Paillette feeding device

A technology of sequins and guide sheets, applied in the field of sewing devices, can solve problems such as reducing sewing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

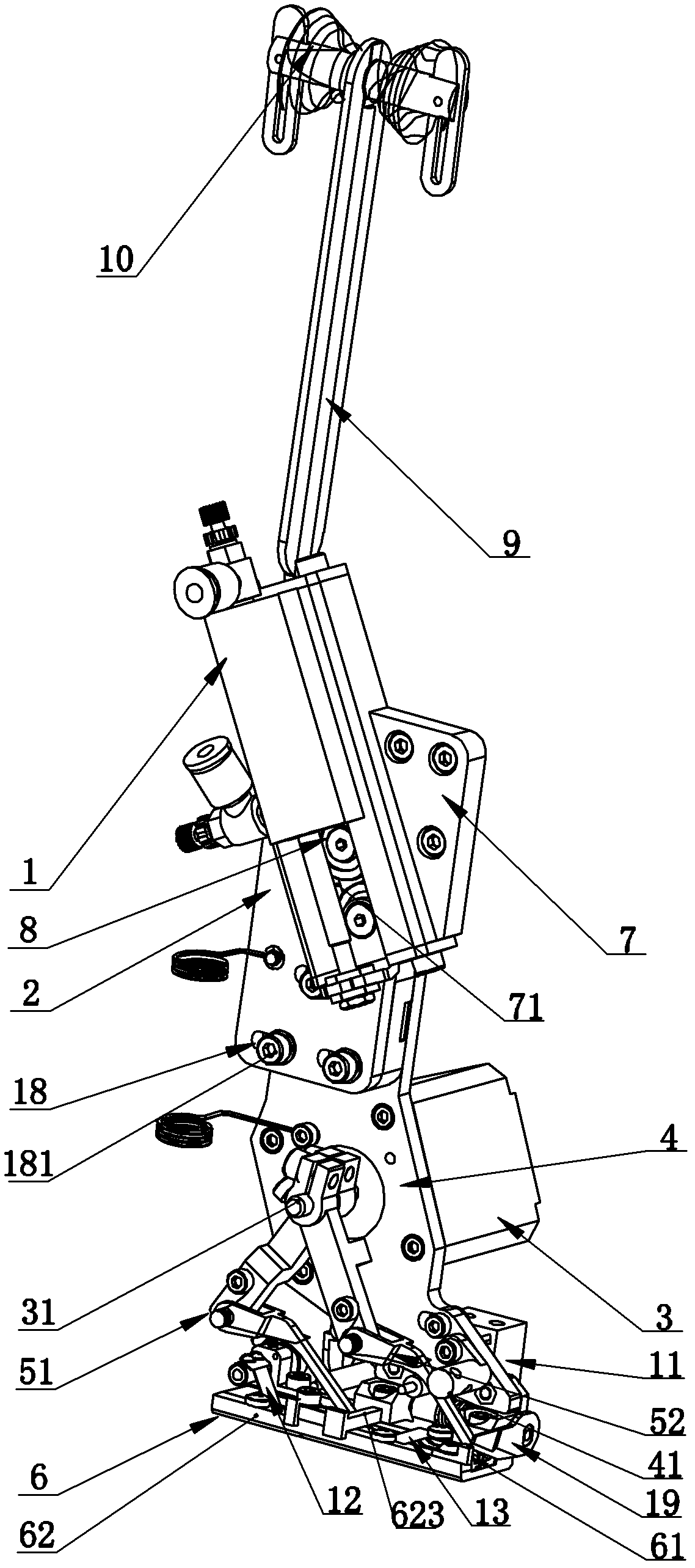

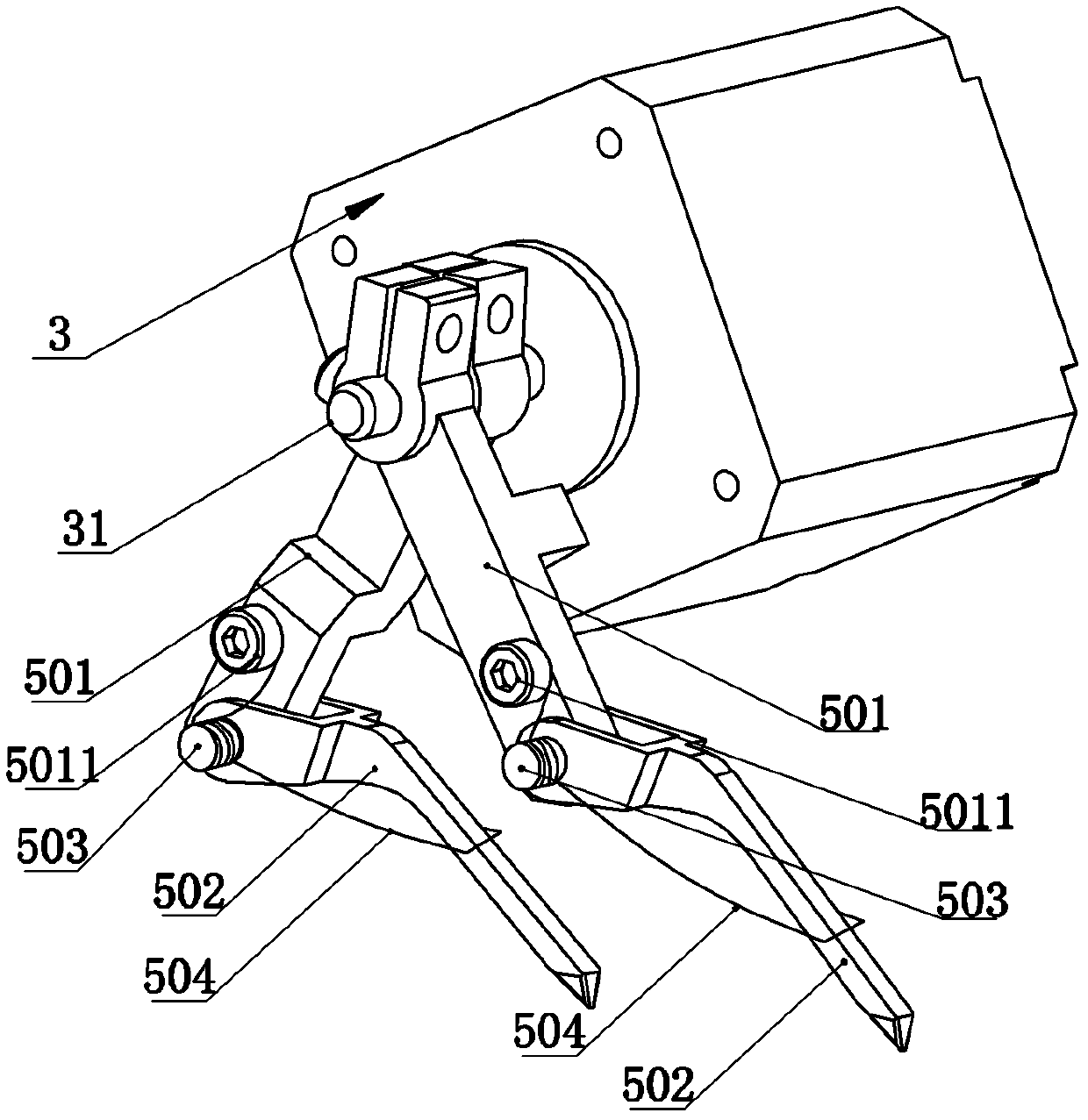

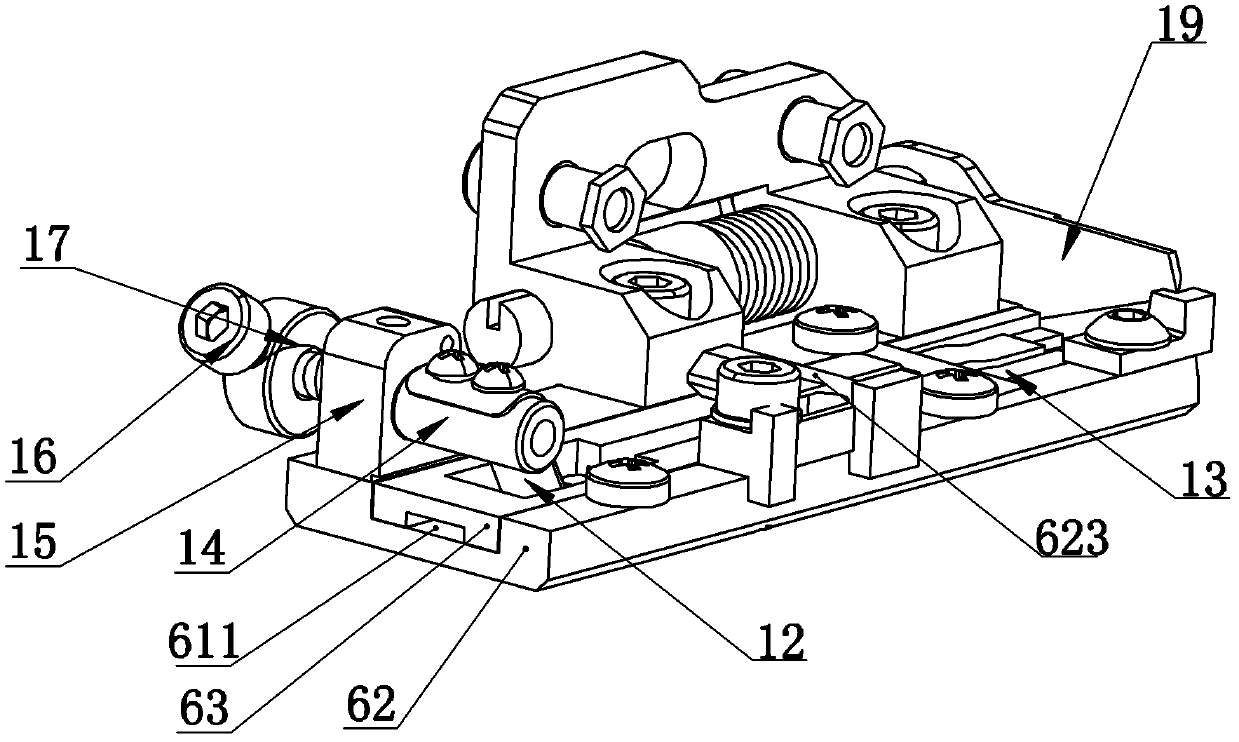

[0028] Such as figure 1 , 2 , 3, a sequin feeding device includes a cylinder 1, a moving guide plate 2, a motor 3, a motor plate 4, two shift forks 51, 52, and a bottom knife 6, and the cylinder 1 is fixed with a guide rail Seat 7, the guide rail seat 7 and the opposite surface of the moving guide plate 2 are provided with a guide rail 71, the described moving guide plate 2 is provided with a pulley 8 that can slide on the guide rail 71, and the described cylinder 1 is obliquely arranged on the moving guide plate 2. On the guide plate 2, the cylinder 1 controls the movement of the guide plate 2 along the inclined direction, the guide rail seat 7 is used to be fixedly connected with the embroidery machine, the motor plate 4 is coordinated with the movable guide plate 2, and the movable guide plate 2 moves along the inclined direction Drive the motor plate 4 to move along the inclined direction, the motor 3 is arranged on the inner side of the motor plate 4, and the bottom knif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com