Body moveable structure of sewing machine

A sewing machine and mobile technology, applied in the field of sewing machines, can solve problems such as limiting sewing machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

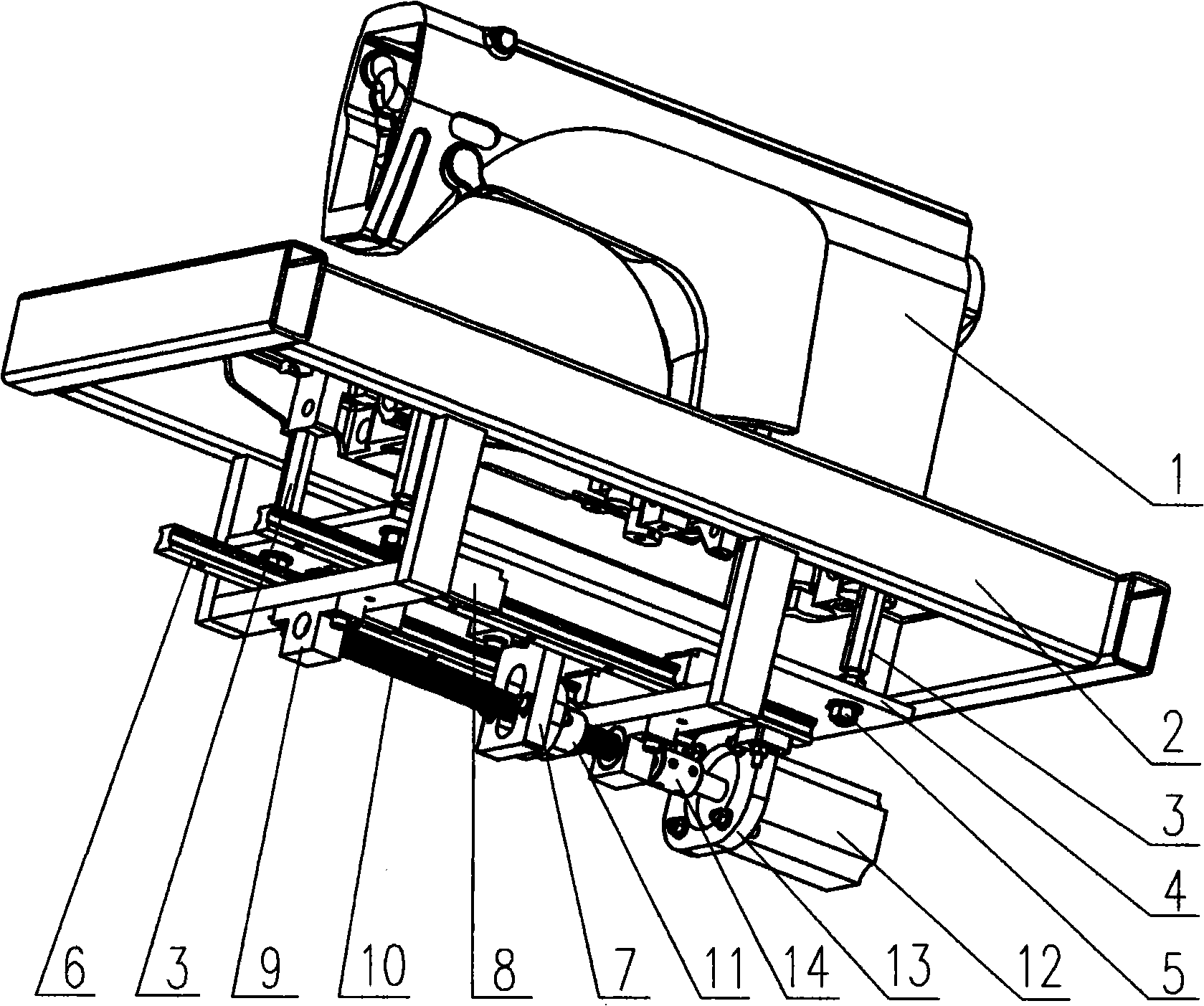

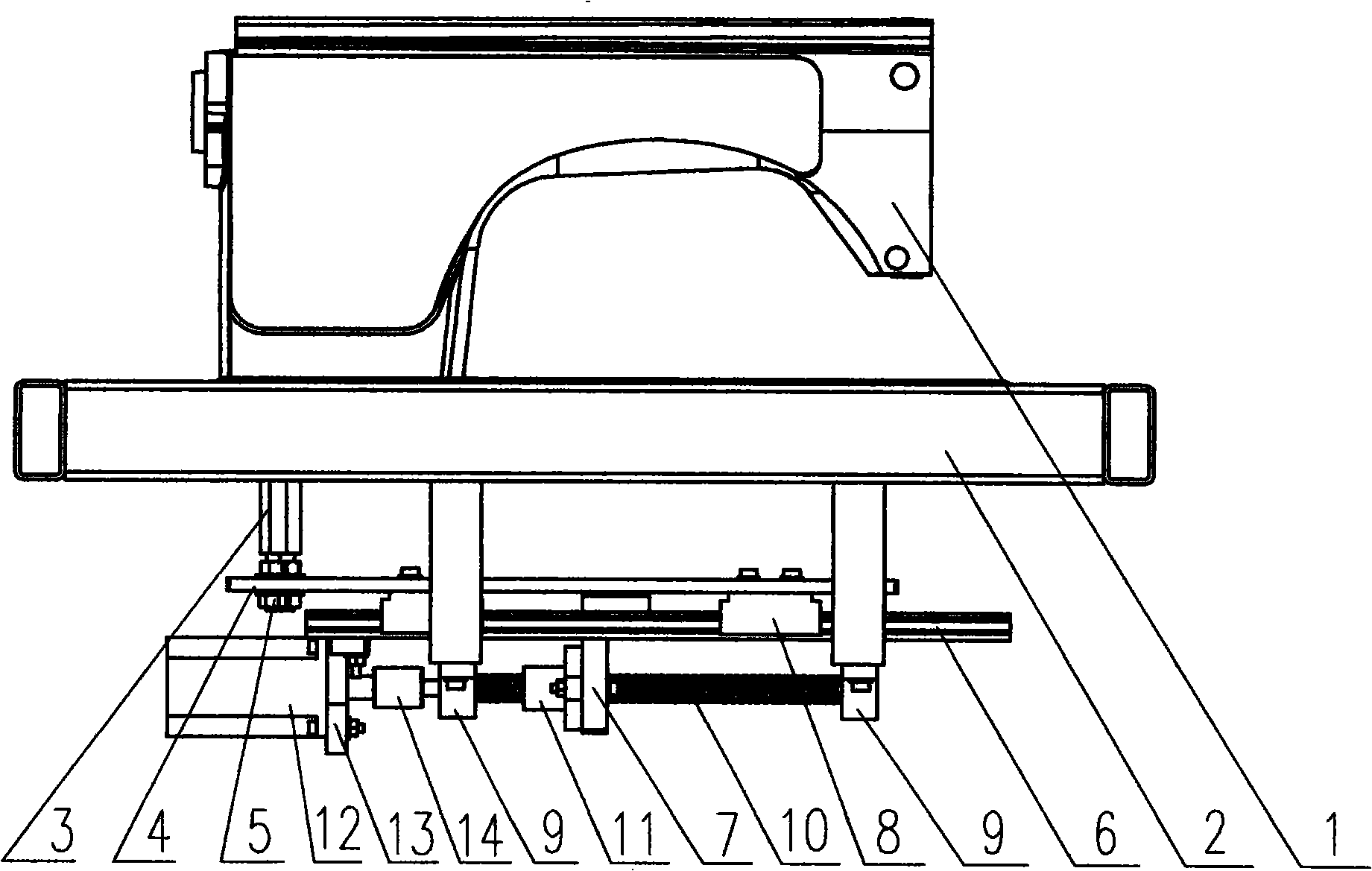

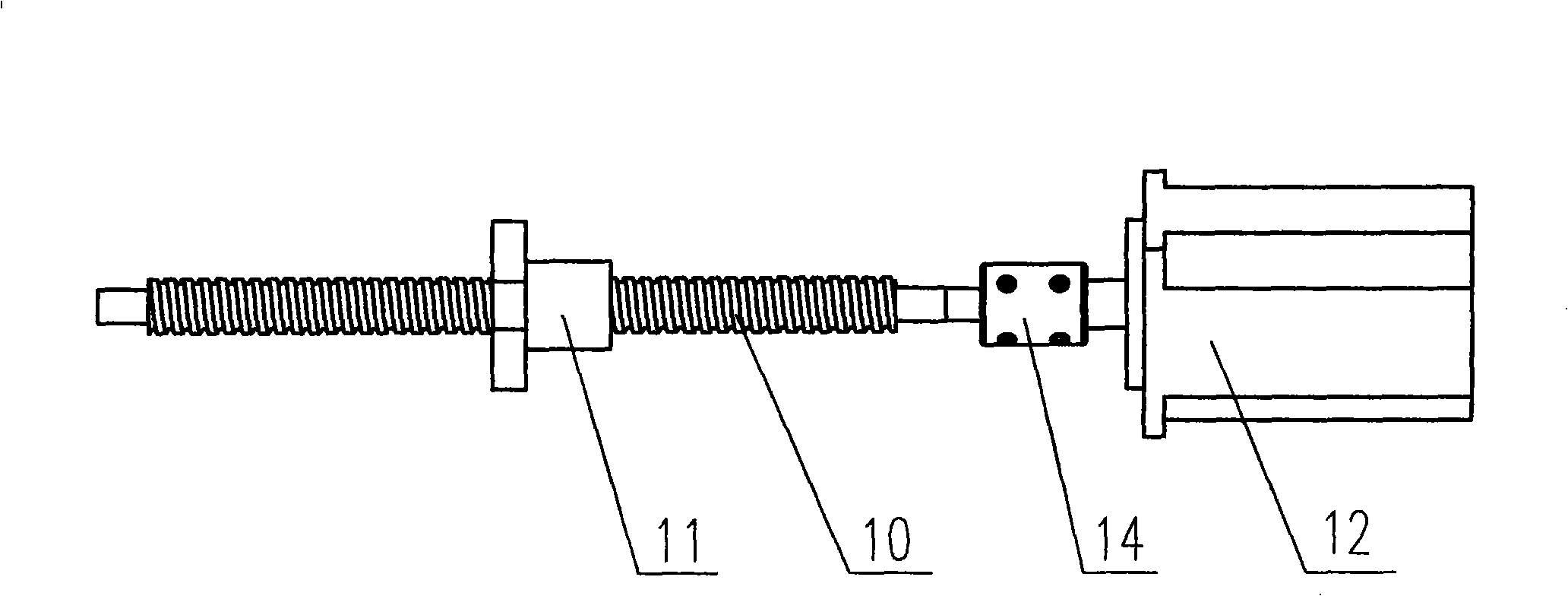

[0010] refer to figure 1 , figure 2 , image 3 , Figure 4 , Place the sewing machine head 1 on the frame 2, and at the same time install the sewing machine head 1 on the head fixing plate 4, and fix them together with the support studs 3 and nuts 5. This can make the sewing machine head 1 move along the guide rail 6 under the action of the power bracket 7 , and at this moment, the power bracket 7 is connected with the head fixing plate 4 . In order that the sewing machine head 1 can move smoothly on the guide rails 6, a slider group 8 is respectively installed at the two ends of the two guide rails 6, and the slider group 8 is also fixed together with the head fixing plate 4, so that There are supports in the middle and four corners of the head fixing plate 4, which can make the movement of the sewing machine head 1 more stable. And the power of the fuselage movable structure of whole sewing machine is provided by motor 12, and motor 12 is installed on the guide rail 6 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com