Exhaust manifold installation structure and method for assembling and disassembling same

A technology for exhaust manifolds and installation structures, which is applied in the direction of exhaust devices, mufflers, engine components, etc., which can solve the problems of increased probability of bolt slippage, inconvenient disassembly, and delay in working hours, etc., so as to reduce the probability of bolt slippage , easy installation and disassembly, precise positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

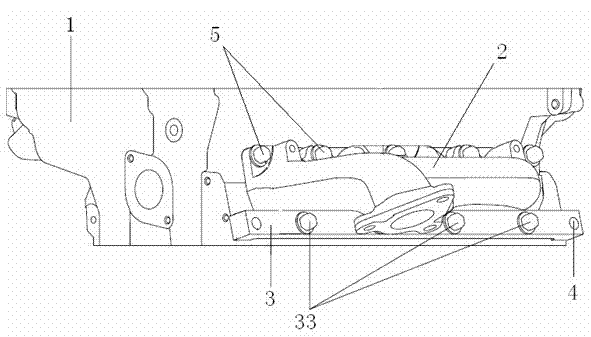

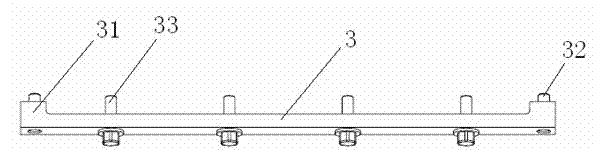

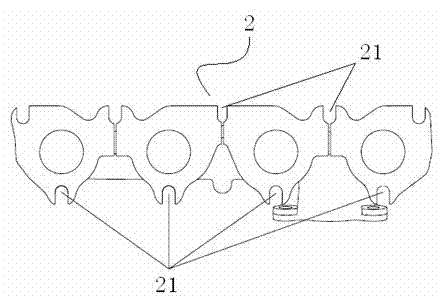

[0020] As shown in the figure, the installation structure of the exhaust manifold in this embodiment includes a cylinder head 1, an exhaust manifold 2 and a mounting bracket 3, and the flange surfaces on the upper and lower sides of the exhaust manifold 2 are provided with "U " type mounting holes 21, the cylinder head 1 is provided with bolt mounting holes at the position corresponding to the upper flange surface of the exhaust manifold, and a positioning hole is provided at the position corresponding to the lower flange surface of the exhaust manifold; the installation bracket 3 Both ends are provided with protrusions 31 facing the inner side thereof, and positioning pin holes 32 corresponding to the positioning holes are provided on the protrusions 31, and a position facing and protruding into the mounting bracket 3 is provided at the position corresponding to the "U"-shaped mounting hole. The positioning column 33 on the side is mounted on the body of the mounting bracket 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com