Patents

Literature

867results about "Auxillary devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

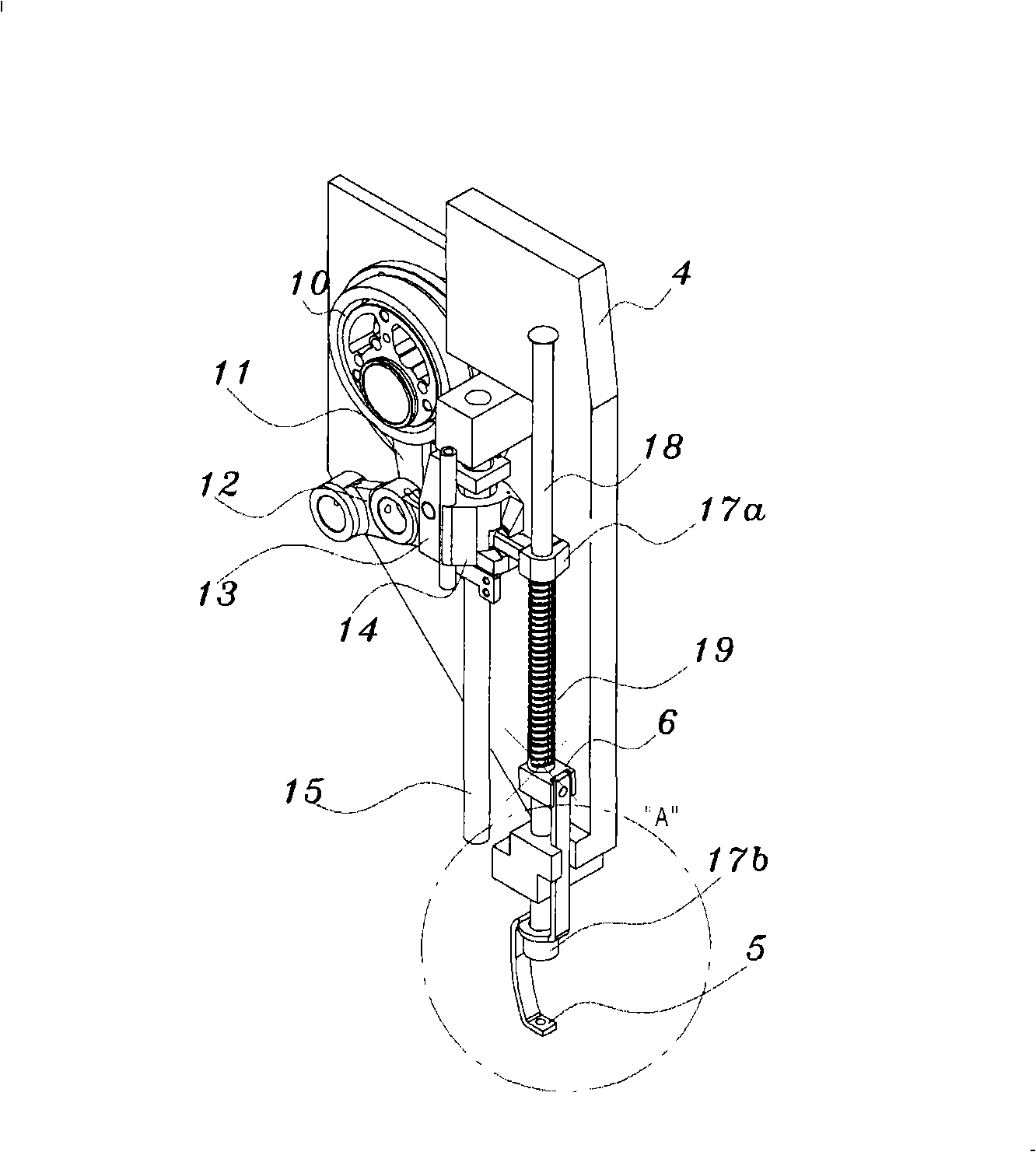

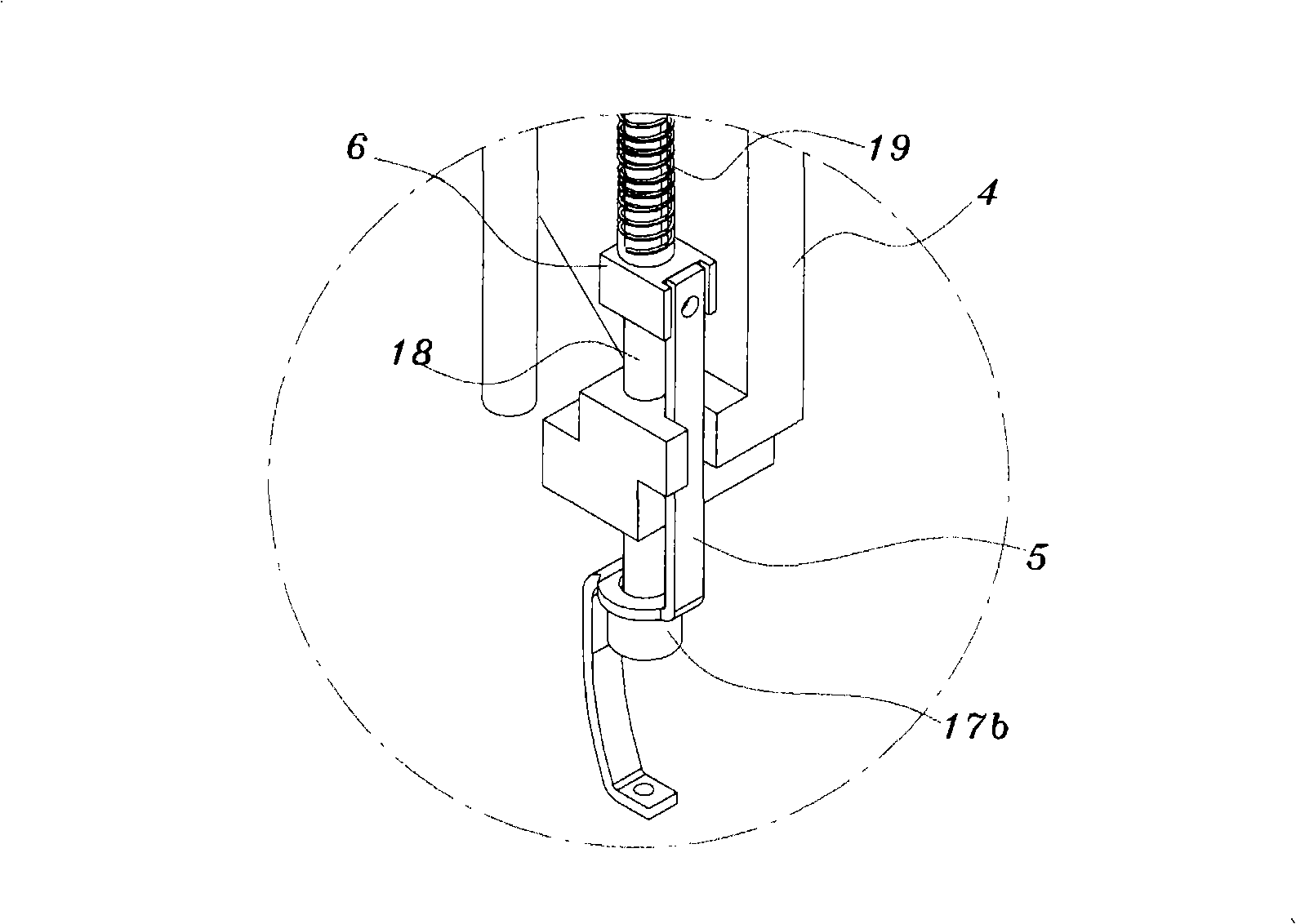

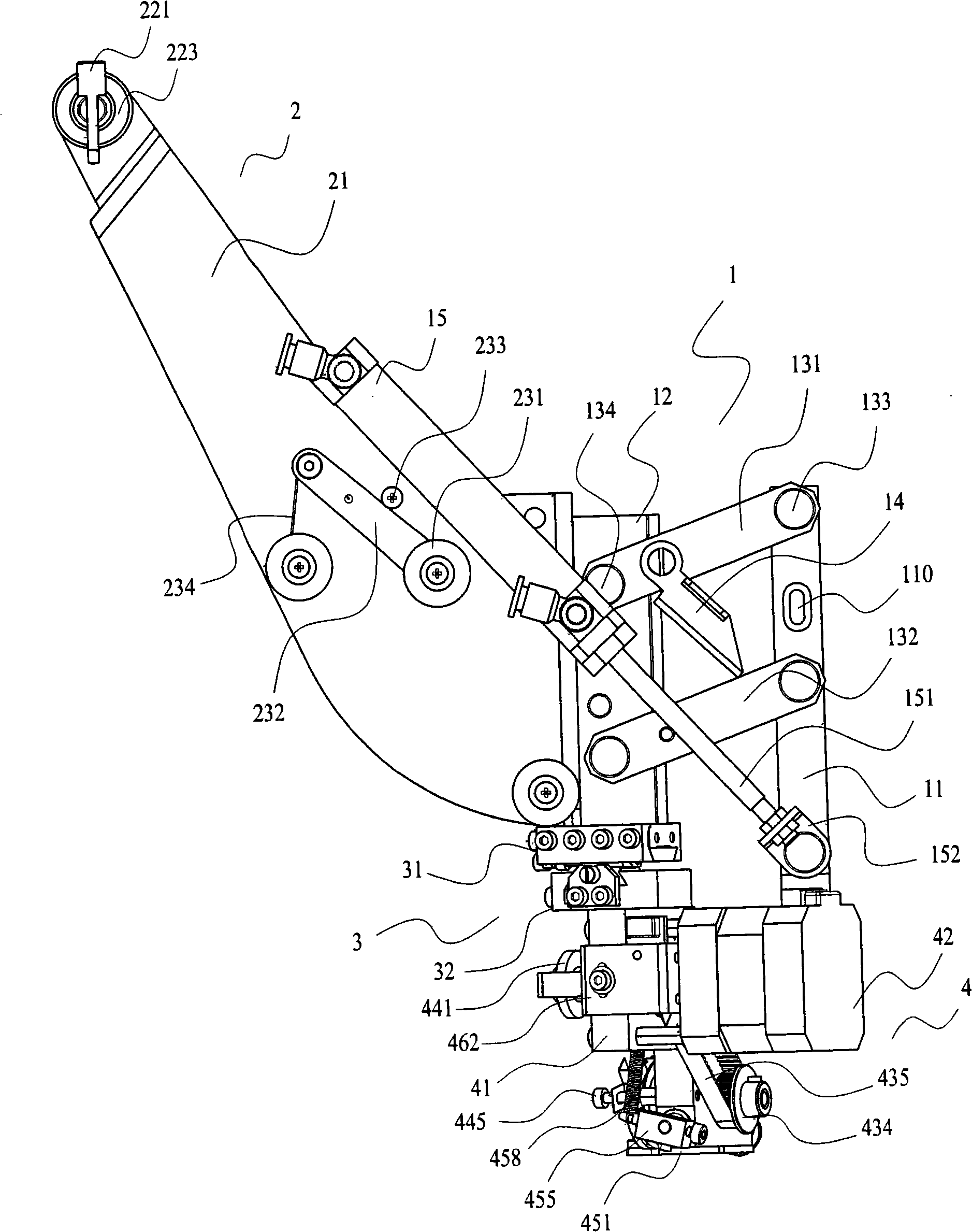

Embroidery machine

InactiveCN101260601AChange itineraryProgramme-controlled sewing machinesPressersEngineeringPRESSURE FEET

An embroidery machine includes a sewing arm having an upper shaft for providing a driving force, a needle bar support case, which is assembled to a front portion of the sewing arm so as to be laterally movable, a needle bar provided in a needle bar support case, the needle bar having a needle at a lower end thereof and vertically carrying the needle using a rotation driving force of the upper shaft, and a presser foot, which is provided in the needle bar support case so as to be vertically movable, characterized in that each of the needle bar and the presser foot is operated by an individual drive mechanism. The presser foot is separately driven by its own drive source, independent of the drive source of the needle bar.

Owner:SUSR PRECISION CO LTD

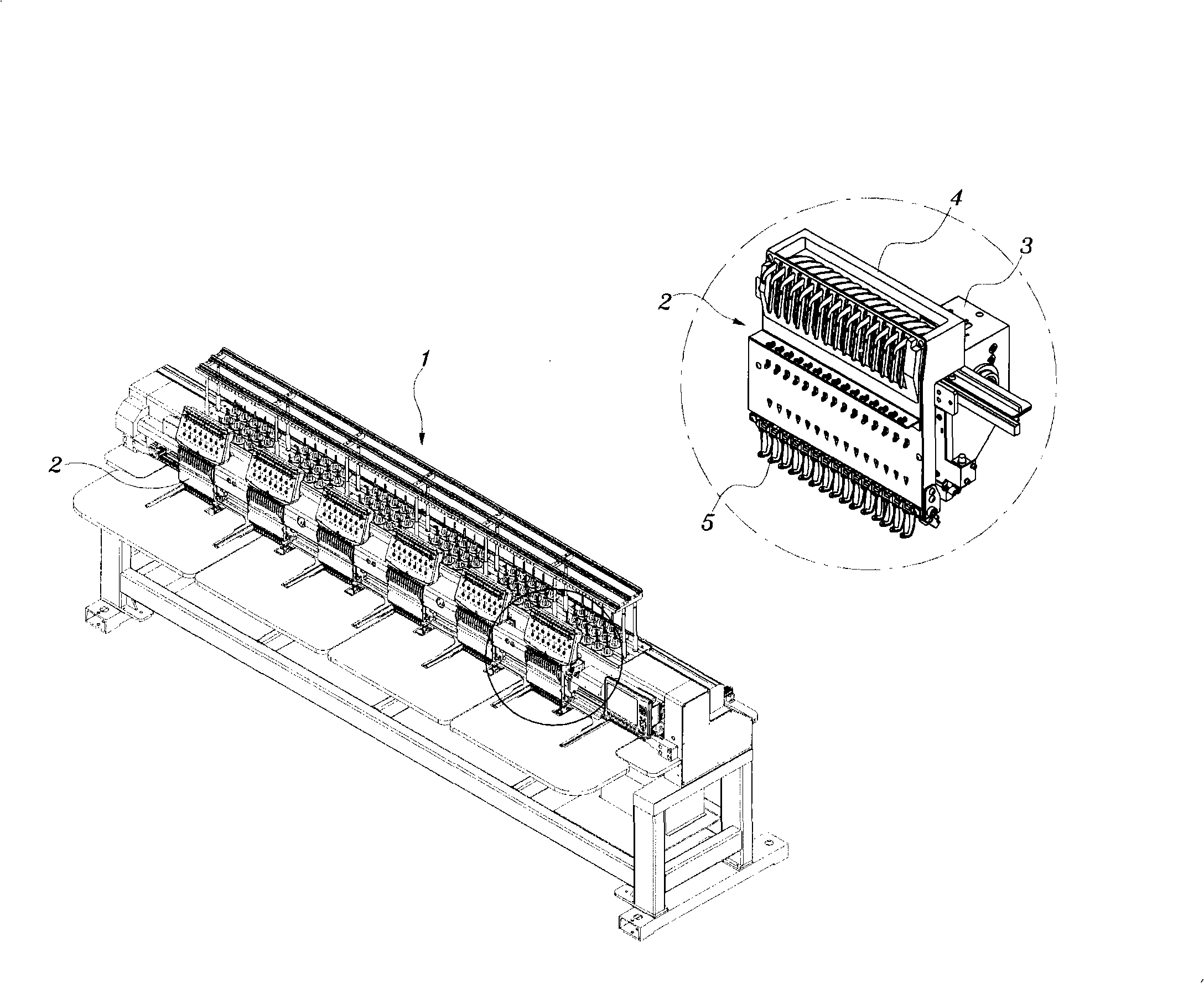

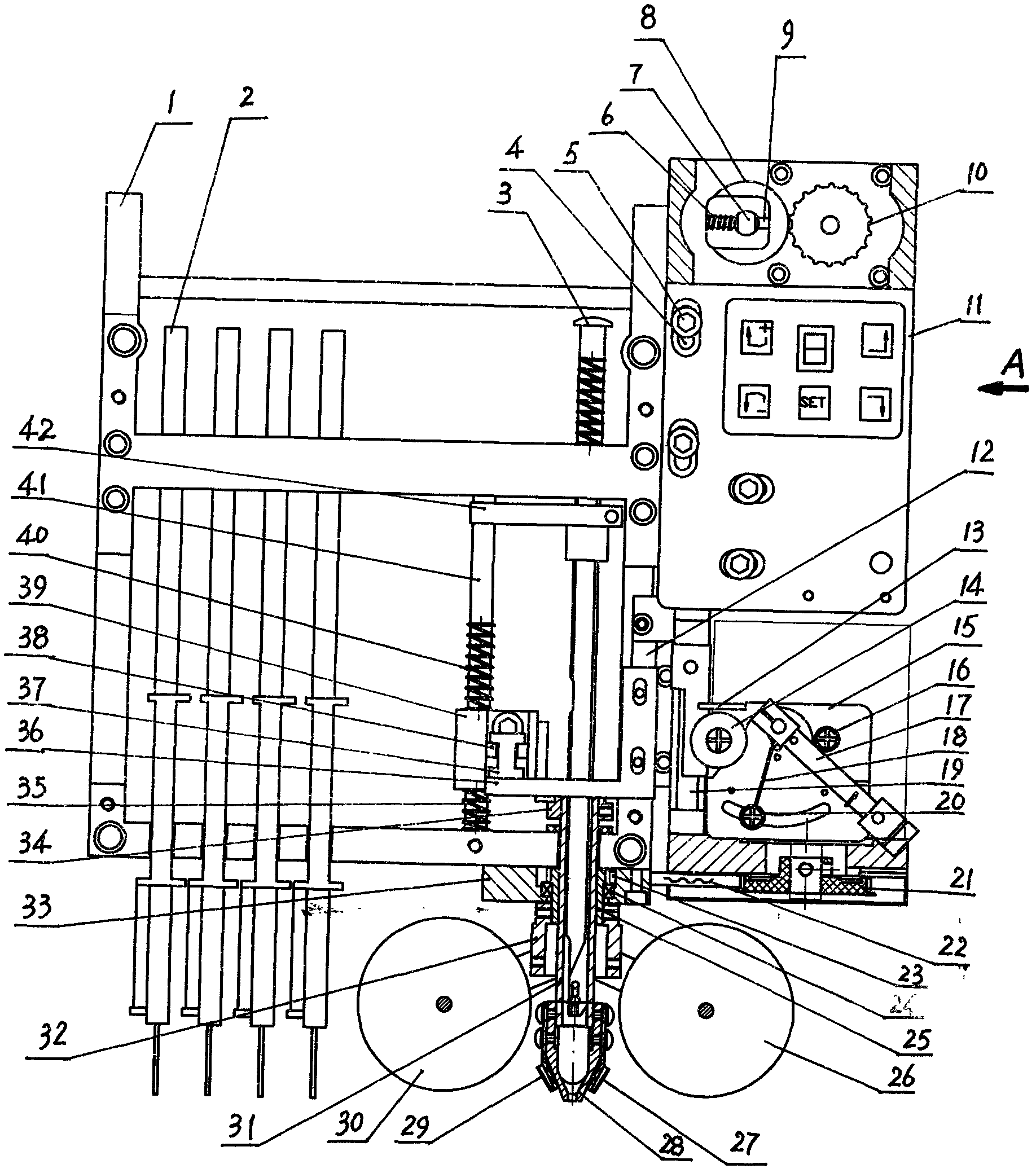

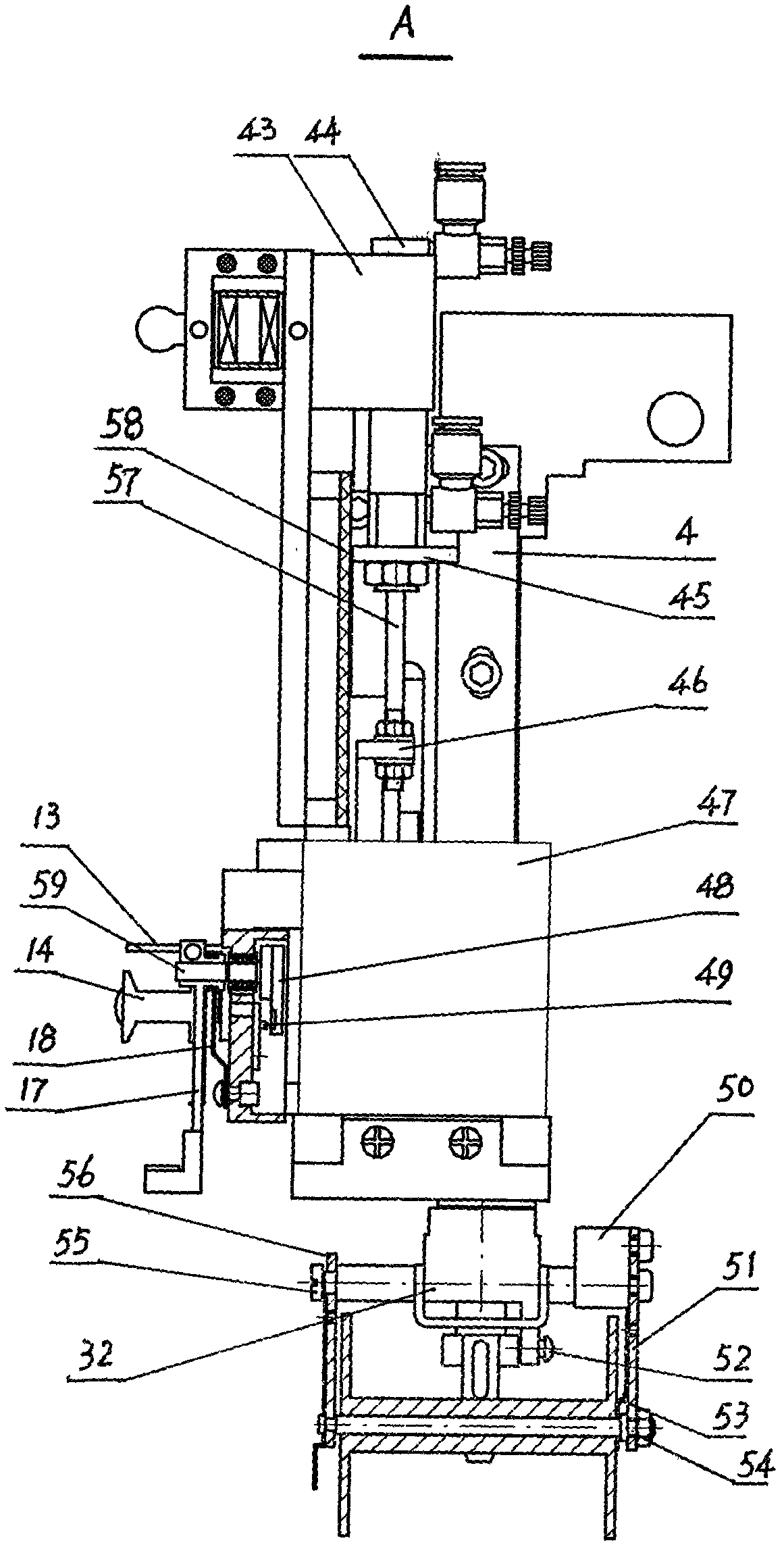

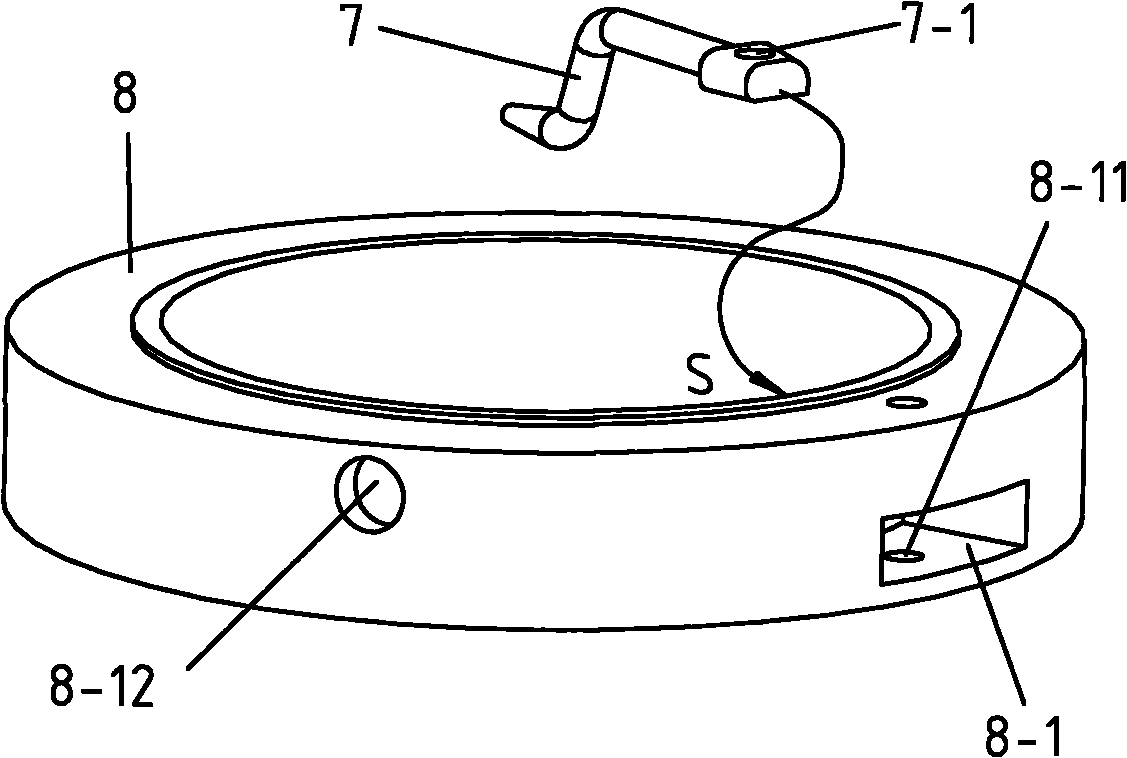

Bead embroidery embroidering machine and bead feeding method

ActiveCN103866501APrecisely throughPrecise positioningAutomatic machinesAuxillary devicesMechanical engineeringBead embroidery

The invention discloses a bead embroidery embroidering machine. The bead embroidery embroidering machine comprises an engine body, wherein the engine body is provided with one or more than one machine head; the machine head is connected with a feeding mechanism for gradually conveying embroidery beads to a position right below an embroidering needle of the embroidering machine one by one; the feeding mechanism is provided with a clamping opening for clamping and positioning the embroidery beads; a bead guide rod for supplying the embroidery beads to the feeding mechanism is suspended above the feeding mechanism; the embroidery beads are threaded on the bead guide rod to form a bead cluster; a positioning structure for positioning the embroidery beads which need to slide to corresponding feeding positions of the feeding mechanism from the bead guide rod is further arranged above the feeding mechanism; the positioning center of the positioning structure and the positioning center of the clamping structure are concentric. The bead guide rod is provided with the bead cluster formed by the embroidery beads and the bead cluster can be continuously fed to the feeding mechanism; the bead guide rod and the positioning structure can be used for accurately positioning the embroidery beads so that the embroidery beads accurately slide into the corresponding parts of the feeding mechanism according to requirements and the embroidery beads are conveniently and accurately positioned and conveyed, and furthermore, the embroidering needle can accurately penetrate through needle holes in the embroidery beads to embroider the embroidery beads on a textile.

Owner:诸暨市化工机械厂

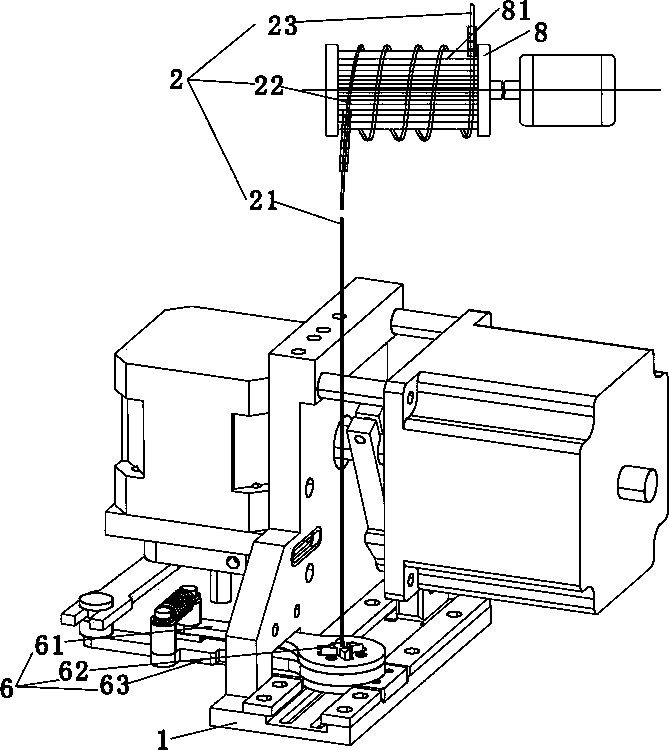

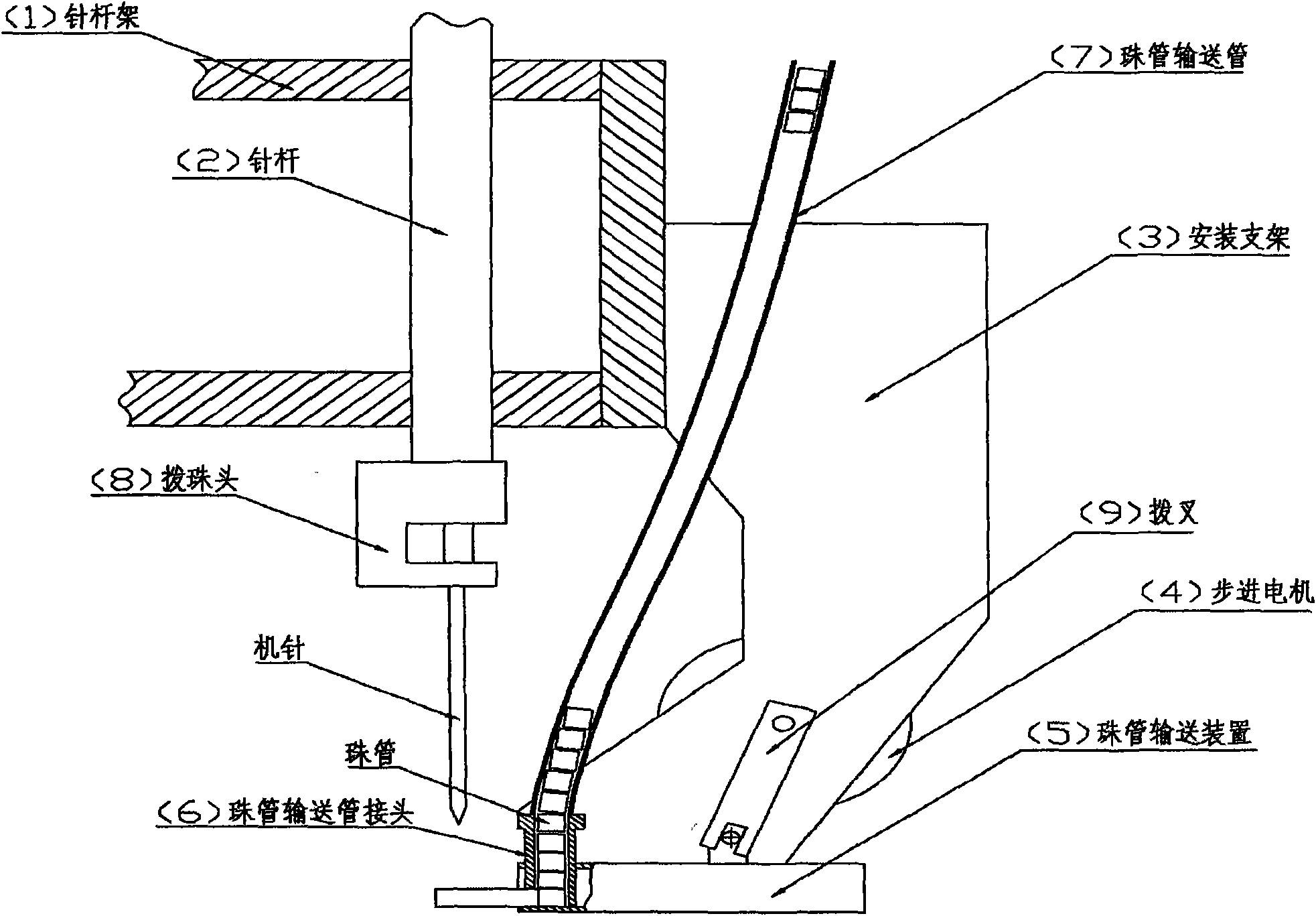

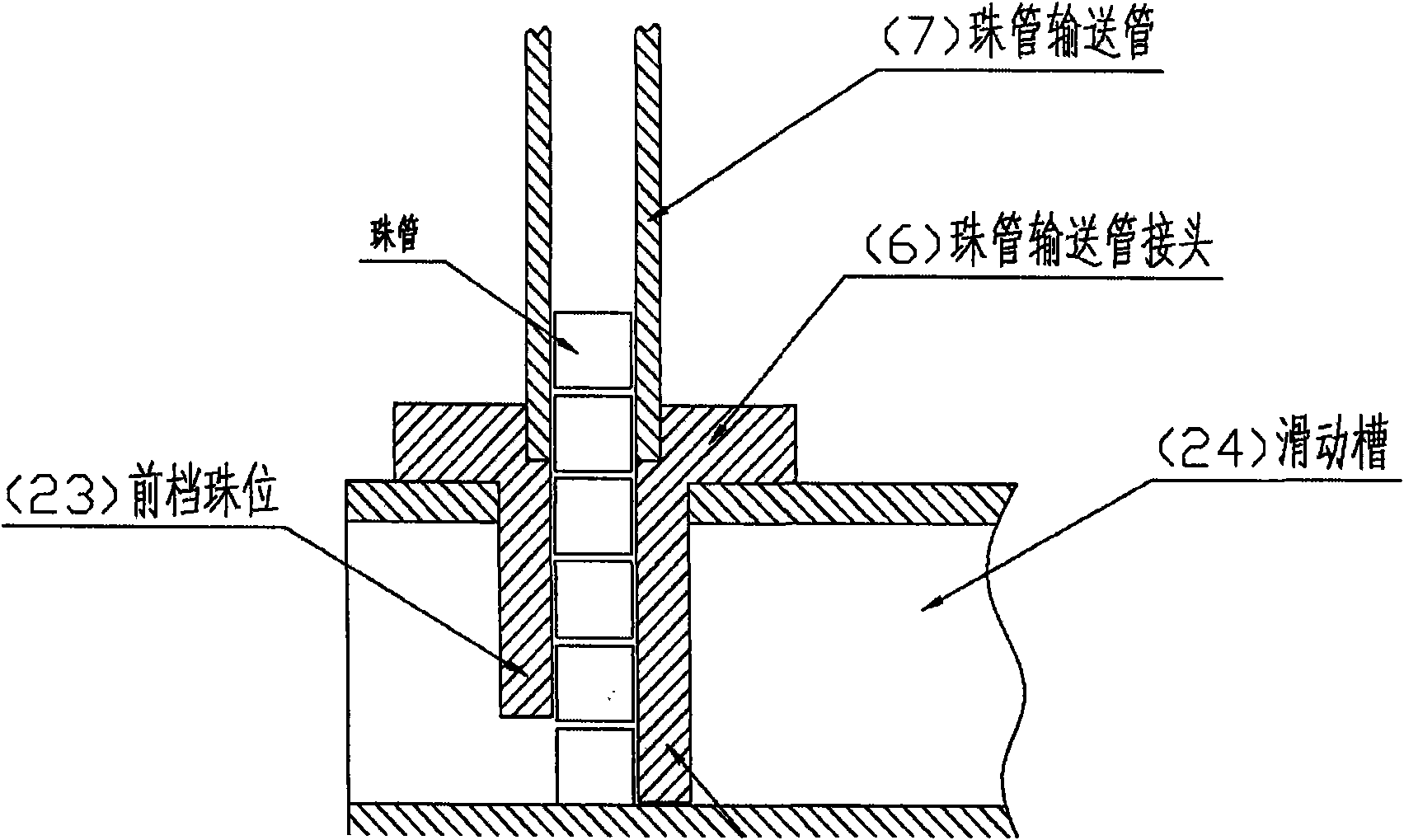

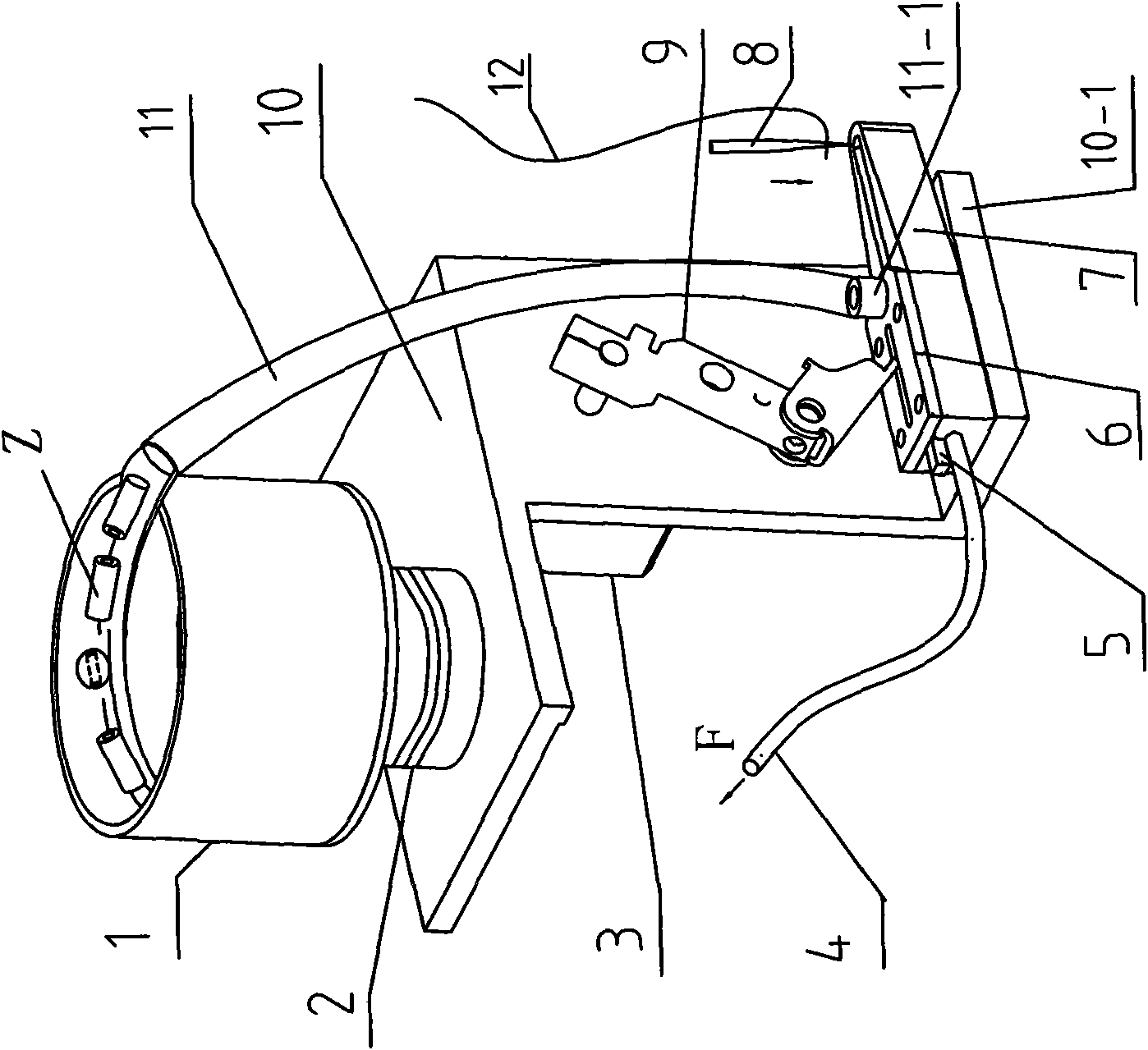

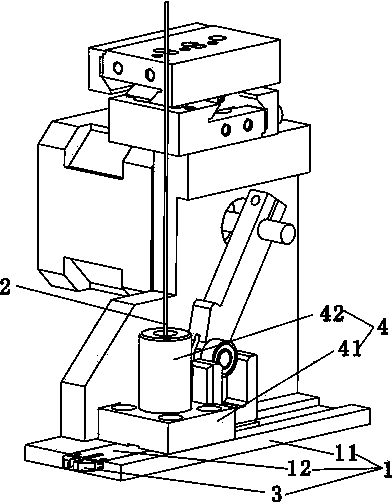

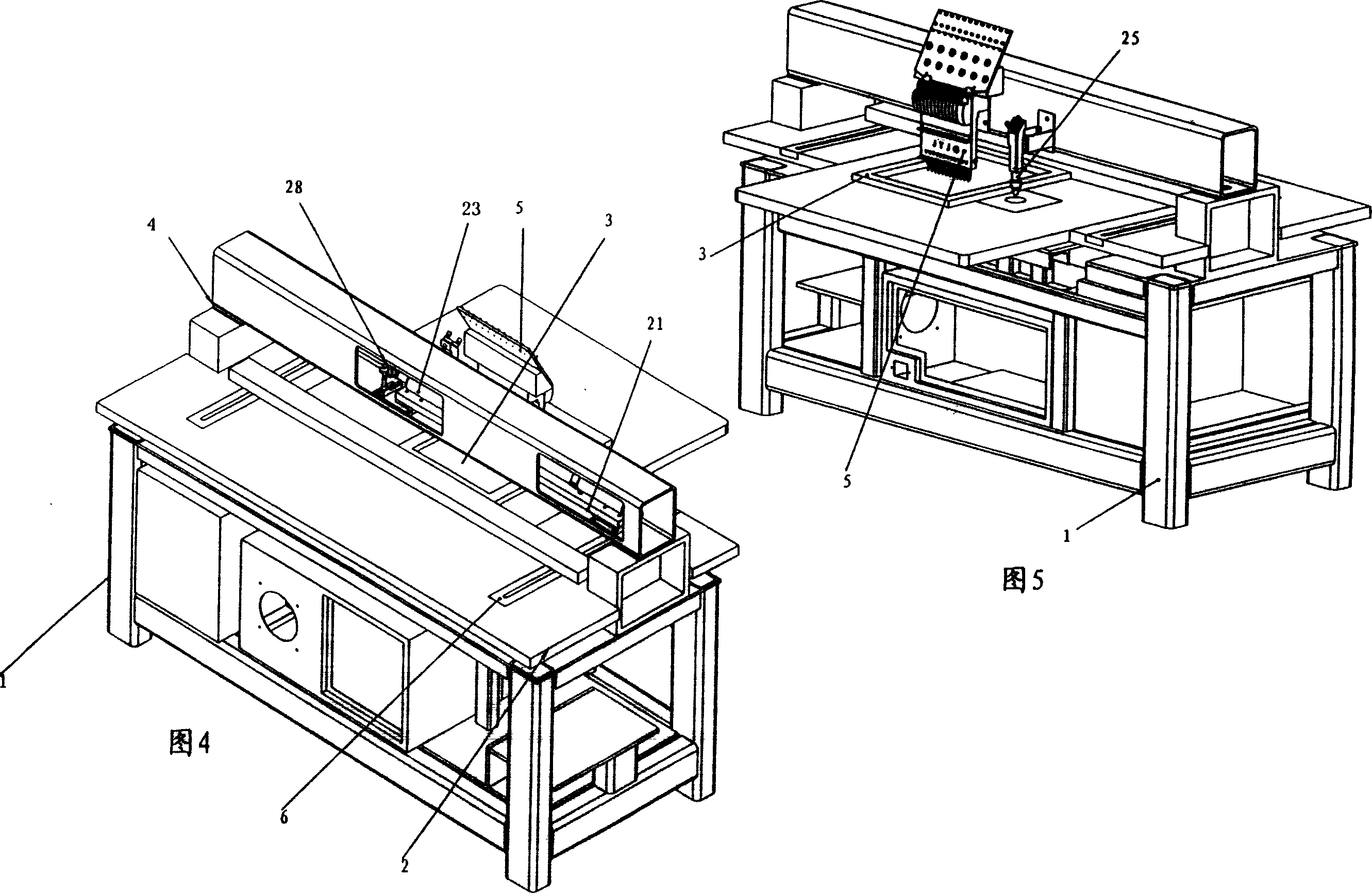

Device for arranging embroidering bead tube for common embroidery machine

InactiveCN101798732AAccurate penetrationBeautifully placedAutomatic machinesAuxillary devicesElectric machineryEngineering

The invention discloses a device for arranging an embroidering bead tube for a common embroidery machine, which comprises that: a bead shifting head and a machine needle are fixed on the lower part of a needle rod in a needle rod frame; a mounting bracket is fixed on the side face of the needle rod frame; a stepping motor is fixed in the middle of the mounting bracket; a bead tube conveying device is fixed on the lower part of the mounting bracket and is movably connected with the stepping motor through a shifting fork; a bead tube conveying pipe joint is arranged on the front plane of the bead tube conveying device; and the bead tube conveying pipe is connected with the bead tube conveying pipe joint. The device has the advantages that: the device has simple and reasonable structure and convenient operation, and can accurately feed unpackaged bead tubes to the underside of the machine needle of the common embroidery machine, so that the bead tubes are embroidered on shell fabrics according to the requirement on patterns through holes in the bead tubes by the machine needle, the production efficiency is high, the droppoints of the embroidered patterned bead tubes are accurate, the shell fabrics are brilliant and attractive, the level and ornamental property of the shell fabrics are greatly improved, and the like.

Owner:王仁坤

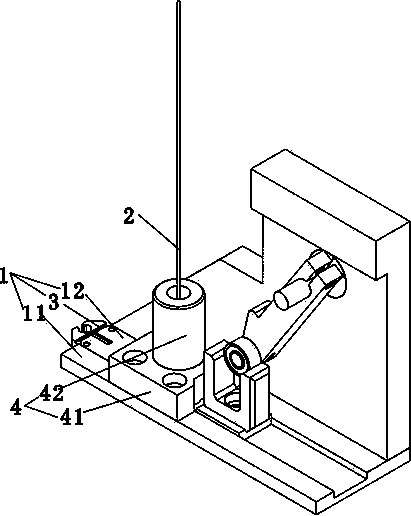

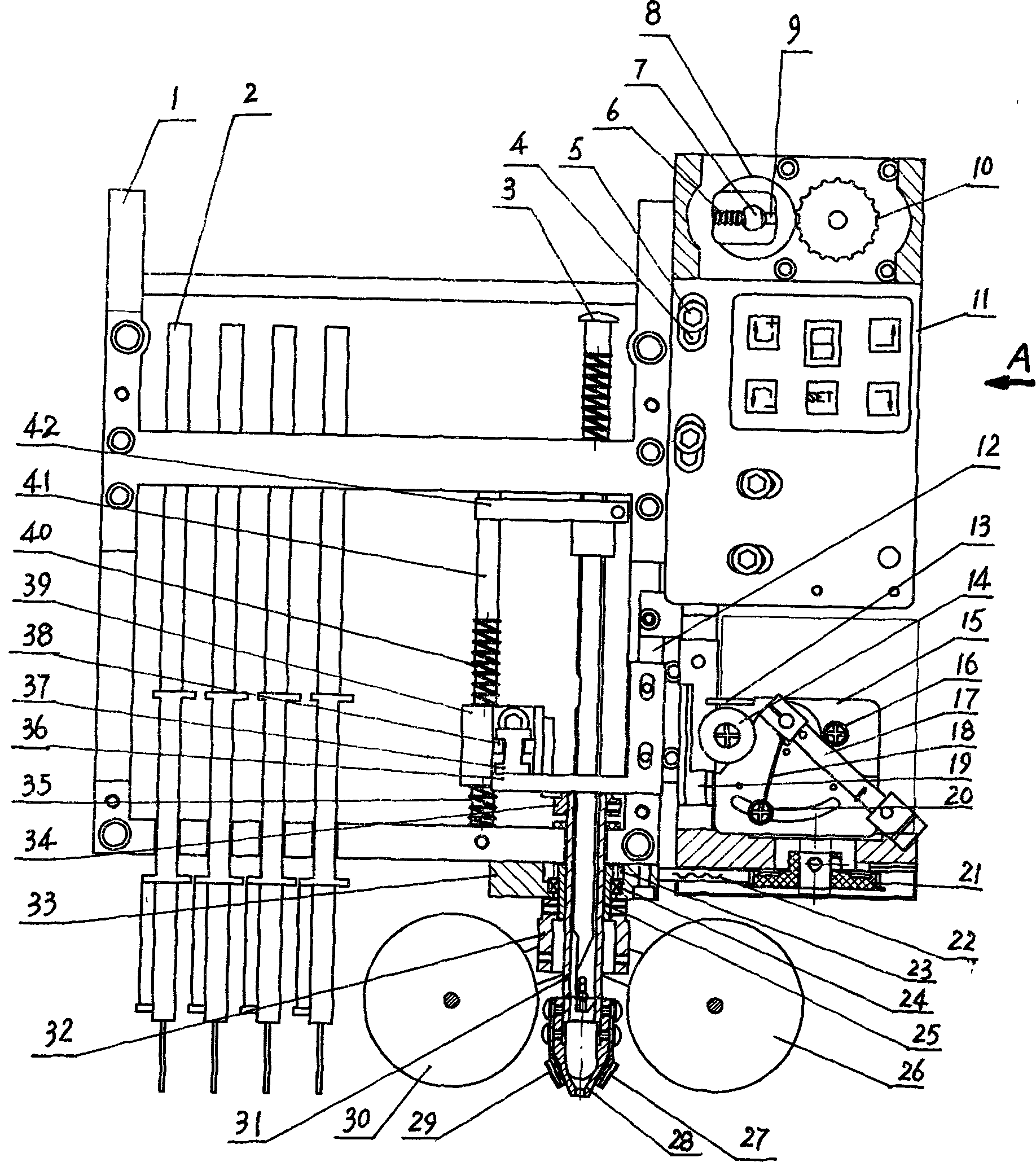

Embroidered bead feeding device and method

ActiveCN103866502APrecise deliveryPrecisely throughAutomatic machinesAuxillary devicesEngineeringMechanical engineering

The invention discloses an embroidered bead feeding device. The embroidered bead feeding device comprises a feed mechanism for delivering embroidered beads to the position under a needle of an embroidery machine one by one, wherein the feed mechanism is provided with a clamping hole for clamping and positioning the embroidered beads; a bead guide rod for supplying the embroidered beads to the feed mechanism is hung above the feed mechanism; the embroidered beads are strung on the bead guide rod to form a bead string; a positioning structure for positioning the embroidered beads which are about to slide into the corresponding feed positions of the feed mechanism from the bead guide rod is also arranged above the feed mechanism; the positioning center of the positioning structure and the clamping hole are concentric. The embroidered bead feeding device has the beneficial effects that the hung bead guide rod and the positioning structure for positioning the embroidered beads which are about to slide into the corresponding feed positions of the feed mechanism from the bead guide rod are arranged above the feed mechanism, the bead guide rod is provided with the bead string formed by the embroidered beads, the bead string can continuously supply materials to the feed mechanism, and the bead guide rod and the positioning structure can accurately position the embroidered beads to enable the embroidered beads to accurately slide into the corresponding positions of the feed mechanism as required so as to accurately position and deliver the embroidered beads, so that the needle can accurately penetrate through the needle holes in the embroidered beads to embroider the embroidered beads on fabrics.

Owner:诸暨市化工机械厂

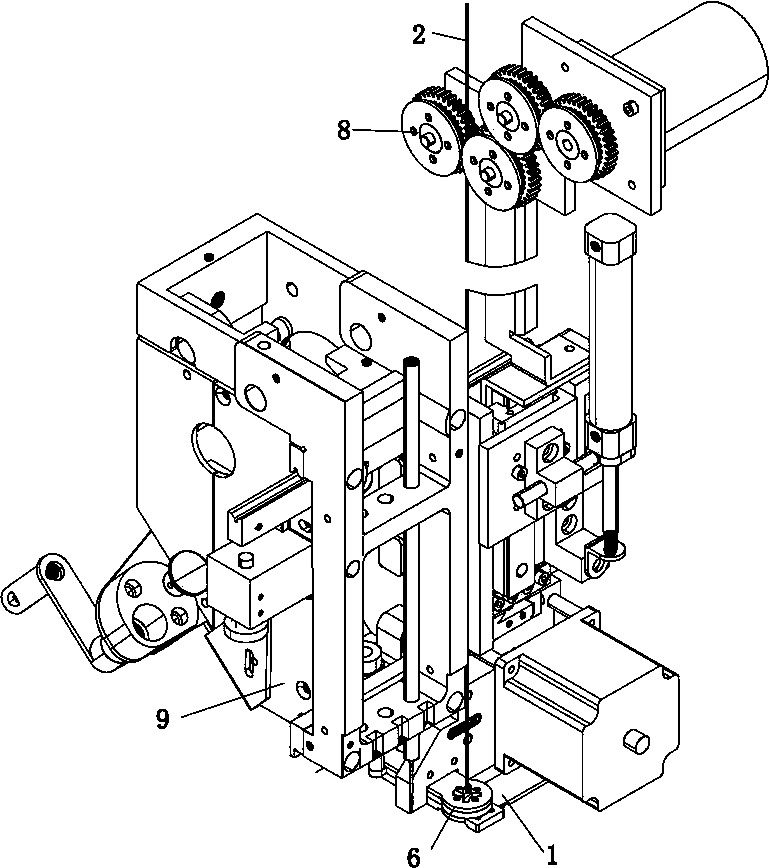

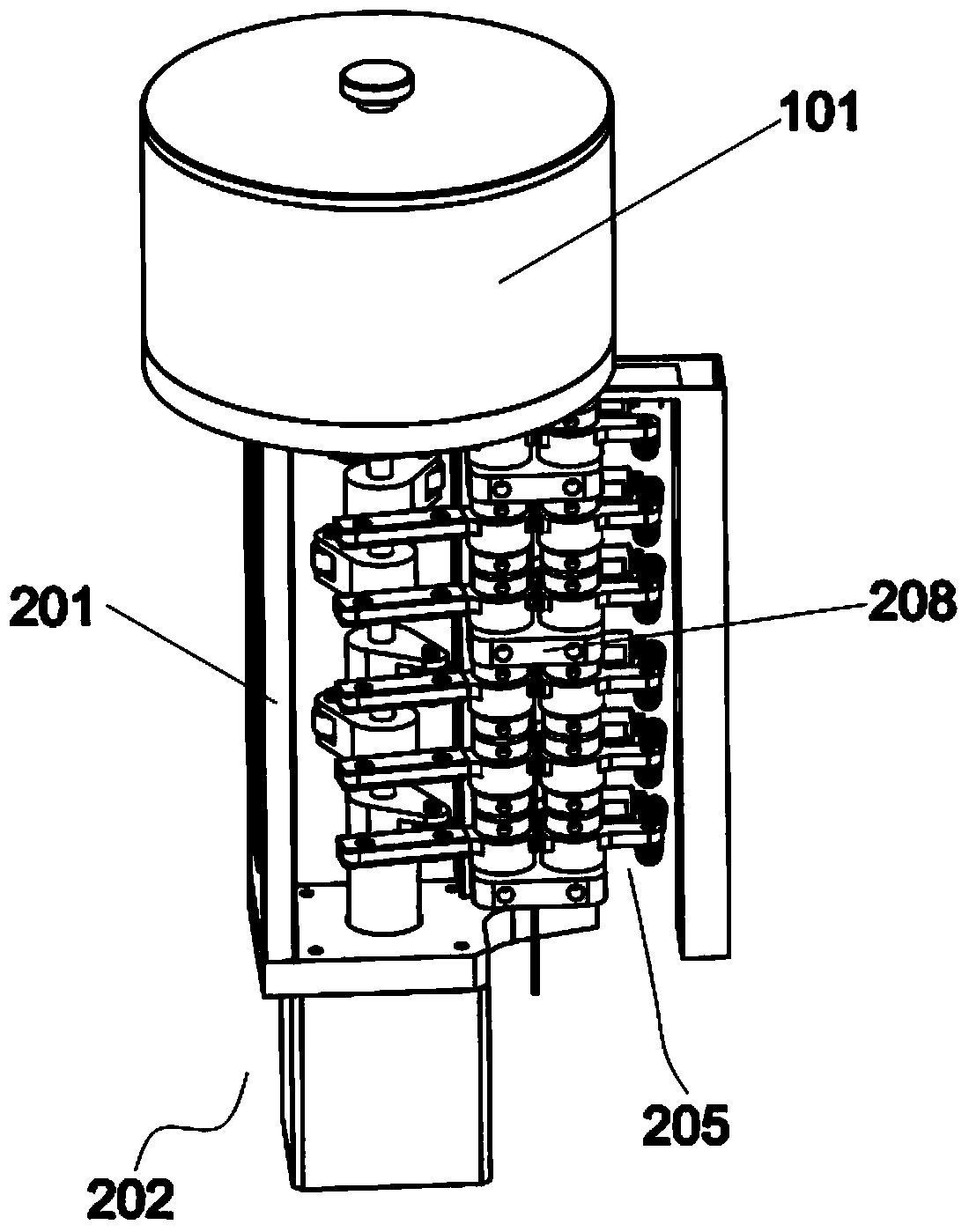

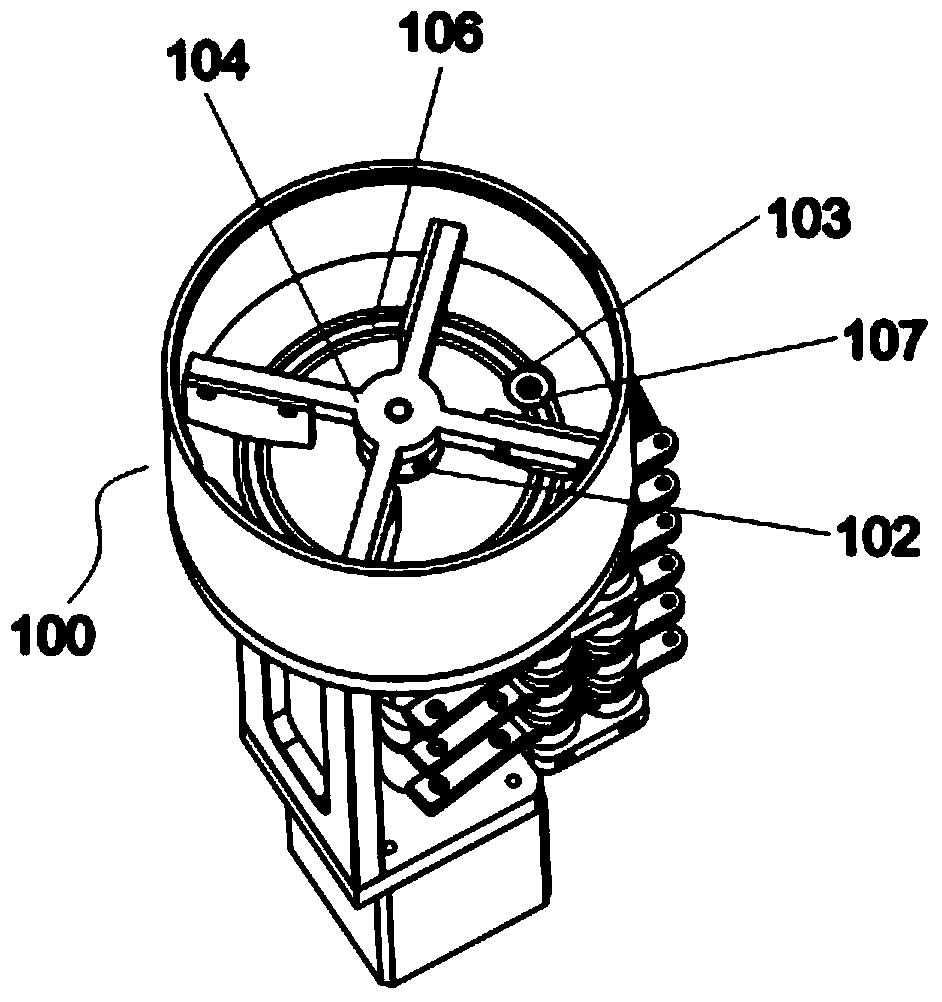

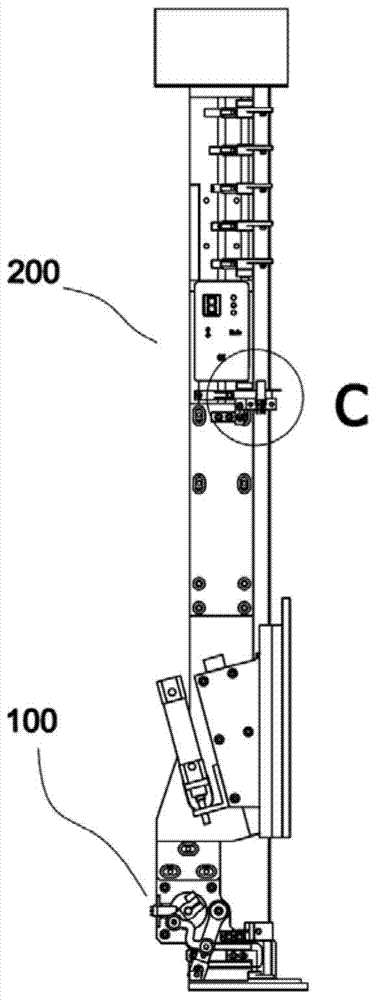

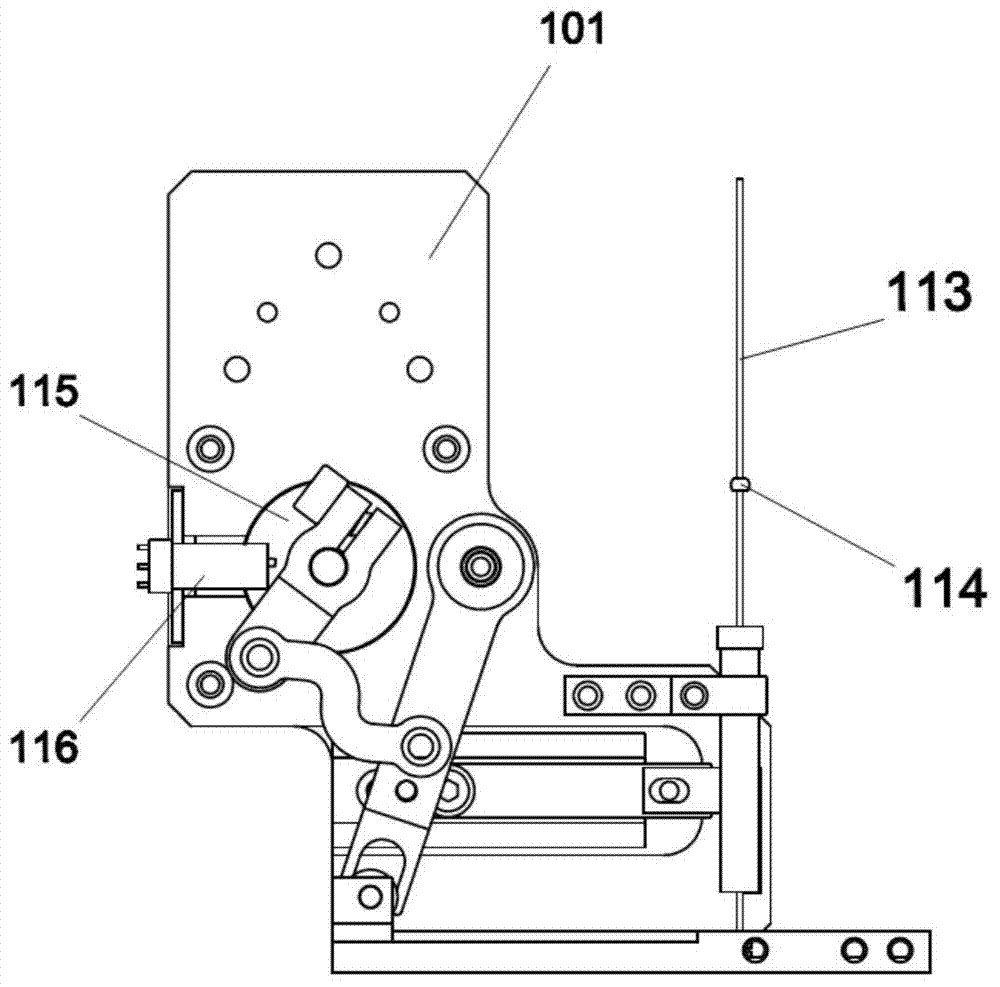

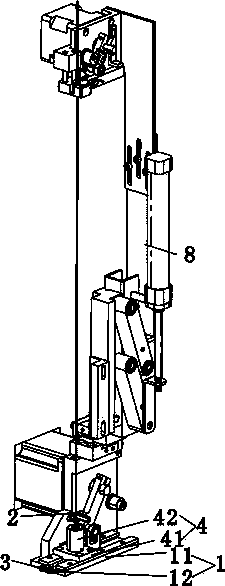

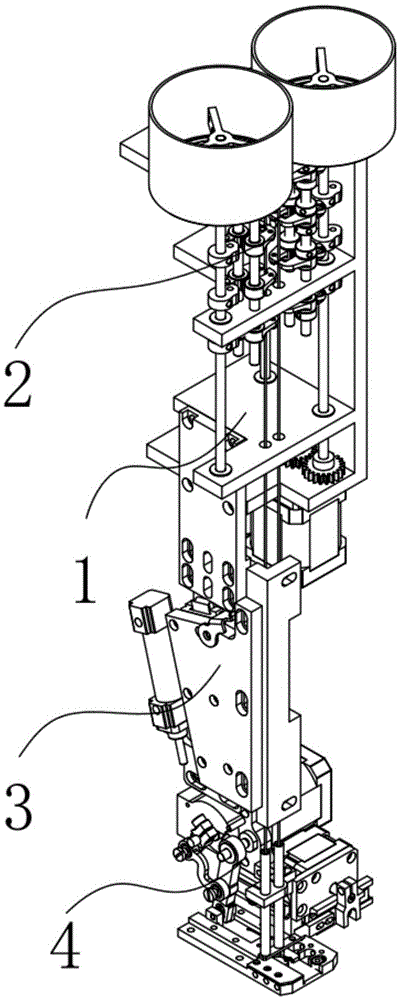

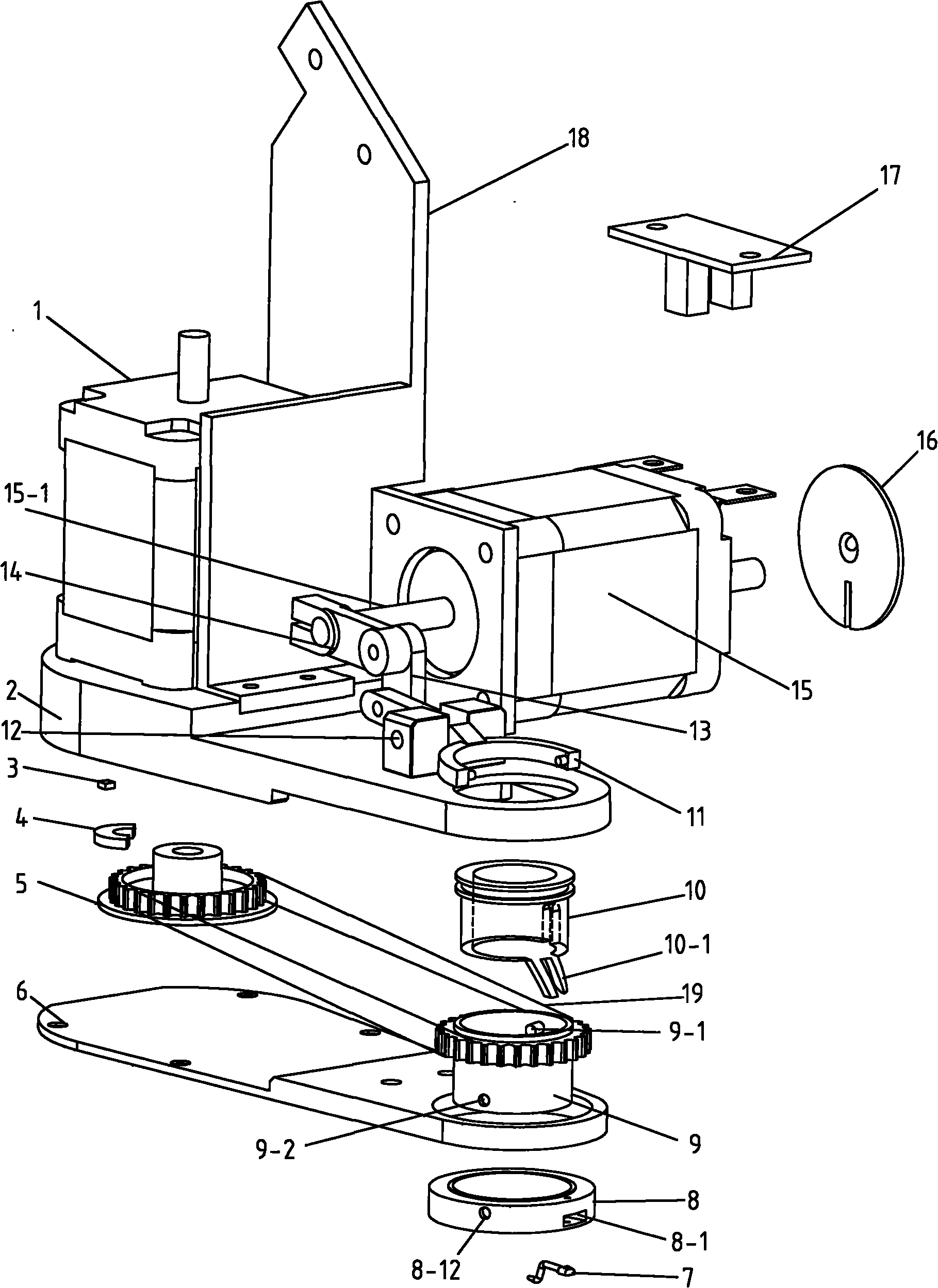

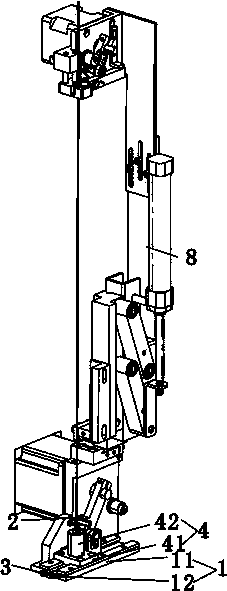

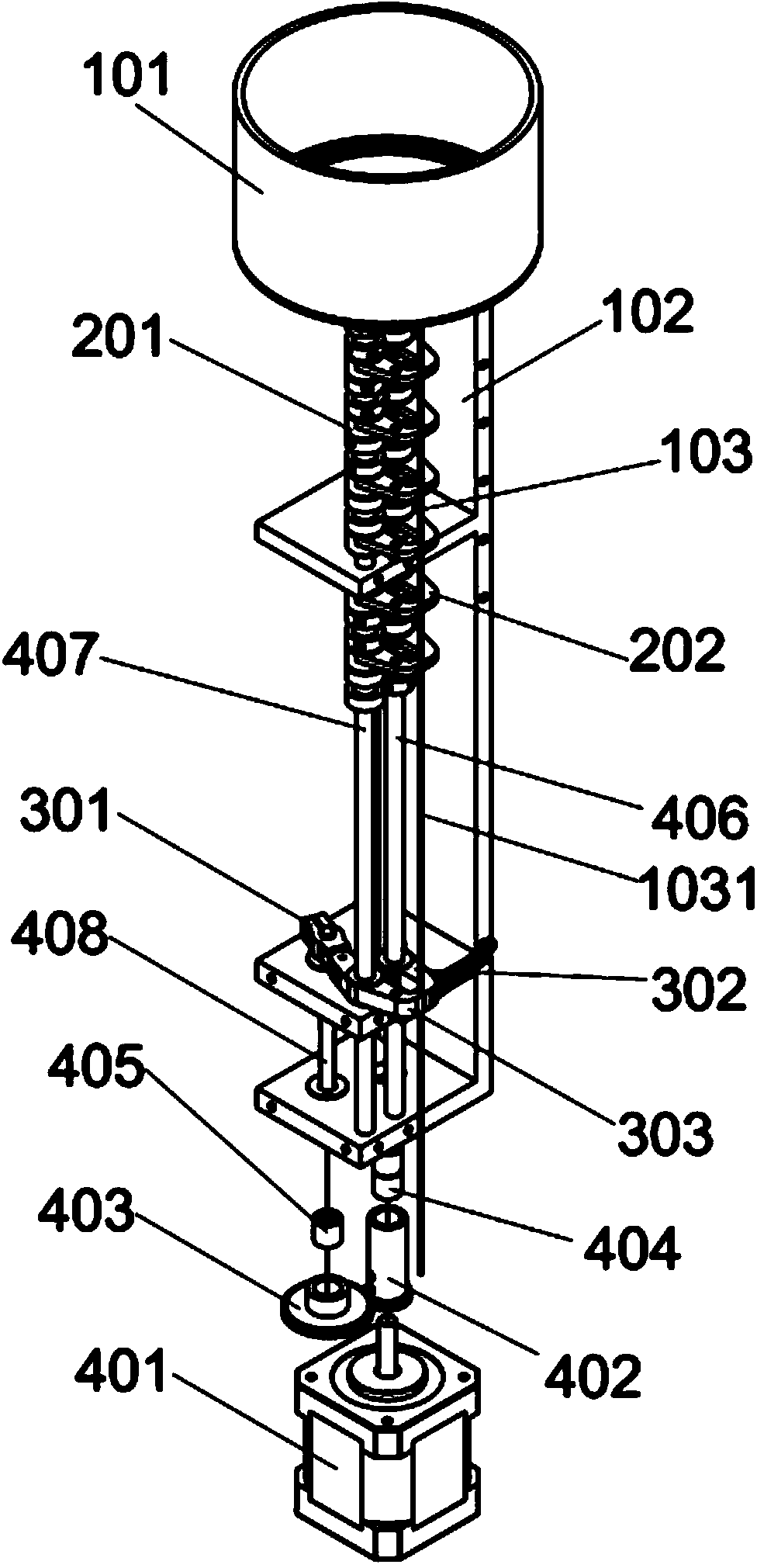

Automatic beading device of pearl embroidery

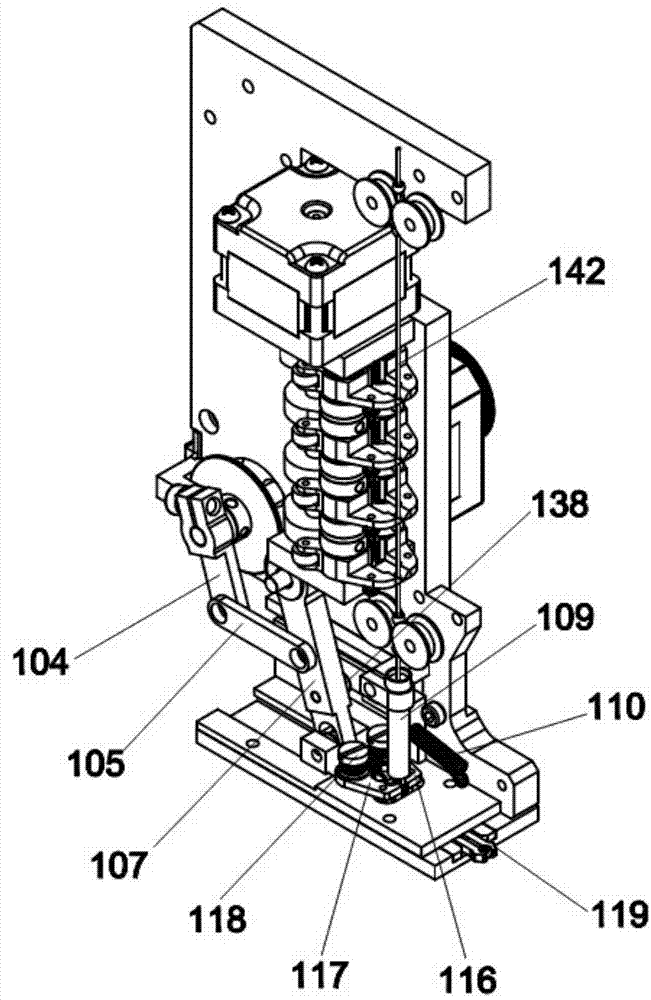

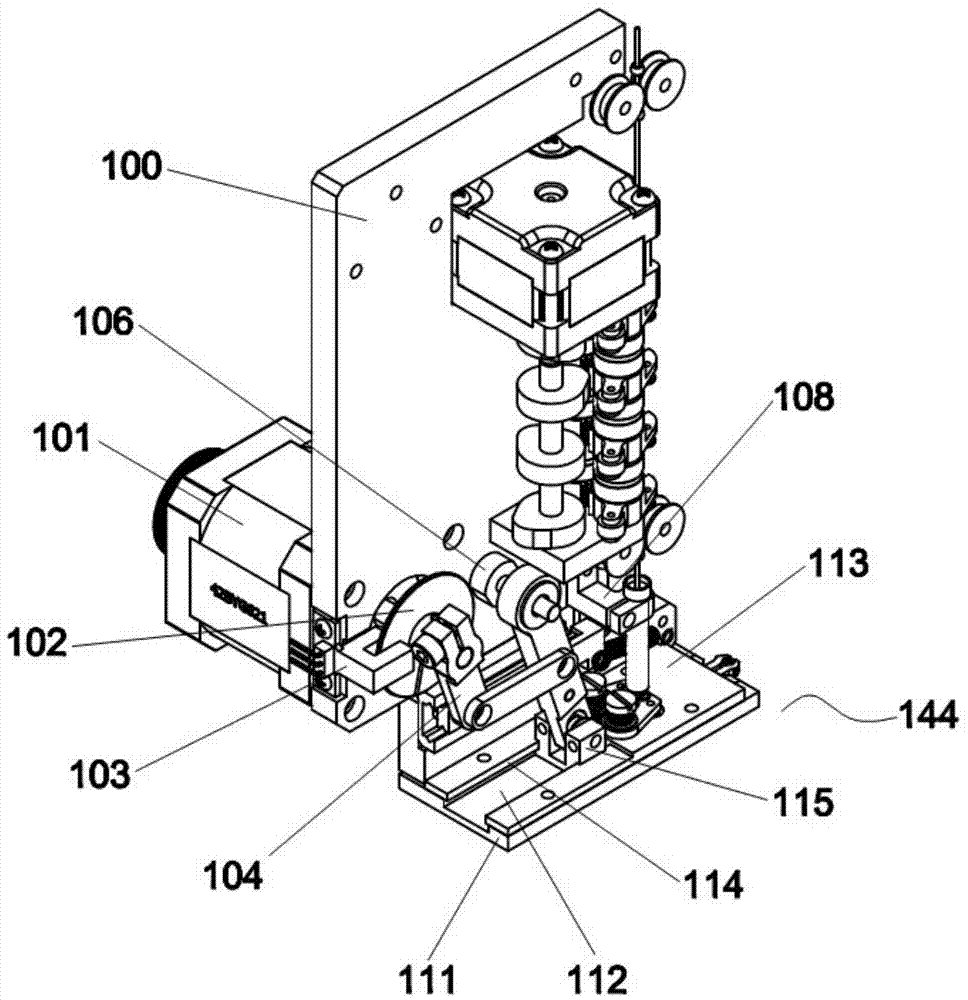

ActiveCN104213345AImprove the purpose of rowing pearlsArranged in orderAutomatic machinesAuxillary devicesWork performanceDrive shaft

The invention discloses an automatic beading device of pearl embroidery. The automatic beading device comprises a pearl guide pole used for guiding embroidery pearls to fall and a pearl feeding mechanism. The pearl feeding mechanism comprises a frame, a power driving device, a transmission shaft and a clamping device. The power driving device is arranged at the lower end of the frame. A plurality of eccentric blocks are arranged on the transmission shaft. The clamping device comprises a plurality of clamping jaw mechanisms matched with the eccentric blocks in use. One ends of the clamping jaw mechanisms clamp the pearl guide pole, and the other ends of the clamping jaw mechanisms butt against the eccentric blocks. The power driving device drives the transmission shaft to rotate further to drive the eccentric blocks to rotate alternately, thereby opening and closing the corresponding clamping jaw mechanisms to clamp the pearl guide pole alternately so as to achieve downward conveying of the embroidery pearls. The automatic beading device has the advantages of being high in the automation degree, stable in the work performance, high in production efficiency and applicable to embroidery pearls in different size and different shape.

Owner:WENZHOU OULUOHUA INDAL

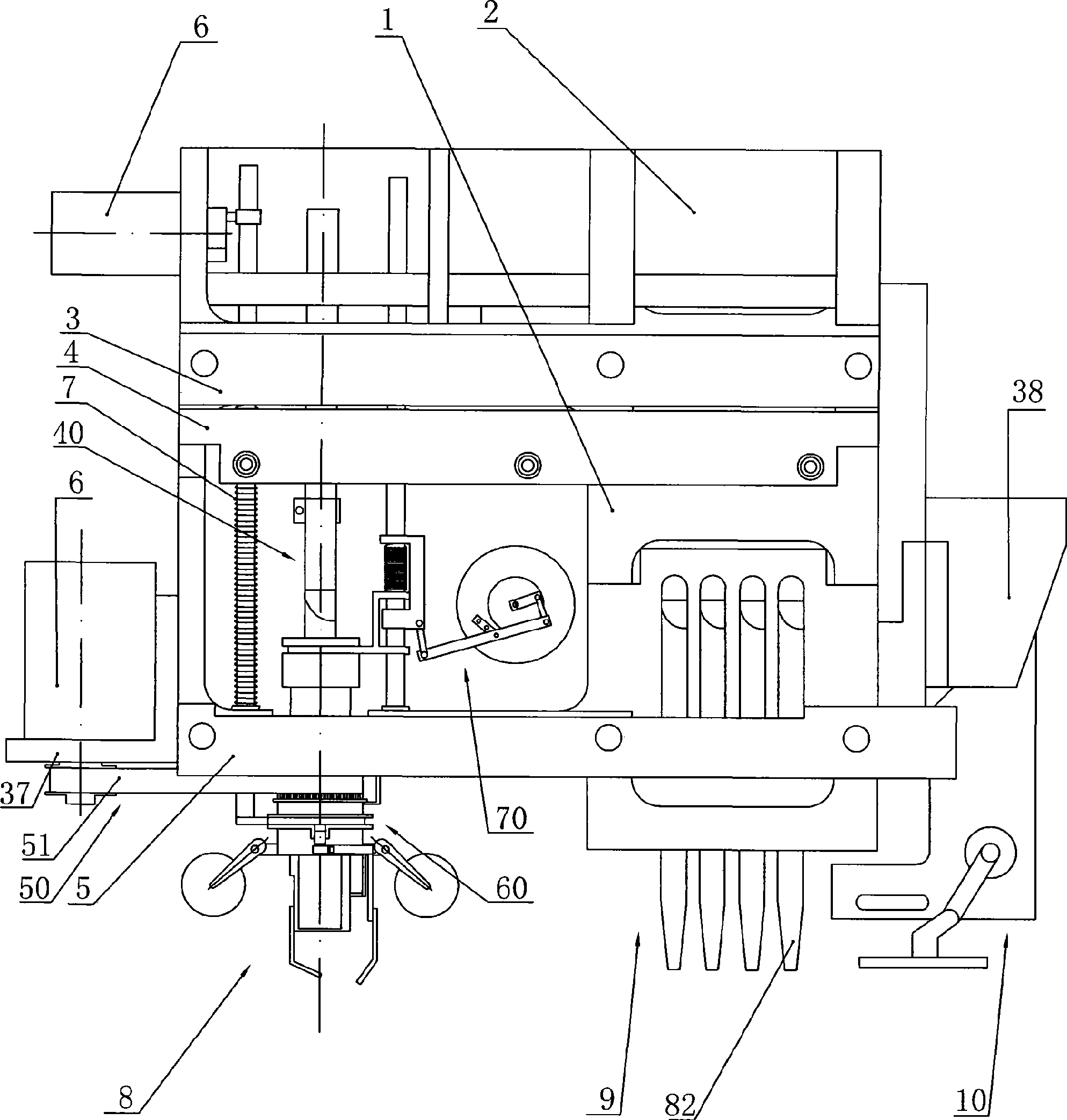

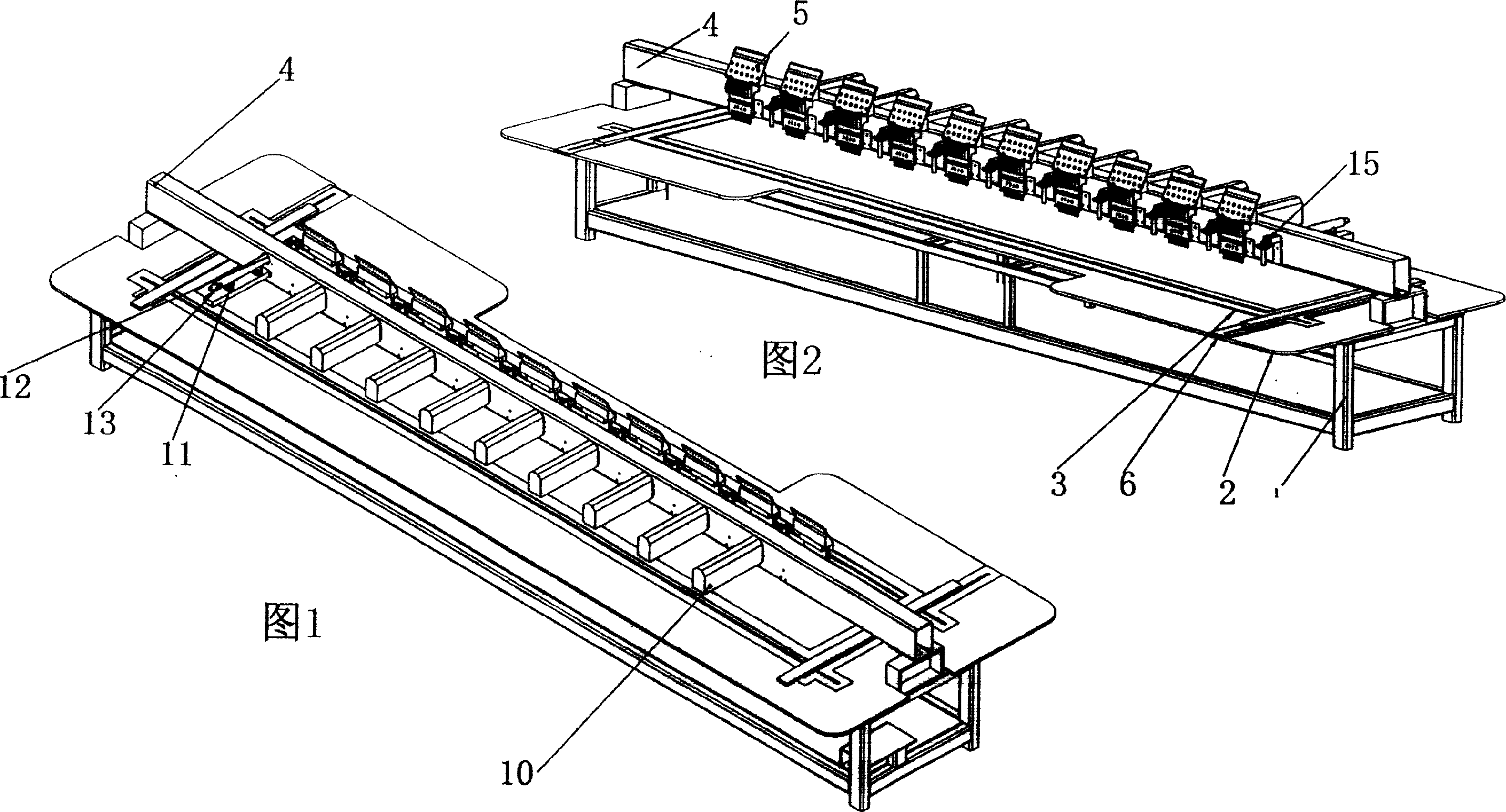

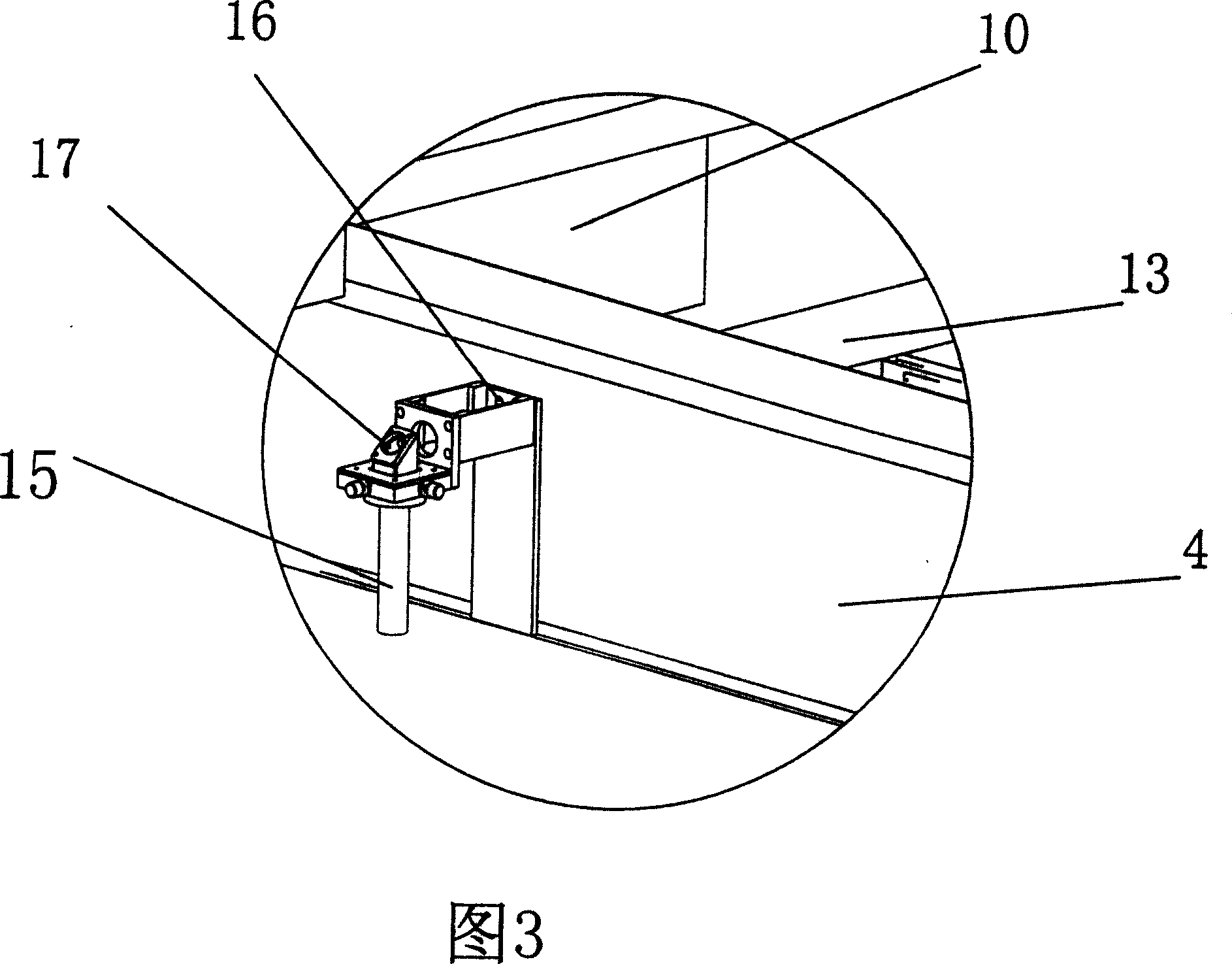

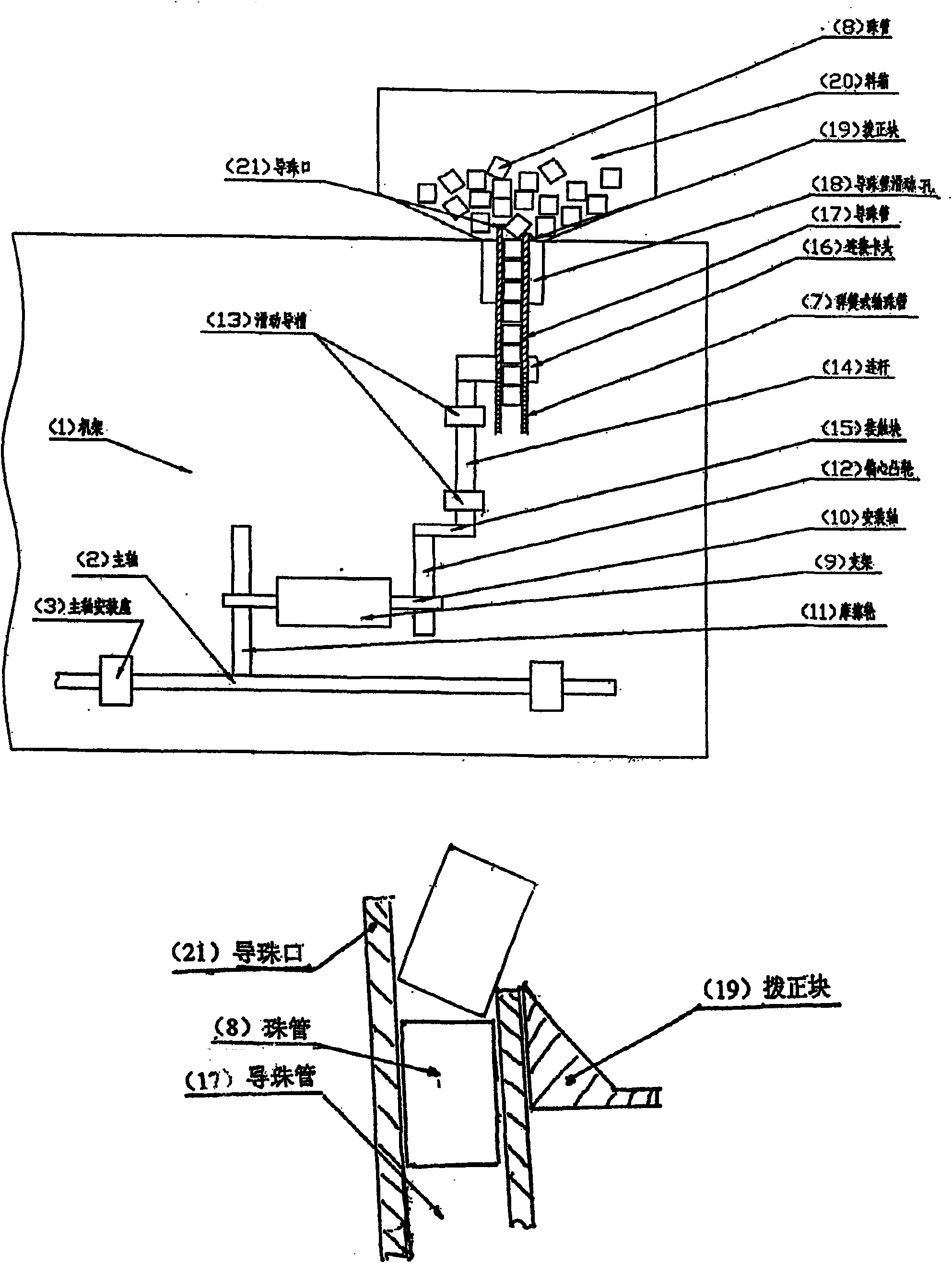

Tube-bead embroidery automatic feeding device

InactiveCN101603254ARealize fully automatic operationImprove sewing qualityAutomatic machinesAuxillary devicesReciprocating motionEngineering

The invention relates to an embroidering machine, and aims to provide a special sewing machine for tubes or beads, which can realize the automatic sewing of tubes or beads, and has the advantages of good sewing quality, high working efficiency and low processing cost. The technical proposal of the invention is characterized in that: the tube-bead embroidery automatic feeding device comprises a feeding device and a pushing device which is matched with the feeding device and is capable of making the straight reciprocating motion, wherein the feeding device is provided with a vibration type feeder, and a bead guide tube of the feeder is an output pipeline of tubes or beads; the pushing device faces the outlet end of the bead guide tube and is provided with a bead guide seat provided with a horizontal track, a bead pushing plate capable of making the reciprocating motion along the track, a swinging mechanism driving the bead pushing plate to move and an air suction device sucking air in a cavity in the bead guide seat through an air suction tube; and the front end of the bead guide seat is provided with a bead guide hole vertically downward, and a space is reserved between the bottom end face of the bead guide hole and the surface of the working table, so that the tubes or beads can be conveniently outputted.

Owner:ZHUJI MAYA ELECTRIC APPLIANCE MACHINERY

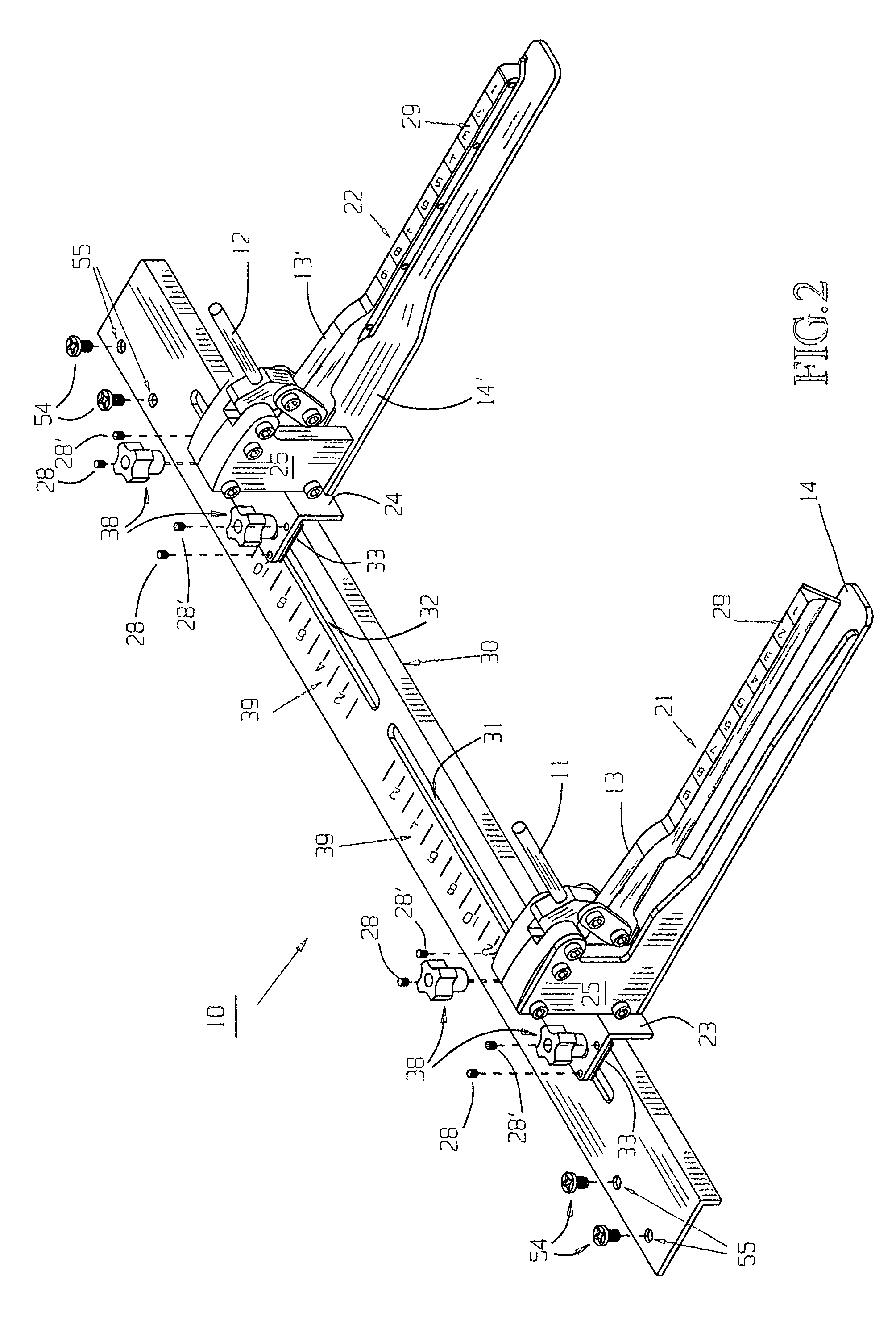

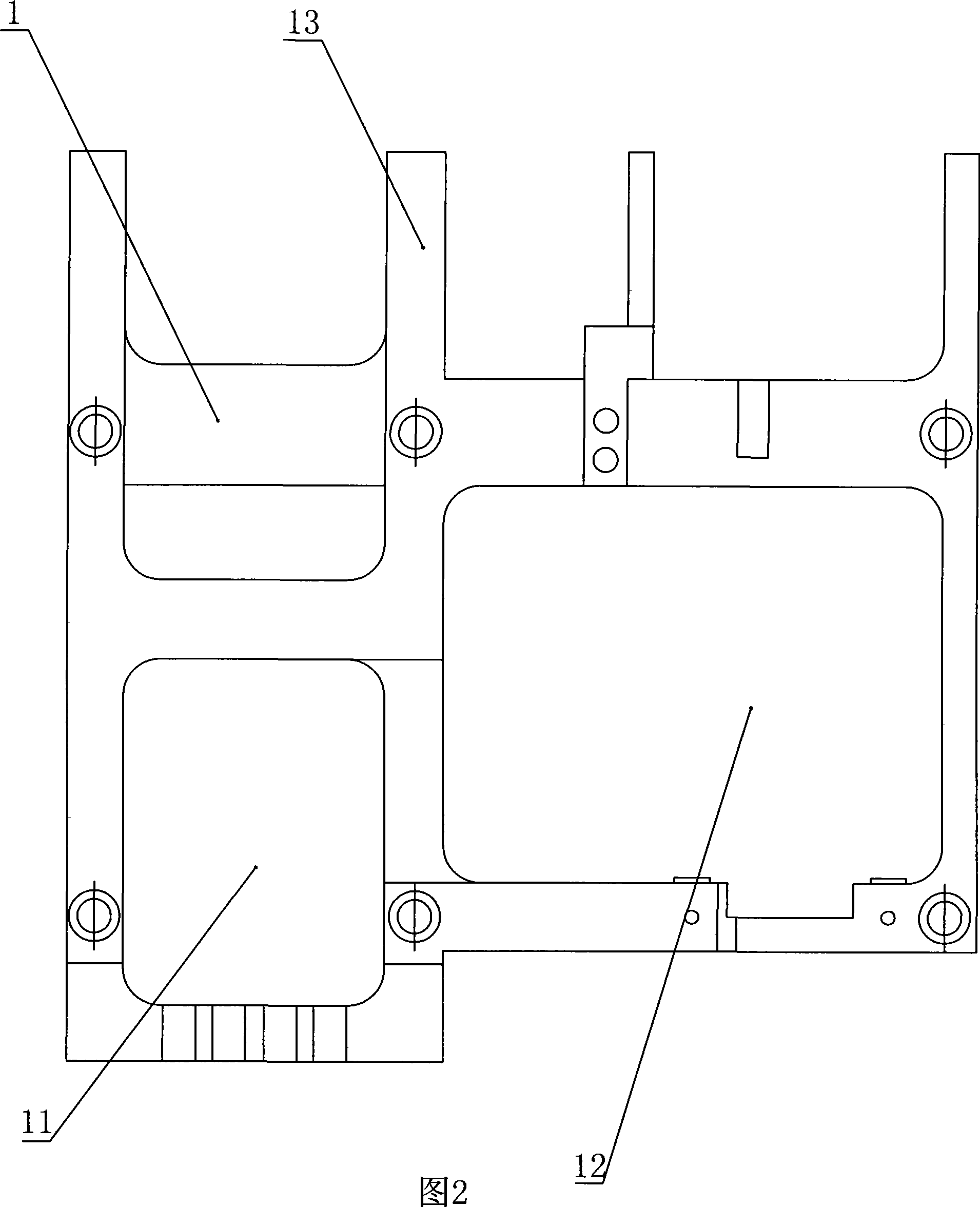

Clamping device for a sewing machine and method

ActiveUS7377222B1Assures speed and efficiencyWork-feeding meansTake-up devicesEngineeringSewing machine

A clamping device and method for a conventional sewing or embroidery machine has a pair of movable arms. Each of the arms includes a fixed section and a movable section for receiving material or item to be embroidered therebetween. A manual lever allows the movable arm to be raised for insertion of the material and a scale on the arm allows the depth of insertion to be easily determined for accurate insertion. Each arm is movable along a slotted mounting plate affixed to the sewing machine proximate the sewing head. The clamping device provides uniform, taut material for accurate, smooth embroidering.

Owner:EFP INC

Real-time monitoring method and monitoring system for thread condition of computerized embroidery machine

InactiveCN102505381ADynamic tension adjustmentReduce labor intensityAuxillary devicesMonitoring systemElectric control

The invention discloses a real-time monitoring method and a monitoring system for the thread condition of a computerized embroidery machine. The monitoring method is mounting a thread flow condition monitoring device and a thread tension adjusting device on a machine head adjusting platform, so as to detect and judge the real-time condition of an embroidering thread during embroidery, carry out corresponding recording, warning or compensation according to the real-time condition, and transmit to an electric control system. The monitoring system comprises the machine head adjusting platform, wherein the thread flow condition monitoring device and the thread tension adjusting device are mounted on the machine head adjusting platform; and the embroidering thread can pass through the thread flow condition monitoring device and the thread tension adjusting device sequentially. The invention has the advantages that real-time embroidering thread condition monitoring, embroiderer tension adjustment and thread consumption calculation can be carried out during embroidery; thread breakage detection, real-time thread quantity variance compensation, and accurate judgment on thread flowing quantity and thread flowing direction can be carried out accurately, so as to reduce thread breakage rate, and improve embroidery quality and the like; and important information such as thread consumption quantity can be collected, so as to optimize production management.

Owner:HUI ZHOU SHENTIAN PRECISION MACHINES

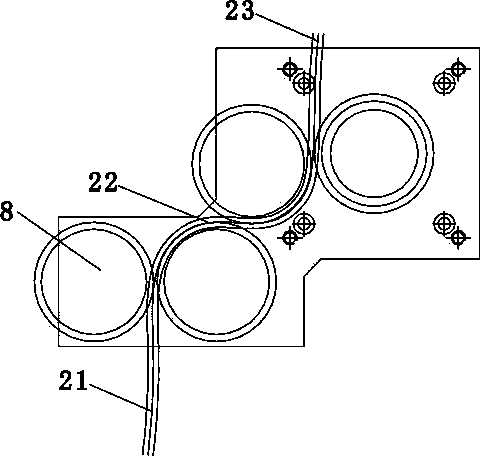

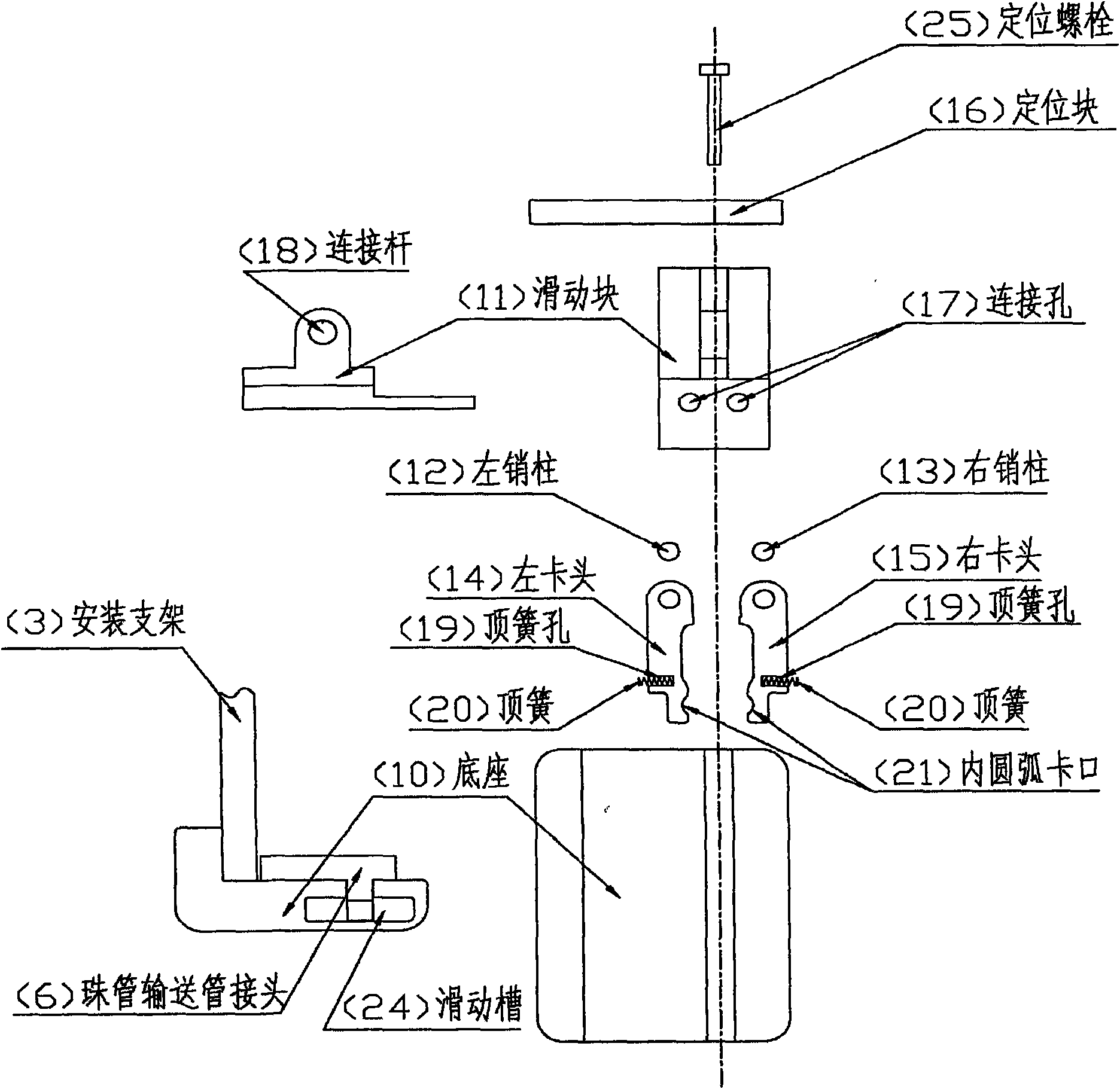

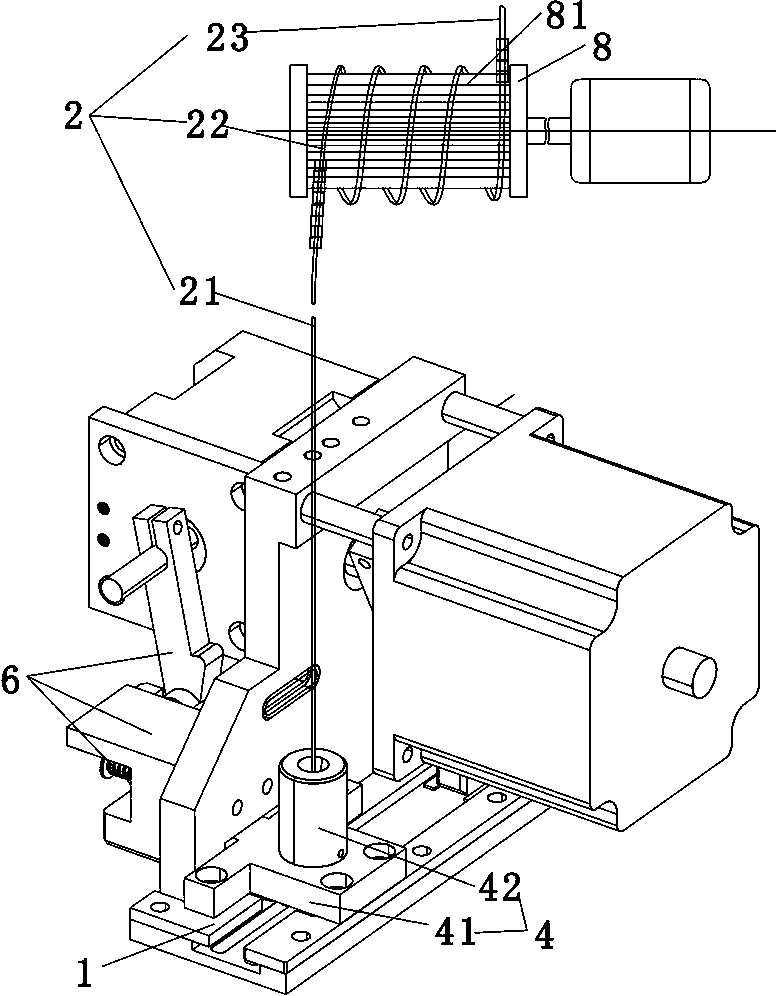

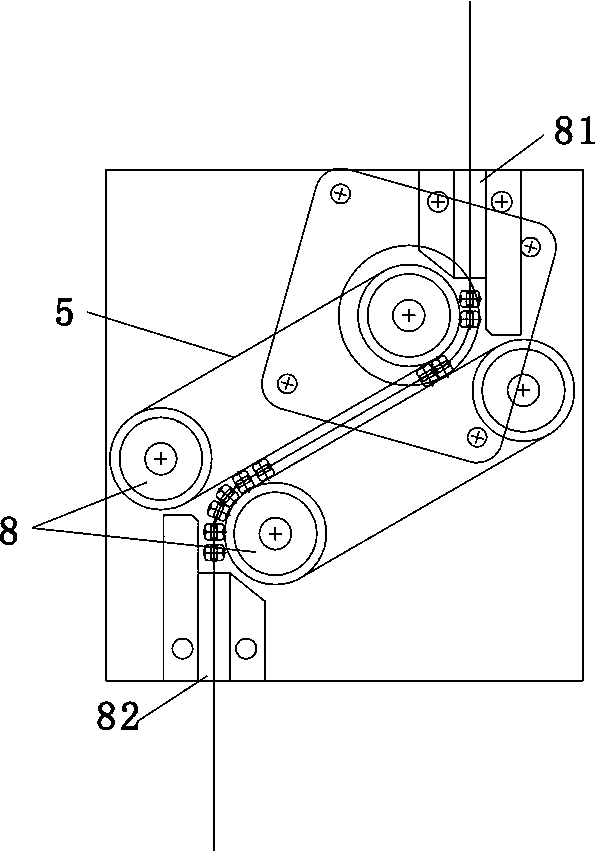

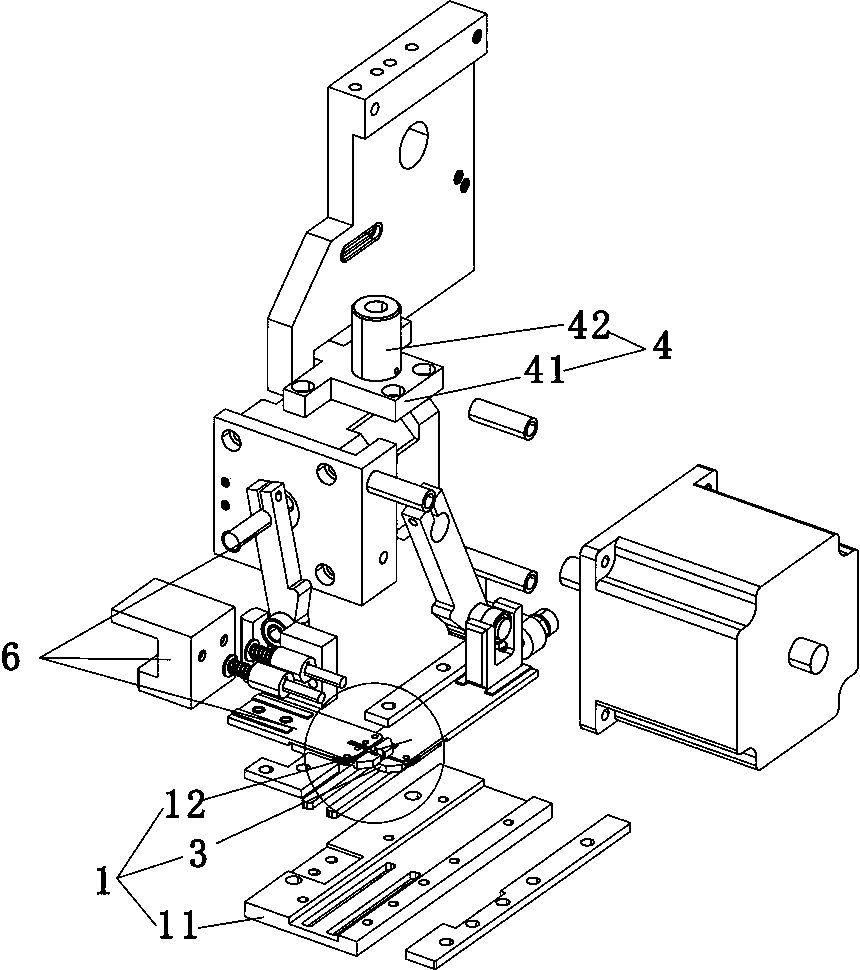

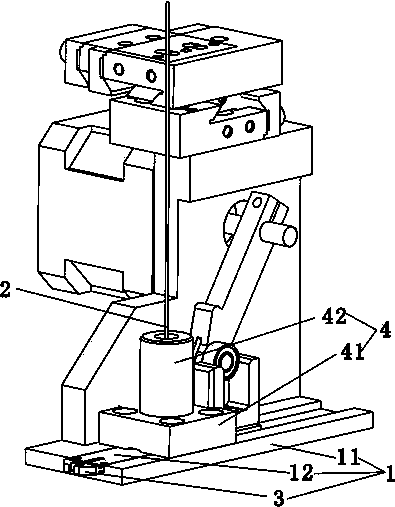

Pearl embroidery device for computerized embroidery machine

ActiveCN104514104ASimple structureEasy maintenanceAutomatic machinesAuxillary devicesRejection rateBead embroidery

The invention discloses a pearl embroidery device for a computerized embroidery machine. The pearl embroidery device comprises a conveying mechanism, a feeding mechanism and a pearl guiding wire, wherein the conveying mechanism comprises a base and a holder, a chute is arranged on the base, the holder is mounted in the chute in a matched manner, a jaw slideway is arranged on the base, a jaw formed by two parallelly arranged holding arms is arranged at one end of the holder, at least one group of hold-down devices is symmetrically arranged on two sides of the jaw slideway, and the hold-down devices enable the holding arms on the holder, which slides in the jaw slideway, to be always subjected to a force pressing the jaw. The pearl embroidery device is simple in structure; the hold-down devices enable pearls to be always subjected to a force pressing the jaw when sliding in the jaw slideway to ensure that the pearls are always in a pressing state, so that accurate positioning of the pearls is guaranteed, and the embroidery product is improved. The pearl embroidery device is convenient to maintain, safe and reliable in operation and smooth and uninterrupted in pearl supply, improves the working efficiency and lowers the rejection rate.

Owner:WENZHOU OULUOHUA INDAL

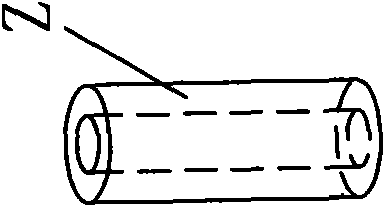

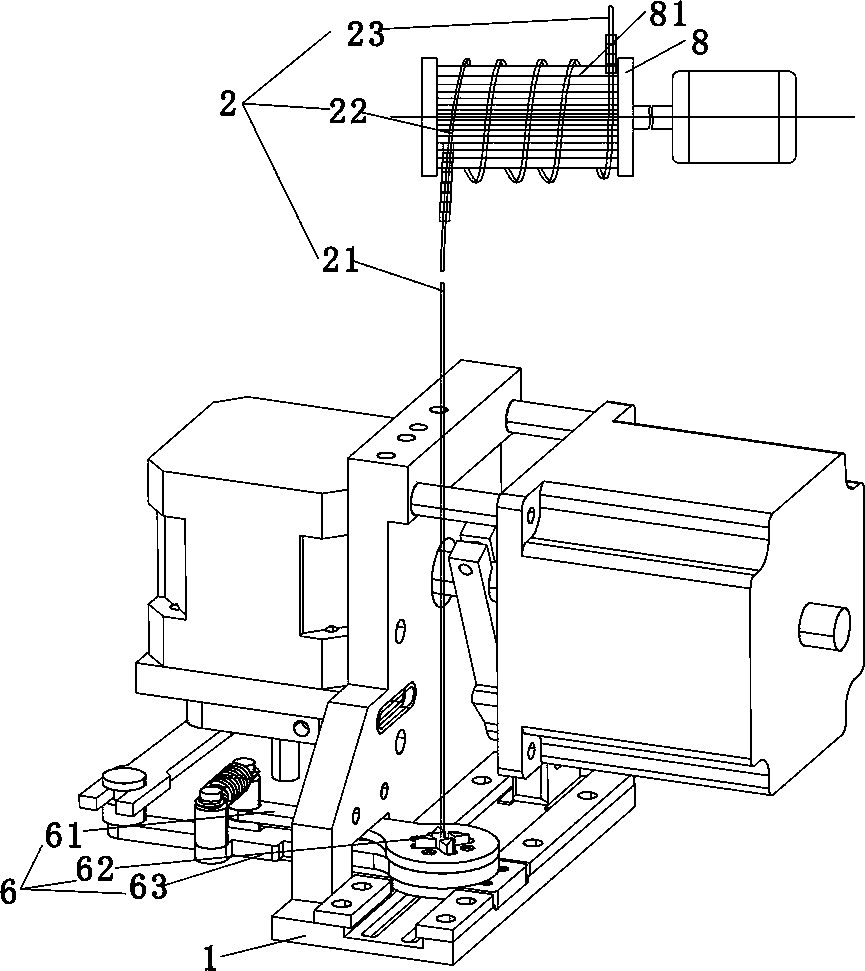

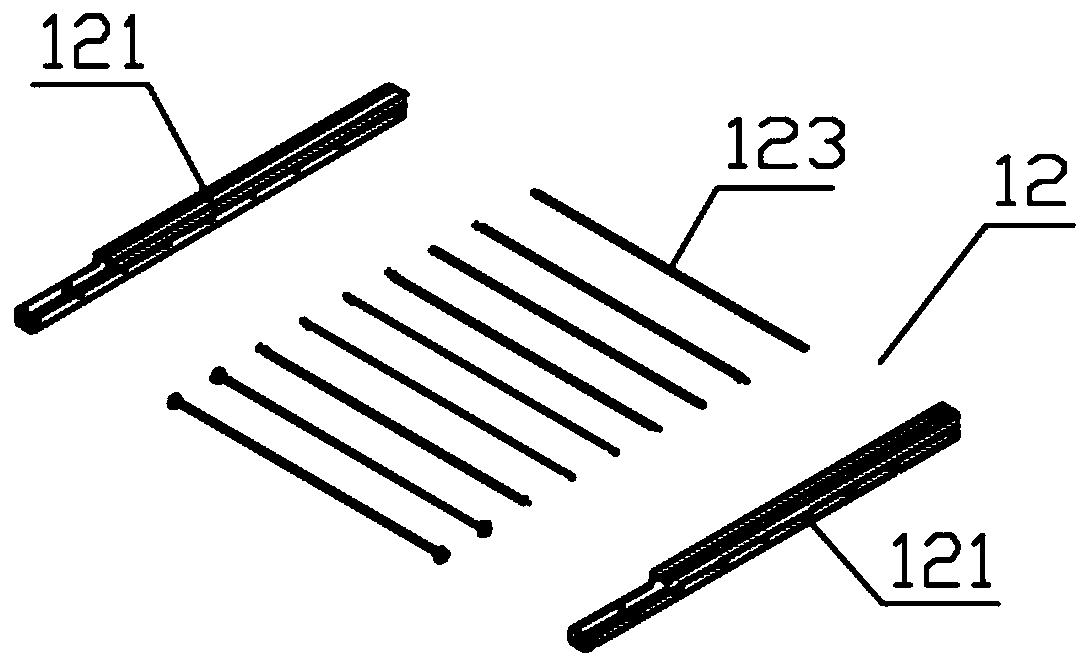

Embroidery bead supply device and embroidery machine using same

ActiveCN103757836APrecise positioningPrecisely throughAutomatic machinesAuxillary devicesEngineeringMechanical engineering

The invention discloses an embroidery bead supply device and an embroidery machine using the same. The device comprises a feeding mechanism which conveys embroidery beads one by one to a position right below an embroidery needle of an embroidery machine and also comprises a bead guide bar which is suspended above the feeding mechanism and used for continuously supplying the embroidery beads to the feeding mechanism, wherein the bead guide bar is threaded through the embroidery beads to form a bead string. According to the invention, the bead guide bar is suspended above the feeding mechanism, the bead string composed of the embroidery beads is arranged on the bead guide bar, the bead string can realize continuous supply to the feeding mechanism, and a bead guide pipe in the bead string can accurately position the embroidery beads, so that an embroidery needle can be accurately threaded through pinholes in the embroidery beads, thus embroidering the embroidery beads on textile. The bead guide bar is arranged on a machine head in a detachable manner, so that the bead guide bar can be accurately positioned; and meanwhile, the bead guide bar can be used for replacing the bead string, thus facilitating continuous supply.

Owner:湖州南浔魅力新农村建设有限公司

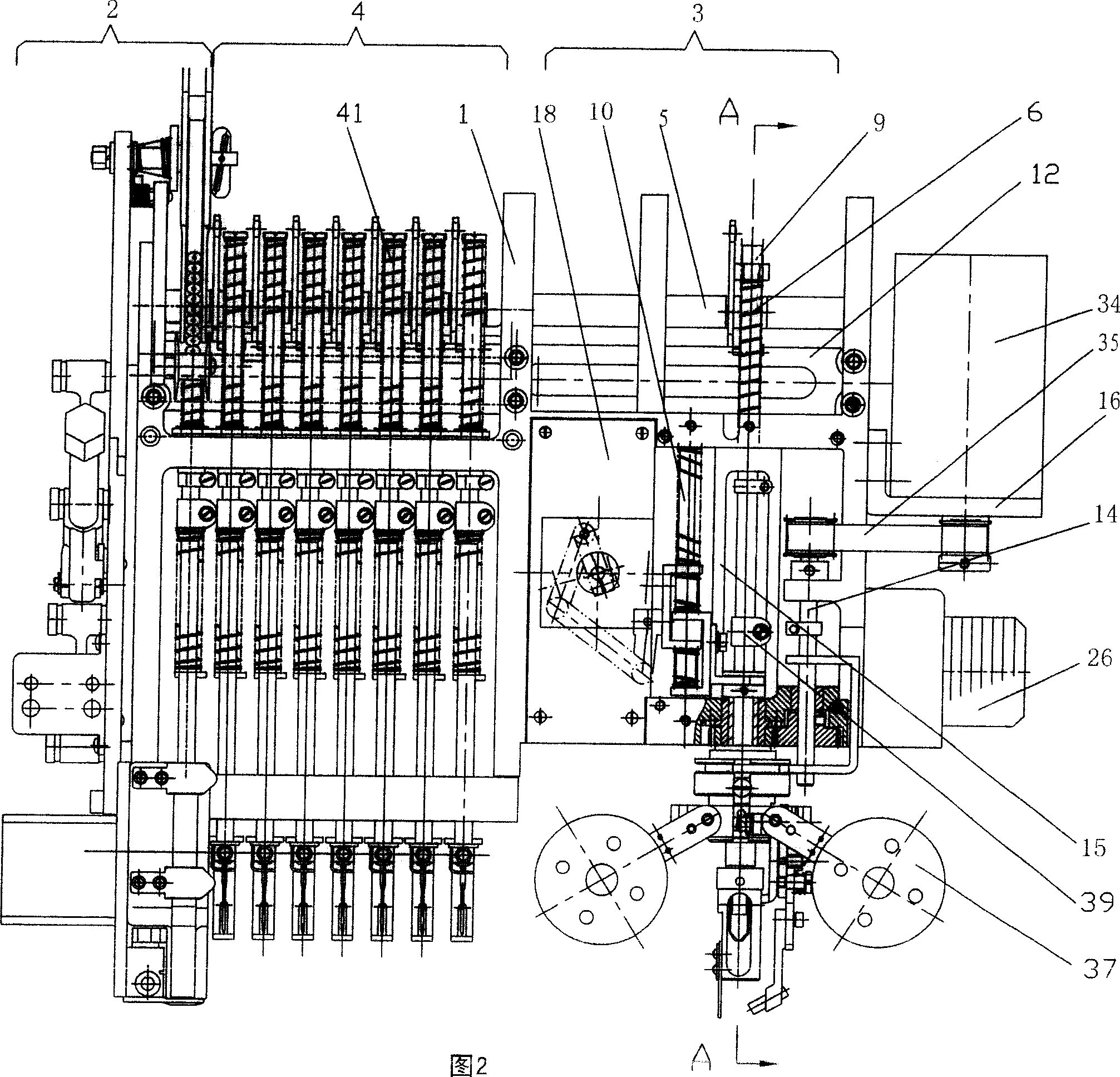

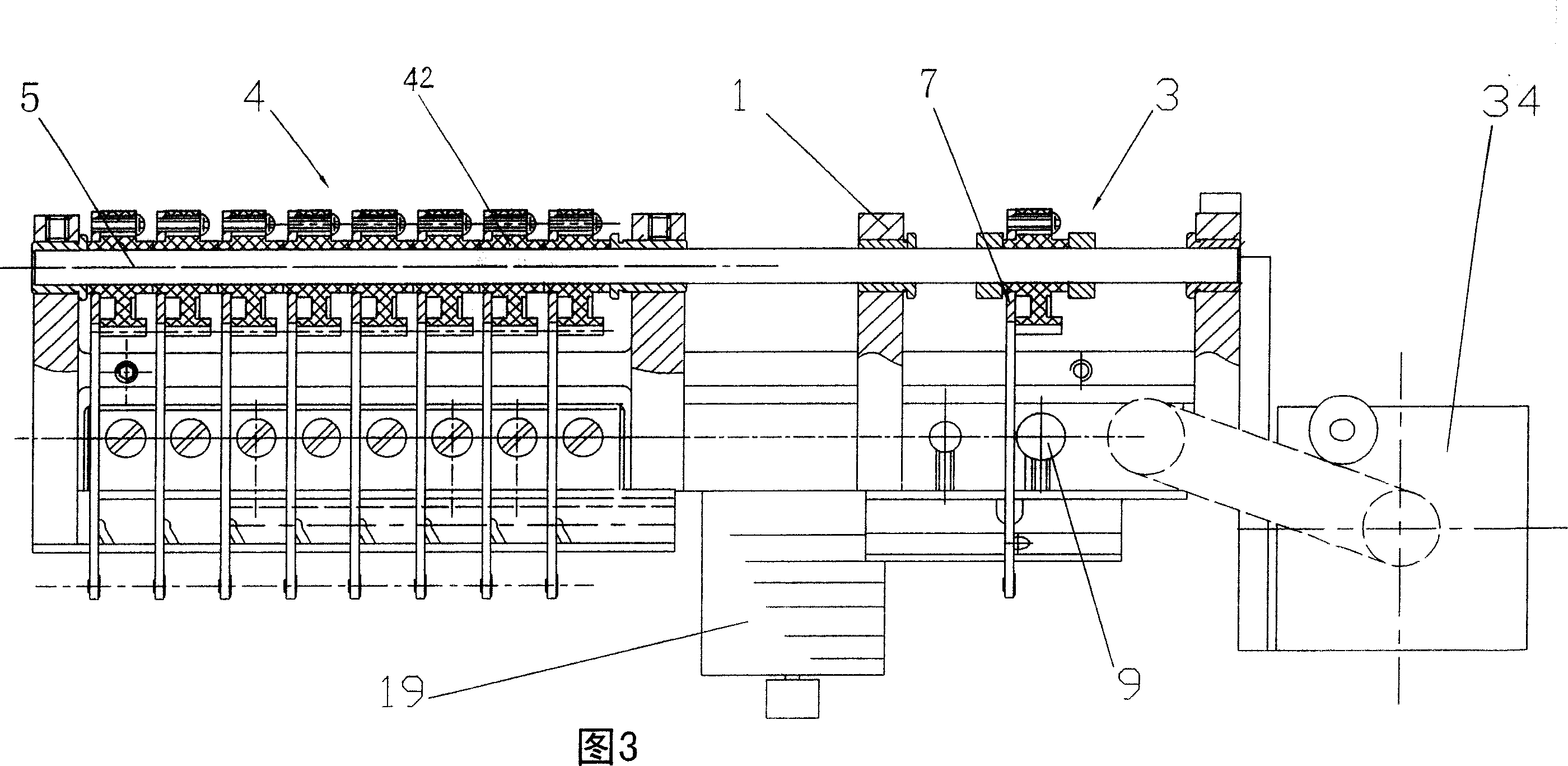

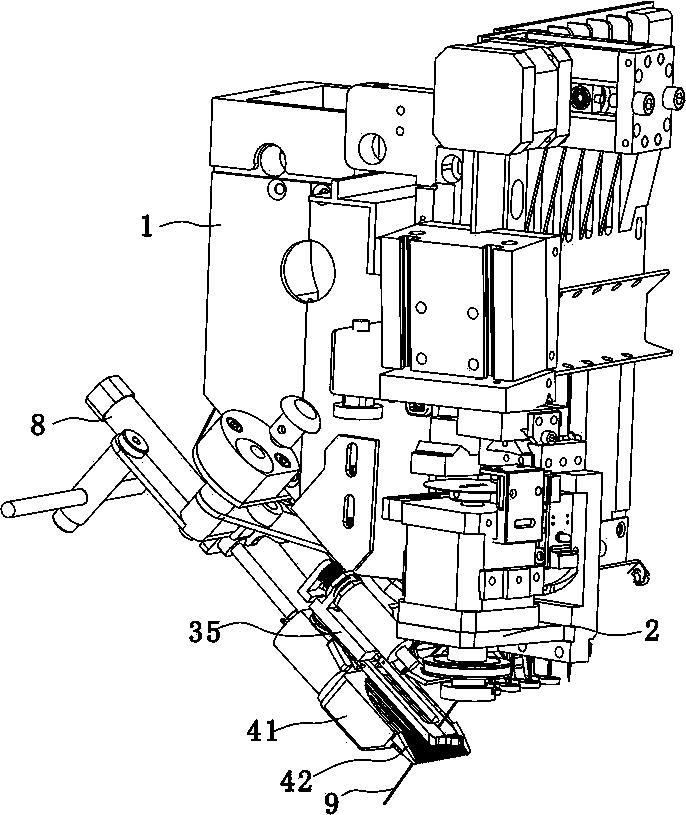

Main drive shaft sharing integrated embroidery machines

InactiveCN101397732AEasy to switchAchieve embroidery effectAutomatic machinesAuxillary devicesState of artDrive shaft

The invention relates to an all-in-one sharing embroidery machine that shares a main transmission shaft, integrates braid embroidery, flat embroidery and spangle embroidery and adopts the same transmission shaft for control, which solves the defects that the prior art needs a plurality of transmission shafts and has complicated structure and large size. The embroidery machine is mainly characterized in that a braid embroidery module, a flat embroidery module and a spangle embroidery module are fixed on an overall frame, arranged on a chassis by a back transmission seat and connected with the main transmission shaft so as to share the same main transmission shaft; the overall frame is divided into a braid embroidery module frame and a flat embroidery module frame; the braid embroidery module comprises a strip rotating mechanism, a braid wobbler mechanism, a presser foot height controlling mechanism and a pricker stretching and drawing control mechanism; each mechanism is provided with an independent driving device, integrated as a whole and connected by the transmission seat, thereby sharing the same main transmission shaft, having simple structure and conveniently reducing size and switching between embroidery methods of various characteristics.

Owner:浙江科宇缝制设备制造有限公司

Multifunctional intelligent embroidery machine nose

InactiveCN102560923AIncrease the number ofSave installation spaceAutomatic machinesAuxillary devicesBiomedical engineering

The invention relates to a multifunctional intelligent embroidery machine nose comprising a plain embroidery device and a band and rope embroidery device, wherein the plain embroidery device comprises plain embroidery needle bars, a needle bar frame and a computer embroidery controller, the plain embroidery needle bars are arranged on the needle bar frame in parallel, and a transmission arm of the plain embroidery needle bars is connected with the output end of the computer embroider controller; and the band and rope embroidery device comprises band and rope embroidery needle bars, a band andrope embroidery controller and an installation frame, the band and rope embroidery needle bars and the plain embroidery needle bars are installed on the needle bar frame in parallel, the installationframe is fixedly arranged on the needle rod frame through screws, and a transmission arm of the plain embroidery needle bars is connected with the output end of the computer embroidery controller. The multifunctional intelligent embroidery machine nose realizes plain embroidery and band and rope embroidery, saves an installation space, increases the number of embroidery machine heads on unit length, has the advantages of high production efficiency, low work noise, simple structure, long service life and the like, and is applicable to a multifunctional computer embroidery machine with the functions of plain embroidery, band embroidery and rope embroidery.

Owner:永嘉县德宝机械有限公司

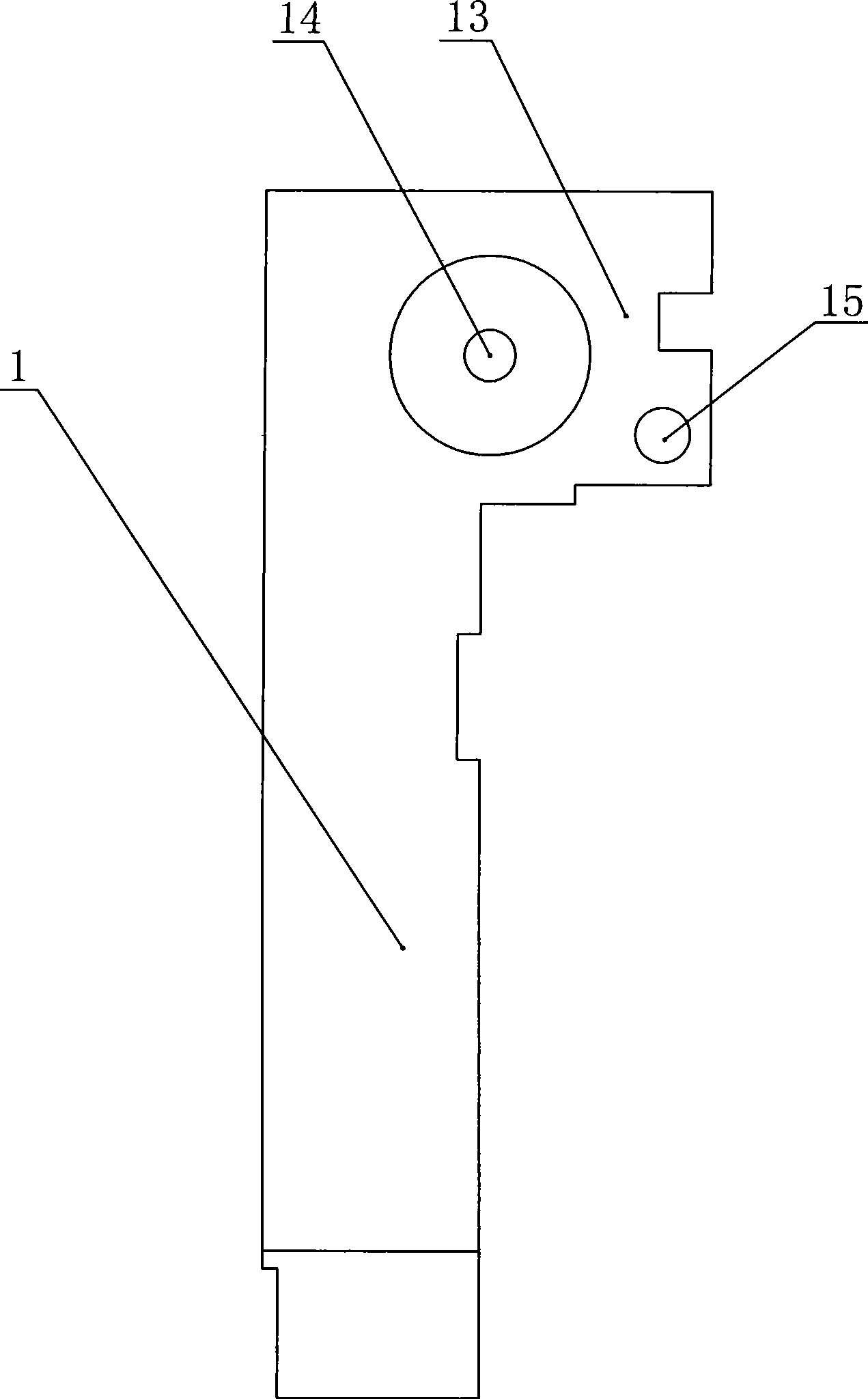

Two-color bead embroidery machine head

ActiveCN105624942AMeet the simultaneous useImprove performanceAutomatic machinesAuxillary devicesEngineeringGuide tube

The invention discloses a two-color bead embroidery machine head. The two-color bead embroidery machine head comprises a frame, a bead stringing device and a feeding device, wherein the bead stringing device comprises a first bead guide tube and a second bead guide tube; the two-color bead embroidery machine head further comprises a sorting device; the sorting device is arranged on the frame and comprises a driving mechanism and a sorting plate arranged on the driving mechanism; a bead sorting hole is formed in the sorting plate and is used for feeding a bead to be embroidered to the jaw of the feeding device. The two-color bead embroidery machine head can meet the requirement on using beads with different specifications at the same time, and is stable in performance and high in efficiency.

Owner:WENZHOU OULUOHUA INDAL

Embroidered bead delivery device and feeding method

ActiveCN103866503APrecise deliveryPrecisely throughAutomatic machinesAuxillary devicesMechanical engineering

The invention discloses an embroidered bead delivery device. The embroidered bead delivery device comprises a feed mechanism for delivering embroidered beads to the position under a needle of an embroidery machine one by one, wherein the feed mechanism is provided with a clamping hole for clamping and positioning the embroidered beads; a bead guide rod for supplying the embroidered beads to the feed mechanism is hung above the feed mechanism; the embroidered beads are strung on the bead guide rod to form a bead string; a positioning structure for positioning the embroidered beads which are about to slide into the corresponding feed positions of the feed mechanism from the bead guide rod is also arranged above the feed mechanism. The embroidered bead delivery device has the beneficial effects that the hung bead guide rod and the positioning structure for positioning the embroidered beads which are about to slide into the corresponding feed positions of the feed mechanism from the bead guide rod are arranged above the feed mechanism, the bead guide rod is provided with the bead string formed by the embroidered beads, the bead string can continuously supply materials to the feed mechanism, and the bead guide rod and the positioning structure can accurately position the embroidered beads to enable the embroidered beads to accurately slide into the corresponding positions of the feed mechanism as required so as to accurately position and deliver the embroidered beads, so that the needle can accurately penetrate through the needle holes in the embroidered beads to embroider the embroidered beads on fabrics.

Owner:诸暨市化工机械厂

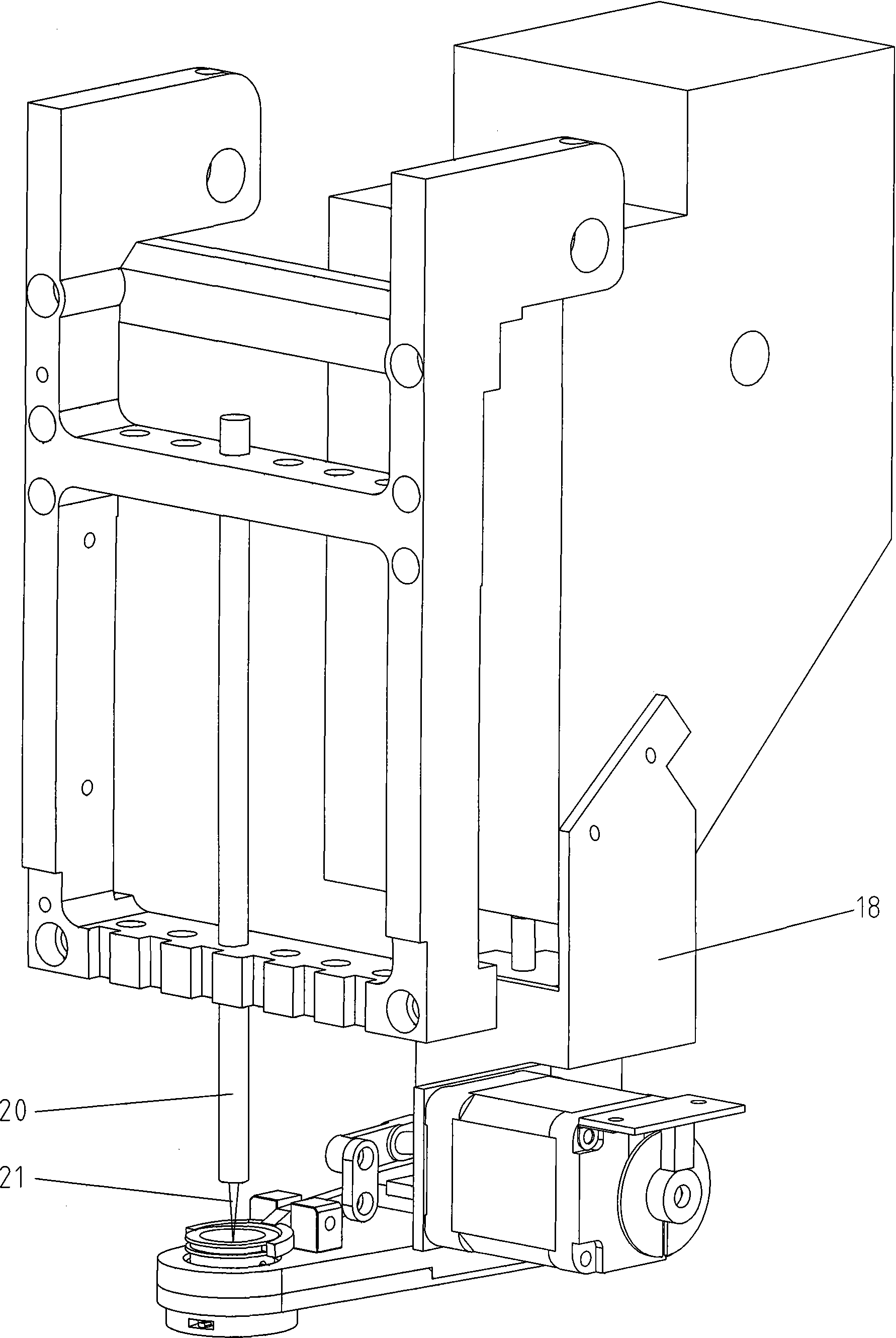

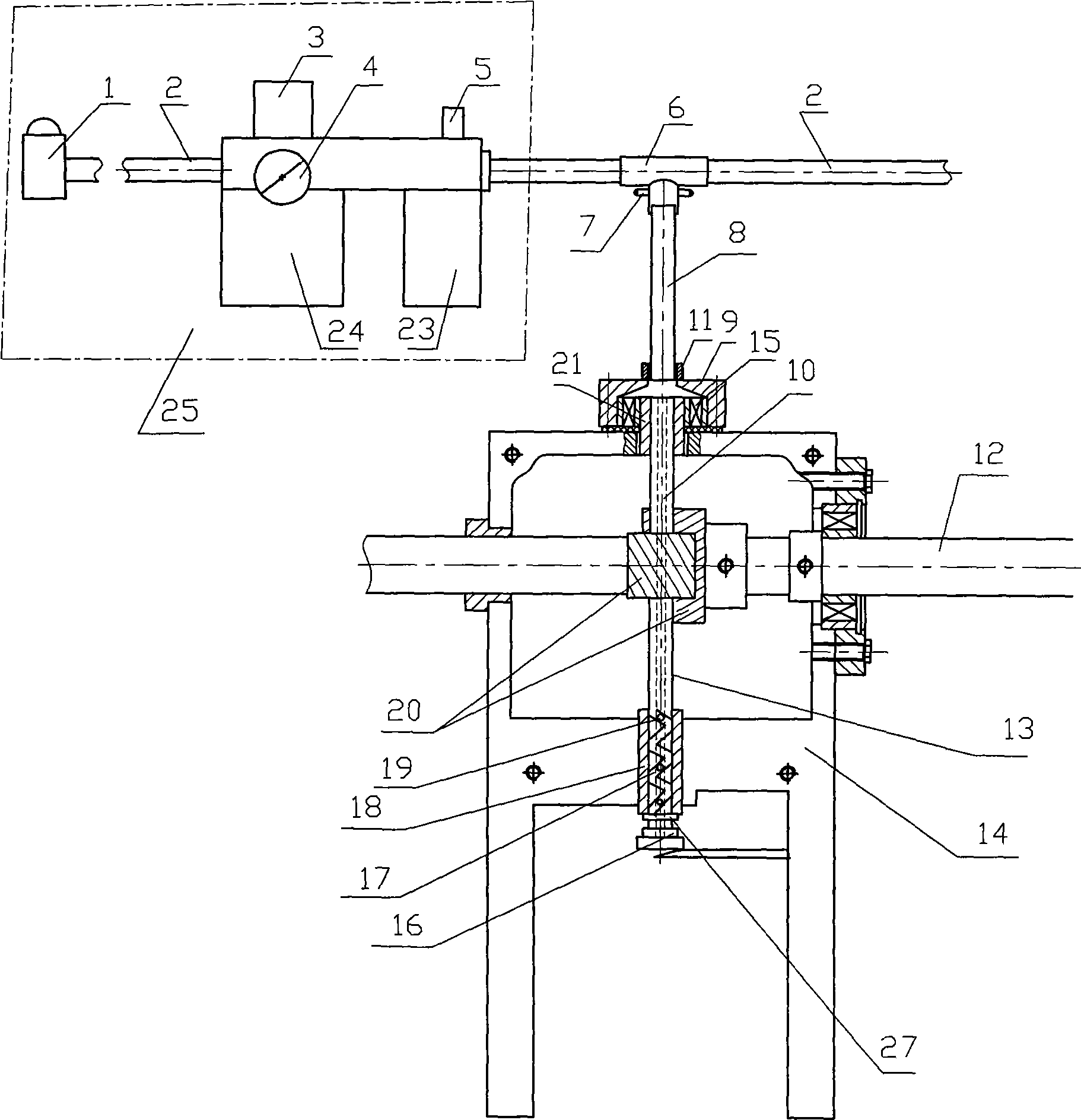

360-degree omnibearing additional towel embroidery device

InactiveCN101831769APerfect and effective embroideryImprove product added valueAutomatic machinesAuxillary devicesReciprocating motionEngineering

The invention relates to a towel embroidery device matched on a shuttle-type computer embroidery machine, aiming to solve the technical problems that the provided device is required to embroider towel stitches in any direction within a 360-degree range of a shell fabric plane, the embroidering effect is ideal, and the quality of an embroidery product is good. The invention adopts the technical scheme that the 360-degree omnibearing additional towel embroidery device comprises a stand and a controller; and the device is also internally provided with a towel deflector rod capable of rotating around a vertical axis, a combined set provided with the towel deflector rod, a vertical motion mechanism used for driving the combined set to do vertical reciprocating motions and a rotating mechanism used for driving the combined set to rotate around the vertical axis, wherein the stand is provided with a detector for detecting the rotating angle of the towel deflector rod and a second detector for detecting the vertical reciprocating motions of the combined set, and the detector and the second detector are both communicated with the controller through data lines.

Owner:蔡国忠

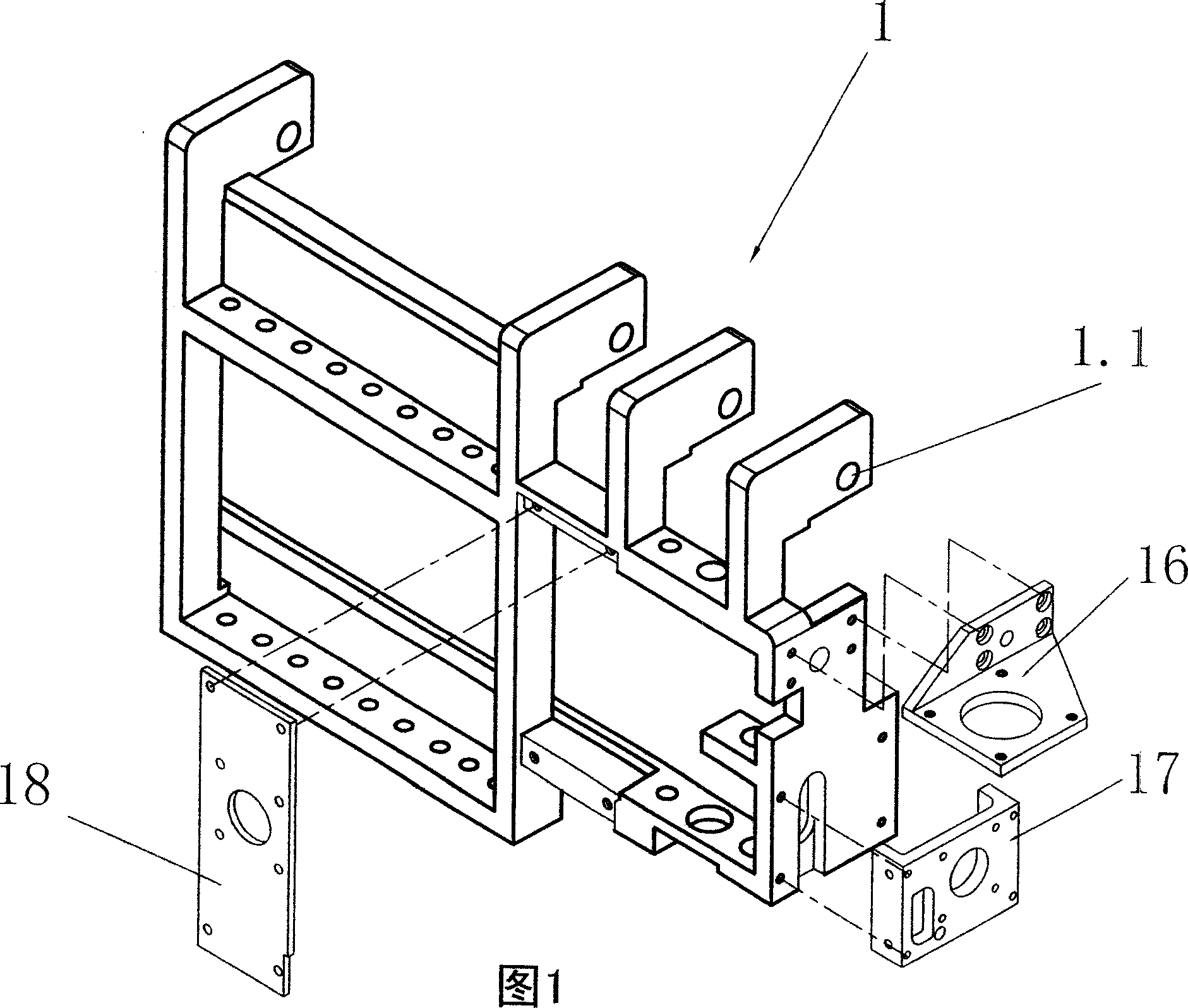

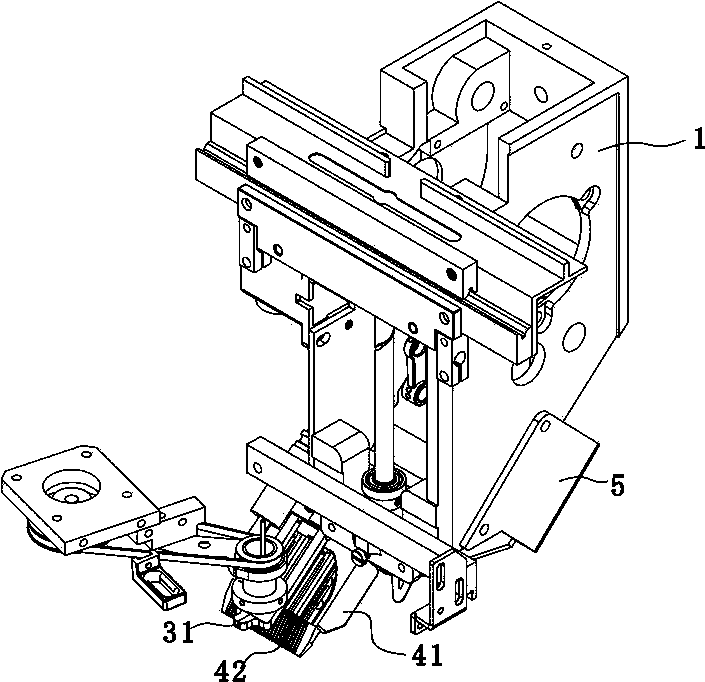

Composite embroidering needle bar rack set of computer embroidering machine

InactiveCN101003933AIncrease embroidery areaCompact structureAutomatic machinesAuxillary devicesElectric machineryEngineering

The present invention belongs to the field of garment machinery, in particular, it relates to a mixed embroidery needle bar frame device of computer embroidery machine. Said device includes gold piece embroidery mechanism, flat embroidery needle bar mechanism and coil band embroidery mechanism. On the needle bar frame a lengthened upper guideway, a lower guideway and a take-up lever shaft are mounted. Besides, said invention also includes a drive motor seat, a swinging motor seat and a presser lifting motor seat. Said invention also provides the connection mode of all the above-mentioned components.

Owner:浙江珠光集团临海电脑刺绣设备有限公司

Embroidery bead supply method

ActiveCN103757837APrecise positioningPrecisely throughAutomatic machinesAuxillary devicesEngineeringMechanical engineering

The invention discloses an embroidery bead supply method which comprises the following steps: threading a bead guide bar through embroidery beads to form a bead string, suspending the bead string in a position corresponding to a feeding mechanism, and matching with the feeding mechanism for continuous supply to the feeding mechanism. According to the invention, the bead guide bar is suspended above the feeding mechanism, the bead string composed of the embroidery beads is arranged on the bead guide bar, the bead string can realize continuous supply to the feeding mechanism, and a bead guide pipe in the bead string can accurately position the embroidery beads, so that an embroidery needle can be accurately threaded through pinholes in the embroidery beads, thus embroidering the embroidery beads on textile. The bead guide bar is arranged on a machine head in a detachable manner, so that the bead guide bar can be accurately positioned; and meanwhile, the bead guide bar can be used for replacing the bead string, thus facilitating continuous supply.

Owner:JIANGXI HEFENG ELECTRONICS MACHINES

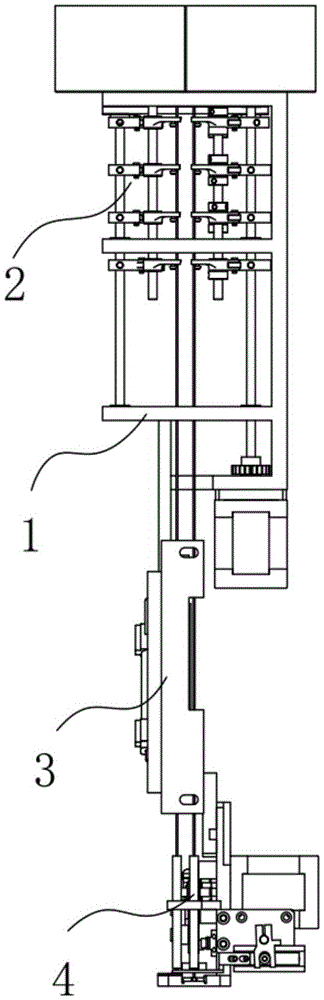

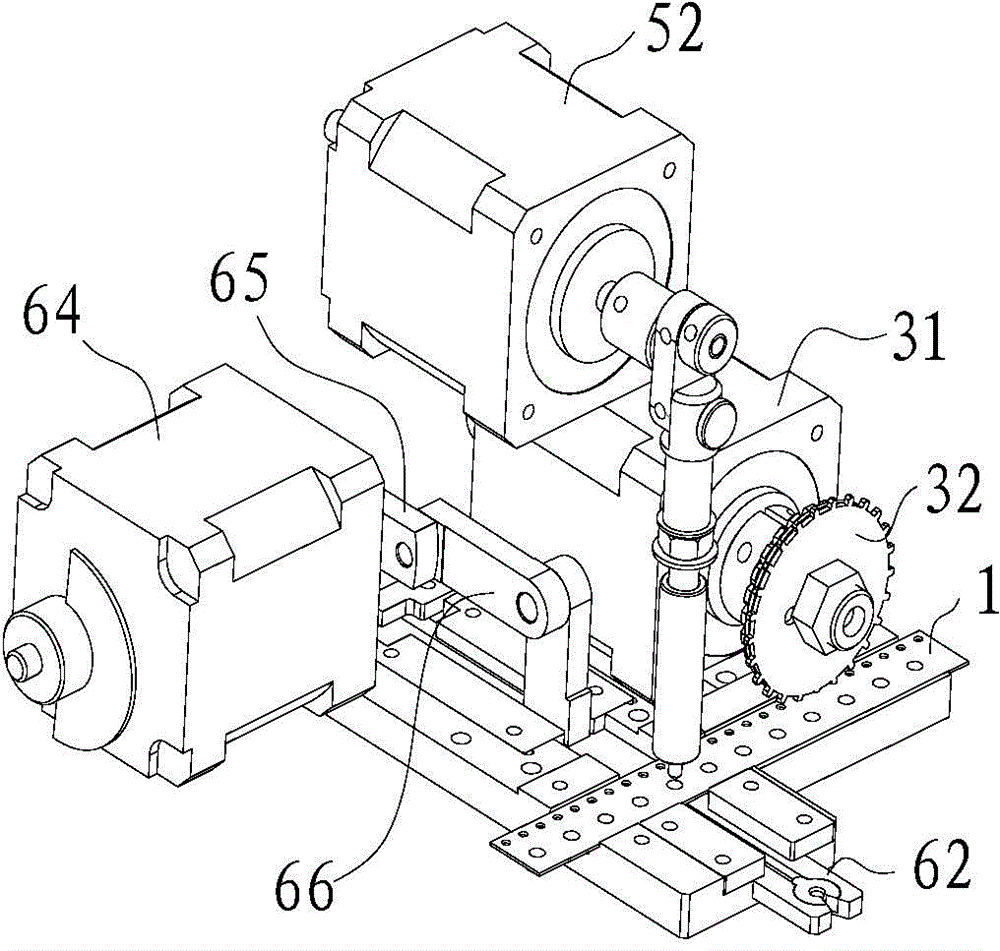

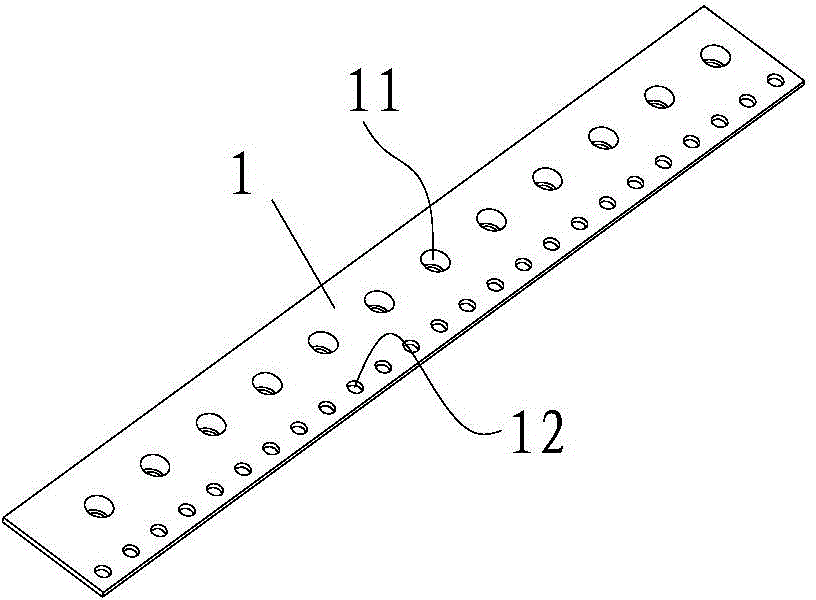

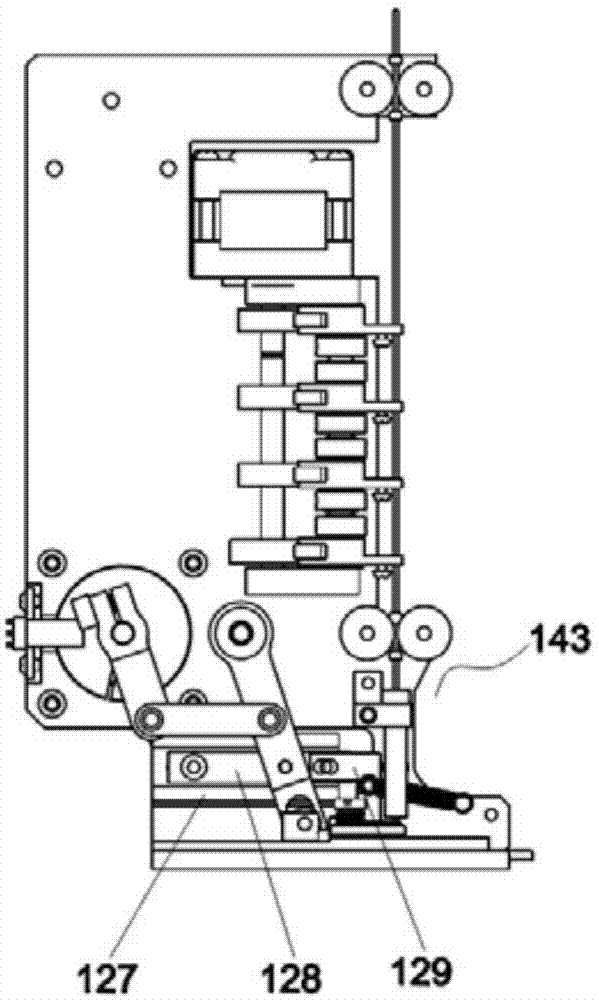

Bead embroidering mechanism of embroidering machine

ActiveCN104878536AImprove controllabilityImprove beading efficiencyAutomatic machinesAuxillary devicesEngineeringMechanical engineering

The invention provides a bead embroidering mechanism of an embroidering machine. The bead embroidering mechanism comprises a material belt, a first power device, a support, a pushing device and a feeding device, wherein a plurality of mounting positions used for holding beads are longitudinally arranged on the material belt; the first power device is used for driving the material belt to move longitudinally; a discharging position disposed on one side of the material belt is arranged on the support; the pushing device is mounted on the support and comprises a pushing head and a second power device used for driving the pushing head to move so as to push the beads at the mounting positions to the discharging position; the feeding device comprises a clamp for clamping the bead at each discharging position and a third power device used for driving the clamp to move between the discharging position and a position distant from the discharging position, and a first through hole allowing each bead to pass through is formed in the clamp. The bead embroidering mechanism is capable of embroidering the beads efficiently and stably.

Owner:SHENZHEN NODROBOT CO LTD

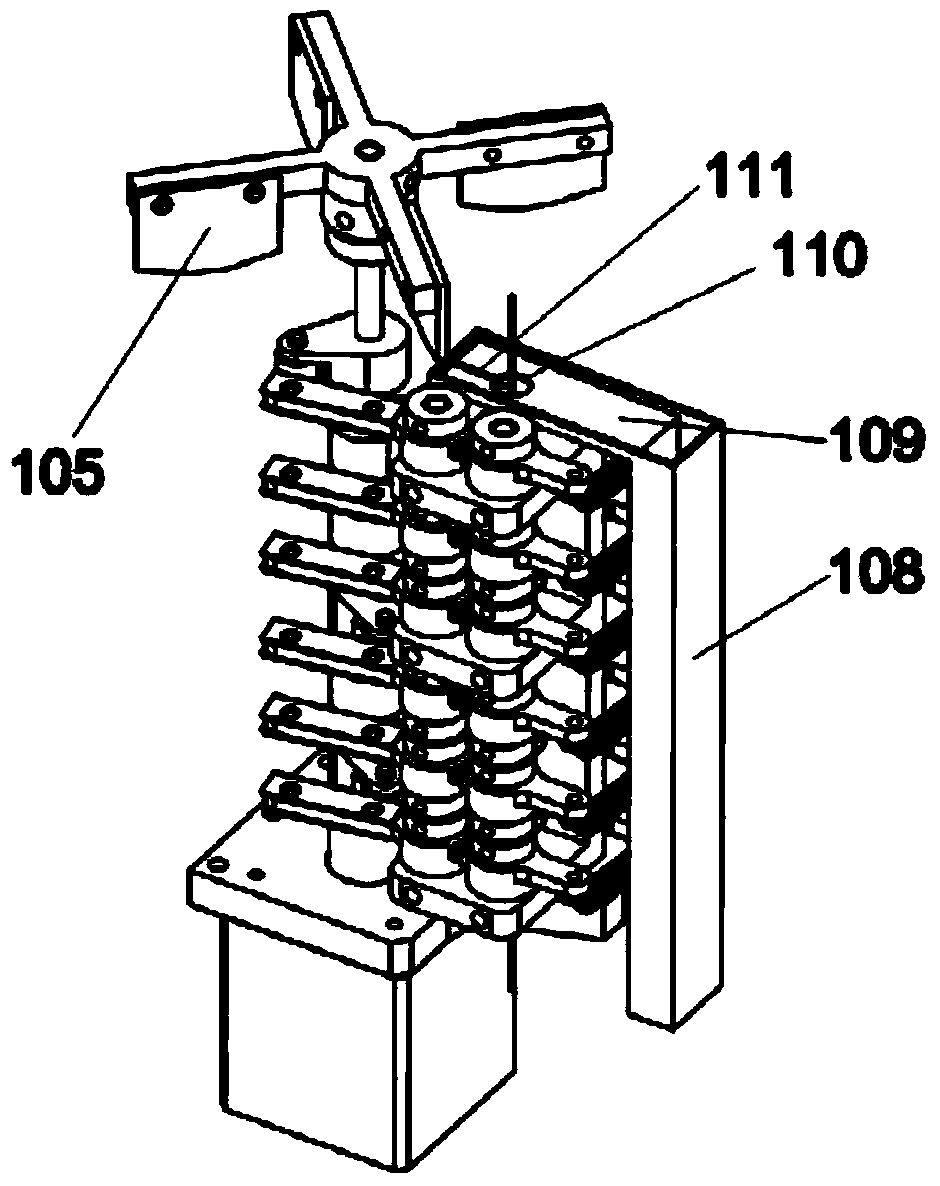

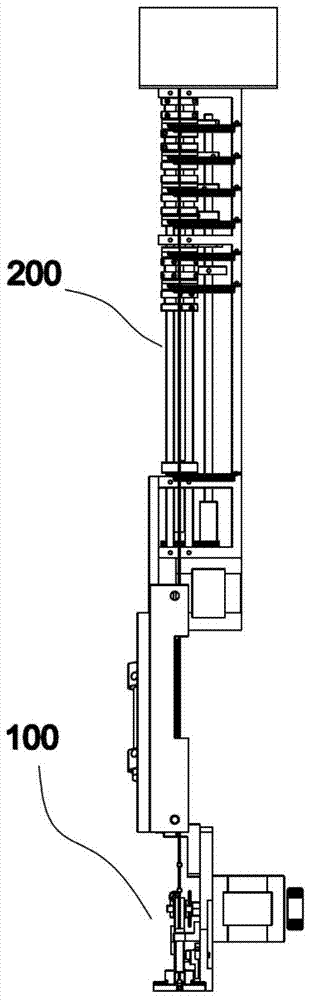

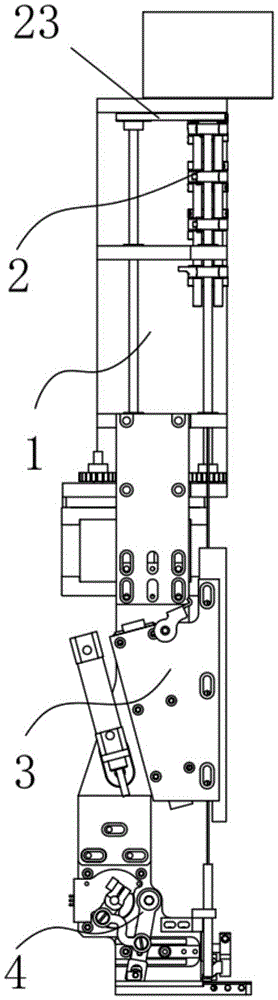

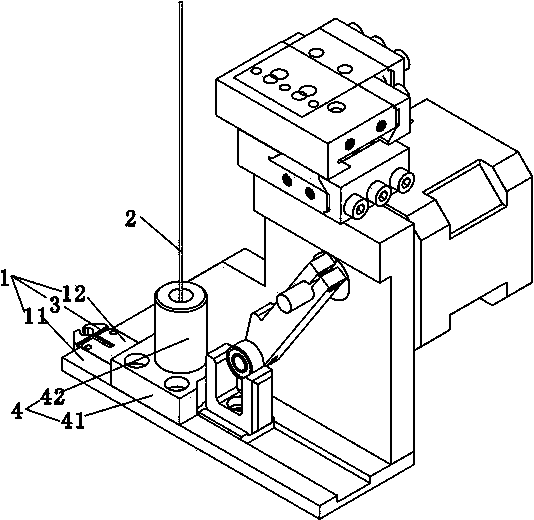

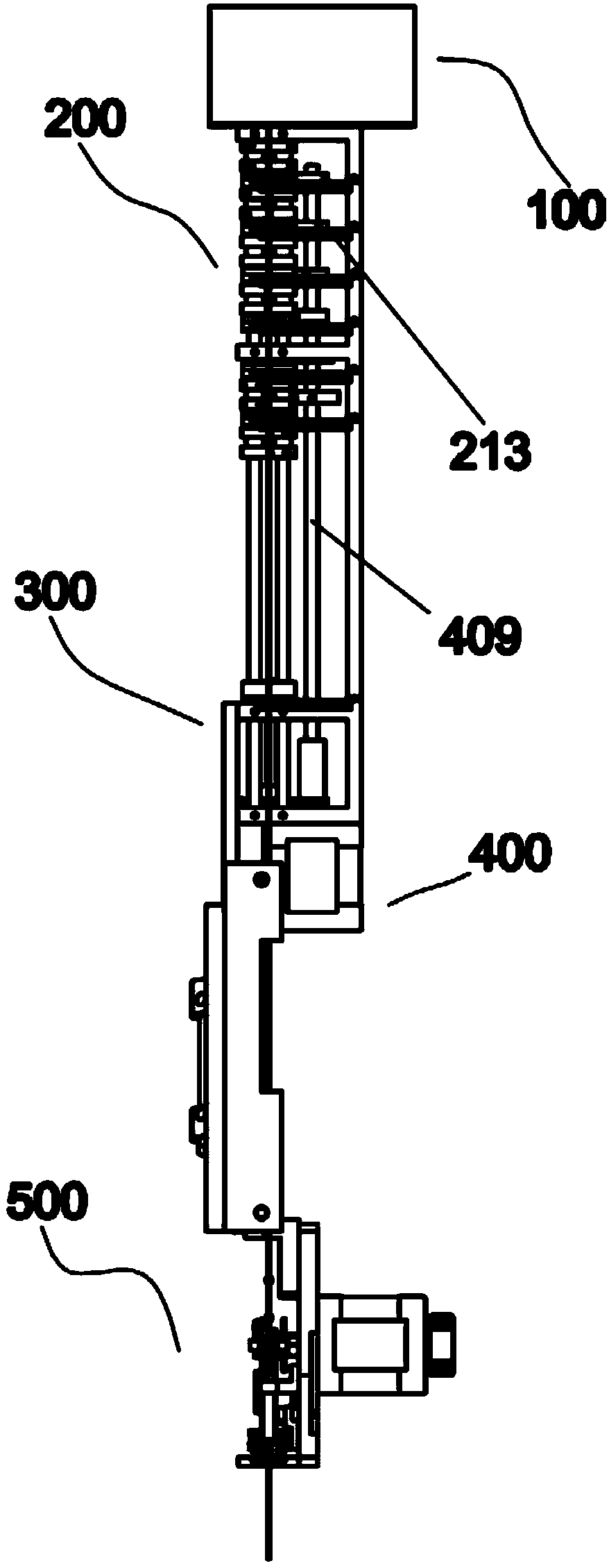

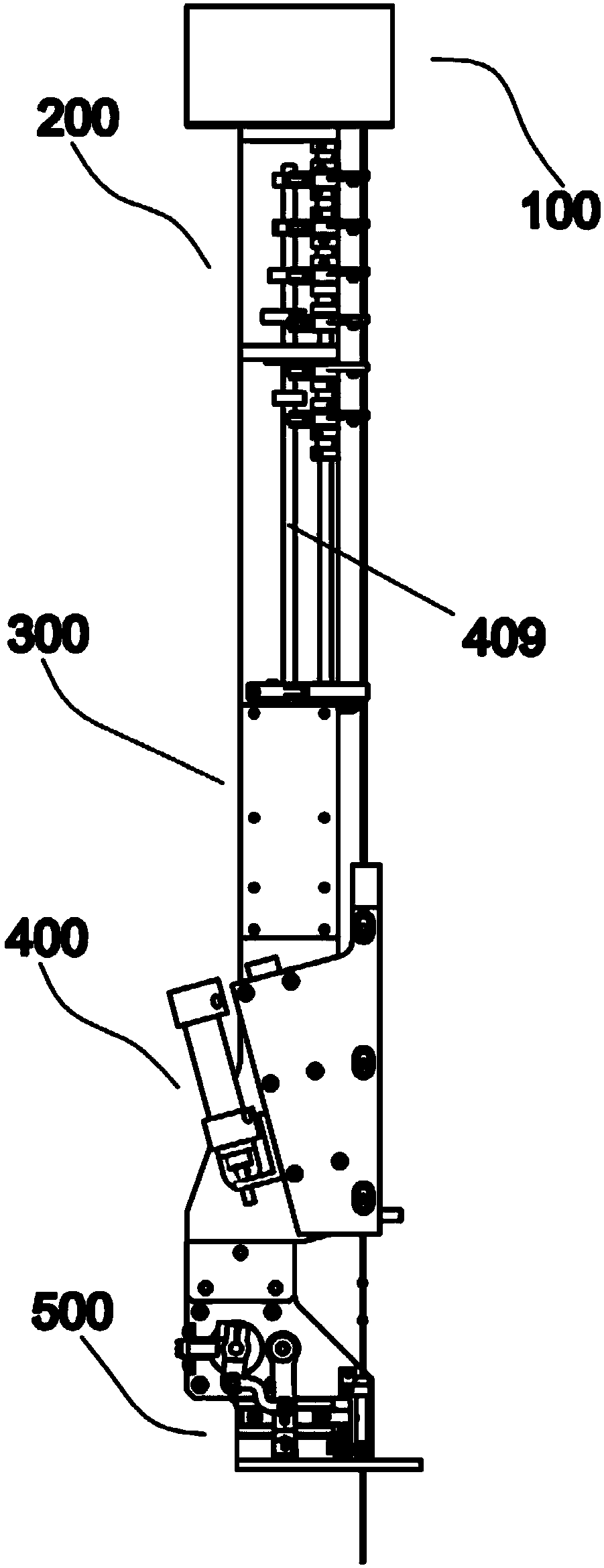

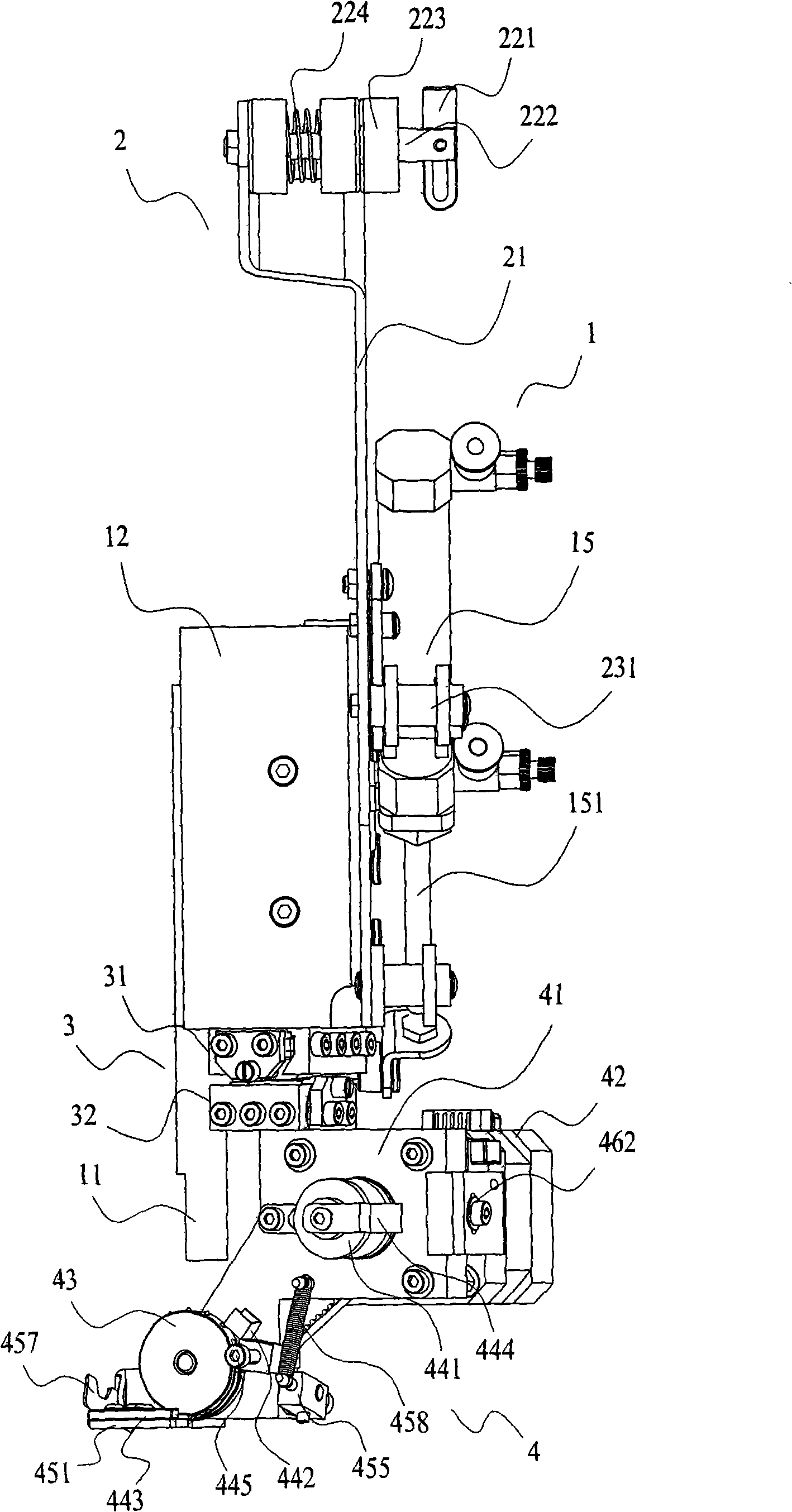

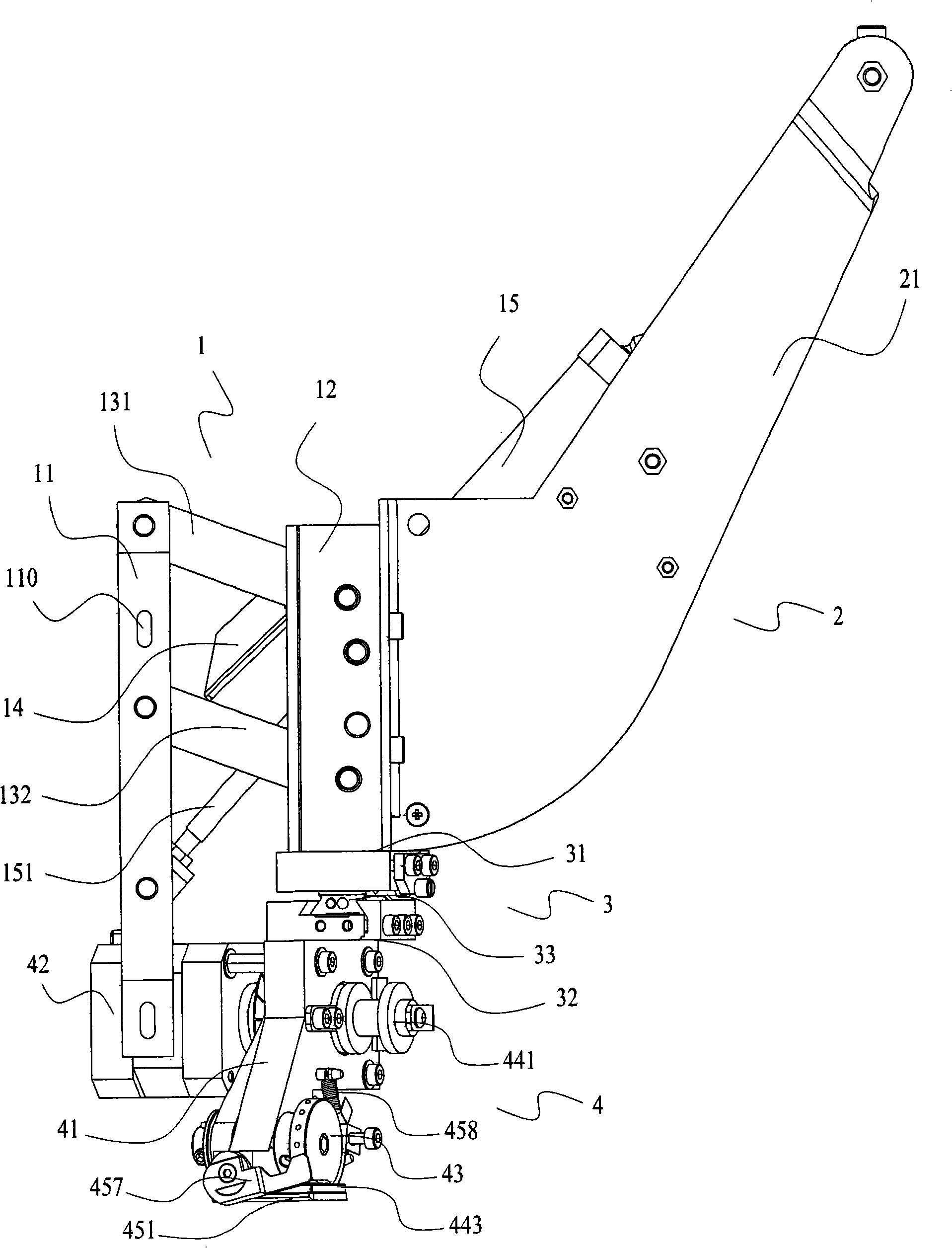

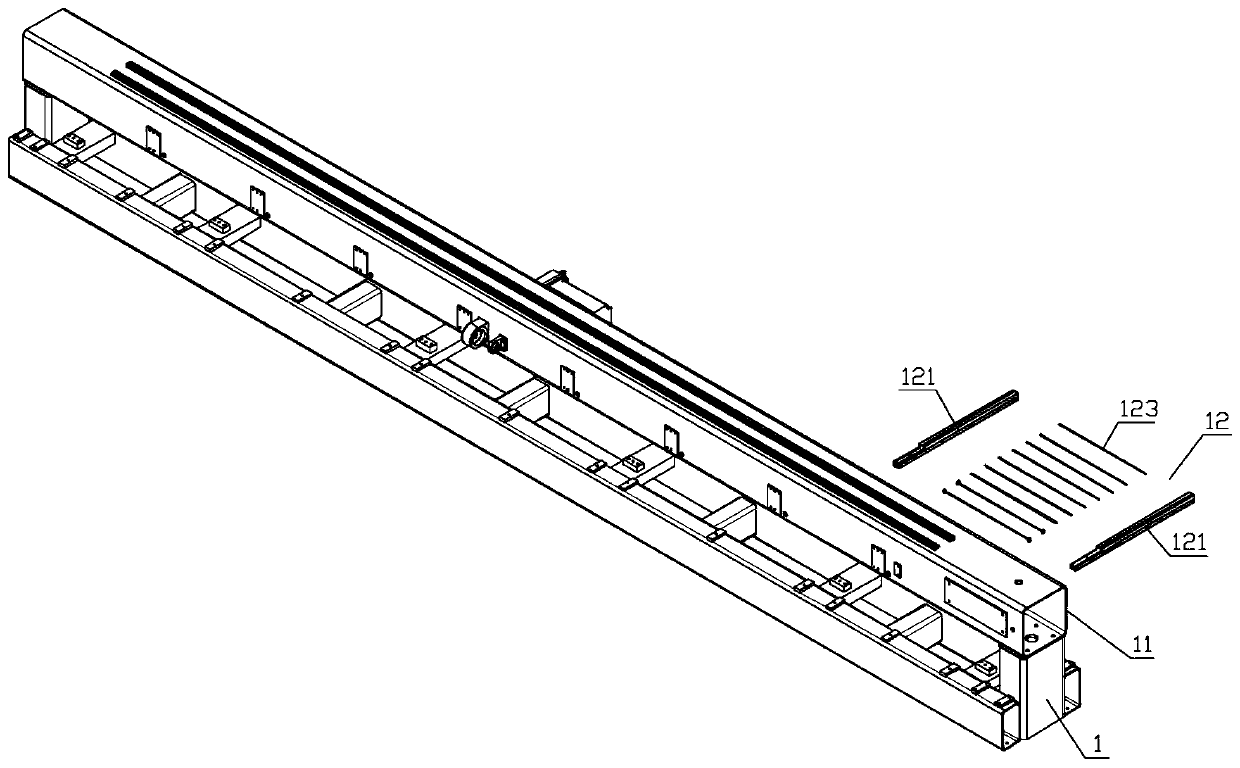

Bead arranging and feeding device of bead embroidery device

ActiveCN104372542AGuaranteed to stay the sameAchieve teleportationAutomatic machinesAuxillary devicesEngineeringMechanical engineering

The invention discloses a bead arranging and feeding device of a bead embroidery device. The bead arranging and feeding device comprises a rack, a power driving and distributing device which is fixedly arranged on the rack, a bead guide rod for guiding beads to drop and provided with a bead containing section, an upper bead feeding section movably arranged on the rack, and a lower bead feeding section movably arranged on the rack, wherein a bead arranging device is arranged at the upper part of the rack, the upper bead feeding section comprises a plurality of upper section clamping devices, the power driving an distributing device drives at least one upper section clamping device which is used for clamping the bead guide rod; and the lower bead feeding section comprises a lower section clamping device, the power driving and distributing device drives the lower section clamping device to clamp the bead guide rod, and the lower section clamping device is away from the closest upper section clamping device by a distance, so that the enough beads can penetrate the bead containing section between the lower section clamping device and the closest upper section clamping device. The bead arranging and feeding device has a simple structure, can be used conveniently, has the high production efficiency and can clamp the bead guide rod stably.

Owner:WENZHOU OULUOHUA INDAL

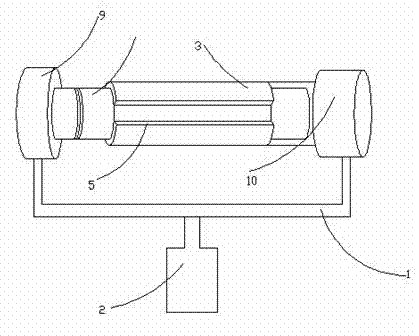

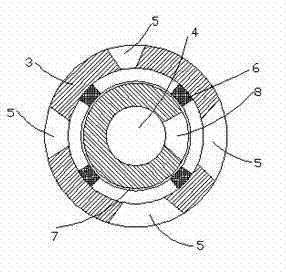

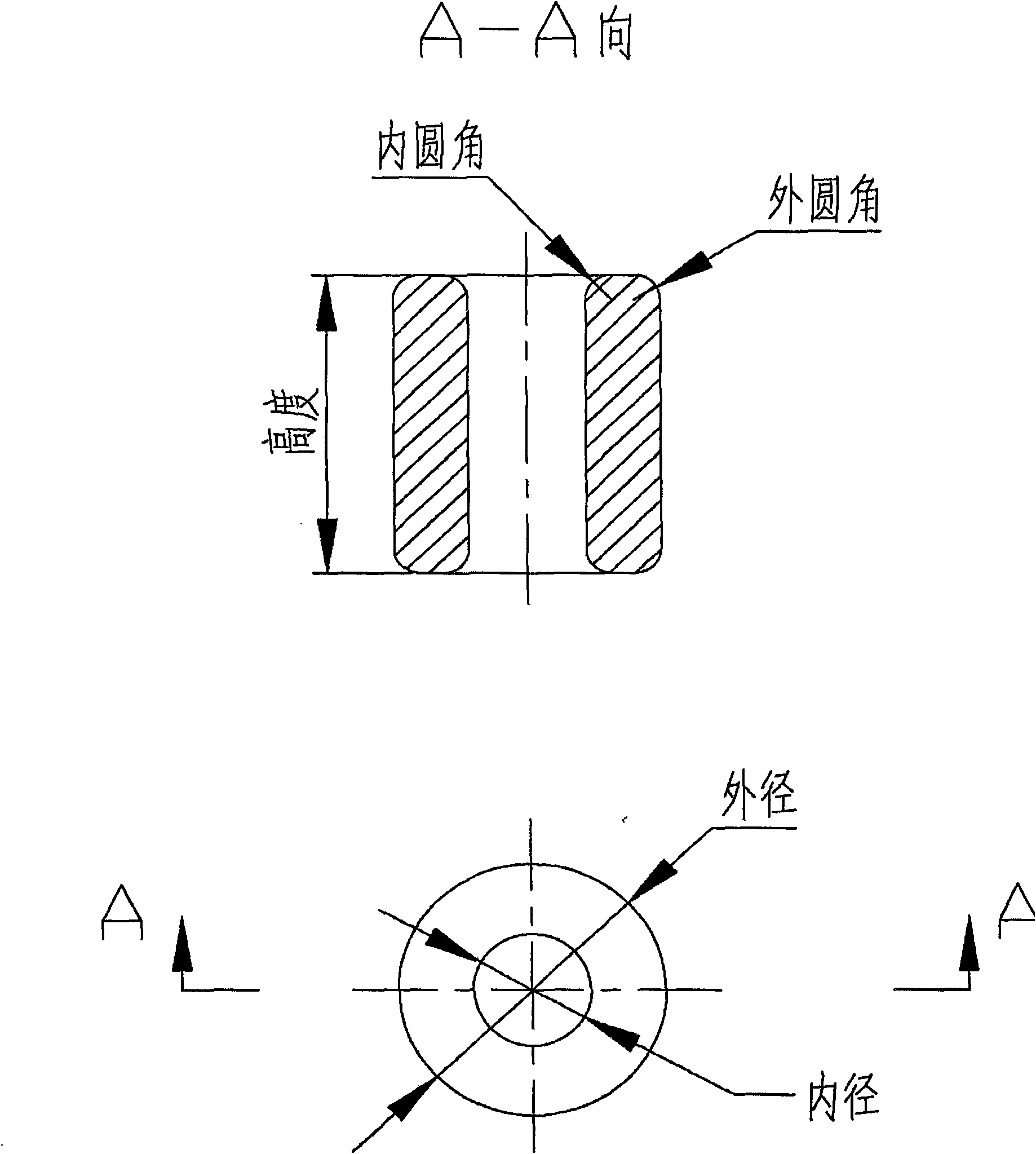

Lubrication system for rotating shuttle components of embroidery machines

ActiveCN101545184AExtend your lifeIncrease rotation speedLubrication/cooling devicesAuxillary devicesEngineeringGuide tube

The invention relates to a lubrication system for rotating shuttle components of embroidery machines, in particular to a rotating-shuttle-component lubrication system consisting of a rotating shuttle, a rotating-shuttle shaft and a rotating-shuttle shaft sleeve, wherein the inside of the rotating-shuttle shaft is provided with a through hole coaxial with the rotating-shuttle shaft; one end of the through hole is a lubricating oil inlet communicated with a rotating-shuttle oil supply device through a duct, and the other end of the through hole is a lubricating oil outlet communicated with an inner cavity of the rotating shuttle; and the surface of the rotating-shuttle shaft is provided with an oil spray hole communicated with the through hole. The lubrication system not only can continue oiling the rotating shuttle, the rotating-shuttle shaft and the rotating-shuttle shaft sleeve, but also can cool and clean the components.

Owner:杭州大云自动化科技有限公司

Bead embroidering device

ActiveCN104264394ASimple structureEasy maintenanceAutomatic machinesAuxillary devicesProcessing costBead embroidery

The invention discloses a bead embroidering device. The bead embroidering device comprises a bead guide rod, a conveying mechanism, a positioning and clamping mechanism and a feeding mechanism; the positioning and clamping mechanism is arranged above the feeding mechanism, wherein one end of the positioning and clamping mechanism is pivoted on the feeding mechanism, a positioning and clamping opening formed in the other end of the positioning and clamping mechanism is driven by power to clamp or stretch, and the positioning center of the positioning and clamping opening is concentric with that of the bead guide rod. The bead embroidering device is driven by a shifting fork motor; beads are fixed by use of the positioning and clamping mechanism and then fed orderly, and then the beads are clamped, delivered and positioned by use of a special sliding clamping plate with a jaw; as a result, the bead embroidering device is simple in structure, convenient to maintain, low in processing cost, high in automatic production efficiency and wide in application prospect; besides, the labor intensity of a worker can be reduced.

Owner:WENZHOU OULUOHUA INDAL

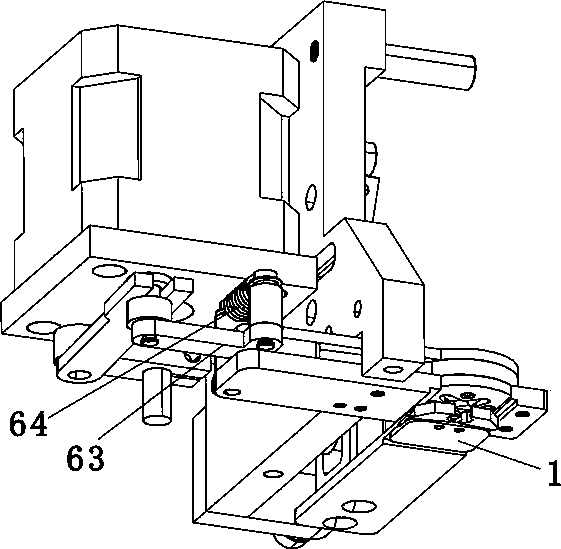

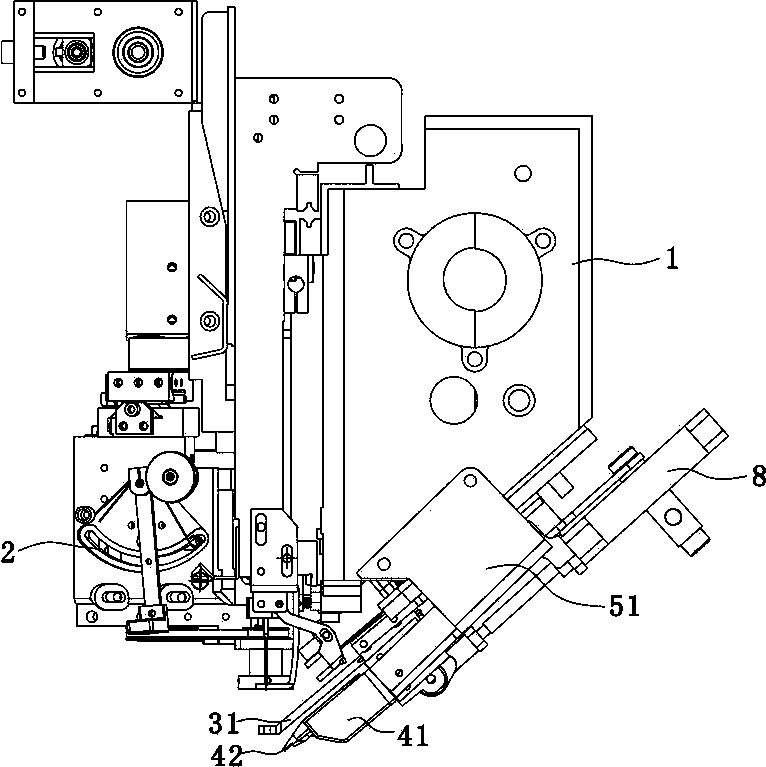

Oblique decorative sheet feeding device

InactiveCN101338500AExtended service lifeAvoid swingingWork-feeding meansAutomatic machinesFeed driveActuator

An oblique decorative plate feeding device comprises a lifting mechanism, which is provided with a fixed bracket fixed on the needle bar box of an embroidering machine and a movable bracket movably connected with the fixed bracket and driven by an actuator to lift; a feeding mechanism, which is provided with a bearing base connected with the movable bracket, a stepping motor arranged on the bearing base, a feeding drive mechanism driven by the stepping motor, a feeding guide mechanism and a cutting mechanism. The feeding mechanism arranged in the oblique front of the needle bar box can lift between a standby position and a work position; when the feeding mechanism lifts to the work position, the feeding guide mechanism points to the decorative plate stitching position from the oblique front of the needle bar box. The present invention overcomes the shortcomings of the prior horizontal or front devices, thus not hindering the threading operation of the embroidering machine and not occupying the lateral space of the head, which is suitable for the embroidering machine with small head distance. In addition, the feeding device is also provided with a regulation fastening mechanism and a photoelectric automatic aligning device.

Owner:FUJIAN YONGXIN NUMERICAL CONTROL TECH

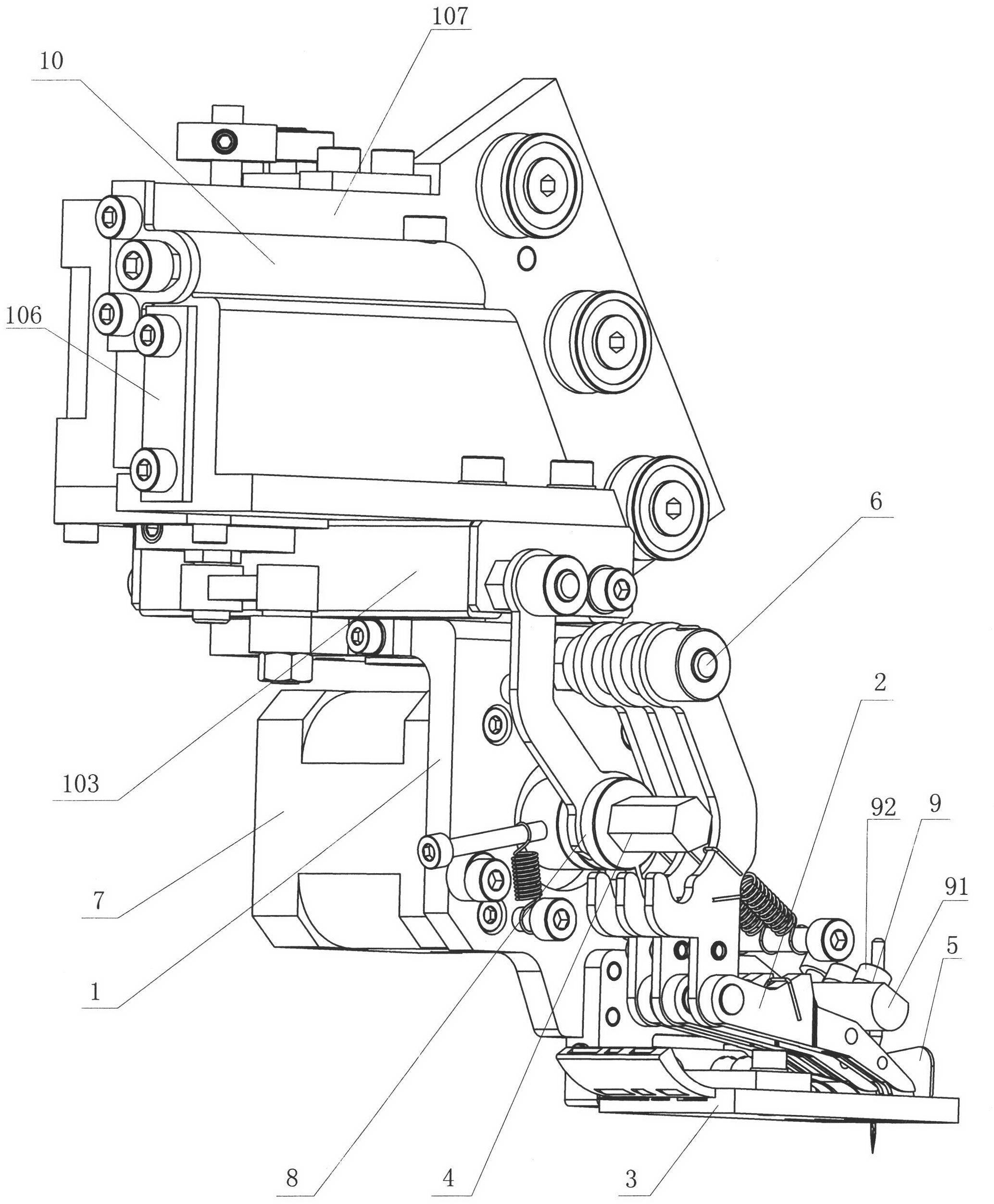

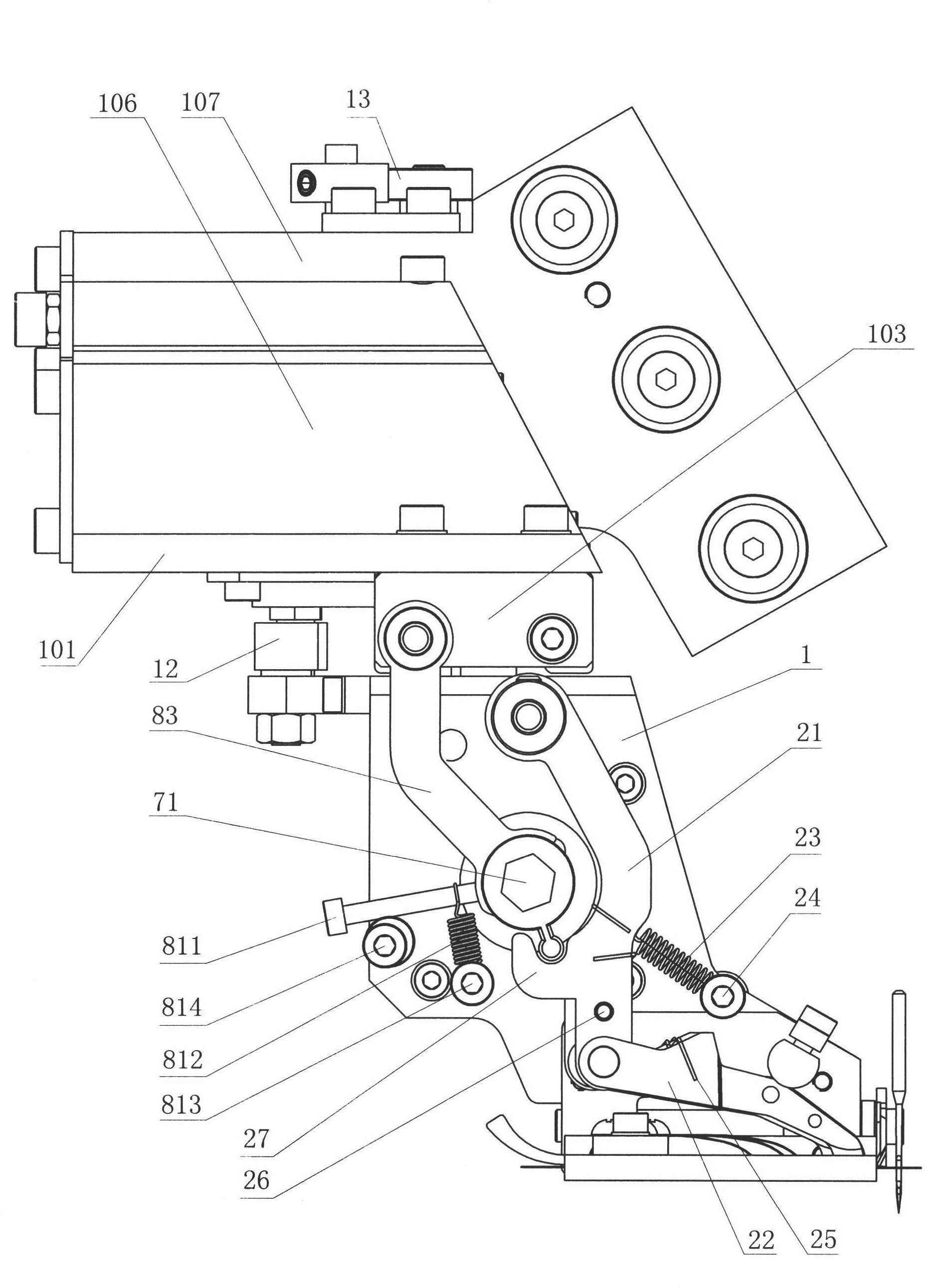

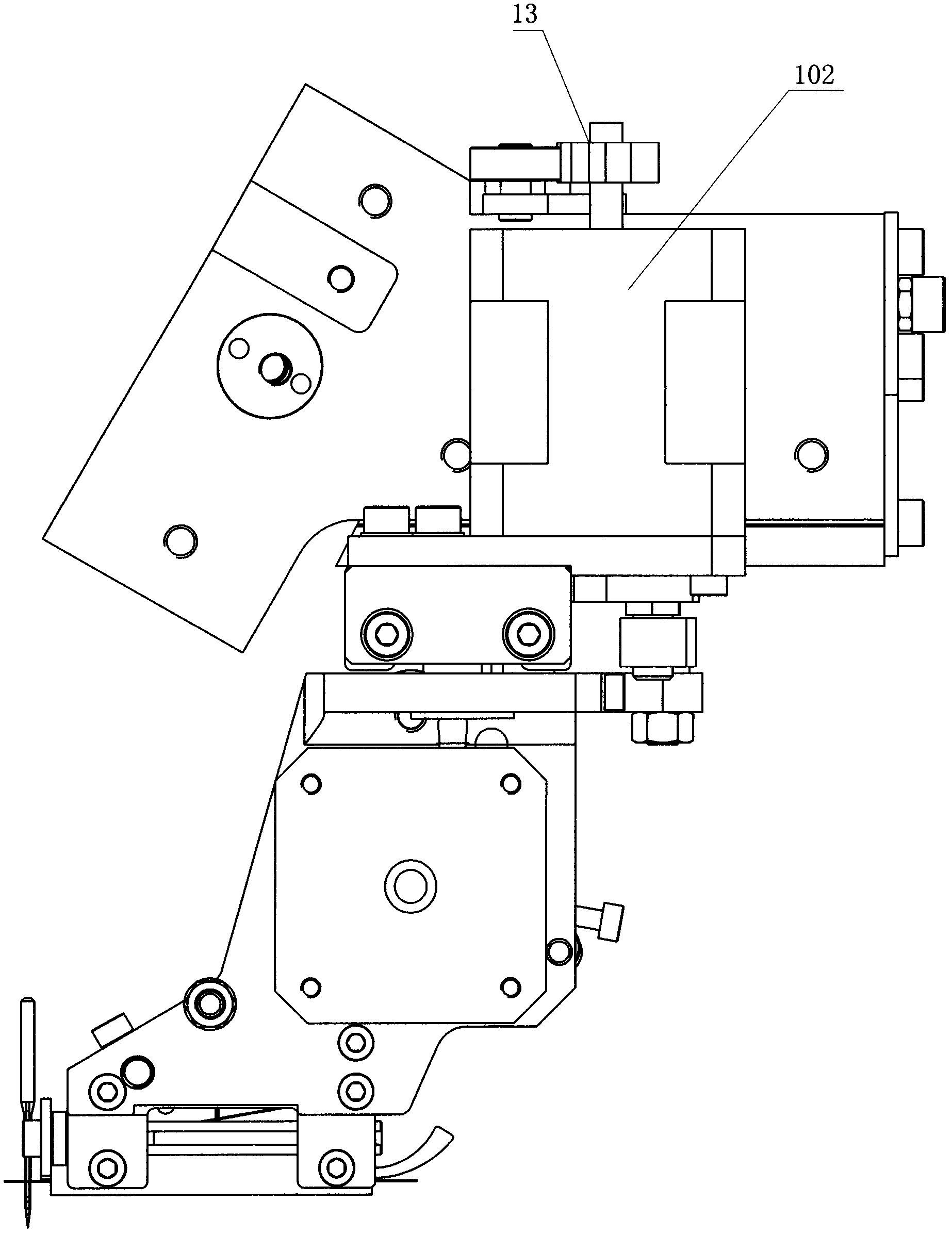

Rope embroidery machine head

ActiveCN103668816AAvoid wastingNeat cutAutomatic machinesAuxillary devicesControl systemIndustrial engineering

The invention discloses a rope embroidery machine head including a machine head frame, a rope transmission device and a control system, the rope transmission device bottom on an embroidery rope output path is orderly provided with a clamping device and a cutting device for cutting an embroidery rope, the control system drives the clamping device and the cutting device to work together, the clamping device comprises a jaw for clamping the embroidery rope and a jaw driving structure for controlling of open and close of the jaw, and the cutting device comprises a scissor head, a first drive structure for driving the scissor head to work, and a second drive structure for driving the scissor head to a corresponding position to cut the embroidery rope. According to the rope embroidery machine head, the clamping device and the cutting device are controlled by the control system, a rope cutting program can be preset by the control system, and redundant embroidery rope online non-stop cutting without remaining of rope ends can be realized. During a switching period of two discontinuous flower types, the embroidery rope is temporarily vised by the jaw, the embroidery rope can be saved, and the embroidery rope waste can be prevented. The rope embroidery machine head equipment can simplify the technological process in the prior art, the embroidery rope heads can be neatly trimmed, and the trimming quality is high.

Owner:HUZHOU GUANJIONG MECHANICAL & ELECTRICAL TECH CO LTD

Three-gold embroidery side-by-side piece feeding mechanism

InactiveCN102286860AAvoid easy cloggingNot easy to cleanAutomatic machinesAuxillary devicesPush and pullDrive shaft

The invention discloses a three gold foil embroidery side-by-side foil conveying mechanism. The mechanism comprises a foil conveying inversion mechanism which can move in the directions of X and Y axes, a foil conveying engine base, three foil conveying foot pushing devices, a foil conveying slot with three side-by -side positions, a foil changing device and a foil cutting device; the upper ends of pushing arms of the three foil conveying foot pushing devices are connected in series and hinged with the same dead axle; three tension springs and three pressure springs are used for resetting and tabletting; push-and-pull hooks are extended out of the lower part of pushing arms in parallel; the foil changing device comprises a motor, a rotation axis and a foil changing clutch which is coupled with a transmission shaft and alternately drives the three foil conveying foot pushing devices to act; the foil changing clutch comprises a connection sleeve, a clutch wheel, and a shifting fork which stirs the clutch wheel to slide; and the edge of the clutch wheel is provided with a stirring hammer which is positioned in a hook groove of the push-and-pull hook and stirs each pushing arm to act along with the rotation of the motor. The three gold foil embroidery side-by-side foil conveying mechanism has the advantages that: gold foils are not easy to block, the efficiency is high, the three gold foil embroidery in different forms and of various specifications can be realized, and the number of used motors is small.

Owner:WUYI UNIV

Air suction device on embroiderer rack

ActiveCN104233668ARealize the wind suction effectMeet actual job needsAuxillary devicesEngineeringDrive motor

The invention discloses an air suction device on an embroiderer rack. The air suction device is characterized by comprising an air suction pipe and an air suction pump connected with the air suction pipe, the air suction pipe is provided with a steam cylinder through a bracket and comprises an outer pipe and an inner pipe, a plurality of different air suction openings are formed in the pipe wall of the outer pipe, fixed strip-shaped rubber platforms are arranged on the two sides of the air suction openings on the inner wall and are connected with a fixing plate together, the inner pipe is connected on the inner wall of the fixing plate through a bearing, one end of the inner pipe is an open end and is connected with the air suction pump, an air outlet is arranged on the pipe wall of the inner pipe, the other end of the inner pipe is a closed end, a first drive motor is arranged at the closed end, a second drive motor is arranged at one end of the outer pipe, and the first drive motor and the second drive motor are arranged on the bracket. The air suction device of the embroiderer rack forms an air suction surface, so that the operation range is regulated, the air suction amount is also regulated, the practical operation requirements are met, the cost is saved, and the energy consumption is reduced.

Owner:汕头市坤兴刺绣有限公司

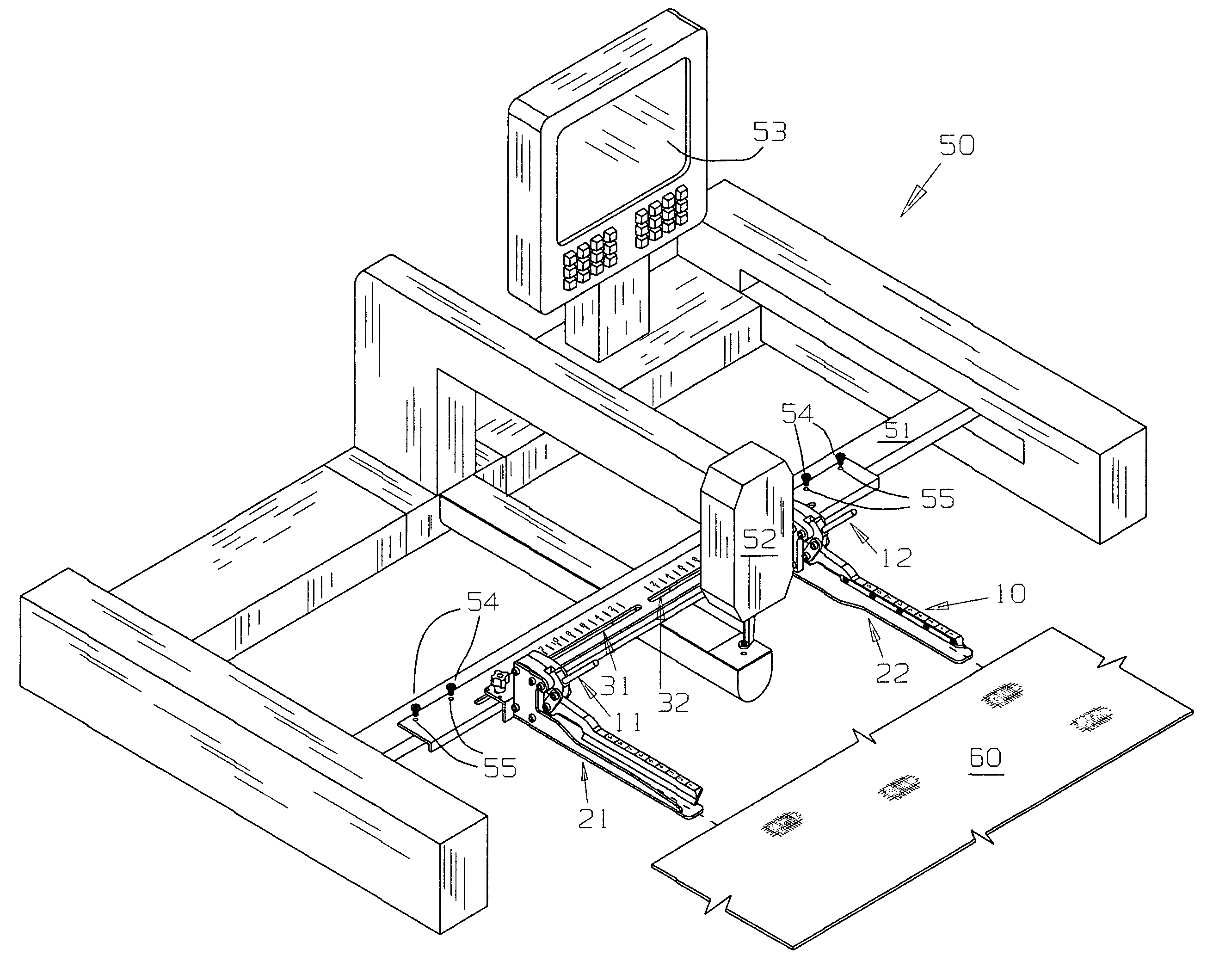

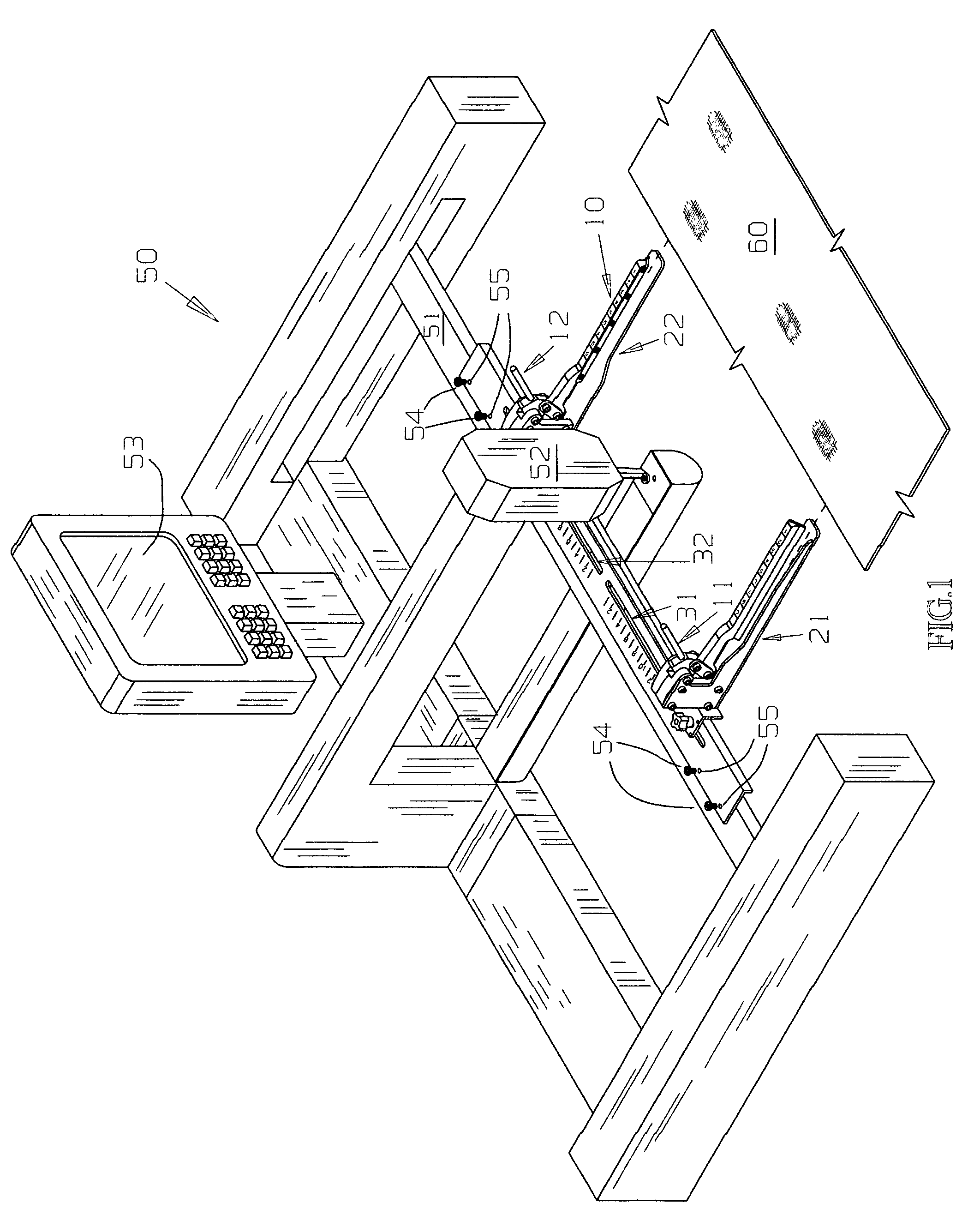

Laser embroidery integrated machine and processing method

InactiveCN101012611AMatureRealize automatic alignmentWorkpiece carriersAutomatic machinesEngineeringLaser cutting

The invention discloses an integrative machine with laser embroidery and the manufacturing method. The integrative machine comprises support rack; working plate on the support rack; embroidery frame on the working plate, which can moves in two dimension; connecting beam on the support rack; single embroidery equipment or multiple embroidery equipments on the beam; laser tube, laser path and laser cutting head connected on the beam. The laser cutting head is corresponding to the embroidery equipment and it is set at the side of embroidery equipment. The invention is the subliming machine under the lack of laser cutting machine in embroidery area. It not only continues the superiority of laser machine to the conventional embroidery process but also compensates the lack. It is another jump in efficiency and effect from hand to mechanism and to the laser. The integrative machine with laser embroidery changes the conventional process method of embroidery machine thoroughly.

Owner:WUHAN GOLDEN LASER

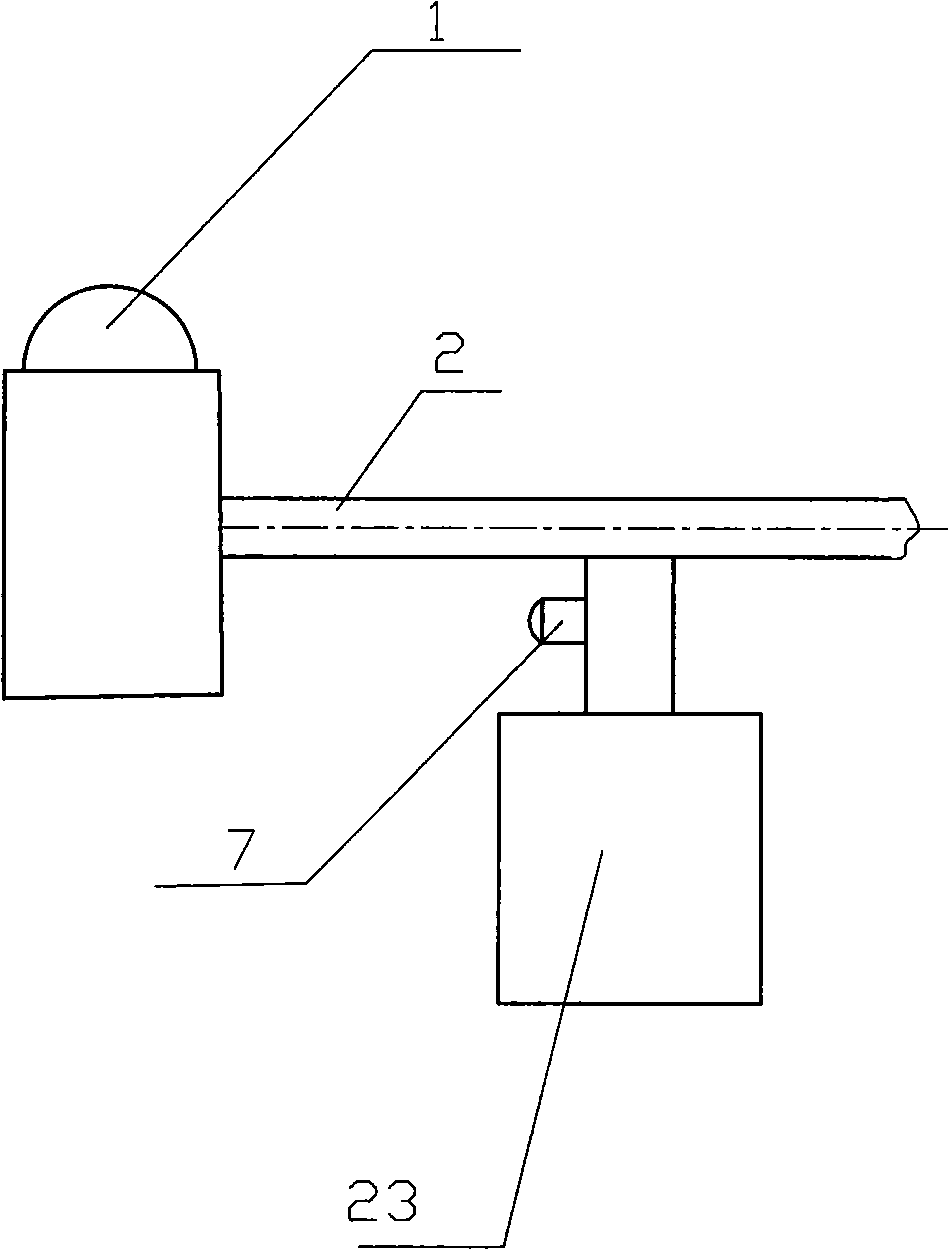

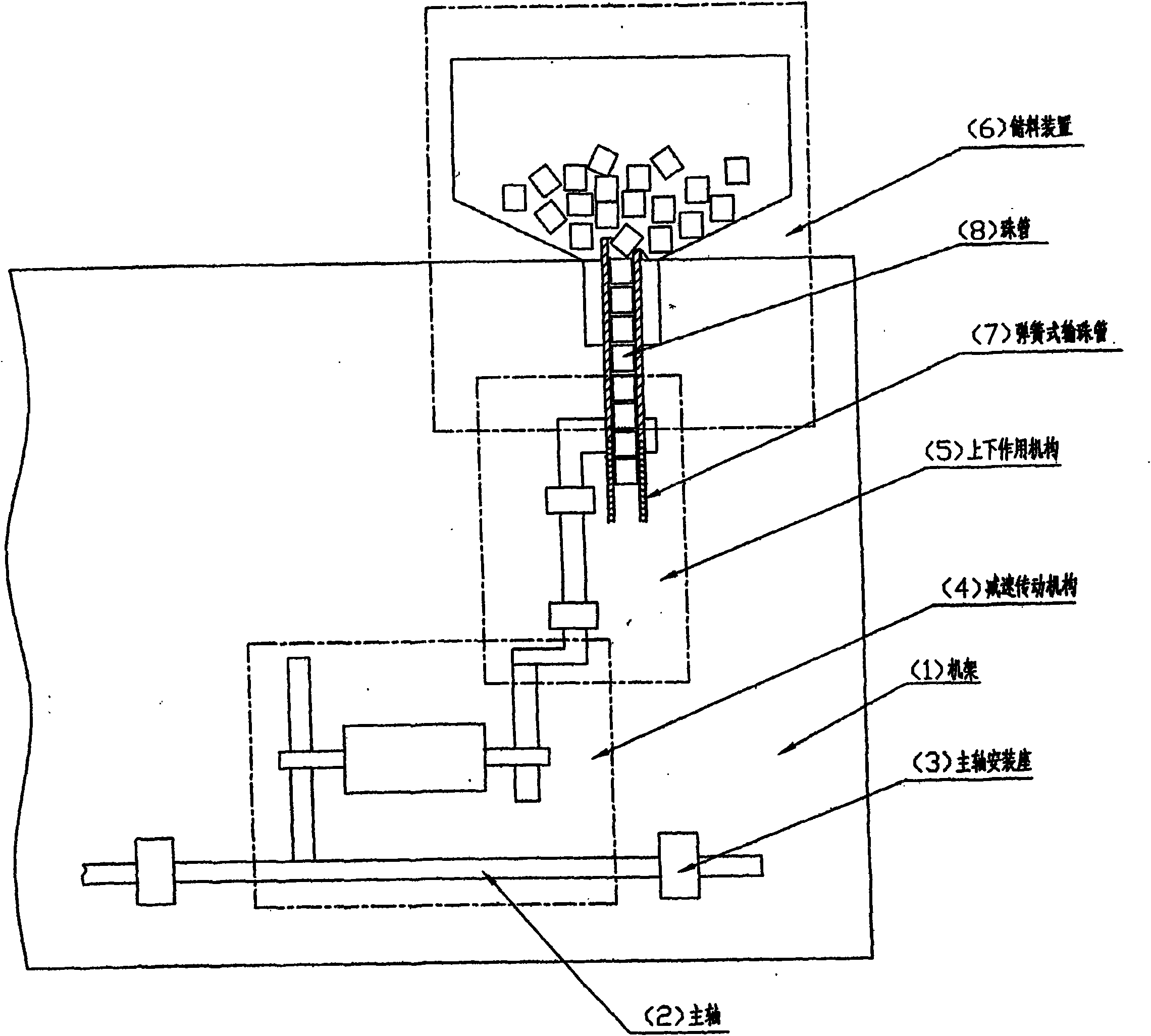

Device and bead pipe adding on common embroidery machine for arranging bead pipe direction

InactiveCN101798733ASpeed up the fallGuaranteed embroidery requirementsAutomatic machinesAuxillary devicesElectrical and Electronics engineeringMechanical construction

The invention discloses a device and a bead pipe adding on a common embroidery machine for arranging bead pipe direction; the device comprises a spindle which is arranged on a frame, a reducing transmission mechanism, an up and down acting mechanism, a storage device and a spring-type bead pipe; and the reducing transmission mechanism is matched with the spindle, the up and down acting mechanism is communicated with the reducing transmission mechanism, the storage device is connected with the up and down acting mechanism, the spring-type bead pipe is connected with the storage device, and the bead pipe is arranged in the storage device; and the device has the advantages of simple and reasonable mechanical structure as well as convenient operation, the capability of vertically conveying bead pipes in bulk into the spring-type bead pipe for machine embroidery, greatly improving the placing speed of the bead pipe, meeting the material use requirements of machine embroidery, creating conditions for mechanically embroidering beautiful and aesthetic patterns with precision placement of the bead pipe, and greatly reducing the labor cost, and the like.

Owner:王灿华

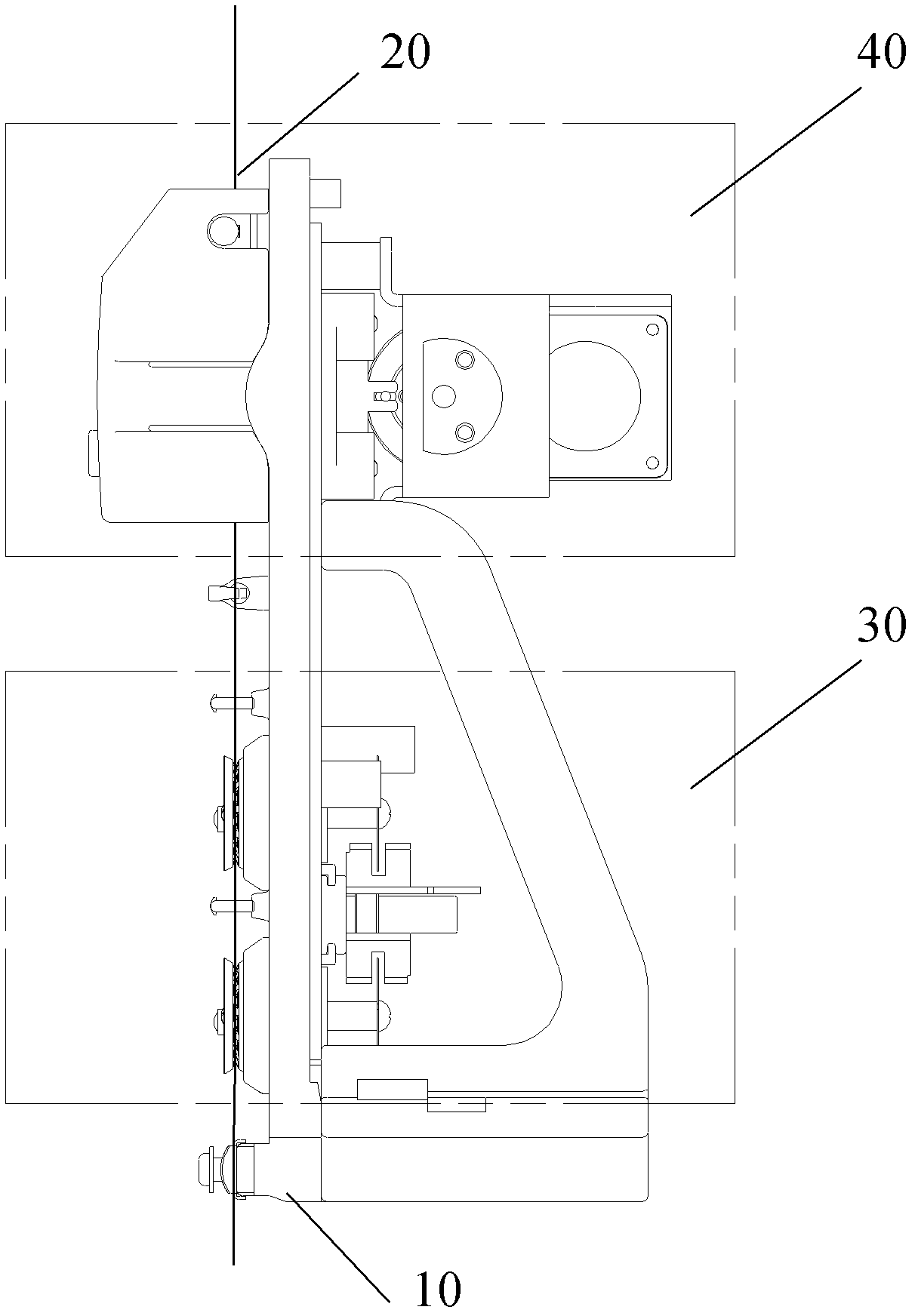

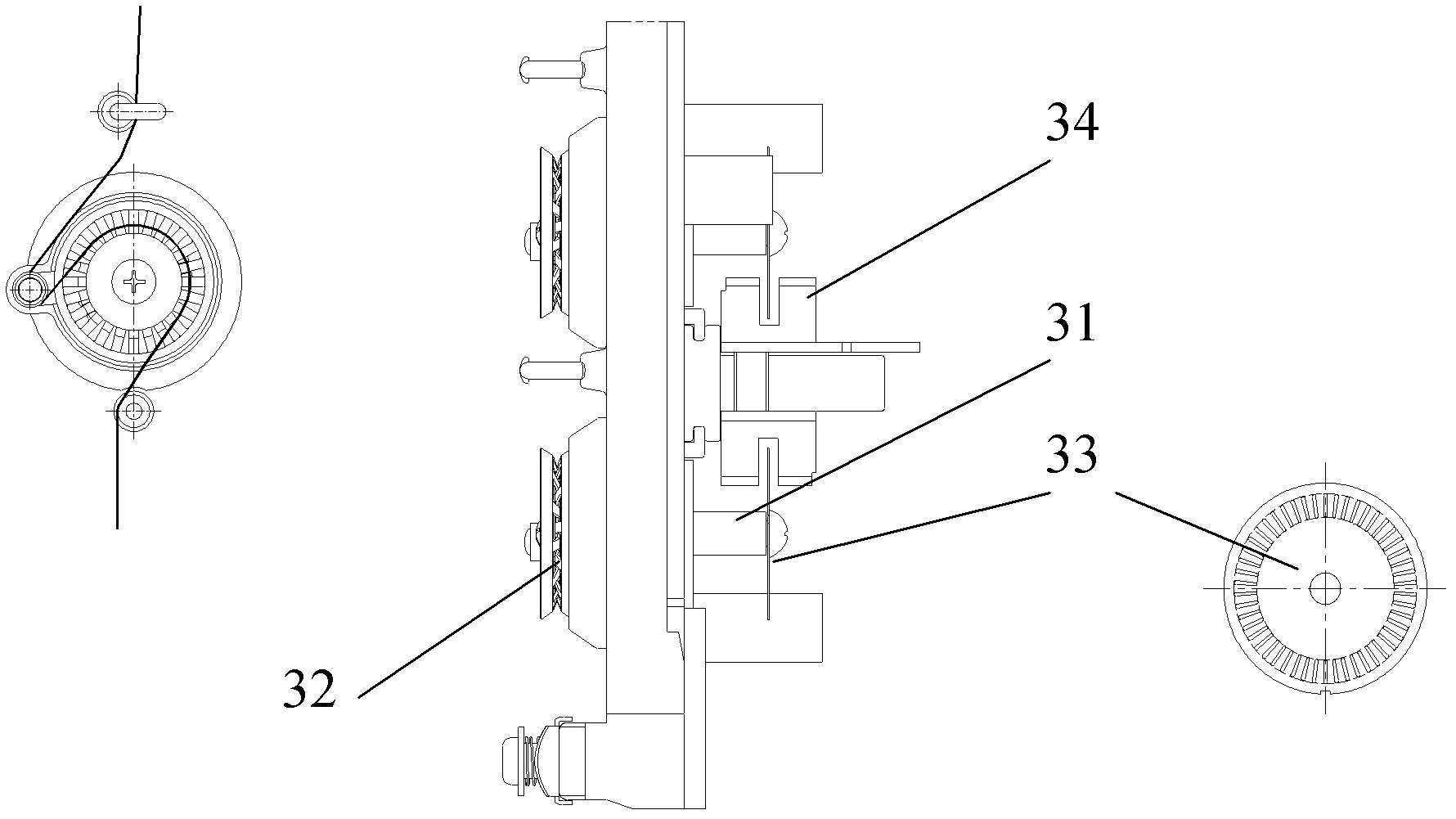

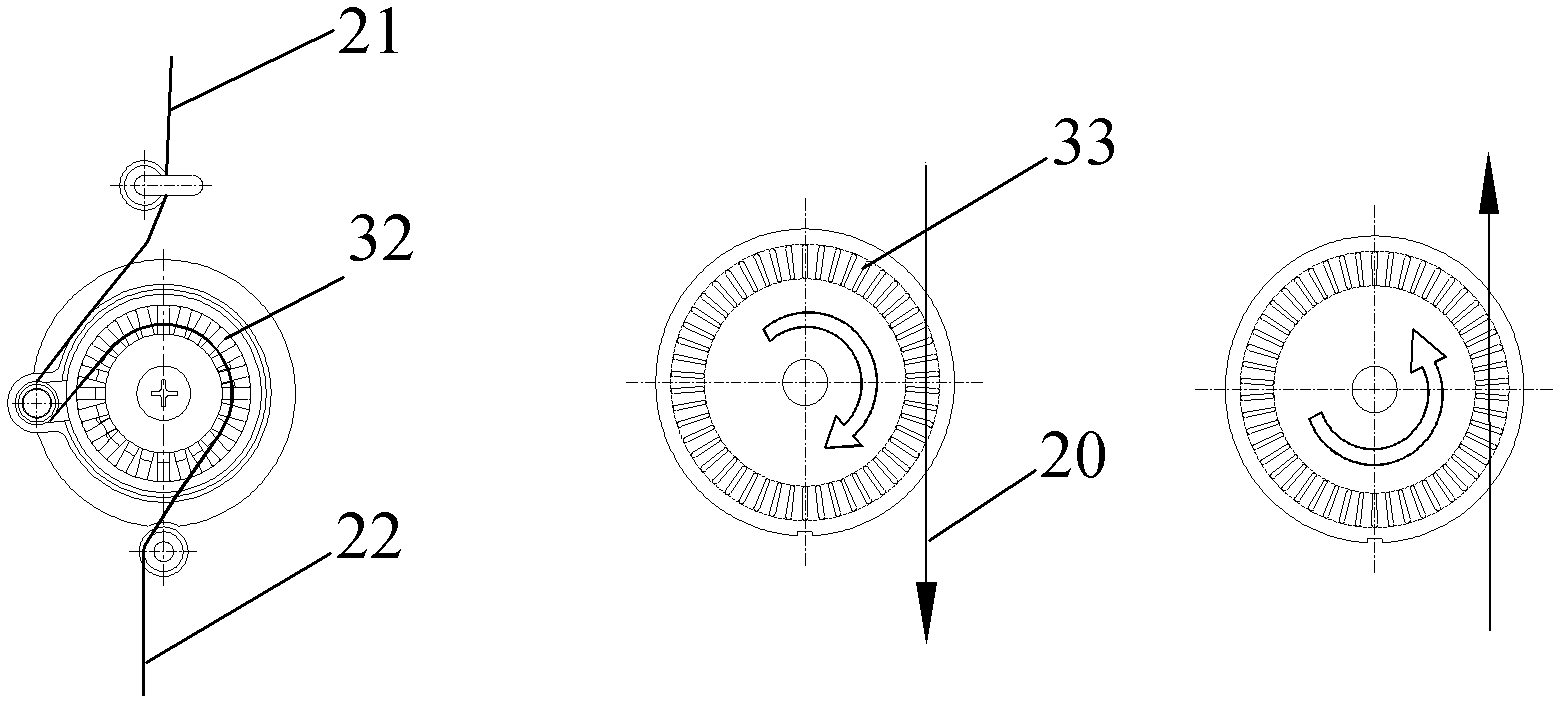

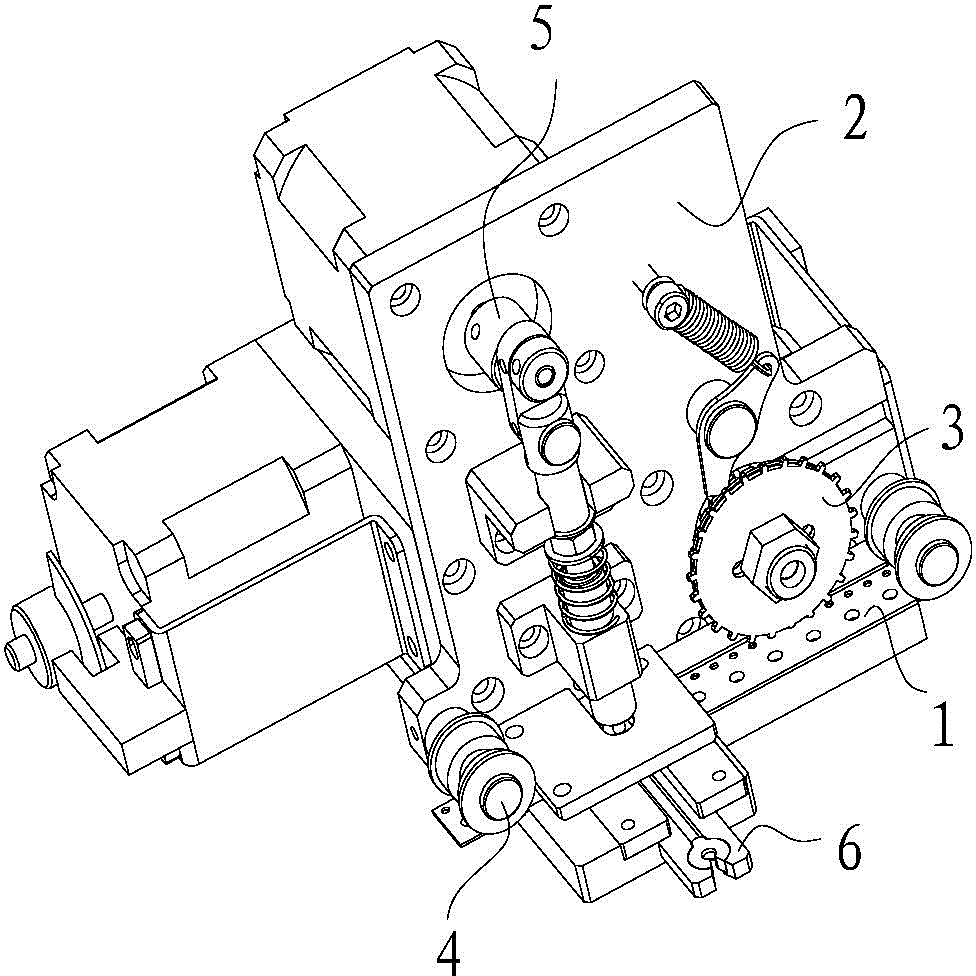

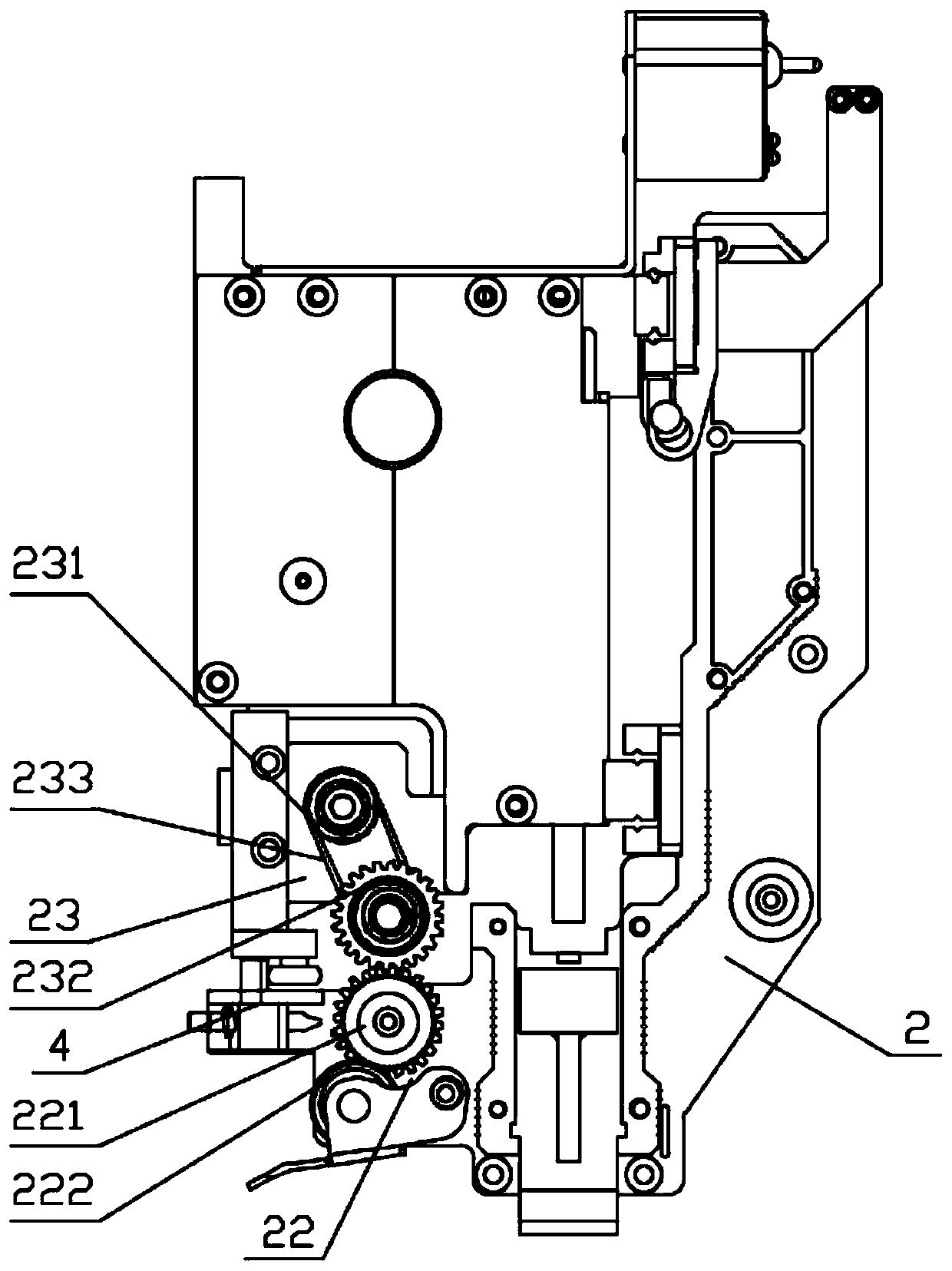

Machine head assemblies of ironing sheet machine and ironing sheet machine

ActiveCN111304843ASimplify the collection structureAutomatic machinesAuxillary devicesGear wheelElectric machinery

The present invention discloses machine head assemblies of an ironing sheet machine and the ironing sheet machine. The ironing sheet machine comprises an ironing sheet machine shell assembly and at least two ironing sheet machine head assemblies arranged side by side; each ironing sheet machine head assembly comprises a machine head shell and a sheet conveying roller set mounted on the machine head shell; each sheet conveying roller set comprises drive rollers; the ironing sheet machine shell assembly comprises a machine shell and a sheet conveying motor mounted on the machine shell; the sheetconveying motor drives the drive rollers to rotate through a sheet conveying transmission mechanism; the sheet conveying transmission mechanism comprises a sheet conveying drive gear and a sheet conveying driven gear which are meshed; the sheet conveying driven gear is connected with the drive rollers; the ironing sheet machine further comprises a sheet conveying driven gear self-locking mechanism for locking the sheet conveying driven gear after color change; and the sheet conveying driven gear self-locking mechanism comprises a self-locking push rod which can be clamped in a driven gear tooth groove. A plate-by-plate waste collection structure of a conventional ironing sheet machine is greatly simplified and the sheet conveying driven gear is prevented from rotating by vibration due tomachine operation.

Owner:ZHEJIANG XINSHENG SEWING EQUIP

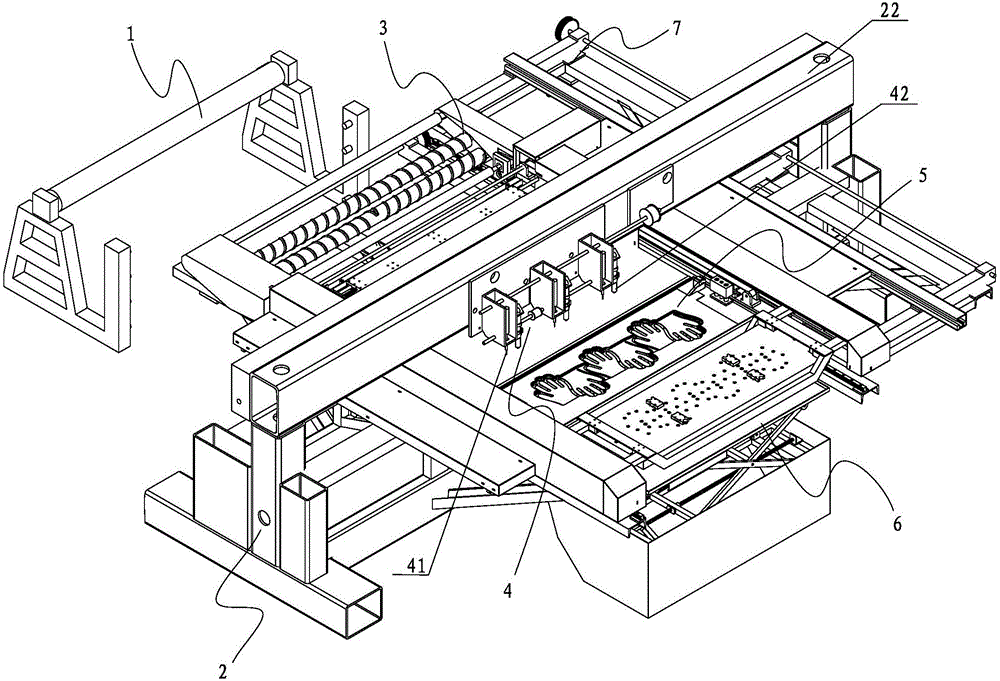

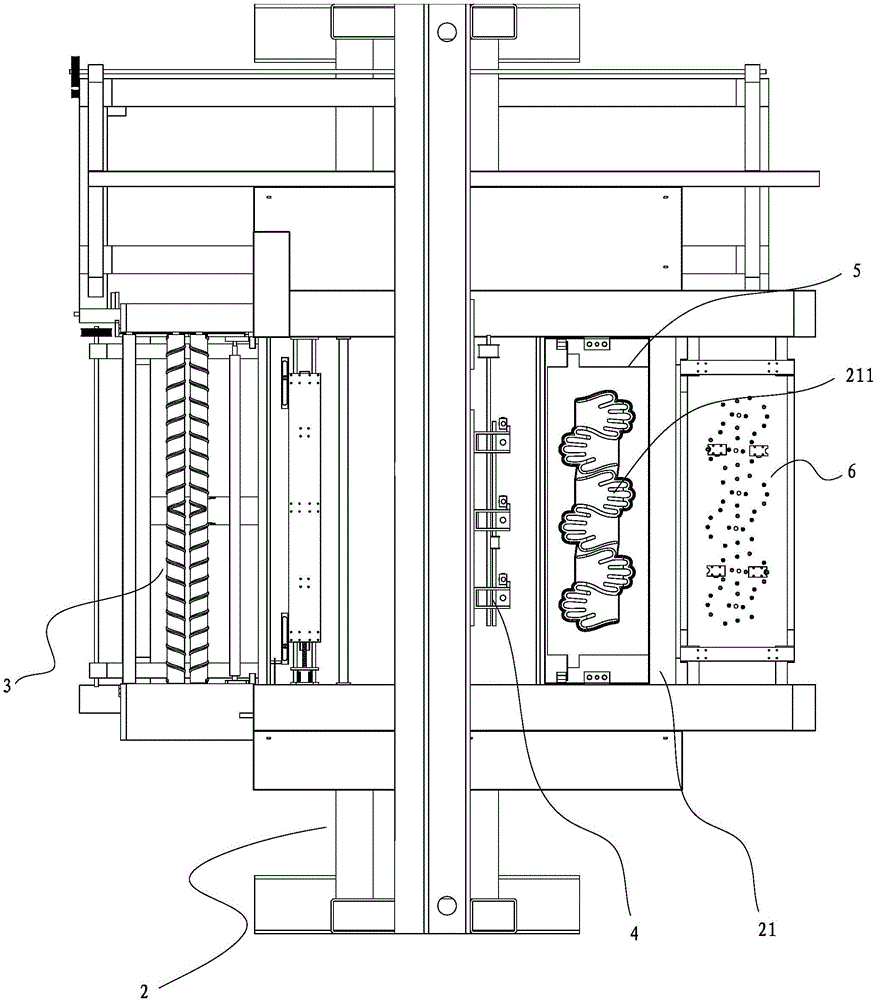

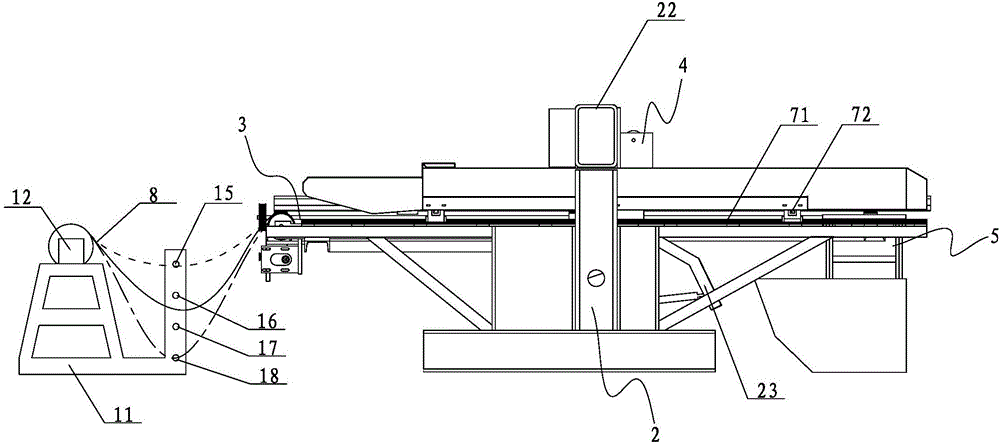

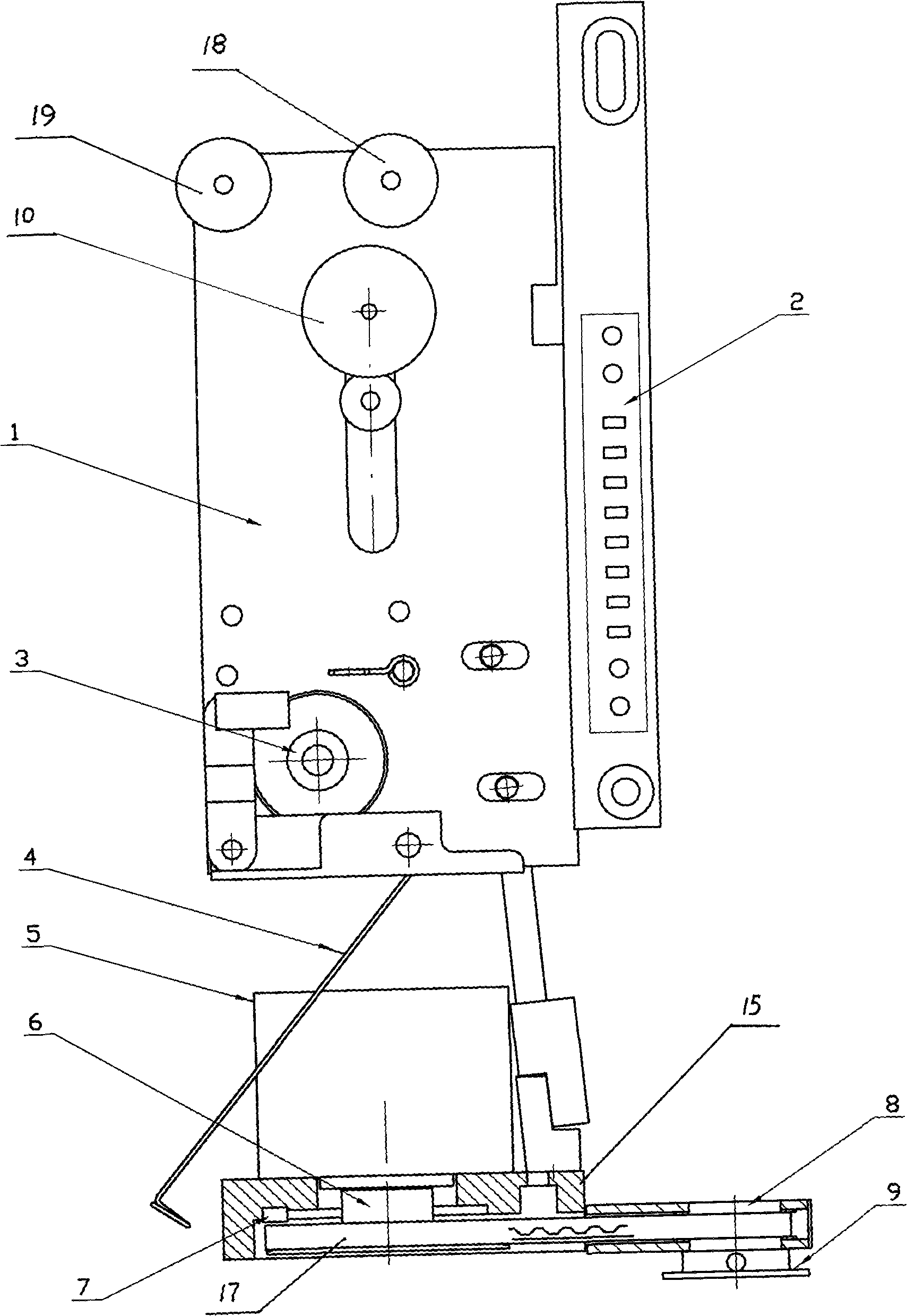

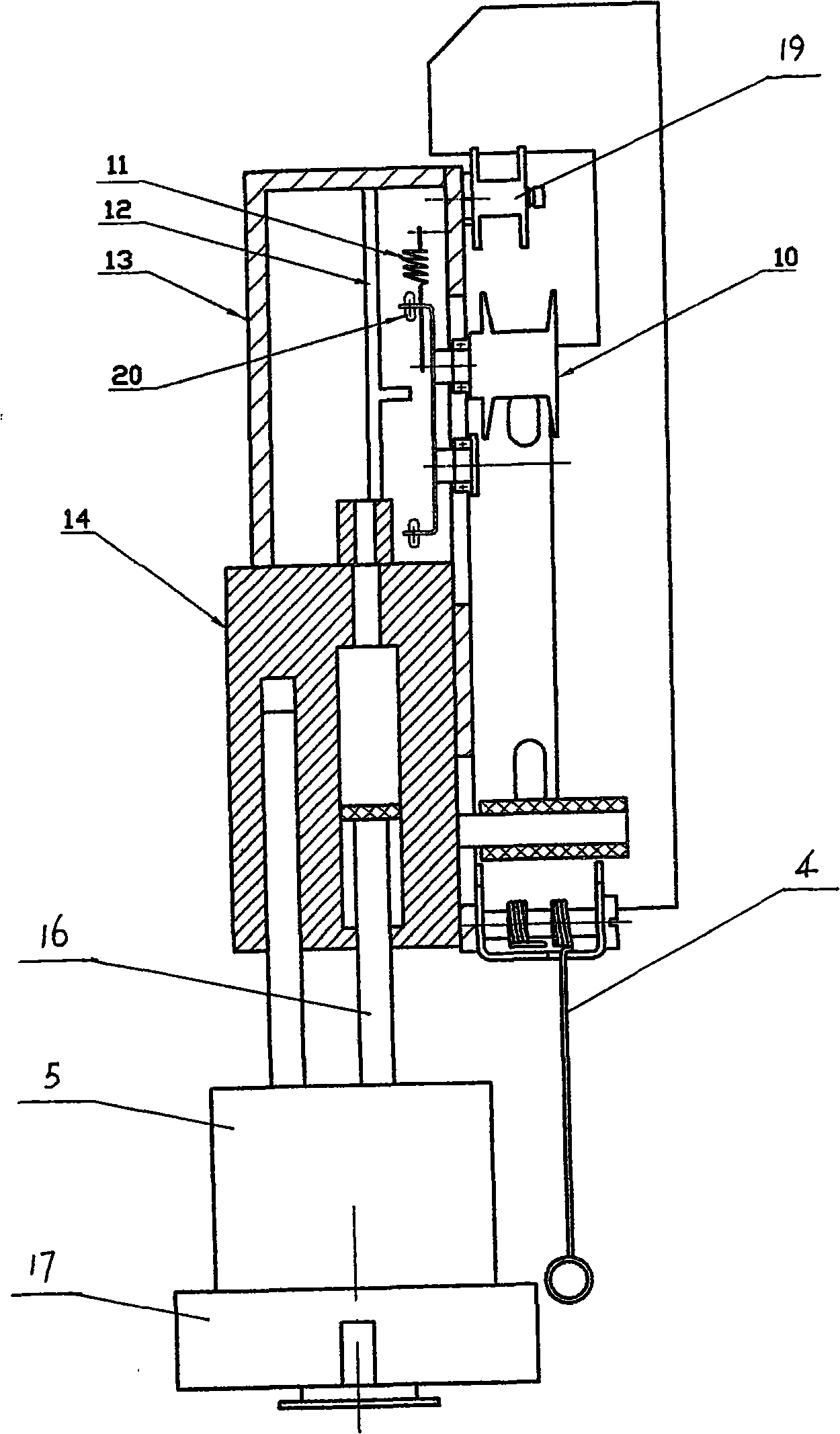

Integrated glove machine and production technology thereof

ActiveCN106436082ANo human intervention requiredAutomatic machinesLaser beam welding apparatusEngineeringLaser cutting

The invention discloses an integrated glove machine and a production technology thereof. The glove machine comprises a machine base, a distribution alignment mechanism, a cloth grasping mechanism, a cloth embroidering mechanism, a glove placement mechanism, a driving mechanism and a control mechanism, wherein the distribution alignment mechanism, the cloth grasping mechanism, the cloth embroidering mechanism, the glove placement mechanism, the driving mechanism and the control mechanism are arranged on the machine base. The distribution alignment mechanism comprises a guide roller set and an alignment assembly. The cloth grasping mechanism comprises a cloth grasping frame and a first cylinder driving the cloth grasping frame to move. The cloth embroidering mechanism comprises an embroidering machine head and a laser cutting machine head. The glove placemat mechanism comprises a glove grasping assembly and a glove collection assembly. A bottom plate is disposed on the machine base, the driving mechanism is connected with the bottom plate, and cloth is conveyed onto the bottom plate through the guide roller set, aligned by the alignment assembly, dragged by the cloth grasping frame, sewn by the embroidering machine head, cut by the laser cutting machine head, grasped by the glove grasping assembly and finally sorted and collected by the glove collection assembly in sequence. The integrated glove machine can achieve full-automatic processing and collection of gloves.

Owner:Zhejiang Baixiang Technology Co Ltd

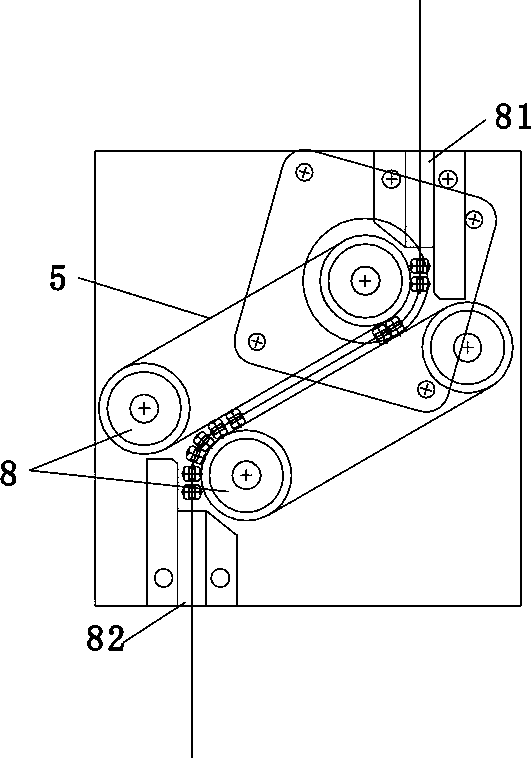

Multifunctional smart embroidery machine head of computerized embroidery machine

InactiveCN101538786AReduce the number of installationsEasy to useAutomatic machinesAuxillary devicesLow noiseElectric machinery

The invention relates to a multifunctional smart embroidery machine head of a computerized embroidery machine, comprising a support body, a control circuit board, an instruction operation circuit board, a feeding motor and a drive cylinder, and a driving belt wheel on the feeding motor is connected with a driven belt wheel on a thread guide port through a drive belt. The multifunctional smart embroidery machine head is mainly provided with an inner through hole in the thread guide port, the inner through hole is sleeved on the outside of a needle bar of a flat embroidery machine head; a tension motor, a mobile guide wheel, a tension swing spring, a first fixed guide wheel and a second fixed guide wheel are arranged on the support body; a stroke control switch is arranged between the driving belt wheel and a mounting base, and the stroke control switch is connected in a forward and backward rotation control circuit of the feeding motor. The multifunctional smart embroidery machine head does not need to change the mounting position of the original flat embroidery machine head, does not reduce the mounting number of the flat embroidery machine head and has the advantages of convenient installation and use, high production efficiency, low noise, long service life and so on. The multifunctional smart embroidery machine head is applicable to the computerized embroidery machines of flat embroidery, belt embroidery, rope embroidery, bead embroidery and coil embroidery.

Owner:永嘉县德宝机械有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com