Patents

Literature

465results about "Sewing-machine casings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

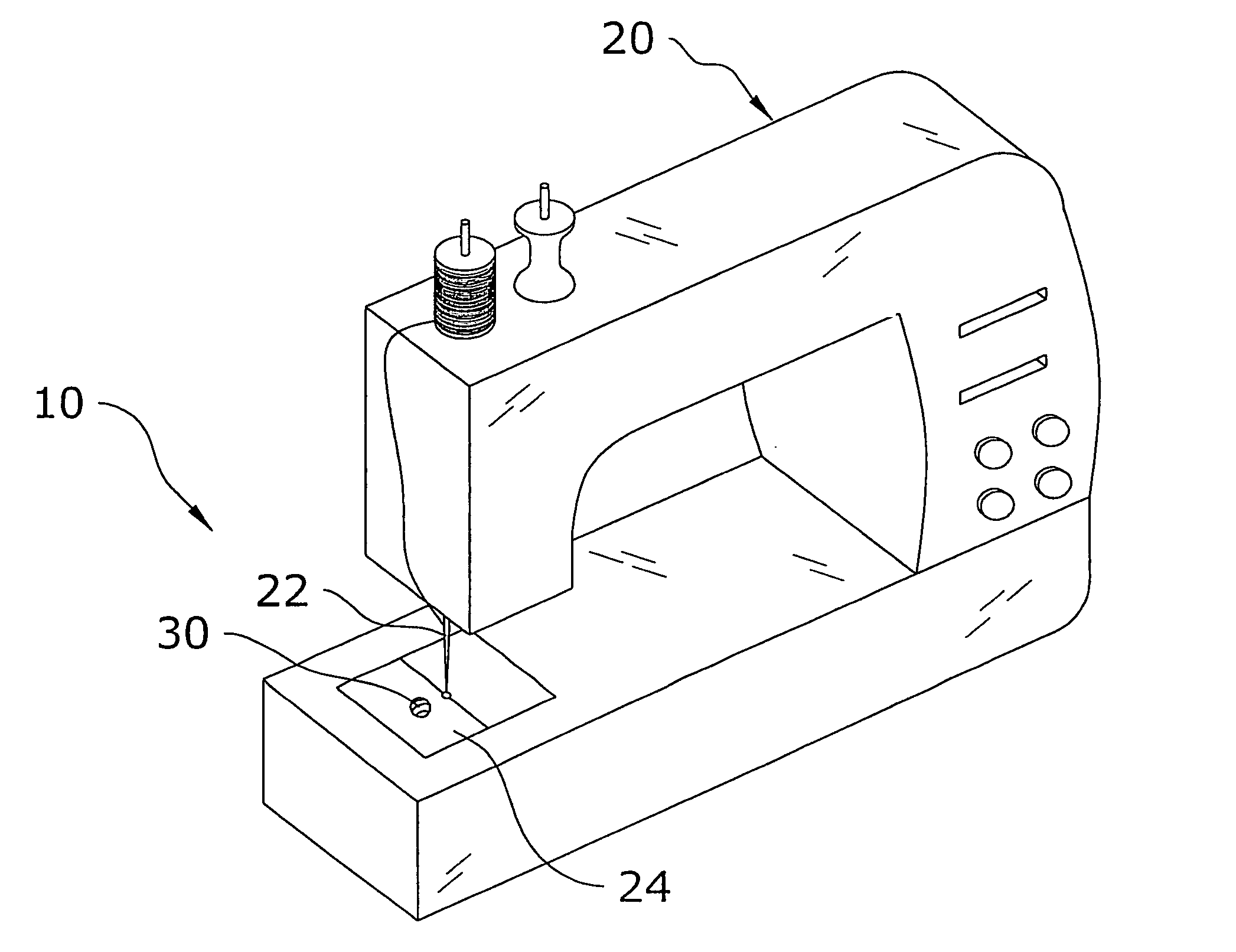

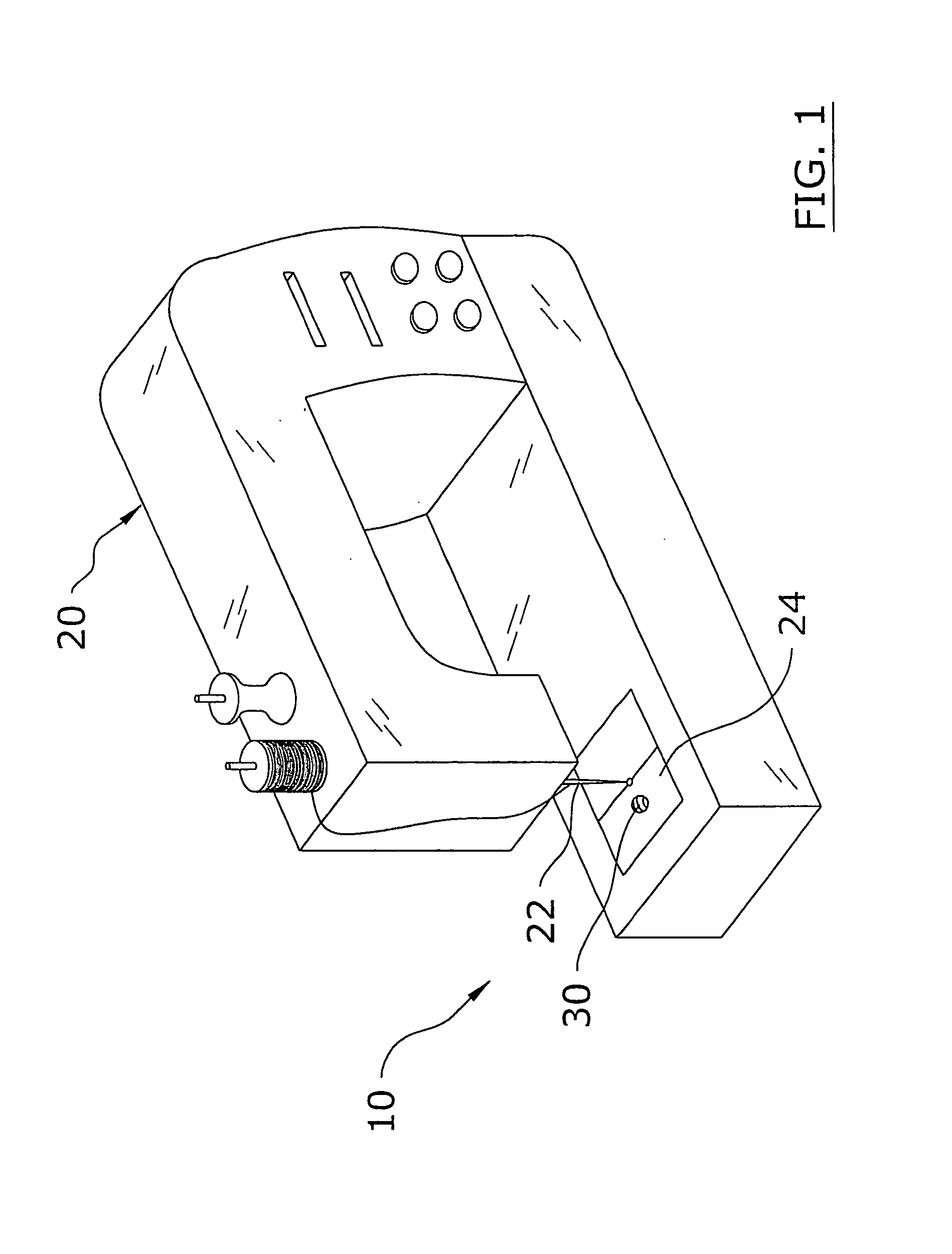

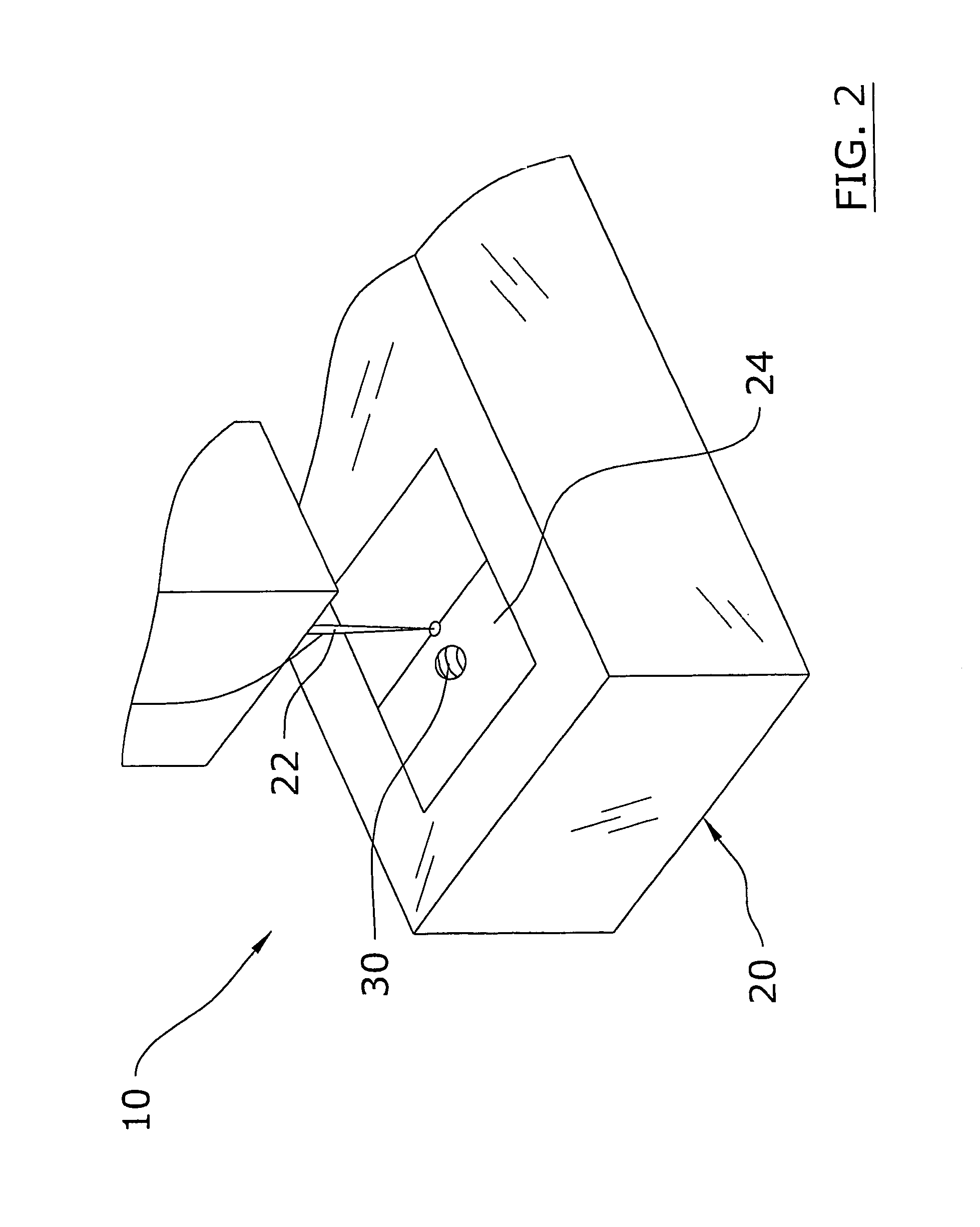

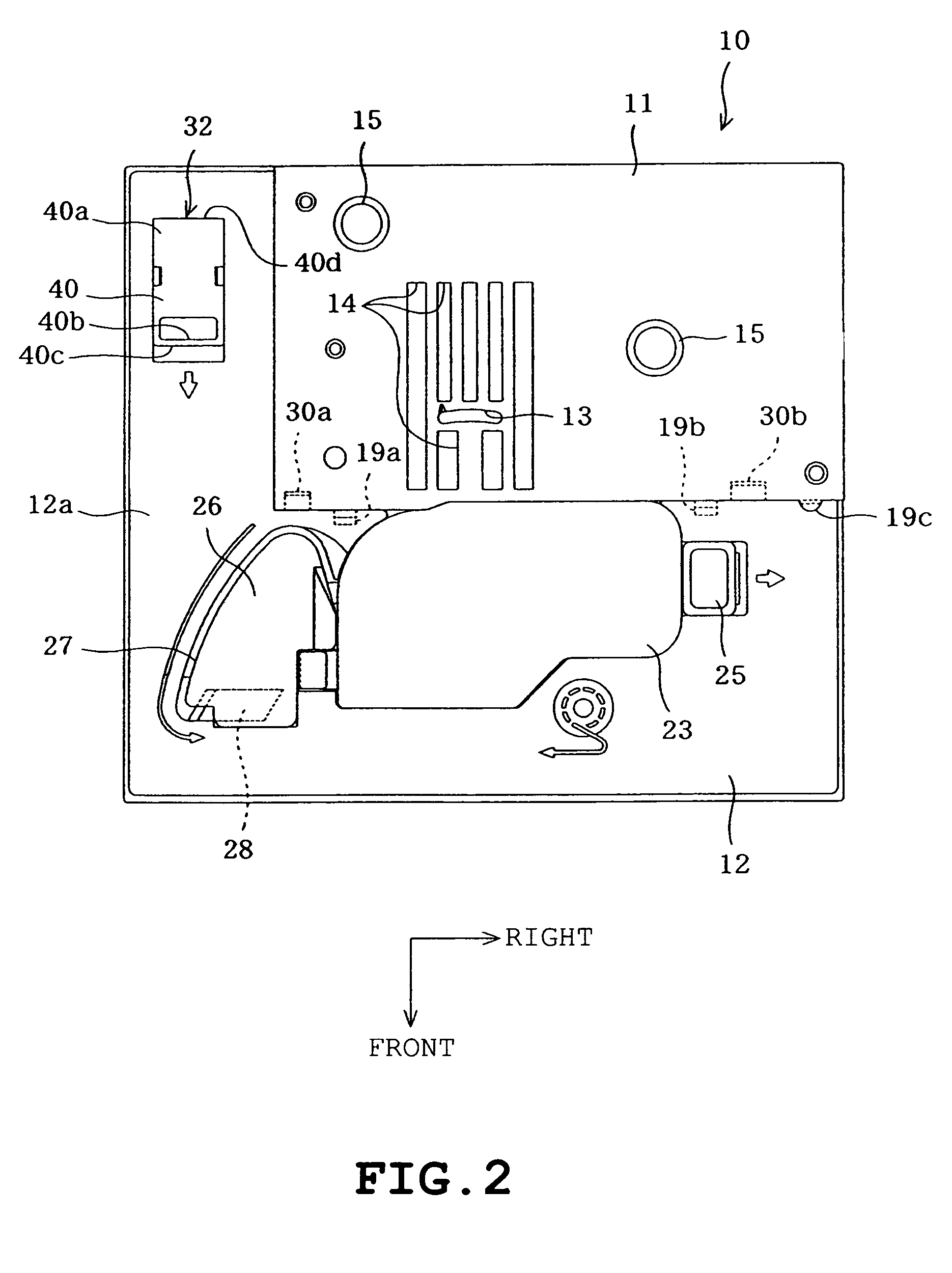

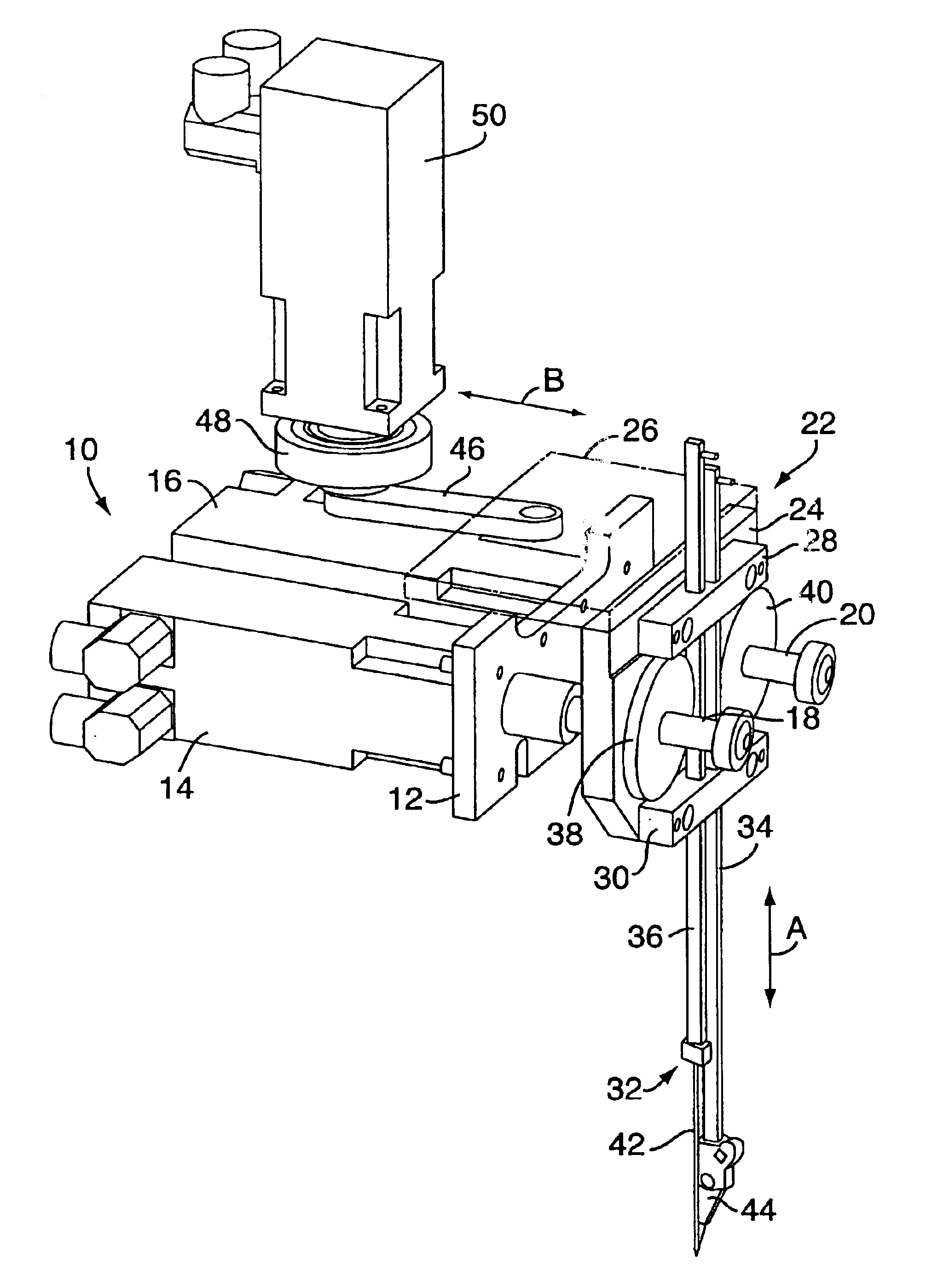

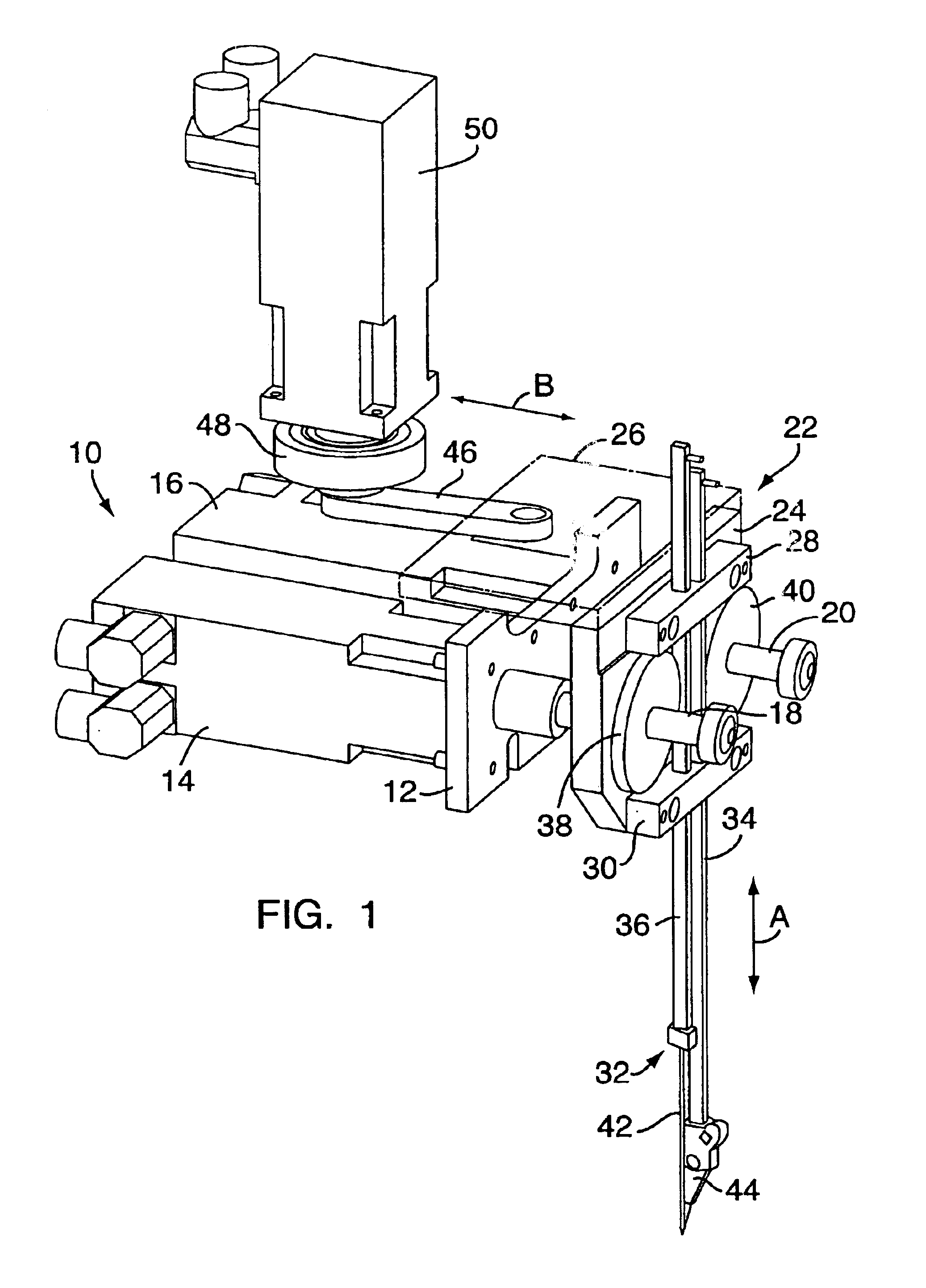

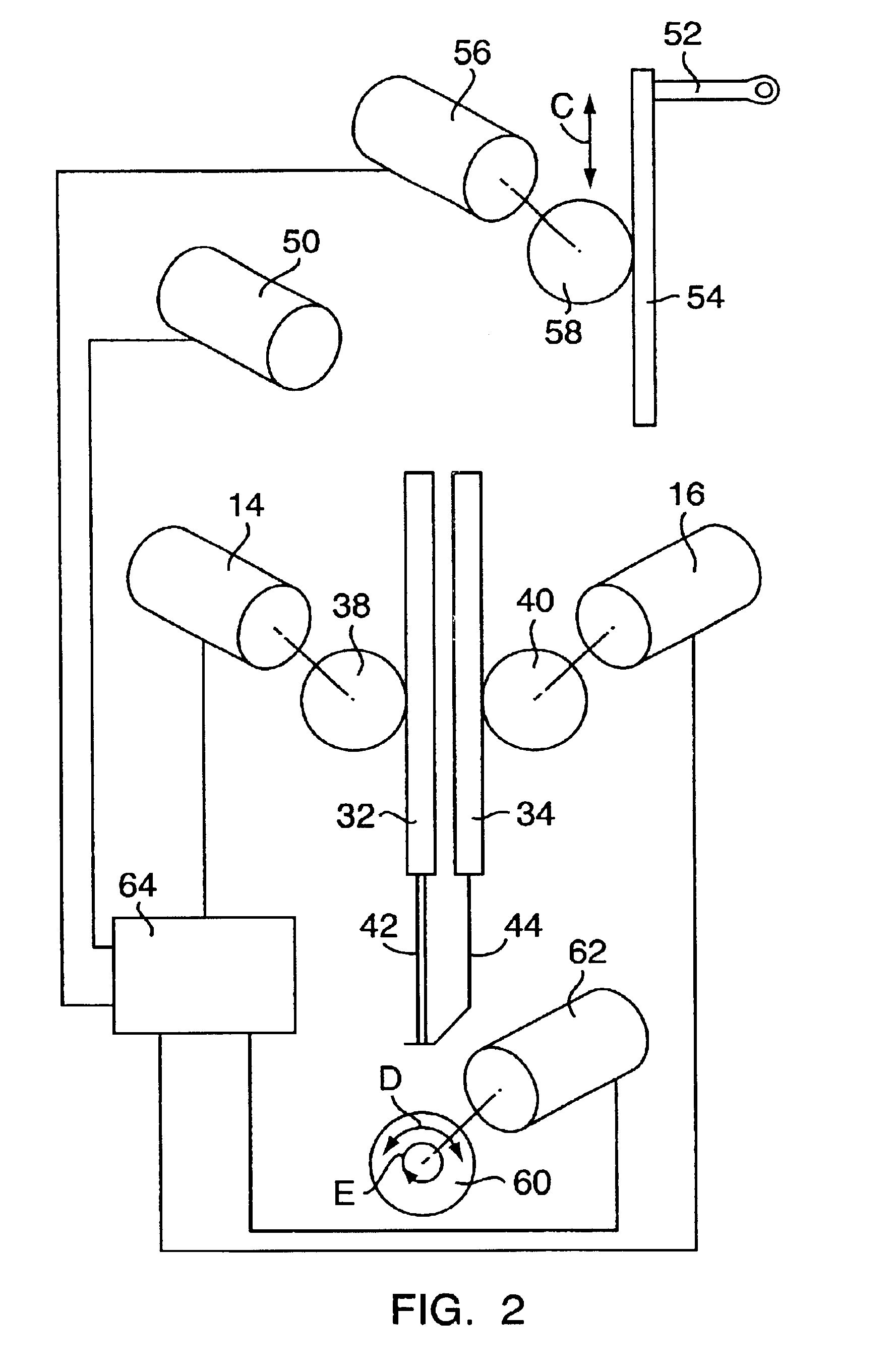

Optical stitch regulator system

InactiveUS6959657B1Effective supervisionProgramme-controlled sewing machinesSewing-machine casingsEngineeringControl unit

An optical stitch regulator system for efficiently regulating the stitch length and stitch frequency of a sewing machine. The optical stitch regulator system includes at least one optical sensor within or external of the sewing platform of a sewing machine for sensing the motion of the fabric being sewn. The motion data is communicated to a control unit which communicates with the sewing machine for controlling the stitch length and frequency.

Owner:DUVAL RICHARD J

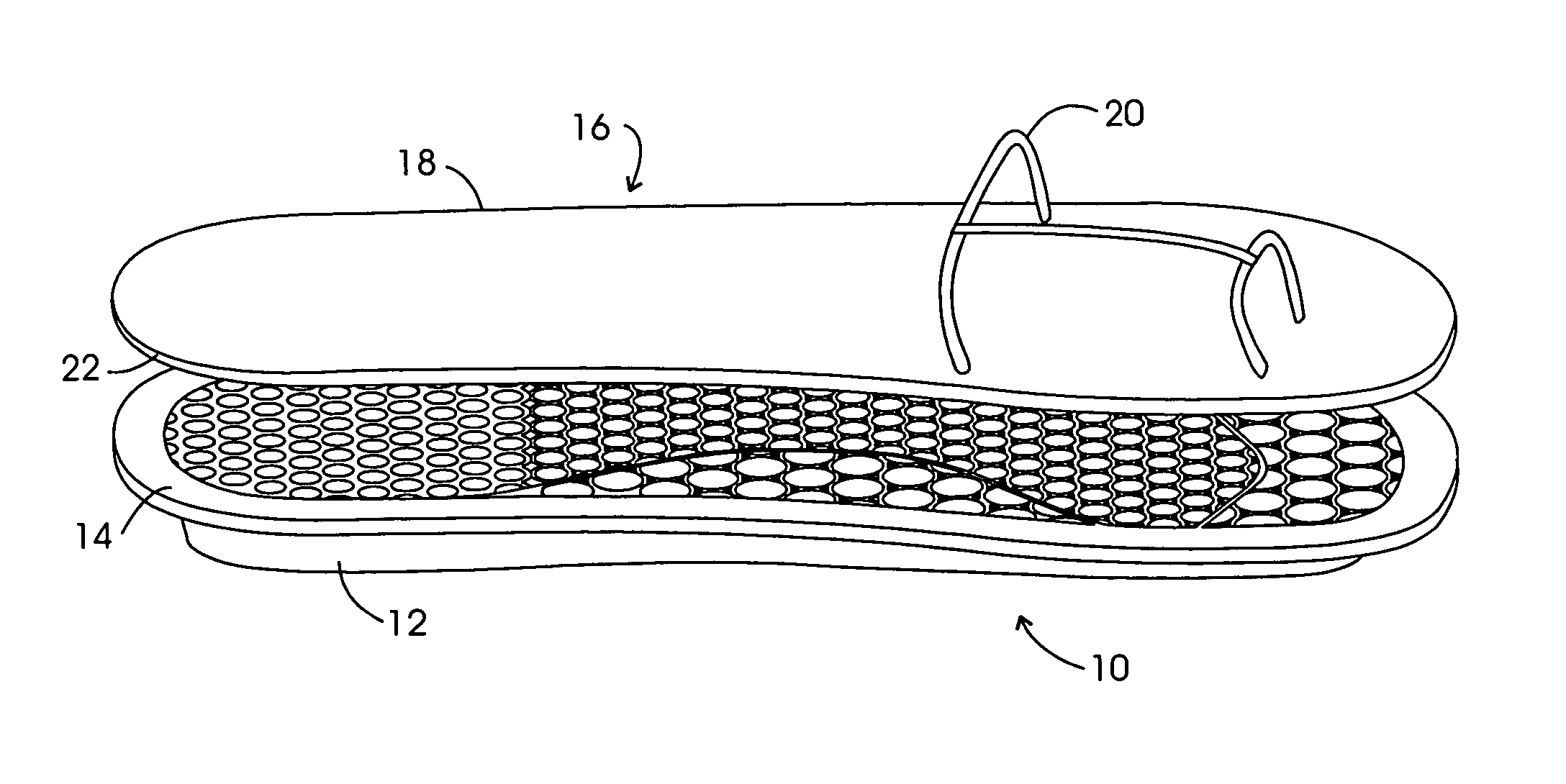

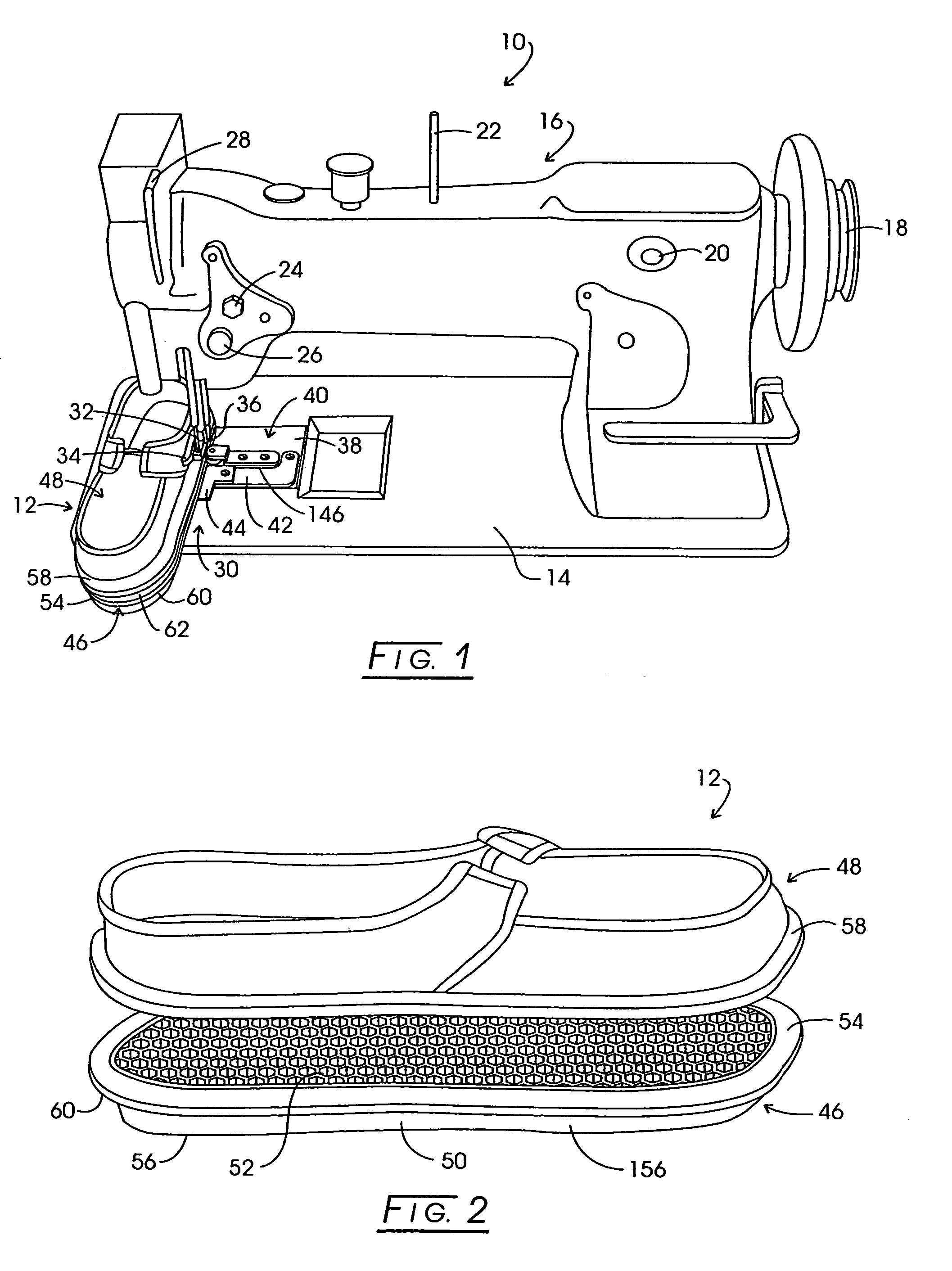

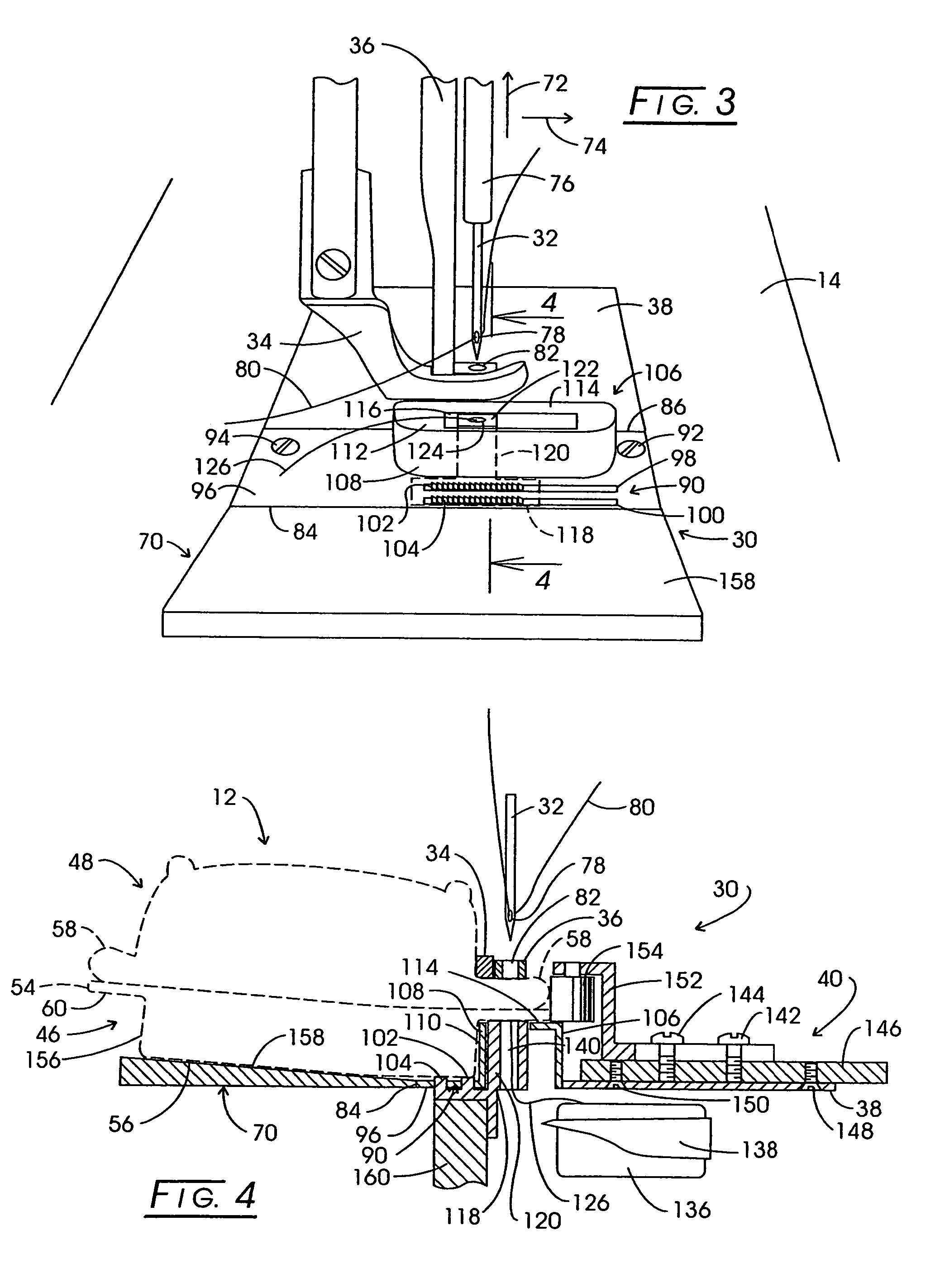

Elastomeric sole for use with converted flatbed sewing machine

The present invention addresses an elastomeric sole having a sidewall with a height less that 0.625 inch, forming a cavity and a horizontally disposed rim extending from the top surface of the sidewall. The sole includes at least two upstanding regions extending upwardly from the cavity lower surface, each region formed from elastomer and having a different effective modulus of elasticity. The invention also includes the combination of an elastomeric sole and an upper and a method for sewing an elastomeric sole to an upper by means of a converted sewing machine.

Owner:SEWING INNOVATIONS & MACHINE COMPANY

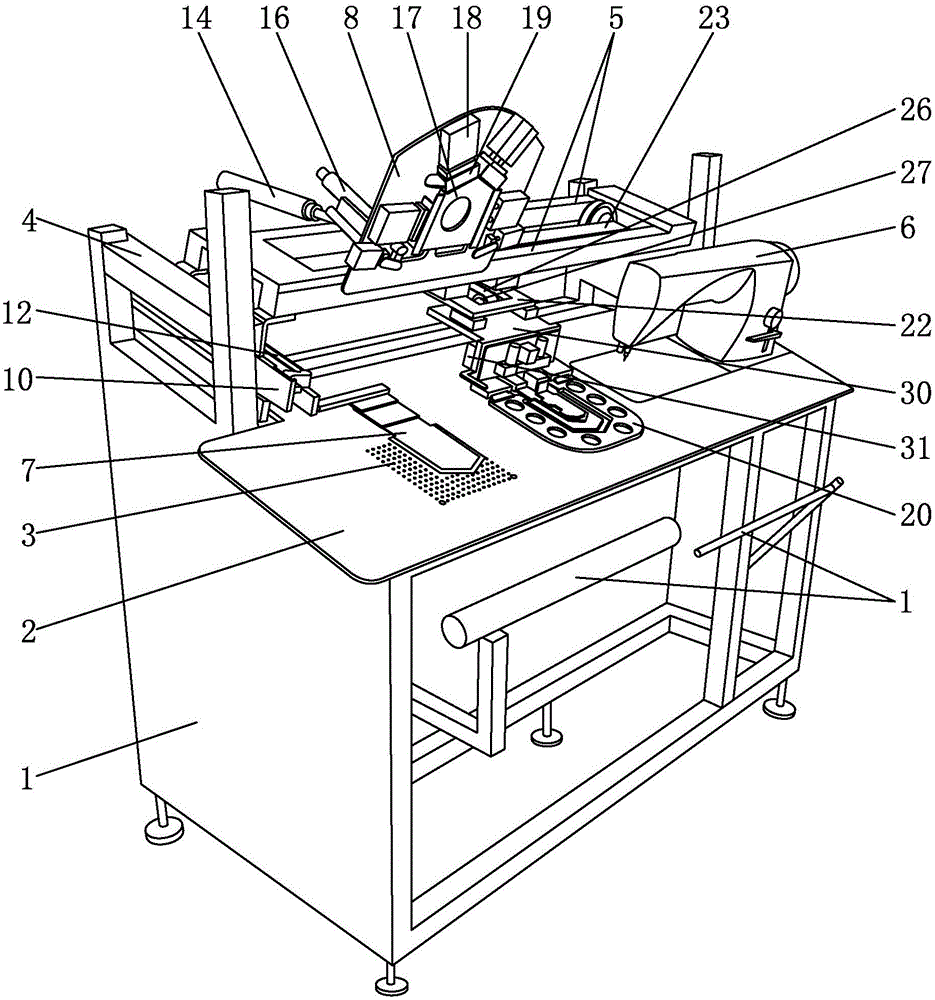

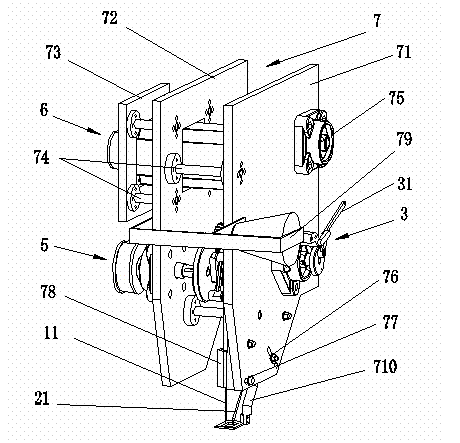

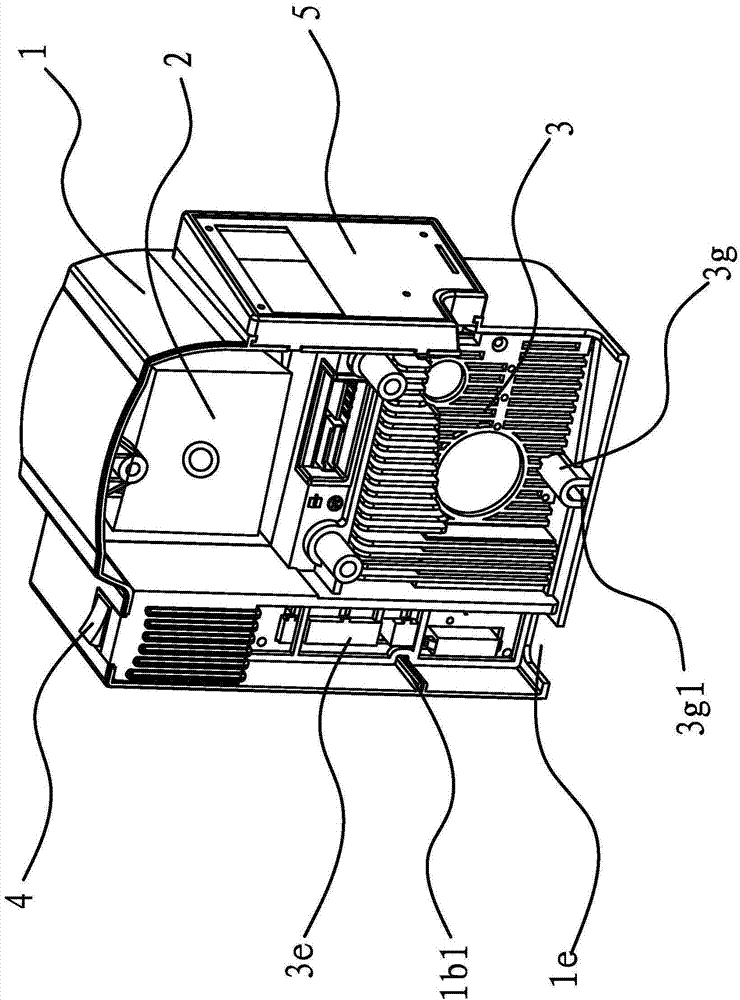

Patch pocket sewing machine

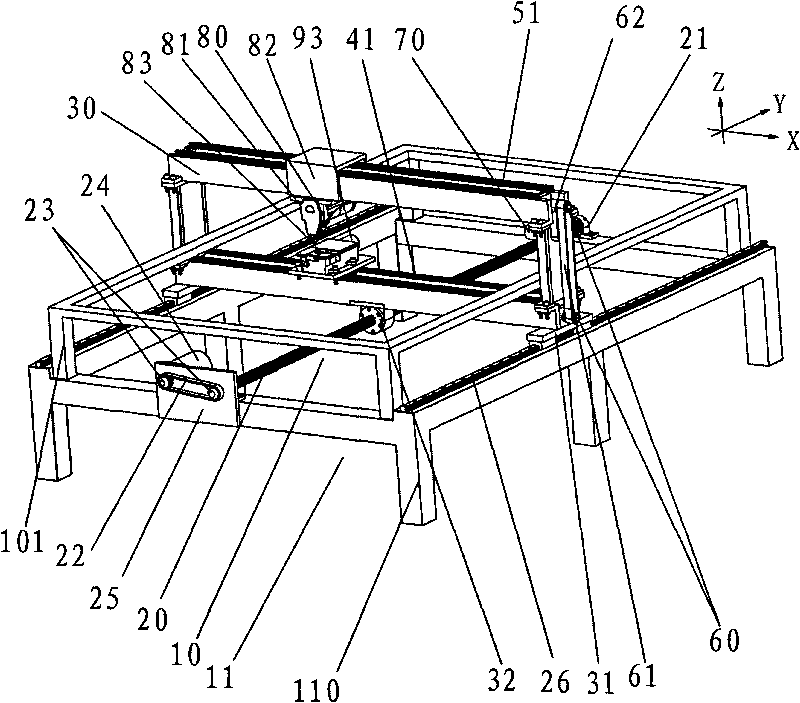

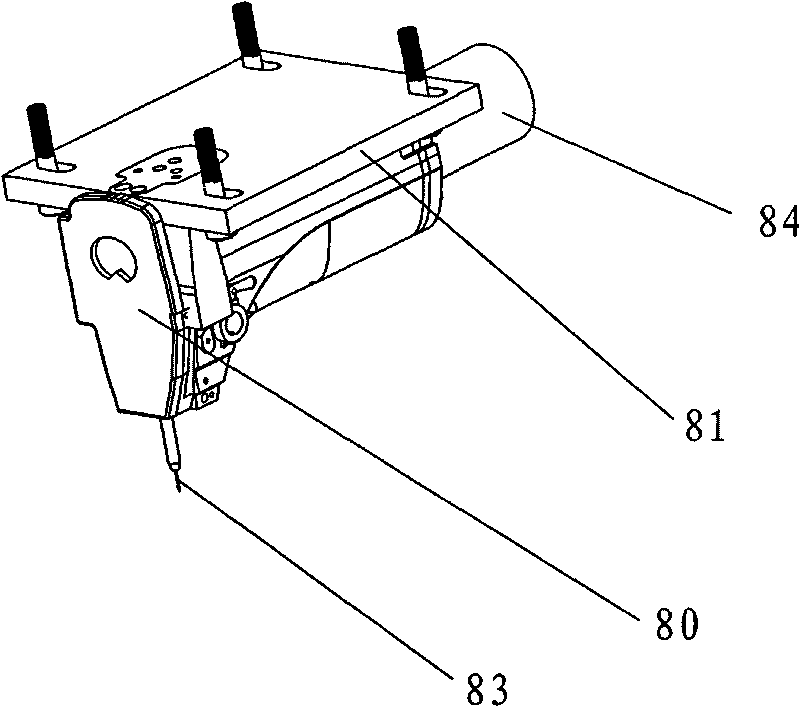

InactiveCN105839299AOutstanding and Beneficial Technical EffectsImprove qualitySewing-machine casingsWork-feeding meansEngineeringSewing machine

The invention belongs to the technical field of sewing machines, and particularly refers to a patch pocket sewing machine, including a body, the table of the workbench is high at the rear and low at the front to form a forward inclination, and a bracket is provided on the body at the rear side of the workbench, and the left side of the workbench There are upper and lower molds on the support for folding and shaping the pockets. The right side of the workbench is equipped with a sewing machine head that sews the pockets on the fabric. Move the folded pockets and fabrics on the left side of the workbench to the presser foot on the head side of the sewing machine. The presser foot can be driven by the servo motor to move horizontally and vertically. The advantage is: the table top of the workbench is higher at the rear and lower at the front to form a forward tilt , when sewing plaid shirt pockets or striped shirt pockets, it is convenient for the operator to align the grid or stripes on the pocket with the grid or stripes on the fabric, so that there is no obvious splicing trace between the sewn pocket and the fabric, which improves the The sewing workmanship of the shirt pocket effectively improves the quality of the shirt.

Owner:蔡丰俭

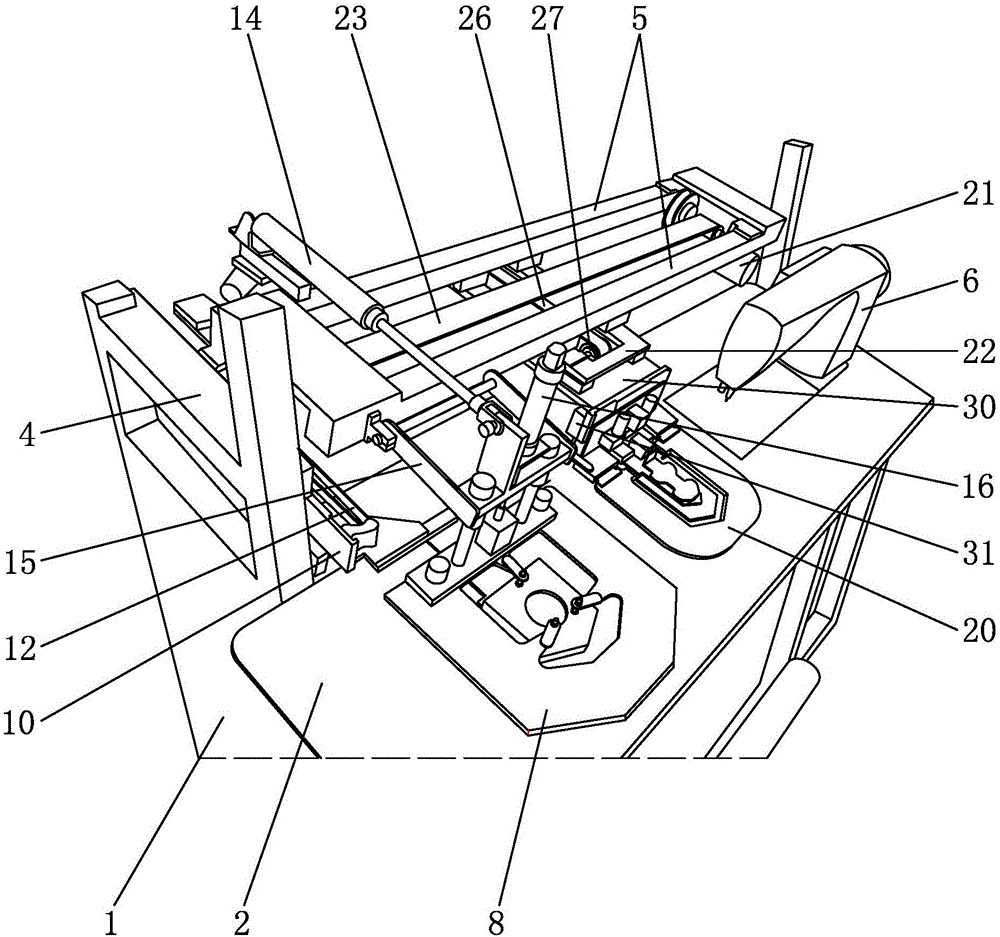

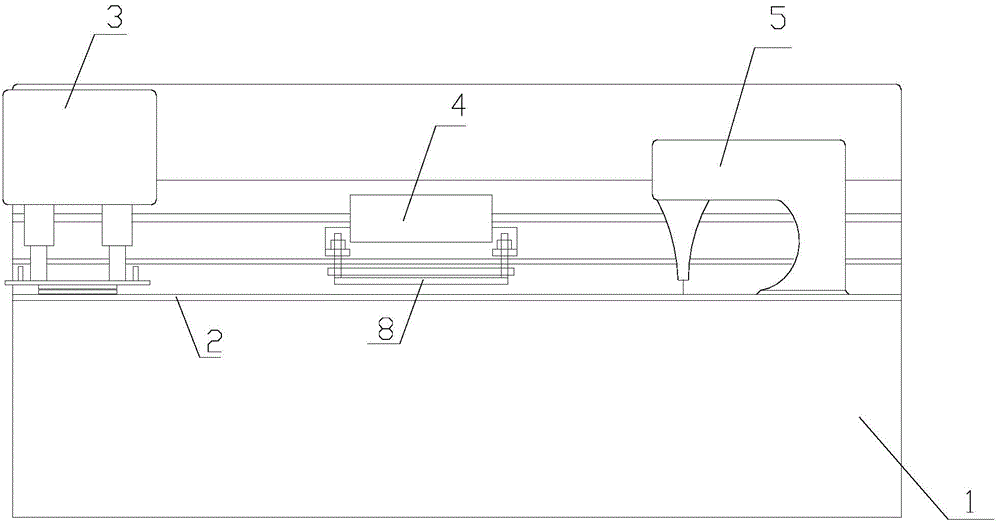

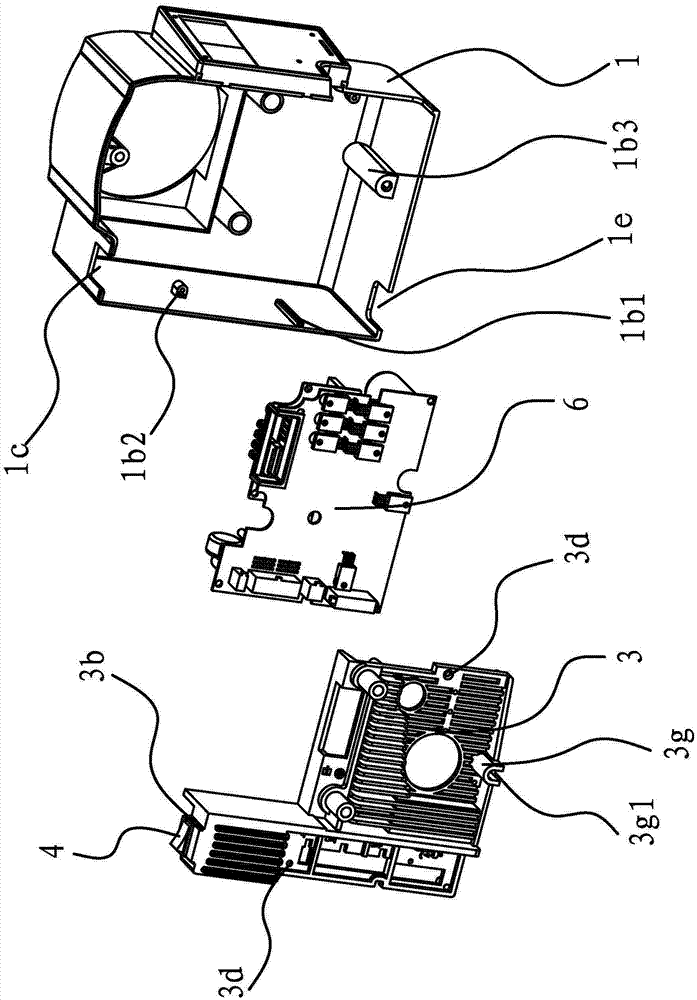

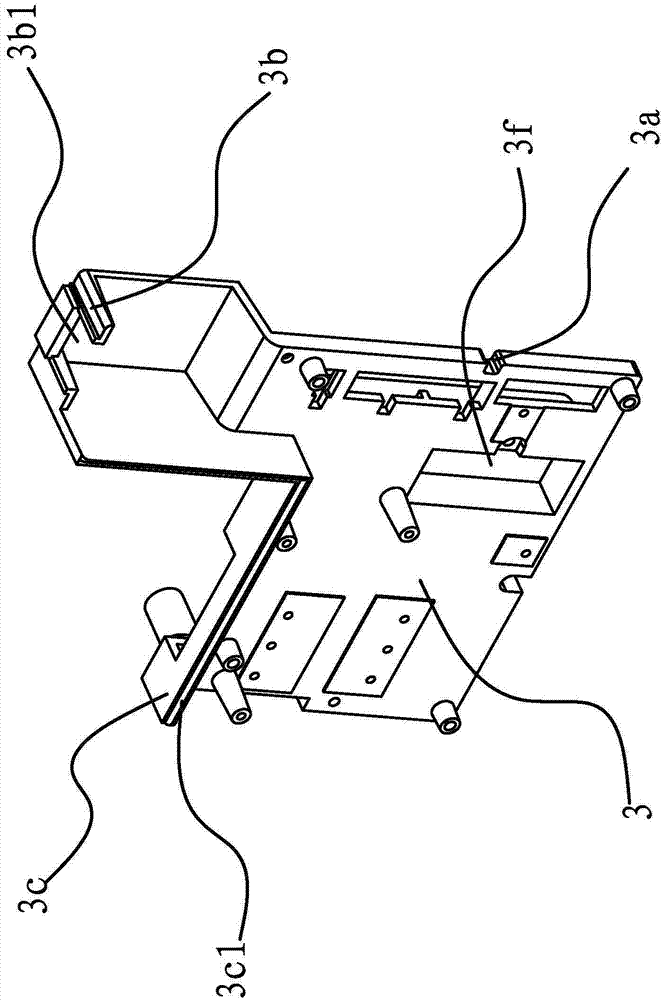

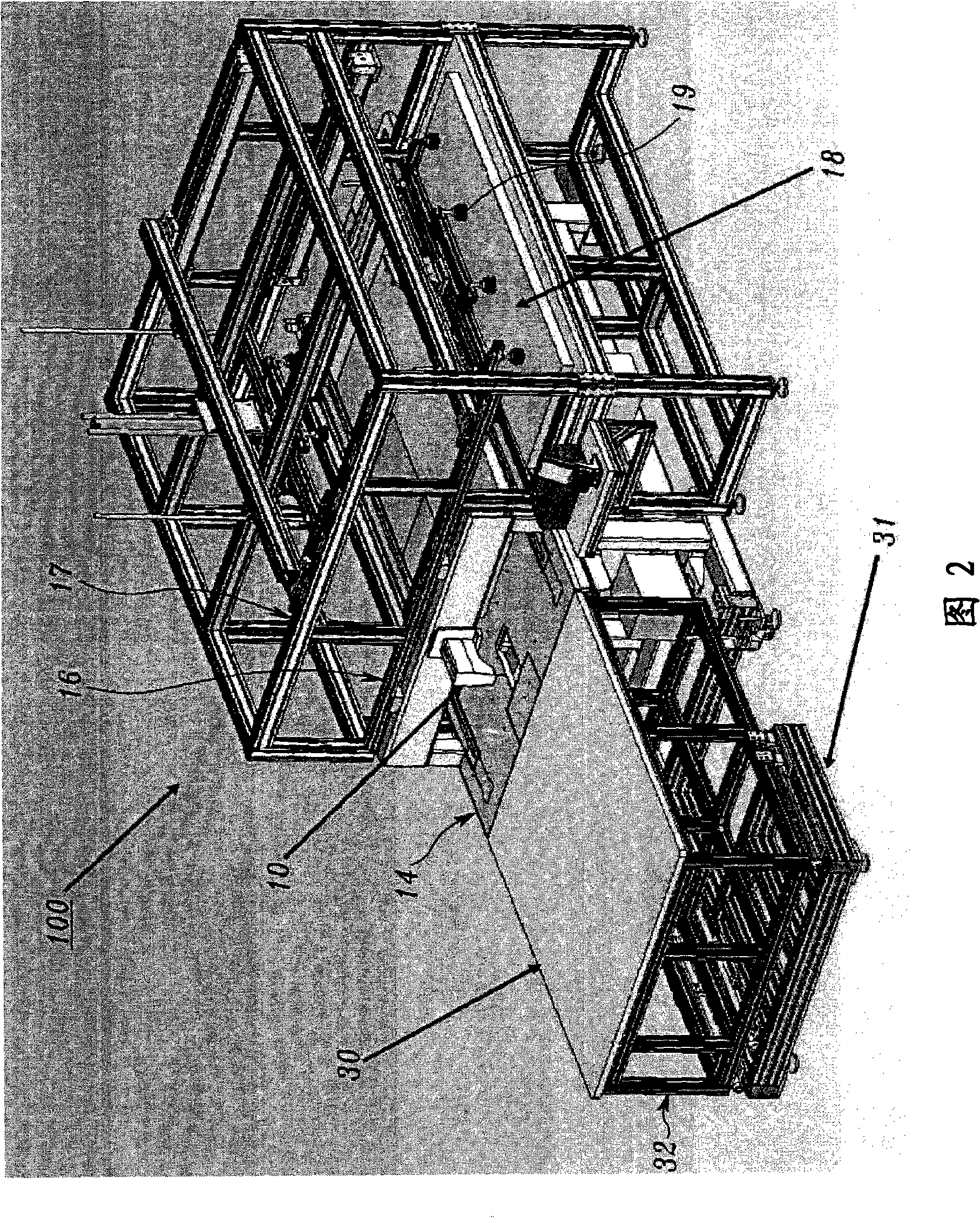

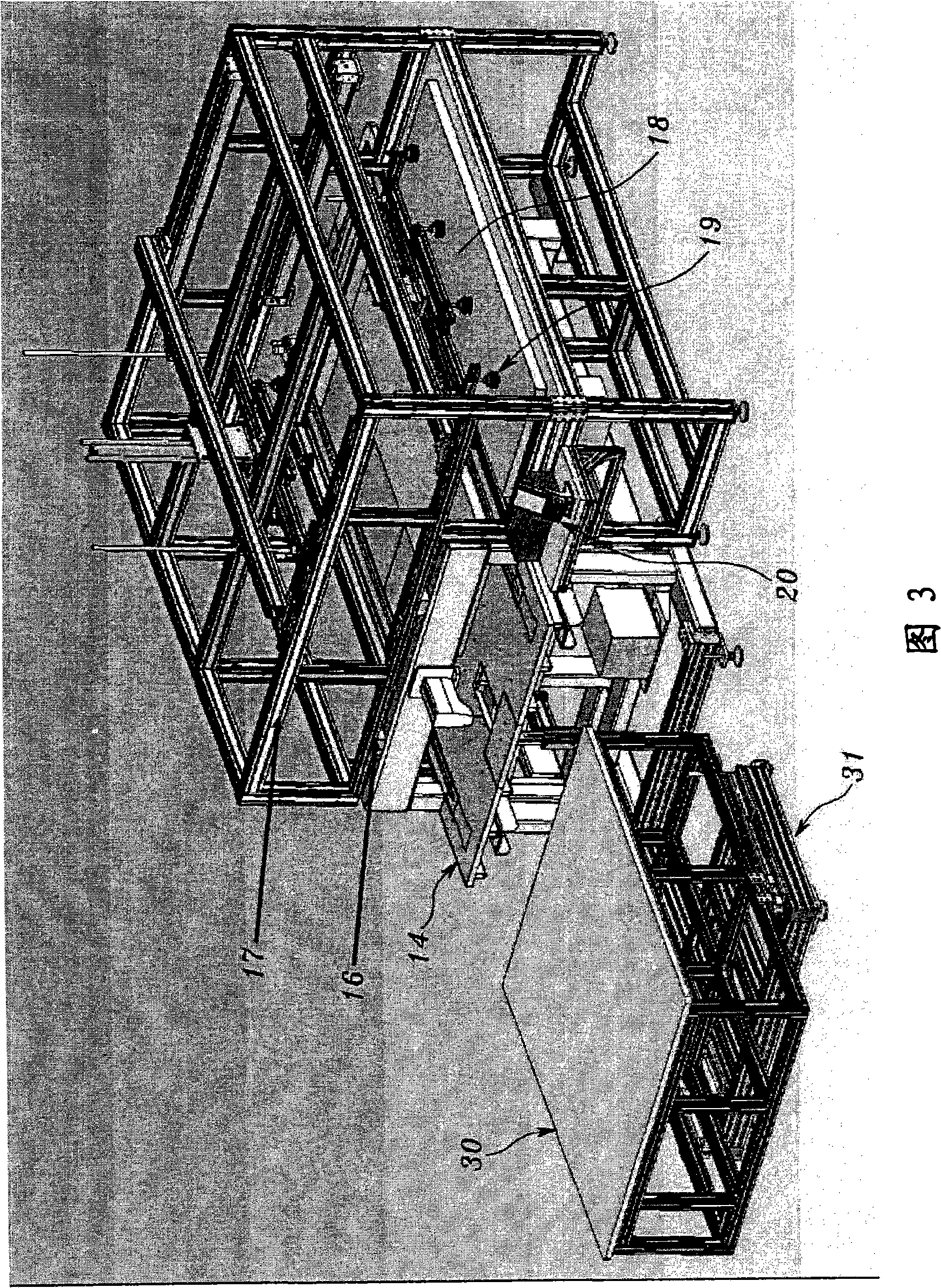

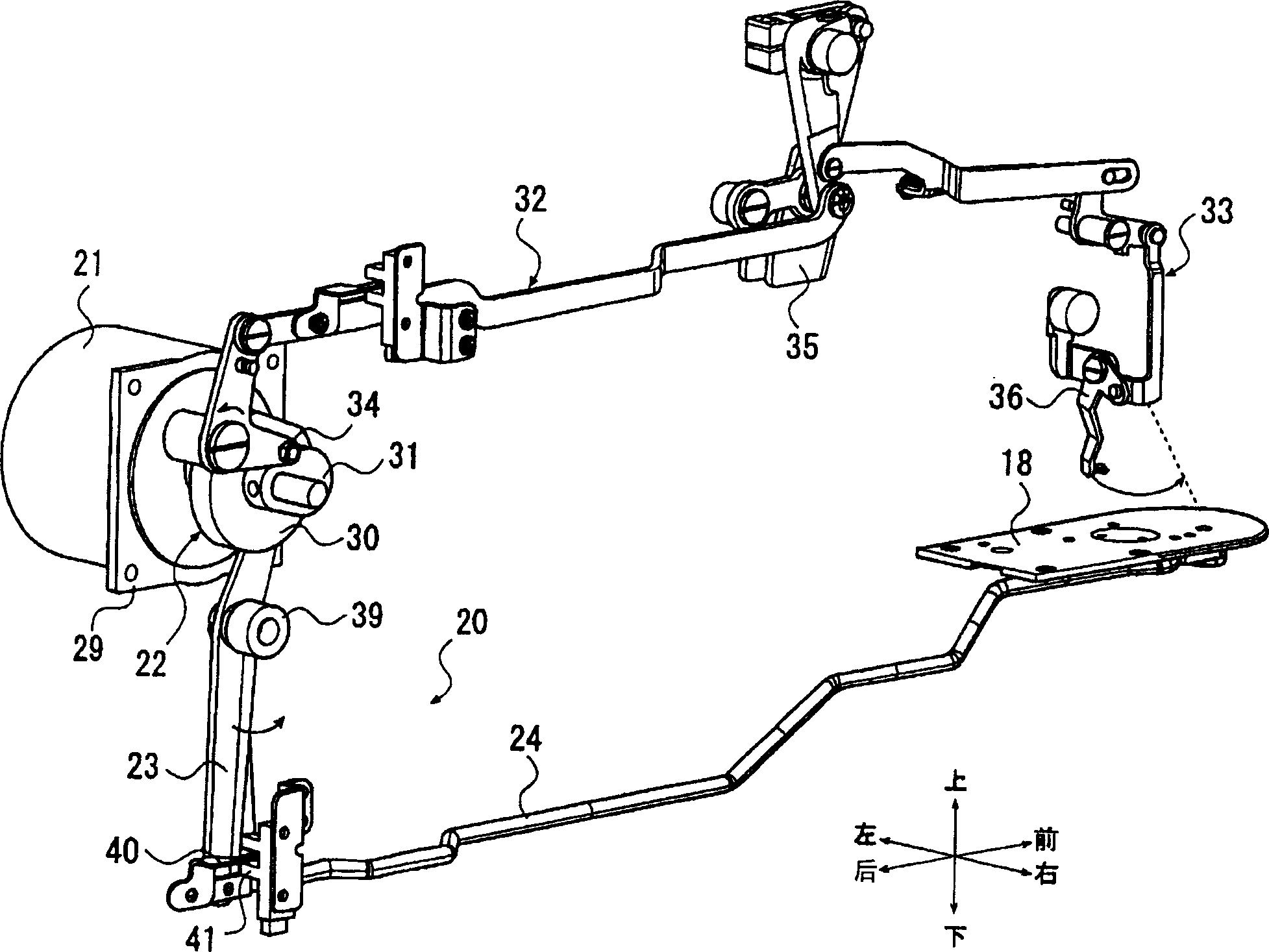

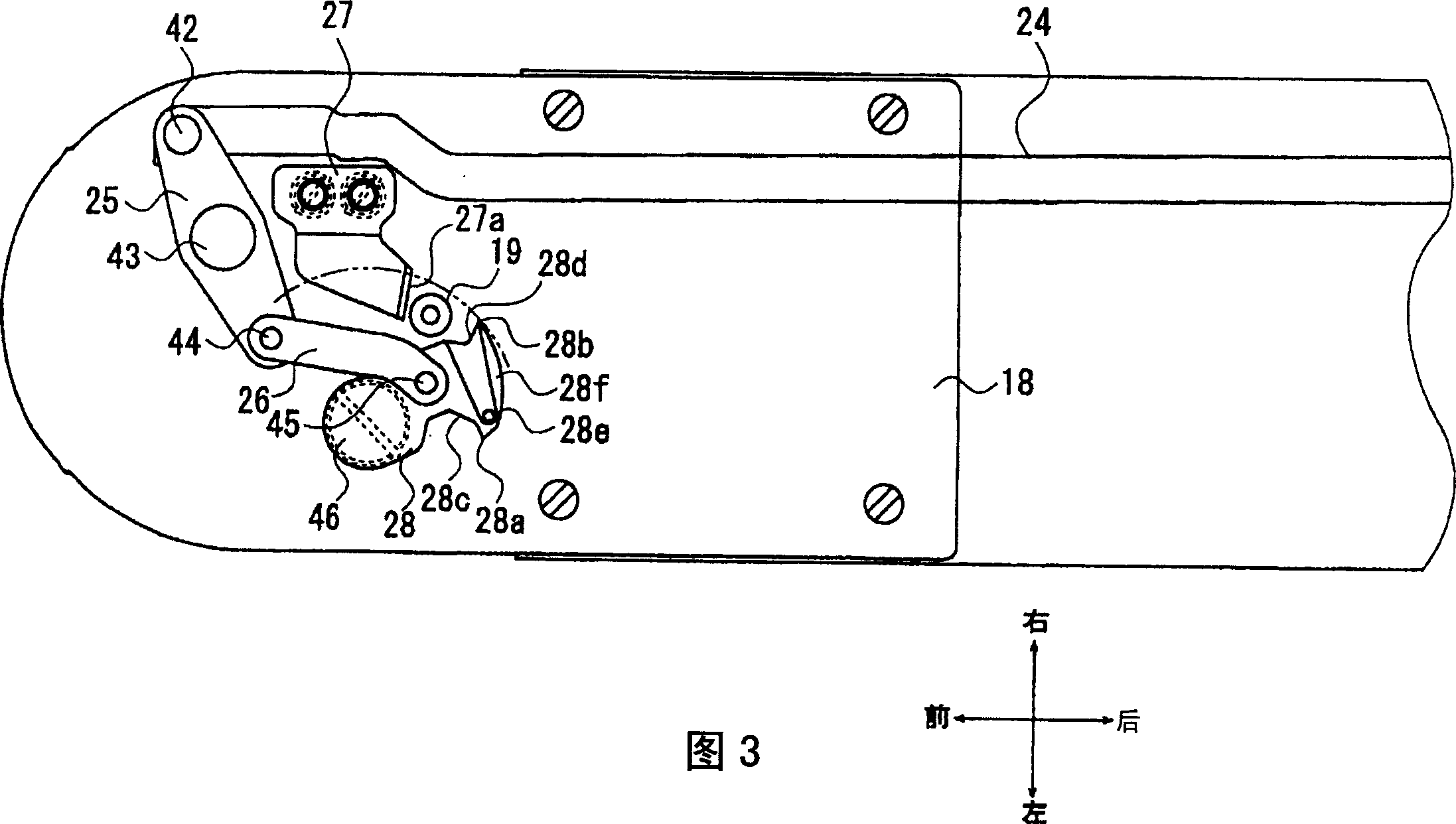

Machine head and machine base split type pattern sewing machine

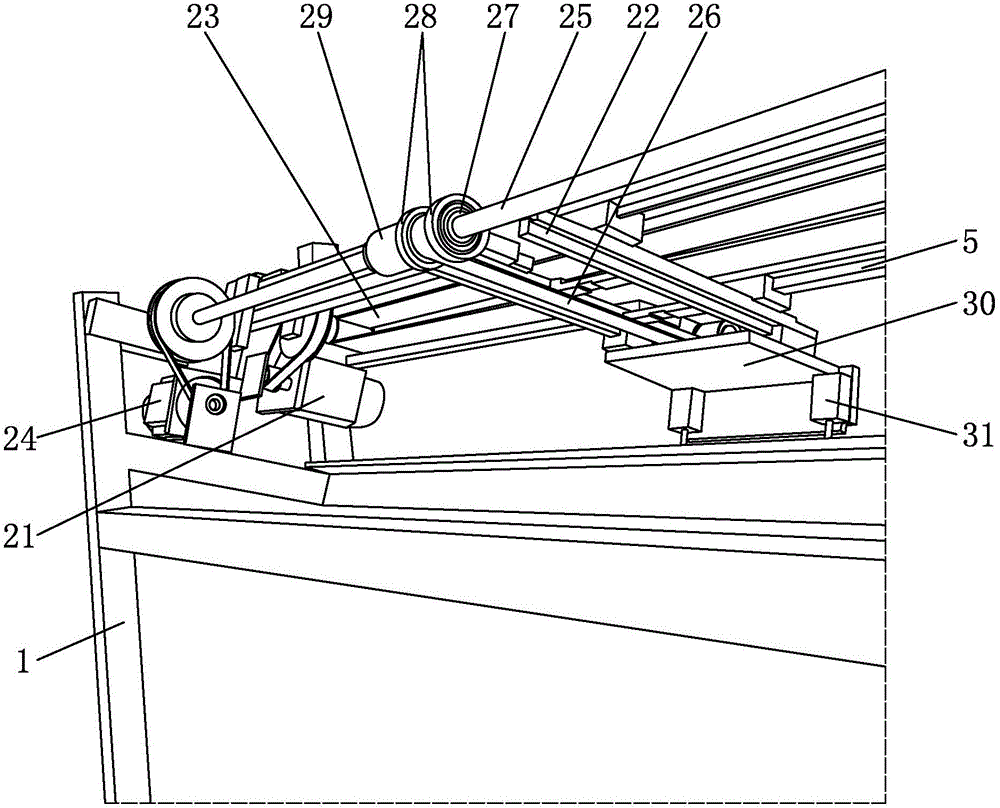

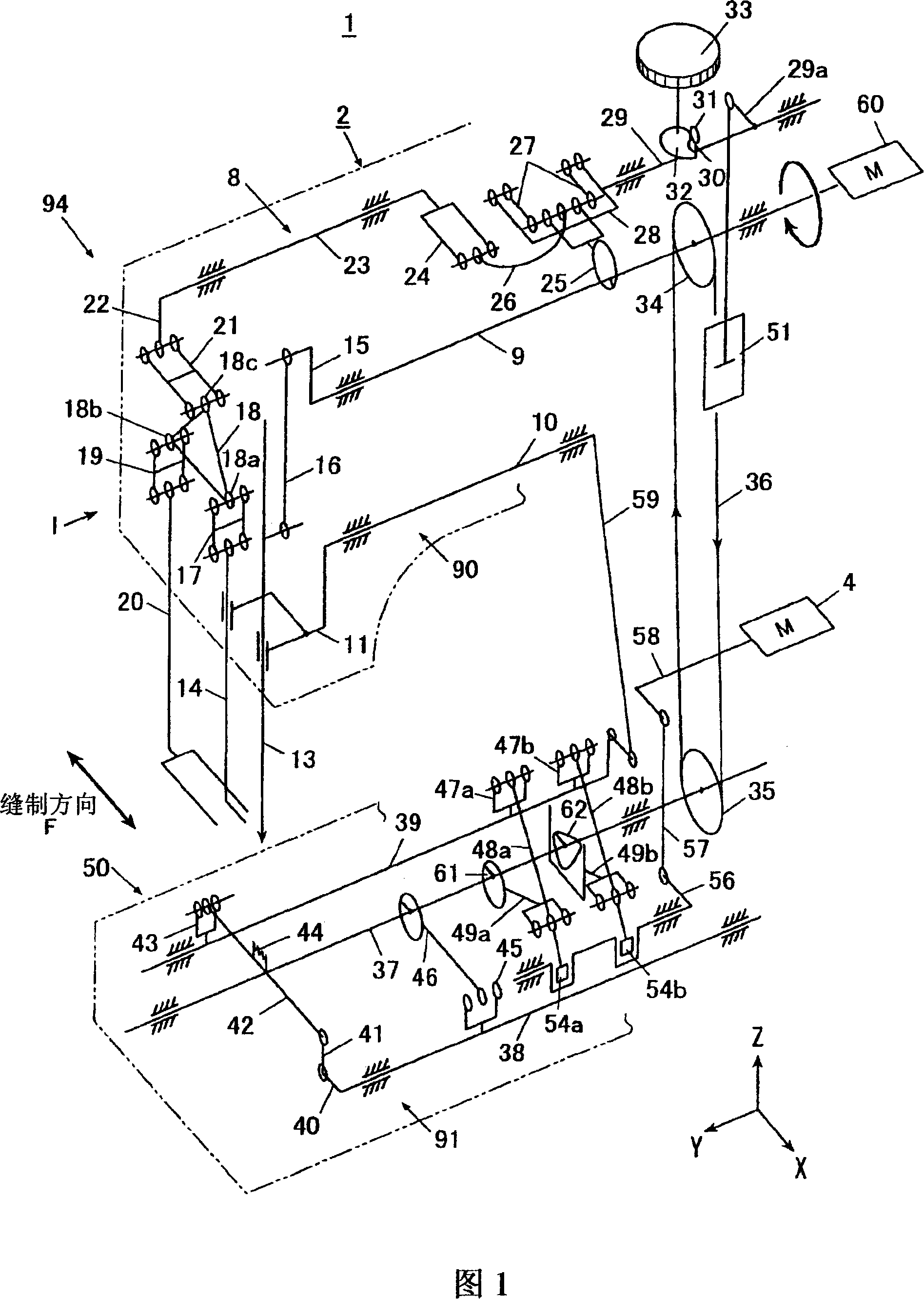

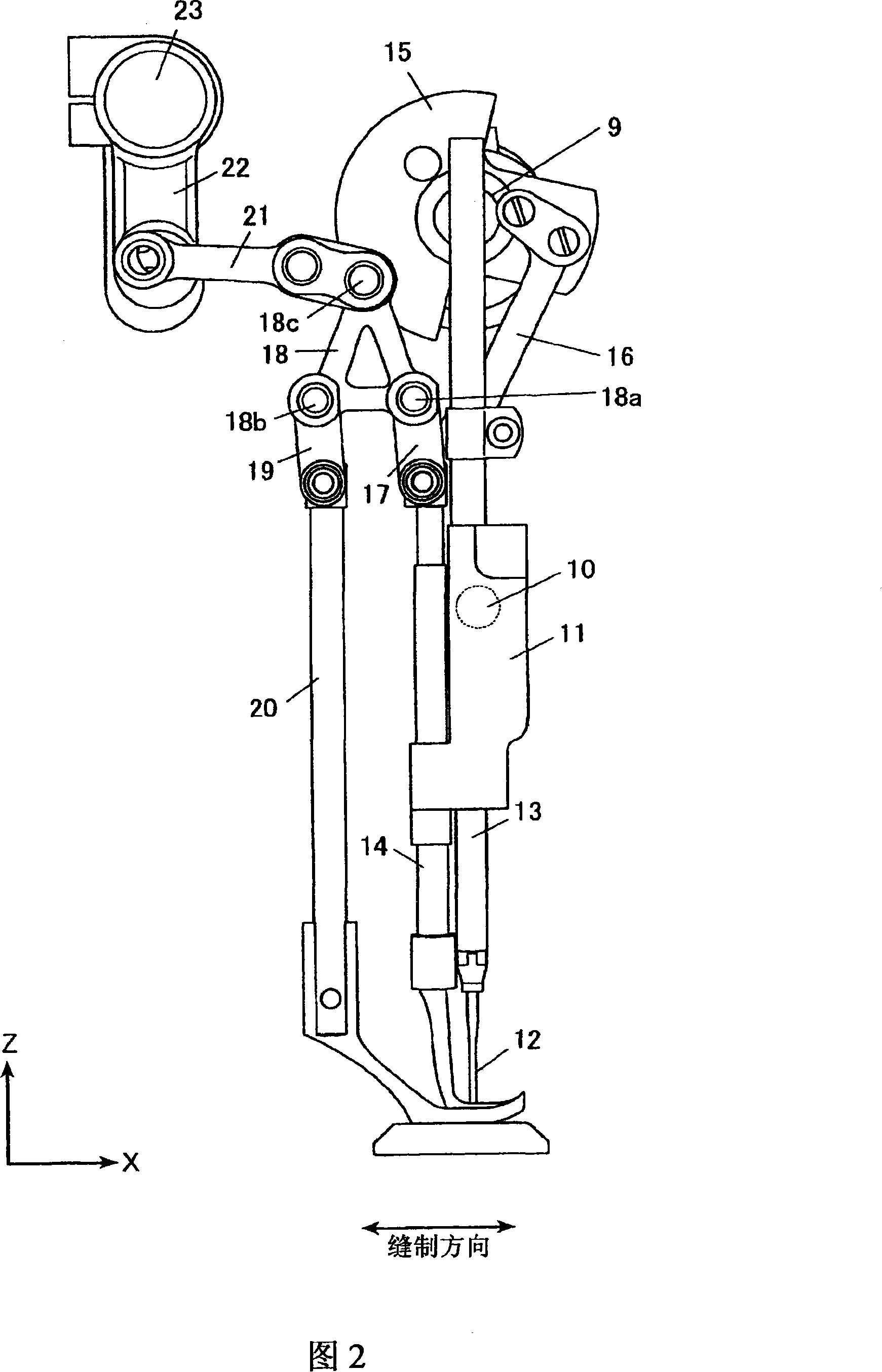

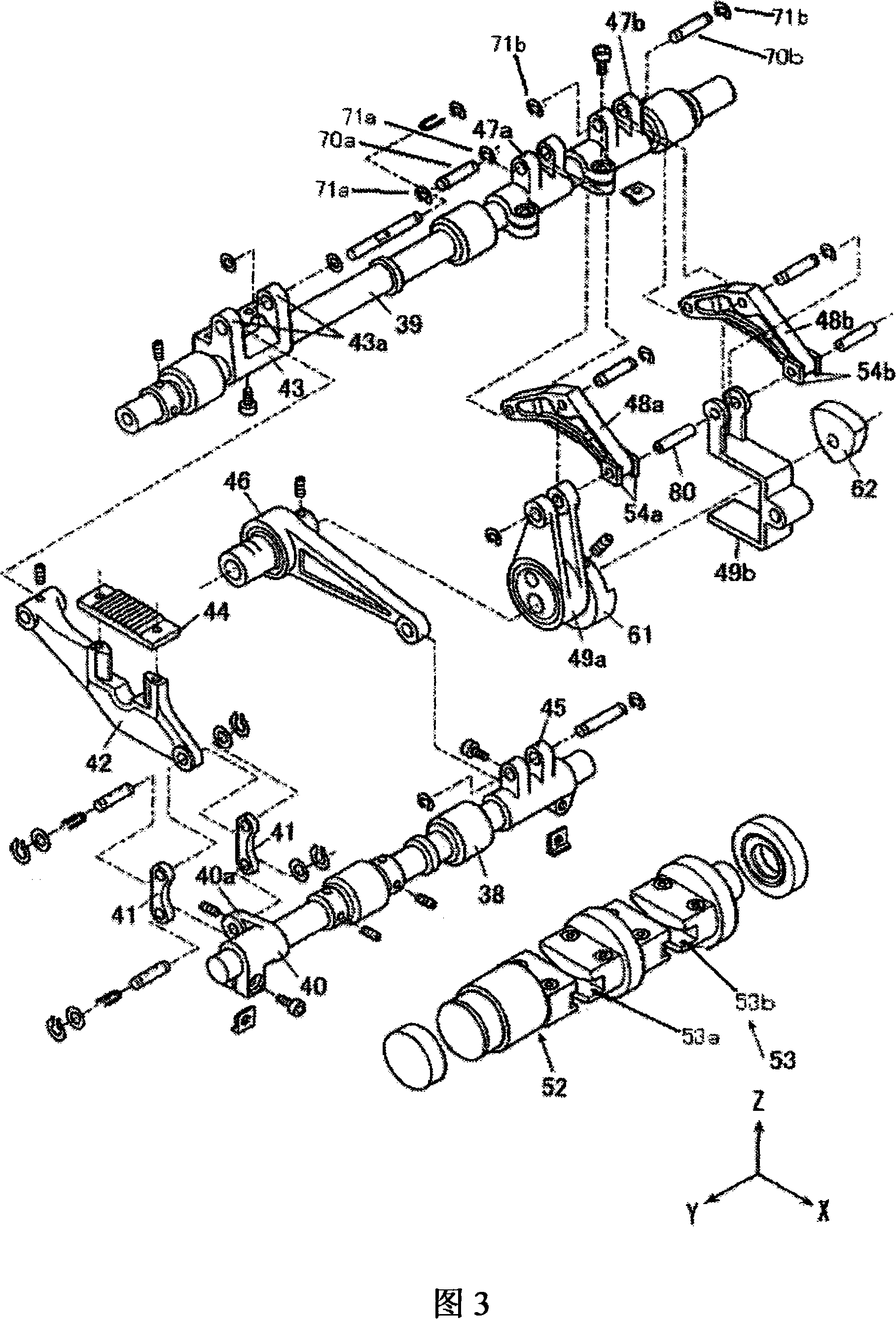

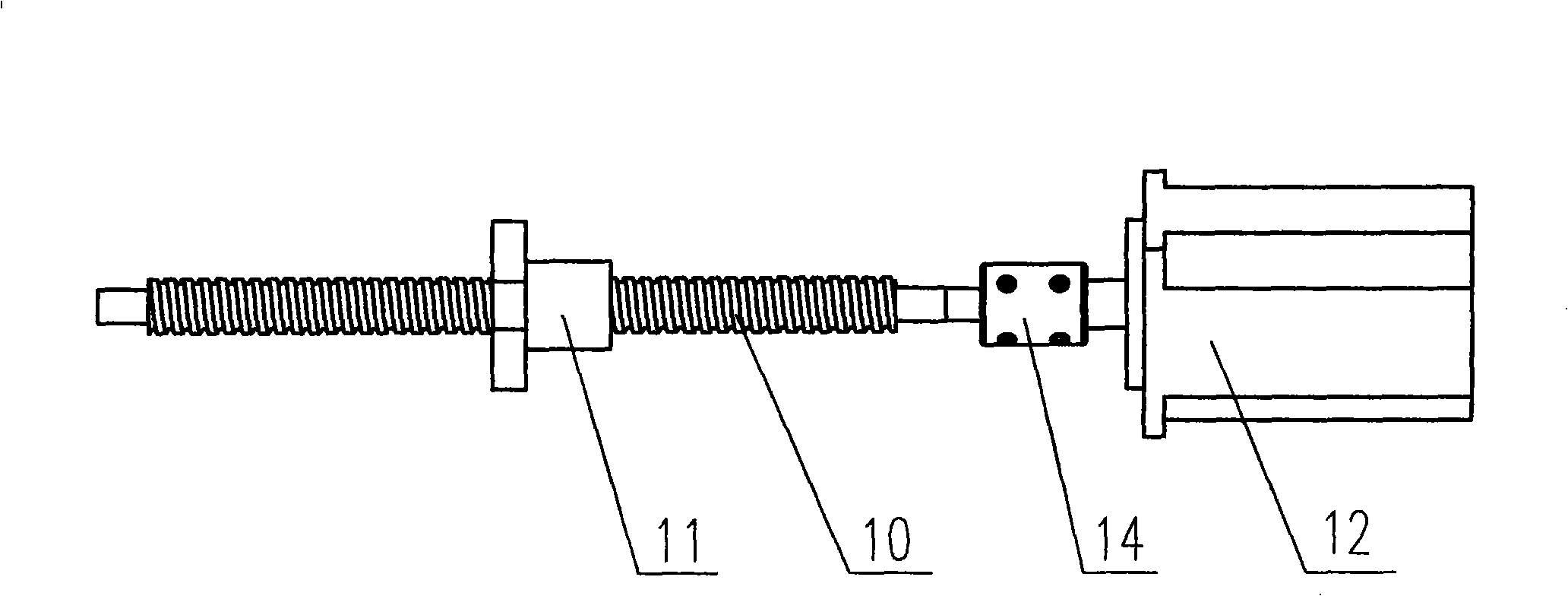

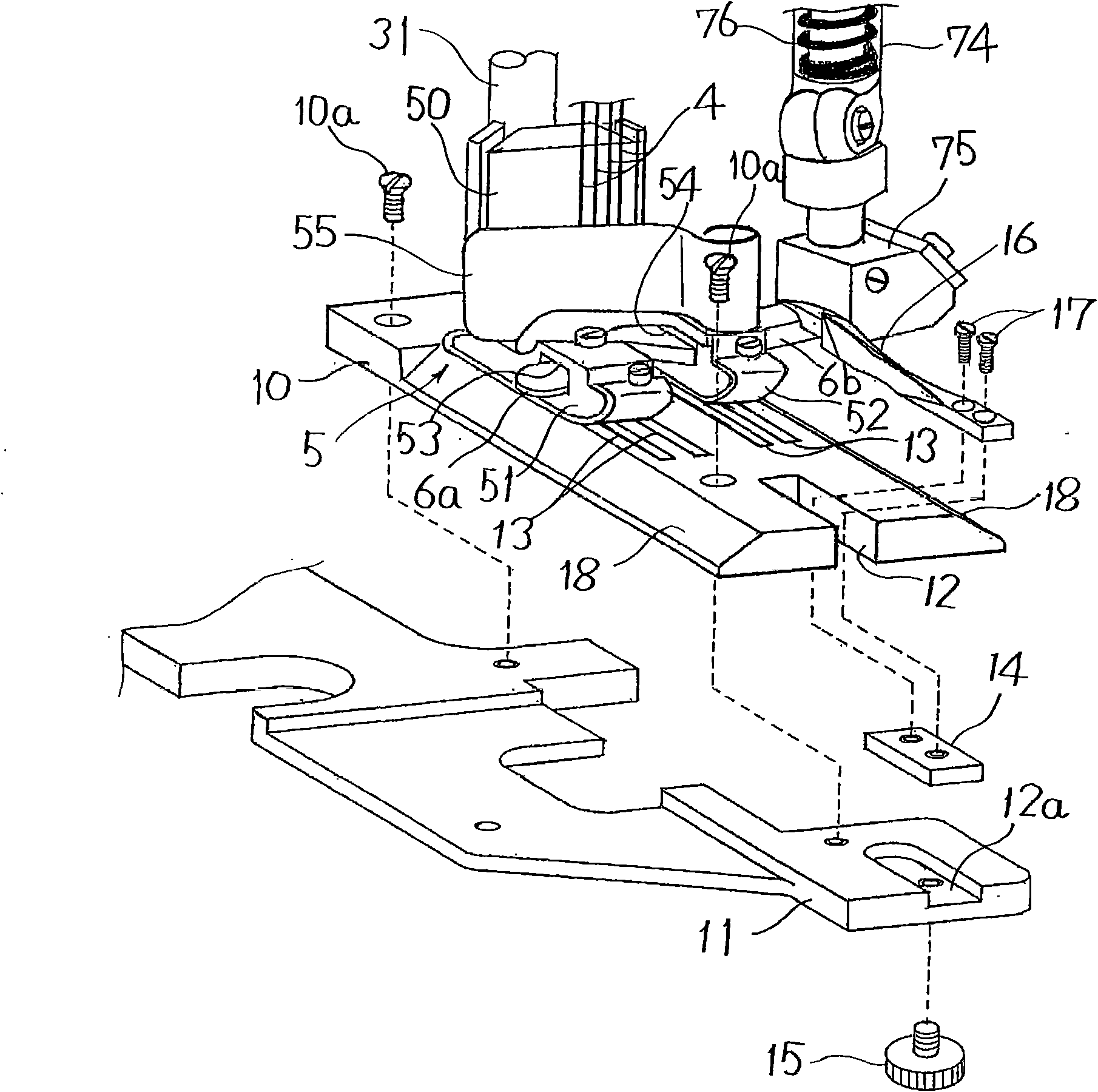

InactiveCN101696534ASimple structureEasy to operateSewing-machine casingsWork-feeding meansBall screwElectric machinery

The invention relates to a machine head and machine base split type pattern sewing machine belonging to the technical field of sewing machines. The machine head and machine base split type pattern sewing machine comprises an X-direction feed device, a Y-direction feed device, a machine head, a machine base and a stand, wherein the X-direction feed device and the Y-direction feed device are driven by respectively independent motors; the Y-direction feed device drives the X-direction feed device to move along a Y direction; the X-direction feed device is provided with a double-ball screw, and the synchronous feed of the double-ball screw is realized through a synchronous belt so that the machine base and the machine head which are arranged on the X-direction feed device can synchronously move. The invention has simple structure and easy operation and can move along an X direction and the Y direction and achieve the purposes of sewing patterns with large areas and enhancing the work efficiency; in addition; the pattern sewing machine can more stably work through the double-ball screw arranged on the X-direction feed device.

Owner:JACK SEWING MASCH CO LTD

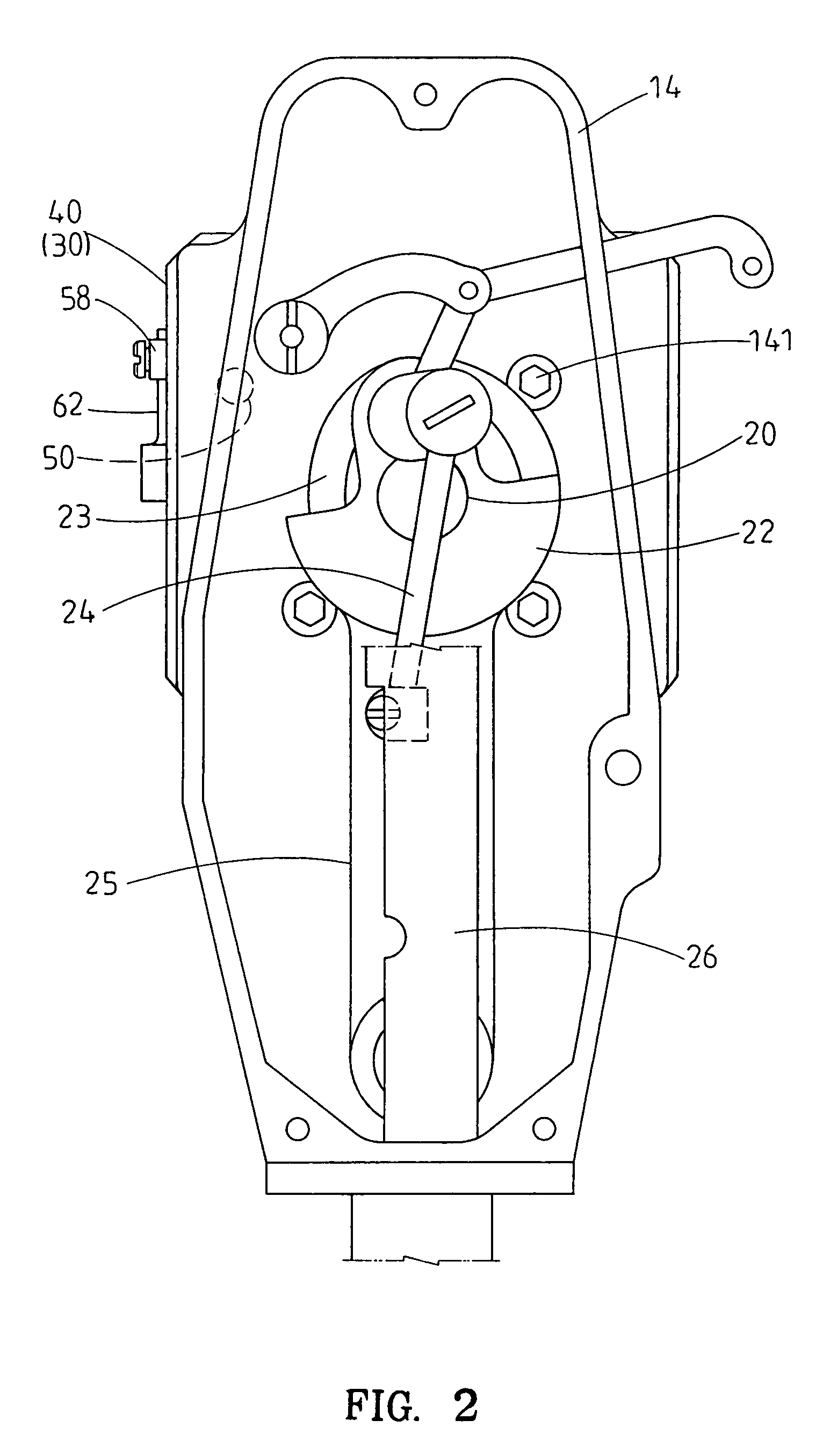

Feeding mechanism for sewing machine

InactiveCN101168885AEasy to operateImprove productivitySewing-machine casingsWork-feeding meansEngineeringCam

Owner:JUKI CORP

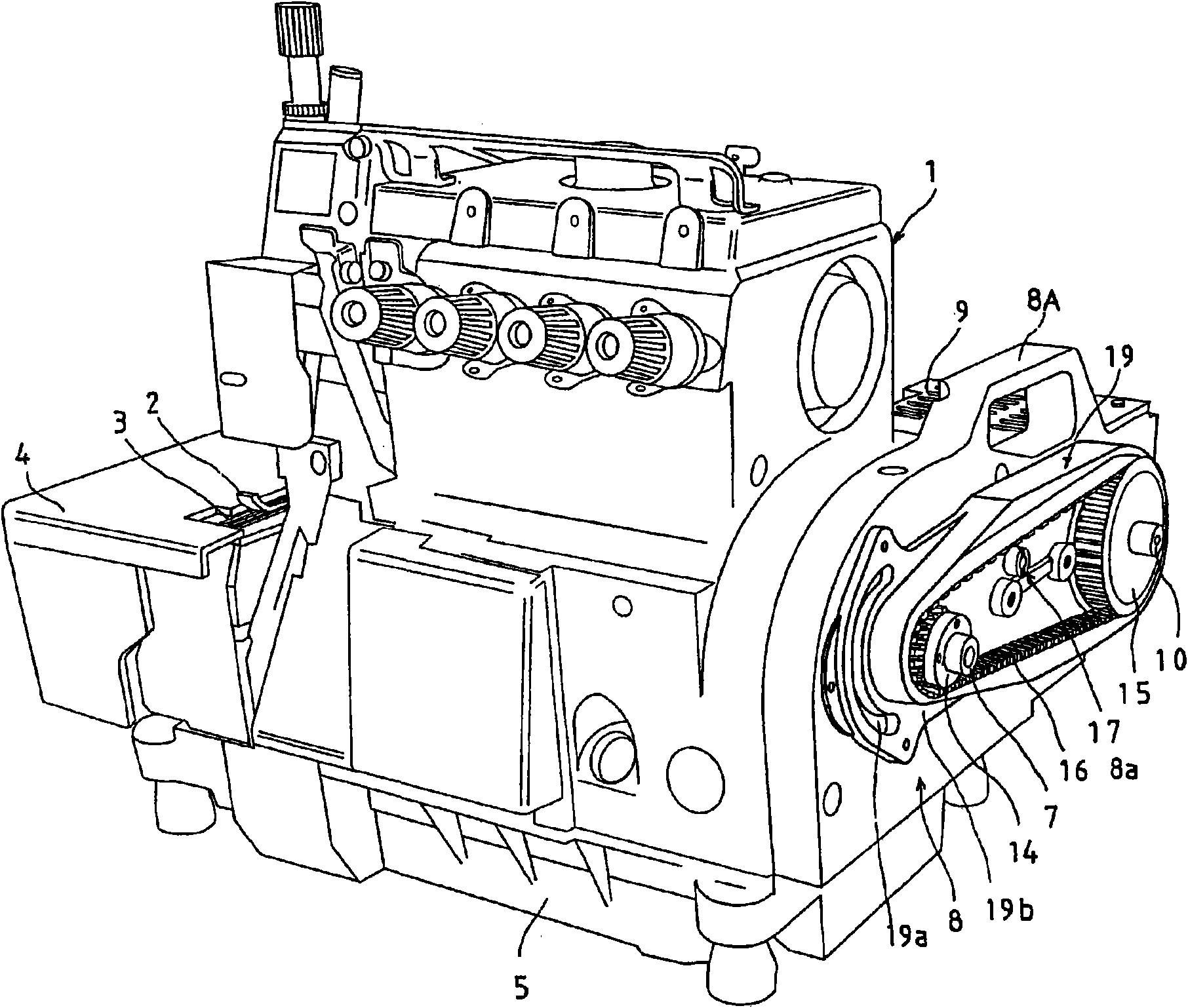

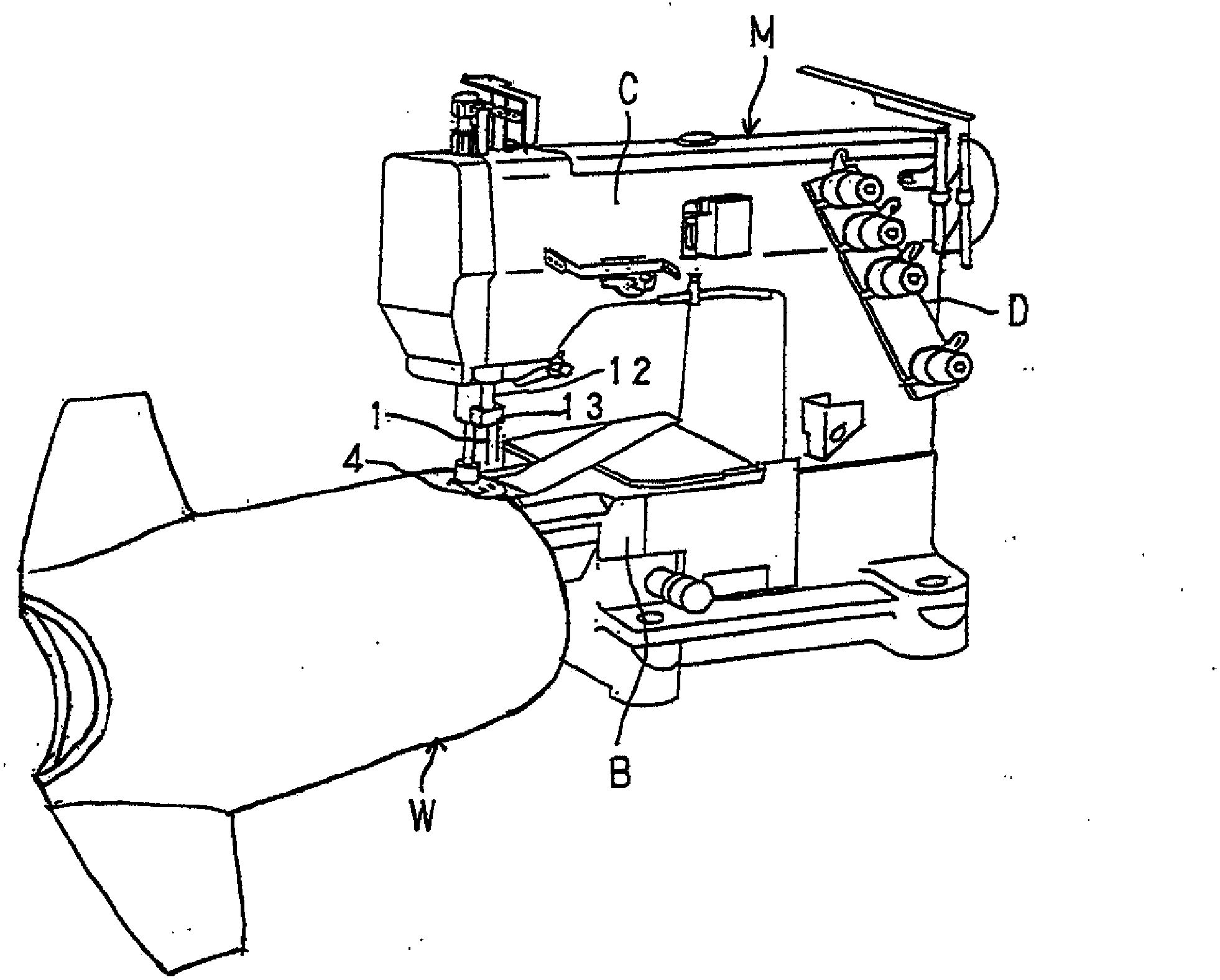

Double-needle cup seaming machine

InactiveCN1381625AOptimize the extraction processSewing-machine casingsNeedle severing devicesEngineeringSewing machine

A double-needle overlock sewing machine, comprising: an outer claw formed as a part of a needle plate and extending along the feeding direction, a middle claw parallel to the outer claw and slidably arranged along the extending direction thereof, and an outer claw arranged on the needle plate The empty wire loop holder and cutter at the front. The sewing machine has: a presser foot disposed above the needle plate, an urging member for urging the presser foot toward the needle plate, and a rotatably supported back surface of the sewing machine frame against the urging force of the urging member. Presser foot lifter that raises the presser foot from the needle plate. The middle claw is connected with the presser foot handle, and when the presser foot is raised by the operation of the presser foot handle, the front end of the middle claw is hidden by the open pinhole of the needle plate. Accordingly, it is possible to provide a double-needle overlock sewing machine capable of operating the middle claw with a low-cost structure and without impairing the operator's workability of the material.

Owner:PEGASUS SEWING MACHINE MFG

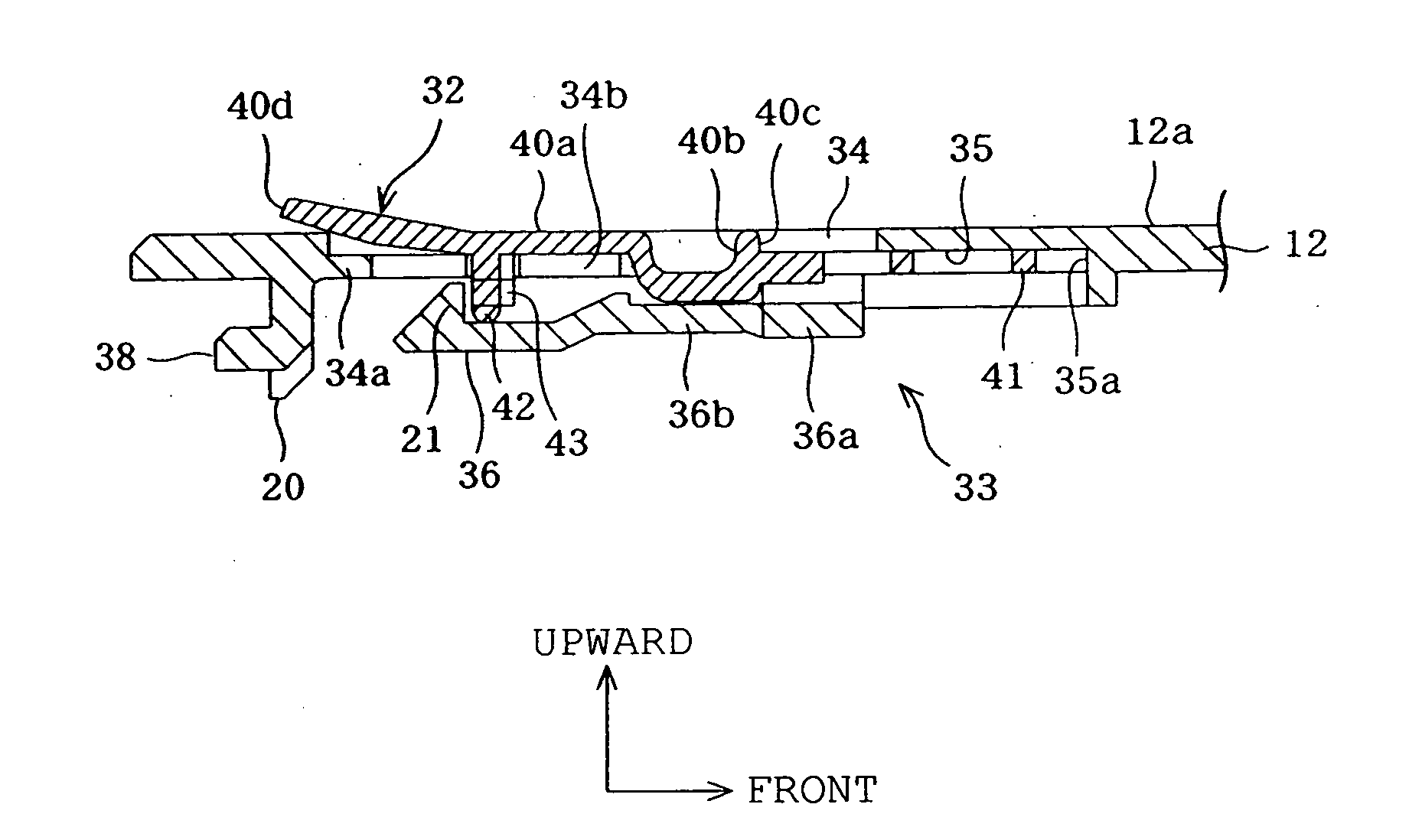

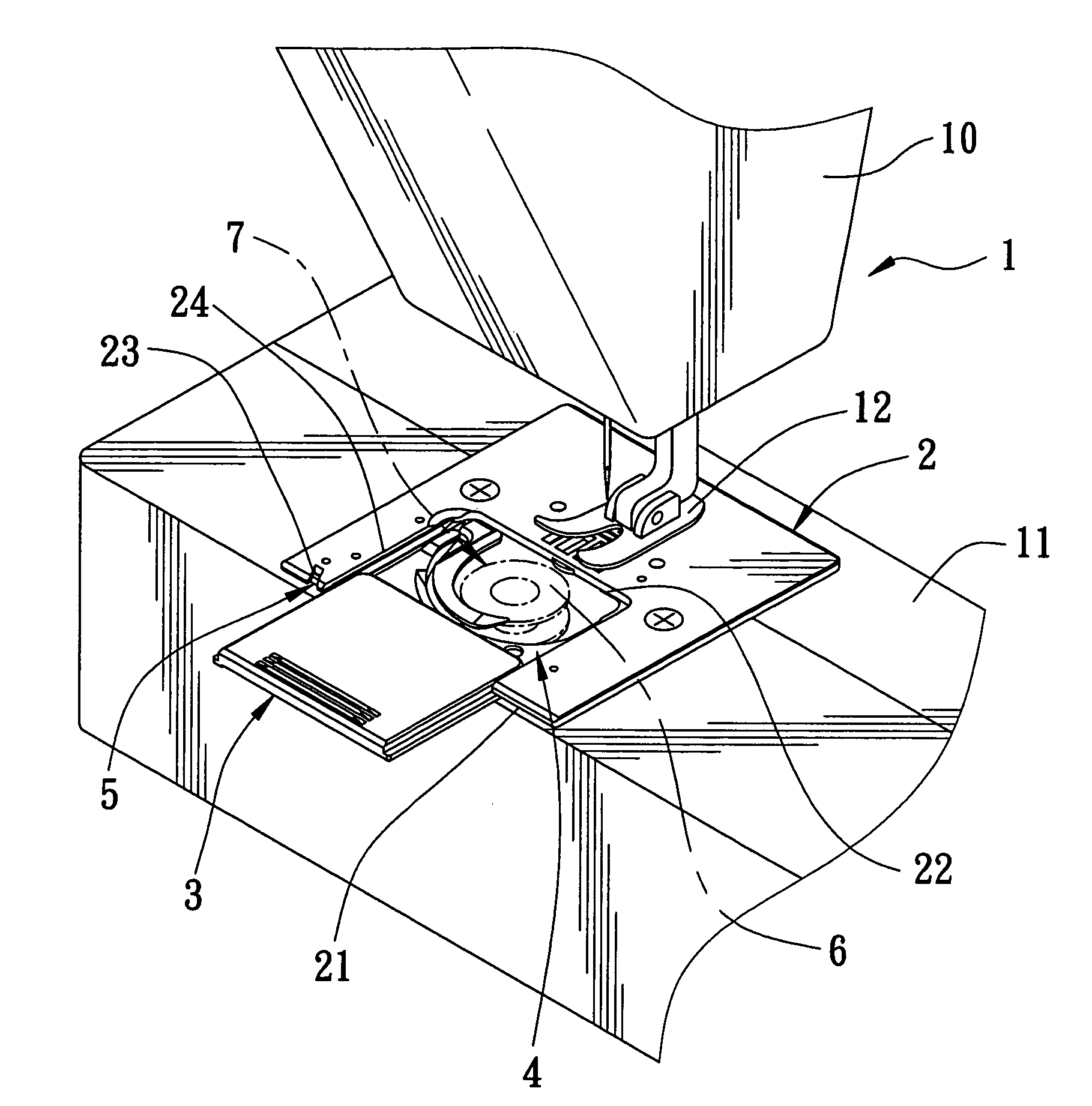

Needle plate and sewing machine provided therewith

A needle plate for a sewing machine includes a first needle plate fixed to a sewing machine bed and formed with a needle hole through which a needle passes and a rectangular hole through which a feed dog appears, a second needle plate disposed in front of the first needle plate and detachably attached to the first needle plate, an engagement mechanism sliding the second needle plate rearward from a front side of the first needle plate, thereby engaging the second needle plate with the first needle plate, and a disengagement operating member located on the second needle plate so as to operate the engagement mechanism so that the second needle plate is disengaged from the first needle plate. The disengagement operating member is moved frontward from a rear side of the first needle plate thereby to disengage the second needle plate from the first needle plate.

Owner:BROTHER KOGYO KK

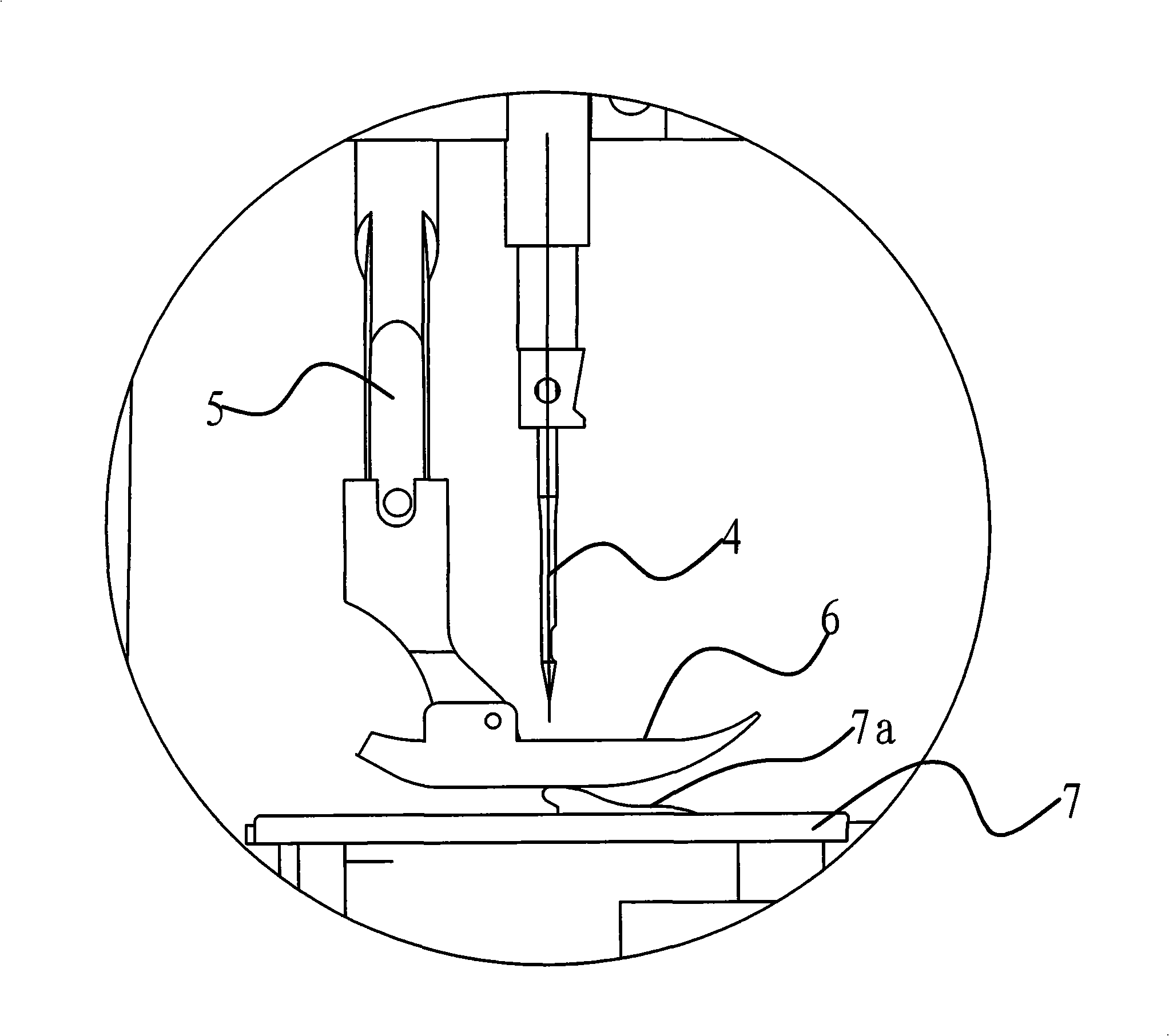

Bent two-needle sewing machine

InactiveCN101525814AHigh precisionEasy to replaceSewing-machine casingsPressersEngineeringSewing machine

The invention provides a bent two-needle sewing machine, belongs to the mechanical technical field, and solves the technical problems that the existing bent two-needle sewing machine can not be conveniently installed and maintained, and can not manufacture different three-dimensional stripes. The bent two-needle sewing machine comprises a sewing machine head, a bottom board, a needle clamp and two needles fixedly connected on the needle clamp, wherein, the sewing machine head is fixedly connected on the bottom board; the needle clamp is connected with the sewing machine head; and a detachable mechanism is arranged between the needle clamp and the sewing machine head. The bent two-needle sewing machine has the advantages of high positioning precision of needles, convenient disassembly, assembly, replacement and maintenance, etc.

Owner:新通宇缝纫机股份有限公司

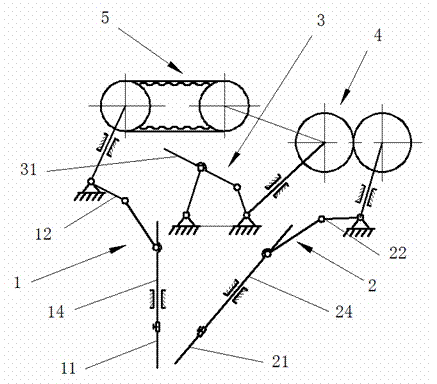

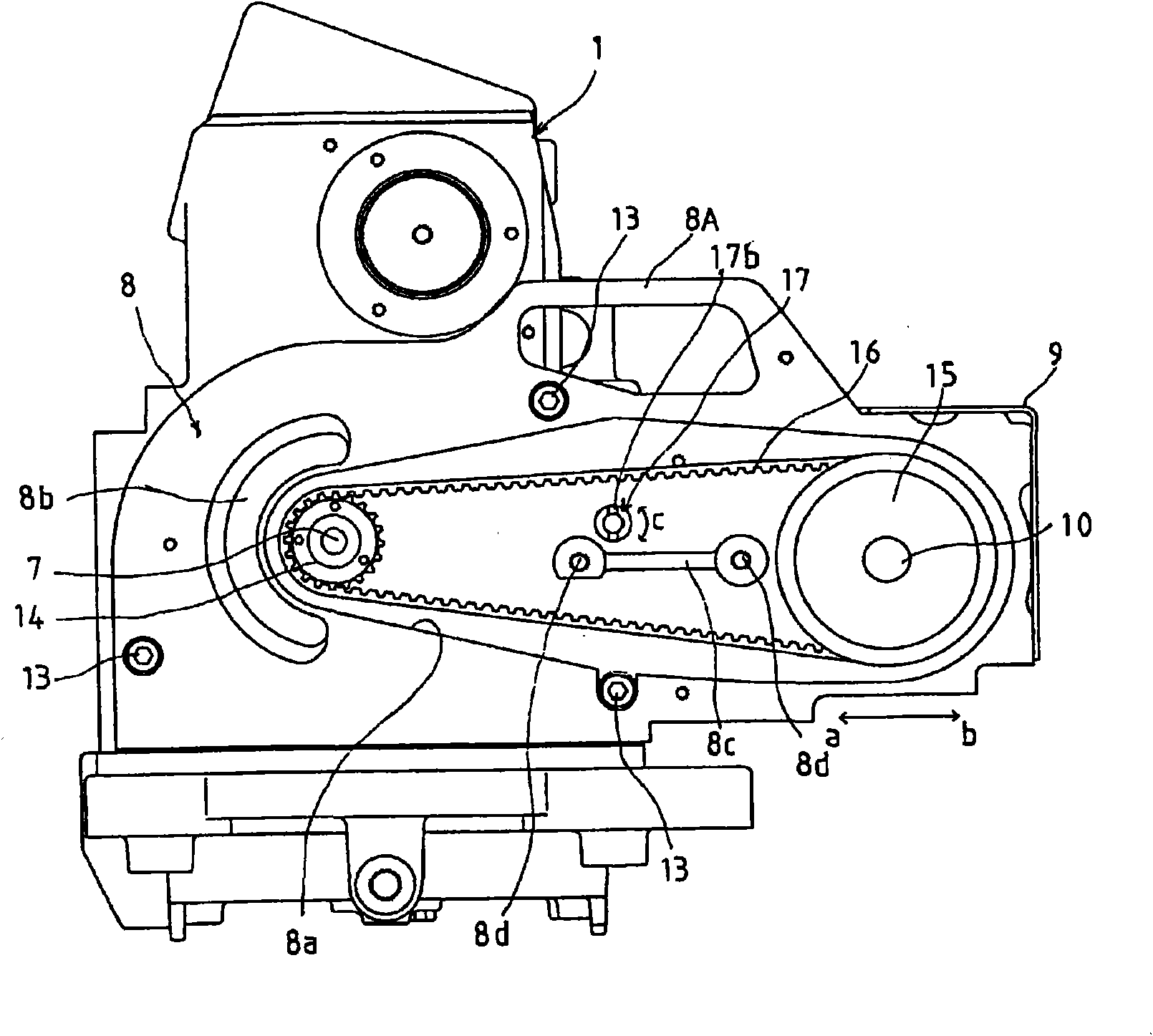

Single-side sewing device

InactiveCN102899807ASimple structureAdaptableSewing-machine casingsSewing-machine control devicesGear wheelElectric machinery

The invention discloses a single-side sewing device, which is characterized in that the device mainly comprises a thread-hooking mechanism, a thread-leading mechanism, a thread-taking-up mechanism, a gear transmission mechanism, a synchronous belt transmission mechanism, a servo motor and a case body rack; the thread-leading mechanism, the thread-hooking mechanism and the thread-taking-up mechanism are transmitted by means of the servo motor, the synchronous belt transmission mechanism and the gear transmission mechanism; the thread-hooking mechanism and the thread-leading mechanism are crank block mechanisms, and a thread-hooking needle and a thread-guiding needle are respectively arranged at the tail ends of the thread-hooking mechanism and the thread-leading mechanism; the thread-taking-up mechanism is a crank rocker mechanism, and a thread-taking-up rod is arranged at the tail end of the thread-taking-up mechanism; the thread-leading mechanism is arranged on a thread-leading shaft; the thread-hooking mechanism is arranged on a thread-hooking shaft; the thread-hooking mechanism, the thread-leading mechanism, the gear transmission mechanism and the servo motor are all arranged inside the case body rack; the thread-taking-up mechanism is arranged outside the case body rack; and the thread-leading mechanism, the thread-hooking mechanism and the thread-taking-up mechanism have the same period of motion.

Owner:TIANJIN POLYTECHNIC UNIV

Needle plate and sewing machine provided therewith

A needle plate for a sewing machine includes a first needle plate fixed to a sewing machine bed and formed with a needle hole through which a needle passes and a rectangular hole through which a feed dog appears, a second needle plate disposed in front of the first needle plate and detachably attached to the first needle plate, an engagement mechanism sliding the second needle plate rearward from a front side of the first needle plate, thereby engaging the second needle plate with the first needle plate, and a disengagement operating member located on the second needle plate so as to operate the engagement mechanism so that the second needle plate is disengaged from the first needle plate. The disengagement operating member is moved frontward from a rear side of the first needle plate thereby to disengage the second needle plate from the first needle plate.

Owner:BROTHER KOGYO KK

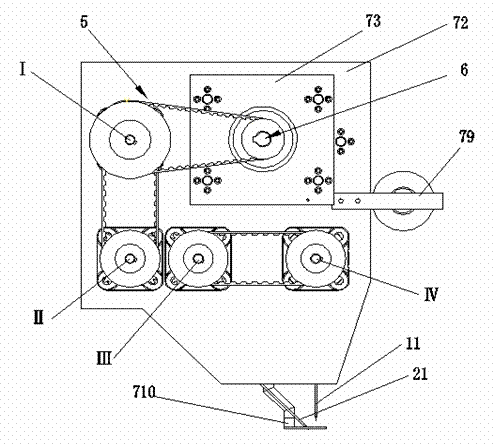

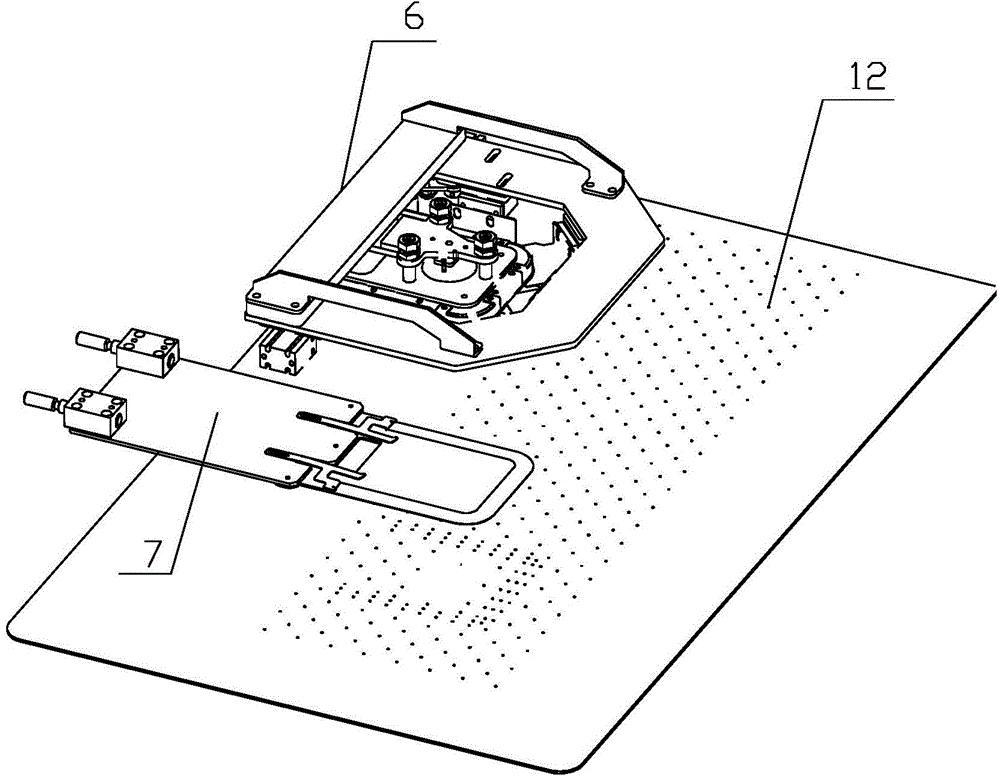

Patch pocket sewing machine

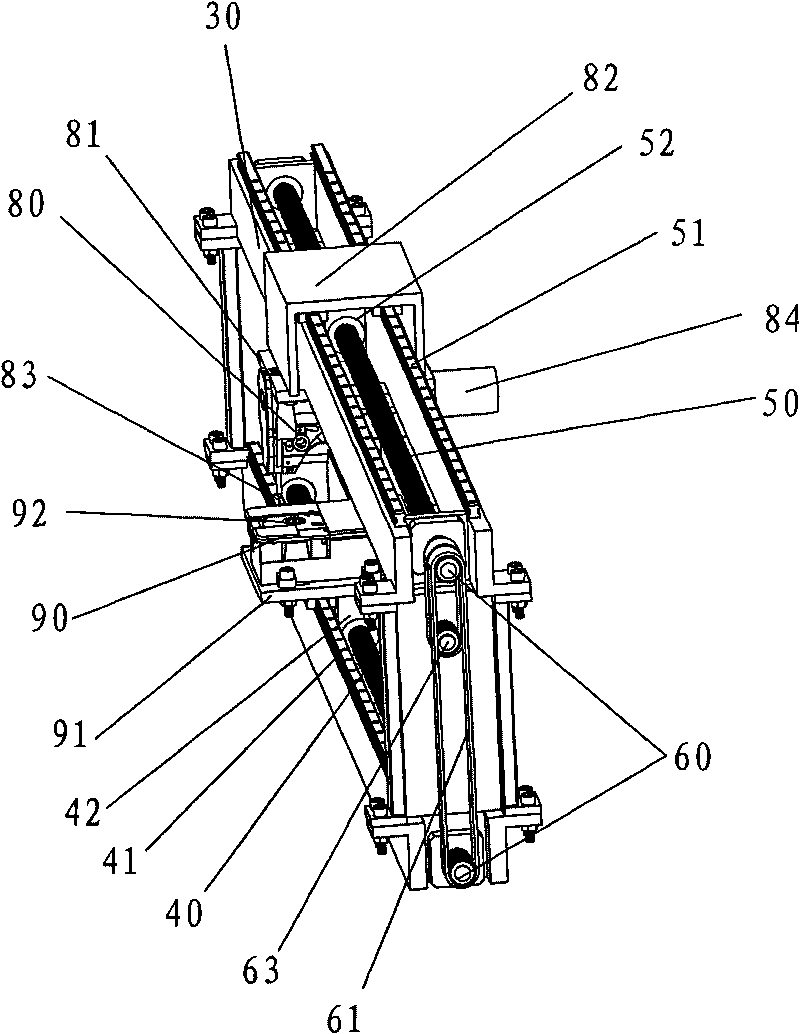

InactiveCN104630991AHigh precisionHigh speedSewing-machine casingsWork-feeding meansMechanical equipmentEngineering

The invention relates to a patch pocket sewing machine and belongs to the field of sewing mechanical equipment. The patch pocket sewing machine comprises a machine body, a pocket folding device, a sewing die, a sewing machine and a driving device. The machine body is a rectangular box body. A working plane is arranged on the upper surface of the machine body. A fan is arranged in the machine body. An air outlet end of the fan is connected with an air inlet end of a blowing-drawing air converting device. An air outlet end of the blowing-drawing air converting device is connected with one end of an air pipe. The other end of the air pipe is communicated into an air cavity below the working plane. A plurality of small air openings are formed in the surface of the working plane. A support is horizontally fixed on the machine body. Two tracks are arranged between the support and the machine body. A guiding track and the support are arranged horizontally in parallel. The pocket folding device is fixed on the left side of the support. The sewing die is fixed on one guiding track of the support. The sewing machine is arranged on the right side of a working platform. According to the patch pocket sewing machine, the fact that during patch pocket operation, conveying and sewing, clothes cannot be wrinkled, during clothes conveying, friction with a working face is small, and a cloth pocket cannot deviate.

Owner:SHANGHAI WEISHI MACHINERY

Sewing machine presser foot

InactiveCN101210364APrevent poor sewingSewing-machine casingsWorkpiece carriersEngineeringKnife blades

The present invention provides a presser foot of sewing machine, including an assistant guiding component locating on a pressing claw of one part of left-right pressing claws extending towards the front of a position for receiving needle between a needle plate, for clamping upper cloth and projecting into a guiding path between a pressing claw of the other part, to optimize the path between the pressing claw of the other part and the assistant guiding component, holding the upper cloth and the lower cloth with a benign standing gesture, feeding material to a position for setting fixed blade and movable blade to cutting the upper end edge uniformly, so as to prevent bad tailoring availably due to imperfectness of cutting.

Owner:YAMATO SEWING MASCH MFG CO LTD

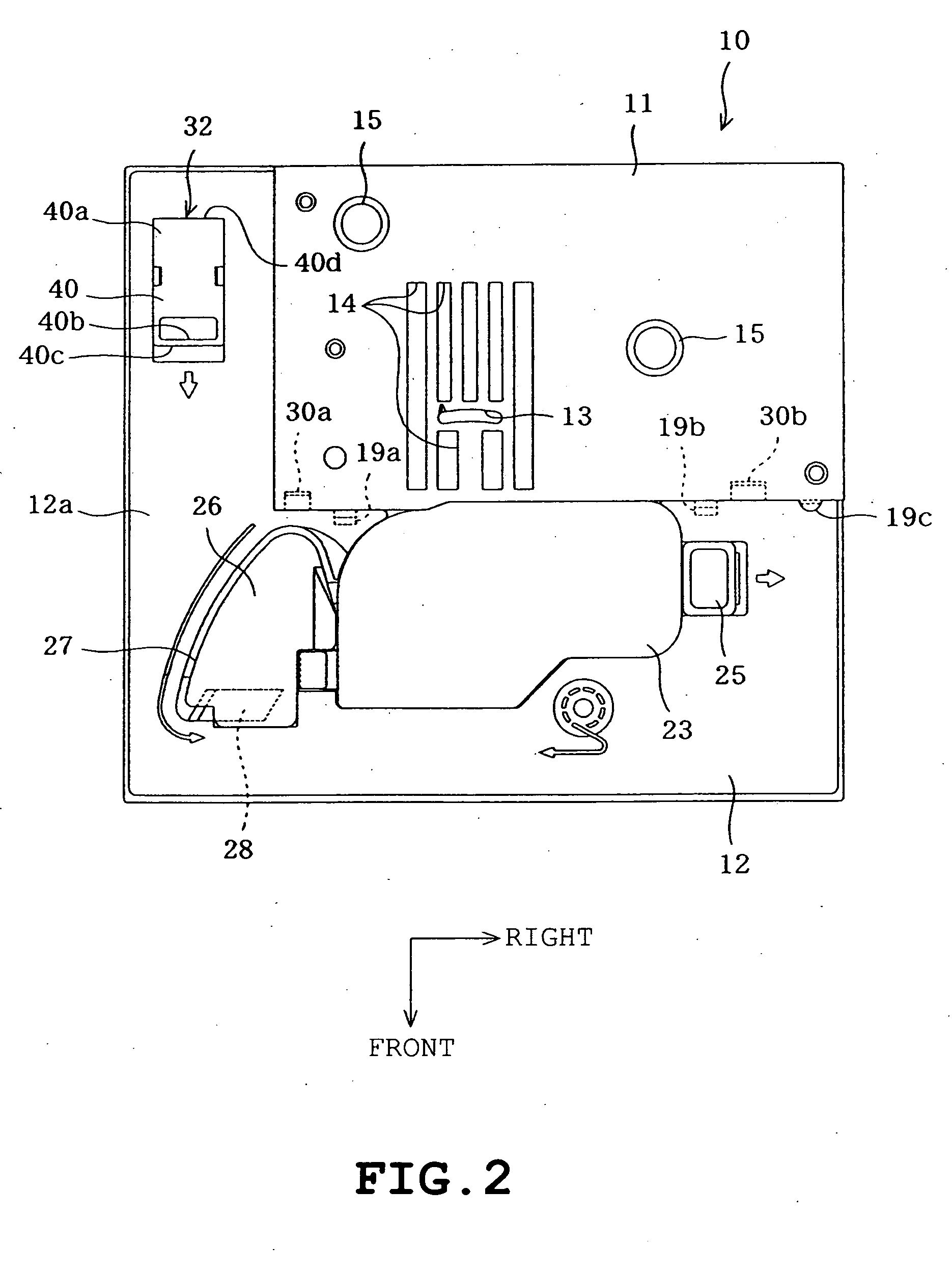

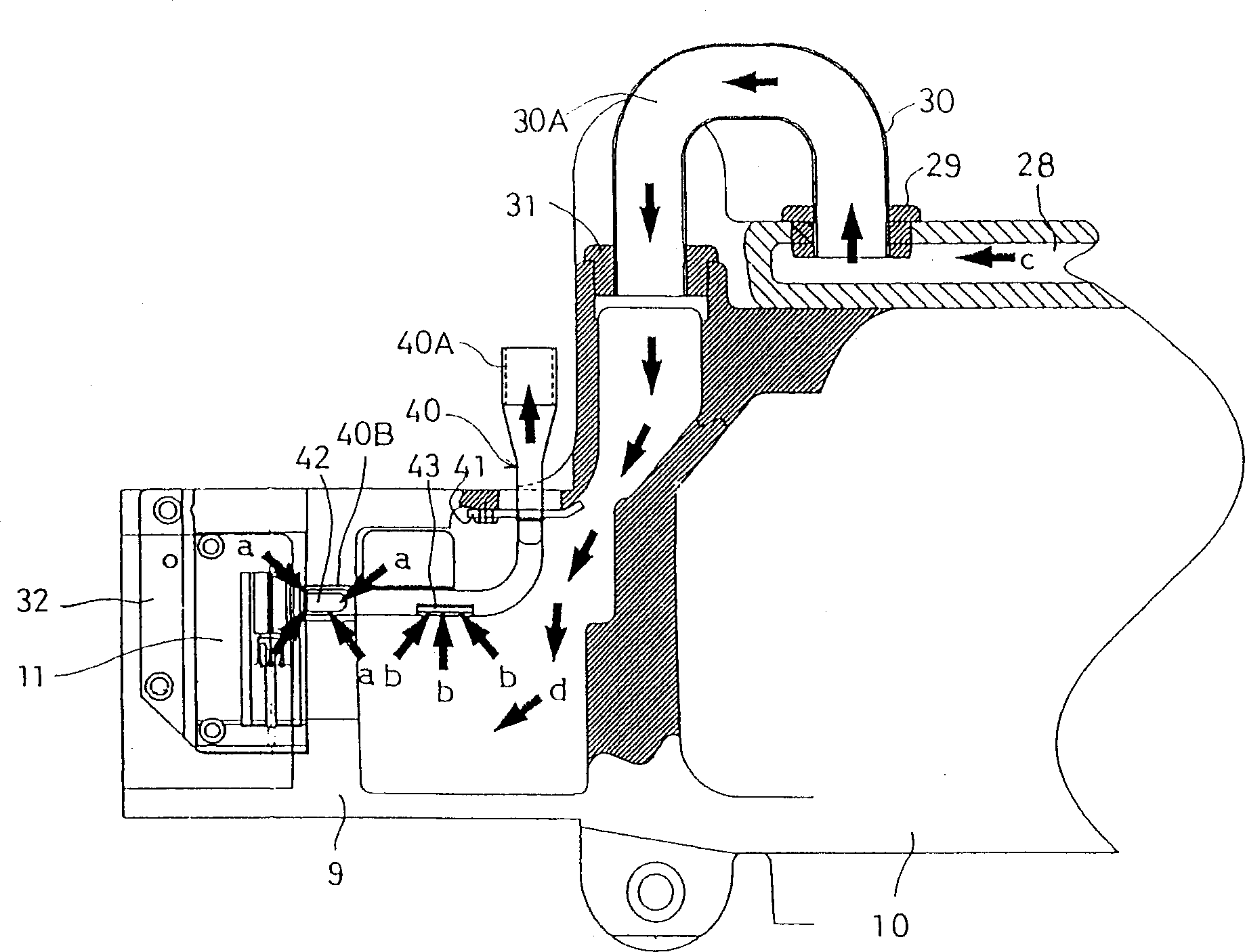

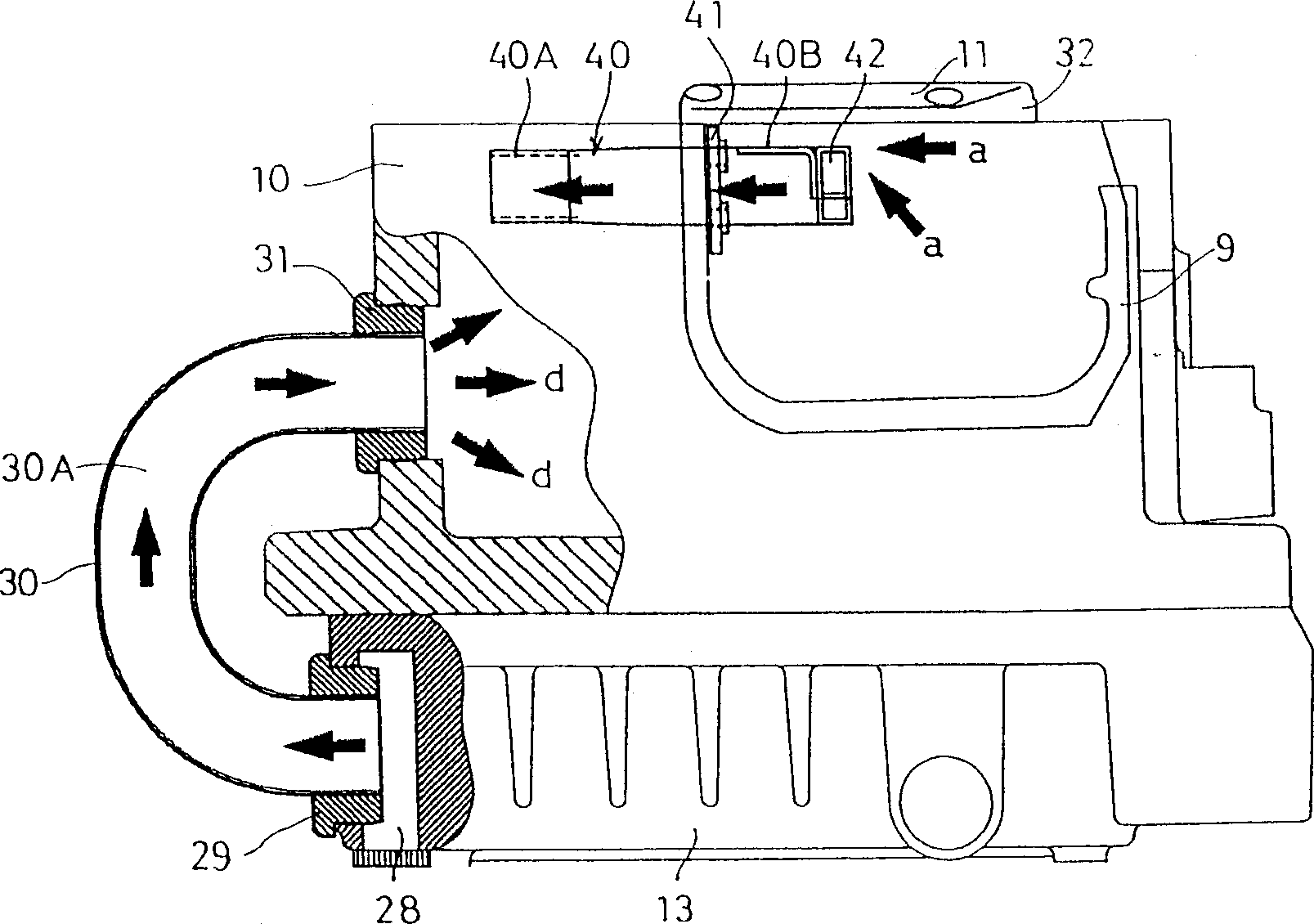

Sewing machine with dust collector

In the present invention, a needle plate is installed on the upper surface and the inside of the cylindrical sewing machine base protrudes from the base of the sewing machine base to accommodate the sewing parts, and a suction pipe is inserted therein. The tip suction port of the dust airflow at the lower part of the plate and the middle suction port including the dust airflow generated near the looper thread path. At the same time, a forced air introduction path is also provided. In the base of the cylindrical sewing machine below the suction port at the front end of the suction pipe, the introduced air is forced to flow toward the suction port at the front end of the suction pipe and the middle suction port. This structure prevents the working environment from deteriorating, effectively sucks and removes a large amount of dust generated at the lower part of the needle plate, and minimizes the amount of dust accumulated in the base of the cylinder sewing machine.

Owner:YAMATO SEWING MASCH MFG CO LTD

Sewing machine

InactiveCN1485488ASewing-machine casingsNeedle severing devicesTop dead centerBiomedical engineering

A sewing machine includes a supporting plate portion and a needle. The supporting plate portion contacts sewing fabric that is moved in a predetermined direction during a sewing operation. The needle is vertically moved between a top dead center above the supporting plate portion and a bottom dead center below the supporting plate portion. The supporting plate portion has a needle hole through which the needle passes. The lower end opening of the needle hole is larger than the upper end opening.

Owner:HASHIMA

Needle plate replacement device with lock

ActiveUS20160040342A1Easy to disassembleReliable lockingSewing-machine casingsLocking mechanismEngineering

A needle plate replacement device including positioning mechanisms provided in an opposing manner in the needle plate and the bed portion, the positioning mechanisms positioning the needle plate to an attaching position in the bed portion; a lock mechanism including a locking member provided in the bed portion and a locked member provided in the needle plate, in which by mounting the needle plate on the attaching position in the bed portion, the locking member and the locked member is locked to each other thus maintaining a locked state; a push-up mechanism provided in the bed portion, the push-up mechanism pushing up the needle plate mounted on the bed portion towards a dismount position above the bed portion; and a release mechanism cancelling the locked state between the locking member and the locked member of the lock mechanism by being interlocked with an operation of the push-up mechanism.

Owner:JANOME CORP

Overlock sewing machine

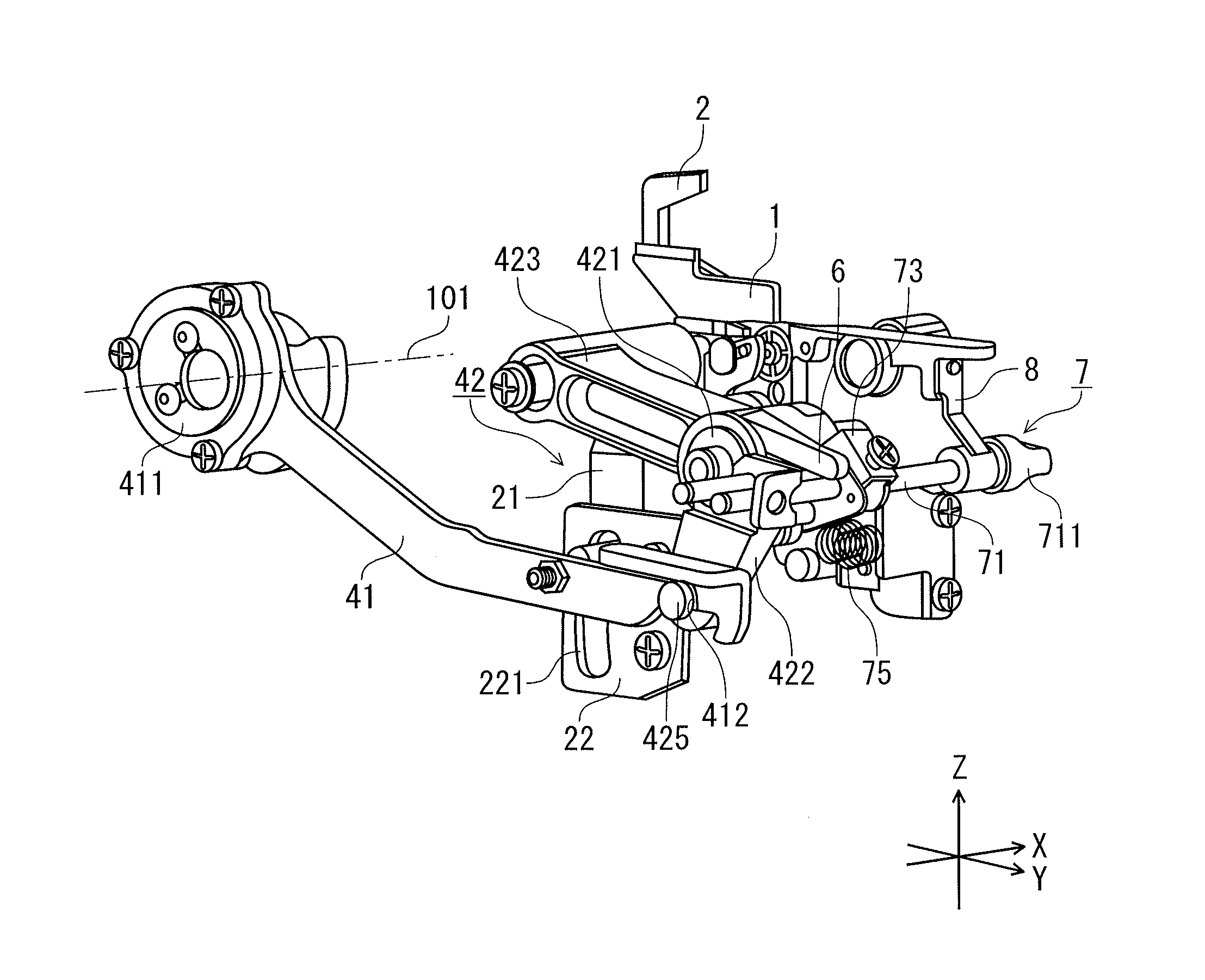

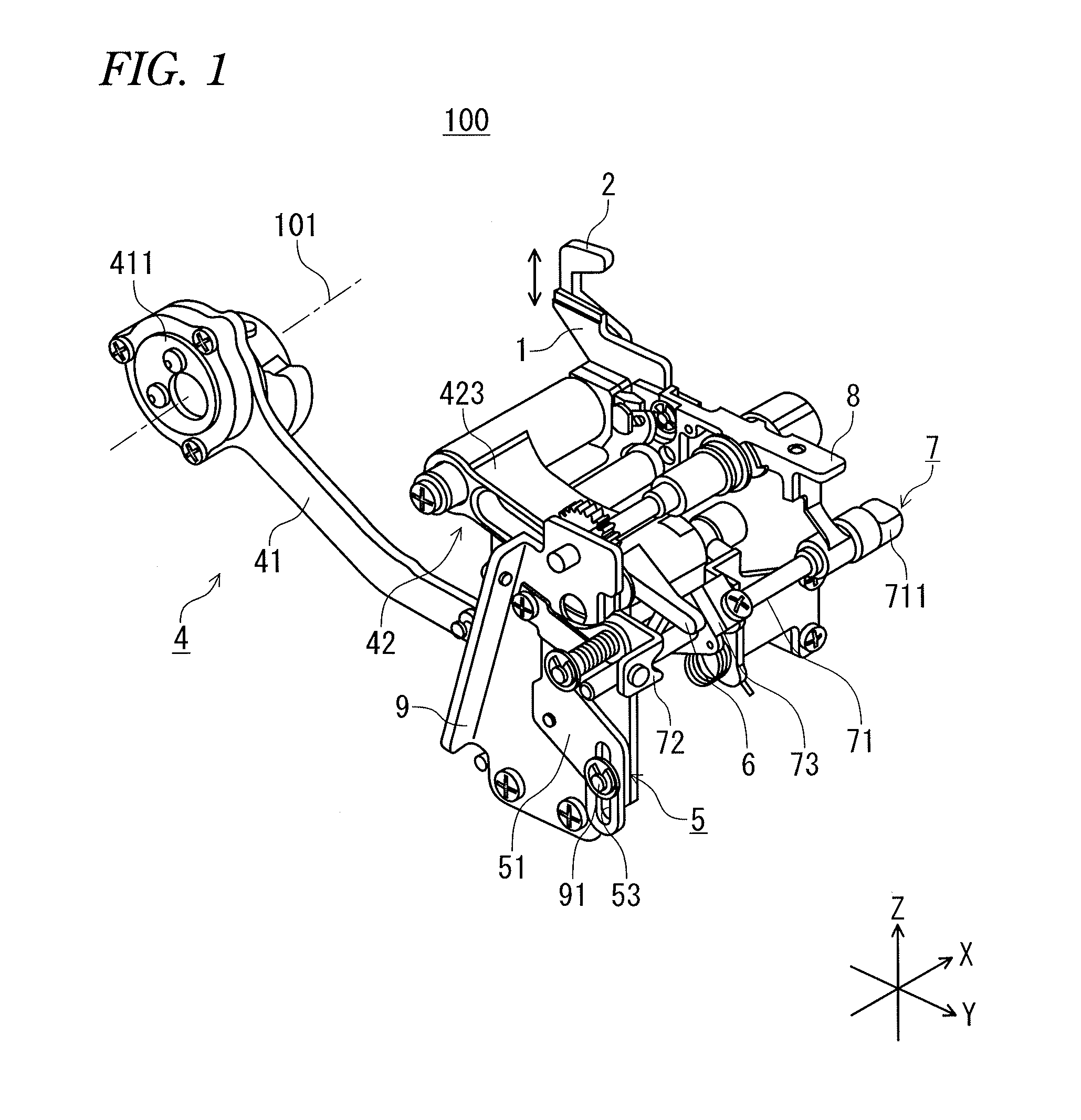

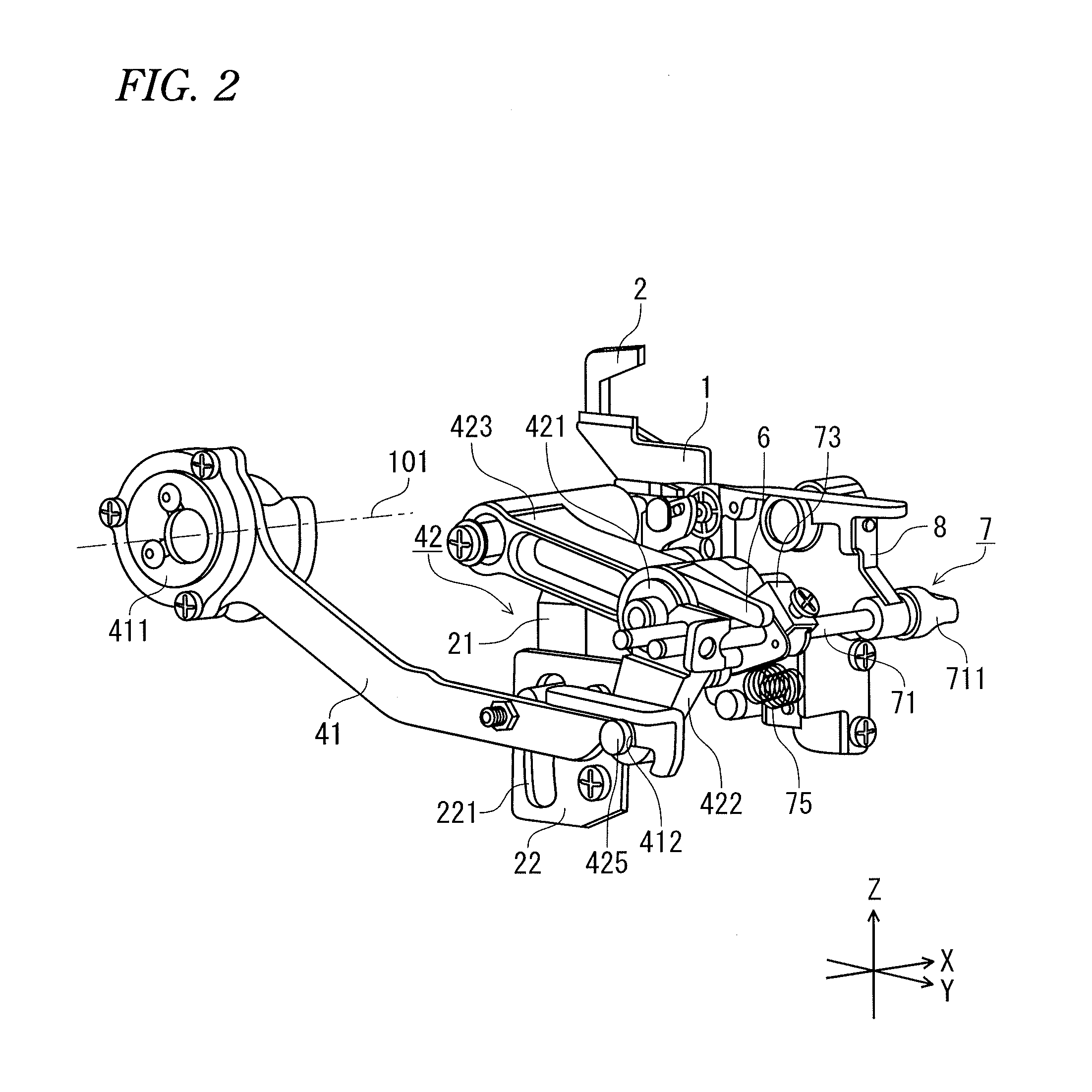

ActiveUS20130333603A1Increase engagementPrevent durabilitySewing-machine casingsWorkpiece carriersElectrical and Electronics engineeringSewing machine

An overlock sewing machine includes an upper knife which is movable to a withdrawn position or a driving position, an upper knife driving unit which moves the upper knife, an interlocking switching unit which switches between an interlocking state in which the upper knife driving unit and the upper knife are interlock and a release state in which the upper knife driving unit and the upper knife are released, an upper knife position switching unit which switches the upper knife to the driving position or the withdrawn position, and an operating unit which drives the interlocking switching unit and the upper knife position switching unit such that the interlocking switching unit is brought into the interlocking state when the upper knife is switched to the driving position, and the interlocking switching unit is brought into the release state when the upper knife is switched to the withdrawn position.

Owner:JUKI CORP

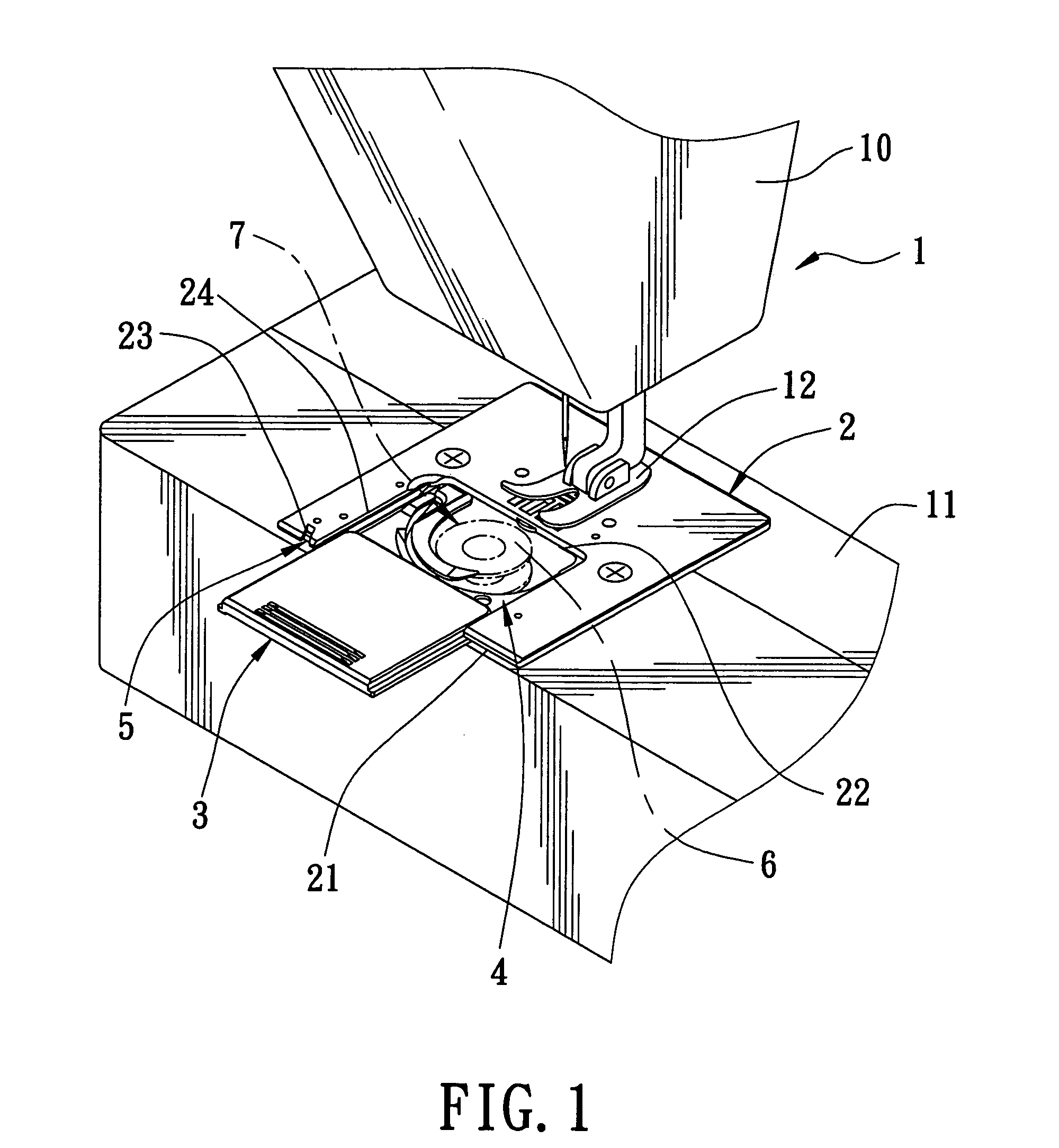

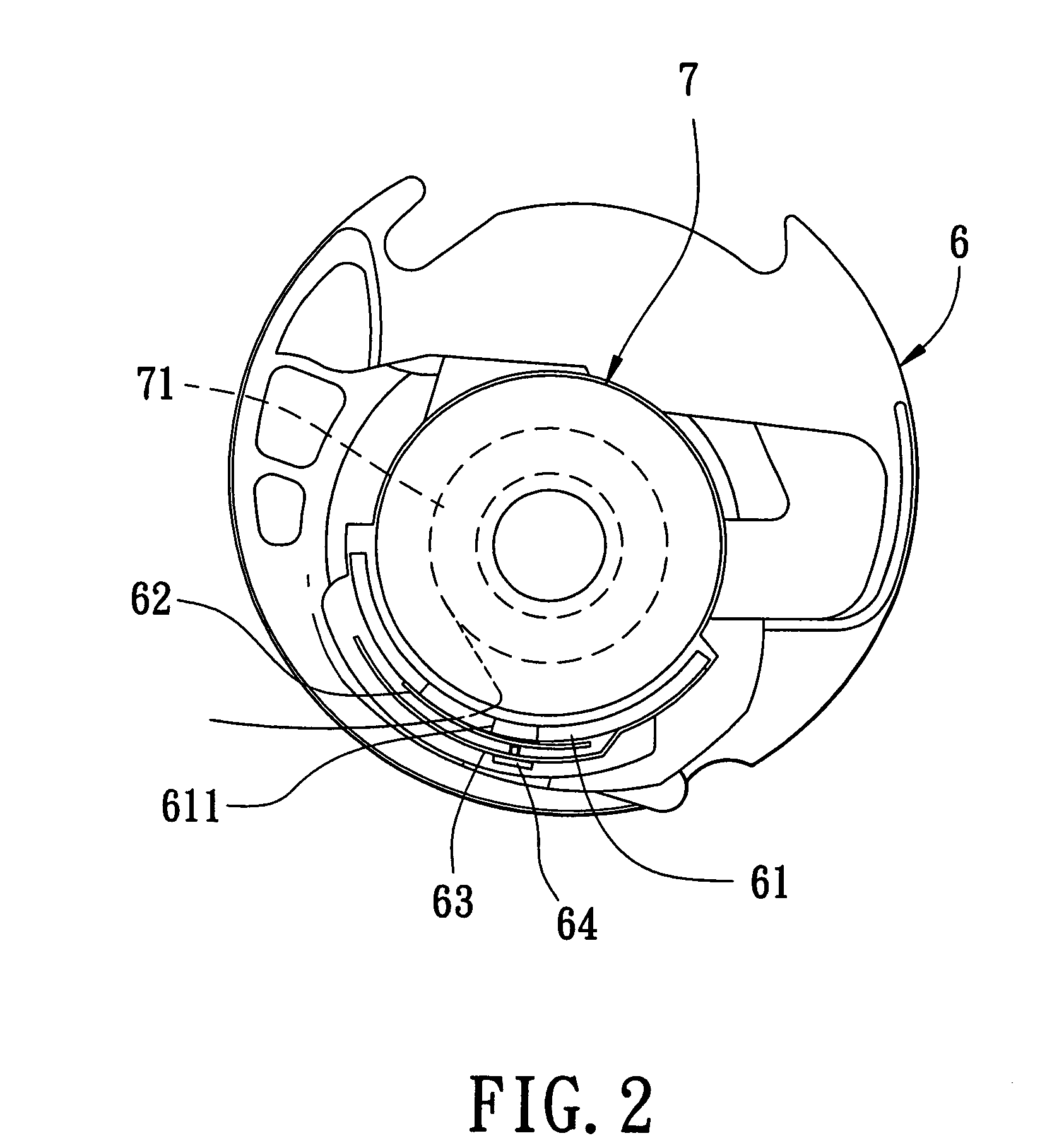

Sewing machine having a lower thread cutter

A sewing machine includes a needle plate with a cutout part, and a guide plate connected to a bottom side of the needle plate and extending substantially across the cutout part. The guide plate includes a pair of slide rails, an opening substantially corresponding in position to a bobbin case, and a curved thread guide slot having one end communicated with the opening and another end extending to one of the slide rails. A slide cover covers the cutout part and is slidable along the slide rails. A cutter is disposed at the lateral edge proximate to one of the slide rails. A lower thread guide extends along one of the slide rails from another end of the thread guide slot toward the cutter for guiding a lower thread from the bobbin case to extend to the cutter.

Owner:ZENG HSING INDUSTRIAL CO LTD

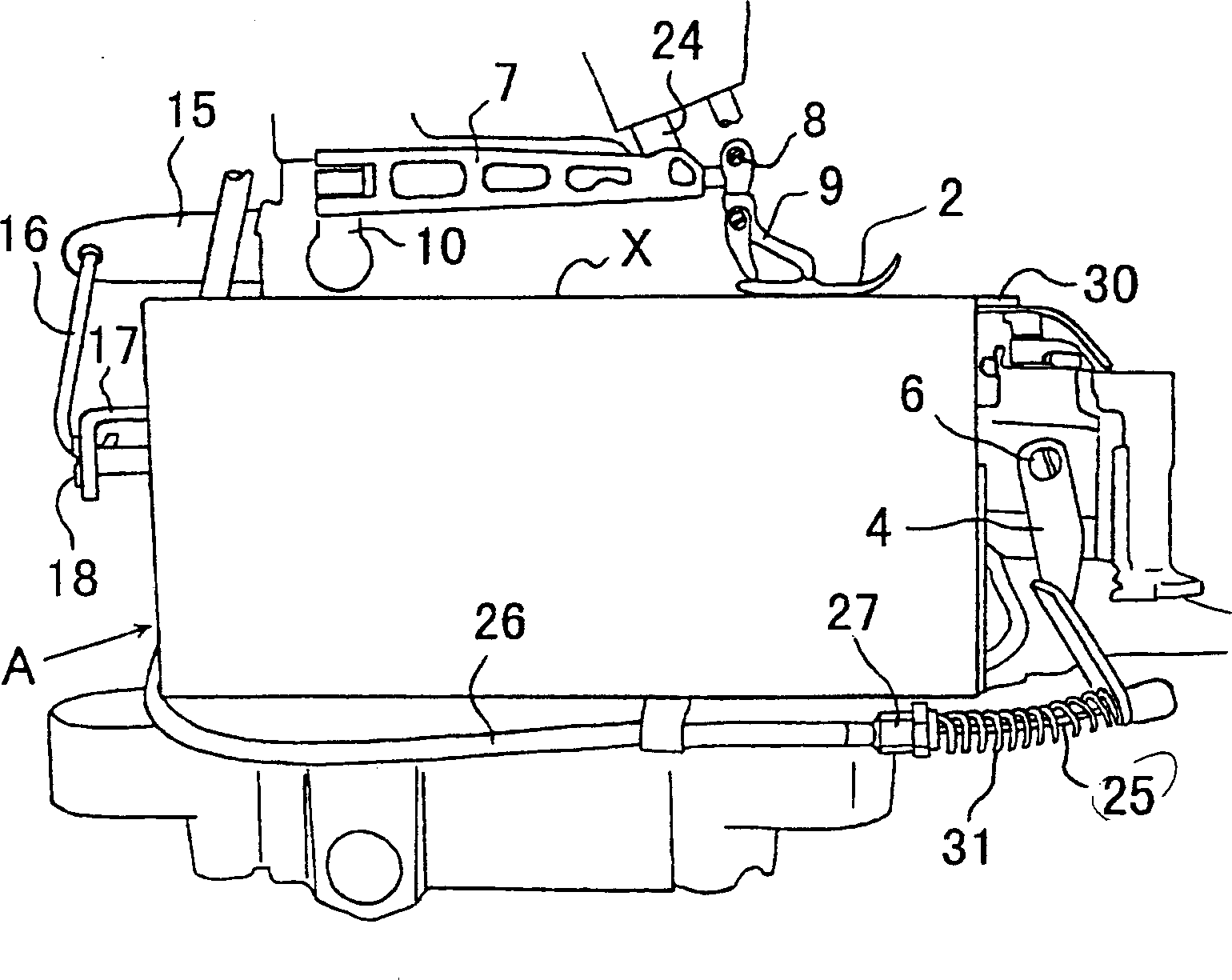

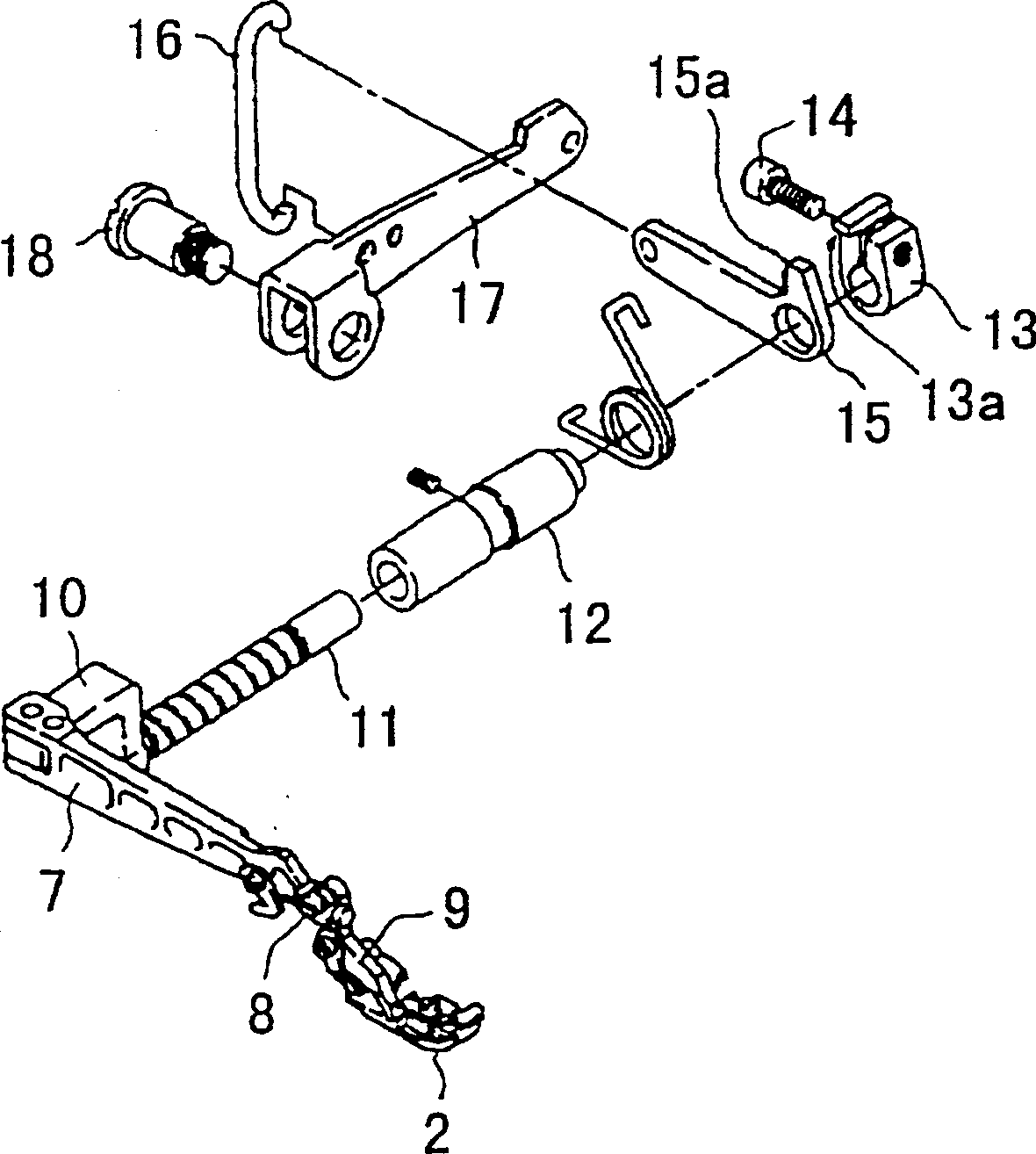

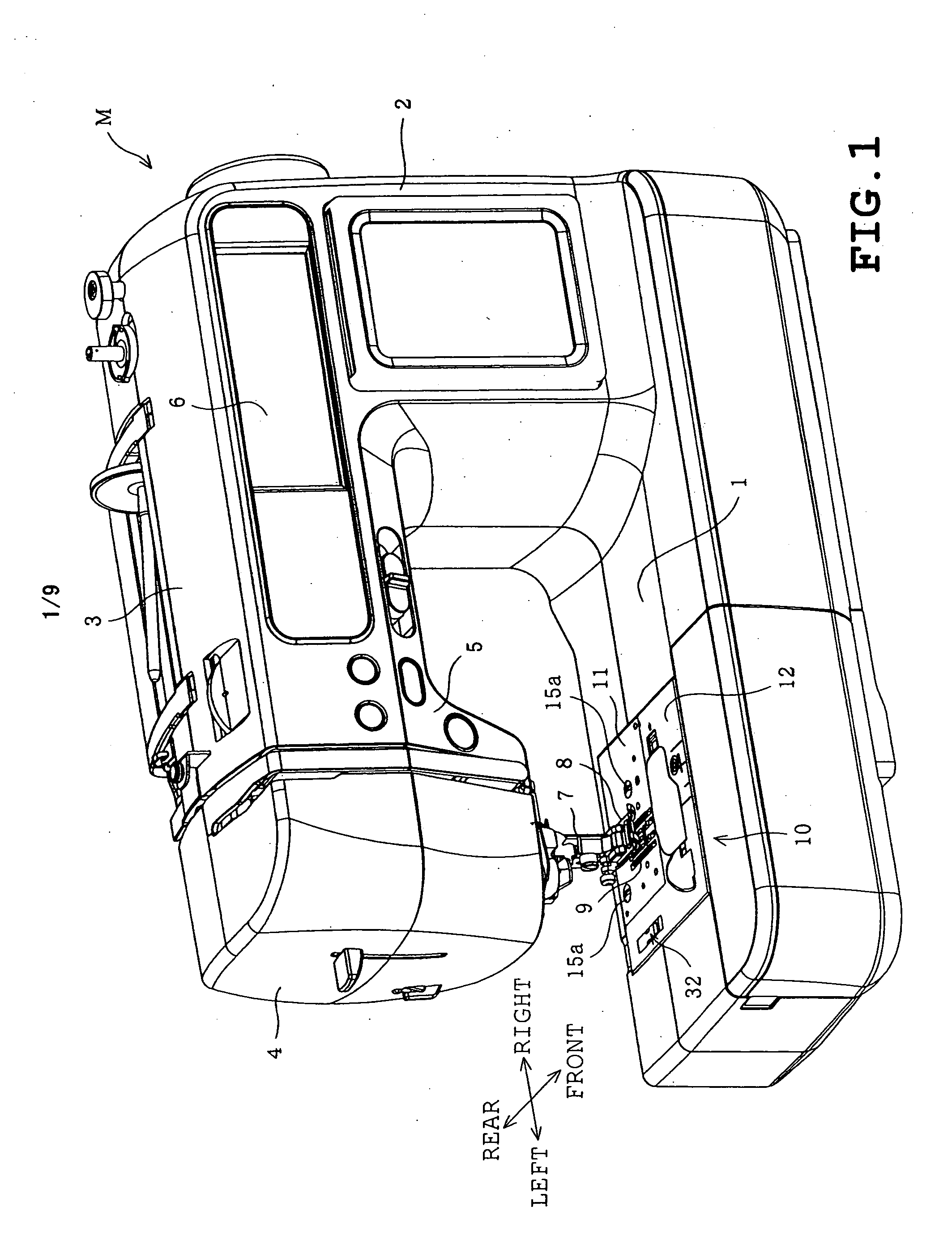

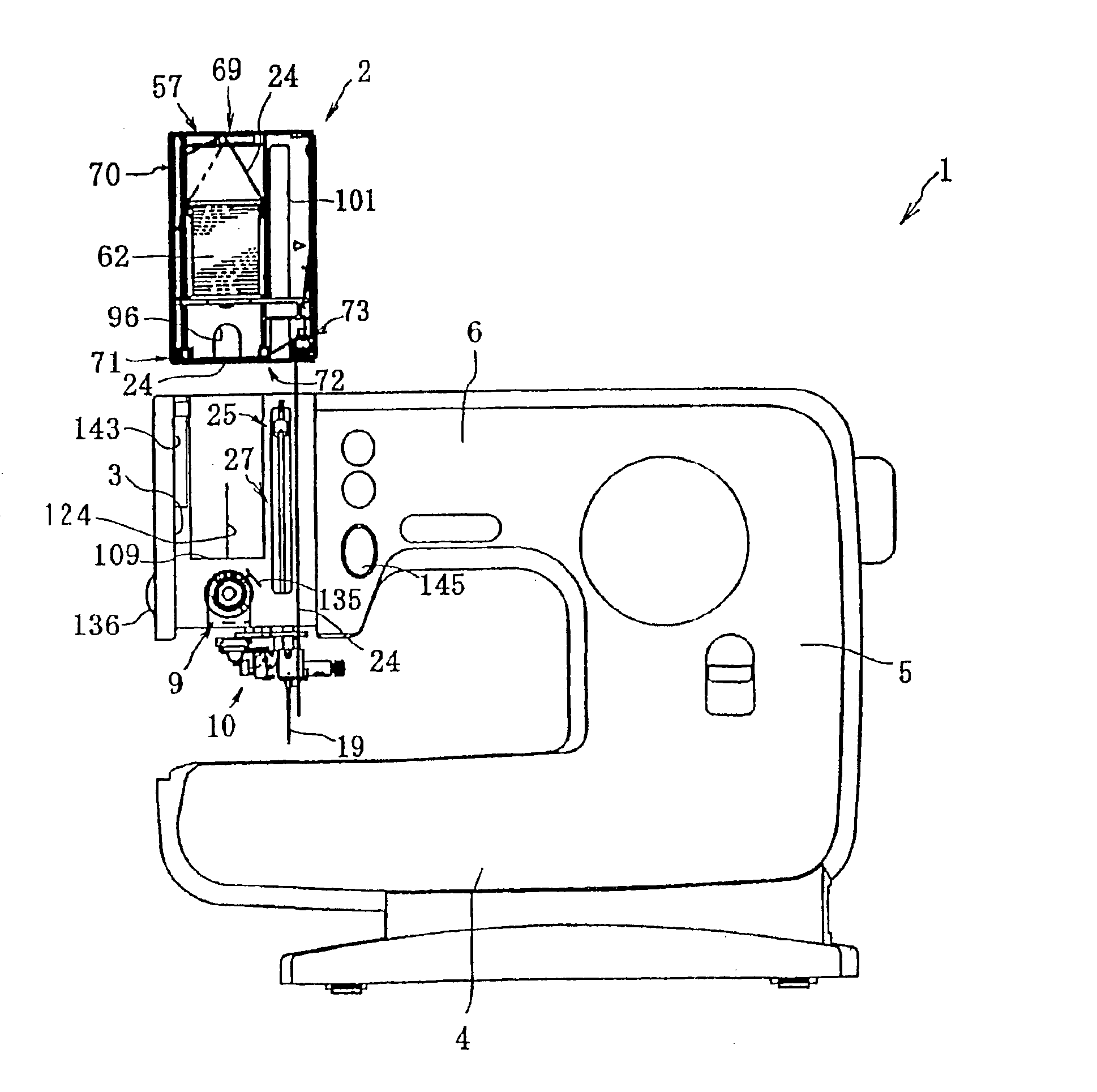

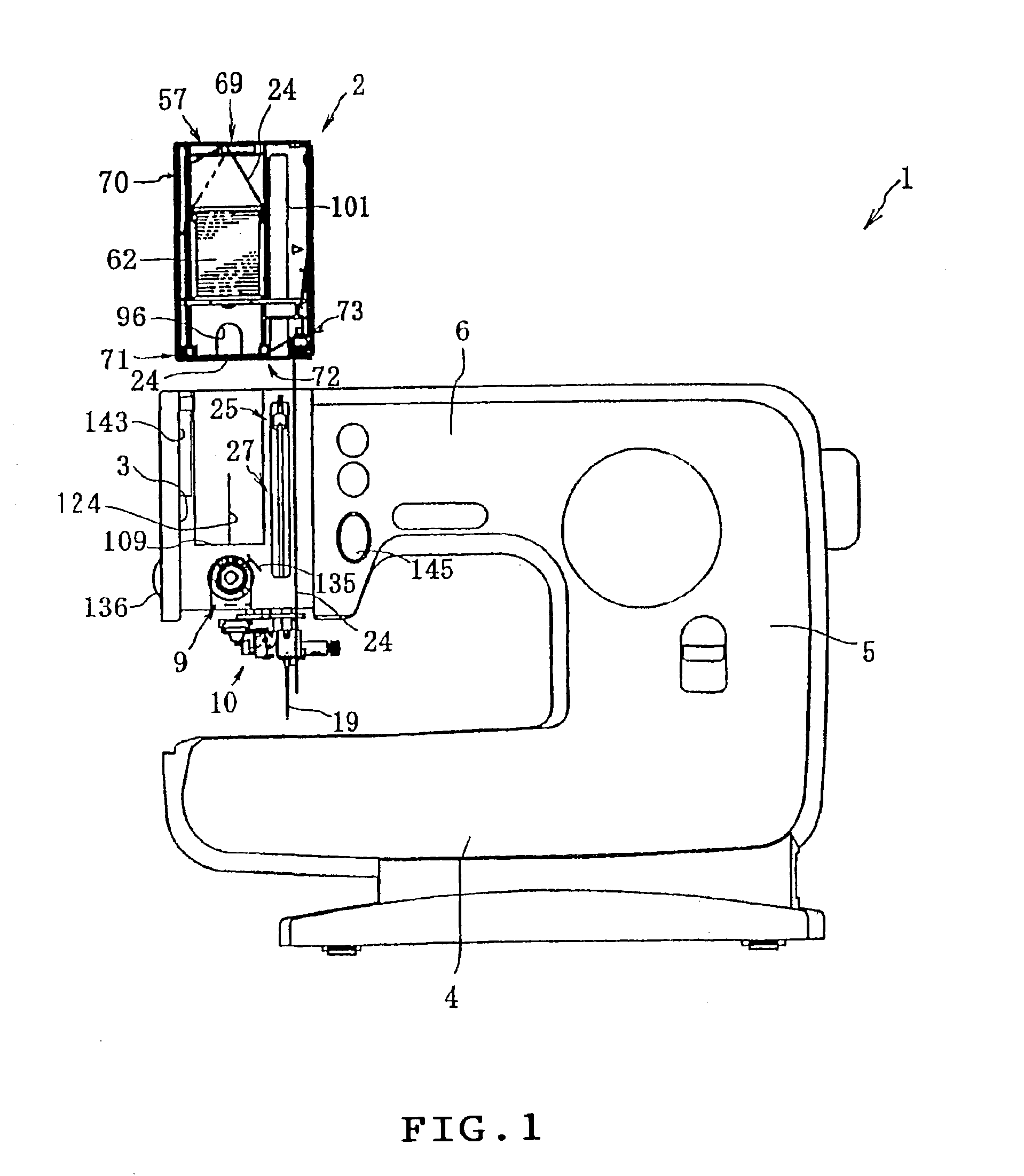

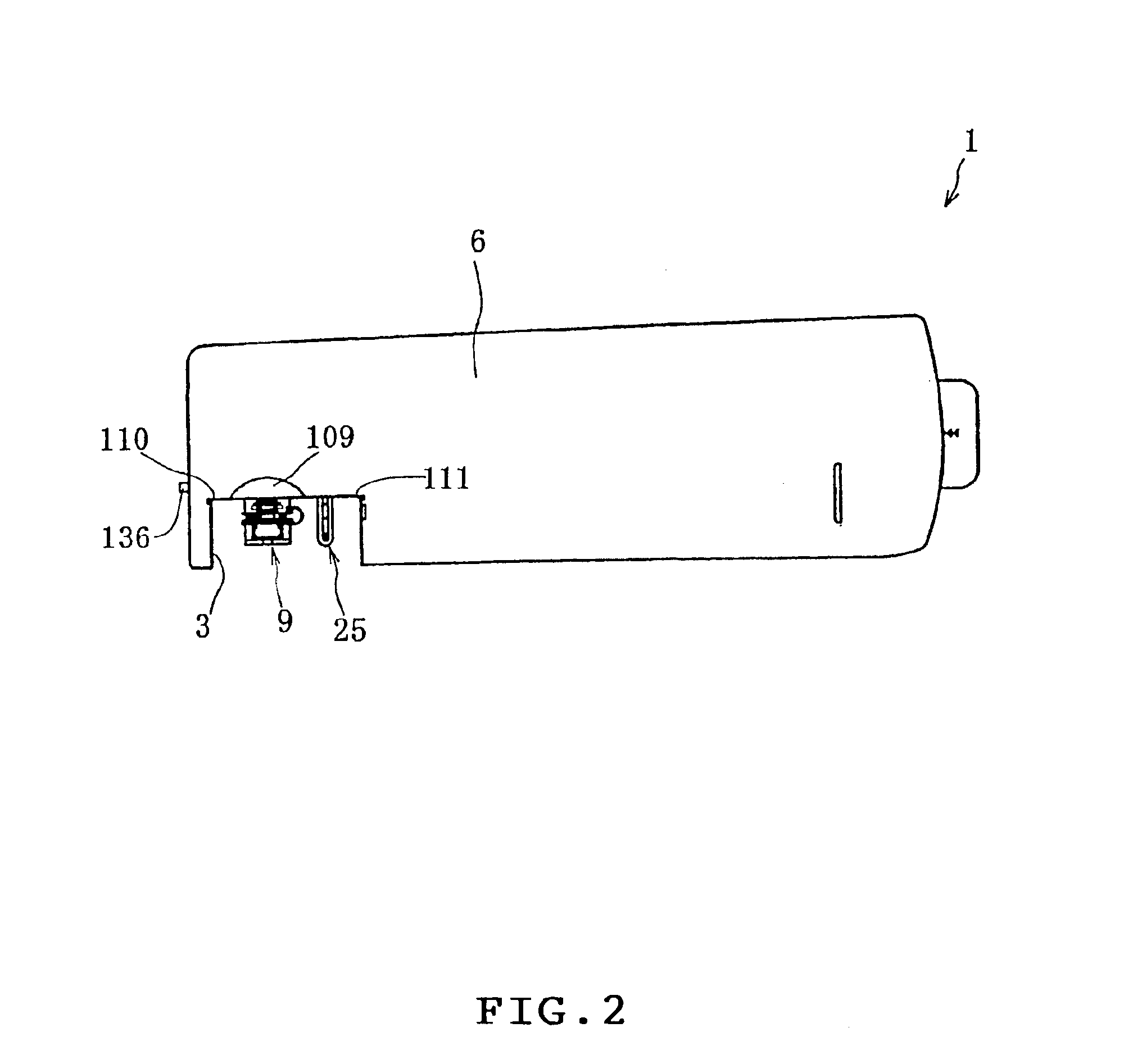

Sewing machine with needle thread cassette and needle thread cassette

InactiveUS6883447B1Improve handlingEasy to operateSewing-machine casingsFilament handlingBobbinEngineering

A sewing machine with a needle thread cassette, wherein a cassette mount (3) is reduced in size. The cassette mount (3) including a thread take-up lever travel region is formed in the form of a vertical groove in the arm head of the sewing machine. A needle thread cassette (2) having a thread bobbin (62) vertically received therein is removably mounted on the cassette mount (3) vertically from above. With a thread take-up lever (25) stopped in a position corresponding to a needle top stop position, the needle thread cassette (2) is mounted on the cassette mount (3), whereby the thread is engaged with the thread guard of the thread take-up lever (25) and a thread tension regulator (9).

Owner:BROTHER KOGYO KK

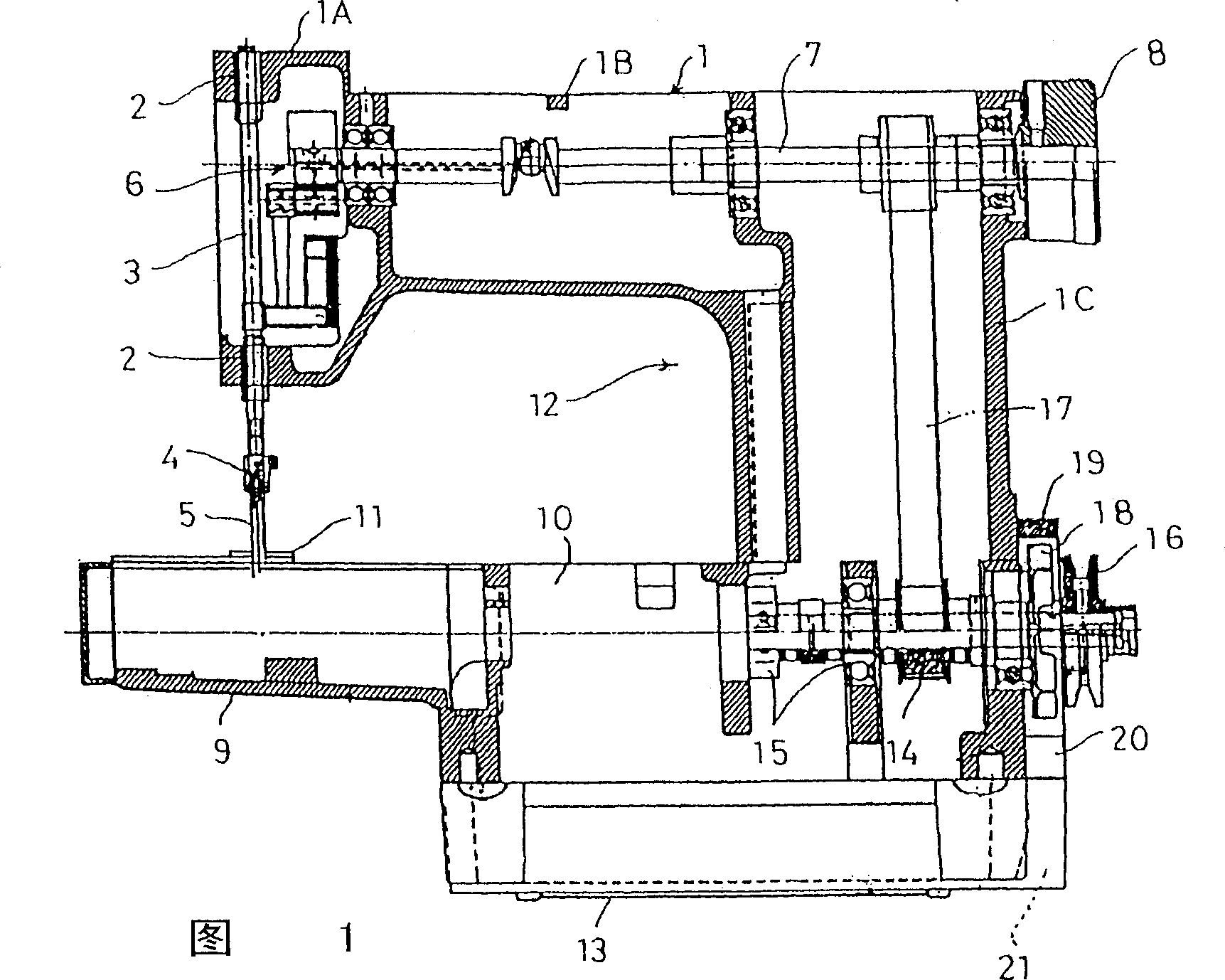

Sewing machine

InactiveUS6920837B2Improve flexible controlHigh possible precisionProgramme-controlled sewing machinesSewing-machine casingsPinionControl unit

A sewing machine including a sewing machine upper portion with a frame, a needle rod and a sewing foot rod, which rods are guided in the frame for back and forth movement parallel to one another, a rack connected with each of the rods and which racks are driven by separate pinions driven by separate electric motors. These motors and possibly other motors for positioning other parts of the sewing machine are separately controlled independently of one another by a program controlled control unit so that the movement of needle road and of the sewing foot rod can be independently program controlled during a sewing procedure.

Owner:PFAFF INDUSTRIESYSTEME & MASCH GMBH

Control system of normal sewing machine

InactiveCN104499208AImprove convenienceLarge adjustment rangeSewing-machine casingsSewing-machine control devicesControl systemControl engineering

The invention provides a control system of a normal sewing machine, belongs to the technical field of machinery and solves the problems of inconvenience in connection and difficulty in mounting in the existing normal sewing machine servo control system. The control system comprises a shell with one end connected to a machine head of the normal sewing machine, one end, connected with the machine head of the normal sewing machine, of the shell is open, the inside of the shell is a cavity which comprises an upper cavity body and a lower cavity body, a servo motor is arranged in the upper cavity body, a control circuit board is arranged in the lower cavity body, the open end of the shell is connected with an aluminum heat dissipation plate which closes the lower cavity body, the control circuit board is fixed to the inner side face of the aluminum heat dissipation plate, the lateral portion of the aluminum heat dissipation plate is provided with a notch, a convex guide bar is arranged on the inner side wall of the lower cavity body of the shell correspondingly and located in the notch, the edge of the open end of the shell is provided with an insertion slot, and an insertion portion is arranged on the aluminum heat dissipation plate protrudingly and inserted into the insertion slot. The control system has the advantages of convenience in connection, compact structure, high practicality and the like.

Owner:QIXING INTELLIGENT TECH CO LTD

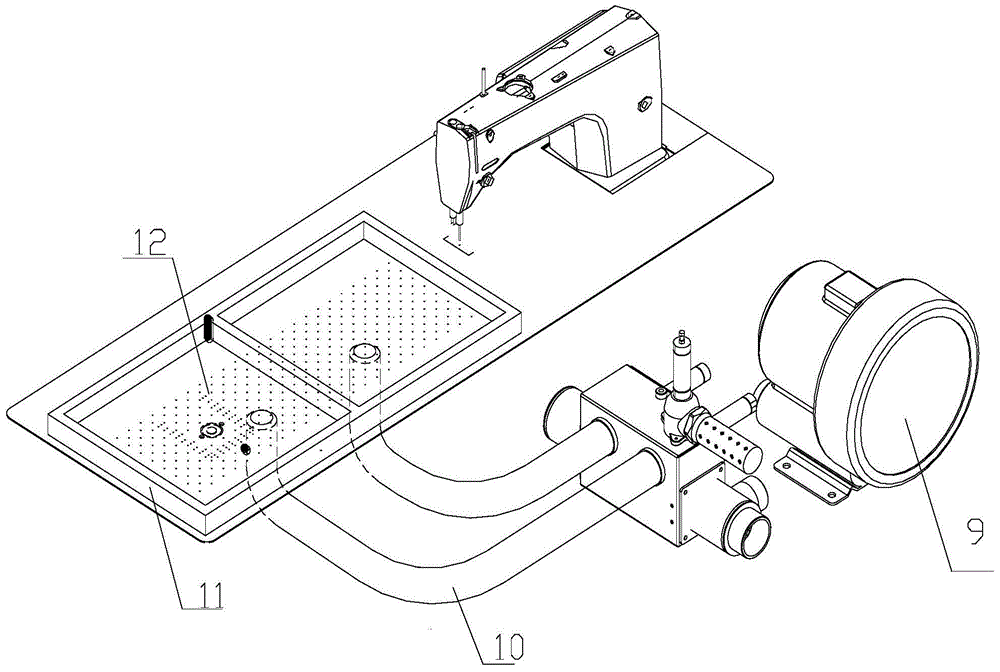

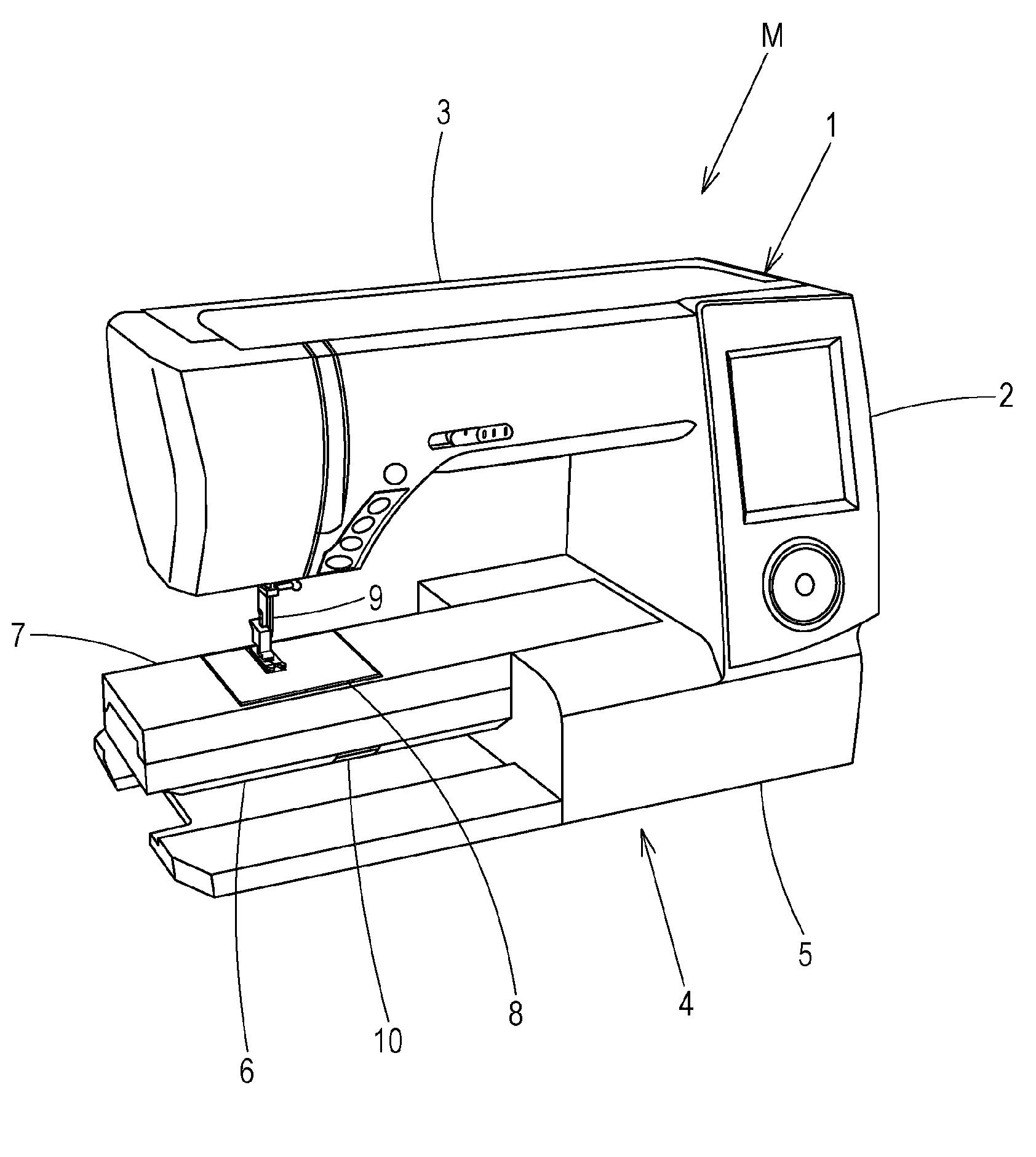

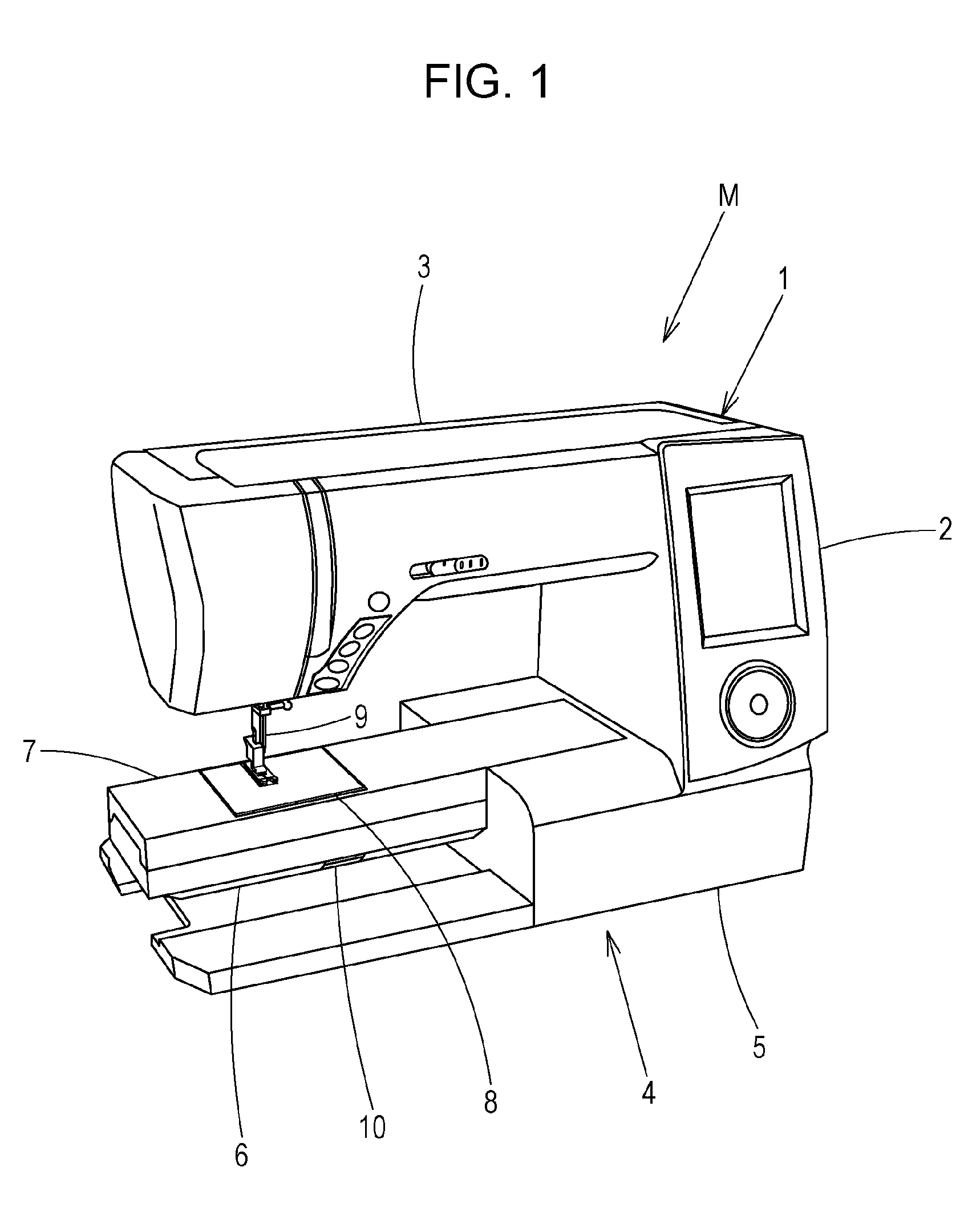

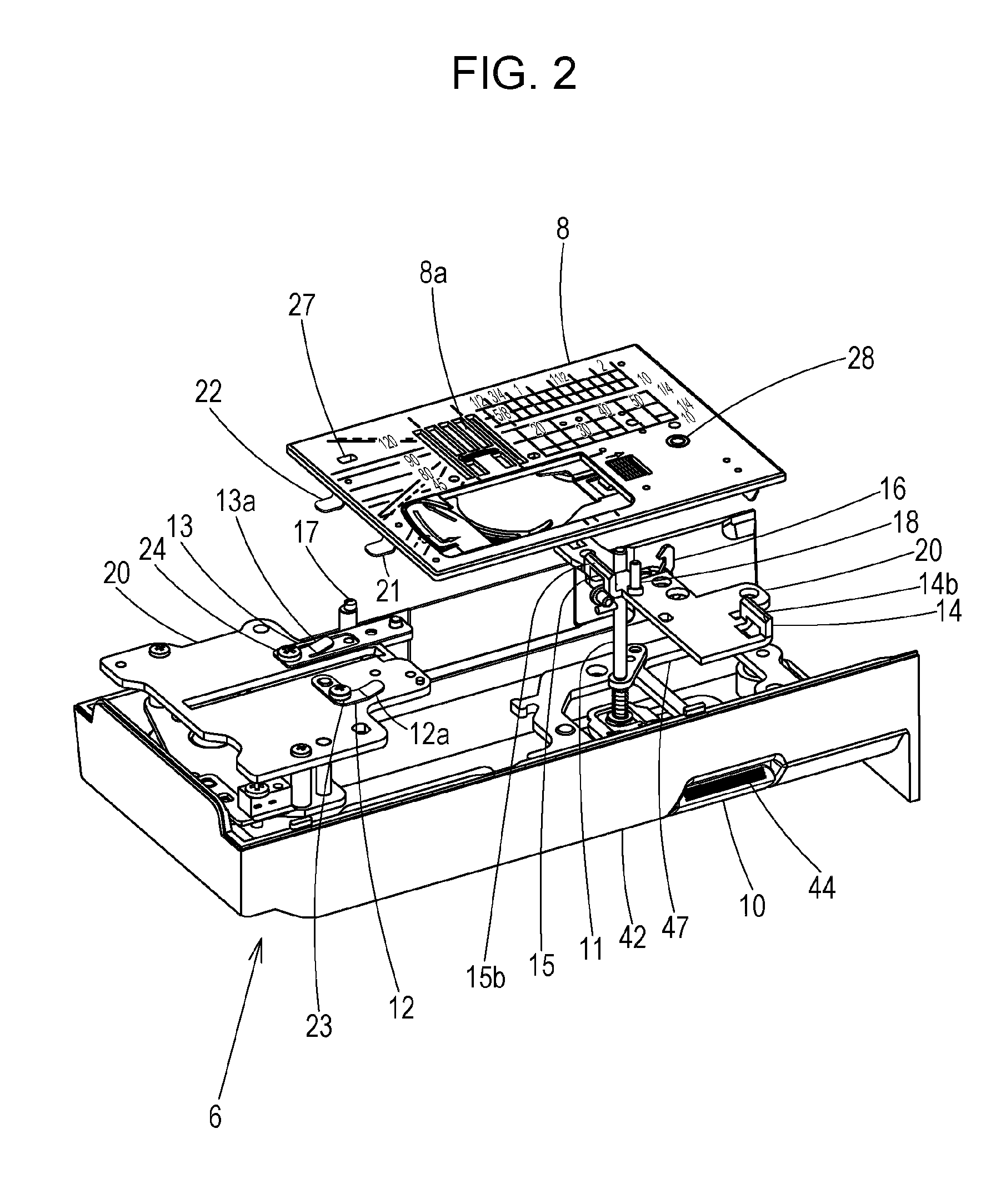

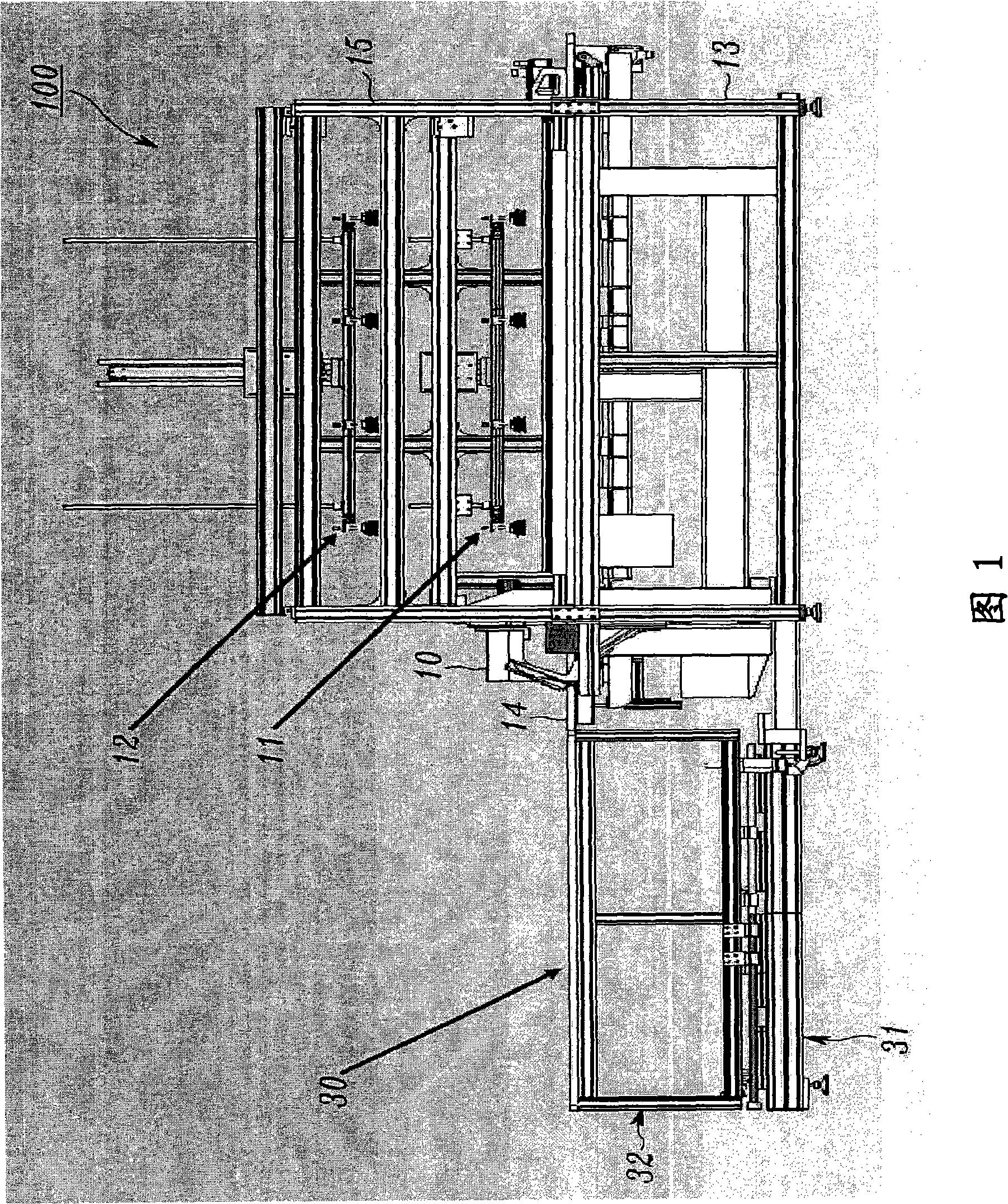

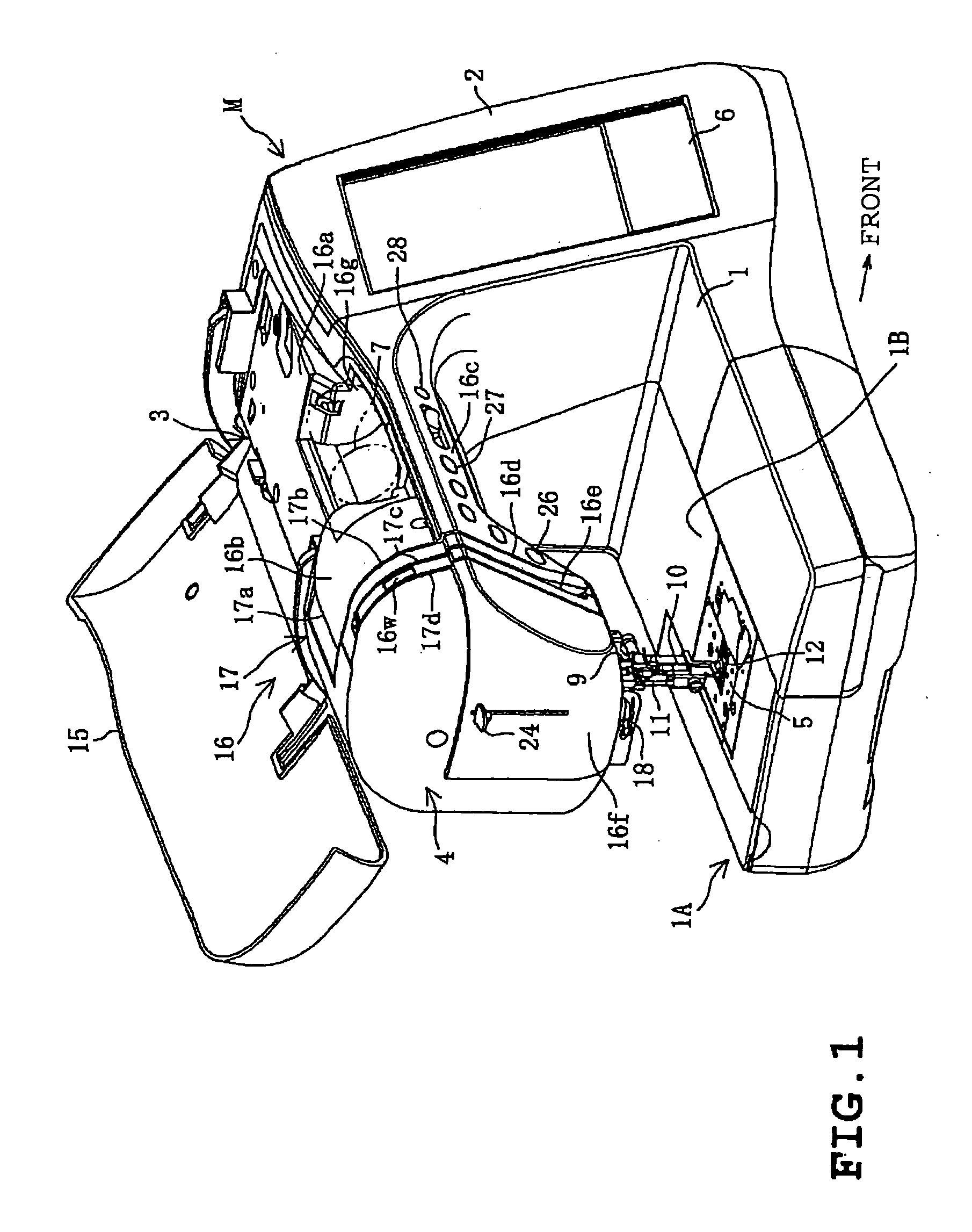

Sewing machine with sewing frame exchanging structure and sequence control method thereof

InactiveCN101280492AConvenience to workWork fasterProgramme-controlled sewing machinesSewing-machine casingsSequence controlBobbin

The present invention relates to a sewing machines with replacing sewing frame structure, sewing large-sized sewing products (cloth) by sequence controlling type, replacing the sewing product by using an actuator automatically when sewing a broad sewing product (cloth), mounting a sub working platform sliding fore and after on a main working platform for sewing the large-sized sewing product easily, after the sub working platform sliding off the main working platform, a shuttle platform is moved downward by using the actuator, this make worker replace a bobbin mounted at the bottom of the main working platform easily, changing or correcting logical (sequence) easily by using series communication mode for transmitting the sequence controlling program of the sewing machines with a changeable sewing frame structure or using the software (UAM: universal application module), the modified sequence can be downloaded (transmitted) at any time by using UAM. The present invention can improve conveniences of the work, and can also improve the working speed to improve productivity.

Owner:MOBASE SUNSTAR CO LTD

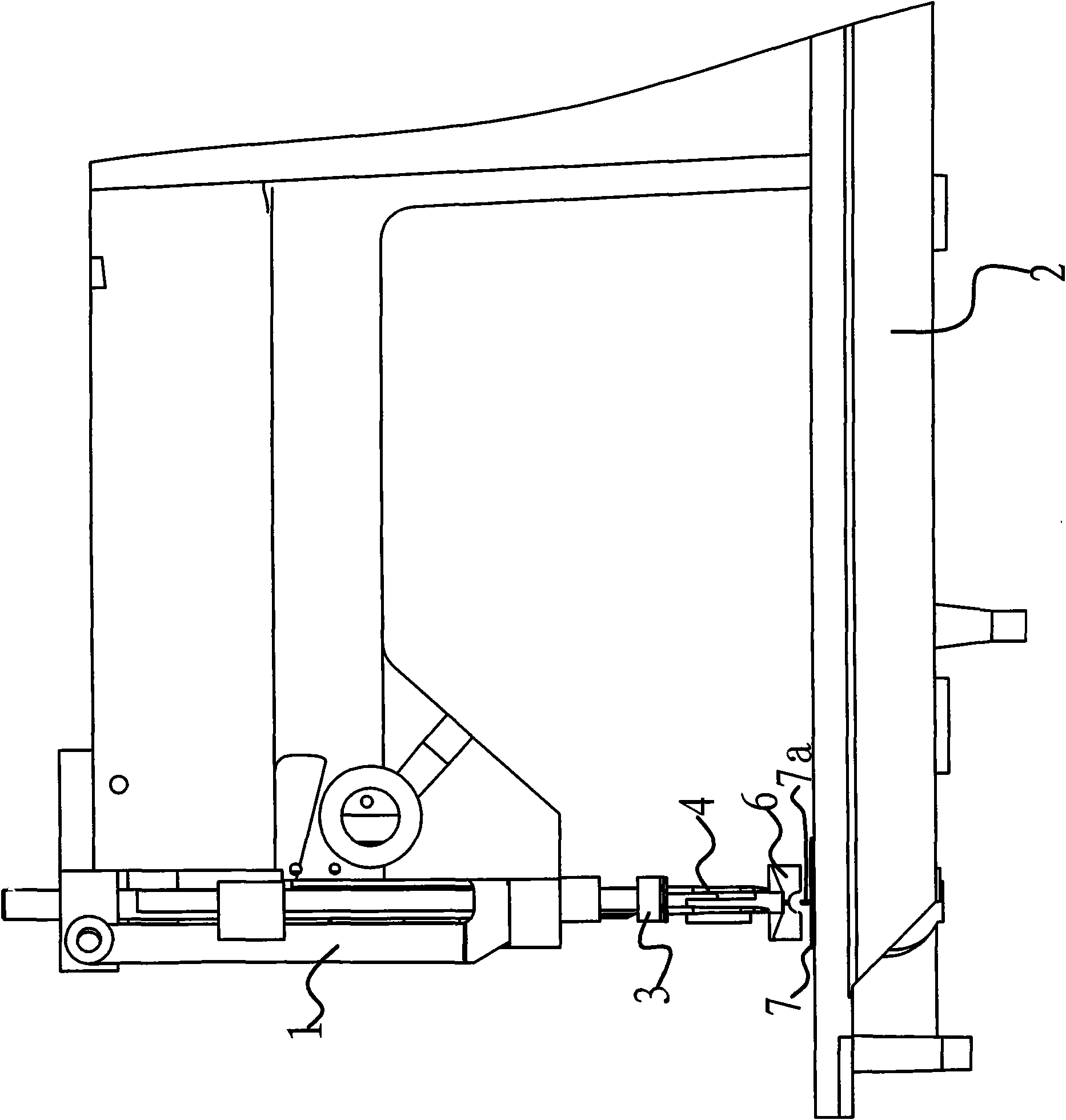

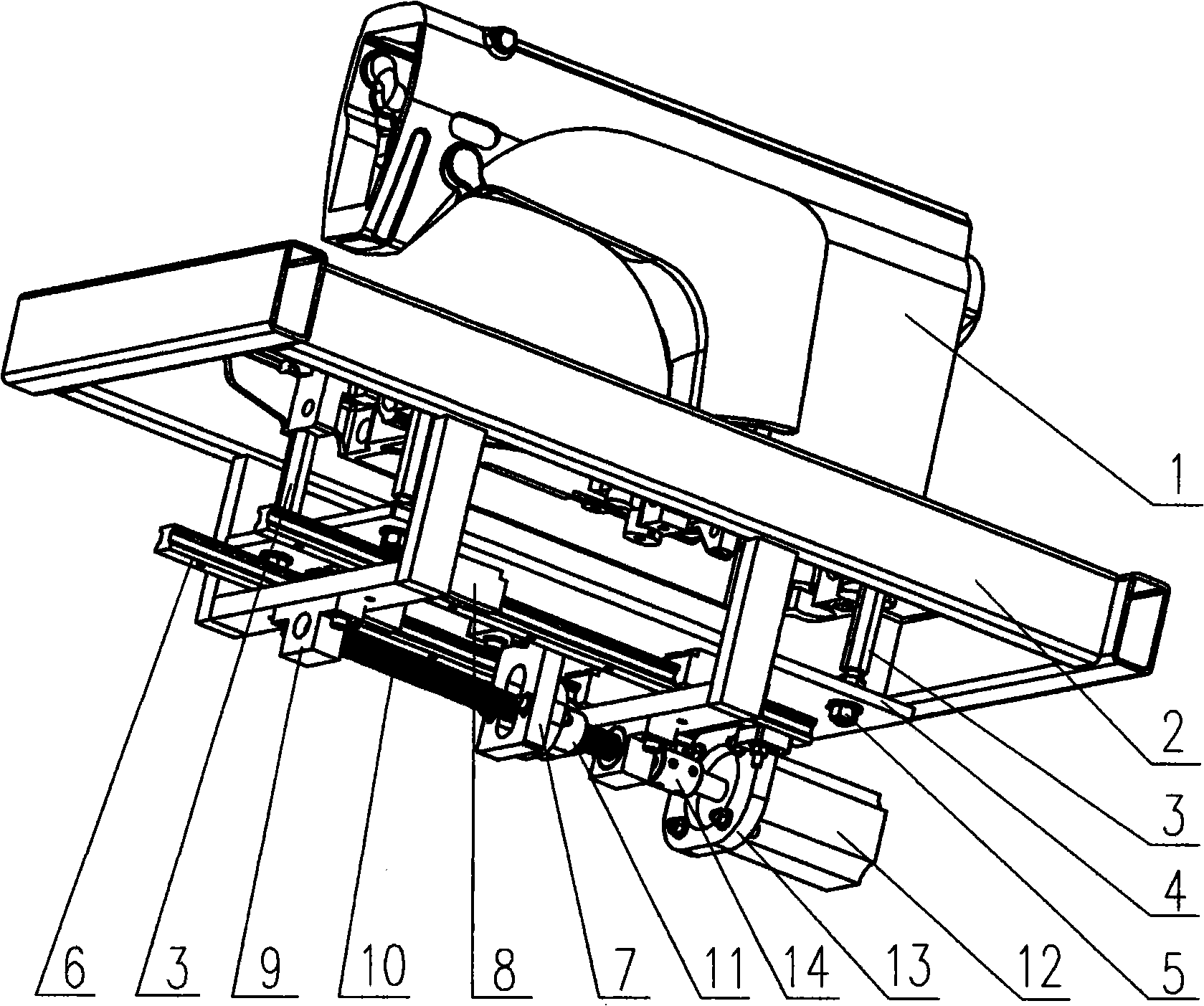

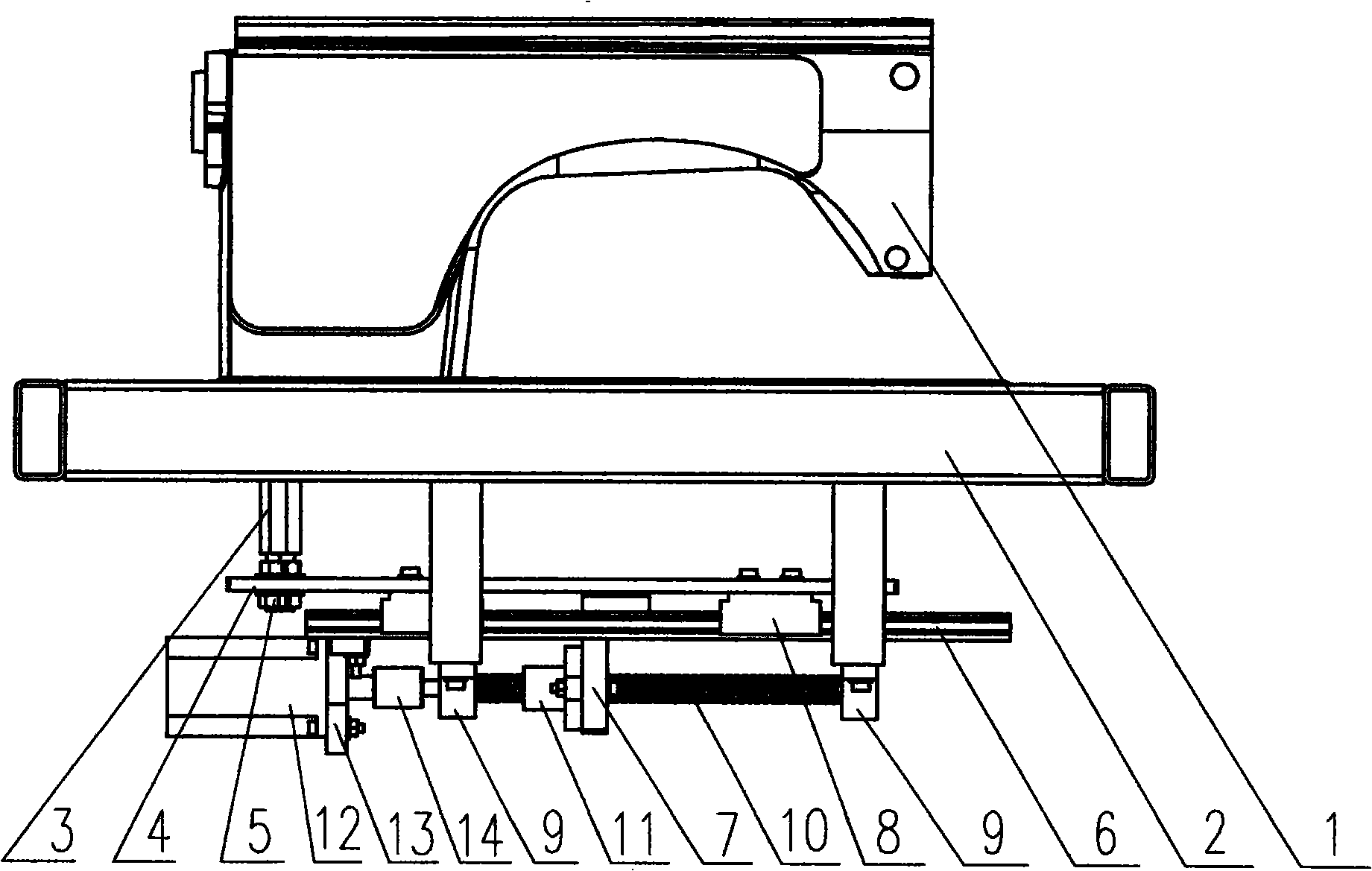

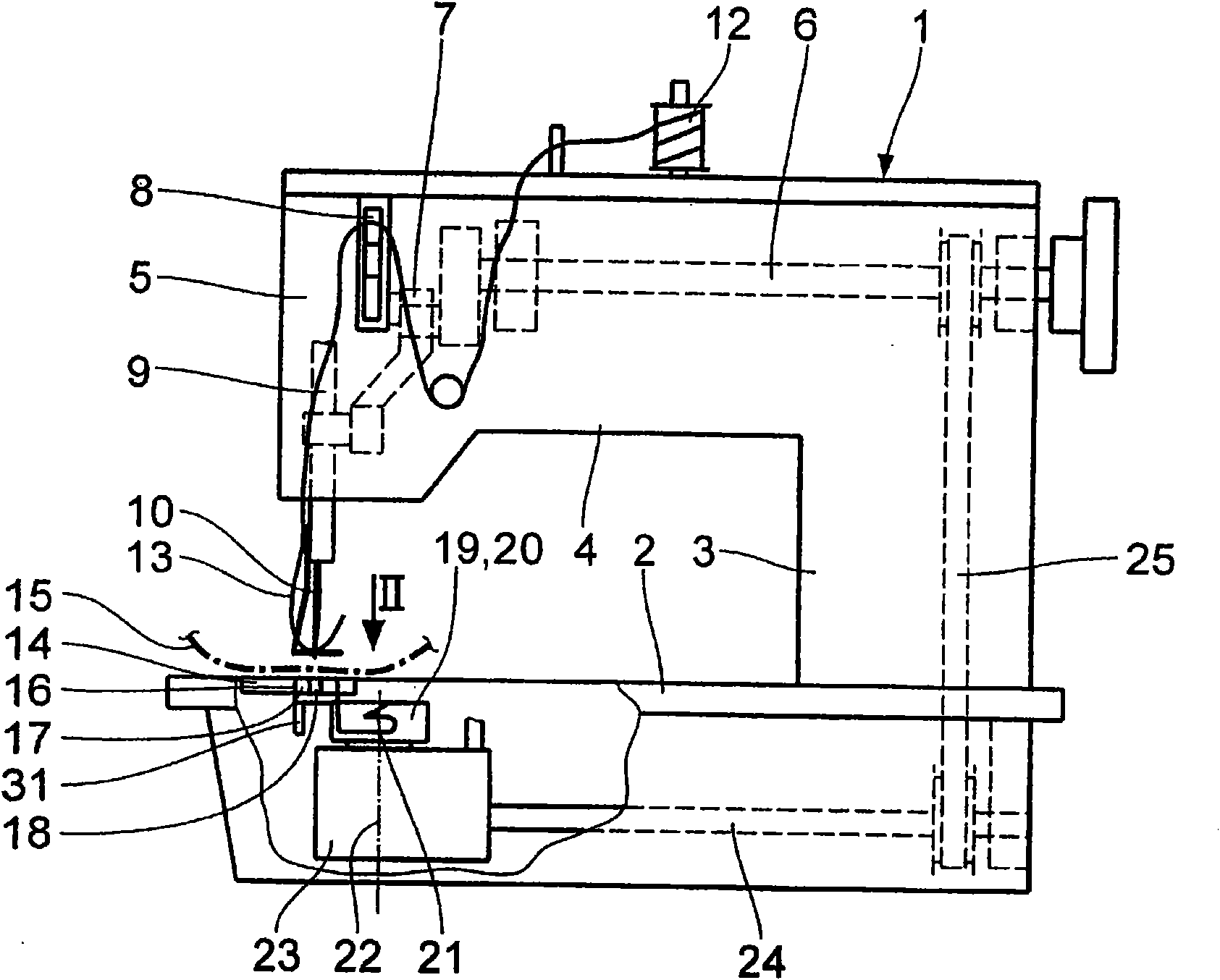

Body moveable structure of sewing machine

The present invention pertains to the sewing machine technology, in particular to a structure of a movable sewing machine body, which ensures that the sewing machine is no longer fixed on the frame and can move within a certain range. The present invention comprises a sewing machine head 1, a frame 2, a support screw bolt 3, a head fixed plate 4, a nut 5, a guide rail 6, a dynamic bracket 7, a sliding block set 8, a lead screw fixed base 9, a lead screw 10, a lead screw nut pair 11, a motor 12, a motor fixed base 13 and a guide bush 14. The present invention is characterized in that a lead screw transmission device is designed and the motor 12 provides the power for driving the sewing machine head to move. The present invention also designs a platform consisting of two guide rails 6 and capable of stably operating the sewing machine head 1. The sewing machine head 1 is arranged on the head fixed plate 4, and the center and the four corners of the head fixed plate 4 are added with a support, thus ensuring more stable operation of the sewing machine head 1.

Owner:JACK SEWING MASCH CO LTD

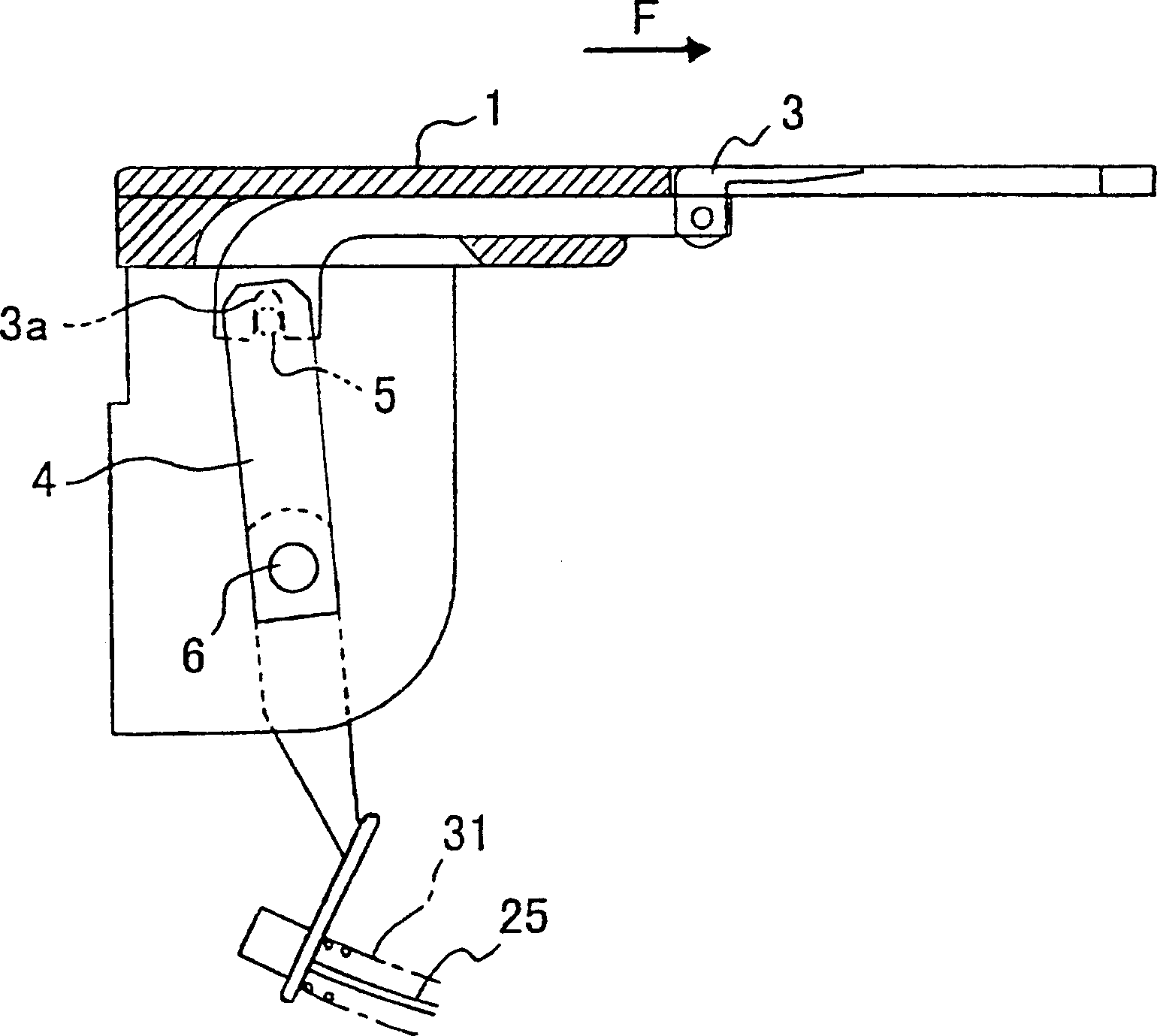

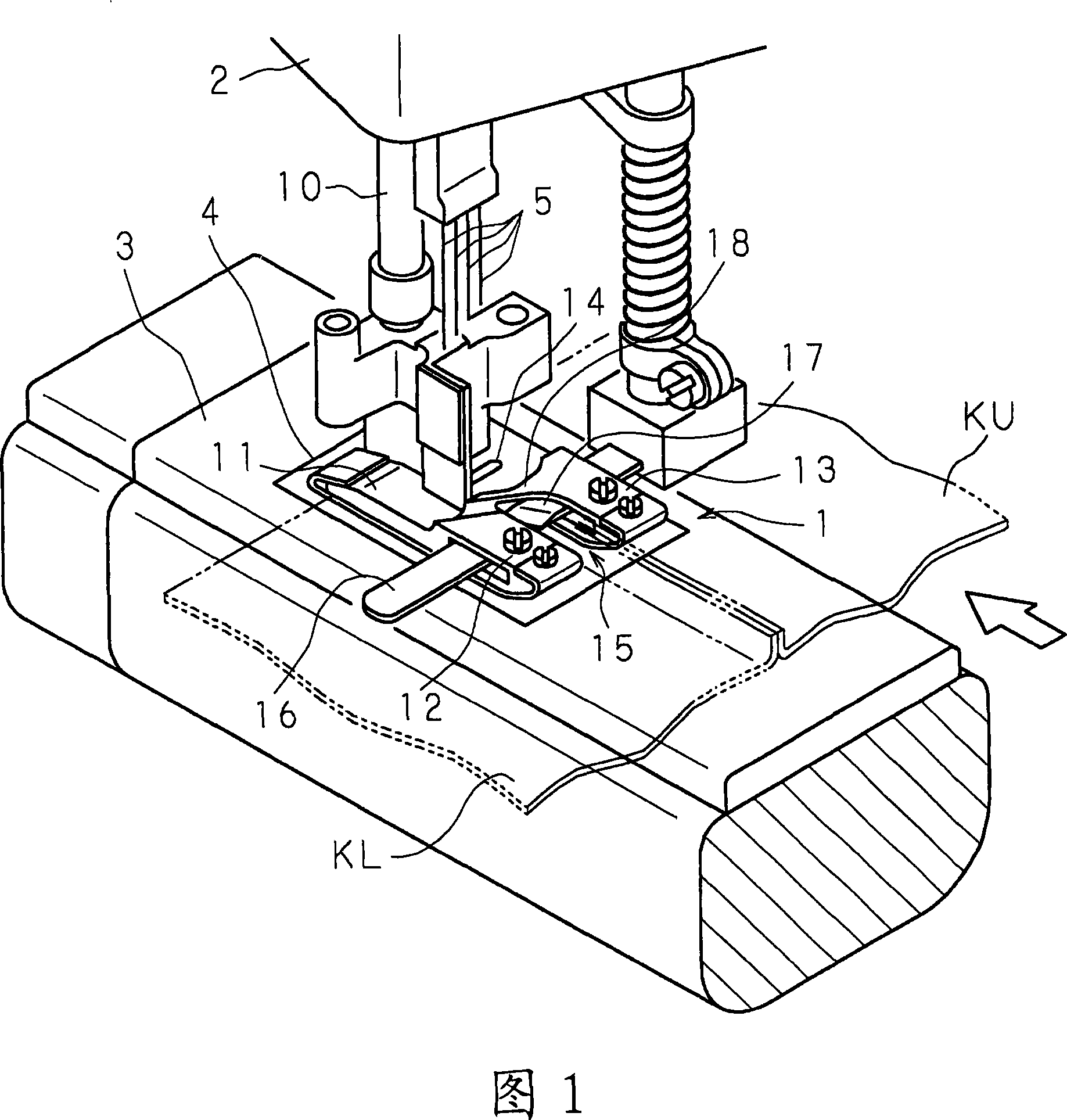

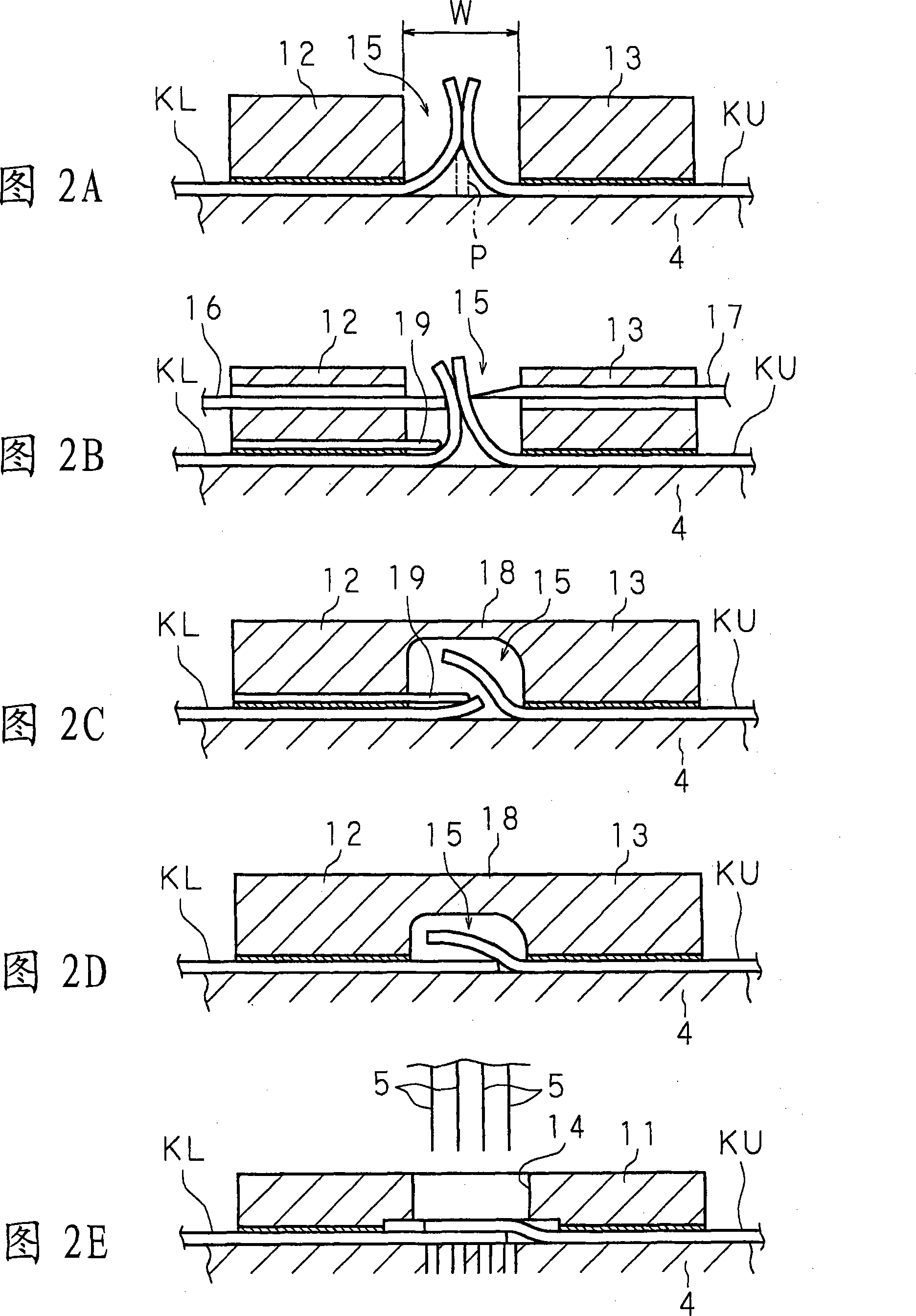

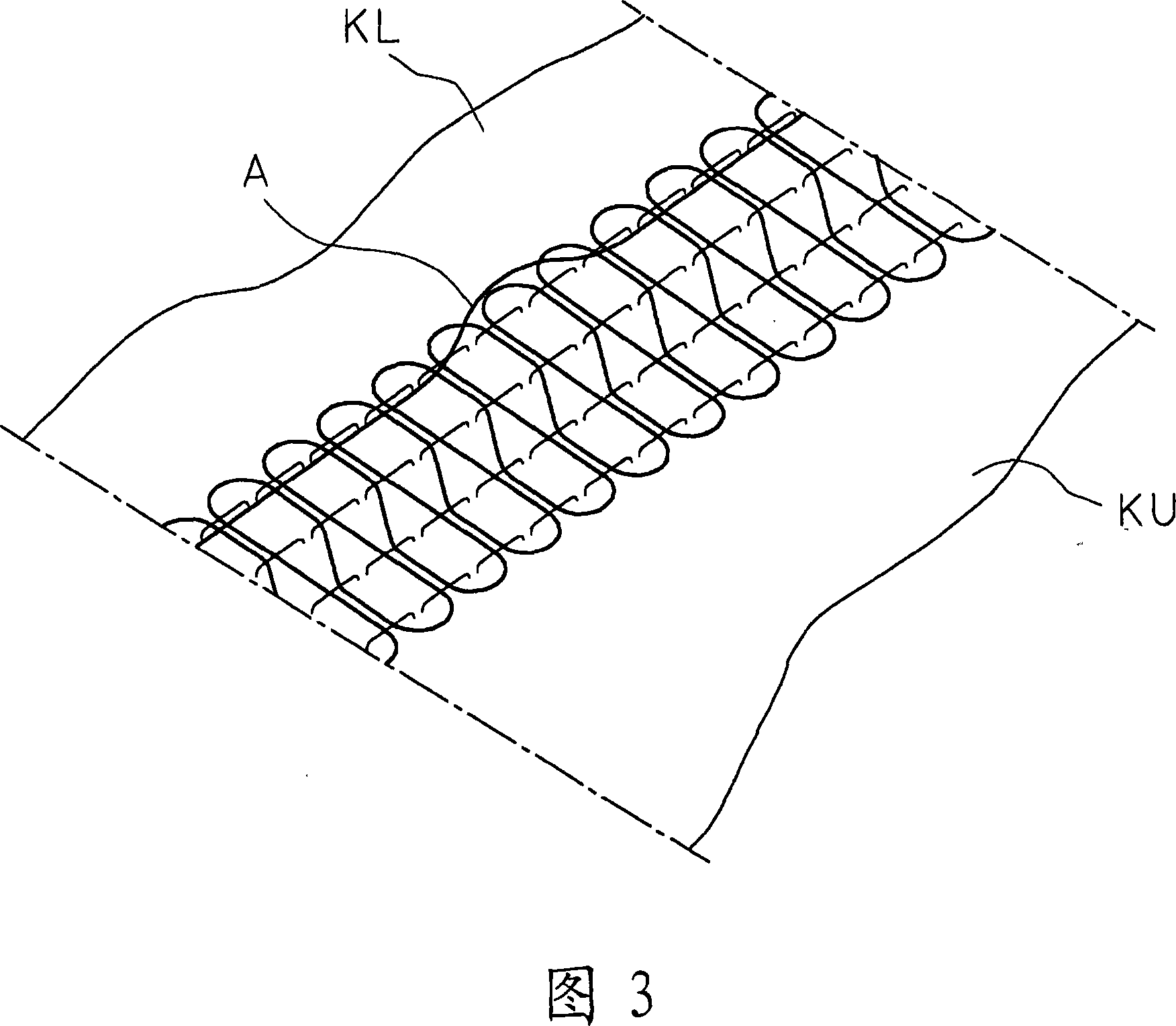

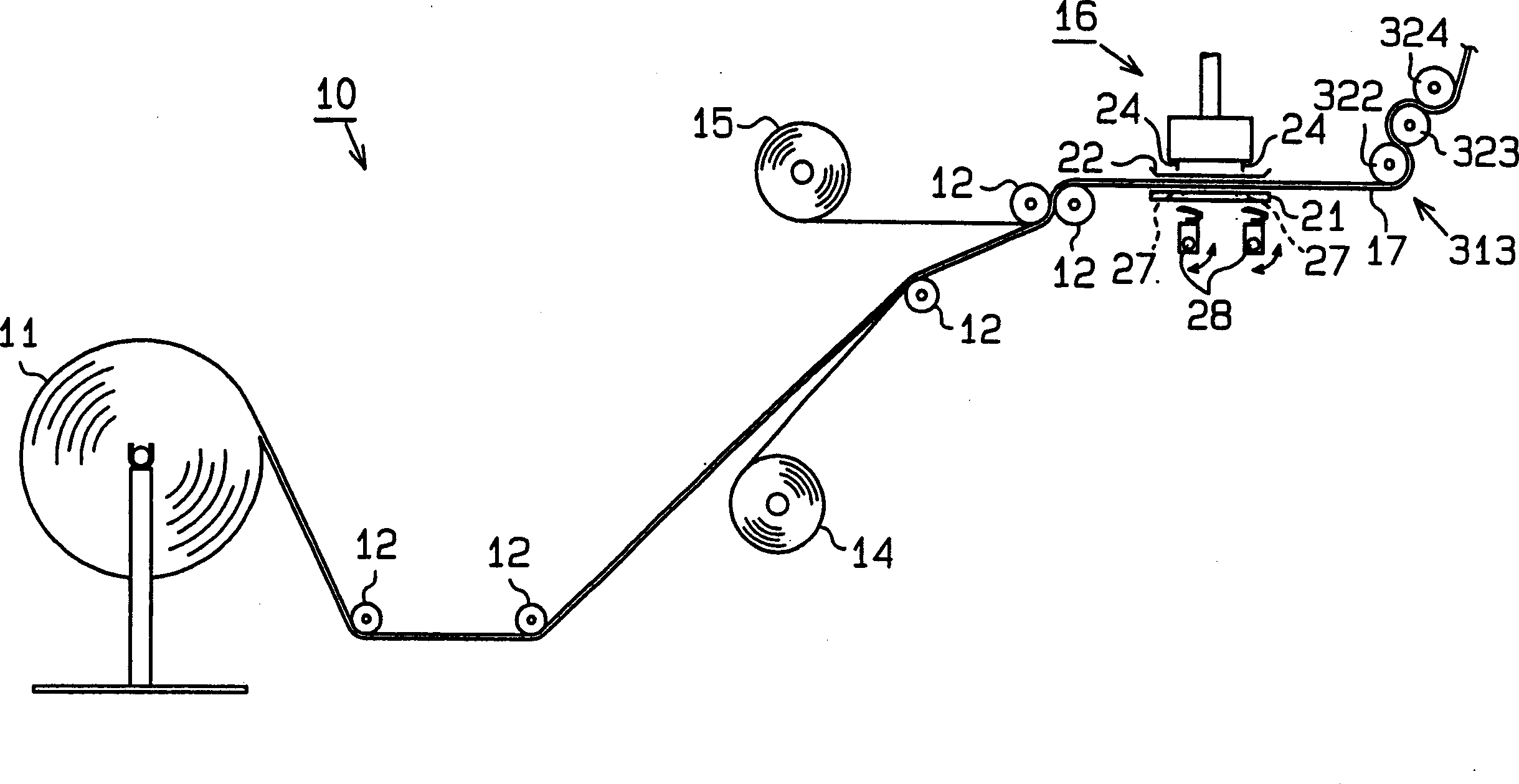

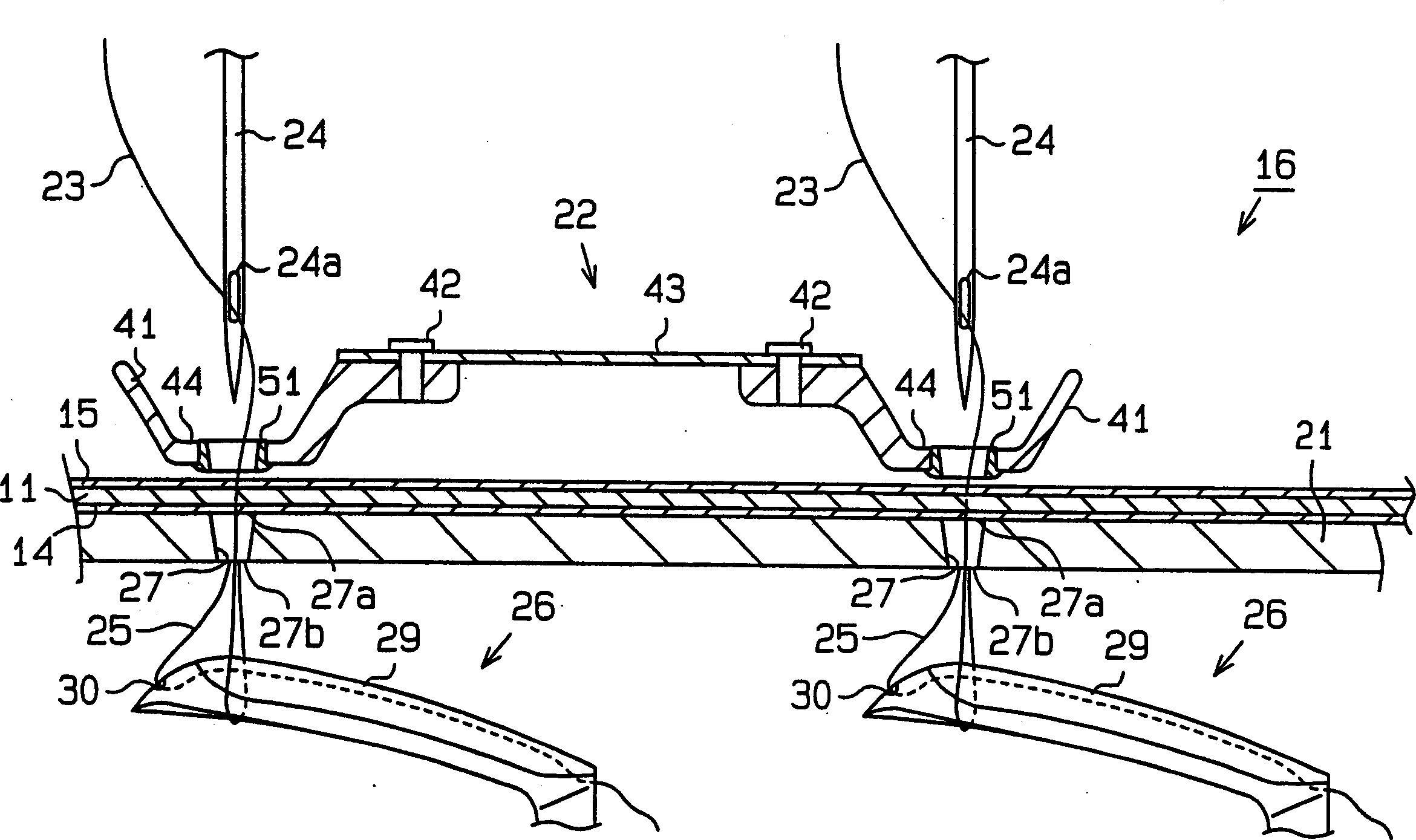

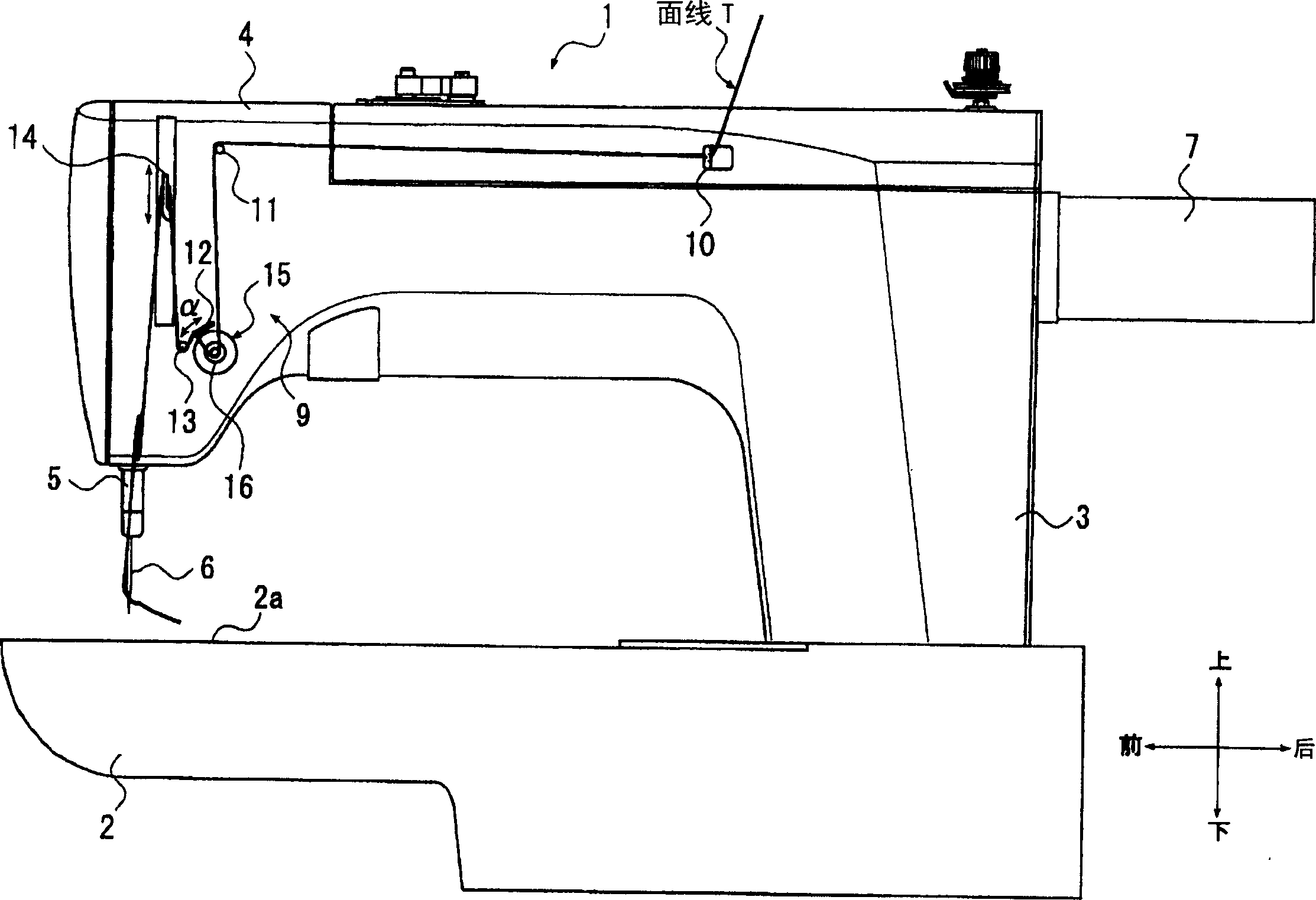

Transporter for transporting sewing material while operating a sewing machine

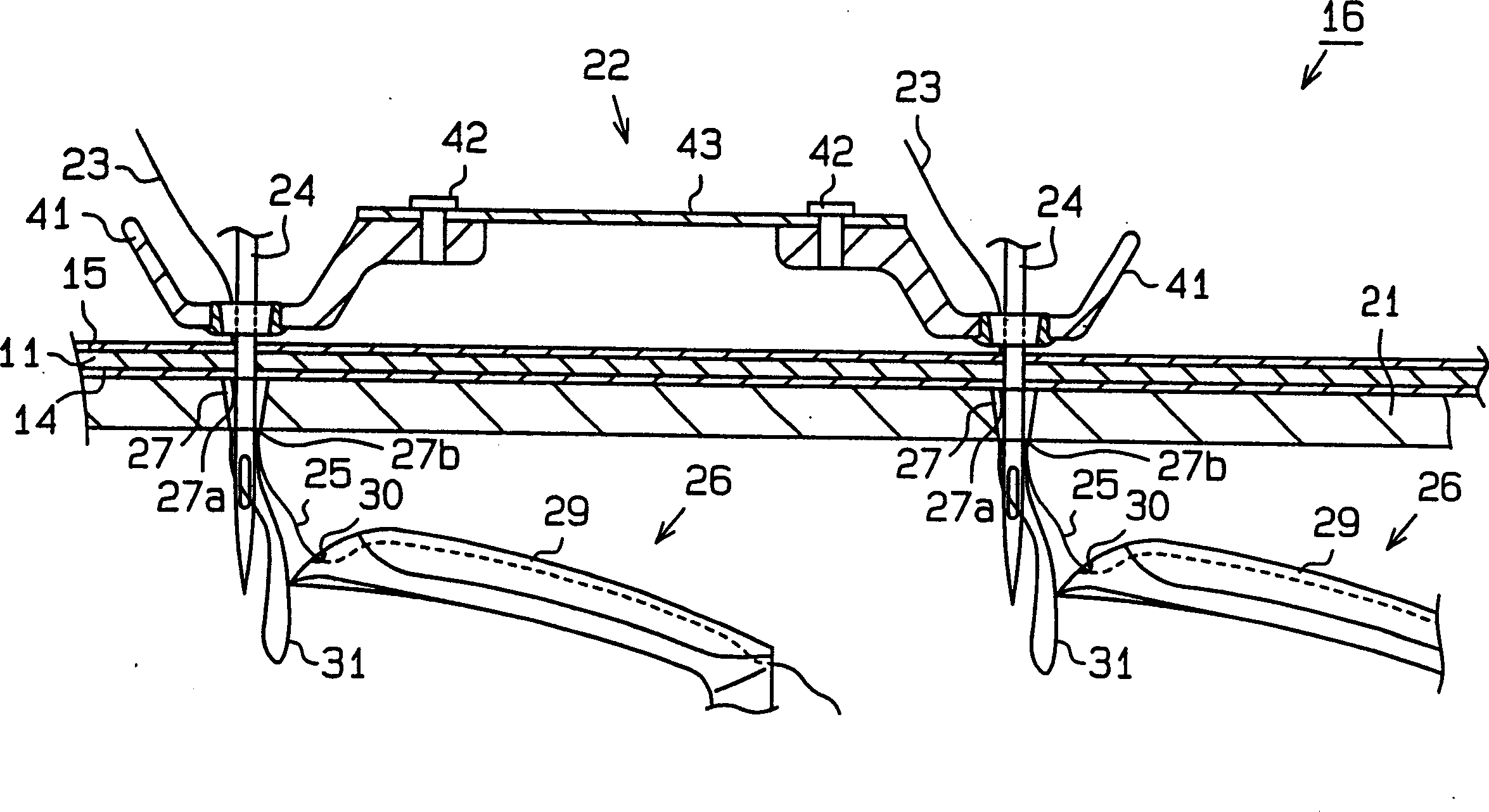

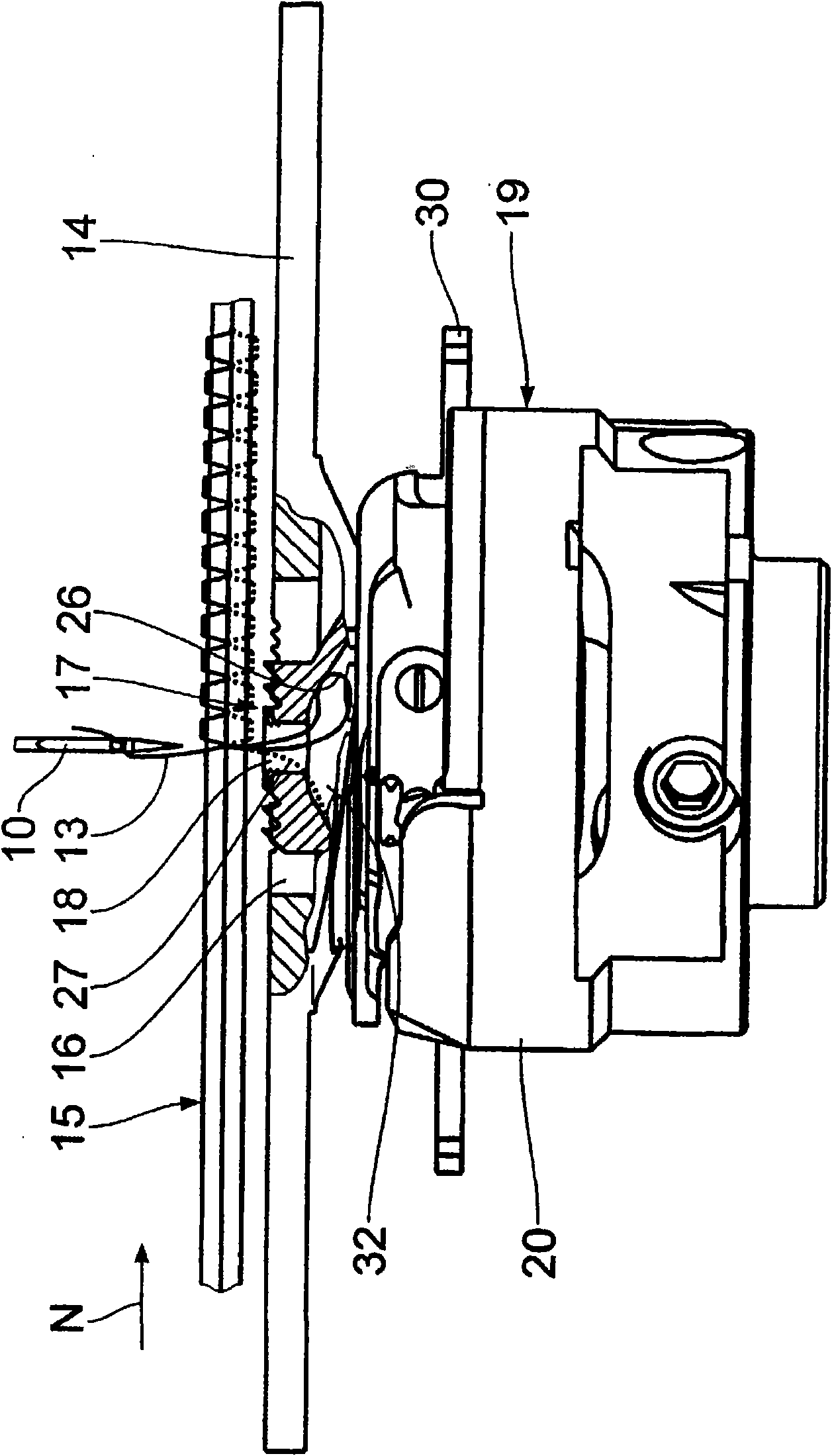

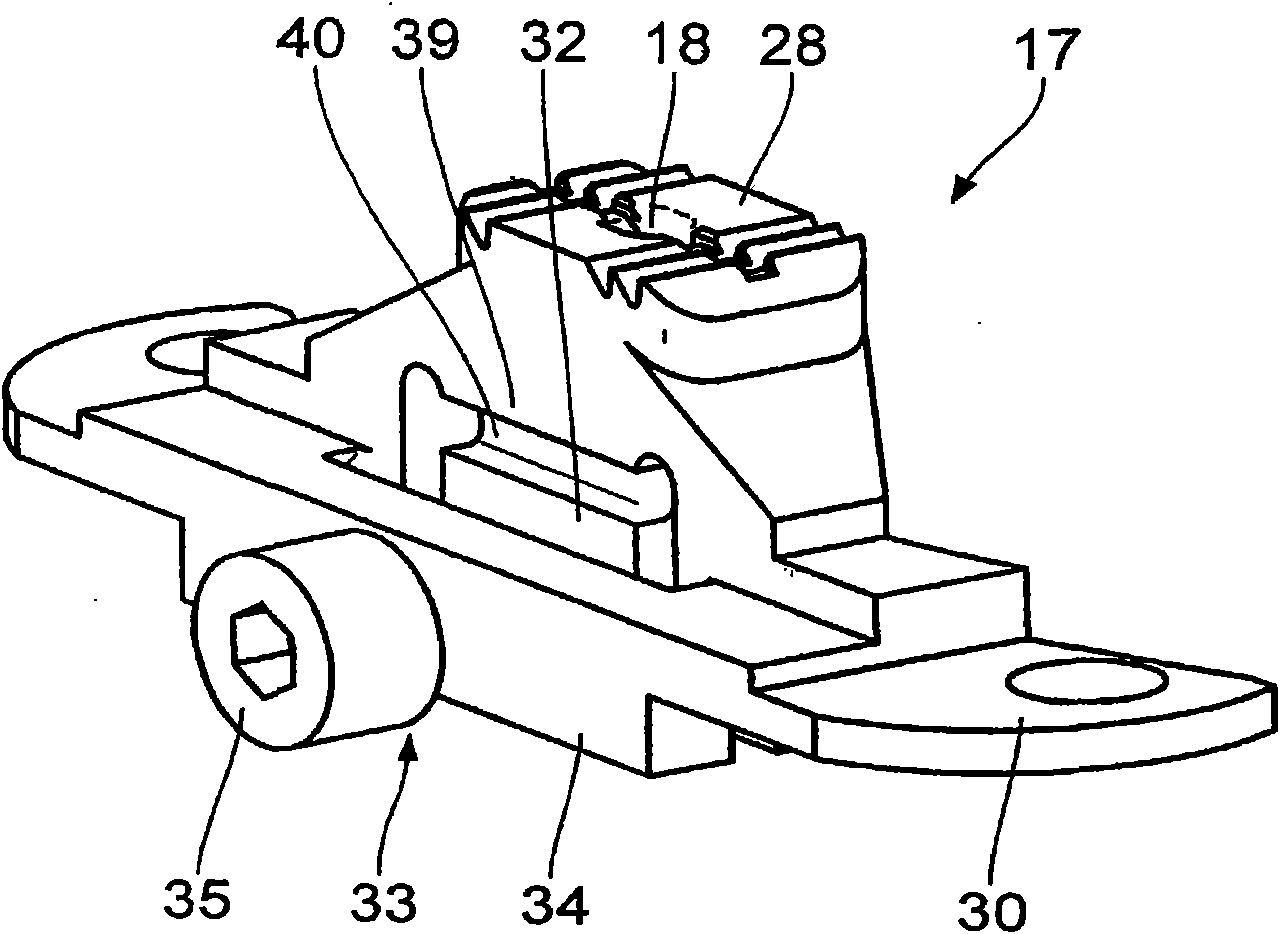

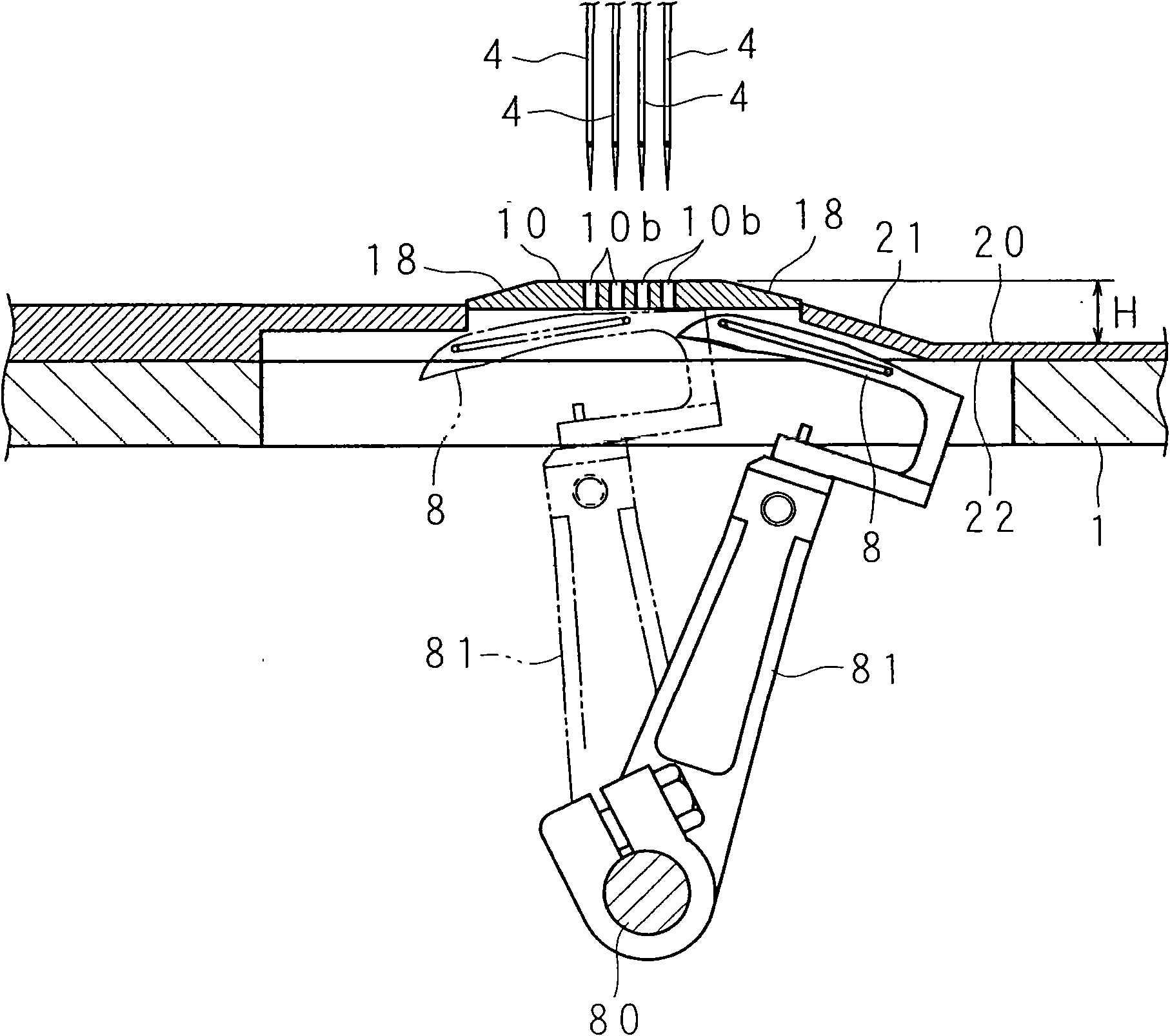

InactiveCN101613913AEffective protectionAvoid breakingSewing-machine casingsWork-feeding meansSewing needleBiomedical engineering

The invention relates to a sewing machine, which includes a needle plate with a needle plate recess and a needle rod connected with a sewing needle thereon, wherein, the needle rod is driven to move up and down above the needle plate. A transporter (17) is arranged in the needle plate recess and used for performing the transportation. The transporter (17) includes a transporting portion (28) which is designed to frictionally interact with sewing material and perform the transportation near a needle movement area. In addition, the transporter (17) includes a base portion, through which the transporting portion (28) is rigidly connected with a transporter bracket. A transporter wall (32) is arranged below the transporting portion (28) near the needle movement area. The transporter wall (32)is designed to extend at one side of the needle when the transporter (17) is mounted, wherein, the side is distant from a stitch formation tool interacting with the needle in the sewing process. The distance of the transporter wall (32) with respect to the needle movement area can be adjusted by means of an adjuster (33). Accordingly, a transporter and a transporter-mounted sewing machine are obtained with lowered likelihood of needle fracture and / or thread missing.

Owner:DURKOPP ADLER AG

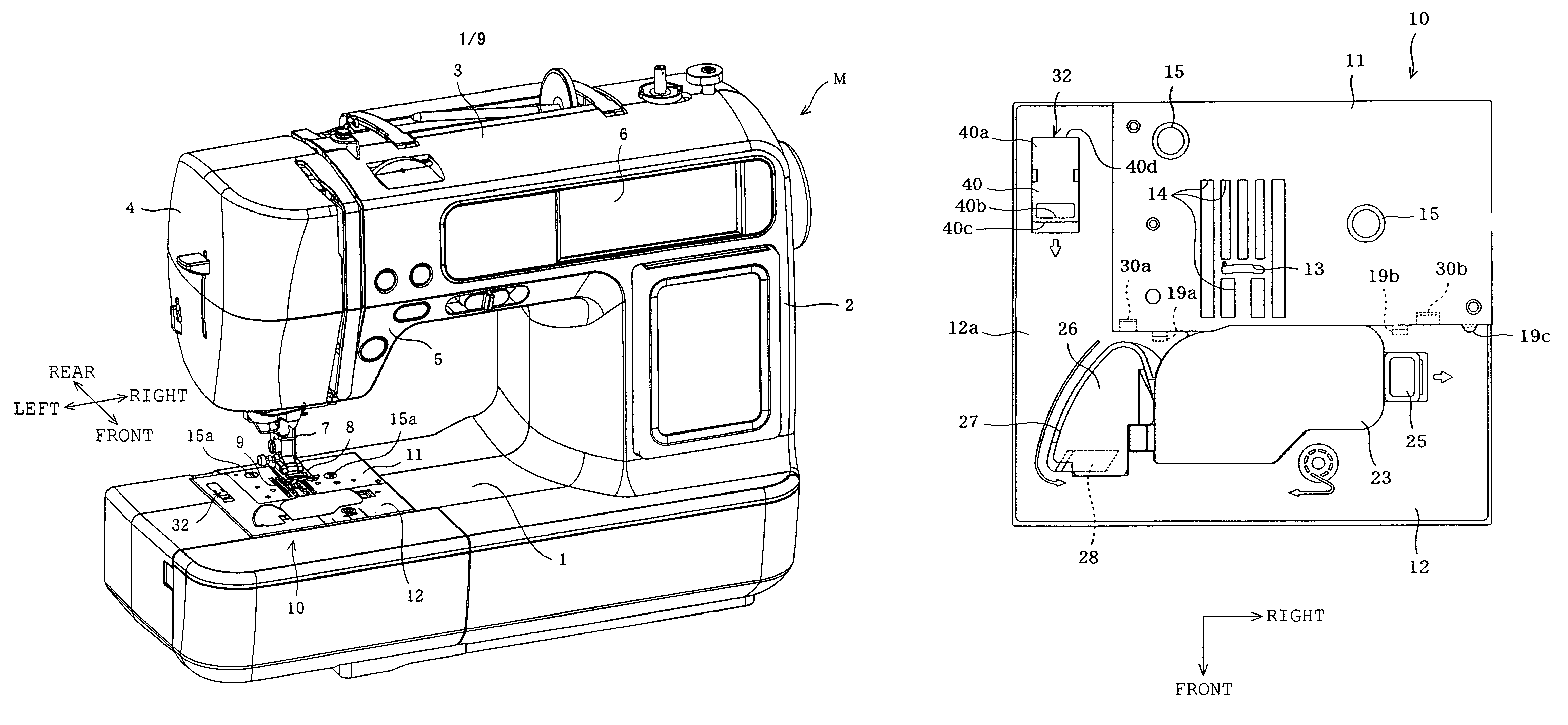

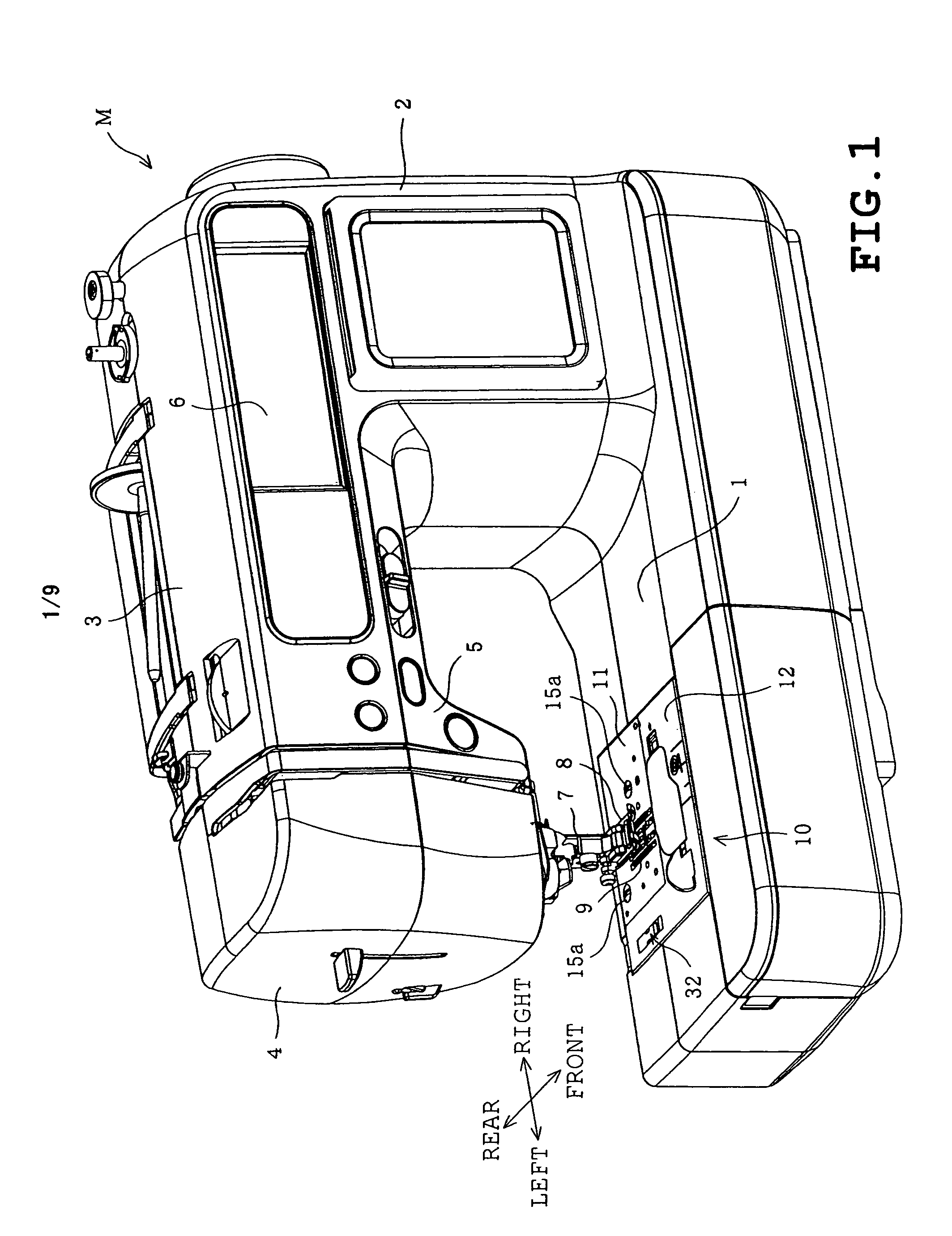

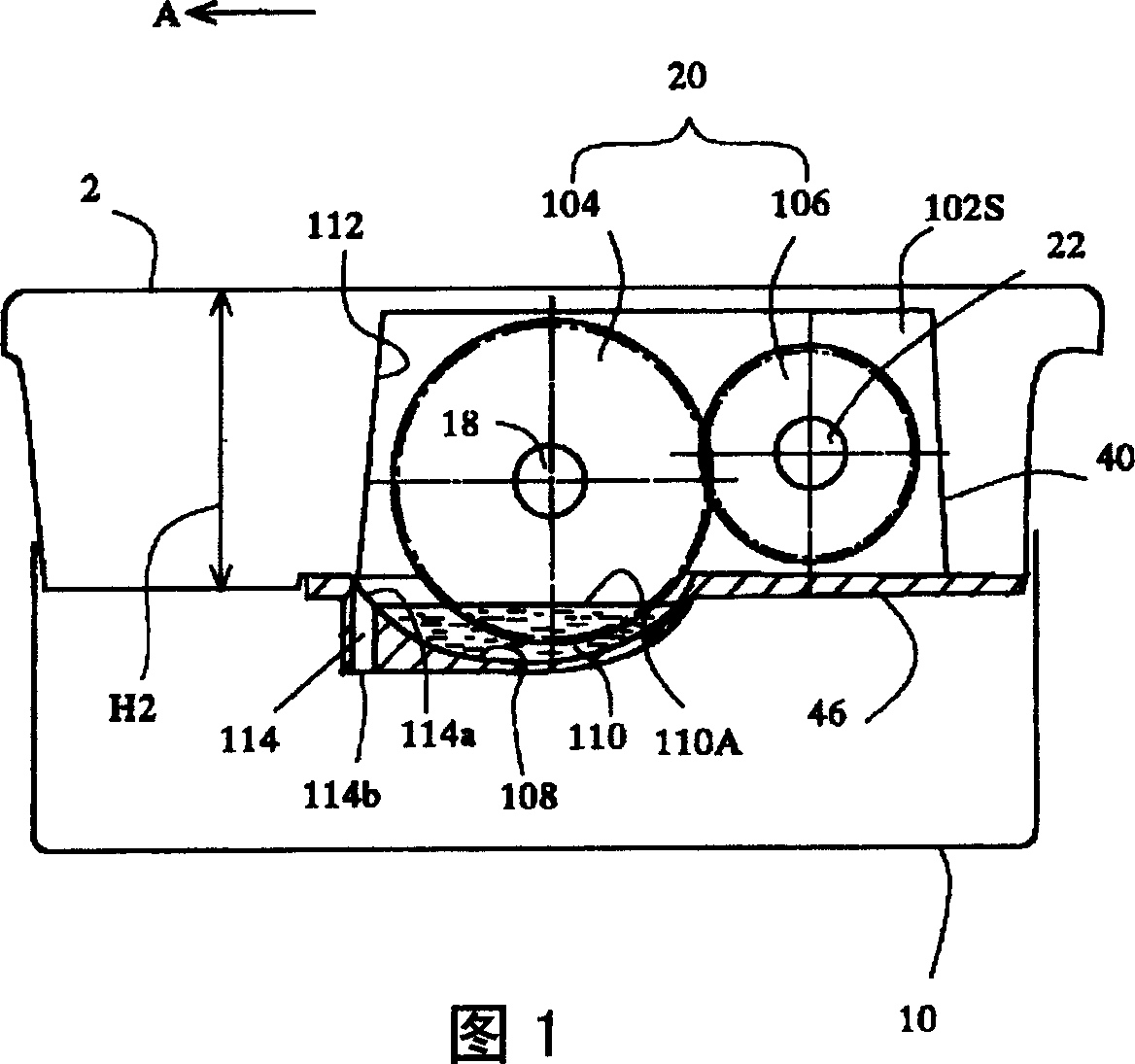

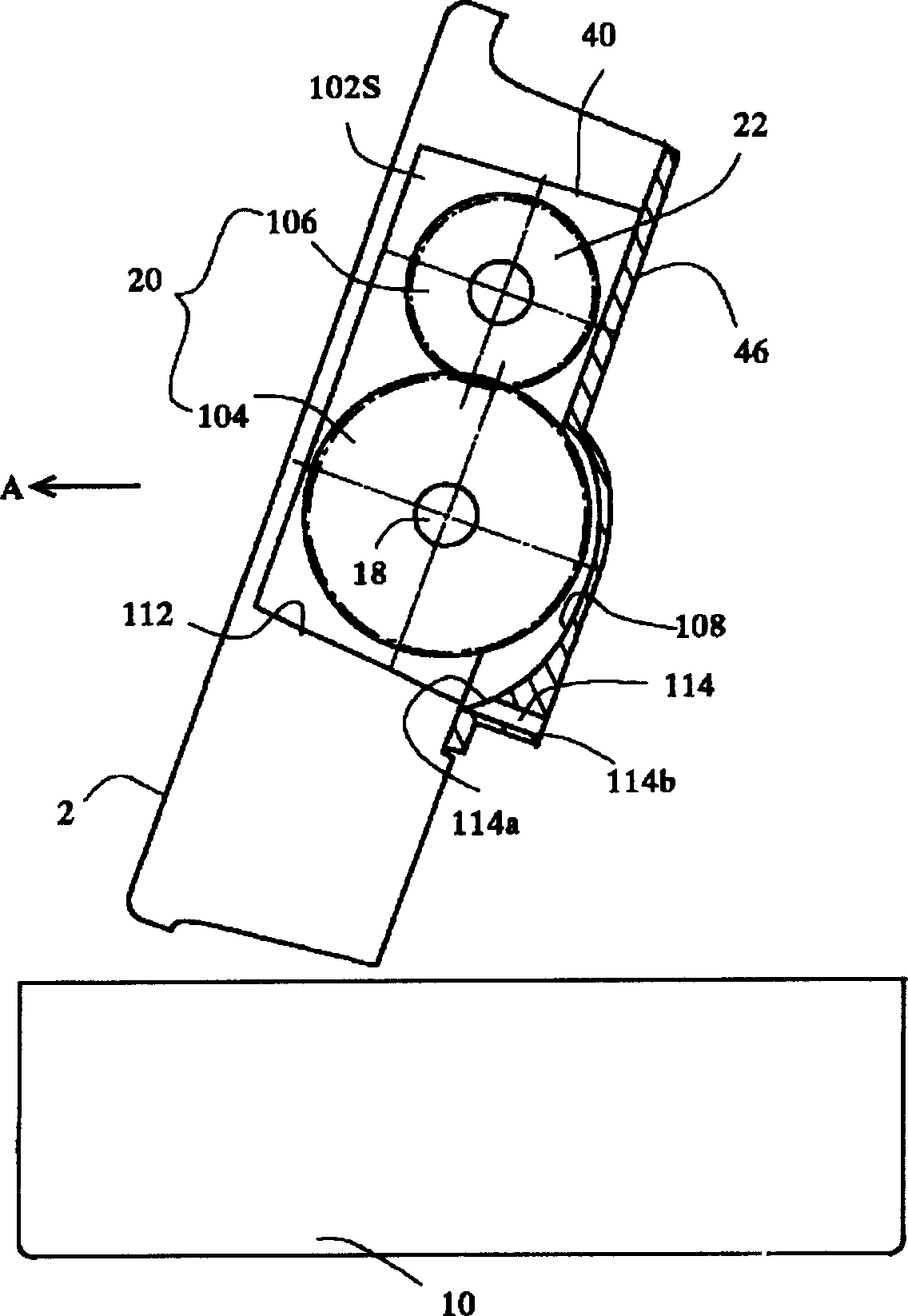

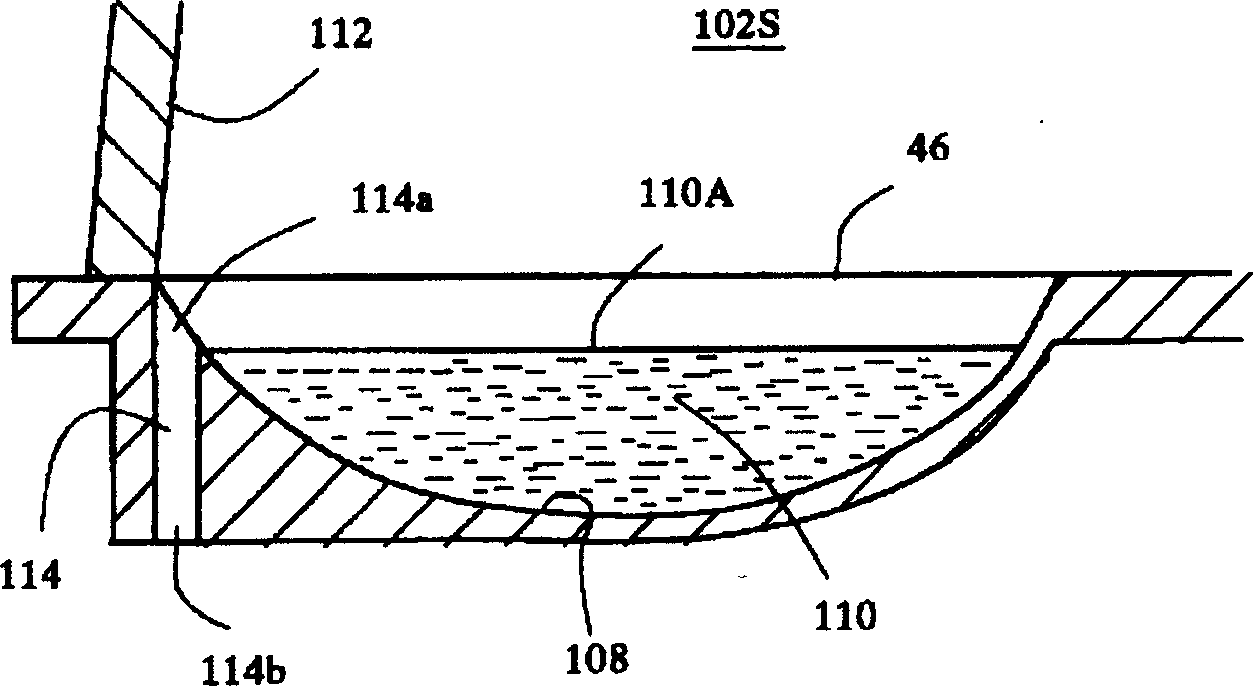

Sewing machines

The invention provides a sewing machine which gets lubricants ejected into an oil pan to leave none thereof in a gear box when the sewing machine is levelled. In the sewing machine which is provided with a bed part 2, the oil pan 10 arranged below the bed part and a gear box 40 which is arranged within the bed part while housing a gear device 20 for transmitting driving forces of the lower shaft 18 to a hook drive shaft 22 and in which the gear box has an under cover 46 with a waste oil port 114 that is so formed as to let the lubricant 110 be ejected within the gear box to the oil pan 10, the waste oil port has an upper opening 114a bored into the gear box 40 and a lower opening 114b bored toward the side of the oil pan 10, the upper opening 114a of the waste oil port 114 is so positioned as to be higher than the lowest part of a space 102S within the gear box 40 when the sewing machine is standing while being down to the lowest of the space within the gear box when it is leveled.

Owner:JUKI CORP

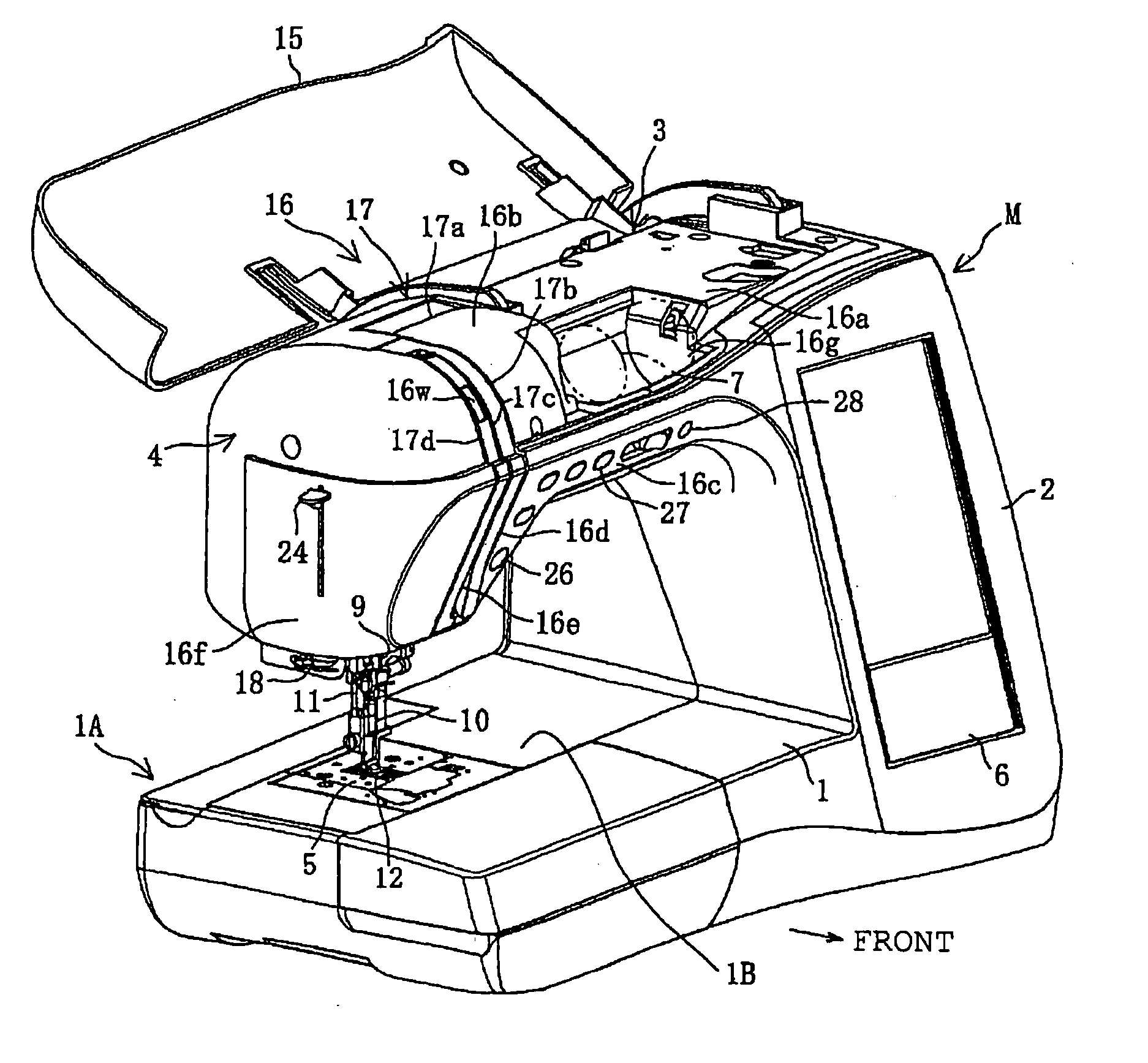

Sewing machine

ActiveUS20060107883A1Easy to operatePromote exchangeProgramme-controlled sewing machinesSewing-machine casingsEngineeringActuator

The sewing machine includes a presser foot that is lowered to press a workpiece cloth; a presser foot lifting lever operating the presser foot; a thread tension mechanism including a thread tension regulator capable of adjusting the thread tension of a needle thread and opening the thread tension regulator based on the lifting operation of the presser foot lifting lever; and a thread guide groove guiding the needle thread at least to the thread tension mechanism, upon carrying out the thread hooking work. The sewing machine further includes a detector detecting a lifting operation of the presser foot lifting lever; a covering member which is movable between a closed position where the covering member covers at least a part of the thread guide groove and an opened position where the covering member opens the thread guide groove. The covering member is moved to the closed position when the presser foot is in a lowered state. An actuator moves the covering member at least from the closed position to the opened position. A controller controls the actuator so that the covering member is moved to the opened position when the detector detects the lifting operation of the presser foot lifting lever.

Owner:BROTHER KOGYO KK

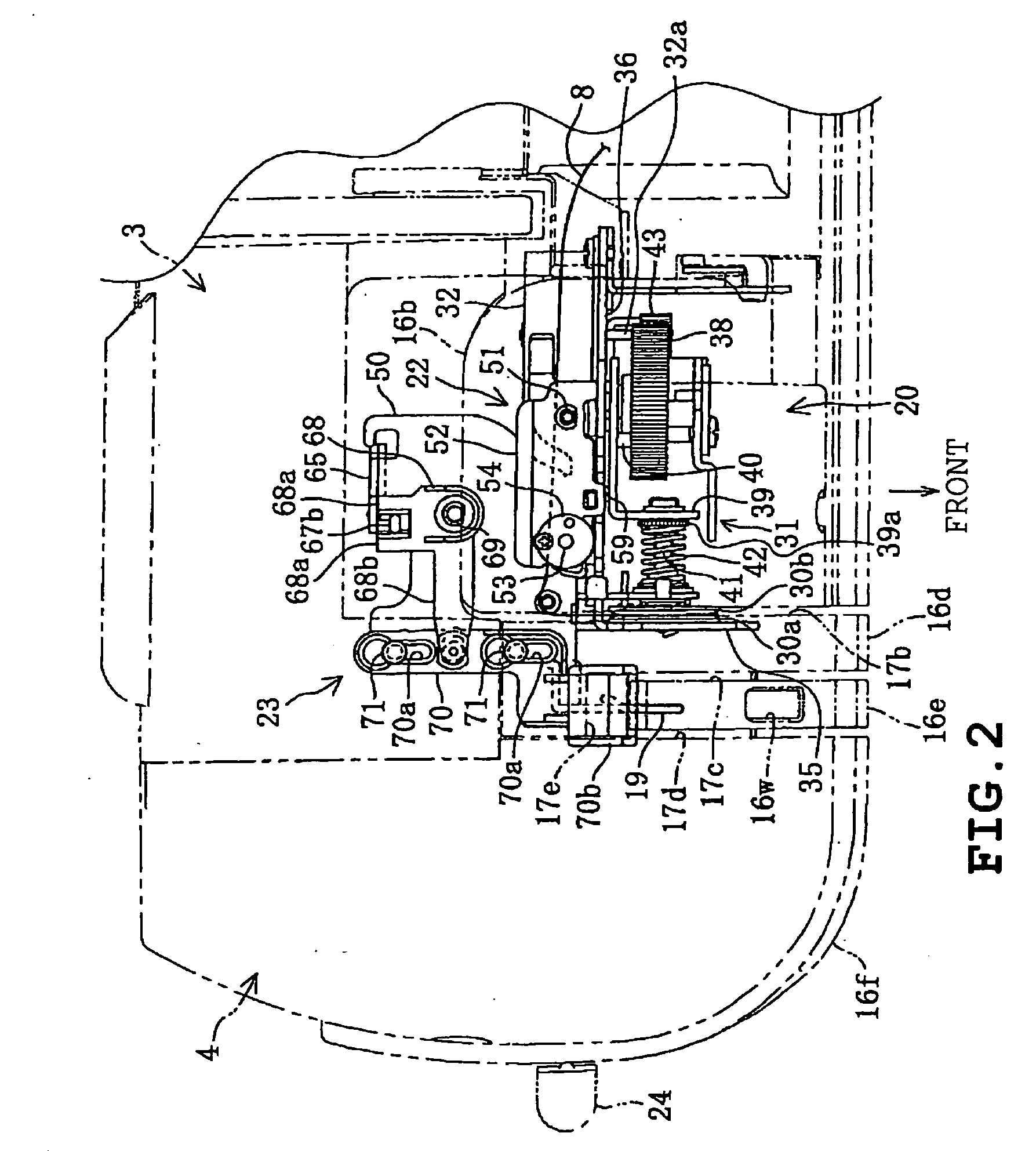

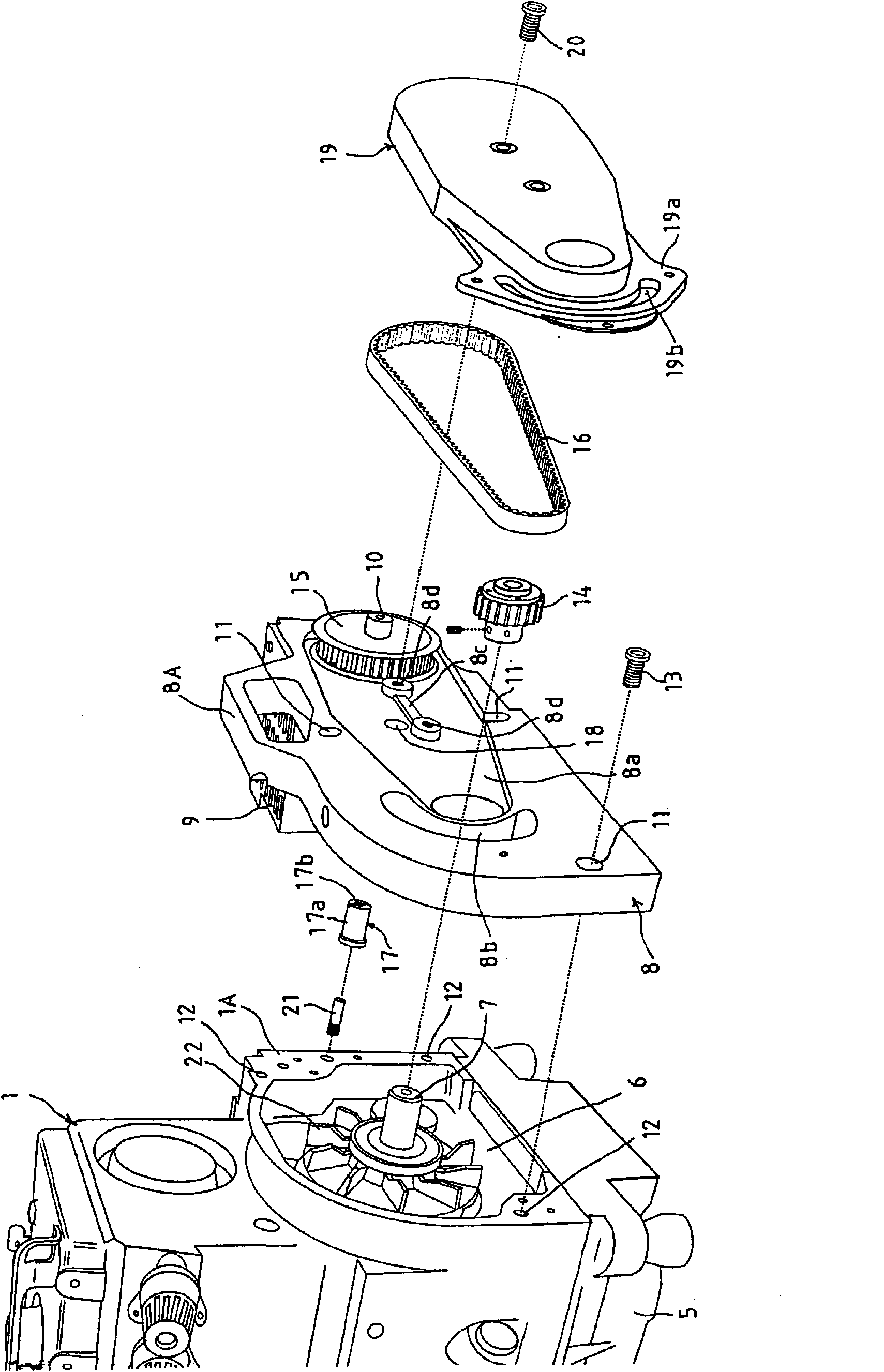

Driving device of industrial sewing machine

InactiveCN101581014AReduce the number of assembly stepsReduce the number of partsSewing-machine casingsSewing-machine control devicesIndustrial sewing machineIndustrial engineering

The present invention provides a driving device of an industrial sewing machine. A main shaft of the sewing machine projects outwards from the side part of the main body of sewing machine. An installation table of an electric motor extends from the side surface part of the main body of sewing machine backwards. The main shaft of the sewing machine and the output shaft of a sewing machine driving motor which is fixedly connected with the back part of the installation table of the electric motor. The side surface part of the main body of sewing machine is equipped with an eccentric cam. The installation table of the electric motor is formed with an opening with the inner peripheral part which slideably contact with the outer peripheral part of the eccentric cam. The position of the installation table of the electric motor is changed through rotating the eccentric cam, and the tension of the synchronous belt can be adjusted thereby obtaining the following advantages: reducing the number of constituent elements and components as possible, simplifying the structure, reducing the number of whole assembling steps of the device, reducing the troubles for adjusting the belt tension, and easily and smoothly operating the device with a small operating force.

Owner:YAMATO SEWING MASCH MFG CO LTD

Sewing machines

InactiveCN1439758AStable residual lengthQuality improvementProgramme-controlled sewing machinesSewing-machine casingsBobbinEngineering

The patent relates to a sewing machine 1 in which a needle thread loop 101 is formed by the co-operation of a needle 6 and a semi-rotating shuttle to perform lock stitch. This sewing machine 1 includes a needle thread take-up lever 14 for taking up the needle thread loop 101, a main shaft motor 7 for driving the needle 6 and the needle thread take-up lever 14, a fixed knife 27 fixed in the vicinity of the semi-rotating shuttle, a movable knife 28 capable of freely approaching and separating from the fixed knife 27, a pulse motor 21 for driving the movable knife 28, and a control device 8 for controlling the pulse motor 21 and the main shaft motor 7. The movable knife 28 is stopped immediately before the movable knife 28 meets the fixed knife 27 at the final stitch under the control of the control device 8, and then the needle thread take-up lever 14 is raised and stopped. After that, the movable knife 28 is moved to cut the needle thread and the bobbin thread with the fixed knife 27. The sewing machine is capable of stabilize the so-called remaining length of a needle thread without lengthening the time required for cutting the needle thread.

Owner:JUKI CORP

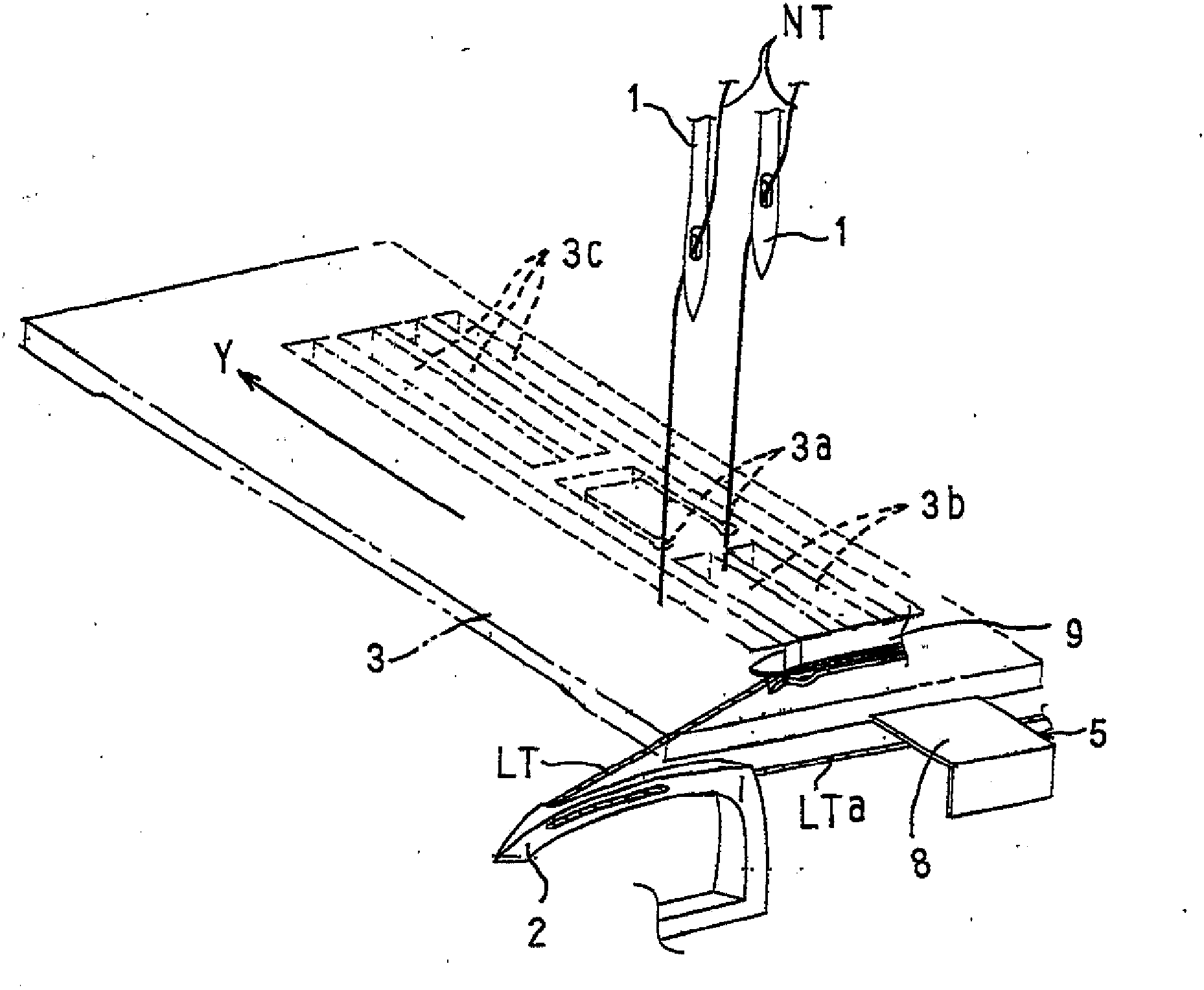

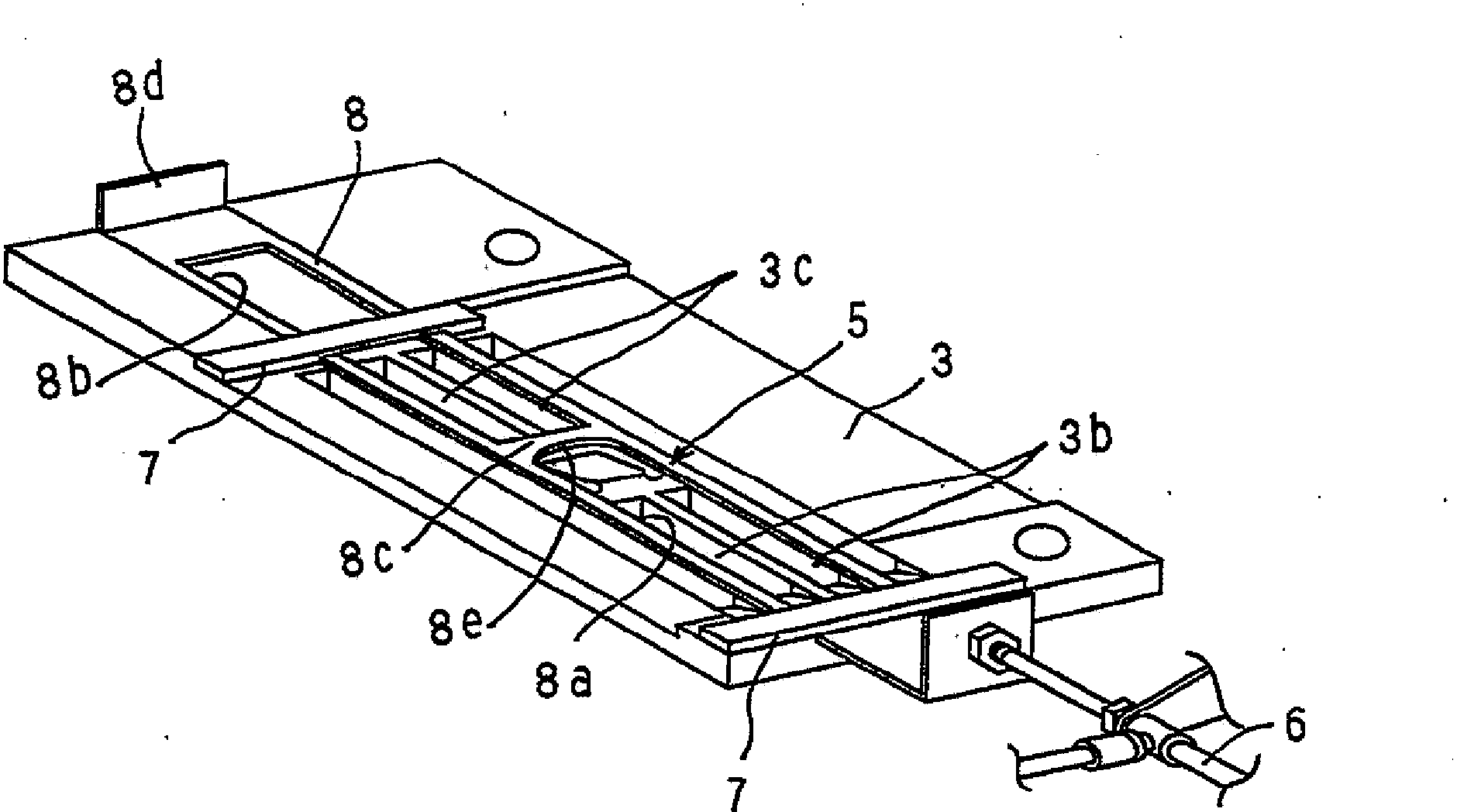

Sewing method of cloth and double-chain-ring sewing machine

ActiveCN103361889AEasy to operateWon't hurtSewing-machine casingsWork-feeding meansOperabilityEngineering

A sewing method of cloth and a double-chain-ring sewing machine transfer the cloth towards a specified sewing advancing direction along an upper surface of a needle plate, and form a stitch ring at a lower side of the needle plate by utilizing two needles which keep stitching and move up and down, and catch the stitch ring through advancing of a curved needle which can advance and retreat in a direction approximately orthogonal to an up-down moving path of the needle, and utilize a looper thread maintained by the curved needle to wind the caught stitch ring, so that double-chain-ring stitch is formed on the cloth, at the moment, a movement guiding stitch diagonal member is utilized to perform movement guide to a stitch end part which is protruded onto a surface of the cloth when the stitch of the first needle begins, so as to form a state of falling and tilting towards a downstream side of the sewing advancing direction, thereby sewing and processing the stitch end part into the double-chain-ring stitch. Therefore, cut processing for the stitch end part does not cost time, thereby realizing labor saving, raising the efficiency of sewing operation and operability of the cloth, and preventing damages to the cloth.

Owner:YAMATO SEWING MASCH MFG CO LTD

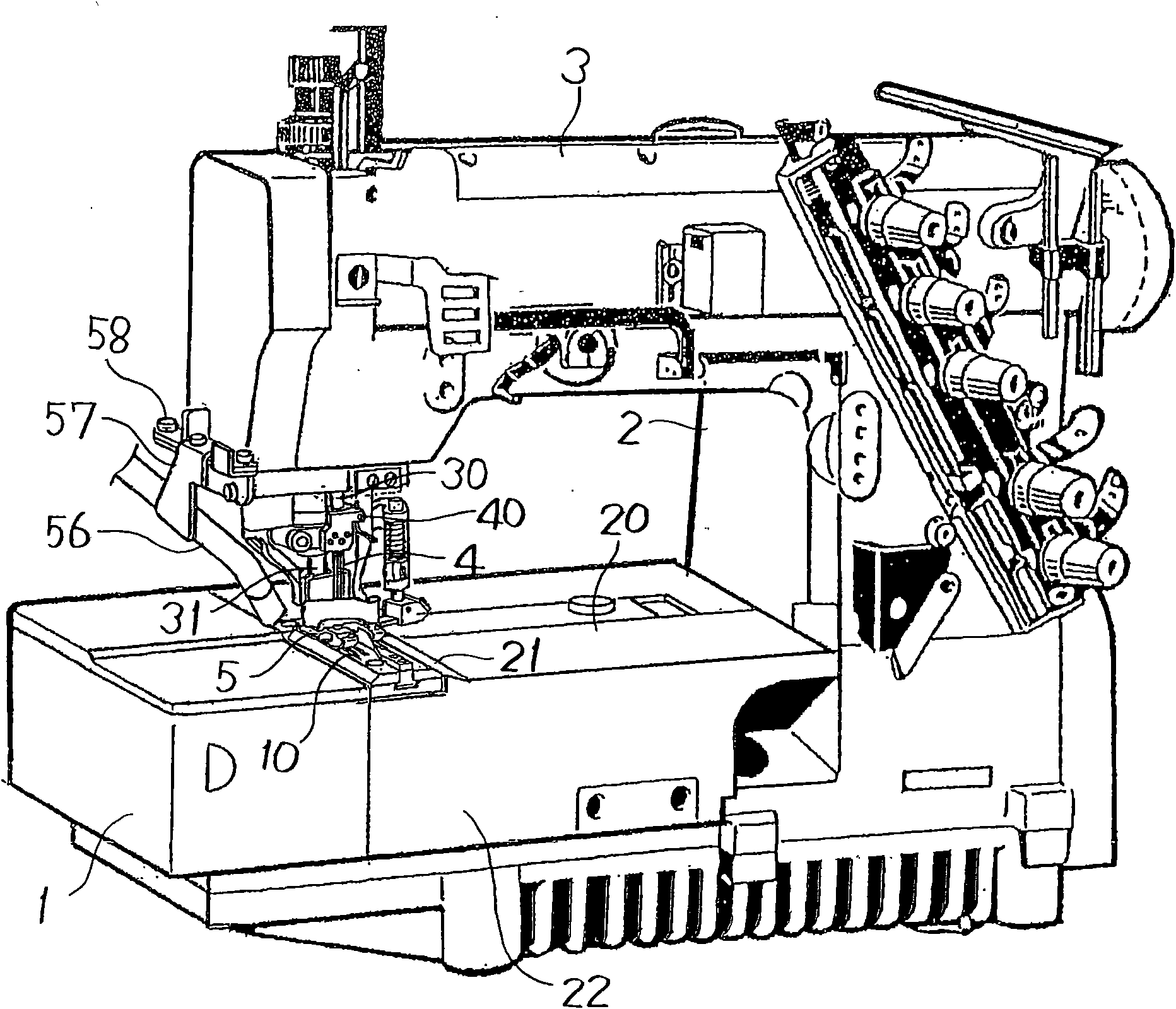

Double-chain stitch sewing machine having box-shaped bed

The invention relates to a double-chain stitch sewing machine having a box-shaped bed, which has a box-shaped sewing machine bed and a presser foot which descends to a needle plate on the sewing machine bed to press the sewing cloth, a knife apparatus is arranged in the presser foot, the sewing cloth is stably supported on a flat upper surface of the sewing machine bed, the edge of the cloth is cut by the knife apparatus, and the sewing cloth is overlapped by certain width to sew. One side or two sides of the needle plate on the upper surface of the sewing machine bed in the width direction is lower than the upper surface of the needle plate to ensure the gap with the projecting part protruding to the knife apparatus outside the presser foot. The operator can utilize the gap to assist theconveying of the sewing cloth by hand in the vicinity of the presser foot, thereby implementing the seam combining of the bulk sewing cloth.

Owner:YAMATO SEWING MASCH MFG CO LTD

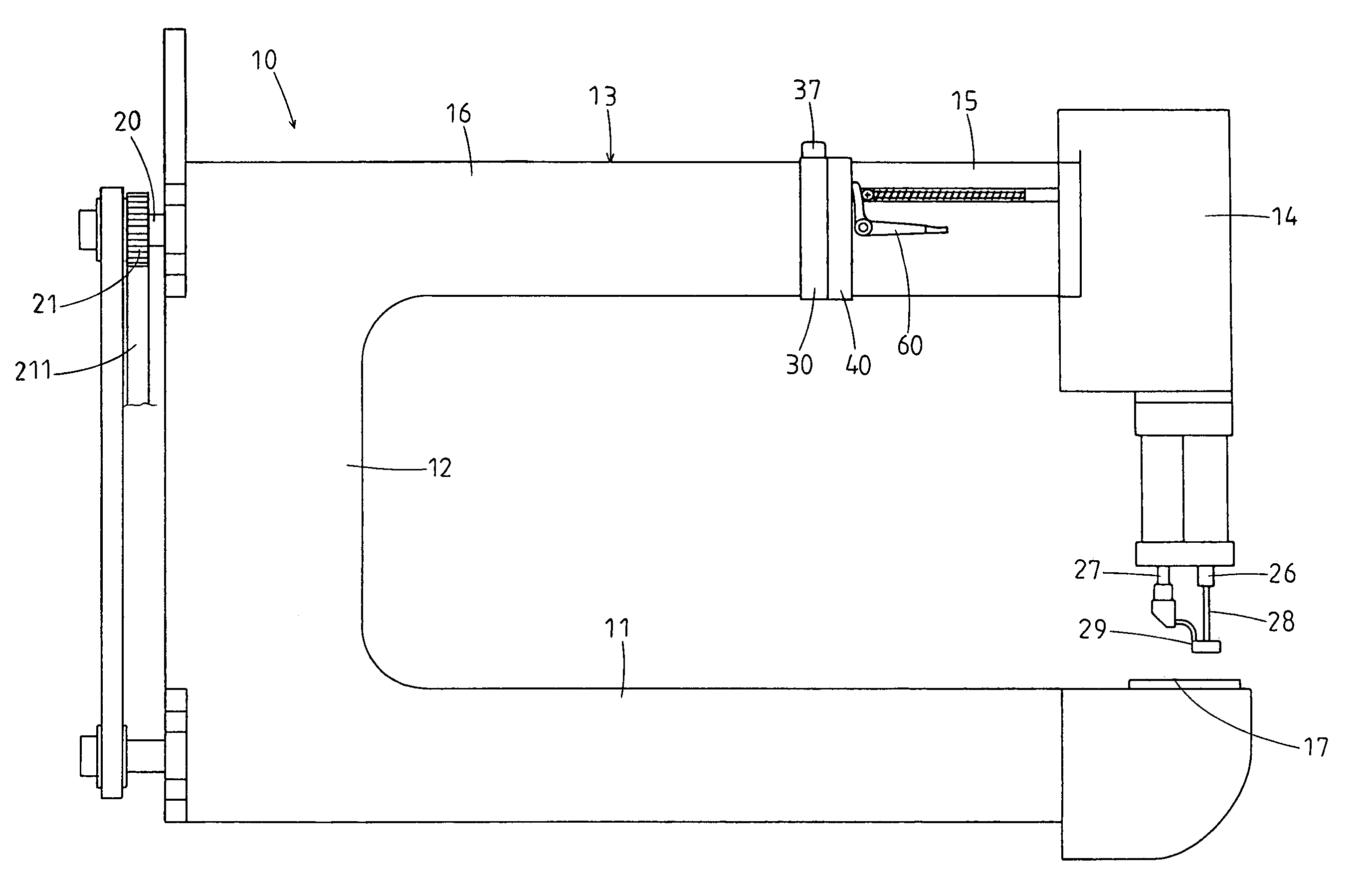

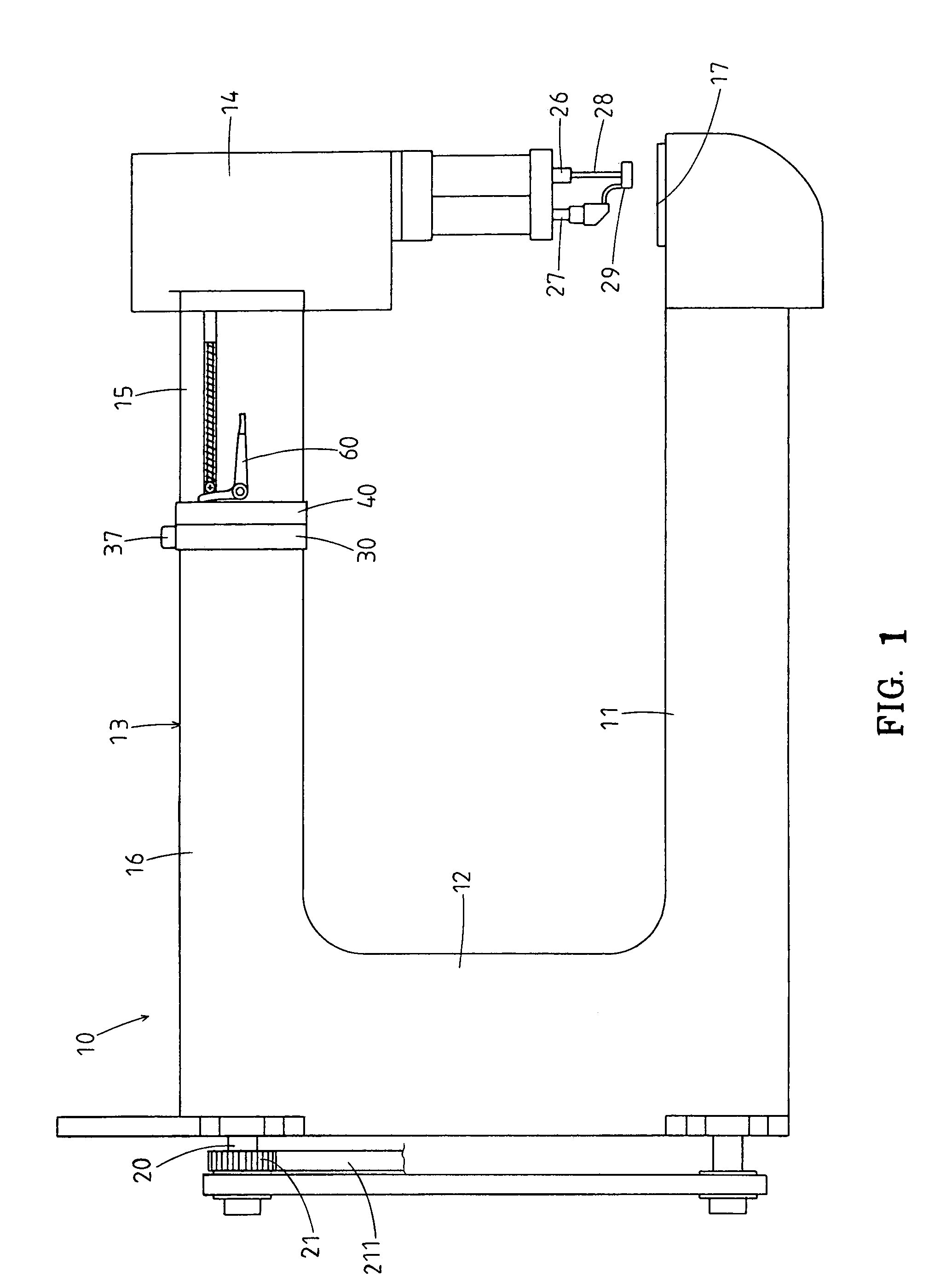

Adjustable positioning device for head of sewing machine

ActiveUS7347152B1Easy to insertEasy to removeSewing-machine casingsLeather sewingEngineeringSewing machine

A sewing machine includes a main frame including a needle seat, a beam, and a head supported by the beam. The head includes elements for sewing operation in association with the needle seat. A fixed seat is fixed to the beam and a rotational seat is fixed to the head to turn therewith. The rotational seat and the fixed seats include aligned axial holes. A shaft sleeve extends from the rotational seat and rotatably extends through the axial hole of the fixed seat. The head and the rotational seat are movable relative to the fixed seat between an operative position allowing sewing operation and an inoperative position angularly spaced from the operative position. A distance between the head and the needle seat is increased when the head is moved from the operative position to the inoperative position, allowing easy insertion and removal of thick materials during a sewing operation.

Owner:SEWTECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com