Patents

Literature

426results about How to "Improve sewing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

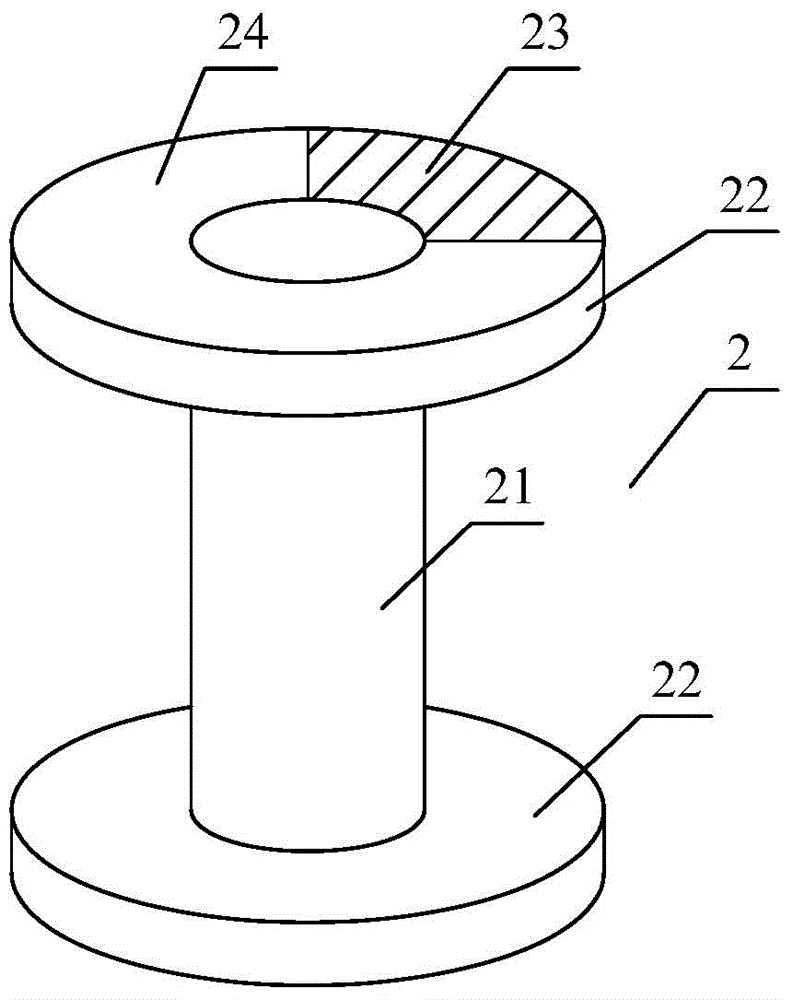

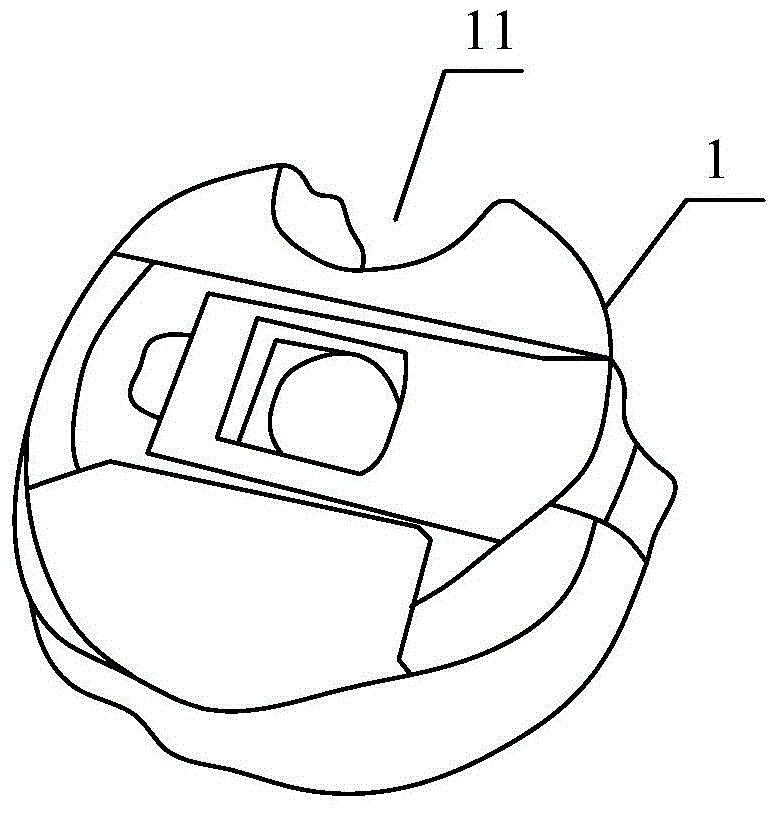

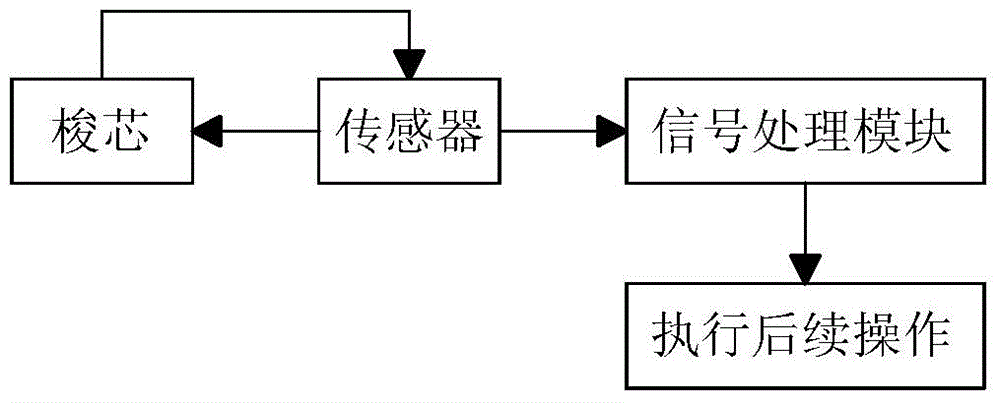

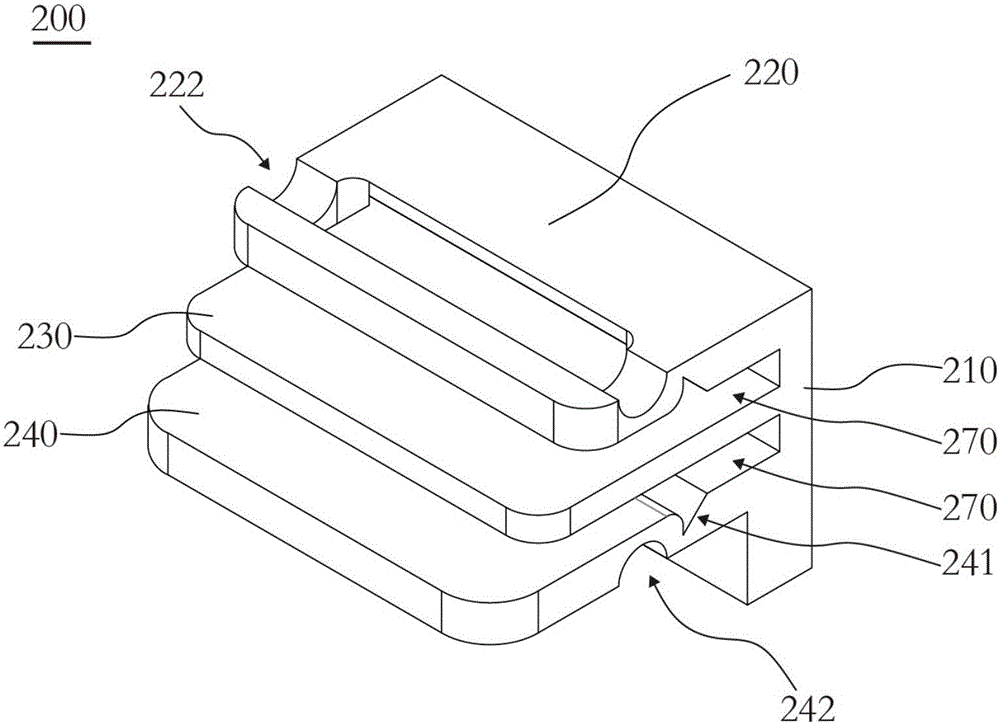

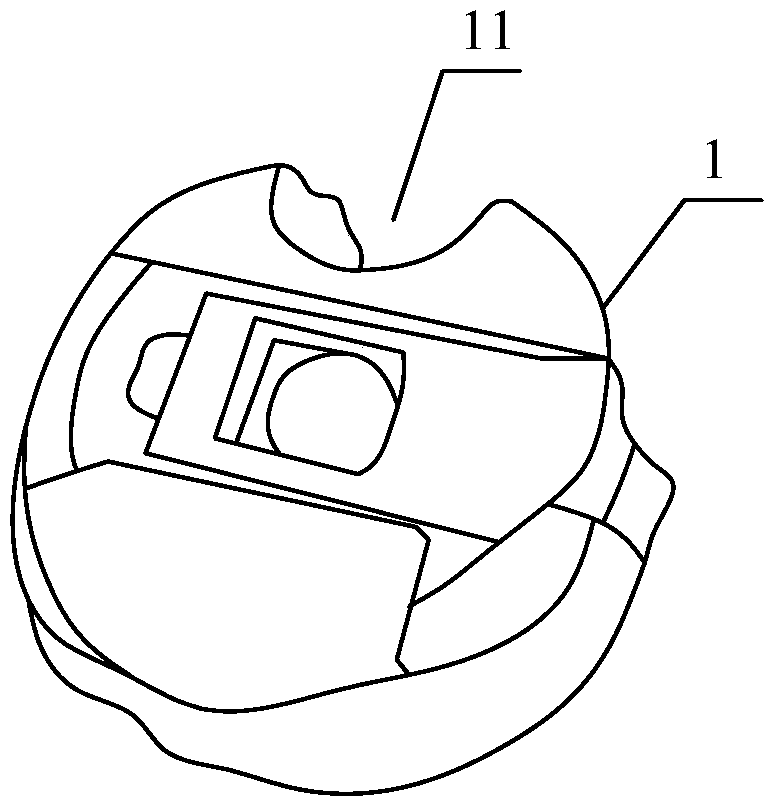

Device and method for detecting amount of bottom thread of sewing machine

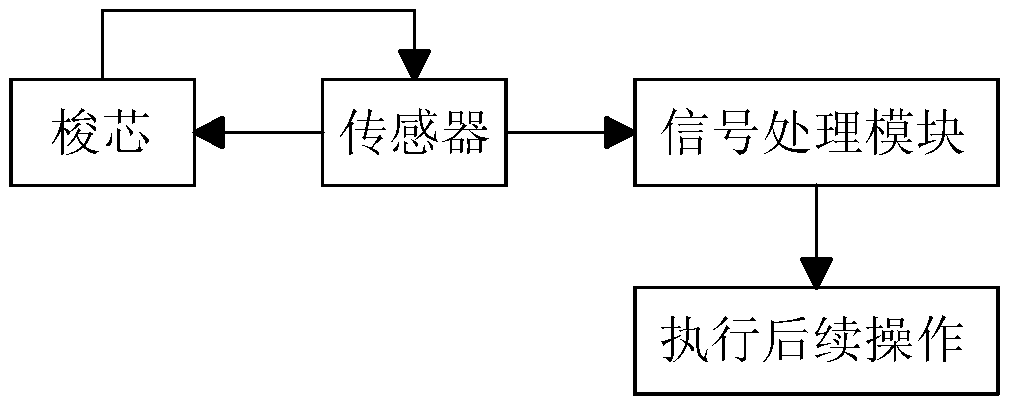

The invention provides a device for detecting the amount of bottom thread of a sewing machine. The sewing machine comprises a bottom plate, a rotating shuttle and an electronic control module, wherein the rotating shuttle comprises a shuttle shell and a shuttle core; the shuttle core comprises a winding post and two flanges; at least one flange in the two flanges is provided with a first surface part and a second surface part on the outer surface; a light hole is formed on the outer wall of the shuttle shell; the first surface part or the second surface part is exposed outside from the light hole; the sewing machine also comprises a sensor fixed in the bottom plate; the sensor comprises a transmitter used for transmitting light, and a receiver used for receiving light; the receiver and the transmitter of the sensor just face to the first surface part or the second surface part exposed outside from the light hole, and the light reflection capabilities of the first surface part and the second surface part are different from each other; the sensor is connected with a signal processing module; the signal processing module is connected with the electronic control module. The device for detecting the amount of the bottom thread of the sewing machine is capable of timely detecting whether the bottom thread is used up or not in real time.

Owner:JACK SEWING MASCH CO LTD

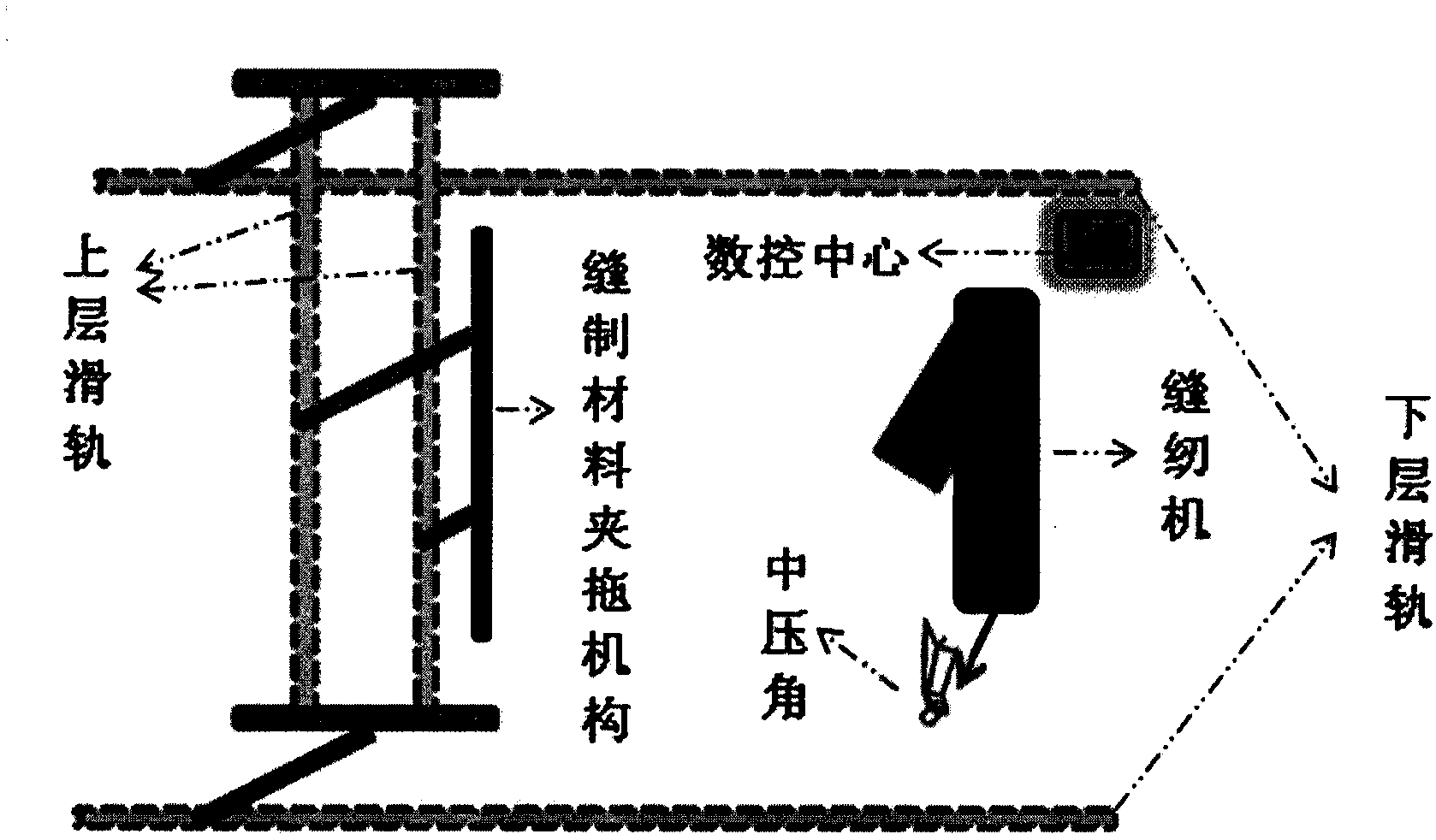

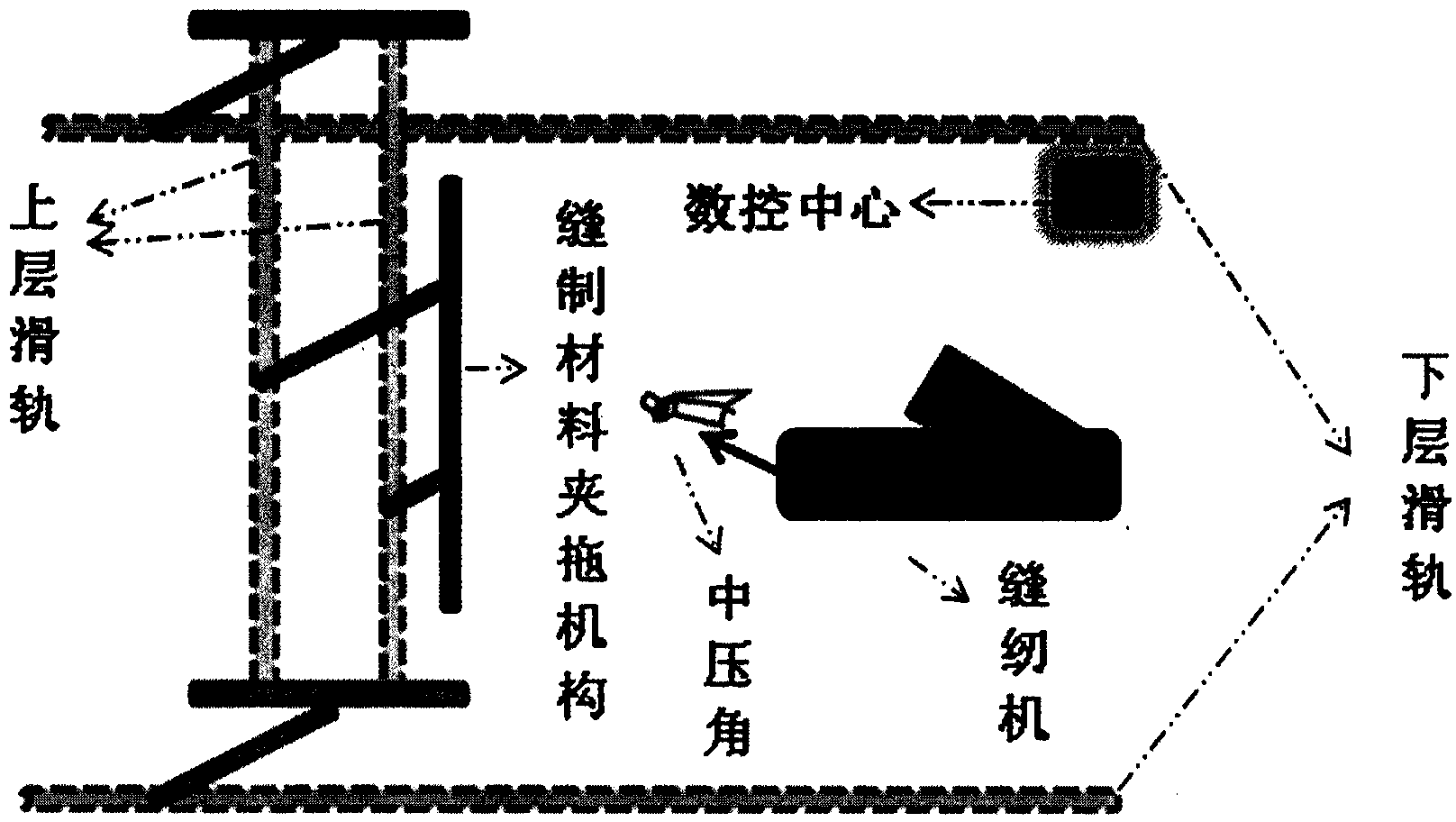

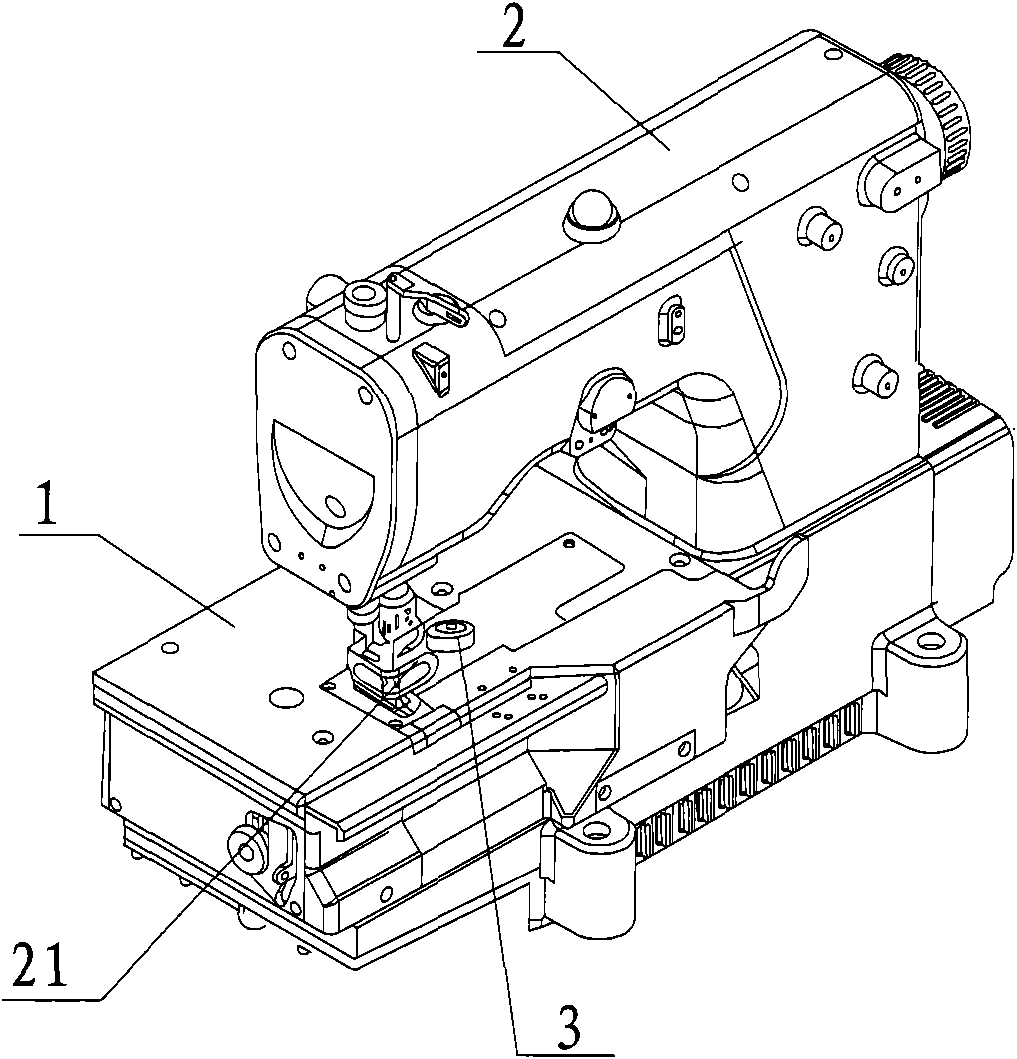

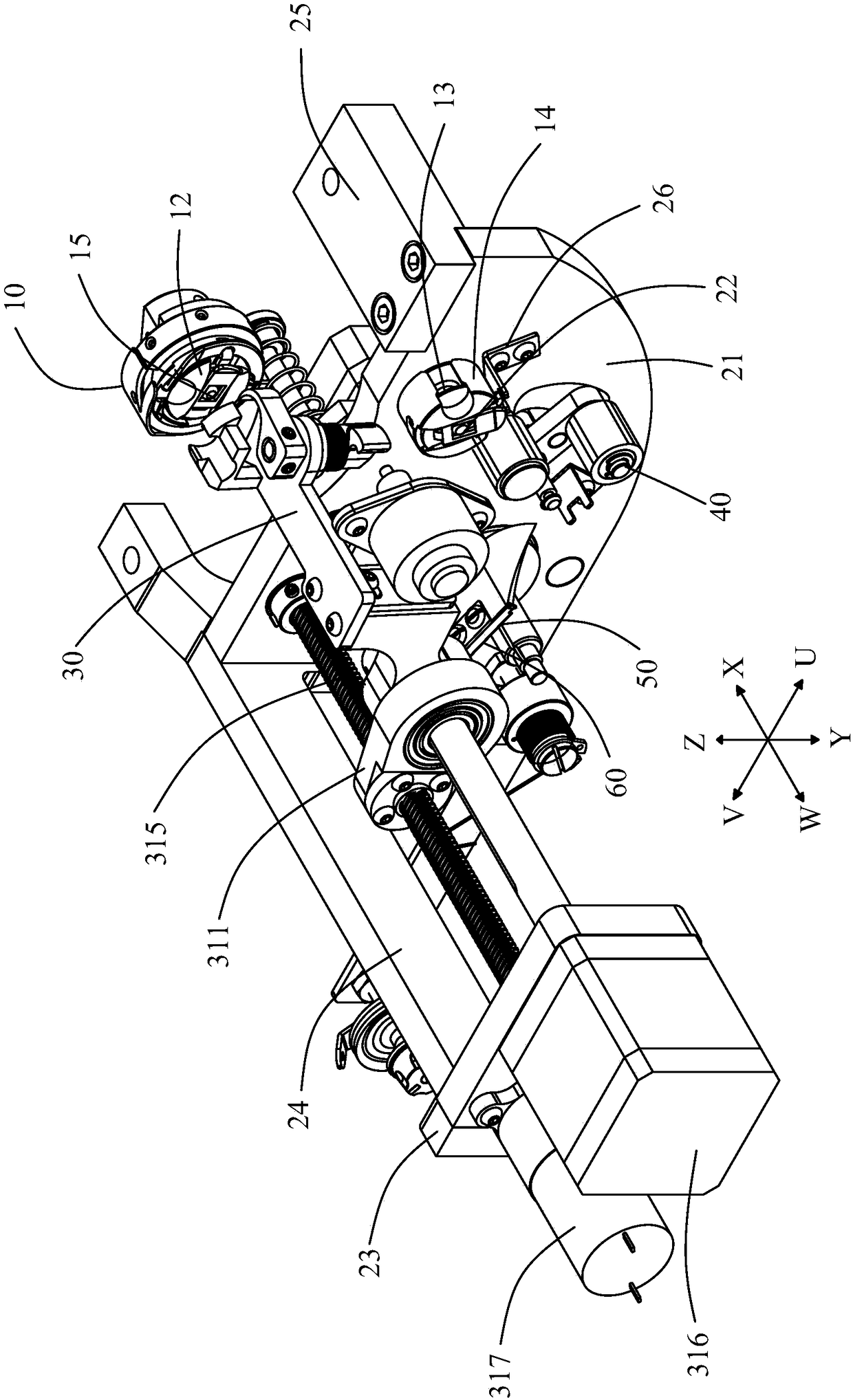

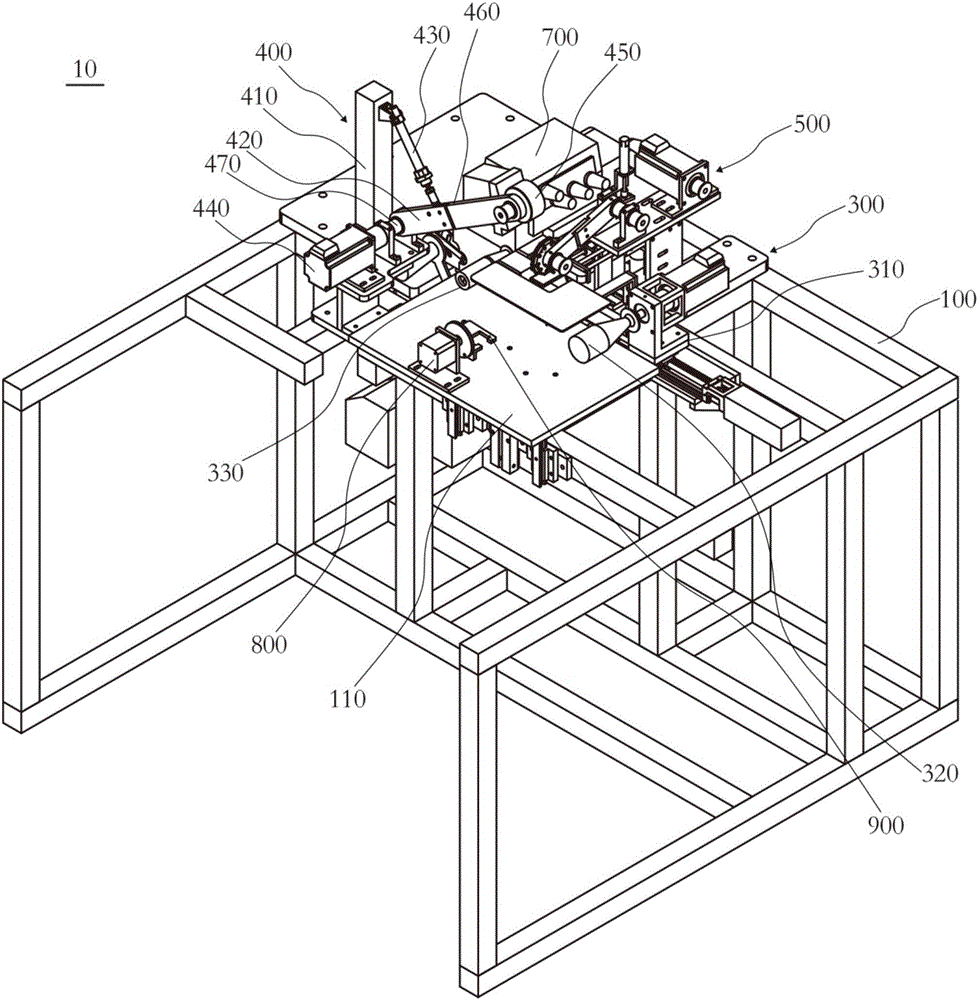

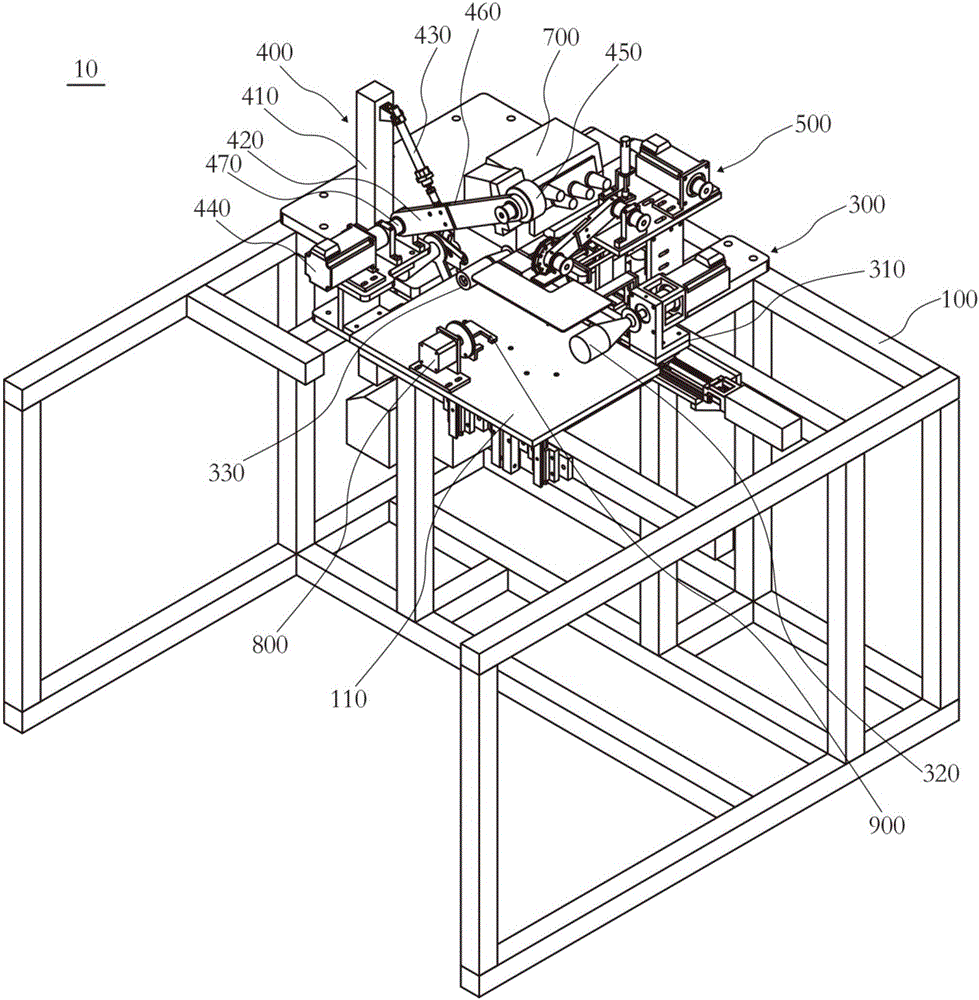

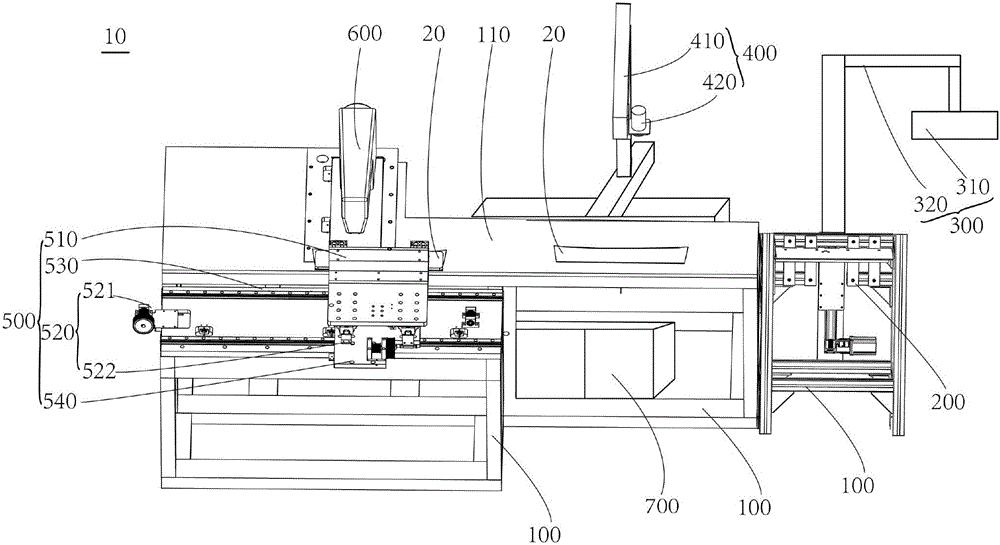

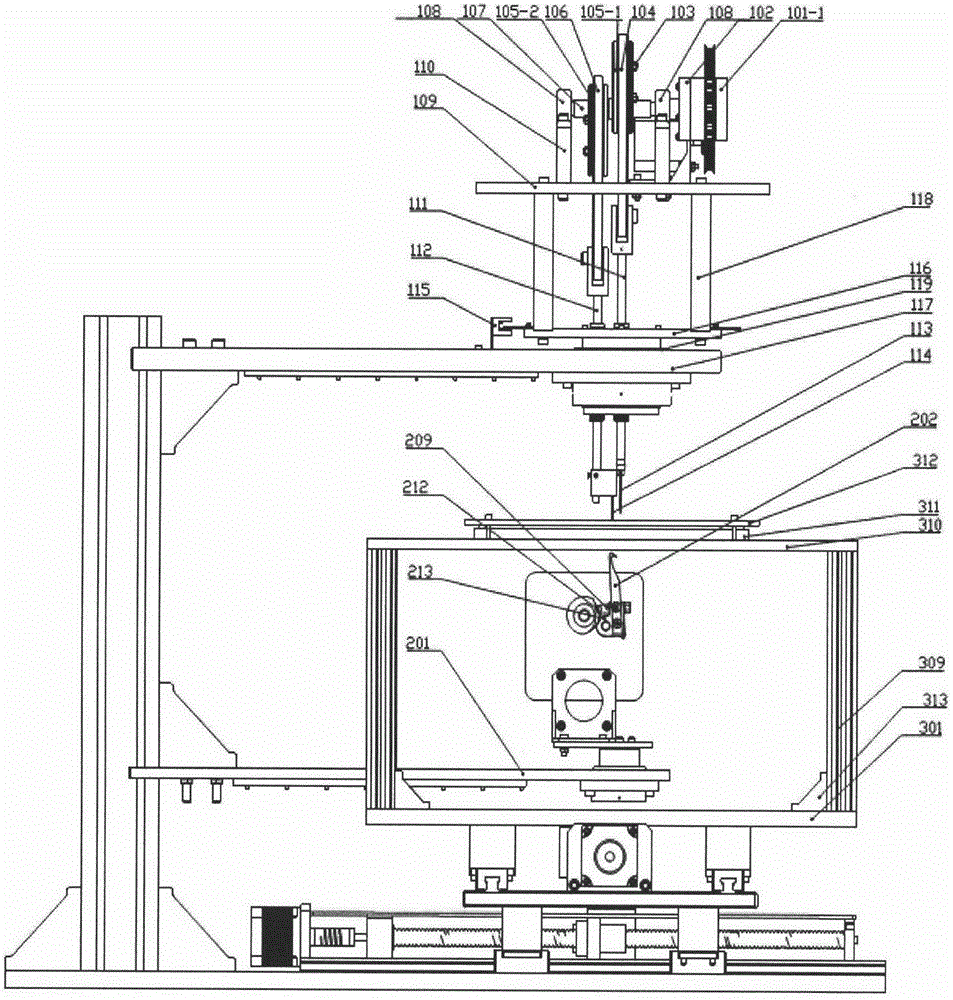

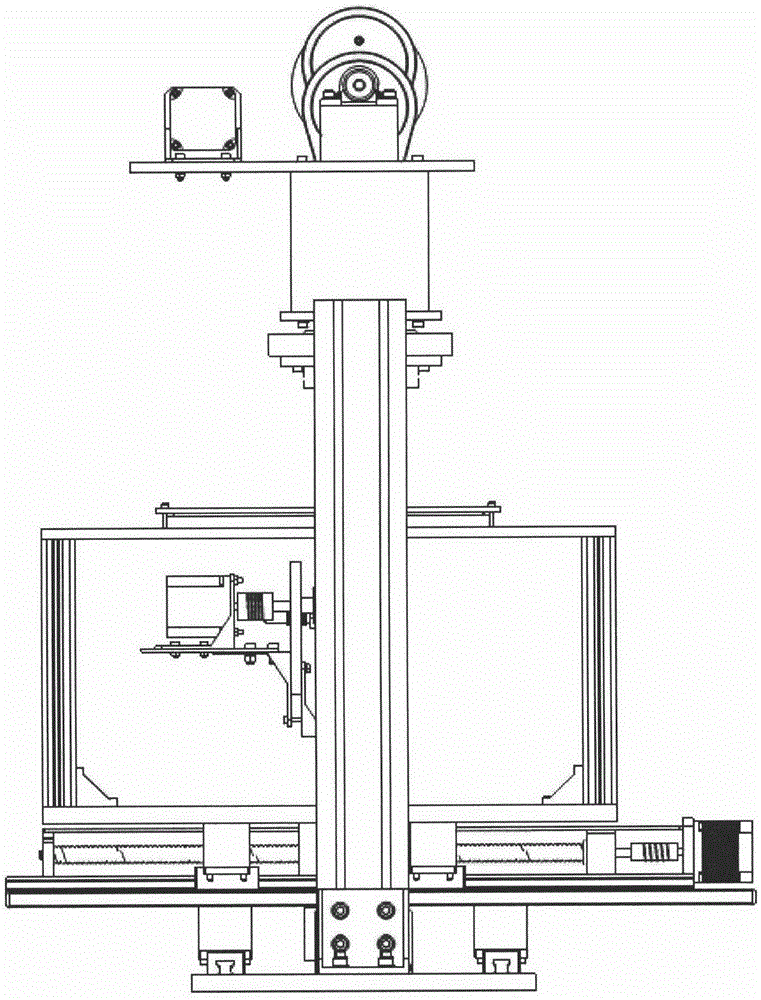

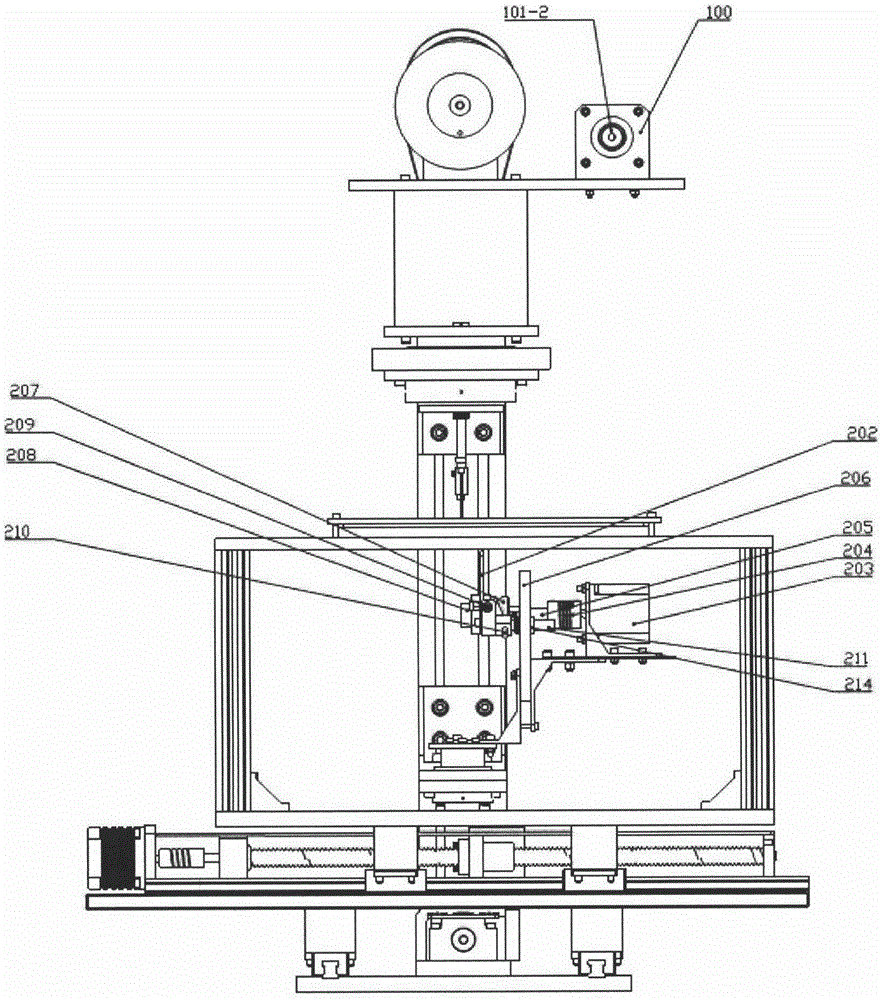

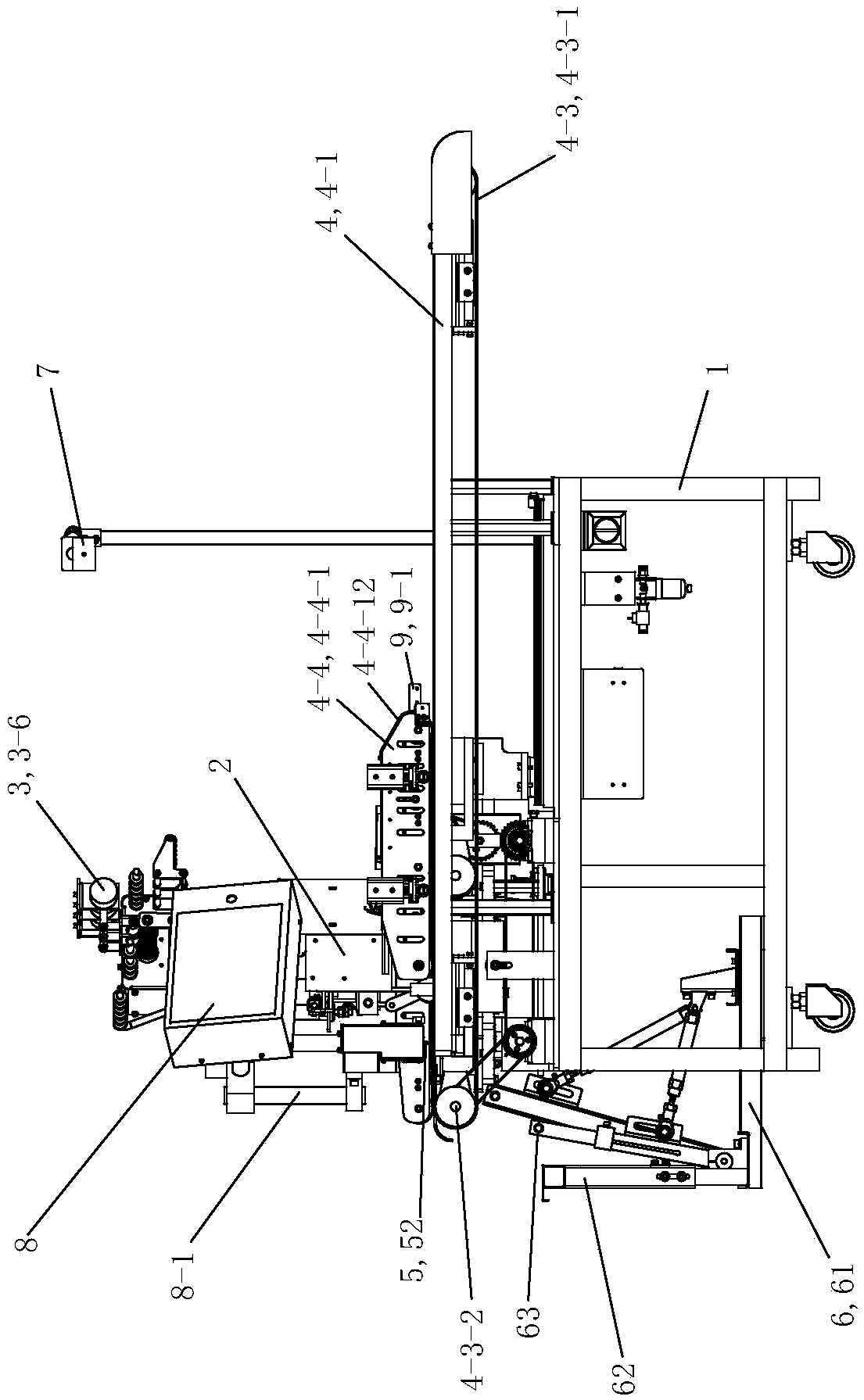

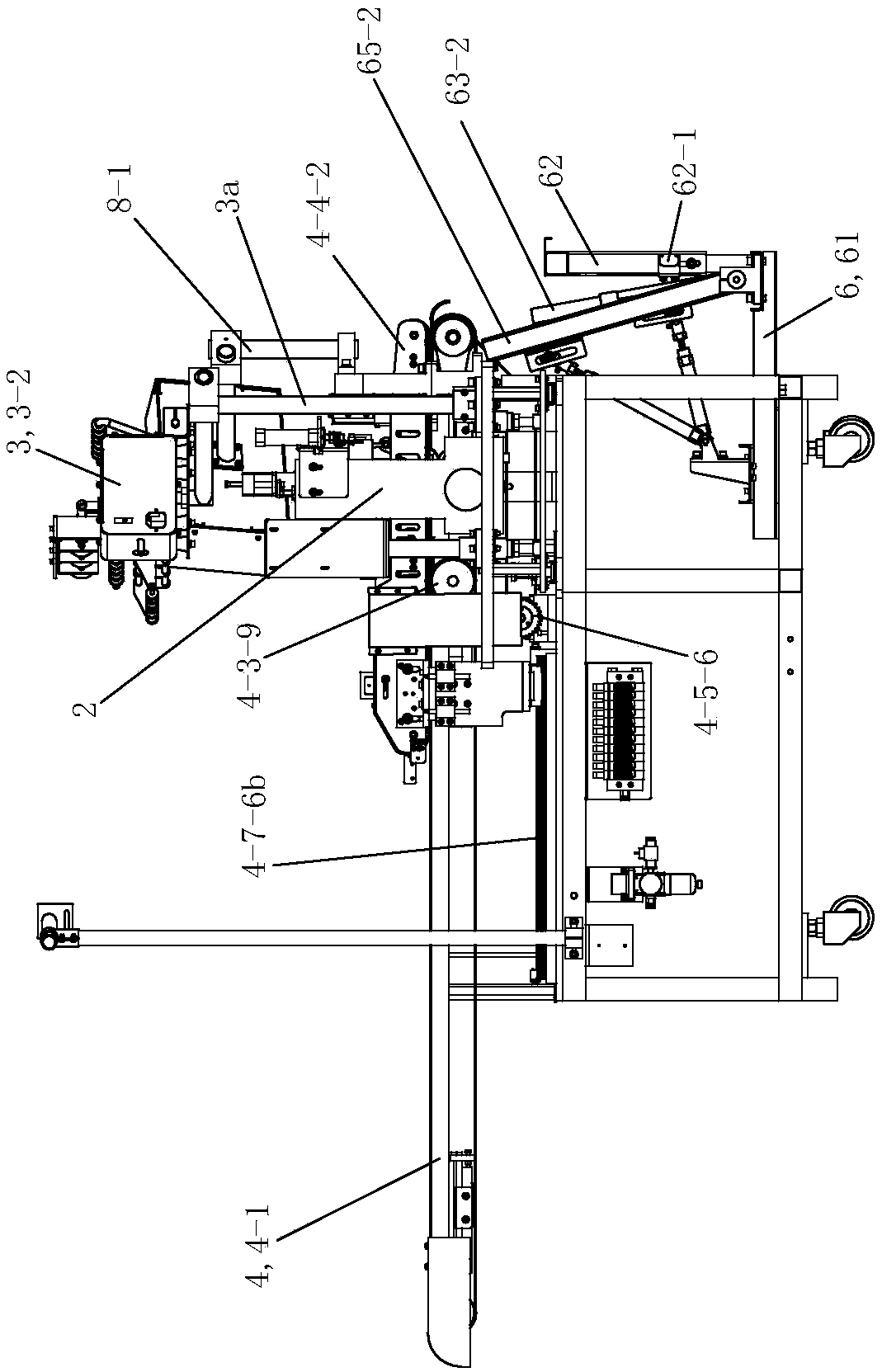

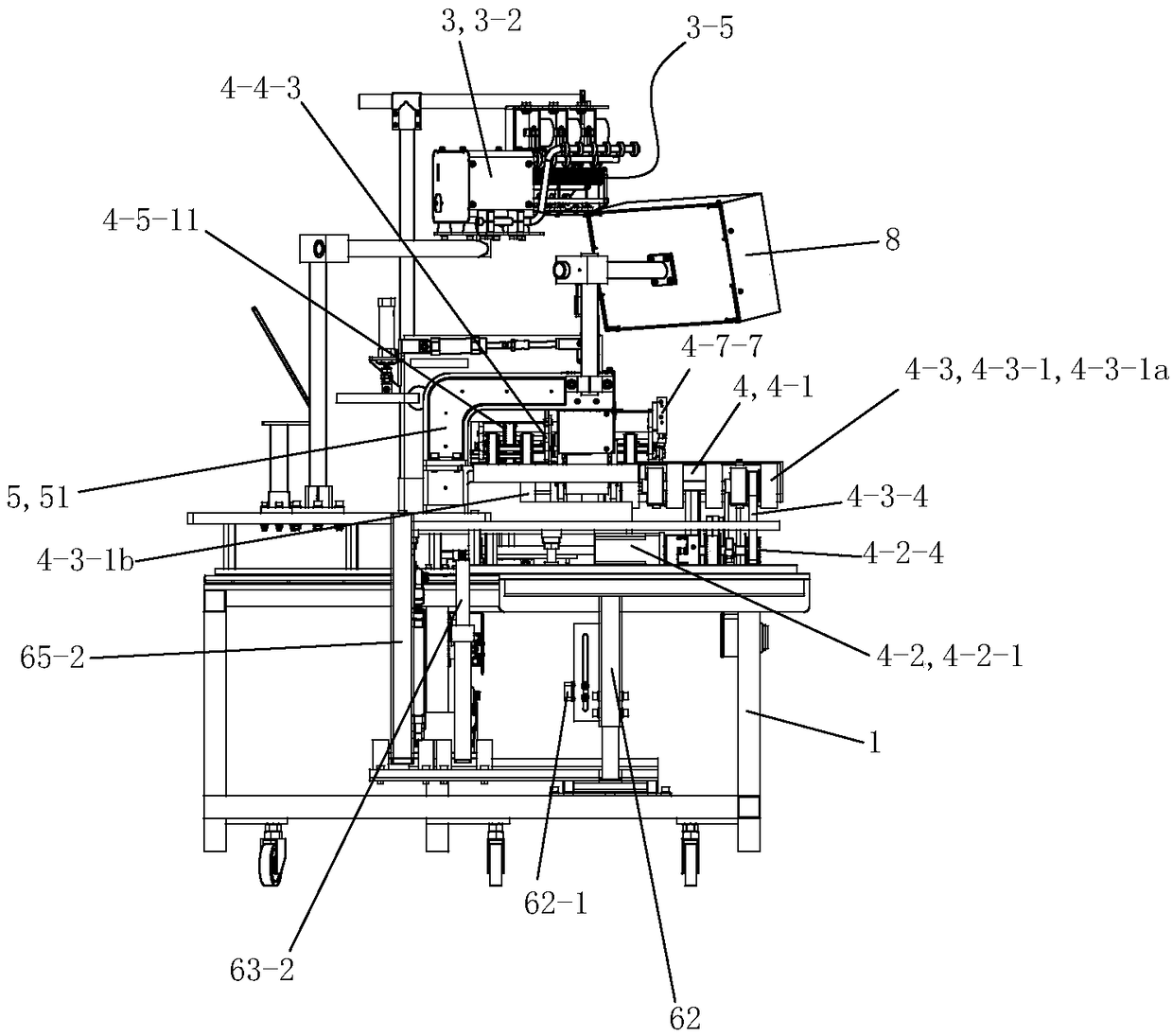

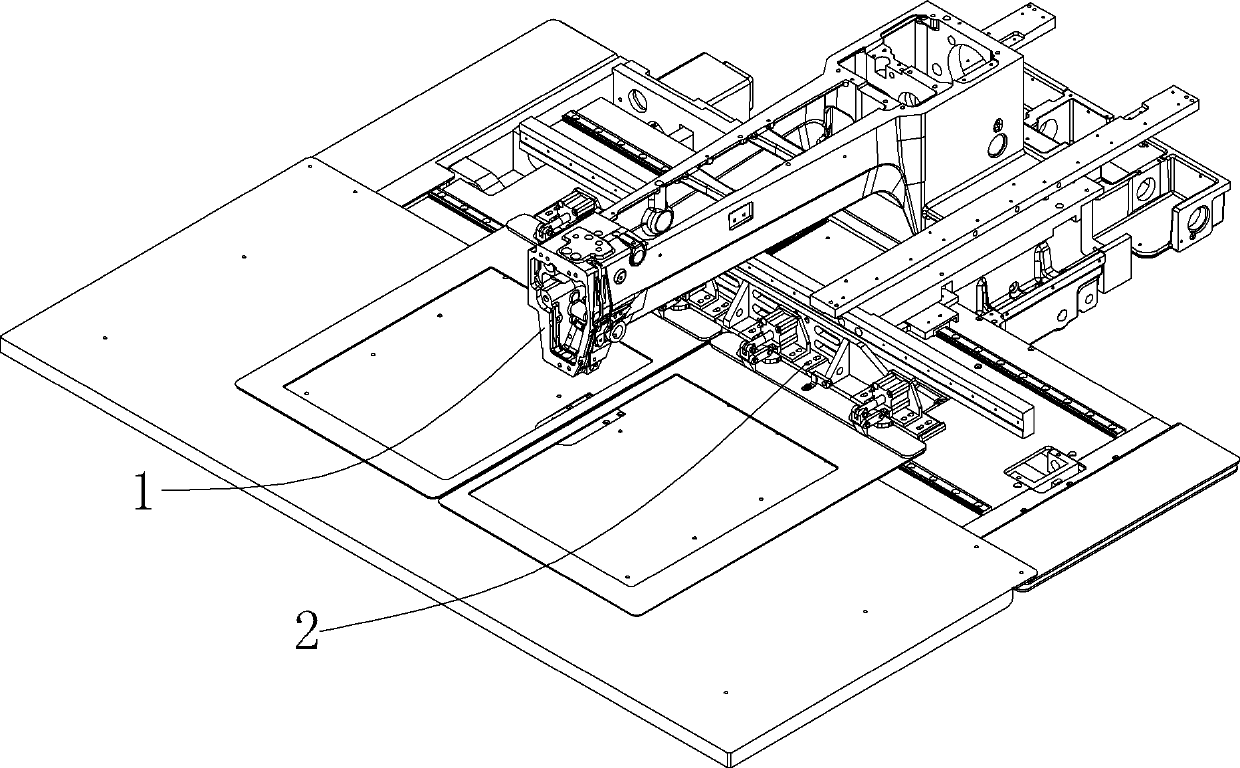

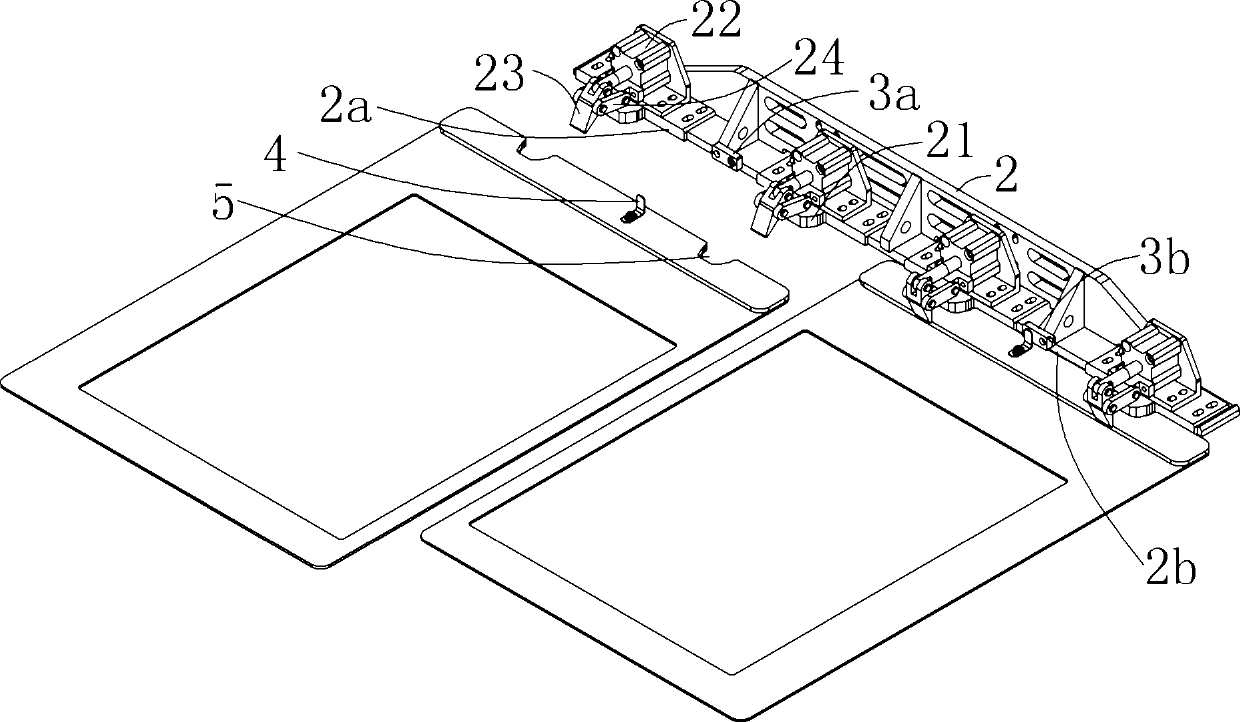

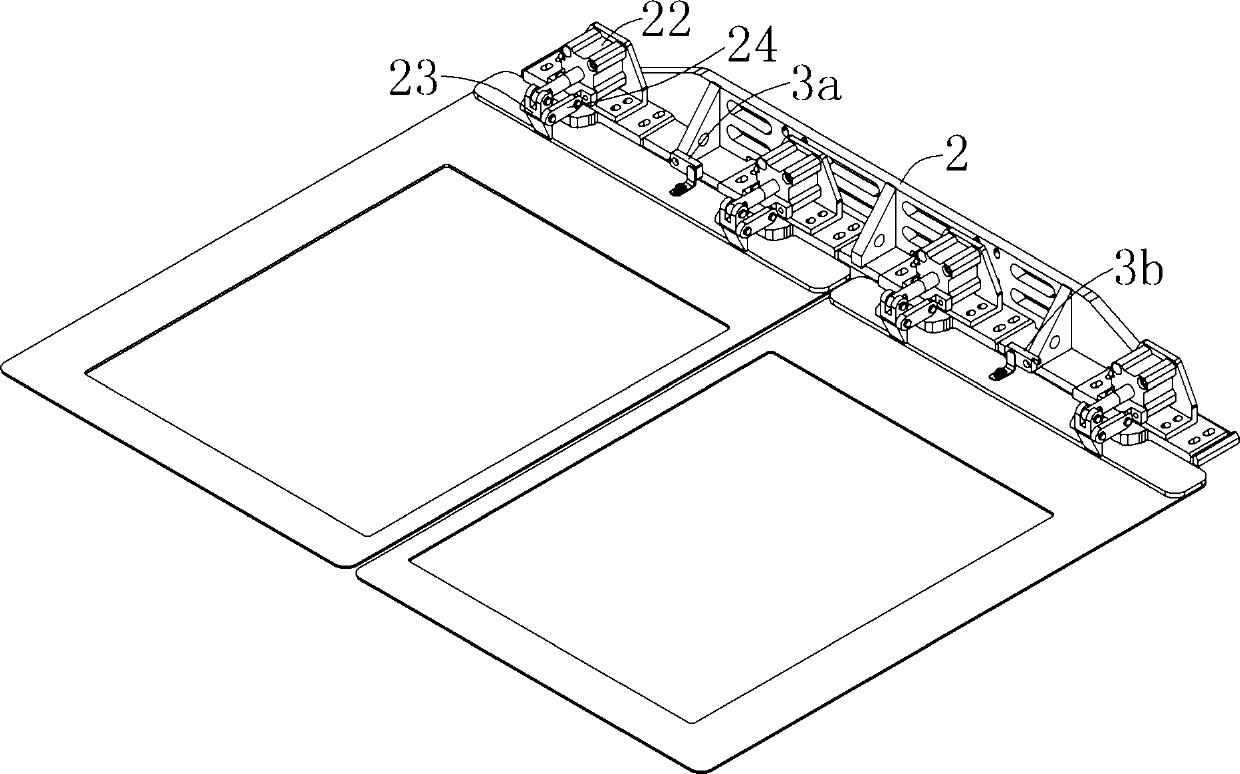

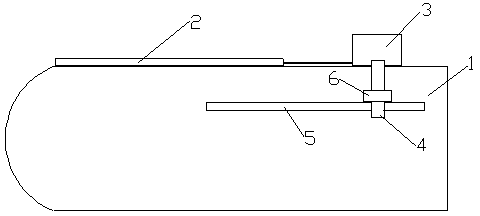

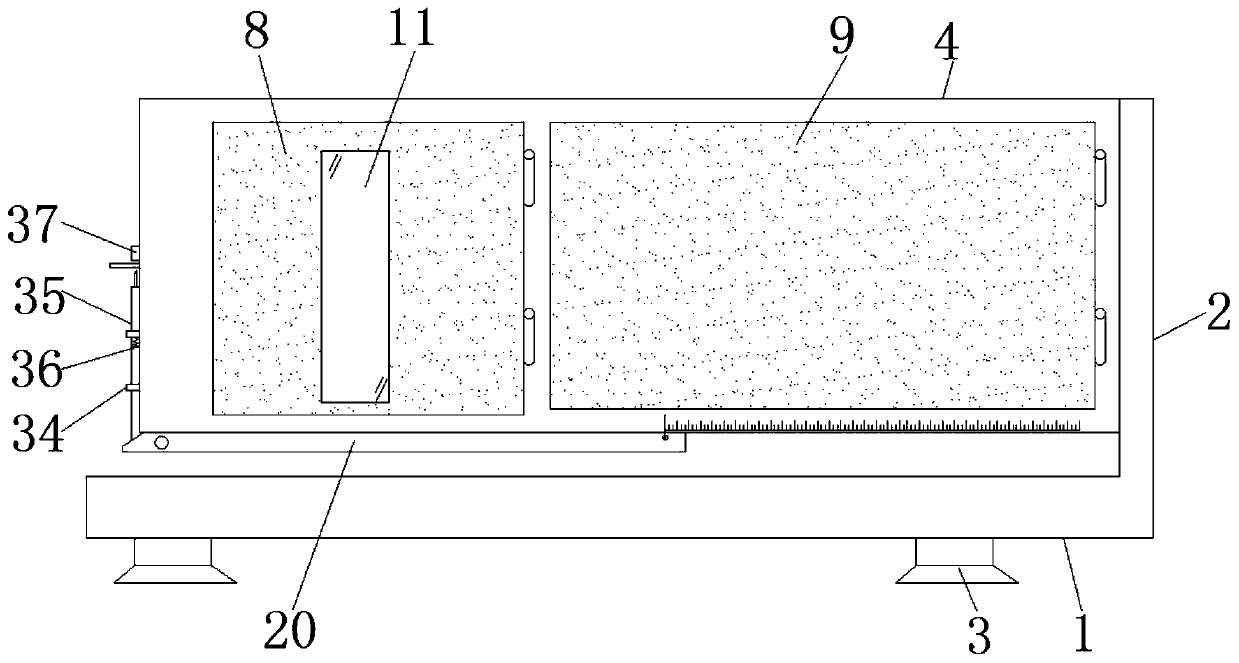

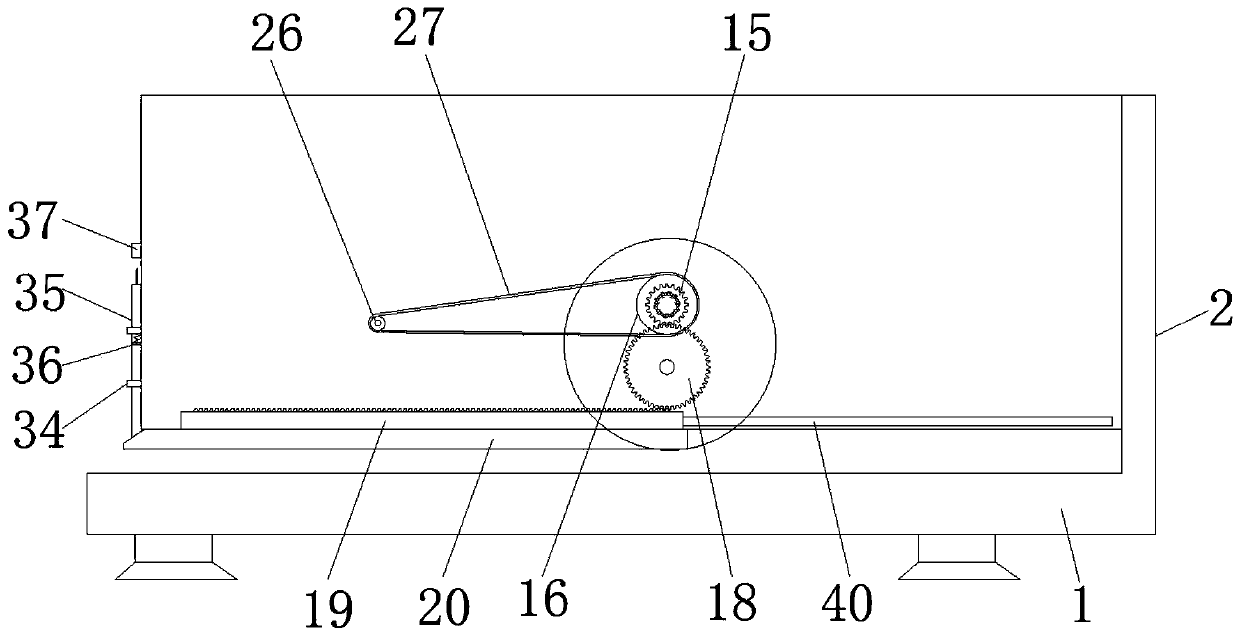

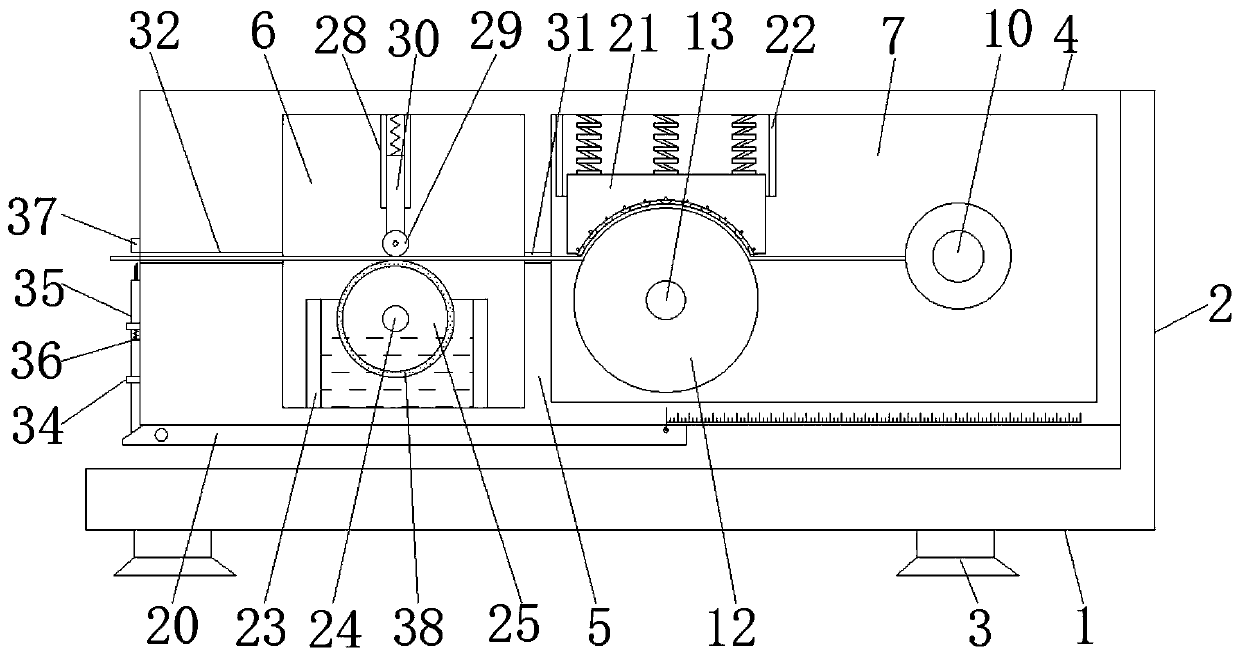

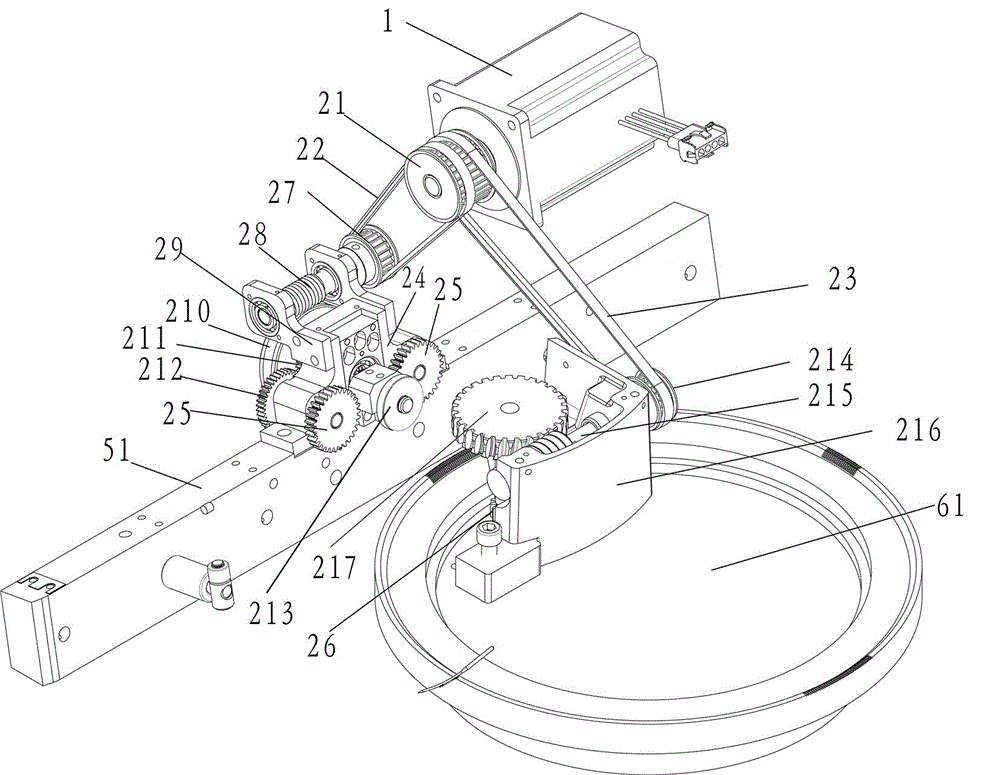

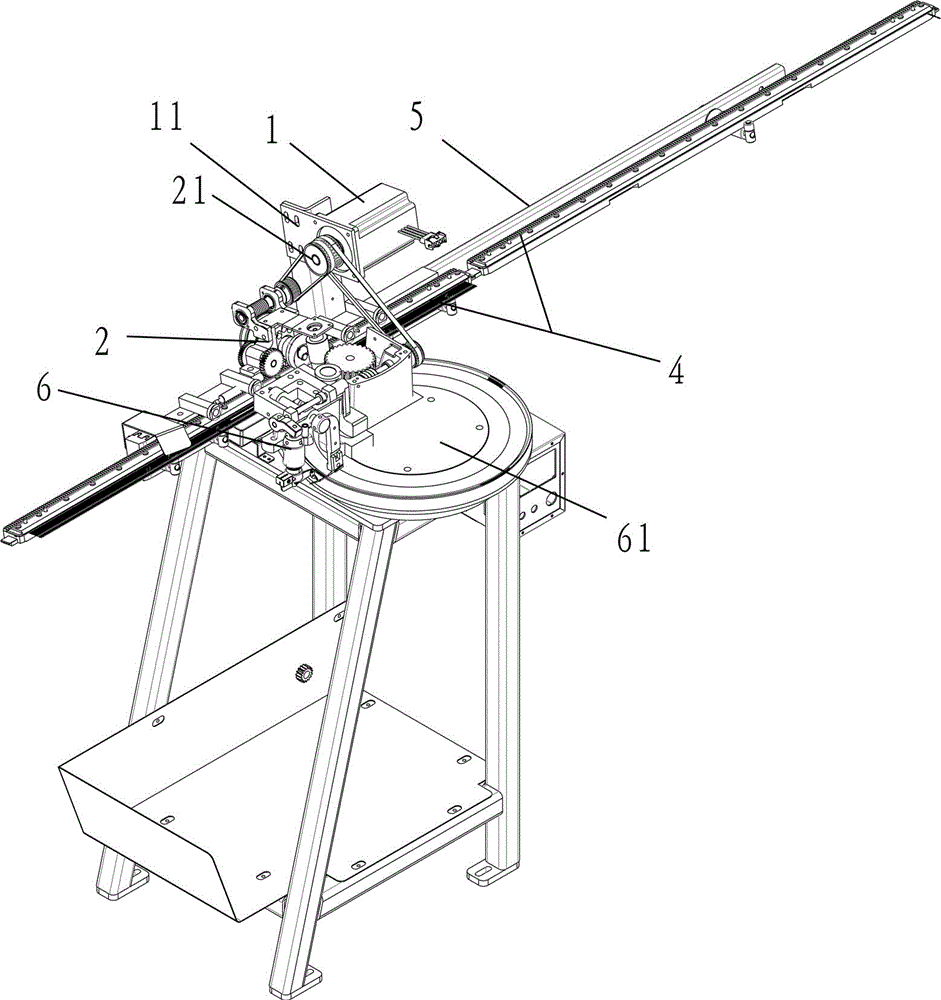

Numerical-control automatic sewing processing equipment

InactiveCN104233641AGuaranteed independenceAvoid the problem of origin positioning deviation easily caused by changing different sewing templatesWork-feeding meansNumerical controlMultiple layer

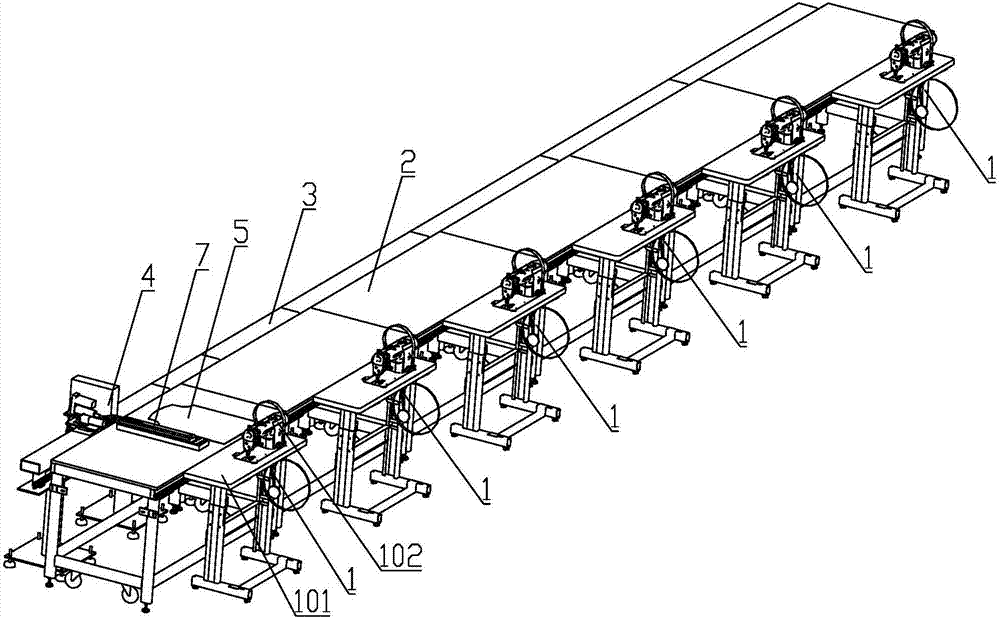

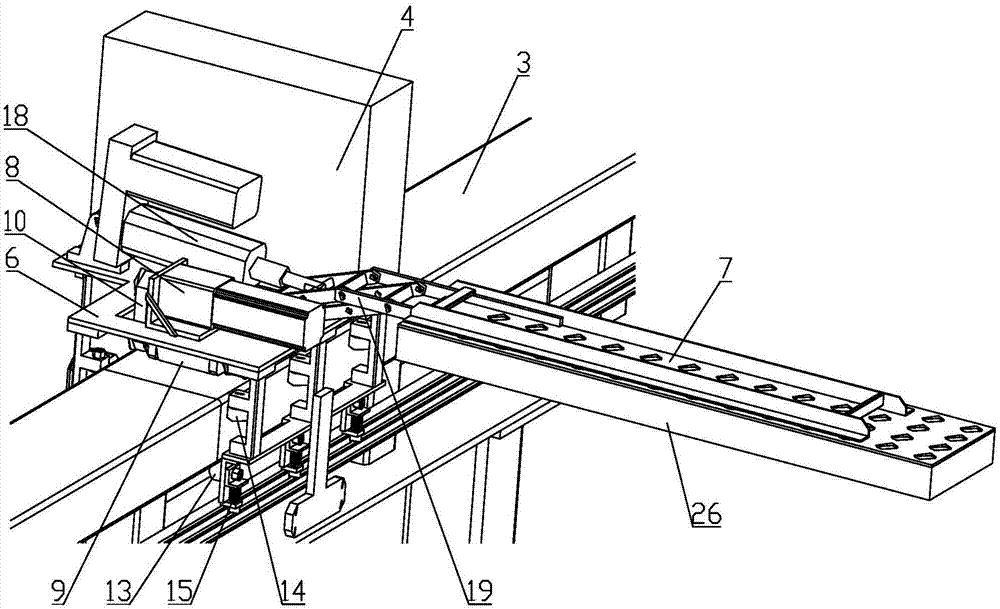

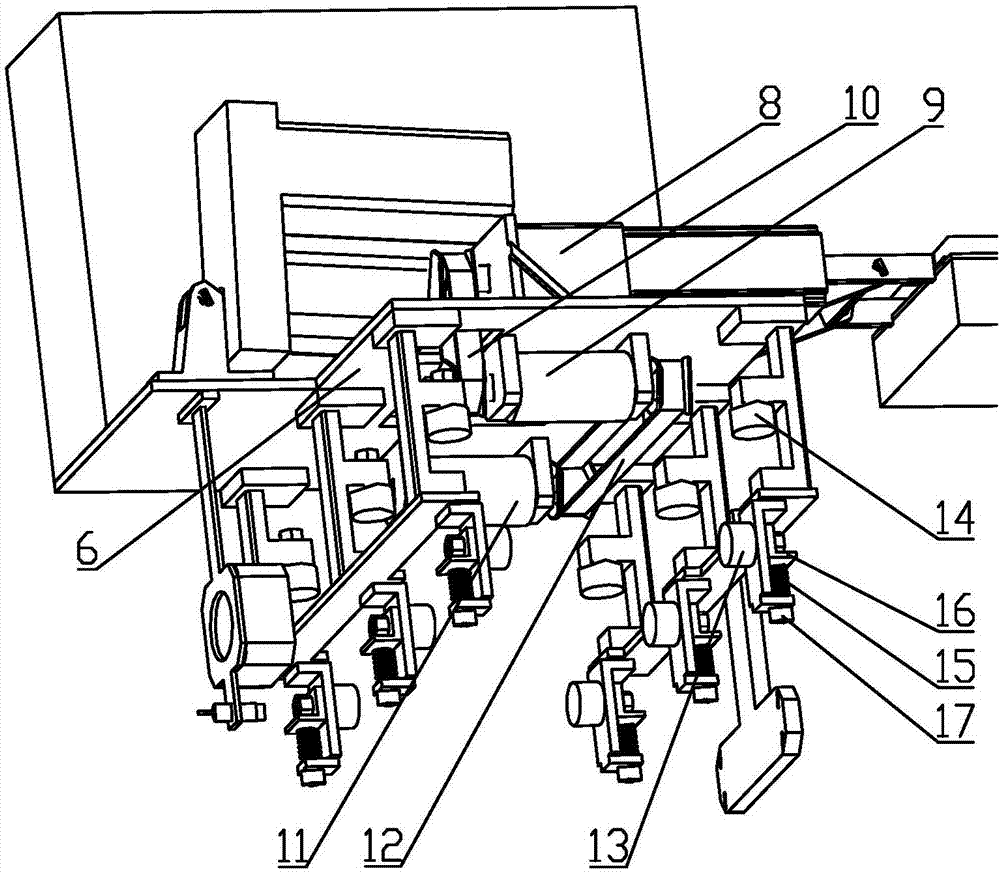

The invention discloses numerical-control automatic sewing processing equipment. The numerical-control automatic sewing processing equipment comprises a sewing machine, a sewing-material clamping and towing mechanism, two parallel sliding rails at the upper layer, two parallel sliding rails at the lower layer and a numerical-control center. The numerical-control automatic sewing processing equipment disclosed by the invention has the advantages that not only can the sewing of multi-layer sewing materials, multiple stitches and multiple layer patterns be realized, but also the working efficiency is improved; the production cost is lower, the installation and the debugging are simple, and the repair and the maintenance of the sewing machine are easy.

Owner:王艳玲

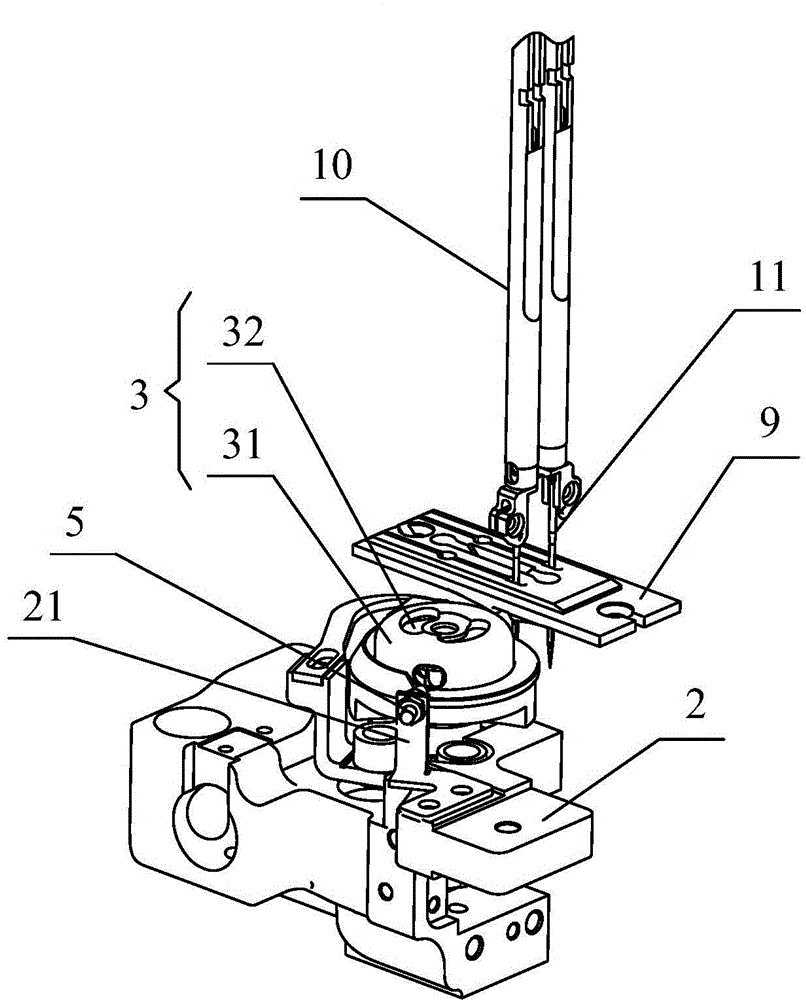

Sewing boundary automatic sewing system and sewing method

ActiveCN106988027AImprove sewing efficiencyHigh precisionProgramme-controlled sewing machinesControl systemEngineering

The invention provides a sewing boundary automatic sewing system and a sewing method. The system comprises a needle pitch detection mechanism, a boundary detection mechanism disposed at the preset distance from a needle hole sewed by a sewing machine needle, and a control system. The needle pitch detection mechanism and the boundary detector are connected with the control system. The control system acquires the current sewing needle pitch in real time according to the needle pitch detection mechanism, and judges whether or not the current sewing state is the terminal sewing according to signals of the boundary detector; if yes, the control system calculates the number of sewing stitches sewn to the fabric boundary with the current sewing needle pitch and performs the sewing according to the number of the sewing stitches; if not, the sewing machine sews normally. The needle pitch detection mechanism is a parameter sensor for collecting swing parameters of feeding tooth holders. According to the sewing boundary automatic sewing system and the sewing method, the automatic sewing process from the last stage to the terminal of the fabric is realized; the sewing efficiency and the sewing precision are improved; the labor cost is lowered.

Owner:JACK SEWING MASCH CO LTD

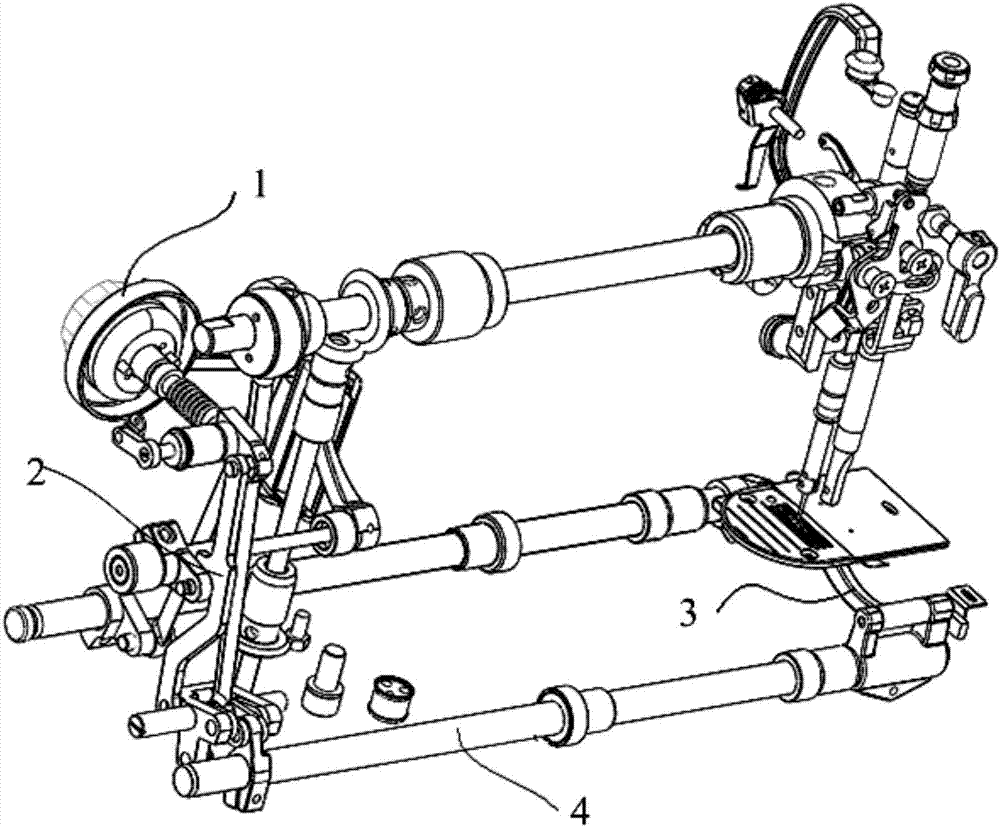

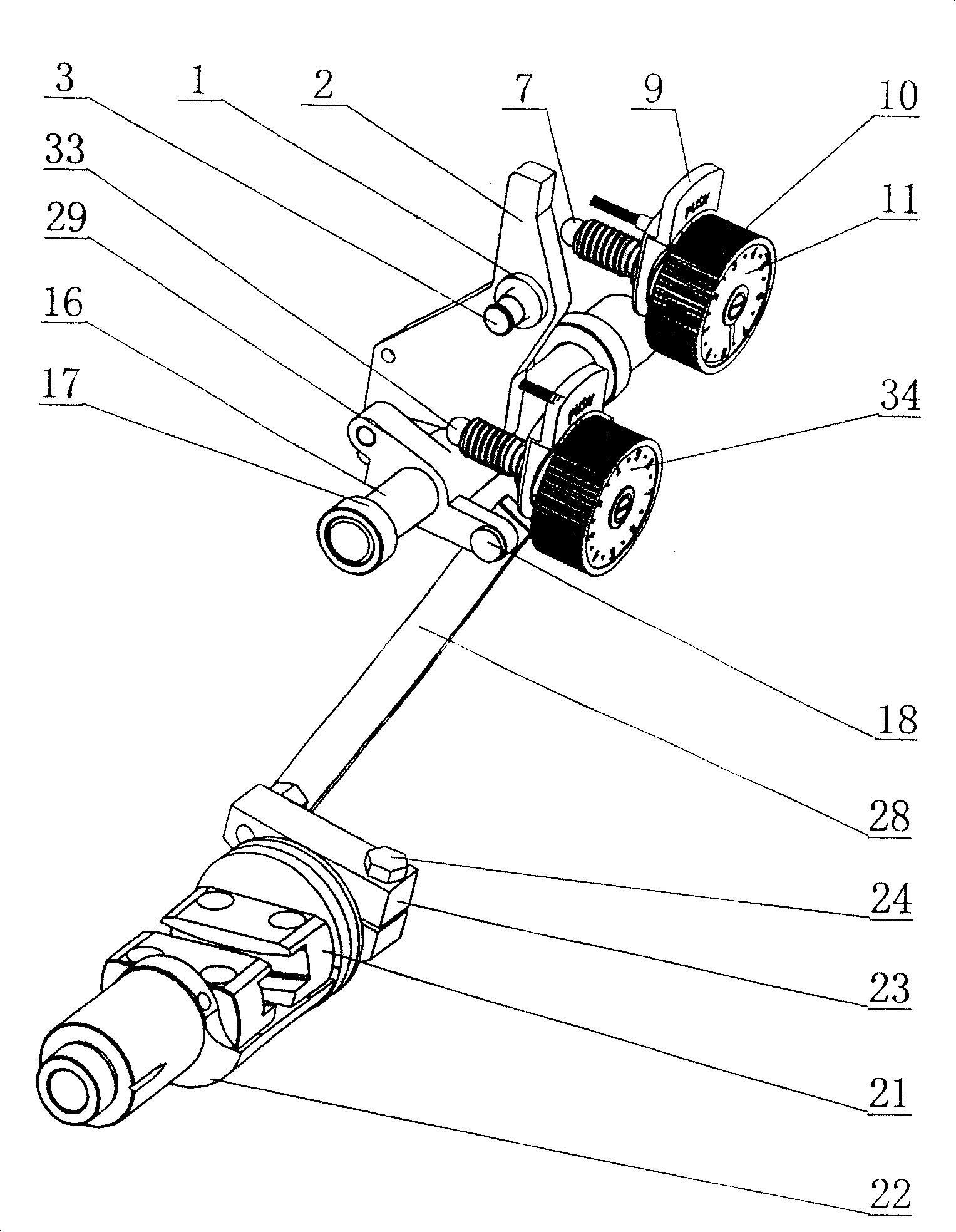

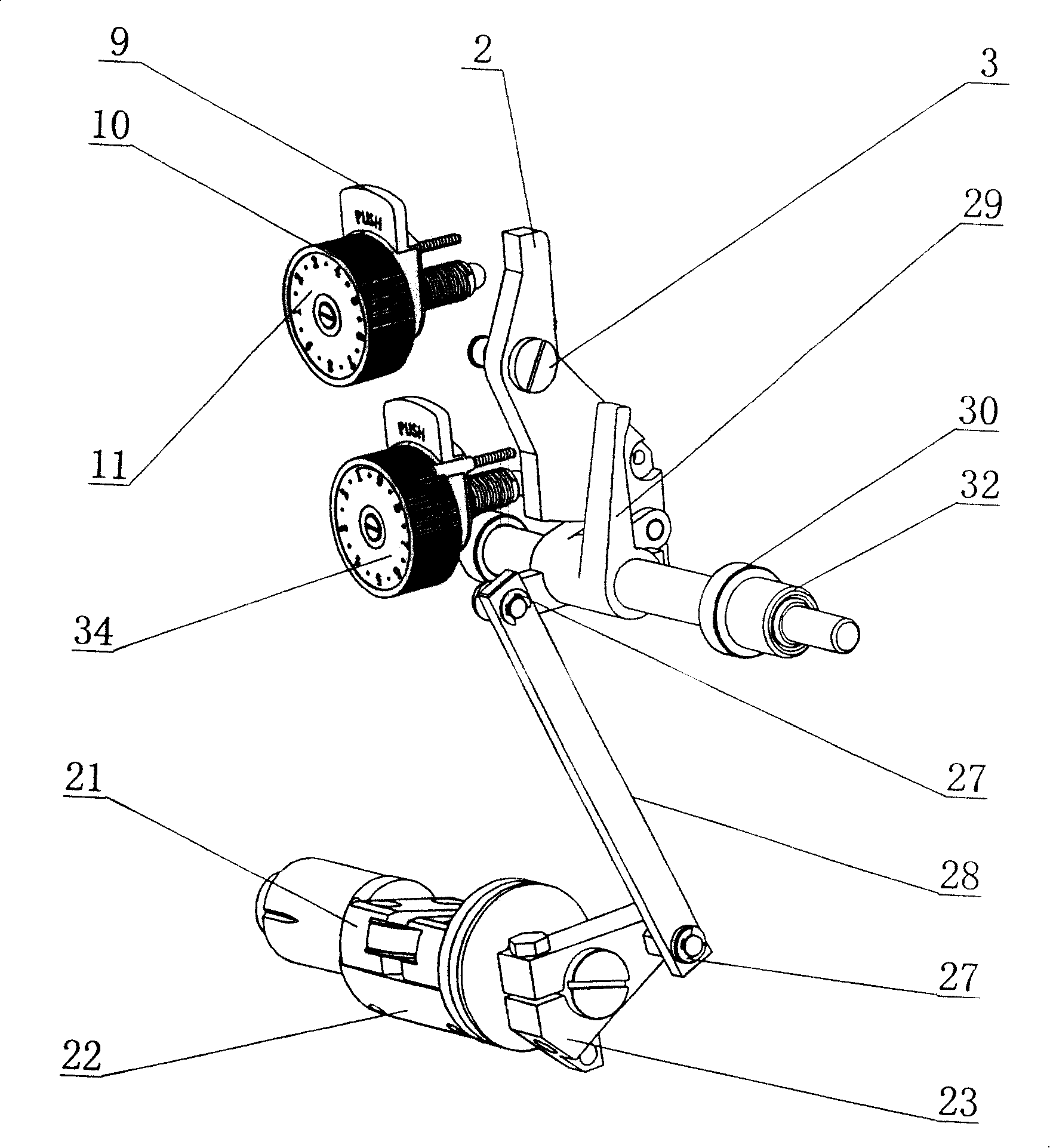

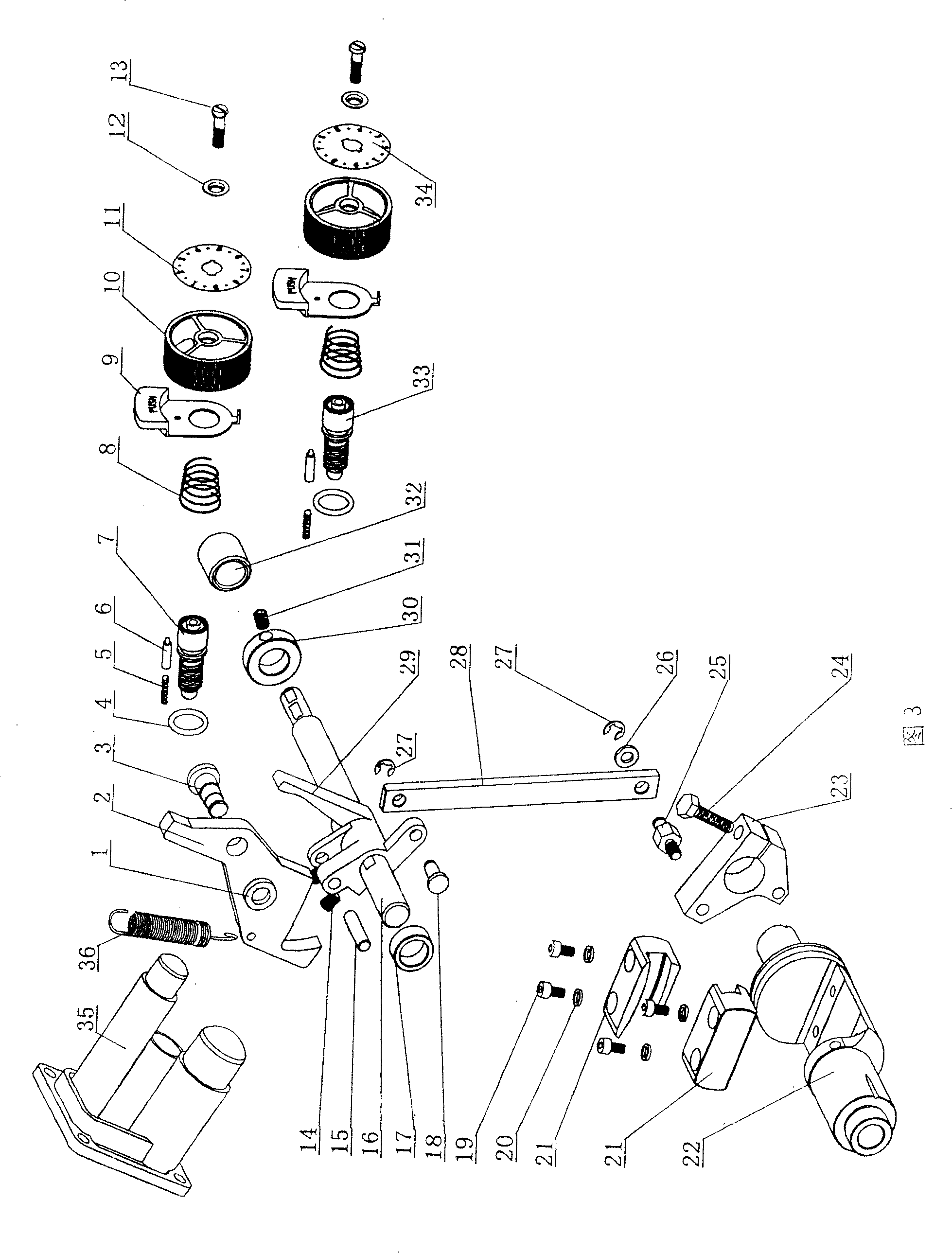

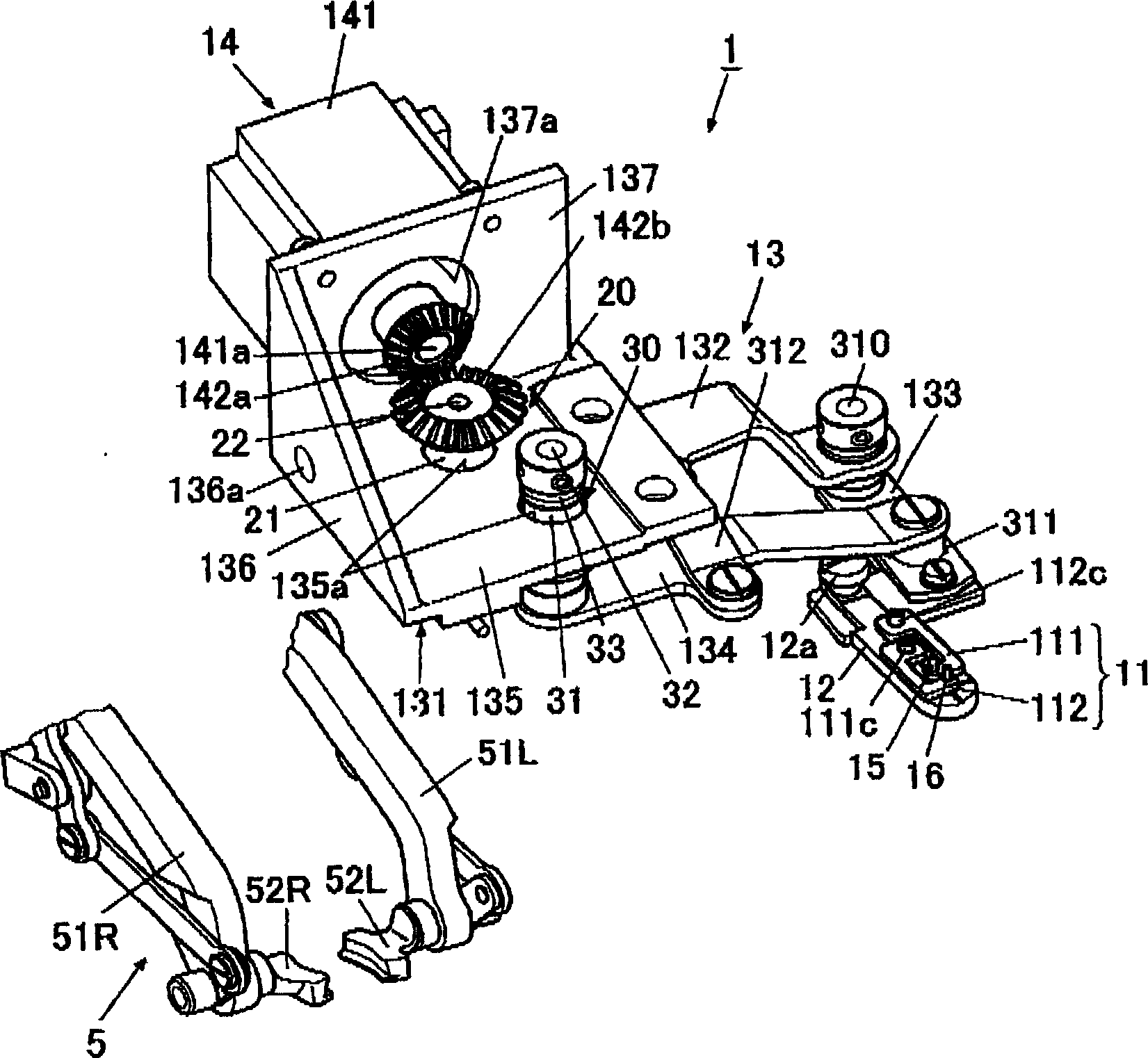

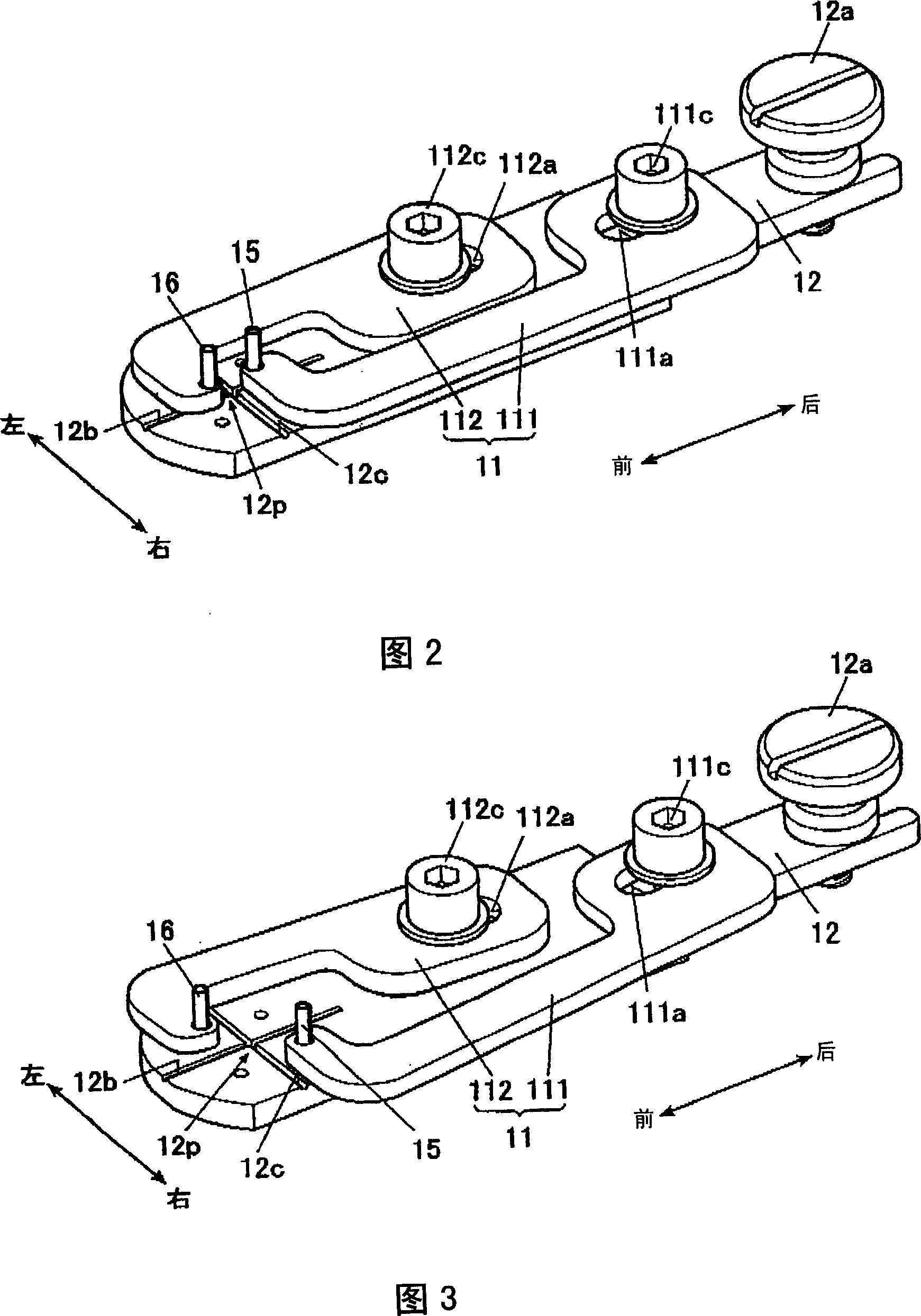

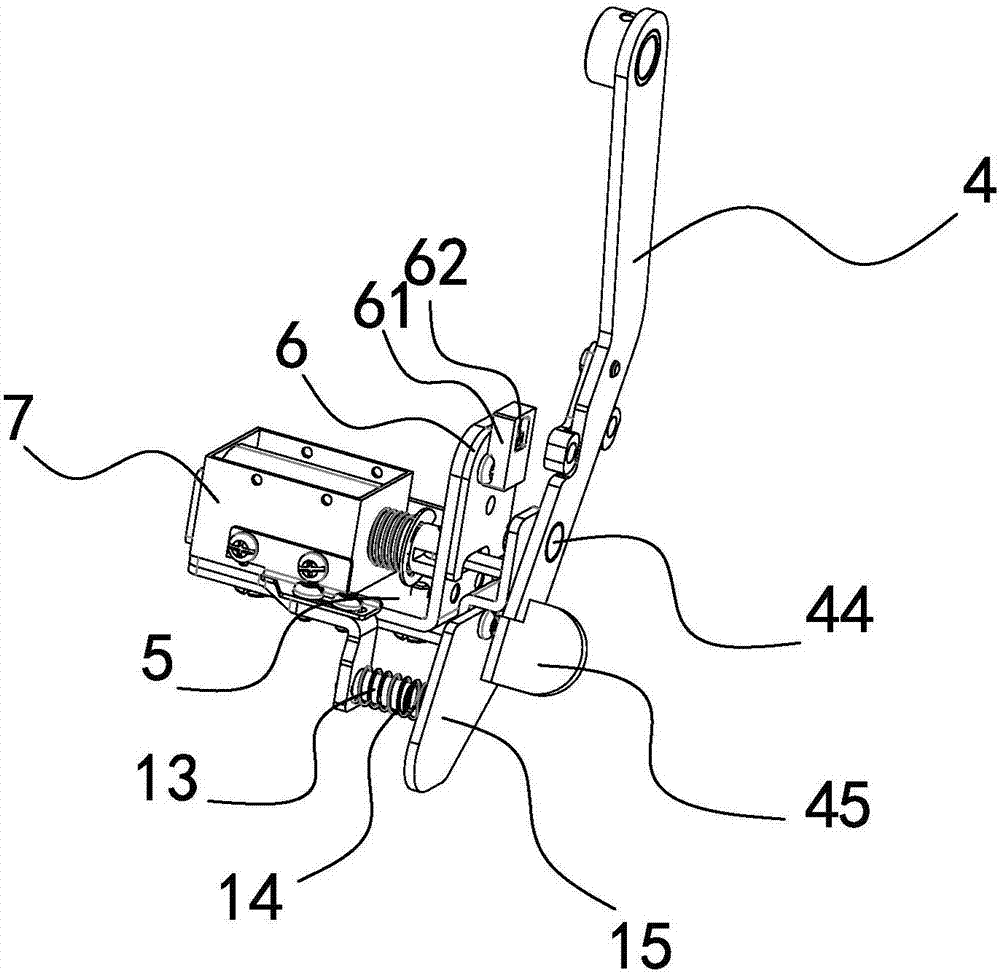

Sewing machine needle distance regulating mechanism

InactiveCN101168888AEasily convert between each otherEasy to operateNeedle barsEngineeringBiomedical engineering

The invention discloses a needle distance adjusting mechanism of a sewing machine, which comprises a needle distance adjusting device, a needle distance adjusting swinging rod, a back sewing crank, and a back sewing table. The needle distance adjusting device has two groups, namely, a large needle distance adjusting device and a small needle distance adjusting device, wherein, the large needle distance adjusting device consists of a large needle distance adjusting threaded rod, a needle distance index disc positioning plate, a needle distance index disc, and a large needle distance index disc panel; the small needle distance adjusting device consists of a small needle distance adjusting threaded rod, a needle distance index disc positioning plate, a needle distance index disc, and a small needle distance index disc panel; the needle distance adjusting swinging rod is driven by a back sewing full needle cylinder and respectively contacted with the large needle distance adjusting threaded rod and the small needle distance adjusting threaded rod. Through the driving of the back sewing full needle cylinder, the product of the invention easily realizes the mutual conversion between the large needle distance adjusting device and the small needle distance adjusting device, and has the advantages that the operation is simple, the sewing efficiency is improved, etc.

Owner:SHANGHAI HUIGONG NO 3 SEWING MACHINE FACTORY CHINA TYPICAL SEWING MACHINE

Shoemaking sewing machine

InactiveCN102061572AEasy and fastConsistent broadside distanceWorkpiece holdersLeather sewingEngineeringSewing machine

The invention relates to a shoemaking sewing machine. The shoemaking sewing machine comprises a worktop, and a handpiece which is arranged on the worktop; the handpiece comprises a presser foot which is opposite to the workbench top and has an adjustable distance; a fixed leg which can rotate around the axis of the presser is arranged on a position, near the presser foot, of the worktop; the peripheral distance from the center of the presser foot to a fixed shaft is the distance from a side edge of a sole to a seam of a shoe upper and the sole; when the shoe upper and the sole are sewn, a side edge of the sole to be sewn is adhered to the periphery of the fixed leg; in the sewing process, when the sole is pushed forwards, the distance from the edge of the sole to the center of the presser foot cannot be changed because of the limit of the fixed leg, so the shoemaking sewing machine ensures that the distance between the suture of the whole shoe upper and the sole and the edge of the sole is consistent; and the fixed leg is pushed by the sole to rotate and provide driving force for the side edge of the sole contacted with the fixed leg, so that the sole can be pushed forwards easily and quickly, and sewing efficiency is improved.

Owner:WUJIANG HENGYING RUSH EMBROIDERY ARTS & CRAFTS FACTORY

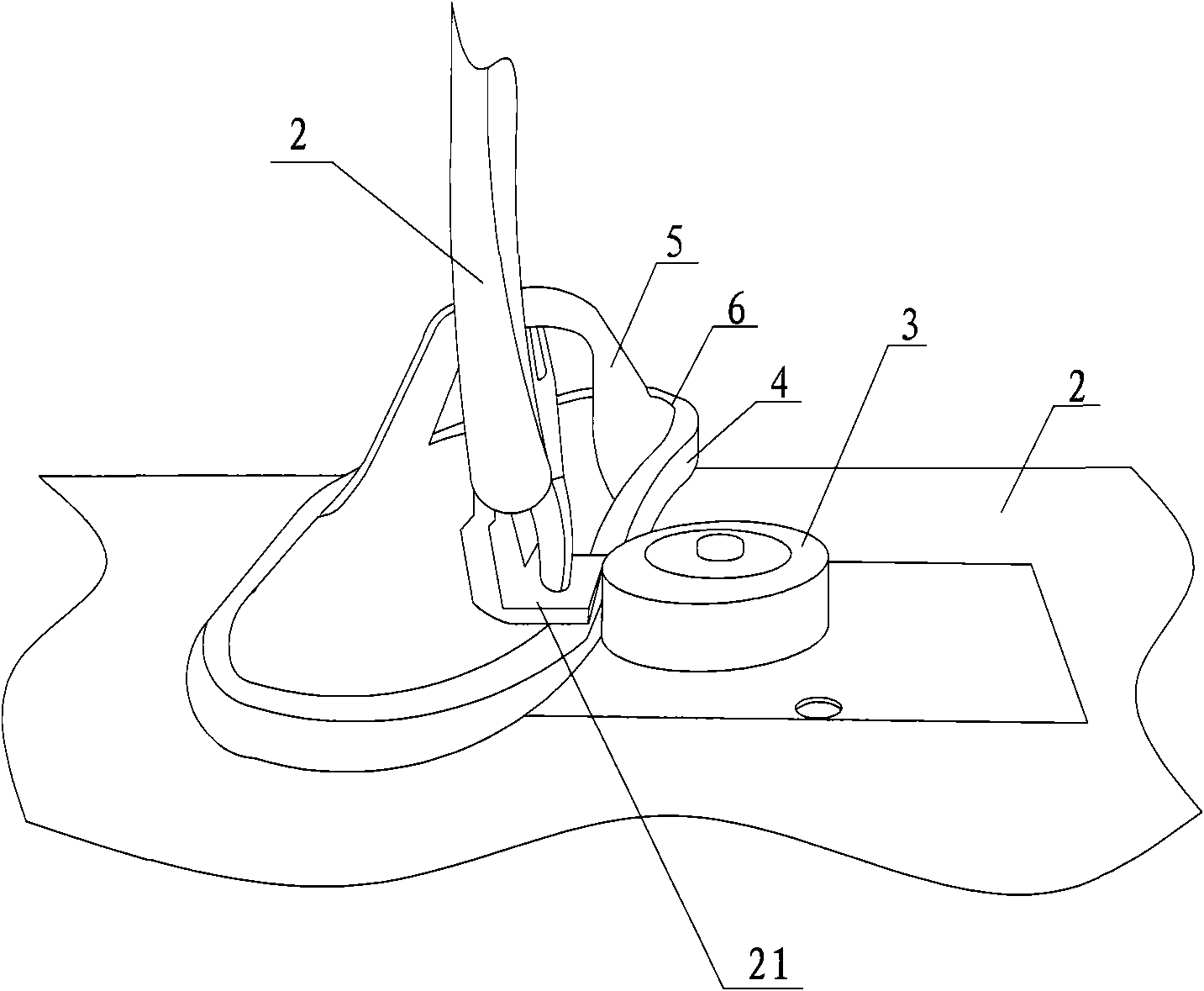

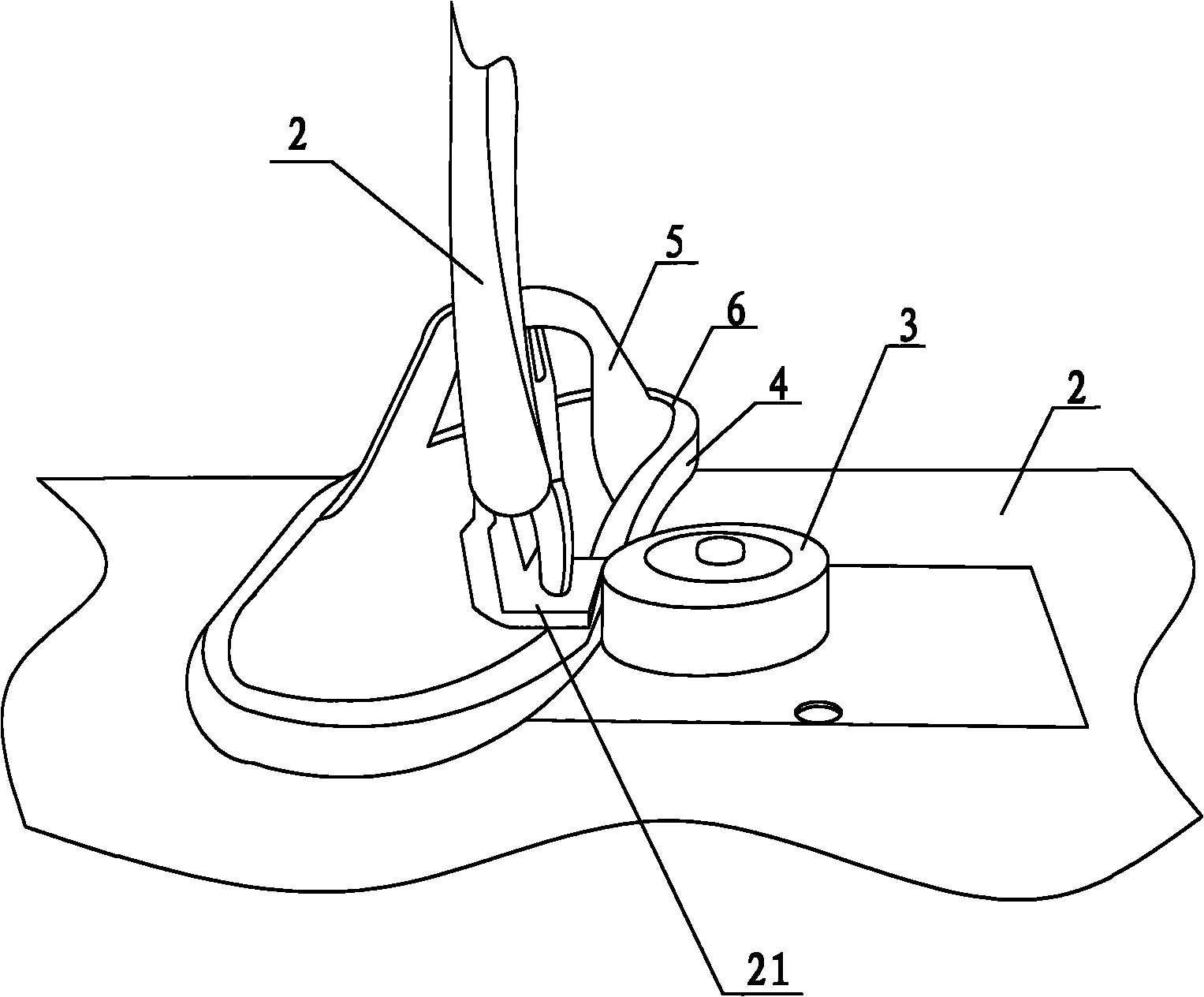

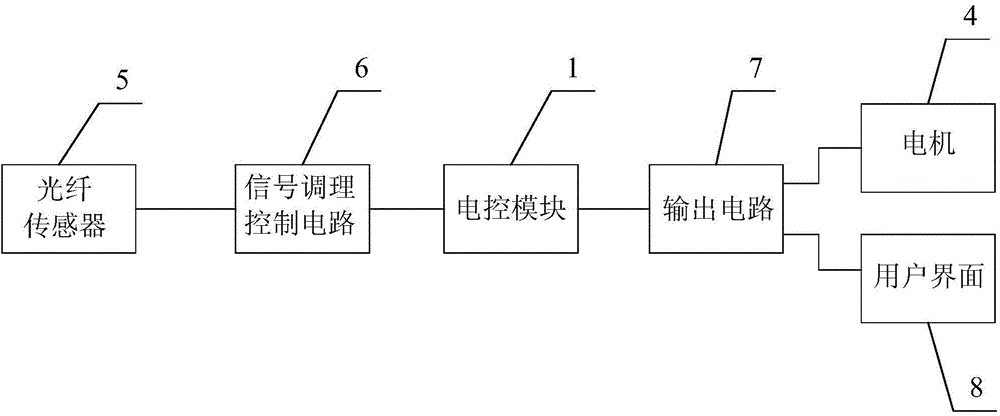

Bottom wire detection control system and method based on optical fiber sensor and applied to industrial sewing machine

ActiveCN104372538AImprove detection accuracyGuaranteed reliabilityBobbin-winding devicesLoop takersBobbinEngineering

The invention provides a bottom wire detection control system based on an optical fiber sensor and applied to an industrial sewing machine. The system comprises an electric control module, a rotating shuttle and a motor. The rotating shuttle comprises a shuttle case and a shuttle core. The shuttle core comprises a winding post and flanges arranged at the two ends of the winding post. A reflective sheet is fixed to the outer circumferential face of the winding post, and bottom wires are wound around the winding post. The optical fiber sensor is fixed to a shuttle support. The shuttle case is provided with an optical fiber emitter inlet and a gap, wherein the optical fiber emitter inlet and the gap are communicated with each other. The optical fiber sensor is connected with the electric control module through a signal conditioning control circuit. The electric control module is also connected with the motor through an output circuit. The bottom wire detection control system applied to the industrial sewing machine can judge whether the shuttle core is not installed in the shuttle case and whether the bottom wires on the shuttle core are enough according to optical signals of reflected light detected by the optical fiber sensor; meanwhile, the optical fiber sensor is adopted as a detection element, so that the system is high in sensitivity, higher and more reliable in detection performance and higher in anti-electromagnetic-interference capability.

Owner:BULLMER ELECTROMECHANICAL TECH

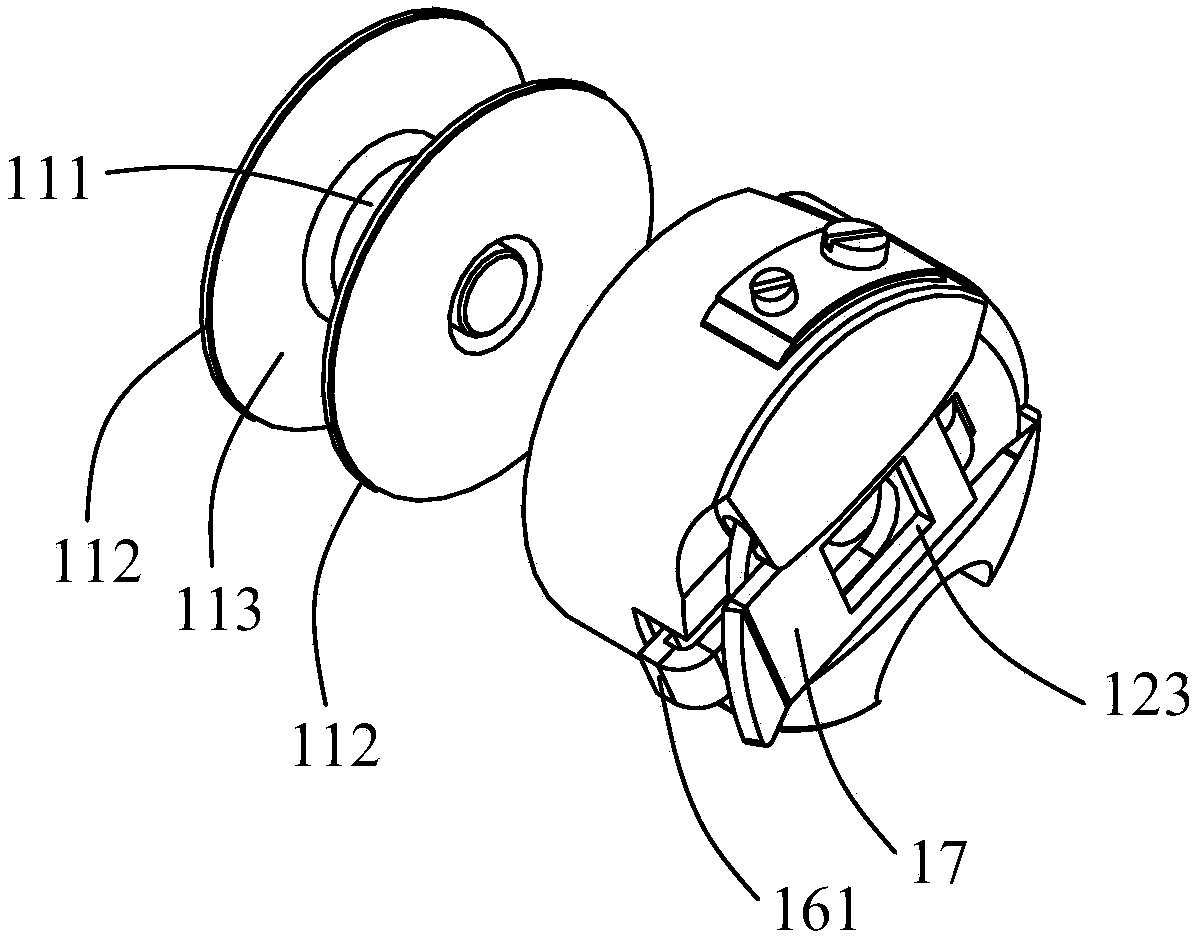

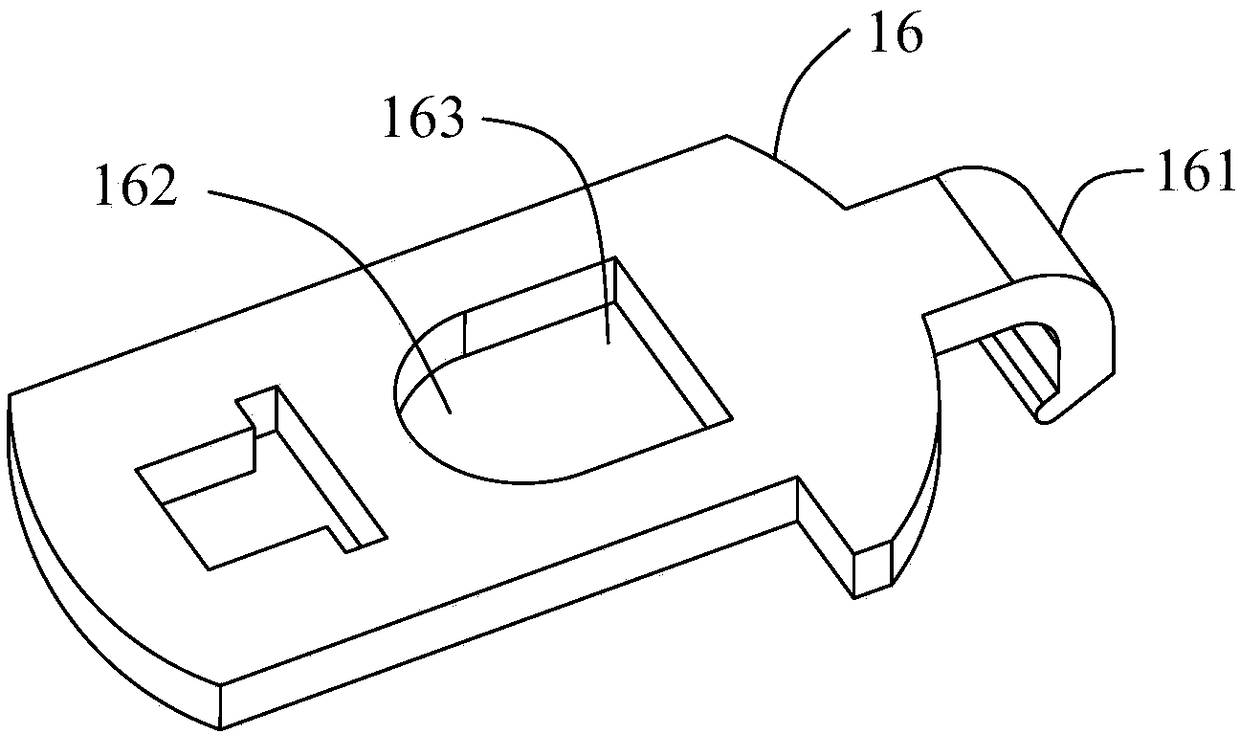

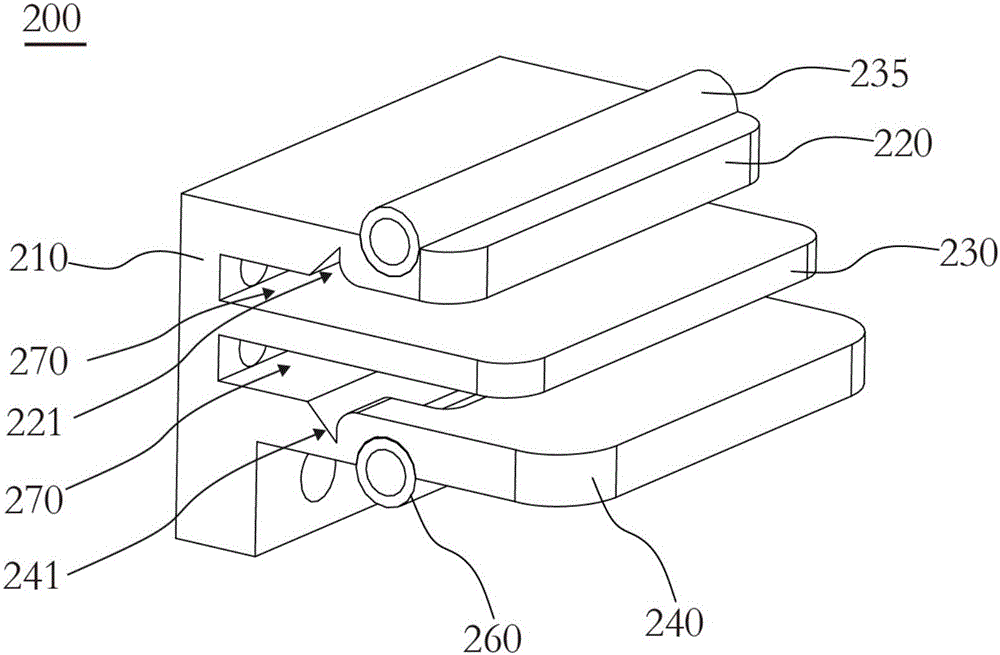

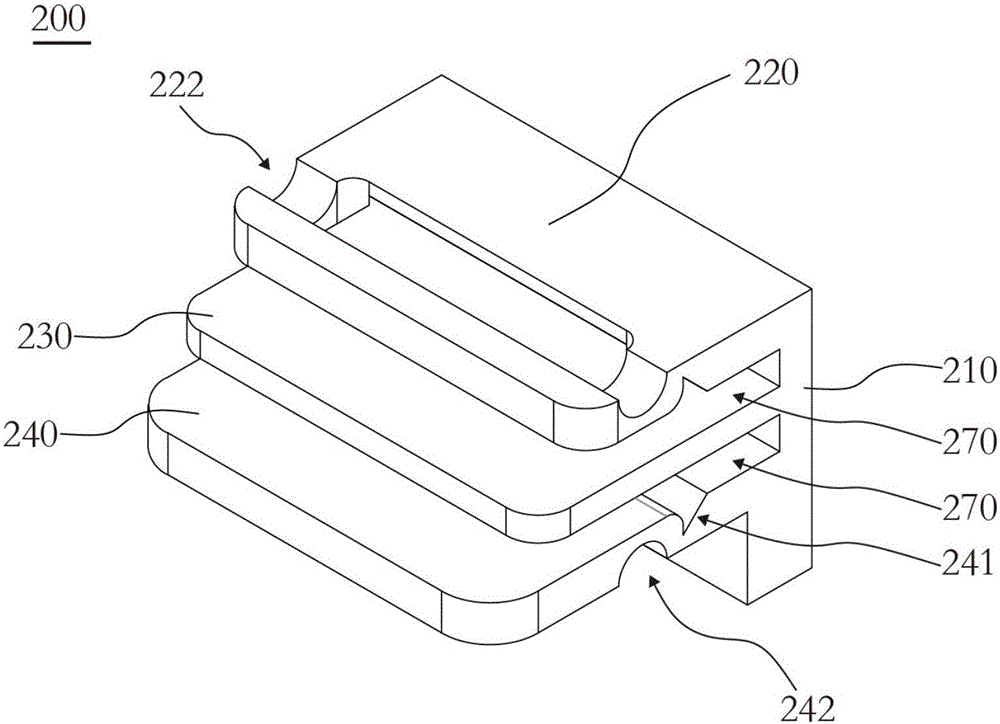

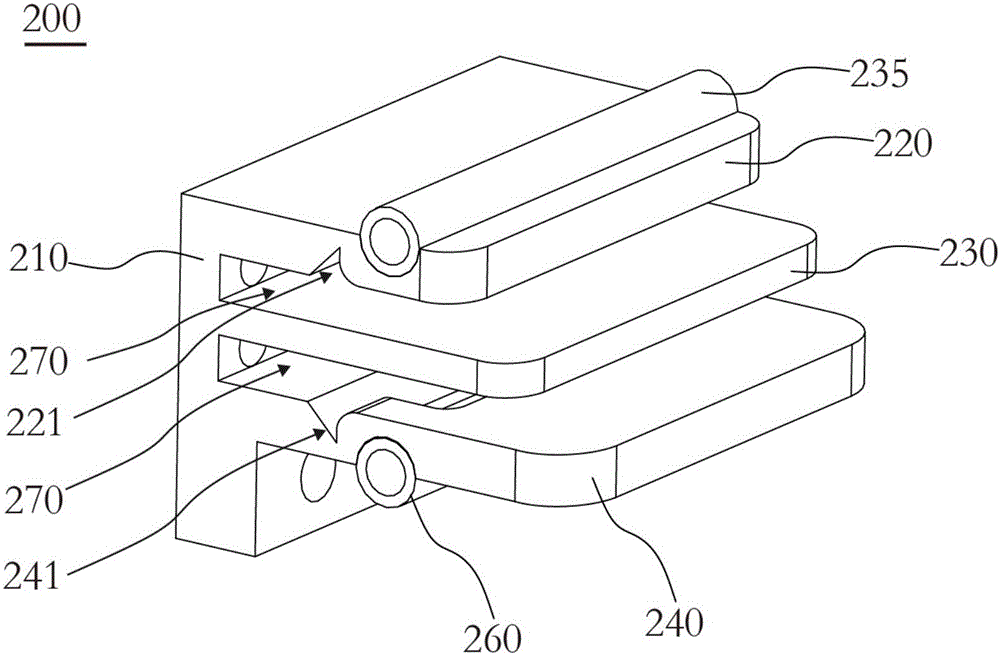

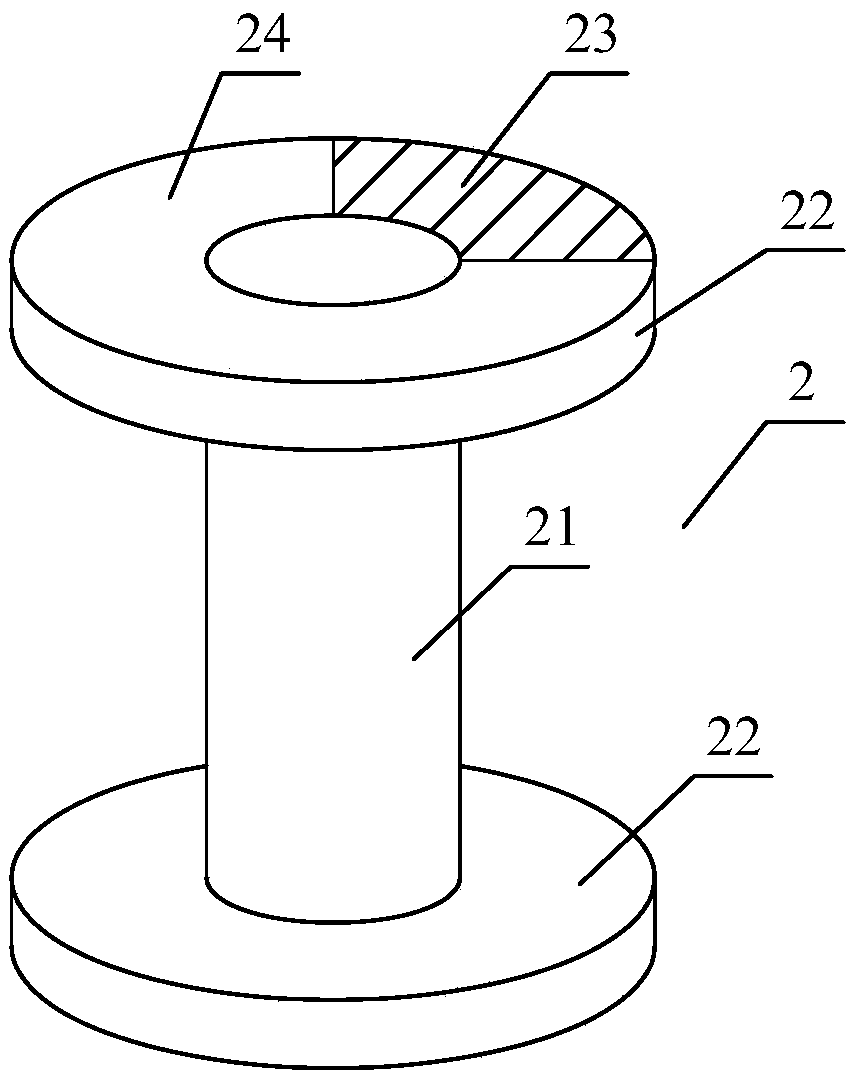

Automatic shuttle replacement device and method and sewing machine

ActiveCN108221203AHigh degree of automationImprove sewing efficiencyBobbin-winding devicesBobbinDrive wheel

The invention provides an automatic shuttle replacement device for replacing a first shuttle with the insufficient allowance of threads and a first shuttle case. The automatic shuttle replacement device comprises a main board, a shuttle case limiting shaft, a shuttle grabbing mechanism, a shuttle remaining thread removal mechanism, a shuttle winding and threading mechanism and a thread cutting mechanism, wherein the shuttle case limiting shaft is sleeved with a second shuttle wound by threads sufficiently and a second shuttle case; the shuttle grabbing mechanism comprises a hook claw base, a shuttle grabbing driving source and a shuttle grabbing hook claw, the shuttle grabbing hook claw is used for hooking a shuttle case plate on the first shuttle case or the second shuttle case; the shuttle remaining thread removal mechanism comprises a fixing shaft, a driving wheel unit and a driven wheel unit which are installed on the main board, and a thread clamping space; the shuttle and windingthreading mechanism comprises a winding shaft and a clamping base, a clamping interval and an interval inlet are formed in the clamping base; the cutting mechanism comprises a thread cutting edge arranged on the clamping base. The second shuttle wound by threads sufficiently and the second shuttle case can be replaced in a rotating shuttle, and automatic remaining thread removal, winding, threading and cutting can be performed on the replaced first shuttle and the second shuttle case, so that the automatic degree is quite high, and then the sewing efficiency is greatly improved.

Owner:JACK SEWING MASCH CO LTD

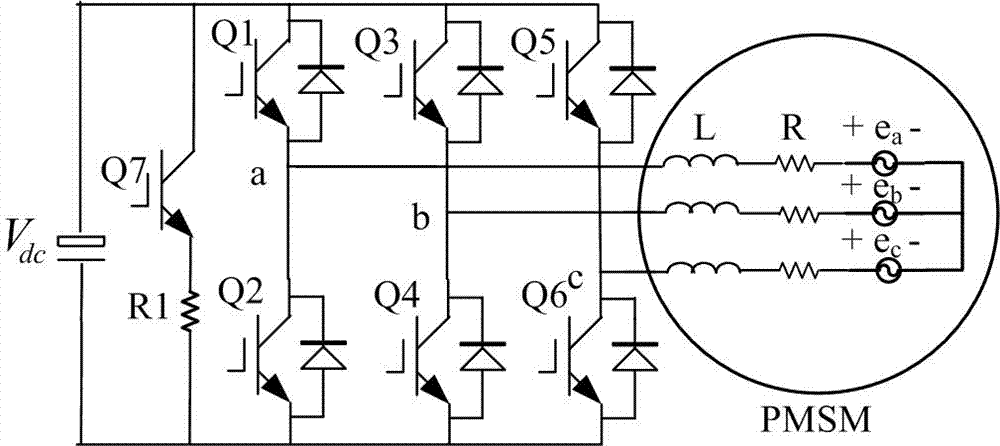

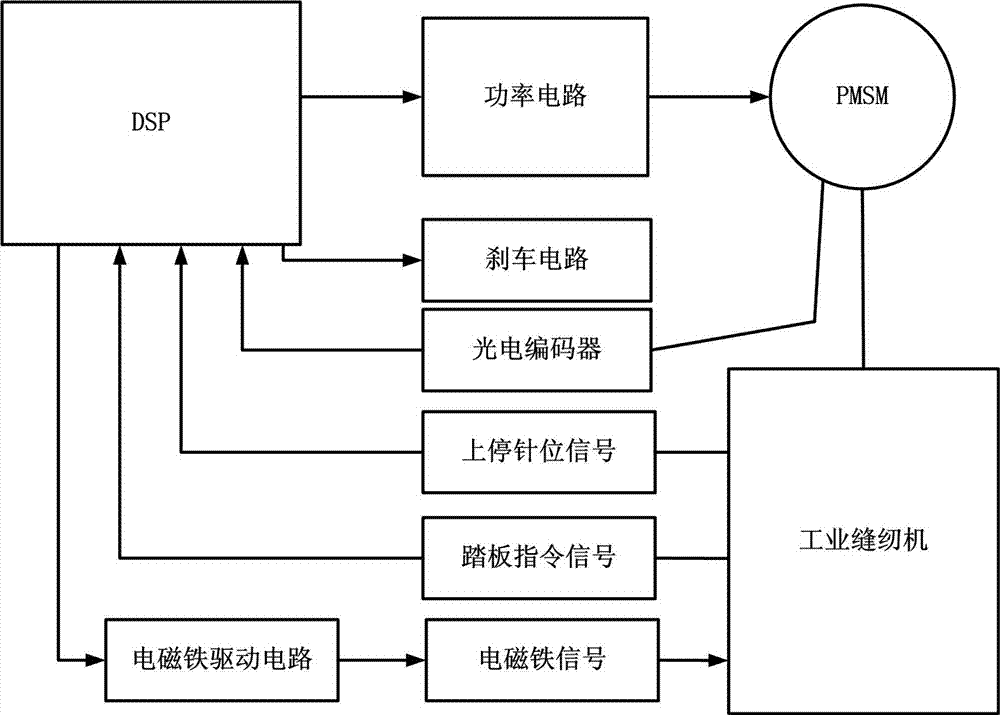

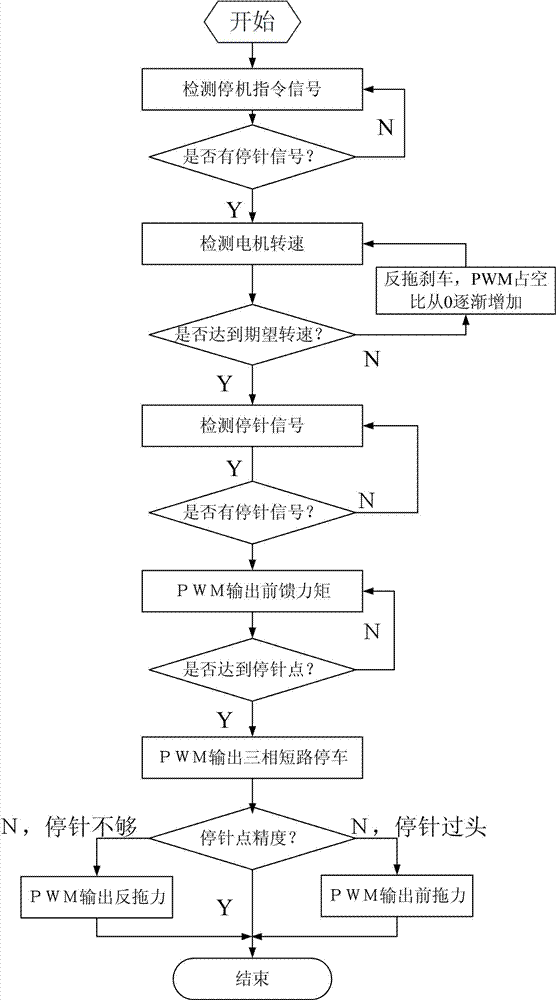

Precise positioning system of industrial sewing machine and working method of precise positioning system

InactiveCN103572514AImprove accuracyEnsure safetySewing-machine control devicesNeedle barsClosed loopComputer module

The invention discloses a precise positioning system of an industrial sewing machine and a working method of the precise positioning system and relates to a positioning system of a sewing machine and a working method of the positioning system. The general phenomena of low stop precision, reversal, shaking, poor stability and the like are caused by a reason that the conventional industrial normal sewing machine positioning method generally adopts an adjustment system with a closed-loop position. The precise positioning system is characterized in that a controller comprises a quick reverse-dragging braking module, a speed adjustment module, a torque feedforward module and a three-phase short-circuit controllable stopping module. According to the technical scheme provided by the invention, the quick reverse-dragging braking module is adopted to enable a servo motor to be deaccelerated quickly, and the speed adjustment module is used for stabilizing the speed within a range; when the sewing machine starts to be positioned near to a trimming point, the sudden load change is maximum, and the torque feedforward module supplies a forward dragging torque in advance to counteract the sudden load change during trimming; when a head of the sewing machine is positioned near to a needle stopping point, the three-phase short-circuit controllable stopping module brakes a three-phase short circuit, so that the problems of inaccurate needle stopping and needle stopping shake, which are caused by reverse-dragging braking, can be solved.

Owner:WOLONG ELECTRIC GRP CO LTD

A plurality of cylindrical cutting piece opposite side machine sewing system

ActiveCN106702610AImprove sewing effectQuality assuranceWork-feeding meansEngineeringMechanical engineering

The invention provides a plurality of cylindrical cutting piece opposite side machine sewing system, which comprises: a machine, an opposite side device, a cylindrical automatic correction mechanism and a machine sewing device. The opposite device locates the edges of a plurality of cutting pieces. The cylindrical automatic correction mechanism comprises a base, a conical limit wheel, a conical driven wheel, a limit plate, a rotating shaft, a rotating drive part, and a moving drive part; the moving drive part is connected with the base to driving the base moving; the cylindrical automatic correction mechanism locates the cylindrical cutting piece. The machine sewing device is used to sew the cutting piece from the two material channels, the cylindrical cutting piece from the conical limit wheel and the body cutting piece from the working panel of the machine. The a plurality of cylindrical cutting piece opposite side machine sewing system saves time and labor and has high product efficiency.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

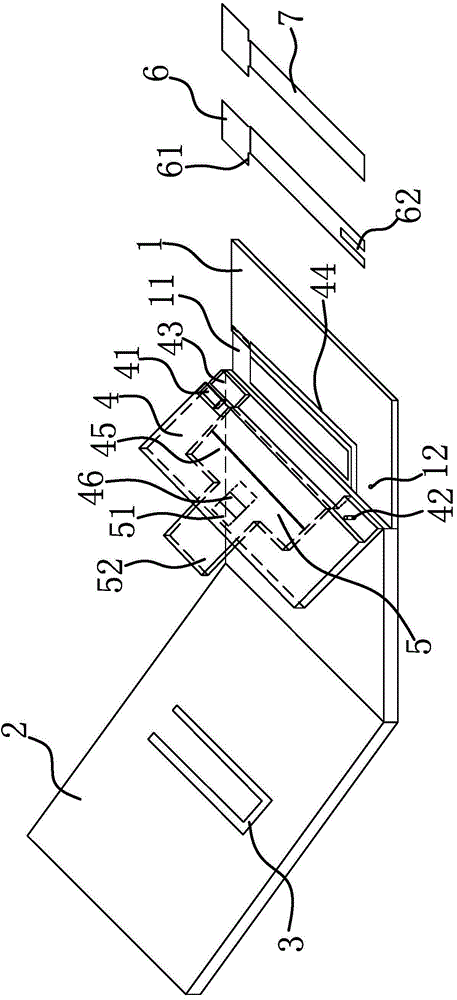

Automatic multilayer cut piece edge aligning mechanism

ActiveCN106757833APlay a role in controlling the borderQuality assuranceWork-feeding meansEngineeringAutomation

The invention discloses an automatic multilayer cut piece edge aligning mechanism. The automatic multilayer cut piece edge aligning mechanism comprises a table, an edge aligning device and a cut piece edge control device. The edge aligning device comprises a fixing seat, a first positioning plate, a second positioning plate, a third positioning plate, a first air blowing tube and a second air blowing tube. The edge aligning device is used for edge alignment of double-layer or multi-layer cut pieces. The cut piece edge control device comprises a positioning part, a sensing part and an edge control part, wherein the positioning part is arranged on a worktable top of the table and located above the fixing seat, and the sensing part tightly attaches to the positioning part. The cut piece edge control device is used for controlling cut pieces to be always kept in a positioning state and not prone to position deviation. The automatic multilayer cut piece edge aligning mechanism is higher in automation degree and saves time and labor.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

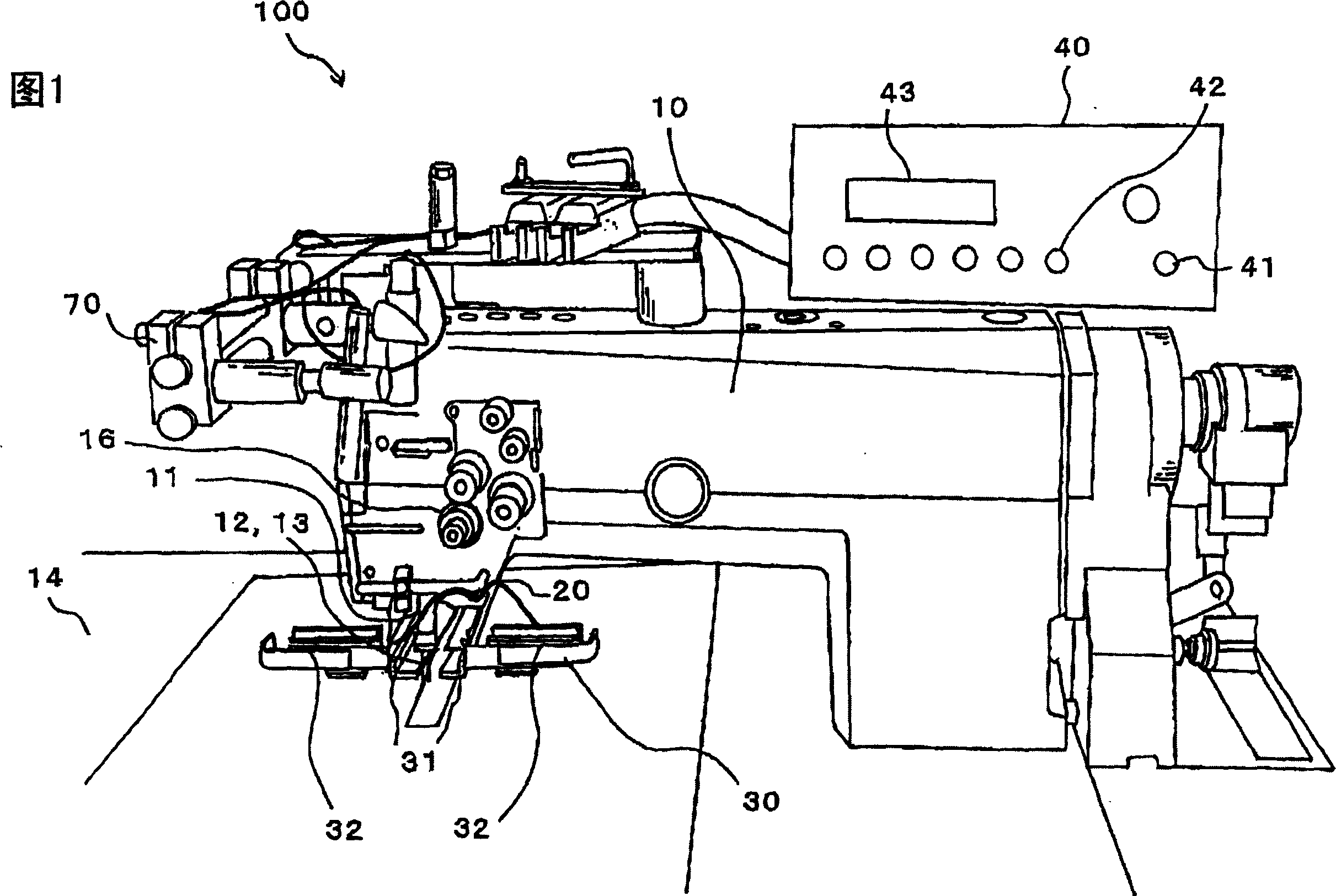

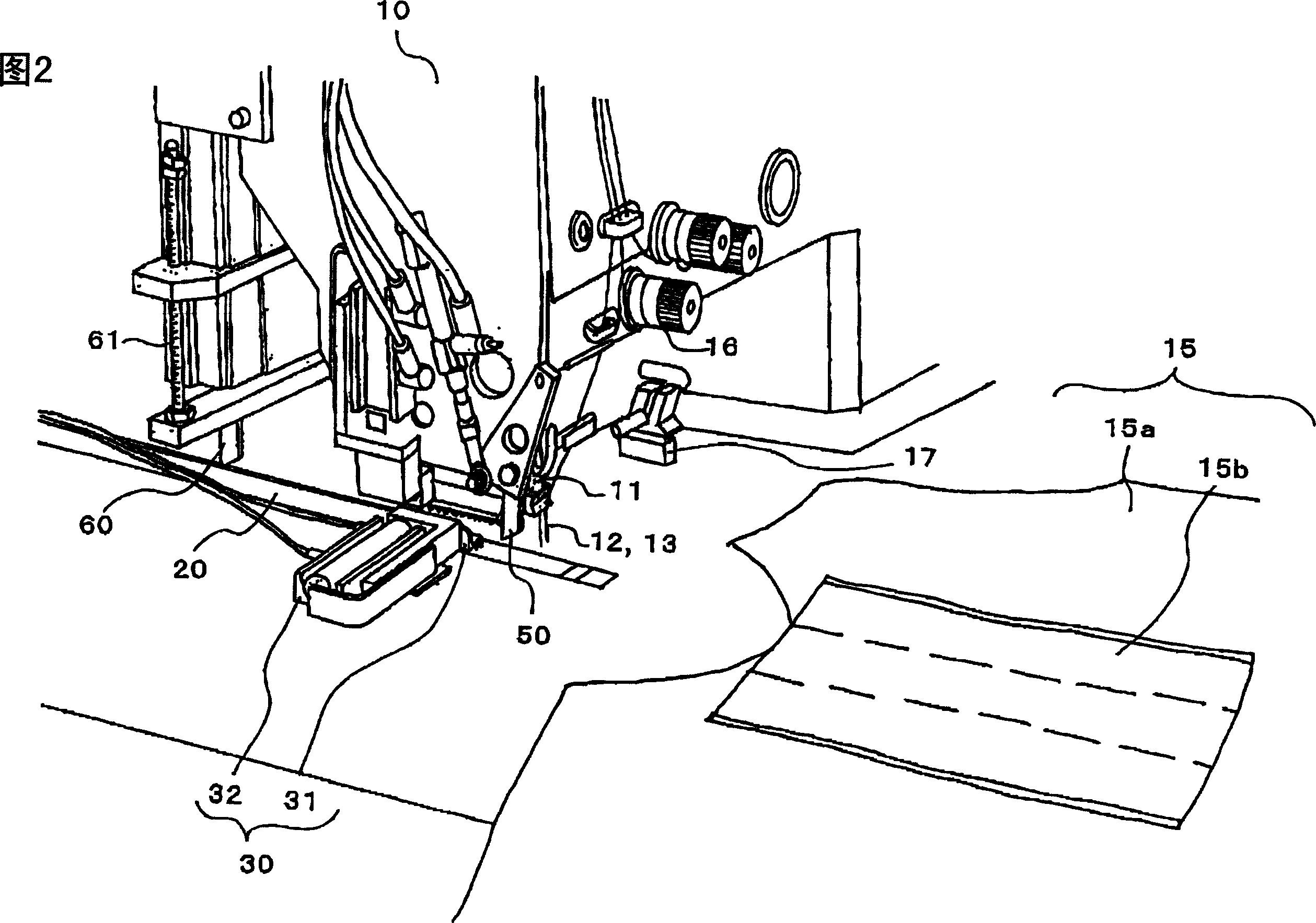

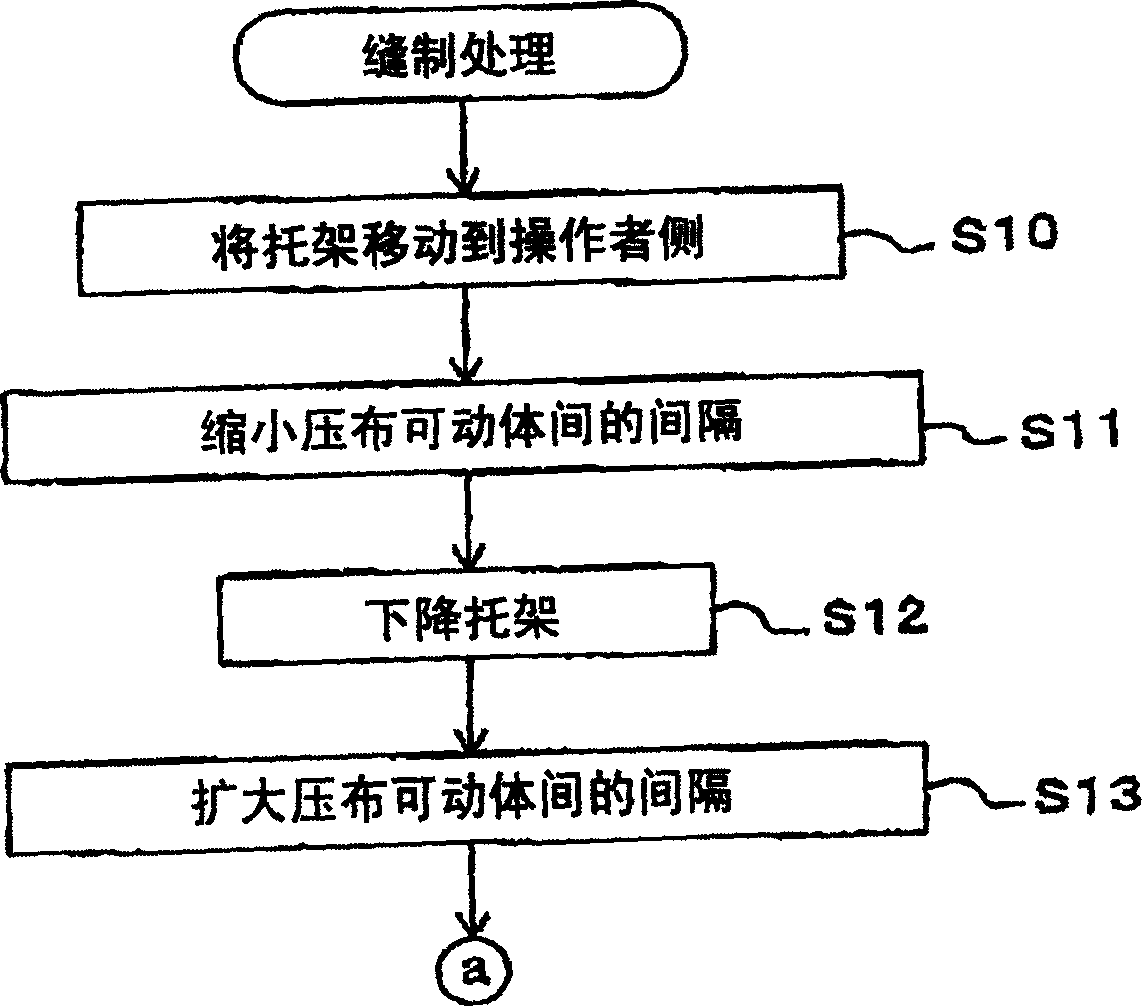

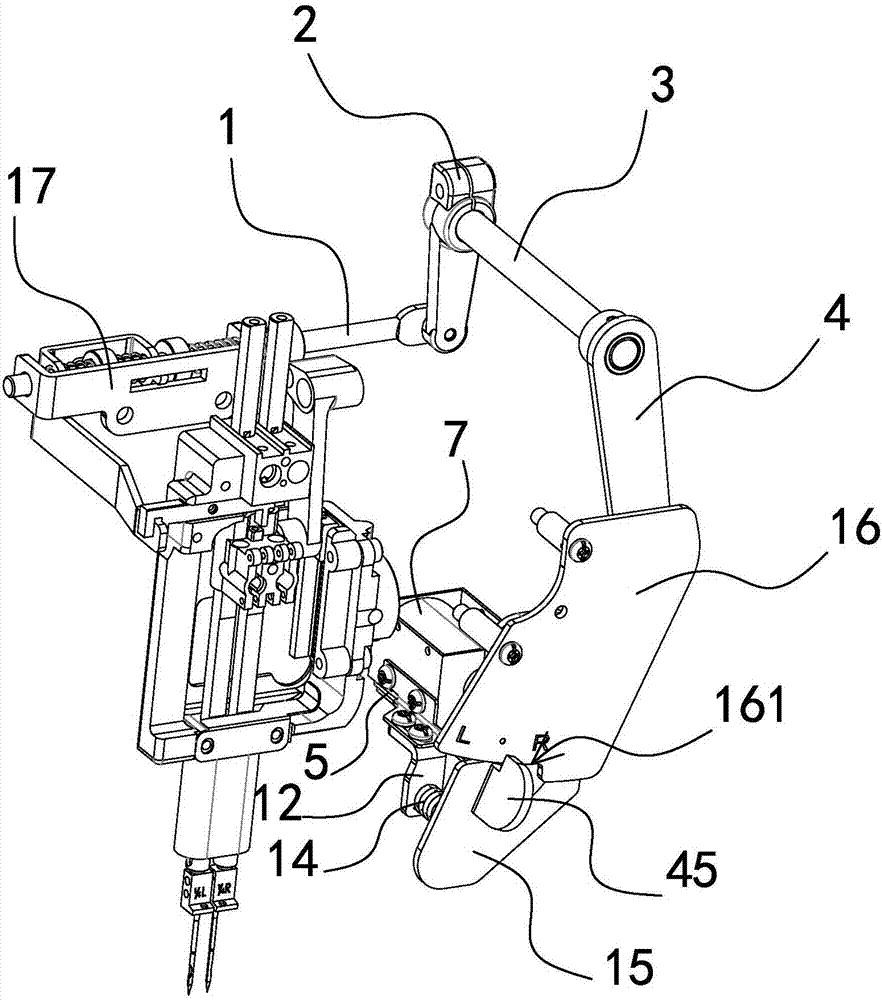

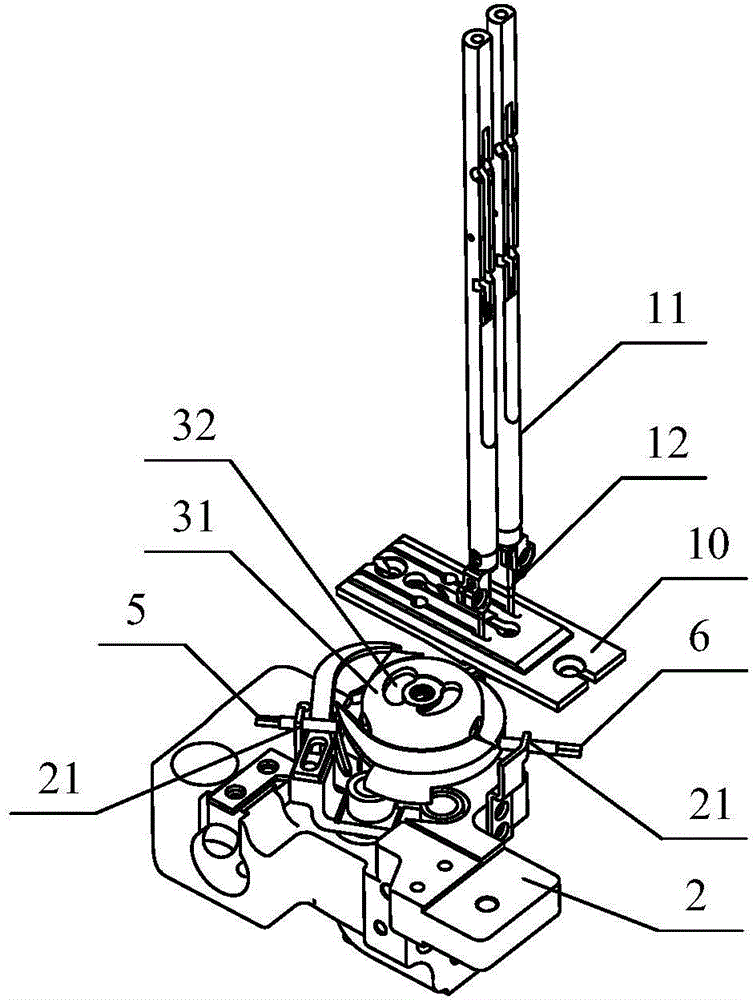

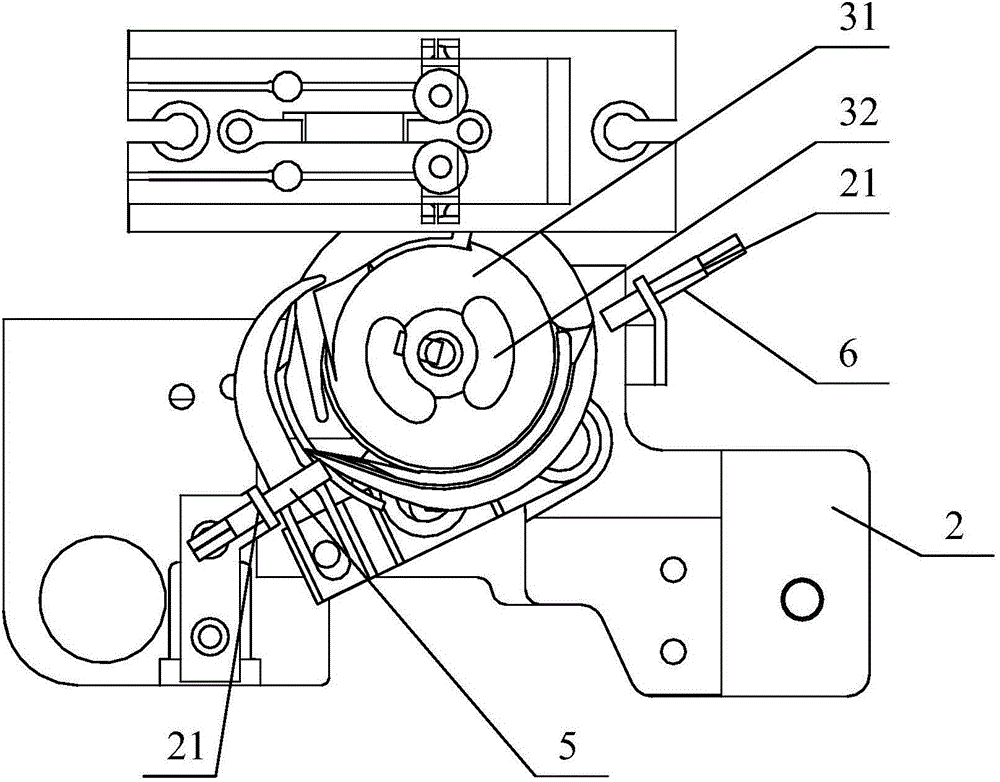

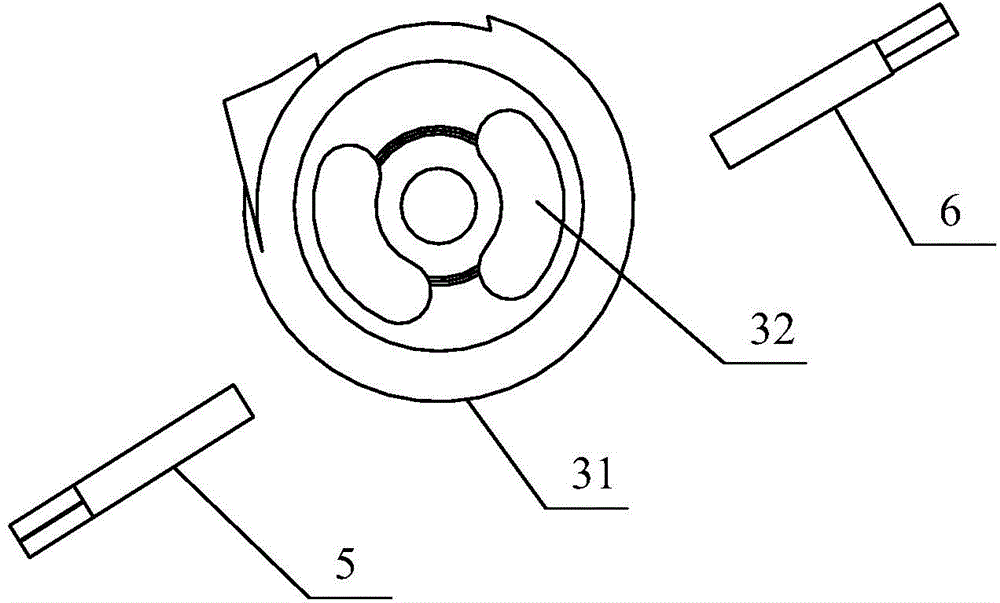

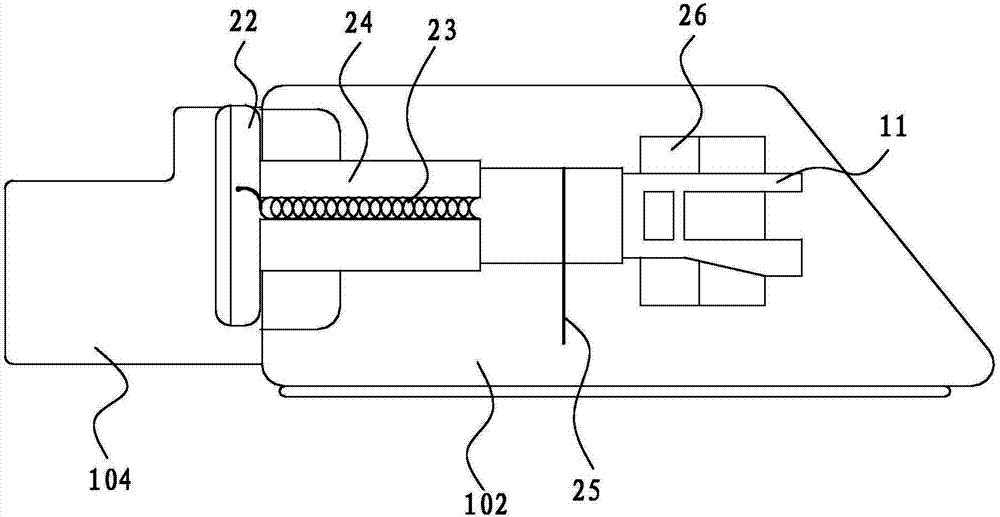

Sewing machine with front lace automatic sewing function for knit goods

InactiveCN1605674AImprove the efficiency of gusset sewingReduce sewing costsProgramme-controlled sewing machinesWorkpiece carriersEngineeringCost of goods

The invention provides an automatic front gusset sewing machine for knitwear. The sewing machine can reduce the troubles in the manual sewing operation, improve the efficiency of the sewing operation, reduce the sewing cost, and can automatically carry out high-quality stitching on the knitwear. Sewn gusset. The sewing machine is an automatic front gusset sewing sewing machine (100) for knitwear with two needles (12, 13) moving up and down on the sewing machine main body (10), and has a pair of left and right brackets (20) and a movable pressing cloth. body (30); a pair of brackets (20) on the left and right are connected to the mechanism that makes it move to the front and back direction of the sewing machine body (10) and the mechanism that makes it lift up and down; the movable body (30) is pressed by Cloth member (31) and the mechanism that expands the opposing interval of this cloth pressing member (31) are constituted, and this cloth pressing member (31) is oppositely arranged at the front end of each bracket (20), and above-mentioned bracket (20) Push the cloth (15) to be sewn on the workbench (14) when descending.

Owner:HASHIMA

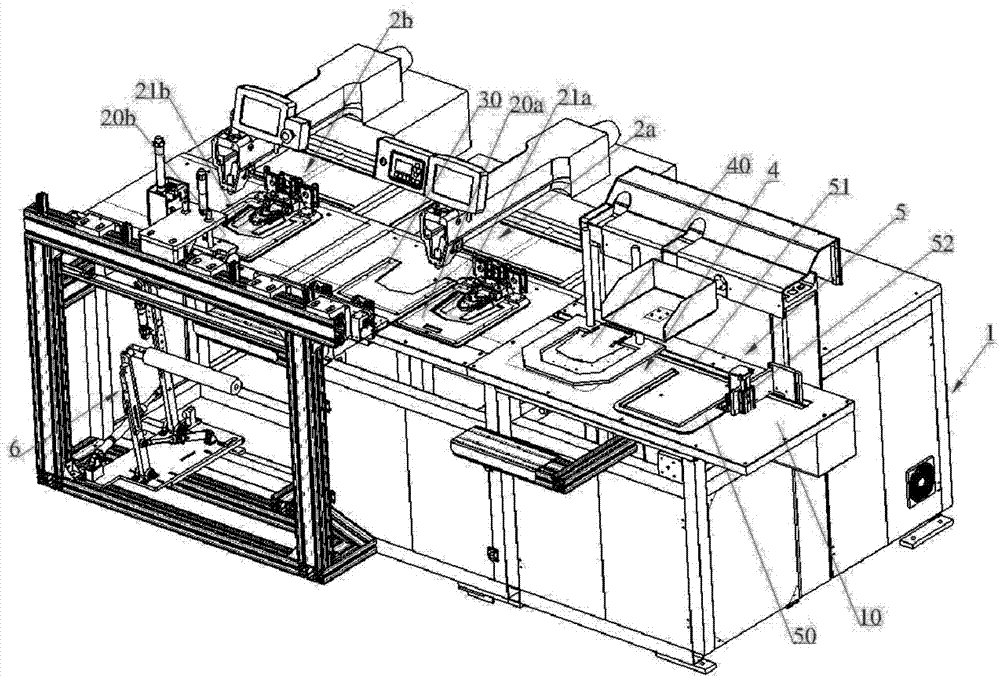

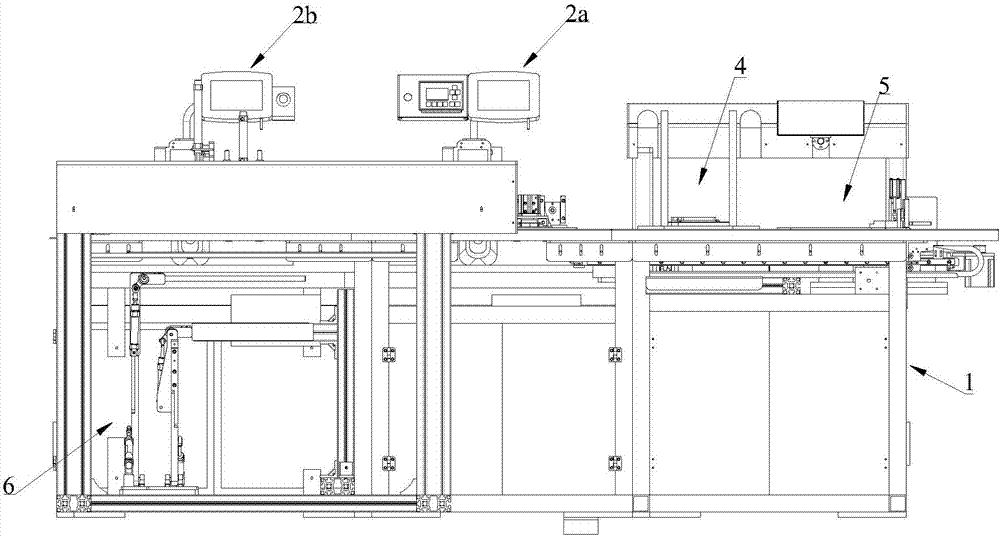

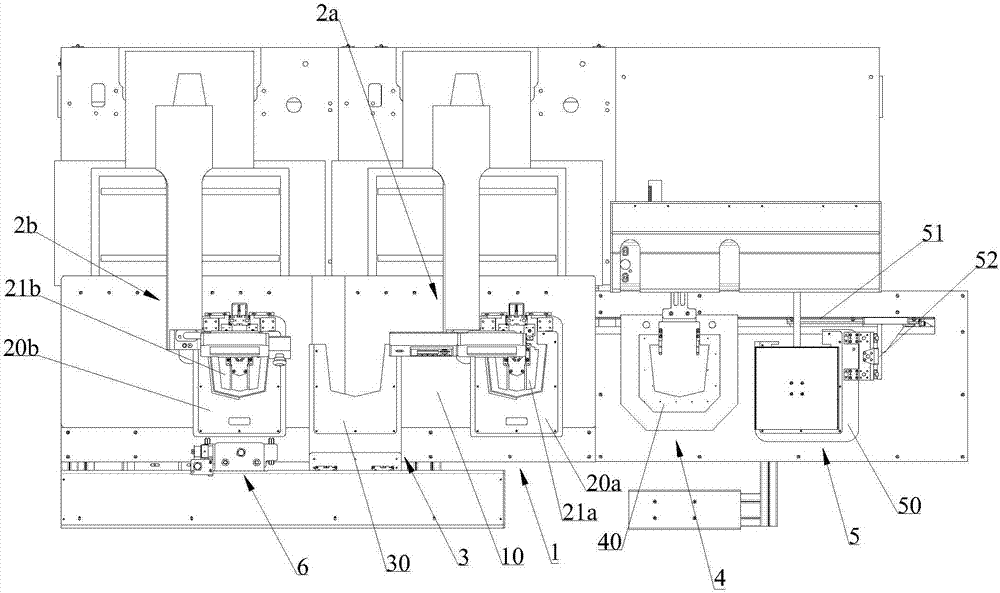

Automatic sewing mechanism and automatic sewing method

ActiveCN105908384AImprove sewing efficiencyAvoid manual controlsProgramme-controlled sewing machinesWork-feeding meansEngineeringMechanical engineering

The invention discloses an automatic sewing mechanism and an automatic sewing method. The automatic sewing mechanism comprises a machine table, a control device, a material grabbing device, a detecting device, a material moving device and a sewing device. A working tabletop is arranged on the machine table. The material grabbing device is arranged on the machine table. A control mechanism is connected to the material grabbing device and used for controlling the material grabbing device to grab cut parts and to send the cut parts onto the working tabletop. A detecting part of the detecting device is arranged on the machine table and located above the machine table. The control device is connected to the detecting part and used for controlling the detecting part to obtain the selvage positions of the cut parts of the working tabletop. The control device generates the movement track of the cut parts according to the obtained selvage positions. The material moving device is arranged on the machine table. The control device is connected to the material moving device and used for controlling the material moving device to press the cut parts and controlling a material driving device to drive the cut parts to move according to the movement track. The sewing device is arranged on the machine table and controlled to sew the cut parts. By means of the automatic sewing mechanism, time and labor are saved, and production efficiency is high.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

Multi-handpiece pocket pasting machine

ActiveCN107881661AImprove sewing efficiencyWork-feeding meansCombination sewing machinesMechanical engineeringCotton material

The invention discloses a multi-handpiece pocket pasting machine. The machine is high in efficiency, and multiple pieces of thread with different colors can be sewed on a pocket. The machine comprisesa rack and two or more handpieces which are arranged on the rack in the front and back direction at intervals, each handpiece comprises a machine needle which is used for sewing a thread on the pocket, and the machine further comprises first material conveying devices which are arranged among two or more handpieces and used for conveying cloth from a front handpiece to a back mechanism; each first material conveying device comprises a first material conveying plate which can slide relative to the rack in the front and back direction, the rack has a working surface which is used for bearing the cloth, and the first material conveying plates are located above the working surface; the machine has a material conveying state, and in the material conveying state, the first material conveying plates are located at the lowest position to drive the cloth between the first material conveying plates and the working surface to move.

Owner:SUZHOU HANDLEY ELECTROMECHANICAL TECH CO LTD

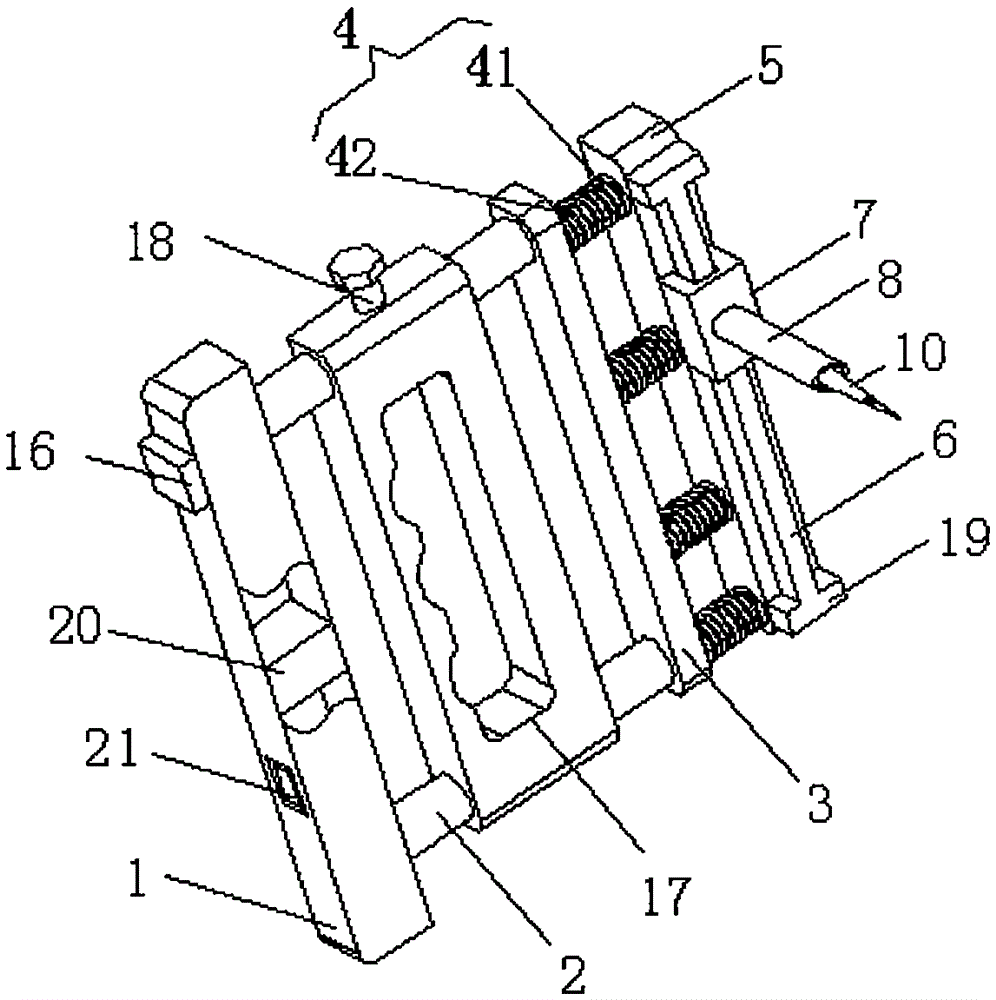

Multilayer carbon cloth stitching device

ActiveCN105420933AStitching achievedImprove sewing efficiencyProgramme-controlled sewing machinesWork-feeding meansAcupuncture needlesYarn

The invention discloses a multilayer carbon cloth stitching device which comprises an acupuncture mechanism for conducting pre-acupuncture and stitching and needling, a latching mechanism, a horizontal workbench for clamping carbon cloth and a control system. A main shaft of the acupuncture mechanism is driven by a stepper motor and drives two eccentric wheels to rotate, the eccentric wheels drive a connection rod, the connection rod is connected with needle rods, one of the needle rods is a pre-acupuncture needle rod, the other one is a needling needle rod, and the two needle rods conduct reciprocating movement under the drive of the stepper motor; a main camshaft of the latching mechanism is connected with the stepper motor, the main camshaft is provided with two cams, and the main camshaft drives a bearded needle on a subsidiary camshaft to conduct reciprocating swing and axial reciprocating movement and conducts synchronous rotation with the acupuncture mechanism; the workbench is composed of an X-direction moving platform and a Y-direction moving platform, and the stepper motor is arranged on the workbench so as to achieve movement of a cloth containing supporting plate. By means of the pre-acupuncture, friction generated when carbon yarn penetrates through the carbon cloth is reduced, damage to the carbon yarn is lowered, and stitching of the multilayer carbon cloth is achieved.

Owner:TIANJIN POLYTECHNIC UNIV

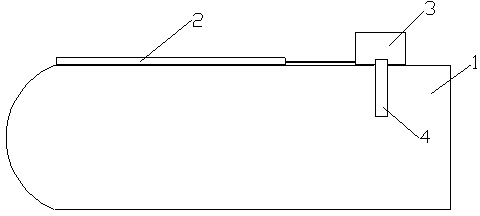

Two-fold garment belt loop sewing template

InactiveCN104562460AEasy flipSimple structureWork-feeding meansProduction qualityComputer engineering

The invention relates to a two-fold garment belt loop sewing template, and belongs to the technical field of garment production. The sewing template solves problems in that prior art that the garment belt loop sewing efficiency is low, and special tools are provided. The two-fold garment belt loop sewing template comprises a bottom plate and a panel which are hinged with each other; a guide groove matched with a belt loop sewing track is formed in the bottom plate and the panel; a reversible turnover plate is arranged on the bottom plate; the back surface of the turnover plate is provided with an upper compression plate and a folding plate which is arranged in the turnover plate in a sliding mode; when cloth to be sewed is pressed against the compression plate, the folding plate can be pushed to fold the cloth; a lower compression plate is arranged at a position corresponding to the upper compression plate after turnover of the turnover plate on the bottom plate; and a lower compression groove used for positioning the lower compression plate is formed in the lower compression plate. The two-fold garment belt loop sewing template has the advantages of simple structure, less working procedures, high production quality, and high efficiency.

Owner:JIAXING UNIV

Button conveying device

Owner:JUKI CORP

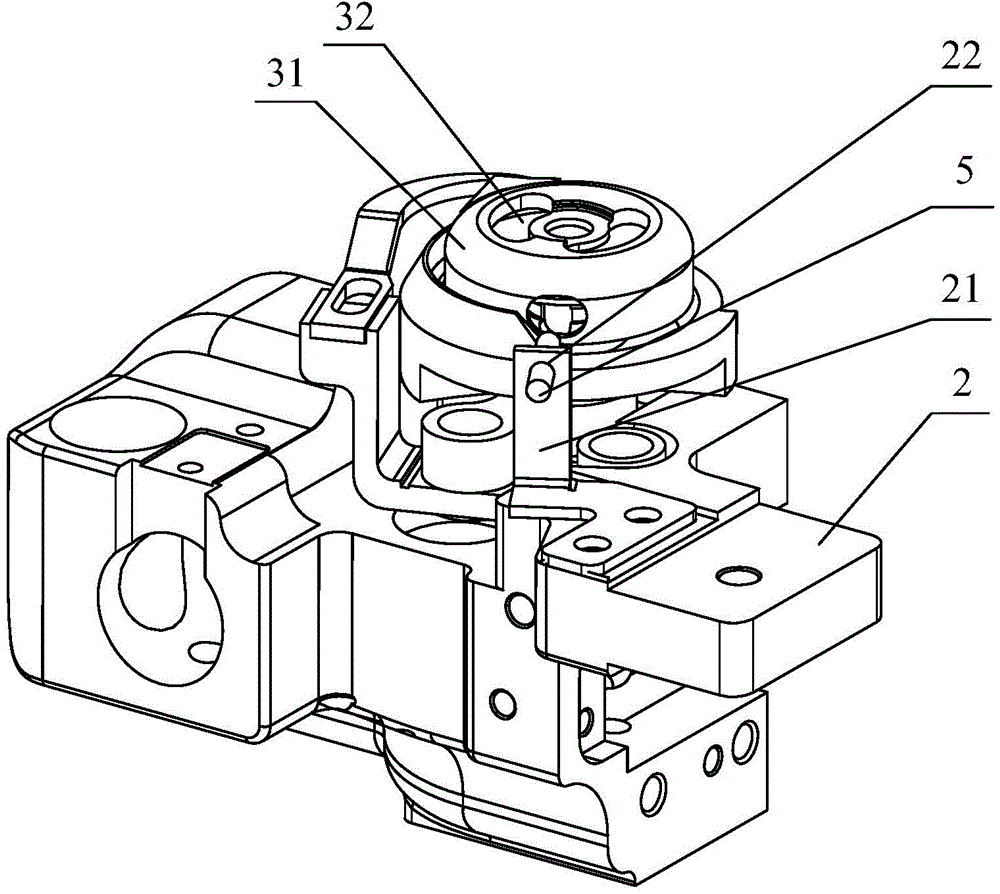

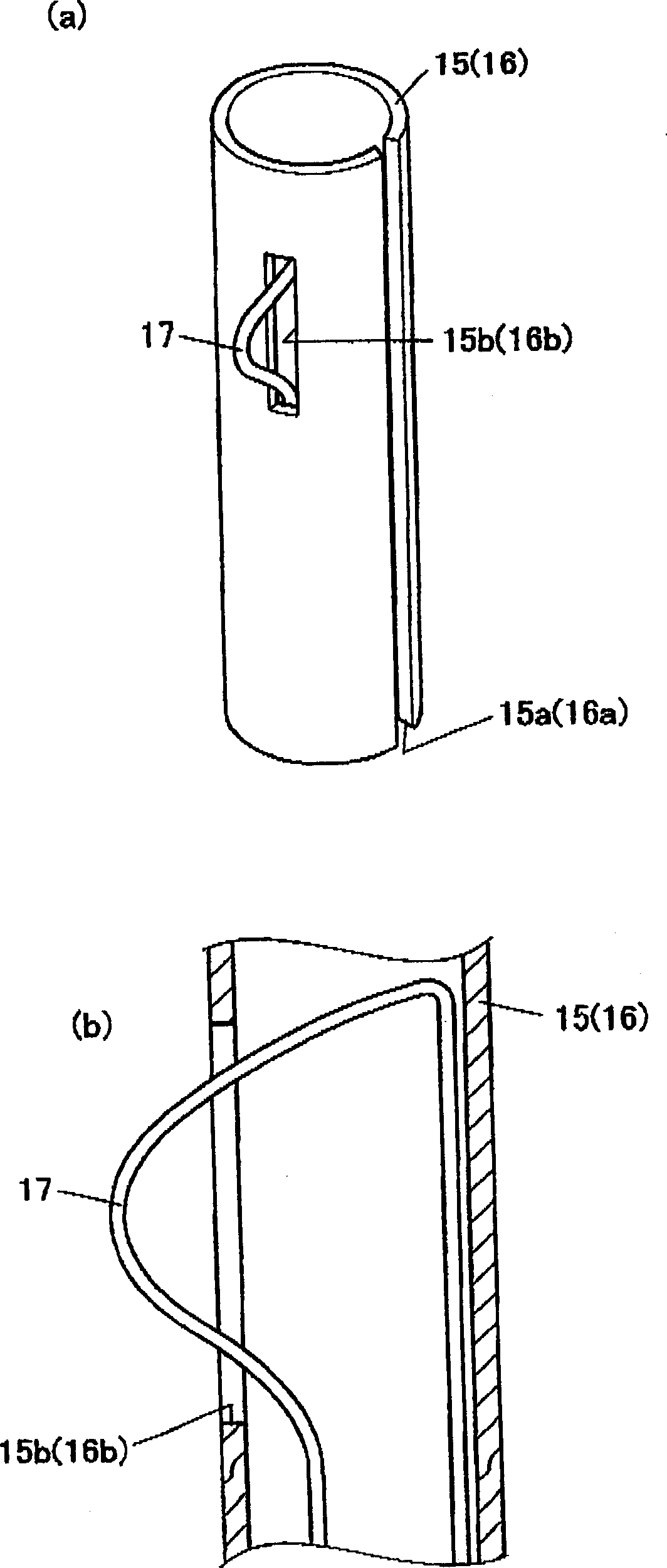

Needle rod clutching mechanism of sewing machine and double-needle machine

ActiveCN106948094ASimple structureEasy to operateProgramme-controlled sewing machinesNeedle barsElectric controlWrench

The invention provides a needle rod clutching mechanism of a sewing machine and a double-needle machine and belongs to the technical field of double-needle machines, aiming at solving the problems of an existing needle rod clutching mechanism of the sewing machine that the separation and resetting stability of a needle rod is poor and the needle rod clutching mechanism easily has faults. The needle rod clutching mechanism of the sewing machine comprises a sliding shaft, wherein one end of the sliding shaft is connected with a separation assembly and the other end of the sliding shaft is connected with a resetting assembly; the separation assembly comprises a rotary shaft, a wrench and a supporting plate assembly mounted on a machine head; the wrench is provided with a pulling sheet and a limiting column; a detection assembly is arranged between the supporting plate assembly and the wrench; the detection assembly is used for detecting leftward and rightward swinging of the wrench, generating left and right separation signals and sending the signals to electric control of the sewing machine; the supporting plate assembly is fixedly provided with a driver which is in electric control connection with the sewing machine. The clutching mechanism has the advantages of simple and beautiful structure, convenience for operation, automatic resetting and good separation and resetting stability.

Owner:JACK SEWING MASCH CO LTD

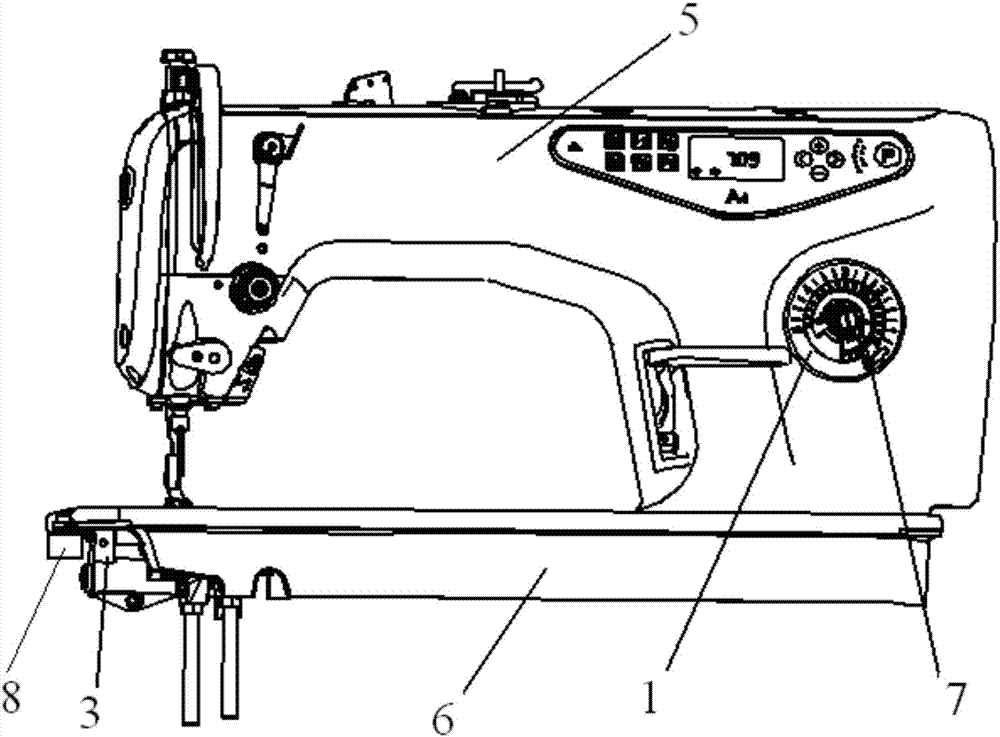

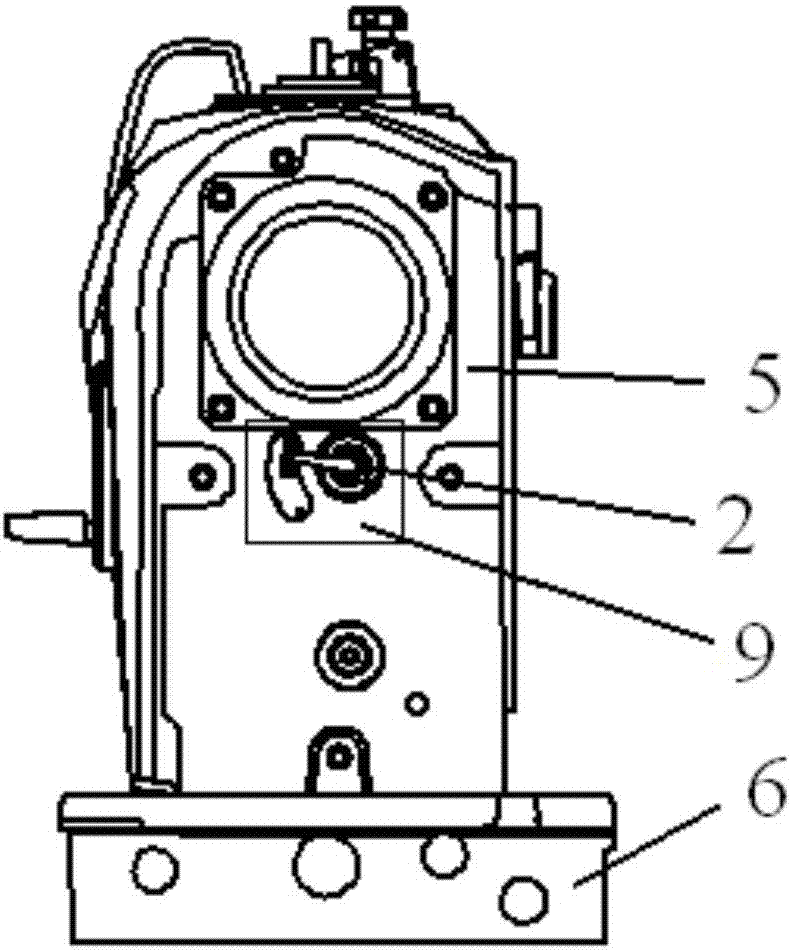

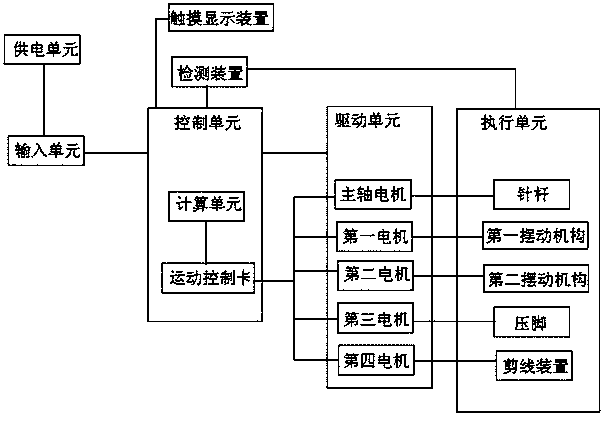

Industrial sewing machine and sewing method

InactiveCN104372530AImprove sewing efficiencyFlexible configurationProgramme-controlled sewing machinesSewing-machine control devicesControl signalDisplay device

The invention relates to an industrial textile processing machine, in particular to an industrial sewing machine and a sewing method. The industrial sewing machine comprises an industrial sewing machine body which is provided with a handpiece. The handpiece is connected with a frame needle through a needle rod. A presser foot matched with the frame needle is arranged at the lower end of the handpiece. The industrial sewing machine further comprises an input unit, a control unit and a drive unit. The drive unit is connected with the control unit and an execution unit and used for receiving and amplifying a control signal and outputting the control signal to the execution unit matched with the drive unit for execution. Compared with the prior art, the industrial sewing machine has the advantages that the modular unitization structure is adopted, all units are internally independent and respectively systematic, the degree of integration is high, the structure is simple, errors are not likely to occur in the sewing process by adoption of the automatic sewing method, sewing is attractive, the sewing efficiency of the industrial textile processing machine is improved due to the high rotation speed of a spindle, and by adoption of a touch screen display device, operation is convenient.

Owner:SHANGHAI POWERMAX TECH INC

Full-automatic multi-decoration strip sewing equipment

PendingCN108642733ASimple structureEasy to useWorkpiece carriersWork-feeding meansHuman–computer interactionControl equipment

The invention discloses a full-automatic multi-decoration strip sewing equipment, which comprises a frame, a multi-needle sewing machine and a control panel, wherein the control panel is provided witha man-machine interaction interface for displaying the equipment state and controlling the equipment. The multi-needle sewing machine is fixedly arranged on the left part of the frame. The equipmentis characterized by also comprising a decorative strip feeding device, a feeding device and a shearing device. A pull cylinder is arranged on the multi-needle sewing machine. The decorative strip feeding device is arranged on the frame and above the multi-needle sewing machine. The decorative strip feeding device is used for making the decorative strip to be sewed to be in a relaxed state to enterthe pulling cylinder of the needle sewing machine to roll the edge. The feeding device is arranged on the frame, and the feeding direction of the feeding device is arranged along the left and right direction. The feeding device is used for feeding the cloth to needle sewing machine to be sewed with the decorative strips with rolled edges, and feeding the cloth sewn with the decorative strips outof the multi-needle sewing machine. The shearing device is used for cutting off the corresponding decorative strips after the sewing is finished.

Owner:CHANGZHOU ZHIGU ELECTROMECHANICAL TECH CO LTD

Sewing machine with templates easy to replace

ActiveCN104047126ASave complex operation stepsRealize non-stop continuous workWork-feeding meansControl systemEmbedded system

The invention discloses a sewing machine with templates easy to replace. The sewing machine with the templates easy to replace comprises a handpiece for sewing, an XY feeding mechanism and a control system, the XY feeding mechanism is provided with a feeding base for mounting of the templates, the feeding base is provided with at least one template mounting position for connecting the templates, and each template mounting position is provided with a sensor for detecting the templates and a fixing mechanism for locking the templates. The sensors detect the templates mounted in the template mounting positions, and then the control system controls the fixing mechanisms to lock put-in templates. The control system controls the fixing mechanism to loosen the templates after sewing procedures are executed to the templates.

Owner:NINGBO SUPREME ELECTRONIC MASCH INC

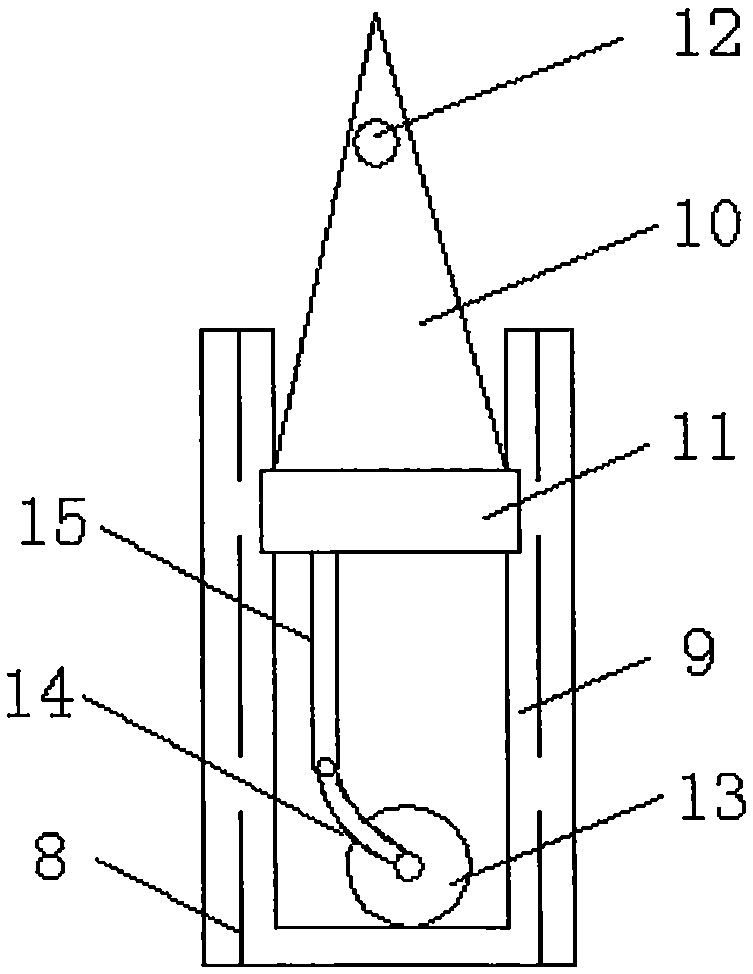

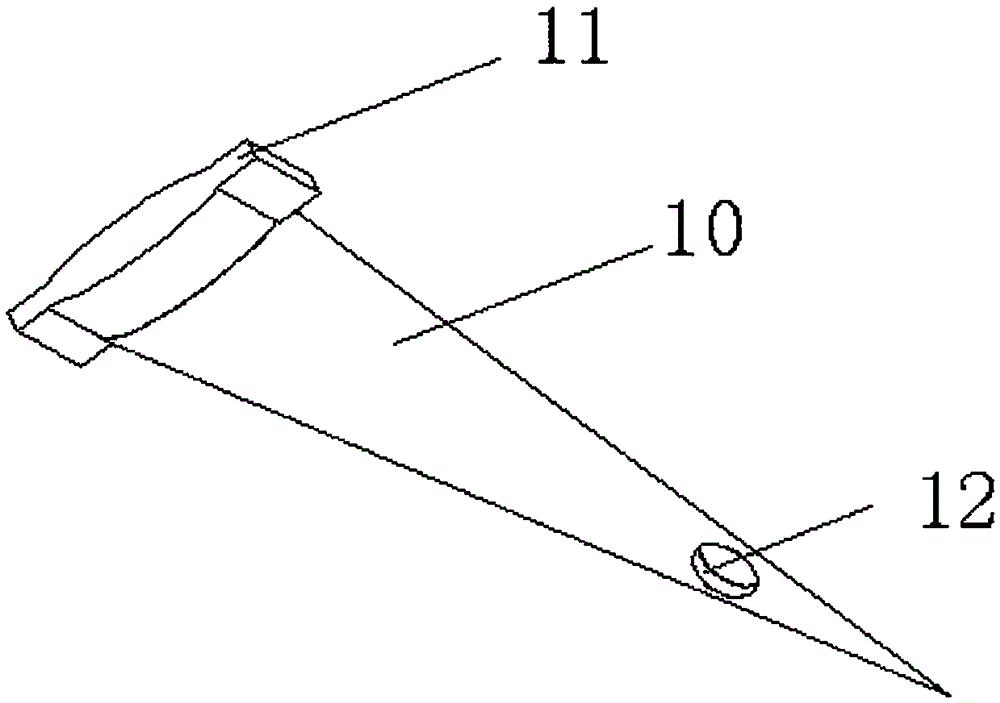

Suturing instrument for surgical operations

InactiveCN105662501AEasy to useReduce laborSuture equipmentsSurgical needlesLinear motionSurgical operation

The invention discloses a suturing instrument for surgical operations. The suturing instrument comprises a first support and a needle head, wherein the first support is connected with a second support by two connecting posts on one side surface; a needle hole is formed in the tail end of the needle head; the second support is connected with a mounting board by telescopic devices; a slide rail is arranged on the surface of the mounting board; a linear motor is movably clamped on the surface of the slide rail; a hollow connecting rod is arranged on the surface of the linear motor. The suturing instrument for surgical operations adopts a hand-held handle for suturing, so that convenience is brought for medical staff; the linear motor conducts linear motion on the slide rail; the needle head is driven by a crank shaft and a rocker to reciprocate in a chute of the connecting rod so as to suture a wound; the medical staff can hold the instrument by hand to control the suturing process by virtue of a controller only by threading a stitch thread into the needle hole, so that the degree of automation and the suturing efficiency are high, and the labor capacity of the medical staff is reduced.

Owner:仉志军

Bottom line detection correlation type photoelectric control system for sewing machine and control method

ActiveCN104372539AGuaranteed uniformityGuaranteed aestheticsBobbin-winding devicesElectric machineryInfrared

The invention provides a bottom line detection correlation type photoelectric control system for a sewing machine. The system comprises an electric control module, a rotating shuttle and a motor, wherein the rotating shuttle comprises a shuttle casing and a shuttle core, the system further comprises an infrared transmitting tube and an infrared receiving tube, an infrared inlet and an infrared outlet are formed in the shuttle casing, and a through hole is formed in a wrapping post of the shuttle core; when the shuttle core is not in the casing, the infrared inlet and the infrared outlet are communicated; when the quantity of bottom lines with which the wrapping post of the shuttle core is wounded is not enough, the through hole is exposed, and the infrared inlet and the infrared outlet are communicated through the through hole; the electric control module is connected with the infrared transmitting tube and the infrared receiving tube through a signal conditioning and controlling circuit and connected with the motor through an output circuit. In the control system, the electric control module can judge if the shuttle core is missing or the quantity of the bottom lines on the shuttle core is not enough according to the intensity of a signal output to the signal conditioning and controlling circuit by the infrared receiving tube, and accordingly sewing efficiency and quality are improved.

Owner:BULLMER ELECTROMECHANICAL TECH

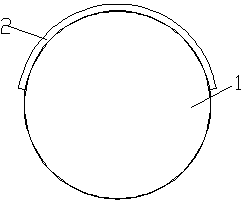

3D (three-dimensional) sewing machine

The invention relates to a 3D (three-dimensional) sewing machine, which comprises a machine needle, a rotating shuttle, a transmission device and a driving device, wherein the driving device respectively and synchronously drives the machine needle and the rotating shuttle through the transmission device, the rotating shuttle is arranged in a work table, the work table is in a cylindrical shape or a circular arc shape, positioning blocks matched with the cylindrical or arc-shaped work table are arranged on the cylindrical or circular arc-shaped work table and are connected with a positioning block driving device, the positioning block driving device is arranged on an annular screw rod connected with the work table and comprises a first driving device, a second driving device and a controller, the first driving device enables the positioning blocks to horizontally move, the second driving device moves along the annular lead screw, and the controller coordinates the work of the first driving device and the second driving device. Because the structure of the work table is in the cylindrical shape or the circular arc shape, the work table can more perfectly adapt to 3D objects to be sewed. The defect that a plane work table cannot sew 3D or irregular-shaped objects can be overcome, the sewing efficiency is improved, the cost is reduced, and meanwhile, the quality of sewed products maintains the consistency.

Owner:贺传均

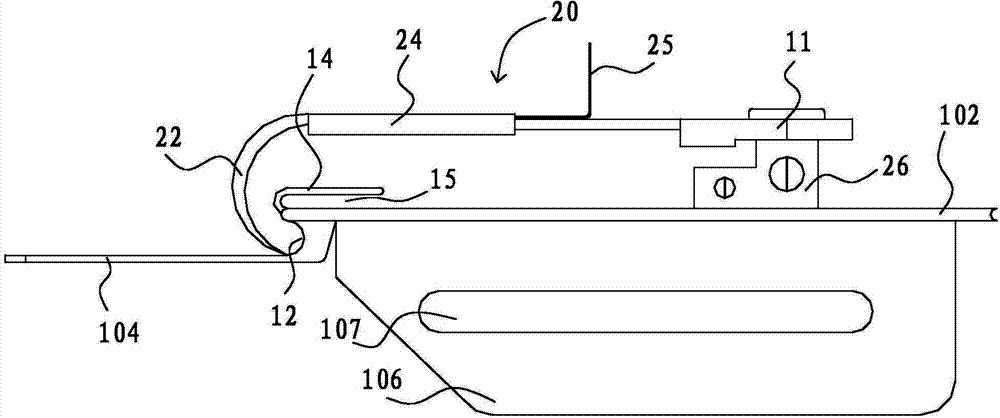

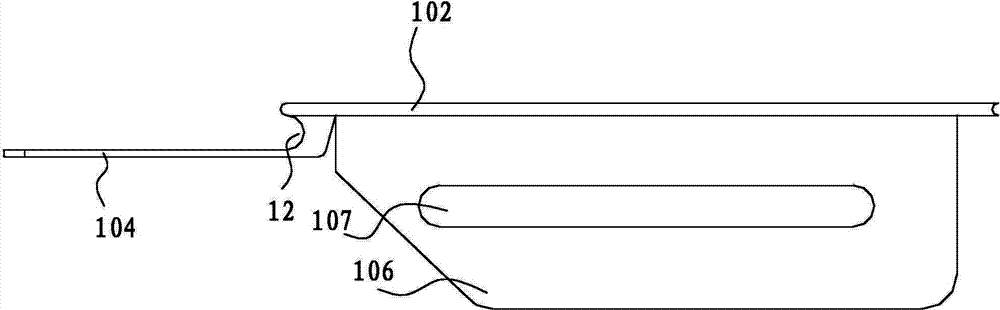

Hemming sewing auxiliary device and hemming sewing method

The invention discloses a hemming sewing auxiliary device and a hemming sewing method. The auxiliary device comprises a base panel and a backing mechanism, wherein the base panel is provided with a groove, the fixed end of the backing mechanism is fixed to the base panel and can be turned over relative to the base panel, a bent backing is arranged at the other end of the backing mechanism and can be clamped to the groove, a seam allowance backing is fixed between the groove and the fixed end of the backing mechanism, a strip-shaped containing space is formed by the seam allowance backing and the base panel, and the opening of the strip-shaped containing space faces the fixed end of the backing mechanism. According to the method, one end of a cutting piece stretches into the strip-shaped containing space, the other end of the cutting piece is wound around the seam allowance backing and located on one side of the groove, then a hem is formed at one end of the cutting piece, and the groove portion is pressed by the bent backing to fix the cutting piece. The hemming sewing auxiliary device is used in cooperation with a sewing device, hemming sewing can be completed just through one procedure, and sewing efficiency is greatly improved.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Surgical suture fixing box for operating room nursing

InactiveCN110584731AMobile will notKeep moistSuture equipmentsSurgical needlesLiquid storage tankOperating theatres

The invention discloses a surgical suture fixing box for operating room nursing. The fixing box comprises a base and a shell; a partition plate is vertically fixed in the shell; the partition plate divides the interior of the shell into a left cavity and a right cavity from left to right; a winding roller and a pay-off reel are sequentially fixed to the right cavity from right to left; one end ofa first fixing shaft horizontally extends out of the side wall of the shell and is fixedly provided with a first gear and a first belt wheel; the first gear is fixed to a first fixing shaft through aone-way bearing; a second fixing shaft is fixed to the outer side wall of the shell; a second gear matched with the first gear is fixed on the second fixing shaft; a liquid storage tank is fixed on the bottom end face of the left cavity; a third fixing shaft is fixed into the liquid storage tank through a bearing; and the third fixing shaft is sleeved with a wetting roller. The fixing box is reasonable in structure, medical staff can accurately and quickly take out surgical sutures with the required length from the surgical suture fixing box when preparing the surgical sutures, the working efficiency is improved, and the surgical sutures can be wetted when being taken out so as to guaranteed that the surgical sutures are always kept wet in the wound suturing process.

Owner:李荣荣

Different stitch length conversion device in sewing system

The invention discloses a different stitch length conversion device in a sewing system. The different stitch length conversion device comprises a main motor, a speed ratio conversion device and a disc sewing machine. The speed ratio conversion device comprises a main driving wheel, a motor shaft of the main motor is sleeved with the main driving wheel, and the main driving wheel is sleeved with a first conveying belt and a second conveying belt. The speed ratio conversion device further comprises a needle rake moving device and a disc moving device, the needle rake moving device is sleeved with the other end of the first conveying belt, and the disc moving device is sleeved with the other end of the second conveying belt. A third gear driving a collar moving needle rake is arranged on the needle rake moving device. The disc moving device is fixed to a disc of the disc sewing machine, and a fourth gear driving the disc to rotate is arranged on the disc moving device. A collar moving needle on the collar moving needle rake and a needle on the disc can do synchronous movement through the first conveying belt and the second conveying belt arranged on the driving belt wheel in a sleeving mode, and conversion from linear stitch length to disc stitch length is achieved.

Owner:NINGBO CIXING

Bottom thread amount detection device and detection method of sewing machine

Owner:JACK SEWING MASCH CO LTD

Automatic cloth transport apparatus and automatic cloth transport line

ActiveCN106868723ASignificant progressGuaranteed normal transmissionCombination sewing machinesSewing-machine elementsEngineeringWorkstation

The invention relates to the technical field of clothing production and sewing, in particular to an automatic cloth transport apparatus and automatic cloth transport line. The automatic cloth transport apparatus comprises a feeding bedplate for holding cloth, a guide rail arranged parallel to the feeding bedplate and a feeding unit arranged on the guide rail in a sliding manner, wherein the feeding bedplate is arranged opposite to a plurality of sewing workstations which are distributed side by side, the guide rail is arranged at one side, away from the sewing workstation, of the feeding bedplate, and the feeding unit can drive the cloth to move on the feeding bedplate. By adopting the automatic cloth transport apparatus, not only can the cloth of a previous sewing workstation be transported to a next adjacent sewing workstation according to the distribution sequence of the plurality of sewing workstations, but also the cloth at one sewing workstation can be directly transported to any designated sewing workstation, that is, the cross-workstation transportation of cloth can be realized without influencing the work of other sewing workstations, the cloth can be high effectively transported among different sewing workstations, the sewing efficiency is improved, and the manpower cost is decreased.

Owner:JACK SEWING MASCH CO LTD

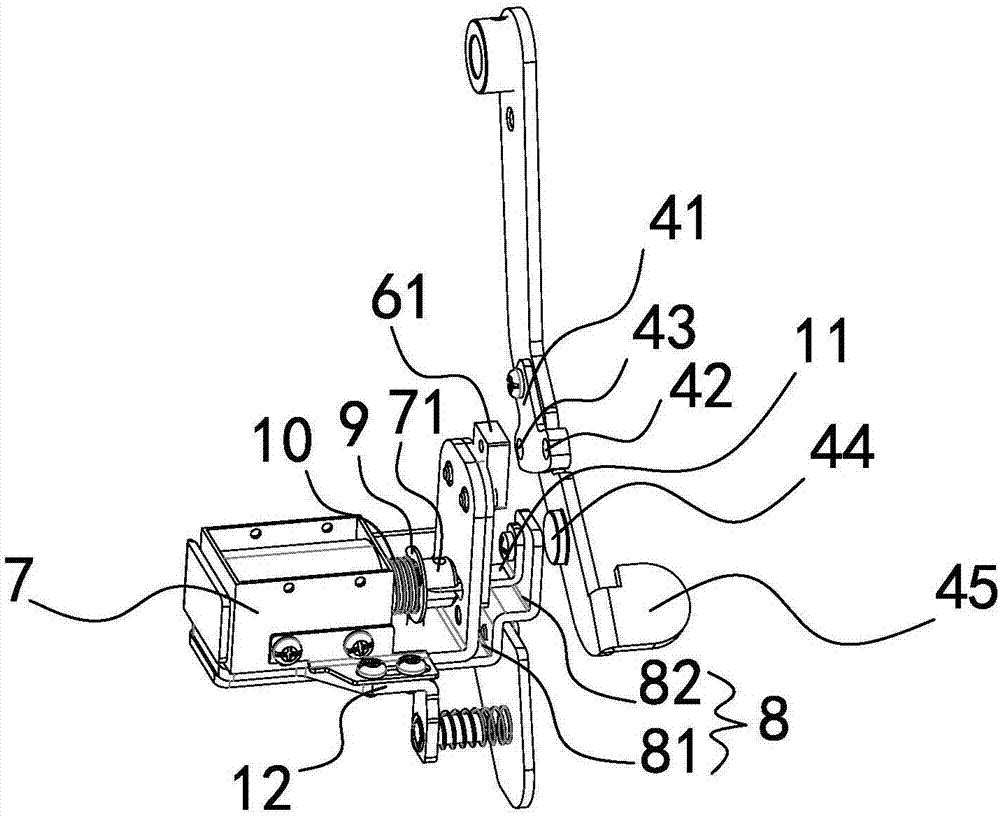

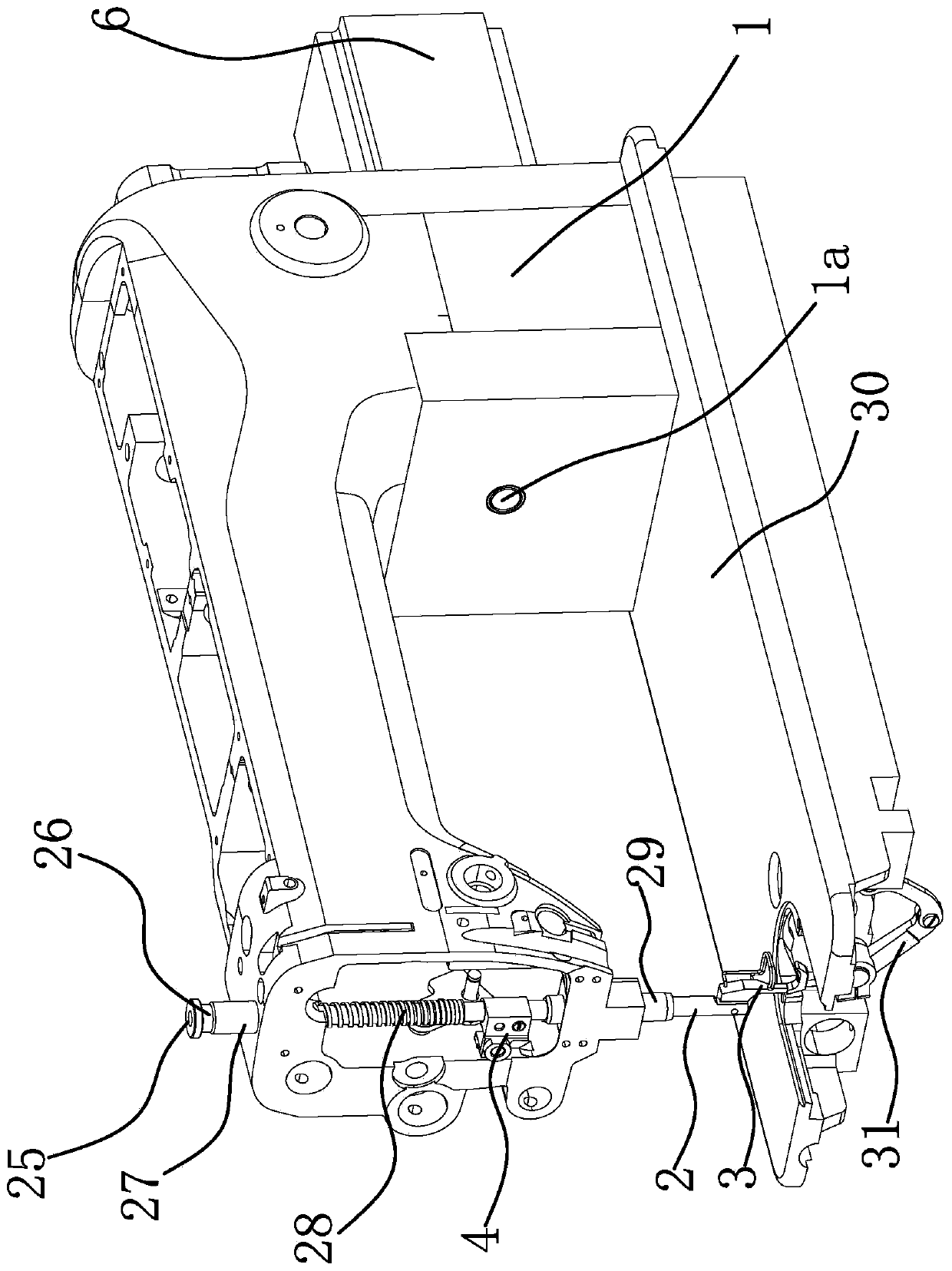

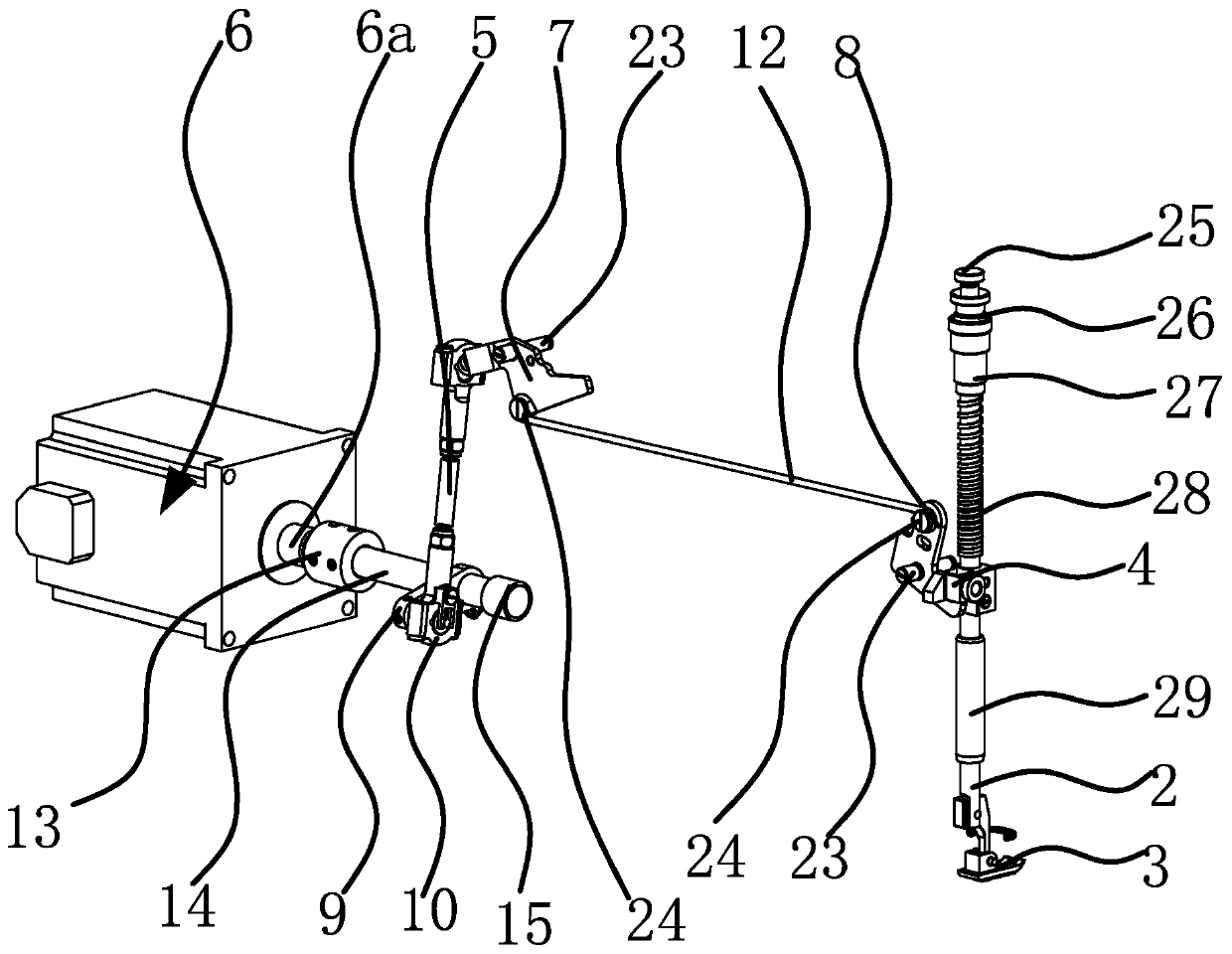

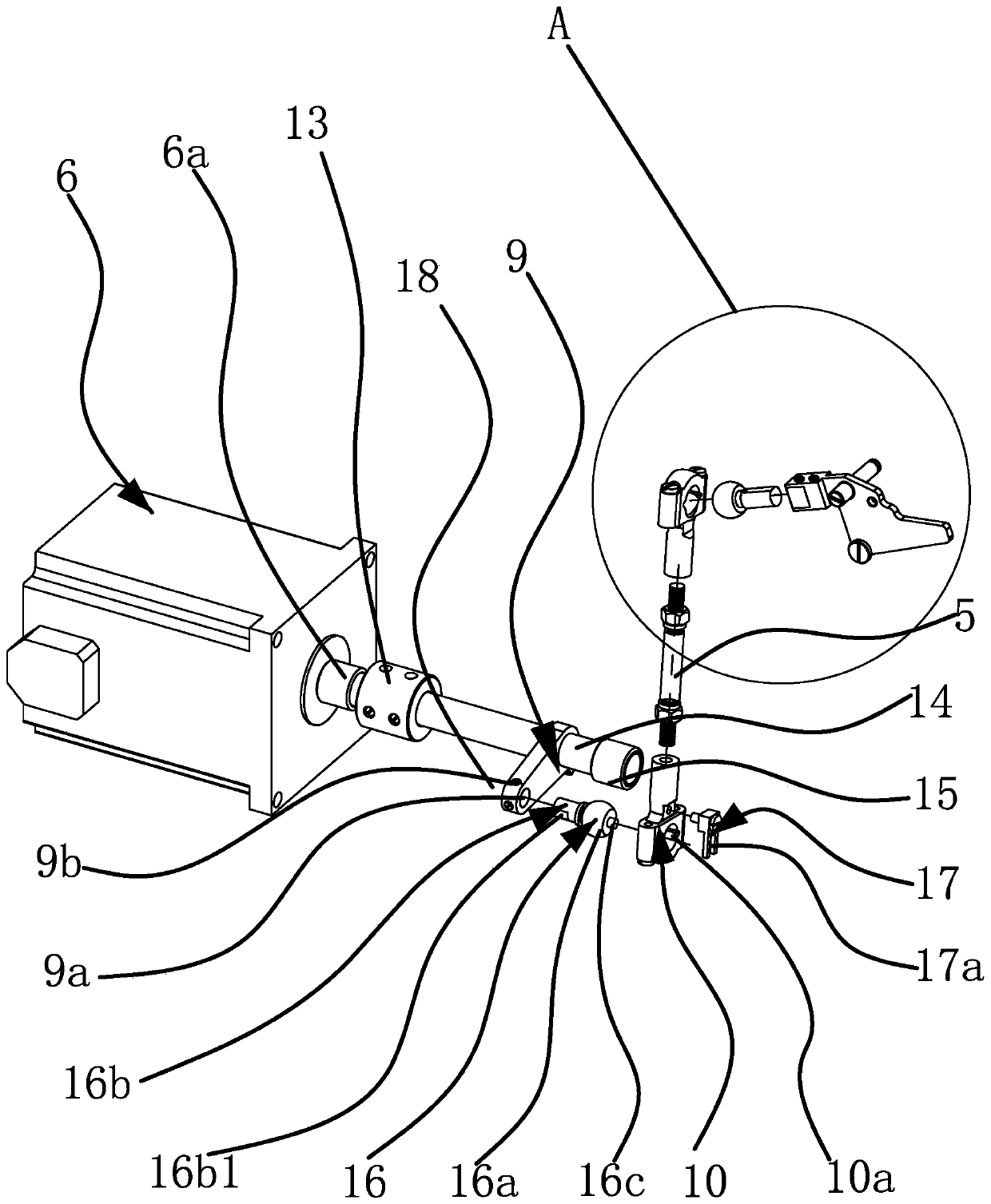

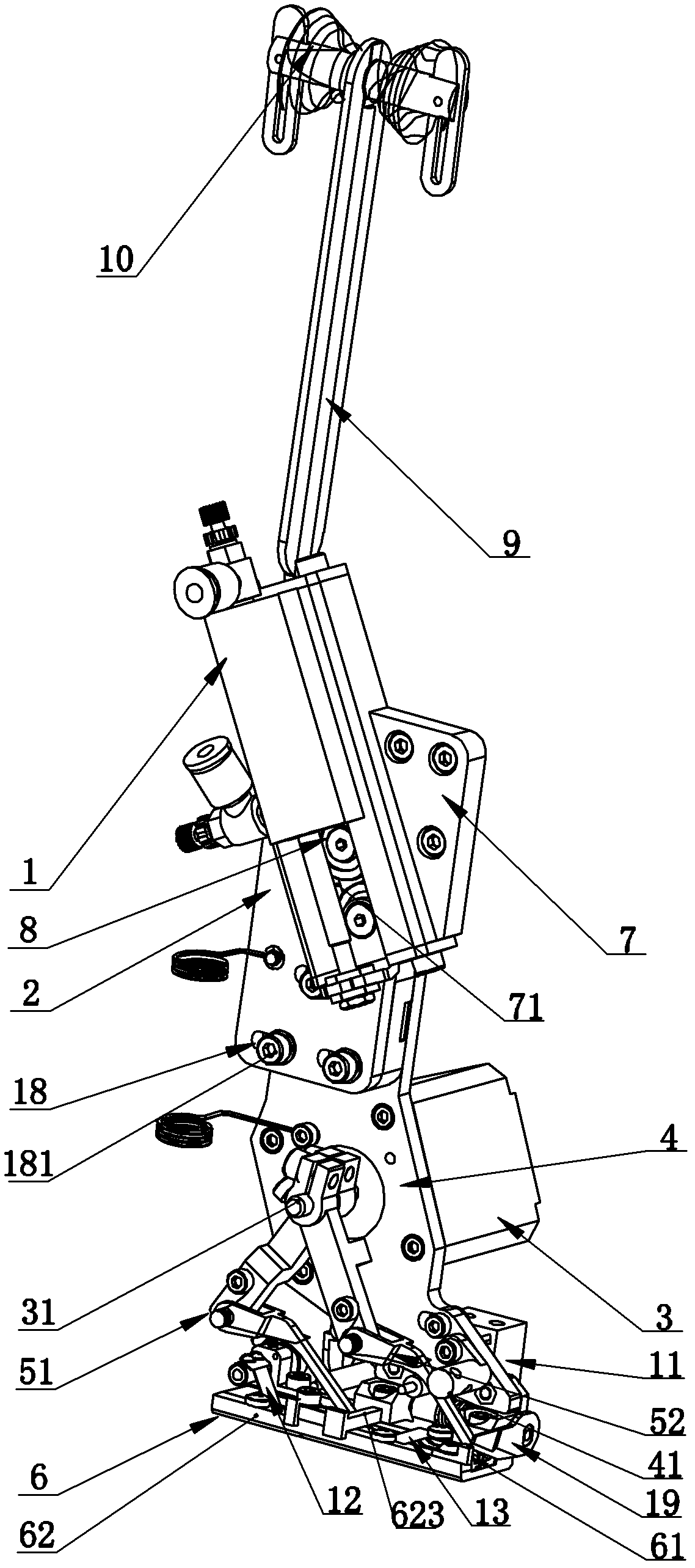

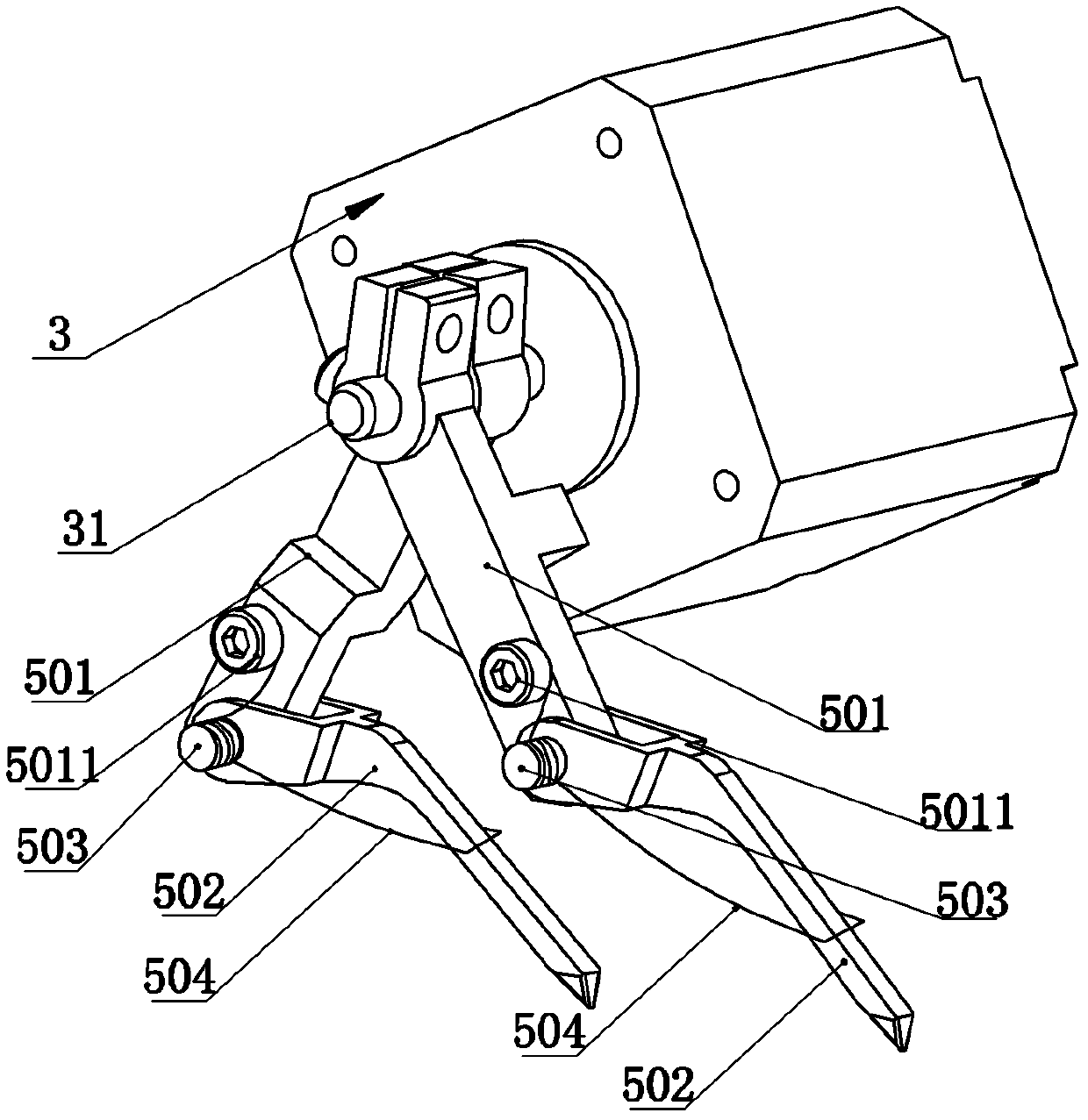

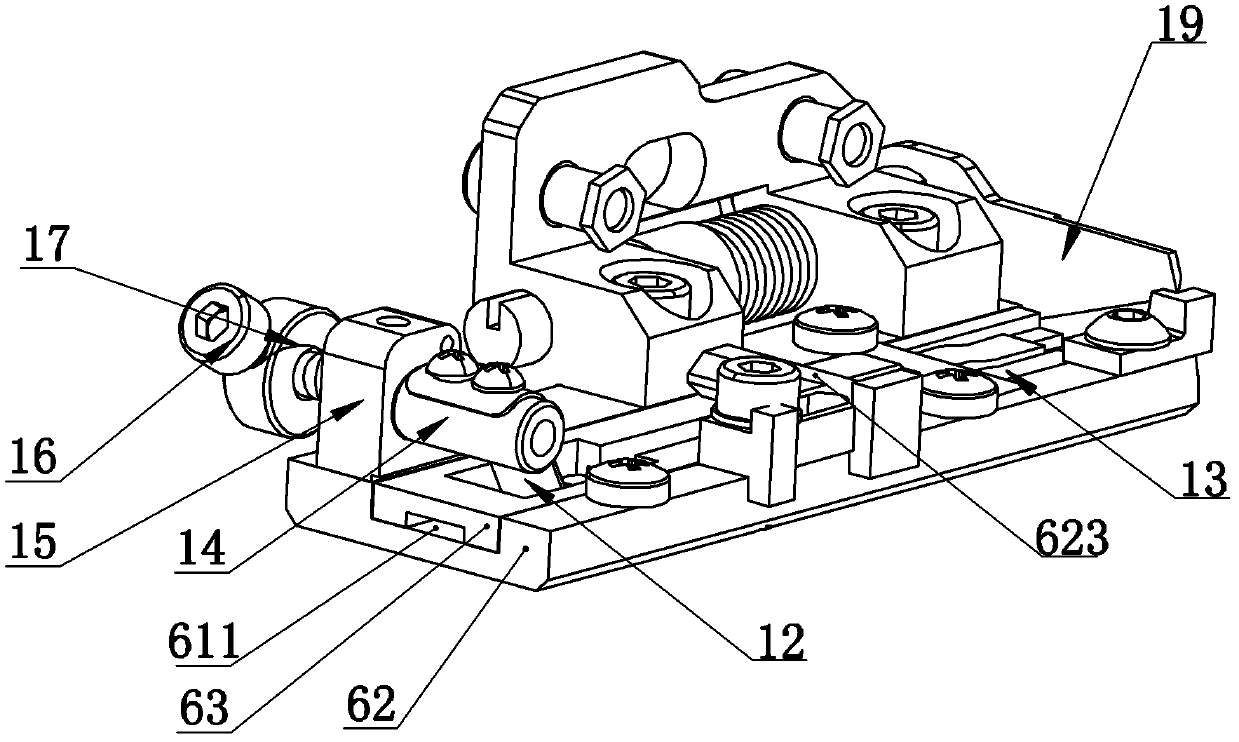

Driving device for automatically lifting presser foot and trimming thread in sewing machine

ActiveCN111534937AReduce machining accuracyReduced installation accuracyNeedle severing devicesSewing-machine control devicesCrankEngineering

The invention provides a driving device for automatically lifting a presser foot and trimming a thread in a sewing machine, and belongs to the technical field of garment manufacturing equipment. The technical problem that an existing driving device for automatically lifting the presser foot and trimming the thread in the sewing machine is unstable in function is solved. The sewing machine comprises a bottom plate, a machine shell, a pressing rod and the presser foot, wherein a guide frame is fixedly arranged on the pressing rod, and a thread trimming assembly is arranged at the bottom of the bottom plate. The driving device comprises a lifting pull rod, a driving part, a left lever and a right lever, wherein a swing crank is connected to an output shaft of the driving part; the lower end of the lifting pull rod is in spherical hinge joint with the outer end of the swing crank through a lower spherical connecting rod; the upper end of the lifting pull rod is in spherical hinge joint with one end of the left lever through an upper spherical connecting rod; the other end of the left lever is connected with one end of the right lever through a lifting connecting rod; the other end of the right lever can abut against the lower side of the guide frame; and the outer end of the swing crank is connected with the thread trimming assembly. The driving device is stable in function, the lifting height of the presser foot can be accurately controlled, and meanwhile the thread trimming function is achieved.

Owner:浙江杰克智能缝制科技有限公司

Paillette feeding device

InactiveCN102168352AImprove sewing efficiencyPrevent disengagementAutomatic machinesAuxillary devicesElectric machineryControl theory

Owner:WENZHOU FEIOU SPECIAL MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com