Patch pocket sewing machine

A sewing machine and sewing machine head technology, applied in the field of sewing machines, can solve the problems of low efficiency, difficult alignment, troublesome manual sewing of shirt pockets or jeans pockets, etc., so as to improve sewing workmanship, save labor costs, and improve sewing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

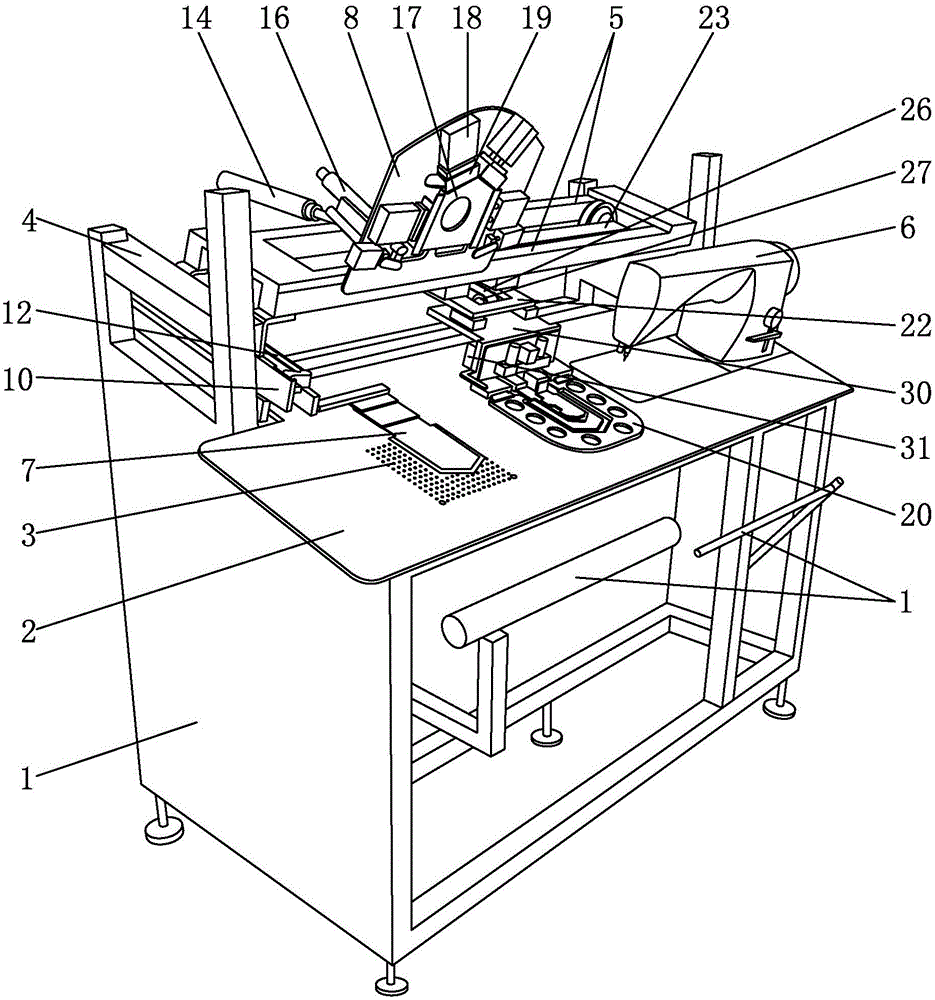

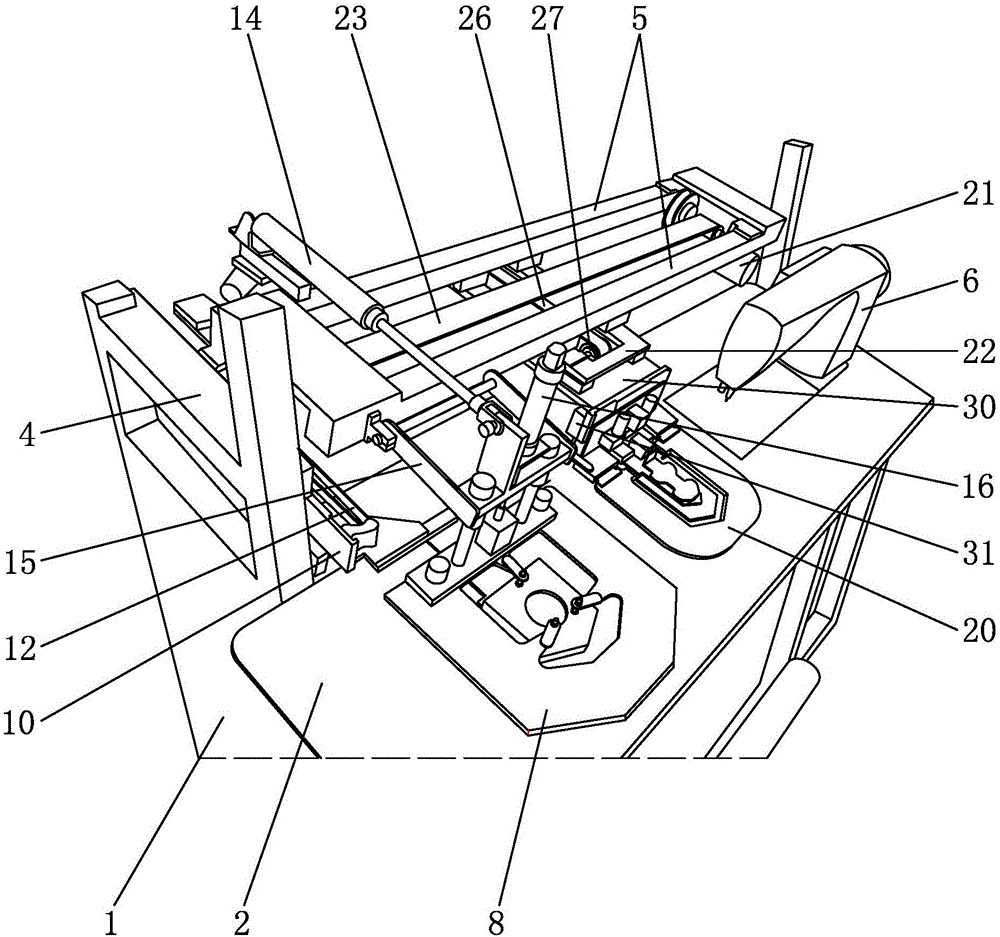

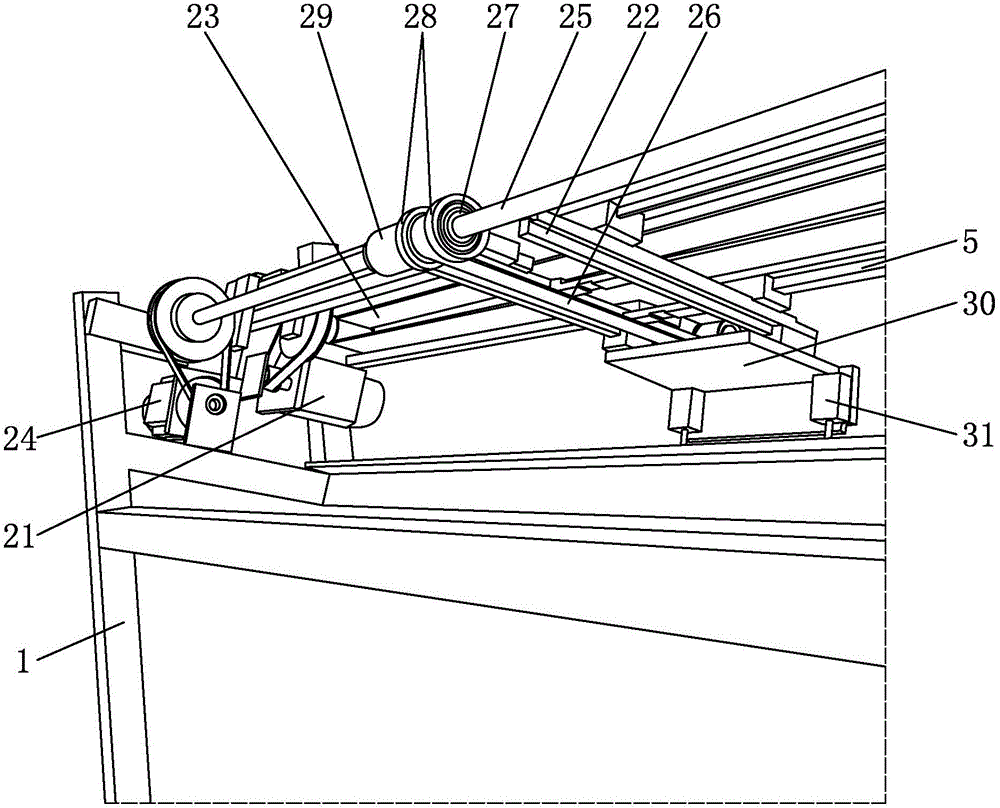

[0024] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 -5:

[0025] The patch pocket sewing machine includes a body 1, on which a workbench 2 is arranged, the workbench 2 has a high back and a front low to form a forward inclination, and the left side of the workbench 2 is provided with a plurality of suction holes 3 at intervals , the fuselage 1 is provided with a fan that absorbs the fabric on the workbench 2 through the suction hole 3, and the fuselage 1 on the rear side of the workbench 2 is provided with a support 4, and the support 4 is horizontally provided with two pieces that are connected to the workbench 2. Parallel guide rails 5, the bracket 4 on the left side of the workbench 2 is provided with an upper mold 8 and a lower mold 7 for folding and shaping the pocket, and the right side of the workbench 2 is provided with a sewing machine head 6 for sewing the pocket on the fabric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com