Seaming device for fabrics with different needle pitches

A suturing device and spacing technology, applied in knitting, textiles and papermaking, etc., can solve the problems of missing stitches, waste of manpower, low work efficiency, etc., and achieve the effect of avoiding missing stitches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

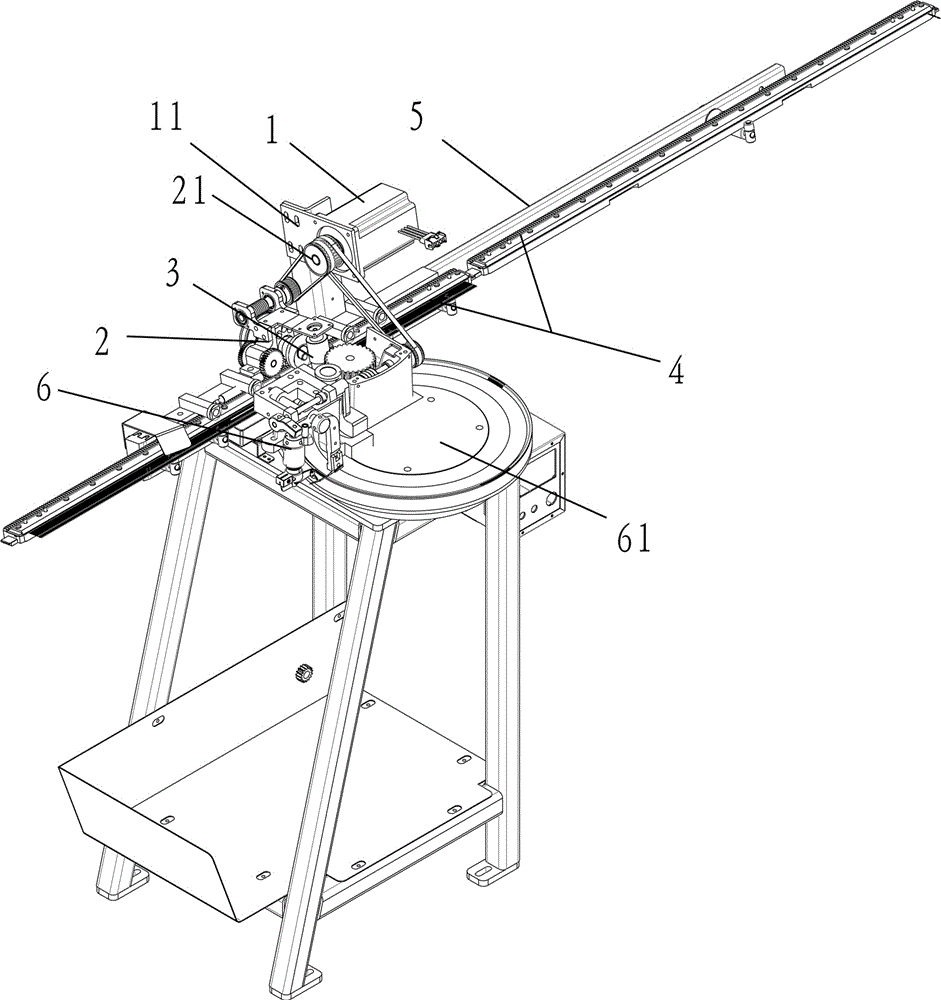

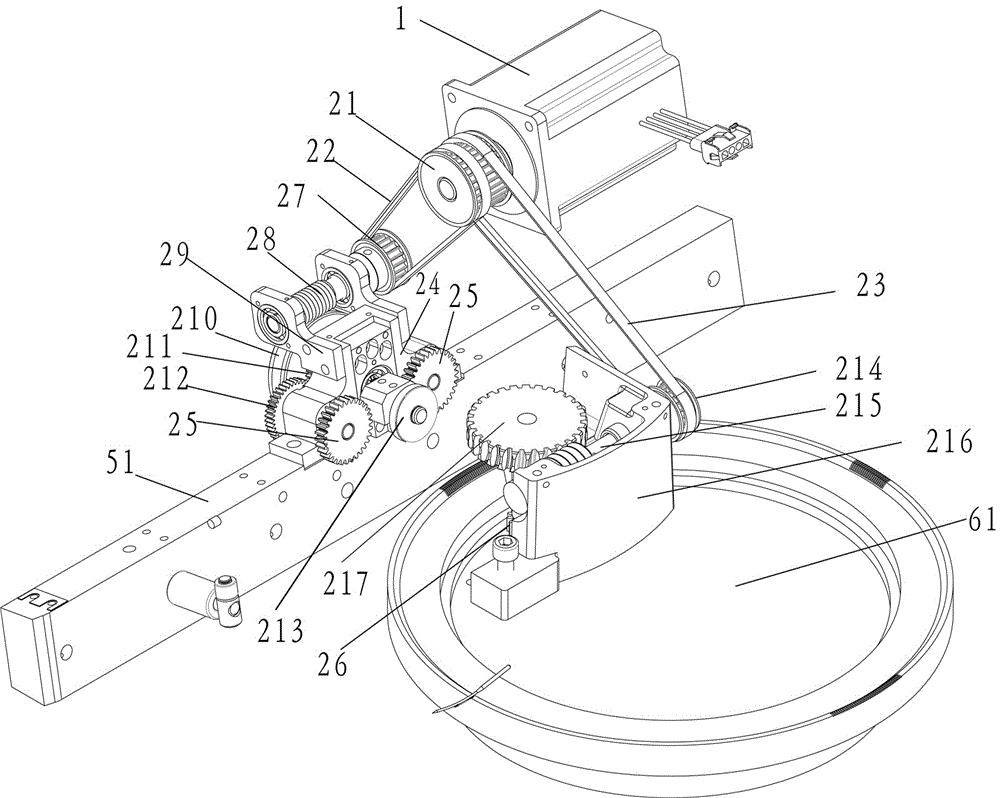

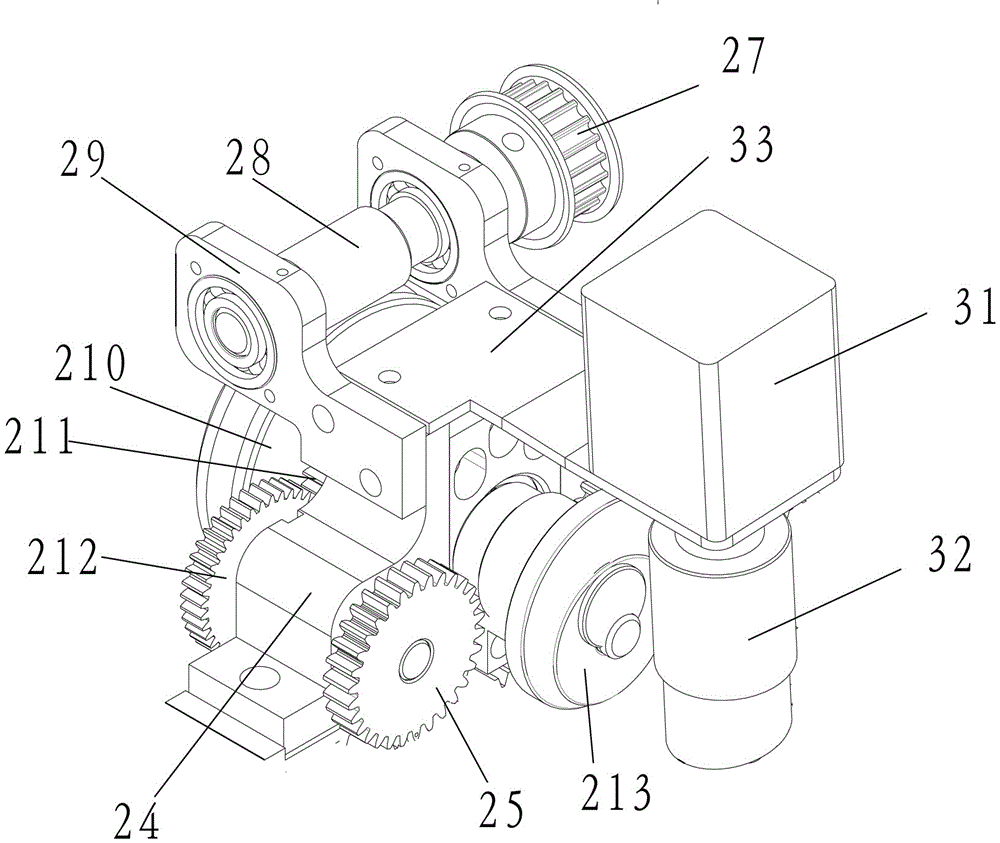

[0023] See attached picture. This embodiment includes a main motor 1, a rotational speed ratio conversion device 2, a coil transfer device 3, a collar transfer needle rake 4, a needle rake track 5 and a disc sewing machine 6; the main motor 1 is fixed on the needle rake through a motor mount 11 The side of the track 5; the speed ratio conversion device 2 includes a main transmission wheel 21 sleeved on the motor shaft of the main motor 1, and the first transmission belt 22 and the second transmission belt 23 are sleeved on the main transmission wheel 21; the rotation speed Ratio conversion device 2 also includes a needle rake movable device and a disc movable device, the other end of the first conveyor belt 22 is sleeved on the needle rake movable device, and the other end of the second conveyor belt 23 is sleeved on the disc movable device; The needle rake 4 is placed on the needle rake track 3, and the needle rake track 3 is fixed on the side of the disc sewing machine 6. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com