Multifunctional smart embroidery machine head of computerized embroidery machine

An embroidery machine and multi-functional technology, applied in the field of embroidery machine heads, can solve the problems of easy wear, low service life, high noise, etc., and achieve the effects of convenient installation and use, reduction of installation quantity, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

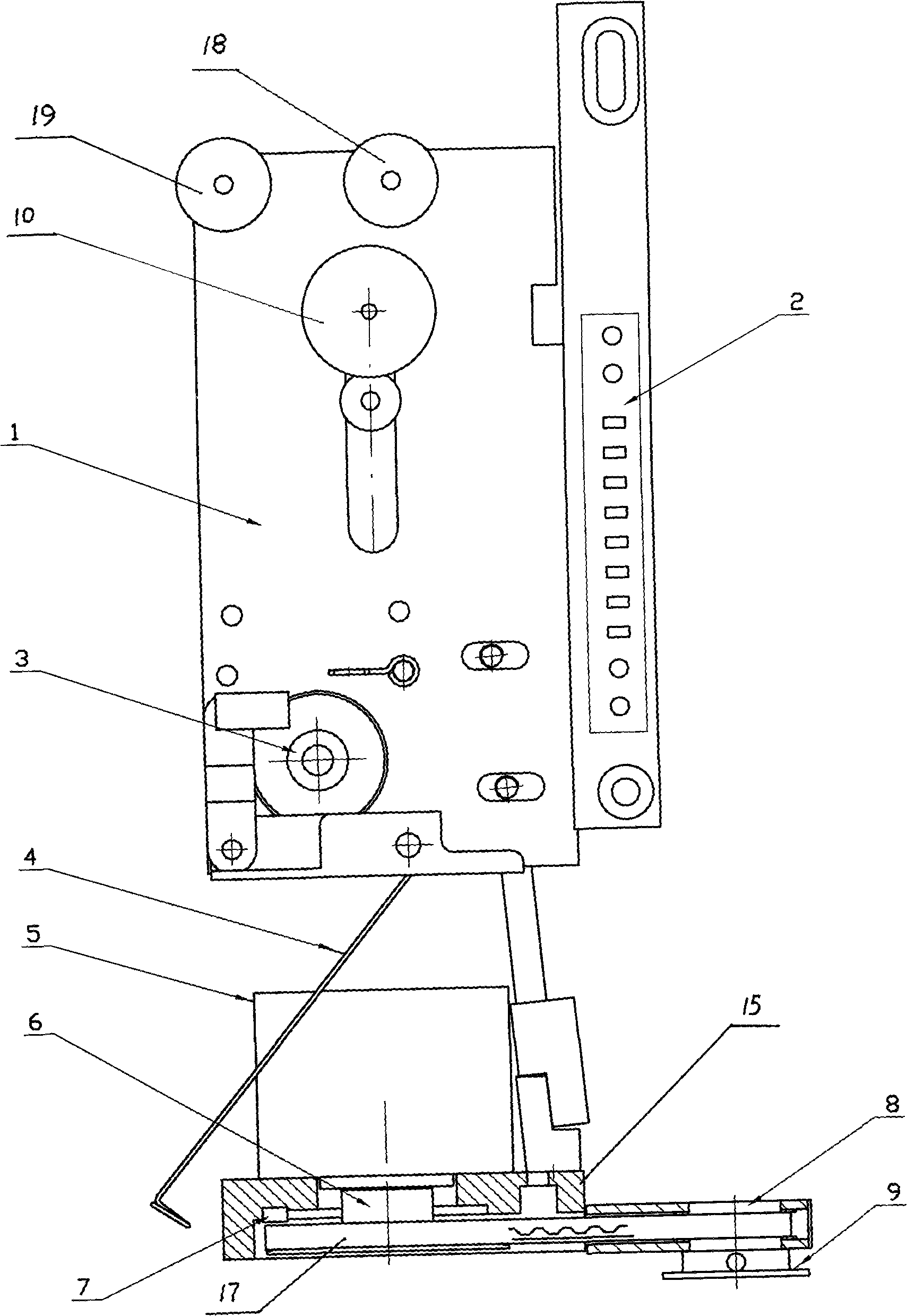

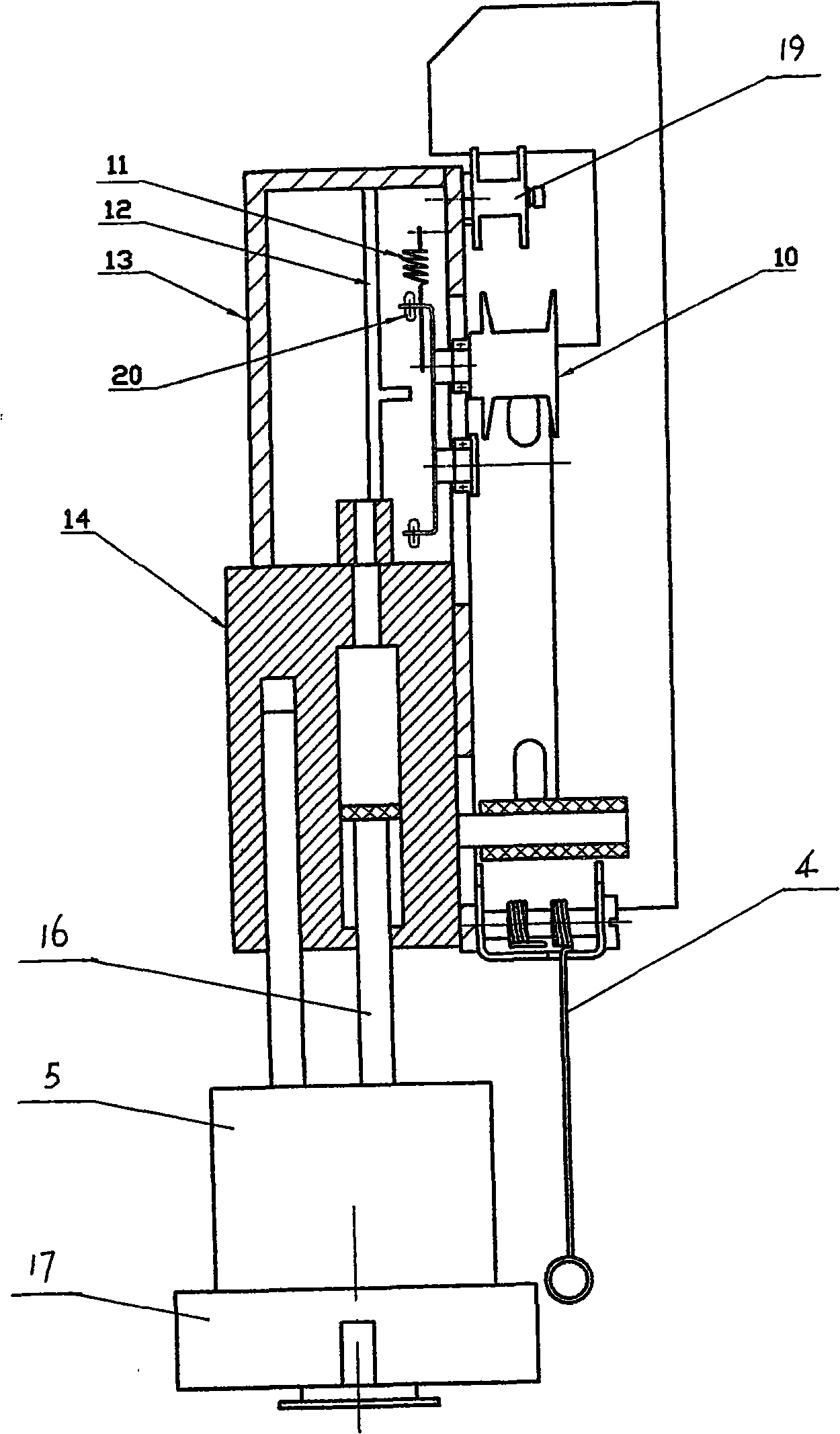

[0010] Such as figure 1 , figure 2 The multifunctional intelligent embroidery head of the computerized embroidery machine shown includes a support body 1, a control circuit board 12, an instruction operation circuit board 2, a feeding motor 5 and a transmission cylinder 14, a control circuit board 12, an instruction operation circuit board 2 and a transmission cylinder 14 is fixedly installed on the bracket body 1, the feeding motor 5 is fixedly connected with the lower end of the piston rod 16 of the transmission cylinder 14 through the mounting seat 15, and the output shaft of the feeding motor 5 is fixedly connected with the driving pulley 6, and the driving pulley 6 is connected to the line through the transmission belt 17. The driven pulley 8 on the material guide port 9 is connected, and the side of the thread guide port 9 is shaped on a thread material hole, and the center is shaped on an inner through hole, and the needle bar of the flat embroidery head of the compute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com