Different stitch length conversion device in sewing system

A conversion device and needle gauge technology, which is applied in knitting, textiles and papermaking, etc., can solve the problems of missing stitches, prone to wrong stitches, and low work efficiency, so as to avoid wrong stitches, increase sewing efficiency and quality, and save human effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

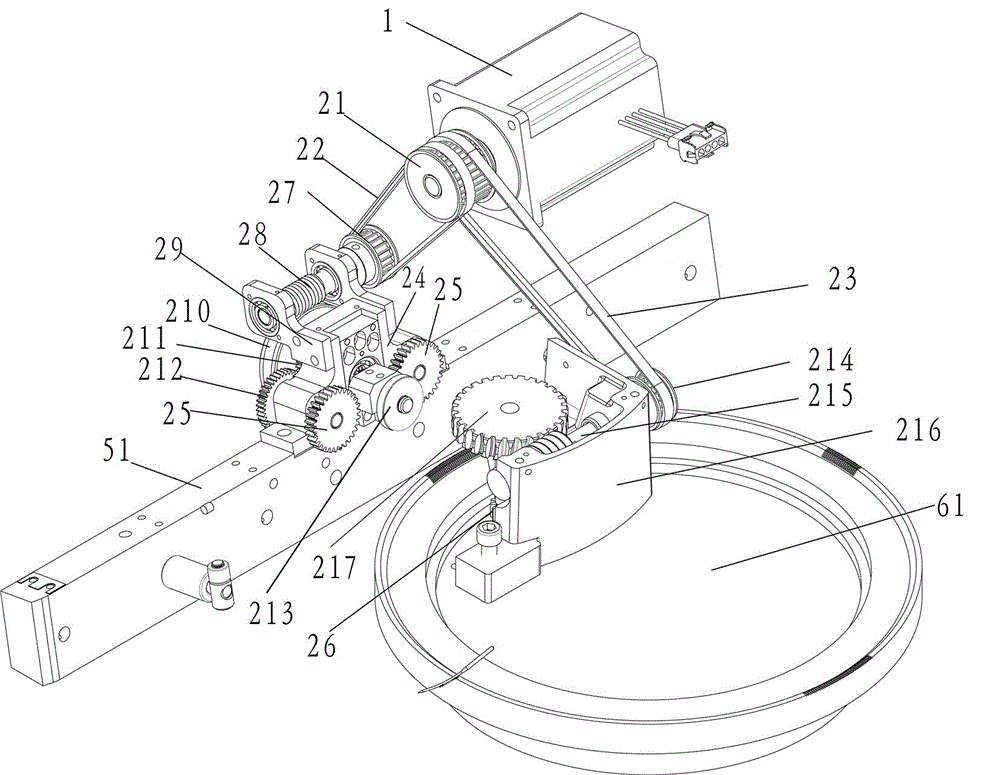

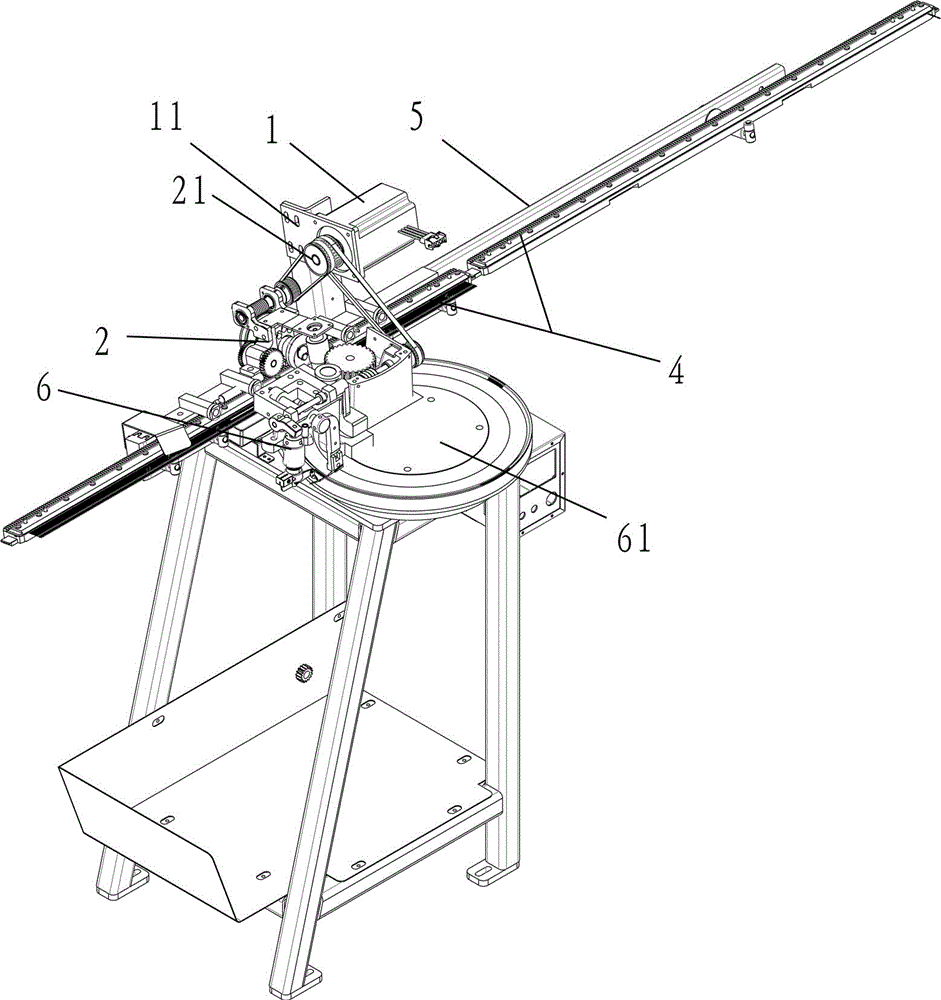

[0015] See attached picture. This embodiment includes a main motor 1, a rotational speed ratio conversion device 2, a needle rake 4 for collar shifting, a needle rake track 5 and a disc sewing machine 6; the main motor 1 is fixed on the side of the needle rake track 5 through a motor mount 11; The speed ratio conversion device 2 includes a main drive wheel 21 sleeved on the motor shaft of the main motor 1, and a first transmission belt 22 and a second transmission belt 23 are set on the main transmission wheel 21; It includes a needle rake movable device and a disc movable device, the other end of the first conveyor belt 22 is set on the needle rake movable device, and the other end of the second conveyor belt 23 is sleeved on the disc movable device; the neck moving needle rake 4 Placed on the needle rake track 3, the needle rake track 3 is fixed on the side of the disc sewing machine 6, and the needle rake track 5 has a side rod 51; the needle rake movable device is fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com