprove sewing qualityThe amount of loose thread is correctProgramme-controlled sewing machinesWork-feeding meansSystem parametersElectrical and Electronics engineering

A sewing machine with top and bottom feeding, comprising: a cloth thickness detection mechanism (50) for detecting the thickness of an object to be sewn; a storage mechanism (84), which stores a plurality of sewing intervals and sewing intervals of each sewing interval; system-related parameters and switch the thickness of the sewing section; and an action control mechanism (80), which, when detecting the thickness of the sewn object in the switching sewing section by the cloth thickness detection mechanism, switches the sewing section, and uses The motion control of the control object is carried out by sewing with the parameters corresponding to each sewing section. This type of top and bottom feed sewing machine can perform sewing corresponding to changes in the thickness of the material.

Owner:JUKI CORP

Thread feed for a sewing machine

Owner:SINGER SOURCING LTD LLC

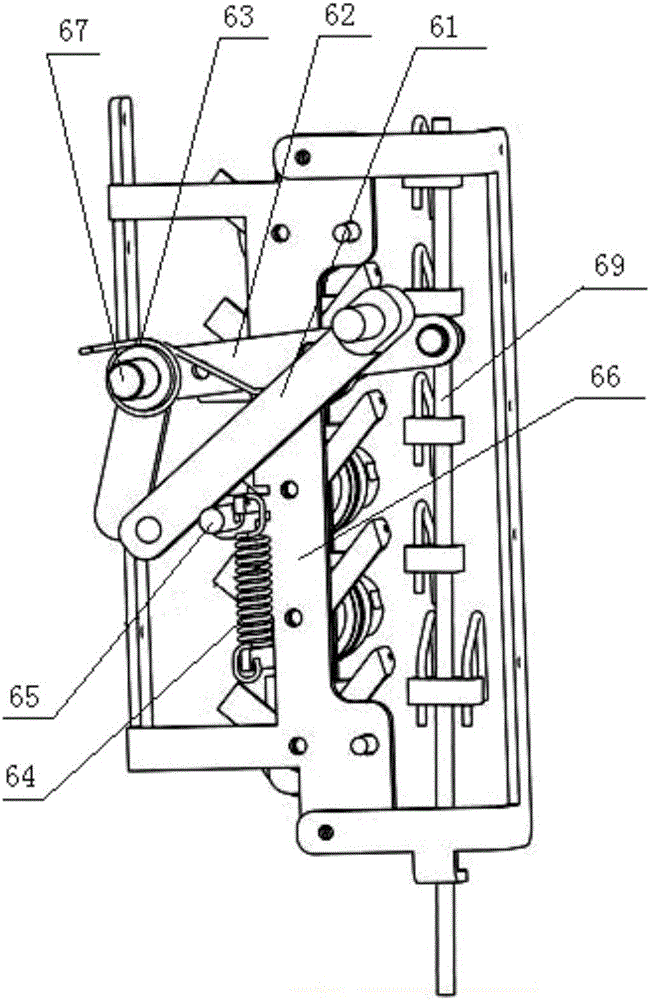

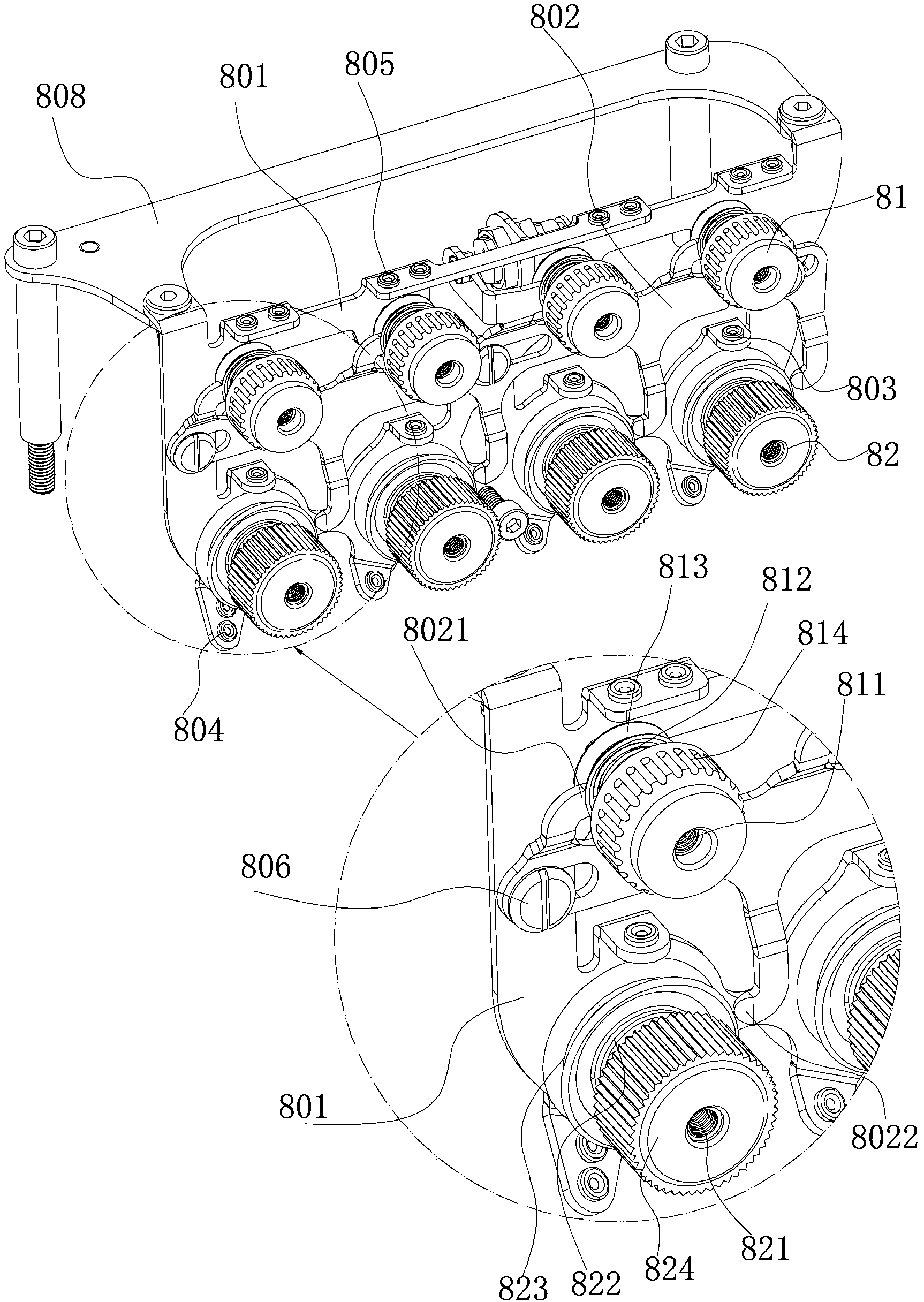

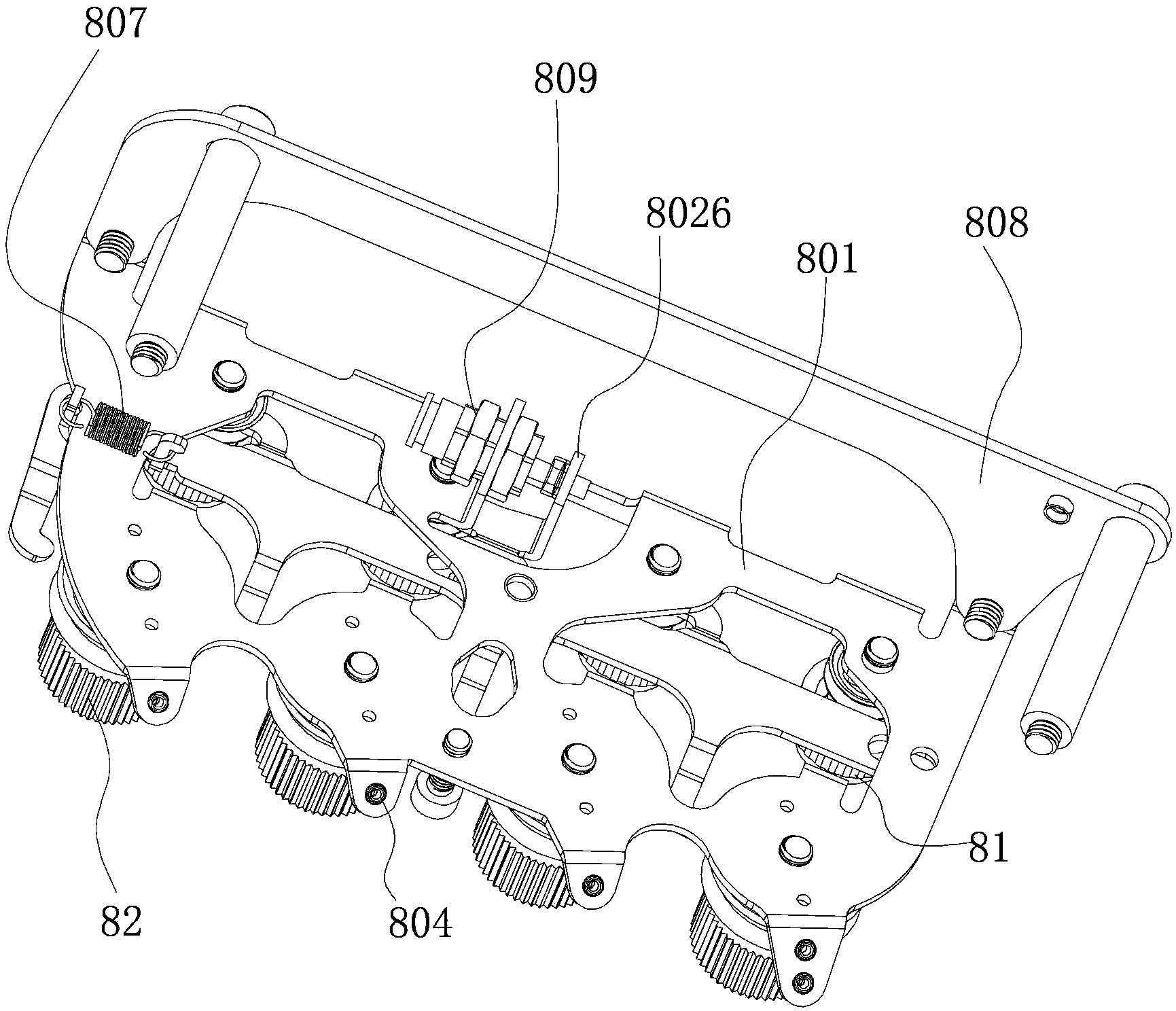

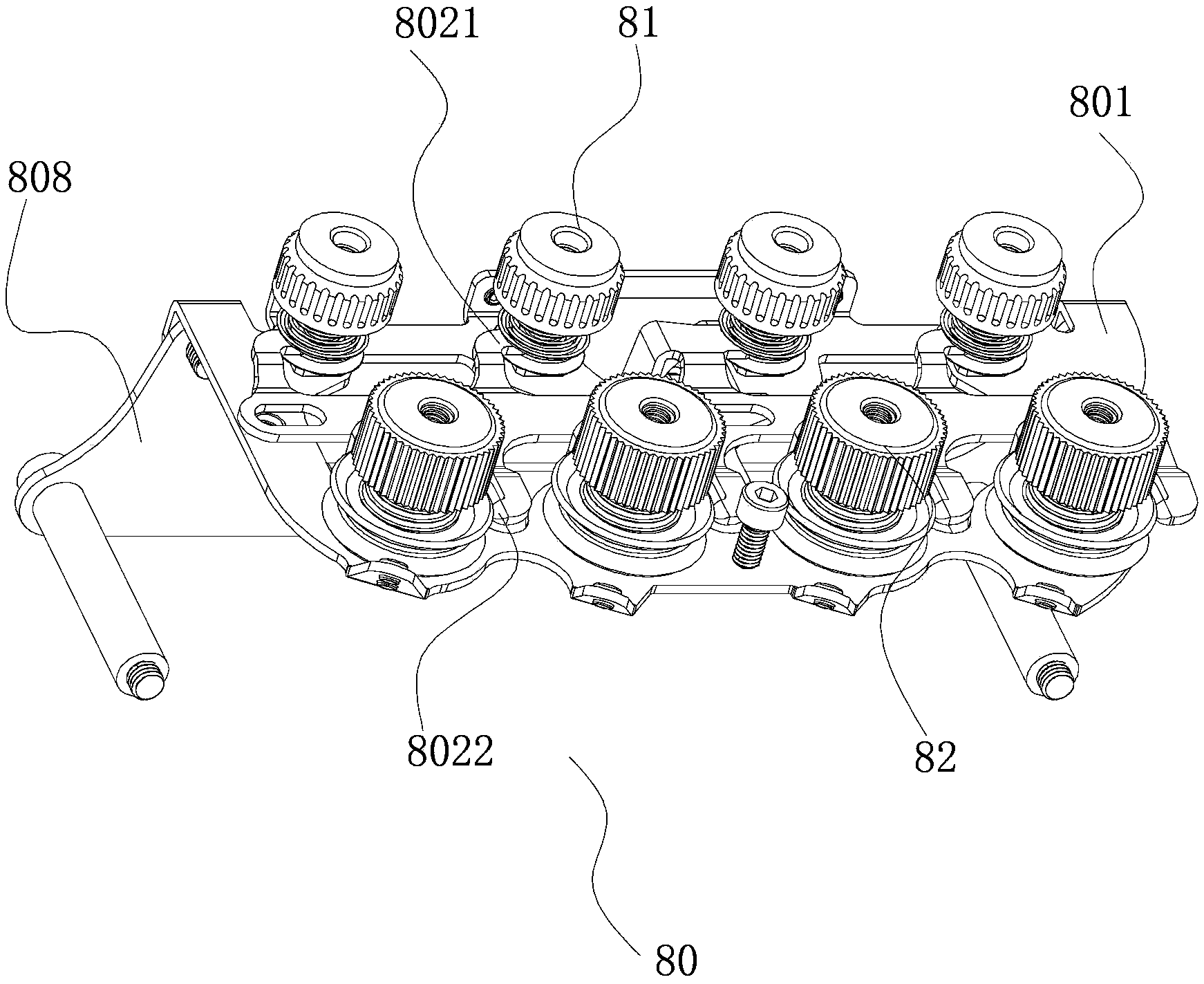

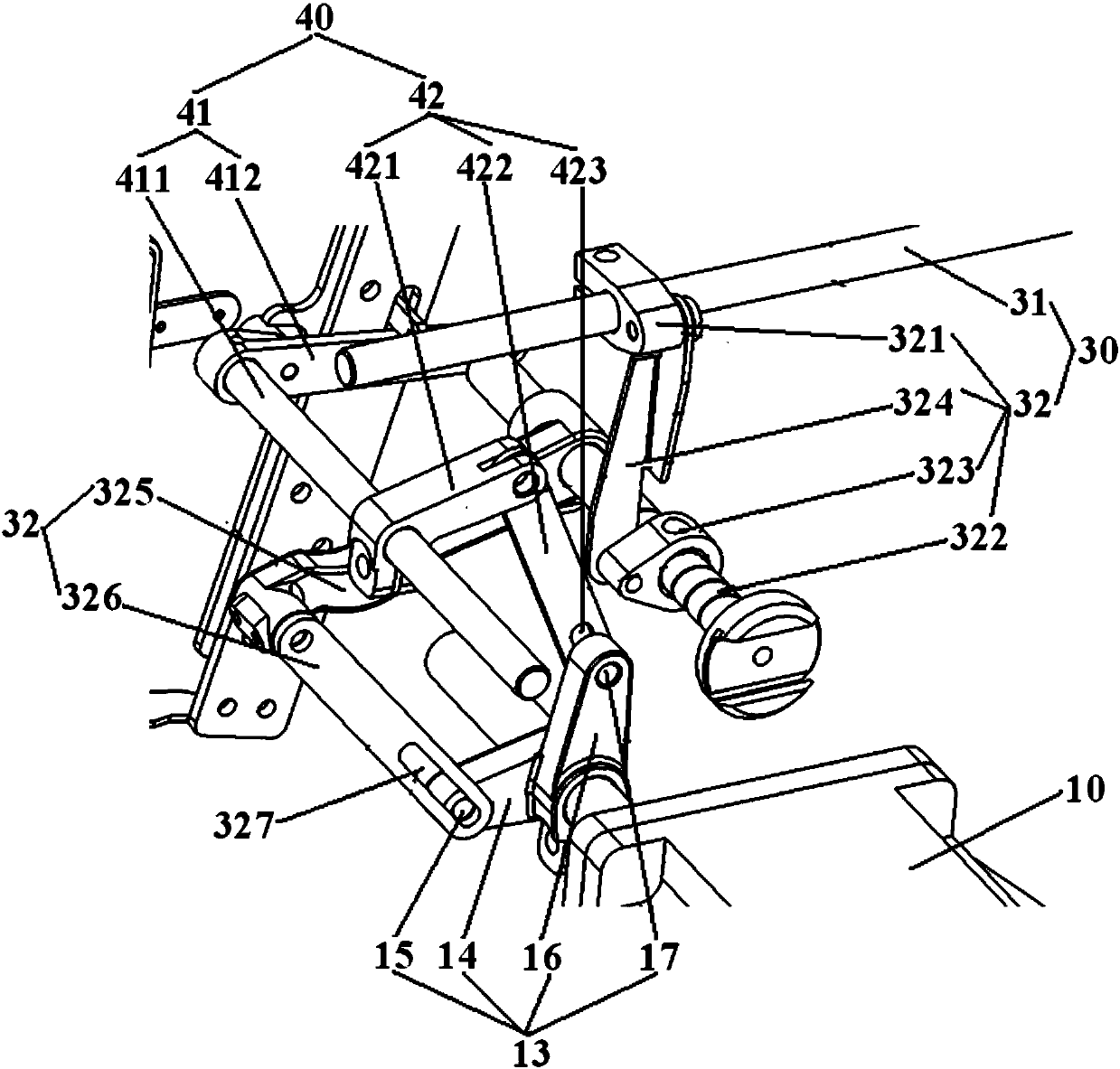

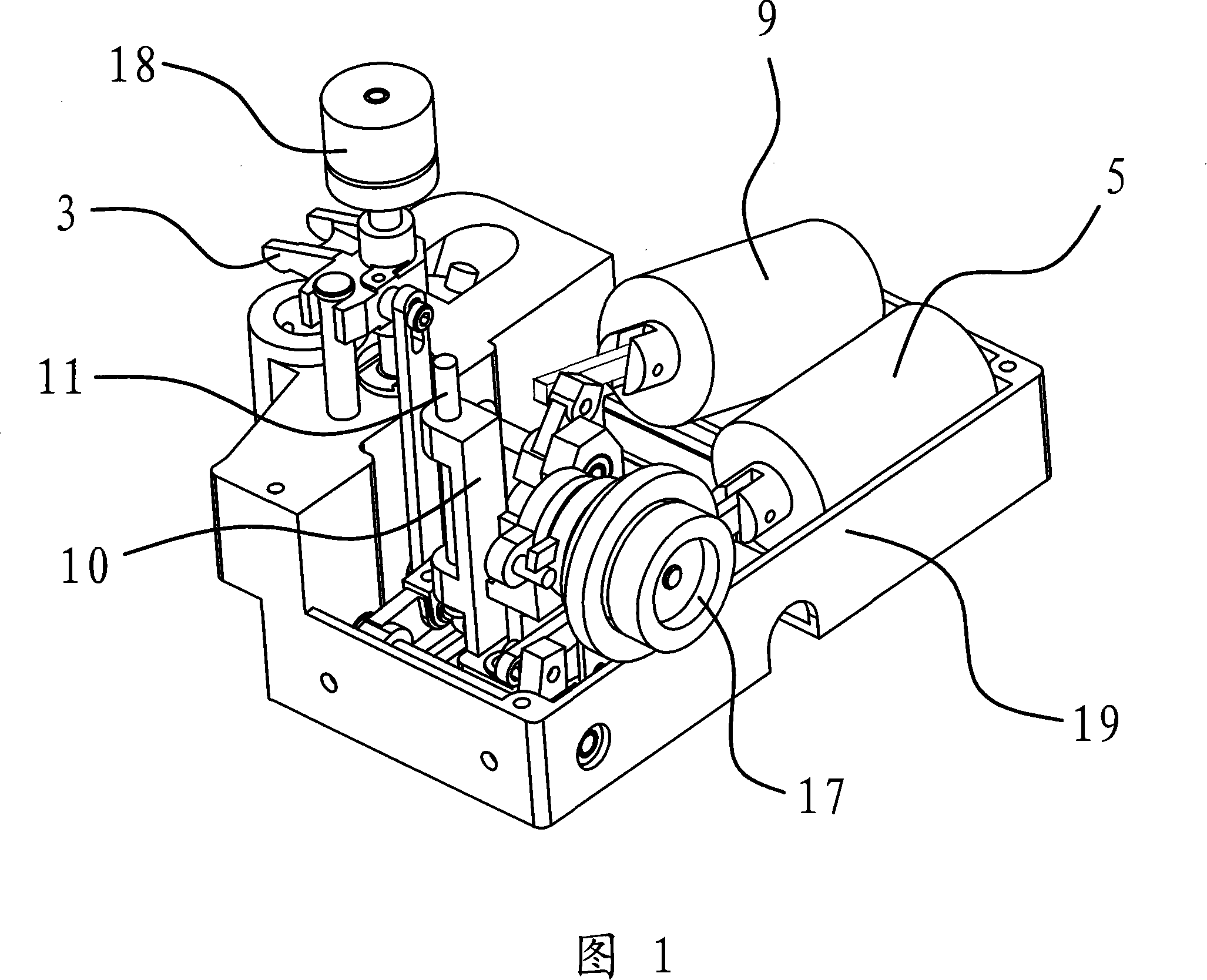

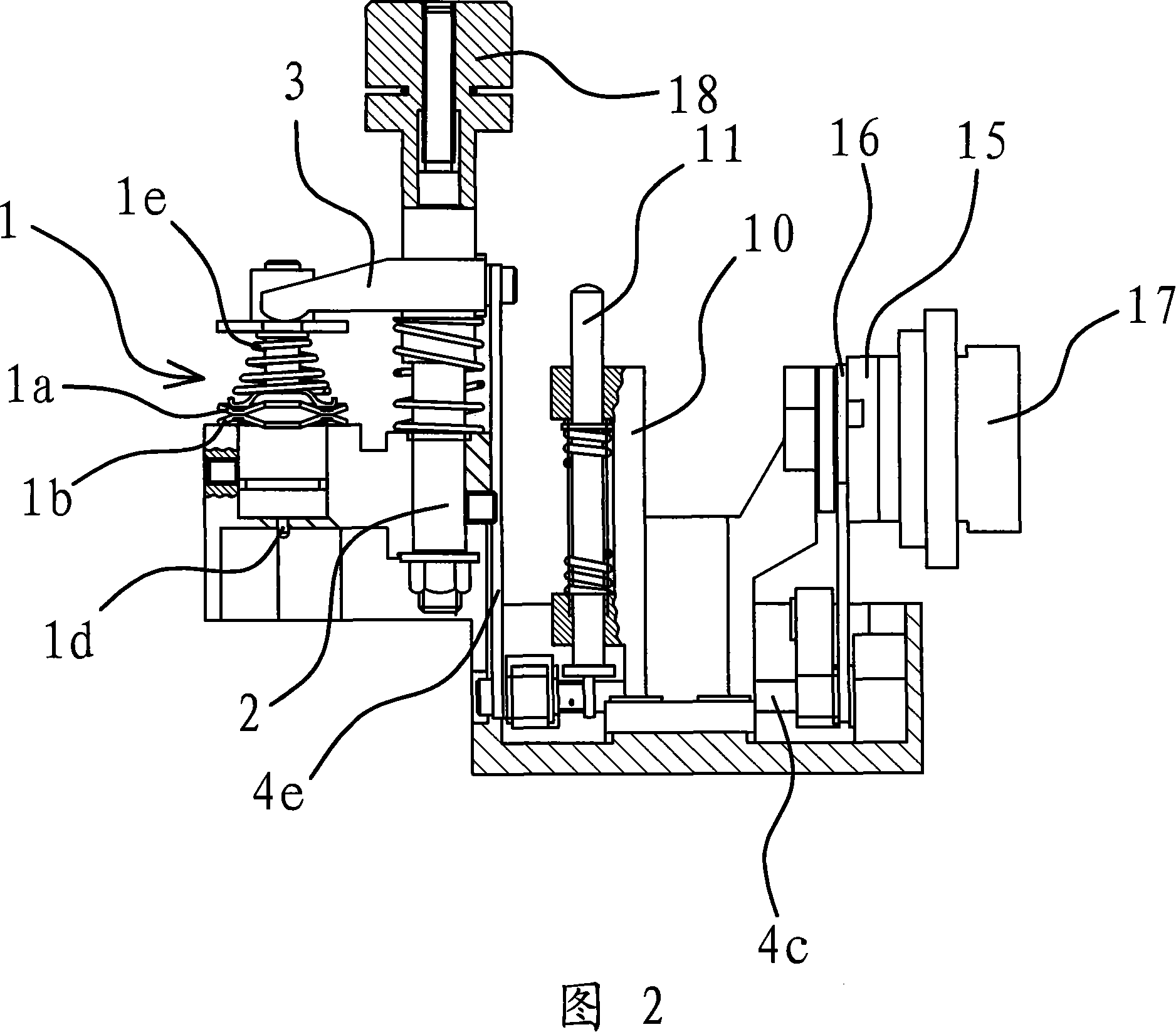

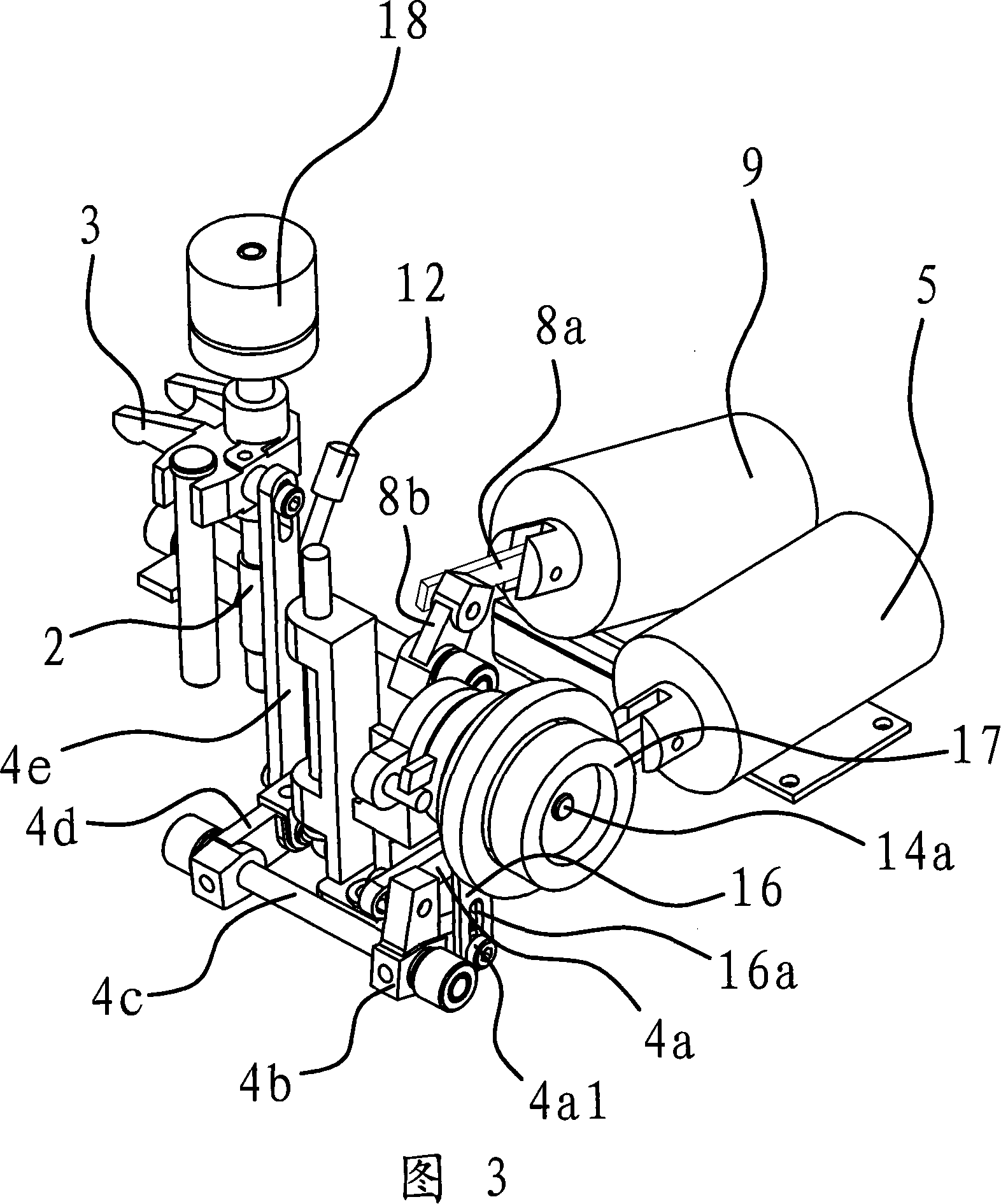

Thread trimming, thread loosening, presser foot lifting and presser foot pressure adjusting device of sewing machine and sewing machine

ActiveCN110983644ASimple structureCompact structureNeedle severing devicesSewing-machine control devicesCrankEngineering

The invention relates to the technical field of sewing machines, in particular to a thread trimming, thread loosening, presser foot lifting and presser foot pressure adjusting device of a sewing machine and the sewing machine comprising the device. The device comprises a power piece, a cam structure, a thread trimming driving crank connected with a thread trimming mechanism and an ejector rod connected with a thread loosening mechanism, a presser foot lifting mechanism and a presser foot pressure adjusting mechanism, a first transmission pin on the thread trimming driving crank is matched witha first driving contour face of the cam structure, and the first driving contour face is provided with a thread trimming driving section for driving the thread trimming mechanism to execute thread trimming action; and a second transmission pin on the ejector rod is matched with a second driving contour face of the cam structure, and the second driving contour face is provided with a thread loosening driving section for driving the thread loosening mechanism to execute thread loosening action, a presser foot lifting driving section for driving the presser foot lifting mechanism to execute presser foot lifting action and a presser foot pressure adjusting driving section for driving the presser foot pressure adjusting mechanism to execute presser foot pressure adjusting action. The four functions of thread trimming, thread loosening, presser foot lifting and presser foot pressure adjusting are achieved through the driving of one power piece.

Owner:JACK SEWING MASCH CO LTD

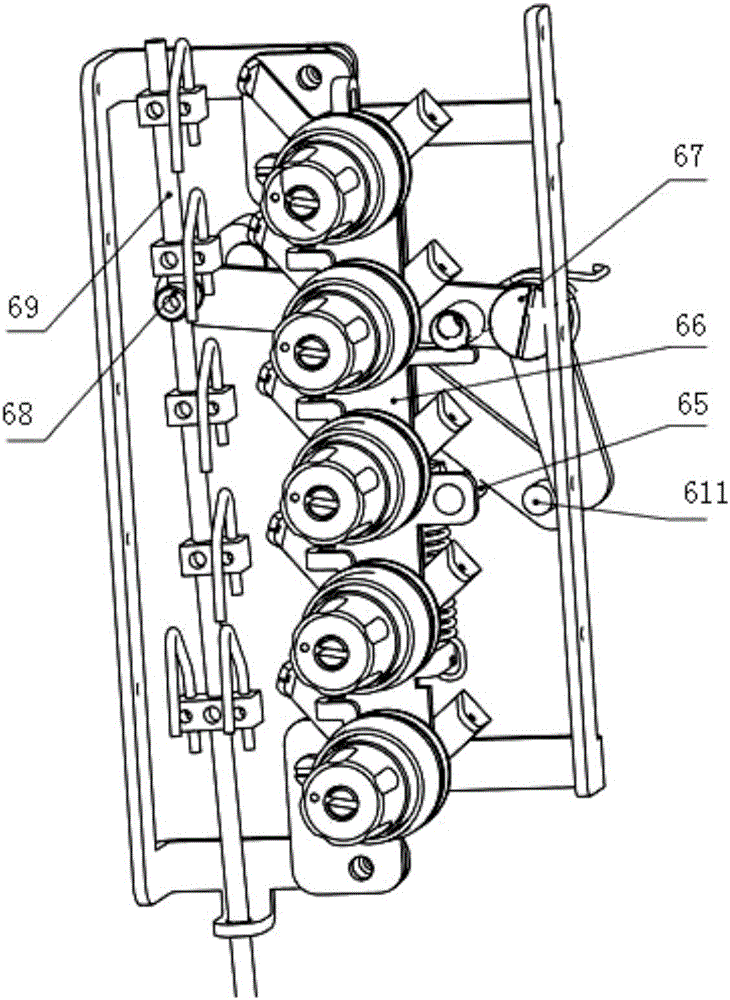

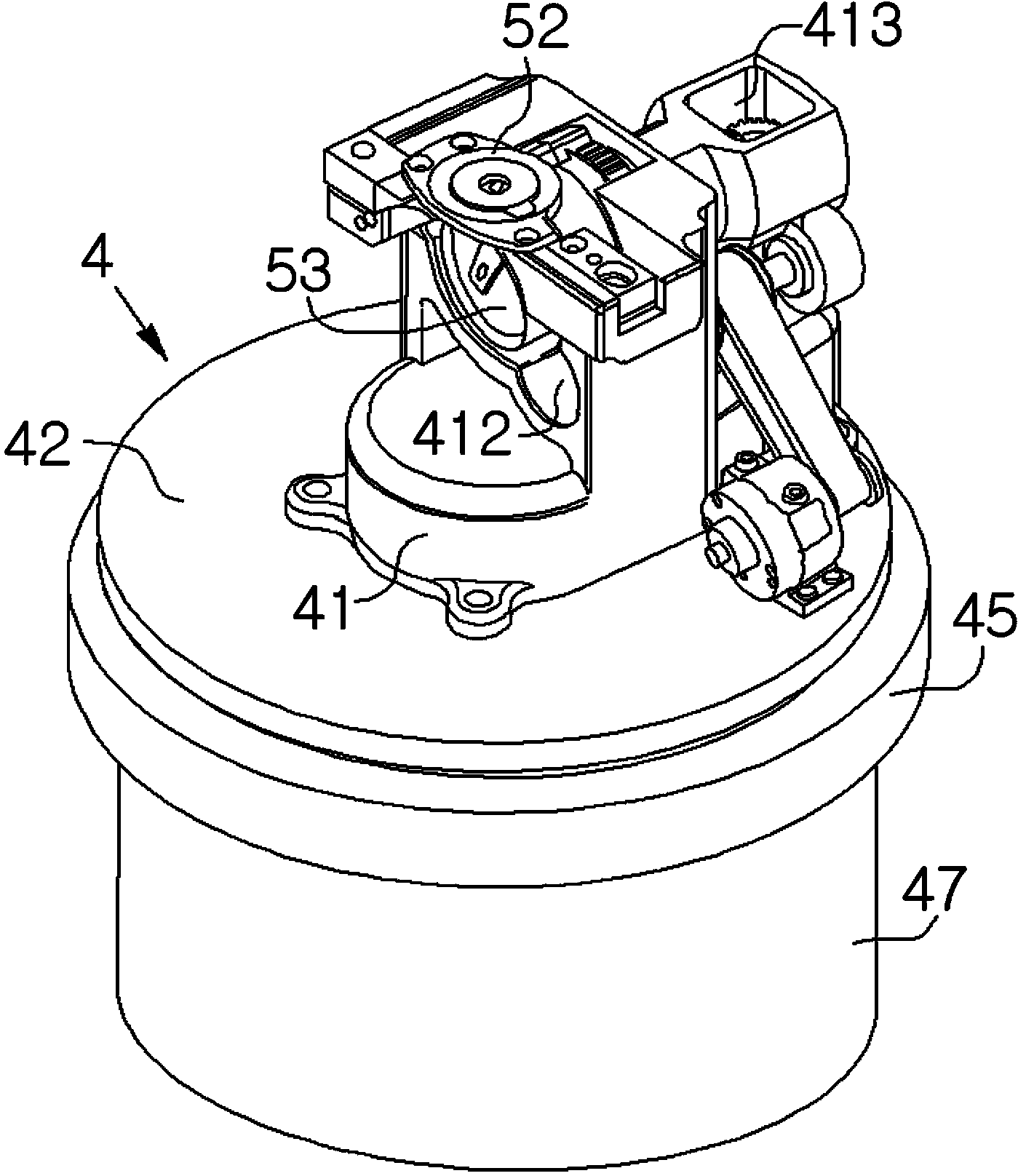

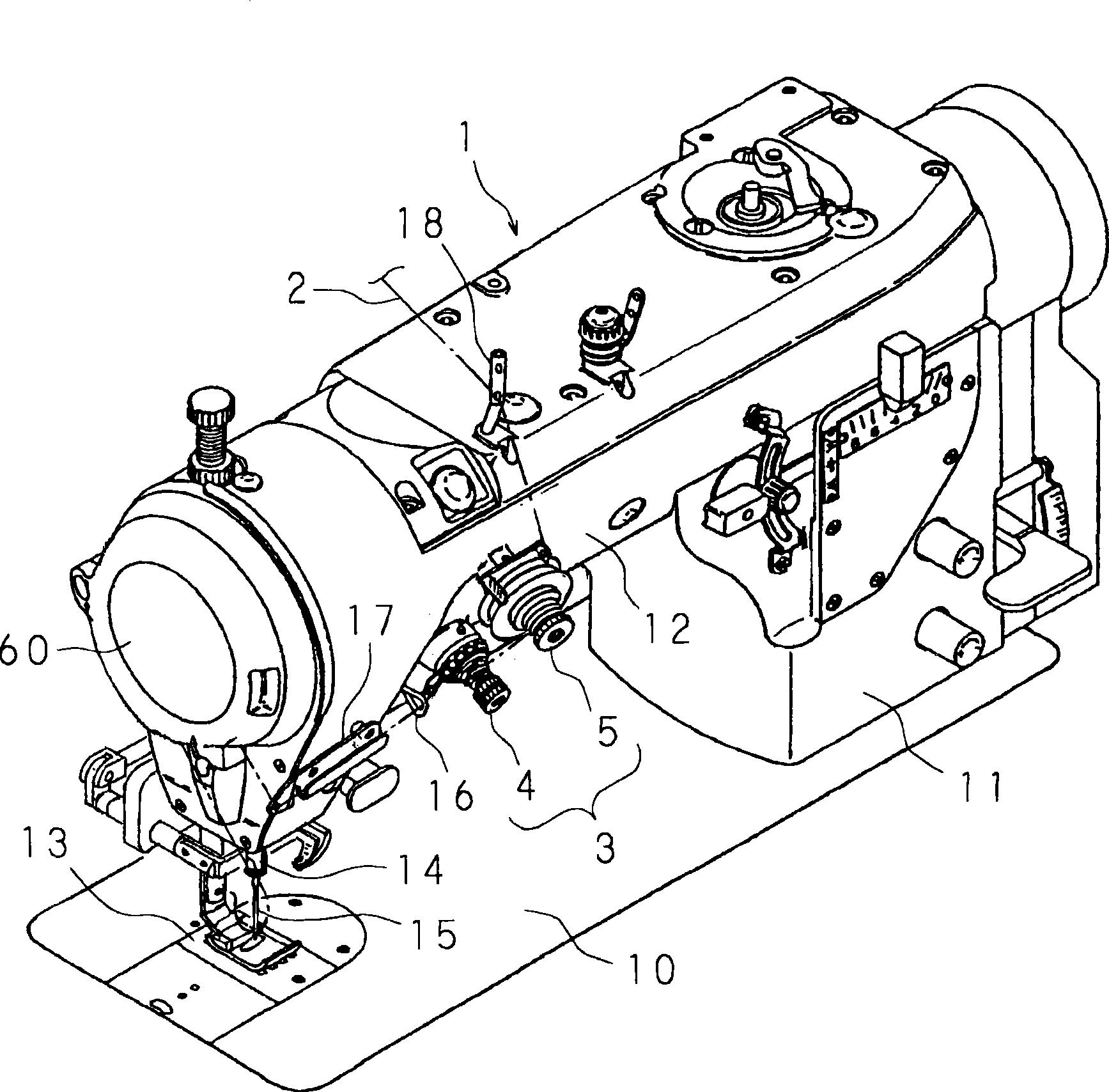

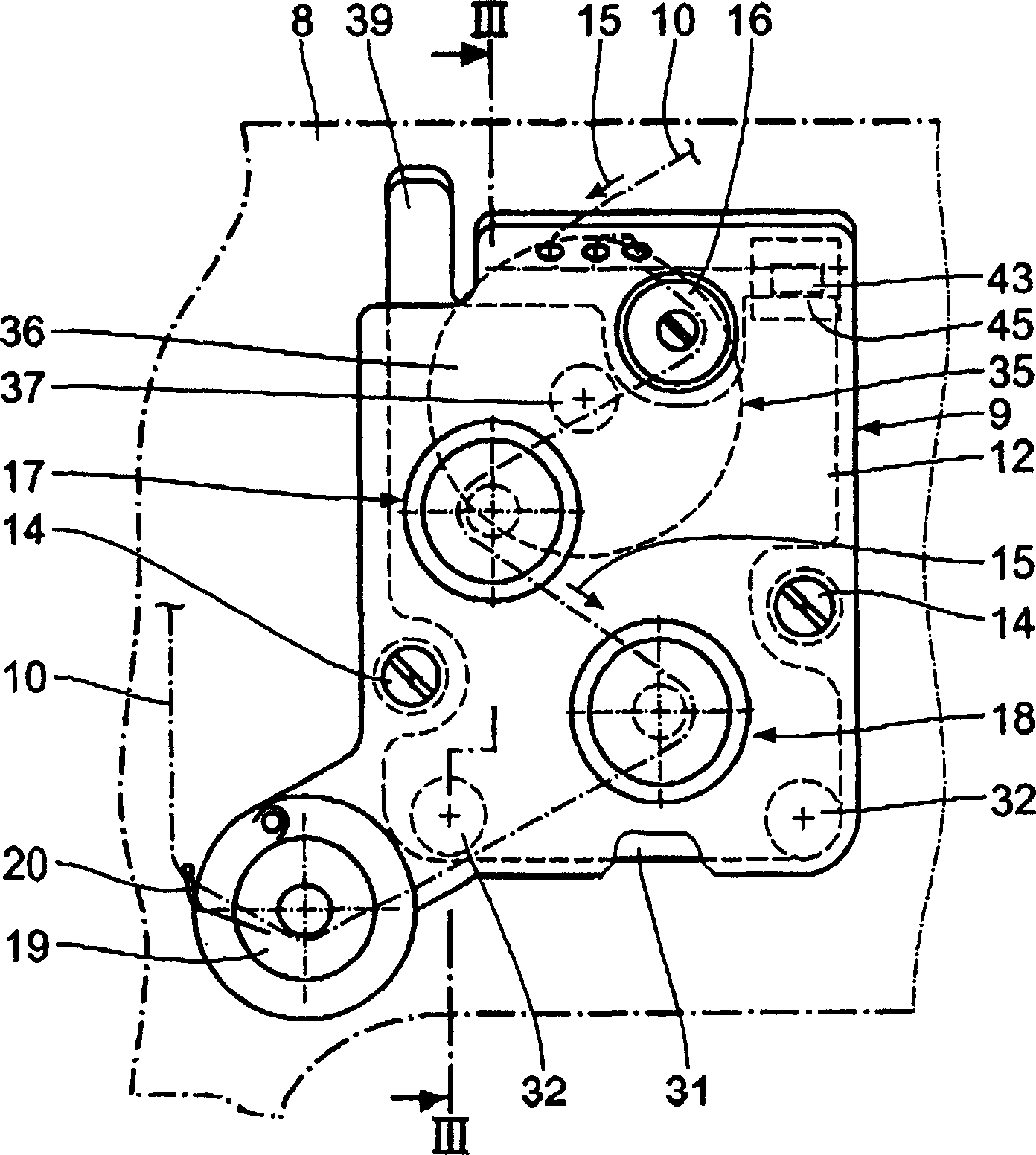

Thread adjusting device of sewing machine

InactiveCN101372796AStable tensionCircumference difference achievedSewing-machine control devicesTensioning devicesCotton materialSewing machine

This invention provides a thread adjusting device of sewing machine, which is capable of stably giving minute tension to the top thread provided to the needle through a balance, and is capable of sewing thin cloth, soft cloth with good quality but without generating stitch defect. The thread adjusting device comprises an auxiliary thread adjusting device for giving preparation tension to the top thread provided to a rotation resistance main thread adjusting device (4), including: a rotary cylinder (51) that winds and keeps several rings top threads in the peripheral width direction in a spaced way, an extruding spring (53) applying thrust to the rotary cylinder (51) and a regulating knob that adjusts the spring of the extruding spring (53). In addition, a guide groove is formed in a thread passage component (8) extending in the width direction of the rotation cylinder (41). The top thread (2) wound on the rotation cylinder (51) is hanged in the guide groove. The perimeter of the top thread (2) is gradually shortened from the thread supply source to the main thread adjusting device (4).

Owner:YAMATO SEWING MASCH MFG CO LTD

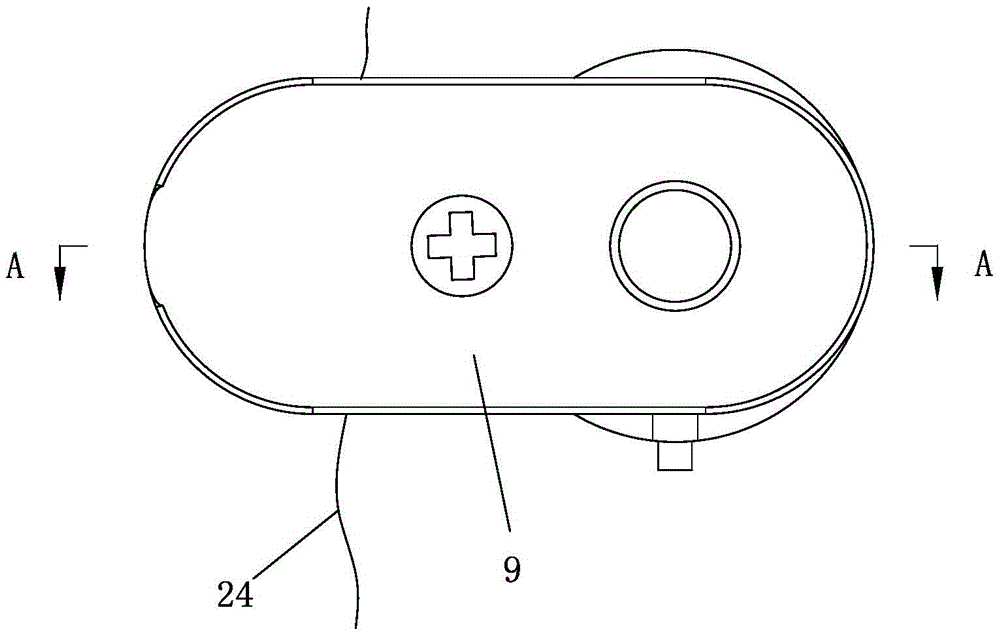

Sewing control system and sewing equipment

ActiveCN103451865ACentralized controlCompact structureNeedle severing devicesSewing-machine control devicesBrushless motorsMotor drive

The invention discloses a sewing control system and sewing equipment. The sewing control system comprises a permanent-magnetic brushless motor, a motor driving circuit, a controller, a power supply circuit, a control panel and a cloth infrared sensor, wherein the motor driving circuit is electrically connected with the permanent-magnetic brushless motor; the controller is electrically connected with the motor driving circuit; the power supply circuit, the control panel and the cloth infrared sensor are electrically connected with the controller. In the sewing control system, each control action on sewing equipment and brushless driving of the permanent-magnetic motor are realized by adopting the same controller, so that the control of the sewing equipment is more concentrated, the structure is more compact, and the production cost is reduced. The sewing equipment disclosed by the invention is simple in structure, is easy to produce and install, and is easy for realizing automatic control and maintenance; an independent thread cutting device is adopted, so that separate thread cutting control can be realized, power loss is reduced in comparison to the conventional thread cutting device, and noise can be lowered.

Owner:SHENZHEN YANO TECH

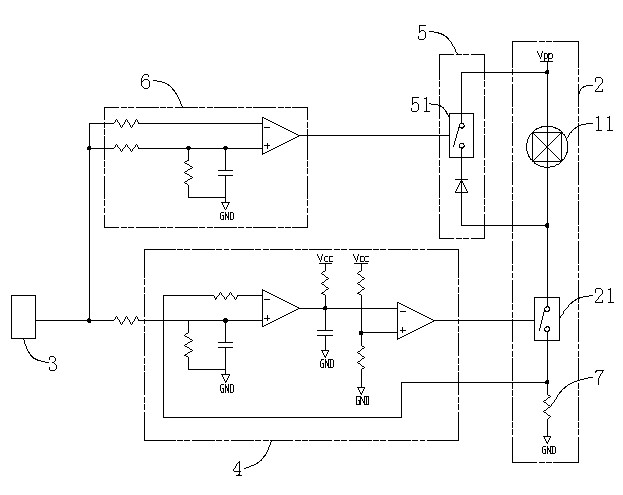

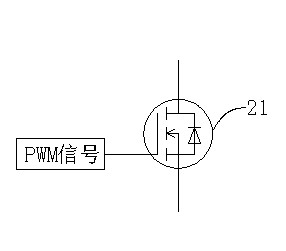

Yarn trapper for sewing machine

InactiveCN102634938AExtended service lifeTemperature controlSewing-machine control devicesTensioning devicesYarnSoftware engineering

The invention discloses a yarn trapper for a sewing machine. The yarn trapper comprises an electromagnet used for driving a yarn trapping disc to trap a yarn and a control circuit for driving the electromagnet to act; the control circuit is provided with a driving circuit connected with a coil in the electromagnet in design; the driving circuit is connected with a driving switch module for controlling the transient on or transient off of the current of the coil; and when the yarn trapping disc is used for trapping a yarn, the driving switch module controls the driving force of the electromagnet by controlling the ratio of the transient on current to the transient off current in the coil. When the ratio of the transient on current to the transient off current in the coil is high, the trapping force of the yarn trapping disc is large. When the ratio of the transient on current to the transient off current in the coil is small, the trapping force of the yarn trapping disc is small. In addition, the adjustment manner in such a way is convenient for effectively controlling the temperature of the coil when the electromagnet works and can be used for preventing the temperature of the coil from being overhigh, and prolonging the service life of the yarn trapper.

Owner:NINGBO SUPREME ELECTRONIC MASCH INC

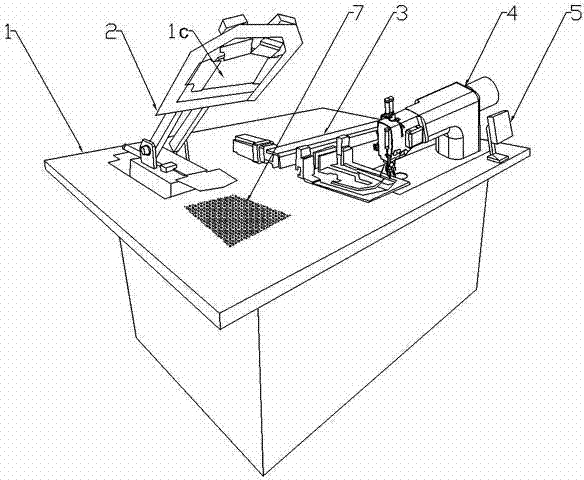

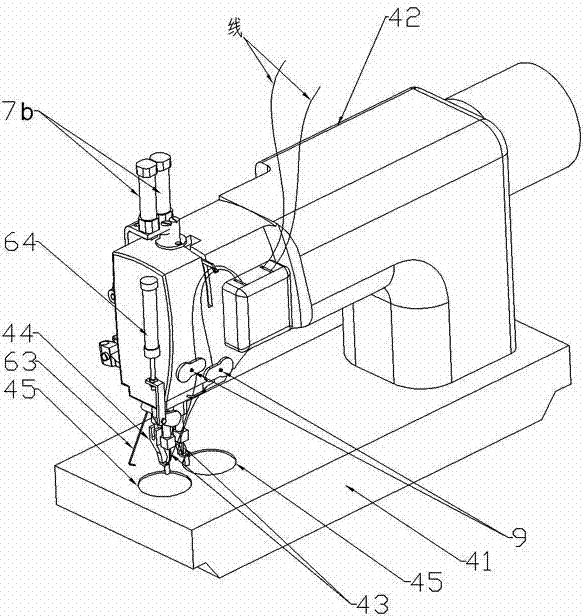

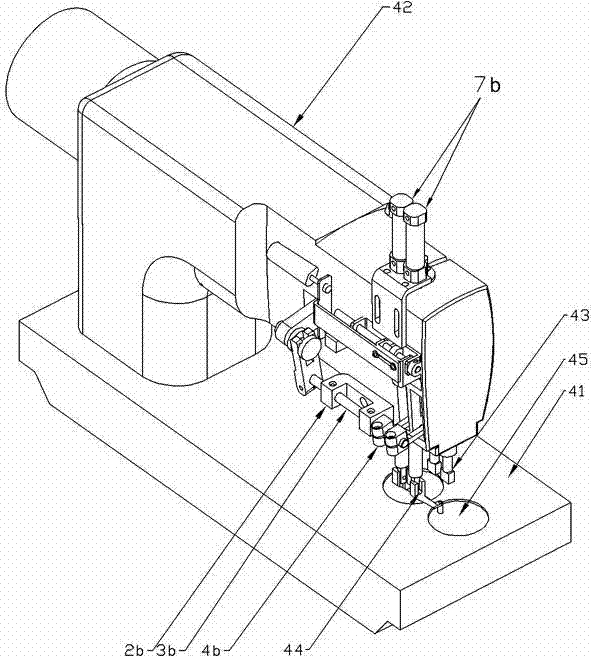

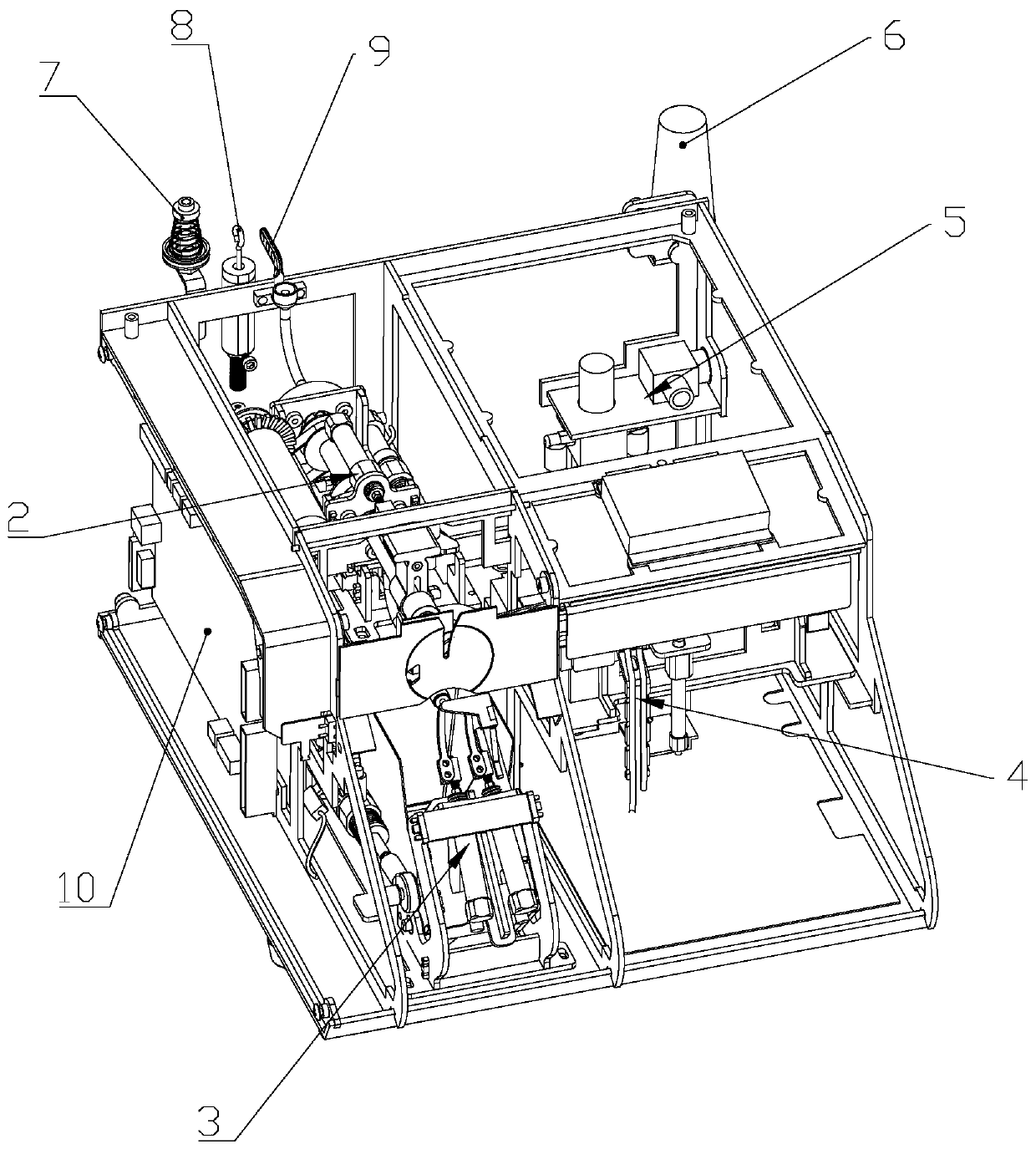

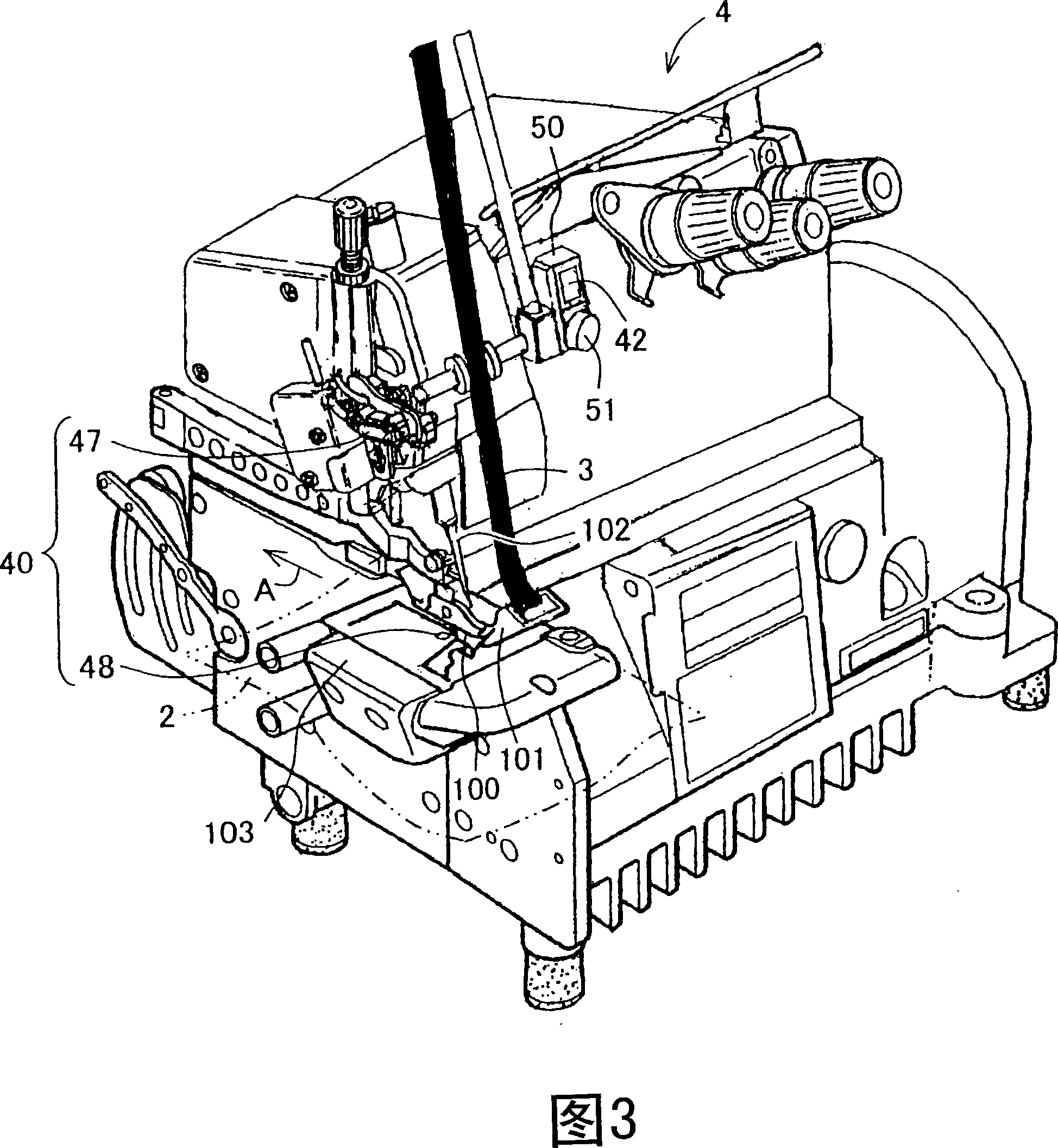

Full-automatic pocket patching machine

ActiveCN104746243ASo as not to damageSolve the contradiction between supply and demandWork-feeding meansPressersEngineeringFully automated

The invention discloses a full-automatic pocket patching machine and accordingly the working efficiency is high, the degree of automation is high, and sewn finished products comprise double sides and multiple colors. The full-automatic pocket patching machine comprises a base station (1) and a material folding mechanism (2), a feeding mechanism (3), a sewing mechanism (4) and a controller (5) which are arranged on the base station (1); the sewing mechanism (4) comprises a sewing table, a head, at least two working needles, a plurality of pressing feet, an automatic needle replacement module and a pressing foot lifting mechanism; the working needles are arranged on the head; the pressing feet are matched with the working needles respectively; the pressing foot lifting mechanism is matched with the pressing feet; the sewing table is provided with at least two spindles which are matched with the working needles respectively. The full-automatic pocket patching machine is applied to the technical field of automatic sewing equipment.

Owner:深圳市达益信智能设备有限公司

Sewing drive structure and sewing machine provided with same

PendingCN109957893ASolve complex structuresWork-feeding meansNeedle severing devicesYarnElectric machinery

The invention provides a sewing drive structure and a sewing machine provided with same. The sewing drive structure comprises a drive motor, a trimming mechanism, a presser foot lifting mechanism anda thread slacking mechanism, wherein the drive motor is separately connected with the trimming mechanism, the presser foot lifting mechanism and the thread slacking mechanism so as to drive the trimming mechanism, the presser foot lifting mechanism and the thread slacking mechanism to operate separately. Therefore, a movable cutter, a yarn trapper and a presser foot can be driven at the same timeby means of the one motor. The problem that in the prior art, the sewing machine adopts two independent devices to drive the movable cutter, the yarn trapper and the presser foot respectively, so thatthe overall structure of the sewing machine is complicated is solved.

Owner:ZHEJIANG ZOJE SEWING MACHINE

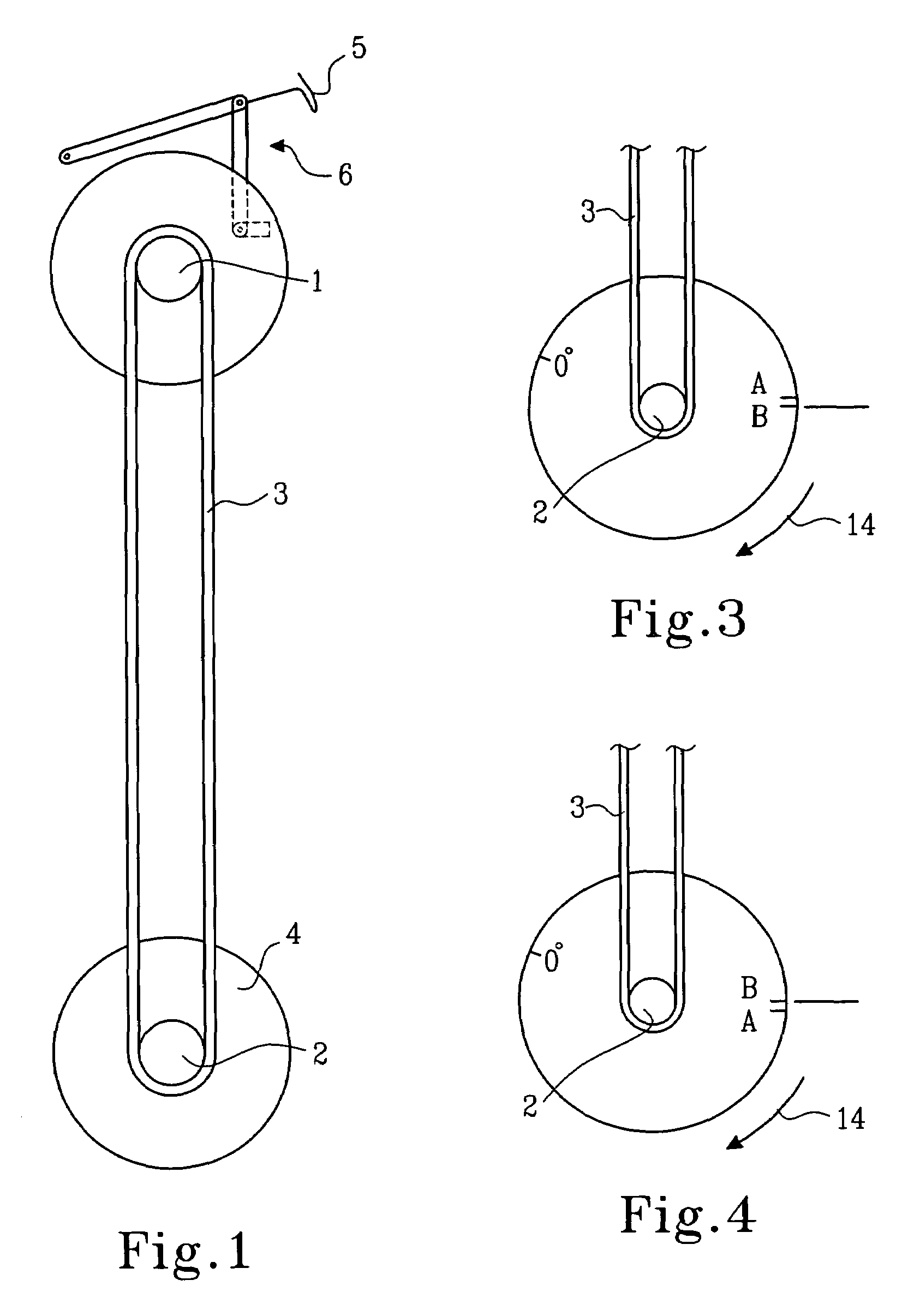

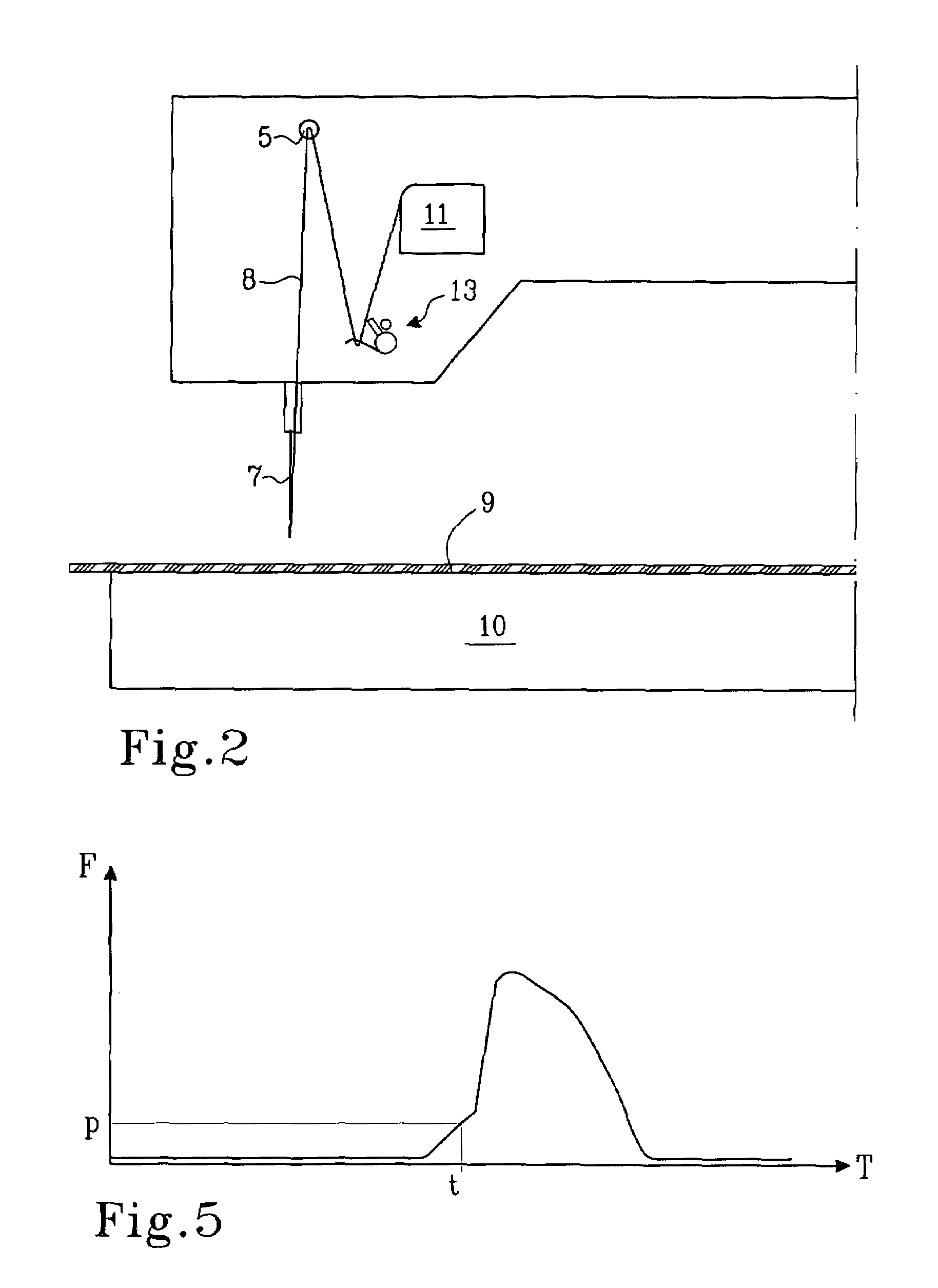

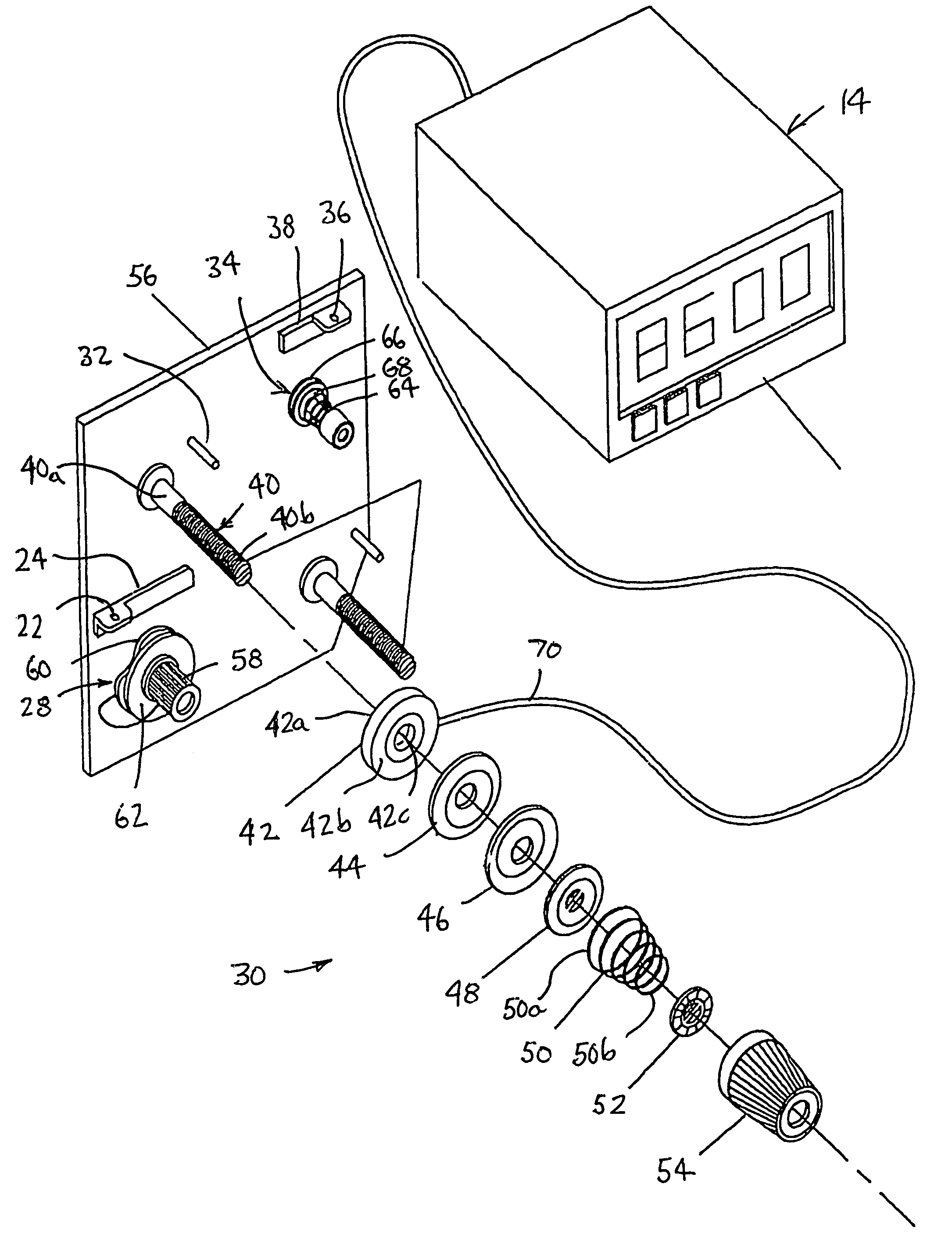

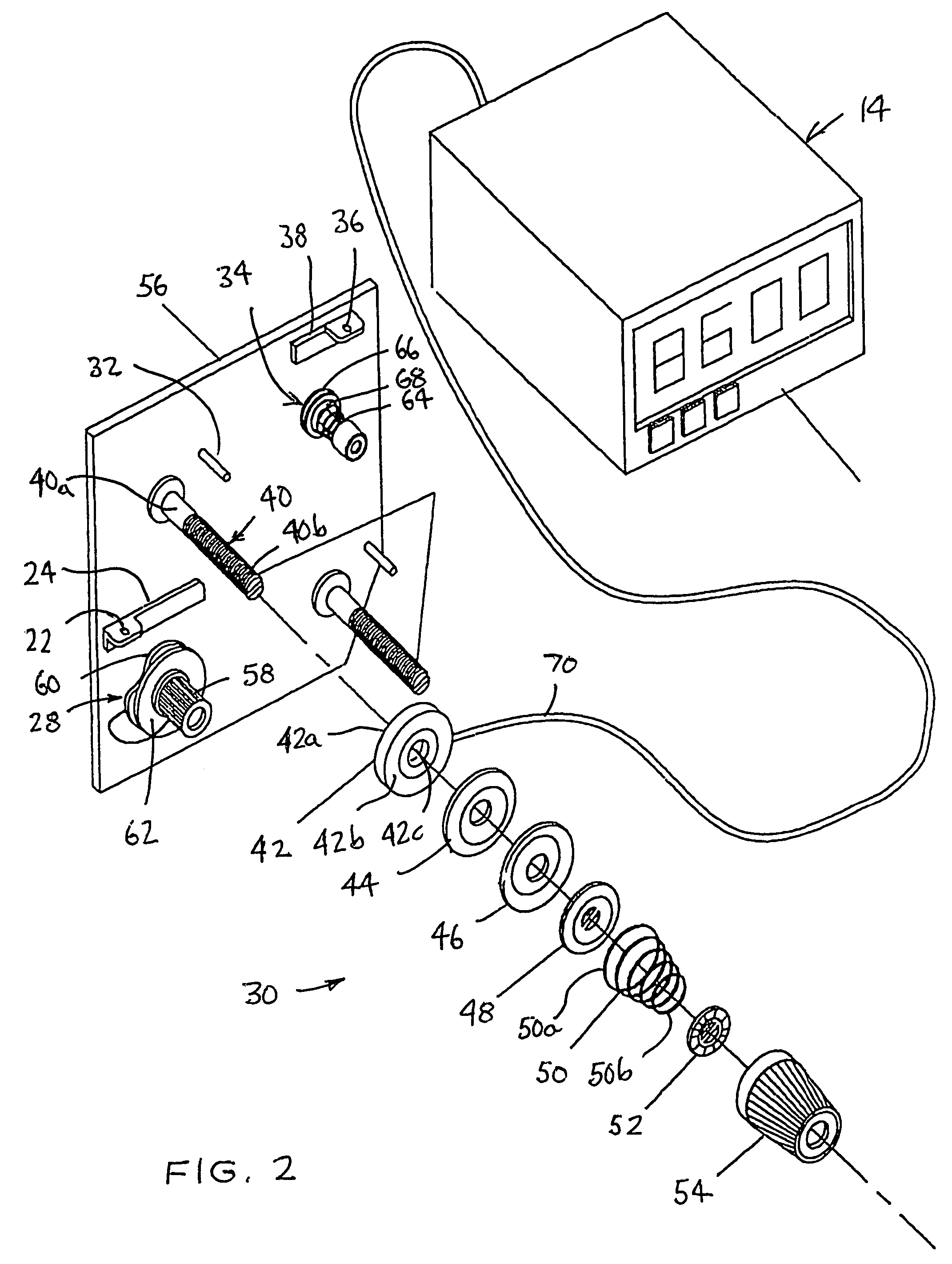

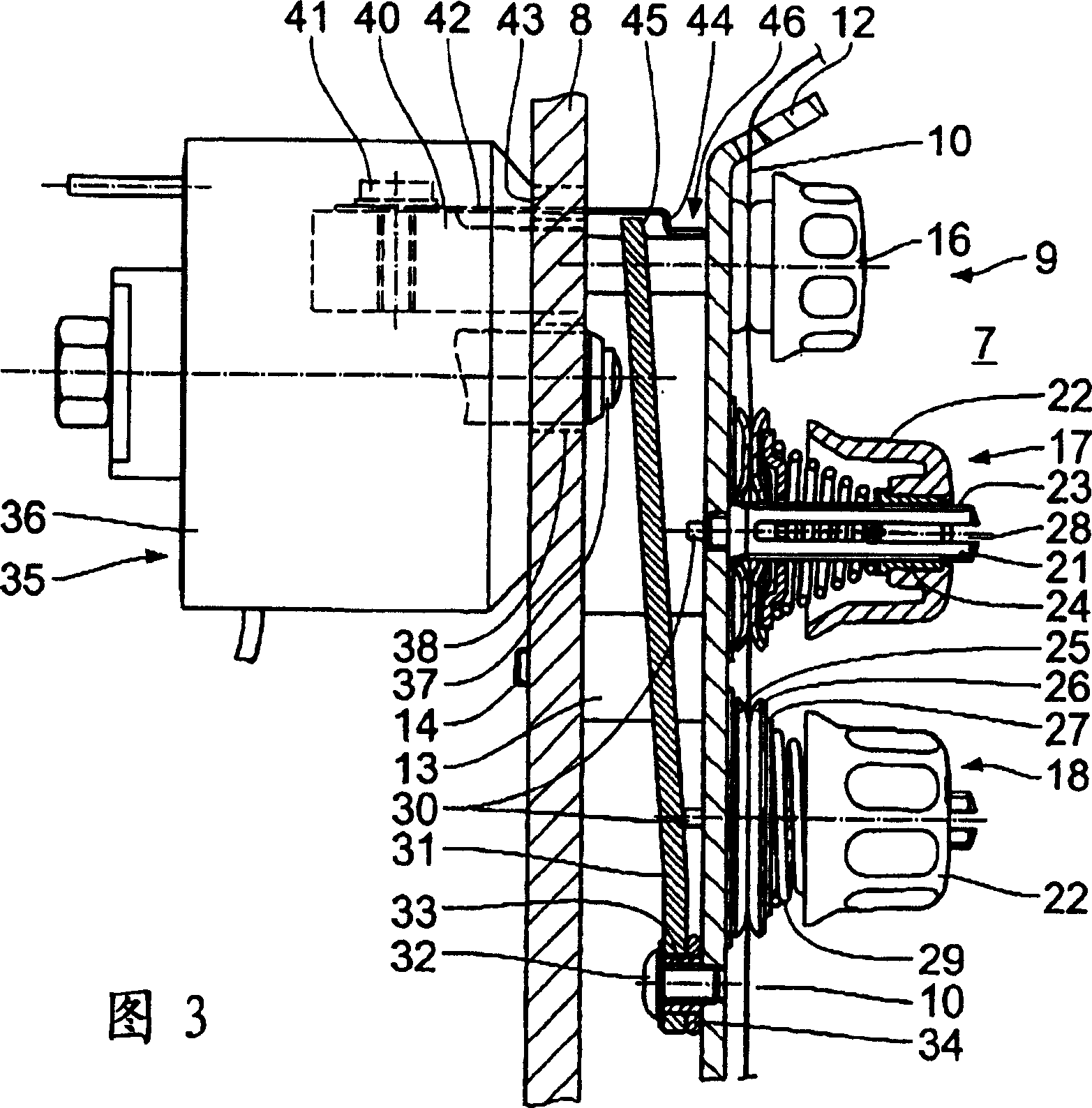

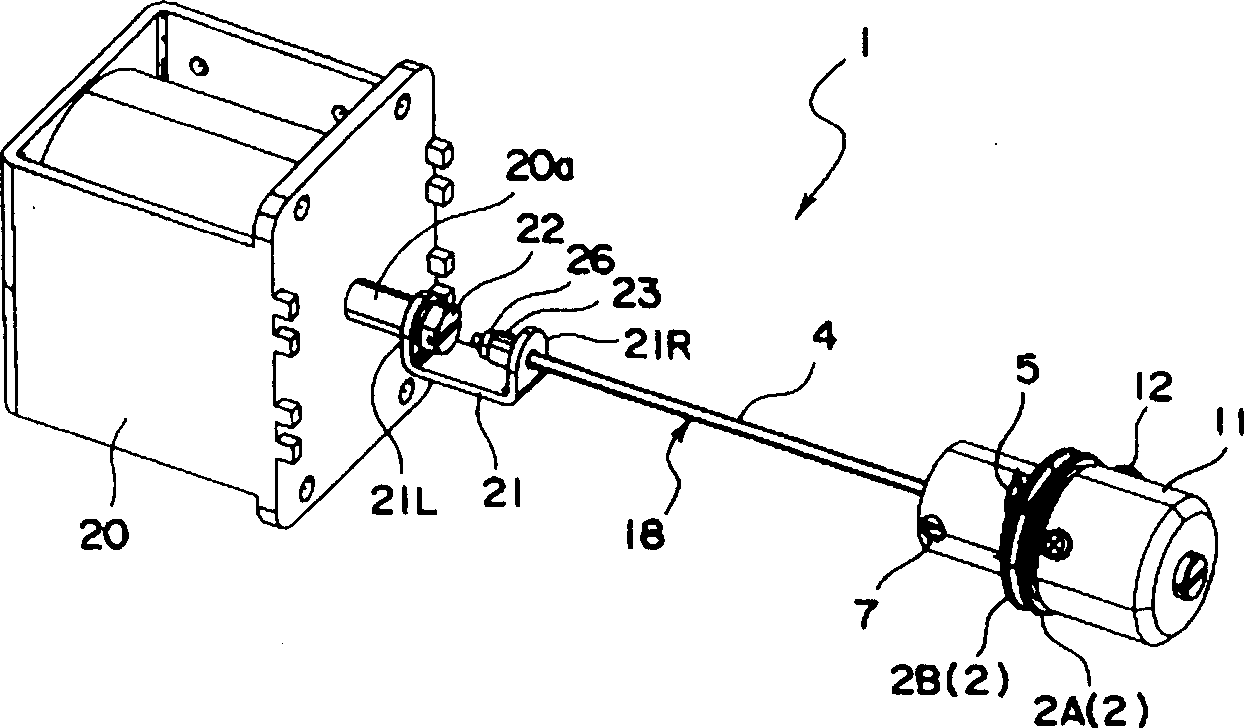

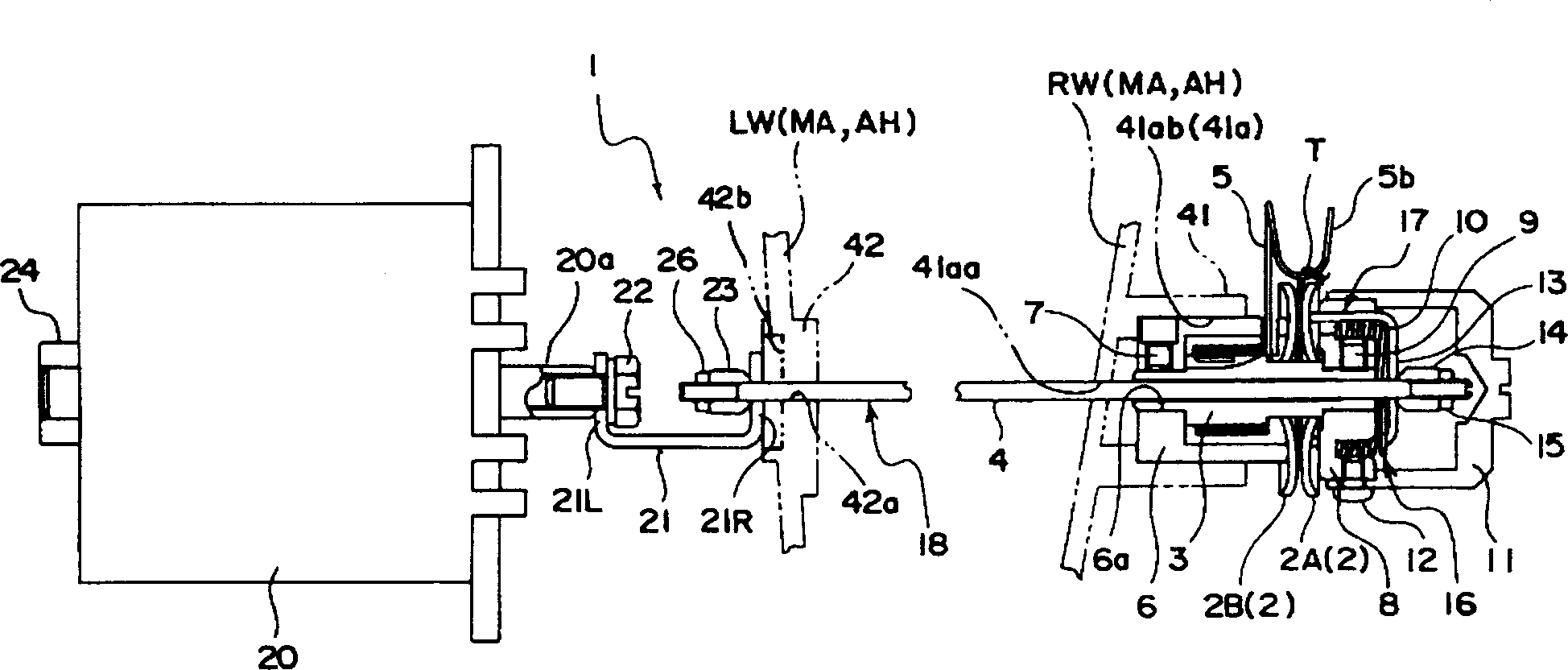

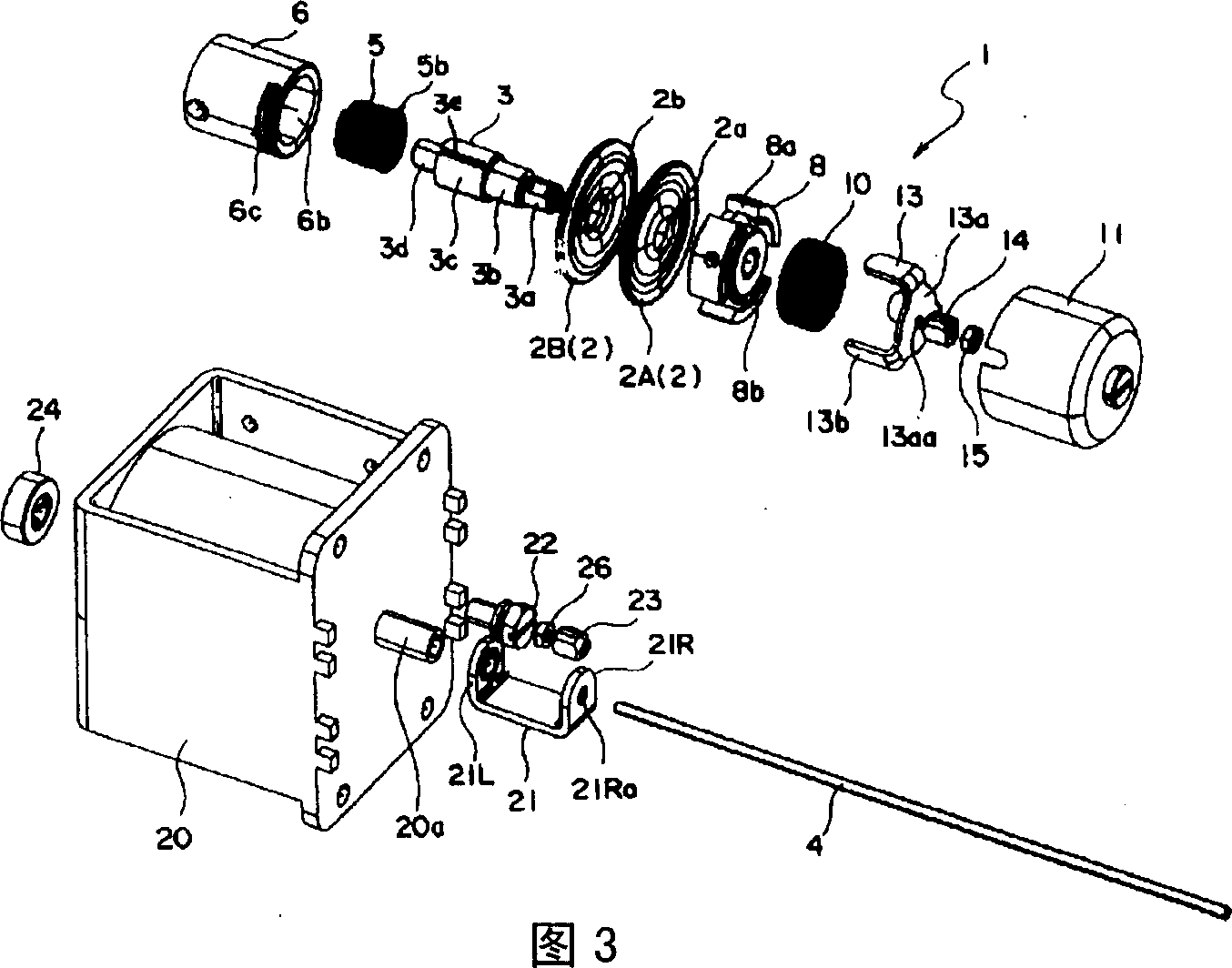

Apparatus for monitoring and controlling thread tensioning force in a sewing machine

ActiveUS7124697B2Accurate and repeatable measurementAccurate and repeatable and monitoringTensometerTensioning devicesEngineeringElectric signal

A thread tensioning device or apparatus for a sewing machine enables accurate, repeatable measurement and monitoring of the compression forces applied to the thread tensioning discs thereof. The apparatus further includes a visual display or output corresponding to the actual amount of compressive force being applied. The device further includes a comparator, which compares the electrical signal to a predetermined reference value to control or regulate the normal operation of the sewing machine.

Owner:FOLEY MARTIN J

Method for thread trimming, thread loosening, presser foot lifting and presser foot pressure adjusting of sewing machine

ActiveCN110983643ASimple structureCompact structureNeedle severing devicesSewing-machine control devicesCamPhysics

The invention relates to the technical field of sewing machines, in particular to a method for thread trimming, thread loosening, presser foot lifting and presser foot pressure adjusting of a sewing machine. A power piece drives a cam structure to rotate, a thread trimming driving section of a first driving contour face of the cam structure drives a thread trimming mechanism to execute thread trimming action, a thread loosening driving section of a second driving contour face of the cam structure drives a thread loosening mechanism to execute thread loosening action, a presser foot lifting driving section of the second driving contour face of the cam structure drives a presser foot lifting mechanism to execute presser foot lifting action, and a presser foot pressure adjusting driving section of the second driving contour face of the cam structure drives a presser foot pressure adjusting mechanism to execute presser foot pressure adjusting action. When current execution action is one ofthe thread trimming action, the thread loosening action, the presser foot lifting action and the presser foot pressure adjusting action, the other three actions are not generated or do not interferewith the current execution action. The four functions of thread trimming, thread loosening, presser foot lifting and presser foot pressure adjusting are achieved through the driving of the power piece.

Owner:JACK SEWING MASCH CO LTD

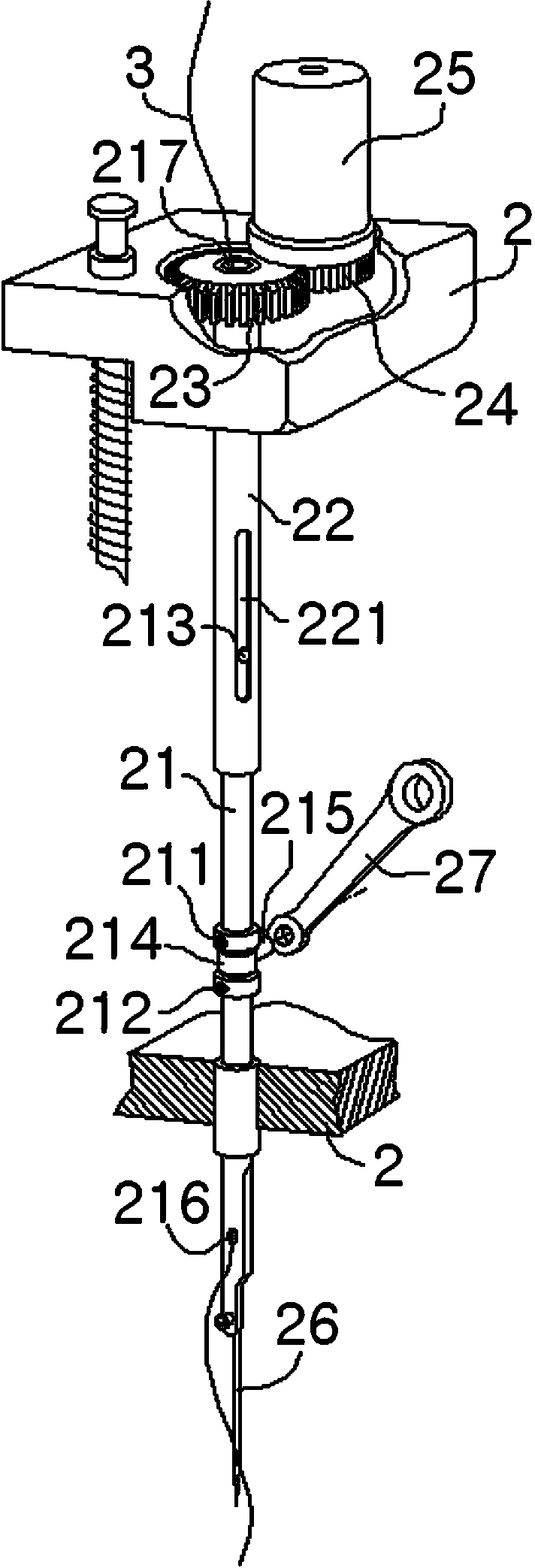

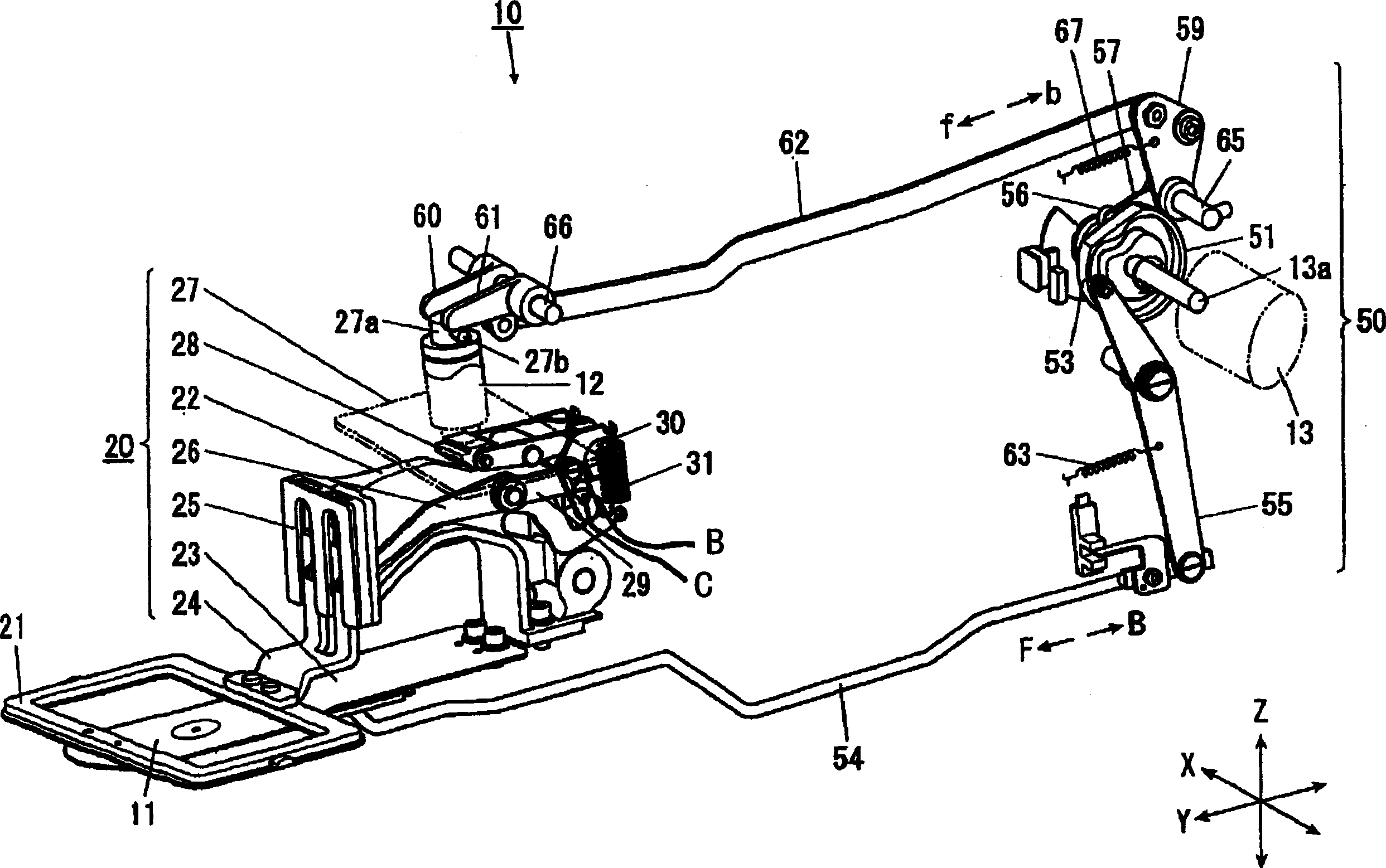

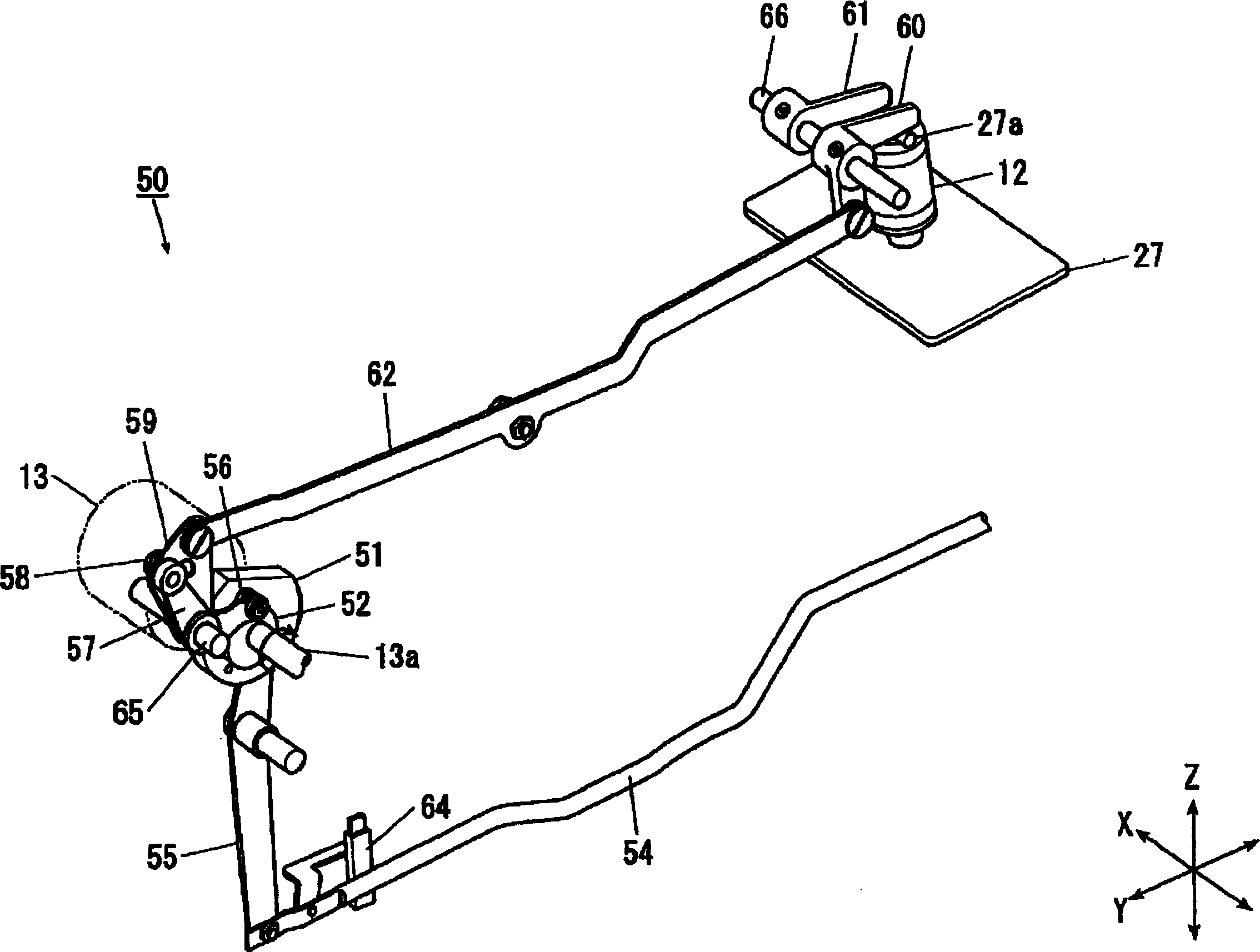

Sewing machine

InactiveCN1757809AShorten the cycle timeAppropriate rotation speedProgramme-controlled sewing machinesWorkpiece carriersYarnDrive motor

A seaming machine (10) comprises a cutter (4) for cutting suture line, a cloth press (20) for lifting compress foot (21), a pulse motor (13) driving the two devices, a ROM93 storing multiple rotation speed data (93c) defining the rotation speed of the pulse motor when the cutter cuts suture line, a rotation speed selector (as CPU91) for selecting the rotation speed data generating the drive torque capable of cutting suture line at least from the ROM, according to the suture line thickness input by a controller (98), relative to the drive voltage of a conchoids (81) driving a yarn change mechanism (80), and a drive controller (as CPU91) for controlling the rotary drive of the pulse motor according to the selected rotation speed data. The invention can optimize the rotation speed of the drive motor when cuts suture line to reduce rotation period.

Owner:JUKI CORP

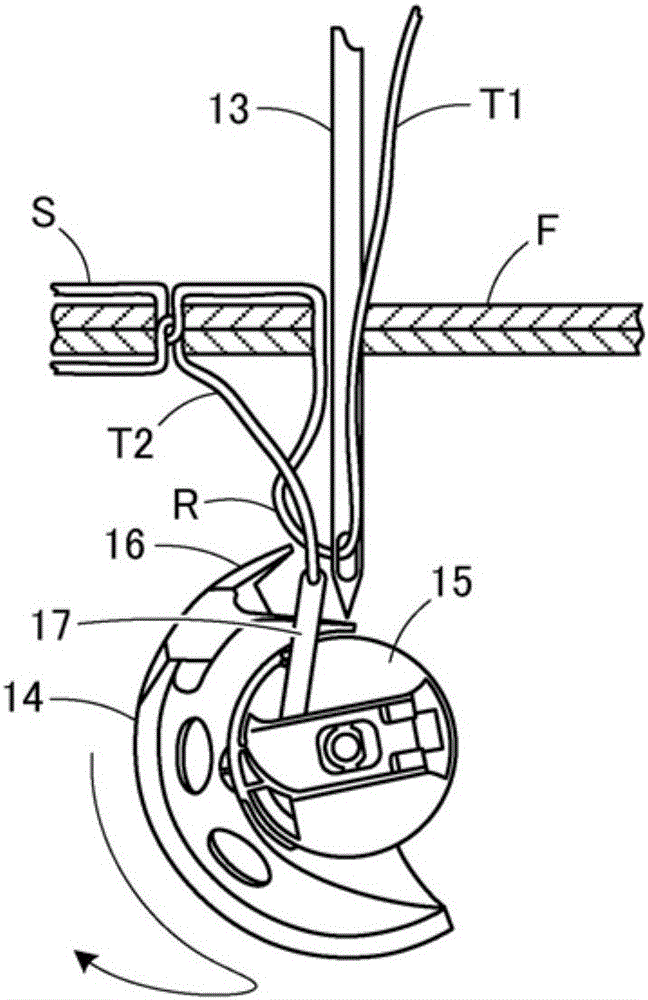

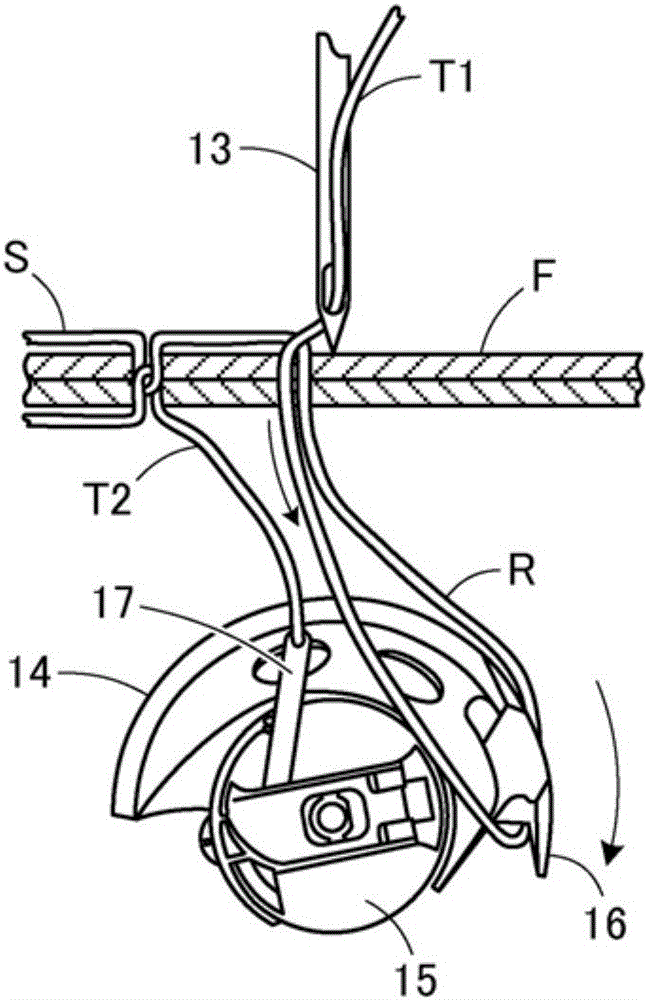

Sewing machine

The invention relates to a sewing machine, which enables an output shaft of a motor, adjusting facial suture tension, to stably follow the sewing action for rotation. The sewing machine comprises a wire-clamping motor and a wire-clamping plate. The wire-clamping plate is fixed to an output shaft of the wire-clamping motor. An operator winds the facial suture to the wire-clamping plate. The wire-clamping motor conducts rotation drive, and changes the tension of the facial suture. The CPU of the sewing machine determines the electrifying module of each coil of the wire-clamping motor based on the detection result of the encoder. The CPU electrifies the plurality of coils of the wire-clamping motor by means of the determined electrifying module, so as to control the driving of the wire-clamping motor. Every time when the CPU determines the electrifying mode, a plurality of coils can be electrified.

Owner:BROTHER KOGYO KK

Novel barrel type sewing machine

ActiveCN107043999ASolve the problem of instability and affecting the quality of sewingStable stitchLubrication/cooling devicesWork-feeding meansLocking mechanismEconomic benefits

The invention relates to the technical field of sewing devices, in particular to a novel barrel type sewing machine. The novel barrel type sewing machine includes a sewing machine body, an oil tan, and a fabric feeding mechanism, a stitch length locking mechanism, a pre-winding device, a dual-clamping machine, and an automatic lubrication system which are arranged on the sewing machine body; the fabric feeding mechanism includes a lower shaft, a tooth lifting cam, a tooth lifting fork, a tooth lifting shaft, a fabric feeding tooth guide rack, a fabric feeding tooth guide rack slide block, a fabric feeding tooth support, a fabric feeding tooth support shaft, a fabric feeding support slide block, and a fabric feeding tooth support positioning plate; the stitch length locking mechanism includes a stitch length button, a locking pin and a locking pin spring; and the pre-winding device includes a base, a winding shuttle core, a shuttle core shaft, a cutter, a shuttle core seat, a winding positioning wheel, a friction wheel, a winding positioning hook, and a limiting adjustment wrench which are fixed on the sewing machine body. The mechanical structure of the conventional sewing machine is changed, the automatic lubrication system is added, the performance of the sewing machine is fully improved, and the novel barrel type sewing machine has good application prospect and economic benefits.

Owner:TYPICAL SEWING MACHINE WANPING MACHINERY

Computerized stitching including embroidering

InactiveUS6871605B1Reduced thread tensionReduce needProgramme-controlled sewing machinesHand sewingEngineeringScrew thread

Owner:MELCO INT

Intelligent full-automatic hot-melting button wrapping machine

PendingCN110820187AAvoid wastingAvoid pulling out and droppingSewing-machine control devicesSpool-pin assembliesWinding machineControl system

The invention discloses an intelligent full-automatic hot-melting button wrapping machine. The intelligent full-automatic hot-melting button wrapping machine comprises a frame and is characterized inthat a winding mechanism, a thread pulling and breaking mechanism, a thread melting and fixing mechanism and a drive device are arranged in the frame, a control system in control connection with the drive device is arranged on the frame, a spool seat for mounting a spool is arranged on the frame, a button wrapping thread tightness adjuster is arranged between the spool seat and the winding mechanism, a thread breaking detecting alarm device is arranged between the button wrapping thread tightness adjuster and the winding mechanism, and the output end of the thread breaking detecting alarm device is connected with the control system. The intelligent full-automatic hot-melting button wrapping machine the thread breaking detecting alarm device is arranged on the frame, the thread breaking detecting alarm device transmits thread breaking information to the control system when the button wrapping thread entering the winding mechanism breaks to guarantee that the machine stops working duringthread breaking, the thread breaking detecting alarm device can also emits notification to notify staff immediately after the thread breaking occurs, and manpower and material resource waste can be avoided.

Owner:谭英

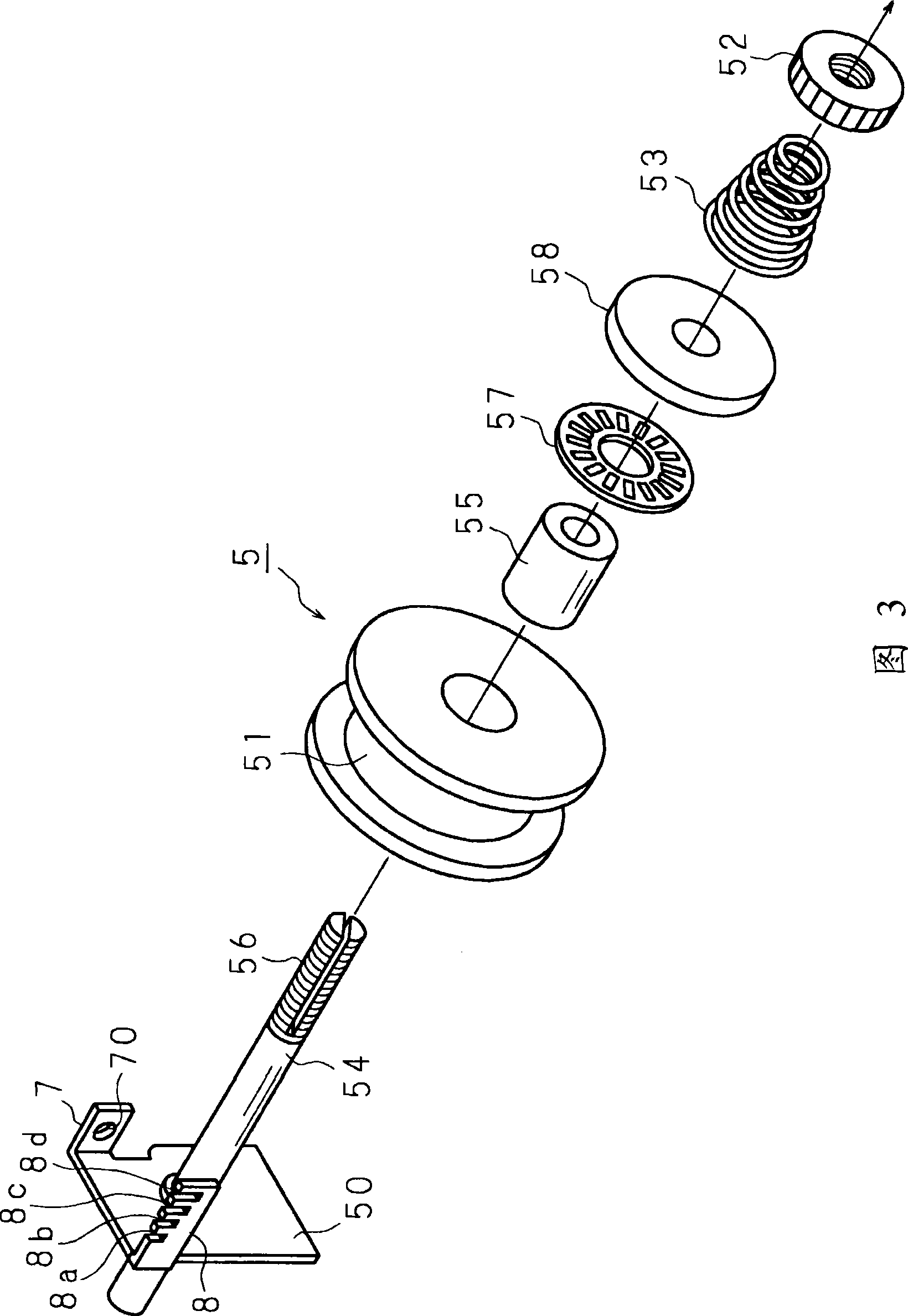

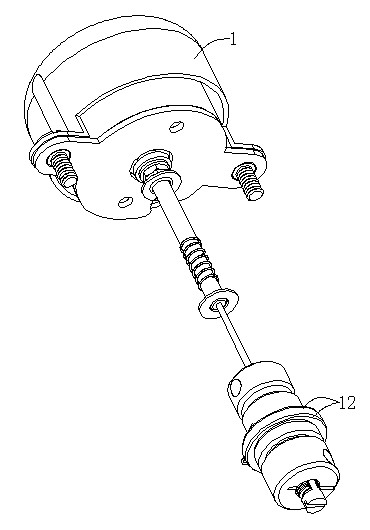

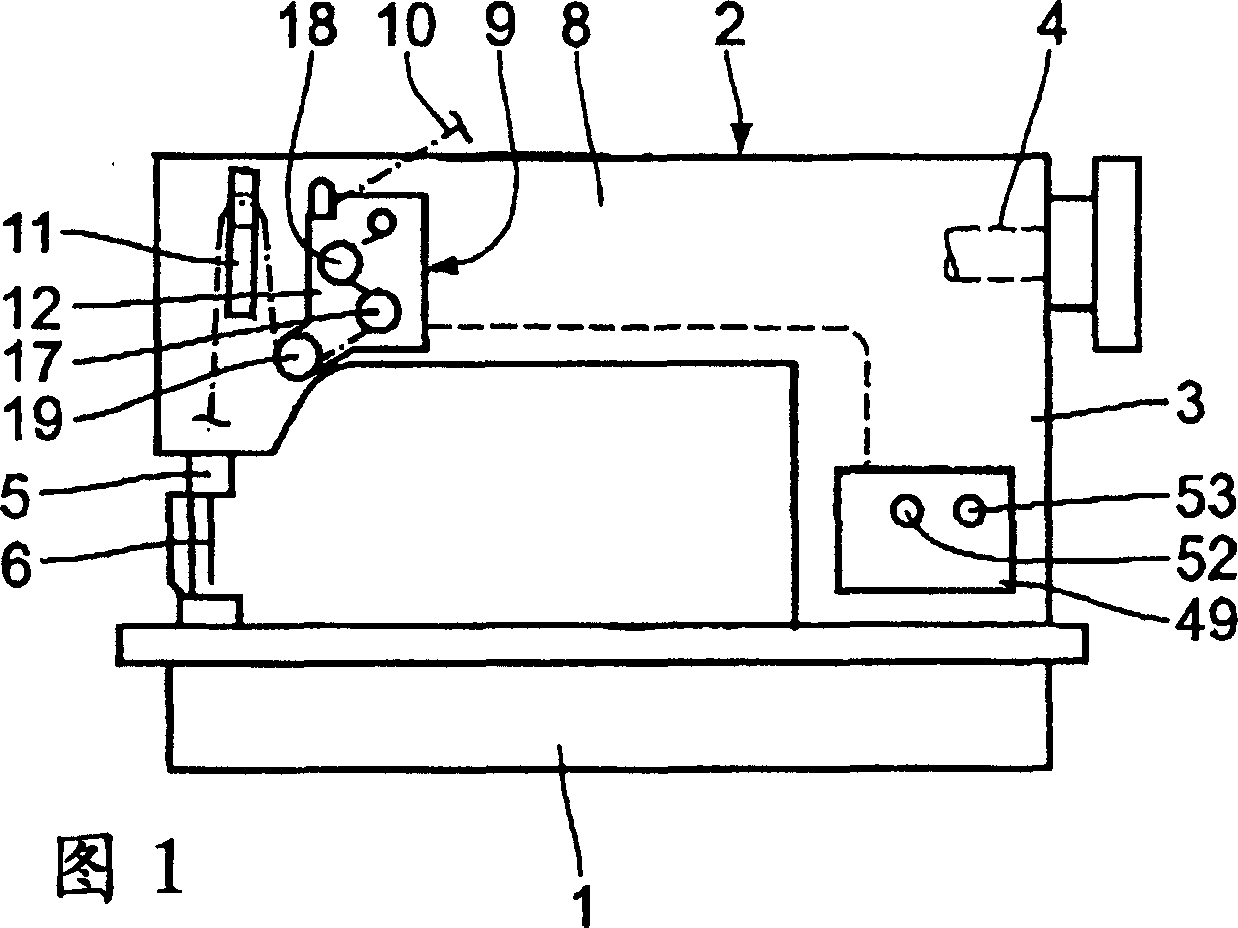

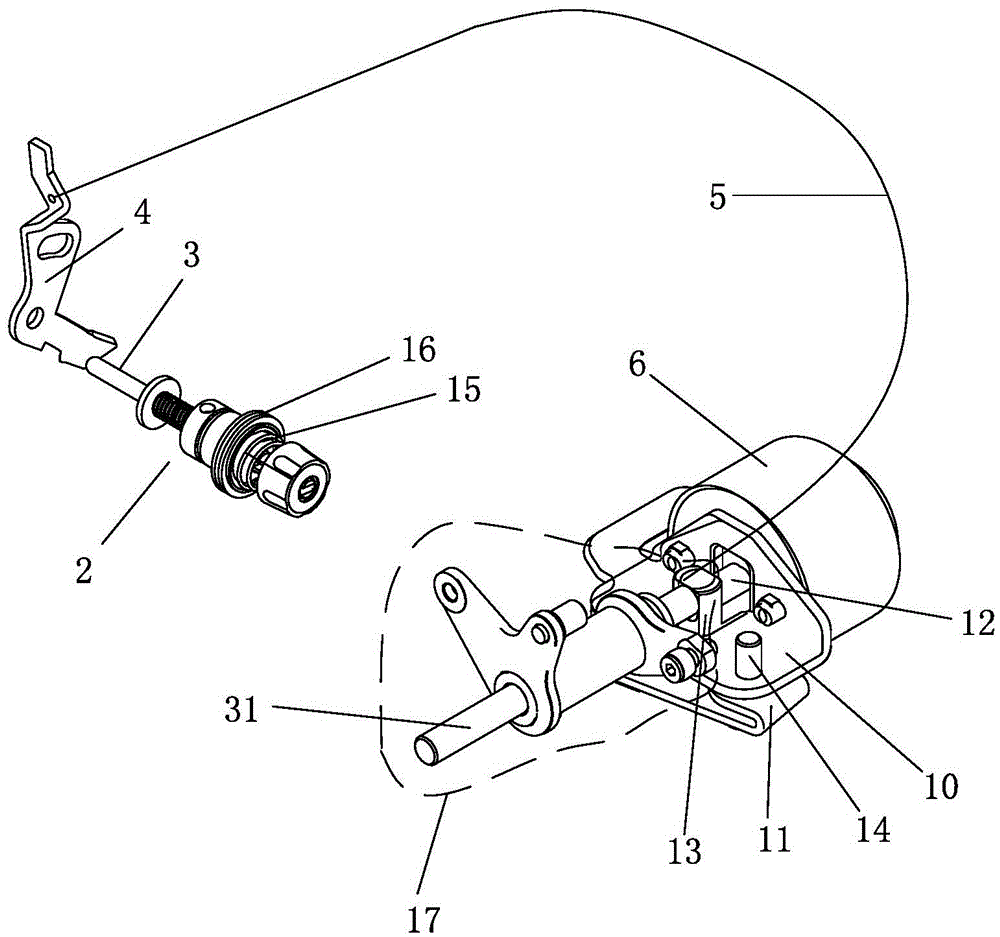

Thread tensioner for a sewing machine

InactiveCN1600932AEasy to controlAdjustable preloadSewing-machine control devicesThread-laying mechanismsEngineeringSewing machine

The thread tensioner (9) for a sewing machine has a supporting plate (12) equipped with a first thread tensioning device (18) and a second thread tensioning device (17) on the supporting plate, and the tension load to the thread (10) is overcome. For the purpose, a release lever (31) is connected with the supporting plate (12), and works to abut on a release pin (30) of the thread tensioning devices (17, 18). The thread tensioner works in a manner that the release lever (31) abuts on the first thread tightening device (18) first and then the second thread tensioning device (17) with the progress of the pivotably moving processes by separate releasing steps by using a solenoid (36).

Owner:DURKOPP ADLER AG

Control device for thread gripper of sewing machine

InactiveCN101139785AExtended service lifeImprove job stabilitySewing-machine control devicesTensioning devicesEngineeringPower apparatus

Owner:ZHEJIANG ZOJE SEWING MACHINE

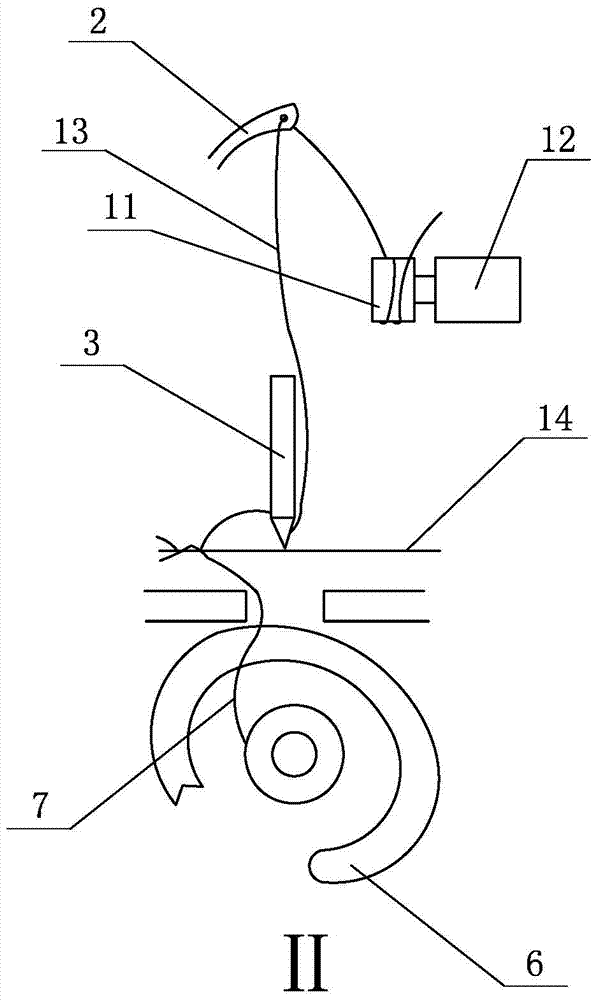

Sewing machine thread loosening device for removing bird nest structure and use method

ActiveCN105568575ALow costGuaranteed aestheticsSewing-machine control devicesTensioning devicesEmbedded systemCam

The invention belongs to the technical field of sewing machines, and particularly relates to a sewing machine thread loosening device for removing a bird nest structure and a use method. The device comprises a thread holder arranged on a machine head, the tail end of the thread holder is connected with a thread loosening device, and the thread loosening device is connected with a thread shearing driver of a thread shearing device through a connecting mechanism. A lower shaft is arranged at one side of the thread shearing driver, a thread shearing cam is arranged on the lower shaft, and a thread shearing driving assembly of the thread shearing device is located on one side of the lower shaft. In the sewing process, the thread shearing driver acts to drive the connecting mechanism to act, and then the thread loosening device is driven to act on the thread holder to achieve the thread loosening action. An idle stroke segment is formed by a downward-recessed portion on the thread shearing cam, the thread shearing driving assembly does not conduct rotating action in the thread loosening process due to the idle stroke segment, and a thread is only loosened without being shorn. The thread shearing driver serves as a thread loosening driving source, an existing thread shearing driver is utilized for loosening the thread in the sewing process, the aim of driving two mechanisms through one driving source to achieve multiple functions is achieved, and cost is reduced.

Owner:JACK SEWING MASCH CO LTD

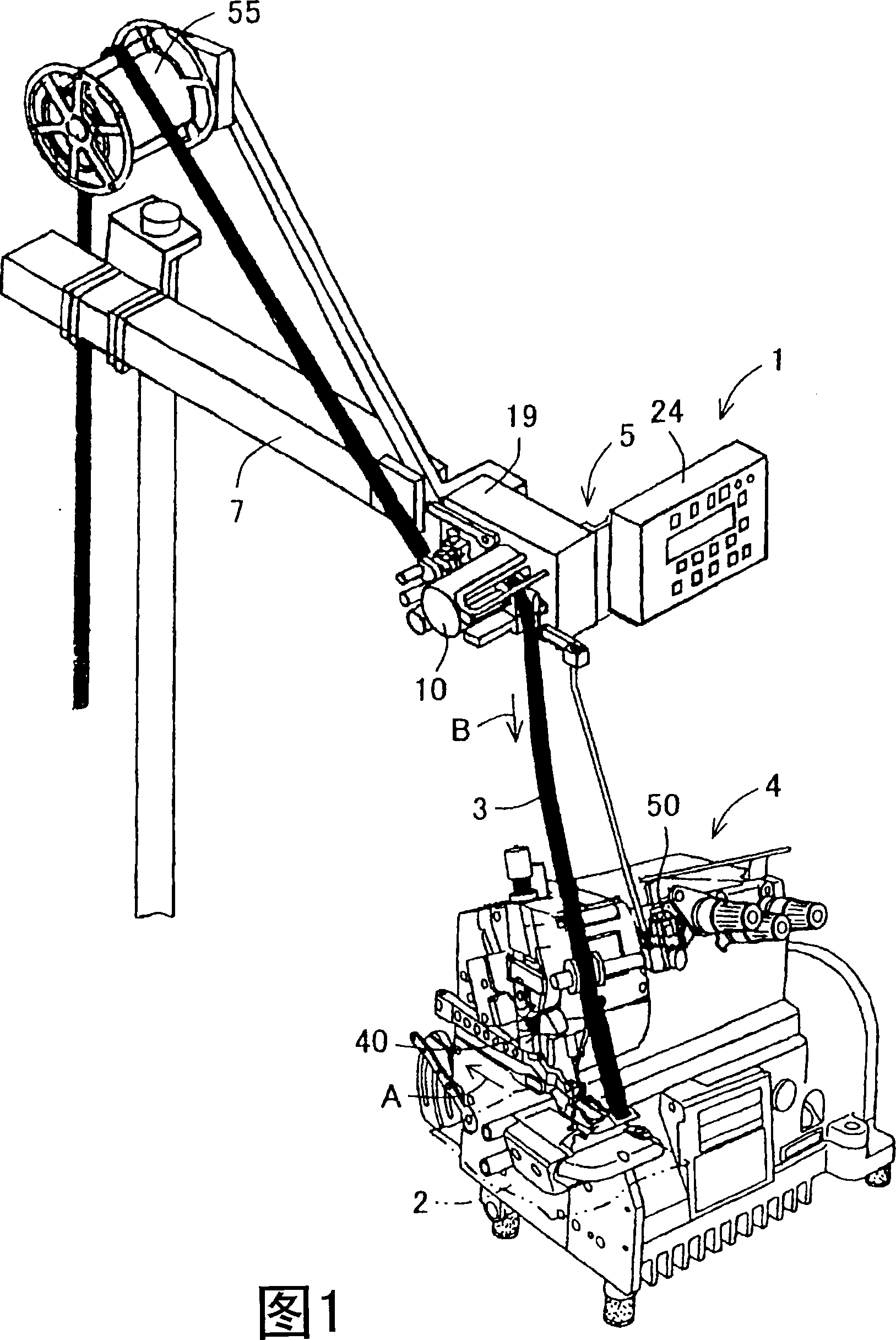

Belt sewing method and device

ActiveCN101070667AEliminate bad conditionsEasy to changeProgramme-controlled sewing machinesWork-feeding meansDrive shaftEngineering

This invention relates to a method and device of ribbon splicing, which can eliminate bad condition controlled by the tension induced by stitch number to splice a ribbon to the blank, no need of detection of action amount of sewing machine. The length dimension of ribbon(3) is set corresponding with tension, when the ribbon(3) is spliced to the blank (2), the feed level and tension of the ribbon(3) are detected. During feeding the ribbon(3) of preset length, the corresponding tension is applied on the ribbon(3). Thus, the tension is controlled by feed level of the ribbon(3) of the sewing machine (4), not by the action amount of the sewing machine (4) of rotational velocity of driving shaft, stitch number.

Owner:YAMATO SEWING MASCH MFG CO LTD

Uper and lower conveying sewing machine and thread adjuster

A sewing machine with up and down conveying, which has an upper fabric conveying mechanism for conveying the upper fabric and a lower fabric conveying mechanism for conveying the lower fabric, by changing the difference in the conveying volume of the two conveying mechanisms, the amount of pleats performed on the sewn fabric is adjusted. The utility model has a thread adjusting device driven by an electric drive device capable of changing the thread tension, and a control mechanism for controlling the thread adjusting device to change the thread tension corresponding to the amount of pleating. It has a setting mechanism capable of setting the set value of the thread tension corresponding to the amount of pleats received; the control mechanism controls the thread adjusting device corresponding to the amount of pleats received, so that it can give the thread tension of the set value set by the setting mechanism. This type of vertical feed sewing machine can always sew with the optimum thread tension even if the amount of gathers varies in the continuous sewing section.

Owner:JUKI CORP

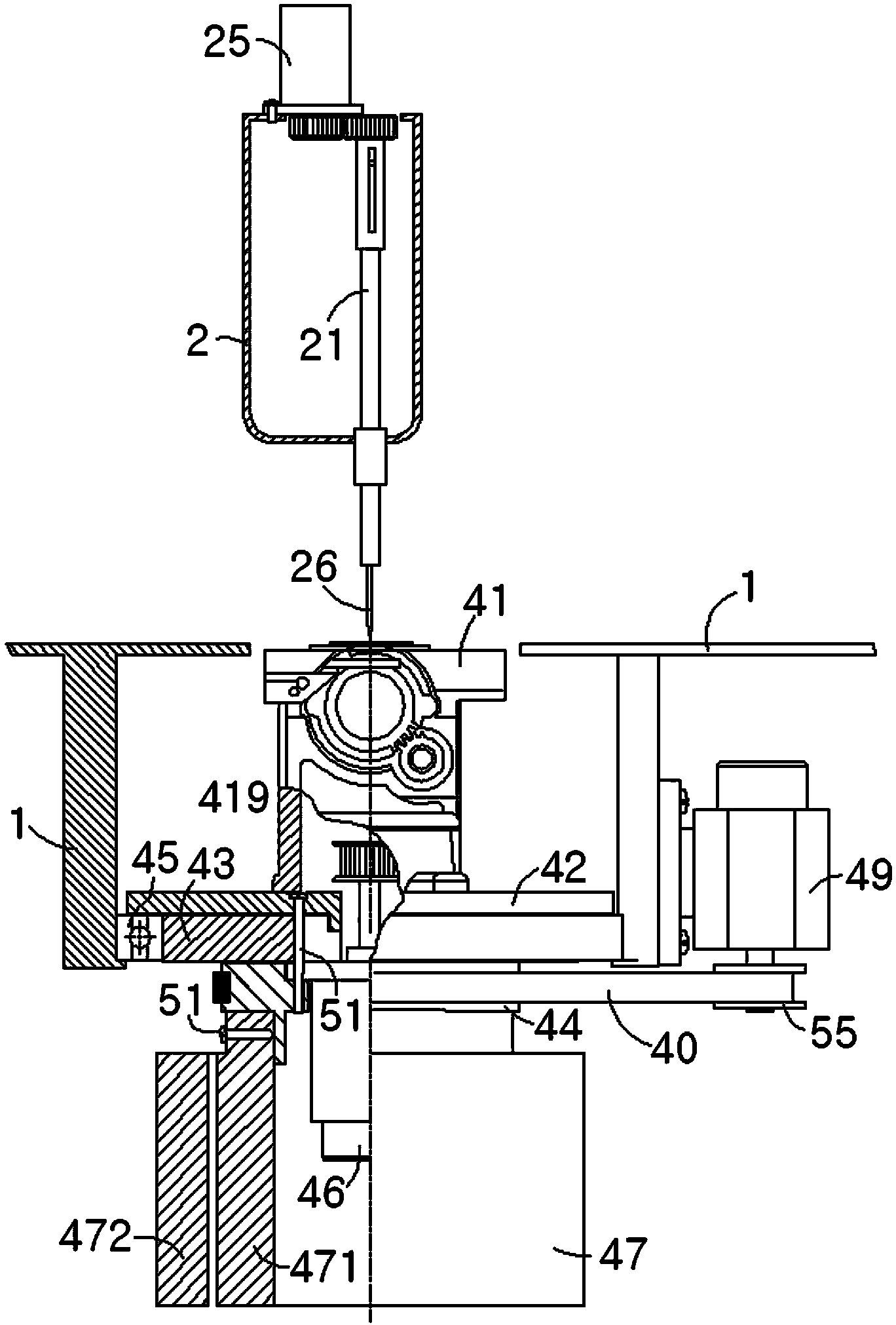

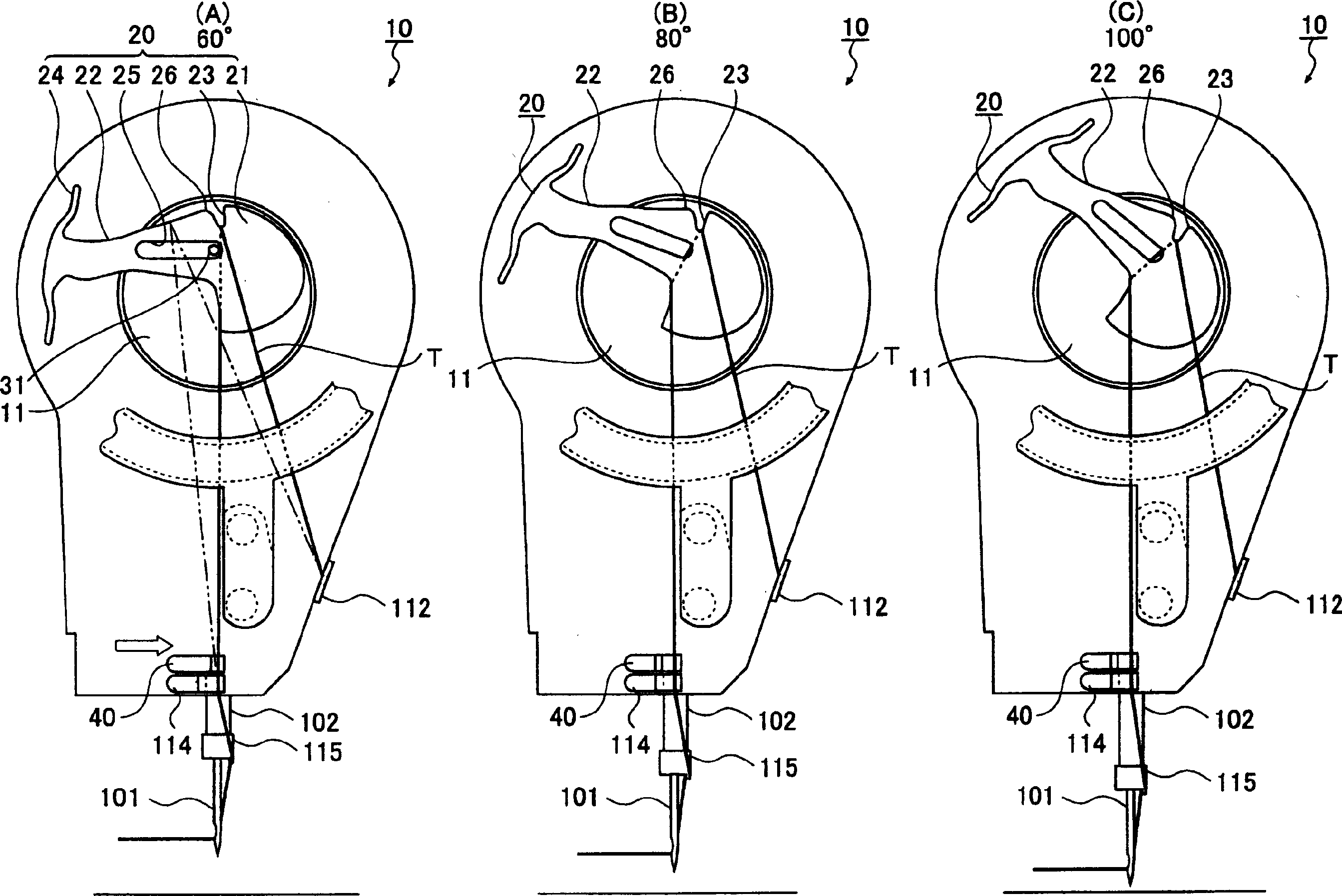

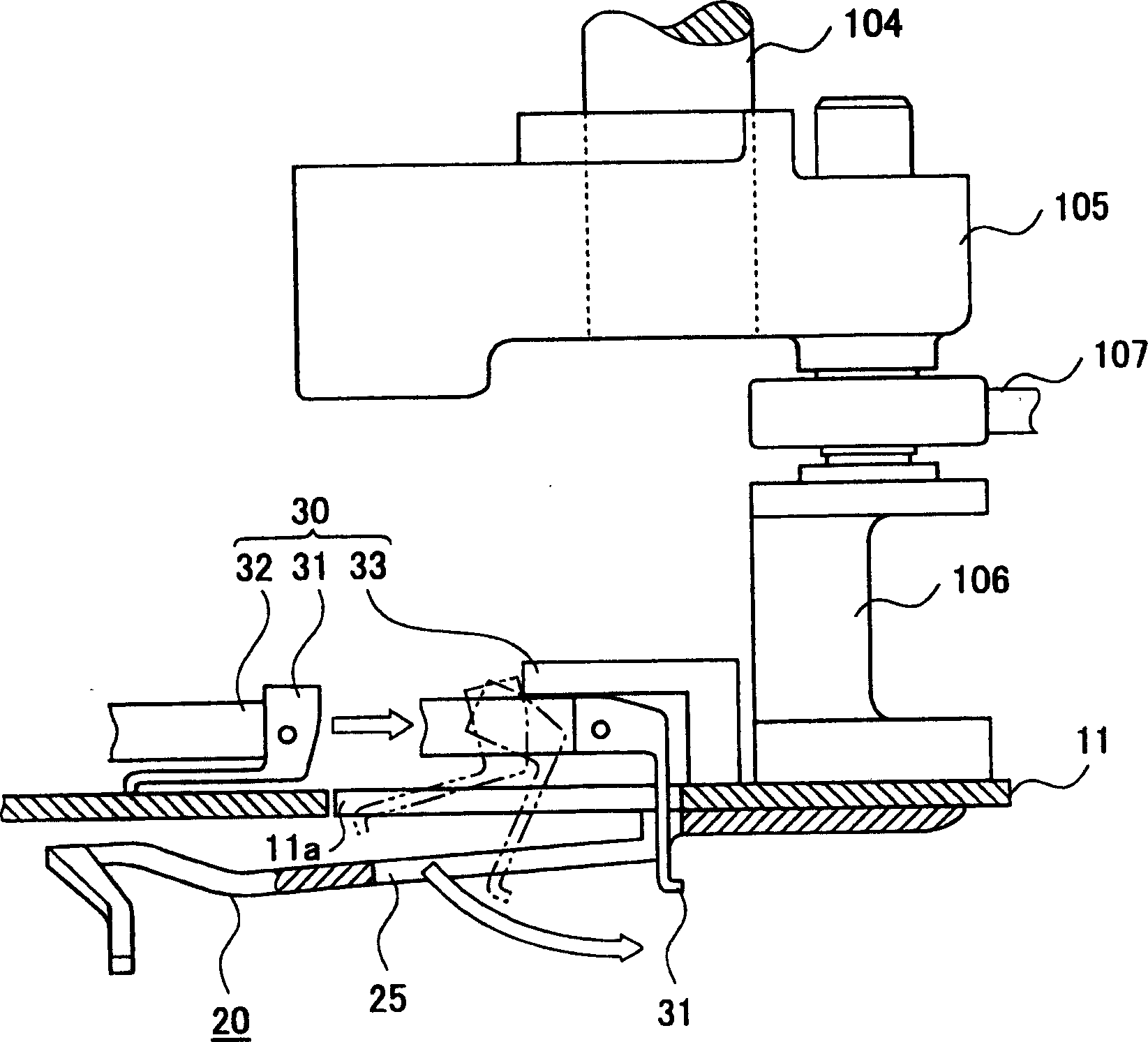

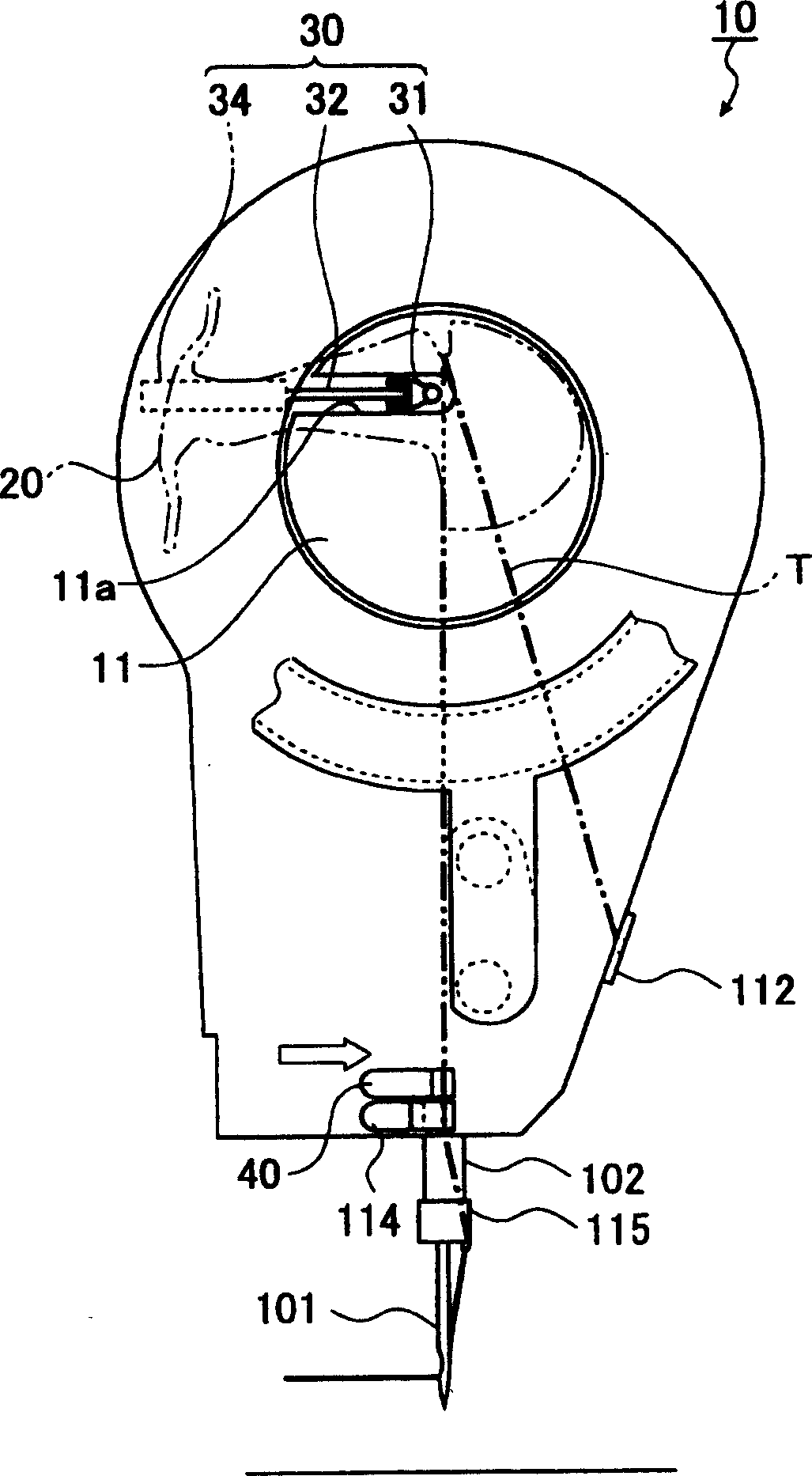

Sewing machine

InactiveCN1607285APrevent movementAbundant supplyProgramme-controlled sewing machinesSewing-machine control devicesSewing needleBiomedical engineering

PROBLEM TO BE SOLVED: To suppress the dropping of a needle thread from a sewing needle at the time of the starting of sewing. SOLUTION: This sewing machine 10 is equipped with a rotary needle thread take up member 20 which is arranged on the upstream side of the sewing needle 101 on a thread needle pathway, and at the same time, imparts a tension which periodically changes by the same cycle as the vertical movement of the sewing needle 101 to the needle thread. The rotary needle thread take up member 20 is equipped with a base section 21 which becomes the pivot side, and an arm section 22 which makes the needle thread T reciprocate in the longitudinal direction by rotating as it remains spanned with the needle thread T. A recess section 23 in which the needle thread T drops from the needle take up upper dead point position 26 of the needle thread T is provided on the arm section 22. The rotary needle thread take up member 20 is constituted by having a needle thread position changing means 30 which moves the needle thread T to the recess section 23 before a first stitch is formed. COPYRIGHT: (C)2005,JPO&NCIPI

Owner:JUKI CORP

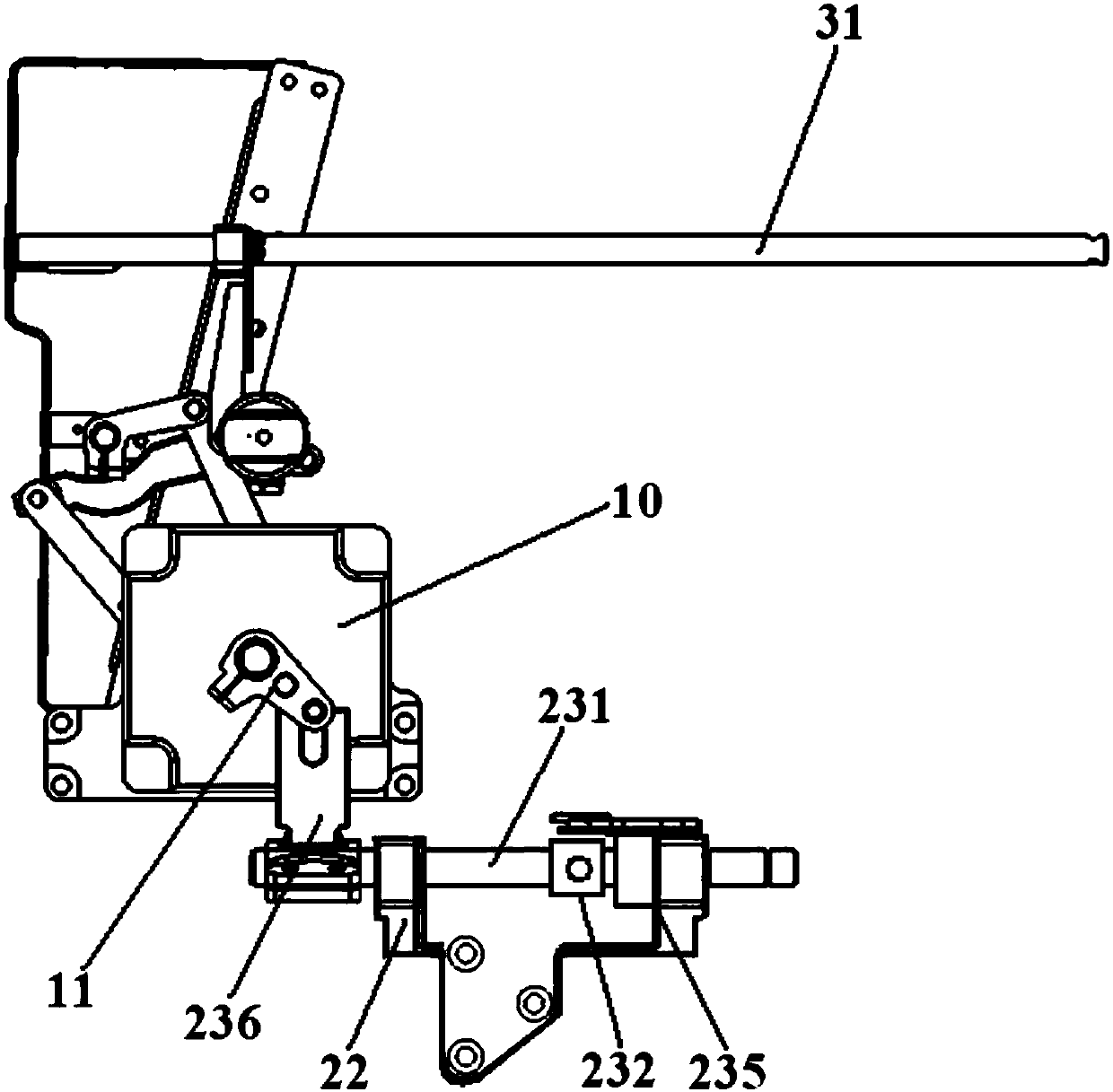

Thread trimming and tread loosening presser foot pressure adjusting device of sewing machine, and sewing machine

ActiveCN110983645ASignificant progressSimple structureNeedle severing devicesSewing-machine control devicesCrankEngineering

The invention relates to the technical field of sewing machines, in particular to a thread trimming and thread loosening presser foot pressure adjusting device of a sewing machine, and a sewing machine comprising the same. The device comprises a power part, a cam structure which is driven to rotate by the power part and is provided with a first driving contour surface and a second driving contoursurface, a thread trimming driving crank connected with a thread trimming mechanism, and an ejector pin for connecting a thread loosening mechanism and a presser foot pressure adjusting mechanism, wherein a first driving pin matched with the first driving contour surface is arranged on the thread trimming driving crank, and the first driving contour surface is provided with a thread trimming driving section for driving the thread trimming mechanism to execute a thread trimming action; a second driving pin matched with the second driving contour surface is arranged at one end of the ejector pin, and the second driving contour surface is provided for a thread loosening driving section for driving the thread loosening mechanism to perform a thread loosening action and a pressor foot pressureadjusting driving section for driving the presser foot pressure adjusting mechanism to execute a presser foot pressure adjusting action. Three functions of trimming, loosening and adjusting the pressure of the presser foot are realized by one power part.

Owner:JACK SEWING MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com