Up and down feeding cloth sewing machine

A sewing machine and cloth feeding technology, which is applied in the direction of cloth feeding mechanism, sewing machine components, program-controlled sewing machines, etc., to achieve the effect of improving sewing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

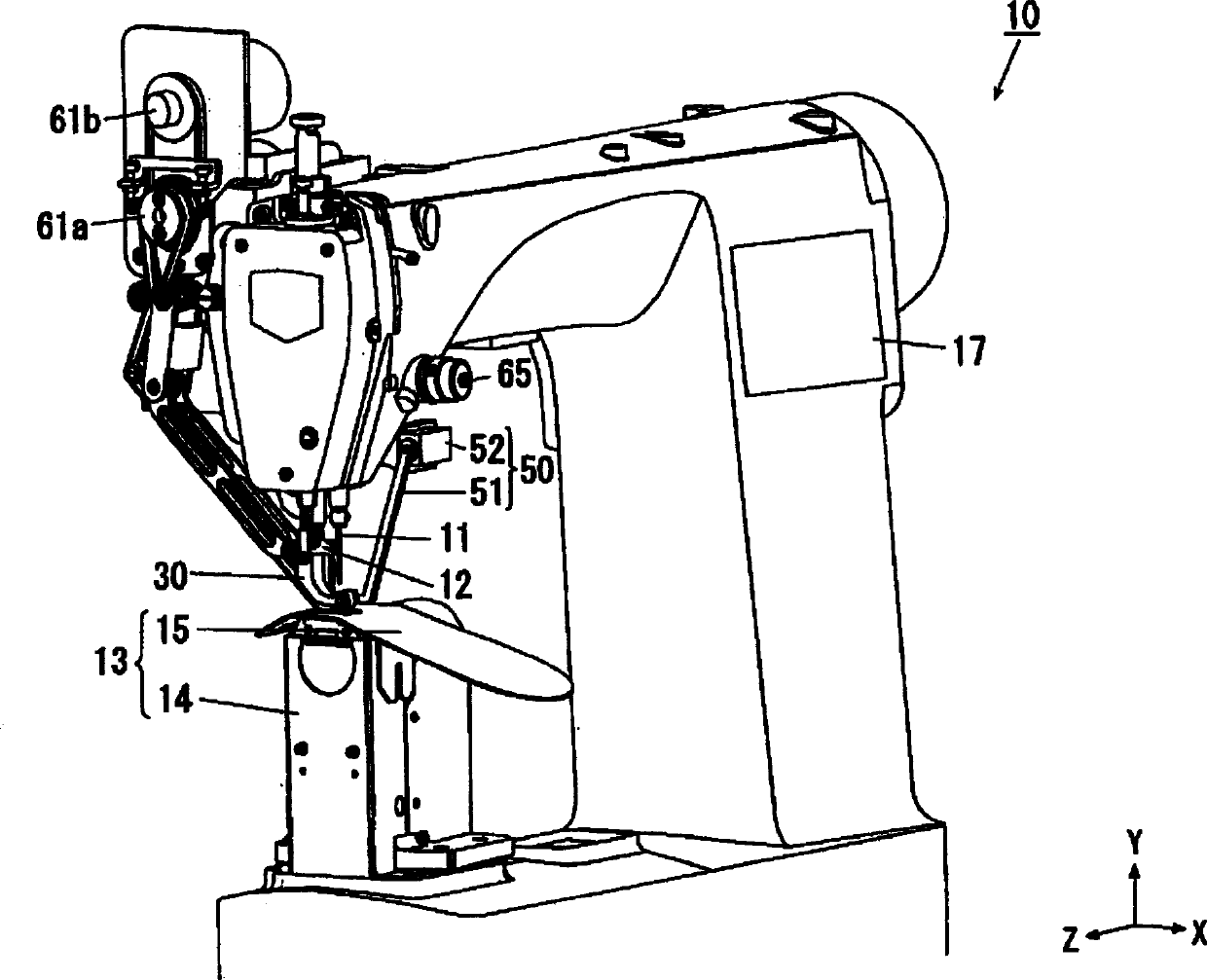

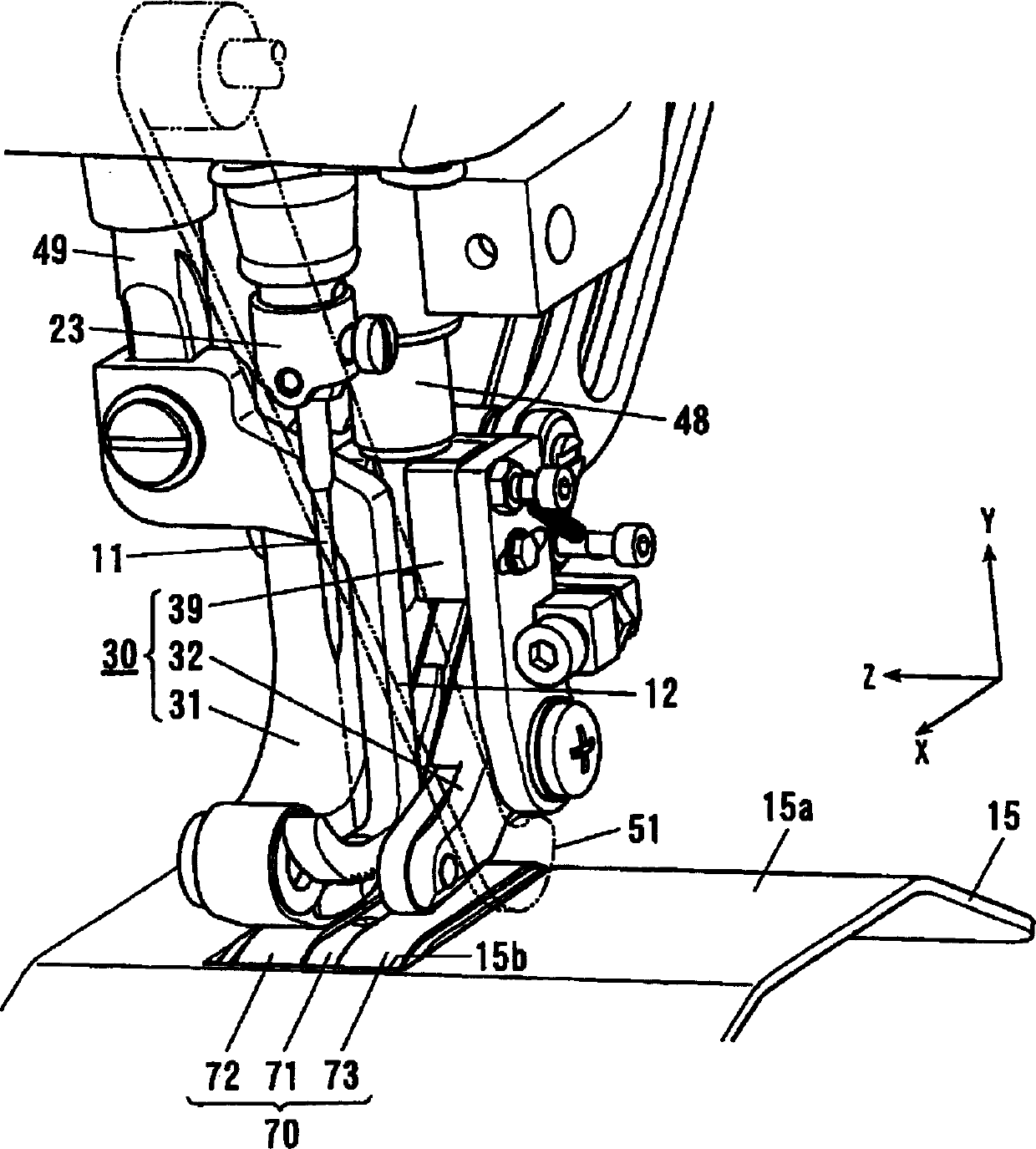

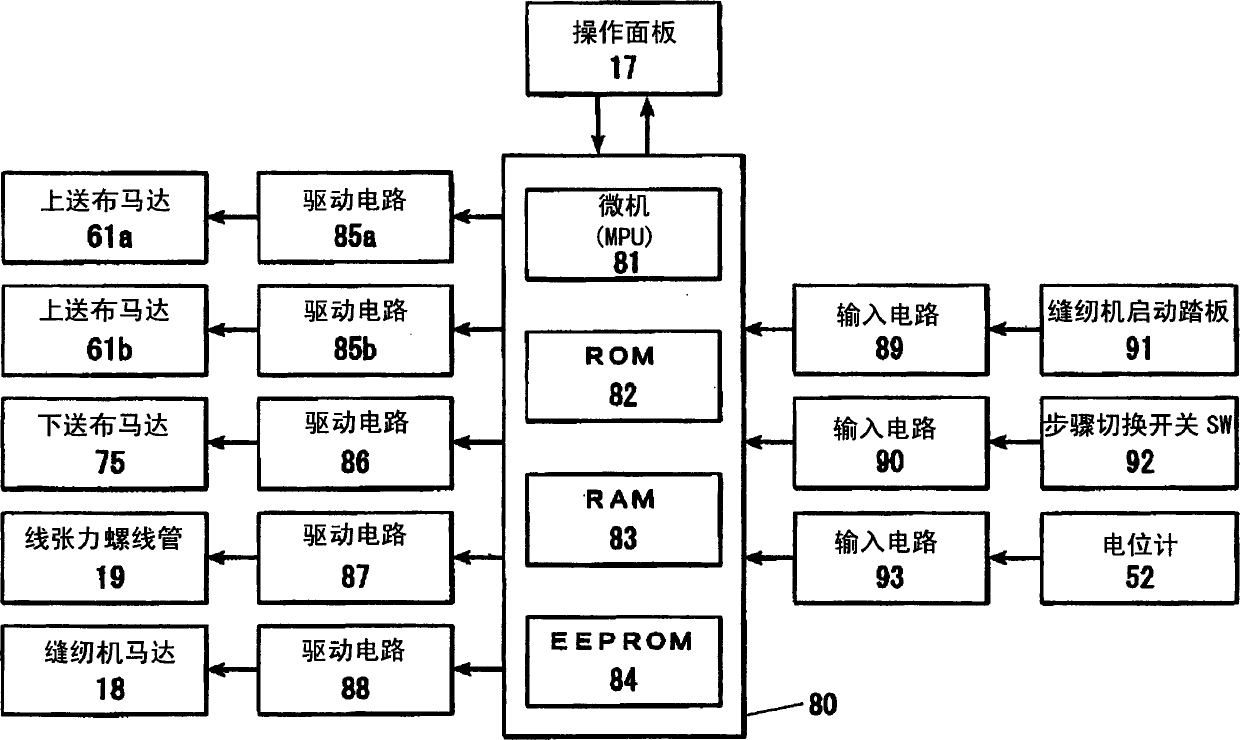

[0035] (Overall configuration of the embodiment)

[0036] Embodiments of the present invention will be described based on FIGS. 1 to 8 . The differential feed sewing machine (bottom feed sewing machine) 10 of the present embodiment is a sewing machine that sews while pulling together by setting the respective feed speed differences of the upper and lower fabrics to be sewn. It is used for shoulder pads when sewing the front and rear body.

[0037] In addition, shirring refers to the difference in pitch width between the upper cloth and the lower cloth, and by increasing this difference (shrinking amount), the sewn clothes can be stretched. Therefore, when sewing the sleeves and the front and rear body, by setting the amount of shirring at the shoulder side to be larger than the amount of shirring at the armpit side, stretchability can be adjusted after sewing. There is room on the shoulder side.

[0038] Here, the direction in which the needle 11 described later moves up an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com