Sewing machine

A technology for sewing machines and sewing needles, which is applied in the direction of sewing machine components, sewing machine needle seats, sewing equipment, etc., which can solve the problems of large moment of inertia of the kettle base, inability to perform high-speed sewing, and increased weight of the kettle base, etc., and achieve reduction error, reduce the moment of inertia, and realize the effect of reducing the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

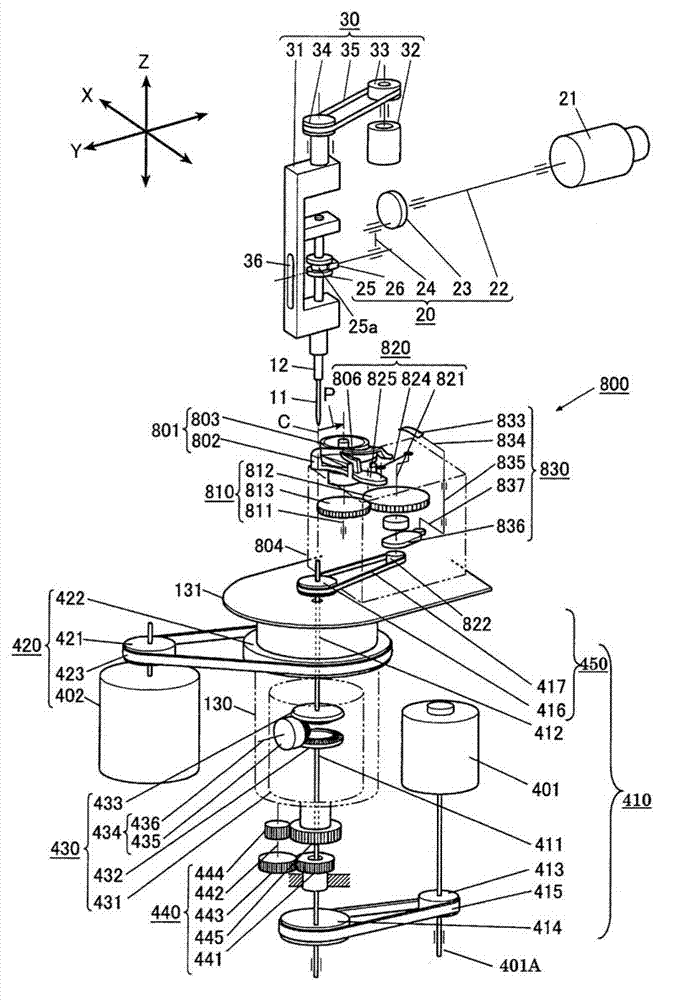

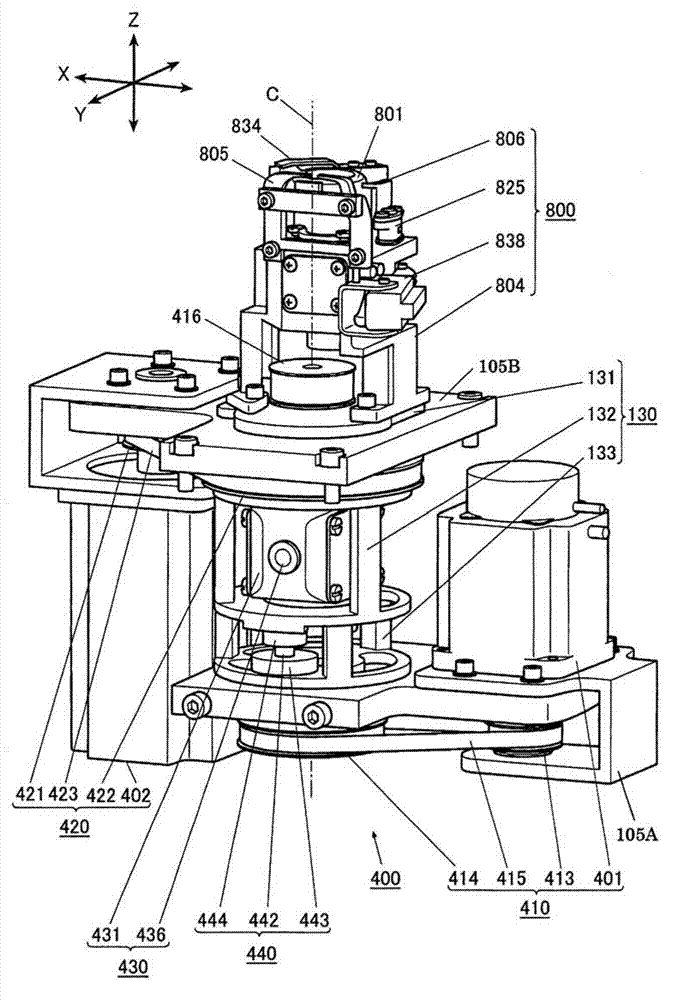

[0144] based on Figure 1 to Figure 12 , the first embodiment of the present invention will be described.

[0145] The sewing machine 100 described below as this embodiment is a so-called electronic cycle sewing machine, and has a holding frame as a cloth holding part for holding the cloth as a sewn object to be sewn. By moving relative to the sewing needle, a sewing pattern based on predetermined sewing data is formed on the cloth held by the holding frame.

[0146] Here, the direction in which the sewing needle 11 described later moves up and down is defined as the Z-axis direction (up-and-down direction), and a horizontal direction perpendicular to this direction is defined as the X-axis direction (left-right direction). Another orthogonal horizontal direction is defined as the Y-axis direction (front-back direction).

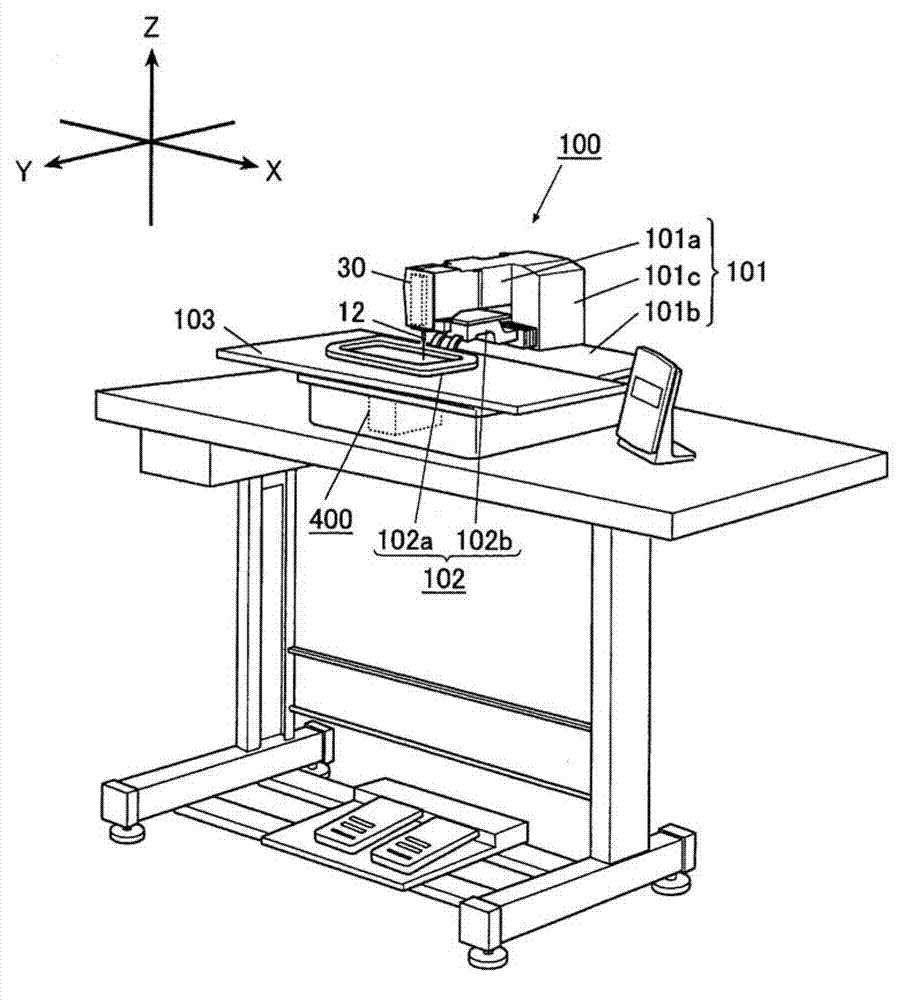

[0147] like figure 1 and figure 2 Shown, sewing machine 100 has sewing machine frame 101, and this sewing machine frame 101 is made up of following par...

no. 2 approach

[0282] A second embodiment of the present invention will be described. In the sewing machine according to the second embodiment, a differential transmission mechanism 400A having a rotary operation portion 420A, a differential mechanism portion 430A, and a rotation interlocking portion 440A is mounted. The rotation interlocking part 440A has a structure different from the rotation operation part 420, the differential mechanism part 430, and the rotation interlocking part 440 of the sewing machine 100 mentioned above.

[0283] In the following description, only the difference between the differential transmission mechanism 400A and the differential transmission mechanism 400 will be described, and the same components will be given the same reference numerals, and redundant descriptions will be omitted.

[0284] exist Figure 13 and Figure 14 Among them, the rotating operation part 420A is different from the above-mentioned rotating operation part 420 in that it does not appl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com